Page 1

DCPS620

20V Max* Pole Saw

Scie à long manche 20 V max*

Instruction Manual

Guide D’utilisation

Manual de instrucciones

Sierra de Poste 20 V Máx*

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT

Page 2

ENGLISH

English (original instructions) 1

Français (traduction de la notice d’instructions originale) 16

Español (traducido de las instrucciones originales) 33

Page 3

ENGLISH

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderateinjury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in propertydamage.

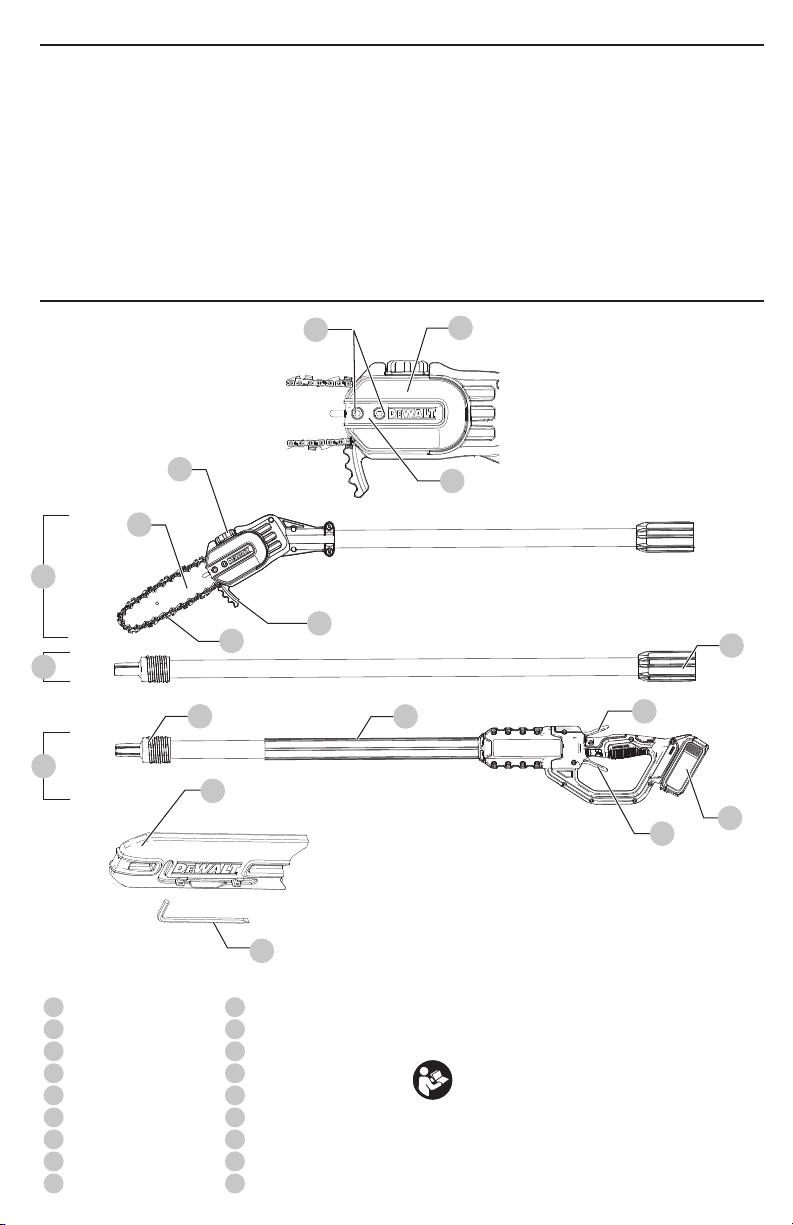

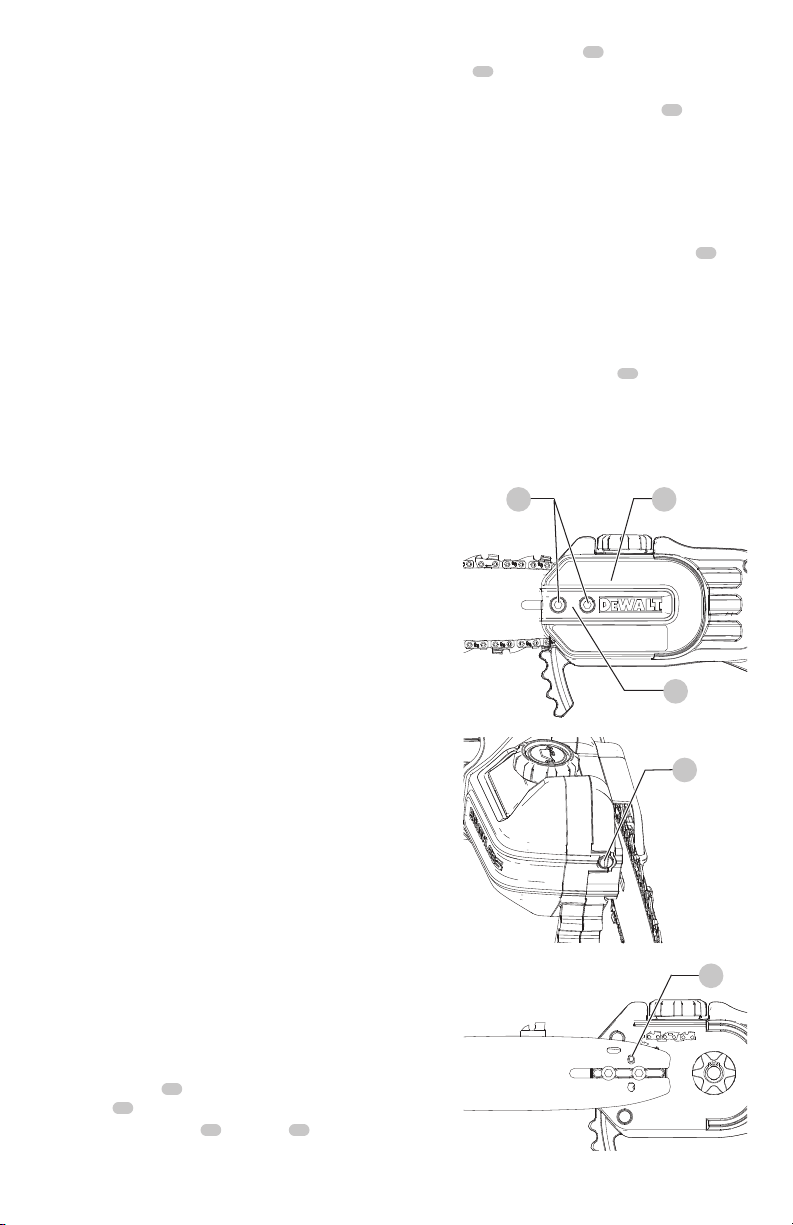

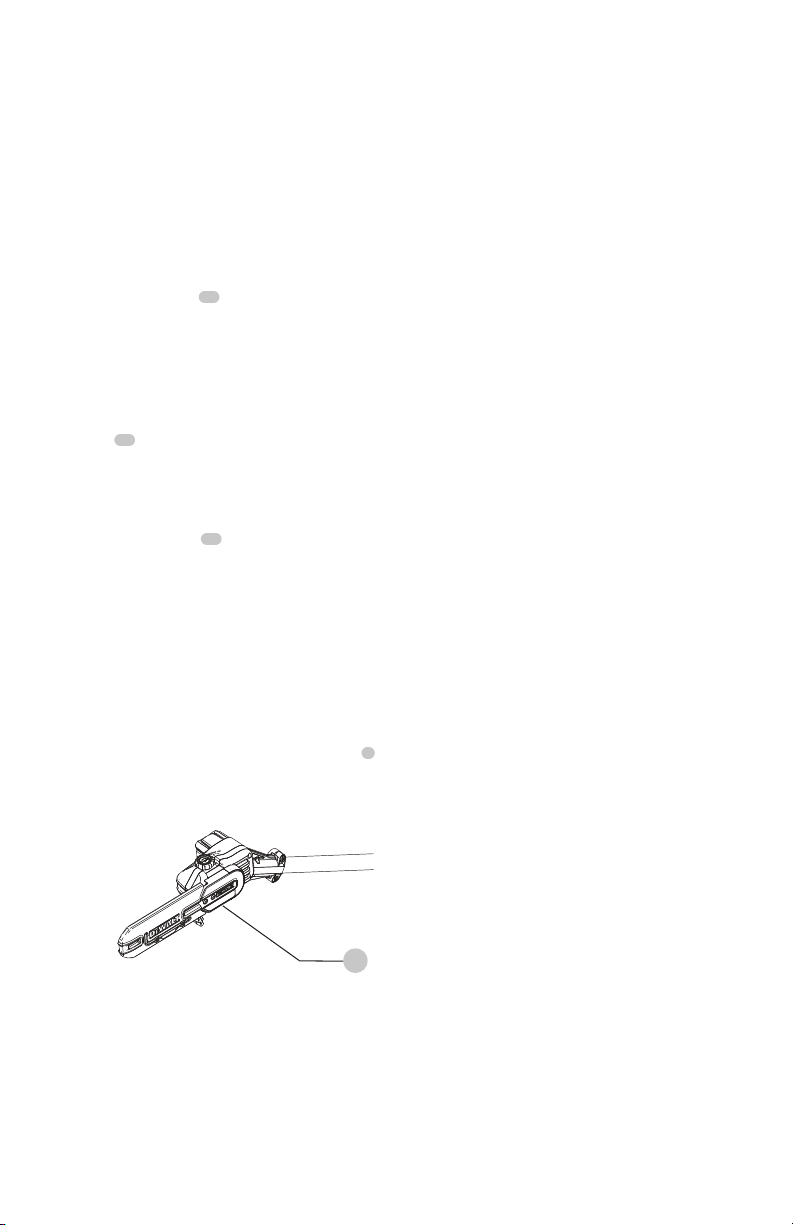

Fig. A

3

2

1

12

17

13

18

14

8

15

11

10

9

7

5

4

6

1

Handle assembly

2

Center extension pole

3

Saw head assembly

4

Trigger switch

5

Lock button

6

Battery

7

Foam gripper

8

Threaded pole

9

Threaded sleeve

16

COMPONENTS

10

Bar clamp

11

Sprocket cover

12

Hex head screws

13

Guide bar

14

Saw chain

15

Scabbard

16

Hex wrench

17

Oil cap

18

Branch removal hook

WARNING: Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

WARNING: To reduce the risk of injury, read the

instructionmanual.

If you have any questions or comments about this or

DeWALT tool, call us toll free at:

any

DeWALT (1-800-433-9258).

1-800-4-

1

Page 4

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce risk of injury:

• Before any use, be sure everyone using this unit

reads and understands all safety instructions and

other information contained in this manual.

