Page 1

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PUR-

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF DEWALT'S

QUALITY IMPROVEMENT PROGRAM.

Questions? See us at www.dewalt.com

CHASE,

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DC608

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO

Y POLIZA DE GARANTiA. ADVERTENCIA: LI_ASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

®

18 Gauge Cordless Nailer

Cloueuse sans fil pour clou de calibre 18

Clavadora inal_mbrica de calibre 18

Page 2

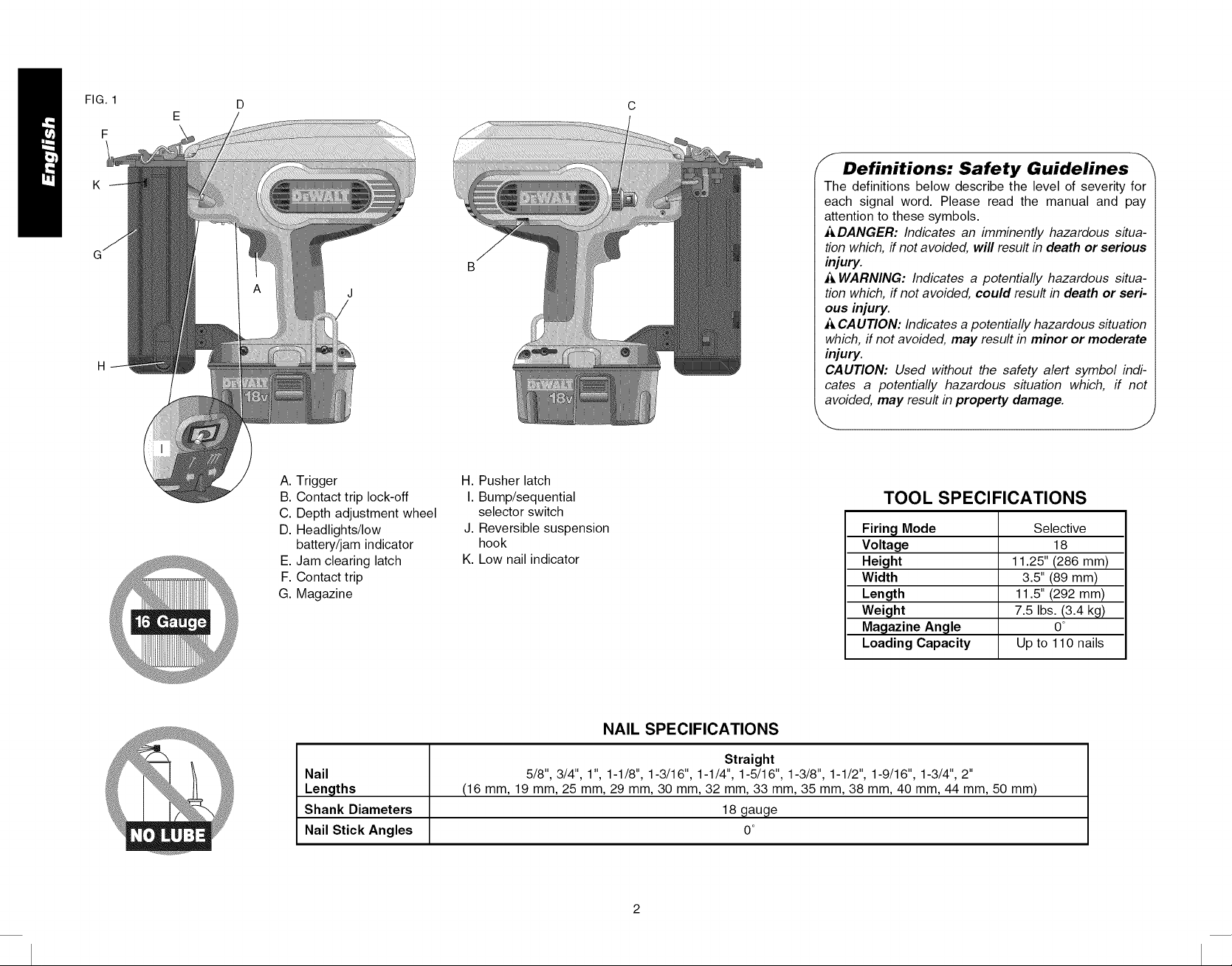

FIG. 1

F

K

f Definitions: Safety Guidelines

The definitions below describe the level of severity for

each signal word. Please read the manual and pay

attention to these symbols.

_IDANGER: Indicates an imminently hazardous situa-

tion which, ffnot avoided, will result in death or serious

injury.

=&WARNING: Indicates a potentially hazardous situa-

tion which, if not avoided, could result in death or seri-

ous injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION: Used without the safety alert symbol indi-

cates a potentially hazardous situation which, if not

avoided, may result in property damage.

A. Trigger

B. Contact trip lock-off

C. Depth adjustment wheel

D. Headlights/low

battery/jam indicator

E. Jam clearing latch

F. Contact trip

G. Magazine

Nail

Lengths

Shank Diameters

Nail Stick Angles

H. Pusher latch

I. Bump/sequential

selector switch

J. Reversible suspension

hook

K. Low nail indicator

TOOL SPECIFICATIONS

Firing Mode Selective

Voltage 18

Height 11.25" (286 mm)

Width 3.5" (89 mm)

Length 11.5" (292 mm)

Weight 7.5 Ibs. (3.4 kg)

Magazine Angle 0°

Loading Capacity Up to 110 nails

NAIL SPECIFICATIONS

Straight

5/8", 3/4", 1", 1-1/8", 1-3/16", 1-1/4", 1-5/16", 1-3/8", 1-1/2", 1-9/16", 1-3/4", 2"

(16 mm, 19 mm, 25 mm, 29 mm, 30 mm, 32 mm, 33 mm, 35 mm, 38 mm, 40 mm, 44 mm, 50 mm)

18 gauge

0o

Page 3

IFYOUHAVEANYQUESTIONSORCOMMENTS

ABOUTTHISORANYDEWALTTOOL,CALLUS

TOLLFREEAT:1-800-4-DEWALT(1-800-433-9258)

General Safety Rules - For All

Battery Operated Tools

_ WARNING! Read and understand all

instructions. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dusL Power tools

create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away

while operating a power tool Distractions can

cause you to lose control.

ELECTRICAL SAFETY

• Do not abuse the cord. Never use the cord to

carry the tooL Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords may create a

fire.

• A battery operated tool with integral batteries or

a separate battery pack must be recharged only

with the specified charger for the battery. A

charger that may be suitable for one type of battery

may create a risk of fire when used with another

battery.

• Use battery operated tool only with the

specifically designed battery pack. Use of any

other batteries may create a risk of fire.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool Do

not use tool while tired or under the influence

of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in

serious personal injury,

• Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothing, jewelry, or long hair can be caught

in moving parts. Air vents often cover moving parts

and should also be avoided.

• Avoid accidental starting. Be sure contact trip

lock-off is in the locked position before inserting

battery pack. Carrying tools with your finger on the

trigger or inserting the battery pack into a tool with

the trigger pulled invites accidents.

• Remove adjusting keys or wrenches before

turning the tool on. A wrench or key that is left

attached to a rotating part of the tool may result in

personal injury.

• Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

• Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body is

unstable and may lead to a loss of control

• Do not force tool Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool ff switch does not turn it on

or off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect battery pack from tool or place

the switch in the locked or off position before

making any adjustments, changing accessories,

or storing the tooL Such preventative safety

measures reduce the risk of starting the tool

accidentally.

• Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal

to another. Shorting the battery terminals together

may cause sparks, bums, or a fire.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation, ff damaged,

have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by

the manufacturer for your model Accessories

that may be suitable for one tool, may become

hazardous when used on another tool

SERVICE

• Tool service must be performed only by

qualified repair personnel Service or maintenance

performed by unqualified personnel could result in a

risk of injury.

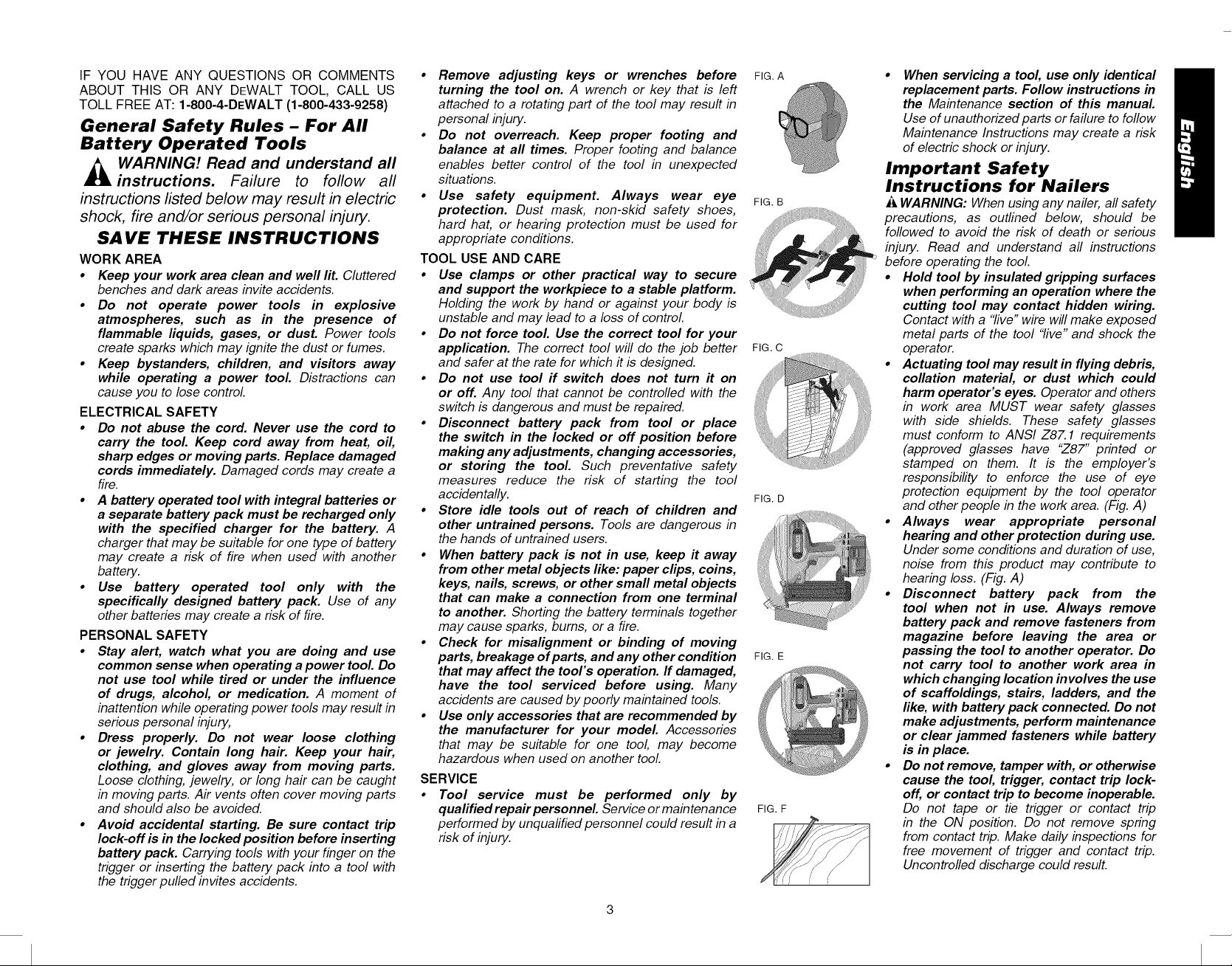

FIG. A

FIG. B

FIG. C

FIG. D

FIG. E

FIG. F

• When servicing a tool use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury.

