Page 1

LULO

r_r_

-J I---

"0 Z

ilL<{

>-

wz

c2_--

@

5W

o,_,

z

o<

> cc

F-<a-

O'F- _

_z

co<

c0%c0

Z(SD

o

€,

DEWALTIndustrialToolCo.,701 EastJoppa Road, Baltimore,MD 21286

(JUN11)Part No. N114762 DW887, DW887N, DW888

Copyright © 2002, 2004, 2005, 2007, 2011 DEWALT

Thefollowingaretrademarksforoneor moreDEWALTpowertools:the yellowand blackcolorscheme;the "D"

shapedairintakegrill;the arrayof pyramidsonthe handgrip;thekit box configuration;andthe arrayof lozenge-

shaped humpson the surfaceof the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please

read the manual and pay attention to these symbols.

A DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

,_ WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

A CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not

avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL

US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}.

WARNING: Toreduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

A ARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2} ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock ifyour body is earthed

or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3} PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury,

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury,

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source andlor the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally,

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tooL

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool's operation. If

J

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5} SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SAFETY INSTRUCTIONS FOR ALL OPERATIONS

Safety Warnings Common for Grinding, Sanding, Wire

Brushing, Polishing or Abrasive, Cutting-Off Operations

a) This power tool is intended to function as a grinder, sander, wire brush, polisher or

cut-off tool Read all safety warnings, instructions, illustrations and specifications

provided with this power tooL Failure to follow all instructions listed below may result in

electric shock, fire and/or serious injury,

b) Do not use accessories which are not specifically designed and recommended by

the tool manufacturer. Just because the accessory can be attached to your power tool, it

does not assure safe operation.

c) The rated speed of the accessory must be at least equal to the maximum speed

marked on the power tooL Accessories running faster than their rated speed can break

and fly apart.

d) The outside diameter and the thickness of your accessory must be within the

capacity rating of your power tool Incorrectly sized accessories cannot be adequately

guarded or controlled.

e) The arbor size of wheels, flanges, backing pads or any other accessory must

properly fit the spindle of the power tool Accessories with arbor holes that do not match

the mounting hardware of the power tool will run out of balance, vibrate excessively and may

cause loss of control

f) Do not use a damaged accessory. Before each use inspect the accessory such as

abrasive wheel for chips and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect

for damage or install an undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from the plane of the rotating

accessory and run the power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this test time.

g) Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of stopping small abrasive or

workpiece fragments. The eye protection must be capable of stopping flying debris

generated by various operations. The dust mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

h) Keep bystanders a safe distance away from work area. Anyone entering the work

area must wear personal protective equipment. Fragments of workpiece or of a broken

accessory may fly away and cause injury beyond immediate area of operation.

i) Hold power tool by insulated gripping surfaces only, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make exposed metal parts of the power tool "live"

and shock the operator.

j) Position the cord clear of the spinning accessory. Ifyou lose control, the cord may be

cut or snagged and your hand or arm may be pulled into the spinning accessory,

k) Never lay the power tool down until the accessory has come to a complete stop.

The spinning accessory may grab the surface and pull the power tool out of your control

I) Do not run the power tool while carrying it at your side. Accidental contact with the

spinning accessory could snag your clothing, pulling the accessory into your body,

m) Regularly clean the power tool's air vents. The motor's fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

n) Do not operate the power tool near flammable materials. Sparks could ignite these

materials.

o) Do not use accessories that require liquid coolants. Using water or other liquid coolants

may result in electrocution or shock.

Causes and Operator Prevention of Kickback

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush

or any other accessory, Pinching or snagging causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power tool to be fomed in the direction opposite of the

accessory's rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump toward or away from the operator, depending

on direction of the wheel's movement at the point of pinching. Abrasive wheels may also break

under these conditions.

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as given below:

a) Maintain a firm grip on the power tool and position your body and arm to allow you

to resist kickback forces. Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up. The operator can control

torque reaction or kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback over your

hand.

c) Do not position your body in the area where power tool will move if kickback

occurs. Kickback will propel the tool in direction opposite to the wheel's movement at the

point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Comers, sharp edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades

create frequent kickback and loss of control

Safety Warnings Specific for Grinding and Abrasive

Cutting-Off Operations Operations

a) Use only wheel types that are recommended for your power tool and the specific

guard designed for the selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

b) The guard must be securely attached to the power tool and positioned for

maximum safety, so the least amount of wheel is exposed towards the operator.

The guard helps to protect operator from broken wheel fragments and accidental contact

with wheel.

c) Wheels must be used only for recommended applications. For example: do not

grind with the side of cut-off wheel. Abrasive cut-off wheels are intended for peripheral

grinding, side forces applied to these wheels may cause them to shatter.

d) Always use undamaged wheel flanges that are of correct size and shape for your

selected wheel Proper wheel flanges support the wheel thus reducing the possibility of

wheel breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

e) Do not use worn down wheels from larger power tools. Wheel intended for larger

power tool is not suitable for the higher speed of a smaller tool and may burst.

Additional Safety Warnings Specific for Abrasive Cutting-

OFF Operations

a) Do not "jam" the cut-off wheel or apply excessive pressure. Do not attempt to

make an excessive depth of cut. Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or

wheel breakage.

b) Do not position your body in line with and behind the rotating wheel. When the

wheel, at the point of operation, is moving away from your body, the possible kickback may

propel the spinning wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut for any reason, switch off the

power tool and hold the power tool motionless until the wheel comes to a complete

stop. Never attempt to remove the cut-off wheel from the cut while the wheel is in

motion otherwise kickback may occur. Investigate and take corrective action to eliminate

the cause of wheel binding.

d) Do not restart the cutting operation in the workpiece. Let the wheel reach full

speed and carefully reenter the cut. The wheel may bind, walk up or kickback if the

power tool is restarted in the workpiece.

e) Support panels or any oversized workpiece to minimize the risk of wheel pinching

and kickback. Large workpieces tend to sag under their own weight. Supports must be

placed under the workpiece near the line of cut and near the edge of the workpiece on both

sides of the wheel

f) Use extra caution when making a "pocket cut" into existing walls or other blind

areas. The protruding wheel may cut gas or water pipes, electrical wiring or objects that can

cause kickback.

Safety Warnings Specific for Sanding Operations

a) Do not use excessively oversized sanding disc paper. Follow manufacturers

recommendations, when selecting sanding paper. Larger sanding paper extending

beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of

the disc or kickback.

Safety Warnings Specific for Polishing Operations

a) Do not allow any loose portion of the polishing bonnet or its attachment strings

to spin freely. Tuck away or trim any loose attachment strings. Loose and spinning

attachment strings can entangle your fingers or snag on the workpiece.

Page 2

Safety Warnings Specific for Wire Brushing Operations

a) Be aware that wire bristles are thrown by the brush even during ordinary operation.

Do not overstress the wires by applying excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire brushing, do not allow any

interference of the wire wheel or brush with the guard. Wire wheel or brush may

expand in diameter due to work and centrifugal forces.

Additional Safety Information

• Do not use Type 11 (flaring cup) wheels on this tool. Using inappropriate accessories can

result ininjury,

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is

16gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

_ WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use

face or dust mask if cutting operation is dusty, ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT_

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3. 19)hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

A WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are."

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. Toreduce

your exposure to these chemicals." work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

A WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury, Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body,

A WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

A WARNING: Always use eye protection. All users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

_ WARNING: When not in use, place grinder on a stable surface where it will not move

inadvertantly, roll or cause a tripping or falling hazard. Serious personal injury may result.

A CAUTION: To reduce the risk of personal injury, use extra care when working into a comer or

edge because asudden, sharp movement of the tool may be experienced when the wheel or other

accessory contacts a secondary surface or a surface edge.

• The label on your tool may include the following symbols. The symbols and their definitions are

as follows."

V.................. volts

Hz................ hertz

min .............. minutes

- --. .......... direct current

(_)................ Class I Construction

[] ................ Class II Construction

.../min ......... per minute

IPM .............. impacts per minute

Not More

Than

6

10

12

16

(grounded)

(double insulated)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

18

18

16

14

A ................... amperes

W.................. watts

"_ ................ alternating current

no ................. no load speed

G .................. earthing terminal

_ .................. safety alert symbol

BPM.............. beats per minute

RPM.............. revolutions per minute

sfpm.............. surface feet per minute

16

16

16

12

................ alternating or direct current

16 14

14 12

14 12

Not Recommended

SAVE THESE INSTRUCTIONS FOR FUTURE USE

Motor

Be sure your power supply agrees with the nameplate marking. Voltage decrease of more than 10%

will cause loss of power and overheating. All DEWALTtools are factory tested; if this tool does not

operate, check the power supply.

