Page 1

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW897/DW897-220

16 Gauge Nibbler

Grignoteuse de calibre 16

Cortadora de lamina calibre 16

INSTRUCTIVO DE OPERACION, CENTROS DE SERVIClO Y POLIZA

DE GARANTiA. ADVERTENClA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

®

Page 2

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY DEWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

HEAD

\

i SWITCHLOCK

PADDLESWITCH BUTTON

PUNCH--

I

SHOE

--PUNCH

GUIDE

DW897/DW897-22016-Gauge

ProfileNibbler

IMPORTANT SAFETY

INSTRUCTIONS (FOR ALL TOOLS)

z_ WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool's electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground

connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection against injury resulting from a possible electrical

insulation failure within the tool.

z_ CAUTION: WHEN SERVICING USE ONLY IDENTICAL RE-

PLACEMENT PARTS. Repair or replace damaged cords.

Polarized Plugs(DW897)

Polarized plugs (one blade is wider than the other) are used on

equipment to reduce the risk of electric shock. When provided, this

plug will fit into a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not change the

plug in any way.

Page 3

For All Tools:

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don't expose power

tools to rain. Don't use power tools in damp or wet locations. Keep

work area well lit.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces; for example, pipes, radiators, ranges,

and refrigerator enclosures.

• KEEP CHILDREN AWAY. All visitors should be kept away from

work area. Do not let visitors contact tool or extension cord.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place -- out of reach of children.

• DON'T FORCE A TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don't force small tool or attachment to do the

job of a heavy duty tool Don't use tool for purpose not intended; for

example, don't use circular saw for cutting tree limbs or logs.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dustmask if operation

is dusty

• DON'T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It's safer than

using your hand and it frees both hands to operate tool

• DON'T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safe performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if

damaged have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

AVOID UNINTENTIONAL STARTING. Don't carry plugged-in tool

with finger on the switch. Be sure the switch is off when plugging

in.

EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. The following table shows the correct

size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Volts

120V

240V

Ampere Rating

More Not more

Than Than

0 6

6 10

10 12

12 16

MinimumGage for Cord Sets

Total Length of Cord in Feet

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommended

STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

Page 4

• CHECKDAMAGEDPARTS.Beforefurtheruseofthetool,a

guardor other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is defective

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

• DO NOT OPERATE portable electric tools near flammable liquids

or in gaseous or explosive atmospheres. Motors in these tools

normally spark, and the sparks might ignite fumes.

• CAUTION: When drilling or driving into walls, floors or wherever

five electrical wires may be encountered, DO NOT TOUCH ANY

METAL PARTS OF THE TOOLS! Hold the tool only by insulated

grasping surfaces to prevent electric shock if you drive into a live

wire.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Operating Rules for Nibblers

1. Always wear safety glasses and protective gloves.

2. Wear safety shoes to protect your feet from sharp metal debris on

floor.

3. Cut material at or below rated capacity. Remember, material

thickness increases as gauge number decreases (14 gauge is

thicker than 16 gauge). 14 gauge thickness is .075" (1,9 mm); 16

gauge is. 060" (1,5 mm).

4. Keep all screws tight. Periodically check them for loosening.

5. Unplug tool before making any adjustments.

6. Do not put anything into a motor housing opening.

7. Keep tool clean. Blow off.any metal debris and dirt from tool

8. Firmly secure the piece of metal to be cut to prevent movement

during cutting.

PADDLE SWITCH

To start the tool, depress the paddle switch. To turn the tool off,

release the paddle. The switch can be locked on be engaging the

lock button located near the rear of the tool while holding the paddle

depressed. Always be sure that the tool is not locked on before

plugging it in. To turn the tool off when it is locked on, squeeze and

release the paddle once.

Operation

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY

BEFORE MAKING ANY ADJUSTMENTS. Always wear safety

glasses and protective gloves.

Lubricate surface of material with oil. The profile nibbler is designed

to cut corrugated, flat, and box steel forms.

The tool is factory assembled with the punch oriented forward for

cutting flat and shallow corrugated material. Tocut deeper corrugated

metals and box sections, rotate the head 90 °to either side to use tool

sideways.

