Page 1

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 Printed in U.S.A. (JUN00-CD-1) Form No. 384122

DW890, DW891, DW891-220 Copyright © 1997, 2000

DW890/384122 9/1/00 3:24 PM Page 2

Page 2

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW890, DW891, DW891-220

Swivel Head Shears

Cisaille à tête pivotante

Cizalla con cabeza giratoria

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DW890/384122 9/1/00 3:24 PM Page 3

Page 3

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool’s electrical system. Tools built with this

insulation system are not intended to be grounded. As a result, your

tool is equipped with a two prong plug which permits you to use

extension cords without concern for maintaining a ground

connection.

NOTE: Double insulation does not take the place of normal safety

precautions when operating this tool. The insulation system is for

added protection against injury resulting from a possible electrical

insulation failure within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Repair or replace damaged cords.

Polarized Plugs(DW890, DW891)

Polarized plugs (one blade is wider than the other) are used on

equipment to reduce the risk of electric shock. When provided, this

plug will fit into a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not change the

plug in any way.

Safety Instructions For All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

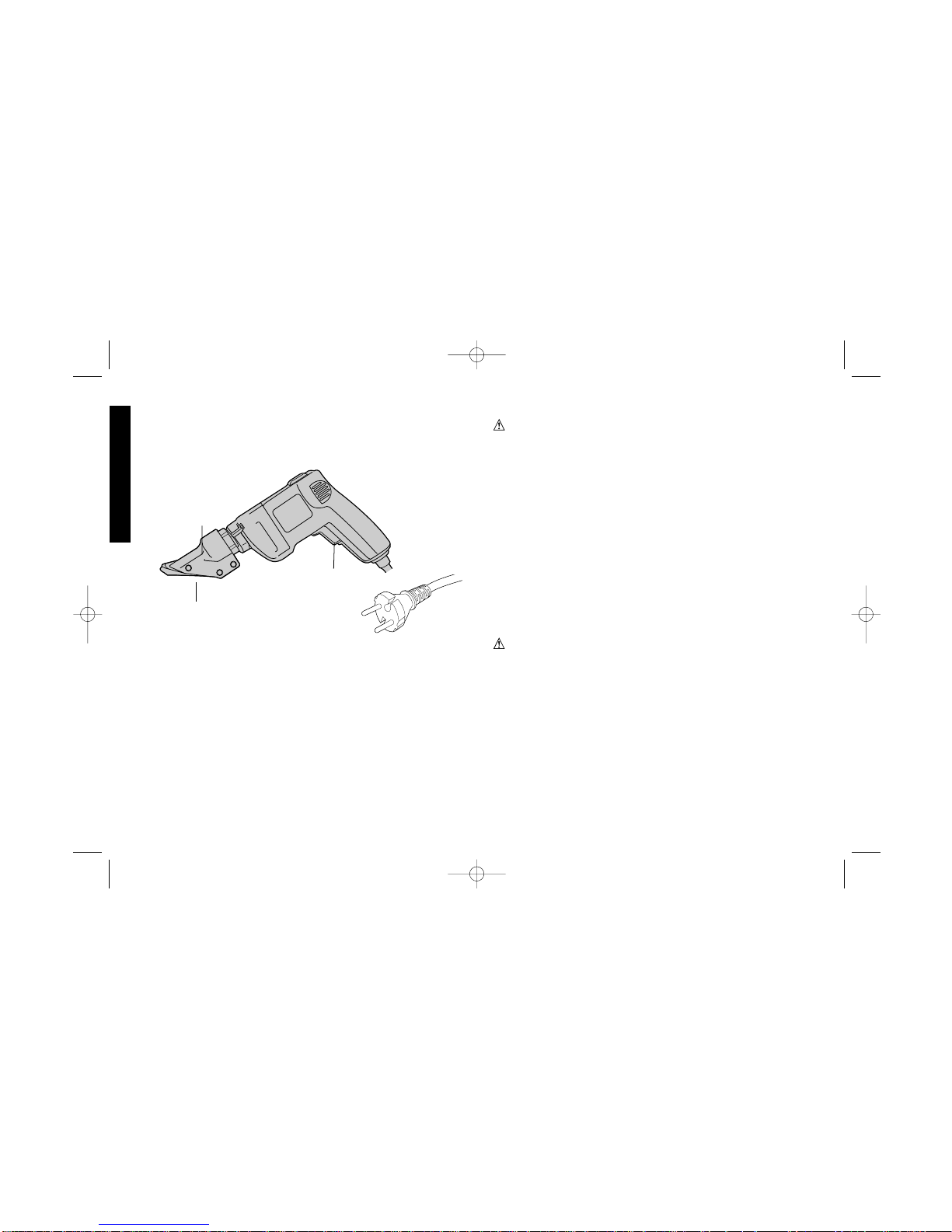

SWIVEL

HEAD

BLADE

DW891-200

TRIGGER

SWITCH

DEWALT... BUILT JOBSITE TOUGH

DeWalt high performance industrial tools are made for America’s

toughest industrial and construction applications. The design of every

tool in the line—from drills to sanders to grinders—is the result of

rigorous use on jobsites and throughout industry. Each tool is

produced with painstaking precision using advanced manufacturing

systems and intense quality control. Every tool is checked before it

leaves the factory to make sure that it meets your standards for

durability, reliability and power.

D

EWALT Built Jobsite Tough…WE GUARANTEE IT.

DW890/384122 9/1/00 3:24 PM Page 4

Page 4

tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges, and

refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let visitors contact tool or

extension cord. All visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place — out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the

rate for which it was intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the

job of a heavy-duty tool. Don’t use tool for purpose not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear

protective hair covering to contain long hair.

• USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle. Keep cord from heat, oil, and sharp

edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all

times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep

handles dry, clean, and free from oil and grease.

• DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

• AVOID UNINTENTIONAL STARTING. Don’t carry tool with finger

on switch. Be sure switch is off when plugging in.

• EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. The following table shows the correct

size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• OUTDOOR USE EXTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors and

so marked.

• STAY ALERT. Watch what you are doing. Use common sense.

Do not operate tool when you are tired.

• CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

1

English

DW890/384122 9/1/00 3:24 PM Page 1

Page 5

2

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

• CAUTION: When cutting into walls, floors or wherever live

electrical wires may be encountered, DO NOT TOUCH ANY

METAL PARTS OF THE TOOL! Hold the tool only by insulated

grasping surfaces to prevent electric shock if you saw into a live

wire.

WARNING: Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out

microscopic particles.

SAVE THESE INSTRUCTIONS

Motor

Your DEW ALT tool is powered by a DEWALT built motor . Be sure your

power supply agrees with the nameplate marking. Voltage decrease

of more than 10% will cause loss of power and overheating. All

D

EWALT tools are factory tested; if this tool does not operate, check

the power supply. If the nameplate marking on the tool shows 120

volts, 60Hz or “AC Only”,(DW890, DW891) your tool must be

operated only with alternateing current and never with direct current.