• Save these instructions and reviewfrequently.

WARNING: When using electric gardening

appliances, basic safety precautions should always

be followed to reduce risk of fire, electric shock, and

personal injury, including thefollowing.

1 . Avoid Dangerous Environment – Don’t use appliances

in damp or wet locations.

2 . Don’t Use In Rain.

3 . Keep Children Away – All visitors should be kept at a

distance from work area.

4 . Dress Properly – Do not wear loose clothing or jewelry.

They can be caught in moving parts. Use of rubber gloves

and substantial footwear is recommended when working

outdoors. Wear protective hair covering to contain longhair.

5 . Use Safety Glasses – Always use face or dust mask if

operation is dusty.

6 . Use Right Appliance – Do not use appliance for any job

except that for which it is intended.

7 . Don’t grasp the exposed cutting blades or cutting

edges when picking up or holding the appliance.

8 . Don’t Force Appliance – It will do the job better and

with less likelihood of a risk of injury at the rate for which

it was designed.

9 . Don’t Overreach – Keep proper footing and balance at

all times.

10 . Stay Alert – Watch what you are doing. Use common

sense. Do not operate appliance when you are tired.

11 . Disconnect Appliance – Remove the battery when not in

use, before servicing, when changing accessories such as

blades, and the like.

12 . Store Idle Appliances Indoors – When not in use,

appliances should be stored indoors in dry, and high or

locked-up place – out of reach of children.

13 . Maintain Appliance With Care – Keep cutting edge

sharp and clean for best performance and to reduce

the risk of injury. Follow instructions for lubricating and

changing accessories. Inspect appliance power source

periodically, and if damaged, have it repaired by an

authorized service facility. Keep handles dry, clean, and

free from oil andgrease.

14 . Check Damaged Parts – Before further use of the

appliance, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other condition that may affect its

operation. A guard or other part that is damaged should

be properly repaired or replaced by an authorized service

center unless indicated elsewhere in this manual.

SAVE THESE INSTRUCTIONS

WARNING - Do not operate near electrical power

lines. The unit has not been designed to provide

protection from electric shock in the event of contact

with overhead electric lines, Consult local regulations

for safe distances from overhead electric power lines

and ensure that the operating position is safe and

secure before operating the saw chain pole pruner.

• Keep all parts of the body away from the saw chain.

Do not remove cut material or hold material to be

cut when blades are moving. Make sure the switch

is off when clearing jammed material. Blades coast

after turn off. A moment of inattention while operating

the pole saw may result in serious personalinjury.

• Carry the pole saw by the handle with the saw chain

stopped. When transporting or storing the pole saw

always fit the saw chain device cover. Proper handling of

the pole saw will reduce possible personal injury from the

saw chain.

• Hold the power tool by insulated gripping surfaces

only, because the cutter blade may contact hidden

wiring. A saw chain contacting a “live” wire may make

exposed metal parts of the tool “live” and could give the

operator an electricshock.

• Do not use the pole saw in bad weather conditions,

especially when there is a risk of lightning. This

decreases the risk of being struck bylightning.

• Always use two hands when operating the pole saw.

Hold the pole saw with both hands to avoid lossofcontrol.

• Always use head protection when operating the

pole saw overhead. Falling debris can result in serious

personalinjury.

SPECIFIC SAFETY RULES

WARNING: Some dust contains chemicals known

to State of California to cause cancer, birth defects

or other reproductive harm. Some examples of these

chemicals are:

• compounds in fertilizers,

• compounds in insecticides, herbicides

andpesticides,

• arsenic and chromium from chemically

treatedlumber.

To reduce your exposure to these chemicals,

wear approved safety equipment such as dust

masks that are specially designed to filter out

microscopicparticles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmfulchemicals.

WARNING: Use of this tool can generate and/

or disburse dust, which may cause serious and

permanent respiratory or other injury. Always

use NIOSH/OSHA approved respiratory protection

2

Page 5

appropriate for the dust exposure. Direct particles

away from face and body.

CAUTION: Wear appropriate personal hearing

protection during use. Under some conditions

and duration of use, noise from this product may

contribute to hearing loss.

Before Operating Pole Saw

• For safe operation, read and understand all

instructions before using the pole saw. Follow all

safety instructions. Failure to follow all safety instructions

listed below, can result in serious personal injury.

• Watch what you are doing. Use common sense. Do not

operate pole saw when you are tired.

• Use pole saw for cutting tree branches only. Do not

use pole saw for purposes not intended. Do not use for

cutting other items.

• Only well-instructed adults should operate pole saw.

Never allow children to operate.

• Do not allow children or untrained individuals to use

this unit.

• Wear the following safety gear when operating pole saw:

- heavy-duty gloves

- steel-toed safety footwear with non-skid soles

- safety glasses, goggles or face screen that are marked

to comply with ANSI Z87

- safety hard hat that is marked to comply with

ANSIZ89.1

- ear mufflers or ear plugs

- face or dust mask (if working in dusty areas)

• Wear heavy long pants and boots. Do not wear

loose fitting clothing, short pants, jewelry of any kind, or

gobarefoot.

• Secure long hair so it is above shoulder level to prevent

entanglement in any moving parts.

• Before cutting, always provide the following:

- clear work area

- secure footing

- planned retreat path from falling limbs

• Inspect tree before trimming. Make allowance for branches

to fall freely to the ground.

• Do not use your pole saw to fell saplings.

While Operating Pole Saw

DANGER: To reduce the risk of electric shock do

not use on wet surfaces. Do not expose to rain.

Storeindoors.

DANGER: Avoid Unintentional Starting –

with battery installed, don’t carry appliance with

with finger on switch. Be sure switch is off when

installingbattery.

• Stay alert. Use common sense while operating the unit.

• Keep work area clean. Cluttered areas invite injuries.

• Always remove battery from pole saw when finished

cutting or when left unattended.

ENGLISH

• Keep children, animals and bystanders at least 50' (15 m)

away from pole saw. Only pole saw user should be in

work area.

• Do not use the pole saw to cut down trees.

• Do not grasp the exposed saw chain when picking up or

holding the pole saw.

• Grip pole saw securely - one hand on the pole, the other on

the handle.

• Keep finger off trigger until ready to make cut.

• Before starting pole saw, make sure chain is not

touchinganything.

• Keep all parts of body away from chain when pole saw

isrunning.

• Do not force pole saw while cutting. Apply light pressure.

It will do the job better and safer at the rate for which it

wasintended.

• Carry pole saw from one place to another:

- with battery removed,

- fingers off/away from trigger,

- by holding pole at balance point, and

- with guide bar and chain to rear and with

scabbardattached.

• Do not cut small brush and saplings with the pole saw.

Slender matter may catch in the chain and be whipped

toward you. This could also pull you off balance.

• Do not operate in poor lighting.

• Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure to

hot surfaces.

• Keep all parts of your body away from any moving part.

• Do not, under any circumstance, use any attachment or

accessory on this product, which was not provided with

the product, or identified as appropriate for use with this

product in this instruction manual.

• Inspect pole saw before each use and after dropping or

other impacts. Ensure there are no significant defects

ordamage.

Do Not Operate Pole Saw:

- while under the influence of alcohol, medication,

ordrugs.

- in rain or in damp or wet areas.

- where highly flammable liquids or gases are present.

- if pole saw is damaged, adjusted incorrectly, or not

fully and securely assembled.

- if trigger does not turn pole saw on and off. Chain

must stop moving when you release trigger. Have

faulty switch replaced by authorized service center. See

Accessories under Maintenance.

- while in a hurry.

- while in a tree or on a ladder.

- while on aerial booms, buckets or platforms.

- during high wind or storming weather.

3

Page 6

ENGLISH

GENERAL SAFETY RULES

DANGER: Shock Hazard. Serious injury or death

from electrocution if power lines are contacted. Never

use near any electrical source, wires, or powerlines.

WARNING: For safe operation read and

understand owner’s manual. Wear face shield

(and/or safety glasses) and hard hat to protect

against falling debris. Always have a clear work area,

retreat path, and be aware of limb/branch location to

avoid falling limbs and debris. Keep bystanders 50 ft

(15 m) away when operating saw. To reduce the risk

of electric shock do not use on wet surfaces. Do not

expose to rain. Store indoors.

• To protect yourself from falling branches do not stand directly

under the branch or limb being cut. This unit should not be

held at an angle over

• Keep the handles dr y, clean, and free of oil.

• Before you start the unit, make sure the chain is not contacting

any object.

• Make sure the cutting chain has stopped before setting the

unit down.

60°

from ground level.

Service

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by

unqualified personnel could result in a risk of injury. Refer

to the Maintenance section of this manual.

• When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric

shock or injury.

Guard Against Kickback

WARNING: KICKBACK may occur when the nose or

tip of the guide bar touches an object, or when the

wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning

fast reverse reaction, kicking the guide bar up and

back towards the operator. Pinching the saw chain

along the top of the guide bar may push the guide

bar rapidly back towards the operator. Either of these

reactions may cause you to lose control of the saw

which could result in serious injury to user.

The following precautions should be followed to

minimize kickback:

• Grip pole saw firmly. Hold the saw firmly with both hands

when the unit is running. Use a firm grip with thumbs and

fingers encircling the saw handle and pole.

• Do not overreach.

• Keep proper footing and balance at all times.

• Don’t let the nose of the guide bar contact a log, branch,

ground or other obstruction.

• Do not extend pole saw handle above shoulder height.

• Use devices such as reduced kickback chain, chain braking

system and special guide bars that reduce the risks

associated with kickback.

4

• Only use replacement bars and chains specified by the

manufacturer or the equivalent.

• Never let the moving chain contact any object at the tip of

the guide bar.

• Keep the working area free from obstructions such as

other trees, branches, rocks, fences, stumps, etc. Eliminate

or avoid any obstruction that your saw chain could hit

while you are cutting through a particular log or branch.

• Keep your saw chain sharp and properly tensioned. A loose

or dull chain can increase the chance of kickback. Check

tension at regular intervals with the motor stopped and

battery removed.

• Begin and continue cutting only with the chain moving at

full speed. If the chain is moving at a slower speed, there is

a greater chance for kickback to occur.

• Cut one branch at a time.

• Use extreme caution when re-entering a previous cut.

Engage spiked bumpers into wood and allow chain to

reach full speed before proceeding with cut.

• Do not attempt plunge cuts or bore cuts.

• Watch for shifting branches or other forces that could

close a cut and pinch or fall into chain.

Kickback Safety Features

WARNING: The following features are included on

your pole saw to help reduce the hazard of kickback;

however such features will not totally eliminate this

dangerous reaction. As a pole saw user do not rely

only on safety devices. You must follow all safety

precautions, instructions, and maintenance in this

manual to help avoid kickback and other forces which

can result in serious injury.

