Page 1

Questions? See us on the World Wide Web at www_dewalt.corn

iNSTRUCTiON MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW896

16-Gauge Nibbler

Grignoteuse de calibre 16

Cortadora de I_rnina calibre 16

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA

DE GARANTfA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

®

Page 2

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT:

I=800=4=DEWALT (1=800=433=9258)

PADDLE

SWITCH

I

PUNCH

Irnportaret Safety Instructiores

_ WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock,

and personal inju_ including the following:

READ A££ INSTRUCTIONS

Double Iresulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool's electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection against injury resulting from a possible electrical

insulation failure within the tool.

.&CAUTION: WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS. Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on

equipment to reduce the risk of electric shock. When provided, this

plug will fit in the polarized outlet only one way. If the plug does not fit

fully into the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not change the plug

in any way.

Safety Instructieres For All Tools

* KEEP WORKAREA CLEAN. Cluttered areas and benches invite

injuries.

* CONSIDER WORKAREA ENVIRONMENT. Don't expose power

tools to rain. Don't use power tools in damp or wet locations. Keep

work area weft fit. Do not use tool in presence of flammable liquids

or gases.

Page 3

* GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

* KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. Aft visitors should be kept away from work area.

* STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place -- out of reach of children.

* DON'T FORCE TOOL. It will do the job better and safer at the

rate for which # was intended.

* USE RIGHT TOOL. Don't force smafl tool or attachment to do the

job of a heavy-duty tool. Don't use tool for purpose not intended.

* DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

* USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

* DON'T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

* SECURE WORK. Use clamps or a vise to hold work. It's safer than

using your hand and # frees both hands to operate tool.

* DON'T OVERREACH. Keep proper footing and balance at aft

times.

* MAiNTAiN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

* DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

o

AVOID UNINTENTIONAL STARTING. Don't carry tool with finger

on switch. Be sure switch is off when plugging in.

o

EXTENSION CORDS. Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole receptacles that accept

the tool's plug. Replace or repair damaged cords. Make sure your

extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating, ff in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Volts

120V

240V

Ampere Rating

More Not more

Than Than

0 6

6 10

10 12

12 16

Minimum Gage for Cord Sets

Total Length of Cord in Feet

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 NotRecommended

OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

o

STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

o

CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

Page 4

manual.Havedefectiveswitchesreplacedbyauthorizedservice

center.Donotusetoolifswitchdoesnotturnitonandoff.

SAVE THESE INSTRUCTIONS

Motor

Your DEWALTtool is powered by a DEWALT built motor. Be sure your

power supply agrees with the nameplate marking. Voltage decrease of

more than 10% will cause loss of power and overheating. All DEWALT

tools are factory tested; if this tool does not operate, check the power

supply.