A marking of 220/240 volts, 50-60 Hz or “AC Only” (DW891-220)

English

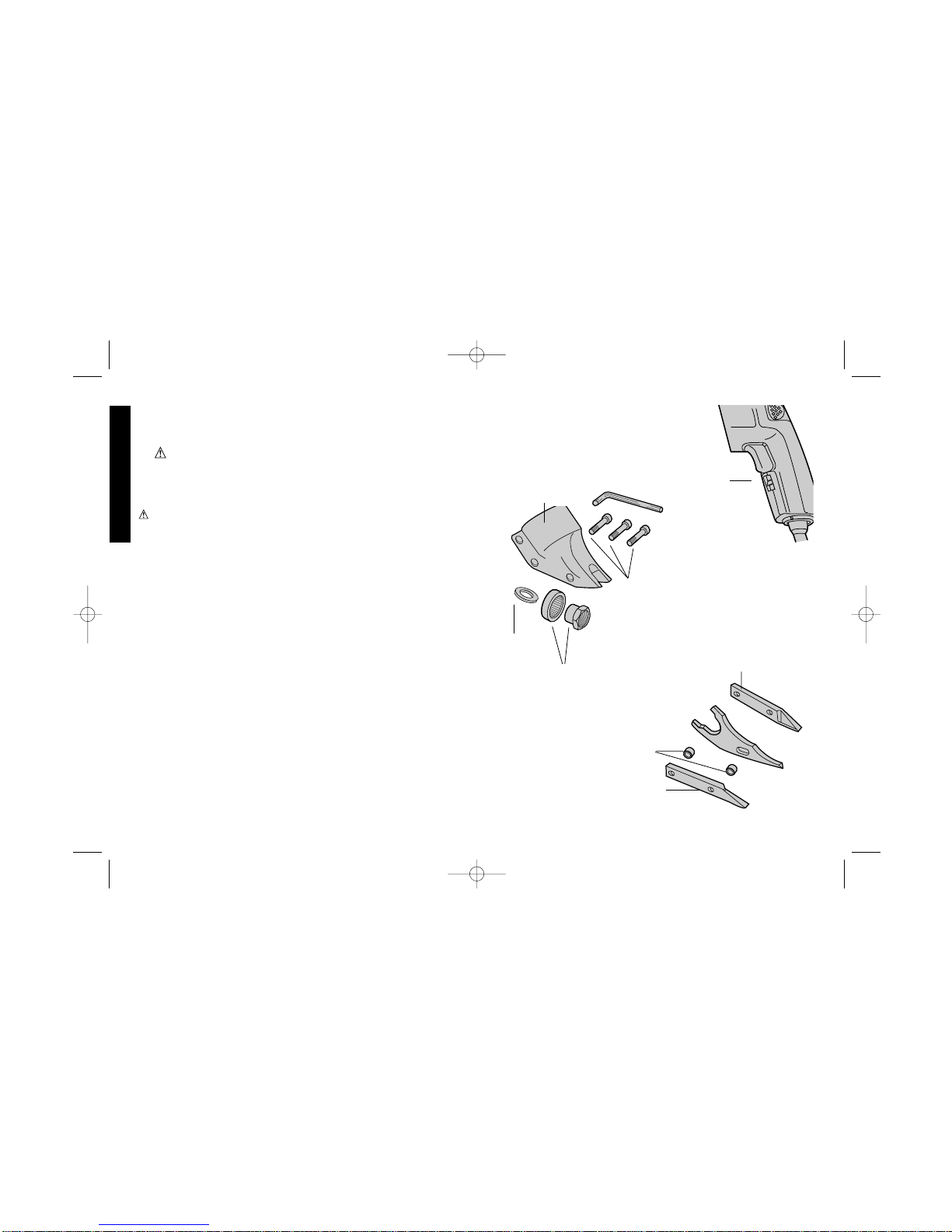

FIG. 1

LOCK

BUTTON

FIG. 2

CAP

SCREWS

HOUSING

ECCENTRIC

BEARING

ASSEMBLY

WASHER

FIG. 3

SIDE KNIFE AND

SIDE SPACER

SPACER

BUSHINGS

LEFT SIDE KNIFE

DW890/384122 9/1/00 3:24 PM Page 2

Page 6

means your tool must be operated with alternating current never

with direct current.

Switch

To start tool, depress trigger switch. To stop tool, release the trigger.

To lock the trigger in the on position for continuous operation,

depress trigger, push up the lock button (Figure 1), and gently

release the trigger. To release the locking mechanism, depress the

trigger fully, then release it. Before using the tool each time, be sure

that the lock button release mechanism is working freely. Be sure to

release the switch lock button before disconnecting the plug from

the power supply. Failure to do so will cause the tool to start

immediately the next time it is plugged in. Damage or injury could

result. The variable speed trigger switch permits speed control.

The farther the trigger is depressed, the higher the speed of the

shear.

Disassembly and Assembly (Figures 2

and 3)

To remove shear head from motor, loosen 3 cap screws. Remove

shear head by pulling head firmly forward. Slight twisting action may

be required if head does not slide off easily.