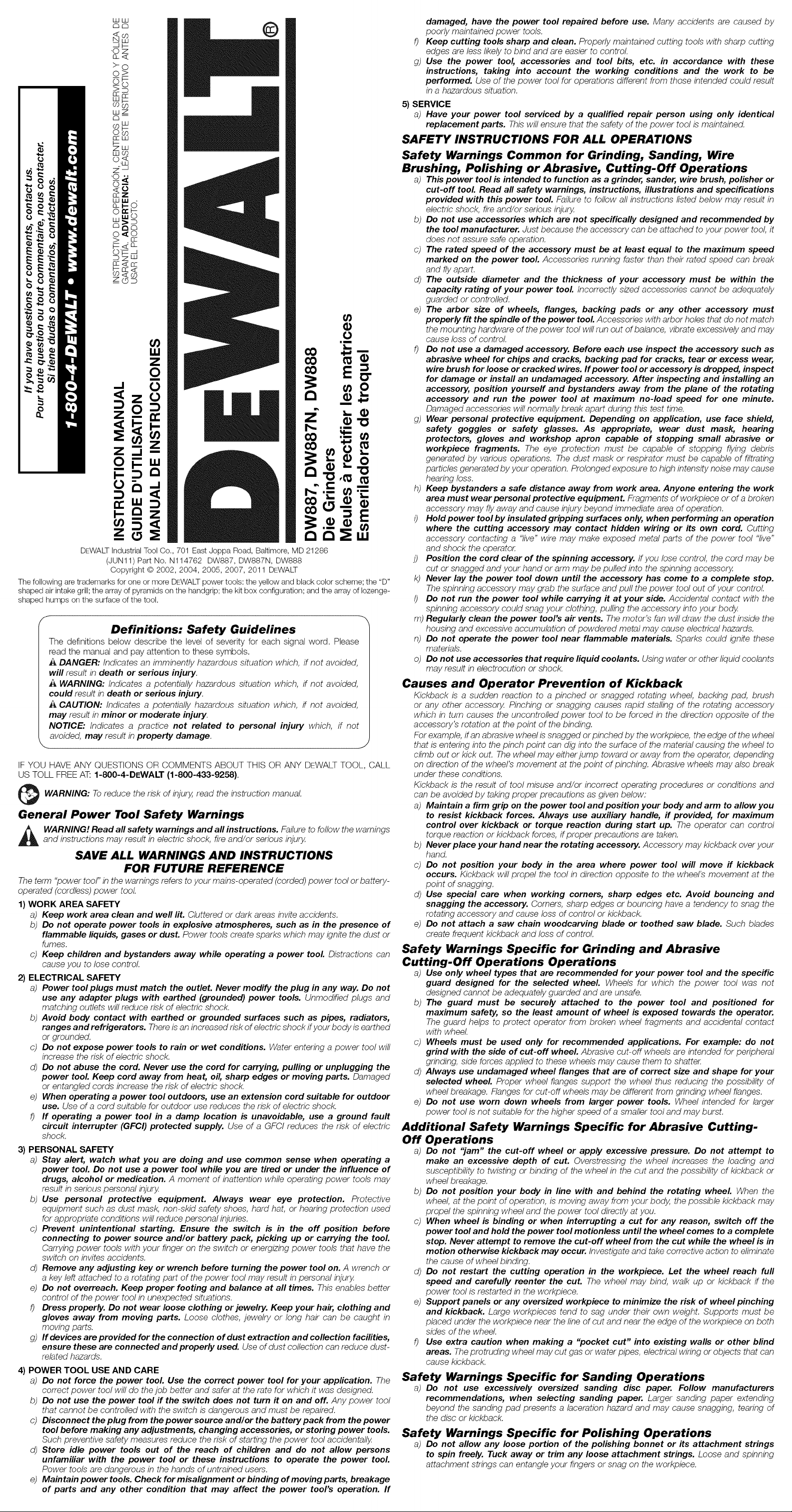

COMPONENTS (Fig. 1, 2)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. Paddle switch (DW887, DW887N)

B. Lock-on button (DW887, DW888)

C. Lock-off lever (DW887, DW887N)

D. Trigger switch (DW888)

INTENDED USE

The DW887, DW887N and DW888 heavy-duty die grinders have been designed for professional

grinding. DO NOT use under wet conditions or in presence of flammable liquids or gases.

These heavy-duty die grinders are professional power tools. DO NOT let children come into contact

with the tool. Supervision is required when inexperienced operators use this tool.

Switches

_ WARNING: Before connecting the tool to a power source depress and release the switch once

without depressing the lock-on button to ensure that the switch is off. Depress and release the

switch as described above after any interruption in power supply to the tool, such as the activation

of a ground fault interrupter, throwing of a circuit breaker, accidental unplugging, or power failure. If

the switch is locked on, the tool will start unexpectedly when it is reconnected.

_ WARNING: Grasp tool firmly with both hands to maintain control of the tool at start up and

during use and until the wheel or accessory stops rotating. Make sure the wheel has come to a

complete stop before laying the tool down.

_, WARNING: To reduce unexpected tool movement, do not switch the tool on or off while under

load conditions. Allow the grinder to run up to full speed before touching the work surface. Lift the

tool from the surface before turning the tool off.

PADDLE SWITCH - DW887, DW887N (FIG. 1)

The lock-off lever (C), located on the paddle switch, is a safety feature that prevents accidental

activation of the grinder.

Toturn the tool on, push the lock-off lever (C)toward the back of the tool, then depress the paddle

switch (A).The tool will run while the switch is depressed. Turn the tool off by releasing the paddle

switch.

A WARNING: Do not disable the lock-off lever. If the lock-off lever is disabled, the tool may start

unexpectedly when it is laid down.

TRIGGER SWITCH - DW888 (FIG. 1, 2)

Depressing the trigger switch turns the tool on. Releasing it turns the tool off. To lock the switch on,

fully depress the trigger switch, press and hold in the lock-on button (B), release the trigger switch

and the lock-on button. The tool will now remain on. To turn turn the tool off, depress and release

the trigger switch.

Lock-on Button - DW887, DW888

The lock-on button offers increased comfort in extended use applications. To lock the tool on, push

the lock-off lever (C) then depress the paddle switch/trigger switch.

With the tool running, depress the lock-on button (B).The tool will continue to run after the paddle

switch is released.

To unlock the tool, depress and release the paddle switch/trigger switch. This will cause the tool

to stop.

A WARNING: Allow the tool to reach full speed before touching tool to the work surface. Lift the

tool from the work surface before turning the tool off.

OPERATION

A WARNING: Toreduce the risk of serious personalinjury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories. Before reconnecting the tool, depress and release the trigger switch to

ensure that the tool is off.

Install Grinding Wheels

1 Remove mounting nut by turning it counterclockwise (when facing outer side of accesssory)

The spindle can be held stationary by holding a wrench on the flats provided on the exposed

portion of the spindle.

2. Only tighten nut sufficiently to drive the wheel without slippage.

3. When starting the tool (with a new or replacement wheel installed) hold the tool in a well

protected area. If the wheel has an undetected crack or flaw, it should burst in less than one

minute. Never start tool with a person in line with the wheel. This includes the operator.

