Page 1

DEWALT Industrial Tool Company, P.O. Box 158, 626 Hanover Pike, Hampstead, MD 21074 Printed in U.S.A. (JUN97-CD-1) Form No. 384483

DW895 Copyright © 1997

DW895/384483 5/2/02 1:11 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW895

12-Gauge Shear

Cisaille de calibre 12

Cizalla calibre 12

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DW895/384483 5/2/02 1:11 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

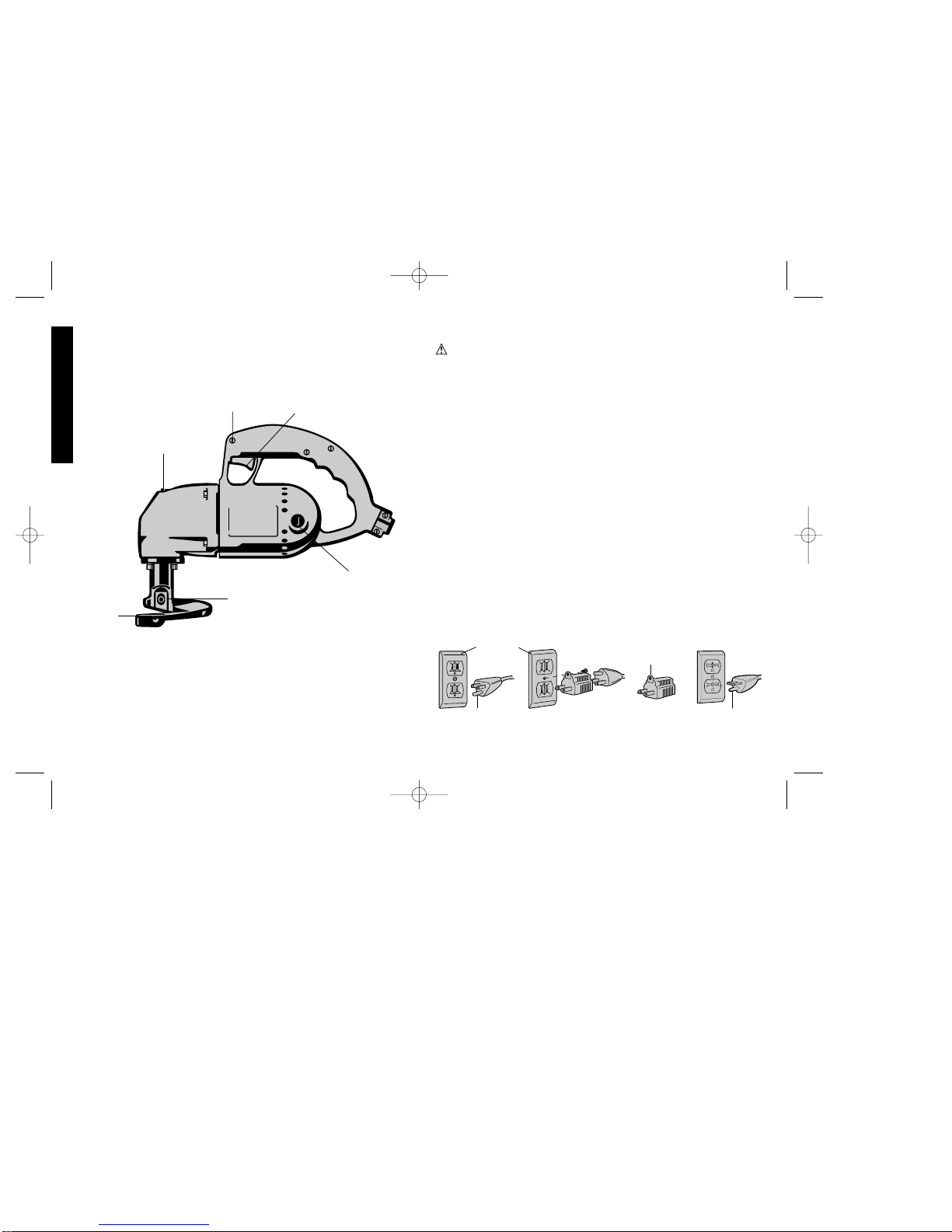

Grounding Instructions

This tool should be grounded while in use to protect the operator from

electric shock. The tool is equipped with a 3-conductor cord and 3prong grounding type plug to fit the proper grounding type receptacle.

The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow) wire

to a live terminal. If your unit is intended for use on less than 150 V,

it has a plug that looks like that shown in sketch A. If it is for use on

150 to 250 V, it has a plug that looks like that shown in sketch D. An

adapter, sketches B and C, is available for connecting sketch A type

plugs to 2-prong receptacles. The green-colored rigid ear, lug, or the

like, extending from the adapter must be connected to a permanent

ground, such as a properly grounded outlet box. No adapter is

available for a plug as shown in sketch D. ADAPTER SHOWN IN

FIGURES B and C IS NOT FOR USE IN CANADA.