3

English

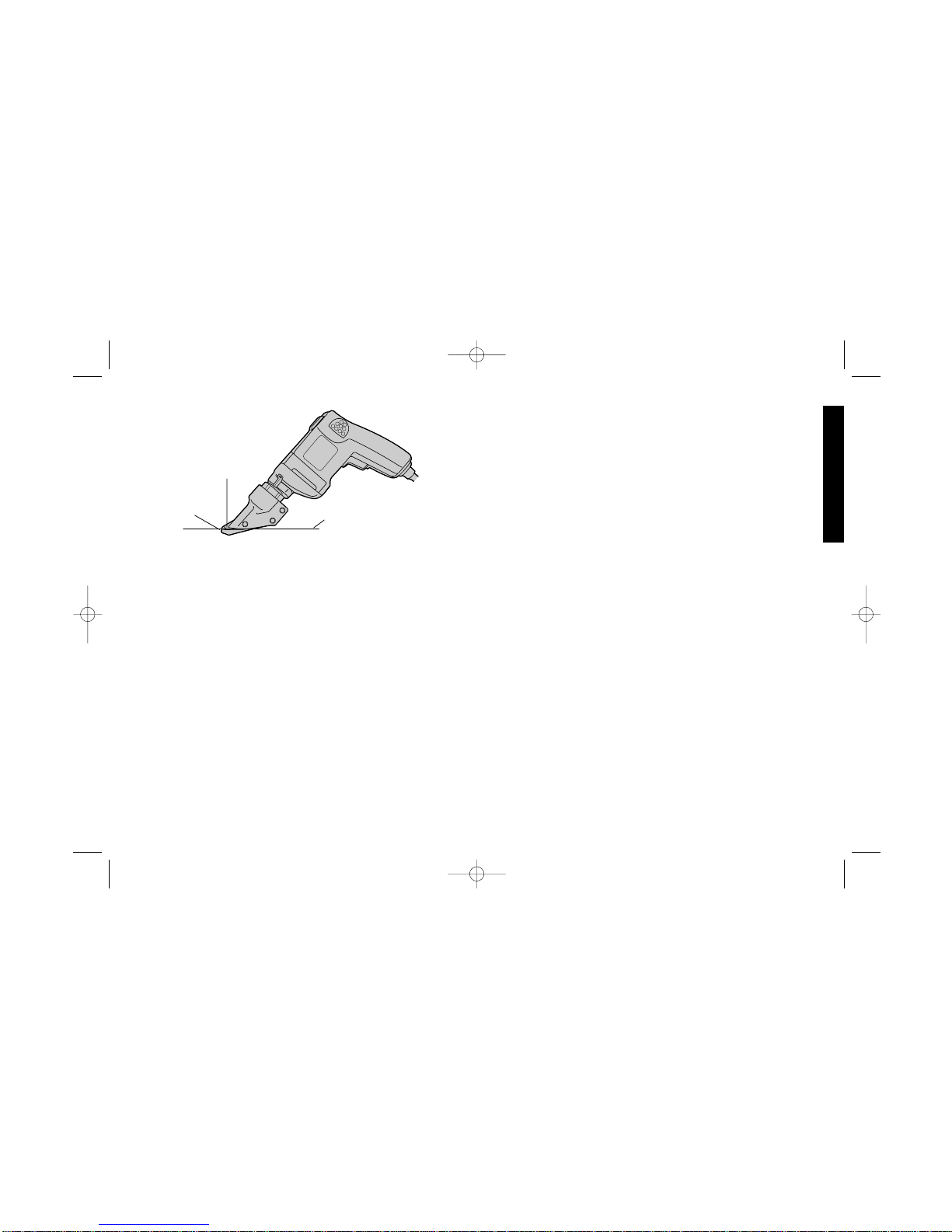

FIG. 4

LOWER

SURFACE OF

SIDE BLADES

BLADE

OPENING

SHEET METAL

To remove cutter blades from shear head, remove 3 cap screws

from shear housing. Be careful not to lose rear spacer bushing when

removing middle cap screw. Remove center blade from housing by

tapping blade gently towards the rear. Side knife and side spacer will

now drop out of the housing.

To remove eccentric bearing assembly from shaft, use an

appropriate wrench to loosen eccentric nut by turning

counterclockwise.

To install eccentric bearing assembly onto shaft, make sure the

large thin washer is first inserted over shaft. Screw eccentric bearing

assembly onto shaft and tighten with appropriate wrench. Lubricate

bearing with a good grade of bearing grease.

To install cutter blades into shear housing, place the side knife

and side spacer into position in the shear housing. Insert center cap

screw through side knife and side spacer with rear spacer bushing

between them. Start cap screw into thread just enough to hold blades

in place. DO NOT TIGHTEN. Insert spacer bushing into hole in center

blade and lubricate. Install center blade into shear housing by tapping

blade gently forward using a drift to line up hole in center blade with

forward holes in housing. Insert and tighten forward cap screw

making sure spacer bushing in center blade stays in position. Apply

good grade of bearing grease to clevis or yoke in center blade where

it rides on the eccentric bearing assembly. Insert rear cap screw into

shear housing but do not completely tighten.

To install shear head assembly onto drive motor, make sure all

cap screws are loosened about 3 or 4 complete turns. Place shear

head onto unit and alternately tighten cap screws snugly to lock head

assembly in place. It may be necessary to gently tap the shear head

into place if it does not readily slip onto the nose of the power unit.

Operation

For accurate work, always clamp or anchor the material to be cut.

DW890/384122 9/1/00 3:24 PM Page 3

Page 7

4

Line up one edge of the tool’s middle blade with the cutting line and

advance blades into the material without forced effort or unnecessary

pressure. A little practice will enable you to determine what forward

pressure gives you the smoothest cutting. It is important to keep the

lower surfaces of the side blades flat on the material being cut

(Figure 4). When cutting curves, do not tilt the tool; keep the side

blades flat and level. For best cutting efficiency, keep blades sharp.

Wear gloves when handling sheet metal. The edges are sharp and

can cause injury.

CAUTION: Do not use the shear with any kind of accessory or

attachment. Such usage might be hazardous.

Adjustment (Figure 5)

To adjust the curl of waste material, the left side knife has elongated

holes. Adjustment may be necessary after changing blades or

material being cut. Loosen cap screws and tap side knife either

forward or backward so that curl of waste does not hit shear housing

or work material while cutting.

Lubrication

All ball bearings are factory lubricated to last the life of the tool. All

sleeve and needle bearings receive their lubrication from grease in

the gear case. Clean and re-lubricate gear case yearly or whenever

English

servicing requires the gear case to be removed. Use type and

quantity of grease shown on the parts bulletin packed with your tool.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your distributor or local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

Important

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement) should

be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from

date of purchase. We will repair, without charge, any defects due to

faulty materials or workmanship. For warranty repair information,

call 1-800-4-D

EWAL T. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALTheavy duty industrial tool, simply return it to the participating

seller within 30 days for a full refund. Please return the complete unit,

transportation prepaid. Proof of purchase may be required.

FIG. 5

ALTERNATELY

TIGHTEN TO SECURE

DW890/384122 9/1/00 3:24 PM Page 4

Page 8

5

Français

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET

OUTIL OU TOUT AUTRE OUTIL D

E

WALT, COMPOSER SANS

FRAIS LE NUMÉRO:

1 800 4-DEWALT (1 800 433-9258)

IMPORTANTES

MESURES DE SÉCURITÉ

(POUR TOUS LES OUTILS)

AVERTISSEMENT : Afin de réduire les risques d’incendie, de

secousses électriques ou de blessures lorsqu’on utilise des outils

électriques, il faut toujours respecter les mesures de sécurité

suivantes.

Double isolation

Les outils à double isolation comportent deux couches distinctes

d’isolant électrique ou une double épaisseur d’isolant qui protègent

l’utilisateur contre les risques de blessures provenant du système

électrique de l’outil.

Ce système de double isolation élimine le besoin de mettre les outils

à la terre. En effet, l’outil est muni d’une fiche à deux broches, ce qui

permet d’utiliser une rallonge ordinaire sans avoir à se soucier

d’assurer la mise à la terre.

NOTE : La double isolation ne dispense pas des mesures de sécurité

normales lors de l’utilisation de l’outil. Elle vise à procurer une

protection supplémentaire contre les blessures que peut entraîner

une défectuosité de l’isolant électrique à l’intérieur de l’outil.

MISE EN GARDE : Lors de l’entretien, N’UTILISER QUE DES

PIÉCES DE RECHANGE IDENTIQUES. Réparer ou remplacer les

cordons endommagés.