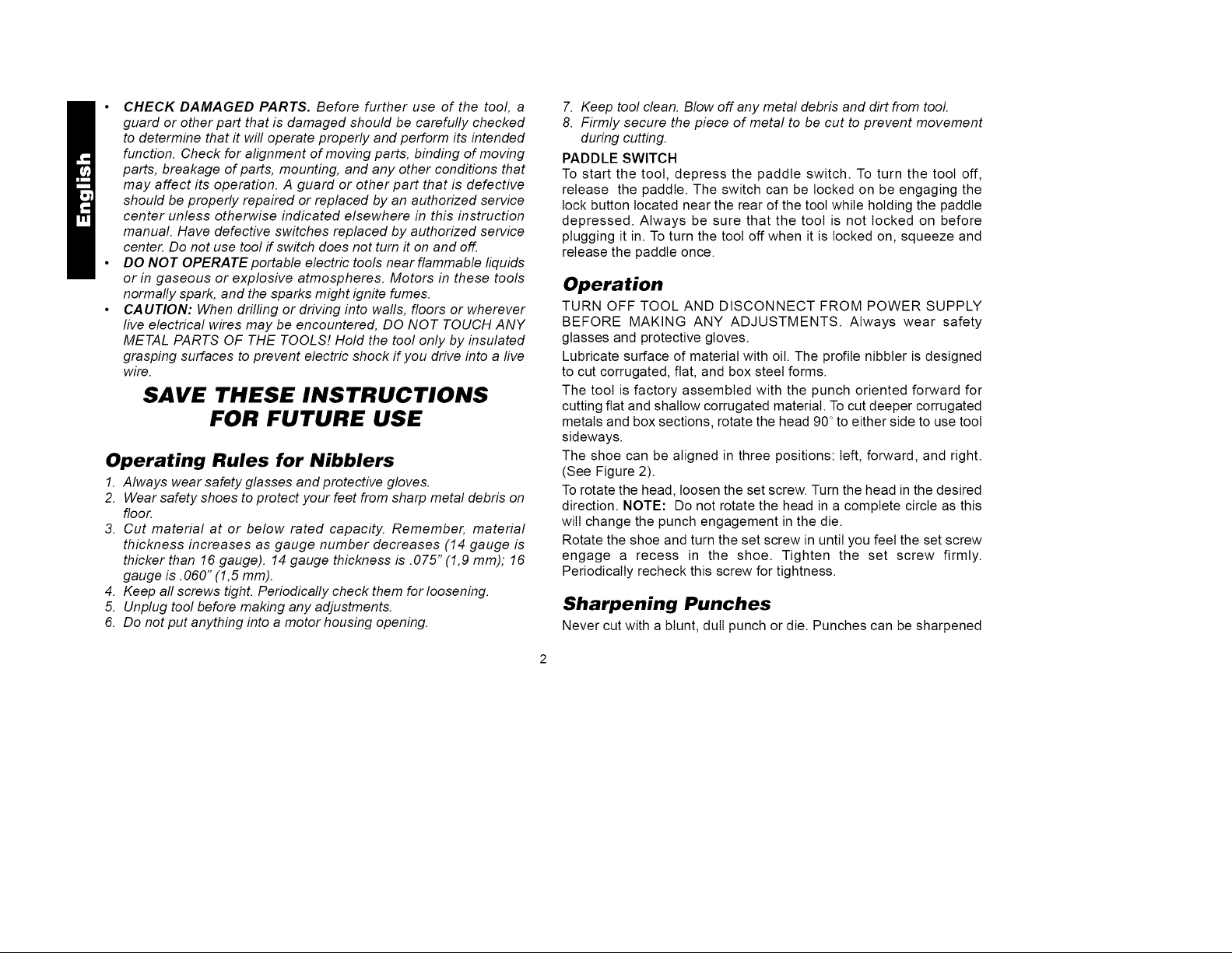

The shoe can be aligned in three positions: left, forward, and right.

(See Figure 2).

Torotate the head, loosen the set screw. Turn the head in the desired

direction. NOTE: Do not rotate the head in a complete circle as this

will change the punch engagement in the die.

Rotate the shoe and turn the set screw in until you feel the set screw

engage a recess in the shoe. Tighten the set screw firmly.

Periodically recheck this screw for tightness.

Sharpening Punches

Never cut with a blunt, dull punch or die. Punches can be sharpened

Page 5

upto1/8"(3mm).Toremovethepunch,loosentheheadsetscrew

about4-5turns(SeeFigure2).Slidetheshoeassemblyfromthe

head.Unscrewthepunchfromtheconnectingrodbushing.Punch

mayberesharpenedcarefullyonabenchgrinderwithafinegrit

wheel.Becarefulthatthepunchdoesnotbecomeshorterthanthe

minimumlengthof2.44inches(2-7/16inchesor61mm).Punches

shorterthanthiswillnotengagethediesufficientlyandmustbe

replaced.Thegroundfacemustbesquaretothepunchaxis.After

grinding,carefullystonethegroundedgestoremoveburrs.Donot

roundovercorners.

Figure2 Figure3

HEAD HEAD CAM

_ SHAFT

Reassembly of Nibbler Head

Screw the punch fully into the connecting rod bushing. Slide the shoe

assembly over the end of the punch and into the head. NOTE:

Lubrication groove in punch face must not be exposed at front of

shoe. Turn the shoe to desired cut orientation. Tighten set screw.

Next, check punch engagement.

Checking Punch Engagement

Since the punch length is now changed, the punch engagement may

have to be adjusted. Check punch engagement by placing a flat

blade screwdriver in the cam shaft slot and turning the shaft. (See

Figure 2) Punch should dip .020" to .04" (.5 to 1.0mm) into the die at

the full down stroke position. Too much punch dip into the die will

result in a loss of capacity (bottom of punch will not clear die enough

on up stroke.)

SHAFT

CONNECTING SET

RODBUSHING SCREW PUNCH

--DIE SHOE--

PUNCH I WEAR

GUIDE SHOE PLATE

i DIE

Punch Engagement Adjustment

If the punch engagement should need adjustment, loosen the set

screw and rotate shoe either clockwise (punch deeper into die) or

counterclockwise (punch out of die). Tighten set screw firmly. Turn

cam shaft with screwdriver in slot to check punch engagement

(moving punch fully down). Repeat as necessary.

Die Replacement

If the die becomes dull, replace it. Replace old die by removing two

screws at the front (Figure 2). Install new die and tighten screws.

Recheck punch engagement and adjust punch depth if necessary.

