Page 1

Final page size: A5 (148mm x 210mm)

DCC1054

Page 2

DeWALT

English (original instructions) 2

Copyright

B

Page 3

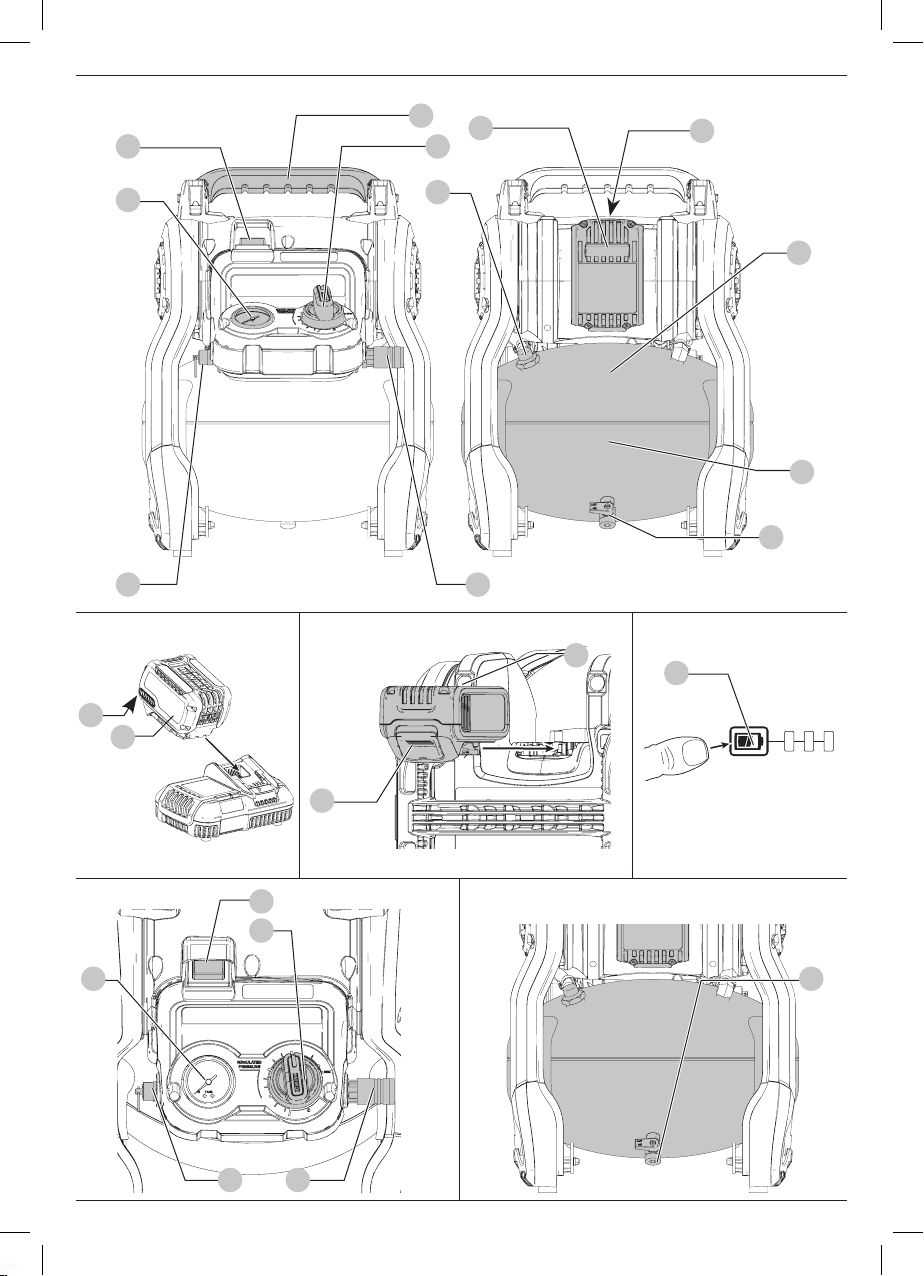

Fig. A

10

1

2

6

3

5

8

4 9

Fig. B Fig. C Fig. D

2

3

2

13

11

7

12

Fig. E

5

1

6

4 9

3

Fig. F

7

1

Page 4

ENGLISH

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

54V 10L CORDLESS AIRCOMPRESSOR

DCC1054

Congratulations!

You have chosen a

product development and innovation make

most reliable partners for professional power toolusers.

Technical Data

Voltage V

Type 1

Battery type Li‑Ion

Air tank capacity Liters 10

Approx. cut‑in pressure BAR 7.2

Approx. cut‑out pressure BAR 9.3

Air displacement l/min 48

Air delivery at 7 BAR l/min 31

Fuse type Time delay

Regulated pressure rating (approximate) BAR 0–9.3

Motor revolutions per minute 3400

Quick connect type Universal EU 1/4"

Pump type Oil‑less

Weight (without battery pack) kg 11.0

Noise valuesaccording to EN1012‑1

LPA (emission sound pressure level) dB(A) 79

LWA (sound power level) dB(A) 92

K (uncertainty for the given sound level) dB(A) 3

The vibration emission level given in this information sheet has

been measured in accordance with a standardised test given in

EN1012‑1 and may be used to compare one tool with another. It

may be used for a preliminary assessment ofexposure.

EC‑Declaration of Conformity

Machinery Directive

54V 10L Cordless Air Compressor

DCC1054

declares that these products described under

Technical Data are in compliance with:

2006/42/EC, EN1012‑1:2010, EN 60204‑1:2006/A1:2009.

2000/14/EC, Compressors , P<15kW,

Annex VII, Deutsche Prüf‑ und Zertifizierungsstelle für Land‑

und Forsttechnik, Spremberger Straße 1, 64823 Groß‑Umstadt,

Notified Body ID No.:0363.

tool. Years of experience, thorough

DC

one of the

DCC1054

54

quick coupling

Level of sound power according to 2000/14/EC

(Article 12, Annex III, No. 9:)

LWA (measured sound power level) dB 91

LWA (guaranteed sound power level) dB 92

These products also comply with Directive 2014/30/EU,

2014/29/EU, and 2011/65/EU. For more information, please

contact

themanual.

The undersigned is responsible for compilation of the technical

file and makes this declaration on behalf of

Markus Rompel

Director Engineering

D‑65510, Idstein, Germany

20.11.2017

at the following address or refer to the back of

, Richard‑Klinger‑Straße 11,

WARNING: To reduce the risk of injury, read the

instructionmanual.

.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

thesesymbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

seriousinjury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or

seriousinjury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderateinjury.

NOTICE: Indicates a practice not related to

personal injury which, if not avoided, may result in

propertydamage.

Denotes risk of electricshock.

Denotes risk offire.