Fiche polarisée(DW890, DW891)

Afin de réduire les risques de secousses électriques, l’outil est muni

d’une fiche polarisée (une lame plus large que l’autre). Ce genre de

fiche n’entre que d’une façon dans une prise polarisée. Lorsqu’on

ne peut insérer la fiche à fond dans la prise, il faut tenter de le faire

après avoir inversé les lames de côté. Si la fiche n’entre toujours

TÉTE

PIVOTANTE

INTERRUPTEUR

À DÉTENTE

COUTEAU

DW890/384122 9/1/00 3:24 PM Page 5

Page 9

6

pas dans la prise, il faut communiquer avec un électricien certifié afin

qu’il installe une prise appropriée. Il ne faut en aucun cas modifier la

fiche.

LIRE TOUTES LES DIRECTIVES.

• BIEN DÉGAGER LA SURFACE DE TRAVAIL. Des surfaces et

des établis encombrés peuvent être la cause de blessures.

• TENIR COMPTE DU MILIEU DE TRAVAIL. Protéger les outils

électriques de la pluie. Ne pas s’en servir dans des endroits

humides ou mouillés. Bien éclairer la surface de travail.

• SE PROTÉGER CONTRE LES SECOUSSES ÉLECTRIQUES.

Éviter tout contact avec des objets mis à la terre, comme des

tuyaux, radiateurs, cuisinières, réfrigérateurs et autres objets du

genre.

• ÉLOIGNER LES ENFANTS. Tous les visiteurs doivent être tenus

à l’écart de l’aire de travail et il faut les empêcher de toucher à

l’outil ou au cordon de rallonge.

• RANGER LES OUTILS INUTILISÉS. Il faut ranger les outils dans

un endroit sec, situé en hauteur ou fermé à clé, hors de la portée

des enfants.

• NE JAMAIS FORCER L’OUTIL. Afin d’obtenir un rendement sûr

et efficace, utiliser l’outil à son rendement nominal.

• UTILISER L’OUTIL APPROPRIÉ. Ne jamais exiger d’un petit outil

ou d’un accessoire le rendement d’un outil de fabrication plus

robuste. Se servir de l’outil selon l’usage prévu (par exemple, ne

pas se servir d’une scie circulaire pour couper des branches

d’arbres ou des bûches).

• PORTER DES VÊTEMENTS APPROPRIÉS. Éviter de porter des

vêtements amples et des bijoux qui peuvent être happés par les

pièces en mouvement. Porter des gants de caoutchouc et des

chaussures à semelle antidérapante pour travailler à l’extérieur.

Protéger la chevelure si elle est longue.

• PORTER DES LUNETTES DE SÉCURITÉ. Porter également un

masque respiratoire si le travail de coupe produit de la poussière.

• NE PAS MANIPULER LE CORDON DE FAÇON ABUSIVE. Ne

pas transporter l’outil par le cordon ni tirer sur ce dernier pour le

débrancher de la prise. Éloigner le cordon des sources de chaleur,

des flaques d’huile et des arêtes tranchantes.

• ASSUJETTIR LA PIÈCE. Immobiliser la pièce à l’aide de brides

ou d’un étau. On peut alors se servir des deux mains pour faire

fonctionner l’outil, ce qui est plus sûr.

• NE PAS DÉPASSER SA PORTÉE. Toujours demeurer dans une

position stable et garder son équilibre.

• PRENDRE SOIN DES OUTILS. Conserver les outils propres pour

qu’ils donnent un rendement supérieur et sûr. Suivre les directives

concernant la lubrification et le remplacement des accessoires.

Inspecter régulièrement le cordon de l’outil et le faire réparer au

besoin à un atelier d’entretien autorisé. Inspecter régulièrement

les cordons de rallonge et les remplacer lorsqu’ils sont

endommagés. S’assurer que les poignées sont toujours propres,

sèches et libres de toute tache d’huile ou de graisse.

• DÉBRANCHER LES OUTILS NON UTILISÉS. Respecter cette

mesure lorsqu’on ne se sert pas de l’outil, ou qu’on doit le réparer

ou en changer un accessoire (comme une lame, un foret ou un

couteau).

• ENLEVER LES CLÉS DE RÉGLAGE. Prendre l’habitude de

vérifier si les clés de réglage ont été retirées avant de faire

démarrer l’outil.

• ÉVITER LES DÉMARRAGES ACCIDENTELS. Ne pas laisser le

doigt sur l’interrupteur lorsqu’on transporte l’outil. S’assurer que

l’interrupteur est à la position hors circuit lorsqu’on branche l’outil.

CORDONS DE RALLONGE PRÉVUS POUR L’EXTÉRIEUR.

Lorsque l’outil est utilisé à l’extérieur, ne se servir que d’un cordon

de rallonge conçu pour l’extérieur et portant la mention appropriée.

Français

DW890/384122 9/1/00 3:24 PM Page 6

Page 10

Calibre minimal des cordons de rallonge

Longueur totale du cordon

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Intensité

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

• DEMEURER VIGILANT. Travailler avec vigilance et faire preuve

de bon sens. Ne pas se servir de l’outil lorsqu’on est fatigué.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES. Vérifier l’alignement

et les attaches des pièces mobiles, le degré d’usure des pièces et

leur montage, ainsi que tout autre facteur susceptible de nuire au

bon fonctionnement de l’outil. Faire réparer ou remplacer tout

protecteur ou toute autre pièce endommagée dans un centre de

service autorisé, sauf si le présent guide fait mention d’un avis

contraire. Confier le remplacement de tout interrupteur défectueux

à un centre de service autorisé. Ne jamais se servir d’un outil

dont l’interrupteur est défectueux.

• NE PAS UTILISER les outils portatifs électriques dans des

endroits où l’atmosphère contient des vapeurs combustibles ou

explosives. Les étincelles que produit le moteur en marche

pourraient enflammer ces produits.

• MISE EN GARDE : Lorsqu’on coupe dans les murs, les

planchers ou tout autre endroit où peuvent se trouver des fils sous

tension, NE PAS TOUCHER À TOUT COMPOSANT MÉTALLIQUE SE TROUVANT À L’AVANT DE L’OUTIL. Ne le saisir que

par ses surfaces de prise isolées afin de se protéger des

secousses électriques.

AVERTISSEMENT : Certains outils, tels que les sableuses

électriques, les scies, les meules, les perceuses ou certains autres

outils de construction, peuvent soulever de la poussière contenant des

produits chimiques susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système

reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de

maçonnerie;

• l’arsenic et le chrome dans le bois de sciage ayant subi un

traitement chimique (CCA).

Le risque associé à de telles expositions peut varier selon la fréquence

avec laquelle on effectue ces travaux. Pour réduire l’exposition à de

tels produits, il faut travailler dans un endroit bien ventilé et utiliser

l’équipement de sécurité approprié tel un masque anti-poussières

spécialement conçu pour filtrer les particules microscopiques.