Important Safety

Instructions for Nailers

WARNING: When using any nailer, all safety

..... precautions, as outlined below, should be

injury. Read and understand all instructions

| before operating the tool.

@ followed to avoid the risk of death or serious

......

• Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring.

Contact with a "live" wire will make exposed

metal parts of the tool "live" and shock the

operator.

Actuating tool may result in flying debris,

collation material, or dust which could

harm operator's eyes. Operator and others

in work area MUST wear safety glasses

with side shields. These safety glasses

must conform to ANSI Z87.1 requirements

(approved glasses have "Z87" printed or

stamped on them. It is the employer's

responsibility to enforce the use of eye

protection equipment by the tool operator

and other people in the work area. (Fig. A)

• Always wear appropriate personal

hearing and other protection during use.

Under some conditions and duration of use,

noise from this product may contribute to

hearing loss. (Fig. A)

• Disconnect battery pack from the

tool when not in use. Always remove

battery pack and remove fasteners from

magazine before leaving the area or

passing the tool to another operator. Do

not carry tool to another work area in

which changing location involves the use

of scaffoldings, stairs, ladders, and the

like, with battery pack connected. Do not

make adjustments, perform maintenance

or clear jammed fasteners while battery

is in place.

• Do not remove, tamper with, or otherwise

cause the tool, trigger, contact trip lock-

off, or contact trip to become inoperable.

Do not tape or tie trigger or contact trip

in the ON position. Do not remove spring

from contact trip. Make daily inspections for

free movement of trigger and contact trip.

Uncontrolled discharge could result.

3

Page 4

• Inspecttoolbefore use. Do notoperate

atoolif any portion of the tool, trigger,

contact trip lock-off, or contact trip is

inoperable, disconnected, altered, or

not working properly. Damaged parts

or missing parts should be repaired or

replaced before use. Refer to Repairs.

• Do not alter or modify the tool in any

way.

• Always assume that the tool contains

fasteners.

• Do not point the tool at co-workers

or yourself at any time. No horseplay!

Work safe! Respect the tool as a working

implement. (Fig. B)

• Keep bystanders, children, and

visitors away while operating a power

tool Distractions can cause you to lose

control When tool is not in use, it should

be locked in a safe place, out of the

reach of children.

• Always use contact trip lock-off when

tool is not in immediate use. Using

the contact trip lock-off will prevent

accidental discharge.

• Do not overreach. Maintain proper

footing and balance at all times. Loss

of balance may cause personal injury.

(Fig. C)

• Use the tool only for its intended

use. Do not discharge fasteners

into open air, concrete, stone,

extremely hard woods, knots or any

material too hard for the fastener

to penetrate. Do not use the body

of the tool or top cap as a hammer.

Discharged fasteners may follow

unexpected path and cause injury.

(Figs. D, F)

• Always keep fingers clear of contact

trip to pre vent injury from inadvertent

release of the pusher (Fig. H)

• Refer to the Maintenance and Repairs

sections for detailed information on

the proper maintenance of the tooL

• Always operate the tool in a clean,

lighted area. Be sure the work surface

is clear of any debris and be careful not

to lose footing when working in elevated

environments such as rooftops.

• Do not drive fasteners near edge

of materiaL The workpiece may split

causing the fastener to ricochet, injuring

you or a co-worker. Be aware that

the nail may follow the grain of the

wood (shiner), causing it to protrude

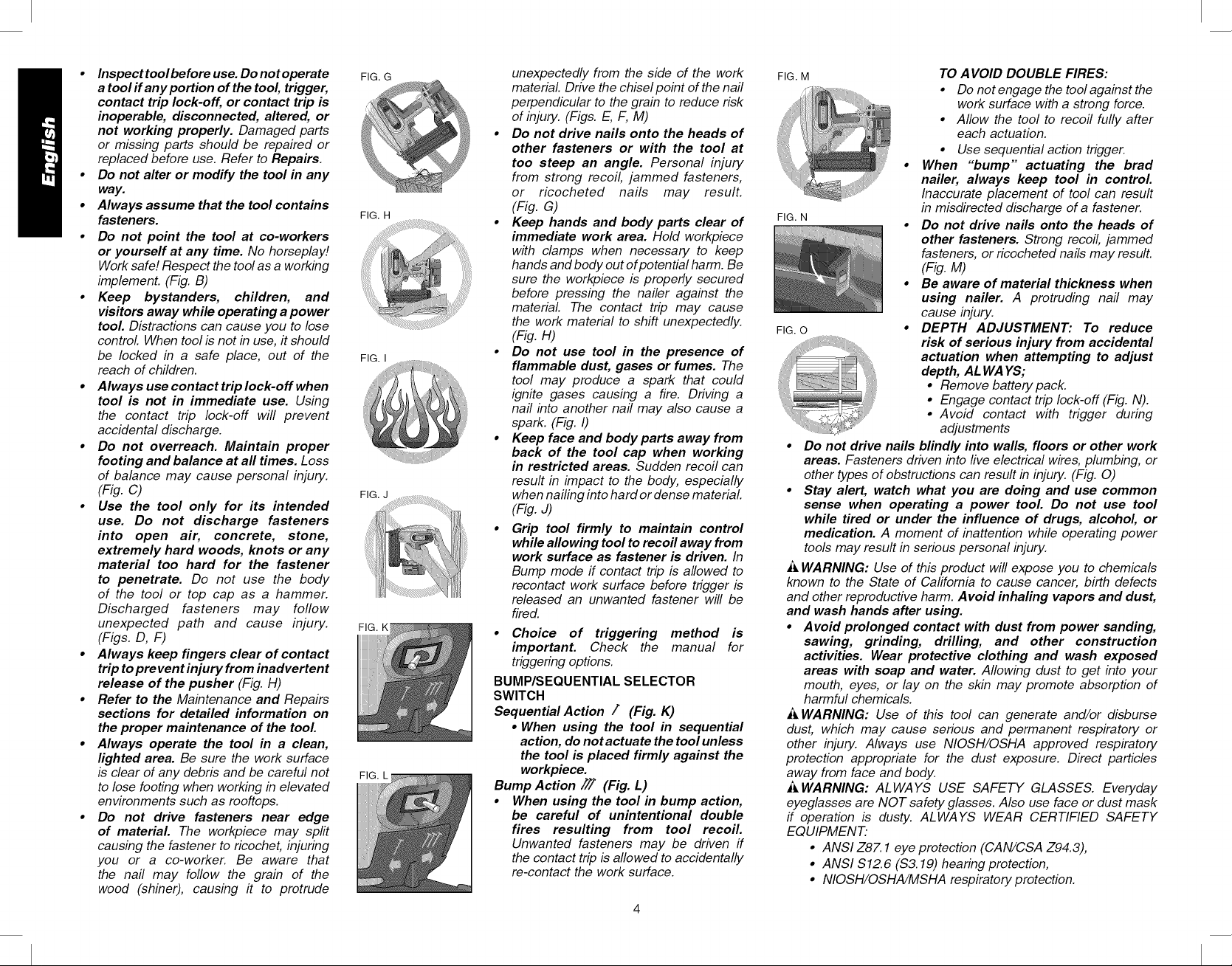

FIG. G

FIG. H

FIG. J

FIG. K

FIG.

unexpectedly from the side of the work

material Drive the chisel point of the nail

perpendicular to the grain to reduce risk

of injury. (Figs. E, F, M)

• Do not drive nails onto the heads of

other fasteners or with the tool at

too steep an angle. Personal injury

from strong recoil, jammed fasteners,

or ricocheted nails may result.

(Fig. G)

• Keep hands and body parts clear of

immediate work area. Hold workpiece

with clamps when necessary to keep

hands and body out of potential harm. Be

sure the workpiece is properly secured

before pressing the nailer against the

material The contact trip may cause

the work material to shift unexpectedly.

(Fig. H)

• Do not use tool in the presence of

flammable dust, gases or fumes. The

tool may produce a spark that could

ignite gases causing a fire. Driving a

nail into another nail may also cause a

spark. (Fig. I)

• Keep face and body parts away from

back of the tool cap when working

in restricted areas. Sudden recoil can

result in impact to the body, especially

when nailing into hard or dense material

(Fig. J)

• Grip tool firmly to maintain control

while allowing tool to recoil away from

work surface as fastener is driven. In

Bump mode if contact trip is allowed to

recontact work surface before trigger is

released an unwanted fastener will be

fired.

• Choice of triggering method is

importanL Check the manual for

triggering options.

BUMP/SEQUENTIAL SELECTOR

SWITCH

Sequential Action /" (Fig. K)

• When using the tool in sequential

action, do not actuate the tool unless

the tool is placed firmly against the

workpiece.

Bump Action iii (Fig. L)

• When using the tool in bump action,

be careful of unintentional double

fires resulting from tool recoil.

Unwanted fasteners may be driven if

the contact trip is allowed to accidentally

re-contact the work surface.

FIG. M

FIG. N

FIG. O

i!!

, • Engage contact trip lock-off (Fig. N).

.....,,,,, ....... • Avoid contact with trigger during

..... adjustments

• Do not drive nails blindly into walls, floors or other work

areas. Fasteners driven into five electrical wires, plumbing, or

other types of obstructions can result in injury. (Fig. O)

• Stay alert, watch what you are doing and use common

sense when operating a power tool Do not use tool

while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power

tools may result in serious personal injury.

A WARNING: Use of this product will expose you to chemicals

known to the State of California to cause cancer, birth defects

and other reproductive harm. Avoid inhaling vapors and dust,

and wash hands after using.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of

harmful chemicals.

A WARNING: Use of this tool can generate and/or disburse

dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles

away from face and body.

_ WARNING: ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask

if operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

TO A VOID DOUBLE FIRES:

• Do not engage the tool against the

work surface with a strong force.

• Allow the tool to recoil fully after

each actuation.

• Use sequential action trigger.

• When "bump" actuating the brad

nailer, always keep tool in control

Inaccurate placement of tool can result

in misdirected discharge of a fastener.

• Do not drive nails onto the heads of

other fasteners. Strong recoil, jammed

fasteners, or ricocheted nails may result.

(Fig. M)

• Be aware of material thickness when

using nailer. A protruding nail may

cause injury.

• DEPTH ADJUSTMENT: To reduce

• Remove battery pack.

depth, AL WAYS;

Page 5

A CAUTION: When not in use, place tool on its side on

a stable surface where it will not cause a tripping or

falling hazard. Some tools with large battery packs will

stand upright on the battery pack but may be easily

knocked over.

• The labelon your toolmayinclude the following symbols.

The symbols and their definitions are as follows:

V. .......... volts

Hz......... hertz

min .......minutes

-- - ....direct current

(_) ......... Class I Construction

(grounded)

......... earthing terminal

[] ......... Class II Construction

(double insulated)

BPM .....beats per minute

BEFORE OPERATING THIS TOOL, CAREFULLY READ

AND UNDERSTAND ALL INSTRUCTIONS IN THE

"IMPORTANT SAFETY INSTRUCTIONS" SECTION.

A ............. amperes

W............ watts

........... alternating

current

no ........... no load

speed

A ........... safety alert

symbol

.../min .....revolutions or

reciprocation

per minute

Important Safety Instructions

for Battery Packs

Your tool uses a DEWALT battery pack. When ordering

replacement battery packs, be sure to include catalog

number and voltage: Extended Run-Time battery packs

deliver more run-time than standard battery packs. Consult

the chart at the end of this manual for compatibility of

chargers and battery packs.

NOTE: Your tool will accept either standard or Extended

Run Time battery packs. However, be sure to select proper

voltage. Batteries slowly lose their charge when they are

not on the charger, the best place to keep your battery is

on the charger at all times.

The battery pack is not fully charged out of the carton.

Before using the battery pack and charger, read the

safety instructions below. Then follow charging procedures

outlined.

