Page 1

NW

_71-

---F

oo

ND

rrrr

,,,_z

C3W

(/? F--

Zr.D

O'.d

_WO

rrl-- _

a-wD

u>c_

C3 _, rr

_'-- _..I

v_z_w

7_ww

_123121

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(APR07) Form No. 651243-00 DW898 Copyright © 2002, 2005, 2007 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the

"D" shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of

lozenge-shaped humps on the surface of the tool,

@

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word.

Please read the manual and pay attention to these symbols.

ADANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

A WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

_CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a poten-

tially hazardous situation which, if not avoided, may result in property

damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

General Safety Rules - For All Tools

_ WARNING! Read all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury. The term "power tool" in all

of the warnings listed below refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tooL Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tooL Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock. Replace or repair damaged cords.

Make sure your extension cord is in good condition. Use only 3-wire extension cords that

have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool's plug.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock. When using

an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length

and nameplate ampere rating, ff in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power toolsmay

result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging

in. Carrying power tools with your finger on the switch or plugging inpower tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jeweftery or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be avoided.

g) ff devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Specific Safety Instructions for Nibblers

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tools may contact hidden wiring or its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock the operator.

• Cut material at or below rated capacity. Remember, material thickness increases as

gauge number deceases (14 gauge is thicker than 16 gauge). 14 gauge thickness is

.075" (1.9 mm); 16 gauge is .060" (1.5 mm).

• NEVER have any part of your body near the blades. Serious personal injury may result.

• Keep hands away from cutting area. A moment of inattention while operating power tools

may result in serious personal injury.

• AL WAYS wear gloves when handling sheet metal The edges are sharp and can cause seri-

ous personal injury.

• Firmly secure the piece of metal to be cut to prevent movement during cutting.

• ALWAYS start tool before engaging material to be cut.

• Always wear safety shoes to protect your feet from sharp metal debris on the floor.

• DO NOT use the nibbler with any kind of accessory or attachment.

• Keep all screws tight. Check periodically for loosening.

• Do not place anything into the motor housing openings.

• Clean out your tool often, especially after heavy use. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an electric shock hazard.

• Stay clear of end pieces that may fall after being cut off. Contact with a sharp edge could

result in personal injury.

• Always keep the power cord away from the edge of the material being cut. Sharp edges

can result in the cord insulation being cut. This condition may create an electrical hazard.

_ WARNING: AL WAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

_ WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

_ WARNING: Always use eye protection. Aft users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

_ WARNING: Some dust created by power sanding, sawing, grinding, drifting, and other

construction activities contains chemicals known to cause cancer, birth defects, or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a weft ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

_ WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V.................... volts A .................... amperes

Hz.................. hertz W ................... watts

min ................ minutes '_ .................. alternating current

Page 2

--- ............. direct current

@ .................. Class I Construction

(grounded)

[] .................. Class II Construction

(double insulated)

no .................. no load speed

................... earthing terminal

.................. safety alert symbol

.../min ............ revolutions or

reciprocation per minute

BPM .............. beats per minute

SAVE THESE INSTRUCTIONS

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees with

the nameplate marking.

Voltage decrease of more than 10% will cause loss of power and overheating. DEWALT tools

are factory tested; if this tool does not operate, check power supply.

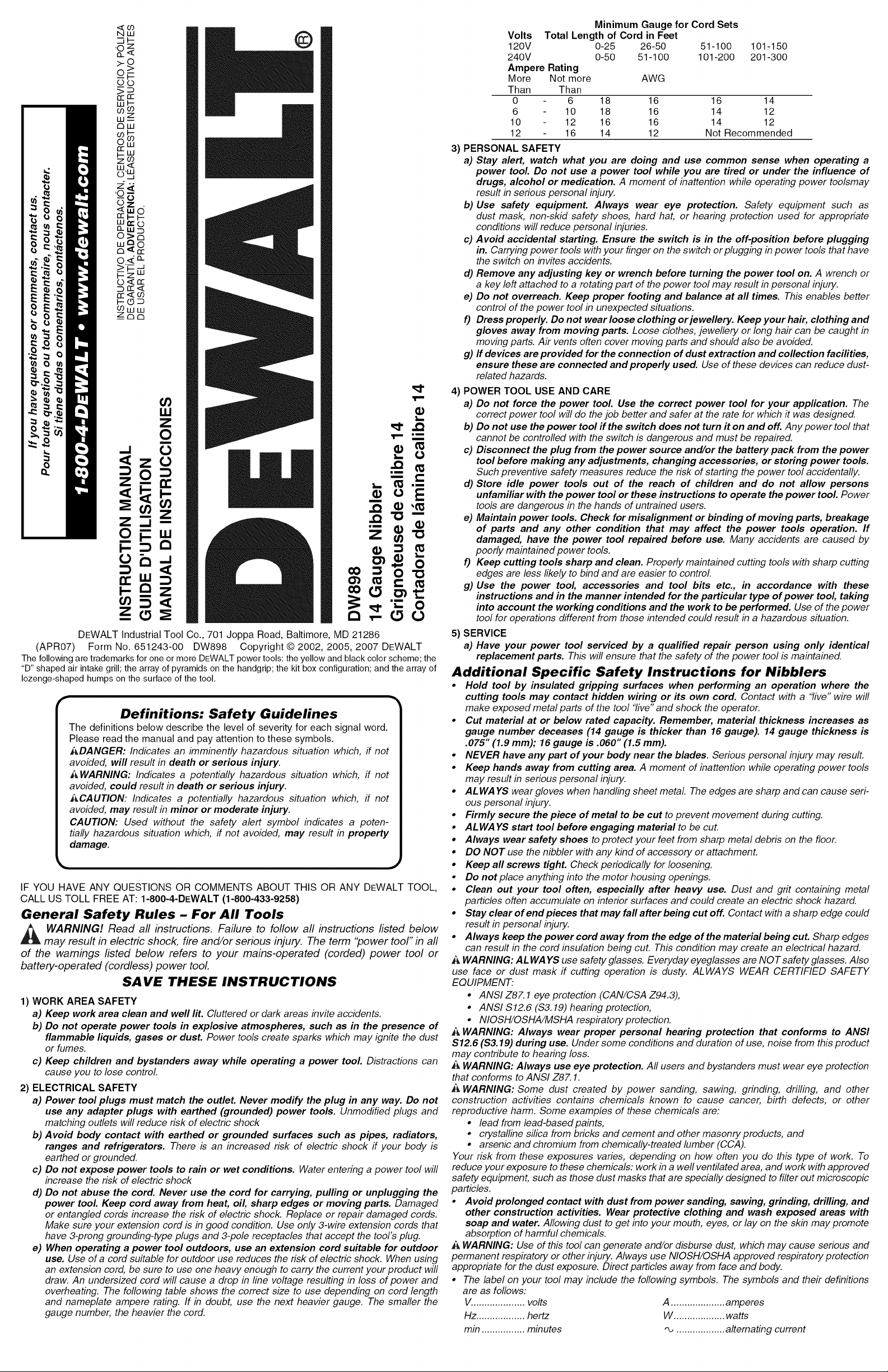

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Head

B. Punch

C. Cover ring

D. Die

E. Housing

F. Paddle switch

G. Switch lock button

H. Set screw

INTENDED USE

The DW898 14-gauge nibbler is designed for professional cutting at various work sites (i.e.,

construction sites). DO NOT use under wet conditions or in presence of flammable liquids or

gases.

The14-gauge nibblers are professional power tools. DO NOT let children come into contact with

the tool. Supervision is required when inexperienced operators use this tool.

Switches (Fig. 1)

To start tool, depress the paddle switch (F). To turn the tool off, release the paddle. The paddle

switch can be locked on by engaging the lock button (G) located near the rear of the tool, while

holding the paddle depressed. Always be sure that the tool is not locked on before plugging in. To

turn the tool off when it is locked on, squeeze and release the paddle once.