• Reduced-Kickback Guide Bar, designed with a small

radius tip which reduces the size of the kickback danger

zone on bar tip. A reduced- kickback guide bar is one

which has been demonstrated to significantly reduce

the number and seriousness of kickbacks when tested

in accordance with safety requirements for electric

chainsaws.

• Reduced Kickback Chain, designed with a contoured

depth gauge and guard link which deflect kickback

force and allow wood to gradually ride into the cutter. A

reduced-kickback chain is a chain which has met kickback

performance requirements of ANSI B175.1–2012. when

tested on the representative sample of chain saws.

Pole Saw Names and Terms

• Drive Sprocket or Sprocket - The toothed part that

drives the saw chain.

• Guide Bar - A solid railed structure that supports and

guides the saw chain.

• Guide Bar Scabbard - Enclosure fitted over guide bar to

prevent tooth contact when saw is not in use.

• Kickback - The backward or upward motion, or both

of the guide bar occurring when the saw chain near the

nose of the top area of the guide bar contacts any object

such as a log or branch, or when the wood closes in and

pinches the saw chain in the cut.

Page 7

• Reduced Kickback Chain - A chain that complies

with the kickback performance requirements of ANSI

B175.1–2012. (when tested on a representative sample of

chain saws.

• Reduced Kickback Guide Bar - A guide bar which has

been demonstrated to reduce kickback significantly.

• Replacement Saw Chain - A chain that complies with

kickback performance requirements of ANSI B175.1–2012.

when tested with specific chain saws. It may not meet

the ANSI performance requirements when used with

othersaws.

• Saw Chain - A loop of chain having cutting teeth, that

cut the wood, and that is driven by the motor and is

supported by the guide bar.

• Spiked Bumper (Spike) - The pointed tooth or teeth for

use when pruning to pivot the saw and maintain position

while sawing.

• Switch - A device that when operated will complete or

interrupt an electrical power circuit to the motor of the

chain saw.

• Switch Lockout - A movable stop that prevents

the unintentional operation of the switch until

manuallyactuated.

• Trimming (Pruning) - Process of cutting limbs from

atree.

• Undercut - An upward cut from underside of a log or

limb. This is done while in normal cutting position and

cutting with top of guidebar.

Storage

1 . Store indoors. The best storage place is one that is cool

and dry away from direct sunlight, excess heat or cold and

out of the reach of children.

2 . Always reduce the tension off the chain again after

finishing work. The chain contracts as it cools down.

If tension is not reduced, it can damage the saw.

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz ....................... hertz

min ..................... minutes

or DC ......direct current

...................... Class I Construction

(grounded)

…/min .............. per minute

BPM .................... beats per minute

IPM ..................... impacts per minute

RPM .................... revolutions per

minute

sfpm ................... surface feet per

minute

SPM .................... strokes per minute

A ......................... amperes

W ........................ watts

or AC ........... alternating current

or AC/DC .... alternating or

direct current

...................... Class II

Construction

(double insulated)

no ....................... no load speed

n ......................... rated speed

...................... earthing terminal

..................... safety alert symbol

..................... visible radiation

..................... wear respiratory

protection

..................... wear eye

protection

..................... wear hearing

protection

..................... read all

documentation

ENGLISH

BATTERIES AND CHARGERS

The battery pack is not fully charged out of the carton.

Before using the battery pack and charger, read the

safety instructions below and then follow charging

proceduresoutlined. When ordering replacement battery

packs, be sure to include the catalog number andvoltage.

Your tool uses a

instructions before using your charger. Consult the chart

at the end of this manual for compatibility of chargers and

batterypacks.

DeWALT charger. Be sure to read all safety

READ ALL INSTRUCTIONS

Important Safety Instructions for All

Battery Packs

WARNING: Read all safety warnings and all

instructions for the battery pack, charger and

power tool. Failure to follow the warnings and

instructions may result in electric shock, fire and/

or serious injury.

• Do not charge or use the battery pack in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Inserting or removing the battery

pack from the charger may ignite the dust orfumes.

• NEVER force the battery pack into the charger. DO

NOT modify the battery pack in any way to fit into

a non-compatible charger as battery pack may

rupture causing serious personal injury. Consult

the chart at the end of this manual for compatibility of

batteries andchargers.

• Charge the battery packs only in designated

DeWALTchargers.

• DO NOT splash or immerse in water or otherliquids.

• Do not store or use the tool and battery pack in

locations where the temperature may reach or

exceed 104°F (40°C) (such as outside sheds or metal

buildings in summer). For best life store battery packs in

a cool, drylocation.

NOTE: Do not store the battery packs in a tool with

the trigger switch locked on. Never tape the trigger

switch in the ONposition.

• Do not expose battery pack or tool/appliance to

fire or excessive temperature. Exposure to fire or

temperature above 265°F (130°C) may cause explosion.

• Do not incinerate the battery pack even if it is

severely damaged or is completely worn out. The

battery pack can explode in a fire. Toxic fumes and

materials are created when lithium ion battery packs

areburned.

• If battery contents come into contact with the skin,

immedicately wash area with mild soap and water.

If battery liquid gets into the eye, rinse water over the open

eye for 15 minutes or until irritation ceases. If medical

attention is needed, the battery electrolyte is composed of

a mixture of liquid organic carbonates and lithiumsalts.

• Contents of opened battery cells may cause

respiratory irritation. Provide fresh air. If symptoms

persist, seek medicalattention.

5

Page 8

ENGLISH

WARNING: Burn hazard. Battery liquid may be

flammable if exposed to spark orflame.

WARNING: Fire hazard. Never attempt to open the

battery pack for any reason. If the battery pack case

is cracked or damaged, do not insert into the charger.

Do not crush, drop or damage the battery pack. Do

not use a battery pack or charger that has received a

sharp blow, been dropped, run over or damaged in

any way (e.g., pierced with a nail, hit with a hammer,

stepped on). Damaged battery packs should be

returned to the service center forrecycling.

Transportation

WARNING: Fire hazard. Do not store or carry

the battery pack so that metal objects can

contact exposed battery terminals. For example,

do not place the battery pack in aprons, pockets, tool

boxes, product kit boxes, drawers, etc., with loose

nails, screws, keys, etc. Transporting batteries

can possibly cause fires if the battery terminals

inadvertently come in contact with conductive

materials such as keys, coins, hand tools and the

like. The US Department of Transportation Hazardous

Material Regulations (HMR) actually prohibit

transporting batteries in commerce or on airplanes in

carry-on baggage UNLESS they are properly protected

from short circuits. So when transporting individual

battery packs, make sure that the battery terminals

are protected and well insulated from materials that

could contact them and cause a short circuit.

NOTE: Lithium-ion batteries should not be put in

checked baggage.

Shipping the

The D

Shipping.

Use Mode: When the FLEXVOLT™ battery stands alone or is

in a D

battery. When the FLEXVOLT™ battery is in a 60V Max* or a

120V Max* (two 60V Max* batteries) product, it will operate

as a 60V Max* battery.

Shipping Mode: When

the cap is attached to

the FLEXVOLT™ battery,

the battery is in Shipping

Mode. Strings of cells are

electrically disconnected within the pack resulting in three

batteries with a lower Watt hour (Wh) rating as compared

to one battery with a higher Watt hour rating. This increased

quantity of three batteries with the lower Watt hour rating

can exempt the pack from certain shipping regulations that

are imposed upon the higher Watt hour batteries.

The battery label indicates two Watt hour ratings (see

example). Depending on how the battery is shipped, the

appropriate Watt hour rating must be used to determine the

applicable shipping requirements. If utilizing the shipping

cap, the pack will be considered 3 batteries at the Watt hour

rating indicated for “Shipping”. If shipping without the cap or

in a tool, the pack will be considered one battery at the Watt

hour rating indicated next to “Use”.

6

DeWALT FLEXVOLT™ Battery

eWALT FLEXVOLT™ battery has two modes: Use and

eWALT 20V Max* product, it will operate as a 20V Max*

Example of Use and Shipping Label Marking

USE: 120 Wh Shipping: 3 x 40 Wh

For example, Shipping Wh rating might indicate 3 x 40 Wh,

meaning 3 batteries of 40 Watt hours each. The Use Wh

rating might indicate 120 Wh (1 battery implied).

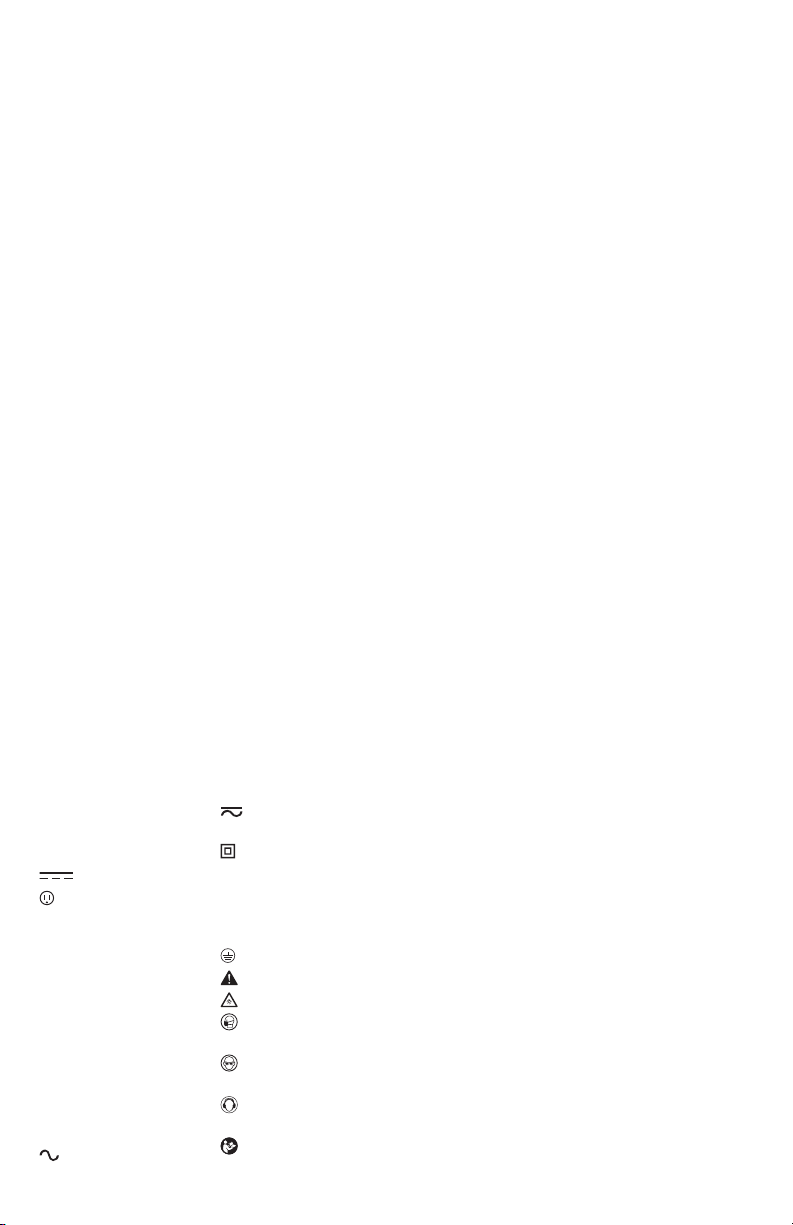

Fuel Gauge Battery Packs

Some DeWALT battery packs include a fuel gauge which

consists of three green LED lights that indicate the level of

charge remaining in the batterypack.

