Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (DEC03) Form No. 384447-00 DW893, DW893-220

Copyright © 1997, 2003

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array

of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW893/DW893-220

12 Gauge Shear

Cisaille de calibre 12

Cizalla calibre 12

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

Page 3

1

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY D

EWALT TOOL, CALL US TOLL FREE AT :

1-800-4-D

EWALT (1-800-433-9258).

PADDLE

SWITCH

SWITCH LOCK

BUTTON

CURL

DEFLECTOR

BLADES

SHOE

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool’s electrical system. Tools built with this insulation system are not intended to be grounded. As a result, your tool is

equipped with a two prong plug which permits you to use extension

cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection against injury resulting from a possible electrical

insulation failure within the tool.

CAUTION: When servicing all tools, USE IDENTICAL REPLACE-

MENT PARTS. Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on equipment to reduce the risk of electric shock. When provided, this plug will

fit into a polarized outlet only one way. If the plug does not fit fully into

the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not change the plug in any way.

Safety Instructions for All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces; for example, pipes, radiators, ranges, and

refrigerator enclosures.

Page 4

2

English

• KEEP CHILDREN AWAY. All visitors should be kept away from

work area. Do not let visitors contact tool or extension cord.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE A TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy duty tool. Don’t use tool for purpose not intended; for

example, don’t use circular saw for cutting tree limbs or logs.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear protective hair covering to contain long hair. Air vents often cover moving parts and should also be avoided.

• USE SAFETY GLASSES. Also use face or dustmask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to dis-

connect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer

than using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safe performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry plugged-in

tool with finger on the switch. Be sure the switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. The table shows the correct size to use

depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0 - 6 18 16 16 14

6- 10 18 16 14 12

10- 12 16 16 14 12

12- 16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS. When tool is used out-

doors, use only extension cords intended for use outdoors and so

marked.

• STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is defective

should be properly repaired or replaced by an authorized service

Page 5

3

English

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

• DO NOT OPERATE portable electric tools near flammable liquids

or in gaseous or explosive atmospheres. Motors in these tools normally spark, and the sparks might ignite fumes.

•When driving or drilling into walls, floors or wherever live electrical

wires may be encountered, DO NOT TOUCH ANY METAL

PARTS OF THE TOOL! Hold the tool only by the insulated grasping surfaces to prevent electric shock if you drive into a live wire.

SAVE THESE INSTRUCTIONS

Operating Rules for Shears

• Always wear safety glasses and protective gloves.

• Always use tool with curl deflector.

•Wear safety shoes to protect your feet from sharp metal debris on

floor.

• Always start tool before engaging material to be cut.

• Don’t cut material thicker than rated capacity. Remember, material thickness increases as gauge number decreases. (14 gauge is

thicker than 16 gauge.)

• Keep all screws tight. Periodically check them for loosening.

• If possible, cut material so scrap curl is to the right. This direction

will move curl down and out of the way.

• Unplug tool before making any adjustments.

• Do not put anything into a motor housing opening.

• Keep tool clean. Blow off any metal debris and dirt from tool.

• Use shears upright. If tool is upside down, metal curl may turn

toward you.

• Firmly secure the piece of metal to be cut to prevent movement

during cutting.

CAUTION: Wear appropriate personal hearing protection dur-

ing use. Under some conditions and duration of use, noise from this

product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grind-

ing, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, saw-

ing, grinding, drilling, and other construction activities. Wear

protective clothing and wash exposed areas with soap and

water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V..........volts A ..........amperes

Hz........hertz W ..........watts

min ......minutes ........alternating current

....direct current

n

o..........no load speed

........Class II Construction …/min ..revolutions or

........earthing terminal ..............reciprocation per minute

........safety alert symbol

Page 6

4

English

• Cut material so that scrap is to the right. This cutting direction will

move curl down and out of the way.

• When cutting a radius, turn the shear counterclockwise for easier

maneuvering.

• Best cutting (least effort) can be achieved when back of tool is

lowered 5˚ - 10˚.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for

use. Tools should be relubricated regularly every sixty days to six

months, depending on usage. (Tools used constantly on production

or heavy-duty jobs and tools exposed to heat may require more frequent lubrication.) This lubrication should only be attempted by

trained power tool repair persons such as those at D

EWALT autho-

rized service centers or in other qualified service organizations.

Paddle Switch

To start the tool, depress the paddle switch. To turn the tool off,

release the paddle. The switch can be locked on be engaging the

lock button located near the rear of the tool while holding the paddle

depressed. Always be sure that the tool is not locked on before plugging it in. To turn the tool off when it is locked on, squeeze and

release the paddle once.

Operation

TURN OFF TOOL AND DISCONNECT FROM POWER SUPPLY

BEFORE MAKING ANY ADJUSTMENTS. Always wear safety glasses and protective gloves. Never use shear without the curl deflector.

Most blade wear (dulling of edges) is on the back edge. Symptoms of

blade wear include: difficulty in cutting material, ragged cut edge,

heavier burr, and increased vibration while cutting.

Your shear is equipped with two identical blades with four cutting

edges on each blade. The moving blade wears faster than the stationary blade. However, it is advisable to rotate both blades to fresh

edges at the same time.