CONSERVER CES

MESURES

À TITRE DE RÉFÉRENCE.

Moteur

Un moteur DeWALT actionne l’outil DeWALTVeiller à ce que la

tension d’alimentation soit conforme aux exigences de la plaque

signalétique de l’outil.

La mention «volts, 50/60 Hz» ou «c.a. seulement» signifie que l’outil

fonctionne uniquement sur une alimentation en courant alternatif, et

jamais en courant continu.

Une baisse de tension de plus de 10 p. 100 entraîne une perte de

puissance et la surchauffeTous les outils DeWALT sont essayés

avant de quitter l’usineLorsque celui-ci refuse de fonctionner, vérifier

la source de courant électrique.

Interrupteur

Enfoncer l’interrupteur à détente pour mettre l’outil en marche. Pour

l’arrêter, relâcher la détente.

7

Français

DW890/384122 9/1/00 3:24 PM Page 7

Page 11

8

Pour verrouiller la détente en mode de fonctionnement continu,

enfoncer la détente, pousser le bouton de verrouillage vers le haut

(fig. 1) et relâcher doucement la détente. Pour dégager le

mécanisme de verrouillage, enfoncer à fond la détente et la relâcher.

Avant d’utiliser l’outil, toujours s’assurer que le bouton de verrouillage

fonctionne librement. Ne pas oublier de dégager le bouton de

verrouillage de l’interrupteur avant de débrancher l’outil sinon celuici démarrera immédiatement lorsqu’il sera branché. Un tel oubli

présente des risques de dommages ou de blessures. L’interrupteur

à détente et à régulateur de vitesse permet de maîtriser la vitesse

de l’outil. Plus on enfonce la détente, plus la vitesse de la cisaille

augmente.

Démontage et montage (Figures 2 et 3)

Pour retirer la tête du moteur, desserrer les trois vis d’assemblage.

Retirer la tête en la tirant fermement vers l’avant. Il peut être

nécessaire de la balancer légèrement si elle ne glisse pas aisément

hors du moteur.

Pour retirer les couteaux de la tête, retirer les trois vis

d’assemblage du boîtier de la cisaille. Prendre soin de ne pas perdre

le palier de la cale arrière lorsqu’on retire la vis d’assemblage

centrale. Enlever le couteau central du boîtier en frappant

légèrement le couteau vers l’arrière. Le couteau latéral et la cale

latérale tombent ensuite du boîtier.

Pour retirer le roulement excentrique équipé de l’arbre, se servir

d’une clé appropriée afin de desserrer l’écrou excentrique en le

faisant tourner dans le sens antihoraire.

Pour installer le roulement excentrique équipé sur l’arbre,

s’assurer d’insérer d’abord la grosse rondelle mince sur l’arbre.

Visser le roulement excentrique équipé sur l’arbre et le serrer à l’aide

d’une clé appropriée. Lubrifier le roulement avec de la graisse à

roulements de bonne qualité.

Pour installer les couteaux dans le boîtier, placer le couteau

Français

FIG. 1

BOUTON DE

VERROUILLAGE

FIG. 2

VIS

D’ASSEMBLAGE

BOITIER

ROULEMENT

EXCENTRIQUE

ÉQUIPÉ

RONDELLE

FIG. 3

COUTEAU LATÉRAL ET

CALE LATÉRALE

PALIERS DE

CALES

COUTEAU

LATÉRAL

GAUCHE

DW890/384122 9/1/00 3:24 PM Page 8

Page 12

9

Français

latéral et la cale latérale dans le boîtier. Insérer la vis d’assemblage

centrale dans le couteau latéral et la cale latérale en plaçant le palier

de la cale arrière entre eux. Serrer à peine la vis d’assemblage afin

de retenir les couteaux en place. NE PAS SERRER. Insérer le palier

de la cale dans le trou du couteau central et le lubrifier. Insérer le

couteau central dans le boîtier en frappant légèrement le couteau

vers l’avant et en alignant le trou du couteau central sur les trous à

l’avant du boîtier. Insérer et serrer la vis d’assemblage avant en

s’assurant que le palier de la cale du couteau central reste en place.

Enduire la manille ou la chape du couteau central de graisse

à roulements de bonne qualité lorsqu’elle repose contre le roulement

excentrique équipé. Insérer la vis d’assemblage arrière dans le

boîtier mais ne pas la serrer complètement.

Pour installer la tête sur le moteur, s’assurer que toutes les vis

d’assemblage sont desserrées d’environ 3 ou 4 tours complets.

Placer la tête et serrer les vis d’assemblage en alternant afin de

bloquer la tête en place. Il peut être nécessaire de frapper

légèrement la tête pour la faire glisser en place si elle ne se place pas

facilement sur le nez du bloc-moteur.

Fonctionnement

Toujours fixer ou ancrer le matériau à découper afin d’assurer la

précision du travail. Aligner un rebord du couteau central de l’outil sur

la ligne de coupe et faire avancer les couteaux dans le matériau sans

forcer l’outil ni y exercer une pression excessive. Avec un peu de

pratique, on peut déterminer quelle pression avant procure une

coupe en douceur. Il est important de laisser les surfaces inférieures

des couteaux latéraux reposer à plat contre le matériau à couper

(fig. 4). Lorsqu’on coupe des courbes, ne pas faire basculer l’outil.

Laisser les couteaux latéraux à plat et de niveau. Afin d’optimiser la

coupe, s’assurer que les couteaux sont affûtés. Porter des gants

lorsqu’on travaille de la tôle. Les rebords en sont tranchants et cela

présente des risques de blessures.

MISE EN GARDE : Ne pas utiliser la cisaille avec tout accessoire.

FIG. 4

FIG. 5

SURFACE

INFÉRIEURE

DES COUTEAUX

LATÉRAUX

OUVERTURE DU

COUTEAU

TOLE

SERRER EN

ALTERNANT AFIN DE

FIXER

DW890/384122 9/1/00 3:24 PM Page 9

Page 13

10

Français

Une telle utilisation peut être dangereuse.

Réglage (Figure 5)

Le couteau latéral gauche comporte des trous allongés afin de régler

la courbure du matériau inutile. Il peut être nécessaire d’en modifier

le réglage lorsqu’on remplace les couteaux ou lorsqu’on change de

matériau à couper. Desserrer les vis d’assemblage et frapper

légèrement le couteau latéral vers l’avant ou vers l’arrière de sorte

que le matériau inutile ne vienne pas frapper contre l’outil ni le bon

matériau pendant la coupe.

Lubrification

Il est conseillé d’ajouter une quantité minimale de graisse aux

engrenages lorsqu’on remplace les balais (ou de redistribuer la

graisse qui reste dans le boîtier).

Les roulements à billes de cet outil ont été lubrifiés en usine et il n’est

pas nécessaire de les lubrifier de nouveau.

