Page 1

DC612, DC613, DC614, DC615, DC616, DC617, DC618, DC619

16 Gauge Cordless Nailer

Cloueur sans fil de calibre 16

Clavadora inalámbrica de calibre 16

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Questions? See us on the World Wide Web at www.dewalt.com

Before returning this product call

1-800-4-DEWALT

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US ACALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF D

E

WALT'S

QUALITY IMPROVEMENT PROGRAM.

644429-00,DC612 7/10/06 11:56 AM Page 1

Page 2

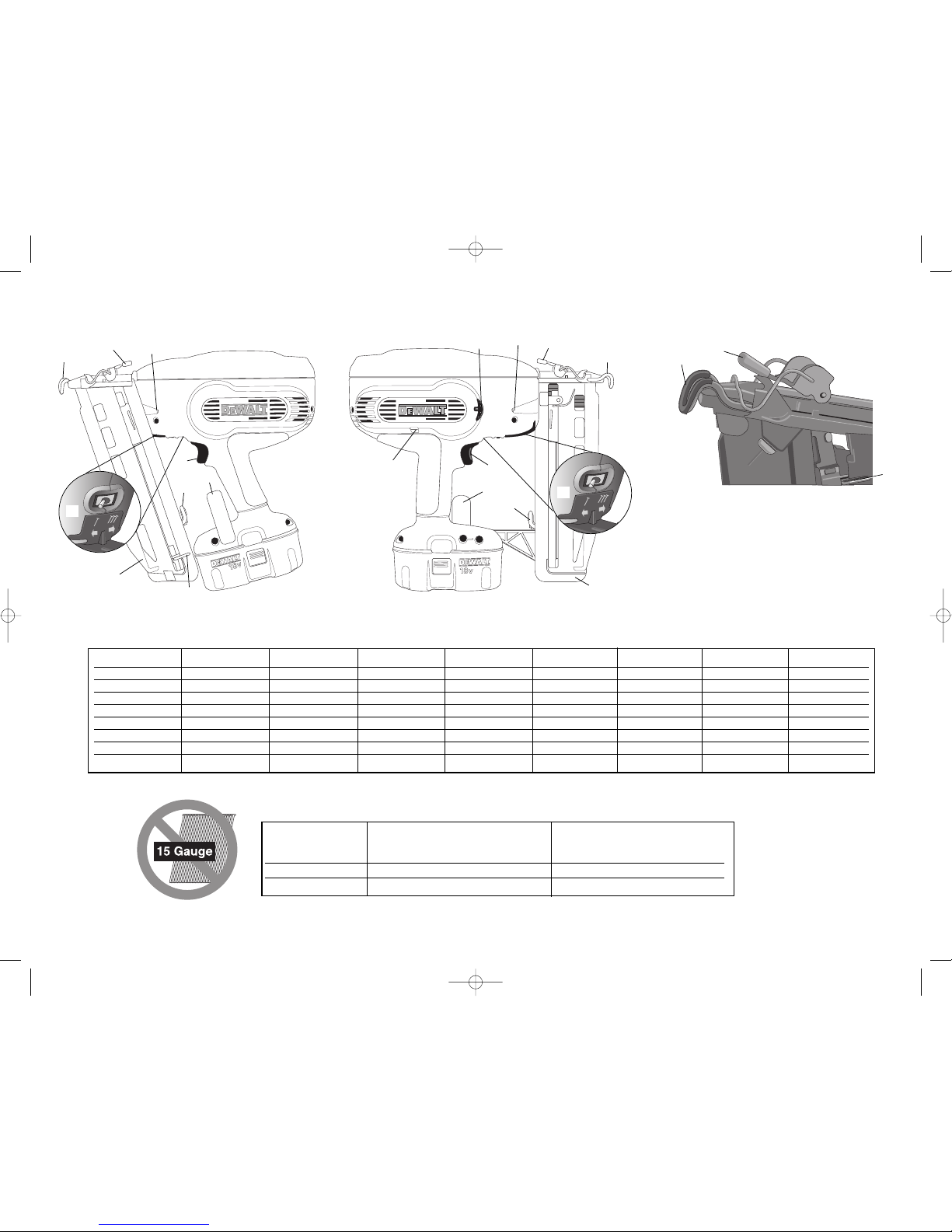

Angled 20˚

J

H

G

L

E

D

A

F

E

A. Trigger

B. Contact trip lock-off

C. Depth adjustment

wheel

D. Headlights/Low

battery indicator

E. Jam clearing latch

F. Contact trip

G. Magazine

H. Pusher

I. Bump/sequential

selector switch

J. Reversible suspension

hook

K. No-mar pad

L. No-mar tip storage

Straight

K

Angled Straight

Nail 1-1/4'', 1-1/2", 1-3/4", 2", 2-1/2" 1-1/4'', 1-1/2", 1-3/4", 2", 2-1/2"

Lengths (32mm, 38mm, 44mm, 51mm, 65mm) (32mm, 38mm, 44mm, 51mm, 65mm)

Shank Diameters 16 gauge 16 gauge

Nail Stick Angles 20˚ 0˚

TOOL SPECIFICATIONS

NAIL SPECIFICATIONS

FIG. 1

I

DC612 DC613 DC614 DC615 DC616 DC617 DC618 DC619

Firing Mode Selective Sequential Selective Sequential Selective Sequential Selective Sequential