The fuel gauge is an indication of approximate levels of

charge remaining in the battery pack according to the

followingindicators:

75–100% charged

51–74% charged

< 50% charged

Pack needs to be charged

To actuate the fuel gauge, press and hold the fuel gauge

button. A combination of the three green LED lights will

illuminate designating the level of charge left. When the

level of charge in the battery is below the usable limit, the

fuel gauge will not illuminate and the battery will need to

berecharged.

NOTE: The fuel gauge is only an indication of the charge left

on the battery pack. It does not indicate tool functionality

and is subject to variation based on product components,

temperature and end-userapplication.

For more information regarding fuel gauge battery packs,

please call 1-800-4website www.dewalt.com.

DeWALT (1-800-433-9258) or visit our

The RBRC® Seal

The RBRC® (Rechargeable Battery

Recycling Corporation) Seal on the nickel

cadmium, nickel metal hydride or lithiumion batteries (or battery packs) indicates

that the costs to recycle these batteries

(or battery packs) at the end of their useful life have already

been paid by

spent nickel cadmium, nickel metal hydride or lithium-ion

batteries in the trash or municipal solid waste stream and

the Call2Recycle® program provides an environmentally

consciousalternative.

Call 2 Recycle, Inc., in cooperation with

battery users, has established the program in the United

States and Canada to facilitate the collection of spent nickel

cadmium, nickel metal hydride or lithium-ion batteries. Help

protect our environment and conserve natural resources by

returning the spent nickel cadmium, nickel metal hydride or

lithium-ion batteries to an authorized

or to your local retailer for recycling. You may also contact

your local recycling center for information on where to drop

off the spent battery. RBRC® is a registered trademark of Call

2 Recycle,Inc.

DeWALT. In some areas, it is illegal to place

DeWALT and other

DeWALT service center

Page 9

Important Safety Instructions for All

Battery Chargers

WARNING: Read all safety warnings and all

instructions for the battery pack, charger and

power tool. Failure to follow the warnings and

instructions may result in electric shock, fire and/

or serious injury.

• DO NOT attempt to charge the battery pack with

any chargers other than the ones in this manual.

The charger and battery pack are specifically designed to

worktogether.

• These chargers are not intended for any uses other

than charging

Any other uses may result in risk of fire, electric shock

orelectrocution.

• Do not expose the charger to rain orsnow.

• Pull by the plug rather than the cord when

disconnecting the charger. This will reduce the risk of

damage to the electric plug andcord.

• Make sure that the cord is located so that it will not

be stepped on, tripped over or otherwise subjected

to damage orstress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in

risk of fire, electric shock orelectrocution.

• When operating a charger outdoors, always provide

a dry location and use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electricshock.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The smaller

the gauge number of the wire, the greater the capacity

of the cable, that is, 16 gauge has more capacity than 18

gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using

more than one extension to make up the total length,

be sure each individual extension contains at least the

minimum wire size. The following table shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

lower the gauge number, the heavier thecord.

Volts

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Ampere Rating

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

• Do not place any object on top of the charger or

place the charger on a soft surface that might block

the ventilation slots and result in excessive internal

DeWALT rechargeable batteries.

Minimum Gauge for Cord Sets

Total Length of Cord in Feet

Not

More

Than

(meters)

American Wire Gauge

ENGLISH

heat. Place the charger in a position away from any heat

source. The charger is ventilated through slots in the top

and the bottom of thehousing.

• Do not operate the charger with a damaged cord

orplug.

• Do not operate the charger if it has received a sharp

blow, been dropped or otherwise damaged in any

way. Take it to an authorized servicecenter.

• Do not disassemble the charger; take it to an

authorized service center when service or repair

is required. Incorrect reassembly may result in a risk of

electric shock, electrocution orfire.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the risk of

electric shock. Removing the battery pack will not reduce

thisrisk.

• NEVER attempt to connect 2 chargerstogether.

• The charger is designed to operate on standard

120V household electrical power. Do not attempt to

use it on any other voltage. This does not apply to the

vehicularcharger.

WARNING: Shock hazard. Do not allow any liquid to

get inside the charger. Electric shock mayresult.

WARNING: Burn hazard. Do not submerge the

battery pack in any liquid or allow any liquid to enter

the battery pack. Never attempt to open the battery

pack for any reason. If the plastic housing of the

battery pack breaks or cracks, return to a service center

for recycling.

CAUTION: Burn hazard. To reduce the risk of injury,

charge only DeWALT rechargeable battery packs.

Other types of batteries may overheat and burst

resulting in personal injury and propertydamage.

NOTICE: Under certain conditions, with the charger

plugged into the power supply, the charger can be

shorted by foreign material. Foreign materials of a

conductive nature, such as, but not limited to, grinding

dust, metal chips, steel wool, aluminum foil or any

buildup of metallic particles should be kept away from

the charger cavities. Always unplug the charger from

the power supply when there is no battery pack in the

cavity. Unplug the charger before attempting toclean.

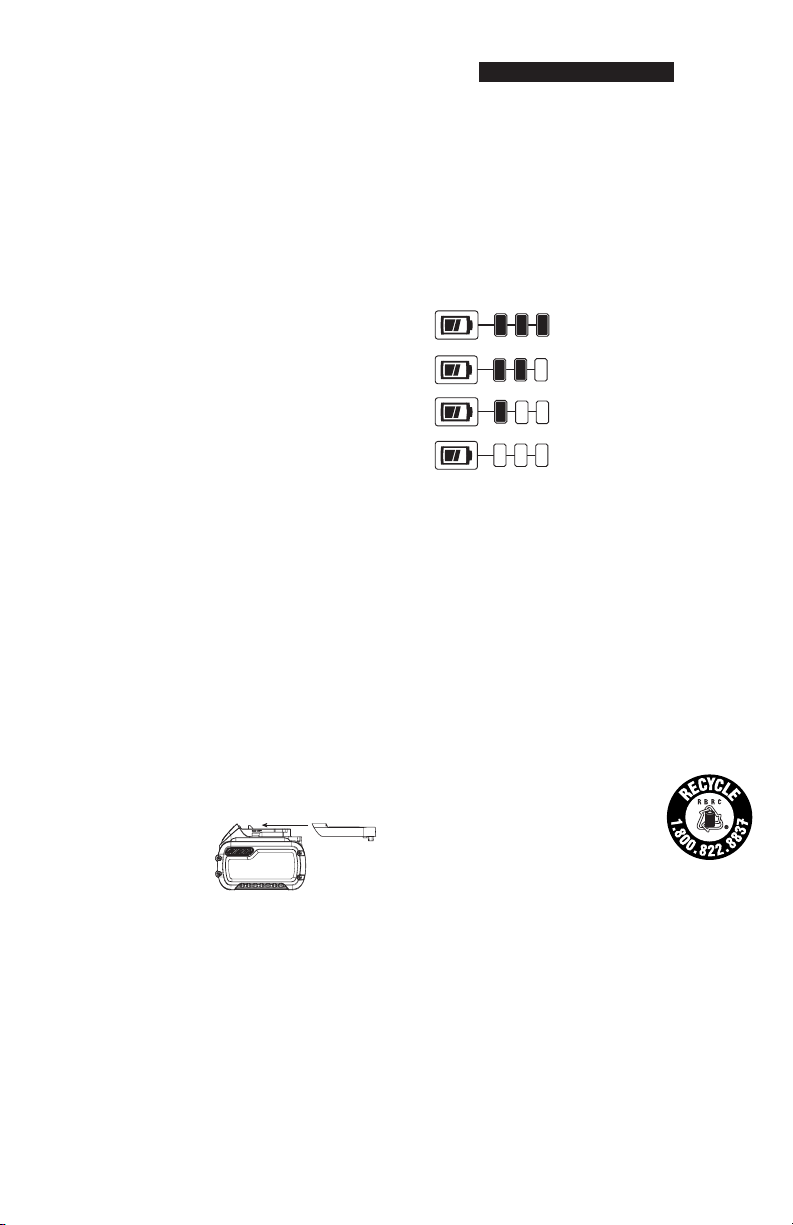

Charging a Battery

1. Plug the charger into an appropriate outlet before

inserting battery pack.

2. Insert the battery pack

the battery pack is fully seated in the charger. The red

(charging) light will blink continuously indicating that

the charging process has started.

3. The completion of charge will be indicated by the red

light remaining ON continuously. The battery pack is

fully charged and may be used at this time or left in the

charger. To remove the battery pack from the charger,

push the battery release button

and then slide the battery pack out of the charger.

6

into the charger, making sure

23

on the battery pack

7

Page 10

ENGLISH

NOTE: To ensure maximum performance and life of lithium-

ion battery packs, charge the battery pack fully before first use.

