Page 1

DW706 (120 Volt) DW706 (230 Volt)

12" Double Bevel Compound Miter Saw

Scie à onglet à angles combinés à biseau double de 30,5 cm (12 po)

Sierras de ingletes de bisel doble del 30,5 cm (12")

INSTRUCTION MANUAL

GUIDE D´UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Before returning this product call

1-800-4-D

E

WALT

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF D

EWALT'S

QUALITY IMPROVEMENT PROGRAM.

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

English

TABLE OF CONTENTS

DOUBLE INSULATION/POLARIZED PLUG INSTRUCTIONS ....................................1

SAFETY INSTRUCTIONS FOR ALL TOOLS ....…………………………………………1

ADDITIONAL SAFETY RULES........……………………………………………………….1

ELECTRICAL CONNECTION ......…………………………………………………………2

ACCESSORIES ..............................................................................................................2

BLADE RECOMMENDATIONS......................................................................................3

UNPACKING YOUR SAW ........……………………………………………………………3

SPECIFICATIONS ..........................................................................................................4

FAMILIARIZATION......………………………………………………………………………4

BENCH MOUNTING ......……………………………………………………………………4

INSTALLING THE BLADE ........……………………………………………………………4

TRANSPORTING THE SAW ........…………………………………………………………5

ADJUSTMENTS ......…………………………………………………………………………6

MITER SCALE ADJUSTMENT....………………………………………………………6

MITER POINTER ADJUSTMENT ..……………………………………………………6

BEVEL SQUARE TO TABLE ....................................................................................6

BEVEL POINTER ......................................................................................................6

BEVEL STOP ADJUSTMENT ..................................................................................6

FENCE ADJUSTMENT …………………………………………………………………6

AUTOMATIC ELECTRIC BRAKE ..............................................................................6

GUARD ACTUATION AND VISIBILITY..………………………………………………7

BRUSHES ........………………………………………………………………………………7

CONTROLS ....................................................................................................................7

OPERATION....................................................................................................................7

SWITCH ..........................................................................................................................7

CUTTING WITH YOUR SAW ........................................................................................7

CROSSCUTS ....................................................................................................................7

BEVEL CUTS ....................................................................................................................8

QUALITY OF CUT ............................................................................................................8

BODY AND HAND POSITION ..........................................................................................8

CLAMPING THE WORKPIECE......................................................................................8

SUPPORT FOR LONG PIECES ....................................................................................9

CUTTING PICTURE FRAMES, SHADOW BOXES

AND OTHER FOUR SIDED PROJECTS ......................................................................9

CUTTING TRIM MOLDING AND OTHER FRAMES ....................................................9

CUTTING COMPOUND MITERS ..................................................................................9

VERNIER SCALE ..............................................................................................................9

CUTTING BASE MOLDING..........................................................................................10

CUTTING CROWN MOLDING ....................................................................................10

SPECIAL CUTS ............................................................................................................11

REMOVING AND REPLACING THE BELT ................................................................11

TABLE 1: COMPOUND MITER CUT ..........................................................................12

MAINTENANCE ............................................................................................................13

WARRANTY ..................................................................................................................13

TROUBLESHOOTING GUIDE ....................................................................................14

Page 3

1

English

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

Important Safety Instructions

WARNING: When using electric tools, basic safety precautions should always

be followed to reduce risk of fire, electric shock, and personal injury, including

the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers of electrical insulation or one double thickness of insulation between you and the tool’s electrical system. Tools

built with this insulation system are not intended to be grounded. As a result, your tool is

equipped with a two prong plug which permits you to use extension cords without concern for

maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precautions when operating

this tool. The insulation system is for added protection against injury resulting from a possible

electrical insulation failure within the tool.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Repair

or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on equipment to reduce the risk of

electric shock. When provided, this plug will fit in the polarized outlet only one way. If the plug

does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not change the plug in any way.

Safety Instructions For All Tools

• KEEP GUARD IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from spindle before turning tool on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet loca-

tions, or expose them to rain or snow. Keep work area well lighted.

• KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter

keys.

• DON’T FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other

jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear protective

hair covering to contain long hair. Air vents may cover moving parts and should also be

avoided.

• ALWAYS WEAR SAFETY GLASSES. Also use face or dust mask if cutting operation is

dusty. Everyday eyeglasses have only impact resistant lenses, they are NOT safety

glasses.

• SECURE WORK. Use clamps or vise when you cannot secure the workpiece on the table

and against the fence by hand or when your hand will be dangerously close to the blade

(within 6").

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest perfor-

mance. Follow instructions for lubricating and changing accessories.

• DISCONNECT TOOLS before servicing; when changing accessories such as blades,

bits, cutters, etc.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in OFF

position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the instruction manual for recommend-

ed accessories. The use of improper accessories may cause risk of injury to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting

tool is unintentionally contacted.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its intended function—check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting and any other conditions that may affect its operation. A

guard or other part that is damaged should be properly repaired or replaced. Do not use

tool if switch does not turn it on and off.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool

until it comes to a complete stop.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors in these tools may spark and

ignite fumes.

• EXTENSION CORDS. Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage

number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

ThanThan

0- 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Additional Safety Rules For Miter Saws

CAUTION: FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL

INJURY AND SERIOUS DAMAGE TO THE SAW.

• DO - Protect electric supply line with at least a 15 ampere time-delay fuse or a circuit

breaker.

• DO - Make certain the blade rotates in the correct direction and that the teeth at the bottom

of the blade are pointing to the rear of the miter saw.

• DO - Be sure all clamp handles are tight before starting any operation.

• DO - Be sure all blade and clamp washers are clean and recessed sides of collars are

against blade. Tighten arbor screw securely.

• DO - Keep saw blade sharp.

• DO - Keep motor air slots free of chips and dirt.

• DO - Use blade guards at all times.

• DO - Keep hands out of path of saw blade.

• DO - Shut off power, disconnect cord from power source and wait for saw blade to stop

before servicing or adjusting tool.

• DO - Support long work with an outboard tool rest.

Page 4

2

English

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

ALWAYS WEAR EYE PROTECTION.

ON MOVING FENCES:

ALWAYS ADJUST FENCE PROPERLY

BEFORE USE. Clamp small pieces

before cutting. See manual.

ON GUARD:

DANGER – KEEP AWAY FROM BLADE.

ON UPPER GUARD:

PROPERLY SECURE BRACKET WITH BOTH SCREWS BEFORE USE.

ON TABLE:

(2 PLACES)

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE. KEEP

HANDS 6" FROM PATH OF SAW BLADE.

NEVER PERFORM ANY OPERATION FREEHAND.

NEVER CROSS ARMS IN FRONT OF BLADE.

THINK! YOU CAN PREVENT ACCIDENTS.

DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE. TURN OFF

TOOL, KEEP SAW HEAD DOWN AND WAIT FOR SAW TO STOP

BEFORE MOVING HANDS, WORKPIECE OR CHANGING SETTINGS.

UNPLUG TOOL BEFORE CHANGING BLADE, MOVING OR SERVICING UNIT.

ON BASE:

Electrical Connection

Be sure your power supply agrees with the nameplate marking. 120 volts, AC means that your

saw will operate on alternating current. The switch is suseptible to failure if direct current is

used. A voltage decrease of 10 percent or more will cause a loss of power and overheating. All

D

EWALT tools are factory tested. If this tool does not operate, check the power supply.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

service center.

CAUTION: The use of any non-recommended accessory such as dado sets, molding cut-

ters, or abrasive wheels may be hazardous.

If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286 or call 1-800-4-D

EWALT (1-800-433-9258).

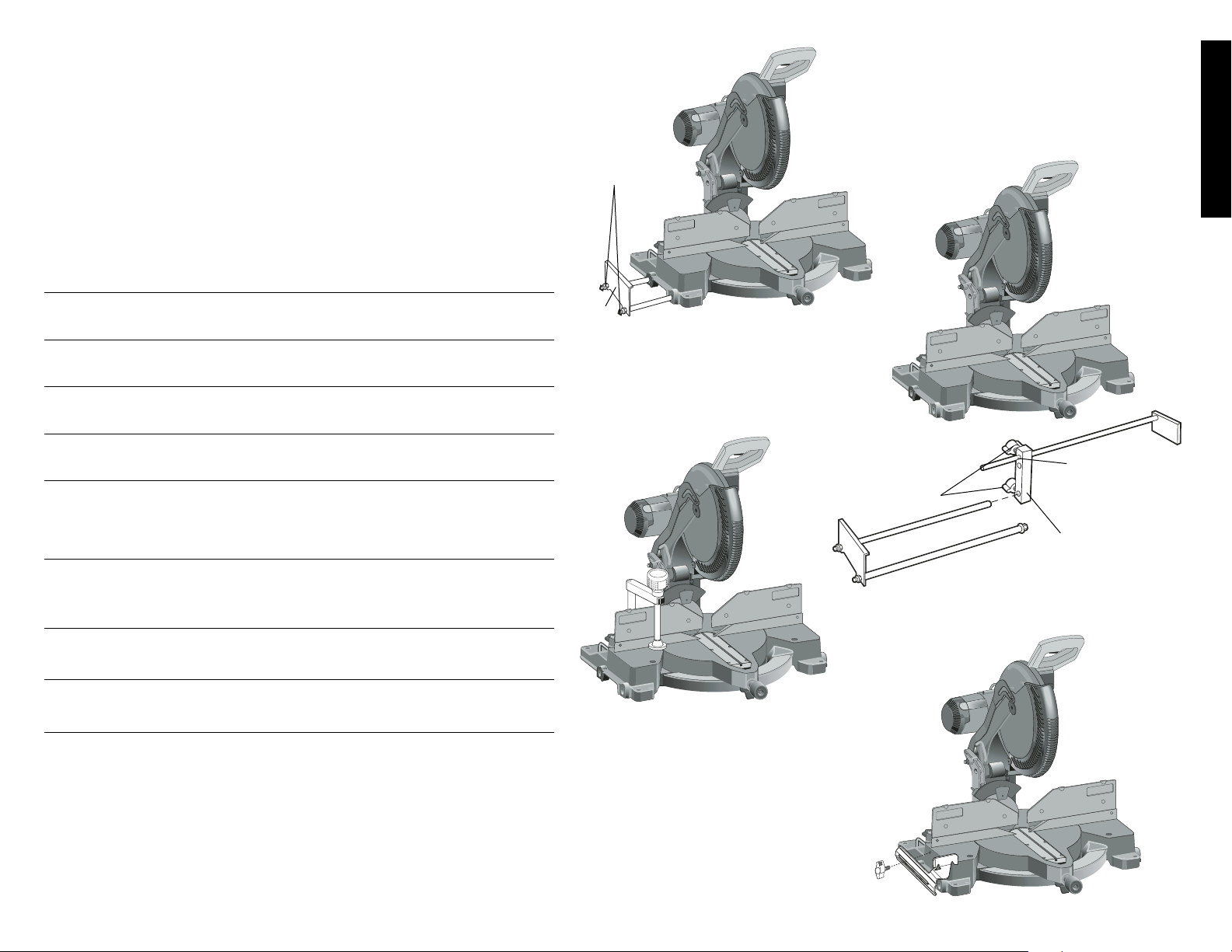

Optional Accessories

The following accessories, designed for your saw, may be helpful. In some cases, other locally obtained work supports, length stops, clamps, etc., may be more appropriate. Use care in

selecting and using accessories.

Extension, Work Support: DW7080

Used to support long overhanging workpieces, the work support is user assembled. Your saw

table is designed to accept two work supports; one on each side.

Adjustable Length Stop: DW7051

Requires the use of one work support (see drawing). It is used to make repetitive cuts of

the same length from 0 to 42".

Clamp: DW7082

Used for firmly clamping workpiece to the saw table for precision cutting (Page 3).

• DON’T - Attempt to operate on anything but designated voltage.

• DON’T - Operate unless all clamp handles are tight.

• DON’T - Use blades larger or smaller than those which are recommended.

• DON’T - Wedge anything against fan to hold motor shaft.

• DON’T - Force cutting action. (Stalling or partial stalling of motor can cause major damage.

Allow motor to reach full speed before cutting.)

• DON’T - Cut ferrous metals (Those with any iron or steel content) or any masonry.

• DON’T - Use abrasive wheels. The excessive heat and abrasive particles generated by

them will damage the saw.

• DON’T - Allow anyone to stand behind saw.

• DON’T - Apply lubricants to the blade when it’s running.

• DON’T - Place either hand in the blade area when the saw is connected to the power

source.

• DON’T - Use blades rated less than 4800 R.P.M.

• DO NOT - Cut small pieces without clamping. Keep hands 6” or more from blade.

• DON’T - Operate saw without guards in place.

• DON’T - Perform any operation freehand.

• DON’T - Reach around or behind saw blade.

• DON’T - Place hands closer than 6 inches from the saw blade.

• DO NOT - Reach underneath the saw unless it is turned off and unplugged. The saw

blade is exposed on the underside of the saw.

• DO NOT - Move either hand from saw or workpiece or raise arm until blade has stopped.

• DO NOT - Use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the

plastic guard. The polycarbonate material used in the guard is subject to attack by

certain chemicals.

• Never use without kerf plate, and replace when kerf plate is damaged because small chip

accumulation under saw may interfere with saw blade or may cause instability of workpiece when cutting.

CAUTION: Do not connect unit to electrical power source until complete instructions are

read and understood.

CAUTION: Wear appropriate personal hearing protection during use. Under some

conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face and body.

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE

OPERATING SAW.