Voltage Multi (14.4 & 12) Multi (14.4 & 12) Multi (14.4 & 12) Multi (14.4 & 12) 18 18 18 18

Height 12'' (305mm) 12'' (305mm) 12.4'' (315mm) 12.4'' (315mm) 12'' (305mm) 12'' (305mm) 12.4'' (315mm) 12.4'' (315mm)

Width 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm) 4.18'' (106mm)

Length 12.75'' (324mm) 12.75'' (324mm) 12.5'' (317mm) 12.5'' (317mm) 12.75'' (324mm) 12.75'' (324mm) 12.5'' (317mm) 12.5'' (317mm)

Weight 7.8lbs. (3.57kg) 7.8lbs. (3.57kg) 7.8lbs. (3.57kg) 7.8lbs. (3.57kg) 8.5lbs. (3.8kg) 8.5lbs. (3.8kg) 8.5lbs (3.8kg) 8.5lbs. (3.8kg)

Magazine Angle Straight Straight Angled 20˚ Angled 20˚ Straight Straight Angled 20˚ Angled 20˚

Loading Capacity Up to 110 Nails Up to 110 Nails Up to 120 Nails Up to 120 Nails Up to 110 Nails Up to 110 Nails Up to 120 Nails Up to 120 Nails

I

C

E

D

F

L

A

G

J

B

H

644429-00,DC612 7/10/06 11:56 AM Page 2

Page 3

English

1

IF YOU HAVE ANY QUESTIONS OR COMMENTS

ABOUT THIS OR ANY D

EWALT TOOL, CALL US TOLL

FREE AT: 1-800-4-D

EWALT (1-800-433-9258)

General Safety Rules – For All

Battery Operated Tools

WARNING! Read and understand all

instructions. Failure to follow all instruc-

tions listed below may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmos-

pheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

• Do not abuse the cord. Never use the cord to carry

the tool. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged cords

immediately. Damaged cords may create a fire.

• A battery operated tool with integral batteries or a

separate battery pack must be recharged only

with the specified charger for the battery. A charg-

er that may be suitable for one type of battery may

create a risk of fire when used with another battery.

• Use battery operated tool only with the specifical-

ly designed battery pack. Use of any other batteries

may create a risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inatten-

tion while operating power tools may result in serious

personal injury,

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose cloth-

ing, jewelry, or long hair can be caught in moving

parts. Air vents often cover moving parts and should

also be avoided.

• Avoid accidental starting. Be sure switch is in the

locked or OFF position before inserting battery

pack. Carrying tools with your finger on the switch or

inserting the battery pack into a tool with the switch on

invites accidents. Be sure contact trip is also in the

locked off position. This prevents nailer from accidental discharge.

• Remove adjusting keys or wrenches before turn-

ing the tool on. A wrench or key that is left attached

to a rotating part of the tool may result in personal

injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate

conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and

support the workpiece to a stable platform.

Holding the work by hand or against your body is

unstable and may lead to a loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off.

Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

• Disconnect battery pack from tool or place the

switch in the locked or off position before making

any adjustments, changing accessories, or storing the tool. Such preventative safety measures

reduce the risk of starting the tool accidentally.

• Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the

hands of untrained users.

• When battery pack is not in use, keep it away from

other metal objects like: paper clips, coins, keys,

nails, screws, or other small metal objects that

can make a connection from one terminal to

another. Shorting the battery terminals together may

cause sparks, burns, or a fire.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous

when used on another tool.

SERVICE

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury.

Important Safety

Instructions for Nailers

WARNING: When using any nailer, all safety

precautions, as outlined below, should be followed to avoid the risk of death or serious

injury. Read and understand all instructions

before operating the tool.

• Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the

operator.

• Actuating tool may result in flying

debris, collation material, or dust which

could harm operator’s eyes. The operator

and all those persons in the general area

should wear safety glasses with permanently attached side shields. Approved

safety glasses are imprinted with the characters “Z87.1”. It is the employer’s responsibility to enforce the use of eye protection

equipment by the tool operator and other

people in the work area. (Fig. A)

• Always wear appropriate personal hear-

ing and other protection during use.

Under some conditions and duration of use,

noise from this product may contribute to

hearing loss. (Fig. A)

• Disconnect battery pack from the tool

whenever clearing a jam, performing any

maintenance or repair, moving the tool

or when the tool is unattended.

• Do not remove, tamper with, or otherwise cause the tool, trigger, contact trip

lock-off, or contact trip to become inoperable. Do not tape or tie trigger or contact

trip in the on position. Do not remove spring

from contact trip. Uncontrolled discharge

could result.

• Do not operate a tool if any portion of the

tool, trigger, contact trip lock-off, or contact trip is inoperable, disconnected,

altered, or not working properly.

Damaged parts or missing parts should be

repaired or replaced before use.

• Do not alter or modify the tool in any way.

• Always assume that the tool contains

fasteners.

FIG. B

FIG. A

FIG. C

FIG. D

FIG. E

FIG. F

644429-00,DC612 7/10/06 11:56 AM Page 1

Page 4

English

2

• Do not point the tool at co-workers or

yourself at any time. No horseplay! Work

safe! Respect the tool as a working implement. (Fig. B)

• Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

When the tool is not in use, it should

be locked in a safe place out of reach of

children.