READ ALL INSTRUCTIONS

DO NOT incinerate the battery pack even if # is

severely damaged or is completely worn out. The

battery pack can explode in a fire.

A small leakage of liquid from the battery pack cells

may occur under extreme usage or temperature

conditions. This does not indicate a failure. However,

if the outer seal is broken and this leakage gets on your

skin:

a. Wash quickly with soap and water.

b. Neutralize with a mild acid such as lemon juice or

vinegar.

c. If battery liquid gets into your eyes, flush them with

clean water for a minimum of 10 minutes and seek

immediate medical attention. (Medical note: The

liquid is 25-35% solution of potassium hydroxide.)

• Charge the batterypacks only in DEWALTchargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in

locations where the temperature may reach or

exceed 105°F (such as outside sheds or metal

buildings in summer).

J_DANGER: Electrocution hazard. Never attempt to open

the battery pack for any reason, ff battery pack case is

cracked or damaged, do not insert into charger. Electric

shock or electrocution may result. Damaged battery packs

should be returned to service center for recycling.

NOTE: Battery storage and carrying caps

are provided for use whenever the battery is

out of the tool or charger. Remove cap before

placing battery in charger or tool.

A WARNING: Fire hazard. Do not store or

carry battery so that metal objects can

contact exposed battery terminals. For example, do not

place battery in aprons, pockets, tool boxes, product kit

boxes, drawers, etc., with loose nails, screws, keys, etc.

without battery cap. Transporting batteries can possibly

cause fires if the battery terminals inadvertently come

in contact with conductive materials such as keys,

coins, hand tools and the like. The US Department of

Transportation Hazardous Material Regulations (HMR)

actually prohibit transporting batteries in commerce or on

airplanes (i.e., packed in suitcases and carry-on luggage)

UNLESS they are properly protected from short circuits. So

when transporting individual batteries, make sure that the

battery terminals are protected and well insulated from

materials that could contact them and cause a short

circuit.

_ CAUTION: Battery pack must be securely attached to

tool ff battery pack is detached, personal injury may result.

The RBRC TM Seal

The RBRC TM (Rechargeable Battery

Recycling Corporation) Seal on the nickel

cadmium and nickel metal hydride batteries

(or battery packs) indicate that the costs to

recycle these batteries (or battery packs) at

the end of their useful life have already been

paid by DEWALT. In some areas, it is illegal to place spent

nickel cadmium and nickel metal hydride batteries in the

trash or municipal solid waste stream and the RBRC

program provides an environmentally conscious

alternative.

RBRC TM in cooperation with DEWALT and other battery

users, has established programs in the United States and

Canada to facilitate the collection of spent nickel cadmium

and nickel metal hydride batteries. Help protect our

environment and conserve natural resources by returning

the spent nickel cadmium and nickel metal hydride batteries

to an authorized DEWALT service center or to your local

retailer for recycling. You may also contact your local

recycling center for information on where to drop off the

spent battery.

RBRCTM is a registered trademark of the Rechargeable Battery

RecyclingCorporation.

Important Safety Instructions for

Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains

important safety instructions for battery chargers.

• Before using charger, read allinstructions and cautionary

markings on charger, battery pack, and product using

battery pack.

A DANGER: Electrocution hazard. 120 volts are present at

charging terminals. Do not probe with conductive objects.

Electric shock or electrocution may result.

i_ WARNING: Shock hazard. Do not allow any liquid to get

inside charger. Electric shock may result.

A CAUTION: Bum hazard. To reduce the risk of injury,

charge only DEWALT nickel cadmium rechargeable

batteries. Other types of batteries may burst causing

personal injury and damage.

ACAUTION: Under certain conditions, with the charger

plugged in to the power supply, the exposed charging

contacts inside the charger can be shorted by foreign

material Foreign materials of a conductive nature such as,

but not limited to, steel wool, aluminum foil, or any buildup of

metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when

there is no battery pack in the cavity. Unplug charger before

attempting to clean.

• DO NOTattempt to charge the batterypack with any

chargers other than the ones in this manuaL The

charger and battery pack are specifically designed to

work together.

• These chargers are not intended for any uses other

than charging DEWAL T rechargeable batteries. Any

other uses may result in risk of fire, electric shock or

electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting

charger. This will reduce risk of damage to electric plug

and cord.

• Make sure that cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to

damage or stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result

in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The

smaller the gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge has more capacity

than 18 gauge. When using more than one extension

to make up the total length, be sure each individual

extension contains at least the minimum wire size.

Page 6

Recommended Minimum Wire Size

for Extension Cords

Total Length of Cord

25ft. 50ft. 75ft. 100ft. 125ft. 150ft. 175ft.

7.6m 15.2m 22.9m 30.5m 38.1 m45.7m 53.3m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place

the charger on a soft surface that might block the

ventilation slots and result in excessive internal

heal Place the charger in a position away from any

heat source. The charger is ventilated through slots in

the top and the bottom of the housing.

• Do not operate charger with damaged cord or plug

-- have them replaced immediately.

• Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in any

way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized

service center when service or repair is required.

Incorrect reassembly may result in a risk of electric

shock, electrocution or fire.

• Disconnect the charger from the outlet before

attempting any cleaning. This will reduce the risk

of electric shock. Removing the battery pack will not

reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard

household electrical power (120 Volts). Do not

attempt to use it on any other voltage. This does not

apply to the vehicular charger.

Using Automatic Tune-Up TM Mode

The automatic Tune-Up TM Mode equalizes or balances the

individual cells in the battery pack allowing it to function at

peak capacity. Battery packs should be tuned up weekly

or after 10 charge/discharge cycles or whenever the pack

no longer delivers the same amount of work. To use the

automatic Tune-Up TM, place the battery pack in the charger

and leave it for at least 8 hours. The charger will cycle

through the following modes.

1. The red light will blink continuously indicating that the

1-hour charge cycle has started.

2. When the 1-hour charge cycle is complete, the light

will stay on continuously and will no longer blink. This

indicates that the pack isfully charged and can be used

at this time.

3. If the pack is left in the charger after the initial 1-hour

charge, the charger will begin the Automatic Tune-Up

mode. This mode continues up to 8 hours or until the

individual cells in the battery pack are equalized. The

battery pack is ready for use and can be removed at

any time during the Tune-Up mode.

4. Once the Automatic Tune Up mode is complete, the

charger will begin a maintenance charge; the red

indicator will remain lit.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Chargers

Your tool uses a DEWALT Charger. Your battery can

be charged in DEWALT 1 Hour Chargers, 15 Minute

Chargers or Vehicular 12 volt charger. Be sure to read all

safety instructions before using your charger. Consult the

chart on the back cover of this manual for compatibility of

chargers and battery packs.

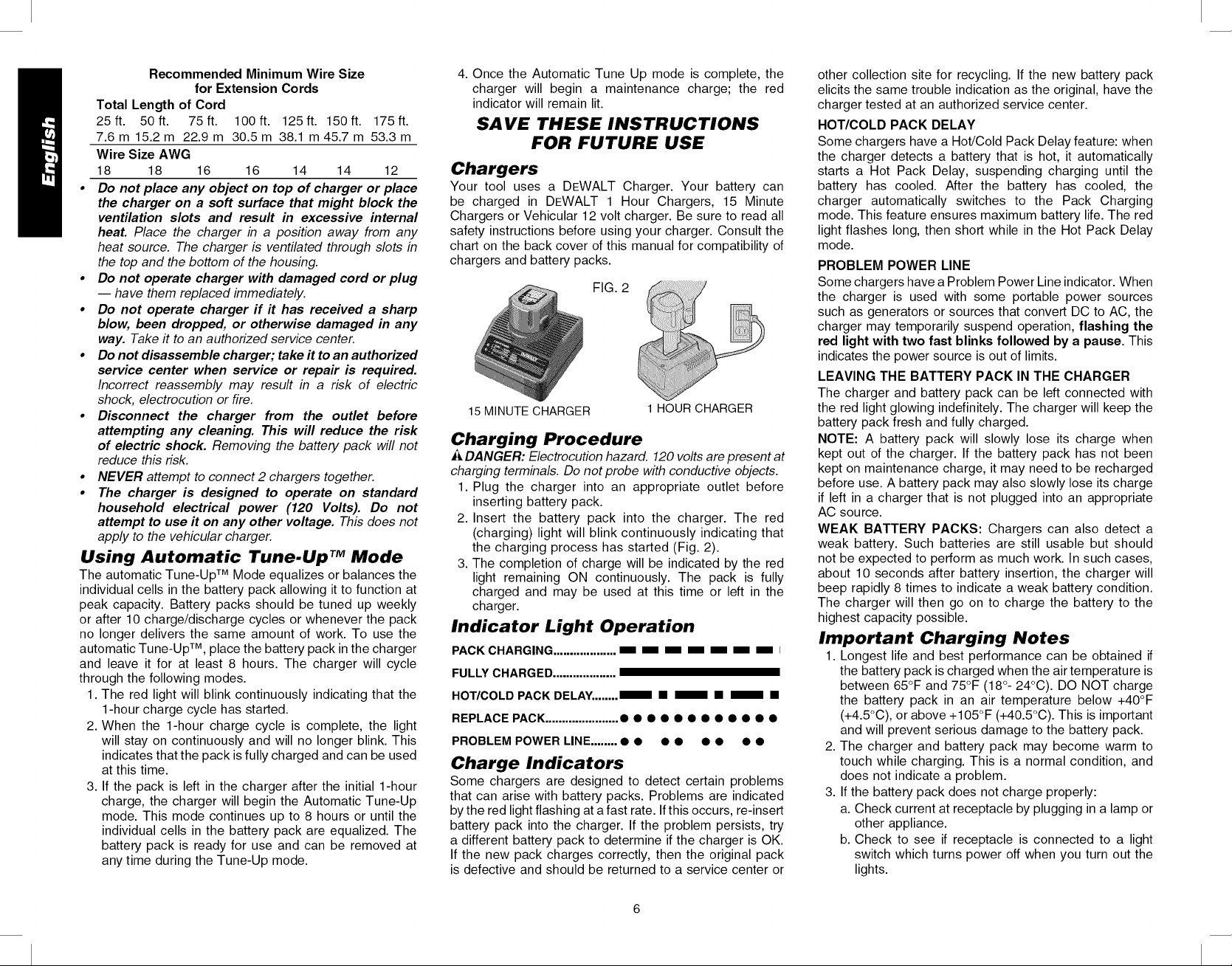

FIG. 2

15 MINUTE CHARGER

1 HOUR CHARGER

Charging Procedure

.&DANGER: Electrocution hazard. 120 volts are present at

charging terminals. Do not probe with conductive objects.

1. Plug the charger into an appropriate outlet before

inserting battery pack.

2. Insert the battery pack into the charger. The red

(charging) light will blink continuously indicating that

the charging process has started (Fig. 2).

3. The completion of charge will be indicated by the red

light remaining ON continuously. The pack is fully

charged and may be used at this time or left in the

charger.

Indicator Light Operation

PACK CHARGING ................... mm mm mm mm mm mm mm I

FUL_ CHARGED ...................

HOT/COLD PACK DELAY........ _ • _ • _ •

REPLACE PACK ...................... ••••••••••••

PROBLEM POWER LINE ........ • • • • • • • •

Charge Indicators

Some chargers are designed to detect certain problems

that can arise with battery packs. Problems are indicated

bythe red light flashing at a fast rate. If this occu rs, re-insert

battery pack into the charger. If the problem persists, try

a different battery pack to determine if the charger is OK.