SAFETY INSTRUCTIONS

Important Safety Instructions for Use of the

Compressor

WARNING: DEATH OR SERIOUS BODILY INJURY

COULD RESULT FROM IMPROPER OR UNSAFE USE

OF COMPRESSOR. TO AVOID THESE RISKS, FOLLOW

THESE BASIC SAFETYINSTRUCTIONS.

2

Page 5

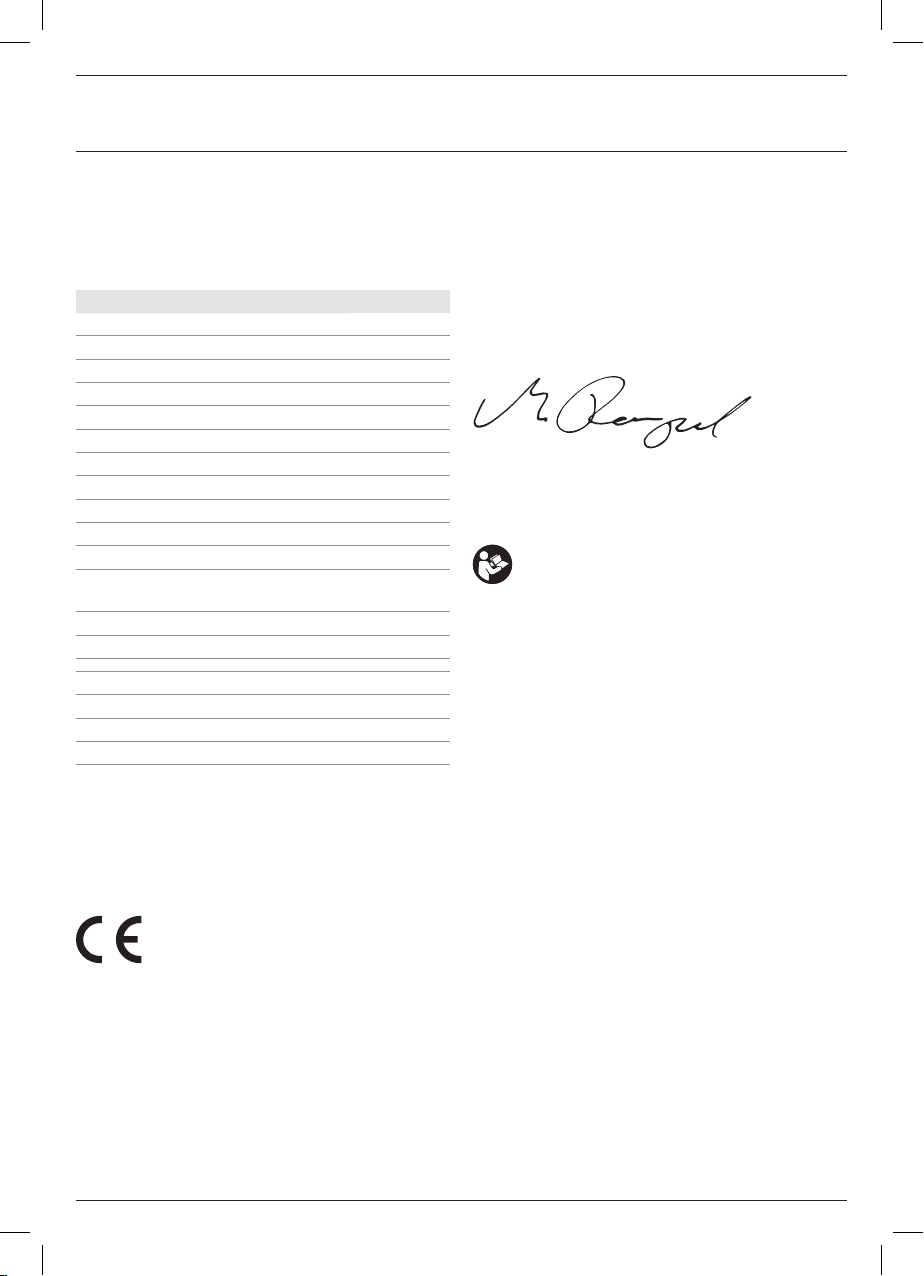

Weight

Batteries Chargers/Charge Times (Minutes)

Cat # V

Ah Weight (kg) DCB107 DCB113 DCB115 DCB118 DCB132 DCB119

DC

DCB546 18/54 6.0/2.0 1.05 270 140 90 60 90 X

DCB547 18/54 9.0/3.0 1.25 420 220 140 85 140 X

DCB181 18 1.5 0.35 70 35 22 22 22 45

DCB182 18 4.0 0.61 185 100 60 60 60 120

DCB183/B 18 2.0 0.40 90 50 30 30 30 60

DCB184/B 18 5.0 0.62 240 120 75 75 75 150

DCB185 18 1.3 0.35 60 30 22 22 22 X

DCB187 18 3.0 0.48 140 70 45 45 45 90

ENGLISH

READ ALL INSTRUCTIONS

1 . NEVER TOUCH MOVING PARTS. Never place your

hands, fingers or other body parts near the compressor’s

movingparts.

2 . NEVER OPERATE WITHOUT ALL GUARDS IN PLACE

Never operate this compressor without all guards or

safety features in place and in proper working order. If

maintenance or servicing requires the removal of a guard or

safety features, be sure to replace the guards or safety feature

before resuming operation of thecompressor.

3 . ALWAYS WEAR EYE PROTECTION. Always wear safety

goggles or equivalent eye protection. Compressed air

must never be aimed at anyone or any part of thebody.

4 . PROTECT YOURSELF AGAINST ELECTRIC SHOCK. Prevent

body contact with grounded surfaces such as pipes,

radiators, ranges and refrigeration enclosures. Never

operate the compressor in damp or wet locations. Never

leave the compressor exposed to adverse weatherconditions.

5 . DISCONNECT THE COMPRESSOR WHEN NOT IN USE.

Always disconnect the compressor from the power source and

remove the compressed air from the air tank before servicing,

inspecting, maintaining, cleaning, replacing or checking

anyparts.

6 . AVOID UNINTENTIONAL STARTING. Do not transport

the compressor over long distances, in a vehicle or in

potentially dangerous situations, for example, on a

ladder or scaffold while it is connected to its power

source or when the air tank is filled with compressed air.

Be sure the auto ON/ OFF switch is in the OFF position before

connecting the compressor to its powersource.

7 . STORE COMPRESSOR PROPERLY. When not in use, the

compressor should be stored in dry place. Keep out of

reach of children. Lock‑out the storagearea.

8 . KEEP WORK AREA CLEAN Cluttered areas invite injuries.

Clear all work areas of unnecessary tools, debris, furnitureetc.

9 . KEEP CHILDREN AWAY. Do not let visitors contact

compressor extension cord. All visitors should be kept safely

away from workarea.