• Do not carry the tool from place to place

holding the trigger. Accidental discharge

could result.

• Always use contact trip lock-off when

tool is not in immediate use. Using the

contact trip lock-off will prevent accidental

discharge.

• Do not overreach. Maintain proper footing

and balance at all times. (Fig. C)

• Use the tool only for its intended use. Do

not discharge fasteners into open air,

concrete, stone, extremely hard woods,

knots or any material too hard for the

fastener to penetrate. Discharged fasten-

ers may follow unexpected path and cause

injury. (Figs. D, F)

• Do not use the body of the tool or top

cap as a hammer.

• Always keep fingers clear of nail track of

magazine to prevent injury from inadvertent release of the pusher. (Fig. G)

• Refer to the Maintenance and Repairs

sections for detailed information on the

proper maintenance of the tool.

• Always operate the tool in a clean, lighted area. Be sure the work surface is clear

of any debris and be careful not to lose footing when working in elevated environments

such as rooftops.

• Do not drive fasteners near edge of

material. The workpiece may split causing

the fastener to ricochet, injuring you or a coworker. Be aware that the nail may follow

the grain of the wood (shiner), causing it to

protrude unexpectedly from the side of the

work material. Drive the chisel point of the

nail perpendicular to the grain to reduce risk

of injury. (Figs. E, F, L)

• Keep hands and body parts clear of

immediate work area. Hold workpiece with

clamps when necessary to keep hands and

body out of potential harm. Be sure the

workpiece is properly secured before pressing the nailer against the material. The contact trip may cause the work material to shift

unexpectedly. (Fig. G)

• Do not use tool in the presence of flam-

mable dust, gases or fumes.The tool may

produce a spark that could ignite gases

causing a fire. Driving a nail into another

nail may also cause a spark. (Fig. H)

• Keep face and body parts away from

back of the tool cap when working in

restricted areas. Sudden recoil can result

in impact to the body, especially when nailing into hard or dense material. (Fig. I)

BUMP/SEQUENTIAL SELECTOR SWITCH

Sequential Action (Fig. J)

• When using the tool in sequential

action, do not actuate the tool unless

the tool is placed firmly against the

workpiece.

Bump Action (Fig. K)

• When using the tool in bump action, be

careful of unintentional double fires

resulting from tool recoil. Unwanted fas-

teners may be driven if the contact trip is

allowed to accidentally re-contact the work

surface.

TO AVOID DOUBLE FIRES:

• Do not engage the tool against the

work surface with a strong force.

• Allow the tool to recoil fully after

each actuation.

• Use sequential action trigger.

• When “bump” actuating the finish nailer,

always keep tool in control. Inaccurate

placement of tool can result in misdirected

discharge of a fastener.

• Do not drive nails onto the heads of other

fasteners. Strong recoil, jammed fasteners,

or ricocheted nails may result. (Fig. L)

• Be aware of material thickness when

using nailer. A protruding nail may cause

injury.

• DEPTH ADJUSTMENT: To reduce risk of

serious injury from accidental actuation

when attempting to adjust depth,

ALWAYS;

• Remove battery pack.

• Engage contact trip lock-off (Fig. M).

• Avoid contact with trigger during adjustments

• Do not drive nails blindly into walls,

floors or other work areas. Fasteners driven into live electrical wires, plumbing, or

other types of obstructions can result in

injury. (Fig. N)

• Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

WARNING: Use of this product will expose

you to chemicals known to the State of

California to cause cancer, birth defects and

other reproductive harm. Avoid inhaling

vapors and dust, and wash hands after

using.

• Avoid prolonged contact with dust from

power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water.

Allowing dust to get into your mouth, eyes,

or lay on the skin may promote absorption

of harmful chemicals.

FIG. K

FIG. J

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: When not in use, place tool on its side on a stable

surface where it will not cause a tripping or falling hazard.

Some tools with large battery packs will stand upright on the battery

pack but may be easily knocked over.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V..........volts A ..........amperes

Hz........hertz W ..........watts

min ......minutes ........alternating current

....direct current

n

o ........no load speed

........Class II Construction ..........earthing terminal

........safety alert symbol .../min....revolutions per minute

BEFORE OPERATING THIS TOOL, CAREFULLY READ AND

UNDERSTAND ALL INSTRUCTIONS IN THE “IMPORTANT

SAFETY INSTRUCTIONS” SECTION.

Important Safety Instructions

for Battery Packs

Your tool uses a DEWALT battery pack. When ordering replacement

battery packs, be sure to include catalog number and voltage:

Extended Run-Time battery packs deliver more run-time than standard battery packs. Consult the chart at the end of this manual for

compatibility of chargers and battery packs.

NOTE: Your tool will accept either standard or Extended Run Time

battery packs. However, be sure to select proper voltage. Batteries

slowly lose their charge when they are not on the charger, the best

place to keep your battery is on the charger at all times.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below.

Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or is completely worn out. The battery pack can explode

in a fire.