If the new pack charges correctly, then the original pack

is defective and should be returned to a service center or

other collection site for recycling. If the new battery pack

elicits the same trouble indication as the original, have the

charger tested at an authorized service center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when

the charger detects a battery that is hot, it automatically

starts a Hot Pack Delay, suspending charging until the

battery has cooled. After the battery has cooled, the

charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life. The red

light flashes long, then short while in the Hot Pack Delay

mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When

the charger is used with some portable power sources

such as generators or sources that convert DC to AC, the

charger may temporarily suspend operation, flashing the

red light with two fast blinks followed by a pause. This

indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with

the red light glowing indefinitely. The charger will keep the

battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when

kept out of the charger. If the battery pack has not been

kept on maintenance charge, it may need to be recharged

before use. A battery pack may also slowly lose its charge

if left in a charger that is not plugged into an appropriate

AC source.

WEAK BATTERY PACKS: Chargers can also detect a

weak battery. Such batteries are still usable but should

not be expected to perform as much work. In such cases,

about 10 seconds after battery insertion, the charger will

beep rapidly 8 times to indicate a weak battery condition.

The charger will then go on to charge the battery to the

highest capacity possible.

Important Charging Notes

1. Longest life and best performance can be obtained if

the battery pack is charged when the air temperature is

between 65°F and 75°F (18°- 24°C). DO NOT charge

the battery pack in an air temperature below +40°F

(+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to

touch while charging. This is a normal condition, and

does not indicate a problem.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or

other appliance.

b. Check to see if receptacle is connected to a light

switch which turns power off when you turn out the

lights.

Page 7

c.Movechargerandbatterypacktoalocationwhere

thesurroundingairtemperatureisapproximately

65OF_75OF(18°-24oc).

d.Ifchargingproblemspersist,takethetool,battery

packandchargertoyourlocalservicecenter.

4.Thebatterypackshouldberechargedwhenitfailsto

producesufficientpoweronjobswhichwereeasily

donepreviously.DONOTCONTINUEtouseunder

theseconditions.Followthechargingprocedure.You

mayalsochargeapartiallyusedpackwheneveryou

desirewithnoadverseaffectonthebatterypack.

5.Undercertainconditions,withthechargerplugged

intothepowersupply,theexposedchargingcontacts

insidethechargercanbeshortedbyforeignmaterial.

Foreignmaterialsofaconductivenaturesuchas,but

notlimitedto,steelwool,aluminumfoil,oranybuildup

ofmetallicparticlesshouldbekeptawayfromcharger

cavities.Alwaysunplugthechargerfromthepower

supplywhenthereis nobatterypackinthecavity.

Unplugchargerbeforeattemptingtoclean.

6.Donotfreezeorimmersechargerinwateroranyother

liquid.

•& WARNING: Shock hazard. Don't allow any liquid to get

inside charger. Electric shock may result. To facilitate the

cooling of the battery pack after use, avoid placing the

charger or battery pack in a warm environment such as in

a metal shed, or an uninsulated trailer.

_ CAUTION: Never attempt to open the battery pack for

any reason. If the plastic housing of the battery pack

breaks or cracks, return to a service center for recycling.

Installing and Removing the

Battery Pack

A CAUTION: Engage contact trip lock-off before removing

or installing battery.

FIG. 3 FIG. 4

M

NOTE: Make sure your battery pack is fully charged.

To install the battery pack into the tool handle, align the

base of the tool with the notch inside the tool's handle and

slide the battery pack firmly into the handle until you hear

the lock snap into place.

To remove the battery pack from the tool, press the

release buttons (M) and firmly pull the battery pack out of

the tool handle. Insert it into the charger as described in the

charger manual (Fig. 4).

COMPONENTS

A WARNING: Lock off trigger, disconnect battery pack

from tool and remove fasteners from magazine before

making adjustments or personal injury may result.

Refer to Figure 1 at the beginning of this manual for a

complete list of components.

OPERA TION

Z&WARNING: Read the section titled Important Safety

Instructions for Nailers at the beginning of this manual

Always wear eye and ear protection when operating this

tool Keep the nailer pointed away from yourself and

others. For safe operation, complete the following

procedures and checks before each use of the nailer.

1. Wear proper eye, hearing and respiratory protection.

2. Remove battery pack from tool

3. Lock the pusher in the back position and remove aft

fasteners from the magazine.

4. Check for smooth and proper operation of contact

trip and pusher assemblies. Do not use tool if either

assembly is not functioning properly. NEVER use

a tool that has the contact trip restrained in the up

position.

5. NEVER use a tool that has damaged parts.

A WARNING: To reduce the risk of personal injury,

disconnect battery pack from tool before performing

maintenance, clearing a jammed fastener, leaving work

area, moving tool to another location or handing the tool to

another person.

Mode Selection

•& WARNING: Always wear proper eye [ANSI Z87.1 (CAN/

CSA Z94.3)] and ANSI $12.6 ($3.19) hearing protection

when operating tool

The DEWALT cordless nailers are assembled in accordance

with the ANSI Standard SNT-101-2002.

Before operating this tool, look at the selector switch

to determine the actuation mode. Read all instructions

before selecting actuation mode.

i_ WARNING: Keep fingers AWAY from trigger when not

driving fasteners to avoid accidental firing. NEVER carry

tool with finger on trigger. In bump mode tool will fire a

fastener if safety is bumped while trigger is depressed.

SEQUENTIAL ACTION /

Use sequential action for intermittent nailing where very

careful and accurate placement and depth control is

desired.

7

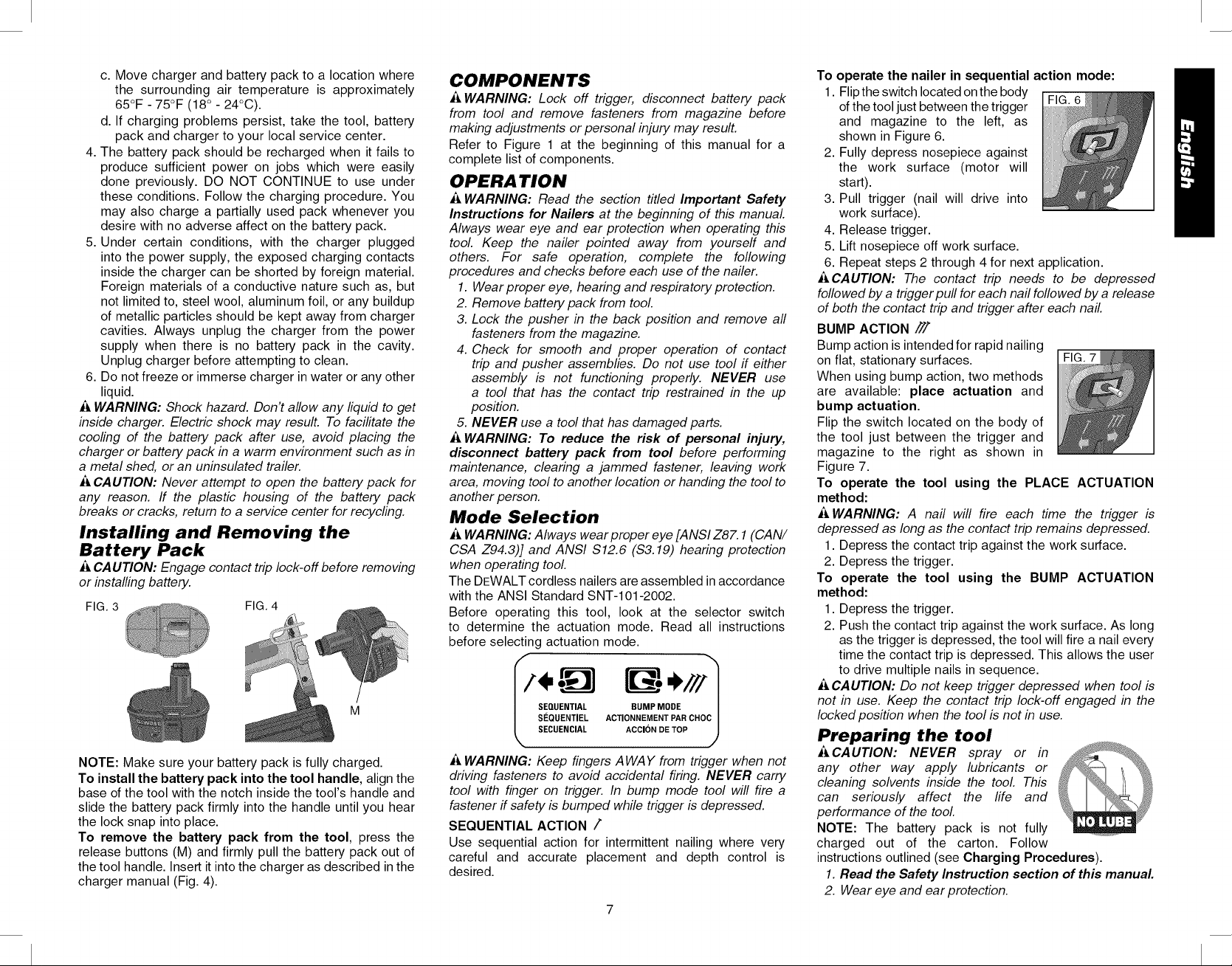

To operate the nailer in sequential action mode:

1. Flip the switch located on the body

ofthe tool just between the trigger

and magazine to the left, as

shown in Figure 6.

2. Fully depress nosepiece against

the work surface (motor will

start).

3. Pull trigger (nail will drive into

work surface).

4. Release trigger.

5. Lift nosepiece off work surface.

6. Repeat steps 2 through 4 for next application.

ACAUTION: The contact trip needs to be depressed

followed by a trigger pull for each nail followed by a release

of both the contact trip and trigger after each nail.

BUMP ACTION ///

Bump action is intended for rapid nailing

on flat, stationary surfaces.

When using bump action, two methods

are available: place actuation and

bump actuation.

Flip the switch located on the body of

the tool just between the trigger and

magazine to the right as shown in

Figure 7.

To operate the tool using the PLACE ACTUATION

method:

WARNING: A nail will fire each time the trigger is

depressed as long as the contact trip remains depressed.

1. Depress the contact trip against the work surface.

2. Depress the trigger.

To operate the tool using the BUMP ACTUATION

method:

1. Depress the trigger.

2. Push the contact trip against the work surface. As long

as the trigger is depressed, the tool will fire a nail every

time the contact trip is depressed. This allows the user

to drive multiple nails in sequence.

A CAUTION: Do not keep trigger depressed when tool is

not in use. Keep the contact trip lock-off engaged in the

locked position when the tool is not in use.

Preparing the tool

.&CAUTION: NEVER spray or in

any other way apply lubricants or

cleaning solvents inside the tooL This

can seriously affect the life and

performance of the tooL

NOTE: The battery pack is not fully

charged out of the carton. Follow

instructions outlined (see Charging Procedures).

1. Read the Safety Instruction section of this manuaL

2. Wear eye and ear protection.

Page 8

3.RemovebatteryfromtooL

4.Ensuremagazineisemptyofallfasteners.

5.Checkfor smoothandproperoperationof contact

tripandpusherassemblies.Donotusetoolffeither

assemblyis notfunctioningproperly.NEVERusea

toolthathasthecontacttriprestrainedintheactuated

position.

6.Keeptoolpointedawayfromyourselfandothers.

7.Insertfullychargedbatterypack.

Using the Contact Trip Lock-off

(Fig. 8, 9)

WARNING: To reduce the risk of serious personal

injury, DO NOT keep trigger depressed when tool is not in

use. Keep the contact trip lock-off switch LOCKED (Fig. 8)

when the tool is not in use.

A WARNING: Toreduce the risk of serious personal injury,

lock off trigger, disconnect battery pack from tool and

remove fasteners from magazine before making adjustments.

Serious personal injury may result.

Each DEWALT nailer is equipped with

a contact trip lock-off (B) which when

pulled downward with the lock

symbol showing in Figure 8, prevents

the tool from firing a nail.