23

6

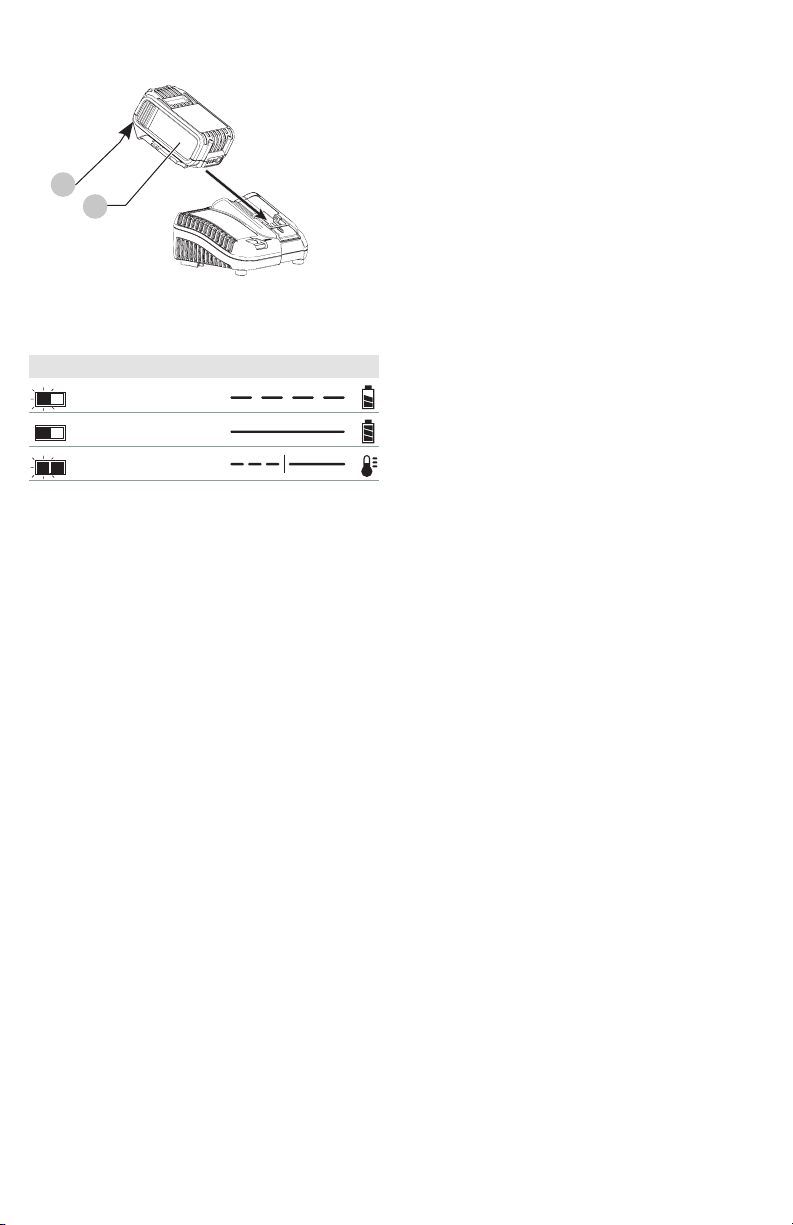

Charger Operation

Refer to the indicators below for the charge status of the

battery pack.

DCB107, DCB112, DCB113, DCB115, DCB118, DCB132

Charging

Fully Charged

Hot/Cold Pack Delay*

* DCB107, DCB112, DCB113, DCB115, DCB118,

DCB132: The red light will continue to blink, but a yellow

indicator light will be illuminated during this operation.

Once the battery pack has reached an appropriate

temperature, the yellow light will turn off and the charger

will resume the charging procedure.

The compatible charger(s) will not charge a faulty battery

pack. The charger will indicate faulty battery pack by

refusing to light.

NOTE: This could also mean a problem with a charger.

If the charger indicates a problem, take the charger and

battery pack to be tested at an authorized service center.

Hot/Cold Pack Delay

When the charger detects a battery pack that is too hot

or too cold, it automatically starts a Hot/Cold Pack Delay,

suspending charging until the battery pack has reached an

appropriate temperature. The charger then automatically

switches to the pack charging mode. This feature ensures

maximum battery pack life.

A cold battery pack will charge at a slower rate than a warm

battery pack. The battery pack will charge at that slower rate

throughout the entire charging cycle and will not return to

maximum charge rate even if the battery pack warms.

The DCB118 charger is equipped with an internal fan

designed to cool the battery pack. The fan will turn on

automatically when the battery pack needs to be cooled.

Never operate the charger if the fan does not operate

properly or if ventilation slots are blocked. Do not permit

foreign objects to enter the interior of the charger.

Electronic Protection System

Li-Ion tools are designed with an Electronic Protection

System that will protect the battery pack against

overloading, overheating or deep discharge.

The tool will automatically turn off if the Electronic

Protection System engages. If this occurs, place the lithiumion battery pack on the charger until it is fully charged.

Wall Mounting

DCB107, DCB112, DCB113, DCB115, DCB118, DCB132

These chargers are designed to be wall mountable or to

sit upright on a table or work surface. If wall mounting,

locate the charger within reach of an electrical outlet,

and away from a corner or other obstructions which may

impede air flow. Use the back of the charger as a template

for the location of the mounting screws on the wall. Mount

the charger securely using drywall screws (purchased

separately) at least 1" (25.4 mm) long, with a screw head

diameter of 0.28–0.35" (7–9mm), screwed into wood to an

optimal depth leaving approximately 7/32" (5.5 mm) of the

screw exposed. Align the slots on the back of the charger

with the exposed screws and fully engage them in the slots.

Charger Cleaning Instructions

WARNING: Shock hazard. Disconnect the charger

from the AC outlet before cleaning. Dirt and grease

may be removed from the exterior of the charger using

a cloth or soft non-metallic brush. Do not use water or

any cleaning solutions.

Important Charging Notes

1. Longest life and best performance can be obtained if

the battery pack is charged when the air temperature is

between 65°F and 75°F (18° – 24°C). DO NOT charge

the battery pack below +40°F (+4.5°C), or above

+104°F (+40°C). This is important and will prevent

serious damage to the battery pack.

2. The charger and battery pack may become warm to the

touch while charging. This is a normal condition, and

does not indicate a problem. To facilitate the cooling of

the battery pack after use, avoid placing the charger or

battery pack in a warm environment such as in a metal

shed or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check operation of receptacle by plugging in a lamp

or other appliance;

b. Check to see if receptacle is connected to a light

switch which turns power off when you turn out the

lights;

c. Move the charger and battery pack to a location

where the surrounding air temperature is

approximately 65°F – 75°F (18° – 24°C);

d. If charging problems persist, take the tool, battery

pack and charger to your local service center.

4. The battery pack should be recharged when it fails to

produce sufficient power on jobs which were easily

done previously. DO NOT CONTINUE to use under these

conditions. Follow the charging procedure. You may also

8

Page 11

charge a partially used pack whenever you desire with

no adverse effect on the battery pack.

5. Foreign materials of a conductive nature such as, but

not limited to, grinding dust, metal chips, steel wool,

aluminum foil, or any buildup of metallic particles

should be kept away from charger cavities. Always

unplug the charger from the power supply when there

is no battery pack in the cavity. Unplug the charger

before attempting to clean.

6. Do not freeze or immerse the charger in water or any

other liquid.

Storage Recommendations

1. The best storage place is one that is cool and dry, away

from direct sunlight and excess heat or cold.

2. For long storage, it is recommended to store a fully

charged battery pack in a cool dry place out of the

charger for optimal results.

NOTE: Battery packs should not be stored completely

depleted of charge. The battery pack will need to be

recharged before use.

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Intended Use

This pole saw is ideal for pruning applications and cutting

limbs up to 8" (203 mm) indiameter.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

This pole saw is a professional power tool. DO NOT let

children come into contact with the tool. Supervision is

required when in experienced operators use thistool.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

ENGLISH

3. To remove the saw chain

19

screw

in the front of the housing using the flat

screwdriver end of the wrench. Turning the screw

counterclockwise allows the guide bar

and reduces the tension on the chain so that it may

beremoved.

4. Lift the worn saw chain out of the groove in the

guidebar.

5. Flip guide bar over.

6. To replace the saw chain, check to make sure that the

slot in the guide bar is over the location pins

in FigureD and that hole below the slot is located over

the adjustment pin.

7. Place new chain in groove of guide bar and around

sprocket. Make sure saw teeth are facing correct direction

by matching the graphic onhousing or guidebar.

8. Rotate the chain tension screw

saw housing clockwise to increase the chain tension.

9. Replace sprocket cover, bar clamp, and hex headscrews.

10. Follow the instructions in the section Adjusting

ChainTension.

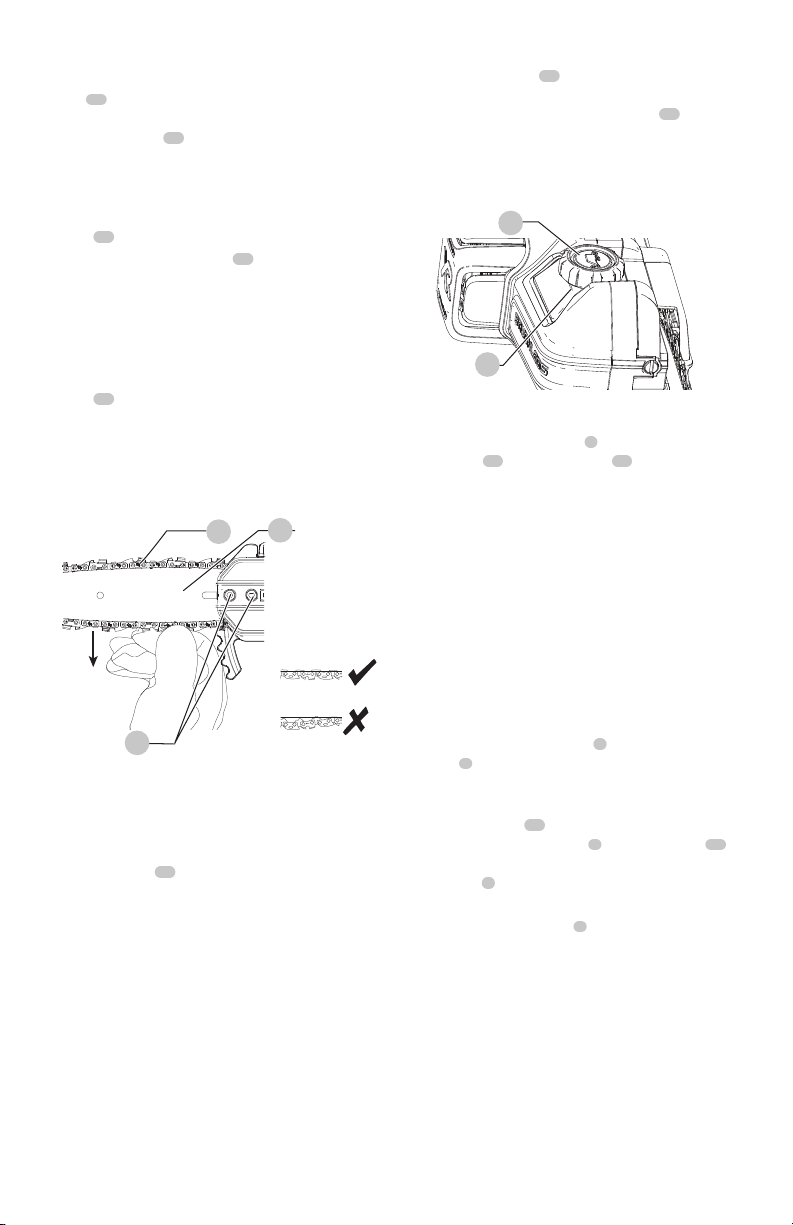

Fig.B

Fig.C

14

, rotate the chain tension

13

to recede

19

in the front of the

1112

10

19

20

shown

Installing and Removing Saw Chain

(Fig. A–D)

WARNING: Sharp moving blade. To prevent

accidental operation, insure that battery is

disconnected from the handle before performing the

following operations. Failure to do this could result in

serious personal injury.