• A small leakage of liquid from the battery pack cells may

occur under extreme usage or temperature conditions. This

FIG. G

FIG. H

FIG. I

FIG. L

FIG. M

FIG. N

644429-00,DC612 7/10/06 11:56 AM Page 2

Page 5

English

3

Canada to facilitate the collection of spent nickel cadmium

and nickel metal hydride batteries. Help protect our environment and conserve natural resources by returning the spent

nickel cadmium and nickel metal hydride batteries to an

authorized D

EWALT service center or to your local retailer for

recycling. You may also contact your local recycling center

for information on where to drop off the spent battery.

RBRC™ is a registered trademark of the

Rechargeable Battery

Recycling Corporation.

Important Safety Instructions for

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains

important safety instructions for battery chargers.

• Before using charger, read all instructions and cautionary

markings on charger, battery pack, and product using battery pack.

DANGER: Electrocution hazard. 120 volts are present at

charging terminals. Do not probe with conductive objects.

WARNING: Shock hazard. Do not allow any liquid to get

inside charger.

CAUTION: Burn hazard. To reduce the risk of injury,

charge only D

E

WALT rechargeable batteries. Other types of

batteries may burst causing personal injury and damage.

CAUTION: Under certain conditions, with the charger

plugged in to the power supply, the exposed charging contacts inside the charger can be shorted by foreign material.

Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup of metallic

particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no

battery pack in the cavity. Unplug charger before attempting

to clean.

• DO NOT attempt to charge the battery pack with any

chargers other than the ones in this manual. The

charger and battery pack are specifically designed to

work together.

• These chargers are not intended for any uses other

than charging D

E

WALT rechargeable batteries. Any

other uses may result in risk of fire, electric shock or

electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting

charger. This will reduce risk of damage to electric plug

and cord.

• Make sure that cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result

in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity

of the cable, that is 16 gauge has more capacity than 18

gauge. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size.

Recommended Minimum Wire Size

for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the

charger on a soft surface that might block the ventilation slots and result in excessive internal heat.

Place the charger in a position away from any heat

source. The charger is ventilated through slots in the top

and the bottom of the housing.

• Do not operate charger with damaged cord or plug —

have them replaced immediately.

• Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in any

way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized

service center when service or repair is required.

Incorrect reassembly may result in a risk of electric shock,

electrocution or fire.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the risk of

electric shock. Removing the battery pack will not

reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard

household electrical power (120 Volts). Do not

attempt to use it on any other voltage. This does not

apply to the vehicular charger.

Using Automatic Tune-Up™ Mode

The automatic Tune-Up™ Mode equalizes or balances the

individual cells in the battery pack allowing it to function at

peak capacity. Battery packs should be tuned up weekly or

after 10 charge/discharge cycles or whenever the pack no

longer delivers the same amount of work. To use the automatic Tune-Up™, place the battery pack in the charger and

leave it for at least 8 hours. The charger will cycle through the

following modes.

1. The red light will blink continuously indicating that the 1hour charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will

stay on continuously and will no longer blink. This indicates that the pack is fully charged and can be used at

this time.

3. If the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up

mode. This mode continues up to 8 hours or until the

individual cells in the battery pack are equalized. The

battery pack is ready for use and can be removed at any

time during the Tune-Up mode.

does not indicate a failure. However, if the outer seal is

broken and this leakage gets on your skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or

vinegar.

c. If battery liquid gets into your eyes, flush them with

clean water for a minimum of 10 minutes and seek

immediate medical attention. (Medical note: The liquid is 25-35% solution of potassium hydroxide.)

• Charge the battery packs only in D

E

WALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations where the temperature may reach or exceed

105°F (such as outside sheds or metal buildings in

summer).

DANGER: Electrocution hazard. Never attempt to open

the battery pack for any reason. If battery pack case is

cracked or damaged, do not insert into charger. Electric

shock or electrocution may result. Damaged battery packs

should be returned to service center for recycling.

NOTE: Battery storage and carrying caps are

provided for use whenever the battery is out of

the tool or charger. Remove cap before placing

battery in charger or tool.

WARNING: Fire hazard. Do not store or

carry battery so that metal objects can

contact exposed battery terminals. For example, do not

place battery in aprons, pockets, tool boxes, product kit

boxes, drawers, etc., with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly

cause fires if the battery terminals inadvertently come in

contact with conductive materials such as keys, coins,

hand tools and the like. The US Department of

Transportation Hazardous Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes (i.e., packed in suitcases and carry-on luggage)

UNLESS they are properly protected from short circuits. So

when transporting individual batteries, make sure that the

battery terminals are protected and well insulated from materials that could contact them and cause a short circuit.

CAUTION: Battery pack must be securely attached to

tool. If battery pack is detached, personal injury may result.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling

Corporation) Seal on the nickel cadmium and

nickel metal hydride batteries (or battery

packs) indicate that the costs to recycle these

batteries (or battery packs) at the end of their

useful life have already been paid by D

EWALT. In some

areas, it is illegal to place spent nickel cadmium and nickel

metal hydride batteries in the trash or municipal solid waste

stream and the RBRC program provides an environmentally

conscious alternative.