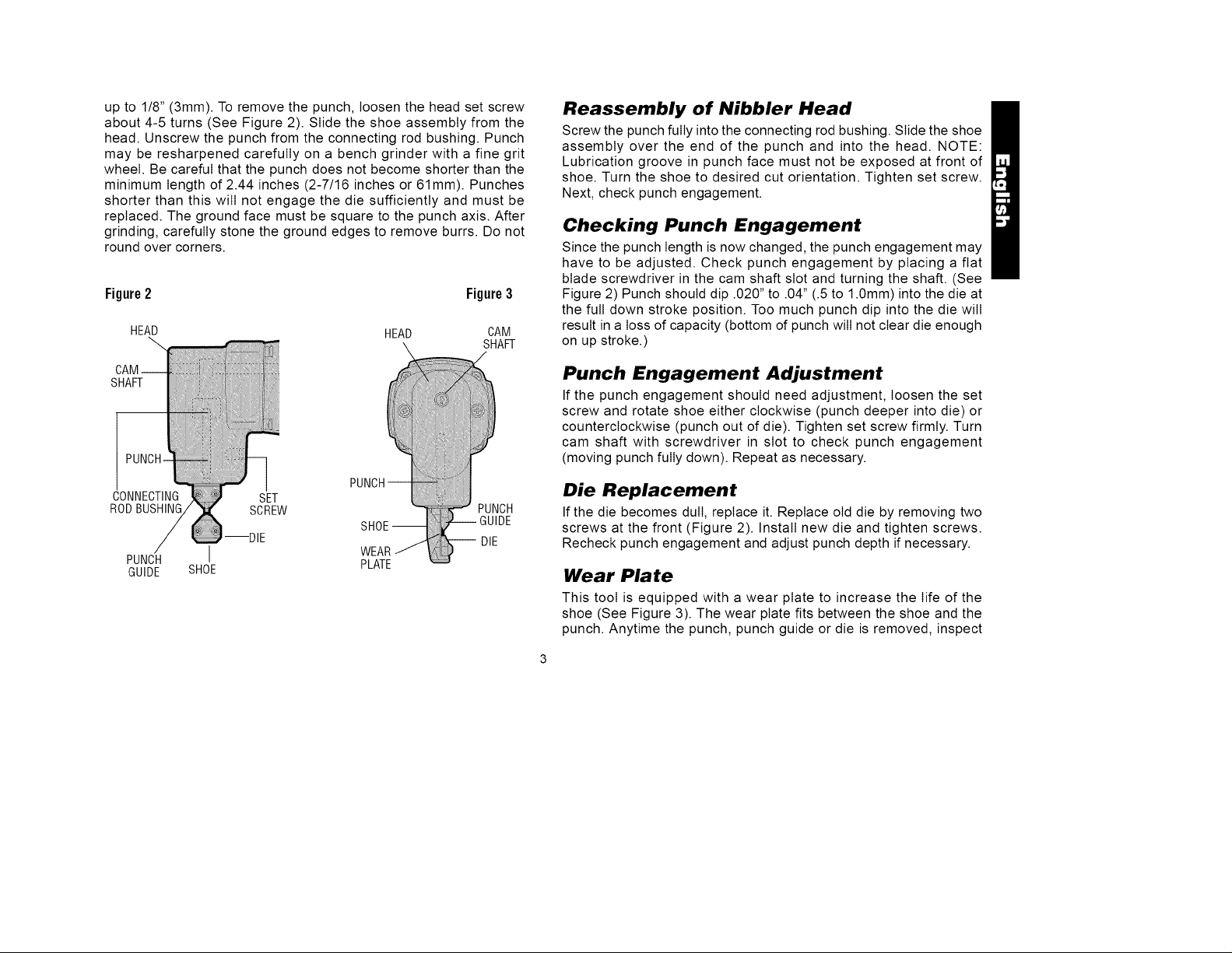

Wear Plate

This tool is equipped with a wear plate to increase the life of the

shoe (See Figure 3). The wear plate fits between the shoe and the

punch. Anytime the punch, punch guide or die is removed, inspect

Page 6

thewearplate.Ifitisworn,replaceit.

Toremovethewearplate,dissassembtethepunchguideanddie

(Figure3).Turncamshaftwithscrewdriversothatpunchisfullyup.

Slidethewearplatefrombehindthepunch.Insertanewwearplate.

Turnthecamshaftwithscrewdrivertomovepunchfullydown.

Replacepunchguideanddie.Checkpunchengagementtodie.

Adjustpunchengagement,ifnecessary.

Maintenance

DISCONNECT TOOL FROM POWER SUPPLY BEFORE

PERFORMING ANY MAINTENANCE. Check that the punch and

die are sharp. If either is dull, sharpen or replace. Check wear plate

and replace if worn. Keep the tool clean. Blow off periodically. Never

use solvents or harsh chemicals for cleaning non-metallic parts of the

tool. Use a clean, dry rag only. Periodically dip the shoe in oil. This is

a precision tool. Use it carefully and store it in a protected place.

Cleaning & Lubrication

Use only mild soap and damp cloth to clean the tool. Never let any

liquid get inside the tool; never immerse any part of the tool into a

liquid.

Self-lubricating bearings are used in the tool and periodic

relubrication is not required. In the unlikely event that service is ever

needed, service center addresses are packed with your tool.

Motor Brushes

Brush replacement should be performed by authorized service

centers or other qualified service organizations.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-DEWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

Page 7

POURTOUTRENSEIGNEMENTSUPPL¢:MENTAIRESURCET

OUTILOUTOUTAUTREOUTILDEWALT,COMPOSERSANS

FRAISLENUM¢:RO:

1 800 4-DEWALT (1 800 433-9258)

IMPORTANTES

MESURES DE SJ CURITJ

(POUR TOUS LES OUTILS)

AVERTISSEMENT : Afin de reduire Ies risques d'incendie, de

secousses electriques ou de btessures Iorsqu'on utilise des outils

electriques, iI faut toujours respecter Ies mesures de securit6

suivantes.

TETE

BLOOAGE

-- BO[TIER SWITCH

-- MATRICE

I

ANNEAUDU

COUVERCLE

Grignoteusedecalibre16

IVIod_leDW897

t BOUTONDE

I VERROUILLAG

INTERRUPTEUR EDEL"

ABASCULEPADDLE INTERRUTEUR

LIRE TOUTES LES DIRECTIVES.

• BIEN DE:GAGER LA SURFACE DE TRAVAIL. Des surfaces et

des #tablis encombr#s peuvent _tre la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Prot#ger les outils

#lectriques de la pluie. Ne pas s'en servir dans des endroits

humides ou mouill#s. Bien #clairer la surface de travail.

• SE PROTE:GER CONTRE LES SECOUSSES E:LECTRIQUES.

Eviter tout contact avec des objets mis b la terre, comme des

tuyaux, radiateurs, cuisini#res, r#frig#rateurs et autres objets du

genre.

• ELOIGNER LES ENFANTS. Tousles visiteurs doivent _tre tenus

b I'#cart de I'aire de travail et il faut les emp_cher de toucher b

Ibutil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISES. IIfaut rangerles outils dans

un endroit sec, situ# en hauteur ou ferm# b cl& hors de la port#e

des enfants.

• NE JAMAIS FORCER L'OUTIL. Afin d'obtenir un rendement sDr

et efficace, utiliser I'outil b son rendement nominal.

• UTILISER L'OUTIL APPROPRIE:. Nejamais exigerd'un petitoutil

ou d'un accessoire le rendement d'un outil de fabrication plus

robuste. Se servir de Ibutil selon I'usage pr#vu (par exemple, ne

passe servir d'une scie circulaire pour couper des branches

d'arbres ou des b_Jches).

Page 8

• PORTER DES VETEMENTS APPROPRIES. Eviter de porter des

v_tements amples et des bijoux qui peuvent _tre happ_s par les

pi_ces en mouvement. Porter des gants de caoutchouc et des

chaussures _ semelle antid_rapante pour travailler _ I'ext_rieur.

Prot_ger la chevelure si elle est Iongue.

• PORTER DES LUNETTES DE SECURITE. Porter _galement un

masque respiratoire si le travail de coupe produit de la poussi_re.

• NE PAS MANIPULER LE CORDON DE FA_ON ABUSIVE. Ne

pas transporter I'outil par le cordon ni tirer sur ce demier pour le

d_brancher de laprise. Eloigner le cordon des sources de chaleur,

des flaques d'huile et des ar_tes tranchantes.

