Page 1

INSTRUCTION MANUAL

DC545, DC546, DC547 Heavy-Duty 18V Cordless Adhesive Gun

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CA

UTION:

Indicates a potentially hazardous situation which, if not a

voided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

WARNING:

To reduce the risk of injury, read the instruction manual.

General Power T

ool Safety W

ar

nings

WARNING! Read all safety warnings and instructions

Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SA

VE ALL W

ARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “po

wer tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have

the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose c lothing or jewellery. Keep your hair , c lothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the manufacturer. A charger that is

suitable for one type of battery pack may create a risk of fire when used with another

battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other

battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like paper

clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another. Shorting the battery terminals together may

cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery, avoid contact. If

contact accidentally occurs, flush with water. If liquid contacts eyes, additionally

seek medical help. Liquid ejected from the battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts.

This will ensure that the safety of the power tool is maintained.

Additional Specifi c Safety Instructions for

Adhesive Guns

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will

also make exposed metal parts of the tool "live" and shock the operator.

• Keep hands out of the plunger and plunger rod area of the caulk/adhesive gun. Fingers

can be crushed between the tube holder and the plunger.

• When operating the caulk/adhesive gun overhead, do not have plunger rod in the

path of your eyes or head. Plunger rod may slip back in direction of user. Always wear eye

protection when using the caulk/adhesive gun.

• Always work in properly ventilated area and wear appropriate respiratory protection if

necessary. Fumes from some caulks and adhesives can be noxious.

• Turn unit off and disconnect battery pack before installing and removing accessories,

before adjusting or when making repairs. An accidental start-up can cause injury.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may be hazardous when used on another tool.

The use of improper accessories may cause risk of injury to persons.

• Lock trigger in the OFF position when not in use to avoid inadvertent release of material.

• Take care not to get caulk or adhesive on battery contact points.

• ALWAYS read and follow all manufacturer’s instructions regarding caulk or adhesive.

Failure to do so may result in personal injury.

WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety

equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3)

• ANSI S12.6 (S3.19) hearing protection

• NIOSH/OSHA/MSHA respiratory protection.

CAUTION: When not in use, place tool on its side on a stable surface where it will not

cause a tripping or falling hazard. Some tools with large battery packs will stand upright on

the battery pack but may be easily knocked over.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V .....................volts A .....................amperes

Hz ...................hertz W ....................watts

min .................minutes

...................alternating current

..............direct current ...................alternating or direct

...................Class I Construction ........................current

.......................(grounded)

n

o....................no load speed

...................Class II Construction ....................earthing terminal

.......................(double insulated) ....................safety alert symbol