When the contact trip lock-off is

oriented as shown in Figure 9, the

tool will be fully operational. The

contact trip lock-off should

always be locked off (Fig. 8)

whenever any adjustments are

made or when tool is not in

immediate use.

NOTE: Tools equipped with selective

actuation, when in bump fire mode

will allow the motor to start upon

trigger pull. This is normal operation. The contact trip lock-

off constrains the contact trip from discharging a nail.

Loading the Tool

_ WARNING: Keep the tool pointed away from yourself

and others. Serious personal injury may result.

•_J,WARNING: Never load nails with the contact trip or

trigger activated. Personal injury may result.

A WARNING: Always remove battery pack before loading

or unloading nails. Serious personal injury may result.

_CAUTION: Keep fingers clear of pusher to prevent

injury.

A CAUTION: The contact trip lock-off should always be

locked off whenever any adjustments are made or when

tool is not in use.

1. Press pusher latch (H) and pull magazine back.

2. Insert fasteners into the side of the magazine. Be sure

the fasteners ride on their tips in the nail channel.

3. Push magazine closed until it locks into place.

UNLOADING

THE TOOL

A WARNING: The

contact trip lock-off

should always be

locked off whenever

any adjustments are

made or when tool is

not in use.

1. Press the nail

pusher latch

(H) and pull the

magazine (G)

rearward. H

2. Tip the tool up

until the nails

slide freely out of

the magazine.

3. Open the jam clear door on the nosepiece to verify

there are no nails remaining.

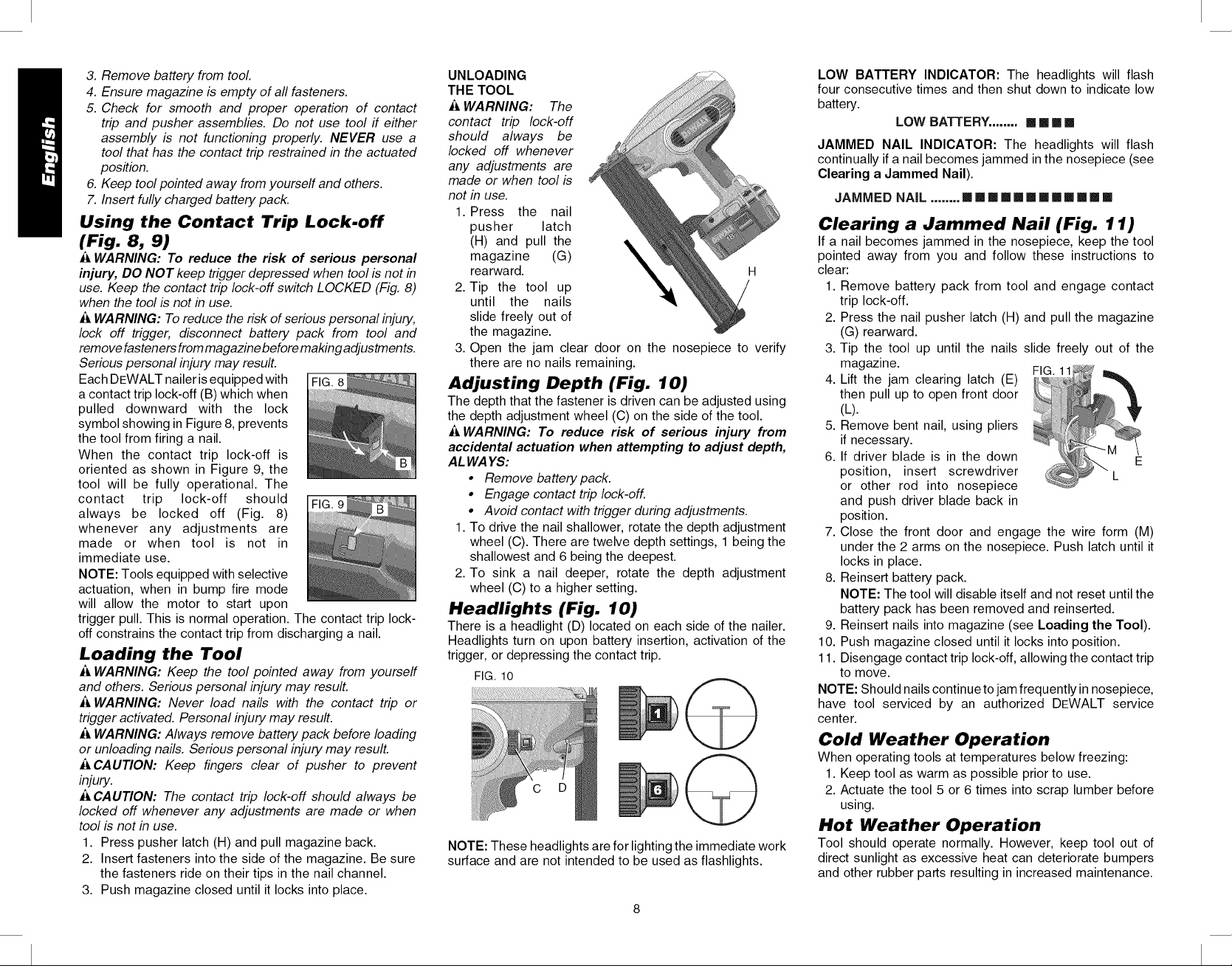

Adjusting Depth (Fig. 10)

The depth that the fastener is driven can be adjusted using

the depth adjustment wheel (C) on the side of the tool.

A WARNING: To reduce risk of serious injury from

accidental actuation when attempting to adjust depth,

AL WAYS:

• Remove battery pack.

• Engage contact trip lock-off.

° Avoid contact with trigger during adjustments.

1. To drive the nail shallower, rotate the depth adjustment

wheel (C). There are twelve depth settings, 1 being the

shallowest and 6 being the deepest.

2. To sink a nail deeper, rotate the depth adjustment

wheel (C) to a higher setting.

Headlights (Fig. 10)

There is a headlight (D) located on each side of the nailer.

Headlights turn on upon battery insertion, activation of the

trigger, or depressing the contact trip.

FIG, 10

NOTE: These headlights are for lighting the immediate work

surface and are not intended to be used as flashlights.

LOW BATTERY INDICATOR: The headlights will flash

four consecutive times and then shut down to indicate low

battery.

LOW BATTERY. ....... [] [] [] []

JAMMED NAIL INDICATOR: The headlights will flash

continually if a nail becomes jammed in the nosepiece (see

Clearing a Jammed Nail).

JAMMED NAiL ........ [][][][][][][][][][][][]

Clearing a Jammed Nail (Fig. 11)

If a nail becomes jammed in the nosepiece, keep the tool

pointed away from you and follow these instructions to

clear:

1. Remove battery pack from tool and engage contact

trip lock-off.

2. Press the nail pusher latch (H) and pull the magazine

(G) rearward.

3. Tip the tool up until the nails slide freely out of the

magazine.

4. Lift the jam clearing latch (E)

then pull up to open front door .......... -

5. Remove bent nail, using pliers

(L).

if necessary.

position, insert screwdriver

6. If driver blade is in the down L E

or other rod into nosepiece

and push driver blade back in

position.

7. Close the front door and engage the wire form (M)

under the 2 arms on the nosepiece. Push latch until it

locks in place.

8. Reinsert battery pack.

NOTE: The tool will disable itself and not reset until the

battery pack has been removed and reinserted.

9. Reinsert nails into magazine (see Loading the Tool).

10. Push magazine closed until it locks into position.

11. Disengage contact trip lock-off, allowing the contact trip

to move.

NOTE: Should nails continue to jam frequently in nosepiece,

have tool serviced by an authorized DEWALT service

center.

Cold Weather Operation

When operating tools at temperatures below freezing:

1. Keep tool as warm as possible prior to use.

2. Actuate the tool 5 or 6 times into scrap lumber before

using.

Hot Weather Operation

Tool should operate normally. However, keep tool out of

direct sunlight as excessive heat can deteriorate bumpers

and other rubber parts resulting in increased maintenance.

Page 9

Suspension Hook

(Fig. 12) FIG,12

A WARNING: Remove nails from

magazine before making any

adjustments or servicing this tool

Failure to do so may result in serious

injury.

A WARNING: To reduce the risk of J

serious personal injury, disconnect

battery pack from tool before making any adjustments,

changing accessories, servicing, or moving the tool.

Such preventative safety measures reduce the risk of

starting the tool accidentally.

A CAUTION: When not in use, place tool on its side on

a stable surface where it will not cause a tripping or

falling hazard. Some tools with large battery packs will

stand upright on the battery pack but may be easily

knocked over.

The DEWALT cordless nailers include an integrated

suspension hook (J) and can be attached to either side of

the tool to accommodate left- or right-handed users.

If the hook is not desired at all, it can be removed from

the tool.

TO REMOVE SUSPENSION HOOK

1. Remove battery pack from tool.

2. To switch the tool from right- to left-hand usage simply

remove the screw and reassemble on the other side.

3. Replace battery pack.

MAINTENANCE

A WARNING: To reduce the risk of serious personal

injury, disconnect battery pack from tool before making

any adjustments, changing accessories, servicing, or

moving the tool. Such preventative safety measures

reduce the risk of starting the tool accidentally.

Daily Maintenance Chart

ACTION

WHY

HOW

ACTION

WHY

HOW

Clean magazine, pusher, and contact trip

mechanism.

Permits smooth operation of magazine, reduces

wear, and prevents jams.

The use of oils, lubricants periodically or solvents is

not recommended as they tend to attract debris.

Before each use, check to insure all screws, nuts

and fasteners are tight and undamaged.

Prevents jams and premature failure of tool parts.

Tighten loose screws or other fasteners using the

appropriate Allen wrench or screwdriver

Cleaning

A WARNING: To reduce the risk of serious personal

injury, disconnect battery pack from tool before

cleaning and inspection. Make sure tool is in proper

working condition before placing the tool back in use or

serious personal injury may result.

A CAUTION: When cleaning, use only a damp cloth on

plastic parts. Many household cleaners contain chemicals

which could seriously damage plastic parts. Also, do not

use gasoline, turpentine, lacquer or paint thinner, dry

cleaning fluids or similar products which may seriously

damage plastic parts. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

A WARNING: To reduce the risk of personal injury,

disconnect the charger from the AC outlet before cleaning.

Dirt and grease may be removed from the exterior of the

charger using a cloth or soft non-metallic brush. Do not use

water or any cleaning solutions

Lubrication

ACAUTION: NEVER spray or

in any other way apply lubricants or

cleaning solvents inside the tool This

can seriously affect the life and

performance of the tool

DEWALT tools are properly lubricated

at the factory and are ready for use.

However, it is recommended that, once a year, you take or

send the tool to a certified service center for a thorough

cleaning and inspection.

Repairs

A WARNING: To reduce the risk of serious personal

injury, remove nails from magazine before making any

adjustments or servicing this tool

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment (including brush inspection

and replacement) should be performed by a DEWALT

factory service center, a DEWALT authorized service

center or other qualified service personnel. Always use

identical replacement parts. Refer to the Troubleshooting

Guide at the end of this section.

Accessories

A WARNING: Since accessories, other than those offered

by DEWAL T, have not been tested with this product, use of

such accessories with this tool could be hazardous. To

reduce the risk of injury, only DEWAL T, recommended

accessories should be used with this product.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. If you need assistance in locating any

accessory, please contact DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286, call 1-800-

4-DEWALT (1-800-433-9258) or visit our website www.

dewalt.com.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty

coverage and warranty repair information, visit www.

dewalt.com or call 1-800-4-DEWALT (1-800-433-9258).

This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states or

provinces.

In addition to the warranty, DEWALT tools are covered by

our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first

year after purchase.

2 YEARS FREE SERVICE ON

DEWALT BATTERY PACKS

DC9096, DC9091, DC9071, DC9360 and DC9280

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your DEWALT Power Tool, Laser, or Nailer for any reason,

you can return it within 90 days from the date of purchase

with a receipt for a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America,

see country specific warranty information contained either

in the packaging, call the local company or see website for

warranty information.