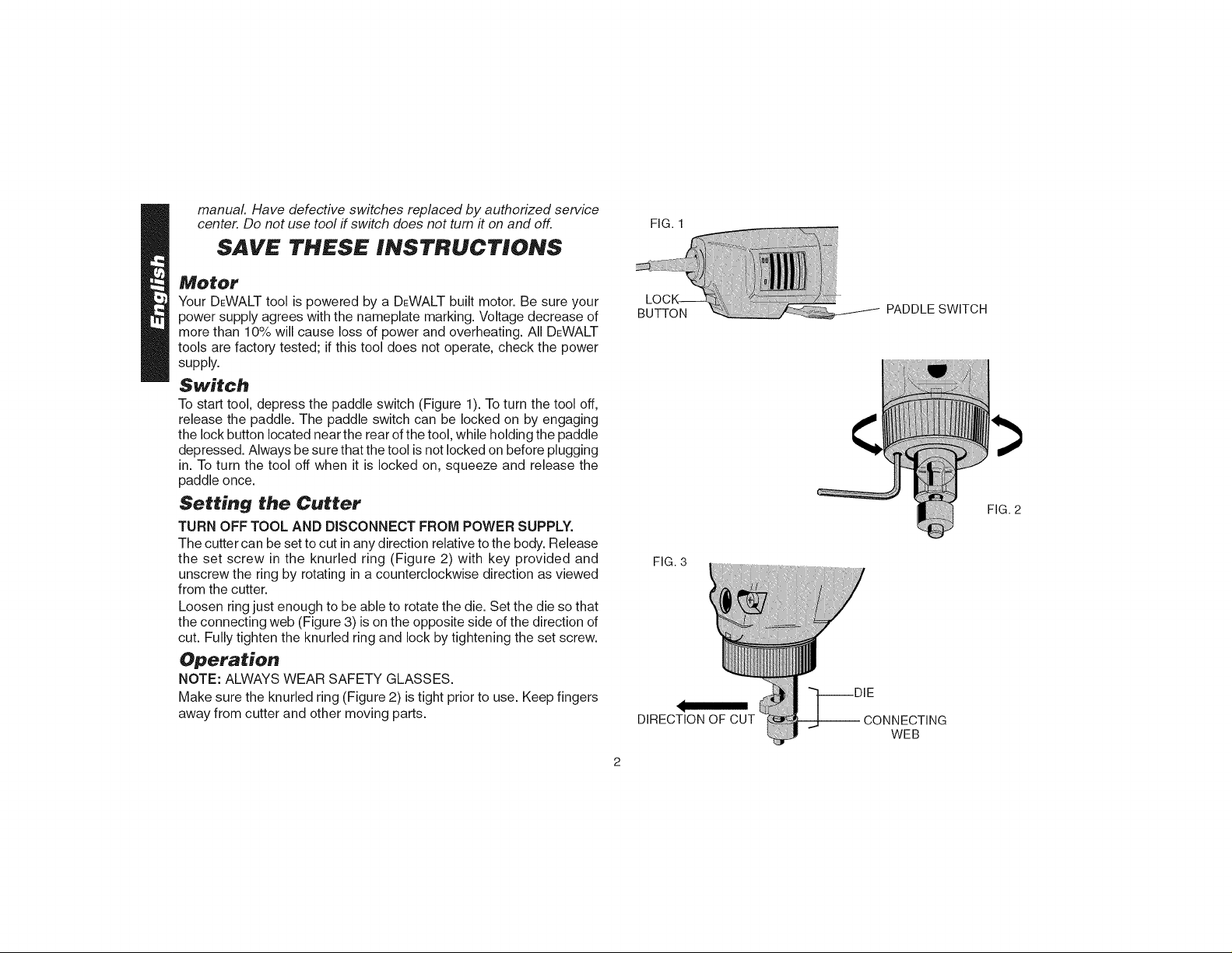

Switch

To start tool, depress the paddle switch (Figure 1). To turn the tool off,

release the paddle. The paddle switch can be locked on by engaging

the lock button located near the rear of the tool, while holding the paddle

depressed. Always be su rethat the tool is not locked on before plugging

in. To turn the tool off when it is locked on, squeeze and release the

paddle once.

Setting the Cutter

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY.

The cutter can be set to cut in any direction relative to the body. Release

the set screw in the knurled ring (Figure 2) with key provided and

unscrew the ring by rotating in a counterclockwise direction as viewed

from the cutter.

Loosen ring just enough to be able to rotate the die. Set the die so that

the connecting web (Figure 3) is on the opposite side of the direction of

cut. Fully tighten the knurled ring and lock by tightening the set screw.

Operation

NOTE: ALWAYS WEAR SAFETY GLASSES.

Make sure the knurled ring (Figure 2) is tight prior to use. Keep fingers

away from cutter and other moving parts.

BUTTON

FIG. 3

DIRECTION OF CUT

---DIE

CONNECTING

PADDLE SWITCH

FIG. 2

WEB

Page 5

FIG.6

FIG.4

FIG.5

The nibbler cuts a slot in the work 6mm wide so remember to

compensate for this when marking out and calculating material

requirements.

When starting the cut from an edge, place the nibbler so the slot in the

die engages the work and the edge is against the punch, which is the

moving part when cutting (Figure 4).

Start the nibbler by depressing the paddle switch. Hold the body

parallel to the work surface.

Exert only enough forward pressure to start the nibbler cutting and

maintain this pressure. Extra pressure will not increase the rate of cut

as the amount of material removed at each cutting stroke is fixed and

the rate of cut is dependent only on the speed of the nibbler. The

cutting line of the work should be lightly coated with oil to lubricate the

punch and die while cutting.

NOTE: Punch and die should be lubricated by immersing in a good

quality cutting oil approximately every 30 feet of cutting.

When the cut is to be started or finished within the periphery of the

work, a 13mm (1/2") hole must first be drilled in the work at the start or

finish point. This enables the die to be entered or withdrawn as it is

larger in diameter than the slot being cut in the work (Figure 5).

Circular holes should be cut inthe manner shown in Figure 6, starting

at the 13mm (1/2") diameter hole within the circle.

Punch and Die Replacement

After a period of cutting, the punch will become blunted and require

replacement. At the same time, check the die for sharpness and replace

if necessary.

To remove the die, release the knurled ring (Figure 7). Having removed

the die, rotate the motor by turning the armature fan, accessible through

the side cooling slot, until the punch retaining nut is clear of the face of

the gearbox. With the spanner provided, release this nut

counterclockwise and remove the punch, Figure 8.Assemble in reverse

order.

Page 6

Keepyournibblerascleanaspossiblebywipingwithacleanclothand

occasionallyblowingairthroughit.

Cleaning

Blowing dust and grit out of the main housing by means of air hose is

recommended and may be done as often as dirt is seen collecting in

and around the ventilator vents. The motor should be running while air

is being blown into the air vents.

Lubrication

DEWALTtools are properly lubricated at the factory and are ready to

use. Tools should be relubricated regularly every 60 days to 6 months,

depending on usage. Tools used constantly on production or heavy-

duty jobs and tools exposed to heat may require more frequent

lubrication. This lubrication should only be attempted by trained power

tool repairmen such as those at DEWALTcertified service centers.

Motor Brushes

When the brushes on this tool become worn out, the tool will

automatically stop and prevent damage to the motor. Brush

replacement should be performed by DEWALT service centers.

Accessories

Recommended accessories for use with your tool are available at extra

cost from your distributor or local service center.

A CAUTION: The use of any non-recommended accessory may be

hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

FiG. 7

DiE

KNURLED RiNG

I

FiG. 8

!

--PUNCH

Page 7

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This

warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALT Power Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

- no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT for a free

replacement.

POUR TOUT RENSEIGNEMENT SUPPLE_MENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSER SANS

FRAIS LE NUMI_RO:

1 800 4-DEWALT (1 800 433-9258)

IINTERRUPTEUR ,_

PALETTE

I

POINOON

Irnportantes rnesures de s_curit_

_ VERTISSEMENT : Afin de r6duire les risques d'incendie, de

secousses electriques oude blessures Iorsqu'on utilise des outils

61ectriques, il faut toujours respecter les mesures de securit6 suivantes.

LIRE TOUTES LES DIRECTIVES

Double isolation

Les outils & double isolation comportent deux couches distinctes

d'isolant 61ectrique ou une double _paisseur d'isolant qui prot_gent

I'utilisateur contre les risques de blessures provenant du syst_me

Page 8

61ectriquedeI'outil.Cesyst_mededoubleisolation_liminelebesoin

demettrelesoutils&laterre.Eneffet,I'outilestmunid'unefiche&

deuxbroches,cequipermetd'utiliserunerallongeordinairesansavoir

sesoucierd'assurerlamise&laterre.