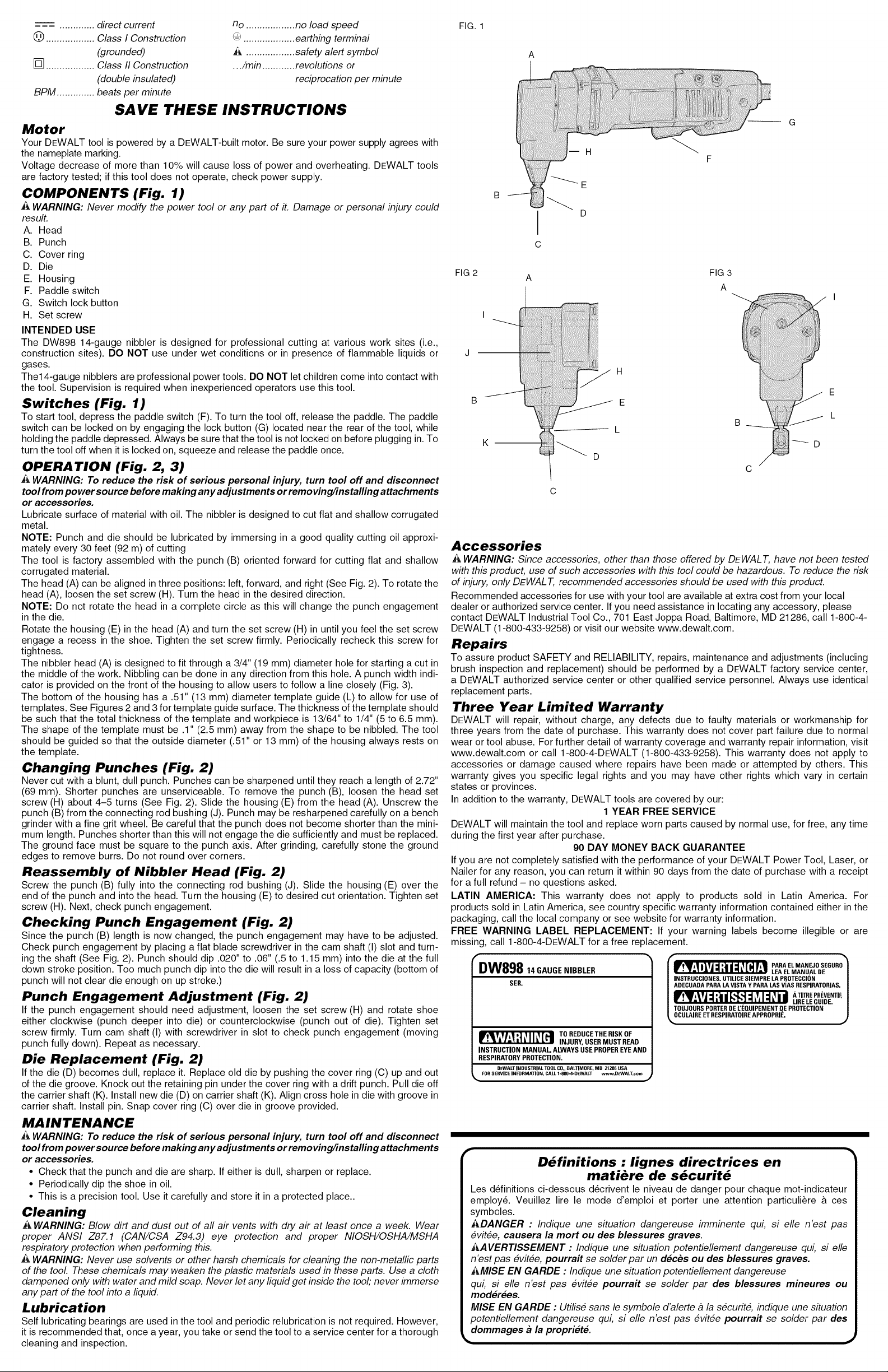

OPERA TION (Fig. 2, 3)

i_ WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

Lubricate surface of material with oil. The nibbler is designed to cut flat and shallow corrugated

metal.

NOTE: Punch and die should be lubricated by immersing in a good quality cutting oil approxi-

mately every 30 feet (92 m) of cutting

The tool is factory assembled with the punch (B) oriented forward for cutting flat and shallow

corrugated material.

The head (A) can be aligned in three positions: left, forward, and right (See Fig. 2). To rotate the

head (A), loosen the set screw (H). Turn the head in the desired direction.

NOTE: Do not rotate the head in a complete circle as this will change the punch engagement

in the die.

Rotate the housing (E) in the head (A) and turn the set screw (H) in until you feel the set screw

engage a recess in the shoe. Tighten the set screw firmly. Periodically recheck this screw for

tightness.

The nibbler head (A) is designed to fit through a 3/4" (19 mm) diameter hole for starting a cut in

the middle of the work. Nibbling can be done in any direction from this hole. A punch width indi-

cator is provided on the front of the housing to allow users to follow a line closely (Fig. 3).

The bottom of the housing has a .51" (13 mm) diameter template guide (L) to allow for use of

templates. See Figures 2 and 3 for template guide surface. The thickness ofthe template should

be such that the total thickness of the template and workpiece is 13/64" to 1/4" (5 to 6.5 mm).

The shape of the template must be .1" (2.5 mm) away from the shape to be nibbled. The tool

should be guided so that the outside diameter (.51" or 13 mm) of the housing always rests on

the template.

Changing Punches (Fig. 2)

Never cut with a blunt, dull punch. Punches can be sharpened until they reach a length of 2.72"

(69 mm). Shorter punches are unserviceable. To remove the punch (B), loosen the head set

screw (H) about 4-5 turns (See Fig. 2). Slide the housing (E) from the head (A). Unscrew the

punch (B) from the connecting rod bushing (J). Punch may be resharpened carefully on a bench

grinder with a fine grit wheel. Be careful that the punch does not become shorter than the mini-

mum length. Punches shorter than this will not engage the die sufficiently and must be replaced.

The ground face must be square to the punch axis. After grinding, carefully stone the ground

edges to remove burrs. Do not round over corners.

Reassembly of Nibbler Head (Fig. 2)

Screw the punch (B) fully into the connecting rod bushing (J). Slide the housing (E) over the

end of the punch and intothe head. Turn the housing (E) to desired cut orientation. Tighten set

screw (H). Next, check punch engagement.

Checking Punch Engagement (Fig. 2)

Since the punch (B) length is now changed, the punch engagement may have to be adjusted.

Check punch engagement by placing a flat blade screwdriver inthe cam shaft (I) slot and turn-

ing the shaft (See Fig. 2). Punch should dip .020" to .06" (.5 to 1.15 mm) into the die at the full

down stroke position. Too much punch dip into the die will result in a loss of capacity (bottom of

punch will not clear die enough on up stroke.)

Punch Engagement Adjustment (Fig. 2)

If the punch engagement should need adjustment, loosen the set screw (H) and rotate shoe

either clockwise (punch deeper into die) or counterclockwise (punch out of die). Tighten set

screw firmly. Turn cam shaft (I) with screwdriver in slot to check punch engagement (moving

punch fully down). Repeat as necessary.

Die Replacement (Fig. 2)

If the die (D) becomes dull, replace it. Replace old die by pushing the cover ring (C) up and out

of the die groove. Knock out the retaining pin under the cover ring with a drift punch. Pull die off

the carrier shaft (K). Install new die (D) on carrier shaft (K). Align cross hole in die with groove in

carrier shaft. Install pin. Snap cover ring (C) over die in groove provided.

MAINTENANCE

i_ WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing attachments

or accessories.

• Check that the punch and die are sharp. If either is dull, sharpen or replace.

• Periodically dip the shoe in oil.

• This is a precision tool. Use it carefully and store it in a protected place..

Cleaning

,& WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear

proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA

respiratory protection when performing this.

i& WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tooL These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

Self lubricating bearings are used in the tool and periodic relubrication is not required. However,

it is recommended that, once a year, you take or send the tool to a service center for a thorough

cleaning and inspection.

FIG, 1

A

" " ii!iiiiiiii!i !i!i!iiiiiii!iiiii!!iiiiiiiii!!i !i ili i i ii iiii -

_E

D

C

FIG 2

L

D

C

Accessories

_, WARNING: Since accessories, other than those offered by DEWAL T, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only DEWAL T, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-

DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-DEWALT for a free replacement.

f •

DW898 14GAUGENIBBLE.

SER.

TO REDUCE THE RISK OF

INSTRUCTION MANUAL ALWAYS USE PROPER EYE AND

RESPIRATORY PROTECTION.

DEWALTINDUSTRIAL TOOLCO,,BALTIMORE,MD 21286USA

FOR SERVICE INFORMATION, CALL I.-800.-4-OEWALT www.DEWALT.com

% •

INJURY, USER MUST READ

(_ _ _m_ II PARAEL MANEJO SEGUR0"_

[ _, . e.l"J=_z=g'_LL'J,.'= LEAELMANUAL DE |

[ INSTRUCCIONES.UTILICESIEMPRELA PROTECCION |

[ ADECUADA PARALAVISTAY PARA[.ASVIAS RESPIRATORIAS.I

[ W ,_ ! _ J k ATITREPRI'_VENTIF,[

[,m • =..=_,==,_._,.,_,=m LIRELEGUIDE. |

[ TOUJOURS PORTERDEL*EQUIPEMENTDE PROTECTION |

LOCULAIRE ETRESPIRATOIREAPPROPRIE. J

Ddfinitions : lignes directrices en

matidre de sdcuritd

Lee d6finitions ci-dessous d6crivent le niveau de danger pour chaque mot-indicateur

employ& Veuillez lire le mode d'emploi et porter une attention particuli_re & ces

symboles.

i_DANGER : Indique une situation dangereuse imminente qui, si elle n'est pas

evitee, causera la mort ou des blessures graves.

,&AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle

n'est pas evit6e, pourrait se solder par un deces ou des blessures graves.

i_MISE EN GARDE : Indique une situation potentiellement dangereuse

qui, si elle n'est pas evit6e pourra# se solder par des blessures mineures ou

moderees.

MISE EN GARDE : Utilise sans le symbole d'alerte a la securite, indique une situation

potentiellement dangereuse qui, si elle n'est pas evit6e pourrait se solder par des

dommages a la propriete.