Page 5

3

English

Dust Bag: DW7053 (Included with some models)

Equipped with a zipper for easy emptying, the dust bag will capture the majority of

the sawdust produced. (Not shown)

NOTE: Deflector on dust spout channels debris to ground. Spout has a provision

to attach a vacuum hose to collect sawdust. Lift dust spout to connect hose.

Crown Molding Fence: DW7084

Used for precision cutting of crown molding.

Kerf Plate Blank: DW7055

Used to limit back side tear out of material or as a replacement kerf plate.

SAW BLADES: ALWAYS USE 12" SAW BLADES WITH 1" ARBOR HOLES. SPEED

RATING MUST BE AT LEAST 4800 RPM. Never use a smaller diameter blade. It will

not be guarded properly.

D

EWALT NO. OF BLADE APPLICATION TYPE OF CUT

BLADE TEETH DESC.

RANGE

Series 20 40 Thin Kerf Gen. Purpose Smooth,

Construction Yellow Rim (Trim, Decking, Splinter Free

Coating Framing)

Series 20 60 Thin Kerf Fine Trim Very Smooth,

Construction Yellow Rim Molding Splinter Free

Coating

Series 40 40 Laser Cut Body Gen. Purpose Smooth,

Woodworking Large Carbide (Trim, Decking, Splinter Free

Teeth Framing)

Series 40 60 Laser Cut Body Fine Trim, Very Smooth,

Woodworking Large Carbide Molding Splinter Free

Teeth

Series 40 80 Laser Cut Body Fine Trim Ultra Smooth,

Woodworking Large Carbide Molding Splinter Free

Teeth Decorative

Hardwood

& Plywood

Series 40 80 Laser Cut Body Melamines, Ultra Smooth

Woodworking Large Carbide Veneers, Chip/Splinter

Teeth, Special Laminates Free

Tooth Geometry

Series 40 60 Laser Cut Body Plastics, Corian® Very Smooth

Woodworking Special Tooth and other solid Chip Free

Geometry surface materials

Series 40 80 Laser Cut Body Non-ferrous metals Very Smooth

Woodworking Special Tooth (aluminum, copper, Burr Free

Geometry brass, etc.)

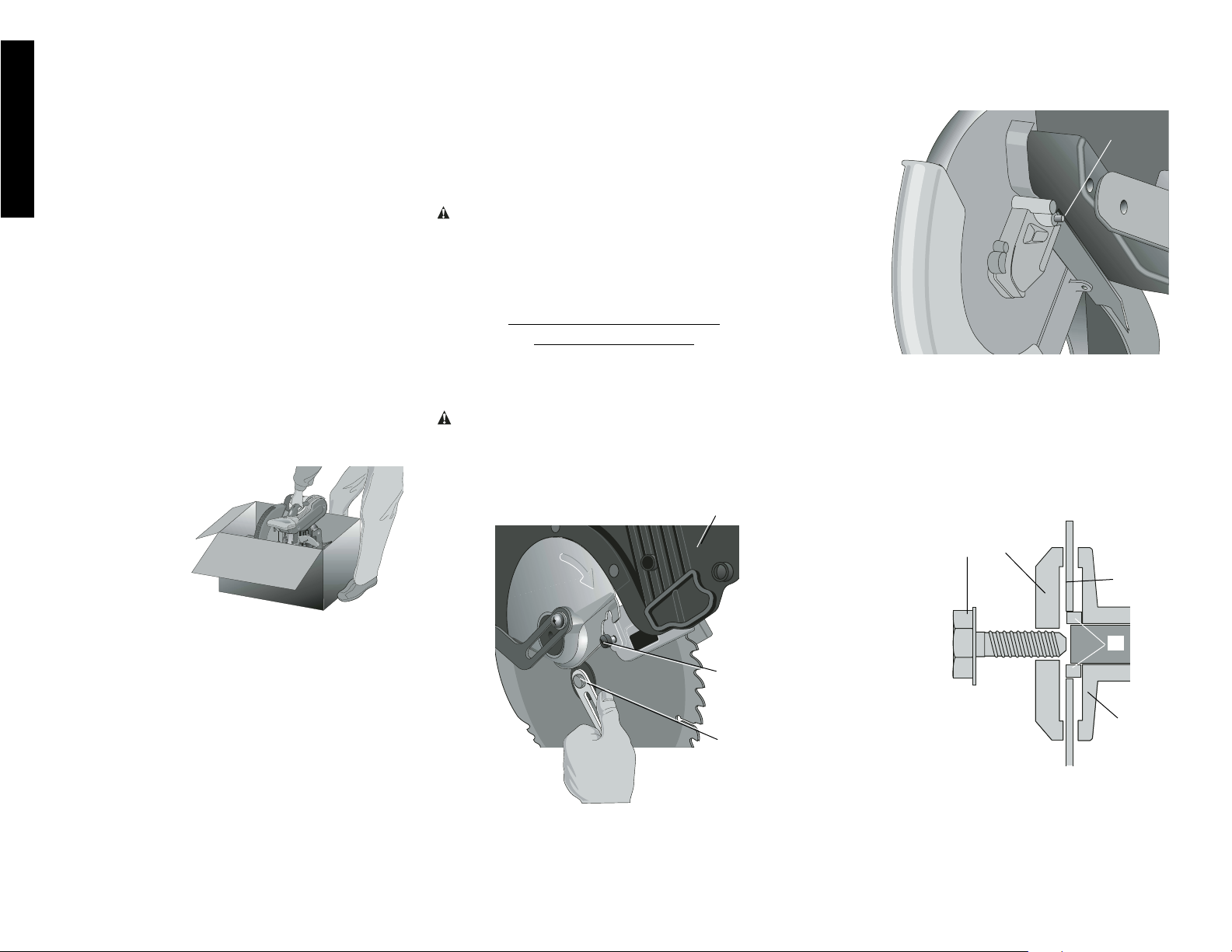

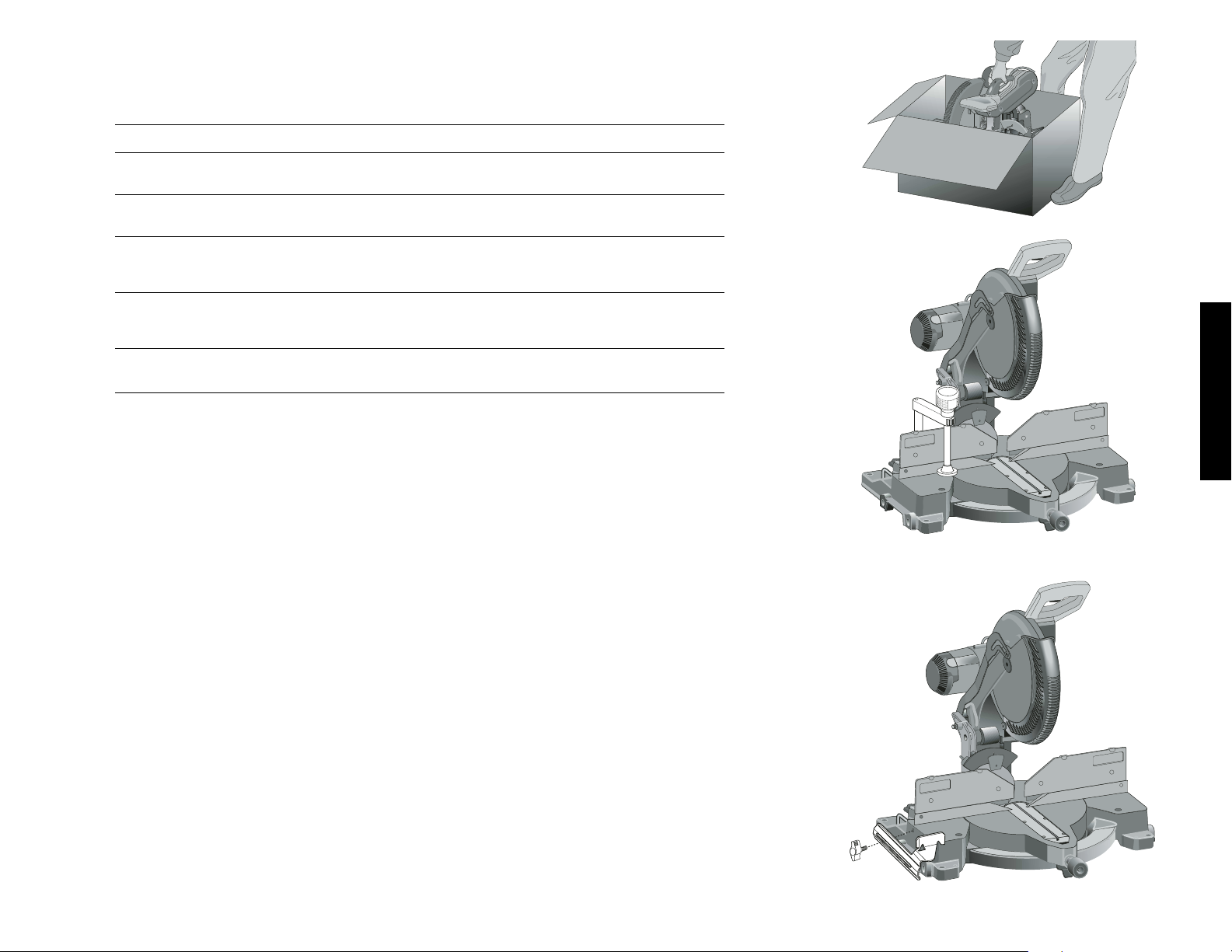

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have received all

parts. In addition to this instruction manual, the carton should contain:

1. One No. DW706 miter saw.

2. One D

EWALT 12" dia. saw blade

3. One blade wrench in wrench pocket shown in Figure 2.

4. One DW7053 dustbag (some models)

DW7051

KNOBS

BRACKET

TOP HOLE

(USE FOR

DW706)

LOCKNUTS

END

PLATE

DW7080

DW7082

DW7084

Page 6

4

English

3. Loosen, but do not remove guard bracket screw (B)

until the bracket can be raised far enough to access the

blade screw. Lower guard will remain raised due to the

position of the guard bracket screw.

4. Depress the spindle lock button (C) while carefully

rotating the saw blade by hand until the lock engages.

5. Keeping the button depressed, use the other hand and

the wrench provided (D) to loosen the blade screw.

(Turn clockwise, left-hand threads)

6. Remove the blade screw (E), outer clamp washer (F),

and blade (G). The 1" (25.4mm) blade adapter (H), if

used, and the inner clamp washer (I), may be left on

the spindle.

NOTE: For blades with a blade hole of 5/8" (15.88mm), the

1" (25.4mm) blade adapter is not used.

Installing a Blade

1. Unplug the saw.

2. With the arm raised, the lower guard held open and

the pivot plate raised, place the blade on the spindle,

onto the blade adapter [if using a blade with a 1"

-DETAIL 2-

E

F

G

I

H

C

-DETAIL 1-

Specifications

CAPACITY OF CUT

50˚ miter left and right

48˚ bevel left and right

0˚ miter Max. Height 3.5" Result Width 7.4"

Max. Width 7.9" Result Height 2.9"

45˚ miter Max. Height 3.5" Result Width 5.3"

Max. Width 5.6" Result Height 2.9"

45˚ bevel - Left Max. Height 2.3" Result Width 7.4"

Max. Width 7.9" Result Height 1.9"

45˚ bevel - Right Max. Width 7.9” Result Height 1.2"

Max. Height 1.6" Result Width 7.4”

Your saw is capable of cutting baseboard moldings 0.9” thick

by 6.0” tall on a 45˚ right or left miter.