10 . DRESS PROPERLY. Do not wear loose clothing or

jewellery. They can be caught in moving parts. Wear

protective hair covering to contain longhair.

11 . STAY ALERT. Watch what you are doing. Use common

sense. Do not operate compressor when you are tired.

Compressor should never be used by you if you are under

the influence of alcohol, drugs or medication that makes

youdrowsy.

12 . CHECK FOR DAMAGED PARTS AND AIR LEAKS. Before

further use of the compressor, carefully check the guard

and other parts for damage to make sure that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, air leak, and any

other conditions that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced by an authorized service centre

unless otherwise indicated elsewhere in this Instruction

Manual. Have defective pressure switches replaced

by authorized service centre. Do not use compressor

if switch does not turn it on and off. Never attempt

to repair a leaking or damaged air tank. Replace tank

immediately at an authorized servicecentre.

13 . NEVER USE COMPRESSOR FOR APPLICATIONS OTHER

THAN THOSE SPECIFIED. Never use compressor for

applications other than those specified in the Instruction

Manual. Never use compressed air for breathing or

respiration. Never stand on thecompressor.

14 . HANDLE COMPRESSOR CORRECTLY. Operate the

compressor according to the instructions provided

herein. Never allow the compressor to be operated by

children, individuals unfamiliar with its operation or

unauthorisedpersonnel.

15 . KEEP ALL SCREWS, BOLTS AND COVERS TIGHTLY

IN PLACE. Keep all screws, bolts, and plates tightly

mounted. Check their conditionsperiodically.

16 . KEEP MOTOR AIR VENT CLEAN The motor air vent must

be kept clean so that air can freely flow at all times.

Check for dust build‑upfrequently.

17 . OPERATE COMPRESSOR AT THE RATED VOLTAGE.

Operate the compressor at voltages specified on their

nameplates. If using the compressor at a higher voltage

than the rated voltage, it will result in abnormally fast motor

revolution and may damage the unit and burn out themotor.

18 . NEVER USE A COMPRESSOR WHICH IS DEFECTIVE OR

OPERATING ABNORMALLY. If the compressor appears to

3

Page 6

ENGLISH

DeWALT

DeWALT

DeWALT

be operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange for

repairs by an authorized servicecentre.

19 . DO NOT WIPE PLASTIC PARTS WITH SOLVENT. Solvents

such as gasoline, thinner, benzine, carbon tetrachloride,

and alcohol may damage and crack plastic parts. Do not

wipe them with such solvents. Wipe plastic parts with a soft

cloth lightly dampened with soapy water and drythoroughly.

20 . USE ONLY GENUINE REPLACEMENT PARTS. Replacement

parts not original may void your warranty and can lead

to malfunction and resulting injuries. Genuine parts are

available from yourdealer.

21 . DO NOT MODIFY THE COMPRESSOR. Do not modify

the compressor. Always contact the authorized service

centre any repairs. Unauthorised modification may

not only impair the compressor performance but may

also result in accident or injury to repair personnel who

do not have the required knowledge and technical

expertise to perform the repair operations correctly.

Unauthorised modifications may increase the risk of injury to

the user or the risk of propertydamage.

22 . TURN OFF THE SWITCH WHEN THE COMPRESSOR IS NOT

USED. When the compressor is not used, turn the switch OFF,

disconnect it from the power source and open the drain cock

to discharge the compressed air from the airtank.

23 . NEVER TOUCH HOT SURFACE. To reduce the risk of burns,

do not touch tubes, heads, cylinder andmotors.

24 . DO NOT DIRECT AIR STREAM AT BODY. Risk of injury, do

not direct air stream at persons oranimals.

25 . DRAIN TANK DAILY OR AFTER EACH USE. Open the

drain valve and tilt compressor to completely empty

accumulated water. Failure to properly drain tank may

result in excessive corrosion, which may cause sudden air tank

rupture orexplosion.

26 . DO NOT STOP COMPRESSOR BY PULLING OUT THE

BATTERY. Use the auto ON/ OFFswitch.

27 . USE ONLY RECOMMENDED AIR HANDLING PARTS

ACCEPTABLE FOR PRESSURE NOT LESS THAN 9.3 BAR

Risk of bursting. Use only recommended air handling parts

acceptable for pressures not less than 9.3bar.

28 . WEAR PROPER HEARING AND HEAD PROTECTION.

Suitable protective clothing must be worn when

operating the compressor and connected tool or

accessory. Consult the tool/ accessory manual and adhere to

any safetyrequirements.

29 . MAKE ALLOWANCE FOR ENVIRONMENTAL CONDITIONS.

Never leave the compressor in the rain. Never use the

compressor in damp or wet conditions. Provide good

lighting. Never use the compressor near combustible liquids

orgases.

30 . DO NOT OPERATE IN EXPLOSIVE ATMOSPHERES, SUCH

AS IN THE PRESENCE OF FLAMMABLE LIQUIDS, GASES OR

DUST. Compressors can create sparks which may ignite the

dust orfumes.

31 . CHECK THE PRESSURE VESSEL FOR SIGNS OF RUST AND

DAMAGE EACH TIME BEFORE USING. Do not use the

compressor with a damaged or rusty pressurevessel.

Residual Risks

In spite of the application of the relevant safety regulations

and the implementation of safety devices, certain residual risks

cannot be avoided. These are:

• Impairment ofhearing.

• Risk of personal injury due to flyingparticles.

• Risk of burns due to accessories becoming hot

duringoperation.

• Risk of personal injury due to prolongeduse.

• Risk of personal injury if the adjusted pressure is higher than

maximum pressure of thetool.

Electrical Safety

The electric motor has been designed for one voltage only.

Always check that the battery pack voltage corresponds to the

voltage on the rating plate. Also make sure that the voltage of

your charger corresponds to that of yourmains.

Your

accordance with EN60335; therefore no earth wire

isrequired.

If the supply cord is damaged, it must be replaced by a

specially prepared cord available through the

serviceorganisation.

charger is double insulated in

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the oldplug.

• Connect the brown lead to the live terminal in theplug.

• Connect the blue lead to the neutralterminal.

WARNING: No connection is to be made to the

earthterminal.

Follow the fitting instructions supplied with good quality plugs.

Recommended fuse: 3A.

Using an Extension Cable

An extension cord should not be used unless absolutely

necessary. Use an approved extension cable suitable for

the power input of your charger (see Technical Data). The

minimum conductor size is 1mm2; the maximum length

is30m.

When using a cable reel, always unwind the cablecompletely.

SAVE THESE INSTRUCTIONS

Chargers

chargers require no adjustment and are designed to be

as easy as possible tooperate.

4

Page 7

Important Safety Instructions for All

DeWALT

DeWALT

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important

safety and operating instructions for compatible battery

chargers (refer to TechnicalData).