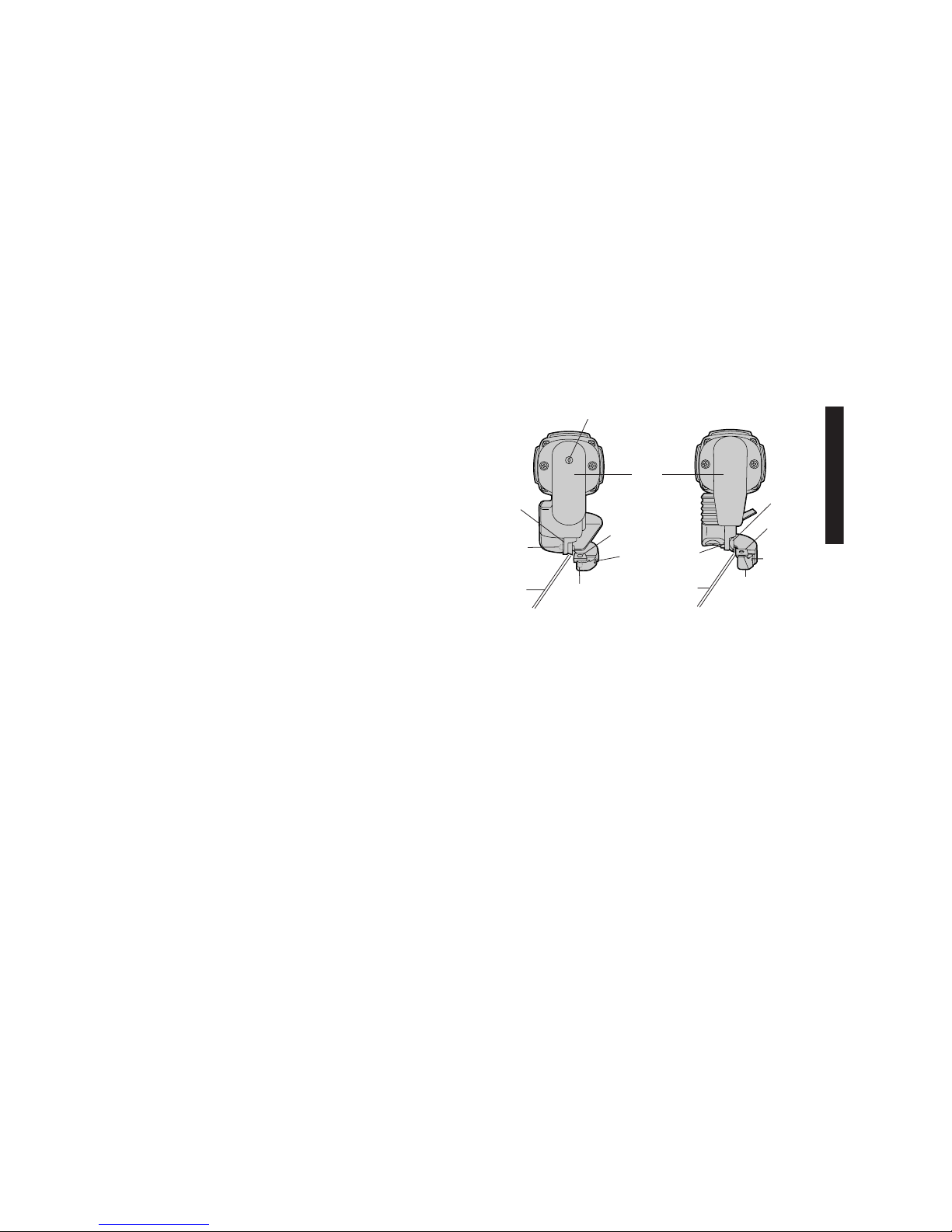

TO ROTATE THE BLADES

Remove the two blade clamp screws. Rotate each blade to a fresh

edge. Replace screws exactly as they were removed. Note that the

stationary blade clamp screw is longer and will cause damage to the

tool if it is used to secure the moving blade. (See Figure 2)

Stationary blade must be snug against the gap adjusting screw.

Check and adjust blade gap if necessary. (See following section on

adjusting the blade gap.) Tighten all screws.

Cutting Tips

• Proper blade gap is important.

• Dull blades increase user pressure on tool to cut and could result

in damage to tool.

• Always start tool before engaging material.

• Keep metal surface dry. Otherwise, shear will tend to rebound

(slide back) at each cutting stroke.

CAM SHAFT

STATIONARY

BLADE

GAP

ADJUSTING

SCREW

STATIONARY

BLADE CLAMP

SCREW

MOVING

BLADE

BLADE

GAP

BLADE

CLAMP

SCREW

HEAD

STATIONARY

BLADE

GAP

ADJUSTING

SCREW

STATIONARY

BLADE CLAMP

SCREW

BLADE

GAP

BLADE

CLAMP

SCREW

MOVING

BLADE

FIGURE 2

Page 7

5

English

Motor Brushes

Brush replacement should be performed by DEWALT authorized ser-

vice centers or other qualified service organizations.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

personnel, always using identical replacement parts.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, contact:

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286.

CAUTION: The use of any other accessory not recommended for

use with this tool could be hazardous.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information, call

1-800-4-D

EWALT. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT heavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT for a free

replacement.

Page 8

6

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-D

EWALT (1 800 433-9258)

Importantes mesures de sécurité

AVERTISSEMENT : Afin de réduire les risques d’incendie, de sec-

ousses électriques ou de blessures lorsqu’on utilise des outils électriques, il faut toujours respecter les mesures de sécurité suivantes.

LIRE TOUTES LES DIRECTIVES

Double isolation

Les outils à double isolation comportent deux couches distinctes

d’isolant électrique ou une double épaisseur d’isolant qui protègent

l’utilisateur contre les risques de blessures provenant du système

électrique de l’outil.

Ce système de double isolation élimine le besoin de mettre les outils

à la terre. En effet, l’outil est muni d’une fiche à deux broches, ce qui

permet d’utiliser une rallonge ordinaire sans avoir à se soucier

d’assurer la mise à la terre.

NOTE : La double isolation ne dispense pas des mesures de sécurité

normales lors de l’utilisation de l’outil. Elle vise à procurer une protection supplémentaire contre les blessures que peut entraîner une

défectuosité de l’isolant électrique à l’intérieur de l’outil.