DRIVE

120 Volt Motor

2200 Watts 15 Amp Motor

4000 RPM Cut Helical Gears

Multi-V Belt Roller Bearings

Automatic Electric Brake Carbide Blade

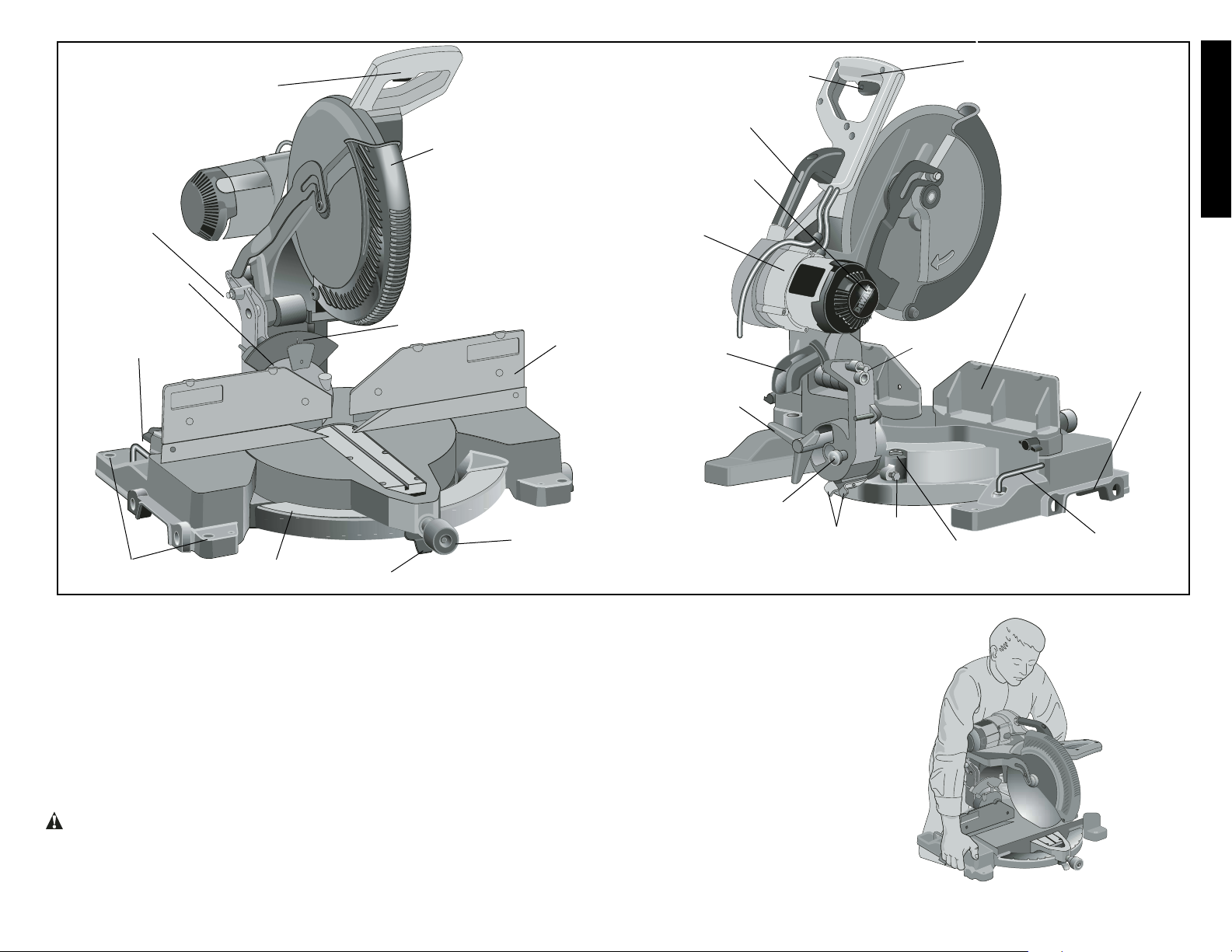

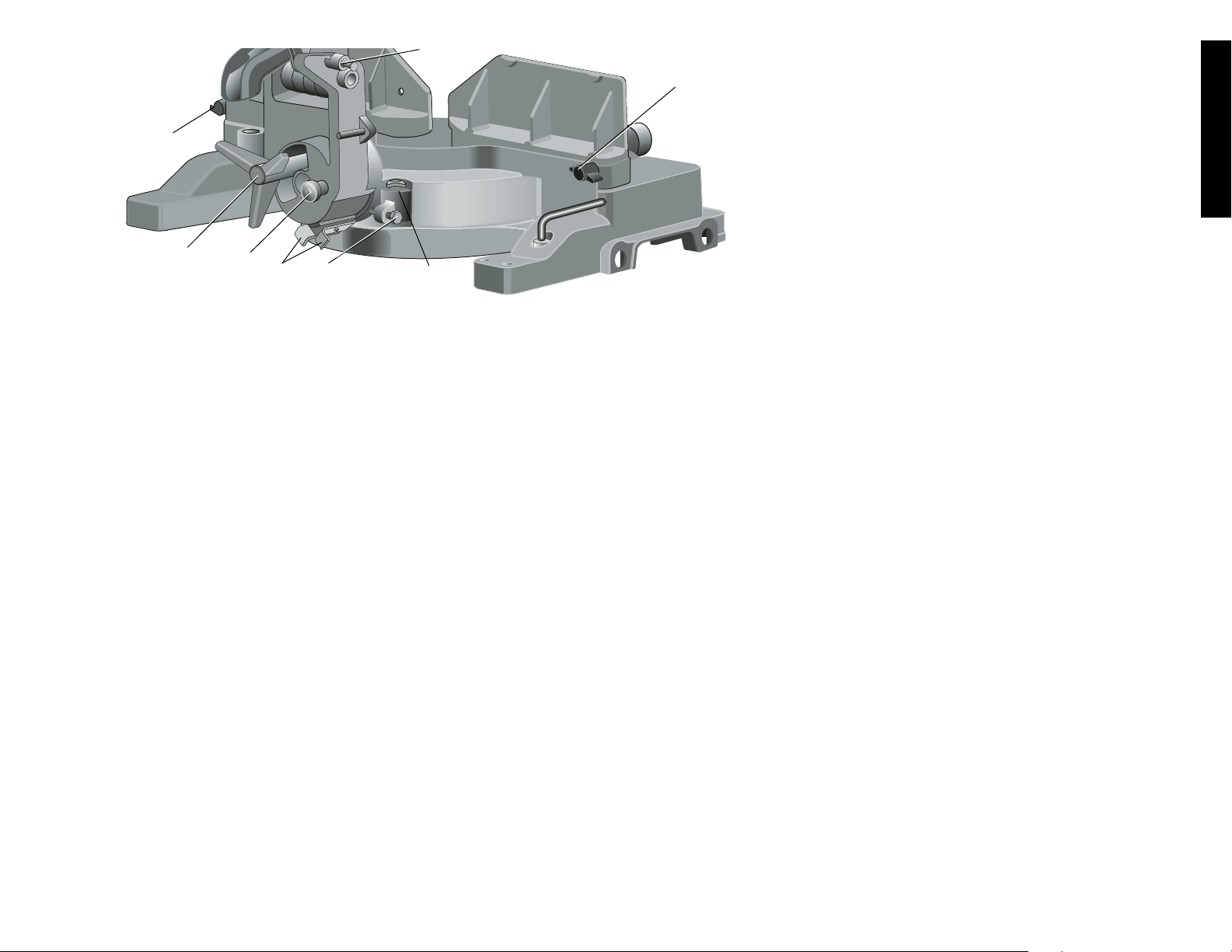

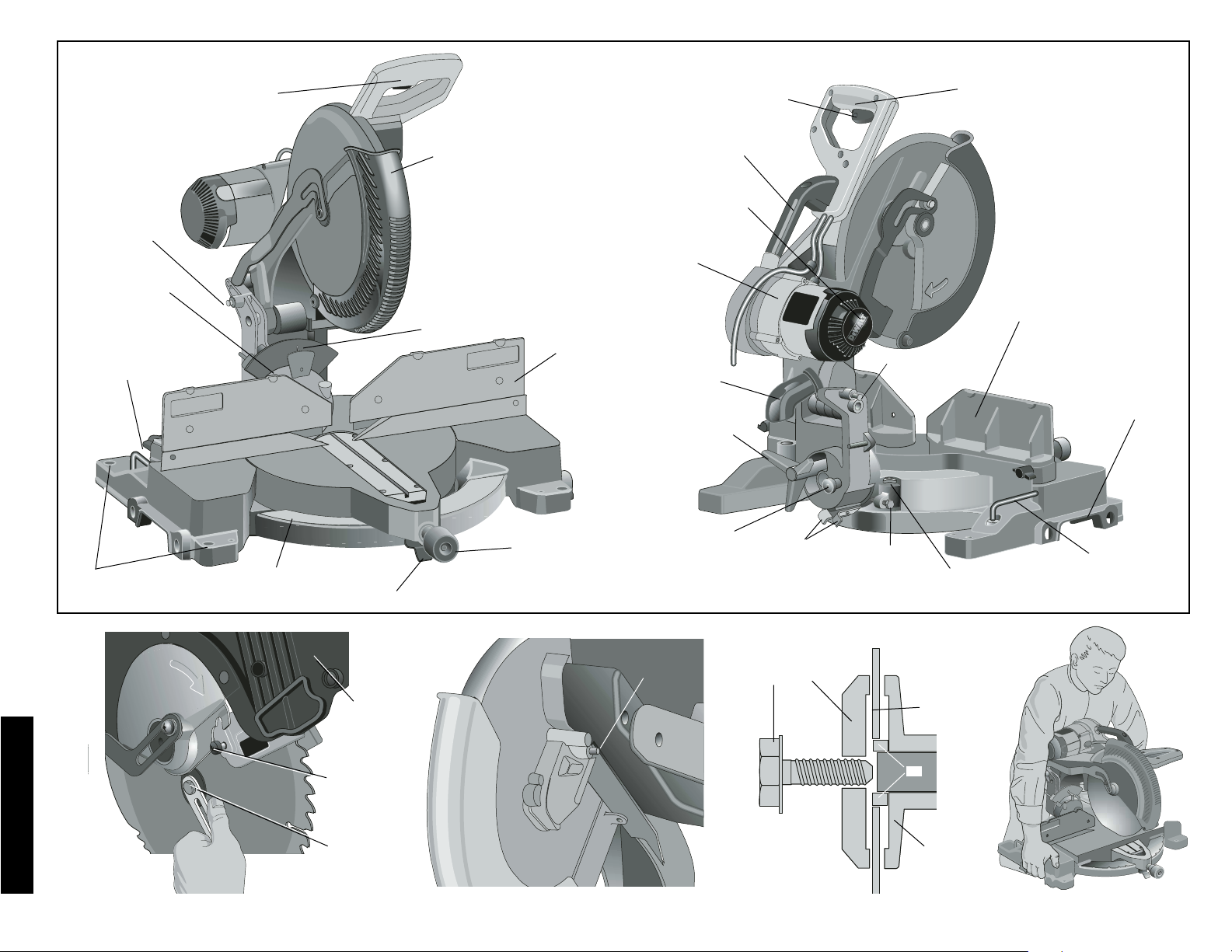

Familiarization

Your miter saw is fully

assembled in the carton. Open the box and

lift the saw out by the

convenient carrying

handle, as shown in

Figure 1.

Place the saw on a

smooth, flat surface

such as a workbench or

strong table.

Examine the two figures on page 5 to become familiar with

the saw and its various parts. The section on adjustments

will refer to these terms and you must know what and where

the parts are.

Press down lightly on the operating handle and pull out the

lock down pin, as shown in Figure 2. Gently release the

downward pressure and hold the arm allowing it to rise to its

full height. Use the lock down pin when carrying the saw from

one place to another. Always use the carrying handle to

transport the saw or the hand indentations shown in Fig. 2.

Bench Mounting

Holes are provided in all four feet to facilitate bench mounting, as shown in Figure 2. (Two different sized holes are provided to accommodate different sizes of screws. Use either

hole, it is not necessary to use both.) Always mount your

saw firmly to a stable surface to prevent movement. To

FIG. 1

enhance the tool’s portability, it can be mounted to a piece

of 1/2" or thicker plywood which can then be clamped to

your work support or moved to other job sites and

reclamped.

NOTE: If you elect to mount your saw to a piece of plywood, make sure that the mounting screws don’t protrude

from the bottom of the wood. The plywood must sit flush on

the work support. When clamping the saw to any work surface, clamp only on the clamping bosses where the mounting screw holes are located. Clamping at any other point

will surely interfere with the proper operation of the saw.

CAUTION: To prevent binding and inaccuracy, be sure

the mounting surface is not warped or otherwise uneven. If

the saw rocks on the surface place a thin piece of material

under one saw foot until the saw sits firmly on the mounting

surface.

IMPORTANT SAFETY

INSTRUCTIONS

Changing or Installing a New Saw

Blade (Fig. 3)

CAUTION:

• Never depress the spindle lock button while the blade is

under power or coasting.

• Do not cut ferrous metal (containing iron or steel) or

masonry or fiber cement product with this miter saw.

Removing the Blade

1. Unplug the saw.

2. Raise the arm to the upper position and raise the lower

guard (A) as far as possible.

A

B

D

FIG. 3

Page 7

5

English

FIG. 2

GUARD

RIGHT SIDE

FENCE

MITER

CLAMP

KNOB

MITER

LATCH

MITER

SCALE

BENCH MOUNTING

HOLES

LEFT SIDE FENCE

CLAMPING KNOB

LOCK DOWN

PIN

OPERATING HANDLE

BEVEL SCALE

FIG. 4

TRIGGER

SWITCH

OPERATING

HANDLE

LEFT SIDE

FENCE

MOTOR

HOUSING

45˚ BEVEL

OVERRIDE

LEVERS

DUST

SPOUT

MOTOR END

CAP

0˚ BEVEL

OVERRIDE

KNOB

LOCK DOWN

PIN

BEVEL STOP–

33.85˚ PAWLS

CARRY HANDLE

BLADE

WRENCH

45˚

BEVEL STOP–

ADJUSTMENT

SCREW

BEVEL

LOCK

KNOB

HAND

INDENTATIONS

0˚ BEVEL STOP

ADJ. SCREW

(25.4mm) diameter blade hole] and against the inner

clamp washer with the teeth at the bottom of the blade

pointing toward the back of the saw.

3. Assemble the outer clamp washer onto the spindle.

4. Install the blade screw and, engaging the spindle lock,

tighten the screw firmly with wrench provided. (Turn

counterclockwise, left-hand threads)

NOTE: When using blades with a 5/8" (15.88mm) diameter

blade hole, the blade adapter will not be used and should be

stored in a safe place for future use.

5. Return the guard bracket to its original position and

firmly tighten the guard bracket screw to hold bracket in

place.

WARNING:

• The guard bracket must be returned to

its original position and the screw tightened before activating the saw.

• Failure to do so may allow the guard to

contact the spinning saw blade resulting in damage to the saw and severe

personal injury.

Transporting the Saw

TURN OFF AND UNPLUG THE MITER SAW BEFORE

ATTEMPTING TO MOVE IT OR MAKE ANY ADJUSTMENTS WHAT SO EVER!

In order to conveniently carry the miter saw from place to

place, a carrying handle has been included on the top of the

saw arm and hand indentations in the base, as shown in

Figure 4.

Page 8

6

English

FIG. 7

FIG. 6

MITER

SCALE

POINTER

J

K

T

To adjust the right 45˚ bevel angle, loosen the bevel lock

handle and pull the bevel stop override knob (Fig. 2) to override the 0˚ bevel stop. When the saw is fully to the right, if

the pointer does not indicate exactly 45˚, turn the right bevel

stop screw (O) until the pointer indicates 45˚.