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

AB CD

GROUNDING PIN

GROUNDED

OUTLET

BOX

GROUNDING

MEANS

GROUNDING PIN

ADAPTER

OILING CAP

TRIGGER

SWITCH

BRUSH

INSPECTION CAP

(2)

MOVING

BLADE

LOCK

BUTTON

FIXED

BLADE

DW895/384483 5/2/02 1:11 PM Page 4

Page 4

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the rate

for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles

dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Use only 3-wire extension cords that have 3-

prong grounding-type plugs and 3-pole receptacles that accept the

tool’s plug. Replace or repair damaged cords. Make sure your

extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage.

The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

1

English

DW895/384483 5/2/02 1:11 PM Page 1

Page 5

2

• CHECK DAMAGED PARTS. Before further use of the tool, a guard

or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

SAVE THESE INSTRUCTIONS

Motor

Your DEWalt tool is powered by a DEWalt-built motor. Be sure your power

supply agrees with the nameplate marking.

Volts 50/60 Hz or “AC only” means your tool must be operated on

alternating current and never with direct current.

Voltage decrease of more than 10% will cause loss of power and

overheating. D

EWalt tools are factory tested; if this tool does not operate,

check power supply.

Switch

Depress the trigger switch to turn the tool on. Releasing the trigger

turns the tool off. To lock the trigger in the on position for continuous

operation, depress the trigger, push in the lock button on the left

side of the handle, and then release the trigger. To release the

locking mechanism, depress trigger fully, then release it.

English

Operation

1. For accurate work, be sure material to be cut is anchored firmly.

2. Grasp tool and turn switch on.

3. WITHOUT LETTING BLADES ENGAGE THE MATERIAL,

position tool so that the material rests on the top of the front edge

of the shoe.

4. Line up tool with the cutting line and advance tool into the

material. Use a firm forward pressure when cutting, but do not

force the tool.

NOTE: If tool does not cut efficiently, check the following: dull

blades, blades incorrectly set, material which exceeds the rated

capacity of the tool.

Blade Adjustment

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY

BEFORE ADJUSTING BLADES.

HORIZONTAL CLEARANCE: The setting of the horizontal

clearance between blades depends upon the capacity of the tool and

the thickness of the material being cut. When cutting sheet steel,

clearance should not be over .009". When cutting lighter material, the

clearance should be reduced in proportion.

VERTICAL CLEARANCE: Position the moving blade at the top of its

stroke. Adjust the vertical clearance so that the material to be cut can

be inserted 1/2 way into the “V” shaped opening.

NOTE: After adjusting horizontal and vertical clearances, rotate fan

manually to ensure that the blades do not interfere during any portion

of the stroke.

DW895/384483 5/2/02 1:11 PM Page 2

Page 6

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

DEWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

3

English

Maintenance

Shears should be cleaned, inspected, and lubricated at a DEWALT

certified service center every 2-6 months depending on usage.

Inspect carbon motor brushes frequently by unplugging tool,

removing the brush inspection caps, and withdrawing the brush and

spring assembly. Replace the assembly when the brushes are worn

down to the line closest to the spring, or when spring exerts

insufficient pressure to hold brush against commutator. Keep brushes

clean and sliding freely in their guides.

An oiling cap is located at the top front of the tool. Each time before

operating, and every 3 hours during operation, add 20 to 30 drops of

SAE 20W or 30W oil to the tool by depressing the ball valve in the

oiling cap.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

DW895/384483 5/2/02 1:11 PM Page 3

Page 7

4

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vous devez lire et comprendre toutes les

instructions. Le non-respect, même partiel, des instructions ci-après

entraîne un risque de choc électrique, d’incendie et/ou de blessures

graves.

CONSERVEZ CES INSTRUCTIONS.

AIRE DE TRAVAIL

• Veillez à ce que l’aire de travail soit propre et bien éclairée. Le

désordre et le manque de lumière favorisent les accidents.

• N’utilisez pas d’outils électriques dans une atmosphère

explosive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

• Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

• Les outils à double isolation sont équipés d’une fiche

polarisée (une des lames est plus large que l’autre), qui ne

peut se brancher que d’une seule façon dans une prise

polarisée Ne modifiez pas la fiche de l’outil. La double

isolation élimine le besoin d’un cordon d’alimentation à trois fils

avec mise à la terre ainsi que d’une prise de courant mise à la terre.

• Évitez tout contact corporel avec des surfaces mises à la terre

(tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.). Le

risque de choc électrique est plus grand si votre corps est en

contact avec la terre.

• N’exposez pas les outils électriques à la pluie ou à l’eau. La

présence d’eau dans un outil électrique augmente le risque de choc

électrique.

• Ne maltraitez pas le cordon. Ne transportez pas l’outil par son

cordon et ne débranchez pas la fiche en tirant sur le cordon.

N’exposez pas le cordon à la chaleur, à des huiles, à des arêtes

BOUCHON DE

REMPLISSAGE

D’HUILE

INTERRUPTEUR

COUVERCLE

D’INSPECTION

DES BALAIS (2)

LAME MOBILE

BOUTON DE

VERROUILLAGE

LAME

FIXE

DW895/384483 5/2/02 1:11 PM Page 4

Page 8

vives ou à des pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un cordon endommagé

augmente le risque de choc électrique.