FIG 3

A

E

L

C

Page 3

POURTOUTEQUESTIONOUTOUTCOMMENTAIRERELATIFCETOUTILOUAPROPOS

DETOUTAUTREOUTILDEWALT,COMPOSERSANSFRAISLE: 1(800)4-DEWALT

(1(800)433-9258)

R_gles g_n_rales de s_curit_ concernant

les outils a piles

_ A VERTISSEMENT : Lire toutes ces directives. Tout manquement aux directives

suivantes pose des risques de choc #lectrique, d'incendie et/ou de blessure

grave. Le terme , outil #lectrique , dans tousles avertissements ci-apr#s se rapporte

votre outil #lectrique _ alimentation sur secteur (avec ill) ou par piles (sans ill).

CONSERVER CES DIRECTIVES

1) SI_CURITI_ - AIRE DE TRAVAIL

a) Maintenir I'aire de travail propre et bien eclairee. Les /ieux encombres ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner un outil electrique clans une atmosphere explosive, en

presence par exemple de poussieres, gaz ou liquides inflammables. Les outils elec-

triques peuvent engendrer des etincelles qui pourraient enflammer toute emanation ou

poussiere ambiante.

c) Tenir les enfants, ou toute autre personne, eloignes pendant I'utilisation d'un outil

electrique. Toute distraction pourrait vous faire perdre la maftrise de ce demier.

2) SI_CURITI_ - I_LECTRICITI_

a) La fiche electrique de I'outil doit correspondre a la prise murale. Ne jamais

modifier la fiche en aucune fagon. Ne jamais utiliser de fiche d'adaptation avec un

outil electrique mis a la terre. L'utilisation de fiches d'origine et de prises appropriees

reduira les risques de choc electrique.

b) Eviter tout contact corporel avec des elements mis a la terre comme tuyaux,

radiateurs, cuisinieres ou refrigerateurs. Les risques de choc electrique augmentent

Iorsque le corps est mis a la terre.

c) Ne pas exposer les outils electriques a la pluie ou a I'humidite. Toute pen6tration d'un

outil electrique par un liquide augmente les risques de choc electrique.

(t) Ne pas utiliser le cordon de fagon abusive. Ne jamais utiliser le cordon pour trans-

porter, tirer ou debrancher un outil electrique. Proteger le cordon de la chaleur,

de I'huile et de tout bord tranchant ou piece mobile. Les cordons endommages ou

emm61es augmentent les risques de choc electrique. Remplacer ou faire reparer tout cor-

don endommag& S'assurer que la rallonge est en bon etat. N'utiliser que des rallonges

trifilaires munies de fiches tripolaires et des prises tripolaires acceptant la fiche de I'outil.

e) Lors de I'utilisation d'un outil electrique a I'exterieur, n'utiliser que des rallonges

congues pour I'exterieur. L'utilisation d'une rallonge congue pour I'exterieur reduit les

risques de choc electrique. En cas d'utilisation d'une rallonge, s'assurer que les valeurs

nominales de la rallonge utilisee correspondent bien a celles de I'outil aliment& L'usage

d'une rallonge de calibre insuffisant causera une chute de tension entrafnant perte de

puissance et surchauffe. Le tableau ci-dessous illustre les calibres a utiliser selon la Ion-

gueur de rallonge et I'intensite nominale indiquee sur la plaque signaletique. En cas de

doutes, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter

de courant.

Calibre minimum pour une rallonge

Volts Longueur totale de la rallonge en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensit6 nominale

Plus Pas plus AWG

de de

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Non recommand6

3) S¢'CURIT¢' PERSONNELLE

a) Rester vigilant en tout temps et faire preuve de jugement pendant I'utilisation

d'un outil electrique. Ne pas utiliser d'outil electrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de medicaments. Tout moment d'inattention

pendant I'utilisation d'un outil electrique pose des risques de blessure grave.

b) Utiliser le materiel de securite approprie. Toujours porter des lunettes de protection.

Le fait de porter un masque anti-poussieres, des chaussures antiderapantes, un casque

de securite ou des protecteurs auditifs Iorsque la situation le requiert reduira les risques de

blessure.

c) Eviter tout demarrage accidenteL S'assurer que I'interrupteur est en position

d'arr6t avant tout branchement. Transporter un outil le doigt sur I'interrupteur ou

brancher un outil electrique alors que I'interrupteur est en position de marche invite les

accidents.

d) Retirer toute cle de reglage avant de demarrer I'outil. Une cle laissee sur une piece

rotative d'un outil electrique pose des risques de blessure.

e) Ne pas effectuer de travaux hors de portee. Les pieds doivent rester bien ancres au

sol afin de maintenir son equilibre en tout temps. Cela permet de mieux maftriser I'outil

electrique dans les situations imprevues.

f) Porter des v6tements appropries. Ne pas porter de v6tements amples ni de bijoux.

Maintenir cheveux, v6tements et gants eloignes des pieces mobiles. V6tements

amples, bijoux ou cheveux longs risquent de rester coinces dans ces pieces mobiles.

Prendre des precautions autour des events car ils recouvrent des pieces mobiles.

g) Lorsque un dispositif de connexion a un systeme de depoussierage ou d'elimination

est fourni, s'assurer qu'il est connecte et utilise correctement. L'utilisation de ces dis-

positifs peut reduire les risques engendres par les poussieres.

4) UTILISATION ET ENTRETIEN DES OUTILS I_LECTRIQUES

a) Ne pas forcer un outil electrique. Utiliser I'outil approprie au travail en cours. L'outil

approprie effectuera un meilleur travail, de fagon plus s_re eta la vitesse pour laquelle il a

ete congu.

b) Ne pas utiliser un outil electrique dont I'interrupteur est defectueux. Tout apparefl

dont I'interrupteur est defectueux est dangereux et doit 6tre repar&

c) Debrancher la fiche du secteur et/ou le bloc-piles de I'outil electrique avant de

faire tout reglage ou changement d'accessoire, ou avant de ranger ce demier. Ces

mesures preventives reduisent les risques de demarrage accidentel de I'appareil.

d) Apres usage, ranger les outils electriques hors de la portee des enfants, et ne

permettre a aucune personne n'etant pas familiere avec un outil electrique (ou son

manuel d'instruction) d'utiliser ce dernier. Les outils peuvent 6tre dangereux entre/es

mains des novices.

e) Entretenir les outils electriques. Verifier les pieces mobiles pour s'assurer qu'elles

sont bien alignees et tournent librement, qu'elles sont en bon etat et ne sont affec-

tees d'aucune condition susceptible de nuire au bon fonctionnement de I'outil. En

cas de dommage, faire reparer I'outil electrique avant toute nouvelle utilisation. Bien

des accidents sont causes par des outils mal entretenus.

f) Maintenir tout outil de coupe bien aiguise et propre. Les outils de coupe bien entrete-

nus et affDtes sont moins susceptibles de se coincer et sont plus faciles a contr61er.

g) Utiliser un outil electrique, ses accessoires, meches, etc., conformement aux

presentes directives et suivant la maniere prevue pour ce type particulier d'outil

electrique, en tenant compte des conditions de travail et du travail a effectuer.

L'utilisation d'un outil electrique pour toute operation autre que celle pour laquelle il a ete

congu est dangereuse.

5) RI_PARATION

a) Faire entretenir les outils electriques par un reparateur qualifie en n'utilisant que

des pieces de rechange identiques. Cela permettra d'assurer I'integrite de I'outil elec-

trique et la securite de I'utilisateur.

poussiere si I'operation de decoupe genere de la poussiere. TOUJOURS PORTER UN

produits chimiques : travailler dans un endroit bien ventile et porter un equipement de securite

i_AVERTISSEMENT : L'utilisation de cet outil peut produire et/ou disperser des poussieres

pouvant causer des problemes respiratoires graves et permanents ou d'autres blessures.

chauffe. LES OUTILS DEWALT sont test6s en usine; si cet outil ne fonctionne pas, v6rifier

_A VERTISSEMENT : Ne jamais modifier I'outil electrique ou I'une de ses parties. Une telle

pratique risque de provoquer des dommages materiels ou des blessures corporelles.

chantiers. NE PAS utiliser dans des conditions humides ou en pr6sence de liquides ou de gaz

9ant le bouton de verrouillage (G) qui se trouve pros de I'arri_re de I'outil tout en maintenant

fonctionnement continu avant de le brancher. Pour arr_ter routil Iorsque ce dernier est en mode

Directives de s_curit_ sp_cifiques suppl_mentaires pour

les grignoteuses

• Tenir I'outil par sa surface de prise isolee Iors d'operations ob les outils de coupe

peuvent entrer en contact avec un c&blage cache ou avec leur propre cordon

d'alimentation. Tout contact avec un fil ,, sous tension, mettra ,, sous tension, les pieces

metalliques exposees de I'outil et provoquera un choc electrique chez I'operateur de I'outil.

• Couper le materiau en fonction de la capacite nominale de la grignoteuse ou sous

celle-cL Se rappeler que plus un materiau est epais, plus son calibre est petit (ainsi,

un materiau de calibre 14 est plus epais qu'un autre de calibre 16). En effet, I'epaisseur

d'un materiau de calibre 14 est de 1,9 mm (0,075 po) et celui de calibre 16, de 1,5 mm

(O,06 po).