FIG. 1

DW887

1-1/2" (38 mm) DIE GRINDER

MEULES _, RECTIFIER LES MATRICES DW887

DE 38 mm (1-1/2 pc)

ESMERILADORA DE TROQUEL DW887

DE 38 mm (1-1/2")

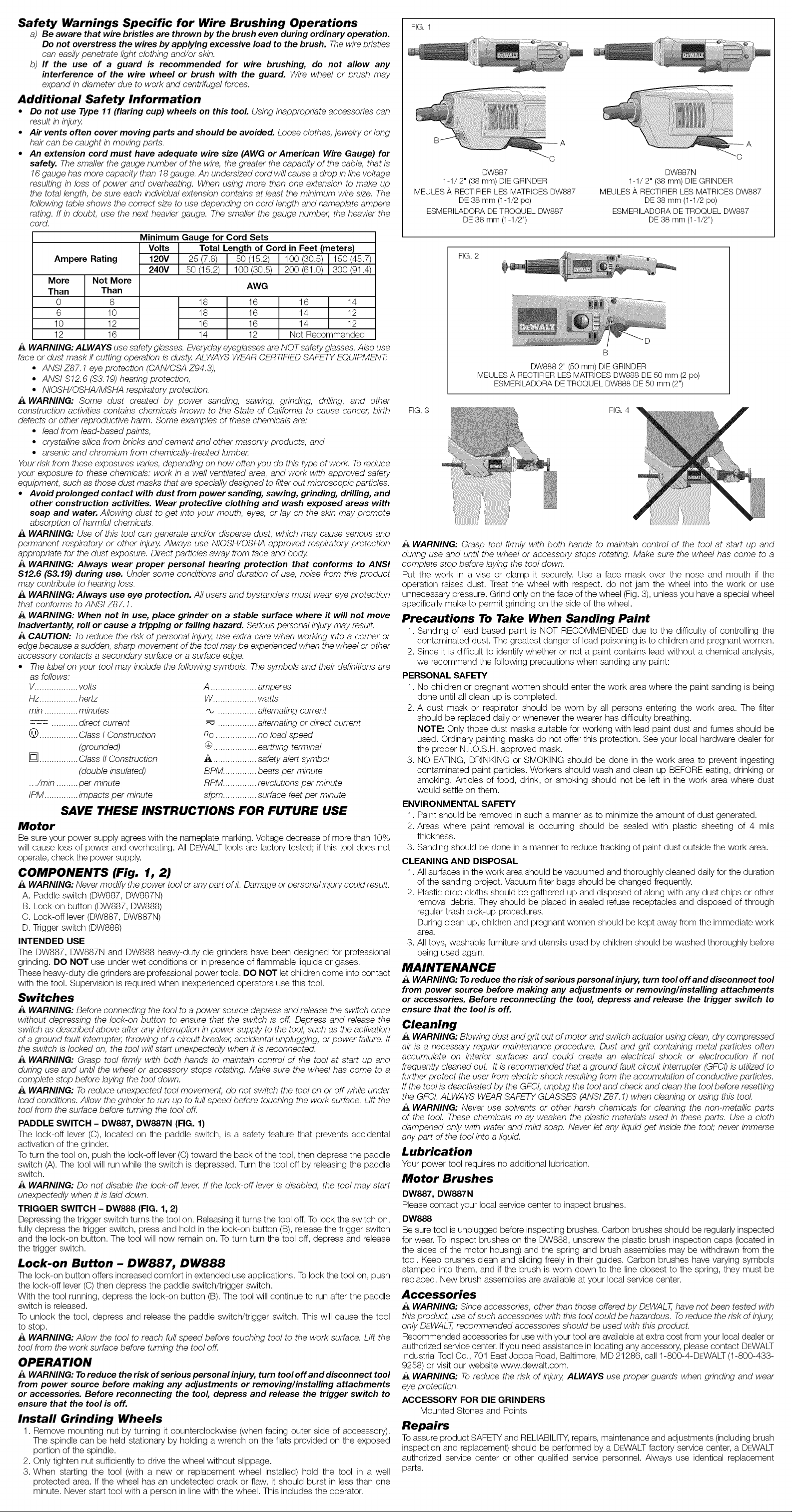

FIG. 2

DW888 2" (50 mm) DIE GRINDER

MEULES _, RECTIFIER LES MATRICES DW888 DE 50 mm (2 pc)

ESMERILADORA DE TROQUEL DW888 DE 50 mm (2")

FIG. 3 FIG. 4

A WARNING: Grasp tool firmly with both hands to maintain control of the tool at start up and

during use and until the wheel or accessory stops rotating. Make sure the wheel has come to a

complete stop before laying the tool down.

Put the work in a vise or clamp it securely. Use a face mask over the nose and mouth if the

operation raises dust. Treat the wheel with respect, do not jam the wheel into the work or use

unnecessary pressure. Grind only on the face of the wheel (Fig.3), unless you have a special wheel

specifically make to permit grinding on the side of the wheel.

1-1/2" (38 mm) DIE GRINDER

MEULES _, RECTIFIER LES MATRICES DW887

ESMERILADORA DE TROQUEL DW887

DW887N

DE 38 mm (1-1/2 pc)

DE 38 mm (1-1/2")

Precautions To Take When Sanding Paint

1 Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without a chemical analysis,

we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

1. No children or pregnant women should enter the work area where the paint sanding is being

done until all clean up is completed.

2. A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be

used. Ordinary painting masks do not offer this protection. See your local hardware dealer for

the proper N.I.O.S.H. approved mask.

3. NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting

contaminated paint particles. Workers should wash and clean up BEFORE eating, drinking or

smoking. Articles of food, drink, or smoking should not be left in the work area where dust

would settle on them.

ENVIRON MENTAL SAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust generated.

2. Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

3. Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

CLEANING AND DISPOSAL

1. All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration

of the sanding project. Vacuum filter bags should be changed frequently.

2. Plastic drop cloths should be gathered up and disposed of along with any dust chips or other

removal debris. They should be placed in sealed refuse receptacles and disposed of through

regular trash pick-up procedures.

During clean up, children and pregnant women should be kept away from the immediate work

area.

3. All toys, washable furniture and utensils used by children should be washed thoroughly before

being used again.

MAINTENANCE

A WARNING: Toreduce the risk of serious personalinjury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories. Before reconnecting the tool, depress and release the trigger switch to

ensure that the tool is off.

Cleaning

WARNING: Blowing dust and grit out of motor and switch actuator using clean, dry compressed

air is a necessary regular maintenance procedure. Dust and grit containing metal particles often

accumulate on interior surfaces and could create an electrical shock or electrocution if not

frequently cleaned out. It is recommended that a ground fault circuit interrupter (GFCI)is utilized to

further protect the user from electric shock resulting from the accumulation of conductive particles.

Ifthe tool is deactivated by the GFCI, unplug the tool and check and clean the tool before resetting

the GFCI. ALWAYS WEAR SAFETY GLASSES (ANSI Z87.1) when cleaning or using this tool

A WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool," never immerse

any part of the tool into a liquid.

Lubrication

Your power tool requires no additional lubrication.

Motor Brushes

DW887, DW887N

Please contact your local service center to inspect brushes.

DW888

Be sure tool is unplugged before inspecting brushes. Carbon brushes should be regularly inspected

for wear. To inspect brushes on the DW888, unscrew the plastic brush inspection caps (located in

the sides of the motor housing) and the spring and brush assemblies may be withdrawn from the

tool. Keep brushes clean and sliding freely in their guides. Carbon brushes have varying symbols

stamped into them, and if the brush is worn down to the line closest to the spring, they must be

replaced. New brush assemblies are available at your local service center.

Accessories

A WARNING: Since accessories, other than those offered by DEWALT,have not been tested with

this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury,

only DEWALT,recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. Ifyou need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-

9258) or visit our website www.dewalt.com.

A WARNING: To reduce the risk of injury, ALWAYS use proper guards when grinding and wear

eye protection.

ACCESSORY FOR DIE GRINDERS

Mounted Stones and Points

Repairs

Toassure product SAFETY and RELIABILITY,repairs, maintenance and adjustments (including brush

inspection and replacement) should be performed by a DEWALTfactory service center, a DEWALT

authorized service center or other qualified service personnel. Always use identical replacement

parts.

Page 3

Three Year Limited Warranty

DEWALTwill repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

Ifyou are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer

for any reason, you can return it within 90 days from the date of purchase with a receipt for a full

refund - no questions asked.

LATIN AMERICA" This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing,

call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

f

DWXXX1 (38mo)DiE

SER.