• Lorsque vous utilisez un outil électrique à l’extérieur,

employez un prolongateur pour l’extérieur marqué «W-A» ou

«W». Ces cordons sont faits pour être utilisés à l’extérieur et

réduisent le risque de choc électrique. S’assurer que le cordon de

rallonge est en bon état. Lorsqu’on se sert d’un cordon de rallonge,

s’assurer qu’il est de calibre approprié pour la tension nécessaire au

fonctionnement de l’outil. L’utilisation d’un cordon de calibre

inférieur occasionne une baisse de tension entraînant une perte de

puissance et la surchauffe. Le tableau suivant indique le calibre

approprié selon la longueur du cordon et les mentions de la plaque

signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement

proportionnel au calibre du cordon.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16 14 12 Non recommandé

SÉCURITÉ DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N’utilisez pas un outil électrique si vous

êtes fatigué ou sous l’influence de drogues, d’alcool ou de

médicaments. Un instant d’inattention suffit pour entraîner des

blessures graves.

• Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. N’approchez

jamais les cheveux, les vêtements ou les gants des pièces en

mouvement. Des vêtements flottants, des bijoux ou des cheveux

longs risquent d’être happés par des pièces en mouvement.

• Méfiez-vous d’un démarrage accidentel. Avant de brancher

l’outil, assurez-vous que son interrupteur est sur ARRÊT. Le fait

de transporter un outil avec le doigt sur la détente ou de brancher un

outil dont l’interrupteur est en position MARCHE peut mener tout

droit à un accident.

• Enlevez les clés de réglage ou de serrage avant de démarrer

l’outil. Une clé laissée dans un pièce tournante de l’outil peut

provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui et

restez en équilibre en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

• Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le matériau sur une surface stable au moyen de

brides ou de toute autre façon adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps offre un stabilité insuffisante et

peut amener un dérapage de l’outil.

• Ne forcez pas l’outil. Utilisez l’outil approprié à la tâche. L’outil

correct fonctionne mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

• N’utilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est

dangereux et droit être réparé.

• Débranchez la fiche de l’outil avant d’effectuer un réglage, de

changer d’accessoire ou de ranger l’outil. De telles mesures

préventives de sécurité réduisent le risque de démarrage accidentel

de l’outil.

• Rangez les outils hors de la portée des enfantes et d’autres

personnes inexpérimentées. Les outils sont dangereux dans les

mains d’utilisateurs novices.

• Prenez soin de bien entretenir les outils. Les outils de coupe

5

Français

DW895/384483 5/2/02 1:11 PM Page 5

Page 9

6

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

• Soyez attentif à tout désalignement ou coincement des pièces

en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de l’outil. Si vous

constatez qu’un outil est endommagé, faites-le réparer avant

de vous en servir. De nombreux accidents sont causés par des

outils en mauvais état.

• N’utilisez que des accessoires que le fabricant recommande

pour votre modèle d’outil. Certains accessoires peuvent convenir

à un outil, mais être dangereux avec autre.

RÉPARATION

• La réparation des outils électriques doit être confiée à un

réparateur qualifié. L’entretien ou la réparation d’un outil électrique

par un amateur peut avoir des conséquences graves.

• Pour la réparation d’un outil, n’employez que des pièces de

rechange d’origine. Suivez les directives données à la section

«Réparation» de ce manuel. L’emploi de pièces non autorisées ou

le non-respect des instructions d’entretien peut créer un risque de

choc électrique ou de blessures.

• Tenez l’outil par ses surfaces de prise isolées pendant toute

opération où l’outil de coupe portrait venir en contact avec un

câblage dissimulé ou avec son propre cordon. En cas de

contact avec un conducteur sous tension, les pièces métalliques à

découvert de l’outil transmettraient un choc électrique à l’utilisateur.

Mesures de sécurité additionnelles

• Ne le saisir que par ses poignées en plastique afin de se protéger

des secousses électriques que provoqueraient le contact de la lame

avec un fil sous tension.Lorsqu’on scie dans les murs, les planchers

ou tout autre endroit où peuvent se trouver des fils sous tension, ne

pas toucher à tout composant métallique de l’outil.

• S’assurer que les poignées sont toujours propres, sèches et

libres de toute tache d’huile ou de graisse. Il est recommandé de

porter des gants de caoutchouc. On améliore de la sorte la maîtrise

de l’outil.

• Les symboles suivants peuvent se trouver sur l’étiquette de l’outil.

V ......................volts

A ......................ampères

Hz ....................hertz

W......................watts

min ..................minutes

....................courant alternatif

................courant continu

n

o....................sous vide

....................construction de classe II

…/min ..............tours ou courses à la minute

....................borne de mise à la terre

....................symbol d´avertissement

Moteur

Un moteur DEWALT actionne l'outil DEWALT. Veiller à ce que la

tension d'alimentation soit conforme aux exigences de la plaque

signalétique de l'outil.

La mention «Volts 50-60 Hz» ou «c.a. seulement» signifie que l'outil

fonctionne sur du courant alternatif et jamais sur de courant continu.

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffe. Tous les outils DEWALT sont essayés

avant de quitter l'usine. Lorsque celui-ci refuse de fonctionner,

vérifier la source de courant électrique.