NOTE:Ladoubleisolationnedispensepasdesmesuresdes6curit6

normalesIorsdeI'utilisationdeI'outil.Ellevise&procurerune

protectionsuppl_mentairecontrelesblessuresquepeutentrafner

uned_fectuosit_deI'isolant_lectriqueaI'int6rieurdeI'outil.

MISE EN GARDE : LORS DE L'ENTRETIEN, N'UTILISER QUE

DES PIE-CES DE RECHANGE IDENTIQUES. Reparer ou remplacer

les cordons endommages.

Fiche polaris_e

Afin de r_duire les risques de secousses _lectriques, I'outiiest muni

d'une fiche polaris6e (une lame plus large que I'autre). Ce genre de

fiche n'entre que d'une fa£on dans une prise polaris6e. Lorsqu'on ne

peut ins6rer la fiche a fond dans la prise, il faut tenter de le faire apr_s

avoir invers6 les lames de c6t& Si la fiche n'entre toujours pas dans

la prise, il faut communiquer avec un 61ectricien certifi& II ne faut en

aucun cas modifier la fiche.

Mesures de s_curif:_ pour tous les outiis

• BIEN DF:GAGER LA SURFACE DE TRAVAIL. Des surfaces et

des 6tab/is encombr6s peuvent _tre /a cause de b/essures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Prot6ger/es outi/s

6/ectriques de/a p/uie. Ne pas s'en servir clans des endroits humides

ou moui//6s. Bien 6c/alter/a surface de travail. Ne passe servir de

I'outi/ en pr6sence de/iquides ou de vapeurs inflammables.

• SE PROTEGER CONTRE LES SECOUSSES E:LECTRIQUES.

E-vitertout contact avec des objets mis a/a terre, comme des tuyaux,

radiateurs, cuisinibres, refrig6rateurs et autres objets du genre.

• E:LOIGNER LES ENFANTS. Tous/es visiteurs doivent _tre tenus

/'6cart de/'aire de travail et il faut /es emp_cher de toucher

I'outi/ ou au cordon de ra//onge.

• RANGER LES OUTILS INUTILISE:S. fl faut ranger/es outils clans

un endroit sec, situe en hauteur ou ferme a c/6, hors de/a portee

des enfants.

• NE JAMAIS FORCER L'OUTIL. Afin d'obtenir un rendement s_r

et efficace, uti/iser /'outi/ a son rendement nominal

• UTILISER L'OUTIL APPROPRIE:. Nejamais exiger d'un petit outi/

ou d'un accessoire /e rendement d'un outi/ de fabrication plus

robuste. Se servir de I'outil selon /'usage prevu;

• PORTER DES Vt:TEMENTS APPROPRIES. Eviter de porter des

v_tements amples et des bijoux qui peuvent _tre happes par les

pibces en mouvement. Porter des gants de caoutchouc et des

chaussures a semelle antid6rapante pour travailler a I'exterieur.

Prot6ger la chevelure si elle est Iongue.

• PORTER DES LUNETTES DE SECURITE:. Porter egalement un

masque respiratoire si le travail de coupe produit de la poussibre.

• NE PAS MANIPULER LE CORDON DE FA_ON ABUSIVE. hie

pas transporter I'outil par le cordon ni tirer sur ce demier pour le

d6brancher de la prise. Eloigner le cordon des sources de chaleur,

des flaques d'huile et des ar_tes tranchantes.

• ASSUJETTIR LA PIF=CE. Immobiliser la pibce a I'aide de brides

ou d'un _tau. On peut alors se servir des deux mains pour faire

fonctionner l'outil, ce qui est plus sot.

• NE PAS DEPASSER SA PORTEE. Toujours demeurer clans une

position stable et garder son _quilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu'ils donnent un rendement superieur et sot. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter regulibrement le cordon de I'outil et le faire reparer au

besoin a un atelier d'entretien autorise. Inspecter regulibrement les

cordons de rallonge et les remplacer Iorsqu'ils sont endommages.

S'assurer que les poign_es sont toujours propres, seches et libres

de toute tache d'huile ou de graisse.

• DE:BRANCHER OU VERROUILLER EN POSITION HORS

TENSION LES OUTILS NON UTILISE:S. Respecter cette mesure

Iorsqu'on ne se sert pas de I'outil, ou qu'on doit le reparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

Page 9

ENLEVERLESCLE.SDERF=GLAGE.PrendreI'habitudede

v@rifiersi lescl@sder@glageont@t@retir@esavantdefaire

d@marrerI'outiL

E:VITERLESDF=MARRAGESACCIDENTELS.Nepaslaisserle

doigtsurI'interrupteurIorsqu'ontransporteI'outiLS'assurerque

I'interrupteurestalapositionhorscircuitIorsqu'onbrancheI'outiL

CORDONSDERALLONGE.S'assurerquelecordonderallonge

estenbon@tat.Lorsqu'onsesertd'uncordonderaflonge,

s'assurerqu'ilestdecalibreappropri@pourlatensionn@cessaire

aufonctionnementdeI'outiLL'utilisationd'uncordondecalibre

inf@rieuroccasionneunebaissedetensionentrMnantunepertede

puissanceetlasurchauffe.Letableausuivantindiquelecalibre

appropri@selonlaIongueurducordonetlesmentionsdelaplaque

signal@tiquedeI'outiLEncasdedoute,utiliseruncordondecalibre

sup@rieur.Le chiffreindiquantle cafibreest inversement

proportionnelaucalibreducordon.

Calibre minimal des cordons derallonge

Tension

120 V

240 V

Intensit_ (A)

Au Au

moins plus

0 6

6 10

10 12

12 16

* CORDONS DE RALLONGE PRE:VUS POUR L'EXTt:RIEUR.