• NE JAMAIS mettre une pattie du corps pres des couteaux. Une telle pratique peut entraf-

ner des blessures corporelles graves.

• Eloigner les mains de la zone de decoupe. Un simple moment d'inattention en utilisant un

outil electrique peut entrafner des blessures corporelles graves.

• TOUJOURS porter des gants Iors de la manipulation de feuilles de metal En effet, les bords

sont tranchants et peuvent infliger de graves blessures corporelles.

• Abloquer la piece metallique a couper afin d'emp6cher tout deplacement en cours de

coupe.

• TOUJOURS actionner I'outil avant d'inserer le materiau a couper.

• Toujours porter des chaussures de securite pour proteger les pieds contre les debris

m#talliques pointus sur le plancher.

• NE PAS utiliser la grignoteuse avec des accessoires.

• S'assurer de serrer toutes les vis. Les verifier regulierement.

• Ne rien inserer dans les orifices du carter du moteur.

• Nettoyer I'outil regulierement, particulierement apres une utilisation intensive. La

poussiere et les saletes contenant des particules metalliques s'accumulent souvent sur les

surfaces internes de I'outil et pourraient creer un risque de choc electrique.

• Se tenir a I'ecart des extremites de la piece, car des morceaux pourraient tomber apres

la coupe. Un contact avec un bord tranchant risque de se solder par une blessure corpo-

relle.

• Toujours tenir le cordon d'alimentation a I'ecart du bord du materiau coupe. Les bords

tranchants risquent de couper I'isolant du cordon d'alimentation et pourraient creer un risque

d'origine electrique.

_AVERTISSEMENT : TOUJOURS porter des lunettes de securit& Les lunettes de vue ne

constituent PAS des lunettes de securite. Utiliser egalement un masque facial ou anti-

EQUIPEMENT DE PROTECTION HOMOLOGUE :

• protection oculaire conforme a la norme ANSI Z87.1 (CAN/CSA Z94.3),

• protection auditive conforme a la norme ANSI $12.6 ($3.19) et

• protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

_A VERTISSEMENT : TOUJOURS porter une protection auditive appropriee conforme-

ment a la norme ANSI $12.6 ($3.19) Iors de I'utilisation du produit. Dans certaines condi-

tions et selon la duree d'utilisation, le bruit emis par ce produit peut contribuer a une perte

auditive.

_A VERTISSEMENT : Toujours utiliser une protection oculaire. Tousles utilisateurs et per-

sonnes a proximite doivent porter une protection oculaire conforme a la norme ANSI Z87.1.

i_A VERTISSEMENT : Certaines poussieres produites par les activites de pongage, sciage,

meulage, pergage et autres activites de construction peuvent contenir des produits

chimiques pouvant causer le cancer, des anomalies congenitales ou d'autres problemes lies aux

fonctions reproductrices. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures a base de plomb;

• la silice cristalline de la brique, du ciment et d'autres produits de magonnerie; et

• I'arsenic et chrome provenant de bois traite chimiquement.

Les risques relies a I'exposition aces poussieres varient selon la frequence a laquelle

I'utilisateur travaille avec ce type de materiaux. Pour reduire votre exposition a ces

approuve comme un masque antipoussieres congu specialement pour filtrer les particules

microscopiques.

• Eviter le contact prolonge avec les poussieres produites par les activites de pongage,

sciage, meulage, pergage et autres activites de construction. Porter des v6tements

de protection et laver les parties du corps exposees avec une solution d'eau et de

savon. Laisser la poussiere penetrer dans la bouche, les yeux ou reposer sur la peau peut

favoriser I'absorption de produits chimiques nocifs.

Toujours porter une protection des voies respiratoires approuvee par la NIOSH/OSHA Iors d'une

exposition a la poussiere. Diriger les particules loin du visage et du corps.

• L'etiquette apposee sur votre outil peut comprendre les symboles suivants. Les symboles et

leurs definitions sont indiques ci-apres :

V..................... volts

Hz................... hertz

min ................. minutes

--- .............. courant continu

(_) ................... Construction de classe I

(mis a la terre)

[] ................... Construction de classe II

(a double isolation)

BPM ............... coups par minute

A.................... amperes

W................... watts

'-_-,................. courant altematif

no .................. vitesse a vide

................... borne de terre

_&.................. symbole d'alerte a la securite

.../min ............ rotations ou alternance

par minute

CONSERVER CES DIRECTIVES

Moteur

Un moteur DEWALT actionne I'outil DEWALT. S'assurer que le bloc d'alimentation est compatible

avec I'inscription de la plaque signal6tique.

Une diminution de tension de plus de 10 % provoquera une perte de puissance et une sur-

I'alimentation 61ectrique.

COMPONENTS (fig. 11

A. T_te

B. Poingon

C. Anneau de couvercle

D. Matrice

E. Boftier

F. Interrupteur & palette

G. Bouton de verrouillage de I'interrupteur

H. Vis de calage

UTILISATION PR#VUE

La grignoteuse DW898 de calibre 14 est congue pour la coupe professionnelle dans diff6rents

inflammables.

Les grignoteuses de calibre 14 sont des outils 61ectriques professionnels. NE PAS laisser

les enfants toucher & I'outil. Les op6rateurs inexp6riment6s doivent _tre supervis6s Iorsqu'ils

utilisent cet outil.

Interrupteur (fig. 1)

Pour mettre I'outil en marche, enfoncer I'interrupteur & bascule (F). Pour I'arr_ter, rel&cher

I'interrupteur & bascule. On peut verrouiller I'interrupteur en mode de fonctionnement en enfon-

enfonc_ I'interrupteur & bascule. Toujours s'assurer que I'outil ne se trouve pas en mode de

de fonctionnement continu, il suffit d'enfoncer et de rel&cher imm6diatement I'interrupteur.

Page 4

FONCTIONNEMENT [fig. 2, 3)

_AVERTISSEMENT : Pour reduire le risque de blessures corporelles graves, eteindre

I'outil et le debrancher avant d'effectuer tout reglage ou d'enlever ou d'installer des

accessoires.

Lubrifier la surface du mat@iau avec de I'huile. La grignoteuse est congue pour d_couper du

m_tal plat et I_g@ement ondul&

REMARQUE : il faut lubrifier le poingon et la matrice en les immergeant dans de I'huile de coupe

de bonne qualit_ apr_s environ chaque 9 m (30 pi) de coupe.

L'outil est mont_ en usine avec le poingon (B) en position avant pour couper des mat@iaux plats

et I_g@ement ondul_s.

La t6te (A) se place dans I'une des trois positions : vers la gauche, vers I'avant et vers la droite

(consulter la fig. 2). Pour faire tourner la t6te (A), desserrer la vis de calage (H). Faire tourner la

t6te jusqu'& la position voulue.

REMARQUE : ne pas faire tourner compl_tement la t6te sur elle-m6me au risque de modifier

I'insertion du poingon dans la matrice.

Faire tourner le boftier (E) dans la t6te (A) et faire tourner la vis de calage (H) jusqu'& ce que la

vis s'ins@e dans un espace creux du patin. Serrer solidement la vis de calage. V@ifier r6guli_-

rement si cette vis est bien serr6e.

La t6te (A) de la grignoteuse est congue pour s'ins@er dans un trou de 19 mm (3/4 po) de

diam_tre afin de pouvoir d_couper au milieu de la piece. Le grignotage se fait dans un sens

ou I'autre dans le trou. A I'avant du boftier, on retrouve un indicateur de la largeur du poingon

permettant & I'utilisateur de suivre un trac6 (fig. 3).

La face inf@ieure du boftier comporte un guide pour gabarit de 13 mm (0,51 po) de diam_tre

(L) pr6vu pour I'utilisation des gabarits. Consulter les figures 2 et 3 pour obtenir la surface du

guide de gabarit. L'6paisseur (totale) du gabarit et de la piece doit se situer entre 5 et 6,5 mm

(13/64 et 1/4 po). La forme du gabarit doit se trouver &2,5 mm (0,1 po) de la forme & grignoter.

II faut guider I'outil de sorte que le diam_tre ext@ieur (13 mm ou 0,51 po) du boftier repose

toujours contre le gabarit.

Remplacement des poinr:ons (fig. 2)

Ne jamais couper avec un poingon _mouss& On peut afft]ter les poingons jusqu'& une Iongueur

minimale de 69 mm (2,72 po). Des poingons plus courts ne peuvent 6tre utilis6s. Pour retirer le

poingon (B), desserrer la vis de calage (H) de la t6te d'environ 4 ou 5 tours (consulter la fig. 2).

Faire glisser le boftier (E) hors de la t6te (A). D_visser le poingon (B) de la douille de la bielle (J).

IIfaut afft]ter avec soin les poingons & I'aide d'une meuleuse d'_tabli munie d'une meule & grains

fins. S'assurer de ne pas raccourcir le poingon au-del& de la Iongueur minimale. Un poingon plus

court ne s'ins@era pas suffisamment dans la matrice et devra 6tre remplac& La face meul_e

doit 6tre perpendiculaire & I'axe du poingon. Apr_s le meulage, _barber soigneusement les

rebords afft]t6s & la meule. Ne pas en arrondir les coins.