RBRC™ in cooperation with D

EWALT and other battery

users, has established programs in the United States and

644429-00,DC612 7/10/06 11:56 AM Page 3

Page 6

English

4

4. Once the Automatic Tune Up mode is complete, the

charger will begin a maintenance charge; the red indicator will remain lit.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Chargers

Your tool uses a DEWALT Charger. Your battery can be

charged in D

E

E

WALT 1 Hour Chargers, 15 Minute Chargers

or Vehicular 12 volt charger. Be sure to read all safety

instructions before using your charger. Consult the chart on

the back cover of this manual for compatibility of chargers

and battery packs.

FIG. 2

Charging Procedure

DANGER: Electrocution hazard. 120 volts are present at

charging terminals. Do not probe with conductive objects.

1. Plug the charger into an appropriate outlet before

inserting battery pack.

2. Insert the battery pack into the charger. The red

(charging) light will blink continuously indicating that

the charging process has started (Fig. 2).

3. The completion of charge will be indicated by the red light

remaining ON continuously. The pack is fully charged and

may be used at this time or left in the charger.

Indicator Light Operation

Charge Indicators

Some chargers are designed to detect certain problems that

can arise with battery packs. Problems are indicated by the

red light flashing at a fast rate. If this occurs, re-insert battery

pack into the charger. If the problem persists, try a different

battery pack to determine if the charger is OK. If the new

pack charges correctly, then the original pack is defective

and should be returned to a service center or other collection

site for recycling. If the new battery pack elicits the same

trouble indication as the original, have the charger tested at

an authorized service center.

1 HOUR CHARGER

15 MINUTE CHARGER

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when

the charger detects a battery that is hot, it automatically

starts a Hot Pack Delay, suspending charging until the battery has cooled. After the battery has cooled, the charger

automatically switches to the Pack Charging mode. This feature ensures maximum battery life. The red light flashes

long, then short while in the Hot Pack Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When

the charger is used with some portable power sources such

as generators or sources that convert DC to AC, the charger

may temporarily suspend operation, flashing the red light

with two fast blinks followed by a pause. This indicates

the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the

red light glowing indefinitely. The charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept

out of the charger. If the battery pack has not been kept on

maintenance charge, it may need to be recharged before

use. A battery pack may also slowly lose its charge if left in

a charger that is not plugged into an appropriate AC source.

WEAK BATTERY PACKS: Chargers can also detect a

weak battery. Such batteries are still usable but should not

be expected to perform as much work. In such cases, about

10 seconds after battery insertion, the charger will beep

rapidly 8 times to indicate a weak battery condition. The

charger will then go on to charge the battery to the highest

capacity possible.

Important Charging Notes

1. Longest life and best performance can be obtained if the

battery pack is charged when the air temperature is

between 65°F and 75°F (18°- 24°C). DO NOT charge

the battery pack in an air temperature below +40°F

(+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to

touch while charging. This is a normal condition, and

does not indicate a problem.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or

other appliance

b. Check to see if receptacle is connected to a light

switch which turns power off when you turn out the

lights.

c. Move charger and battery pack to a location where

the surrounding air temperature is approximately

65°F - 75°F (18° - 24°C).

d. If charging problems persist, take the tool, battery

pack and charger to your local service center.

4. The battery pack should be recharged when it fails to

produce sufficient power on jobs which were easily done

previously. DO NOT CONTINUE to use under these

conditions. Follow the charging procedure. You may also

charge a partially used pack whenever you desire with

no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into

the power supply, the exposed charging contacts inside

the charger can be shorted by foreign material. Foreign

materials of a conductive nature such as, but not limited

to, steel wool, aluminum foil, or any buildup of metallic

particles should be kept away from charger cavities.

Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger

before attempting to clean.

6. Do not freeze or immerse charger in water or any other

liquid.

WARNING: Shock hazard. Don't allow any liquid to get

inside charger.

CAUTION:Never attempt to open the battery pack for any

reason. If the plastic housing of the battery pack breaks or

cracks, return to a service center for recycling.

Installing and Removing the

Battery Pack

CAUTION: Engage contact trip lock-off before removing

or installing battery.

NOTE: Make sure your battery pack is fully charged.

To install the battery pack into the tool handle, align the

base of the tool with the notch inside the tool’s handle and

slide the battery pack firmly into the handle until you hear the

lock snap into place.

To remove the battery pack from the tool, press the

release buttons (M) and firmly pull the battery pack out of the

tool handle. Insert it into the charger as described in the

charger manual (Fig. 4).

COMPONENTS

Refer to Figure 1 at the beginning of this manual for a complete list of components.

OPERATION

Mode Selection

WARNING: Always wear eye and ear protection when

operating tool.

The DEWALT cordless nailers are assembled in accordance

with the ANSI Standard SNT-101-2002.

FIG. 3

FIG. 4

M

644429-00,DC612 7/10/06 11:56 AM Page 4

Page 7

3. Release the pusher.

LOCK AND LOAD METHOD

CAUTION: Keep fingers clear of pusher to prevent injury.

CAUTION: The contact trip lock-off should always be

locked off whenever any adjustments are made or when tool

is not in use.

1. Pull pusher back until it locks.

2. Insert fasteners into the rear of the magazine.

3. Push forward on the pusher until it releases and slides

forward.

UNLOADING THE TOOL

CAUTION: The contact trip lock-off should always be

locked off whenever any adjustments are made or when tool

is not in use.

1. Pull pusher back until it locks.

2. Tip the tool up until the nails slide freely out the back of

the magazine

3. Open the jam clear door on the nosepiece to verify there

are no nails remaining.