Lorsque Ibutil est utilis@a I'ext@rieur, ne se servir que d'un cordon

de rallonge congu pour I'ext@rieuret portant la mention appropri@e.

* DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pa.s se servir de I'outil Iorsqu'on est fatigu6.

* VE.RIFIER LES PIECES ENDOMMAGEES. Avant de continuer

utiliser I'outil, fl faut v@rifier si le protecteur ou toute autre pi@ce

endommag@e rempfit bien la fonction pour laquelle il a @t@pr@vu.

V@rifierI'alignement et les attaches des pi@ces mobiles, le degr@

d'usure des pi@ces et leur montage, ainsi que tout autre facteur

Longueur totale du cordon en pieds

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

Calibre rnoyen de fil (AWG)

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Non recommand@

susceptible de nuire au bon fonctionnement de IbutiL Faire r@parer

ou remplacer tout protecteur ou toute autre pi@ce endommag@e

clans un centre de service autoris@, sauf si le pr@sent guide fait

mention d'un avis contraire. Confier le remplacement de tout

interrupteur d@fectueux a un centre de service autoris@.Ne jamais

se servir d'un outil dont I'interrupteur est d@fectueux.

CONSERVER CES MESURES

Moteur

Un moteur DEWALT actionne I'outil DEWALT.Veiller & ce que latension

d'alimentation soit conforme aux exigences de la plaque signal@tique

de I'outil. Une baisse de tension de plus de 10 p. 100 entrafne une

perte de puissance et la surchauffe. Tousles outils DEWALT sont

essay@s avant de quitter I'usine. Lorsque celui-ci refuse de fonctionner,

v@rifierla source de courant @lectrique.

Interrupteur

Pour mettre I'outil en marche, enfoncer I'interrupteur & palette (fig. 1).

Pour I'arr@ter,rel&cher la palette. On peut verrouiller I'interrupteur en

mode de fonctionnement en enfongant le bouton de verrouillage qui se

trouve pr@sde I'arri_re de I'outil tout en maintenant enfonc@ la palette.

Toujours s'assurer que I'outil ne se trouve pas en mode de

fonctionnement continu avant de le brancher. Pour arr@ter I'outil

Iorsque ce dernier est en mode de fonctionnement continu, il suffit

d'enfoncer et de rel&cher imm@diatement la palette.

R_glage du couteau

METTRE L'OUTIL HORS TENSION ET LE DEBRANCHER.

On peut r@glerle couteau dans tousles sens par rapport au corps de

I'outil. Desserrer la vis de pression dans la bague molet@e (fig. 2)

I'aide de la cl@fournie et d@visser la bague en la faisant tourner dans

le sens antihoraire Iorsqu'on se place du c6t@du couteau.

Desserrer la bague suffisamment pour faire tourner la matrice. Placer

la matrice de sorte que la flasque de raccordement (fig. 3) se trouve

I'oppos@du sens de coupe. Bien serrer la bague molet@eet verrouiller

en serrant la vis de pression.

Page 10

Fonct ionnernent

NOTE : TOUJOURS PORTER DES LUNETTES DE SECURITt _.

S'assurer que la bague molet6e (fig. 2) est serr6e avant d'utiliser

I'outil. t_loigner les doigts du couteau et des autres pi_ces mobiles.

La grignoteuse coupe une fente de 6 mm de large dans le mat6riau.

IIfaut se rappeler de pr6voir cette fente lots du trac6 et des calculs.

Lorsque la coupe commence sur un rebord, placer la grignoteuse de

sorte que la fente de la matrice s'engage dans le mat6riau et que le

rebord repose contre le poin£on (la piece mobile Iors de lacoupe) (fig.

4).

Actionner la grignoteuse en enfon(2ant I'interrupteur & palette.

Maintenir le corps de I'outil parall_le &la surface de travail.

Exercer seulement la pression suffisante vers I'avant pour engager la

coupe, puis maintenir cette pression. Une pression excessive

n'augmente pas le taux de coupe puisque la quantit6 de mat6riau

enlev6e a chaque course est fixe et le taux de coupe d6pend

uniquement de la vitesse de la grignoteuse. II est conseill6 d'enduire

une mince pellicule d'huile sur la ligne de coupe afin de lubrifier le

poin£on et la matrice pendant la coupe.

NOTE : II faut lubrifier le poin£on et la matrice en les immergeant dans

de I'huile de bonne qualit6 apr_s environ chaque 9 m (30 pi) de coupe.

IIfaut d'abord percer un trou de 13 mm (1/2 po) au d6but ou a latin de

la coupe Iorsque celle-ci se fait en p6riph6rie de la piece a ouvrer. On

peut ainsi ins6rer ou retirer la matrice puisque celle-ci est plus large

que la fente coup6e autour de la piece (fig. 5).

Les trous circulaires doivent 6tre coup6s de la fa£on illustr6e a la

figure 6 en per£ant un trou d'un diam_tre de 13 mm (1/2 po) dans le

cercle.

Rernplacernent du poin_on et de la

rnatrice

Apr_s une ce_aine p6riode de coupe, le poin_on devient 6mouss6 et

ilfaut le remplacer. V6rifier en m6me temps I'aff_tage de la matrice et

la remplacer, le cas 6ch6ant.