Interrupteur

Enfoncer l'interrupteur à détente pour mettre l'outil en marche. Pour

l'arrêter, relâcher la détente. Pour verrouiller la détente en mode de

fonctionnement continu, enfoncer la détente, pousser le bouton de

verrouillage qui se trouve du côté gauche de la poignée, puis

Français

DW895/384483 5/2/02 1:11 PM Page 6

Page 10

relâcher la détente. Pour dégager le mécanisme de verrouillage,

enfoncer à fond la détente et la relâcher immédiatement.

Fonctionnement

1. Pour s'assurer de la précision de la coupe, bien fixer le matériau

à couper.

2. Saisir l'outil et le mettre en marche.

3. SANS LAISSER LES LAMES ENTRER EN CONTACT AVEC LE

MATÉRIAU, placer l'outil de sorte que le matériau repose contre

le dessus du rebord avant du patin.

4. Aligner l'outil sur la ligne de coupe et avancer l'outil vers le

matériau. Exercer une pression ferme vers l'avant sur l'outil sans

le forcer.

NOTE : Lorsque l'outil ne coupe pas bien, vérifier les points

suivants : si les lames sont émoussées, si les lames sont mal

réglées ou si l'épaisseur du matériau excède la capacité nominale

de l'outil.

Réglage des lames

METTRE L'OUTIL HORS TENSION ET LE DÉBRANCHER AVANT

DE RÉGLER LES LAMES.

JEU HORIZONTAL : Le réglage du jeu horizontal entre les lames

dépend de la capacité de l'outil et de l'épaisseur du matériau à

couper. Lorsqu'on coupe de l'acier en feuilles, le jeu ne devrait pas

dépasser XX mm (0,009 po). Lorsqu'on coupe un matériau plus

léger, il faut réduire le jeu en conséquence.

JEU VERTICAL : Placer la lame mobile dans le haut de sa course.

Régler le jeu vertical de sorte qu'on puisse introduire la moitié du

matériau à couper dans l'ouverture en forme de «Y».

NOTE : Après avoir réglé les jeux horizontal et vertical, faire tourner

le ventilateur manuellement afin de s'assurer que les lames ne s'y

accrochent pas pendant le course.

Entretien

Il faut confier le nettoyage, l'inspection et la lubrification de la cisaille

au personnel d'un centre de service DEWALT autorisé aux 2 à 6

mois, en fonction de l'utilisation de l'outil.

Vérifier souvent les balais de carbone du moteur en débranchant

l'outil, en retirant les couvercles d'inspection des balais et en retirant

les assemblages balai-ressort. Remplacer les assemblages lorsque

les balais sont usés jusqu'à la ligne la plus près du ressort ou lorsque

le ressort n'exerce plus la pression suffisante pour retenir le balai

contre le commutateur. S'assurer que les balais sont propres et qu'ils

glissent librement dans leurs guides.

Il y a un bouchon de remplissage d'huile sur le dessus de l'outil, à

l'avant. Avant chaque utilisation et après chaque 3 heures

d'utilisation, verser de 20 à 30 gouttes d'huile SAE 20W ou 30W dans

l'outil en enfonçant le tournant sphérique du bouchon de remplissage

d'huile.

Lubrification

Les roulements à billes et les paliers lisses de l’outil ont été lubrifiés

en permanence à l’usine. La graisse du boîtier d’engrenages lubrifie

les roulements à aiguilles. Il faut nettoyer et lubrifier de nouveau le

boîtier d’engrenages annuellement ou lorsque l’entretien nécessite le

retrait du boîtier d’engrenages. Utiliser le type et la quantité de

graisse mentionnée dans la liste des pièces incluse dans

l’emballage.

Pour enlever le boîtier d’engrenages, desserrer les trois vis situées

sur le devant de l’outil. Lorsque le mandrin est trop gros pour enlever

les deux vis du haut, consulter la rubrique relative au retrait du

mandrin.

7

Français

DW895/384483 5/2/02 1:11 PM Page 7

Page 11

8

Accessoires

On peut se procurer séparément les accessoires recommandés pour

l’outil chez les détaillants ou au centre de service de la région.

Pour trouver un accessoire, prière de communiquer avec D

EWALT

Industrial Tool Company, 626 Hanover Pike, P.O. Box 158, 626

Hanover Pike, Hampstead, MD 21074, É.-U., ou composer sans frais

le 1 (800) 433-9258.

MISE EN GARDE : L’utilisation de tout accessoire non

recommandé peut être dangereuse.

Par mesure de sécurité, n’utiliser que les accessoires suivants et

uniquement ceux ne dépassant pas les dimensions maximales

recommandées.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’à un centre de service

ou à un atelier d’entretien autorisé n’utilisant que des pièces de

rechange identiques.