• Before using charger, read all instructions and cautionary

markings on charger, battery pack, and product using

batterypack.

WARNING: Shock hazard. Do not allow any liquid to get

inside charger. Electric shock mayresult.

WARNING: We recommend the use of a residual current

device with a residual current rating of 30mA orless.

CAUTION: Burn hazard. To reduce the risk of injury,

charge only

batteries may burst causing personal injury anddamage.

CAUTION: Children should be supervised to ensure that

they do not play with theappliance.

NOTICE: Under certain conditions, with the charger

plugged into the power supply, the exposed charging

contacts inside the charger can be shorted by foreign

material. Foreign materials of a conductive nature such

as, but not limited to, steel wool, aluminum foil or any

buildup of metallic particles should be kept away from

charger cavities. Always unplug the charger from the

power supply when there is no battery pack in the cavity.

Unplug charger before attempting to clean

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual. The charger

and battery pack are specifically designed to worktogether.

• These chargers are not intended for any uses other than

charging

may result in risk of fire, electric shock orelectrocution.

• Do not expose charger to rain orsnow.

• Pull by plug rather than cord when disconnecting

charger. This will reduce risk ofdamage to electric plug

andcord.

• Make sure that cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage orstress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk

of fire,electric shock, orelectrocution.

• Do not place any object on top of charger or place

the charger on a soft surface that might block the

ventilation slots and result in excessive internal heat.

Place the charger in a position away from any heat source. The

charger is ventilated through slots in the top and the bottom

of thehousing.

• Do not operate charger with damaged cord or plug—

have them replacedimmediately.

• Do not operate charger if it has received a sharp blow,

been dropped, or otherwise damaged in any way. Take it

to an authorised servicecentre.

• Do not disassemble charger; take it to an authorised

service centre when service or repair is required. Incorrect

rechargeable batteries. Other types of

rechargeable batteries. Any other uses

ENGLISH

reassembly may result in a risk of electric shock, electrocution

orfire.

• In case of damaged power supply cord the supply cord must

be replaced immediately by the manufacturer, its service agent

or similar qualified person to prevent anyhazard.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the risk of

electric shock. Removing the battery pack will not reduce

thisrisk.

• NEVER attempt to connect two chargerstogether.

• The charger is designed to operate on standard

230V household electrical power. Do not attempt to

use it on any other voltage. This does not apply to the

vehicularcharger.

Charging a Battery (Fig. B)

1. Plug the charger into an appropriate outlet before inserting

batterypack.

2. Insert the battery pack

battery pack is fully seated in the charger. The red (charging)

light will blink repeatedly indicating that the charging

process hasstarted.

3. The completion of charge will be indicated by the red

light remaining ON continuously. The battery pack is fully

charged and may be used at this time or left in the charger.

To remove the battery pack from the charger, push the

battery release button

NOTE: To ensure maximum performance and life of lithium‑ion

battery packs, charge the battery pack fully before firstuse.

2

into the charger, making sure the

3

on the batterypack.

Charger Operation

Refer to the indicators below for the charge status of the

batterypack.

Charge Indicators

Charging

Fully Charged

Hot/Cold Pack Delay*

* The red light will continue to blink, but a yellow indicator light

will be illuminated during this operation. Once the battery pack

has reached an appropriate temperature, the yellow light will

turn off and the charger will resume the chargingprocedure.

The compatible charger(s) will not charge a faulty battery pack.

The charger will indicate faulty battery by refusing to light or by

displaying problem pack or charger blinkpattern.

NOTE: This could also mean a problem with acharger.

If the charger indicates a problem, take the charger and battery

pack to be tested at an authorised servicecentre.

Hot/Cold Pack Delay

When the charger detects a battery pack that is too hot or too

cold, it automatically starts a Hot/Cold Pack Delay, suspending

charging until the battery pack has reached an appropriate

temperature. The charger then automatically switches to the

5

Page 8

ENGLISH

DeWALT

DeWALT

pack charging mode. This feature ensures maximum battery

packlife.

A cold battery pack will charge at a slower rate than a warm

battery pack. The battery pack will charge at that slower rate

throughout the entire charging cycle and will not return to

maximum charge rate even if the battery packwarms.

The DCB118 charger is equipped with an internal fan designed

to cool the battery pack. The fan will turn on automatically

when the battery pack needs to be cooled. Never operate the

charger if the fan does not operate properly or if ventilation slots

are blocked. Do not permit foreign objects to enter the interior

of thecharger.

Electronic Protection System

XR Li‑Ion tools are designed with an Electronic Protection

System that will protect the battery pack against overloading,

overheating or deepdischarge.

The tool will automatically turn off if the Electronic Protection

System engages. If this occurs, place the lithium‑ion battery

pack on the charger until it is fullycharged.

Wall Mounting

These chargers are designed to be wall mountable or to sit

upright on a table or work surface. If wall mounting, locate the

charger within reach of an electrical outlet, and away from a

corner or other obstructions which may impede air flow. Use

the back of the charger as a template for the location of the

mounting screws on the wall. Mount the charger securely using

drywall screws (purchased separately) at least 25.4mm long

with a screw head diameter of 7–9mm, screwed into wood to

an optimal depth leaving approximately 5.5mm of the screw

exposed. Align the slots on the back of the charger with the

exposed screws and fully engage them in theslots.

Charger Cleaning Instructions

WARNING: Shock hazard. Disconnect the charger

from the AC outlet before cleaning. Dirt and grease

may be removed from the exterior of the charger using a

cloth or soft non‑metallic brush. Do not use water or any

cleaning solutions. Never let any liquid get inside the tool;

never immerse any part of the tool into aliquid.

Battery Packs

Important Safety Instructions for All

Battery Packs

When ordering replacement battery packs, be sure to include

catalogue number andvoltage.

The battery pack is not fully charged out of the carton. Before

using the battery pack and charger, read the safety instructions

below. Then follow charging proceduresoutlined.

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Inserting or removing the battery from the charger may

ignite the dust orfumes.

• Never force battery pack into charger. Do not modify

battery pack in any way to fit into a non‑compatible

charger as battery pack may rupture causing serious

personalinjury.

• Charge the battery packs only in

• DO NOT splash or immerse in water or otherliquids.

• Do not store or use the tool and battery pack in

locations where the temperature may reach or exceed

40 ˚C (104 ˚F) (such as outside sheds or metal buildings

insummer).

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

lithium‑ion battery packs areburned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If

battery liquid gets into the eye, rinse water over the open eye

for 15 minutes or until irritation ceases. If medical attention

is needed, the battery electrolyte is composed of a mixture of

liquid organic carbonates and lithiumsalts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persists, seek

medicalattention.

WARNING: Burn hazard. Battery liquid may be flammable

if exposed to spark orflame.