Accessoires

Les accessoires recommandés pour cet outil sont vendus chez les

détaillants ou au centre de service de la région. Pour trouver un

accessoire, communiquer avec le détaillant ou le centre de service

de la région.

MISE EN GARDE : L’utilisation de tout autre accessoire non

recommandé pour l’outil peut être dangereuse.

Important

Pour assurer la SÉCURITÉ D’EMPLOI et la FIABILITÉ de l’outil, n’en

confier la réparation, l’entretien et les rajustements (y compris

l’inspection et le remplacement des balais) qu’à un centre de service

ou à un atelier d’entretien autorisé n’utilisant que des pièces de

rechange identiques.

Garantie complète

Les outils industriels de service intensif DEWALT sont garantis

pendant un an à partir de la date d’achat. Toute pièce d’un outil

D

EWALT qui s’avérait défectueuse en raison d’un vice de matière ou

de fabrication sera réparée ou remplacée sans frais. Pour obtenir de

plus amples renseignements sur les réparations couvertes par la

garantie, composer le 1 (800) 4-D

EWALT (! (800) 433-9258). La ga

rantie ne couvre pas les accessories ni les réparations tentées ou

effectuées par des tiers. Les modalités de la présente garantie

donnent des droits légaux spécifiques. L’utilisateur peut également

se prévaloir d’autres droits selon l’état ou la province qu’il habite.

En outre, la garantie suivante couvre les outils D

EWALT.

GARANTIE DE SATISFACTION DE 30 JOURS OU ARGENT REMIS

Si, pour quelque raison que ce soit, l’outil industriel de service intensif

D

E

WALT ne donne pas entière satisfaction, il suffit de le retourner

chez le marchand participant dans les 30 jours suivant la date

d’achat afin d’obtenir un remboursement complet. Il faut retourner,

port payé, l’outil complet. On peut exiger une preuve d’achat.

Voir la rubrique “Outils électriques”

des Pages Jaunes

pour le service et les ventes.

DW890/384122 9/1/00 3:24 PM Page 10

Page 14

Reglas generales de seguridad

¡ADVERTENCIA! Lea y comprenda todas las instrucciones.

No hacerlo puede originar riesgos de choque eléctrico, incendio y

lesiones personales de gravedad.

CONSERVE EST AS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su área de trabajo limpia y bien iluminada. Las

bancas amontonadas y las zonas oscuras propician los

accidentes.

• No opere herramientas eléctricas en atmósferas explosivas,

como en presencia de líquidos, gases o polvos inflamables.

Las herramientas eléctricas producen chispas que pueden originar

la ignición de los polvos o los vapores.

• Conserve a observadores, niños y visitantes alejados

mientras opera una herramienta eléctrica. Las distracciones

pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas aterrizadas deben conectarse a una toma

de corriente correctamente instalada y aterrizada de

conformidad con todos los códigos y reglamentos. Nunca

elimine la pata de conexión a tierra ni modifique la clavija en

ninguna manera. No utilice adaptadores. Verifique con un

electricista calificado si tiene dudas acerca de la conexi–n a

tierra de su toma. Si las herramientas tienen algún mal

funcionamiento eléctrico, la tierra proporciona una vía para alejar

del operador la electricidad.

• Las herramientas con doble aislamiento están equipadas con

una clavija polarizada (con una pata más ancha que la otra.)

Esta clavija se acoplará únicamente en una toma de corriente

polarizada de una manera. Si la clavija no se acopla al

contacto, inviértala. Si aún así no se ajusta, comuníquese con

un electricista calificado para que le instalen una toma de

11

Español

CABEZA

GIRATORIA

INTERRUPTOR DE

GATILLO

CUCHILLA

DEWALT...PARA TRABAJOS PESADOS

Las herramientas industriales DeWalt de alto rendimiento se han

fabricado para las más duras condiciones industriales y de

construcción. El diseño de cada una de las herramientas de esta

línea desde taladros hasta lijadoras y esmeriladoras es resultado de

su empleo bajo rigurosas condiciones en centros de trabajo e

instalaciones industriales. Cada instrumento se ha fabricado con

precisión extrema bajo sistemas avanzados de manufactura y rígido

control de calidad. Cada herramienta se verifica concienzudamente

antes de dejar la fábrica, para asegurarse de que satisface sus

estándares de durabilidad, confiabilidad y potencia.

D

EWALT Para trabajos pesados_LO GARANTIZAMOS.

Epecificaciones DW890 DW891

Tensión de alimentación 120 V CA/CD 120 V CA/CD

Potencia nominal: 470 W 470 W

Frecuencia de operación: 60 Hz 60 Hz

Consumo de corriente: 5 A 5 A

DW890/384122 9/1/00 3:24 PM Page 11

Page 15

12

corriente polarizada apropiada. El doble aislamiento elimina la

necesidad de cables con tres hilos y sistemas de alimentación con

conexión a tierra.

• Evite el contacto corporal con superficies aterrizadas tales

como tuberías, radiadores, hornos y refrigeradores. Hay un

gran riesgo de choque eléctrico si su cuerpo hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a

condiciones de mucha humedad. El agua que se introduce en

las herramientas aumenta el riesgo de descargas eléctricas.

• No maltrate el cable. Nunca tome el cable para transportar

una herramienta ni para desconectarla de la toma de

corriente. Consérvelo alejado de calor aceite, bordes afilados

o piezas móviles. Cambie inmediatamente los cables

dañados. Los cables dañados aumentan el riego de choque

eléctrico.

• Cuando opere una herramienta eléctrica a la intemperie,

utilice una extensión marcada “W-A” o “W”. Estas extensiones

están clasificadas para uso a la intemperie y para reducir el riesgo

de choques eléctricos. Cuando utilice una extensión, asegúrese

de emplear una con el calibre suficiente para soportar la corriente

necesaria para su herramienta. Una extensión con calibre

inadecuado causará una caída en el voltaje de la línea resultando

en pérdida de potencia y sobrecalentamiento. La tabla siguiente

muestra el calibre correcto para usarse, relativo a la longitud de la

extensión y el amperaje mencionado en la placa de identificación.

Si tiene dudas, utilice el calibre siguiente. Mientras más pequeño

sea el número del calibre, mayor será su capacidad.

Calibre mínimo requerido (AWG) para cables de extensión

Longitud total del cable de extensión

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.,6 m 15,2 m 22,9 m 30,5 m 38,1 m 45,7 m 53,3 m

Calibre promedio del alambre

18 AWG 18 AWG 16 AWG 16 AWG 14 AWG 14 AWG 12 AWG

SEGURIDAD PERSONAL

• Esté alerta concéntrese en lo que está haciendo. Recurra al

sentido común cuando opere una herramienta eléctrica. No

opere ninguna herramienta si se encuentra fatigado o bajo la

influencia de drogas, alcohol o medicamentos. Un momento

de desatención mientras se operan herramientas eléctricas puede

ocasionar lesiones graves.