_USER MUST READ iNSTRUCTiON

MANUAL. ALWAYS USE PROPER GUARUS WHEN GRINDING AND

WEAREYEPROTECTION,ALWAYSUSEPROPEDRESPIRATORY

PROTECTION. USE ONLY ACCESSORIES RATED AT LEAST EQUAL TO

THE MAXIMUM SPEED MARRED ON THE TOOL

DEWALT iNDUSTRiAL TOOL CO., BALTIMORE, MD 2128_ USA

FOR SERVICE iNFORMAl]ON, CALL 1-800-4-D_WALT www.DEWALT.com

TO REDUCE THE RJSR OE iNJURY,

-_ ARAELMANEJOSEGUROLEAEL _'_

UTDISEMEMPSELASGUARSASASSOPISUAS,UTILISESMMPSELA /

PROTECSl6NADESNADAPARALAVISTAYPASAL_SViASSESPIRATORIAS,

UTILiCESOLOASCESOSIOSSAt_SADOSPARAUTiUZASALAVELOSiDAD

MAXIMAMARCADAENLAHE_SAMiENTA_CUMOMit_lMO_

_A _T_EPSEVENTIE_tMELE

PROTECTIONOCULAMEETSESPM_OISEAPPSOPM_,UTItlSES

ENSLUMVEMENTSESASSESSUISESDONTL_VITESSENOMINALEEST

EQNIVAL_t_TEUUSOPEMEUREA CELLESESOMMANR_ESUSL'_TIQOETf_

....................................................j

'AVESTISS_MENT_EL'OUTIL

MANUAL DE INSTSCCCffiNE$.

RUIDE_TUUJOUSS_iUSER

/

Ddfinitions : lignes directrices en

mati_re de sdcuritd

Les definitions ci-dessous decrivent le niveau de danger pour chaque

mot-indicateur employe. Lire le mode d'emploi et porter une attention

particuliere a.ces symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n'est pas

evitee, entra_nera la mort ou des blessures graves.

_AVERTISSEMENT : indique une situation potentiel/ement dangereuse qui,

si elle n'est pas evitee, pourrait entra_nerla mort ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle

n'est pas evitee, pourrait entra_nerdes blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de dommages

corporels mais qui par contre, si rien n 'est fait pour I'eviter,pourrait poser des

_ risques de dommages materiels.

J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE

OUTIL DEWALT,COMPOSEZ LE NUMFt:ROSANS FRAIS : 1 800 433-9258 (1 800 4-DEWALT}.

_ AVERTISSEMENT : afin de reduire le risque de blessures, life le mode d'emploi de I'outil.

Avertissements de s_curit_ g_n_raux pour les outils

dlectriques

_ AVERTISSEMENT! Life tousles avertissements de s_curit_ et toutes les directives.

Le non-respect des avertissements et des directives pourrait se solder par un choc

dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES LES

DIRECTIVES POUR UN USAGE ULTERIEUR

Le terme _ outil dectrique _ cite dans les avertissements se rapporte a votre outil electrique

alimentation sur secteur (avec ill) ou par piles (sans fil).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les Iieux encombres ou sombres sont

propices aux accidents.

b) Ale pas faire fonctionner d'outils _lectriques clans un milieu d_flagrant, tel qu'en

presence de liquides, de gaz ou de poussi_res inflammables. Les outils electriques

produisent des etincelles qui pourraient enflammer la poussiere oules vapeurs.

c) Eloigner les enfants et les personnes a proximit_ pendant rutilisation d'un outil

_lectrique. Une distraction pourrait en faire perdre la ma_trisea I'utilisateur.

2) SI_CURITI_ EN MATI#RE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre a la prise. Ne jamais modifier

la fiche d'aucune faqon. Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera reduit par I'utilisation de fiches

non modifiees correspondant a la prise.

b) Eviter tout contact physique avec des surfaces mises a la terre comme des tuyaux,

des radiateurs, des cuisini_res et des r_frig_rateurs. Le risque de choc dectrique est

plus deve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques a la pluie oub I'humidit_. La penetration de I'eau

dans un outil dectrique augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou d_brancher un outil _lectrique. Tenir le cordon _loign_ de

la chaleur, de I'huile, des bords tranchants et des pi_ces mobiles. Les cordons

endommages ou enchev_tres augmentent les risques de choc dectrique.

e) Pour I'utilisation d'un outil _lectrique a I'ext_rieur, se servir d'une rallonge

convenant a cette application. L'uti/isation d'une ra//onge conque pour/'exterieur reduira

les risques de choc dectrique.

S'il est impossible d'_viter I'utilisation d'un outil _lectrique clans un endroit

humide, brancher I'outil clans une prise ou sur un circuit d'alimentation dot_s d'un

disjoncteur de fuite a la terre (GFCI). L'utilisation de ce type de disjoncteur reduit les

risques de choc dectrique.

3) SI_CURITI_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectu_ et faire preuve de jugement Iorsqu'un outil

_lectrique est utilis_. Ale pas utiliser d'outil _lectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un simple moment d'inattention

en utilisant un outil dectrique peut entra_nerdes blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle. Toujours porter une protection

oculaire. L'utilisation d'equipements de protection comme un masque antipoussiere, des

chaussures antiderapantes, un casque de securite ou des protecteurs auditifs Iorsque la

situation le requiert reduira les risques de blessures corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que I'interrupteur se trouve a la

position d'arr_t avant de relier I'outil a une source d'alimentation et/ou d'ins_rer un

bloc-piles, de ramasser ou de transporter I'outil. Transporter un outi/ e/ectrique a/ors

que le doigt repose sur I'interrupteur ou brancher un outil dectrique dont I'interrupteur est

la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ avant de d_marrer I'outil. Une cle ou une cle de

reglage attachee a une pattie pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son _quilibre en tout temps. Cela permet de

mieux ma_triser I'outil dectrique dans les situations imprevues.

S'habiller de mani_re appropri_e. Ne pas porter de v_tements amples ni de bijoux.

Garder les cheveux, les v_tements et les gants a I'_cart des pi_ces mobiles. /es

v_tements amples, les bijoux oules cheveux longs risquent de rester coinces dans les pieces

mobiles.

g) Sides composants sent fournis pour le raccordement de dispositifs de d_poussi_rage

et de ramassage, s'assurer que ceux-ci sent bien raccord_s et utilis_s. L'ut//isat/on

d'un dispositif de depoussierage peut reduire les dangers engendres par les poussieres.

4} UTILISATION ET ENTRETIEN D'UN OUTIL #LECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique appropri_ a I'application.

L'outil dectrique approprie effectuera un mei/leur travail, de faqon plus sore eta la vitesse

pour laquelle ila ete conqu.

b) Ne pas utiliser un outil _lectrique dont I'interrupteur est d_fectueux. Tout outil

dectrique dont /'interrupteur est defectueux est dangereux et doit _tre repare.

c) D_brancher la fiche de la source d'alimentation et/ou du bloc-piles de I'outil

_lectrique avant de faire tout r_glage ou changement d'accessoire ou avant de

ranger I'outil. Ces mesures preventives reduisent les risques de demarrage accidentel de

I'outil dectrique.

d) Ranger les outils _lectriques hers de la pottle des enfants et ne permettre

aucune personne n'_tant pas famili_re avec un outil _lectrique ou son mode

d'emploi d'utiliser cet outil. Les outi/s dectriques deviennent dangereux entre/es mains

d'utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces mobiles sent mal align_es ou

coinc_es, si des pi_ces sent bris_es ou pr_sentent toute autre condition susceptible

de nuire au ben fonctionnement de I'outil _lectrique. En cas de dommage, faire

r_parer I'outil _lectrique avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

S'assurer que les outils de coupe sent aiguis_s et propres. Les outils de coupe bien

entretenus et affOtes sont moins susceptibles de se coincer et sont plus faciles a ma_triser.

g) Utiliser I'outil _lectrique, les accessoires, les forets, etc. conform_ment aux

pr_sentes directives en tenant compte des conditions de travail et du travail

effectuer. L'utilisation d'un outil dectrique pour toute operation autre que celle pour laquelle

ila ete conquest dangereuse.

5) R#PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur professionnel en n'utilisant que

des pi_ces de rechange identiques. Cela permettra de maintenir une utilisation securitaire

de I'outil dectrique.