Remontage de la t#te de la grignoteuse (fig. 2)

Visser le poingon (B) & fond dans la douille de la bielle (J). Faire glisser le boitier (E) sur

I'extr_mit_ du poingon et dans la t6te. Faire tourner le boftier (E) jusqu'& la position de coupe

voulue. Serrer la vis de calage (H). Ensuite, v@ifier I'insertion du poingon.

V_rification de I'insertion du point:on (fig. 2)

Puisque la Iongueur du poingon (B) est maintenant diff@ente, il faut peut-6tre r_gler I'insertion

du poingon. La v@ifier en plagant un tournevis & lame plate dans la fente de I'arbre & cames

(I) et en faisant tourner I'arbre (consulter la fig. 2). Le poingon devrait s'affaisser de 0,5 &

1,15 mm (0,020 & 0,06 po) dans la matrice & la position la plus basse de la course. Lorsque

I'affaissement du poingon dans la matrice est trop grand, il en r6sulte une perte de rendement

(l'extr6mit6 inf@ieure du poingon ne se d_gage pas suffisamment de la matrice au plus haut de

la course).

R_glage de I'insertion du point:on (fig. 2)

Lorsqu'il faut r_gler I'insertion du poingon, desserrer la vis de calage (H) et faire tourner le patin

dans le sens horaire (pour enfoncer davantage le poingon dans la matrice) ou dans le sens

antihoraire (pour le faire sortir de la matrice). Serrer solidement la vis de calage. Faire tourner

I'arbre & cames (I) & I'aide du tournevis dans la fente afin de v@ifier I'insertion du poingon (en

abaissant le poingon compl_tement). R_p_ter au besoin.

Remplacement de la matrice (fig. 2)

Lorsque la matrice (D) est _mouss_e, la remplacer. Remplacer I'ancienne matrice en poussant

I'anneau de couvercle (C) vers le haut, hors de la rainure de la matrice. Se servir d'un chasse-

goupille pour faire sortir la tige de retenue du dessous de I'anneau de couvercle. Retirer la

matrice de I'arbre-porteur (K). Ins@er une matrice (D) neuve sur I'arbre-porteur (K). Aligner le

trou-guide de la matrice sur la rainure de I'arbre-porteur. Ins@er la tige. Enclencher I'anneau de

couvercle (C) dans la rainure disponible.

ENTRETIEN

A_AVERTISSEMENT : Pour reduire le risque de blessures corporelles graves, eteindre

I'outil et le debrancher avant d'effectuer tout reglage ou d'enlever ou d'installer

des accessoires.

• S'assurer que le poingon et la matrice sont afft]t_s. Lorsque I'un d'eux est _mouss_, I'afft]ter

ou le remplacer.

• Tremper r6guli@ement le patin dans de I'huile.

• II s'agit d'un outil de pr6cision. S'en servir avec soin et le ranger dans un endroit prot6g&

Nettoyage

_A VERTISSEMENT : Enlever les saletes et la poussiere hors des events au moyen d'air com-

prime sec, au moins une fois par semaine. Porter une protection oculaire conforme a la norme

ANSI Z87.1 (CAN/CSA Z94.3) et une protection des voies respiratoires conforme aux normes

NIOSH/OSHA/MSHA au cours de cette t_che de nettoyage.

_AVERTISSEMENT : Ne jamais utiliser de solvants ni d'autres produits chimiques puissants

pour nettoyer les pieces non metalliques de I'outiL Ces produits chimiques peuvent affaiblir les

materiaux de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau

et de savon doux. A!ejamais laisser de liquide penetrer dans I'outil et n'immerger aucune partie

de I'outil dans un liquide.

Lubrification

Tousles outils DEWALT sont lubrifi_s en permanence en usine et ils sont pr_ts & servir. Les

outils devraient _tre lubrifi_s r6guli@ement aux 60 jours & 6-mois, selon leur utilisation. Les

outils constamment utilis_s pour la production ou pour des travaux intensifs et ceux expos6s &

la chaleur peuvent n6cessiter une lubrification plus fr6quente. Seul le personnel qualifi_ d'un

centre de service DEWALT peut lubrifier les outils.

Accessoires

A VERTISSEMENT : Puisque les accessoires autres que ceux offerts par DEWAL T n'ont pas

ete testes avec ce produit, leur utilisation pourrait s'averer dangereuse. Pour reduire le risque

de blessures, utiliser exclusivement les accessoires DEWAL T recommandes avec le present

produit.

Les accessoires recommand_s pour votre outil peuvent _tre achet6s aupr_s du distributeur local

ou d'un centre de r6paration agr_& Si vous avez besoin d'assistance pour trouver un accessoire

pour votre outil, veuillez contacter DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286, €:tats-Unis, composer le 1(800) 4-DEWALT (1-800-433-9258) ou visiter notre site Web

&www.dewalt.com.

R_parations

Pour assurer la SI2CURITI2 et la FIABILITI2 du produit, les r_parations, I'entretien et les r_glages

(y compris I'inspection et le remplacement des balais) doivent _tre r6alis6s par un centre de

r6paration en usine DEWALT, un centre de r6paration autoris_ DEWALT ou par un personnel de

r6paration professionnel. Toujours utiliser des pi_ces de rechange identiques.

Garantie limit_e de trois ans

DEWALT r_parera gratuitement tous les probl_mes dus & des d_fauts de mat@iau ou de

fabrication pendant trois ans & compter de la date d'achat. Cette garantie ne couvre pas des

d_faillances de piece dues & une usure normale ou & une mauvaise utilisation de I'outil. Pour

plus de d_tails relatifs & la couverture de la garantie et aux r6parations sous garantie, visiter le

site Web www.dewalt.com ou composer le 1-800-4-DEWALT (1-800-433-9258). Cette garantie

ne s'applique pas aux accessoires ni aux dommages causes par des r6parations r6alis_es ou

tent6es par des tiers. Cette garantie vous accorde des droits I_gaux sp_cifiques et il est possible

que vous ayez d'autres droits qui varient d'un Etat ou d'une province & I'autre.

En plus de la garantie, les outils DEWALT sont couverts par notre :

SERVICE D'ENTRETIEN GRATUlT DE 1 AN

DEWALT entretiendra I'outil et remplacera les pi_ces us_es par une utilisation normale et ce,

gratuitement, &tout instant pendant la premi@e annie &compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'_tes pas enti@ement satisfait des performances de votre outil _lectrique, laser ou

de votre marteau-cloueur DEWALT pour quelque raison que ce soit, vous pouvez le retourner

accompagn_ d'un regu dans les 90 jours suivant la date d'achat et nous vous rembourserons

enti@ement - sans poser de questions.

AM#RIQUE LATINE : cette garantie ne s'applique pas aux produits vendus en Am@ique latine.

Pour ceux-ci, veuillez consulter les informations relatives &la garantie sp_cifique pr6sente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives

&cette garantie.

REMPLACEMENT GRATUlT DES #TIQUETTES D'AVERTISSEMENT : si les _tiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1-800-4-DEWALT pour

en obtenir le remplacement gratuit.

f

DW898 14GAUGENIBBLER

SER.

TO REDUCE THE RISK OF

INSTRUCTION MANUAL. ALWAYS USE PROPER EYE AND

RESPIRATORY PROTECTION.

DeWALT INOUSTRIAL TOOL CO., BALTIMORE, MB 21286 USA

FORSERVICE INFORMATION,CALLI-SCO-4-DEWALT www.DEWALT,com

INJURY, USER MUST READ

¢_ PARAELMANEJ0 SEGURO_

I =r • '_.,_-J=-_,..'_Lz-J,.,= LEAELMANUAL DE |

_ INSTRUCCIONES. UTILICE SIEMPRE LAPROTECCION |

_ ADECUADAPARALAVISTAY PARA LASVIAS RESPIRATORIAS.1

J ! ,t ._ _ _, ATITREPREVENTIF,I

I = " l.z=_,==,-x,.,,_,,,_z=m LIRELEGUIDE. |

_ TOUJOURS PORTERDEI_EOUIPEMENTD,EPROTECTION |

kOCULAIRE ET RESPIRATOIREAPPROPRIE. J

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de

seSal. Lea el manual y preste atenci6n a estos simbolos.

_PELIGRO: indica una situacidn de peligro inminente que, si no se evita,

provocara la muerte o lesiones graves.

i_ADVERTENClA: indica una situacidn de peligro potencial que, si no se

evita, podria provocar la muerte o lesiones graves.

PRECAUClON: indica una situacidn de peligro potencial que, si no se evita,

posiblemente provocarfa lesiones leves o moderadas.

PRECAUClON: cuando se utiliza sin el sfmbolo de alerta de seguridad indica

una situacidn de peligro potencial que, si no se evita, puede provocar dafios

en la propiedad.