FIG. 1

BOUTON DE

VERROUILLAGE

FIG. 3

SENS DE COUPE

J MATRICE

FLASQUE DE

RACCORDEMENT

INTERRUPTEUR

PALETTE

FIG. 2

Page 11

FIG.6

FIG.4

FIG.5

'UEDE

RACCORDEMENT

Pour retirer la matrice, d@gager la bague molet@e(fig. 7). Apr_s avoir

enlev@ la matrice, faire tourner le moteur en faisant tourner le

ventilateur de I'induit, accessible par la fente de ventilation lat@ale,

jusqu'& ce que I'@croude retenue du poin£on ne se trouve plus devant

le boftier des engrenages. ,g,I'aide de la cl@a fourche fournie, d@gager

I'@croudans le sens antihoraire et retirer le poin(2on(fig. 8). Remonter

dans I'ordre inverse.

S'assurer de la propret@ de la grignoteuse, dans la mesure du

possible, en I'essuyant avec un chiffon propre et y soufflant

occasionnellement de I'air par les orifices.

Nettoyage

II est conseill@ d'utiliser un boyau d'air comprim@ afin de chasser la

poussi@e et les salet@s du corps de I'outil. Effectuer cette tb,che d_s

I'apparition de salet@dans les @vents et autour de ceux-ci. Le moteur

de I'outil devrait fonctionner Iorsqu'on souffle de I'air dans les @ventsde

I'outil.

Lubrification

Les outils DEWALT sont bien lubrifi@sen usine et ils sont pr@s & servir.

IIfaut les lubrifier de nouveau r@guli@ement &tous les 60 jours & 6

mois, selon I'usage. Les outils utilis@sconstamment pour la production

ou des t&ches de service intensif ainsi que les outils expos@s & la

chaleur peuvent n@cessiter une lubrification plus fr@quente. Confier la

lubrification de I'outil seulement au personnel qualifi@ des centres de

service DEWALT.

Balais du rnoteur

Un syst_me arr@e automatiquement I'outil Iorsque les balais sont us@s

afin de ne pas endommager le moteur. II faut confier le remplacement

des balais au personnel

Accessoires

Les accessoires recommand@s pour I'outil sont vendus s@ar@ment

chez les d@aillants ou au centre de service autoris@de la r@gion.

i_,MISE EN GARDE : L'utilisation de tout accessoire non

recommand@ peut @tredangereuse.

Page 12

B_paraf:ions

Pour assurer la SECURIT¢: D'EMPLOI et la FIABILIT¢: de routil, n'en

confier la r6paration, I'entretien et les rajustements (y compris

I'inspection des balais) qu'a un centre de service ou a un atelier

d'entretien autoris6 n'utilisant que des pi_ces de rechange identiques.

Gararetie lirnit_ de trois ares

DEWALT r6parera, sans frais, tout produit d6fectueux caus6 par un

d6faut de mat6riel ou de fabrication pour une p6riode de trois ans

compter de la date d'achat. La pr6sente garantie ne couvre pas les

pi_ces dont la d6fectuosit6 a 6t6 caus6e par une usure normale ou

I'usage abusif de I'outil. Pour obtenir de plus amples renseignements

sur les pi_ces ou les r6parations couvertes par la pr6sente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-DEWALT). Cette garantie ne s'applique pas aux accessoires et ne

vise pas les dommages caus6s par des r6parations effectu6es par un

tiers. Cette garantie conf@e des droits 16gauxparticuliers a I'acheteur,

mais celui-ci pourrait aussi b6n6ficier d'autres droits variant d'un 6tat

ou d'une province a I'autre.

En plus de la pr6sente garantie, les outils DEWALT sont couverts par

notre :

CONTRAT D'ENTRETIEN GRATUIT D'UN AN

DEWALT entretiendra I'outil et remplacera les pi_ces us6es au cours

d'une utilisation normale et ce, gratuitement, pendant une p6riode d'un

an a compter de la date d'achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas enti@ement satisfait, pour quelque raison que

ce soit, du rendement de I'outil 61ectrique, du laser ou de la cloueuse

DEWALT,celui-ci peut le retoumer, accompagn6 d'un re,u, dans les 90

jours _,compter de la date d'achat, pour obtenir un remboursement

int6gral, sans aucun probl_me.

REMPLACEMENT GRATUIT DES I_TIQUETTES

D'AVERTISSEMENT : Si les 6tiquettes d'avertissement deviennent

illisibles ou sont perdues, composer le 1 800 4-DEWALT (1 800 433-

9258) pour obtenir un remplacement gratuit.

FIG. 7

-- BAGUE MOLETEE

MATRICE

I

I

lO

Page 13

INTERRUPTOR

DEPALETA

UEL

I

PUNZON

Instrucciorees irnportaretes de seguridad

_ ADVERTENClA: Es indispensable sujetarse alas precauciones

basicas de seguridad, con la finalidad de reducir el peligro de

incendio, choque el#ctrico y lesiones personales, en todas las

ocasiones en que se utilicen herramientas el#ctricas. Entre estas

precauciones se incluyen la siguientes:

LEA TODAS £AS INSTRUCCIONES

Doble aislamiento

Las herramientas doblemente aisladas se han elaborado de manera

integral con dos "capas" separadas, o una de DOBLE espesor, de

aislamiento el6ctrico entre usted y el sistema el_ctrico que contienen.

Las herramientas elaboradas con este sistema de aislamiento no

requieren conectarse a tierra. Como resultado, su unidad estb,

equipada con una clavija de dos patas que le permite emplear

cordones de extensi6n sin preocuparse por tener una conexi6n a

tierra.

NOTA: el doble aislamiento no substituye alas precauciones normales

de seguridad cuando se opera esta herramienta. La finalidad de este

sistema de aislamiento es ofrecer a usted proteccion a_adida contra la

lesi6n resultante de fallas en el aislamiento el6ctrico interno de la

unidad.

i¢ PRECAUCION: UTILICE SOLAMENTE REFACCIONES

IDENTICAS cuando se haga servicio a cualquier herramienta. Repare

o reemplace los cordones el6ctricos da#ados.