To adjust the left 45˚ bevel stop, first loosen the bevel lock

handle and tilt the head to the left. If the pointer does not

indicate exactly 45˚, turn the left bevel stop screw until the

pointer reads 45˚.

ADJUSTING THE BEVEL STOP TO 33.85˚ (FIG. 9)

NOTE: Adjust the 33.85˚ bevel angles only after performing

the 0˚ bevel angle and pointer adjustment.

To set the 33.85˚ bevel angle, flip out the stop pawls (P).

Loosen the bevel lock handle (Q) and tilt the head to the left.

If the pointer does not indicate exactly 33.85˚, turn the screw

contacting the pawl until the pointer reads 33.85˚.

To adjust the right 33.85˚ bevel angle, flip out the stop pawl.

Loosen the bevel lock handle and pull the bevel stop override button to override the 0˚ bevel stop. When the saw is

fully to the right, if the pointer does not indicate exactly

33.85˚, turn the screw contacting the pawl until the pointer

indicates 33.85˚.

FENCE ADJUSTMENT

Turn Off and Unplug the Miter Saw

In order that the saw can bevel to a full 48 degrees left or

right, the fences can be adjusted to provide clearance. To

adjust a fence, loosen the plastic knob (Figure 9, R), and

slide the fence outward. Make a dry run with the saw turned

off and check for clearance. Adjust the fence to be as close

to the blade as practical to provide maximum workpiece

support, without interfering with arm up and down movement. Tighten knob securely. When the bevel operations are

complete, don’t forget to relocate the fence.

NOTE: The guide groove of the fences can become clogged

with sawdust. If you notice that it is becoming clogged, use

a stick or some low pressure air to clear the guide groove.

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an automatic electric blade brake

which stops the saw blade within 5 seconds of trigger

release. This is not adjustable.

On occasion, there may be a delay after trigger release to

brake engagement. On rare occasions, the brake may not

engage at all and the blade will coast to a stop.

If a delay or “skipping” occurs, turn the saw on and off 4 or

5 times. If the condition persists, have the tool serviced by

an authorized D

EWALT service center.

Always be sure the blade has stopped before removing it

from the kerf. The brake is not a substitute for guards or for

ensuring your own safety by giving the saw your complete

attention.

FIG. 5

FIG. 8

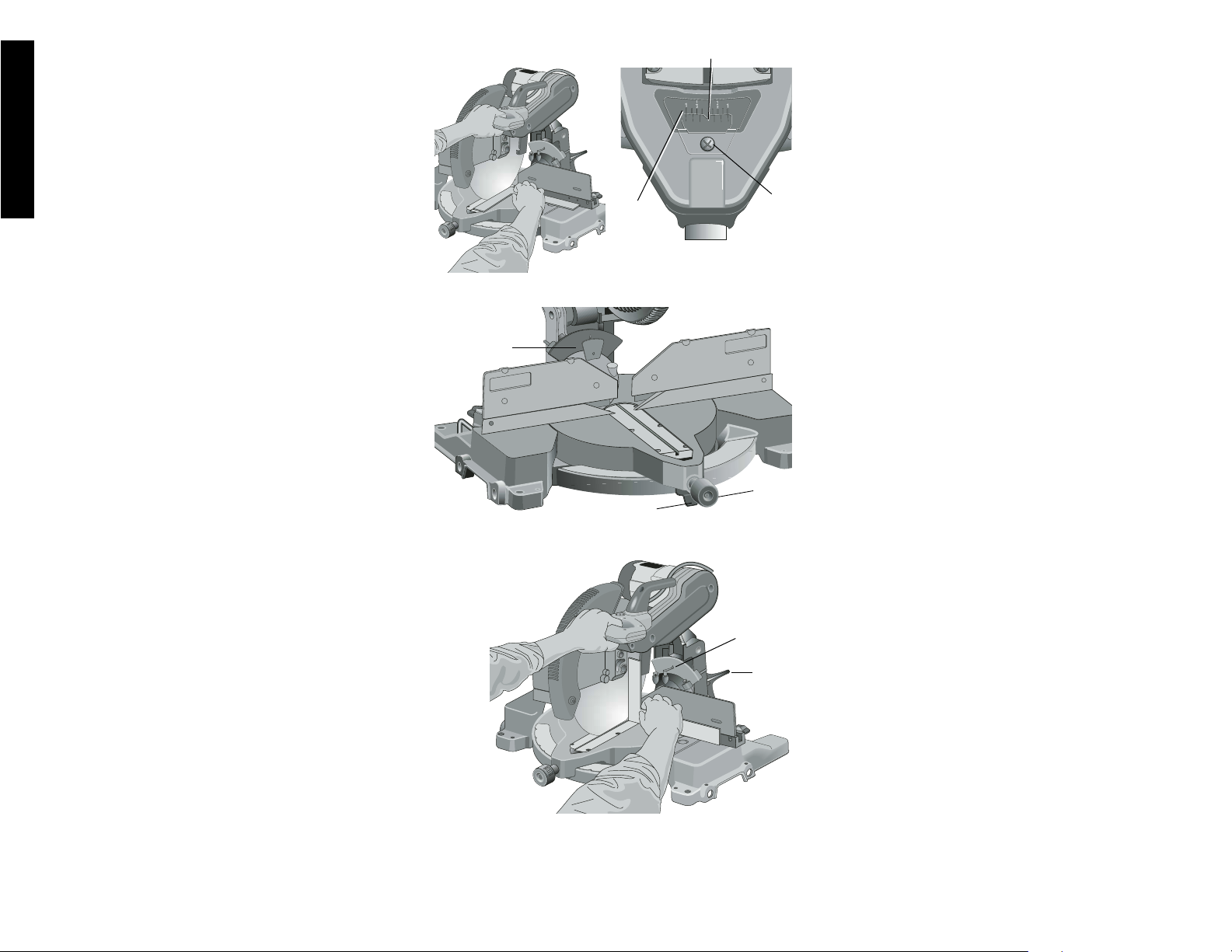

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE MITER

SAW UNPLUGGED

NOTE: Your miter saw is fully and accurately adjusted at the

factory at the time of manufacture. If readjustment due to

shipping and handling or any other reason is required, follow

the steps below to adjust your saw.

Once made, these adjustments should remain accurate.

Take a little time now to follow these directions carefully to

maintain the accuracy of which your saw is capable.

MITER SCALE ADJUSTMENT (FIG. 5)

Place a square against the saw’s fence and blade, as

shown. (Do not touch the tips of the blade teeth with the

square. To do so will cause an inaccurate measurement.)

Loosen the miter clamp knob and swing the miter arm until

the miter latch locks it at the 0 miter position. Do not tighten

the clamp knob. If the saw blade is not exactly perpendicular to the fence, loosen the three screws that hold the miter

scale to the base and move the scale left or right until the

blade is perpendicular to the fence, as measured with the

square. Retighten the three screws. Pay no attention to the

reading of the miter pointer at this time.

MITER POINTER ADJUSTMENT (FIG. 6, 7)

Loosen the miter clamp knob (J) Fig. 7 by turning counterclockwise and squeeze the miter latch (K) to move the miter

arm to the zero position. With the miter clamp knob loose

allow the miter latch to snap into place as you rotate the

miter arm to zero. Observe the pointer and miter scale

through the viewing opening shown in Figure 6. If the pointer does not indicate exactly zero, loosen the screw holding

the pointer in place, reposition the pointer and tighten the

screw.

BEVEL SQUARE TO TABLE (FIG. 8)

To align the blade square to the rotary table, lock the arm in

the down position. Place a square against the blade taking

care to not have the square on top of a tooth. Loosen the

bevel lock knob (L) and ensure the arm is firmly against the

0˚ bevel stop. Move the 0˚ bevel stop adjusting screw as

necessary so that the blade is at zero degrees bevel to the

table.

BEVEL POINTER (FIG. 8)

If the bevel pointer (M) does not indicate zero, loosen the

screw that holds it in place and move the pointer as necessary. Do not remove the steel plate in front of the bevel

pointer. This plate prevents wood resin from accumulating

on the bevel scale during use.

ADJUSTING THE BEVEL STOP TO 45˚ LEFT OR RIGHT

(FIG. 9)

NOTE: Adjust the 45˚ bevel angles only after performing the

0˚ bevel angle and pointer adjustment. Ensure the 45˚ bevel

override levers (N) are pushed inward to obtain an accurate

adjustment.

POINTER

ADJUST.

SCREW

L

M

Page 9

7

English

FIG. 9

GUARD ACTUATION AND VISIBILITY

The blade guard on your saw has been designed to automatically raise when the arm is brought down and to lower

over the blade when the arm is raised.

The guard can be raised by hand when installing or removing saw blades or for inspection of the saw. NEVER RAISE

THE BLADE GUARD MANUALLY UNLESS THE SAW IS

TURNED OFF.

NOTE: Certain special cuts of large material will require that

you manually raise the guard. See page 11.

The front section of the guard is louvered for visibility

while cutting. Although the louvers dramatically reduce flying debris, they are openings in the guard and safety

glasses should be worn at all times when viewing through

the louvers.

Brushes

DISCONNECT PLUG FROM POWER SUPPLY

Inspect carbon brushes regularly by unplugging tool, removing the motor end cap (Fig. 2), lift the brush spring and withdraw the brush assembly. Keep brushes clean and sliding

freely in their guides. Always replace a used brush in the

same orientation in the holder as it was prior to its removal.

Carbon brushes have varying symbols stamped into their

sides, and if the brush is worn down to approximately 1/2

inch, the spring will no longer exert pressure and they must

be replaced. Use only identical D

EWALT brushes. Use of

the correct grade of brush is essential for proper operation

of electric brake. New brush assemblies are available at

D

EWALT service centers. The tool should be allowed to “run

in” (run at no load) for 10 minutes before use to seat new

brushes. The electric brake may be erratic in operation until

the brushes are properly seated (worn in). Always replace

the brush inspection cap after inspection or servicing the

brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE

LOCK THE TRIGGER SWITCH ON. HOLD BY HAND

ONLY.

Controls

Your compound miter saw has several main controls, which

will be discussed briefly here. For more information on these

controls, see the respective sections later in the manual.

MITER CONTROL (FIG. 7)

The miter lock/adjustment lever and trigger allows you to

miter your saw 50˚ left and right. To miter the saw, loosen

the miter lock handle (J) by rotating it counterclockwise,

squeeze the detent trigger (K) and set the miter angle

desired on the miter scale. Tighten the miter lock handle by

rotating it clockwise.

TRIGGER SWITCH

The trigger switch (Fig. 2) turns your saw on and off. A hole

is provided in the trigger for insertion of a padlock to secure

the saw.

BEVEL LOCK (FIG. 9)

The bevel lock handle (Q) allows you to bevel the saw 48˚

left or right. To loosen the handle and adjust the bevel setting, turn the handle counterclockwise, the saw head bevels

easily to the left or to the right once the 0˚ bevel override

knob (S) is pulled. To tighten, turn the handle clockwise.

Bevel degree markings are on the bottom front of the saw

arm. (Fig. 7, T)

0˚ BEVEL OVERRIDE (FIG. 9)

The bevel stop override (S) allows you to bevel the saw to

the right past the 0˚ mark.

The saw will automatically stop at 0˚ when brought up from

the left. To move past 0˚ to the right, pull the bevel stop

knob. The stop knob can be locked out by pulling the knob

out and rotating it 180˚.

Q

S

R

R

P

U

O

45˚ BEVEL STOP OVERRIDES (FIG. 9)

The bevel stop overrides are held secure with their attachment screw to prevent inadvertent movement. Use the bit

on the blade wrench to loosen the attachment screw. This

allows the slides, to be pulled outward and the saw head to

pivot past the 45˚ mark. Be sure to retighten the attachment

screw when finished.

33.85˚ BEVEL STOPS (FIG. 9)

The two pawls (P) are used to stop the saw head bevel setting at 33.85˚. This setting is used primarily for cutting crown

moldings laid flat on the table.

HEAD DOWNLOCK PIN (FIG. 9)

To lock the saw head in the down position, push the head

down, push the pin (U) in and release the saw head. This

will hold the saw head safely down for moving the saw from

place to place. To release, press the saw head down and

pull the pin out.

Operation

Plug the saw into any household 60 Hz power source. Refer

to the nameplate for voltage. Be sure the cord will not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the

tool off, release the switch. Allow the blade to spin up to full

operating rpm before making the cut. Release the trigger

switch and allow the brake to stop the blade before raising

the saw head. There is no provision for locking the switch

on, but a hole is provided in the trigger for insertion of a padlock to lock the saw off.

CUTTING WITH YOUR SAW

NOTE: Although this saw will cut wood and many non-

ferrous materials, we will limit our discussion to the cutting

of wood only. The same guidelines apply to the other materials. DO NOT CUT FERROUS (IRON AND STEEL)

MATERIALS OR MASONRY WITH THIS SAW. Do not use

any abrasive blades.

CROSSCUTS

Cutting of multiple pieces is not recommended but can be

done safely by ensuring that each piece is held firmly

against the table and fence. A crosscut is made by cutting

wood across the grain at any angle. A straight crosscut is

made with the miter arm at the zero degree position. Set the

miter arm at zero, hold the wood on the table and firmly

against the fence. Turn on the saw by squeezing the trigger.

When the saw comes up to speed (about 1 second) lower

the arm smoothly and slowly to cut through the wood. Let the

blade come to a full stop before raising arm.