Reglas de seguridad generales

A iADVERTENCIA! Lea todas las instrucciones. El incumplimiento con alguna de

las instrucciones enumeradas m4s abajo puede resultar en descarga el#ctrica,

incendio y/o lesiones corporales serias. El uso del t#rmino "m4quina herramienta" en

las advertencias que se encuentran a continuacidn, se refiere a su mbquina

herramienta ya sea operada por la red de suministro (con cable de alimentacidn) o a

baterfa (inal4mbrica).

CONSERVE LAS INSTRUCCIONES

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga su #rea de trabajo limpia y bien iluminada. Los accidentes abundan en las

areas de trabajo desordenadas u oscuras.

b) No opere maquinas herramienta en ambientes explosivos, tales como en presencia

de liquidos, gases o polvos inflamables. Las maquinas herramienta generan chispas

que pueden inflamar el polvo o los gases.

c) No use maquinas herramienta en presencia de nMos u otras personas circunstan-

tes. Las distracciones pueden hacerle perder el control.

2) SEGURIDAD ELI_CTRICA

a) Los enchufes de las maquinas herramienta deben poder acoplarse a la toma de cor-

riente. Jambs modifique el enchufe de ninguna manera. No emplee adaptadores de

enchufe con maquinas herramienta conectadas a tierra. Los enchufes no modificados

y las tomas de corriente que correspondan al enchufe reduciran el riesgo de descarga

electrica.

b) Evite el contacto corporal con superficies conectadas a tierra, tales como tuber/as,

radiadores, cocinas y refrigeradores. Existe un mayor riesgo de descarga electrica

cuando su cuerpo esta conectado a tierra.

c) No exponga maquinas herramienta a condiciones Iluviosas o h#medas. Si entra

agua a la maquina herramienta, aumentara el riesgo de descarga electrica.

d) No abuse del cable. Jambs transporte, arrastre o desenchufe la maquina

herramienta por el cable. Mantenga el cable alejado de fuentes de calor, aceite,

bordes afilados o piezas en movimiento. Los cables dafiados o enredados aumentan

el riesgo de descarga electrica. Cambie o repare aquellos cables que esten dafiados.

Verifique que su alargador este en buenas condiciones. Utilice sdlo alargadores de

3 hilos con enchufes de 3 patas, con conexidn a tierra y tomas de corriente de 3 polos que

acepten el enchufe de la herramienta.

e) Cuando opere una maquina herramienta a la intemperie, use un alargador disefiado

para uso a la intemperie. El uso de un alargador disefiado para uso a la intemperie

reduce el riesgo de descarga electrica. Cuando use un alargador, aseg#rese de usar uno

de un calibre suficiente como para cargar con la corriente que requerira su producto. Un

alargador de menor calibre causara una cafda en el voltaje de la ffnea Io que resultara

en perdida de potencia y sobrecalentamiento. El siguiente cuadro muestra el tamafio

correcto a utilizar, dependiendo del largo del cable y el amperaje nominal En caso

de duda, utilice el de mayor calibre. Mientras menor el n#mero del calibre, mayor la

capacidad del cable.

Calibre minimo para los juegos de cables

Voltios Largo total del cable en pies

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Capacidad nominal en amperio

Mas No mas AWG

que que

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 No recomendado

3) SEGURIDAD PERSONAL

a) Mantengase alerta, fijese en Io que esta haciendo y utilice su sentido comdn

cuando opere una maquina herramienta. No utilice una maquina herramienta si

esta cansado o bajo la influencia de drogas, alcohol o medicamentos Sd/o hace fa/ta

un momento de distraccidn durante la operacidn de maquinas herramienta para causar

lesiones corporales serias.

b) Use equipo de seguridad. Utilice siempre proteccion ocular. El uso de un equipo de

seguridad apropiado a las condiciones de trabajo, tal como mascaras antipolvo, calzado

de seguridad anti-derrapante, cascos o proteccidn auditiva, reducira la posibilidad de sufrir

lesiones corporales.

Page 5

c) Evite encender la maquina herramienta en forma accidental. Verifique que el

conmutador este apagado antes de enchufar la maquina herramienta. El sujetar una

maquina herramienta con el dedo en el conmutador o enchufar maquinas herramienta con

el conmutador encendido se presta para que ocurran accidentes.

d) Retire toda Ilave de ajuste antes de encender la mgquina herramienta. Si se deja

alguna Ilave en una pieza giratoria de la maquina herramienta, podrfa provocar lesiones.

e) No se sobreextienda. Mantengase siempre bien apoyado y equilibrado. Esto permite

tener un mayor control de la mbquina herramienta en situaciones inesperadas.

f) Vistase debidamente. No se ponga ropa suelta o joyas. Mantenga su pelo, ropa y

guantes alejados de piezas moviles. La ropa suelta, las joyas y el pelo largo pueden

quedar atrapados en las piezas m6viles. Los orificios de ventilacidn suelen cubrir piezas

en movimiento, por Io que tambien se deben evitar.

g) Si la maquina herramienta viene con al g#n dispositivo de conexion para la

extraccion y coleccion de polvo, aseg#rese que este sea debidamente conectado

y utilizado. El uso de estos dispositivos puede reducir los peligros relacionados a la

generacidn de polvo.

4) USO Y CUlDADO DE LA MAQUlNA HERRAMIENTA

a) No fuerce la maquina herramienta. Use la maquina herramienta correcta para su

aplicacion. La maquina herramienta apropiada hara un trabajo mejor y mas seguro si se

usa de la forma para la cual fue disehada.

b) No use la maquina herramienta si el conmutador no puede encenderla y apagarla.

Cualquier maquina herramienta que no pueda ser controlada con el conmutador es

peligrosa y debe ser reparada.

c) Desenchufe la maquina herramienta de la toma de corriente y/o de la unidad de

alimentacion antes de ajustarla, cambiar de accesorio o guardarla. Estas medidas

de seguridad preventiva reducen el riesgo de poner en marcha la maquina herramienta

acciden talmen te.

d) Guarde su maquina herramienta fuera del alcance de ni#os cuando no la este

usando y no permita que personas que no esten familiarizadas con la maquina

herramienta o estas instrucciones la usen. Las maquinas herramienta son peligrosas

en manos de personas no capacitadas.

e) Mantenga su maquina herramienta. Revise la maquina herramienta para verificar

que no este mal alineada, que sus piezas moviles no esten trabadas o rotas y que no

exista otra condicion que pudiera afectar su operacion. Siesta da#ada, haga reparar

la maquina herramienta antes de utilizarla. Muchos accidentes son causados por usar

maquinas herramienta que no han sido bien mantenidas.

f) Mantenga maquinas herramienta que son usadas para cortar afiladas y limpias. Las

maquinas herramienta de corte debidamente mantenidas y afiladas tienen menos proba-

bilidades de trabarse y son mas faciles de controlar.

g) Use la maquina herramienta, sus accesorios, etc., en cumplimiento con estas

instrucciones yen la manera para la cual la maquina herramienta fue dise#ada,

tomando en cuenta las condiciones de trabajo y el trabajo a realizar. El uso de una

maquina herramienta para operaciones fuera de aquellas para las que fue disehada

podrfa resultar en una situaci6n peligrosa.

5) SERVIClO

a) Haga reparar su maquina herramienta por un tecnico de reparacion calificado,

utilizando solo repuestos originales. Esto garantizara la seguridad de la maquina

herramienta.

Instrucciones de seguridad adicionales especificas

para recortadoras

• Sostenga la herramienta por las superficies de agarre aisladas cuando realice

una operacion en que las herramientas de corte puedan tocar cables electricos

escondidos o su propio cable. El contacto con un cable con corriente electrica hara que las

partes expuestas de la herramienta tengan corriente y que el operador reciba una descarga

electrica.

• Corte el material a la capacidad nominal o por debajo de esta. Recuerde que el grosor

del material incrementa a medida que disminuye el n#mero de calibre (el calibre 14 es

mas grueso que el calibre 16). El grosor del calibre 14 es de 1,9 mm (0,075"); el calibre

16 es 1,5 mm (0,060'').

• NUNCA se ubique de modo que alguna parte del cuerpo este cerca de las hojas. Puede

causar lesiones personales graves.

• Mantenga las manos lejos de las zonas de corte. Un momento de descuido mientras se

opera una herramienta electrica podrfa provocar dahos personales graves.

• SlEMPRE utilice guantes de proteccidn cuando maneje laminas de metal Los bordes son

filosos y pueden producir lesiones personales graves.

• Sujete con firmeza la pieza de metal que desee cortar para evitar movimientos durante el

corte.

• SIEMPRE encienda la herramienta antes de tocar el material que se va a cortar.

• Siempre use calzado de seguridad para proteger sus pies de los desechos de metal

afilado en el piso.

• NO use la recortadora con ning#n accesorio ni dispositivo.

• Mantenga ajustados todos los tomillos. Revise el ajuste de la herramienta

periddicamente.

• No coloque ning#n objeto en las aberturas del alojamiento del motor.

• Limpie su herramienta con frecuencia, especialmente despues de un uso intensivo.

A menudo se acumulan sobre las superficies interiores polvo y suciedad que contienen

partfculas met#licas, que pueden provocar riesgo de descarga electrica.

• Mantengase alejado de las piezas que puedan caerse despues de realizar cortes. El

contacto con un borde filoso puede provocar lesiones personales.