CAUTION: Sharp moving blade. Always wear

protective gloves when installing or removing the

chain. The chain is sharp and can cut you when it is

not running.

1. Place the pole saw on a firm surface. Rotate the two

hex head screws

wrench

2. Remove sprocket cover

headscrews.

16

provided.

12

counterclockwise with the hex

11

, bar clamp

10

, and hex

Fig.D

20

9

Page 12

ENGLISH

Adjusting Chain Tension (Fig. A, C, E, F)

1. With the pole saw still on a firm surface check the saw

14

tension. The tension is correct when the saw

chain

chain snaps back after being pulled 1/8" (3 mm) away

from the guide bar

finger and thumb as shown in FigureE. There should be

no “sag” between the guide bar and the saw chain on

the underside as shown in FigureF.

2. To adjust saw chain tension, loosen hex head

12

screws

3. Rotate the chain tension screw

housing using the flat screwdriver end of the wrench.

4. Do not over-tension the saw chain as this will lead to

excessive wear and will reduce the life of the guide bar

and saw chain. Overtensioning also reduces the amount

of cuts you will get per battery charge.

5. Once saw chain tension is correct, tighten hex head

12

screws

6. When the saw chain is new check the tension frequently

(after disconnecting battery) during the first 2 hours of

use as a new chain stretches slightly.

NOTE: Saw chain tension should be adjusted regularly.

Fig.E

13

.

to clamp bar.

12

with light force from the middle

19

in the front of the

14

13

Fig.F

Saw Chain and Guide Bar Oiling (Fig.G)

Auto Oiling System

This pole saw is equipped with an auto oiling system that

keeps the saw chain and guide bar constantly lubricated.

The oil level indicator

chain saw. If the oil level is less than a quarter full, remove

the battery from the pole saw and refill with the correct

type of oil.

NOTE: Always empty oil tank when finishedcutting.

NOTE: Use a high quality bar and chain oil for proper chain

and bar lubrication. As a temporary substitute, a nondetergent SAE30 weight motor oil can be used. The use of

a vegetable based bar and chain oil is recommended when

pruning trees. Mineral oil is not recommended because it

may harm trees. Never use waste oil or very thick oil. These

may damage your pole saw.

25

shows the level of the oil in the

Filling the Oil Reservoir

• Remove the oil cap

recommended bar and chain oil until the oil level has

reached the top of the oil level indicator

• Refit the oil cap.

• Periodically switch the chain saw off and check the oil

level indicator to ensure the bar and chain are being

properlyoiled.

Fig.G

25

17

and fill the reservoir with the

17

25

.

Transporting Pole Saw (Fig. A)

Always remove the battery pack

the saw chain

the pole saw.

14

with the scabbard

6

from the handle and cover

15

when transporting

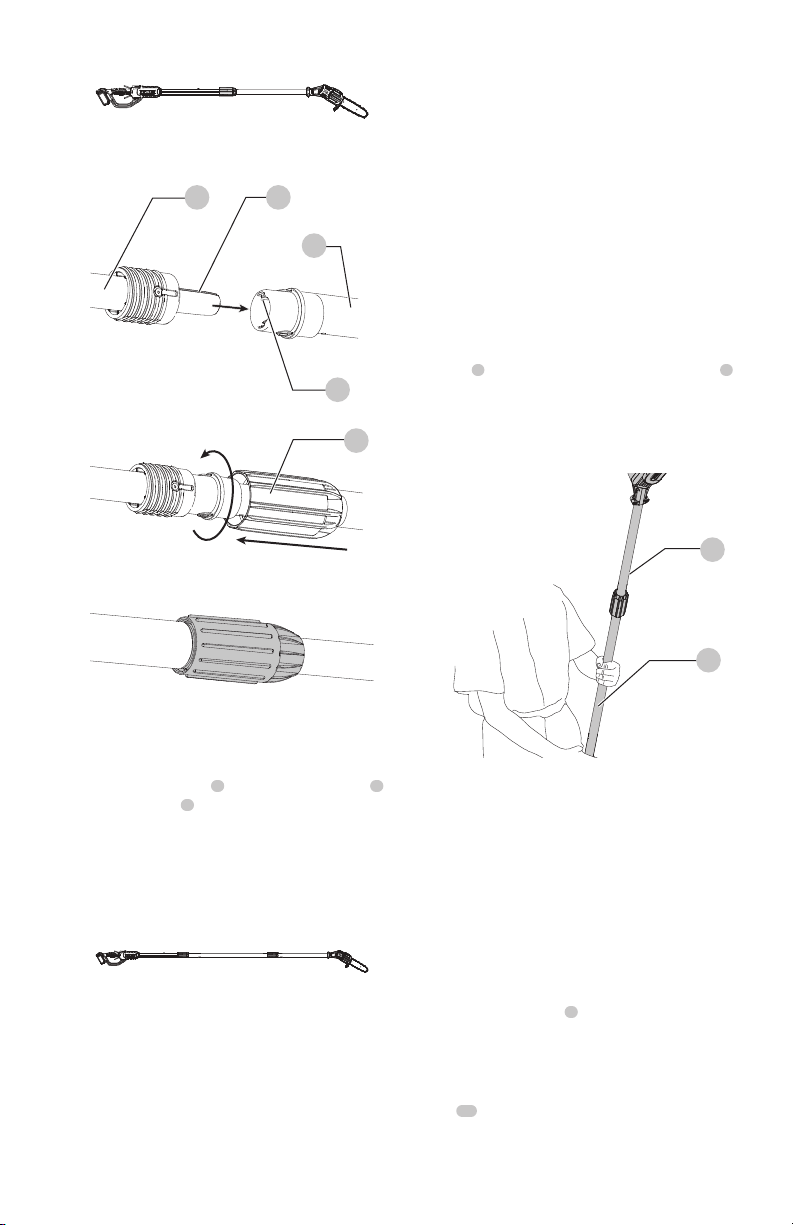

Joining Saw Head Module to

HandleModule (Fig. H–K)

WARNING: Sharp moving blade. To prevent

accidental operation, insure that battery is

disconnected from the handle and that the protective

scabbard is in place on the chain before performing

the following operations. Failure to do this could result

in serious personal injury.

The three assembliess which make up the pole saw are

keyed to insure correct assembly. If an assembly does not

smoothly attach to another do not force fit.

Combining the handle assembly

3

assembly

(1.8m) in length as shown in Figure H.

To attach the handle assembly to the saw head assembly:

1. Align the groove

2. Slide the threaded sleeve

creates a pole saw that is approximately 6'

end of the handle assembly

on the inside of the coupling end of the saw head

assembly

completelytogether. Refer to FigureJ.

down as far as possible and rotate the sleeve clockwise

until it stops and completely covers the threads as

shown in FigureK.

WARNING: Always check to make sure that the

sleeve is completely threaded on and that the red

threads are no longer visible. Not threading the sleeve

completely on could result in the assemblys becoming

disconnected creating a hazardous condition.

Periodically check the connections to insure that no

red threads are visible.

21

3

. Refer to FigureI. Push the two sections

1

to the saw head

on the outside of the coupling

1

with the tongue

9

on the saw head assembly

22

10

Page 13

Fig.H

Fig.I

Fig.J

Fig.K

ENGLISH

DISASSEMBLY

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

1

21

3

22

9

Detaching Saw Head Module (Fig. M)

WARNING: Sharp moving blade. To prevent

accidental operation, insure that battery is

disconnected from the handle and that the protective

scabbard is in place on the chain before performing

the following operations. Failure to do this could result

in serious personal injury.

When detaching the assemblies, whether it is in the two

assembly or three assembly mode, always detach the saw head

1

assembly

the ground and grasp the center of the saw head assembly

with one hand as shown in FigureM. Use your other hand to

loosen the threaded sleeve and then pull the two halves apart.

Repeat this process if the center extension wasattached.

Fig.M

first. To do this, rest the handle assembly

2

on

1

Joining Center Extension to Saw Head

Module and Handle Module (Fig. A, L)

Adding the center extension

and saw head assembly

approximately 10' (3 m) in length as shown in FigureL.

Refer to to Joining Saw Head Module to HandleModule

for directions on how to attach the middle assembly to the

handle assembly and saw head assembly.

Fig.L

WARNING: Always check to make sure that the

sleeve is completely threaded on and that the red

threads are no longer visible. Not threading the sleeve

completely on could result in the assemblys becoming

disconnected creating a hazardous condition.

Periodically check the connections to insure that no

red threads are visible.

2

to the handle assembly

3

creates a pole saw that is

1

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

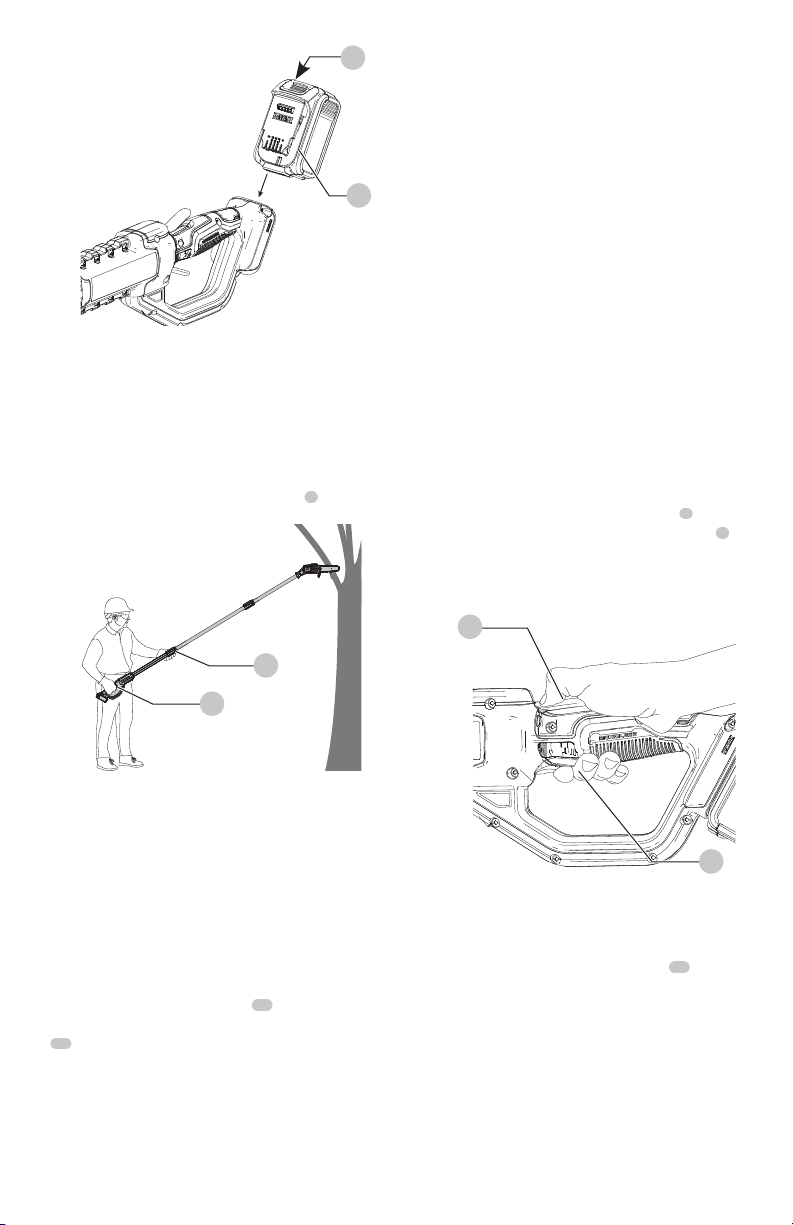

Installing and Removing the Battery Pack

(Fig. N)

NOTE: For best results, make sure your battery pack is

fullycharged.