Miter crosscuts are made with the miter arm at some angle

other than zero. This angle is often 45 degrees for making

corners, but can be set anywhere from zero to 50 degrees

left or right. After selecting the desired miter angle, be sure

to tighten the miter clamp knob. Make the cut as described

above.

N

Page 10

8

English

BEVEL CUTS

A bevel cut is a crosscut made with the saw blade at a

bevel to the wood. In order to set the bevel, loosen the

bevel clamp knob and move the saw to the left as desired.

(It is necessary to move the fence to allow clearance).

Once the desired bevel angle has been set, tighten the

bevel clamp knob firmly.

Bevel angles can be set from 48 degrees right to

48 degrees left and can be cut with the miter arm set

between zero and 50 degrees right or left. At some extreme

angles, the right or left side fence might have to be

removed. To remove the left or right fence, unscrew the

knobs several turns and slide the fence out.

QUALITY OF CUT

The smoothness of any cut depends on a number of variables.

Things like material being cut, blade type, blade sharpness and

rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other

precision work, a sharp (60 tooth carbide) blade and a

slower, even cutting rate will produce the desired results.

Ensure that material does not creep while cutting, clamp it

securely in place. Always let the blade come to a full stop

before raising arm.

If small fibers of wood still split out at the rear of the workpiece, stick a piece of masking tape on the wood where the

cut will be made. Saw through the tape and carefully

remove tape when finished.

For varied cutting applications, refer to the list of recommended saw blades for your saw and select the one that

best fits your needs (Page 3).

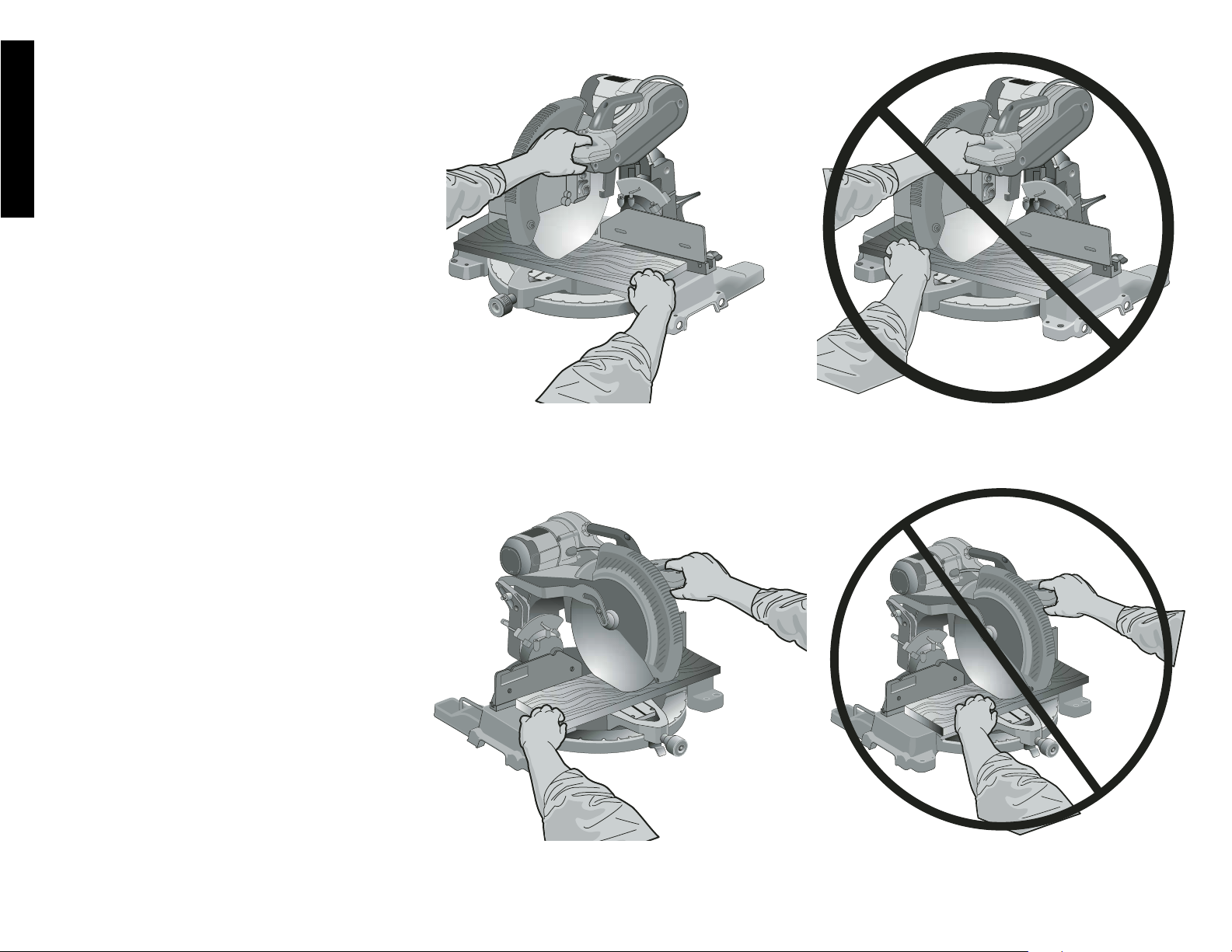

BODY AND HAND POSITION (FIG. 10)

Proper positioning of your body and hands when operating

the miter saw will make cutting easier, more accurate and

safer. Never place hands near cutting area. Place hands no

closer than 6" from the blade. Hold the workpiece tightly to

the table and the fence when cutting. Keep hands in position until the trigger has been released and the blade has

completely stopped. ALWAYS MAKE DRY RUNS

(UNPOWERED) BEFORE FINISH CUTS SO THAT YOU

CAN CHECK THE PATH OF THE BLADE. DO NOT

CROSS HANDS, AS SHOWN IN FIGURE 10A.

Keep both feet firmly on the floor and maintain proper balance. As you move the miter arm left and right, follow it and

stand slightly to the side of the saw blade. Sight through the

guard louvers when following a pencil line.

CLAMPING THE WORKPIECE

Turn Off and Unplug Saw

If you cannot secure the workpiece on the table and against

the fence by hand, (irregular shape, etc.) or your hand

would be less than 6" from the blade, a clamp or other fixture must be used.

IMPROPER CUT

IMPROPER CUT

PROPER CUT

FIG. 10

PROPER CUT

FIG. 10A

FIG. 10B

FIG. 10C

Page 11

9

English

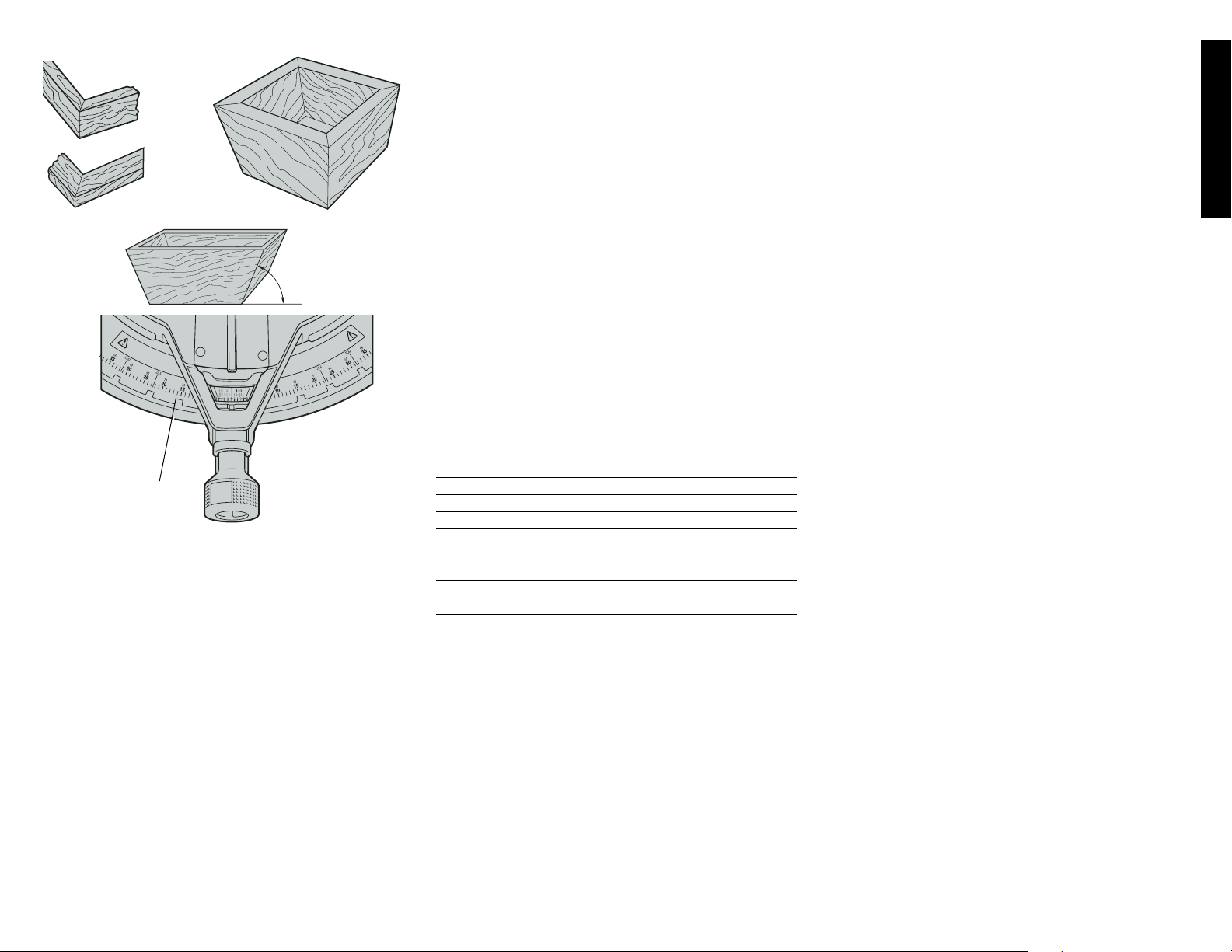

Your saw is the perfect tool for mitering corners like the one

shown in Figure 12. Sketch A in Figure 11 shows a joint

made by using the bevel adjustment to bevel the edges of

the two boards at 45 degrees each to produce a 90 degree

corner. For this joint the miter arm was locked in the zero

position and the bevel adjustment was locked at 45 degrees.

The wood was positioned with the broad flat side against the

table and the narrow edge against the fence. The cut could

also be made by mitering right and left with the broad surface against the fence.

CUTTING TRIM MOLDING AND OTHER FRAMES

Sketch B in Figure 11 shows a joint made by setting the

miter arm at 45 degrees to miter the two boards to form a 90

degree corner. To make this type of joint, set the bevel

adjustment to zero and the miter arm to 45 degrees. Once

again, position the wood with the broad flat side on the table

and the narrow edge against the fence.

The two sketches in Figure 11 are for four side objects only.

As the number of sides changes, so do the miter and bevel

angles. The chart below gives the proper angles for a variety of shapes.

(The chart assumes that all sides are of equal length.) For a

shape that is not shown in the chart, use the following formula. 180 degrees divided by the number of sides equals

the miter (if the material is cut vertically) or bevel angle (if the

material is cut laying flat).

- EXAMPLES -

NO. SIDES ANGLE MITER OR BEVEL

445°

536°

630°

7 25.7°

8 22.5°

920°

10 18°

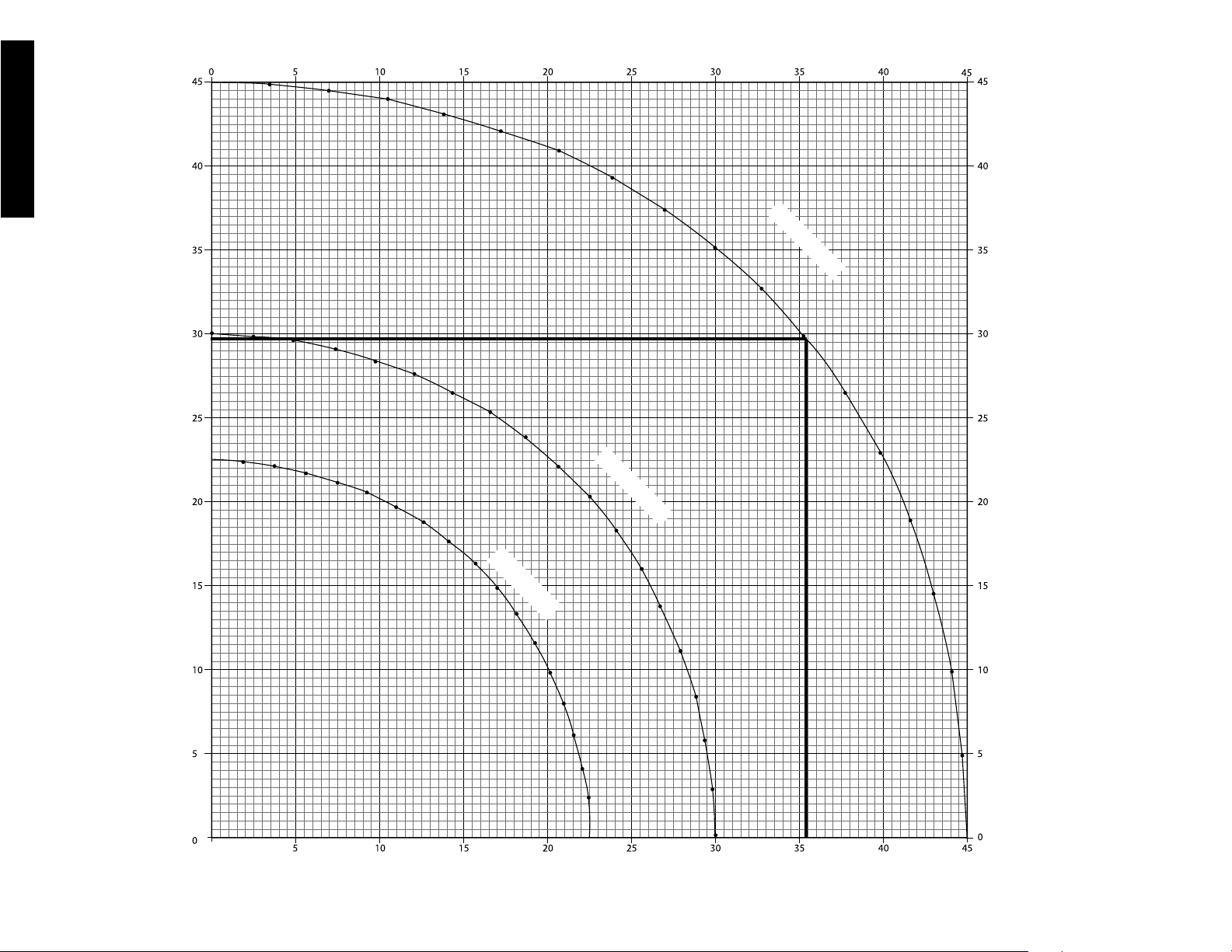

CUTTING COMPOUND MITERS

A compound miter is a cut made using a miter angle and a

bevel angle at the same time. This is the type of cut used to

make frames or boxes with slanting sides like the one shown

in Figure 13.