• Vístase de manera adecuada. No tenga puestas ropas o

artículos de joyería flojos. Cubra su cabello si lo tiene largo.

Conserve su cabello, sus ropas y guantes alejados de las

piezas móviles. Las piezas de vestir flojas, las joyas y el cabello

largo pueden resultar atrapados por las piezas móviles.

• Evite el encendido accidental. Asegúrese que el interruptor

esté en posición de apagado antes de conectar. Sostener una

herramienta con el dedo en el interruptor o conectarla sin fijarse si

el interruptor está en posición de encendido propicia los

accidentes.

• Retire las llaves de ajuste antes de encender la herramienta.

Una llave que se deja en una pieza giratoria puede ocasionar

lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien

apoyados, al igual que el equilibrio. La posición correcta de los

pies y el equilibrio permiten controlar mejor la herramienta en

situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protección en

los ojos. Se deben utilizar mascarillas contra polvo, zapatos

Español

DW890/384122 9/1/00 3:24 PM Page 12

Page 16

13

Español

antiderrapantes, casco o protectores para los oídos para tener las

condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios prácticos para asegurar y

apoyar la pieza de trabajo en una plataforma estable. Sujetar

las piezas con la mano o contra su cuerpo es inestable y puede

originar la pérdida de control.

• No fuerce la herramienta. Emplee la herramienta correcta para

su aplicación. La herramienta correcta hará el trabajo mejor y de

manera más segura y bajo las especificaciones para las que fue

diseñada.

• No utilice la herramienta si el interruptor no enciende y apaga.

Cualquier herramienta que no pueda controlarse por medio del

interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer

cualquier ajuste, cambio de accesorios o de guardar la

herramienta. Tales medidas de seguridad preventivas reducirán

el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los niños y de

otras personas no capacitadas. Las herramientas son

peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte

afiladas y limpias. Las herramientas que reciben un

mantenimiento adecuado, con piezas de corte afiladas,

difícilmente se atascan y son más fáciles de controlar.

• Verifique la alineación de las piezas móviles, busque fracturas

en las piezas y cualesquiera otras condiciones que puedan

afectar la operación de las herramientas. Si está dañada, lleve

su herramienta a servicio antes de usarla de nuevo. Muchos

accidentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para

su modelo de herramienta. Los accesorios que estén diseñados

para una herramienta, pueden volverse peligrosos cuando se

emplean con otra.

ADVERTENCIA : Parte del polvo creado al lijar, aserruchar, moler o

perforar con máquina, así como al realizar otras actividades de la

construcción, contiene substancias químicas que se sabe producen

cáncer, defectos congénitos u otras afecciones reproductivas. Algunos

ejemplos de esas substancias químicas son:

• plomo de pinturas a base de plomo,

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la frecuencia

en que se haga este tipo de trabajo. Para reducir la exposición a esas

substancias químicas: trabaje en un área bien ventilada, y trabaje con

equipos de seguridad aprobados, tales como máscaras contra el polvo

especialmente diseñadas para filtrar las partículas microscópicas.

•REVISE LAS PARTES DAÑADAS. Antes de seguir utilizando su

herramienta, una guarda u otra parte que esté dañada debe ser

revisada cuidadosamente para determinar si operará

apropiadamente y realizará la función para la que está destinada.

Verifique la alineación y la sujeción de las piezas móviles, ruptura

en las piezas, sus montajes y cualesquiera otras condiciones

que pudiesen afectar su operación. Una guarda u otras pieza

dañadas deberán repararse o reemplazarse por un centro de

servicio autorizado, a menos que se indique lo contrario en este

manual de instrucciones. Haga reemplazar los interruptores

defectuosos por un centro de servicio autorizado. No utilice la

herramienta si el interruptor no funciona.

PRECAUCION: Cuando corte en muros, pisos o dondequiera que

pudiese encontrar cables eléctricos vivos, ¡NO TOQUE

NINGUNA PIEZA METALICA DE LA HERRAMIENTA! Sujétela

únicamente por las superficies aislantes para evitar descargas

eléctricas en el caso de cortar un cable vivo.

DW890/384122 9/1/00 3:24 PM Page 13

Page 17

14

Motor

Su herramienta DeWalt cuenta con un motor DeWalt interconstruido.

Asegúrese que el voltaje de su toma de corriente concuerda con las

especificaciones de la placa de la unidad. 120 Volts, 60 Hz, AC/DC

indican que su herramienta puede operarse con corriente alterna o

con corriente continua. Las disminuciones del voltaje mayores de

10% harán que la herramienta pierda potencia y se sobrecaliente.

T odas las herramientas DeW alt se han probado en fábrica; si ésta no

operara, verifique la toma de corriente del sitio en que la opera.

Interruptor

Oprima el interruptor de gatillo para encender la herramienta,

suéltelo para apagarla. Para asegurar el interruptor en posición de

encendido para operación continua, oprima el gatillo, empuje hacia

arriba el botón de encendido permanente (figura 1), y a continuación

libere suavemente el gatillo. Para liberar el mecanismo de encendido

permanente, oprima a fondo el gatillo y suéltelo a continuación.

Antes de emplear la herramienta cada vez, asegúrese que el

mecanismo de liberación del botón del seguro funciona libremente.

Asegúrese de liberar el botón del seguro antes de desconectar la

clavija de la toma de corriente. No hacerlo ocasionará que la

herramienta se encienda inmediatamente la próxima vez que la

conecte, con el consiguiente riesgo de daños y lesiones. El gatillo

interruptor de velocidad variable le permite controlar la velocidad.

Mientras más a fondo oprima el gatillo, mayor será la velocidad de

la cizalla.

Desensamblaje y ensamblaje

(figuras 2 y 3)

Para retirar la cabeza de la cizalla del motor, afloje los 3 tornillos

con cabeza redonda. Saque la cabeza de la cizalla tirando de ella

con firmeza hacia adelante. Puede requerirse una pequeña torsión

sin la cabeza no se desliza con facilidad.

Español

FIG. 1

BOTON DE

ENCENDIDO

PERMANENTE

FIG. 2

TORNILLOS DE

CABEZA REDONDA

CARCAZA

MONTAJE DE

BALERO

EXCENTRICO

ROLDANA

FIG. 3

CUCHILLA LATERAL

Y ESPACIADOR

LATERAL

BUJES

ESPACIADORES

CUCHILLA LATERAL

IZQUIERDA

DW890/384122 9/1/00 3:24 PM Page 14

Page 18

15

Español

Para retirar las cuchillas de la cabeza, saque los 3 tornillos de la

carcaza de la cizalla. Sea cuidadoso para no perder el buje

espaciador trasero cuando quite el tornillo de enmedio. Saque la

cuchilla central de la carcaza aplicándole unos golpecillos hacia

atrás. La cuchilla y el espaciador laterales saldrán ahora de la

carcaza.