CONSlGNES DE SECURITE POUR TOUTES LES OPERATIONS

Avertissements de sdcuritd communs _ toutes les opdrations de

meulage, pont;age, brossage _ I'aide d'une brosse mdtallique,

polissage ou de coupe

a) Cet outil _lectrique est con_u pour fonctionner comme une meule, une ponceuse,

une brosse m_tallique, une polisseuse ou un outil de coupe. Life tous les

avertissements de s_curit_, les directives, les illustrations et les specifications

fournies avec cet outil _lectrique. Neg/iger de suivre /'ensemble des directives

suivantes pourrait entra_ner des risques de choc electrique, d'incendie et/ou de blessures

graves.

b) Ne pas utiliser d'accessoire non con_u sp_cifiquement pour cet outil ou qui

n'aurait pas requ une approbation sp_cifique du fabricant de I'outil. En effet, i/ est

parfois possible de fixer un accessoire a I'outil dectrique; toutefois, cela ne garantit pas une

utilisation securitaire.

c) Le r_gime nominal de I'accessoire dolt _tre au moins _gal au r_gime maximal

inscrit sur I'outil _lectrique. Les accessoires soumis a un regime plus deve que ce/ui pour

/eque/ i/s sont conqus peuvent se briser et _tre projetes.

d) Le diam_tre externe et I'_paisseur de I'accessoire doivent _tre ad_quats pour

la capacit_ de I'outil _lectrique. // est impossible de proteger /'uti/isateur d'un bris

d'accessoire de mauvais calibre ou de le ma_triser correctement.

e) Le trou pour arbre d'entra_nement des meules, brides, tampons ou de tout autre

accessoire dolt s'ajuster correctement a la broche de I'outil _lectrique; autrement,

I'outil sera desequilibre, vibrera excessivement et risquerait de provoquer une perte de

ma_trise.

Ne jamais utiliser un accessoire endommag_. Avant toute utilisation, inspecter la

meule abrasive a la recherche d'_clats et de fissures; le tampon pour tout signe

de fissures, d_chirures ou d'usure excessive; et la brosse m_tallique, pour d_celer

s'il y a des ills m_talliques fissures ou d_tach_s. En cas de chute de I'outil ou de

I'accessoire, les inspecter a la recherche de dommages ou insurer un accessoire

non endommag_. Apr_s I'inspection et I'insertion d'un accessoire, se positionner

(l'utilisateur ou quiconque aux alentours) hers du plan de rotation de I'accessoire

et faire tourner, pendant une minute, I'outil _lectrique a plein r_gime, a vide.

Normalement, tout accessoire endommage se brisera au cours de cette periode d'essai.

g) Porter un _quipement de protection individuelle. Utiliser un masque facial, des

lunettes de s_curit_ ou des lunettes protectrices en fonction de I'application. Au

besoin, porter un masque antipoussi_res, des protecteurs auditifs, des gants et

un tablier d'atelier capable d'arr_ter de petits fragments d'abrasifs ou de pi_ces.

La protection oculaire doit _tre en mesure d'arr_ter tout debris produit par les diverses

operations et le masque antipoussieres oule respirateur, de filtrer les particules produites par

I'operation en cours. Une exposition prolongee a un bruit d'intensite devee pourrait causer

une perte auditive.

h) Eloigner tout observateur a une distance s_curitaire de la zone de travail. Toute

personne qui p_n_tre clans la zone de travail devra _galement porter un _quipement

de protection individuelle. // est possible qu'un fragment de piece ou un accessoire brise

soit projete et provoque des blessures au-dela de la zone immediate de travail.

i) Tenir I'outil _lectrique uniquement par sa surface de prise isol_e clans une situation

o[i I'accessoire de coupe pourrait entrer en contact avec un c&ble _lectrique

dissimul_ ou avec son propre cordon d'alimentation. Tout contact entre un fi/ _ sous

tension _ et I'accessoire de coupe pourrait egalement mettre _ sous tension _ les pieces

metalliques exposees de I'outil et dectrocuter I' operateur.

j) Positionner le cordon d'alimentation hers d'atteinte de I'accessoire en mouvement.

En cas de perte de ma_trise,il est possible de couper ou d'effilocher le cordon et la main ou

le bras de I'utilisateur risqueraient d'etre happes par I'accessoire en mouvement.

k) Nejamais d_poser I'outil _lectrique avant I'immobilisation complete de I'accessoire.

L'accessoire en mouvement risquerait de mordre dans la surface et de projeter I'outil

dectrique.

I) Mettre I'outil hers tension pour tout d_placement de celui-ci par I'utilisateur. Un

contact accidentel avec I'accessoire en mouvement pourrait happer les v_tements de

I'operateur et projeter I'accessoire contre son corps.

m) Nettoyer r_guli_rement les _vents de I'outil _lectrique. Le ventilateur du moteur

aspirera la poussiere a I'interieur du bo_tier.Une accumulation excessive de poudre metallique

represente un danger d'origine dectrique.

n) Ne pas faire fonctionner I'outil _lectrique a proximit_ de mati_res inflammables. Les

etincelles produites risquent de les enflammer.

o) Ne pas utiliser d'accessoires qui exigent I'utilisation d'un liquide de refroidissement.

L'utilisation d'eau ou de tout autre liquide de refroidissement pourrait se solder par une

dectrocution ou une secousse dectrique.

Causes de reffet de rebond et prevention par I'op_rateur

L'effet de rebond est une reaction soudaine d'une meule, d'un tampon, d'une brosse ou d'un

tout autre accessoire, en mouvement, qui est pince ou qui s'accroche. Un pincement ou un

accrochage provoque un arr_t rapide de I'accessoire en mouvement qui, a son tour, projette

I'outil dectrique, hors de ma_trise, dans la direction opposee a la rotation de I'outil au point de

grippage.

Par exemple, si une meule abrasive se pince ou s'accroche dans la piece, lebord de lameule

introduite au point de pincement peut mordre dans la surface de la piece et projeter la meule

hors de la rainure. La meule peut _tre projetee vers I'operateur ou dans la direction opposee

selon le sens de rotation de la meule au point de pincement. II est egalement possible que les

meules abrasives se brisent dans ces conditions.

Un effet de rebond est le resultat d'une mauvaise utilisation de I'outil et/ou de procedures

ou conditions de fonctionnement incorrectes. II peut _tre evite en prenant les precautions

necessaires telles que decrites ci-dessous :

a) Saisir fermement I'outil _lectrique et positionner le corps et les bras de sorte

r_sister a la force de I'effet de rebond. Utiliser toujours la poign_e auxiliaire, s'il y

en a une, pour contrSler au maximum I'effet de rebond ou le couple de r_action au

d_marrage. Avec de bonnes precautions, I'operateur est en mesure de contr_ler le couple

de reaction ou I'effet de rebond.

b) Ne jamais placer les mains pros de I'accessoire en mouvement. //pourrait en effet _tre

projete sur cel/es-ci en cas de rebond.

c) Ne pas positionner le corps clans la trajectoire probable de I'outil _lectrique, en

cas de rebond. Au moment du grippage, I'outil sera projete dans la direction opposee au

deplacement de la meule.

d) Etre particuli_rement attentif lots de travaux clans un coin, sur des bords

tranchants, etc. Eviter de faire rebondir I'accessoire. Eviter tout type de grippage

de raccessoire. Un travail dans un coin ou sur des bords tranchants ou un travail en faisant

rebondir I'accessoire provoquent souvent un grippage et une perte de ma_trisede I'outil ou

un effet de rebond.

e) Ne pas fixer de lame de tron_onneuse pour sculpter le bois ou de lame de scie

dent_e. Ces types de lames provoquent des effets de rebond et des pertes de ma_trise

frequents.

Avertissements de s_curit_ sp_cifiques aux operations de

meulage et de coupe par abrasion

a) Utiliser uniquement les types de meules recommand_s pour I'outil _lectrique ainsi

que le capet protecteur particulier conqu pour la meule s_lectionn_e. //est impossible

de bien proteger I'operateur lots de I'utilisation de meules non conques pour I'outil. En effet,

le capot protecteur sera alors inadequat et I'utilisation de la meule, dangereuse.

b) II faut fixer solidement le capet protecteur a I'outil _lectrique et le positionner

pour maximiser la s_curit_ de I'op_rateur, soit en minimisant la surface expos_e

de la meule en direction de I'op_rateur. En effet, /e capot protecteur sert a proteger

I'operateur contre la projection de fragments de meule brisee et de contact accidentel avec

celle-cL

c) Utiliser uniquement les meules pour les applications pr_vues pour chacune d'entre

elles. Par exemple : ne pas meuler avec le bord d'une meule tronqonneuse. Les

meules tronqonneuses par abrasion sont conques pour travail/er en peripherie. L'application

de fomes laterales sur ces meules risquerait de les faire eclater.

d) Toujours utiliser des brides de meule intactes, de la bonne dimension et de la forme

appropri_e pour la meule s_lectionn_e. Les brides de meule appropriees supportent

bien la meule et reduisent ainsi la possibilite d'un bris de meule. Les brides conques pour les

meules tronqonneuses pourraient differer des brides pour meules a ponqage.

e) Ne pas utiliser de meule us_e en provenance d'outil de dimension plus importante.