NOTE: If the cutting angle varies from cut to cut, check that

the bevel clamp knob and the miter lock knob are securely

tightened. These knobs must be tightened after making any

changes in bevel or miter.

The chart shown on page 12 will assist you in selecting the

proper bevel and miter settings for common compound miter

cuts. To use the chart, select the desired angle “A” (Figure

13) of your project and locate that angle on the appropriate

arc in the chart. From that point follow the chart straight

down to find the correct bevel angle and straight across to

find the correct miter angle.

Set your saw to the prescribed angles and make a few trial

cuts. Practice fitting the cut pieces together until you develop a feel for this procedure and feel comfortable with it.

Example: To make a 4 sided box with 26° exterior angles

(Angle A, Figure 13), use the upper right arc. Find 26° on the

arc scale. Follow the horizontal intersecting line to either side

to get miter angle setting on saw (42°). Likewise, follow the

vertical intersecting line to the top or bottom to get the bevel

angle setting on the saw (18°). Always try cuts on a few scrap

pieces of wood to verify settings on saw.

VERNIER SCALE

Your saw is equipped with a vernier scale for added precision. The vernier scale allows you to accurately set miter

angles to the nearest 1/4 degree. To use the vernier scale

follow the steps listed below.

(As an example, let’s assume that the angle you want to

miter is 24 1/4 degree right).

1. Turn off miter saw.

2. Set the miter angle to the nearest whole degree desired

by aligning the center mark in the vernier scale, shown

in Figure V1, with the whole degree number etched in

the miter scale. Examine Figure V2 closely; the setting

shown is 24 degrees right miter.

3. To set the additional 1/4 degree, squeeze the miter arm

lock and carefully move the arm to the RIGHT until the

1/4 degree vernier mark aligns with the CLOSEST

degree mark on the miter scale. In our example, the

closest degree mark on the miter scale happens to be

25 degrees. Figure V2 shows a setting of 24-1/4

degrees right miter.

For settings that require partial degrees (1/4, 1/2, 3/4

degrees) align the desired vernier mark with the CLOSEST

degree mark on the miter scale, as described below (The

plastic vernier plate is inscribed with marks for 1/4, 1/2, 3/4

and 1 degrees. Only the 1/2 degree and the 1 degree are

numerically labeled.)

WHEN MITERING TO THE RIGHT

To increase the miter angle when mitering to the right, move

the arm to align the appropriate vernier mark with the closest mark on the miter scale to the right. To decrease the

miter angle when mitering to the right, move the arm to align

the appropriate vernier mark with the closest mark on the

miter scale to the left.

WHEN MITERING TO THE LEFT

To increase the miter angle when mitering to the left, move

the arm to align the appropriate vernier mark with the closest mark on the miter scale to the left. To decrease the miter

angle when mitering to the left, move the arm to align the

appropriate vernier mark with the closest mark on the miter

scale to the right.

FIG. 11

FIG. 12

FIG. 13

A

B

ANGLE “A”

FIG. 14

MITER

SCALE

For best results use the DW7082 clamp made for use with

your saw. It is available for purchase at your local retailer or

D

EWALT service center.

Other aids such as spring clamps, bar clamps or C-clamps

may be appropriate for certain sizes and shapes of material. Use care in selecting and placing these clamps. Take

time to make a dry run before making the cut. The left or

right fence will slide from side to side to aid in clamping.

SUPPORT FOR LONG PIECES

Turn Off and Unplug Saw

ALWAYS SUPPORT LONG PIECES

For best results, use the DW7080 extension work support to

extend the table width of your saw. Available from your dealer at extra cost. Support long workpieces using any convenient means such as sawhorses or similar devices to keep

the ends from dropping.

CUTTING PICTURE FRAMES, SHADOW BOXES AND

OTHER FOUR SIDED PROJECTS

To best understand how to make the items listed here, we

suggest that you try a few simple projects using scrap wood

until you develop a “FEEL” for your saw.

Page 12

10

English

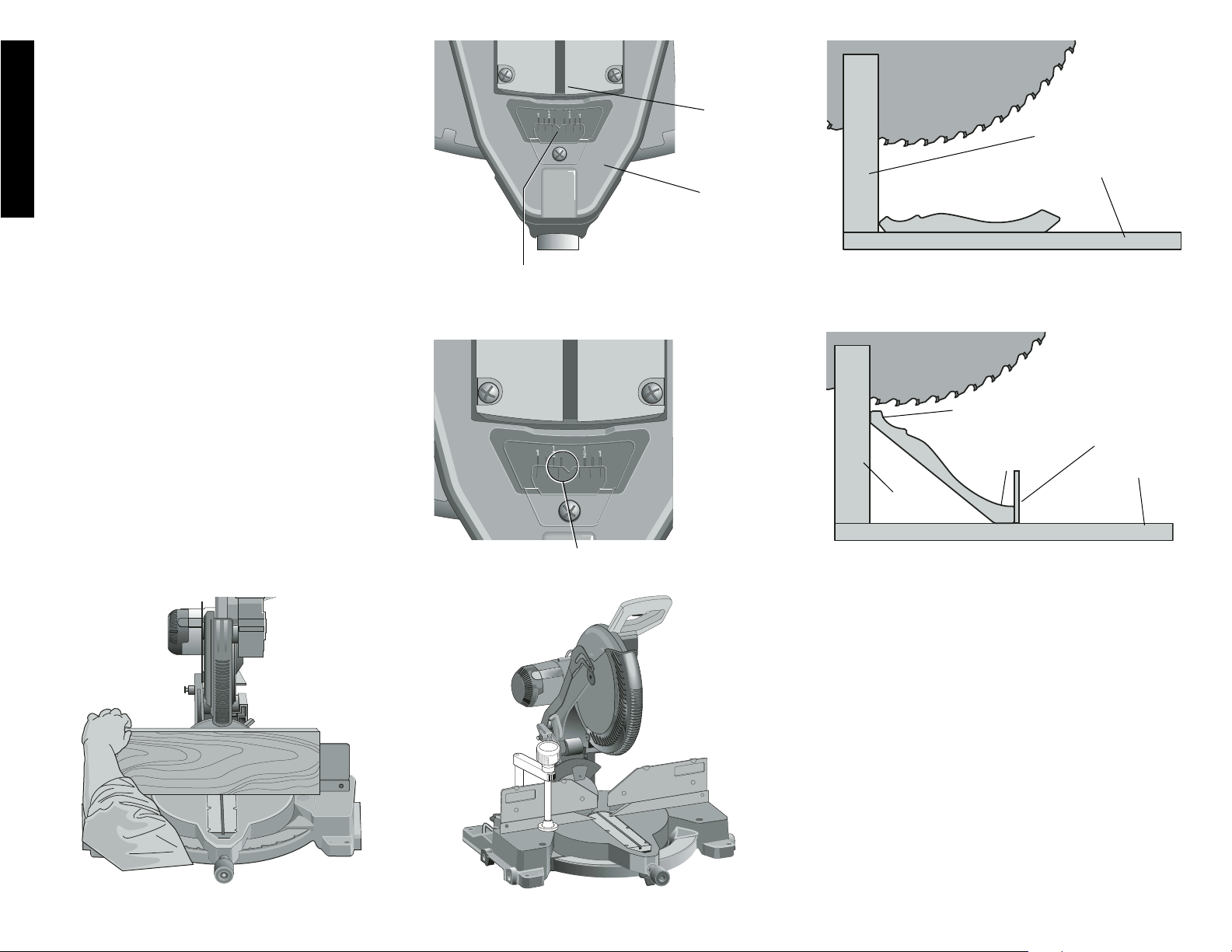

FIG. V1

FIG. V2

MITER ARM

CENTER MARK ON VERNIER SCALE ALIGNS

WITH DESIRED WHOLE ANGLE ON MITER SCALE

(24° RIGHT MITER)

1/4° VERNIER MARK ALIGNS WITH CLOSET WHOLE

DEGREE MARK ON MITER SCALE (24-1/4° RIGHT MITER)

KERF

PLATE

CUTTING BASE MOLDING

ALWAYS MAKE A DRY RUN WITHOUT POWER BEFORE

MAKING ANY CUTS.

Straight 90 degree cuts:

Position the wood against the fence and hold it in place

as shown in Figure 15. Turn on the saw, allow the blade

to reach full speed and lower the arm smoothly through

the cut.

CUTTING BASE MOLDING UP TO 6" HIGH VERTICALLY

AGAINST THE FENCE

Position material as shown in Figure 15.

All cuts made with the back of the molding against the fence

and bottom of the molding against the base.

INSIDE CORNER:

Left side

1. Miter left 45°

2. Save left side of cut

Right side

1. Miter Right 45°

2. Save right side of cut

OUTSIDE CORNER:

Left side

1. Miter right at 45°

2. Save left side of cut

Right side

1. Miter left at 45°

2. Save right side of cut

Material up to 6" can be cut as described above.

CUTTING CROWN MOLDING

Your miter saw is better suited to the task of cutting crown

molding than any tool made. In order to fit properly, crown

FIG. 16

FIG. 17

FENCE

TABLE

CROWN MOLDING FLAT ON TABLE AND

AGAINST FENCE

CROWN MOLDING BETWEEN FENCE AND TABLE

TABLE

FENCE

BOTTOM SIDE

OF MOLDING

TOP SIDE OF

MOLDING

FIG. 17A

DW 7084 CROWN

MOLDING FENCE

molding must be compound mitered with extreme accuracy.

The two flat surfaces on a given piece of crown molding are

at angles that, when added together, equal exactly 90

degrees. Most, but not all, crown molding has a top rear

angle (the section that fits flat against the ceiling) of 52

degrees and a bottom rear angle (the part that fits flat

against the wall) of 38 degrees.

Your miter saw has special pre-set miter latch points at

31.62 degrees left and right for cutting crown molding at the

proper angle and bevel stop pawls at 33.85˚ left and right.

There is also a mark on the Bevel scale at 33.85 degrees.

The chart on page 11 gives the proper settings for cutting

crown molding. (The numbers for the miter and bevel settings are very precise and are not easy to accurately set on

your saw.) Since most rooms do not have angles of precisely 90 degrees, you will have to fine tune your settings

anyway.

FIG. 15

Page 13

11

English

PRETESTING WITH SCRAP MATERIAL IS EXTREMELY

IMPORTANT!

INSTRUCTIONS FOR CUTTING CROWN MOLDING

LAYING FLAT AND USING THE COMPOUND FEATURES

1. Molding laying with broad back surface down flat on

saw table (Figure 17).

2. The settings below are for All Standard (U.S.) crown

molding with 52° and 38° angles.

BEVEL SETTING TYPE OF CUT

LEFT SIDE, INSIDE CORNER:

33.85° Left 1. Top of molding against fence

2. Miter table set right 31.62°

3. Save left end of cut

RIGHT SIDE, INSIDE CORNER:

33.85° Right 1. Top of molding against fence.

2. Miter table set at left 31.62°

3. Save right end of cut

LEFT SIDE, OUTSIDE CORNER:

33.85° Right 1. Top of molding against fence.

2. Miter table set at left 31.62°

3. Save left end of cut

RIGHT SIDE, OUTSIDE CORNER:

33.85° Left 1. Top of molding against fence

2. Miter table set right 31.62°

3. Save right end of cut

When setting bevel and miter angles for all compound

miters, remember that:

The angles presented for crown moldings are very

precise and difficult to set exactly. Since they can

easily shift slightly and very few rooms have exactly

square corners, all settings should be tested on scrap

molding.

PRETESTING WITH SCRAP MATERIAL IS

EXTREMELY IMPORTANT!

ALTERNATIVE METHOD FOR CUTTING CROWN

MOLDING

Place the molding on the table at an angle between the

fence and the saw table, as shown in Figure 17A. Use of the

crown molding fence accessory (DW7084) is highly recommended because of its degree of accuracy and convenience. The crown molding fence accessory is available for

purchase from your local dealer.