Adjusting Depth (Fig. 10)

The depth that the fastener is driven can be adjusted using

the depth adjustment wheel (C) on the side of the tool.

WARNING: To reduce risk of serious injury from accidental actuation when attempting to adjust depth,

ALWAYS:

• Remove battery pack.

• Engage contact trip lock-off.

• Avoid contact with trigger during adjustments.

1. To drive the nail shallower, rotate the depth adjustment

wheel (C) counterclockwise. There are six depth settings,

1 being the shallowest and 6 being the deepest.

2. To sink a nail deeper, rotate the depth adjustment wheel

(C) clockwise.

Headlights (Fig. 10)

There is a headlight (D) located on each side of the nailer.

Headlights turn on upon battery insertion, activation of the

trigger, or depressing the contact trip. The lights will automatically shut off after 10 seconds unless tool remains in use.

NOTE: These headlights are for lighting the immediate work

surface and are not intended to be used as flashlights.

LOW BATTERY INDICATOR: The headlights will flash four

consecutive times and then shut down to indicate low battery.

C

D

FIG. 10

English

5

Before operating this tool, look at the selector switch to

determine the actuation mode. Read all instructions before

selecting actuation mode.

• D

EWALT cordless nailers DC613,

DC615, DC617, and DC619 are

ONLY capable of operating in

sequential action mode (Fig. 5).

SEQUENTIALACTION

Use sequential action for intermittent

nailing where very careful and accurate

placement is desired.

To operate the nailer in sequential

action mode:

1. Flip the switch located on the body

of the tool just between the trigger

and magazine to the left, as shown

in Figure 6.

2. Fully depress nosepiece against

the work surface (motor will start).

3. Pull trigger (nail will drive into work

surface).

4. Release trigger.

5. Lift nosepiece off work surface.

6. Repeat steps 2 through 4 for next application.

CAUTION: The contact trip needs to be depressed fol-

lowed by a trigger pull for each nail followed by a release of

both the contact trip and trigger after each nail.

• DEWALT cordless nailers DC612, DC614, DC616, and

DC618 are equipped with a bump/sequential selector

switch (Fig. 6).

BUMP ACTION

Bump action is intended for rapid nailing

on flat, stationary surfaces.

When using bump action, two methods

are available: place actuation and

bump actuation.

Flip the switch located on the body of the

tool just between the trigger and magazine

to the right as shown in Figure 7.

To operate the tool using the PLACE ACTUATION

method:

CAUTION: A nail will fire each time the trigger is

depressed as long as the contact trip remains depressed.

1. Depress the contact trip against the work surface.

2. Depress the trigger.

To operate the tool using the BUMP ACTUATION

method:

1. Depress the trigger.

FIG. 7

FIG. 6

FIG. 5

2. Push the contact trip against the work surface. As long

as the trigger is depressed, the tool will fire a nail every

time the contact trip is depressed. This allows the user to

drive multiple nails in sequence.

CAUTION: Do not keep trigger depressed when tool is

not in use. Keep the contact trip lock-off engaged in the

locked position when the tool is not in use.

Preparing the Tool

CAUTION: NEVER spray or in any other way apply lubri-

cants or cleaning solvents inside the tool. This can seriously

affect the life and performance of the tool.

NOTE:The battery pack is not fully charged out of the carton.

Follow instructions outlined (see Charging Procedures).

1.

Read the Safety Instruction section of this manual.

2. Wear eye and ear protection.

3. Ensure magazine is empty of all fasteners.

4. Check for smooth and proper operation of contact trip

and pusher assemblies. Do not use tool if either assembly is not functioning properly. NEVER use a tool that has

the contact trip restrained in the actuated position.

5. Keep tool pointed away from yourself and others.

6. Insert fully charged battery pack.

Using the Contact Trip Lock-off

(Fig. 8, 9)

WARNING: Always wear eye and

ear protection when operating tool.

Each DEWALTnailer is equipped with a

contact trip lock-off (B) which when

pulled downward with the lock symbol

showing as shown, prevents the tool

from firing a nail.

When the contact trip lock-off is

folded in as shown, the tool will be

fully operational. The contact trip lockoff should always be locked off whenever any adjustments are made or

when tool is not in immediate use.

NOTE: Tools equipped with selective

actuation, when in bump fire mode will

allow the motor to start upon trigger pull. This is normal operation. The contact trip lock-off constrains the contact trip from

discharging a nail.

Loading the Tool

CAUTION: Keep tool pointed in a safe direction when

loading nails.

CAUTION: Never load nails with the contact trip or trigger

activated.

CAUTION:Always remove battery pack before loading or

unloading nails.

LOAD AND DRAW METHOD (FIG. 1)

1. Insert fasteners into the rear of the magazine (G).

2. Pull pusher (H) back until the nail follower falls behind

the nails.

B

FIG. 9

B

FIG. 8

644429-00,DC612 7/10/06 11:56 AM Page 5

Page 8

English

6

WARNING: Remove nails from magazine before making

any adjustments or servicing this tool. Failure to do so may

result in serious injury.

CAUTION: Disconnect battery pack from tool before

making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures

reduce the risk of starting the tool accidentally.