To install the battery pack

battery pack with the rails inside the tool’s handle and slide

it into the handle until the battery pack is firmly seated in

the tool and ensure that it does notdisengage.

To remove the battery pack from the tool, press the release

23

button

handle. Insert it into the charger as described in the charger

section of thismanual.

and firmly pull the battery pack out of the tool

6

into the tool handle, align the

2

11

Page 14

ENGLISH

Fig.N

Proper Hand Position (Fig. O)

WARNING: To reduce the risk of serious personal

injury, ALWAY S use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAY S hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the main

handle( 24 and one hand on the foam gripper

Fig.O

7

.

23

Pole Saw Trimming/Pruning

WARNINGS:

• Never stand directly under the limb you are cutting.

Always position yourself out of the path of falling debris.

• Always wear head, eye, foot and body protection.

6

Wearing body protection helps reduce the risk of injury

when operating this unit.

• Never stand on a ladder or other unstable support

while using the pole saw. Always avoid any position

which can cause you to loose your balance and cause

severe injury.

• Keep other persons at least 50' (15 m) from the work

area. Distractions can cause you to lose control.

• Electrocution Hazard. To prevent shock, do not operate

within 50' (15 m) of overhead electrical lines. Always check

surrounding area for hidden electrical lines.

• Do not extend pole saw switch handle above

shoulderheight.

On/Off Switch (Fig. P)

Always be sure of your footing and grip the pole saw firmly

with both hands with the thumb and fingers encircling the

handle. To turn the tool ON pull the lock button

with your thumb and then squeeze the trigger switch

with your fingers as shown in Figure P. (Once the tool is

running you can release the lock button.) To turn the tool

OFF, release the trigger.

5

back

4

7

24

Operating the Pole Saw (Fig. A)

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious personalinjury.

CAUTION: Always reduce the tension off the chain

again after finishing work. The chain contracts as it

cools down. If it is not slackened off, it can damage

the pole saw.

IMPORTANT: Never operate a pole saw that is damaged or

improperly adjusted or that is not completely and securely

assembled. Be sure that the saw chain

when the trigger switch is released. Never adjust the guide

13

bar

or saw chain when the motor is operating or the

battery is attached.

14

stops moving

Fig.P

5

4

Branch Removal Hook (Fig. A)

CAUTION: The branch removal hook is not a belt hook.

Your pole saw includes a branch removal hook

intended purpose of helping to remove small to moderately

sized pruned branches.

18

for the

12

Page 15

Pruning With the Pole Saw (Fig. A, O, Q)

WARNING: Let the tool work at its own pace.

Do notoverload.

WARNING: When pruning trees: guard against

kickback which can result in severe injury or death.

See Guard Against Kickback, to avoid the risk of

kickback. Do not overreach. Make sure your footing

is firm. Keep feet apart. Divide your weight evenly on

both feet.

1. Use both hands to grip pole saw as shown in FigureO.

Use a firm grip. Thumbs and fingers must wrap around

pole saw handle and pole. Keep fingers away from

sawdust exhaust chute

2. Never operate while in a tree, in any awkward position

or on a ladder or other unstable surface. You may lose

control of pole saw causing severe injury.

3. Follow directions below to trim a tee.

a. Make sure pole saw is running at full speed before

making a cut. When starting a cut, place moving saw

14

chain

against limb. Hold pole saw firmly in place

to avoid possible bouncing or skating (sideways

movement) of pole saw.

b. Guide pole saw using light pressure. Make first cut

6" (152 mm) from tree trunk on underside of limb.

Use top of guide bar

through diameter of limb. Then make the finish cut

from the top. If you try to cut off thick branches

from the bottom, the branch may close in and pinch

the saw chain in the cut. If you try to cut off thick

branches from the top, without a shallow undercut,

the branch may splinter. Do not force pole saw.

The motor will overload and can burn out. It will

do the job better and safer at the rate for which it

wasintended.

c. Remove pole saw from cut while it is running at full

speed. Stop pole saw by releasing trigger switch

Make sure saw chain has stopped before setting pole

saw down.

Fig.Q

26

shown in FigureQ.

13

to make this cut. Cut 1/3

4

.

26

Saw Chain Sharpness

CAUTION: Sharp chain. Always wear protective

gloves when handling the chain. The chain is sharp

and can cut you when it is not running.

IMPORTANT: The chain cutters will dull immediately if they

touch the ground, stones, masonry or a nail whilecutting.

To get the best possible performance from your chain saw it

is important to keep the teeth of the saw chain sharp. Chain

ENGLISH

sharpening services are available from your nearest

servicecenter.

NOTE: Each time the saw chain is sharpened, it loses some

of the reduced kickback qualities and extra caution should

be used. It is recommended that a saw chain be sharpened

no more than four times.

DeWALT

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

Regular maintenance ensures a long effective life for the

tool. After every 10 minutes of use be sure to remove the

battery (be aware the chain and bar can be hot!) check

the bar and chain for correct tension and lubricate per

Adjusting Chain Tension and Chain Oiling.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis procedure.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of the

tool. These chemicals may weaken the plastic materials

used in these parts. Use a cloth dampened only with

water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into aliquid.

Accessories

WARNING: Since accessories, other than those

offered by DeWALT, have not been tested with this

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only DeWALT

recommended accessories should be used with

thisproduct.

Replacement chain and bar are available from your

nearest

DeWALT servicecenter.

• DCPS620 requires replacement chain service part

number DWO1DT608. Replacement 8” (203 mm) bar,

service part numberDWZCSB8.

Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorized service center. If you need assistance in

locating any accessory, please contact

Tool Co., 701East Joppa Road, Towson, MD 21286, call

DeWALT (1-800-433-9258) or visit our website:

1-800-4www.dewalt.com.

DeWALT Industrial

Repairs

The charger and battery pack are notserviceable.

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement, when

applicable) should be performed by a

service center or a DeWALT authorized service center.

Always use identical replacementparts.

DeWALT factory

13

Page 16

ENGLISH

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRANTY SERVICE: Registering your product will

help you obtain more efficient warranty service in case

there is a problem with yourproduct.

• CONFIRMATION OF OWNERSHIP: In case of

an insurance loss, such as fire, flood or theft, your

registration of ownership will serve as your proof

ofpurchase.

• FOR YOUR SAFETY: Registering your product will

allow us to contact you in the unlikely event a safety

notification is required under the Federal Consumer

SafetyAct.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DeWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty

coverage and warranty repair information, visit www.

dewalt.com or call 1-800-4warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others.

THIS LIMITED WARRANTY IS GIVEN IN LIEU OF ALL OTHERS,

INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, AND EXCLUDES

ALL INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some

states do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of incidental

or consequential damages, so these limitations may not

apply to you. This warranty gives you specific legal rights

and you may have other rights which vary in certain states

orprovinces.

In addition to the warranty,

byour:

DeWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

afterpurchase.

2 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DC9071, DC9091, DC9096, DC9182, DC9280, DC9360, DCB120,

DCB127, DCB201, DCB203BT, DCB207, DCB361

DeWALT (1-800-433-9258). This

DeWALT tools are covered

1 YEAR FREE SERVICE

3 YEARS FREE SERVICE ON DEWALT BATTERY PACKS

DCB200, DCB203, DCB204, DCB204BT, DCB205, DCB205BT,

DCB206, DCB230, DCB606, DCB609, DCB612

NOTE: Battery warranty voided if the battery pack is

tampered with in any way.

injury caused by tampering and may prosecute warranty

fraud to the fullest extent permitted bylaw.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your

DeWALT Power Tool, Laser, or Nailer for any reason, you

can return it within 90 days from the date of purchase with a

receipt for a full refund – no questionsasked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in

the packaging, call the local company or see website for

warrantyinformation.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4(1-800-433-9258) for a freereplacement.

DeWALT is not responsible for any

DeWALT

14

Page 17

ENGLISH

TROUBLESHOOTING GUIDE

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

For assistance with your product, visit our website at www.dewalt.com for a list of service centers, or call

1-800-4-DeWALT (1-800-433-9258).

PROBLEM POSSIBLE CAUSE SOLUTION

Unit will not start. Battery pack not installed properly. Check battery pack installation.

Battery pack not charged. Check battery pack charging requirements.

Lock button not actuated. Pull back on lock button/actuate trigger.

Pole connections not properly tightened. Refer to Joining Saw Head Module to Handle Module.

Battery pack will not charge. Battery pack not inserted into charger. Insert battery pack into charger until LED illuminates.

Charger not plugged in. Plug charger into a working outlet. Refer to Important

Surrounding air temperature too hot or

too cold.

Bar/chain overheated. Chain too tight. Refer to Adjusting Chain Tension.

Lubrication needed. Refer to Chain Oiling.

Chain is loose. Chain tension set incorrectly. Refer to Adjusting Chain Tension.

Poor cut quality. Chain tension set incorrectly. Refer to Adjusting Chain Tension. NOTE: Excessive

Chain needs replacement. Refer to Installing and Removing Saw Chain.

Unit runs but does not cut. Chain installed backwards. Refer to Installing and Removing Saw Chain.

Charging Notes for more details.

Move battery pack to a surrounding air temperature of above

40 °F (4.5 °C) or below 104 °F (+40 °C).

tension leads to excessive wear and reduction in life of bar &

chain. Lubricate after every 10 minutes of use.

DeWALT at

15

Page 18

FRANÇAIS

FRANÇAIS

Définitions: symboles et termes d'alarmes sécurité

Ces guides d'utilisation utilisent les symboles et termes d'alarmes sécurité suivants pour vous prévenir de situations

dangereuses et de risques de dommages corporels ou matériels.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée, entraînera la mort ou des

blessuresgraves.

AVERTISSEMENT: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessuresgraves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères oumodérées.