MISE EN GARDE : Lors de l’entretien, n’utiliser que des piÉces de

rechange identiques. Réparer ou remplacer les cordons endommagés.

Fiche polarisée

Afin de réduire les risques de secousses électriques, l’outil est muni

d’une fiche polarisée (une lame plus large que l’autre). Ce genre de

fiche n’entre que d’une façon dans une prise polarisée. Lorsqu’on ne

peut insérer la fiche à fond dans la prise, il faut tenter de le faire après

avoir inversé les lames de côté. Si la fiche n’entre toujours pas dans

la prise, il faut communiquer avec un électricien certifié afin qu’il

installe une prise appropriée. Il ne faut en aucun cas modifier la fiche.

Pour tous les outils

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

INTERRUPTEUR

À PALETTE

BOUTON DE

VERROUILLAGE

DE

L´INTERRUTEUR

DÉFLECTEUR

LAMES

MATRICE

Page 9

7

Français

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à l’outil

ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit

outil ou d’un accessoire le rendement d’un outil de fabrication

plus robuste. Se servir de l’outil selon l’usage prévu (ainsi, ne pas

se servir d’une scie circulaire pour couper des branches ou des

bûches).

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue. Se tenir éloigné des évents

puisque ces derniers pourraient camoufler des pièces mobiles.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• MANIPULER LE CORDON AVEC SOIN. Ne pas transporter l’outil

par le cordon ni tirer sur ce dernier pour le débrancher de la prise.

Éloigner le cordon des sources de chaleur, des flaques d’huile et

des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides ou

d’un étau. On peut alors se servir des deux mains pour faire fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres et

affûtés pour qu’ils donnent un rendement supérieur et sûr. Suivre

les directives concernant la lubrification et le remplacement des

accessoires. Inspecter régulièrement le cordon de l’outil et le faire

réparer au besoin à un atelier d’entretien autorisé. Inspecter

régulièrement les cordons de rallonge et les remplacer lorsqu’ils

sont endommagés. S’assurer que les poignées sont toujours propres, sèches et libres de toute tache d’huile ou de graisse.

• DÉBRANCHER OU VERROUILLER EN POSITION HORS TEN-

SION LES OUTILS NON UTILISÉS. Respecter cette mesure

lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer ou en

changer un accessoire (comme une lame, un foret ou un couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de véri-

fier si les clés de réglage ont été retirées avant de faire démarrer

l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

• CORDONS DE RALLONGE. S’assurer que le cordon de rallonge

est en bon état. Lorsqu’on se sert d’un cordon de rallonge, s’assurer qu’il est de calibre approprié pour la tension nécessaire au fonctionnement de l’outil. L’utilisation d’un cordon de calibre inférieur

occasionne une baisse de tension entraînant une perte de puissance et la surchauffe. Le tableau suivant indique le calibre approprié selon la longueur du cordon et les mentions de la plaque signalétique de l’outil. En cas de doute, utiliser un cordon de calibre

supérieur. Le chiffre indiquant le calibre est inversement proportionnel au calibre du cordon.

Page 10

8

Français

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en pieds

120 V 0-25 26-50 51-100 101-150

240 V 0-50 51-100 101-200 201-300

Intensité (A)

Au Au Calibre moyen de fil (AWG)

moins plus

0- 6 18 161614

6- 10 18 16 14 12

10 - 12 16161412

12 - 16 14 12 Non recommandé

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant de continuer à

utiliser l’outil, il faut vérifier si le protecteur ou toute autre pièce

endommagée remplit bien la fonction pour laquelle il a été prévu.

Vérifier l’alignement et les attaches des pièces mobiles, le degré

d’usure des pièces et leur montage, ainsi que tout autre facteur

susceptible de nuire au bon fonctionnement de l’outil. Faire réparer ou remplacer toute pièce ou tout protecteur endommagé dans

un centre de service autorisé, sauf si le présent guide fait mention

d’un avis contraire. Confier le remplacement de tout interrupteur

défectueux à un centre de service autorisé. Ne jamais se servir

d’un outil dont l’interrupteur est défectueux.

• NE PAS UTILISER les outils portatifs électriques dans des

endroits où l’atmosphère contient des vapeurs combustibles ou

explosives. Les étincelles que produit le moteur en marche pourraient enflammer ces produits.

MISE EN GARDE : Lorsqu’on perce dans les murs, les planchers

ou tout autre endroit où peuvent se trouver des fils sous tension, NE

PAS TOUCHER À TOUT COMPOSANT MÉTALLIQUE SE TROUVANT À L’AVANT DE L’OUTIL. Ne le saisir que par ses surfaces de

prise isolées afin de se protéger des secousses électriques.

CONSERVER CES MESURES

Mesures de sécurité relatives aux

cisailles

• Toujours porter des lunettes de sécurité et des gants protecteurs.

• Toujours utiliser l'outil avec le déflecteur.

• Porter des chaussures de sécurité afin de se protéger contre les

débris métalliques pointus sur le sol.

• Toujours actionner l'outil avant d'insérer le matériau à couper.

• Ne pas couper des matériaux plus épais que celle indiquée sous la

capacité nominale de l'outil. Se rappeler que l'épaisseur du matériau est inversement proportionnelle au calibre (ainsi, un matériau

de calibre 14 est plus épais qu'un matériau de calibre 16).

• S'assurer que toutes les vis sont serrées. Les vérifier régulièrement.

• Dans la mesure du possible, couper le matériau de sorte que la

partie rejetée se trouve à droite de l'outil. De la sorte, le matériau

sera abaissé et éloigné de l'utilisateur.

• Débrancher l'outil avant de le régler.

• Ne rien insérer dans les orifices du carter du moteur.

• S'assurer que l'outil est propre. Souffler tout débris métallique et

tout saleté hors de l'outil.