WARNING: Never attempt to open the battery pack for

any reason. If battery pack case is cracked or damaged,

do not insert into charger. Do not crush, drop or damage

battery pack. Do not use a battery pack or charger that

has received a sharp blow, been dropped, run over or

damaged in any way (i.e., pierced with a nail, hit with

a hammer, stepped on). Electric shock or electrocution

may result. Damaged battery packs should be returned to

service centre forrecycling.

WARNING: Fire hazard. Do not store or carry the

battery pack so that metal objects can contact

exposed battery terminals. For example, do not place

the battery pack in aprons, pockets, tool boxes, product kit

boxes, drawers, etc., with loose nails, screws, keys,etc.

CAUTION: When not in use, place tool on its side on

a stable surface where it will not cause a tripping

or falling hazard. Some tools with large battery packs

will stand upright on the battery pack but may be easily

knockedover.

Transportation

WARNING: Fire hazard. Transporting batteries can

possibly cause fire if the battery terminals inadvertently

come in contact with conductive materials. When

transporting batteries, make sure that the battery

terminals are protected and well insulated from materials

that could contact them and cause a shortcircuit.

batteries comply with all applicable shipping

regulations as prescribed by industry and legal standards which

include UN Recommendations on the Transport of Dangerous

Goods; International Air Transport Association (IATA) Dangerous

Goods Regulations, International Maritime Dangerous Goods

(IMDG) Regulations, and the European Agreement Concerning

chargers.

6

Page 9

The International Carriage of Dangerous Goods by Road (ADR).

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

Lithium‑ion cells and batteries have been tested to section 38.3

of the UN Recommendations on the Transport of Dangerous

Goods Manual of Tests andCriteria.

In most instances, shipping a

excepted from being classified as a fully regulated Class 9

Hazardous Material. In general, only shipments containing a

lithium‑ion battery with an energy rating greater than 100 Watt

Hours (Wh) will require being shipped as fully regulated Class 9.

All lithium‑ion batteries have the Watt Hour rating marked on

the pack. Furthermore, due to regulation complexities,

does not recommend air shipping lithium‑ion battery packs

alone regardless of Watt Hour rating. Shipments of tools with

batteries (combo kits) can be air shipped as excepted if the Watt

Hour rating of the battery pack is no greater than 100Whr.

Regardless of whether a shipment is considered excepted

or fully regulated, it is the shipper's responsibility to consult

the latest regulations for packaging, labeling/marking and

documentationrequirements.

The information provided in this section of the manual is

provided in good faith and believed to be accurate at the time

the document was created. However, no warranty, expressed or

implied, is given. It is the buyer’s responsibility to ensure that its

activities comply with the applicableregulations.

Transporting the FLEXVOLTTM Battery

The

andTransport.

Use Mode: When the FLEXVOLTTM battery stands alone or is in

a

18V product, it will operate as an 18V battery. When

the FLEXVOLTTM battery is in a 54V or a 108V (two 54V batteries)

product, it will operate as a 54Vbattery.

Transport Mode: When the cap is attached to the FLEXVOLTTM

battery, the battery is in Transport mode. Keep the cap for

shipping.

When in Transport mode, strings

of cells are electrically

disconnected within the pack

resulting in 3 batteries with a

lower Watt hour (Wh) rating as compared to 1 battery with a

higher Watt hour rating. This increased quantity of 3 batteries

with the lower Watt hour rating can exempt the pack from

certain shipping regulations that are imposed upon the higher

Watt hour batteries.

For example, the Transport

Wh rating might indicate

3x36 Wh, meaning 3

batteries of 36 Wh each.

The Use Wh rating might

indicate 108Wh (1batteryimplied).

FLEXVOLTTM battery has two modes: Use

battery pack will be

Example of Use and Transport Label Marking

Storage Recommendations

1. The best storage place is one that is cool and dry away

from direct sunlight and excess heat or cold. For optimum

battery performance and life, store battery packs at room

temperature when not inuse.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool, dry place out of the charger for

optimalresults.

NOTE: Battery packs should not be stored completely

depleted of charge. The battery pack will need to be recharged

beforeuse.

Labels on Charger and Battery Pack

In addition to the pictographs used in this manual, the

labels on the charger and the battery pack may show the

followingpictographs:

Read instruction manual beforeuse.

See Technical Data for chargingtime.

Do not probe with conductiveobjects.

Do not charge damaged batterypacks.

Do not expose to water.

Have defective cords replacedimmediately.

Charge only between 4 ˚C and 40 ˚C.

Only for indooruse.

Discard the battery pack with due care for

theenvironment.

Charge

than the designated

other dangeroussituations.

Do not incinerate the batterypack.

USE (without transport cap). Example: Wh rating

indicates 108 Wh (1 battery with 108 Wh).

TRANSPORT (with built‑in transport cap). Example:

Wh rating indicates 3 x 36 Wh (3batteries of 36Wh).

battery packs only with designated

chargers. Charging battery packs other

charger may make them burst or lead to

batteries with a

Battery Type

The DCC1054 operates on a 54 volt battery pack.

These battery packs may be used: DCB546, DCB547. Refer to

Technical Data for moreinformation.

ENGLISH

7

Page 10

ENGLISH

DeWALT

Package Contents

The package contains:

1 Air compressor

2 Li‑Ion battery packs (T2 models only)

1 Charger (T2 models only)

1 Instruction manual

NOTE: Battery packs, chargers and kitboxes are not included

with N‑models.

• Check for damage to the tool, parts or accessories which may

have occurred duringtransport.

• Take the time to thoroughly read and understand this manual

prior tooperation.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual beforeuse.

Wear earand eyeprotection.

Air tankcapacity.

Approx. cut‑outpressure.

Airdisplacement.

Oil‑lesspump.

Set outlet pressure to zero before the air hose is

attached orremoved.

Risk of hightemperatures.

CAUTION: the compressor contains some parts

which might reach hightemperatures.

Risk of accidental start‑up.

NOTICE: The compressor could start

automatically in case of a black‑out and

subsequentreset.

WARNING: Compressor unit may start

withoutwarning.

Outdoor noise level

Important Information

Read and understand all of the operating instructions, safety

precautions and warnings in the Instruction Manual before

operating or maintaining this compressor. Most accidents that

result from compressor operation and maintenance are caused by

the failure to observe basic safety rules or precautions. An accident

can often be avoided by recognizing a potentially hazardous

situation before it occurs, and by observing appropriate safety

8

procedures. Basic safety precautions are outlined in the “SAFETY”

section of this Instruction Manual and in the sections which

contain the operation and maintenance instructions. Hazards

that must be avoided to prevent bodily injury or machine damage

are identified by WARNINGS on the compressor and in this

InstructionManual.

Date Code Position (Fig. A)

The date code

is printed on a label on the rear of thetank.