…/min ...........per minute BPM ................beats per minute

RPM ...............revolutions per minute

Important Safety Instructions for All Battery Packs

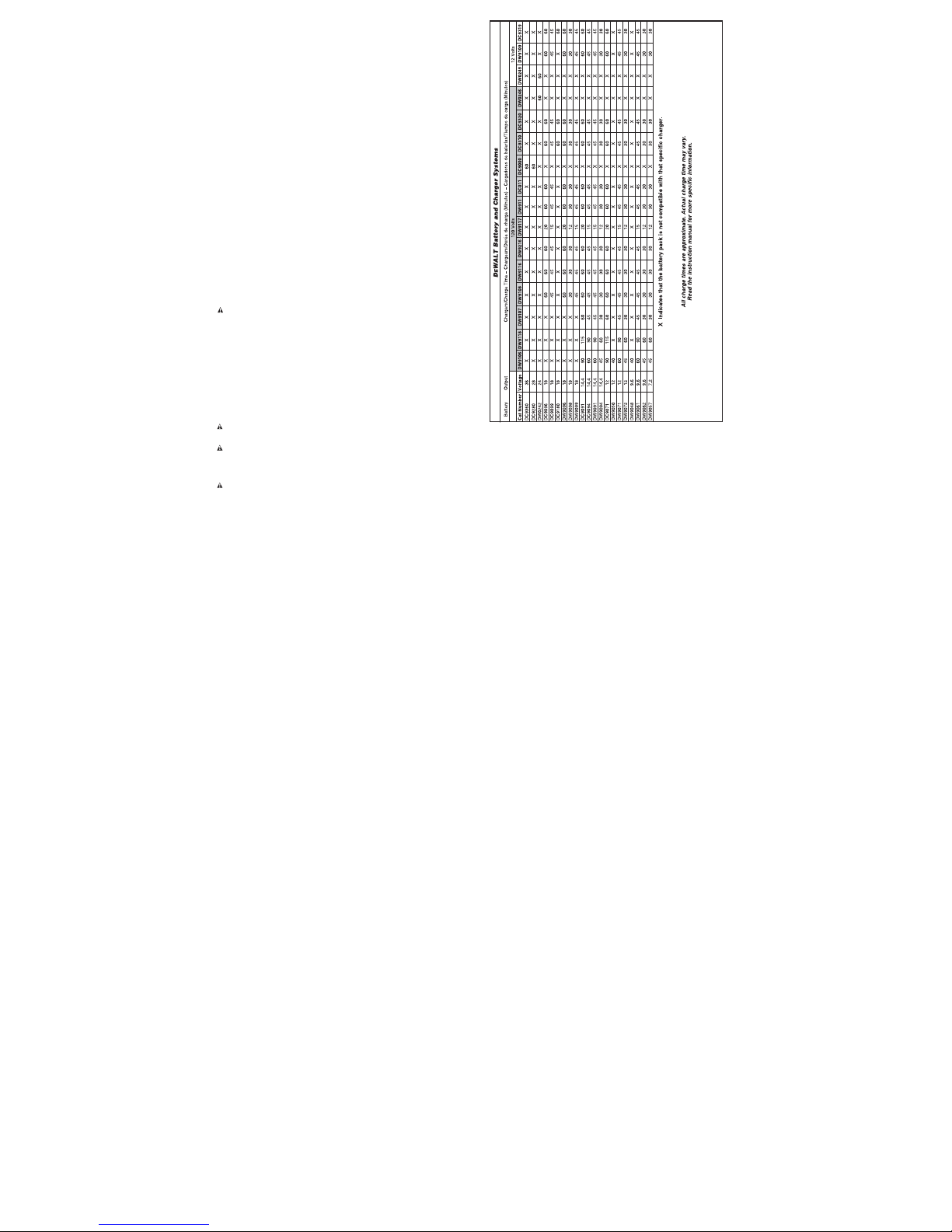

When ordering replacement battery packs, be sure to include catalog number and voltage.

Consult the chart at the end of this manual for compatibility of chargers and battery packs.

The battery pack is not fully charged out of the carton. Before using the battery pack and

charger, read the safety instructions below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use battery in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Inserting or removing the battery from the charger may

ignite the dust or fumes.

• NEVER force battery pack into charger. DO NOT modify battery pack in any way

to fit into a non-compatible charger as battery pack may rupture causing serious

personal injury. Consult the chart at the end of this manual for compatibility of batteries and

chargers.

• Charge the battery packs only in D

E

WALT chargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations where the temperature may

reach or exceed 105°F (40˚C) (such as outside sheds or metal buildings in summer).

DANGER: Electrocution hazard. Never attempt to open the battery pack for any reason.

If battery pack case is cracked or damaged, do not insert into charger. Do not crush, drop or

damage battery pack. Do not use a battery pack or charger that has received a sharp blow,

been dropped, run over or damaged in any way (i.e., pierced with a nail, hit with a hammer,

stepped on). Electric shock or electrocution may result. Damaged battery packs should be

returned to service center for recycling.

NOTE: Battery storage and carrying caps are provided for use whenever the battery

is out of the tool or charger. Remo

ve cap before placing battery in charger or tool.

WARNING: Fire hazar

d. Do not store or carry battery so that metal objects

can contact exposed battery terminals. For example, do not place battery in

aprons, pockets, tool boxes, product kit boxes, drawers, etc., with loose nails,

screws, keys, etc. without battery cap. Transporting batteries can possibly cause

fires if the battery terminals inadvertently come in contact with conductive materials such

as keys, coins, hand tools and the like. The US Department of Transportation Hazardous

Material Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes

(i.e., packed in suitcases and carry-on luggage) UNLESS they are properly protected from short

circuits. So when transporting individual batteries, make sure that the battery terminals are

protected and well insulated from materials that could contact them and cause a short circuit.