• Utiliser la cisaille à l'endroit. Lorsqu'on renverse l'outil, la partie

rejetée est dirigée vers l'utilisateur.

• Bien fixer la pièce de métal à couper afin de l'empêcher de bouger

pendant la coupe.

MISE EN GARDE : Porter des protecteurs d’oreilles appro-

priés durant l’utilisation. Selon les conditions et la durée d’utilisa-

tion, le bruit émis par cet outil peut causer une perte auditive.

AVERTISSEMENT : Certaines poussières créées par le ponçage,

le sciage, le meulage et le forage mécanique ainsi que d’autres activités de construction contiennent des produits chimiques susceptibles

de causer le cancer, des anomalies congénitales ou d’autres anomalies liées à la reproduction. Parmi ces produits chimiques, citons

notamment :

Page 11

9

Français

• le plomb des peintures au plomb;

• la silice cristalline provenant des briques, du béton et autres

matériaux de maçonnerie;

• l’arsenic et le chrome provenant du bois traité (arséniate de

cuivre et de chrome).

Le risque associé à ces expositions varie selon la fréquence de ces

types de travaux. Pour réduire l’exposition aux produits chimiques : travailler dans un local bien ventilé et utiliser du matériel de sécurité

approuvé, comme les masques anti-poussières spécialement conçus

pour filtrer les particules microscopiques.

• Éviter le contact prolongé avec la poussière provenant du

ponçage, du sciage, du meulage et du forage mécanique ainsi

que d’autres activités de construction. Porter des vêtements

de protection et laver les parties exposées au savon et à l’eau.

Le fait de permettre à la poussière de pénétrer dans la bouche et

les yeux ou de se déposer sur la peau peut favoriser l’absorption

de produits chimiques nocifs.

AVERTISSEMENT : Toute personne entrant la zone de travail

devrait porter un masque anti-poussières ou un appareil respiratoire.

Le filtre doit en être remplacé quotidiennement ou chaque fois que l'utilisateur commence à avoir des difficultés à respirer. Se renseigner

auprès de son quincaillier local pour la liste des masques anti-poussières approuvés par le NIOSH/OSHA.

• L’étiquette apposée sur l’outil peut comprendre les symboles suivants.Voici les symboles et leurs définitions :

V..........volts A ..........ampères

Hz........hertz W ..........watts

min ......minutes ........courant alternatif

....courant direct

n

o ........régime sans charge

........construction …/min ..tours ou va-et-vient

............de classe II ..............par minute

........borne de mise ........symbole d’alerte

............à la terre ..............relatifs à la sécurité

Interrupteur à palette

Enfoncer l'interrupteur à palette pour mettre l'outil en marche. Pour

l'arrêter, relâcher la palette. Pour verrouiller l'interrupteur à palette en

mode de fonctionnement continu, enfoncer le bouton de verrouillage

qui se trouve près de l'arrière de l'outil tout en maintenant la palette

enfoncée. Toujours s'assurer que l'outil n'est pas verrouillé en mode

de fonctionnement avant de le brancher. Pour arrêter l'outil lorsqu'il

est verrouillé en mode de fonctionnement, enfoncer à fond la palette

et la relâcher immédiatement.

Fonctionnement

METTRE L'OUTIL HORS TENSION ET LE DÉBRANCHER AVANT

DE LE RÉGLER. Toujours porter des lunettes de sécurité et des gants

protecteurs. Ne jamais se servir de la cisaille sans le déflecteur.

L'usure de la lame se produit surtout sur l'arête arrière. On sait que la

lame est usée lorsqu'on éprouve de la difficulté à couper le matériau,

que le rebord tranché semble déchiqueté, que la coupe produit beaucoup d'ébarbures et que les vibrations augmentent pendant la coupe.

La cisaille comporte deux lames identiques à quatre arêtes tranchantes par lame. La lame mobile s'use plus rapidement que l'autre.

Toutefois, il est conseillé de faire tourner les deux lames simultanément pour obtenir une arête nette.

POUR FAIRE TOURNER LES LAMES

Retirer les deux vis de serrage des lames. Faire tourner chaque lame

afin d'obtenir une nouvelle arête. Remettre les vis exactement comme

elles étaient. Remarquer que la vis de la lame fixe est plus longue que

l'autre et il y a risque de dommage à l'outil si on s'en sert pour fixer la

lame mobile (fig. 2).

La lame fixe doit bien reposer contre la vis de réglage du jeu. Vérifier

et régler le jeu de la lame au besoin. (Consulter la rubrique suivante

relative au réglage du jeu de la lame). Serrer toutes les vis.

Page 12

10

Français

Conseils pratiques relatifs à la coupe

• Un jeu approprié de la lame est primordial.

• Lorsque la lame est émoussée, l'utilisateur exerce plus de pression sur l'outil et cela présente des risques de dommage.

• Toujours actionner l'outil avant de s'approcher du matériau.

• S'assurer que les surfaces métalliques sont sèches. Sinon, la

cisaille risque de rebondir (glisser vers l'arrière) à chaque course.

• Couper le matériau de sorte que la partie rejetée se trouve à droite

de l'outil. De la sorte, le matériau sera abaissé et éloigné de l'utilisateur.

• Lorsqu'on coupe un rayon, faire tourner l'outil dans le sens antihoraire afin d'en faciliter la manœuvre.

• On optimise les résultats (avec des efforts moindres) lorsqu'on

abaisse l'arrière de l'outil de 5 à 10°.

Lubrification

Les outils DEWALT sont bien lubrifiés en usine et ils sont prêts à servir.

Il faut les lubrifier de nouveau régulièrement à tous les 60 jours à 6

mois, selon l'usage. (Les outils utilisés constamment pour la production ou pour des tâches de service intensif ainsi que les outils exposés

à la chaleur peuvent nécessiter une lubrification plus fréquente.)