Clavija polarizada

Se emplean clavijas polarizadas (con una pata m_s ancha que la otra)

para reducir los riesgos de choque el6ctrico. Cuando el cord6n el_ctrico

cuente con este tipo de clavija, ajustarA en un contacto polarizado

solamente de una manera. Si la clavija no ajusta completamente en su

contacto, invi_rtala. Si a0n asi no ajusta, Ilame a un electricista

calificado para que le instale un contacto polarizado apropiado. No

modifique o haga cambios en la clavija por ning0n motivo.

Instrucciones de seguridad para todas

las herramieretas

* CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

* OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No deje

las herramientas electricas expuestas a la Iluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada lazona de

trabajo. No utilice la herramienta en presencia de liquidos o gases

inflamados.

* PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberfas, radiadores, antenas y gabinetes de refrigeracidn.

* CONSERVE APARTADOS A LOS NINOS. No permita que los

visitantes toquen las herramientas o los cables de extensidn. Los

visitantes deben estar alejados del area de trabajo.

11

Page 14

* GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se est#n utilizando deben guardarse en un

lugar seco y elevado o bajo Ilave, fuera del alcance de los ni#os.

NO FUERCE LA NERRAMIENTA. Esta cumplir# su funci6n mejor y

con m#s seguridad a la velocidad y la presi6n para las que se dise#6.

EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta peque#a o a sus dispositivos de montaje en un

trabajo de tipo pesado. No emplee la herramienta en una tarea

para la que no se dise#6.

* VISTASE DE LA MANERA ADECUADA. No tenga puestas ropas

o artfculos dejoyerfa flojos, pues podrfan quedar atrapados pot las

partes m6viles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaja al

aire libre. C#brase bien la cabeza para sujetarse el pelo si Io tiene

largo.

* COLOQUESE ANTEOJOS DE SEGURIDAD. P6ngase tambi@n

una mascarilla contra el polvo si Io produce la operaci6n de corte

que va a efectuar.

* TENGA MUCHO CUIDADO CON EL CORDON ELECTRICO.

Nunca levante la herramienta pot el cord6n ni tire de @ste para

desconectarlo del enchufe. Apbrtelo del calor y los objetos

calientes, las sustancias grasosas y los hordes cortantes.

* SUJETE FIRMEMENTE LOS OBJETOS SOBRE LOS QUE

TRABAJE. Utilice prensas o tornillos de banco para sujetar bien

los objetos sobre los que va a trabajar. Esto ofrece mayor

seguridad que sujetar los objetos con la mano, y ademas deja

libres ambas manos para operar la herramienta.

* NO SALGA DE EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, Io mismo que el equilibrio.

* CUIDE BIEN SUS HERRAMIENTAS. Conserve sus herramientas

bien afiladas y limpias para que funcionen mejor y con mayor

seguridad. Obedezca las instrucciones de lubricaci6n y cambio

de accesorios. Inspeccione los cordones el@ctricos con frecuencia

y, si los encuentra da#ados, hagalos cambiar o reparar en un

centro de servicio autorizado. Revise tambi@n con frecuencia las

extensiones el@ctricasy reemplacelas si estan da#adas. Conserve

los mangos secos, limpios y libres de aceites y grasas.

DESCONECTE LAS NERRAMIENTAS. Hagalo cuando no las

emplee, antes de darles servicio y cuando vaya a cambiarles

accesorios como seguetas, discos, brocas y otros dispositivos de

corte.

RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el habito de asegurarse de que se hart retirado /as flaves de ajuste

de la herramienta antes de accionarla.

EVITE QUE LA HERRAMIENTA SE ACCIONE

ACCIDENTALMENTE. Nunca sostenga una herramienta con el

dedo en el interruptor si se encuentra conectada a la corriente

el@ctrica. Aseg#rese que el interruptor esta en la posici6n de

"apagado" antes de conectarla.

CORDONES DE EXTENSION. Aseg#rese que su extensi6n est@

en buenas condiciones. Cuando utifice un cord6n de extensi6n,

aseg#rese de emplear uno con el calibre suficiente para soportar

la corriente necesaria para su producto. Una extensi6n con calibre

menor al necesario causara una cafda en el voltaje de la Ifnea,

resultando en p@rdida de potencia y sobrecalentamiento. El

cuadro siguiente muestra los calibres correctos para usarse de

acuerdo con la Iongitudde la extensi6n y el amperaje especificado.

Si tiene dudas, utilice el cafibre siguiente, m#s pesado. Cuanto

mas peque#o el n#mero de calibre del alambre, mayor la

capacidad del cable.

Calibre minimo paracordonesde extensi6n

Volts

120V 0-7.62

240V 0-15.24

AMPERAJE

Mb,s No mb,s

de de

0-6 18

6-10 18

10-12 16

12-16 14

Longitud total del cord6n en metros

7.63-15.24 15.25-30.48 30.49-45.72

15.25-30.48 30.49-60.96 60.97-91.44

Calibre del cord6n AWG

16 16 14

16 14 12

16 14 12

12 No se recomienda

12

Page 15

CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

trabaje a la intemperie, utilice siempre cordones de extensidn

dise#ados exclusivamente para esta finalidad.

NO SE DISTRAIGA. Concentrese en Io que esta haciendo.

Recurra al sentido com#n. No opere ninguna herramienta si se

encuentra fatigado.

VERIFIQUE LAS PARTES DAI_IADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes da#adas puedan

operar de la manera adecuada para cumplir con su funci6n.