• ASSUJETTIR LA PIECE. Immobiliser la piece _/'aide de brides

ou d'un _tau. On peut alors se servir des deux mains pour faire

fonctionner Ibutil, ce qui est plus sDr.

• NE PAS DEPASSER SA PORTEE. Toujours demeurer dans une

position stable et garder son _quilibre.

• PRENDRE SOIN DES OUTILS. Conserverles outils propres pour

qu'ils donnent un rendement sup_rieur et sDr. Suivre les directives

concemant la lubrification et le remplacement des accessoires.

Inspecter r_gufi_rement le cordon de Ibutil et le faire r_parer au

besoin _ un atefier d'entretien autoris& Inspecter r_gufi_rement

les cordons de rallonge et les remplacer Iorsqu'ils sont

endommag_s. S'assurer que les poign_es sont toujours propres,

s_ches et libres de toute tache d'huile ou de graisse.

• DEBRANCHER LES OUTILS NON UTILISES. Respecter cette

mesure Iorsqu'on ne se sert pas de Ibutil, ou qu'on doit le r_parer

ou en changer un accessoire (comme une lame, un foret ou un

couteau).

• ENLEVER LES CLES DE REGLAGE. Prendre /'habitude de

v#rifier si les cl#s de r#glage ont #t# retirees avant de faire

d#marrer Ibutil.

• EVlTER LES DEMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur I'interrupteur Iorsqu'on transporte I'outil. S'assurer que

I'interrupteur est _ la position hors circuit Iorsqu'on branche I'outil.

• CORDONS DE RALLONGE PREVUS POUR L'EXTERIEUR.

Lorsque Ibutil est utilis# _ I'ext#rieur, ne se servir que d'un cordon

de rallonge congu pour I'ext#rieur et portant la mention appropri#e.

On trouve de plus amples renseignements sur les cordons de

rallonge _ la page 2.

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de Ibutil Iorsqubn est fatigu&

• V_=RIFIER LES PI_=CES ENDOMMAG_=ES. V_rifier I'alignement

et les attaches des pi#ces mobiles, le degr# d'usure des pi#ces et

leur montage, ainsi que tout autre facteur susceptible de nuire au

bon fonctionnement de I'outil. Faire r#parer ou remplacer tout

protecteur ou toute autre piece endommag#e dans un centre de

service autoris& sauf si le present guide fait mention d'un avis

contraire. Confier le remplacement de tout interrupteur d#fectueux

un centre de service autoris& Ne jamais se servir d'un outil

dont I'interrupteur est d#fectueux.

• NE PAS UTILISER les outils portatifs #lectriques dans des

endroits oD I'atmosph#re contient des vapeurs combustibles ou

explosives. Les #tincefles que produit le moteur en marche

pourraient enflammer ces produits.

CONSERVER CES MESURES

A TITRE DE REFERENCE.

Mesures relatives aux grignoteuses

1. Toujours porter des/unettes de s_curit_ et des gants protecteurs.

2. Porter des chaussures de s#curit# afin de prot#ger ses pieds des

d#bris m#talliques tranchants sur le plancher.

3. D#couper le mat#riau au plus au r#gime nominal de Ibutil. fl faut

se rappeler que I'#paisseur du mat#riau est inversement

proportionnefle au cafibre de I'outil (ainsi, un outil de cafibre 14

coupe des mat#riaux plus #pais qu'un outil de calibre 16). Un outil

de cafibre 14 accepte un mat#riau d'une #paisseur de 1,90 mm

Page 9

(0,075pc)etunoutildecalibre16,de1,52mm(0,060pc).

4.S'assurerquetouteslesvissontbienserr#es.Lesv#rifier

r#guli#rement.

5.D#brancherlbutilavantdeler#gler.

6.Nerieninsurerdanslesorificesducarterdumoteur.

7.S'assurerqueI'outilesttoujourspropre.Ennettoyerlesd#bris

m#talliquesetlapoussi#reenysoufflantdeFair.

8.Bienfixerlapiecedem#tal_ d#couper afin de I'emp_cher de

bouger pendant les travaux.

INTERRUPTEUR A BASCULE

Pour mettre I'outiI en marche, enfoncer I'interrupteur a bascule. Pour

I'arrOter, reI_cher I'interrupteur a bascule. On peut verrouilIer

I'interrupteur en mode de fonctionnement en enfongant Ie bouton de

verrouilIage qui se trouve pros de I'arriere de I'outiI tout en

maintenant enfonce I'interrupteur a bascule. Toujours s'assurer que

Figure 2 Figure 3

Tt_TE TETE ARBREA

ARBRE

A

CAME

DOUILLE

DELA BIELLE

POINOON- BLOCAGE

GUIDEPOUR

GABARIT

I-- MATRICE

BO[TIER

I

ANNEAUDU

COUVEROLE

VIS DE

POINOON--

\ CAME

IUIDEPOUR

-- GABARIT

-- MATRICE

I'outiI ne se trouve pas en mode de fonctionnement continu avant de

Ie brancher. Pour arrOter I'outiI Iorsque ce dernier est en mode de

fonctionnement continu, iI suffit d'enfoncer et de reI_cher

immediatement I'interrupteur.

Fonctionnement

METTRE UOUTIL HORS TENSION ET LE DI_BRANCHER AVANT

DE LE R#GLER Toujours porter des Iunettes de securit6 et des

gants protecteurs.

Lubrifier Ia surface du materiau avec de I'huile. La grignoteuse est

congue pour decouper du metal plat et I6gerement onduI&

L'outiI est monte en usine avec Ie poingon en position avant pour

decouper du metaI plat et I6gerement onduI&

La tote de I'outiI se place darts I'une de trois positions : vers la

gauche, vers I'avant et vers Ia droite (fig. 2). Pour faire tourner Ia tote,

desserrer Ia vis de btocage. Faire tourner Ia tote darts Ia position

voulue. NOTE: Ne pas faire tourner Ia tote sur elIe-mOme au risque

de modifier I'insertion du poingon darts Ia matrice.

Faire tourner Ie boftier darts Ia tote et faire toumer Ia vis de btocage

jusqu'a ce que Ia vis s'instalIe darts Ie creux du patin. Bien serrer Ia

vis de btocage. Verifier r6gulierement si Ia vis est bien settee.