Confier la lubrification de l'outil seulement au personnel qualifié des

centres de service D

EWALT ou d'ateliers d'entretien autorisés.

Accessoires

Des accessoires recommandés pour l’utilisation avec l’outil sont

disponibles à un coût supplémentaire auprès du détaillant ou du centre de service autorisé local. Afin d’obtenir de l’aide pour se procurer

un accessoire destiné à cet outil, communiquer avec : D

EWalt

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286.

MISE EN GARDE : L’utilisation de tout autre accessoire non

recommandé avec cet outil pourrait être dangereux.

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les centres de

service autorisés ou autres services de réparation compétents doivent

effectuer les réparations, l’entretien et le réglage. Toujours utiliser des

pièces de rechange identiques.

Garantie complète

Les outils industriels à service intensif DEWALT sont garantis pour un

an à compter de la date d’achat. Nous réparerons sans frais toute

défectuosité causée par des défauts de matériaux ou de fabrication.

Pour obtenir de plus amples renseignements sur les réparations couvertes par la garantie, composer le 1 800 4-D

EWALT. La présente

garantie ne s’applique pas aux accessoires ni aux dommages causés

à la suite de réparations effectuées ou tentées par des personnes non

qualifiées. Cette garantie confère des droits juridiques particuliers ainsi

que d’autres droits selon les États ou les provinces.

FIG. 2

CAM SHAFT

LAME FIXE

VIS POUR

AJUSTE DE

LA LAME

VIS DE LA

LAME FIXE

LAME

MOBILE

JEU DE

LA LAME

VIS DE

SERRAGE

DE LAME

TÊTE

LAME FIXE

VIS POUR

AJUSTE DE

LA LAME

VIS DE LA

LAME FIXE

JEU DE

LA LAME

VIS DE

SERRAGE

DE LAME

LAME

MOBILE

Page 13

11

Français

Outre la présente garantie, les outils DEWALT sont couverts par

notre :

GARANTIE SANS RISQUE DE 30 JOURS

l’on n’est pas entièrement satisfait du rendement de cet outil industriel à service intensif D

EWALT, il suffit de le retourner au vendeur par-

ticipant dans les 30 jours pour obtenir un remboursement intégral.

Retourner l’outil et tous ses accessoires en port payé. Une preuve

d’achat peut être exigée.

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : Si les étiquettes d’avertissement deviennent illisibles ou sont

perdues, composer le 1 800 4-D

EWALT pour en obtenir le remplace-

ment gratuit.

Page 14

Español

12

INTERRUPTOR

DE PALETA

EL BOTON DE

ENCENDIDO

PERMANENTE

DEFLECTOR

DEV RIZOS

CUCHILLAS

ZAPATA

Instrucciones importantes de seguridad

ADVERTENCIA: Es indispensable sujetarse a las precauciones

básicas de seguridad, con la finalidad de reducir el peligro de incendio, choque eléctrico y lesiones personales, en todas las ocasiones en

que se utilicen herramientas eléctricas. Entre estas precauciones se

incluyen la siguientes:

LEA TODAS LAS INSTRUCCIONES

Doble aislamiento

Las herramientas DOBLEMENTE aisladas se han elaborado de manera integral con dos capas separadas de aislamiento eléctrico o una

capa doble de aislamiento entre usted y el sistema eléctrico que contienen. Las herramientas construidas con este sistema de aislamiento

no requieren conectarse a tierra. Como resultado su herramienta está

equipada con una clavija de dos patas que le permite emplear cordones de extensión sin preocuparse por tener una conexión a tierra.

NOTA: El doble aislamiento no substituye a las precauciones normales de seguridad cuando se opera esta herramienta. La finalidad

de este sistema de aislamiento es ofrecer a usted protección añadida

contra lesiones resultantes de fallas en el aislamiento eléctrico interno de la herramienta.

PRECAUCION: UTILICE SOLAMENTE REFACCIONES ORIG-

INALES CUANDO HAGA SERVICIO a cualquier herramienta.

Repare o reemplace los cordones eléctricos dañados.

Clavijas polarizadas

Se emplean clavijas polarizadas (con una pata más ancha que la

otra) para reducir los riesgos de choque eléctrico. Cuando el cordón

eléctrico cuente con este tipo de clavija, ajustará en un contacto

polarizado solamente de una manera. Si la clavija no ajusta completamente en su contacto, inviértala. Si aún así no ajusta, llame a un

electricista calificado para que le instale un contacto polarizado

apropiado. No modifique o haga cambios en la clavija por ningún

motivo.

Instrucciones de seguridad para todas

las herramientas

• CONSERVE LIMPIA LA ZONA DE TRABAJO. Las superficies y

los bancos con objetos acumulados en desorden propician los

accidentes.

• OTORGUE PRIORIDAD A LA ZONA DE TRABAJO. No deje las

herramientas eléctricas expuestas a la lluvia. No las utilice en

lugares inundados o mojados. Conserve bien iluminada la zona de

trabajo. No utilice la herramienta en presencia de líquidos o gases

inflamables.

• PROTEJASE CONTRA EL CHOQUE ELECTRICO. Evite el con-

tacto corporal con superficies aterrizadas, por ejemplo, tuberías,

radiadores, antenas y gabinetes de refrigeración.

• CONSERVE APARTADOS A LOS NIÑOS. No permita que los

visitantes toquen las herramientas o los cables de extensión.

Todos los visitantes deben estar alejados de la zona de trabajo.

• GUARDE LAS HERRAMIENTAS QUE NO EMPLEE. Las her-

ramientas que no se utilizan deben guardarse en un lugar seco y

elevado o bajo llave — fuera del alcance de los niños.

Page 15

13

Español

• NO FUERCE LA HERRAMIENTA. Esta cumplirá su función mejor

y con más seguridad a la velocidad y la presión para las que se

diseñó.