Garantie complète

Les outils industriels de service intensif DeWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

DeWALT utilisé en service commercial ou offert en location qui

s’avérait défectueuse en raison d’un vice de matière ou de fabrication

sera réparée ou remplacée sans frais. Selon une entente convenue

entre DeWALT et Black & Decker Canada Inc., la Division des outils

industriels de Black & Decker Canada Inc. s’engage à effectuer les

réparations couvertes par la présente garantie. Il suffit de retourner

l’outil port payé à l’un des centres de service d’outils industriels

Black & Decker ou à tout autre atelier d’entretien d’outils industriels

accrédité. DeWAL T n’assume aucune responsabilité pour les avaries

dues au mauvais usage, à une manoeuvre négligente, ou aux

réparations tentées ou effectuées par des tiers. Aucune autre

garantie, écrite ou verbale, ne sera reconnue.

NOTE : La présente garantie et les dispositions précédentes peuvent

ne pas être valides dans certaines provinces.

GARANTIE DE SATISFACTION DE 30 JOURS OU

ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

Dewalt ne donne pas entière satisfaction, il suffit de le retourner, avec

tous les accessoires, port payé au vendeur participant .

On peut exiger une preuve d’achat pour recevoir un remboursement.

Français

Imported by / Importé par

Black & Decker Canada Inc.

100 Central Ave.

Brockville (Ontario) K6V 5W6

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

DW895/384483 5/2/02 1:11 PM Page 8

Page 12

ADVERTENCIA: Por su propia seguridad lea el manual de

instrucciones antes de operar la herramienta.

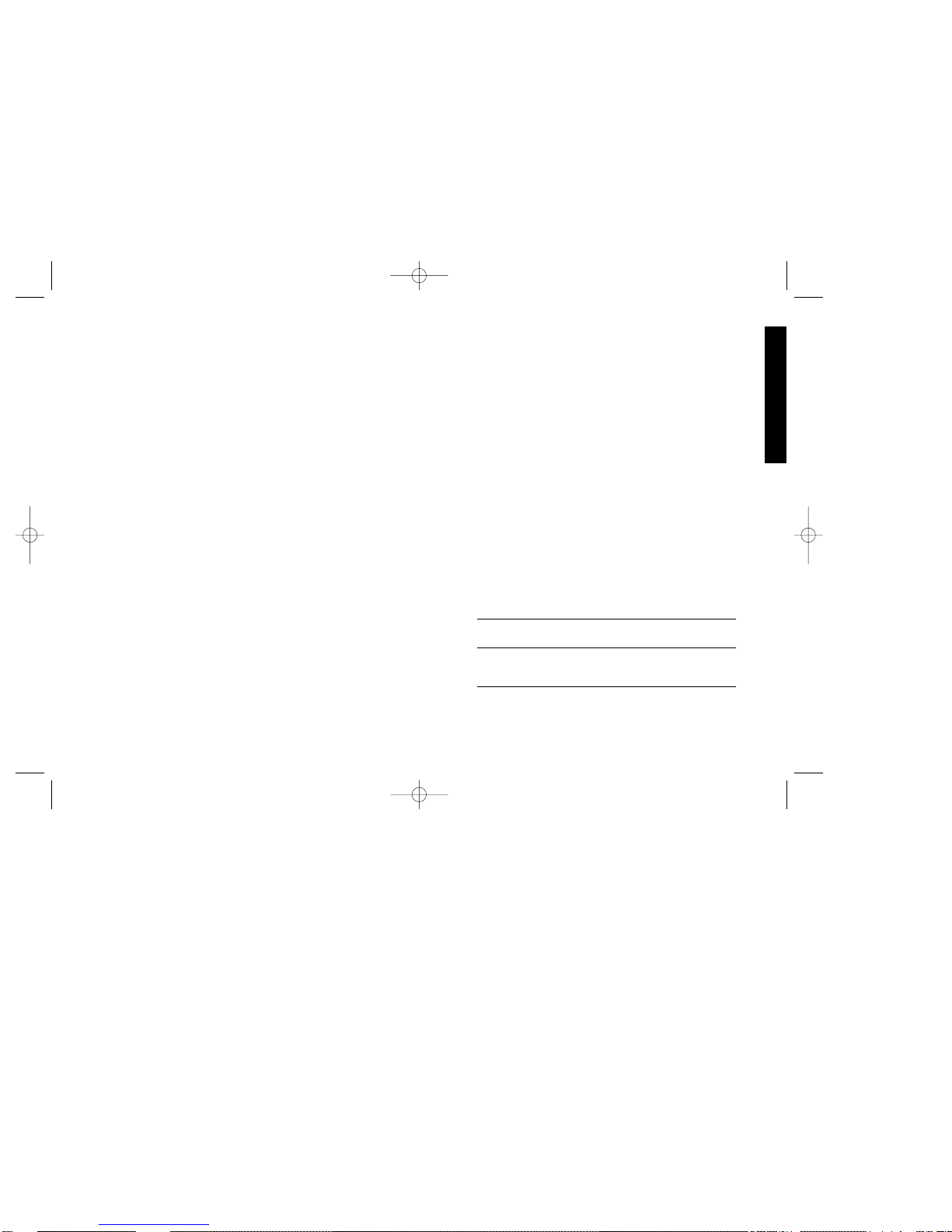

Instrucciones de conexión a tierra

En el caso de mal funcionamiento, la tierra proporciona una vía de

menor resistencia a la corriente eléctrica para reducir el riesgo de

choque eléctrico. Esta herramienta está equipada con un cable

eléctrico con un conductor a tierra y pata de aterrizaje. La clavija debe

conectarse a una toma de corriente instalada correctamente y

aterrizada de conformidad con todos los reglamentos locales. No

modifique la clavija, si no se ajusta a la toma de corriente, haga que

un electricista calificado le instale una toma adecuada.