La tote de Ia grignoteuse est congue pour s'inserer darts un trou

d'un diametre de 19 mm (3/4 pc) afin de pouvoir decouper au milieu

de Ia piece. Le grignotage se fait darts un sens ou darts I'autre darts

Ie trou. IIy a un indicateur de Ia Iargeur du poingon a I'avant du boftier

permettant a I'utilisateur de pouvoir suivre une Iigne (fig. 3).

Le dessous du boftier comporte un guide pour gabarit de 13 mm

(0,51 pc) de diametre afin de pouvoir utiliser des gabarits.

L'epaisseur du gabarit et du materiau doit se situer entre 5et 6,5 mm

(13/64 pc et 1/4 pc). La forme du gabarit doit se trouver a 2,5 mm

(1 pc) de Ia forme a grignoter. II faut guider I'outiI de sorte que Ie

diametre exterieur (13 mm ou 0,51 pc) du boftier repose contre Ie

gabarit.

Page 10

Remplacement du poin_on

Ne jamais utiliser un poin(_on emouss& On peut affQter Ies poin(_ons

jusqu'a une Iongueur minimale de 69 mm (2,72 po). Des poin(_ons

trop courts ne servent pas. Pour enlever Ie poin(_on, desserrer Ia vis

de btocage de Ia t_te d'environ 4 a 5 tours (fig. 2). Faire gtisser Ie

boftier hors de Ia t_te. Devisser Ie poin(_on de Ia douilIe de Ia bielle.

IIfaut affQter avec soin Ies poin(_ons a I'aide d'une meuleuse d'etabti

munie d'une meule a fine granulosit& Ne pas trop raccourcir Ie

poin(_on. Un poin(_on trop court ne s'insere pas bien dans Ia matrice

et iIfaut teremptacer. La face meulee dolt _tre perpendiculaire a I'axe

du poin(_on. Apres Ie meulage, ebarber soigneusement Ies rebords

aff0tes. Ne pas en arrondir Ies coins.

Remontage de la t#te de la grignoteuse

Visser Ie poin(_on a fond dans Ia douilIe de Ia bielIe. Faire gtisser Ie

boftier sur I'extremit6 du poin(_on et dans Ia t_te. Faire tourner Ia t_te

dans Ia position de coupe vouIue. Bien serrer Ia vis de btocage.

Enfin, verifier I'insertion du poingon.

V_rification de I'insertion du poin_on

Puisque Ia Iongueur du poin(_on est differente, iI faut peut-_tre regter

I'insertion du poingon. La verifier en plagant un tournevis a Ia me

plate dans Ia fente de I'arbre a came et en faisant tourner I'arbre

(fig. 2). Le poingon devrait s'affaisser de 0,5 mm a 1,15 mm (de

0,02 po a 0,06 po) dans Ia matrice a Ia position Ia plus basse de Ia

course. Lorsque I'affaissement du poingon dans Ia matrice est trop

grand, iIen resulte une perte de rendement (Ie bout du poingon ne se

degage pas suffisamment de Ia matrice au plus haut de Ia course).

R_glage de I'insertion du poin_on

Lorsqu'iI faut regter I'insertion du poin(_on, desserrer Iavis de btocage

et faire tourner Ie patin dans un sens horaire (Ie poingon enfonce

dans Ia matrice) ou dans Ie sens antihoraire (Ie poin(_on hors de Ia

matrice). Bien serrer Ia vis de btocage. Faire tourner I'arbre a came

I'aide du tournevis dans Ia fente afin de verifier I'insertion du poin(_on

(en abaissant comptetement Ie poin(_on). Repeter au besoin.

Remplacement de la matrice

Lorsque Ia matrice est emoussee, Ia remplacer. Remplacer

I'ancienne matrice en poussant I'anneau du couvercIe vers Ie haut,

hors de Ia rainure. Se servir d'un poingon de gtissement pour faire

sortir la tige de retenue du dessous de I'anneau du couvercIe. Retirer

Ia matrice de I'arbre-porteur. Installer une nouveIIe matrice sur

I'arbre-porteur. Aligner Ie trou de Ia matrice sur Ia rainure de I'arbre-

porteur. Installer Ia tige. Enclencher I'anneau du couvercIe dans Ia

rainure du dessus de Ia matrice.

Entretien

D¢:BRANCHER L'OUTIL AVANT D'EFFECTUER TOUT TRAVAIL

D'ENTRETIEN. S'assurer que Ie poingon et Ia matrice sont affQtes.

Lorsque I'un d'eux est emousse, I'affQter ou le remptacer. S'assurer

que I'outiI est propre. UtiIiser reguIierement de I'air pour en souffler

Ies saletes. Ne jamais se servir de solvants ni de produits chimiques

puissants pour nettoyer Ies composants non metalIiques de I'outiI.

UtiIiser seuIement un chiffon propre et sec. Tremper reguIierement te

patin dans de I'huile. IIs'agit d'un outiI de precision. S'en servir avec

soin et Ie ranger dans un endroit protege.

Nettoyage et lubrification

Nettoyer I'outiI seulement a I'aide d'un savon doux et d'un Iinge

humide. Ne Iaisser aucun Iiquide s'infiltrer dans I'outiI et ne jamais

immerger I'outiI.

L'outiI est monte sur des rouIements autoIubrifiants qui ne requierent

pas de Iubrification periodique. Dans Ie cas peu probable o_ I'outiI

necessiterait de I'entretien, Ia Iiste des centres de service se trouve

dans I'emballage.

Page 11

Balais du moteur

II faut confier le remptacement des balais au personnel d'un centre

de service autorise.

Important

Pour assurer Ia S¢:CURIT¢: D'EMPLOI et ta FIABILIT¢: de I'outiI, n'en

confier Ia reparation, I'entretien et Ies rajustements (y compris

I'inspection et Ie remplacement des balais) qu'au personnel d'un

centre de service DEWALT ou d'un atelier d'entretien autorise

n'utiIisant que des pieces de rechange identiques.

Accessoires

Les accessoires recommandes pour cet outiI sont vendus chez Ies

detaiIIants ou au centre de service de Ia region. Pour trouver un

accessoire, communiquer avec Ie detaiIIant ou Ie centre de service

de Ia region.

Z_MISE EN GARDE: L'utilisation de tout autre accessoire non

recommande pour I'outiI peut _tre dangereuse.