• EMPLEE LA HERRAMIENTA ADECUADA. No fuerce a una her-

ramienta pequeña o a sus dispositivos de montaje en un trabajo

de tipo pesado. No emplee la herramienta en una tarea para la

que no se diseñó.

• VISTASE DE LA MANERA ADECUADA. No use ropas o artícu-

los de joyería flojos, pues podrían quedar atrapados por las partes

móviles de las herramientas. Se recomienda el empleo de

guantes de caucho y calzado antiderrapante cuando se trabaje al

aire libre. Cúbrase bien la cabeza para sujetarse el cabello si lo

tiene largo. Los orificios de ventilación suelen cubrir piezas en

movimiento, por lo que también se deben evitar.

• COLOQUESE ANTEOJOS DE SEGURIDAD. Póngase también

una mascarilla contra el polvo si lo produce la operación que va a

efectuar.

• TENGA CUIDADO CON EL CORDON ELECTRICO. Nunca lev-

ante la herramienta tomándola por el cordón, ni tire de éste para

desconectarlo del enchufe. Apártelo del calor y los objetos

calientes, las substancias grasosas y los bordes cortantes.

• ASEGURE LOS OBJETOS SOBRE LOS QUE TRABAJE. Utilice

prensas o tornillos de banco para sujetar los objetos sobre los que

va a trabajar. Esto ofrece mayor seguridad que sujetar los objetos

con la mano, y además deja libres ambas manos para operar la

herramienta.

• CONSERVE EL EQUILIBRIO. Conserve en todo momento bien

apoyados los pies, lo mismo que el equilibrio.

• CUIDE SUS HERRAMIENTAS. Conserve sus herramientas afi-

ladas y limpias para que funcionen mejor y con mayor seguridad.

Siga las instrucciones para lubricación y cambio de accesorios de

su unidad. Revise periódicamente el cordón eléctrico y hágalo

reparar o reemplazar por un centro de servicio si está dañado.

Cambie los cordones de extensión si están dañados. Conserve

las empuñaduras secas, limpias y libres de aceite y grasa.

• DESCONECTE Y APAGUE LAS HERRAMIENTAS cuando no

las use, antes de darles servicio y cuando cambie accesorios,

tales como discos, brocas y otros dispositivos de corte.

• RETIRE LAS LLAVES DE AJUSTE Y DE TUERCAS. Adquiera

el hábito de asegurarse que se han retirado las llaves de ajuste de

las herramientas antes de accionarlas.

• EVITE QUE LA HERRAMIENTA SE ACCIONE ACCIDENT-

ALMENTE. Nunca sostenga una herramienta que está conectada

con el dedo en el interruptor. Asegúrese que el interruptor está en

posición de “apagado” antes de conectar la unidad.

• CORDONES DE EXTENSION. Asegúrese que su cordón de

extensión esté en buenas condiciones. Cuando utilice un cordón

de extensión, asegúrese que tenga el calibre suficiente para

soportar la corriente necesaria para su herramienta. Un cordón

eléctrico con calibre insuficiente causará una caída en el voltaje de

la línea, resultando en pérdida de potencia y sobrecalentamiento.

La tabla siguiente ilustra el calibre correcto que debe utilizarse de

conformidad con la longitud del cordón y el amperaje descrito por

la placa de identificación. Si tiene alguna duda, utilice el cable con

el calibre siguiente (mayor). Mientras más chico sea el número,

mayor será su calibre.

Calibre mínimo para cordones de extensión

VoltsLongitud total del cordón en metro

120V 0-7.62 7.63-15.24 15.25-30.48 30.49-45.72

240V 0-15.24 15.25-30.48 30.49-60.96 60.97-91.44

AMPERAJE

Más No más Calbre del cordón

de de

0- 6 18 16 16 14

6- 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No Recomendado

Page 16

14

Español

• CORDONES DE EXTENSION PARA INTEMPERIE. Cuando

opere su herramienta a la intemperie, utilice únicamente cordones

de extensión diseñados y marcados para este fin.

• NO SE DISTRAIGA. Concéntrese en lo que está haciendo.

Recurra al sentido común. No opere ninguna herramienta si está

fatigado.

• VERIFIQUE LAS PARTES DAÑADAS. Antes de seguir emple-

ando cualquier herramienta, es indispensable verificar con mucho

cuidado que las guardas u otras partes dañadas puedan operar

de la manera adecuada para cumplir con su función. Verifique la

alineación de las partes móviles, la firmeza con que deben encontrarse sujetas a sus montaduras, las partes rotas, las propias montaduras y cualesquiera otros detalles que pudieran afectar la

operación de la herramienta. Las guardas y otras partes que se

encuentren dañadas deberán cambiarse o repararse en un centro

de servicio autorizado, a menos que se diga otra cosa en el manual del usuario. Haga que se cambien los interruptores dañados

en un centro de servicio autorizado. No emplee ninguna herramienta que tenga estropeado o inutilizado el interruptor.

Reglas de operación para cizallas

• Utilice siempre anteojos de seguridad y guantes protectores.

• Utilice siempre la herramienta con el deflector de rizos

• Calce zapatos de seguridad para proteger sus pies de rebabas afiladas que pudieran estar en el suelo.

• Siempre encienda la herramienta antes de colocarla en el material

por cortar.

• No corte materiales con espesor mayor a la capacidad especificada. recuerde que el espesor del material aumenta cuando el

nœmero de calibre disminuye. (El calibre 14 es más grueso que el

calibre 16).

• Conserve apretados todos los tornillos. Revise periódicamente

que no estén flojos.

• Si es posible, corte el material de manera que el rizo de desperdicio quede a la derecha. Esta dirección moverá el rizo hacia abajo

y fuera del camino.