Ces meules, prevues pour un outil dectrique plus grand, ne conviennent pas au regime plus

deve d'un outil de plus petite dimension et pourraient eclater.

Avertissements de s_curit_ suppl_mentaires sp_cifiques

aux opdrations de coupe par abrasion

a) Ne pas _ coincer _, la meule tron_onneuse ou ne pas appliquer une pression

excessive. Ne pas essayer de couper a une profondeur trop importante. Une

contrainte excessive sur la meule accro_tra la charge et la possibi/ite de tordre ou de gripper

la meule dans le trait de coupe et ainsi provoquer un effet de rebond ou un bris de la meule.

b) Ne pas positionner le corps sur la trajectoire de la meule en mouvement ni derriere

celle-cL Lorsque la meule, au point de contact avec la piece, s'doigne du corps de

I'operateur, un effet de rebond potentiel risque de projeter la meule en rotation, ainsi que

I'outil, en direction de I'utilisateur.

c) Lorsque la meule se grippe ou lots de I'arr_t d'une coupe pour une raison

quelconque, mettre I'outil hers tension et maintenir I'outil immobile jusqu'& I'arr_t

complet de la meule. Ne jamais essayer de retirer la meule tronqonneuse du trait

de coupe alors que celle-ci est encore en mouvement. Une telle pratique risquerait

de provoquer un effet de rebond. Rechercher et prendre /'action corrective necessaire

pour diminer les causes du grippage de lameule.

Page 4

d) Ne pas reprendre la coupe avec la meule clans le trait de coupe de la piece.

Attendre que la meule soit a plein r_gime puis la r_ins_rer soigneusement clans le

tra_t de coupe. Si I'outil dectrique redemarrait avec la meule appuyee sur lapiece, celle-ci

risquerait de gripper, de se deplacer ou de reculer.

e) Pour r_duire le risque de pincement ou de recul de la meule, soutenir les panneaux

ou toute autre piece surdimensionn_e. Les grandes pieces tendent a s'affaisser sous

leurpropre poids. Disposer des appuis sous la piece, le long de la Iigne de coupe et pres du

bord de la piece, des deux c6tes de la meule.

Faire particuli_rement attention lots de la r_alisation de _ d_coupe en poche _,clans

des murs existants ou d'autres zones sans visibilitY. La portion de /a meu/e faisant

saillie risque de couper un tuyau d'alimentation en eau ou en gaz, des ills electriques ou des

objets pouvant provoquer un effet de rebond.

Avertissements de s_curit_ sp_cifiques aux operations de

pon_;age

a) Ne pas utiliser un papier pour disque abrasif excessivement surdimensionn_.

Respecter les recommandations des fabricants lots de la s_lection du papier

abrasif. Un papier abrasif plus grand que le plateau de ponqage represente un risque de

laceration. Le papier risque egalement de s'accrocher, de se dechirer ou de provoquer un

effet de rebond.

Avertissements de s_curit_ sp_cifiques aux operations de

polissage

a) Ne pas laisser tourner librement une partie I_che de la coiffe a polir ou ses ficelles.

Bien insurer les extr_mit_s des ficelles qui d_passent sous la coiffe ou les couper.

Des ficelles I_ches et en rotation peuvent s'enchev_trer dans les doigts ou s'accrocher a la

piece.

Avertissements de s_curit_ sp_cifiques aux operations

utilisant une brosse m_tallique

a) Etre attentif, car la brosse peut projeter des soles m_talliques m_me lots de travaux

normaux. Ne pas surcharger la brosse en appliquant une force excessive sur celle-

ci. Les soies meta//iques penetrent faci/ement /es v_tements /egers ou /apeau.

b) Si I'utilisation d'un capet protecteur est recommand_e avec la brosse m_tallique,

s'assurer qu'il n'interf_re pas avec la rotation de la brosse m_tallique a touret ou

de la brosse m_tallique. En cours de travail et sous /a force centrifuge, /e diametre de/a

brosse metallique a touret ou de la brosse metallique s'accro_t.

Consigne de s_curit_ suppl_mentaire

• Ne jamais utiliser de meules de type 11 (boisseau conique) sur cet outil. L'ut//isat/on

d'accessoires inadequats peut se solder par des blessures.

• Prendre des precautions a proximit_ des _vents, car ils cachent des pi_ces mobiles.

V_tements amples, bijoux ou cheveux longs risquent de rester coinces dans ces pieces mobiles.

• Pour la s_curit_ de I'utilisateur, utiliser une rallonge de calibre ad_quat (AWG,

American Wire Gauge [calibrage am_ricain normalis_ des ills _lectriques]). Plus le

calibre est petit, et plus sa capacite est grande. Un calibre 16, par exemple, a une capacite

superieure a un calibre 18. L'usage d'une rallonge de calibre insuffisant causera une chute de

tension qui entra_neraperte de puissance et surchauffe. Si plus d'une rallonge est utilisee pour

obtenir une certaine Iongueur, s'assurer que chaque rallonge presente au moins le calibre de

fil minimum. Le tableau ci-dessous illustre les calibres a utiliser selon la Iongueur de rallonge

et I'intensite nominale indiquee sur la plaque signaletique. En cas de doute, utiliser le calibre

suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Intensit_ (en amperes)

Sup_rieur

0

6

10

12

_AVERTISSEMENT : porter SYSTEMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque.antipoussieres si

la decoupe dolt en produire beaucoup. PORTER SYSTEMATIQUEMENT UN EQUIPEMENT DE

SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

• Protection auditive ANSI S 12.6 ($3.19) ;

• Protection des voles respiratoires NIOSH/OSHA/MSHA.

need to verify with compliance if the following text (Prop 65) is the correct wording for this tool :

AVERTISSEMENT : les scies, meules, ponceuses, perceuses ou autres outils de construction

peuvent produire des poussieres contenant des produits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou _tre nocifs au systeme reproducteur. Parmi

ces produits chimiques, on retrouve :

• Le plomb dans les peintures a base de plomb ;

• La silice cristallisee dans les briques et le ciment, ou autres produits de maqonnerie ; et

• L'arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associe a de telles expositions varie selon la frequence a laquelle on effectue ces travaux.

Pour reduire toute exposition a ces produits : travailler dans un endroit bien aere, en utilisant du

materiel de securite homologue, tel un masque antipoussieres specialement conqu pour filtrer les

particules microscopiques.

• Limiter toute exposition prolong_e avec les poussi_res provenant du pon_age, sciage,

meulage, perqage ou toute autre activit_ de construction. Porter des v_tements de

protection et nettoyer a I'eau savonneuse les parties du corps expos_es. Le fait de

laisser la poussiere penetrer dans labouche, les yeux ou la peau peut favoriser I'absorption de

produits chimiques dangereux.

_AVERTISSEMENT : cet outil peut produire et/ou repandre de la poussiere susceptible de

causer des dommages serieux et permanents au systeme respiratoire. Utiliser systematiquement

un appareil de protection des voles respiratoires homologue par le NIOSH ou I'OSHA. Diriger les

particules dans le sens oppose au visage et au corps.

J_AVERTISSEMENT : pendant I'utilisation, porter syst_matiquement une protection

auditive individuelle adequate homologu_e ANSI $12.6 ($3.19). Sous certa/nes conditions

et suivant la duree d'utilisation, le bruit emanant de ce produit pourrait contribuer a une perte de

I'acuite auditive.

_AVERTISSEMENT : toujours utiliser une protection oculaire. Tous les utilisateurs et

personnes a proximite doivent porter une protection oculaire conforme a la norme ANSI Z87.1

•_AVERTISSEMENT : Iorsqu'elle est inutilis_e, d_poser la meuleuse sur une surface

stable ob elle sera immobile et ne risquera pas de fouler ou de faire tr_bucher ou chuter

quiconque. Une telle pratique peut entra_ner des blessures corporelles graves.