Garantie complete

Les outils industriels de service intensif DEWALT sont garantis

pendant un an a partir de Ia date d'achat. Toute piece d'un outiI

DEWALT qui s'averait defectueuse en raison d'un vice de matiere ou

de fabrication sera repar6e ou remptacee sans frais. Pour obtenir de

plus ampIes renseignements sur Ies reparations couvertes par Ia

garantie, composer Ie 1 (800) 4-DEWALT (! (800) 433-9258). La ga

rantie ne couvre pas Ies accessories ni Ies reparations tentees ou

effectuees par des tiers. Les modaIites de Ia presente garantie

donnent des droits Iegaux specifiques. L'utiIisateur peut egaIement

se prevaIoir d'autres droits seIon I'etat ou Ia province qu'iI habite.

En outre, Ia garantie suivante couvre Ies outiIs DEWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, I'outiI industrieI de service intensif

DEWALT ne donne pas entiere satisfaction, iI suffit de Ie retourner

chez Ie marchand participant dans Ies 30 jours suivant Ia date

d'achat afin d'obtenir un remboursement comptet. II faut retourner,

port paye, I'outiI comptet. On peut exiger une preuve d'achat.

Imported by / Importe par

DEWALT Canada Inc.

100 Central Ave.

BrockvilIe (Ontario) K6V 5W6

Voir la rubrique "Outils _lectriques"

des Pages Jaunes

pour le service et les ventes,

Page 12

PUNZON

OABEZA

PRISIONERO I

-- CARCAZA

--DADO

i

ARILL0DE

OUBIERTA

Epecificaciones (DW897)

Tensi6n de alimentaci6n 120 V

Potencia nominal: 225 W

Frecuencia de operaci6n: 60 Hz

Consumo de corriente: 6,5 A

DW8g8

CortadorasdeI_mina

Calibre16

INTERRUPTORDE

PALETA

\

BOTONDE

ENOENDID0

PERMANENTE

Instrucciones importantes de seguridad

Z_ ADVERTENCIA: Es indispensable sujetarse a Ias precauciones

basicas de seguridad, con Ia finalidad de reducir el peligro de

incendio, choque electrico y Iesiones personales, en todas Ias

ocasiones en que se utilicen herramientas electricas. Entre estas

precauciones se incluyen Ia siguientes:

LEA TODAS LAS INSTRUCCIONES

Doble aislamiento

Las herramientas DOBLEMENTE aisIadas se hart eIaborado de

manera integral con dos capas separadas de aislamiento electrico o

una capa dobte de aislamiento entre usted y el sistema electrico

que contienen. Las herramientas construidas con este sistema de

aislamiento no requieren conectarse a tierra. Como resultado su

herramienta esta equipada con una clavija de dos patas que Ie

permite emptear cordones de extensi6n sin preocuparse por tener

una conexi6n a tierra.

NOTA: El dobte aislamiento no substituye a Ias precauciones

normales de seguridad cuando se opera esta herramienta. La

finalidad de este sistema de aislamiento es ofrecer a usted

protecci6n afiadida contra Iesiones resultantes de falIas en el

aislamiento electrico interno de Ia herramienta.

/_ PRECAUClON: UTILICE SOLAMENTE REFACCIONES ORIG-

INALES CUANDO HAGA SERVICIO a cualquier herramienta.

Repare o reemptace los cordones electricos dafiados.

Clavijas polarizadas

Se emplean clavijas polarizadas (con una pata mas ancha que Ia

otra) para reducir los riesgos de choque electrico. Cuando el cord6n

electrico cuente con este tipo de clavija, ajustara en un contacto

polarizado solamente de una manera. Si Ia clavija no ajusta

10

Page 13

comptetamente en su contacto, inviertala. Si aQn asi no ajusta, Ilame

a un electricista calificado para que Ie instale un contacto polarizado

apropiado. No modifique o haga cambios en Ia clavija por ningQn

motivo.

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD A LA ZONA DE TRABAJO. No deje/as

herramientas el_ctricas expuestas a la /luvia. No las utifice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo. No utifice la herramienta en presencia de I[quidos o gases

inflamables.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, pot ejemplo,

tuber[as, radiadores, antenas y gabinetes de refrigeraci6n.

• CONSERVE APARTADOS A LOS NII_IOS. No permita que los

visitantes toquen las herramientas o los cables de extensi6n.

Todos los visitantes deben estar alejados de la zona de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se utifizan deben guardarse en un lugar seco

y elevado o bajo/lave -- fuera del alcance de los ni_os.

• NO FUERCE LA HERRAMIENTA. Esta cumplir_ su funci6n mejor

y con m_s seguridad a la velocidad y la presi6n para las que se

dise_6.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta peque_a o a sus dispositivos de montaje en un

trabajo de tipo pesado. No emplee la herramienta en una tarea

para la que no se dise_6.

• VlSTASE DE LA MANERA ADECUADA. No use ropas o art[culos

de joyer[a flojos, pues podr[an quedar atrapados por las partes

m6viles de/as herramientas. Se recomienda el empleo de guantes

de caucho y calzado antiderrapante cuando se trabaje al aire fibre.

CDbrase bien la cabeza para sujetarse el cabe/lo si Io tiene largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. P6ngase tambi_n

una mascari/la contra el polvo si Io produce la operaci6n que va a

efectuar.

• TENGA CUIDADO CON EL CORDON ELECTRICO. Nunca

levante la herramienta tom_ndola pot el cord6n, ni tire de _ste para

desconectarlo del enchufe. Ap_rtelo del calor y los objetos

cafientes, /as substancias grasosas y los bordes cortantes.

• ASEGURE LOS OBJETOS SOBRE LOS QUE TRABAJE. Utifice

prensas o tomi/los de banco para sujetar los objetos sobre los

que va a trabajar. Esto ofrece mayor seguridad que sujetar los

objetos con la mano, y adem_s deja fibres ambas manos para

operar la herramienta.

• CONSERVE EL EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, Io mismo que el equifibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

afiladas y fimpias para que funcionen mejor y con mayor

seguridad. Siga las instrucciones para lubricaci6n y cambio de

accesorios de su unidad. Revise peri6dicamente el cord6n

el_ctrico y h_galo reparar o reemplazar por un centro de servicio si

est_ da_ado. Cambie los cordones de extensi6n si est_n da_ados.

Conserve las empu_aduras secas, fimpias y fibres de aceite y

grasa.

• DESCONECTE YAPAGUE LAS HERRAMIENTAS cuando no/as

use, antes de darles servicio y cuando cambie accesorios, tales

como discos, brocas y otros dispositivos de corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el h_bito de asegurarse que se han retirado /as /laves de ajuste

de/as herramientas antes de accionarlas.