The advantage to cutting crown molding using this method is

that no bevel cut is required. Minute changes in the miter

angle can be made without affecting the bevel angle. This

way, when corners other than 90 degrees are encountered,

the saw can be quickly and easily adjusted for them. Use the

crown molding fence accessory to maintain the angle at

which the molding will be on the wall.

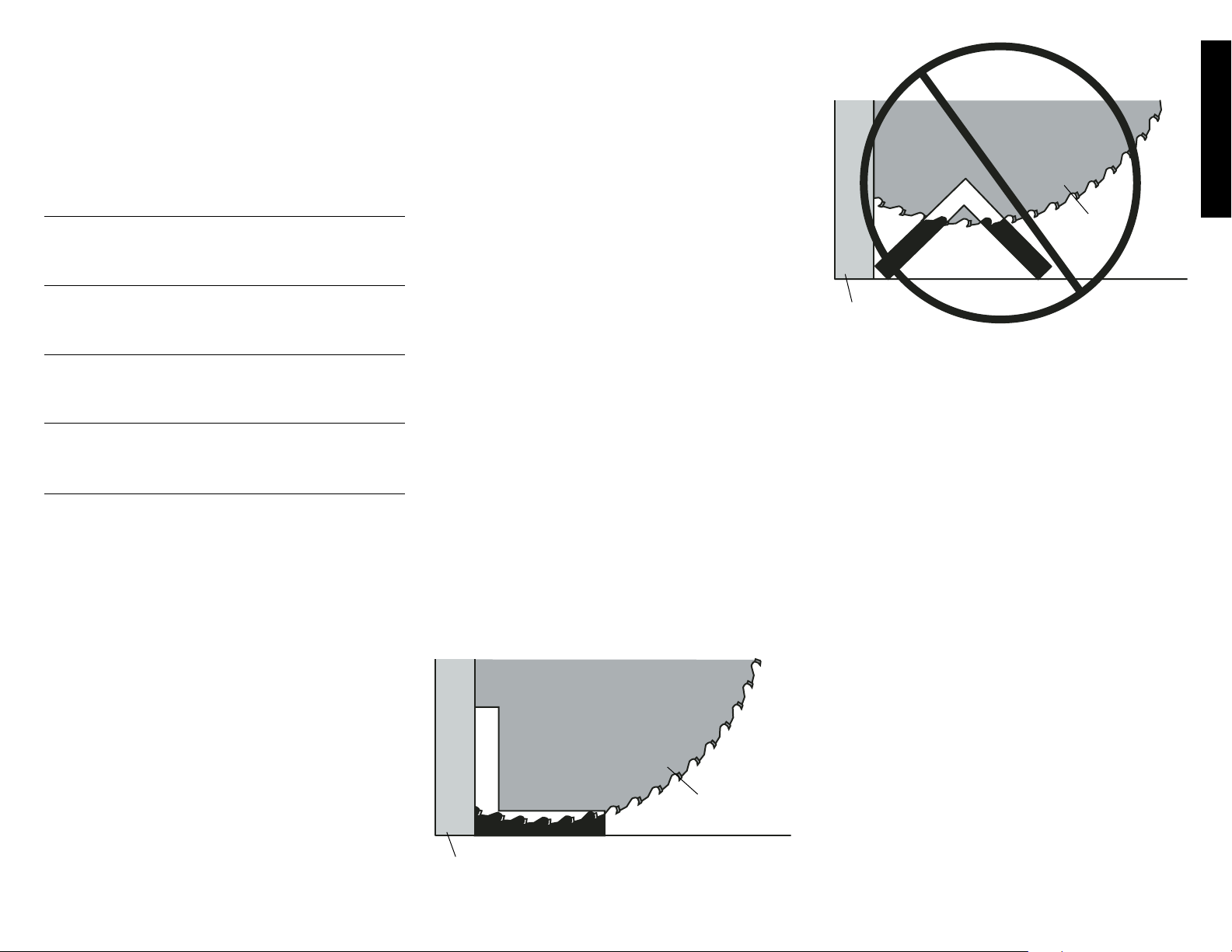

FIG. 18

BLADE

FENCE

RIGHT

FIG. 19

BLADE

FENCE

WRONG

INSTRUCTIONS FOR CUTTING CROWN MOLDING ANGLED

BETWEEN THE FENCE AND BASE OF THE SAW FOR ALL

CUTS:

1. Angle the molding so the bottom of the molding (part

which goes against the wall when installed) is against the

fence and the top of the molding is resting on the base of

the saw, as shown in Figure 17A.

2. The angled “flats” on the back of the molding must rest

squarely on the fence and base of the saw.

INSIDE CORNER:

Left side

1. Miter right at 45°

2. Save the right side of cut

Right side

1. Miter left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Miter left at 45°

2. Save right side of cut

Right side

1. Miter right at 45°

2. Save left side of cut

Special Cuts

NEVER MAKE ANY CUT UNLESS THE MATERIAL IS

SECURED ON THE TABLE AND AGAINST THE FENCE.

Aluminum Cutting:

ALWAYS USE THE APPROPRIATE SAW BLADE MADE

ESPECIALLY FOR CUTTING ALUMINUM. These are

available at your local D

EWALT retailer or DEWALT service

center. Certain workpieces, due to their size, shape or

surface finish, may require the use of a clamp or fixture to

prevent movement during the cut. Position the material so

that you will be cutting the thinnest cross section, as shown

in Figure 18. Figure 19 illustrates the wrong way to cut these

extrusions. Use a stick wax cutting lubricant when cutting

aluminum. Apply the stick wax directly to the saw blade

before cutting. Never apply stick wax to a moving blade.

The wax, available at most hardware stores and industrial

mill supply houses, provides proper lubrication and keeps

chips from adhering to the blade.

Be sure to properly secure workpiece. Refer to page 3 for

correct saw blade.

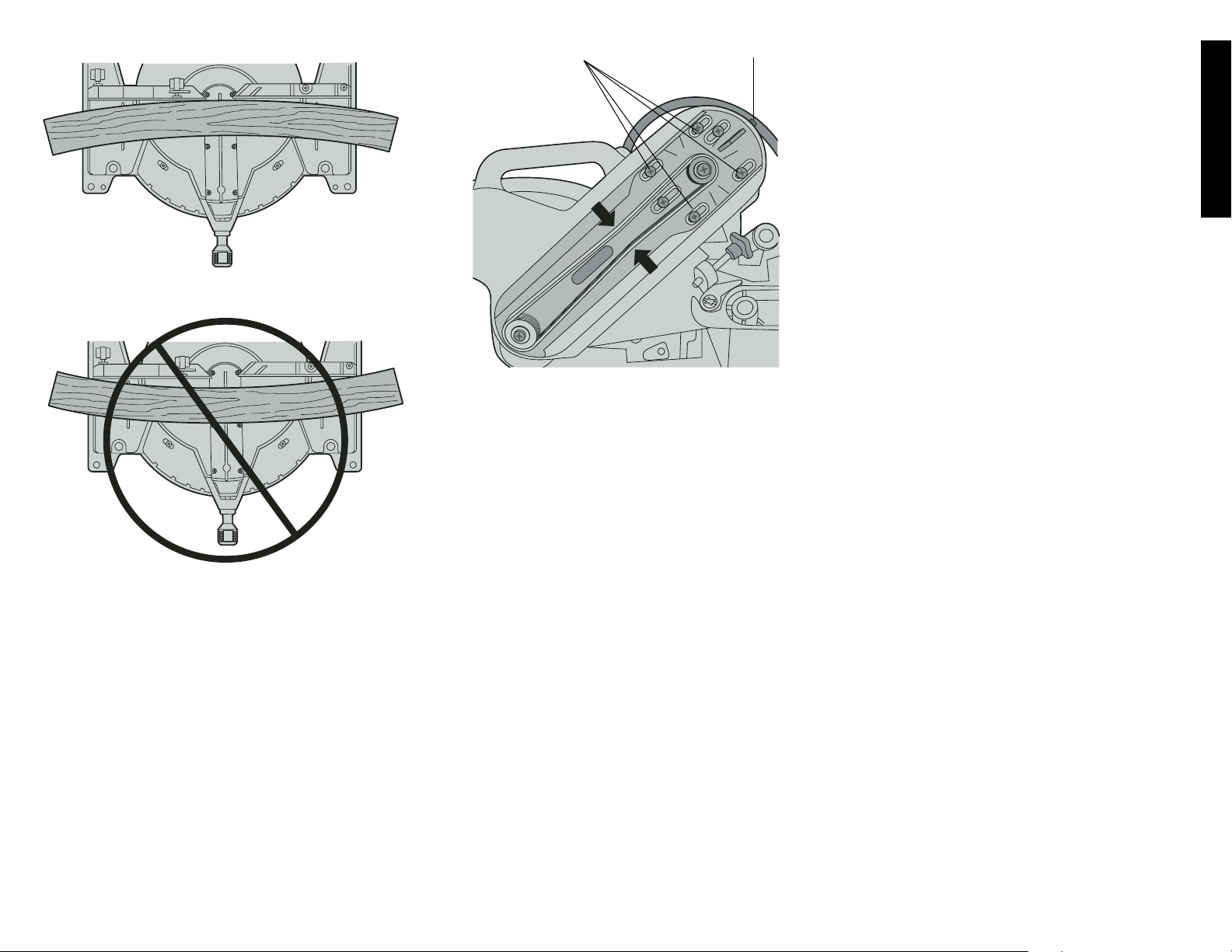

Bowed Material:

When cutting bowed material always position it as shown in

Figure 20 and never like that shown in Figure 21. Positioning

the material incorrectly will cause it to pinch the blade near

the completion of the cut.

Cutting Plastic Pipe or Other Round Material:

Plastic pipe can be easily cut with your saw. It should be cut

just like wood and CLAMPED OR HELD FIRMLY TO THE

FENCE TO KEEP IT FROM ROLLING. This is extremely

important when making angle cuts.

Cutting Large Material:

Occasionally you will encounter a piece of wood a little too

large to fit beneath the blade guard. A little extra height can

be gained by rolling the guard up out of the way. Avoid doing

this as much as possible, but if need be, the saw will operate properly and make the bigger cut. NEVER TIE, TAPE,

OR OTHERWISE HOLD THE GUARD OPEN WHEN

OPERATING THIS SAW.

Removing and Replacing Belt

The belt is designed to last the life of the tool. However,

abuse of the tool could cause the belt to fail.

Page 14

12

English

TABLE 1 COMPOUND MITER CUT (POSITION WOOD WITH BROAD FLAT SIDE ON THE TABLE AND THE NARROW EDGE AGAINST THE FENCE)

SET THIS MITER ANGLE ON SAW

SQUARE BOX

6-SIDED BOX

SET THIS BEVEL ANGLE ON SAW

8-SIDED BOX

10

20

10

10

20

20

30

40

30

40

50

30

50

60

40

50

60

70

60

70

70

80

80

80

Page 15

13

English

If the blade does not turn when the motor is running, the belt

has failed. To inspect or replace the belt, remove the belt

cover screws. Remove the belt cover. Inspect the ribs of the

belt for wear or failure. Check belt tension by squeezing the

belt as shown in Figure 22. The belt halves should almost

touch when squeezing firmly with the thumb and index finger.

To adjust the tension, loosen, but do not remove, the four

Phillips head screws shown. Then rotate the set screw on

the top of the motor plate casting until the proper tension is

achieved. Tighten the four screws securely and replace the

belt cover.

NOTE: Over tightening the belt will cause premature motor

failure.

Maintenance

1. All bearings are sealed. They are lubricated for life and

need no further maintenance.

2. Periodically clean all dust and wood chips from around

AND UNDER the base and the rotary table. Even

though slots are provided to allow debris to pass

through, some dust will accumulate.

3. The brushes are designed to give you several years of

use. If they ever need replacement follow the instructions on page 7 or return the tool to the nearest service

center for repair. Service center locations are packed

with your tool.

Repairs

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (including brush inspection

and replacement) should be performed by authorized service centers or other qualified service organizations, always

using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to

faulty materials or workmanship for three years from the

date of purchase. This warranty does not cover part failure

due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-

9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you

may have other rights which vary in certain states or

provinces.

SET SCREW

SCREWS

FIG. 22

In addition to the warranty, DEWALT tools are covered by

our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your D

EWALT Power Tool, Laser, or Nailer for any reason,

you can return it within 90 days from the date of purchase

with a receipt for a full refund – no questions asked.

RECONDITIONED PRODUCT: Reconditioned product is

covered under the 1 Year Free Service Warranty. The 90

Day Money Back Guarantee and the Three Year Limited

Warranty do not apply to reconditioned product.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4D

EWALT for a free replacement.

FIG. 20

FIG. 21

RIGHT

WRONG

Patent Notification

Manufactured under U.S. patent No. 5,425,294

Other patents may be pending.

Page 16

14

English

Troubleshooting Guide

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE! SAW WILL NOT START

WHAT’S WRONG? WHAT TO DO…

1. Saw not plugged in 1. Plug in saw.

2. Fuse blown or circuit breaker tripped 2. Replace fuse or reset circuit breaker

3. Cord damaged 3. Have cord replaced by authorized service center

4. Brushes worn out 4. Have brushes replaced by authorized service center

or replace them yourself as instructed on page 7.

TROUBLE! SAW MAKES UNSATISFACTORY CUTS

WHAT’S WRONG? WHAT TO DO…

1. Dull blade 1. Replace blade. See page 4.

2. Blade mounted backwards 2. Turn blade around. See page 4.

3. Gum or pitch on blade 3. Remove blade and clean with turpentine and coarse

steel wool or household oven cleaner.