La conexión incorrecta del conductor a tierra del equipo puede

originar riesgos de choque eléctrico. El conductor cuyo aislamiento es

de color verde con o sin franjas amarillas es el conductor a tierra del

equipo. Si se requiere reparación o cambio del cable eléctrico o la

clavija, no conecte el conductor a tierra a una terminal viva.

Consulte con un electricista si no comprende perfectamente las

instrucciones de aterrizaje, o si tiene dudas acerca de la conexión a

tierra de su equipo.

Utilice solamente extensiones de tres cables que tengan clavijas de

tres patas y tomas de corriente de tres polos que acepten la clavija de

la herramienta.

Repare o reemplace inmediatamente los cables dañados o

desgastados.

Esta herramienta está diseñada para utilizarse en circuitos que

tengan una toma de corriente similar a la ilustrada en la figura A. Se

puede utilizar un adaptador temporal, que se parece al mostrado en

las figuras B y C, para conectar esta clavija a una toma de corriente

de dos polos como se observa en la figura B si no dispone de una

toma aterrizada. Solamente debe utilizar el adaptador temporal hasta

que un electricista le instale una toma apropiada.

La oreja, lengüeta, o similar de color verde que se extiende del

9

Español

Epecificaciones

Tensión de alimentación 120 V CA/CD

Potencia nominal: 500 W

Frecuencia de operación: 50/60 Hz

Consumo de corriente: 4,5 A

PERILLA DE

FLUJO DE ACEITE

INTERRUPTOR

DE GATILLO

TAPA DE

INSPECCION DE

CARBON (2)

CUCHILLA

MOVIL

BOTON DE

ENCENDIDO

PERMANENTE

CUCHILL

A FIJA

DW895/384483 5/2/02 1:11 PM Page 9

Page 13

10

adaptador debe conectarse a tierra permanente, como una toma de

corriente aterrizada.

Instrucciones importantes de seguridad

• CONSERVE LAS GUARDAS EN SU SITIO y listas para trabajar.

• CONSERVE LIMPIA EL AREA DE TRABAJO. Las áreas y bancos

con objetos acumulados en desorden propician los accidentes.

• NO SE EMPLEE EN AMBIENTES PELIGROSOS. No utilice

herramientas eléctricas en ligares inundados o mojados, ni las

exponga a la lluvia. Conserve bien iluminada el área de trabajo.

• CONSERVE APARTADOS A LOS NIÑOS. Todos los visitantes

deben permanencer a distancia segura de la zona de trabajo.

• HAGA SU TALLER A PRUEBA DE NIÑOS con candados,

interruptores maestros y retirando las llaves de encendido.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá mejor con su

trabajo y de manera más segura bajo las especificaciones para las

que se diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce una

herramienta o sus dispositivos en una tarea para los que no han

sido diseñados.

• UTILICE UN CABLE DE EXTENSION ADECUADO. Asegúrese

que su extensión esté en buenas condiciones. Cuando utilice una

extensión, asegúrese de emplear una que soporte la corriente que

su herramienta necesita. Una extensión con calibre insuficiente

provocará una caída en el voltaje de la línea, ocasionando pérdida

de potencia y sobrecalentamiento. El cuadro siguiente muestra el

calibre correcto a utilizarse de acuerdo con la longitud y el amperaje

indicado en la placa de identificación. Si tiene dudas, utilice el

calibrte siguiente. Mientras más pequeño sea el número del calibre,

mayor será su capacidad.

Calibre mínimo para cordones de extensión

Volts Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

AMPERAJE

Más No más Calibre del cordón AWG

de de

0-6 18161614

6 - 10 18 16 14 12

10-1216161412

12 - 16- 14 12 No recomendado

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

utilice la herramienta a la intemperie, solamente utilice extensiones

diseñadas para ello y así marcadas.

• VISTA LAS PRENDAS ADECUADAS.No utilice prendas de vestir

flojas, guantes, corbatas, anillos, brazaletes ni otras piezas de

joyería que pudiesen quedar atrapadas en las partes móviles. Se

recomienda el empleo de calzado antiderrapante. Cúbrase el

cabello si lo tiene largo.

• SIEMPRE UTILICE GAFAS DE SEGURIDAD.También utilice una

máscara contra polvo si la operación a efectuar lo produce. Los

anteojos de uso diario solamente tienen lentes resistentes al

impacto, NO SON anteojos de seguridad.

• NO SE SOBREEXTIENDA. Conserve siempre bien apoyados los

pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas

afiladas y limpias para que funcionen mejor y de manera más

segura. Siga las instrucciones de cambio de accesorios.

• DESCONECTE LA HERRAMIENTASantes de efectuarles servicio

y cuando les cambie acesorios, como cuchillas, brocas y similares.

• REDUZCA EL RIESGO DE ENCENDIDO ACCIDENTAL.