• Desconecte la herramienta antes de hacer cualquier ajuste.

• No ponga nada en las abertura de la carcaza del motor.

• Conserve limpia la herramienta. Sopletee cualquier residuo

metálico y el polvo de la herramienta.

• Utilice la cizalla en posición normal. Si la utiliza boca abajo, el rizo

metálico puede dirigirse hacia usted.

• Asegure con firmeza la pieza de metal que vaya a cortar para evitar movimientos durante el corte.

PRECAUCIÓN: Utilice una protección auditiva apropiada

durante el uso. En determinadas condiciones y con utilizaciones

prolongadas, el ruido generado por este producto puede favorecer la

pérdida de audición.

ADVERTENCIA: parte del polvo generado al lijar, serrar, esmeri-

lar y taladrar, así como al realizar otras actividades del sector de la

construcción, contienen productos químicos que pueden producir

cáncer, defectos congénitos u otras afecciones reproductivas.

Ejemplos de esas substancias químicas son:

• plomo procedente de pinturas a base de plomo,

• óxido de silicio cristalino procedente de ladrillos, cemento y

otros productos de mampostería, y

• arsénico y cromo procedentes de madera tratada químicamente (CCA).

El peligro derivado de estas exposiciones que usted enfrente varía en

función de la frecuencia con que se realice este tipo de trabajo. Para

reducir la exposición a esas sustancias químicas: trabaje en una

zona bien ventilada y llevando equipos de seguridad aprobados,

como mascarillas antipolvo especialmente diseñadas para filtrar

partículas microscópicas.

• Evite el contacto prolongado con el polvo procedente del lija-

do, serrado, esmerilado y taladrado eléctricos, así como de

otras actividades del sector de la construcción. Lleve ropa

protectora y lave con agua y jabón las zonas expuestas. Si

permite que el polvo se introduzca en la boca u ojos o quede

sobre la piel, puede favorecer la absorción de productos químicos

peligrosos.

Page 17

15

Español

ADVERTENCIA: Toda persona que entre al área de trabajo

deberá usar una máscara antipolvo o protección respiratoria. El filtro

debería ser reemplazado a diario o cuando el usuario tenga dificultad

para respirar. Puede encontrar la máscara antipolvo apropiada

aprobada por NIOSH/OSHA en su ferretería local.

• La etiqueta de la herramienta puede incluir los siguientes símbolos. A continuación se indican los símbolos y sus definiciones:

V..........volts A ..........amperes

Hz........hertz W ..........watts

min ......minutos ........corriente alterna

....corriente directa

n

o ........velocidad sin carga

........construcción …/min ..revoluciones o

............de Clase II ..............inversiones por minuto

........símbolo de ..........terminal de tierra

............advertencia de seguridad

Interruptor de paleta

Oprima el interruptor de paleta para encender la herramienta.

Suéltela para apagar la unidad. Se puede asegurar el interruptor para

operación continua accionando el botón de encendido permanente

que se localiza cerca de la parte trasera de la herramienta mientras

mantiene la paleta oprimida. Asegœrese siempre que la herramienta

no esté asegurada en posición de encendido permanente antes de

conectarla. Para apagar la herramienta desde esta posición, oprima

y libere el interruptor de paleta una vez.

Operación

APAGUE LA HERRAMIENTA Y DESCONECTELA DE LA TOMA DE

CORRIENTE ANTES DE HACER CUALQUIER AJUSTE. Utilice

siempre anteojos de seguridad y guantes protectores. Nunca utilice

la cizalla sin el deflector de rizos.

El mayor desgaste de la cuchilla (pérdida de filo) es en el filo posterior.

Los s’ntomas de desgaste de la cuchilla incluyen: dificultad para cortar material, bordes mordidos, más rebabas y aumento de vibraciones al cortar.

Su cizalla está equipada con dos cuchillas idénticas con cuatro bordes cortantes cada una. La cuchilla móvil se desgasta más rápido

que la fija. Sin embargo, se aconseja hacer la rotación de filos de

ambas simultáneamente.

PARA HACER LA ROTACION DE CUCHILLAS quite los dos tornillos de sujeción. Gire cada cuchilla hacia un filo nuevo. Coloque los

tornillos exactamente en la manera en que los retiró. Note que el

tornillo de la cuchilla estacionaria es más largo y causar’a daño a la

herramienta si se emplea para sujetar la cuchilla móvil (observe la

figura 2).

La cuchilla estacionaria debe quedar justa contra el tornillo de ajuste

de separación. Revise y ajuste la separación de las cuchillas en caso

necesario. (Consulte la sección que sigue acerca del ajuste de la

separación entre cuchillas.) Apriete todos los tornillos.

Consejos para cortar

• La separación entre cuchillas es importante.

• Las cuchillas desafiladas propician el aumento de presión a la

herramienta por parte del usuario para poder cortar y podr’a ocasionar da–os a la unidad.

• Encienda siempre la herramienta antes de colocarla contra el

material.

• Conserve seca la superficie del metal. De otra manera, la cizalla

rebotará (hacia atrás) con cada golpe de corte.

• Corte el material de manera que el desperdicio quede a la

derecha. Cortar en este sentido dirigirá los rizos hacia abajo y

hacia fuera del camino.

• Cuando corte un radio, gire la cizalla en sentido opuesto a las

manecillas del reloj para maniobrar con mayor facilidad.

• El mejor corte (con menos esfuerzo) se puede lograr cuando la

parte trasera de la herramienta se baja de 5 a 10 grados.