Example:

13

, which also includes the year of manufacture,

2017 XX XX

Year of Manufacture

Description (Fig. A)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury couldresult.

1

Auto On/Off switch

2

Battery

3

Battery release button

4

Safety valve

5

Tank pressure gauge

6

One‑Turn regulator

7

Drain valve

8

Check valve

9

Quick‑connect coupler

10

Carry handle

11

Tank

Intended Use

Your compressor is designed for professional finish nailing and

staplingapplications.

DO NOT use under wet conditions or in the presence

of flammable liquids orgases. DO NOT use or store the

compressor at temperatures below 0°C.

Your compressor is a professional power tool.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

• Young children and the infirm. This appliance is not

intended for use by young children or infirm persons

without supervision.

• This product is not intended for use by persons (including

children) suffering from diminished physical, sensory or

mental abilities; lack of experience, knowledge or skills

unless they are supervised by a person responsible for their

safety. Children should never be left alone with thisproduct.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories. An accidental

start‑up can causeinjury.

WARNING: Use only

battery packs andchargers.

Page 11

Inserting and Removing the Battery Pack

DeWALT

from the Tool (Fig. C, D)

NOTE: Make sure your battery pack

To Install the Battery Pack into the Tool

Handle

1. Align the battery pack

handle (Fig.C).

2. Slide it into the handle until the battery pack is firmly seated

in the tool and ensure that you hear the lock snap intoplace.

To Remove the Battery Pack from the Tool

1. Press the release button

out of the toolhandle.

2. Insert battery pack into the charger as described in the

charger section of thismanual.

Fuel Gauge Battery Packs (Fig. D)

Some

consists of three green LED lights that indicate the level of

charge remaining in the batterypack.

To actuate the fuel gauge, press and hold the fuel gauge

button

illuminate designating the level of charge left. When the level

of charge in the battery is below the usable limit, the fuel gauge

will not illuminate and the battery will need to berecharged.

NOTE: The fuel gauge is only an indication of the charge left on

the battery pack. It does not indicate tool functionality and is

subject to variation based on product components, temperature

and end‑userapplication.

battery packs include a fuel gauge which

12

. A combination of the three green LED lights will

2

is fullycharged.

2

with the rails inside the tool’s

3

and firmly pull the battery pack

OPERATION

Instructions for Use

WARNING: Always observe the safety instructions and

applicableregulations.

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories. An accidental

start‑up can causeinjury.

WARNING: Ensure the compressor is placed firmly

to a stable flat surface. Failure to do so could cause

the compressor to be unstable and fall causing

personalinjury.

Know Your Air Compressor

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE

OPERATING YOUR UNIT. Compare the illustrations with your unit

to familiarise yourself with the location of various controls and

adjustments. Save this manual for futurereference.

Description of Operation (Fig. A)

Become familiar with these controls before operating theunit.

Auto On(I)/Off(O) Switch

position to provide automatic power to the pressure switch and

"Off" to remove power at the end of eachuse.

1

: Place this switch in the "AutoOn"

ENGLISH

Pressure Switch (not shown): The pressure switch

automatically starts the motor when the air tank pressure drops

below the factory set "cut‑in" pressure. It stops the motor when

the air tank pressure reaches the factory set "cut‑out"pressure.

Safety Valve

air compressor at its "cut‑out" pressure setting, the safety

valve will protect against high pressure by "popping out" at its

factory set pressure (slightly higher than the pressure switch

"cut‑out"setting).

Tank Pressure Gauge

the reserve air pressure in thetank.

One-Turn Regulator

the quick‑connect outlet. Turn the One‑Turn regulator clockwise

to increase pressure or anti‑clockwise to decrease pressure. Stop

when indicator matches with desired outlet pressure.

Cooling System (not shown): This compressor contains an

advanced design cooling system. At the heart of this cooling

system is an engineered fan. It is perfectly normal for this fan

to blow air through the vent holes in large amounts. You know

that the cooling system is working when air is beingexpelled.

Air Compressor Pump (not shown): Compresses air into the

air tank. Working air is not available until the compressor has

raised the air tank pressure above that required at the airoutlet.

Drain Valve

tank and is used to drain condensation at the end of eachuse.

Check Valve

check valve is "open", allowing compressed air to enter the air

tank. When the air compressor reaches "cut‑out" pressure, the

check valve "closes", allowing air pressure to remain inside the

airtank.

Motor Overload Protector (not shown): The motor has

a thermal overload protector. If the motor overheats for

any reason, the overload protector will shut off the motor.

The motor must be allowed to cool down before restarting.

Torestart:

1. Set the Auto On/Off switch to "Off".

2. Remove thebattery.

3. Allow the motor tocool.

4. Replace thebattery.

5. Set the Auto On/Off switch to "Auto On"position.

Quick-Connect Coupler

coupling body accepts industrial Push‑to‑Connectplugs.

4

: If the pressure switch does not shut off the

5

: The tank pressure gauge indicates

6

: Controls the air pressure available at

7

: The drain valve is located at the base of the air

8

: When the air compressor is operating, the

9

: The Universal EU 1/4" quick

How to Use Your Unit (Fig. E)

How to Stop

WARNING: When loosening the hose coupling from the

quick‑connect coupler

must be held by hand in order to avoid injuries caused by

the recoilinghose.

1. Set the Auto On/Off switch

2. Turn the One‑Turn regulator

outlet pressure tozero.

3. Remove hose andtool/accessories.

4. Remove battery when not in use.

9

, the coupling piece of the hose

1

to "Off".

6

anti‑clockwise to set the

9

Page 12

ENGLISH

DeWALT

DeWALT

Before Starting

WARNING: Do not operate this unit until you read

this instruction manual for safety, operation and

maintenanceinstructions.

Before Each Start‑Up

1. Set the Auto On/Off switch

2. Remove battery. (Refer to Installing and Removing the

Battery Pack from the Tool)

3. Turn the One‑Turn regulator

outlet pressure to zero.

4. Attach hose andtool/accessories.

WARNING: Risk of unsafe operation. Firmly grasp

air hose in hand when installing or disconnecting to

prevent hosewhip.

WARNING: Risk of unsafe operation. Do not use

damaged or wornaccessories.

NOTE: The hose or accessory will require a quick connect plug if

the air outlet is equipped with a quick connect body

WARNING: Risk of Bursting. Too much air pressure

causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air tools

and accessories. The regulator outlet pressure must never

exceed the maximum pressurerating.

NOTICE: Risk of property damage. Compressed air

from the unit may contain wa ter condensation and oil

mist. Do not spray un fil tered air at an item that could be

damaged by moisture. Some air tools and accessories may

require filtered air. Read the in struc tions for the air tools

andaccessories.