SPECIFIC SAFETY INSTRUCTIONS FOR NICKEL CADMIUM (NiCd) OR NICKEL METAL

HYDRIDE (NiMH)

• Do not incinerate the battery pack even if it is severely damaged or is completely worn

out. The battery pack can explode in a fire.

• A small leakage of liquid from the battery pack cells may occur under extreme usage

or temperature conditions. This does not indicate a failure.

However, if the outer seal is broken:

a. and the battery liquid gets on your skin, immediately wash with soap and water for

several minutes.

b. and the battery liquid gets into your eyes, flush them with clean water for a minimum of

10 minutes and seek immediate medical attention. (Medical note: The liquid is 25-35%

solution of potassium hydroxide.)

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION (LI-ION)

• Do not incinerate the battery pack even if it is severely damaged or is completely

worn out. The battery pack can explode in a fire. Toxic fumes and materials are created

when lithium ion battery packs are burned.

• If battery contents come into contact with the skin, immediately wash area with

mild soap and water. If battery liquid gets into the eye, rinse water over the open eye for

15 minutes or until irritation ceases. If medical attention is needed, the battery electrolyte is

composed of a mixture of liquid organic carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory irritation. Provide fresh air. If

symptoms persists, seek medical attention.

WARNING: Bur

n hazard. Battery liquid may be flammable if exposed to spark or flame.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Cor

p oration) Seal on the nickel

cadmium, nickel metal h

ydride or lithium ion batteries (or battery packs) indicate

that the costs to recycle these batteries (or battery packs) at the end of their

useful life have already been paid by D

E

WALT

. In some areas, it is illegal to place

spent nickel cadmium, nickel metal hydride or lithium ion batteries in the trash or

municipal solid waste stream and the RBRC program provides an environmentally

conscious alternative.

RBRC™ in cooperation with D

E

WALT and other battery users, has established programs in

the United States and Canada to facilitate the collection of spent nickel cadmium, nickel metal

hydride or lithium ion batteries. Help protect our environment and conserve natural resources

by returning the spent nickel cadmium and nickel cadmium, nickel metal hydride or lithium ion

batteries to an authorized D

E

WALT ser

vice center or to your local retailer for recycling. You may

also contact your local recycling center for information on where to drop off the spent battery.

RBRC™ is a registered trademark of the Rechargeable Battery Recycling Corporation.

Important Safety Instructions for All Battery Char

gers

SAVE THESE INSTR

UCTIONS: This manual contains important safety and operating instruc-

tions for battery chargers.

• Before using charger, read all instructions and cautionary markings on charger, battery pack,

and product using battery pack.

DANGER: Electrocution hazard.

120 volts are present at charging terminals. Do not probe

with conductive objects. Electric shock or electrocution may result.

WARNING: Shoc

k hazard. Do not allow any liquid to get inside charger. Electric shock may

result.

CAUTION: Bur

n hazard. To reduce the risk of injury, charge only D

E

WALT rechargeab

le

batteries. Other types of batteries may burst causing personal injury and damage.

CAUTION: Under cer

tain conditions, with the charger plugged in to the power supply, the

exposed charging contacts inside the charger can be shorted by foreign material. Foreign

materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept away from charger cavities. Always unplug the

charger from the power supply when there is no battery pack in the cavity. Unplug charger

before attempting to clean.

• DO NOT attempt to charge the battery pack with any chargers other than the ones in

this manual. The charger and battery pack are specifically designed to work together.

• These chargers are not intended for any uses other than charging D

E

WALT rec

hargeable

batteries. Any other uses may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger. This will reduce risk of

damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of improper

extension cord could result in risk of fire, electric shock, or electrocution.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Page 2

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

• Do not place any object on top of charger or place the charger on a soft surface that

might block the ventilation slots and result in excessive internal heat. Place the charger

in a position away from any heat source. The charger is ventilated through slots in the top and

the bottom of the housing.

• Do not operate charger with damaged cord or plug.

• Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service or

repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution or

fire.