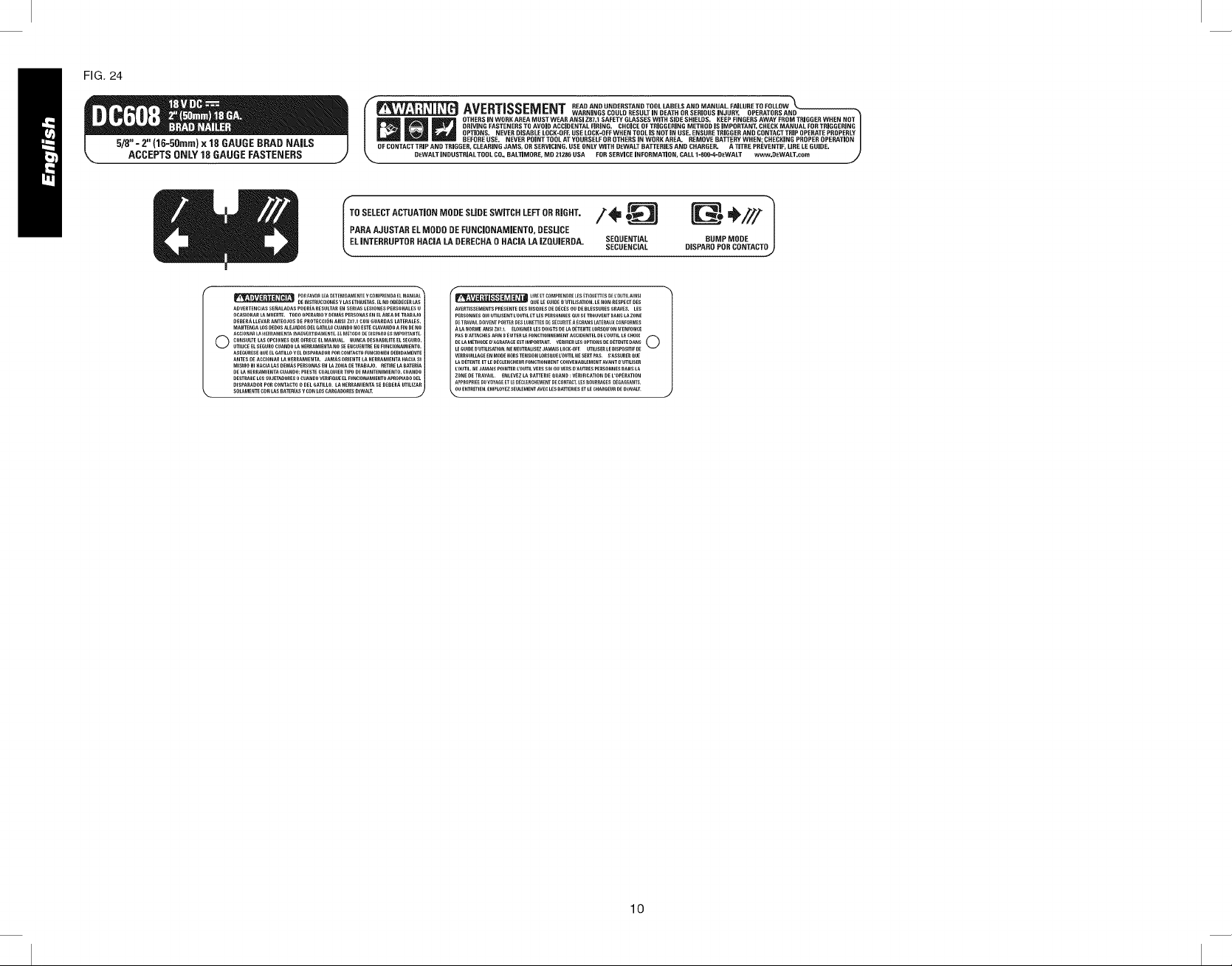

FREE WARNING LABEL REPLACEMENT: Ifyour warning

labels (Fig. 24) become illegible or are missing, call 1-800-

4-DEWALT for a free replacement.

Page 10

FIG. 24

f_ _ll_TICC_mml_KIT READANDUNDERSTANDTOOLLAIIELSANDMANUAL FAILURETOFOLLOW_

r_ m OTHERSIN WOBKAREAMUST WEAR ANSI 7,87.1SAFETYGLASSESWITH SIDE SHIELDS. KEEPFINGEBSAWAY FROM TRIGGERWHEN NOT

OFCONTACT TtlIP ANDTRIGGER, CLEARINGJAMS, 011SEttVICING. USEONLYWITff D_WALT ttATTEIIIES AND CttARGER. A TITHEPREVENTIF,LIRELEGUIBE.

r

TO SELECTACTIJATJONMODE SLIDE SWITCH LEFT OHRIGHT.

PARA A,IUSTAR EL MODO DE FUNCJONAMJENTO, DESLJCE

EL JlITERRUPTOIt HACJALA DERECHA O HACJALA IZQUJERDA.

AOVEeTENClASSE_ALADASPoOeiARESULTARENSERIASLESlONeSPERSONALESU

OCASIONARLAMUERTE.TOOO0PERARIOYOEMASPERSONAS_NELAREAOETRABAJ0

DEBERA LLEVAR ANTEOJOS DE PROTECCION ANSI Z87.1 C0N GUARDAS LATERALE$.

MANTENGA LOS DEDOS ALEJADO8 DEL GATILLO CUANDO NO [ST_ CLAVAND0 A FIN DE NO

ACCl0NA__ _E_RAMIEN1aINJ_DWRTIDAMENTEELI_TO_ODEDISPAR0ESIM_O_1AN1E

CONSULTE LAS OPCIO NES QUE OFREC[ EL MANUAL. NUNCA DES HABILITE EL SEGU[IO.

UTILICE EL SEGURO CUAND0 LA HERRAMIENTA N0 SE ENCUENTRE EN FUNCIONAMIENT0.

ASEGORESE QUE EL GATILLO Y ELDISPARADOR POR CONTACT0 FUNCIONEN DEE_IDAMENTE

ANTES DE ACCIONAll LA HERllAMIENTA. JAM_.S ORIENTE LA HERRAMIENTA HACIA SI

MISMO NI HACIA LAS DEM,_S pERSONA$ EN LA ZONA DE TRAE_AJO. I_ETIRE LA BATERiA

I© _ .........................................il

DE LA BERRAMIENTA CUANDO: pREST_ CUALQUIER TIP0 DE MANTENIMIENTO, CUAND0

DESTRABE LOS SUJETADORES 0 CUAND0 VERIFIQU[ EL FUNCIONAMIENT0 APROPIADO DEL

DISPARADOR pOR CONTACTO 0 OIL GATILL0. LA HERRAMIENTA SE DEBERA UTILIZAR

SOLAMENTECONLASBATERiAsY CONLOSCARGADORE_DEWALT

DE INST_UCCIONES Y LA$ [TIGUETAS ELNO OBEDECER LAS

1'41Vrrll|l_t_il-IvIr'nl§ WARNINGSCOULDRESilLTINDEATHO_ISEIIIOUSINJilIW. OPEIIATORSAND_

DRIVINGFASTENERSTOAVOID ACCIDENTALFIRING. CHOICE 0FTFIIGGERiNGMETHOD IS iMPORTANT. CHECI(MANUAL FORTRiGGERiNG

OPTIONS. NEVEtl DISABLELOCI,(-OFKUSELOCK-OFFWHEN TOOLISNOTIN USE. EIISUtlE TFIIGGEIIAND CONTACTTRIPOPERATEPROIPERLY

BEFOttEUSE. NEVEItPOINTTOOLATYOURSELFOROTHERSINWOItt(AREA. REMOVEtlATrEIIYWHEN_CttECKINGPIIOPEROPERATION

DEWALT iNDUSTRiAL TOOLCO., BALTIMORE,MD 21286USA FORSERVICEiNFORMATiON, CALL1-800.4-.DI:WALT www.DEWALT.com

13iI+/x!