Verifique la afineaci6n de las partes m6viles, la firmeza con que

deben encontrarse sujetas en sus montaduras, las partes rotas,

las propias montaduras y cualesquiera otros detalles que pudieran

afectar a la operaci6n de la herramienta. Las guardas y las otras

partes que se encuentren da#adas deberan repararse bien o

cambiarse en un centro de servicio autorizado, a menos que se

diga otra cosa en el manual de/usuario. Haga que se cambien los

interruptores da#ados en un centro de servicio autorizado. No

emplee ninguna herramienta que tenga inutilizado o estropeado

el interruptor.

CONSERVE ESTAS INSTRUCCiONES

Motor

Su herramienta DEWALT.funciona con un motor DEWALT.integrado.

AsegOrese que la alimentaci6n de corriente concuerde con la

seSalada en la placa de identificaci6n. Disminuciones en el voltaje

mayores a 10% causara p6rdida de potencia y sobrecalentamiento.

Las herramientas DEWALT.se prueban en la f_,brica; siesta

herramienta no funciona, revise la alimentaci6n de corriente.

Interruptor

Oprima el interruptor de paleta para encender la herramienta (figura 1),

su61telo para apagarla. El interruptor de paleta se puede asegurar en

posici6n de encendido activando el bot6n de encendido permanente

que se encuentra cerca de la parte posterior de la herramienta, al

mismo tiempo que se conserva el interruptor de paleta oprimido.

AsegOrese siempre que la herramienta no tenga activado el

mecanismo de encendido permanente antes de conectarla. Para

apagar la unidad cuando este mecanismo est,. activado, oprima y

libere la paleta una vez.

Ajuste de la cortadora

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA

DE CORRIENTE.

La cuchilla se puede ajustar en cualquier direcci6n en relaci6n con el

cuerpo. Saque el pfisionero del anillo moleteado (figura 2) con la Ilave

provista y desenrosque el anillo girandolo en sentido contrario alas

manecillas del reloj, visto desde lacuchilla.

Afloje el anillo Io suficiente para que alcance a girar eltroquel. Coloque

el troquel de manera que la conexiSn (figura 3) quede del lado opuesto

a la direcci6n de corte. Apriete bien el anillo moleteado y asegSrelo

apretando el prisionero.

Operaci6n

NOTA: UTILICE SIEMPRE GAFAS DE SEGURIDAD.

AsegOrese que el anillo moleteado (figura 2) est6 apretado antes de

usar la unidad. Conserve los dedos alejados de la cuchilla y otras

piezas m6viles.

La unidad corta una ranura en la pieza de trabajo de 6 mm de ancho,

asi que recuerde compensar esto cuando marque y calcule sus

requerimientos de material.

Cuando inicie el corte desde un borde, coloque lacortadora de manera

que la ranura del troquel se enganche con lapieza de trabajo y el borde

quede contra elpunz6n, que el lapieza m6vil al cortar (figura 4).

Encienda la herramienta oprimiendo el interruptor de paleta. Sujete el

cuerpo en paralelo a lasuperficie de trabajo.

Ejerza Onicamente la presi6n hacia delante suficiente para que la

herramienta inicie el corte y cons6rvela asi. La presi6n adicional no

incrementar_, la velocidad de corte, ya que la cantidad de material

removido en cada corte es fija y depende Onicamente de la velocidad

13

Page 16

delacortadora.Lalineadecorteenlapiezadetrabajodeberecubrirse

ligeramenteconaceiteparalubricarelpunz6nyeltroquelduranteel

corte.

NOTA:Elpunz6nyeltroqueldebenlubricarsesumergi_ndolosen

aceiteparacortedebuenacalidadaproximadamentecada9metros

decorte.

Cuandosevayaainiciaroaterminarelcortecentrodelaperiferiadel

trabajo,dedebeperforarprimerounorificiode13mmenesepunto

Estopermitealtroquelentrarosaliryaqueesmayorendi_.metroque

laranuraqueproduceenlapiezadetrabajo(fig.5).

Losorificioscircularesdebencortarsecomosemuestraenlafigura6,

iniciandoenlaperforaci6nde13mmquesehizodentrodelcirculo.

Reernplazo del punz6n y el troquel

Despu6s de un periodo de corte, el punz6n quedar_, romo y deber_

cambiarse. AI mismo tiempo, verifique el filo del troquel y reempl_.celo

en caso necesario.

Para sacar el troquel, afloje el anillo moleteado (figura 7). Despu6s de

quitar el troquel, gire el motor ayudAndose el ventilador, accesible a

trav6s de la ranura de ventilaci6n, hasta que la tuerca de retenci6n del

punz6n est_ libre de la caja de engranes. Con la Ilave provista, afloje

esta tuerca en sentido opuesto a las manecillas del reloj y saque el

punz6n, figura 8. Ensamble inviertiendo el orden de estos pasos.

Conserve su cortadora tan limpia como sea posible frot_.ndola con un

trapo limpio y soplete_.ndola de vez en cuando.

Lirnpieza

Se recomienda sopletear el polvo y la mugre de la carcaza principal

con aire comprimido, este procedimiento se puede Ilevar a cabo tan

frecuente como se note que se acumula la mugre alrededor de la

rejillas de ventilaci6n. El motor debe funcionar mientras se sopletean

las ventilas.

LubHcaci6n

Las herramientas DEWALT.se lubrican apropiadamente en la f_brica y

estan listas para usarse. Las herramientas deben lubricarse

FIG. 1

BOTON

ENCENDIDO

FIG. 3

iUEL

DIRECCION DE

CORTE

14

INTERRUPTOR

DE PALETA

FIG. 2

Page 17

FIG.6

FIG.4

FIG.5

regularmente cada 60 dias a 6 meses, depende de su uso. Las

herramientas que se emplean constantemente en producci6n o en

trabajos pesados y las que se exponen al calor pueden requerir

lubricaci6n m_s frecuente. Esta lubricaci6n solamente debe realizarla

personal entrenado como el de los centros de servicio certificados

DEWALT.