How to Start

1. Install the battery into thecompressor.

2. Attach hose andtool/accessories.

3. Set the Auto On/Off switch

tank pressure to build. Motor will stop when tank pressure

reaches "cut‑out"pressure.

4. Turn One‑Turn regulator

and stop when desired pressure isreached.

NOTE: Make sure that the desired pressure is not more

than the maximum pressure of the connected hose or the

connectedtool.

WARNING: Risk of unsafe operation. If any unusual

noise or vibration is noticed, stop the compressor

immediately and have it checked by a trained

servicetechnician.

WARNING: Ensure the regulator is set to a pressure lower

than the maximum operating pressure of thetool.

The compressor is ready foruse.

1

to "Off".

6

counterclockwise to set the

9

1

to "Auto On" and allow

6

clockwise to increase pressure

.

MAINTENANCE

Your

over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool

care and regularcleaning.

power tool has been designed to operate

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories. An accidental

start‑up can causeinjury.

The charger and battery pack are notserviceable.

Customer Responsibilities

Before each use Daily or after each use

Check Safety Valve X

Drain Tank X

Check for air leaks X

Check for unusual noise/vibration X

Check hose and tool connection X

Adjustment of pressure control X

WARNING: Risk of unsafe operation. Unit cycles

automatically when power is on. When performing

maintenance, you may be exposed to voltage sources,

compressed air, or moving parts. Personal injuries can

occur. Before performing any maintenance or repair,

disconnect power source from the compressor and bleed

off all airpressure.

NOTE: Refer to the Operation section for the location

ofcontrols.

To Check Safety Valve (Fig. E)

WARNING: Risk of Bursting. If the

safety valve does not work properly,

over‑pressurization may occur, causing air

tank rupture or anexplosion.

WARNING: Risk from Flying Objects. Always wear

certified eye protection with sideshields.

Before starting compressor, pull the ring on the safety valve

to make sure that the safety valve operates freely. If the valve

is stuck or does not operate smoothly. Contact the

servicecentre.

WARNING: Do not pull the ring of the safety valve if the

tank is under pressure!

To Drain Tank (Fig. E, F)

WARNING: Risk of Unsafe Operation. Air

tanks contain high pressure air. Keep face

and other body parts away from outlet of

drain. Use eye protection when draining as

debris can be kicked up intoface.

WARNING: Risk from noise. Always wear

proper hearing protection during use. Under

some conditions and duration of use, noise from this

product may contribute to hearingloss.

NOTE: All compressed air systems generate condensate that

accumulates in any drain point (e.g., tanks, filter, aftercoolers,

dryers). This condensate contains lubricating oil and/or

substances which may be regulated and must be disposed of in

accordance with currentregulations.

4

10

Page 13

WARNING: Risk of Bursting. Water will condense in the

DeWALT

DeWALT

DeWALT

air tank. If not drained, water will corrode and weaken the

air tank causing a risk of air tankrupture.

NOTICE: Risk of Property Damage. Drain water from

air tank may contain oil and rust which can causestains.

1. Set the Auto On/Off switch

2. Remove thebattery.

3. Turn the One‑Turn regulator

outlet pressure tozero.

4. Remove the air tool oraccessory.

WARNING: When loosening the hose coupling from the

quick‑connect coupler

must be held by hand in order to avoid injuries caused by

the recoilinghose.

5. Place a suitable container under the drain valve to

catchdischarge.

6. Pull ring on safety valve

tank until tank pressure is approximately 1.4 BAR. Release

safety valvering.

7. Drain water from air tank by opening drain valve

bottom oftank.

8. After the water has been drained, close the drain valve. The

air compressor can now bestored.

NOTE: If drain valve is blocked, release all air pressure by

connecting a tool to the airline and operating it until tank

pressure is zero BAR and contact the

1

to "Off".

6

counterclockwise to set the

9

, the coupling piece of the hose

4

allowing air to bleed from the

7

servicecentre.

on

Storage

Before you store the air compressor, make sure you do

thefollowing:

1. Review the Maintenance section and perform scheduled

maintenance asnecessary.

2. Always toggle Auto On/Off Switch to "Off" and remove

battery. Drain water from air tank. Refer to To Drain Tank

underMaintenance.

WARNING: Water will condense in the air tank. If not

drained, water will corrode and weaken the air tank

causing a risk of air tankrupture.

3. Store the air compressor in a clean and drylocation.

4. Make sure the air compressor is secured in such a way that it

cannot be started up again by any unauthorizedperson.

5. Frost destroys the pump and accessories as both always

contain water. If there is a risk of danger of frost, store in

frost‑freeconditions.

Cleaning

WARNING: Blow dirt and dust out of the main housing

with dry air as often as dirt is seen collecting in and around

the air vents. Wear approved eye protection and approved

dust mask when performing thisprocedure.

WARNING: Never use solvents or other harsh chemicals

for cleaning the non‑metallic parts of the tool. These

chemicals may weaken the materials used in these parts.

ENGLISH

Use a cloth dampened only with water and mild soap.

Never let any liquid get inside the tool; never immerse any

part of the tool into aliquid.

Optional Accessories

WARNING: Since accessories, other than those offered

by

of such accessories with this tool could be hazardous.

To reduce the risk of injury, only

accessories should be used with thisproduct.

Consult your dealer for further information on the

appropriateaccessories.

, have not been tested with this product, use

recommended

Protecting the Environment

Separate collection. Products and batteries marked

with this symbol must not be disposed of with normal

householdwaste.

Products and batteries contain materials that can

be recovered or recycled reducing the demand for raw

materials. Please recycle electrical products and batteries

according to local provisions. Further information is available at

www.2helpU.com.

Rechargeable Battery Pack

This long life battery pack must be recharged when it fails

to produce sufficient power on jobs which were easily done

before. At the end of its technical life, discard it with due care for

our environment:

• Run the battery pack down completely, then remove it from

thetool.

• Li‑Ion cells are recyclable. Take them to your dealer or a

local recycling station. The collected battery packs will be

recycled or disposed ofproperly.

GLOSSARY

Cut-In Pressure: While the motor is off, air tank pressure drops

when accessory is used. When the tank pressure drops to a

certain low level the motor will restart automatically. The low

pressure at which the motor automatically restarts is called

cut-inpressure.

Cut-Out Pressure: When an air compressor is turned on and

begins to run, air pressure in the air tank begins to build. It

builds to a certain high pressure before the motor automatically

shuts off, protecting your air tank from pressure higher than

its capacity. The high pressure at which the motor shuts off is

called cut-outpressure.

Duty Cycle: This air compressor pump is capable of running

continuously. However, to prolong the life of your air

compressor, it is recommended that a 50%–75% average duty

cycle be maintained; that is, the air compressor pump should

not run more than 30–45 minutes in any givenhour.