• Mantenga siempre el cable electrico lejos del borde del material que va a cortar. Los

bordes filosos pueden cortar el aislamiento del cable. Esta situacidn podrfa provocar un

riesgo de descarga electrica.

AADVERTENClA: Use SIEMPRE Lentes de seguridad. Los anteojos de uso diario NO

son lentes de seguridad. Utilice tambien mascaras faciales o para polvo si el corte produce

polvillo. UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• proteccidn para los ojos ANSI Z87. I(CAN/CSA Z94.3),

• proteccidn auditiva ANSI $12.6 ($3.19),

• proteccidn respiratoria seg#n las normas NIOSH/OSHA/MSHA..

A ADVERTENClA: Durante el uso, use siempre proteccion auditiva adecuada que cumpla

con la norma ANSI S12.6 (S3.19). Bajo ciertas circunstancias y seg#n el perfodo de uso, el

ruido producido por este producto puede contribuir a la perdida de audicidn.

J_,ADVERTENClA: Utilice siempre proteccion para los ojos. Todos los usuarios y

espectadores deben utilizar proteccidn para los ojos conforme con las normas ANSI Z87.1.

_&ADVERTENClA: Algunas partfculas originadas al lijar, aserrar, amolar, taladrar y realizar

otras actividades de construccidn contienen productos qufmicos que producen cancer,

defectos de nacimiento y otros problemas reproductivos. Algunos ejemplos de estos productos

qufmicos son:

• el plomo de las pinturas de base plomo,

• la sflice cristalina de ladrillos, cemento y otros productos de mamposterfa, y

• el arsenico y el cromo de la madera con tratamiento qufmico.

El riesgo derivado de estas exposiciones varfa seg#n la frecuencia con la que se realice este

tipo de trabajo. Para reducir la exposicidn a estos productos qufmicos, se recomienda trabajar

en areas bien ventiladas y usar equipos de seguridad aprobados, como las mascaras para

polvo especialmente disehadas para filtrar las partfculas microscdpicas.

• Evite el contacto prolongado con las particulas de polvo originadas al lijar, aserrar,

esmerilar, taladrar y realizar demas actividades de la construccion. Use indumentaria

protectora y lave las areas expuestas con agua y jabon. Evite que el polvo entre en la

boca yen los ojos o se deposite en la piel, para impedir la absorcidn de productos qufmicos

nocivos.

AADVERTENClA: El uso de esta herramienta puede generar o dispersar partfculas de polvo,

que pueden causar lesiones respiratorias permanentes y graves u otras lesiones. Use siempre

proteccidn respiratoria apropiada para la exposicidn al polvo aprobada por el Instituto Nacional

de Salud y Seguridad Ocupacional de EE.UU. y la Administracidn de Salud y Seguridad

Ocupacional de EE.UU. (NIOSH y OSHA respectivamente, por sus siglas en ingles). Aleje la

cara y el cuerpo del contacto con las partfculas.

• La etiqueta de su herramienta puede incluir los siguientes sfmbolos. Los sfmbolos y sus

definiciones son los siguientes:

V.................. voltios

Hz................ hertz

min .............. minutos

-- - ........... corriente directa

(_) ................ Construccidn Clase I

(con conexidn a tierra)

[] ................ Construccidn Clase II

(con aislamiento doble)

BPM ............ golpes por minuto

A ................. amperios

W ................ vatios

"_ ............... corriente altema

no ................ velocidad sin carga

................ terminal a tierra

................ sfmbolo de alerta de seguridad

.../min ......... revoluciones o reciprocidad

por minuto

CONSERVE LAS INSTRUCCIONES

Motor

Su herramienta DEWALT esta alimentada por un motor DEWALT. Asegt]rese de que la fuente de

energia concuerde con Io que se indica en la placa.

Un descenso en el voltaje de mAs del 10% producirA una p_rdida de potencia y

sobrecalentamiento. TODAS LAS HERRAMIENTAS DEWALT son probadas en fAbrica; si

esta herramienta no funciona, verifique el suministro el_ctrico.

COMPONENTS (Fig. 1)

_ADVERTENCIA: Nunca modifique la herramienta electrica ni ninguna pieza de esta. Podrfa

ocasionar un daho o una lesidn personal

A. Cabezal

B. Punz6n

C. Anillo de la cubierta

D. Troquel

E. Alojamiento

F. Interruptor de paleta

G. Bot6n de bloqueo del interruptor

H. Tornillo de sujeci6n

USO PREVISTO

La recortadora DW898 calibre 14 ha sido diseSada para realizar cortes profesionales en

diferentes Areas de trabajo (por ejemplo, sitios de construcci6n). NO use la herramienta en

condiciones de humedad o en presencia de gases o liquidos inflamables.

Las recortadoras calibre 14 son herramientas el_ctricas profesionales. NO permita que los

niSos tengan contacto con la herramienta. Se debe supervisar a los operadores inexpertos que

utilizan esta herramienta.

Interruptores (Fig. 1)

Para encender la herramienta, oprima el interruptor de paleta (F). Para apagarla, suelte el

interruptor. El interruptor de paleta puede bloquearse si mantiene presionado el interruptor de

paleta y, simult_meamente, pulsa el bot6n de bloqueo (G) ubicado cerca de la parte posterior

de la herramienta. Asegt]rese siempre de que la herramienta no est6 bloqueada en la posici6n

de encendido antes de enchufarla. Para apagar la herramienta mientras est6 bloqueada en la

posici6n de encendido, oprima y libere el interruptor de paleta una vez.

FUNCIONAMIENTO (Figs. 2, 3)

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y desconectela de la fuente de alimentacion antes de realizar ajustes o de

retirar o instalar cualquier dispositivo o accesorio.

Lubrique la superficie del material con aceite. La recortadora esta dise_ada para cortar metal

piano y corrugado hueco.

NOTA: El punz6n y el troquel deben lubricarse. Para ello, sum_rjalos en aceite de corte de

buena calidad aproximadamente cada 9,2 m (30 pies) de corte.

La herramienta se despacha de fabrica con el punz6n (B) orientado hacia adelante para cortar

material piano y corrugado hueco.

El cabezal (A) puede alinearse en tres posiciones: izquierda, avance y derecha (Consulte

la Fig. 2). Para girar el cabezal (A), afloje el tornillo de sujeci6n (H). Gire el cabezal en la

direcci6n deseada.

NOTA: No gire el cabezal en un circulo completo, ya que esto modificara la posici6n del punz6n

en el troquel.

Rote la cubierta (E) en el cabezal (A) y gire el tornillo de sujeci6n (H) hasta que sienta que

_ste calza en una cavidad de la zapata. Apriete firmemente el tornillo de sujeci6n. Revise

peri6dicamente el ajuste de este tornillo.

El cabezal de la recortadora (A) esta diseSado para caber en un orificio de 19 mm (3/4") con

el fin de poder comenzar un corte en la mitad del trabajo. Los recortes pueden realizarse en

cualquier direcci6n desde este orificio. La parte frontal del alojamiento proporciona un indicador

del ancho del punz6n para permitir que los usuarios sigan una linea con precisi6n (Fig. 3).

La parte inferior del alojamiento tiene una guia de plantilla de 13 mm (0,51") de diametro (L)

que posibilita el uso de plantillas. Consulte las Figuras 2 y 3 para la superficie de la guia de la

plantilla. La plantilla debe tener un grosor tal que, sumado al grosor de la pieza de trabajo, sea

de 5 a 6,5 mm (13/64" a 1/4"). La forma de la plan(ilia debe estar a 2,5 mm (0,1") de distancia

de la forma que debe recortarse. La herramienta debe guiarse de modo que el diametro

exterior (13 mm o 0,51 ") del alojamiento siempre se apoye sobre la plantilla.

Cambio de punzones (Fig. 2)

Nunca corte con un punz6n o troquel desafilado o redondeado. Los punzones pueden afilarse

hasta alcanzar una Iongitud de 69 mm (2,72"). Los punzones mas cortos no pueden recibir

mantenimiento. Para retirar el punz6n (B), afloje el tornillo de sujeci6n del cabezal (H) dandole

aproximadamente 4 a 5 vueltas (Consulte la Fig. 2). Deslice el alojamiento (E) del cabezal (A).

Desatornille el punz6n (B) del buje de la varilla de conexi6n (J). El punz6n puede volver a afilarse

con cuidado en una esmeriladora de banco con un disco de grano fino. Tenga cuidado de que

el punz6n no est_ mas corto que la Iongitud minima. Los punzones mas cortos no se calzaran

en el troquel Io suficiente y deben reemplazarse. La cara esmerilada debe estar en posici6n per-

pendicular al eje del punz6n. Despu_s de esmerilar, lime con cuidado los bordes esmerilados

para retirar las rebabas. No redondee las esquinas.

Reensamblaje del cabezal de la recortadora (Fig. 2)

Atornille el punz6n (B) por completo en el buje de la varilla de conexi6n (J). Deslice el aloja-

miento (E) sobre el extremo del punz6n y hacia dentro del cabezal. Gire el alojamiento (E) a la

orientacion de corte deseada. Apriete el tornillo de sujecion (H). A continuacion, compruebe el

calce del punz6n.