Español

AB C

PATA DE

CONEXION A

TIERRA

TOMA DE

CORRIENTE

ATERRIZADA

MEDIO DE

ATERRIZAJE

ADAPTADOR

DW895/384483 5/2/02 1:11 PM Page 10

Page 14

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD AL AMBIENTE DE TRABAJO. No deje

las herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo. No utilice la herramienta en presencia de líquidos o gases

inflamables.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el

contacto corporal con superficies aterrizadas, por ejemplo,

tuberías, radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión. Los

visitantes deben estar alejados del área de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las

herramientas que no se están utilizando deben guardarse en un

lugar seco y elevado o bajo llave, fuera del alcance de los niños.

• NO FUERCE LA HERRAMIENTA. Esta cumplirá su función mejor

y con más seguridad bajo las especificaciones para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una

herramienta pequeña o a sus dispositivos de montaje en un trabajo

de tipo pesado. No emplee la herramienta en una tarea para la

que no se diseñó.

• VISTASE DE LA MANERA ADECUADA.No tenga puestas ropas

o artículos de joyería flojos, pues podrían quedar atrapados por las

partes móviles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaja al

aire libre. Cúbrase bien la cabeza para sujetarse el pelo si lo tiene

largo.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación que va a

efectuar.

• NO ABUSE DEL CABLE ELECTRICO. Nunca levante la

herramienta por el cordón ni tire de éste para desconectarlo del

enchufe. Apártelo del calor y los objetos calientes, las sustancias

grasosas y los bordes cortantes.

• SUJETE FIRMEMENTE LOS OBJETOS SOBRE LOS QUE

TRABAJE. Utilice prensas o tornillos de banco para sujetar bien los

objetos sobre los que va a trabajar. Esto ofrece mayor seguridad

que sujetar los objetos con la mano, y además deja libres ambas

manos para operar la herramienta.

• NO SE SOBREEXTIENDA. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas bien

afiladas y limpias para que funcionen mejor y con mayor seguridad.

Obedezca las instrucciones de lubricación y cambio de accesorios.

Inspeccione los cordones eléctricos con frecuencia y, si los

encuentra dañados, hágalos cambiar o reparar en un centro de

servicio autorizado. Revise también con frecuencia las extensiones

eléctricas y reemplácelas si están dañadas. Conserve los mangos

secos, limpios y libres de aceites y grasas.

• DESCONECTE LAS HERRAMIENTAS. Hágalo cuando no las

emplee, antes de darles servicio y cuando vaya a cambiarles

accesorios como seguetas, discos, brocas y otros dispositivos de

corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera el

hábito de asegurarse de que se han retirado las llaves de ajuste

de la herramienta antes de accionarla.

• EVITE QUE LA HERRAMIENTA SE ACCIONE ACCIDENTALMENTE. Nunca sostenga una herramienta con el dedo en el

interruptor si se encuentra conectada a la corriente eléctrica.

Asegúrese que el interruptor está en la posición de “apagado” antes

de conectarla.

• CABLES DE EXTENSION. Utilice únicamente extensiones de 3

hilos con clavijas de 3 patas y tomas de corriente de 3 polos que

acepten la clavija de la herramienta. Repare o reemplace los cables

11

Español

DW895/384483 5/2/02 1:11 PM Page 11

Page 15

12

dañados. Asegúrese que su extensión esté en buenas condiciones.

Cuando utilice un cordón de extensión, asegúrese de emplear uno

con el calibre suficiente para soportar la corriente necesaria para su

producto. Una extensión con calibre menor al necesario causará

una caída en el voltaje de la línea, resultando en pérdida de

potencia y sobre calentamiento. El cuadro siguiente muestra los

calibres correctos para usarse de acuerdo con la longitud de la

extensión y el amperaje

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir

empleando cualquier herramienta, es indispensable verificar con

mucho cuidado que las guardas u otras partes dañadas puedan

operar de la manera adecuada para cumplir con su función.

Verifique la alineación de las partes móviles, la firmeza con que

deben encontrarse sujetas en sus montaduras, las partes rotas, las

propias montaduras y cualesquiera otros DETALLES que pudieran

afectar a la operación de la herramienta. Las guardas y las otras

partes que se encuentren dañadas deberán repararse bien o

cambiarse en un centro de servicio autorizado, a menos que se

diga otra cosa en el manual del usuario. Haga que se cambien los

interruptores dañados en un centro de servicio autorizado. No

emplee ninguna herramienta que tenga inutilizado o estropeado el

interruptor.

CONSERVE ESTAS INSTRUCCIONES

Motor

Su herramienta DeWalt funciona con un motor DeWalt integrado.

Asegúrese que la alimentación de corriente concuerde con la

señalada en la placa de identificación.

Volts 50/60 hz o “ac only” significa que su herramienta debe operarse

con corriente alterna y nunca con corriente directa.

Disminuciones en el voltaje mayores a 10% causarán pérdida de

potencia y sobrecalentamiento. Las herramientas DeWalt se

prueban en la fábrica; si esta herramienta no funciona, revise la

alimentación de corriente.