CAUTION: When not in use, place tool on its side on a

stable surface where it will not cause a tripping or falling

hazard. Some tools with large battery packs will stand

upright on the battery pack but may be easily knocked over.

MAINTENANCE

Daily Maintenance Chart

ACTION Clean magazine, pusher, and contact trip mechanism.

WHY Permits smooth operation of magazine, reduces wear,

and prevents jams.

HOW Blow clean with compressor air. The use of oils, lubri-

cants periodically or solvents is not recommended as

they tend to attract debris.

ACTION Before each use, check to insure all screws, nuts and

fasteners are tight and undamaged.

WHY Prevents jams and premature failure of tool parts.

HOW Tighten loose screws or other fasteners using the

appropriate allen wrench or screwdriver.

Cleaning

Use only mild soap and a damp cloth to clean the tool. Many

household cleaners contain chemicals which could seriously

damage plastic. Also, do not use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products.

Never let any liquid get inside the tool; never immerse any

part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Disconnect the charger from the AC outlet

before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic

brush. Do not use water or any cleaning solutions.

Lubrication

CAUTION: NEVER spray or in

any other way apply lubricants or

cleaning solvents inside the tool. This can

seriously affect the life and performance

of the tool.

DEWALT tools are properly lubricated at

the factory and are ready for use.

However, it is recommended that, once a year, you take or

send the tool to a certified service center for a thorough

cleaning and inspection.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and

replacement) should be performed by a D

EWALT factory

JAMMED NAIL INDICATOR: The headlights will flash continually if a nail becomes jammed in the nosepiece (see

Clearing a Jammed Nail).

Clearing a Jammed Nail (Fig. 11)

If a nail becomes jammed in the nosepiece, keep the tool

pointed away from you and follow these instructions to clear:

1. Remove battery pack from tool and engage contact trip

lock-off.

2. Pull the pusher back until it locks in place then remove

the nails.

3. Lift the jam clearing latch (E) then

pull up to open front door (O).

4. Remove bent nail, using pliers if

necessary.

5. If driver blade is in the down

position, insert screwdriver or

other rod into nosepiece and

push driver blade back in position.

6. Close the front door and engage

the wireform under the 2 arms (N) on the nosepiece.

Push latch until it locks in place.

7. Reinsert battery pack.

NOTE: The tool will disable itself and not reset until the

battery pack has been removed and reinserted.

8. Reinsert nails into magazine (see Loading the Tool).

9. Release pusher.

NOTE: Should nails continue to jam frequently in nosepiece,

have tool serviced by an authorized D

EWALT service center.

Cold Weather Operation

When operating tools at temperatures below freezing:

1. Keep tool as warm as possible prior to use.

2. Actuate the tool 5 or 6 times into scrap lumber before

using.

Hot Weather Operation

Tool should operate normally. However, keep tool out of direct

sunlight as excessive heat can deteriorate bumpers and other

rubber parts resulting in increased maintenance.

Suspension Hook (Fig. 12)

The DEWALT cordless nailers include an

integrated suspension hook (J) and can be

attached to either side of the tool to accommodate left- or right-handed users.

If the hook is not desired at all, it can be

removed from the tool.

TO REMOVE SUSPENSION HOOK

1. Remove battery pack from tool.

2. To switch the tool from right- to left-hand usage simply

remove the screw from the opposite side of the tool and

reassemble on the other side.

3. Replace battery pack.

J

FIG. 12

E

O

FIG. 11

N

service center, a DEWALT authorized service center or other

qualified service personnel. Always use identical replacement parts.

CAUTION: Disconnect battery pack from tool before

making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures

reduce the risk of starting the tool accidentally.

CAUTION: Remove nails from magazine before making

any adjustments or servicing this tool. Failure to do so may

result in serious injury.

TO SERVICE

1. Remove 3 T25 slotted screws from top cover. Remove

cover from housing and set aside.

2. Using a nail or punch, apply pressure to the pin (Q)

sliding the pin out from the metal structure (Fig. 13).

3. Push driver/return assembly (R) toward nosepiece and

hold in place against the lower bumper (V) as you roll

back the activation arm Assembly (S). Remove activation

arm assembly and set aside.

4. Use a flat blade screwdriver to pry up on the return cord

assembly (T) until the detents release. Lift up to remove

(Fig. 14).

5. Remove the driver/return assembly (Fig. 15).

6. Inspect lower bumper (V), upper bumper (X), and other

surfaces for cracks or damage and replace if necessary

(Fig. 16). Replace damaged return cord assembly.

TO REPLACE RETURN CORD ASSEMBLY

NOTE: For correct cord position during assembly, refer to the

proper orientation of the return cord assembly in Figure 15.

FIG. 17

RETURN CORD

ASSEMBLY

Available by calling

1-800-4-DEWALT

Y

V

X

FIG. 16

FIG. 15

DRIVER/RETURN ASSEMBLY

Available by calling

1-800-4-DEWALT

T

FIG. 14

R

S

Q

FIG. 13

V

U

W

644429-00,DC612 7/10/06 11:56 AM Page 6

Page 9

English

7

1. Align one of the rubber tabs (Y) from the new return

cord assembly with the corresponding slot in the driver

(Fig. 18).

2. With your finger, push and bend the rubber tab around

corner (Fig. 18) while pulling the rubber cord until tab is

firmly in place (Fig. 19).