Comprobacidn del calce del punzdn (Fig. 2)

Dado que la Iongitud del punz6n (B) ahora se ha modificado, es probable que se deba ajustar

el calce del punz6n. Compruebe el calce del punz6n; para ello, coloque un destornillador de

hoja plana en la ranura del eje del arbol de levas (I) y gire el eje. (Consulte la Fig. 2). El punz6n

debe introducirse entre 0,5 y 1,1 mm (0,020" y 0,06") en el troquel en la posici6n de carrera

completamente hacia abajo. Introducir demasiado el punz6n en el troquel provocara la p_rdida

de capacidad (la parte inferior del punz6n no permitira un espacio suficiente del troquel en la

carrera hacia arriba).

Ajuste del calce del punzdn (Fig. 2)

Si se debe ajustar el calce del punz6n, afloje el tornillo de sujeci6n (H) y gire la zapata en el

sentido de las agujas del reloj(el punz6n se introducira at]n mAs en el troquel) o en el sentido

contrario (el punz6n saldrA del troquel). Apriete firmemente el tornillo de sujeci6n. Gire el eje

del Arbol de levas (I) con un destornillador en la ranura para comprobar el calce del punz6n (el

punz6n se mover& completamente hacia abajo). Repita segt]n sea necesario.

Reemplazo del troquel (Fig. 2)

Si el troquel (D) se redondea, reemplacelo. Reemplace el troquel anterior empujando el anillo

de la cubierta (C) hacia arriba y afuera de la ranura del troquel. Retire la clavija de retenci6n

Iocalizada debajo del anillo de la cubierta con un punz6n de desplazamiento. Empuje el troquel

Page 6

haciaafueradelejeportador(K).Instaleunnuevotroquel(D)enelejeportador(K).Alineeel

orificiotransversaldeltroquelconlaranuradelejeportador.Instalelaclavija.Calceelanillode

lacubierta(C)sobreeltroquelenlaranurasuministrada.

MANTENIMIENTO

_ADVERTENCIA: Para reducir el riesgo de lesiones personales graves, apague la

herramienta y desconectela de la fuente de alimentacion antes de instalar y retirar

accesorios, antes de realizar ajustes o al realizar reparaciones.

• Verifique que el punz6n y el troquel est_n afilados. Si ambos o alguno de los dos estan

desafilados, afilelos o reemplacelos.

• Sumerja peri6dicamente la zapata en aceite.

• €:sta es una herramienta de precisi6n. 0sela con cuidado y guardela en un lugar

protegido.

Limpieza

_,ADVERTENCIA: Sople la suciedad y el polvo de todos los conductos de ventilacidn con aire

seco al menos una vez por semana. Use la adecuada proteccidn para los ojos ANSI Z87.1

(CAN/CSA Z94.3) y la adecuada proteccidn respiratoria NIOSH/OSHA/MSHA cuando realice

esta operacidn.

_&ADVERTENClA: nunca utilice disolventes u otros qufmicos abrasivos para limpiar las piezas

no metalicas de la herramienta. Estos productos qufmicos pueden debilitar los materiales plasti-

cos utilizados en estas piezas. Utilice un pa#o humedecido sdlo con agua y jabdn neutro. Nunca

permita que penetre Ifquido dentro de la herramienta ni sumerja ninguna de las piezas en

un Ifquido.

Lubricacidn

Las herramientas que se emplean constantemente en trabajos pesados o de producci6n, o

aquellas que se exponen al calor, requieren de lubricaci6n mas frecuente. Las herramientas que

se dejan '_fuera de servicio" por periodos prolongados deben lubricarse antes de devolverlas al

trabajo.

Accesorios

,IJ,ADVERTENCIA: Debido a que no se han probado con este producto otros accesorios que

no sean los que ofrece DEWAL T, el uso de dichos accesorios con esta herramienta podrfa ser

peligroso. Para reducir el riesgo de lesiones, con este producto deben usarse sdlo los accesorios

recomendados por DEWAL T.

Los accesorios que se recomiendan para la herramienta estan disponibles para la compra en su

distribuidor local o en el centro de mantenimiento autorizado. Si necesita ayuda para Iocalizar algt]n

accesorio para su herramienta, comuniquese con DEWALT Industrial Tool Co., 701 East Joppa

Road, Baltimore, MD 21286, Ilame al 1-800-4-DEWALT (1-800-433-9258) o visite nuestro sitio Web

www.dewalt.com.

Reparaciones

Para asegurar la SEGURIDAD y la CONFIABILIDAD del producto, las reparaciones, el manten-

imiento y los ajustes (incluyendo revisi6n y cambio de los carbones) deben ser realizados por

un centro de servicio de fabrica DEWALT, un centro de servicio autorizado DEWALT u otro

personal de mantenimiento calificado. Utilice siempre piezas de repuesto id_nticas.

PARA REPARACION Y SERVIClO DE SUS HERRAMIENTAS ELI_CTRICAS, FAVOR DE

CULIACAN, SIN

Av, NicolAsBravo#1063 Sur - Col, Industrial Bravo

GUADALAJARA, JAL

Av, La Paz#1779 - Col, Americana Sector Juarez

MEXICO,D.F.

EjeCentral Lazaro Cardenas No, 18

Local D, Col, Obrera

MERIDA,YUC

CaNe63#459-A - Col, Centro

MONTERREY, N.L.

Av, FranciscoI,Madero No,831- Col, Centro

PUEBLA, PUE

17 Norte#205 - Col, Centro

QUERETARO, QRO

Av, Madero 139 Pte, - Col, Centro

SAN LUlS POTOSl, SLP

Av, Universidad1525- Col, San Luis

TORREON, COAH

Blvd, Independencia,96 Pte, - Col, Centro

VERACRUZ, VER

Prolongaci6nDiaz Mir6n #4280 - Col, Remes

VlLLAHERMOSA, TAB

Constituci6n516-A - Col, Centro

Pdliza de Garantia

IDENTIFICACION DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: Mod./Cat.:

Marca: Nt]m. de serie:

(Datos para ser Ilenados por el distribuidor)

Fecha de compra y/o entrega del producto:

Nombre y domicilio del distribuidor donde se adquiri6 el producto:

DIRIGIRSE AL CENTRO DE SERVIClO MAS CERCANO

(667) 7 12 42 11

(33) 3825 6978

(55) 5588 9377

(999) 928 5038

(81) 8375 2313

(222) 246 3714

(442) 214 1660

(444) 814 2383

(871) 716 5265

(229) 921 7016

(993) 312 5111

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

GARANT|A DE REEMBOLSO DE DINERO DE 90 D|AS

Si por alguna raz6n no estuviera plenamente satisfecho con el rendimiento de la herramienta

el_ctrica, el laser o la clavadora DEWALT, puede devolver el producto dentro de los 90 dias

siguientes a la fecha de compra acompaSado del recibo de compra. De esta manera, se le

reintegrara el importe total del producto sin formularle pregunta alguna.

AMI_RICA LATINA: Esta garantia no se aplica a los productos que se venden en Am@ica

Latina. Para los productos que se venden en Am@ica Latina, debe consultar la informaci6n de

la garantia especffica del pais que viene en el empaque, Ilamar a la compaSia local o visitar el

sitio Web a fin de obtener esa informaci6n.

REEMPLAZO GRATUlTO DE LAS ETIQUETAS DE ADVERTENClA: si sus etiquetas de

advertencia se tornan ilegibles o faltan, Ilame al 1-800-4-DEWALT para que se las reemplacen

gratuitamente.

"uVV898r'"14GAUGENIBBLER

SER,

TOREDUCETHERISKOF

INSTRUCTION MANUAL ALWAYS USE PROPER EYE AND

RESPIRATORY PROTECTION,

DEWALTINDUSTRIALTOOLCO.,BALTIMORE, MD 21286USA

FORSERVICEINFORMATION, CALLI.-800-4-OEWALT www,DEWALT,com

• J

INJURY, USER MUST READ

Especificaciones

Tensi6n de alimentaci6n

Consumo de corriente

Frecuencia de operaci6n

Potencia nominal

Carreras por minuto

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS, 3A. SECCION, CP 05120

DELEGACION CUAJIMALPA, MEXICO, D.F

Para servicio y ventas consulte _"-_ "

"HERRAMIENTAS ELECTRICAS" SECCI_

TEL. 5 326 7100

R.F.C.: BDE810626-1W7

en la secci6n amarilla, ll!,_!t!A

INSTRUCCIONES. UTIUCE SIEMPRE LAPI_OTECCION

ADECUADAPARA LAVISTAY PARA LASVIAS RESPIRATORIAS.

TOUJOURS PORTERDE L'I_QUIPEMENTDEPROTECTION

OCULAIREET RESPIRATOIREAPPROPRIE.

• J

DW898

120 V AC

6,5 A

60 Hz

225 W

1 950 spm

PARAELMANEJO SEGURO

LEAELMANUAL DE

A TITREPREVENTIE

LIRELEGUIDE.

Este producto esta garantizado por un aSo a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, asi como en materiales y mano de obra empleados para su fab-