Para retirar el montaje del balero excéntrico de la flecha, utilice una

llave apropiada para aflojar la tuerca excéntrica girándola en sentido

contrario a las manecillas del reloj.

Para instalar el montaje del balero excéntrico en la flecha,

asegúrese que la roldana delgada grande sea lo primero en

colocarse en la flecha. Atornille el montaje del balero excéntrico en

la flecha y apriételo con la llave apropiada. Lubrique el balero con

una cantidad generosa de grasa para baleros.

Para instalar las cuchillas en la carcaza de la cizalla, colóquela

cuchilla y el espaciador laterales en su posición en la carcaza.

Inserte el tornillo a través de la cuchilla y el espaciador laterales con

el buje espaciador entre ellos. Enrosque el tornillo lo suficiente para

sujetar las cuchillas en su posición. NO APRIETE. Inserte el buje

espaciador en el orificio de la cuchilla central y lubrique. Instale la

FIG. 4

FIG. 5

SUPERFICIE

INFERIOR DE

LAS CUCHILLAS

LATERALES

ABERTURA DE LA

CUCHILLA

LAMINA DE METAL

APRIETE

ALTERNATIVAMENTE

PARA ASEGURAR

cuchilla central en la cizalla aplicándole unos golpecillos utilizando

un punzón para alinear el orificio de la cuchilla con los orificios

delanteros de la carcaza. Inserte el tornillo delantero y apriételo,

asegurándose que el buje espaciador que se encuentra en la

cuchilla central permanezca en su posición. Aplique una cantidad

generosa de grasa para baleros a la abrazadera o al yunque en la

cuchilla central en la parte que monta en el balero excéntrico. Inserte

el tornillo trasero en la carcaza pero no apriete por completo.

Para instalar el montaje de la cabeza de la cizalla en el motor,

asegúrese que todos los tornillos estén flojos aproximadamente 3 o

4 vueltas completas. Coloque la cabeza de la cizalla en la unidad y

apriete alternativamente los tornillos hasta asegurar la cabeza en su

sitio. Puede ser necesario aplicar unos golpecillos a la cabeza de la

cizalla para colocarla en su sitio si no se desliza con facilidad en la

nariz de la unidad de poder.

Operación

Para trabajar con precisión, siempre sujete o prense el material con

el que vaya a trabajar. Haga coincidir uno de los filos de la cuchilla

DW890/384122 9/1/00 3:24 PM Page 15

Page 19

16

Español

central de la herramienta con la línea de corte y avance las cuchillas

en el material sin esforzarse ni aplicar presión innecesaria. Con un

poco de práctica usted podrá determinar con qué presión hará el

corte más suavemente. Es muy importante conservar los bordes

inferiores de las cuchillas laterales planos sobre el material (figura 4).

Cuando corte curvas, evite levantar la herramienta; conserve las

cuchillas laterales planas y niveladas. Para la mayor eficiencia en el

corte, conserve afiladas las cuchillas. Utilice guantes para manejar

lámina de metal. Los bordes son afilados y pueden causarle una

lesión. PRECAUCION: No utilice la cizalla con ningún tipo de

accesorio o dispositivo. Puede ser peligroso.

Ajustes (figura 5)

Para ajustar la curvatura del material de desperdicio, la cuchilla del

lado izquierdo tiene orificios elongados. Puede ser necesario ajustar

las cuchillas después de cambiarlas o de cambiar el material con que

se trabaja. Afloje los tornillos y mueva la cuchilla hacia adelante o

hacia atrás de manera que el material de desperdicio no haga

contacto con la carcaza ni con la pieza de trabajo al cortar.

Mantenimiento

Utilice únicamente un jabón suave y un trapo húmedo para limpiar

la herramienta. Nunca permita que se introduzca ningún líquido en la

herramienta, ni sumerja ninguna parte de ésta en ningún líquido.

Se han empleado baleros auto lubricantes en la fabricación de esta

herramienta y no se requiere de lubricación periódica. En el

improbable caso que su herramienta llegase a requerir servicio,

llévela a un centro de servicio autorizado.

Importante

Para garantizar la SEGURIDAD y la CONFIABILIDAD del producto,

deberán hacerse reparaciones, mantenimiento y ajustes (incluyendo

revisión y cambio de los carbones) por centros autorizados de

servicio u otras organizaciones calificadas que empleen siempre

refacciones idénticas

PARA REPARACION Y SERVICIO DE SUS HERRAMIENT AS

ELECTRICAS FAVOR DE DIRIGIRSE AL CENTRO DE SERVICIO MAS

CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671) 242 10

GAUDALAJARA

Av. La Paz #1770 (91 3) 826 69 78.

LEON

Polara #32 (91 471) 314 56

MEXICO

Eje Lázaro Cárdenas #18 Local D, Obrera 553-9377

MERIDA

Calle 63 #459 (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #2057 (91 22) 46 90 20

QUERETARO

Av. Madero 139 Pte. (91 42) 14 60 60

SAN LOUIS POTOSI

Pedro Moreno #408 Fracc. la Victoria (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongación Diaz Miron #4280 (91 29) 21 70 18

VILLAHERMOSA

Zaragoza #105 (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

Accesorios

Dispone usted de los accesorios para su herramienta por un cargo

adicional con su distribuidor local autorizado Se incluye una lista

completa de los centros de servicio con su herramienta..Si necesita

DW890/384122 9/1/00 3:24 PM Page 16

Page 20

17

Español

ayuda para encontrar cualquier accesorio, por favor comuníquese con

D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286 o llame al teléfono 1-800-732-4441.

Garantía Completa

Las herramientas industriales DEWalt están garantizadas durante un año a

partir de la fecha de compra. Repararemos, sin cargos, cualquier falla debida

a material o mano de obra defectuosos. Por favor regrese la unidad completa,

con el transporte pagado, a cualquier Centro de Servicio para Herramientas

Industriales de DEWalt o a las estaciones de servicio autorizado enlistadas

bajo "Herramientas Eléctricas" en la Sección Amarilla. Esta garantía no se

aplica a los accesorios ni a daños causados por reparaciones efectuadas

por terceras personas. Esta garantía le otorga derechos legales específicos,

y usted puede tener otros derechos que pueden variar de estado a estado.

En adición a la garantía, las herramientas DEWALT están amparadas por

nuestra:

GARANTÍA DE SATISFACCIÓN SIN RIESGO POR 30 DÍAS

Si usted no se encuentra completamente satisfecho con el desempeño de

su herramienta industrial DEWalt, sencillamente devuélvala a los vendedores

participantes durante los primeros 30 días después de la fecha de compra

para que le efectúen un reembolso completo. Por favor regrese la unidad

completa, con el transporte pagado. Se puede requerir prueba de compra.

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

05120 MÉXICO, D.F

TEL. 326-7100

SECCI N

AMARILLA

Si funciona…

y funciona muy bien.

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

DW890/384122 9/1/00 3:24 PM Page 17

Loading...

Loading...