Carbones del motor

Cuando los carbones del motor se hayan desgastado, la herramienta

se apagar_ automAticamente para evitar da_os al motor. El cambio de

carbones debe efectuarse [_nicamente en centros de servicio DEWALT.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deber_.n

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio DEWALT u otras organizaciones

autorizadas. Estas organizaciones prestan servicio a las herramientas

DEWALTy emplean siempre refacciones legitimas DEWALT.

P61iza de Gararetia

IDENTIFICACION DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: Mod./Cat.:

Marca: NOra.de serie:

(Datos para set Ilenados por el distribuidor)

Fecha de compra y/o entrega del producto:

Nombre y domicilio del distribuidor donde se adquiri6 el producto:

Este producto esta garantizado por un a_o a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, asi como en

materiales y mano de obra empleados para su fabricaci6n. Nuestra

garantia incluye la reparaci6n o reposici6n del producto y/o

componentes sin cargo alguno para el cliente, incluyendo mano de

obra, asi como los gastos de transportaci6n razonablemente erogados

derivados del cumplimiento de este certificado.

15

Page 18

ParahacerefectivaestagaranfiadeberApresentarsuherramienta

y estap61izaselladaporel establecimientocomercialdondese

adquiri6elproducto,denocontarcon6sta,bastarAlafacturade

compra.

EXCEPClONES.

EstagarantianoserAv&lidaenlossiguientescasos:

• Cuandoel productosehubieseutilizadoencondiciones

distintasalasnormales;

• Cuandoelproductonohubiesesidooperadodeacuerdoconel

instructivodeusoqueseacompaSa;

• Cuandoelproductohubiesesidoalteradooreparadopor

personasdistintasalasenlistadasalfinaldeestecertificado.

AnexoencontrarAunarelaci6ndesucursalesdeserviciodefAbrica,

centrosdeservicioautorizadosy franquiciadosenlaRepOblica

Mexicana,dondepodrahacerefectivasugarantiayadquirirpartes,

refaccionesyaccesoriosoriginales.

Garantia lirnitada per tres a_os

DEWALT repararA, sin cargo, cualquier falla que surja de defectos en

el material o la fabricaci6n del producto, pot hasta tres aSos a contar

de la fecha de compra. Esta garantia no cubre fallas de las piezas

causadas por su desgaste normal o abuso a la herramienta. Para

mayores detalles sobre la cobertura de la garantia e informaci6n

acerca de reparaciones realizadas bajo garantia, visitenos en

www.dewalt.com o IIAmenos al 1 800 433-9258 (1-800-4-DEWALT).

Esta garantia no aplica a accesorios o a daSos causados por

reparaciones realizadas o intentadas pot terceros. Esta garantia le

otorga derechos legales especificos, ademAs de los cuales puede

tenet otros dependiendo del estado o provincia en que se encuentre.

AdemAs de la garantia, las herramientas DEWALT estAn cubiertas por:

1 ANO DE SERVlClO GRATUITO

DEWALTmantendrA la herramienta y reemplazarA las piezas gastadas

por su uso normal, sin cobro, en cualquier momento durante un ago a

contar de la fecha de compra.

FIG. 7

MOLETEADO

FIG. 8

TROQUELDIE_

!

!

GARANT|A DE REEMBOLSO DE SU DINERO POR 90 DiAS

Si no esta completamente satisfecho con el desempeSo de su

mAquina herramienta, laser o clavadora DEWALT, cualquiera sea el

motivo, podrA devolverlo hasta 90 dias de la fecha de compra con su

recibo y obtener el reembolso completo de su dinero - sin necesidad

de responder a ninguna pregunta.

SUSTITUClON GRATUITA DE LAS ETIQUETAS DE

ADVERTENClA: Si las etiquetas de advertencia se vuelven ilegibles

o se pierden, Ilame al 1-800-4-DEWALT para conseguir gratuitamente

otras de repuesto.

16

Page 19

PARA REPARACION Y SERVIClO DE SUS HERRAMIENTAS

ELECTRICAS, FAVOR DE DIRIGIRSE AL CENTRO DE

SERVICIO IVlAS CERCANO

CUUACAN, SIN

Av. Nicolb,s Bravo #1063 Sur - Col. industrial Bravo (667) 7 12 42 11

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juarez (33) 3825 6978

MEXICO, D.E

Eje Central Lb,zaro Cardenas No. 18 (55) 5588 9377

Local D, Col. Obrera

MERIDA, YUC

Calie 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco J.Madero No.831 - Col. Centro (81) 8375 2313

PUEBLA, PUE

17 Notre #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. Madero 139 Pte.- Col. Centro (442) 214 1660

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Jndependencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongaci6n Diaz Mir6n #4280 - Col. Remes (229) 921 7016

VlLLAHERMOSA, TAB

Constituci6n 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCAUDADES LLAME AL: (55) 5326 7100

Tensi6n de alimentaci6n 120 V CA/CD

Epecificaciones (DW896)

Potencia nominal: 380 W

Frecuencia de operaci6n: 60 Hz

Consumo de corriente: 3,0 A

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS, 3A. SECCION, CP 05120

DELEGACION CUAJIMALPA, MEXICO, D.F

Para servicioy ventasconsulte /..... ',,,

"HERRAMIENTAS ELECTRICAS" SECCJ_'

TEL. 5 326 7100

R.F.C.: BDE810626-1W7

en la secci6n arnarilla. AMARILLA

17

Page 20

DEWALTIndustrialToolCo., 701 EastJoppa Road,Baltimore,MD 21286 (APR04) Form No. 384263-00 DW896

Copyright © 1997, 2004

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the "D" shaped air intake grill; the array of

pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...