4. Incorrect blade for work being done 4. Change the blade type. See page 3.

TROUBLE! BLADE DOES NOT COME UP TO SPEED

WHAT’S WRONG? WHAT TO DO…

1. Extension cord too light or too long 1. Replace with adequate size cord. See page 1.

2. Low house current 2. Contact your electric company

TROUBLE! MACHINE VIBRATES EXCESSIVELY

WHAT’S WRONG? WHAT TO DO…

1. Saw not mounted securely to stand or work bench 1. Tighten all mounting hardware. See page 4.

2. Stand or bench on uneven floor 2. Reposition on flat level surface. See page 6.

3. Damaged saw blade 3. Replace blade. See page 4.

TROUBLE! DOES NOT MAKE ACCURATE MITER CUTS

WHAT’S WRONG? WHAT TO DO…

1. Miter scale not adjusted correctly 1. Check and adjust. See page 6.

2. Blade is not square to fence 2. Check and adjust. See page 6.

3. Blade is not perpendicular to table 3. Check and adjust fence. See page 6.

4. Workpiece moving 4. Clamp workpiece to fence or glue 120 grit sandpaper

to fence with rubber cement.

TROUBLE! MATERIAL PINCHES BLADE

WHAT’S WRONG? WHAT TO DO…

1. Cutting bowed material 1. Position bowed material as shown on page 13.

Page 17

Français

15

Table des matières

DIRECTIVES CONCERNANT LA DOUBLE ISOLATION ET LES

FICHES POLARISÉES ..................................................................................................16

CONSIGNES DE SÉCURITÉ RELATIVES À TOUS LES OUTILS ..............................16

CONSIGNES DE SÉCURITÉ ADDITIONNELLES ........................................................16

RACCORDEMENT ÉLECTRIQUE ................................................................................18

ACCESSOIRES ..............................................................................................................18

RECOMMANDATIONS CONCERNANT LA LAME ......................................................19

DÉBALLAGE DE LA SCIE..............................................................................................19

CARACTÉRISTIQUES TECHNIQUES ..........................................................................19

FAMILIARISATION..........................................................................................................19

MONTAGE SUR UN ÉTABLI..........................................................................................21

INSTALLATION D’UNE LAME........................................................................................21

TRANSPORT DE LA SCIE ............................................................................................21

RÉGLAGES ....................................................................................................................21

RÉGLAGES DE L’ÉCHELLE DE COUPE EN ONGLET..........................................22

RÉGLAGES DE L’INDICATEUR DE L’ONGLET......................................................22

RÉGLAGE DU BISEAU EN ÉQUERRE....................................................................22

BUTÉE DU BISEAU ..................................................................................................22

RÉGLAGE DE LA BUTÉE D’ANGLE DE BISEAU ..................................................22

RÉGLAGE DU GUIDE ..............................................................................................22

FREIN ÉLECTRIQUE AUTOMATIQUE ....................................................................22

VISIBILITÉ ET DÉCLENCHEMENT DU PROTÈGE-LAME ....................................22

BALAIS ............................................................................................................................23

COMMANDES ................................................................................................................23

FONCTIONNEMENT ......................................................................................................24

INTERRUPTEUR ............................................................................................................24

MÉTHODES DE COUPE ................................................................................................24

COUPES TRANSVERSALES ........................................................................................24

COUPES EN BISEAU ....................................................................................................24

QUALITÉ DE LA COUPE................................................................................................24

POSITION DU CORPS ET DES MAINS........................................................................25

FIXATION DE L’OUVRAGE............................................................................................25

SUPPORT DE LONGS OUVRAGES ............................................................................24

COUPE DE CADRES, DE COFFRAGES OU D’AUTRES OUVRAGES

QUADRILATÉRAUX........................................................................................................25

COUPE DE BOISERIES OU D’AUTRES TYPES DE MOULURES..............................25

COUPES EN ONGLET À ANGLES COMBINÉS ..........................................................26

VERNIER ........................................................................................................................26

COUPES DE PLINTHES ................................................................................................26

COUPES DE MOULURES EN COURONNE ................................................................26

TABLEAU 1 ONGLETS MIXTES....................................................................................27

COUPES PARTICULIÈRES............................................................................................29

RETRAIT ET REMPLACEMENT DE LA COURROIE ..................................................29

ENTRETIEN ....................................................................................................................29

GARANTIE ......................................................................................................................29

GUIDE DE DÉPANNAGE ..............................................................................................30

Page 18

Français

16

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT

AUTRE OUTIL D

EWALT, COMPOSER LE NUMÉRO SANS FRAIS :

1 800 4-DEWALT (1 800 433-9258)

Importantes consignes de sécurité

AVERTISSEMENT : lorsqu’on utilise un outil électrique, on doit toujours suiv-

re les consignes de sécurité, y compris celles décrites ci-dessous, afin de

réduire les risques d’incendie, de choc électrique et de blessure.

LIRE TOUTES LES DIRECTIVES

Double isolation

Afin de protéger l’utilisateur contre les chocs électriques, les outils à double isolation sont

complètement recouverts de deux couches distinctes d’isolant électrique ou d’une double

épaisseur de matière isolante. Les outils possédant ce type d’isolation ne sont pas destinés

à être mis à la terre et, par conséquent, sont munis d’une fiche à deux broches permettant

d’utiliser une rallonge ne nécessitant aucune prise de masse.

REMARQUE : le fait que cet outil soit muni d’une double isolation ne signifie pas que l’utilisateur doit cesser de suivre les consignes de sécurité qui s’imposent; l’isolation offre une

protection supplémentaire contre les blessures causées par un choc électrique lorsque les

systèmes d’isolation internes font défaut.

MISE EN GARDE : LORS DE L’ENTRETIEN, N’UTILISER QUE DES PIÈCES DE

RECHANGE IDENTIQUES; faire réparer ou remplacer également les cordons endommagés, y compris les rallonges.

Fiches polarisées

Afin de réduire les risques de choc électrique, cet outil est muni d’une fiche polarisée (c’està-dire que l’une des lames est plus large que l’autre), et ne peut être raccordé qu’à une rallonge polarisée et ce, dans un seul sens. On doit l’inverser si on est incapable de l’enfoncer

complètement. Si la fiche ne s’adapte toujours pas, on doit demander à un électricien qualifié d’installer la prise appropriée. On ne doit jamais modifier la fiche.

Consignes de sécurité relatives à tous les outils

• GARDER LES DISPOSITIFS DE PROTECTION EN PLACE et en bon état de fonction-

nement.

• RETIRER LES CLÉS DE RÉGLAGE; prendre l’habitude de s’assurer que les clés de

réglage soient retirées de l’outil avant de le démarrer.

• GARDER LA ZONE DE TRAVAIL PROPRE; les espaces de travail et les établis encom-

brés sont propices aux accidents.

• UTILISER L’OUTIL DANS DES ENDROITS APPROPRIÉS; ne pas exposer l’outil à la

pluie ou à la neige, ni l’utiliser dans des endroits humides ou mouillés. Garder la zone de

travail bien éclairée.

• TENIR LES ENFANTS À L’ÉCART; s’assurer que personne ne s’approche de la zone

de travail.

• S’ASSURER QUE L’ATELIER SOIT SÛR POUR LES ENFANTS; utiliser des cadenas,

des interrupteurs centraux ou enlever les commandes de démarrage.

• NE PAS FORCER L’OUTIL; pour obtenir de meilleurs résultats et prévenir les risques de

blessure, laisser l’outil couper à la vitesse pour laquelle il a été conçu.

• UTILISER L’OUTIL APPROPRIÉ; ne pas forcer l’outil ou l’accessoire, ni l’utiliser pour

des travaux autres que ceux pour lesquels il a été conçu.

• PORTER DES VÊTEMENTS APPROPRIÉS; ne pas porter de vêtements amples ni de

gants, de cravate, de bague, de bracelet ou d’autres bijoux, car ceux-ci peuvent rester

coincés dans les pièces mobiles. On recommande le port de chaussures antidérapantes.

Couvrir ou attacher les cheveux longs.

• TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ; porter aussi un masque facial ou

un masque anti-poussières lorsqu’on soulève de la poussière. Les lunettes ordinaires protègent uniquement les yeux contre les chocs et ne sont PAS des lunettes de protection.

• IMMOBILISER L’OUVRAGE; retenir l’ouvrage au moyen d’un étau ou de butées fixes s’il

s’avère impossible de le fixer manuellement sur le plateau et contre le guide, ou si les mains

risquent de s’approcher de moins de 15 cm (6 po) de la lame.

• NE PAS TROP ÉTENDRE LES BRAS; les pieds doivent rester ancrés fermement sur le

sol afin de maintenir son équilibre en tout temps.

• BIEN ENTRETENIR L’OUTIL; afin d’obtenir de meilleurs résultats et faire preuve de pru-

dence, garder l’outil propre et bien aiguisé. Suivre les consignes lorsqu’on lubrifie ou qu’on

remplace les accessoires.

• DÉBRANCHER L’OUTIL avant de procéder à l’entretien ou de remplacer des accessoires

comme les lames, les mèches, les organes de coupe, etc.

• RÉDUIRE LES RISQUES DE DÉMARRAGE ACCIDENTEL; s’assurer que l’interrupteur

soit en position d’ARRÊT avant de brancher l’outil.

• UTILISER LES ACCESSOIRES RECOMMANDÉS; consulter le manuel d’utilisation pour

savoir quels accessoires sont appropriés. L’utilisation d’accessoires autres que ceux

recommandés pourrait entraîner des blessures.

• NE JAMAIS METTRE LES PIEDS SUR L’OUTIL; si l’outil se renverse ou est acciden-

tellement mis en marche, il pourrait entraîner des blessures graves.

• VÉRIFIER LES PIÈCES ENDOMMAGÉES; avant de poursuivre les travaux, on doit exam-

iner attentivement les dispositifs de protection, ou toute autre pièce endommagée, afin de

s’assurer qu’il fonctionne toujours adéquatement et qu’il est en mesure d’effectuer les

travaux pour lesquels il a été conçu. Vérifier les pièces mobiles afin de s’assurer qu’elles

soient bien alignées et qu’elles ne restent pas coincées; vérifier également les pièces et les

assemblages afin de s’assurer qu’il n’y ait aucun bris ni aucune autre condition susceptible

de nuire au bon fonctionnement de l’outil. On doit faire réparer ou remplacer toute pièce

endommagée, y compris les dispositifs de protection. Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne fonctionne pas.

• NE JAMAIS LAISSER L’OUTIL FONCTIONNER SANS SURVEILLANCE; COUPER

L’ALIMENTATION et attendre que l’outil s’arrête complètement avant de quitter les lieux.

• NE PAS UTILISER L’OUTIL À PROXIMITÉ DE LIQUIDES, DE GAZ OU DE

POUSSIÈRES INFLAMMABLES; le moteur pourrait créer des étincelles et enflammer les

vapeurs environnantes.

• UTILISER LES RALLONGES APPROPRIÉES; s’assurer que la rallonge électrique soit en

bon état et qu’elle soit en mesure de porter le courant nécessaire à l’outil. Une rallonge de

calibre inférieur entraînera une chute de tension se traduisant par une perte de puissance

et une surchauffe. Le tableau ci-dessous illustre les calibres que l’on doit utiliser selon la

longueur de la rallonge et l’intensité nominale indiquée sur la plaque signalétique. En cas

de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut porter de

courant.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en mètres

120 V De 0 à 7 De 7 à 15 De 15 à 30 De 30 à 45

240 V De 0 à 7 De 7 à 15 De 15 à 39 De 30 à 45

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Consignes de sécurité additionnelles relatives aux

scies à onglets

MISE EN GARDE : AFIN DE RÉDUIRE LES RISQUES DE BLESSURE ET D’ÉVITER

D’ENDOMMAGER SÉRIEUSEMENT L’OUTIL, ON DOIT SUIVRE À LA LETTRE LES CONSIGNES SUIVANTES.

Page 19

Français

17

MISE EN GARDE : Porter un dispositif de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le

bruit émanant de ce produit pourrait contribuer à la perte d’audition.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les

meules, les perceuses ou certains autres outils de construction, peuvent soulever de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions peut varier selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un

endroit bien ventilé et utiliser l’équipement de sécurité approprié tel un masque anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres out-

ils électriques. Porter des vêtements de protection et nettoyer les parties exposées

du corps avec de l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire anti-poussières approprié approuvé par le NIOSH ou l’OSHA. Diriger les

particules dans le sens opposé du visage et du corps.

Pour des fins pratiques et de sécurité, la scie à onglets comprend les étiquettes d’avertissement suivantes.

SUR LE CARTER DU MOTEUR :

AVERTISSEMENT : AFIN DE TRAVAILLER EN TOUTE SÉCURITÉ, LIRE ATTEN-

TIVEMENT LE MANUEL D’UTILISATION AVANT D’UTILISER LA SCIE.

LORS DE L’ENTRETIEN, N’UTILISER QUE DES PIÈCES DE RECHANGE IDEN-

TIQUES.

NE PAS EXPOSER À LA PLUIE NI UTILISER DANS DES ENDROITS HUMIDES.

TOUJOURS PORTER DES LUNETTES DE PROTECTION.

SUR LES GUIDES MOBILES :

TOUJOURS BIEN RÉGLER LE GUIDE

AVANT D’UTILISER LA SCIE. FIXER

SOLIDEMENT LES OUVRAGES DE

PETITES DIMENSIONS AVANT DE

PROCÉDER À LA COUPE.

CONSULTER LE MANUEL.