ATTENTION : pour reduire le risque de blessure corporelle, _tre encore plus prudent lots de

travaux dans un coin ou sur un rebord. En effet, le contact inopine de la meule ou d'un autre

accessoire sur une surface indirecte ou un rebord pourrait provoquer un mouvement brusque et

soudain de I'outil.

• L'etiquette apposee sur votre outil peut inclure les symboles suivants. Les symboles et leur

definition sont indiques ci-apres :

V.................. volts

Hz ................ hertz

min .............. minutes

- --. .......... courant continu

(_)................ classe I fabrication

[] ................ fabrication classe II

.../min ......... par minute

IPM .............. impacts par minute

sfpm ............ pieds lineaires par minute (plpm)

Inf_rieur

6

10

12

16

(mis a la terre)

(double isolation)

volts Longueur totale de cordon en mbtres (pieds)

120 V 7,6 (25) 30,5 (100) 45,7 (150)

240 V 15,2 (50) 61,0 (200) 91,4 (300)

18

18

16

14

15,2 (50)

30,5 (100)

AWG

16

16

16

12

A...................... amperes

W..................... watts

* ................... courant altematif

................... courant altematif ou

no .................... vitesse a vide

..................... borne de terre

,_,..................... symbole d' avertissement

BPM ................ battements par minute

r/min ................ tours par minute

16 14

14 12

14 12

Non recommande

continu

CONSERVER CES CONSIGNES POUR

UTILISATION ULTERIEURE

Moteur

Veiller ace que la tension d'alimentation soit conforme aux exigences de la plaque signaletique

de I'outil. Une baisse de tension de plus de 10-p.-100 peut entra_nerune perte de puissance et la

surchauffe. Tous les outils DEWALTsont essayes avant de quitter I'usine. Lorsque celui-ci refuse de

fonctionner, verifier la source de courant electrique.

COMPOSANTS (FIG. 1, 2)

_AVERTISSEMENT: ne jamais modifier I'outil dectrique ou I'une de ses parties. Une telle

pratique risque de provoquer des dommages materiels ou des blessures corporelles.

A. Interrupteur a.detente (DW887, DW887N)

B. Bouton de verrouillage (DW887, DW888)

C. Levier de verrouillage (DW887, DW887N)

D. G_.chette (DW888)

USAGE PR#VU

Les meules a.rectifier les matrices DW887, DW887N et DW888 ont ete con_ues pour le meulage

professionnel. NE PAS les utiliser en milieu ambiant humide ou en presence de liquides ou de gaz

inflammables.

Ces meules a. rectifier les matrices industrielles sont des outils electriques de professionnels. NE

PAS les laisser a.la portee des enfants. Une supervision est necessaire aupres de tout utilisateur

non experimente.

Interrupteurs

_, AVERTISsEMENT : avant de brancher I'outil sur le secteur appuyer puls rel_cher I'interrupteur

une lois, sans appuyer sur le bouton de verrouillage pour s'assurer que I'interrupteur est en position

d'arr_t. Appuyer puis rel_cher I'interrupteur comme decrit ci-dessus apres toute coupure de

courant, comme en cas d'activation d'un disjoncteur de fuite a la terre, d'activation du disjoncteur,

de debranchement accidentel ou de toute autre cause de coupure de courant. Si I'interrupteur

etait verrouille en etat de marche, I'outil pourrait demarrer accidentellement Iorsque le courant sera

restaure.

_, AVERTISSEMENT : maintenir I'outil fermement a deux mains pour garder le contr_le de I'outil

au demarrage et pendant son utilisation, et ce, jusqu'a arr_t complet de la meule ou de tout autre

accessoire. Avant de poser I'outil, s'assurer que la meule s'est completement arr_tee de toumer.

_AVERTISSEMENT : pour reduire tout mouvement accidentel de I'outil, ne pas arr_ter ou

demarrer I'outil alors qu'il est en contact avec une surface quelconque. Laisser la meule tourner

plein regime avant de la mettre en contact avec la surface a travailler. Retirer I'outil de lasurface

travailler avant de I'arr_ter.

INTERRUPTEUR A DE"FENTE - DW887, DW887N (FIG. 1)

Le levier de verrouillage (C), situe sur I'interrupteur a. detente, est un dispositif de securite pour

prevenir ractivation accidentelle de la meule.

Pour mettre routil en marche, poussez le levier de verrouillage (C) vers I'arriere de I'outil, puis

appuyez sur rinterrupteur a.detente (A). L'outil fonctionnera tant que rinterrupteur restera appuye.

Pour arr_ter I'outil, relb.chezrinterrupteur a.detente.

,_,AVERTISSEMENT : ne pas desactiver le levier de verrouillage. Si le levier de verrouillage etait

desactive, I'outil pourrait demarrer accidentellement alors qu'il est pose.

GACHETTE - DW888 (FIG. 1, 2)

Appuyer sur lagb.chette, met I'outil en marche. Rel_.cherla gb.chette, arr_te I'outil. Pour verrouiller la

gb.chette en marche, appuyez a. fond sur la gb.chette, maintenez appuye le bouton de verrouillage

(B), puis rel_.chez la gb.chette et le bouton de verrouillage. Uoutil restera alors en marche. Pour

arr_ter I'outil, appuyez sur la gb.chette puis rel_.chez.

Bouton de verrouillage -DW887, DW888

Le bouton de verrouillage augmente le confort pour les usages intensifs. Pour verrouiller routil en

marche, appuyez sur lelevier de verrouillage (C)puis appuyez sur I'interrupteur a.detente/gb.chette.

Alors que routil tourne, rel_.chez le bouton de verrouillage (B). Uoutil continuera de tourner Iorsque

I'interrupteur a.detente sera relb.che.

Pour deverrouiller I'outil, appuyez puis rel_.chez I'interrupteur a. detente/gb.chette. Cela arr_tera

I'outil.

_AVERTISSEMENT : laisser I'outil tourner a plein regime avant de le mettre en contact avec la

surface a travailler. Retirer I'outil de la piece a travailler avant de I'arr_ter.

FONCTIONNEMENT

J_AVERTISSEMENT : pour reduire le risque de blessures corporel/es graves, eteindre I'outil et

le debrancher avant d'effectuer tout reglage ou d'enlever ou d'installer des accessoires. Avant de

rebrancher I'outil, enfoncer et rel_cher la detente pour s'assurer que I'outil est bien hors tension.

Installation des meules

1. Retirez I'ecrou de montage en le tournant vers la gauche (en faisant face a.la partie externe

de raccessoire). La broche peut _tre immobilisee en maintenant une cle sur les meplats sur la

portion visible de la broche.

2. Resserrez I'ecrou juste assez pour entra_nerla meule sans derapage.

3. Lorsque vous redemarrez routil (avec une meule neuve, ou apres ravoir changee), maintenez

I'outil dans un espace securitaire. Si le disque est affecte d'une f_lure ou d'un defaut cache, il

pourrait eclater en moins d'une minute. Ne demarrez jamais routil alors qu'un individu se trouve

dans ralignement du disque, y compris rutilisateur.

AVERTISSEMENT : maintenir I'outil fermement a deux mains pour garder le contr_le de I'outil

au demarrage et pendant son utilisation, et ce, jusqu'a arr_t complet de la meule ou de tout autre

accessoire. Avant de poser I'outil, s'assurer que la meule s'est completement arr_tee de toumer.

Maintenez fermement la piece a.travailler a. raide d'un etau ou d'une bride. Portez un ecran facial

sur le nez et la bouche si I'operation produit de la poussiere. Utilisez la meule avec precautions.

Ne bloquez pas le disque dans la piece a. travailler et n'appliquez aucune pression inutile. Ne

meulez qu'avec la partie plane de la meule (Fig. 3), a.moins de posseder une meule con_ue tout

specialement pour le meulage lateral.

Precautions relatives au pon_;age de peinture

1. Le pon_age d'une peinture au plomb N'EST PAS RECOMMAND¢: en raison des difficultes

entourant lecontrOle de la poussiere contaminee. Le danger le plus important d'empoisonnement

au plomb touche les enfants et les femmes enceintes.