SEQUENTIAL BUMP MODE

SECUENCiAL UISPAflO PUB CONTACT(

'-_ LiiiE[TooMI_ItENDIt[LE$ETI(IIJ_]_E$DELOIJTILAINSl

PERSONNES_UlUTILISENTLOUTIL_TLESPE_SONN_SQUISE T_OUVENTOANSLAZONE

D_TRAVAILDOIVE_T_O_T_DESLU_ErIESD_S_CU_IT_AEC_NS_aTE_U_CONFO_ME_

A_ NORM_ANSIZ_7.1. _LOIGN_RL_SOOI_TSOELAOET_NTELO_SQU'ONN'ENFONCE

WRTIS_EM_NTSp_SENTEOESRISt!U_SO_OEOESOUD__LESSUR_S_R_ES. LES

PAS0ArrAON_SAFIN0 EVlTERL_FONCTIONNEMENTACOIOENT_LO_L'OUTILLEC_OI×

ELAM_HODEO'A_RAFAGEESTIMPOR_NT_RIRERLESOPTIONSOEO_T_NT_OANS0

VERROUILLA__NMOOEHORST_NSlONLORS_UEL'OUTILNESE_TPAS S'ASSUR__UE

LAO_TENT__TLEOEOLENC_U_FONCTIONNENTCONVENABL_MENT_ANT0UTILISE_

_OUTIL.N_JAMAISPOINTERL'OUTILVE_SSOlOUWRS0 AUT_ESpE_SONN_SOANSLA

ZONEO_T_AVAIL.ENLEVEZLA_Arr_l_ _UAND: VERIFICATIOND_L'OPE_ATION

AP_O_I_ DUVOYagEETLED_L_NCHEMENTDECONTACT,LE__OU_ D_A_NT_

LI _UIO_DUTILIS_IONNENEUTRALISEZ_AMAISLO_-O_E UTILIS_RLEOISPOSlTIFOE

UENTRET_ENEMPLOY_ZSEULE_Em_EC LES_An'ERI_SET_ECHA_EU_OEO_WALT

QU_LE_UIOEOIUTILI_ATION.LENON_ESP_CTO_S

J

lO

Page 11

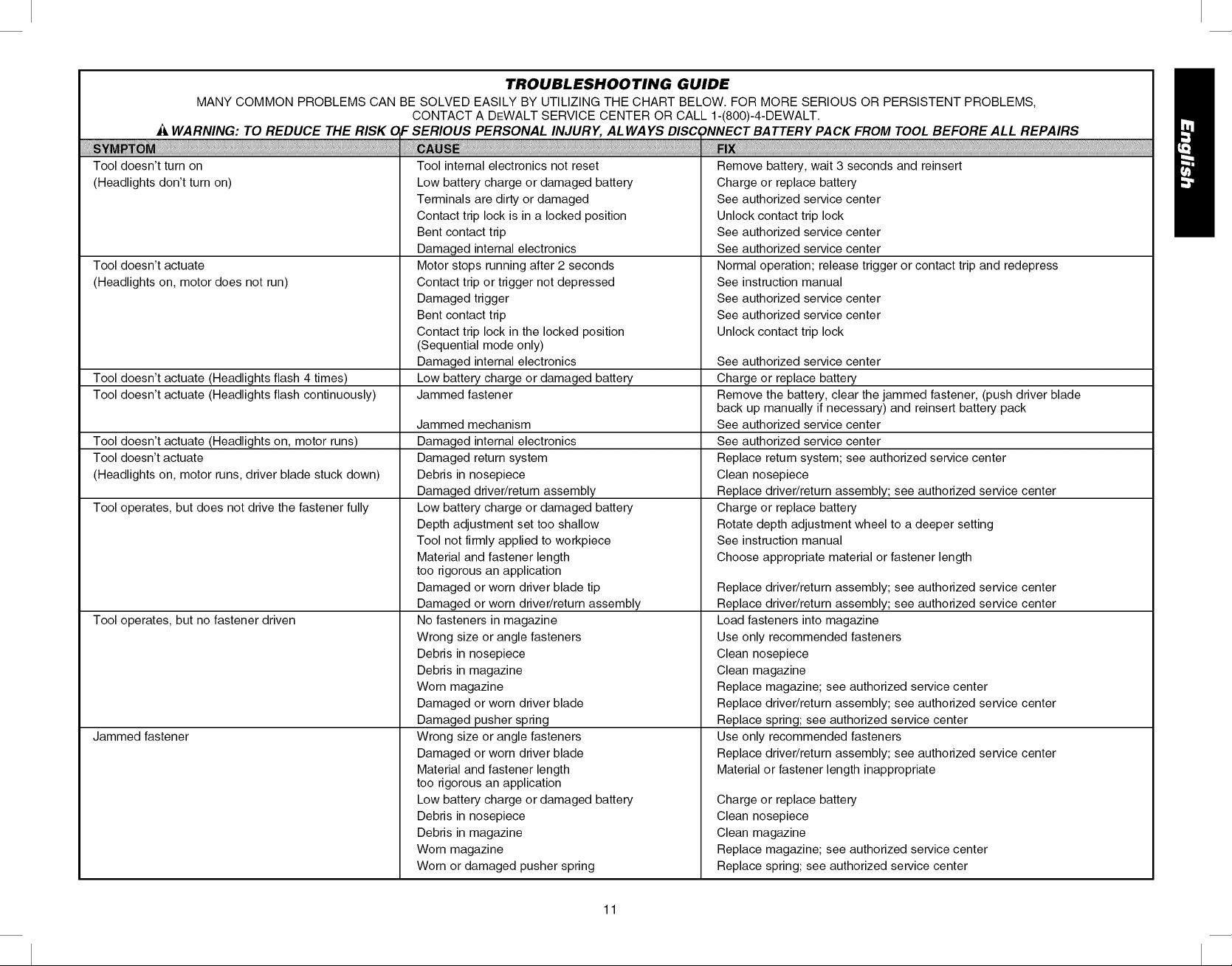

TROUBLESHOOTING GUIDE

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS,

CONTACT A DEWALT SERVICE CENTER OR CALL 1-(800)-4-DEWALT.

A WARNING: TO REDUCE THE RISK d =SERIOUS PERSONAL INJURY, ALWAYS DISC )NNECT BATTERY PACK FROM TOOL BEFORE ALL REPAIRS

Tool doesn't turn on

(Headlights don't turn on)

Tool doesn't actuate

(Headlights on, motor does not run)

Tool doesn't actuate (Headlights flash 4 times)

Tool doesn't actuate (Headlights flash continuously)

Tool doesn't actuate (Headlights on, motor runs)

Tool doesn't actuate

(Headlights on, motor runs, driver blade stuck down)

Tool operates, but does not drive the fastener fully

Tool operates, but no fastener driven

Jammed fastener

Tool internal electronics not reset

Low battery charge or damaged battery

Terminals are dirty or damaged

Contact trip lock is in a locked position

Bent contact trip

Damaged internal electronics

Motor stops running after 2 seconds

Contact trip or trigger not depressed

Damaged trigger

Bent contact trip

Contact trip lock in the locked position

(Sequential mode only)

Damaged internal electronics

Low battery charge or damaged battery

Jammed fastener

Jammed mechanism

Damaged internal electronics

Damaged return system

Debris in nosepiece

Damaged driver/return assembly

Low battery charge or damaged battery

Depth adjustment set too shallow

Tool not firmly applied to workpiece

Material and fastener length

too rigorous an application

Damaged or worn driver blade tip

Damaged or worn driver/return assembly

No fasteners in magazine

Wrong size or angle fasteners

Debris in nosepiece

Debris in magazine

Worn magazine

Damaged or worn driver blade

Damaged pusher spring

Wrong size or angle fasteners

Damaged or worn driver blade

Material and fastener length

too rigorous an application

Low battery charge or damaged battery

Debris in nosepiece

Debris in magazine

Worn magazine

Worn or damaged pusher spring

Remove battery, wait 3 seconds and reinsert

Charge or replace battery

See authorized service center

Unlock contact trip lock

See authorized service center

See authorized service center

Normal operation; release trigger or contact trip and redepress

See instruction manual

See authorized service center

See authorized service center

Unlock contact trip lock

See authorized service center

Charge or replace battery

Remove the battery, clear the jammed fastener, (push driver blade

back up manually if necessary) and reinsert battery pack

See authorized service center

See authorized service center

Replace return system; see authorized service center

Clean nosepiece

Replace driver/return assembly; see authorized service center

Charge or replace battery

Rotate depth adjustment wheel to a deeper setting

See instruction manual

Choose appropriate material or fastener length

Replace driver/return assembly; see authorized service center

Replace driver/return assembly; see authorized service center

Load fasteners into magazine

Use only recommended fasteners

Clean nosepiece

Clean magazine

Replace magazine; see authorized service center

Replace driver/return assembly; see authorized service center

Replace spring; see authorized service center

Use only recommended fasteners

Replace driver/return assembly; see authorized service center

Material or fastener length inappropriate

Charge or replace battery

Clean nosepiece

Clean magazine

Replace magazine; see authorized service center

Replace spring; see authorized service center

11

Page 12

FIG. 1

F

K

tf D_finitions : lignes directrices \

en mati_re de s_curit_

Les d6finitions ci-dessous d6crivent le niveau de danger

pour chaque mot-indicateur employ& Lire le mode d'emploi

et porter une attention particuli_re &ces symboles.

_DANGER : indique une situation dangereuse imminente

qui, si elle n'est pas evit6e, causera la mort ou des bles-

sures graves.

i_A VERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si elle n'est pas evit6e, pourrait causer la

mort ou des blessures graves.

_,MISE EN GARDE : indique une situation potentie//ement

dangereuse qui, si elle n'est pas evit6e, peut causer des

blessures mineures ou moderees.

MISE EN GARDE : utilise sans le symbole d'alerte de

securite, indique une situation potentiellement dangereuse

qui, si elle n'est pas evit6e, peut causer des dommages

materiels.

A. D6tente

B. Dispositif de blocage du

d6clencheur

C. Molette de r6glage de

profondeur

D. T6moin indicateur du

syst_me d'6clairage/

de pile faible/de blocage

E. Loquet de d6gagement

F. D6clencheur par contact

Longueurs

des clous

Diam_tre de la tige

Angle de tir des clous

G. Chargeur

H. Dispositif de blocage du

poussoir

I. S61ecteur de mode choc/

s6quentiel

J. Crochet pour rangement,

&droite ou & gauche

K. Indicateur de bas niveau

de clous

SPE_ClFICATIONS RELATIVES AUX CLOUS

16 mm, 19 mm, 25 mm, 29 mm, 30 mm, 32 mm, 33 mm, 35 mm, 38 mm, 40 mm, 44 mm, 50 mm

(5/8 po, 3/4 po, 1 po, 1 1/8 po, 1 3/16 po, 1 1/4 po, 15/16 po, 1 3/8 po, 1 1/2 po, 1 9/16 po, 1 3/4 po, 2 po)

FICHE TECHNIQUE DE L'OUTIL

Mode de tir S61ectif

Tension 18

Hauteur 286 mm (11,25 po)

Largeur 89 mm (3,5 po)

Longueur 292 mm (11,5 po)

Poids 3,4 kg (7,5 Ib)

Angle du chargeur 0°

Capacit6 du chargeur jusqu'& 110 clous

Droits

calibre 18

0o

12

Page 13

POURTOUTEQUESTIONOUTOUTCOMMENTAIRE

SURCETOUTILOUSURTOUTAUTREOUTILDEWALT,

COMPOSERLENUMCROSANSFRAISSUIVANT:

1-800-4-DEWALT(1-800-433-9258).

R_gles g_n_rales de s_curit_

concernant les outils a piles

_ AVERTISSEMENT! Lire et assimiler

toutes les directives. Le non-respect de

toutes les directives indiquees ci-dessous peut

entra?ner des risques de decharge electrique,

d'incendie ou de blessures graves.

CONSERVER CES DIRECTIVES

ESPACE DE TRAVAIL

• Tenir I'espace de travail propre et bien eclaire. Les

etablis encombres et les endroits sombres sont souvent

propices aux accidents.

• Ne pas faire fonctionner d'outils electriques clans

un milieu deflagrant, par exemple en presence de

liquides, de gaz ou de poussieres inflammables.

Les outils electriques produisent des etincelles qui pour-

raient enflammer la poussiere ou les vapeurs.

• Eloigner les curieux, les enfants et les visiteurs Iors

de I'utilisation d'un outil electrique. Une distraction

pourrait vous en faire perdre la mMtrise.

SI_CURITI_ EN MATIERE D'I_LECTRICITI_

• Ne pas utiliser le cordon de fa_on abusive. Ne

jamais utiliser le cordon d'alimentation pour trans-

porter I'outil. Tenir le cordon eloigne de la chaleur,

de I'huile, des bords tranchants et des pieces

mobiles. Remplacer immediatement tout cordon

endommage. Un cordon d'alimentation endommage

peut provoquer un incendie.

• Un outil a piles integrees ou fonctionnant sur un

bloc-piles exteme doit _tre recharge uniquement au

moyen du chargeur prevu pour les piles utilisees.

L'utilisation d'un chargeur qui convient a un type de

bloc-piles risque de provoquer un incendie s'il est utilise

avec un autre type de bloc-piles.

• Utiliser I'outil fonctionnant sur piles uniquement

avec le bloc-piles con_u specialement pour I'outil.

L'utilisation de toute autre pile peut provoquer un

incendie.

S#CURIT# PERSONNELLE

• Rester vigilant, faire attention au travail en cours et

faire preuve de jugement clans I'utilisation de tout

outil electrique. Ne pas utiliser d'outil en cas de

fatigue ou sous I'emprise de drogues, d'alcool ou

de medicaments. Un simple moment d'inattention en

utilisant un outil electrique peut entrMner des blessures

graves.

• S'habiller de maniere appropriee. Ne pas porter de

v6tements amples ni de bijoux. Attacher les cheveux

longs. Tenir les cheveux, les v_tements et les gants

hors de portee des pieces en mouvement. Les

v6tements amples, bijoux ou cheveux longs pourraient

s'enchev6trer dans les pieces mobiles. Se tenir eloigne

des events puisque ces demiers recouvrent souvent

des pieces en mouvement.

• Eviter les demarrages intempestifs. S'assurer que le

dispositif de blocage du declencheur est en position

verrouillee avant d'inserer le bloc-piles. Transporter

un outil alors que votre doigt repose sur la detente ou

inserer le bloc-piles dans un outil alors que la detente est

en position marche risque de provoquer un accident.

• Retirer les cles de reglage ou les cles a ouverture

fixe avant de mettre I'outil en marche. Une cle

molette ou une cle de reglage qui est laissee fixee a une

partie mobile de I'outil peut entrafner des blessures.

• Ne pas trop tendre les bras. Conserver son equilibre

en tout temps. Un equilibre convenable permettra de

maftriser I'outil lots de situations inattendues.

• Utiliser un equipement de securite. Toujours

porter une protection oculaire. Selon les conditions,

porter un masque antipoussiere, des chaussures de

securite antiderapantes, un casque de securite ou une

protection auditive.

UTILISATION ET ENTRETIEN DE L'OUTIL

• Utiliser des brides de fixation ou tout autre dispositif

de fixation permettant de soutenir et de retenir la

piece sur une plate-forme stable. Tenir la piece avec

la main ou contre son corps est instable et risque de

provoquer une perte de maftrise de I'outil.