Page 18

16

Español

Lubricación

Las herramientas DEWALT se lubrican apropiadamente en la fábrica y

están listas para usarse. las herramientas deben relubricarse regularmente cada 60 d’as a seis meses, dependiendo de su uso. (Las herramientas que se emplean constantemente en tareas de producción o

trabajos pesados pueden requerir lubricación más frecuente.) Esta

lubricación debe ser realizada œnicamente por personal especializado

en reparación de herramientas eléctricas, como el de los centros de

servicio D

EWALT u otras organizaciones de servicio calificado.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán hacerse reparaciones, mantenimiento y ajustes de esta herramienta en

los centros autorizados de servicio D

EWALT u otras organizaciones

autorizadas. Estas organizaciones prestan servicio a las herramientas

D

EWALT y emplean siempre refacciones legitimas DEWALT.

Accesorios

Los accesorios recomendados para su herramienta están disponibles

con un cargo adicional en su distribuidor local o en el centro de servicio autorizado. Si usted necesita ayuda para encontrar un accesorio

para su herramienta, contacte con: D

EWALT Industrial Tool Co., 701

East Joppa Road, Baltimore, MD 21286.

PRECAUCION: La utilización de cualquier accesorio no recomen-

dado para esta herramienta puede ser peligrosa.

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

FIGURA 2

ARBOL DE

LEVAS

CUCHILLA ESTACIONARIA

TORNILLO DE

AJUSTE DE

SEPARACION

TORNILLO DE

SUJECION DE

LA CUCHILLA

ESTACIONARIA

CUCHILLA

MOVIL

SEPARACION

ENTRE

CUCHILLAS

TORNILLO DE

SUJECION DE

LA CUCHILLA

CUCHILLA

ESTACIONARIA

DE SUJECION

DE LA

CUCHILLA

CUCHILLA

MOVIL

CABEZA

TORNILLO DE

AJUSTE DE

SEPARACION

TORNILLO DE

SUJECION DE LA

CUCHILLA

ESTACIONARIA

SEPARACION

ENTRE

CUCHILLAS

Page 19

17

Español

Nombre y domicilio del distribuidor donde se adquirió el producto:

____________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como en

materiales y mano de obra empleados para su fabricación. Nuestra

garantía incluye la reparación o reposición del producto y/o componentes sin cargo alguno para el cliente, incluyendo mano de obra, así

como los gastos de transportación razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y

esta póliza sellada por el establecimiento comercial donde se adquirió

el producto, de no contar con ésta, bastará la factura de compra.

EXCEPCIONES

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el

instructivo de uso que se acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía Completa

Las herramientas industriales DEWALT están garantizadas durante

un año a partir de la fecha de compra. Repararemos, sin cargos,

cualquier falla debida a material o mano de obra defectuosos. Por

favor regrese la unidad completa, con el transporte pagado, a

cualquier Centro de Servicio para Herramientas Industriales de

D

EWALT o a las estaciones de servicio autorizado enlistadas bajo

“Herramientas Eléctricas” en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectu-

adas por terceras personas. Esta garantía le otorga derechos legales

específicos, y usted puede tener otros derechos que pueden variar de

estado a estado.

En adición a la garantía, las herramientas D

EWALT están amparadas

por nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de su herramienta industrial D

EWALT, sencillamente devuélvala

a los vendedores participantes durante los primeros 30 días después

de la fecha de compra para que le efectúen un reembolso completo.

Por favor regrese la unidad completa, con el transporte pagado. Se

puede requerir prueba de compra.

SUSTITUCION GRATUITA DE LAS ETIQUETAS DE ADVERTENCIA: Si las etiquetas de advertencia se vuelven ilegibles o se pierden,

llame al 1-800-4-D

EWALT para conseguir gratuitamente otras de

repuesto.

Page 20

18

Español

PARA REPARACIÓN Y SERVICIO DE SUS HERRAMIENTAS

ELÉCTRICAS DIRÍJASE AL CENTRO DE SERVICIO MÁS CERCANO

AGUASCALIENTES

Av. de los Maestros 903 - Col. España 449-913-38-01

CAMPECHE

Av. Gobernadores 345 - Col. Santa Ana 981-811-34-90

CHIAPAS

5 Norte Oriente 460 - Col. Centro 961-600-02-87

CHIHUAHUA

Av. Universidad 2903 - Col. Universidad 614-413-64-04

DURANGO

Av. 20 de Noviembre 2004 Ote - Col. Centro 618-818-80-77

GUANAJUATO

1 Mayo 482 - Col. Centro 462-626-79-22

GUADALAJARA

Av. Vallarta 4901-a - Col. Prados Vallarta 333-673-28-15

MÉXICO

16 de Septiembre 509 - Col. Alce Blanco 55-358-40-07

OAXACA

Av. Hidalgo 1303 - Col. Centro 951-514-46-12

SINALOA

Blvd. Manuel J. Clouther 3027

Col. Lomas del Blvd. 667-717-89-99

SAN LUIS POTOSÍ

Av. Universidad 1525 - Col. San Luis 444-814-23-83

SONORA

Nayarit 217 - Col. San Benito 662-210-25-50

TABASCO

Periférico 2047 - Col. Periférico 993-350-38-72

TAMAULIPAS

Tiburcio Garza Zamora 1185 - Col. Beatty 813-374-24-16

YUCATÁN

Calle 63 No. 459 - Col. Centro 999-923-08-49

TAMPICO

Av. Hidalgo 1801 - Col. Aurora 833-213-42-61

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

IMPORTADOR: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS, 3A. SECCIÓN, CP 05120

DELEGACIÓN CUAJIMALPA, MÉXICO, D.F

TEL. 5 326 7100

R.F.C.: BDE810626-1W7

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

Información Técnica

DW893 DW893-220

Tensión de alimentación: 120 V AC/CD ( ) 220/240 V AC( )

Consumo de corriente: 6,5A 3.3/3.5A

Frecuencia de alimentación: 50/60 Hz 50/60 Hz

Rotación sin carga: 1 950/min 1 950/min

Loading...

Loading...