2. Etant donne qu'il est difficile d'identifier si une peinture contient ou non du plomb sans une

analyse chimique, nous recommandons de suivre les precautions suivantes Iors du pon_age

d'une peinture :

S#CURIT# PERSONNELLE

1. Les enfants et les femmes enceintes ne devraient pas entrer dans une zone de travail o_ se

fait le pon_age de la peinture avant que la zone n'ait ete entierement nettoyee.

2. Toutes les personnes entrant dans la zone de travail doivent porter un masque antipoussieres

ou un respirateur. Le filtre dolt _tre remplace chaque jour ou des que la personne qui le porte

eprouve de la difficulte a.respirer.

REMARQUE : seuls les masques antipoussieres qui conviennent pour le travail avec de la

poussiere et des emanations de peinture au plomb doivent _tre utilises. Les masques pour

peinture ordinaires n'offrent pas cette protection. Consulter le detaillant de quincaillerie de

votre region pour obtenir un masque antipoussieres homologue N.I.O.S.H.

3. EVlTER DE MANGER, BOIRE et FUMER dans la zone de travail pour emp_cher toute

ingestion de particules de peinture contaminee. Les travailleurs doivent se laver les mains

AVANT de manger, de boire ou de fumer. Ne pas laisser de nourriture, de breuvages ou

d'articles de fumeur dans la zone de travail oO ils risquent de recevoir de la poussiere.

RESPECT DE L'ENVIRONNEMENT

1. La peinture dolt _tre enlevee de fa_on a.minimiser la quantite de poussiere produite.

2. Les zones OL_la peinture est enlevee doivent _tre scellees avec des feuilles de plastique d'une

epaisseur de 101,6 t_m (4 mils).

3. Le pon_age dolt se faire de fa_on a.reduire le reperage de la poussiere de peinture a. I'exterieur

de la zone de travail.

NETTOYAGE ET MISE AU REBUT

1. Toutes les surfaces de la zone de travail doivent _tre nettoyees a.fond a.I'aide d'un aspirateur,

et ce, chaque jour, pour la duree du projet de pon_age. IIfaut changer regulierement les sacs

de filtre pour aspirateur.

2. Les toiles de peinture en plastique doivent _tre rassemblees et mises au rebut avec les

particules de poussiere ou tout autre debris d'enlevement. IIfaut les placer dans des recipients

a.rebut etanches et les eliminer par la collecte des ordures menageres.

Pendant le nettoyage, les enfants et les femmes enceintes doivent eviter de se trouver dans la

zone immediate de travail.

3. Tousles jouets, meubles lavables et les ustensiles utilises par les enfants doivent _tre nettoyes

a.fond avant de les utiliser de nouveau.

ENTRETIEN

_AVERTISSEMENT : pour r_duire le risque de blessures corporelles graves, _teindre

I'outil et le d_brancher avant d'effectuer tout r_glage ou d'enlever ou d'installer des

accessoires. Avant de rebrancher I'outil, enfoncer et rel&cher la d_tente pour s'assurer

que I'outil soil bien hers tension.

Nettoyage

_ AVERTISSEMENT : enlever la poussiere et la salete du moteur et de I'actionneur d'interrupteur

au moyen d'air comprime sec etpropre constitue une procedure d'entretien periodique necessaire.

IIarrive souvent que la poussiere et la salete, composees de particules metalliques, s'accumulent

sur les surfaces internes, ce qui peut causer un choc dectrique ou une dectrocution si un nettoyage

frequent n'est pas realise. IIest recommande d'utiliser un disjoncteur de fuite de terre afin de mieux

proteger I'utilisateur contre tout choc dectrique provoque par une accumulation de particules

conductrices. Sil'outil est desactive parle disjoncteur de fuite de terre, debrancher l' outil, le verifieret le

nettoyer avant de reenclencher le disjoncteur. TOUJOURS PORTERDES LUNETTES DESECURITE

(ANSIZ87.1) au moment de nettoyer ou d'utiliser cet outil.

AVERTISSEMENT: nejamais utiliser de solvants ni d'autres produits chimiques puissants pour

nettoyer les pieces non metalliques de I'outil. Ces produits chimiques peuvent affaiblir les materiaux

de plastique utilises dans ces pieces. Utiliser un chiffon humecte uniquement d'eau et de savon

doux. Nejamais laisser de liquide penetrer dans I'outil et n'immerger aucune pattie de I'outil dans

un liquide.

Lubrification

Cet outil electrique ne requiert aucune lubrificationadditionnelle.

Balais de moteur

DW887, DW887N

Veuillezcontacter votre centre de reparation local pour faire inspecter les balais.

DW888

Assurez-vous que routil est bien debranche avant d'inspecter les balais. Verifiez regulierement I'etat

des balais de charbon. Pour verifier les balais sur la DW888, devissez les capuchons plastiques

d'inspection des balais (situes de chaque cOte du bottler du moteur) de fa_on a.pouvoir retirer les

dispositifs ressort et balai de routil. Maintenez les balais propres et verifiez qu'ils glissent librement

dans leurs supports. Les balais de charbon comportent des symboles varies, et si le balai est use

au niveau de laligne laplus proche du ressort, il faut le changer. Des modules de balais sont a.votre

disposition chez votre centre de reparation local.

Accessoires

•_AVERTISsEMENT: puisque les accessoires autres que ceux offerts par DEWALT n'ont pas

ete testes avec ce produit, I'utilisation de ceux-ci avec I'outil pourrait s'averer dangereuse. Pour

reduire le risque de blessures, utiliser exclusivement les accessoires DEWALT recommandes avec

ce produit.

Les accessoires recommandes pour utilisation avec I'outil sont disponibles, a.un co_t supplementaire,

aupres du distributeur ou du centre de reparation autorise de votre region. Pour toute demande

d'assistance pour trouver un accessoire, communiquer avec DfiiiWaltIndustrial Tool Co., 701 East

Joppa Road, Baltimore, MD 21286, Etats-Unis, composer le 1 800 433-9258 (1 800 4-DEWALT)

ou visiter le site Web www.dewalt.com.

Page 5

AVERTISSEMENT :pour reduire lerisque de blessure, TOUJOURS utiliser les protege-meules

adequats pour lemeulage et porter une protection oculaire appropriee.

ACCESSOIRES POUR LES MEULES .ARECTIFIER LES MATRICES

Pierres et meules sur tige

Rdparations

Pour assurer la S¢:CURITE et la FIABILIT¢:du produit, les reparations, I'entretien et les reglages (y

compris I'inspection et leremplacement des balais) doivent _tre realises par un centre de reparation

en usine DEWALT, un centre de reparation autorise DEWALT ou par un personnel de reparation

professionnel. Toujours utiliser des pieces de rechange identiques.

Garantie limitde trois ans

DEWALTreparera gratuitement tousles problemes dus a.des defauts de materiau ou defabrication

pendant trois ans a.compter de la date d'achat. Cette garantie ne couvre pas des defaillances de

piece dues a.une usure normale ou a.une mauvaise utilisation de I'outil. Pour plus de details relatifs

a.la couverture de la garantie et aux reparations sous garantie, visiter le site Web www.dewalt.

com ou composer le 1 800 433-9258 (1 800 4-DEWALT). Cette garantie ne s'applique pas aux

accessoires ni aux dommages causes par des reparations realisees ou tentees par des tiers. Cette

garantie vous accorde des droits legaux specifiques et ilest possible que vous ayez d'autres droits

qui varient d'un Etat ou d'une province a.I'autre.

En plus de la garantie, les outils DEWALT sont couverts par notre '

SERVICE D'ENTRETIEN GRATUIT DE 1 AN

DEWALT entretiendra I'outil et remplacera les pieces usees par une utilisation normale et ce,

gratuitement, a. tout instant pendant la premiere annee a.compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n'_tes pas entierement satisfait des performances de votre outil electrique, laser ou de votre

marteau-cloueur DEWALT pour quelque raison que ce soit, vous pouvez le retourner accompagne

d'un re_u dans les 90 jours suivant la date d'achat et nous vous rembourserons entierement - sans

poser de questions.

AMI_RIQUE LATINE : cette garantie ne s'applique aux produits vendus en Amerique latine.

Pour ceux-ci, veuillez consulter les informations relatives a. la garantie specifique presente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives a.

cette garantie.

REMPLACEMENT GRATUIT DES I_TIQUETTES D'AVERTISSEMENT : si les etiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 800 433-9258