11

Page 14

ENGLISH

DeWALT

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator

or maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified

technician or yourdealer.

Code Possible Cause Possible Solution

Pressure switch does not shut off motor when

1

compressor reaches cut‑out pressure

2 Pressure switch cut‑out too high Contact a DeWALT service organisation.

Tube fittings are not tight enough Tighten fittings where air can be heard escaping. Check fittings with soapy water solution. Do

3

Defective air tank Air tank must be replaced. Do not repair the leak. Contact a DeWALT service organisation.

4

Leaking seals Contact a DeWALT service organisation.

5

Defective safety valve Operate safety valve manually by pulling on ring. If valve still leaks, it must be replaced. Contact a

6

Regulator is not adjusted correctly for accessory

7

being used

8 Prolonged excessive use of air Decrease amount of air usage.

Compressor doesn't provide enough air

9

for accessory

11 Check valve restricted Contact a DeWALT service organisation.

12 Air leaks Tighten fittings.

Regulator is damaged Contact a DeWALT service organisation.

13

Motor overload protection switch has tripped Refer to Motor Overload Protector under Description of Operations. If motor overload protection

14

Tank pressure exceeds pressure switch

15

cut‑in pressure

16 Loose electrical connections Contact a DeWALT service organisation.

17 Possible defective motor Contact a DeWALT service organisation.

Paint spray on internal motor parts Contact a DeWALT service organisation. Do not operate the compressor in the paint spray area. Refer to

18

Pump does not run because tank pressure is

19

above cut‑in pressure.

Pump does not run due to safety fault. Cycle Auto On/Off Switch from "Off" to "Auto On."

20

Set the Auto On/Off switch to "Off" and remove the batttery, if the unit does not shut off contact a

DeWALT service organisation.

Not Overtighten.

WARNING: Risk of bursting. Do not drill into, weld or otherwise modify air tank or it will

weaken. The air tank can rupture or explode.

DeWALT service organisation.

It is normal for some pressure drop to occur when an accessory is used, adjust the One‑Turn regulator

as instructed in One‑Turn Regulator under Description of Operations if pressure drop is excessive.

NOTE: Adjust the regulated pressure under flow conditions while accessory is being used.

Check the accessory air requirement. If it is higher than the Air Delivery (l/min) or pressure supplied by

your air compressor, a more powerful compressor is needed to operate accessory.

trips frequently, contact a DeWALT service organisation.

Motor will start automatically when tank pressure drops below cut‑in pressure of pressure switch.

flammable vapor warning.

Drain tank to below cut‑in pressure when pump turns on.

Troubleshooting Codes

Problem Code

Excessive air tank pressure‑safety valve pops off 1, 2

Air leaks 3

Air leaks in air tank or at air tank welds 4

Air leaks between head and valve plate 5

Air leaks from safety valve 6

Compressor is not supplying enough air to operate accessories 7, 8, 9, 10, 11, 12

Regulator knob has continuous air leak 13

Regulator will not shut off air outlet 13

Motor will not run 6, 14, 15, 16, 17, 18, 19, 20

12

Page 15

Page 16

Belgique et

Luxembourg België en Luxemburg

DeWALT - Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

www.dewalt.be

enduser.BE@SBDinc.com

Danmark DeWALT (Stanley Black&Decker AS)

Roskildevej 22

2620 Albertslund

Tel: 70 20 15 10

Fax: 70 22 49 10

www.dewalt.dk

kundeservice.dk@sbdinc.com

Deutschland DeWALT

Richard Klinger Str. 11

65510 Idstein

Tel: 06126-21-0

Fax: 06126-21-2770

www.dewalt.de

infodwge@sbdinc.com

Ελλάς DeWALT (Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) – 193 00 Ασπρόπυργος

Τηλ: 00302108981616

Φαξ: 00302108983570

www.dewalt.gr

Greece.Service@sbdinc.com

España DeWALT Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

Tel: 934 797 400

Fax: 934 797 419

www.dewalt.es

respuesta.postventa@sbdinc.com

France DeWALT

5, allée des Hêtres

BP 60105, 69579 Limonest Cedex

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

www.dewalt.fr

scufr@sbdinc.com

Schweiz

Suisse

Svizzera

DeWALT

In der Luberzen 42

8902 Urdorf

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

www.dewalt.ch

service@rofoag.ch

Ireland DeWALT

Building 4500, Kinsale Road

Cork Airport Business Park

Cork, Ireland

Tel: 00353-2781800

Fax: 01278 1811

www.dewalt.ie

Sales.ireland@sbdinc.com

Italia DeWALT

via Energypark 6

20871 Vimercate (MB), IT

Tel: 800-014353

39 039-9590200

Fax: 39 039-9590311

www.dewalt.it

Nederlands DeWALT

Netherlands BVPostbus 83,

6120 AB BORN

Tel: 31 164 283 063

Fax: 31 164 283 200

www.dewalt.nl

Norge DeWALT

Postboks 4613

0405 Oslo, Norge

Tel: 45 25 13 00

Fax: 45 25 08 00

www.dewalt.no

kundeservice.no@sbdinc.com

Österreich DeWALT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

www.dewalt.at

service.austria@sbdinc.com

Portugal DeWALT

Ed. D Dinis, Quina da Fonte

Rua dos Malhoes 2 2A 2º Esq.

Oeiras e S. Juliao da Barra, paço de Arcos e Caxias

2770 071 Paço de Arcos

Tel: +351 214667500

Fax: +351214667580

www.dewalt.pt

resposta.posvenda@sbdinc.com

Suomi DeWALT

PL47

00521 Helsinki, Suomi

Puh: 010 400 4333

Faksi: 0800 411 340

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

Sverige DeWALT

BOX 94

43122 Mölndal

Sverige

Tel: 031 68 61 60

Fax: 031 68 60 08

www.dewalt.se

kundservice.se@sbdinc.com

Türkiye

Sanayi ve Ticareet Bakanlığı tebliğince kullanim ömrü 7 yıldır.

Stanley Black & Decker Turkey Alet Üretim San. Tic. Ltd.Şti.

Kozyataği Mh Değirmen Sk.

Nida Kule No: 18 Kat: 6, 34742

Kadıköy, İstanbul, Türkiye

Tel: +90 216 665 2900

Faks: +90 216 665 2901

www.dewalt.com.tr

info-tr@sbdinc.com

United

Kingdom

DeWALT, 210 Bath Road;

Slough, Berks SL1 3YD

Tel: 01753-567055

Fax: 01753-572112

www.dewalt.co.uk

emeaservice@sbdinc.com

Australia DeWALT

810 Whitehorse Road Box Hill

VIC 3103 Australia

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

www.dewalt.com.au

www.dewalt.co.nz

Middle East Africa DeWALT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.ae

Service.MEA@sbdinc.com

N514792

10/17

Loading...

Loading...