(Si utilisé sans aucun terme) Indique un message propre à la sécurité.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien n’est fait pour

l’éviter, pourrait poser des risques de dommages matériels.

Fig. A

3

2

1

16

12

17

13

14

8

15

18

7

11

10

9

5

4

6

COMPOSANTS

1

Assemblage de la poignée

2

Manche extensible central

3

Assemblage de la tête de

la scie

4

Gâchette

5

Bouton de verrouillage

6

Pile

7

Outil de préhension en

mousse

8

Manche fileté

9

Manchon fileté

16

16

10

Bride de serrage

11

Capot du pignon

12

Vis à tête hexagonale

13

Guide-chaîne

14

Scie à chaîne

15

Étui

16

Clé hexagonale

17

Capuchon de l’huile

18

Crochet pour enlever les

branches

AVERTISSEMENT: lisez tous les

avertissements de sécurité et toutes les

instructions. Ne pas suivre les avertissements et

les instructions peut entraîner un choc électrique,

un incendie et/ou des blessures graves.

AVERTISSEMENT: pour réduire le risque de

blessure, lisez le guide d’utilisation.

Pour toute question ou tout commentaire à

propos de n'importe quel outil

nous au numéro sans frais:

DeWALT (1-800-433-9258).

1-800-4-

DeWALT, appelez-

Page 19

CONSIGNES IMPORTANTES DE SÉCURITÉ

AVERTISSEMENT: afin de réduire le risque de

blessure :

• Avant toute utilisation, assurez-vous que toutes les

personnes qui utiliseront l'outil lisent et comprennent

toutes les consignes de sécurité et les autres

renseignements compris dans le présent manuel.

• Conservez ces instructions et consultez-les souvent.

AVERTISSEMENT: lors de l'utilisation d'outils de

jardinage électriques, les mesures de précaution

de base devraient toujours être prises pour réduire

la possibilité d'incendie, de choc électrique et de

blessures, en suivant les recommandations suivantes.

1 . Évitez les environnements dangereux : ne pas utiliser

des appareils dans des endroits humides ou mouillés.

2 . Ne pas utiliser sous la pluie.

3 . Gardez les enfants éloignés : tous les visiteurs devraient

être gardés à une distance sécuritaire de l'aire de travail.

4 . Portez des vêtements appropriés: ne pas porter des

vêtements amples ou des bijoux. Ils peuvent se coincer

dans les pièces qui se déplacent. L’utilisation de gants en

caoutchouc et de très bonnes chaussures est recommandée

lors du travail extérieur. Portez une protection pour vos

cheveux afin de les retenir.

5 . Utilisez des lunettes de sécurité: utilisez toujours un

masque facial ou antipoussières s’il y a de la poussière

durant l’utilisation.

6 . Utilisez le bon outil : ne pas utiliser cet outil pour toute

tâche autre que celles pour lesquelles il est conçu.

7 . Ne pas saisir les lames de coupe exposées ou les bords

coupants lorsque vous prenez ou tenez l’appareil.

8 . Ne pas forcer l’outil : le travail sera mieux fait et avec

moins de probabilité de risque à la vitesse pour laquelle il

a été conçu.

9 . Ne pas s’étirer : maintenez vos pieds bien d'aplomb sur le

sol et un bon équilibre en tout temps.

10 . Demeurez vigilant: regardez ce que vous faites. Faites

preuve de bon sens. Ne pas utiliser l’appareil lorsque vous

êtes fatigué.

11 . Débranchez l’outil: retirez la pile lorsque vous n’utilisez

pas l’outil, avant de réparer, lorsque vous changez les

accessoires comme les lames et autres.

12 . Entreposez les outils arrêtés à l’intérieur: lorsqu’ils

ne sont pas utilisés, les outils doivent être entreposés à

l’intérieur dans un endroit sec et élevé ou verrouillé hors de

portée des enfants.

13 . Entretenez soigneusement l’outil : gardez les bords

coupants aiguisés et nettoyez pour une meilleure

performance et afin de réduire le risque de blessure. Pour

lubrifier l'outil et remplacer les accessoires, suivez les

directives du manuel. Inspectez régulièrement la source

d’alimentation et si elle est endommagée, faites-la réparer

dans un établissement de services autorisé. Gardez vos

mains sèches, propres et exemptes de graisse et de poussière.

FRANÇAIS

FRANÇAIS

14 . Vérifiez les pièces endommagées : avant toute

utilisation ultérieure de l’outil, un protecteur ou une autre

pièce qui est endommagé doit être soigneusement vérifié

afin de déterminer s’il fonctionnera correctement et s’il

effectuera la fonction prévue. Vérifiez l’alignement des

pièces qui se déplacent, les fixations des pièces qui se

déplacent, le bris des pièces, le montage et tout autre état

qui peut affecter son utilisation. Un protecteur ou une

autre pièce qui est endommagé doit être convenablement

réparé ou remplacé par un centre de services autorisé sauf

si c’est indiqué ailleurs dans ce manuel.

CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT : ne pas utiliser près des lignes

électriques. Cet appareil n’est pas conçu pour offrir

une protection contre les chocs électriques en cas

de contact avec des lignes électriques aériennes.

Consultez les réglementations locales concernant les

distances sécuritaires des lignes électriques aériennes

et assurez-vous que la position d’utilisation est

sécuritaire avant d’utiliser l’échenilloir.

• Gardez toutes les parties de votre corps loin de la

chaîne de la scie. Ne pas retirer la matière coupée

ou la matière maintenue à être coupée lorsque les

lames sont en mouvement. Assurez-vous que la

gâchette est fermée lorsque vous enlevez la matière

coincée. Les lames glissent une fois l’outil éteint. Un

moment d’inattention pendant l’utilisation de la scie à

long manche peut entraîner une blessure corporelle grave.

• Transportez la scie à long manche par la poignée

avec la scie à chaîne arrêtée. Lors du transport ou de

l’entreposage de la scie à chaîne, mettez toujours le capot

de la scie à chaîne. Une manutention appropriée de la scie

à long manche réduira une possible blessure corporelle

due à la scie à chaîne.

• Tenez l’outil électrique seulement les surfaces de

prise isolées puisque la lame de coupe peut entrer

en contact avec les câbles cachés. Une scie à chaîne

entrant un contact avec un câble «sous tension» peut

exposer les pièces métalliques de l’outil «sous tension» et

pourrait donner un choc électrique à l’utilisateur.

• Ne pas utiliser la scie à long manche si les conditions

météorologiques sont mauvaises, particulièrement

s’il y a un risque de foudre. Cela réduit le risque d’être

frappé par la foudre.

• Utilisez toujours les deux mains lorsque vous utilisez

la scie à long manche. Tenez la scie à long manche avec

les deux mains pour éviter de perdre le contrôle.

Utilisez toujours un casque protecteur lorsque vous

utilisez la scie à long manche au-dessus de votre tête. Les

débris tombants peuvent entraîner une blessure corporelle grave.

RÈGLES DE SÉCURITÉ SPÉCIFIQUES

AVERTISSEMENT: certaines poussières contiennent

des produits chimiques reconnus dans l’État de la

Californie pour causer le cancer et des anomalies

congénitales ou autres effets nuisibles sur la

reproduction. Certains exemples de ces produits

chimiques sont:

17

17

Page 20

FRANÇAIS

FRANÇAIS

• des composants de fertilisants,

• des composants d'insecticides, d'herbicides et de

pesticides,

• l’arsenic et le chrome provenant du bois de

construction traité chimiquement.

Pour réduire votre exposition à ces produits chimiques,

porter un équipement de sécurité approuvé, comme

un masque antipoussière spécialement conçu pour

filtrer les particules microscopiques.

• Évitez le contact prolongé avec la poussière

provenant du ponçage mécanique, du sciage, de

l’aiguisage, du perçage et d’autres activités de

construction. Portez des vêtements protecteurs et

lavez vos zones exposées avec du savon et de l’eau.

Permettre à la poussière d’entrer dans votre bouche, vos

yeux ou la laisser sur la peau peut favoriser l’absorption

des produits chimiques dangereux.

AVERTISSEMENT: L

peut générer et/ou disperser de la poussière qui

peut causer des lésions respiratoires graves et

permanentes ou d’autres blessures. Utilisez toujours

une protection respiratoire approuvée par NIOSH/OSHA

appropriée pour l’exposition à la poussière. Dirigez les

particules loin du visage et du corps.

ATTENTION : Portez toujours des protecteurs pour les

oreilles durant l’utilisation. Dans certaines conditions

et selon la durée d’utilisation, le bruit provenant de ce

produit peut contribuer à la perte de l’audition.

’utilisation de cet outil

Avant d’utiliser la scie à long manche

• Pour une utilisation sécuritaire, lisez et comprenez

toutes les instructions avant d’utiliser la scie à long

manche. Suivez toutes les consignes de sécurité. Ne

pas suivre toutes les consignes de sécurité énumérées

ci-dessous peut entraîner une blessure corporelle grave.

• Regardez ce que vous faites. Faites preuve de bon sens.

Ne pas utiliser la scie à long manche lorsque vous êtes

fatigué.

• Utilisez la scie à long manche seulement pour couper

les branches des arbres. Ne pas utiliser la scie à long

manche à des fins non prévues. Ne pas utiliser pour couper

d’autres articles.

• Seulement des adultes bien formés doivent utiliser

la scie à long manche. Ne jamais autoriser les enfants

à l’utiliser.

• Ne pas autoriser les enfants ou des personnes non

formées à utiliser cet appareil.

• Portez l’équipement de sécurité suivant lorsque vous

utilisez la scie à long manche au-dessus de votre tête:

- des gants de travail

- des chaussures de sécurité à embout d’acier avec

semelles antidérapantes

- des lunettes de sécurité ou un écran facial conformes à

la norme ANSI Z87

- un casque de sécurité conforme à la norme ANSIZ89.1

- des cache-oreilles ou des bouchons d’oreilles

18

18

- un masque facial ou antipoussières (si vous travaillez

dans une zone poussiéreuse)

• Portez les pantalons longs et des bottes lourds. Ne

pas porter de vêtements amples, de culotte courte, de

bijoux quelconques ou se promener pieds nus.

• Attachez cheveux longs afin qu’ils soient au-dessus des

épaules afin de prévenir l’emmêlement dans les pièces en

mouvements.

• Avant de scier, prévoyez toujours les éléments suivants:

- une aire de travail dégagée

- les pieds bien d'aplomb

- la trajectoire de retrait planifiée des branches

tombantes

• Inspecter l’arbre avant de le couper. Tenez compte des

branches qui tombent librement sur le sol.

• Ne pas utiliser la scie à long manche pour abattre les gaules.

Pendant l’utilisation de la scie à

long manche

DANGER: Afin de réduire le risque de choc