3. Repeat above procedure for other rubber cord.

TO REASSEMBLE NAILER

1. Insert the tip of the driver/return assembly blade into the

matching hole in the nosepiece (Fig. 20).

2. Move contact trip (Z) to the side while pulling back on

the return cord assembly (Fig. 21).

3. Engage the hooks (AA) on the return cord assembly to

the notch (BB) in the metal structure then push down to

snap into detents (Fig. 22).

4. Slide the driver/return assembly (R) toward the nosepiece and hold.

5. Insert activiation arm assembly by first engaging the cam

pin (U) to the solenoid; then align the pivot holes (W) to

the metal structure (Fig. 13).

6. Slide the pin (Q) through the metal structure, capturing

the activation arm assembly and spring.

7. Ensure the activation arm is fully engaged as shown in

Figure 23.

8. Replace the cover to housing, insert 3 T25 slotted

screws and tighten.

FIG. 23

FIG. 22

AA

BB

FIG. 21

AA

Z

FIG. 20

FIG. 19

FIG. 18

Y

Accessories

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service

center. If you need assistance in locating any accessory,

please contact D

EWALT Industrial Tool Co., 701 East Joppa

Road, Baltimore, MD 21286, call 1-800-4-D

EWALT (1-800-

433-9258) or visit our website www.dewalt.com.

CAUTION: The use of any other accessory not recom-

mended for use with this tool could be hazardous.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com

or call 1-800-4-D

EWALT (1-800-433-9258). This warranty

does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other

rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by

our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

after purchase.

2 YEARS FREE SERVICE ON

XRP

™ BATTERY PACKS

DC9096, DC9091 and DC9071

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your D

EWALT Power Tool, Laser, or Nailer for any reason,

you can return it within 90 days from the date of purchase

with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America, see

country specific warranty information contained either in

the packaging, call the local company or see website for

warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning

labels (Fig. 24) become illegible or are missing, call 1-800-4D

EWALT for a free replacement.

644429-00,DC612 7/10/06 11:56 AM Page 7

Page 10

English

8

FIG. 24

644429-00,DC612 7/10/06 11:56 AM Page 8

Page 11

English

9

TROUBLESHOOTING GUIDE

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS,

CONTACT A D

EWALT SERVICE CENTER OR CALL 1-(800)-4-DEWALT.

DISCONNECT BATTERY PACK FROM TOOL BEFORE ALL REPAIRS

SYMPTOM CAUSE FIX

Tool doesn’t turn on Low battery charge or damaged battery Charge or replace battery

(Headlights don’t turn on) Terminals are dirty or damaged See authorized service center

Contact trip lock is in a locked position Unlock contact trip lock

Bent contact trip See authorized service center

Tool internal electronics not reset Remove battery, wait 3 seconds and reinsert

Damaged internal electronics See authorized service center

Tool doesn’t actuate Motor stops running after 2 seconds Normal operation; release trigger or contact trip and redepress

(Headlights on, motor does not run) Contact trip or trigger not depressed See instruction manual

Damaged trigger See authorized service center

Bent contact trip See authorized service center

Contact trip lock in the locked position Unlock contact trip lock

(Sequential mode only)

Damaged internal electronics See authorized service center

Tool doesn’t actuate (Headlights flash 4 times) Low battery charge or damaged battery Charge or replace battery

Tool doesn't actuate Jammed fastener Remove the battery, clear the jammed fastener, (push driver blade

back up manually if necessary) and reinsert battery pack

Jammed mechanism See authorized service center

Tool doesn’t actuate (Headlights on, motor runs) Damaged internal electronics See authorized service center

Tool doesn’t actuate Damaged return system Replace return system; see authorized service center

(Headlights on, motor runs, driver blade stuck down) Debris in nosepiece Clean nosepiece

Damaged driver/return assembly Replace driver/return assembly; see authorized service center

Tool operates, but does not drive the fastener fully Low battery charge or damaged battery Charge or replace battery

Depth adjustment set too shallow Rotate depth adjustment wheel to a deeper setting

Tool not firmly applied to workpiece See instruction manual

Material and fastener length Choose appropriate material or fastener length

too rigorous an application

Damaged or worn driver blade tip Replace driver/return assembly; see authorized service center

Damaged or worn driver/return assembly Replace driver/return assembly; see authorized service center

Tool operates, but no fastener driven No fasteners in magazine Load fasteners into magazine

Wrong size or angle fasteners Use only recommended fasteners

Debris in nosepiece Clean nosepiece

Debris in magazine Clean magazine

Worn magazine Replace magazine; see authorized service center

Damaged or worn driver blade Replace driver/return assembly; see authorized service center

Damaged pusher spring Replace spring; see authorized service center

Jammed fastener Wrong size or angle fasteners Use only recommended fasteners

Damaged or worn driver blade Replace driver/return assembly; see authorized service center

Material and fastener length Material or fastener length inappropriate

too rigorous an application

Low battery charge or damaged battery Charge or replace battery

Debris in nosepiece Clean nosepiece

Debris in magazine Clean magazine

Worn magazine Replace magazine; see authorized service center

Worn or damaged pusher spring Replace spring; see authorized service center

644429-00,DC612 7/10/06 11:56 AM Page 9

Loading...

Loading...