• Ne pas forcer I'outil. Utiliser le bon outil pour votre

application. L'outil approprie effectuera un meilleur

travail, de fa_on plus s_Jreeta la vitesse pour laquelle il

a ete congu.

• Ne pas utiliser I'outil si I'interrupteur ne fonctionne

pas. Tout outil qui ne peut 6tre regle par I'interrupteur

est dangereux et doit 6tre repare.

• Debrancher le bloc-piles de I'outil ou regler

I'interrupteur a la position de verrouillage ou

d'arr6t avant d'effectuer tout reglage, de changer

d'accessoire ou de ranger I'outil. De telles mesures

de securite preventives reduisent le risque de mettre

I'outil en marche accidentellement.

• Ranger les outils inutilises hors de portee des

enfants et des personnes non formees a leur

utilisation. Les outils sont dangereux entre les mains

d'utilisateurs inexperimentes.

• Lorsque le bloc-piles n'est pas utilise, le tenir

eloigne des objets metalliques, notamment des

trombones, de la monnaie, des cles, des clous, des

vis, etc., qui peuvent etablir une connexion entre les

deux bornes. Le court-circuit des bornes du bloc-piles

risque de provoquer des etincelles, des br_Jlures ou un

incendie.

13

• Verifier les pieces mobiles afin de s'assurer qu'elles

sont bien alignees et qu'elles ne restent pas grippees.

Verifier egalement les pieces afin de s'assurer

qu'il n'y a aucun bris ni aucune autre condition

susceptible de nuire au bon fonctionnement de

I'outil. En cas de dommages, faire reparer I'outil

avant de I'utiliser. Beaucoup d'accidents sont causes

par des outils mal entretenus.

• N'utiliser que les accessoires conseilles par le

fabricant pour le modele de I'outil. Des accessoires

qui conviennent a un outil peuvent devenir dangereux

Iorsqu'ils sont utilises avec un autre outil.

RE_PARATION

• Toute reparation de I'outil ne dolt 6tre effectuee que

par des reparateurs professionnels. Toute reparation

ou tout entretien realise par un personnel non forme

peut entrafner des risques de blessures.

• Pour reparer un outil, n'utiliser que des pieces de

rechange identiques. Suivre les directives figurant

la rubrique Entretien du mode d'emploL L'utilisation de

pieces non autorisees ou le non-respect des directives

d'entretien peuvent entrafner des risques de decharge

electrique ou de blessure.

Instructions de s_curit_

importantes pour les cloueuses

_A VERTISSEMENT : Iors de I'utilisation de tout modele de

cloueuse, suivre toutes les mesures de s6curit6, d6crites

ci-apres, pour eviter un risque de deces ou de blessures

graves. Lire et assimiler toutes les directives avant d'utiliser

I'outil.

• Tenir I'outil par sa surface de prise isolee clans une

situation oO I'outil de coupe peut entrer en contact

avec un c#blage dissimule. Tout contact avec un fil

, sous tension _ mettra _ sous tension _ les pieces

metalliques exposees de I'outil et provoquera une

decharge electrique chez I'operateur de I'outil.

• L'outilactionnepourraitprojeterdes

debris, de la coile d'assemblage ou

de la poussiere, qui peuvent tous

provoquer des lesions oculaires

FIG.A I'operateur. L'operateur et les autres

personnes oeuvrant dans la zone de

travail DOIVENT porter des lunettes de

securite munies deprotecteurs lateraux.

Ces lunettes de securite doivent 6tre

conformes aux exigences de la norme

ANSI Z87.1 (les lunettes homologuees

portent I'inscription , Z87 _ imprimee

ou estampillee). L'employeur a la

responsabilite d'imposer le port d'un

equipement de protection oculaire par

I'operateur de I'outil et toute personne

se trouvant dans la zone immediate de

travail. (fig. ,4)

Page 14

• Toujours porter une protection FIG.B

auditive et toute autre protection

convenable Iors de I'utilisation de

I'outil. Dans certaines conditions et

selon la duree d'utilisation, le bruit emis

par ce produit pourrait contribuer a une

perte auditive. (fig. A)

• Debrancher le bloc-piles de I'outil

Iorsque ce dernier est inutilise.

Toujours retirer le bloc-piles et les

attaches du chargeur avant de quitter FIG.C

la zone de travail ou de passer I'outil

un autre operateur. Nepas transporter

I'outil vers une autre zone de travail

qui comprend des echafaudages, des

marches, des echeiles, etc., avec le

bloc-piles insere. Ne pas effectuer de

reglages, d'entretien ou retirer des

attaches coincees avec le bloc-piles

insere.

• Ne pas retirer, modifier ou rendre FIG.D

inutilisable I'outil, la detente, le

dispositif de blocage du declencheur

par contact ou le declencheur par

contact de quelque fagon que ce soit.

Alepas appliquer de ruban ou d'attache

sur la detente ou le declencheur

pour la ou le maintenir en position de

MARCHE. Ale pas retirer le ressort du

declencheur. Inspecter quotidiennement

le bon fonctionnement de la detente FIG.E

et du declencheur. Une decharge non

contrOlee pourrait survenir.

• Inspecter I'outil avant de I'utiliser.

Ne pas utiliser un outil si une

quelconque partie de I'outil, de la

detente, du dispositif de blocage

du declencheur ou du declencheur

_•• ,• _ii_iii_!_

par contact n'est pas fonctionneile,

est debranchee ou modifiee ou ne

fonctionne pas correctement. Les FIG.F

pieces endommagees ou manquantes

doivent 6tre reparees ou remplacees

avant utilisation. Se reporter ala rubrique

Reparations.

• Ne jamais modifier ni alterer I'outil.

• Toujourspresumerquel'outilcontient

des attaches.

• Ne jamais pointer I'outil sur des

FIG. G

collegues ou sur soi-m6me. Pas de

bousculades! Travailler en toute securit6!

Traiter I'outil comme un instrument

essentiel de travail. (fig. t3)

• Eloigner les curieux, les enfants

et les visiteurs Iors de I'utilisation

d'un outil electrique. Une distraction

pourrait vous en faire perdre la maTtrise.

Verrouiller Ibutil dans un endroit sDr,

hors de la portee des enfants Iorsqu'il

n'est pas utilise.

Toujours utiliser le dispositif de

blocage du declencheur Iorsque

I'outil n'est pas destine a 6tre utilise

immediatement. L'utifisation du

dispositif de blocage du declencheur

previendra une decharge intempestive.

Ne pas trop tendre les bras.

Conserver son equilibre en tout

temps. Une perte d'equilibre risque

d'entra_ner une blessure. (fig. C)

Utiliser I'outil uniquement pour les

travaux pour lesquels il a ete congu.

Ne pas decharger les attaches

I'air libre ou clans des materiaux

trop durs comme le beton, la pierre,

le bois tres dur, les neeuds ou toute

autre matiere trop difficile a penetrer.

Ne pas utiliser le corps de I'outil ou son

couvercle superieur comme marteau.

Les attaches ejectees peuvent suivre

une trajectoire inattendue et provoquer

des blessures. (figs. D, F)

Toujours prendre soin d'eloigner les

doigts du declencheur par contact

pour prevenir une blessure en cas

de rel&chement involontaire du

poussoir (fig. H)

Se reporter a la rubrique Entretien

et Reparations pour obtenir de

plus amples renseignements sur

I'entretien approprie de I'outil.

Toujours utiliser I'outil clans un

endroit propre et eclaire. S'assurer

que la surface de travail est exempte de

debris et prendre soin de ne pas perdre

I'equilibre Iors de travaux en hauteur,

comme sur un toit.

Ne pas enfoncer d'attaches pres du

bord de la piece. La piece risque de se

fendre, faire ricocher I'attache et blesser

I'operateur ou un collegue de travail. II

est possible que le clou suive le fil du

bois et sorte inopinement sur le cbte de

la piece. Enfoncer la pointe biseautee

du clou perpendiculairement au fil du

bois pour reduire le risque de blessures.

(figs. E, F et M)

Ne pas enfoncer de clous sur les

t_tes d'autres attaches ou avec

I'outil a un angle trop aigu. Ceci

FIG. H

FIG. I

FIG. J

FIG. K

FIG. L

pourrait causer une blessure provoquee

par un recul, un coincement d'attache

ou un ricochet de clou. (fig. G)

• Garder les mains et les parties du

corps eloignees de la zone immediate

de travail. Le cas echeant, tenir la piece

I'aide de serres pour proteger les

mains et le corps de dangers potentiels.

S'assurer que la piece est bien fixe avant

d'appuyer la cloueuse contre celle-ci. La

force du declencheur peut entrafner le

deplacement inopine de la piece. (fig. H)

Ne pas utiliser d'outil en presence de

poussieres, de gaz ou d'emanations

inflammables. L'outil peut generer une

etincelle qui risque d'enflammer les

gaz, provoquant ainsi un incendie. Une

etincelle pourrait egalement 6tre produite

si un clou est enfonce sur un autre clou.

(fig. I)

Tenir le visage et le corps a I'#cart

de I'arriere du couvercle de I'outil

Iors de travaux clans des endroits

d'acces limite. En effet, un recu/ inopine

peut entrMner un impact au corps,

particulierement lots d'un clouage dans

une matiere dure ou dense. (fig. J)

• Saisir I'outil fermement pour en garder

la maitrise tout en lui permettant de

reculer hors de la surface de travail

Iorsque I'attache est enfoncee. En

,, mode d'actionnement par choc., si le

declencheur touche la piece de nouveau

avec la detente enfoncee, la cloueuse se

declenchera.

• Le choix de la methode de

declenchement est importanL

Consulter le manuel pour conna_tre les

options de declenchement.

SI_LEOTEUR DE MODE CHOC/

SI_QUENTIEL

Actionnement en mode sequentiel /"

(fig. K)

• Lorsqu'on utilise I'outil par

actionnement en mode sequentiel, ne

pas I'actionner a moins qu'il ne soit

fermement appuye contre la piece.

Actionnement par choc /77 (fig. L)

• Lors de I'utilisation de I'outil en mode

choc, 6tre prudent afin d' eviter le double

declenchement en raison du recul de

I'outil.On peut enfoncer involontairement

des clous si le declencheur touche de

nouveau la piece inopinement.

14

Page 15

FIG. M

FIG. N

FIG. 0

POUR EVlTER LES DOUBLES

DECLENCHEMENTS :

• Ne pas presser Ibutil contre

la piece avec trop de force.

• Permettre a Ibutil d'effectuer

completement son

mouvement de recul apres

chaque actionnement.

• Utiliser la detente pour

I'actionnement en mode

sequentieL

• Lorsqu'on utilise

I'_ actionnement par coup _,

de la cloueuse pour clous

de finition, il faut toujours

bien maitriser I'outil. Un

positionnement imprecis de I'outil

peut entrMner une decharge mal

dirigee d'une attache.

• Ne pas enfoncer de clous sur

les t6tes d'autres attaches. Cette

pratique risque de provoquer un

fort recul, de coincer des attaches

ou de faire ricocher des clous.

(fig.m)

• S'informer de I'epaisseur du materiau Iorsque vous

utilisez une cloueuse. Un c/ou en sai//ie peut causer

des blessures.

• REGLAGE DE LA PROFONDEUR : pour reduire les

risques de blessures graves Iors de I'actionnement

accidentel de I'outil Iorsqu'on tente de regler la

profondeur, TOUJOURS :

• Retirer le bloc-piles.

• Engager le dispositif de blocage du declencheur

(fig. N).

• Eviter tout contact avec la d#tente lots des

r#glages.

• Ne pas enfoncer des clous # I'aveuglette clans les

murs, les planchers et autres zones de travail. Des

attaches enfoncees dans des fils electriques sous

tension, de la plomberie ou d'autres types d'obstacles