Interruptor

Oprima el interruptor de gatillo para encender la cizalla, suéltelo para

apagarla. El interruptor se puede asegurar en posición de encendido

activando el botón de encendido permanente que se encuentra del

lado izquierdo del mango, al mismo tiempo que se conserva el

interruptor oprimido. Asegúrese siempre que la herramienta no tenga

activado el mecanismo de encendido permanente antes de

conectarla. Para apagar la unidad cuando este mecanismo está

activado, oprima y libere el interruptor una vez.

Operación

1. Para trabajos de precisión, debe anclarse firmemente el material

a cortar.

2. Sujete la herramienta y encienda el interruptor.

3. SIN PERMITIR QUE LAS CUCHILLAS HAGAN CONTACTO

CON EL MATERIAL, coloque la herramienta de tal manera que

el material se apoye en la parte superior del borde frontal de la

zapata.

4. Haga coincidir la herramienta con la línea de corte y aváncela

hacia el material. Haga presión firme al cortar, pero no fuerce la

herramienta.

NOTA: Si la herramienta no corta con eficiencia, verifique lo

siguiente: que las cuchillas no estén desafiladas o colocadas

incorrectamente y que el material no exceda la capacidad

especificada de la herramienta.

Ajuste de las cuchillas

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE

CORRIENTE ANTES DE AJUSTAR LAS CUCHILLAS.

Español

DW895/384483 5/2/02 1:11 PM Page 12

Page 16

LUZ HORIZONTAL: El ajuste de la luz horizontal entre las cuchillas

depende de la capacidad de la herramienta y del espesor del

material a cortar. Cuando corte lámina de acero, la luz no deberá

ser mayor a 0,22 mm (0,009”). Cuando corte material más ligero,

deberá reducir la luz proporcionalmente.

LUZ VERTICAL: Coloque la cuchilla móvil en la parte superior de

su carrera. Ajuste la luz vertical de manera que el material pueda

insertarse a medio camino en la abertura con forma de “V”.

NOTA: Después de ajustar las luces horizontal y vertical, gire el

ventilador con la mano para asegurarse que las cuchillas no

interfieran durante ningún momento en el movimiento de la carrera.

Mantenimiento

La cizalla deberá ser limpiada, inspeccionada y lubricada en un

centro de servicio certificado DeWALT cada 2 a 6 meses,

dependiendo de su uso.

Revise con frecuencia los carbones del motor de la siguiente

manera: desconecte la herramienta, retire las tapas de inspección de

los carbones y saque los montajes de los carbones y sus resortes.

Reemplace estos montajes cuando los carbones se hayan

desgastado hasta la línea más cercana al resorte, o cuando el

resorte haga presión insuficiente para sujetar al carbón contra el

conmutador. Conserve los carbones limpios y deslizándose

libremente en sus guías.

En la parte superior del frente de la herramienta se encuentra una

aceitera. Antes de operar la unidad cada vez, y después de cada 3

horas de operación, añada a la herramienta de 20 a 30 gotas de

aceite SAE 20W o 30W oprimiendo la válvula de la aceitera.

Accesorios

Los accesorios recomendados para emplearse con su herramienta

están a su disposición con costo extra con su distribuidor o en el

centro de servicio de su localidad.

PRECAUCION: El uso de cualquier accesorio no recomendado

para emplearse con su herramienta puede ser peligroso.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros certificados de servicio u otras organizaciones

autorizadas que empleen siempre refacciones legítimas DeWALT.

PARA REPARACION Y SERVICIO DE SUS HERRAMIENTAS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1770 (91 3) 826 69 78.

LEON

Polara #32 (91 471) 314 56

MEXICO

Sonora #134 Hiprodromo Condesa 553-9979

MERIDA

Calle 63 #459 (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #2057 (91 22) 46 90 20

QUERETARO

Av. Madero 139 Pte. (91 42) 14 60 60

SAN LOUIS POTOSI

Pedro Moreno #408 Fracc. la Victoria (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 18

VILLAHERMOSA

Zaragoza #105 (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

13

Español

DW895/384483 5/2/02 1:11 PM Page 13

Page 17

14

Póliza de garantía

Black & Decker, S A de C V, garantiza por un año a partir de la fecha

de compra, el funcionamiento de este producto contra cualquier

defecto en los materiales y mano de obra empleados para su

fabricación. Nuestra garantía incluye la reparación, reposición o

cambio del producto y/o componentes sin cargo alguno para el

cliente, incluyendo mano de obra, así como los gastos de

transportación derivados del cumplimiento de este certificado.

Black & Decker, S.A. de C.V., se compromete a entregar el producto

en un lapso no mayor de 30 días contados a partir de la fecha de

recepción del mismo en nuestros talleres de servicio. No se asumirá

responsabilidad alguna en caso de demora del servicio por causas

de fuerza mayor. Para hacer efectiva esta garantía, no podrán

exigirse mayores requisitos que presentarla sellada por el

establecimiento comercial donde se adquirió, de no contar con ésta

bastará la factura de compra.

Español

IMPORTADOR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE RADIATAS NO. 42

BOSQUES DE LAS LOMAS, 05120 MEXICO, D.F.

TEL 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y vientas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

DW895/384483 5/2/02 1:11 PM Page 14

Loading...

Loading...