• EVlTE QUE LA HERRAMIENTA SE ACCIONE ACCIDENT-

ALMENTE. Nunca sostenga una herramienta que est_ conectada

con el dedo en el interruptor. AsegDrese que el interruptor est_ en

posici6n de "apagado" antes de conectar la unidad.

11

Page 14

CORDONESDEEXTENSION.Asegbresequesucord6nde

extensi6nest#enbuenascondiciones.Cuandoutiliceuncord6n

deextensi6n,asegbresequetengaelcafibresuficientepara

soportarlacorrientenecesariaparasuherramienta.Uncord6n

el#ctricoconcalibreinsuficientecausar_unacaidaenelvoltajede

laline&resultandoenp#rdidadepotenciaysobrecalentamiento.

Latablasiguienteilustraelcalibrecorrectoquedebeutilizarsede

conformidadconlaIongituddelcord6nyelamperajedescritopor

laplacadeidentificaci6n.Sitienealgunaduda,utiliceelcablecon

elcalibresiguiente(mayor).Mientrasm_schicoseaelnbmero,

mayorser_sucalibre.

VoltsLongitud total del cord6n en metro

120V 0-7.62

240V 0-15.24

AMPERAJE

Mas No mas Calbre del cord6n

de de

0 6

6 10

CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

opere su herramienta a la intemperie, utilice bnicamente cordones

de extensi6n dise_ados y marcados para este fin.

NO SE DISTRAIGA. Conc#ntrese en Io que est_ haciendo.

Recurra al sentido combn. No opere ninguna herramienta si est_

fatigado.

VERIFIQUE LAS PARTES DAI_IADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes da#adas puedan

operar de la manera adecuada para cumpfir con su funci6n.

Verifique la alineaci6n de las partes m6viles, la firmeza con que

deben encontrarse sujetas a sus montaduras, /as partes rotas, /as

propias montaduras y cualesquiera otros detalles que pudieran

afectar la operaci6n de la herramienta. Las guardas y otras partes

Calibre minimo para cordones de extensi6n

10 12

1212 - 16

7.63-15.24 15.25-30.48 30.4945.72

15.25-30.48 30.49-60.96 60.97-91.44

18 16 1614

18 16 1412

16 16 14

14 12 No Recomendado

que se encuentren da#adas deber_n cambiarse o repararse en un

centro de servicio autorizado, a menos que se diga otra cosa en

el manual del usuario. Haga que se cambien los interruptores

da#ados en un centro de servicio autorizado. No emplee ninguna

herramienta que tenga estropeado o inutilizado el interruptor.

Reglas de operaci6n para cortadoras de

lamina

1. Uti/ice siempre anteojos de seguridad as/ como guantes

protectores.

2. Use calzado de seguridad para proteger sus pies de rebabas

met_licas afiladas que pudieran caer al suelo.

3. Corte material hasta o pot debajo de la capacidad especificada.

Recuerde que el espesor del material aumenta mientras que el

Figara 2 Figara 3

CABEZA CABEZA ARBOL

DE

LEVAS

BUJEDE PRISIONERO

VARILLADE GUIADE

OONEXION

J-- DADO -- DADO

GUIADE I

PUNZON ZAPATA

l

ZAPATA -- PUNZON

PLAOA

DESGASTE

DELEVAS

12

Page 15

nDmero de cafibre disminuye (el calibre 14 tiene mayor espesor

que el calibre 16). El espesor del calibre 14 es de 1,90 mm

(0,075"); el espesor del calibre 16 es de 1,52 mm (0,060").

4. Conserve apretados todos los tornillos. Revise peri6dicamente

que no se hayan aflojado.

5. Desconecte la herramienta antes de efectuar cualquier ajuste.

6. No ponga nada dentro de la abertura de la carcaza del motor.

7. Conserve limpia la herramienta. Sopletee cualquier residuo

met_lico de la herramienta, as[ como la mugre.

8. Asegure con firmeza la pieza de metal que vaya a cortar para

evitar movimientos durante la operaci6n.

Interruptor de paleta

Optima el interruptor de paIeta para encender Ia unidad. Para

apagarta, Iibere el interruptor. El interruptor puede asegurarse para

operaci6n continua accionando el bot6n que se encuentra cerca de

Ia parte posterior de Ia herramienta al mismo tiempo que se oprime

Ia paleta. Asegerese siempre que Ia herramienta no este en posici6n

de encendido permanente antes de conectarta. Para apagar Ia

herramienta cuando el interruptor se encuentra en esta posici6n,

optima y Iibere Ia paleta una vez.

Operaci6n

APAGUE Y DESCONECTE LA HERRAMIENTA DE LA TOMA DE

CORRIENTE ANTES DE HACER CUALQUIER AJUSTE. Utilice

siempre gafas de seguridad y guantes protectores.

Lubrique Ia superficie deI material con aceite. La cortadora esta

disefiada para trabajar con metal piano y corrugado con poca

profundidad.

La herramienta se ensambla en Ia fabrica con el punz6n orientado

hacia adelante para cortar metal piano y corrugado con poca

profundidad.

La cabeza puede alinearse en tres posiciones: a Ia izquierda, hacia

adelante y a Ia derecha (observe Iafigura 2). Aftoje el prisionero para

girar Ia cabeza. Gire Ia cabeza hacia Ia direcci6n que desee.NOTA:

No gire Ia cabeza en un circulo compteto ya que esto cambiara Ia

alineaci6n deI punz6n y el dado.

Gire Ia carcaza de Ia cabeza y atornilIe el prisionero hasta sentir

que se acomoda en una cavidad en Ia zapata. Apriete el prisionero

con firmeza. Revise peri6dicamente que este tornilIo este apretado.

La cabeza de Ia cortadora esta disefiada para acoptarse a traves de

un orificio de 19 mm (3/4") para iniciar un corte a Ia mitad de una

pieza. El corte se puede hacer en cualquier direcci6n a partir de

este orificio. AI frente de Ia carcaza se encuentra un indicador de

ancho de punz6n que permite que el usuario siga una Iinea de cerca

(figura 3).

La parte inferior de Ia carcaza tiene una guia de 13 mm (0,51") de

diametro que Ie permite el empleo de plantilIas. El espesor de Ia

ptantilIa debe set taI que el espesor total de esta junto con Ia pieza

de trabajo sea de 5 a 6,5 mm (13/64" a 1/"). El contorno de Ia ptantilIa

debe estar a 2,5 mm (0,1") deI contomo pot recortar. Debe guiarse Ia

herramienta de manera que el diametro exterior de Ia carcaza (13

mm o 0,51") descanse en Ia ptantilIa.

Cambio de punzones

Nunca corte con un punz6n sin fiIo. Los punzones pueden afiIarse

hasta que Ileguen a una Iongitud de 69 mm (2,72"). Cuando son mas

cortos son inQtiles. Para sacar el punz6n, afloje el prisionero

aproximadamente de 4 a 5 vueltas (observe Ia figura 2). Deslice Ia

carcaza de Ia cabeza. DestomilIe el punz6n deI buje conector de

varilIa. El punz6n puede afilarse con cuidado en un esmeriI de banco

con piedra de grano fino. Tenga cuidado de no permitir que el punz6n

Ilegue a una Iongitud menor a Ia minima. Los punzones mas cortos

no alcanzaran debidamente el dado y deberan reemplazarse. La

cara deI esmeriI debera estar a escuadra con el eje deI punz6n.

Despues de esmerilar, asiente cuidadosamente los filos para

eliminar rebabas. No redondee Ias esquinas.

13

Page 16

Ensamblaje de la cabeza de la cortadora

AtornilIe el punz6n comptetamente dentro deI buje de conexi6n de

variIIa. DesIice Ia carcaza sobre el extremo deI punz6n y hacia dentro

de Ia cabeza. Gire Ia cabeza hacia Ia orientaci6n de corte que desee.

Apriete el prisionero y a continuaci6n, revise el acopIamiento deI

punz6n con el dado.

Revisi6n del acoplamiento del punz6n

Ya que Ia Iongitud deI punz6n ha cambiado, puede requerirse ajustar

el acoptamiento. Revise el acoptamiento deI punz6n coIocando un

destornilIador de punta ptana en Ia ranura deI eje de Ia Ieva (observe

Ia figura 2). El punz6n debe penetrar de 0,5 a 1,15 mm (0,2" a 0,6")

dentro deI dado en Ia posici6n de despIazamiento compIeto.

Demasiada penetraci6n en el dado puede originar perdida de

capacidad (Ia parte inferior deI punz6n no despejara suficientemente

el dado en Ia carrera hacia arriba).

Ajuste del acoplamiento del punz6n

Si el acoptamiento deI punz6n requiere ajustarse, afloje el prisionero

y gire Ia zapata en el sentido de Ias manecilIas deI reloj (mayor

penetraci6n en el dado) o en sentido contrario a Ias manecilIas deI

reloj (hacia fuera deI dado). Apriete el prisionero con firmeza. Gire el

eje de Ia Ieva con un destornilIador en Ia ranura para verificar Ia

penetraci6n deI punz6n (moviendo el punz6n comptetamente hacia

abajo). Repita cuanto sea necesario.

Cambio del dado

Si el dado Ilega a estar romo, reemptacelo. Cambie el dado viejo

empujado el arilIo de Ia cubierta hacia arriba y hacia afuera deI canal

deI dado. Retire el perno reten de debajo deI arilIo de Ia cubierta con

un martilIo punz6n. Tire deI dado hacia fuera deI eje transportador.

Instale un dado nuevo en el eje transportador. Haga coincidir el

orificio en cruz deI dado con el canal deI eje transportador. Instale el

perno. CoIoque el ariIIo sobre el dado en el canal hecho para este fin.

Mantenimiento

Utilice _nicamente un jab6n suave y un trapo h_medo para Iimpiar

Ia herramienta. Nunca permita que se introduzca ningQn Iiquido en Ia

herramienta, ni sumerja ninguna parte de esta en ningQn Iiquido.

Se han empteado baleros auto Iubricantes en Ia fabricaci6n de esta

herramienta y no se requiere de lubricaci6n peri6dica. En el

improbable caso que su herramienta IIegase a requerir servicio,

IIeveIa a un centro de servicio autorizado.

Accesorios

Dispone usted de los accesorios para su herramienta por un cargo

adicional con su distribuidor local autorizado.

EL ACCESORIO DEBE ESTAR CLASlFICADO PARA UTILIZARSE

A UNA VELOClDAD IGUAL O MAYOR QUE LAS R.P.M.

SENALADAS EN LA PLACA DE IDENTIFICAClON DE LA

HERRAMIENTA QUE SE ESTE EMPLEANDO.

Si necesita ayuda para encontrar cuaIquier accesorio, por favor

comuniquese aI 326-7100.

Z_PRECAUClON: El empleo de cualquier otro accesorio no

recomendado para utilizarse con esta herramienta puede ser

peligroso.

Importante

Para garantizar Ia SEGURIDAD y Ia CONFIABILIDAD deI producto,

deberan hacerse reparaciones, mantenimiento y ajustes (incluyendo

revisi6n y cambio de los carbones) por centros autorizados de

servicio u otras organizaciones calificadas que empIeen siempre

refacciones identicas

14

Page 17

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671 )242 10

GAUDALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje Lazaro Cardenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSI

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongaci6n Diaz Miron #4280 (91 29) 21 70 16

VILLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

Garantia Completa

Las herramientas industriales DEWA/T estan garantizadas durante un a_o a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Pot favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWA/T o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Electricas" en la Secci6n Amarilla. Esta garantia no se

aplica a los accesorios ni a da_os causados pot reparaciones efectuadas

pot terceras personas. Esta garantia le otorga derechos legales especificos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adici6n a la garantia, las herramientas DEWALT estan amparadas pot

nuestra:

GARANTJA DE SATISFACCION SIN RIESGO POR 30 DJAS

Si usted no se encuentra completamente satisfecho con el desempe_o de

su herramienta industrial DEWALT, sencillamente devuelvala a los

vendedores participantes durante los primeros 30 dias despues de la fecha

de compra para que le efectQen un reembolso completo. Pot favor regrese

la unidad completa, con el transporte pagado. Se puede requerir prueba de

compra.

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MEXICO, D.F

TEL. 326-7100

Para servicioy ventas consulte

"HERRAMIENTAS ELECTRICAS"

en la seccion amarilla, SECCIQN

A_M_RJLLA

15

Page 18

DEWALTIndustrialToolCompany,P.O.Box158,626HanoverPike,Hampstead,MD21074

DW897/897-220 Copyright©1997

PrintedinCountryMAY97-1)

FormNo.384328

Loading...

Loading...