• Disconnect the charger from the outlet before attempting any cleaning. This will reduce

the risk of electric shock. Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard 120V household electrical power. Do

not attempt to use it on any other voltage. This does not apply to the vehicular charger.

Using Automatic Tune-Up™ Mode

The automatic Tune-Up™ Mode equalizes or balances the individual cells in the battery pack

allowing it to function at peak capacity. Battery packs should be tuned up weekly or after 10

charge/discharge cycles or whenever the pack no longer delivers the same amount of work. To

use the automatic Tune-Up™, place the battery pack in the charger and leave it for at least 8

hours. The charger will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on continuously and will no

longer blink. This indicates that the pack is fully charged and can be used at this time.

3. If the pack is left in the charger after the initial 1-hour charge, the charger will begin the

Automatic Tune-Up mode. This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use and can be remov ed at an y

time during the Tune-Up mode.

4. Once the Automatic Tune Up mode is complete, the charger will begin a maintenance

charge; the red indicator will remain lit.

Chargers

Your tool uses a DEWALT 7.2, 9.6, 12, 14.4, or 18 Volt charger. Be sure to read all safety

instructions before using your charger. Consult the chart at the end of this manual for compatibility

of chargers and battery packs.

Charging Procedure

DANGER: Electrocution hazard. 120 volts present at charging terminals. Do not probe with

conductive objects. Danger of electric shock or electrocution.

1. Plug the charger into an appropriate outlet before inserting battery pack.

2. Insert the battery pack into the charger. The red (charging) light will blink continuously

indicating that the charging process has started.

3. The completion of charge will be indicated by the red light remaining ON continuously. The

pack is fully charged and may be used at this time or left in the charger.

Indicator Light Operation

Charge Indicators

Some chargers are designed to detect certain problems that can arise with battery packs.

Problems are indicated by the red light flashing at a fast rate. If this occurs , re-insert battery pack

into the charger. If the problem persists, try a different battery pack to determine if the charger is

OK. If the new pack charges correctly, then the original pack is defective and should be returned

to a service center or other collection site for recycling. If the new battery pack elicits the same

trouble indication as the original, have the charger tested at an authorized service center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger detects a battery that is

hot, it automatically starts a Hot Pack Delay, suspending charging until the battery has cooled.

After the battery has cooled, the charger automatically switches to the Pack Charging mode.

This feature ensures maximum battery life. The red light flashes long, then short while in the Hot

Pack Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some

portable power sources such as generators or sources that convert DC to AC, the charger may

temporarily suspend operation, flashing the red light with two fast blinks followed by a pause.

This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the charger. If the battery pack

has not been kept on maintenance charge, it may need to be recharged before use. A battery

pack may also slowly lose its charge if left in a charger that is not plugged into an appropriate

AC source.

WEAK BATTERY PACKS: Chargers can also detect a weak battery pack. Such batteries are

still usable but should not be expected to perform as much work. The charger will indicate to

replace battery pack.

Important Char

ging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when the

air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack in

an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This is important and

will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a normal

condition, and does not indicate a problem. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm environment such as in a metal

shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other appliance;

b. Check to see if receptacle is connected to a light switch which turns power off when you

turn out the lights;

c. Move charger and battery pack to a location where the surrounding air temperature is

approximately 65°F - 75°F (18°- 24°C);

d. If charging problems persist, take the tool, battery pack and charger to your local service

center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs which

were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack whenever you desire with no

adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power supply, the exposed

charging contacts inside the charger can be shorted by foreign material. Foreign materials

of a conductive nature such as, but not limited to, grinding dust, metal chips, steel wool,

aluminum foil, or any buildup of metallic particles should be kept away from charger cavities.

Always unplug the charger from the power supply when there is no battery pack in the cavity .

Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING:

Shock hazard. Don’t allow any liquid to get inside charger. Electric shock may

result.

CAUTION:

Never attempt to open the battery pack for any reason. If the plastic housing of

the battery pack breaks or cracks, return to a service center for recycling.

Storage Recommendations

1. The best storage place is one that is cool and dry away from direct sunlight and excess heat

or cold.

2. Long storage will not harm the battery pack or charger. Under proper conditions, they can be

stored for 5 years or more.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

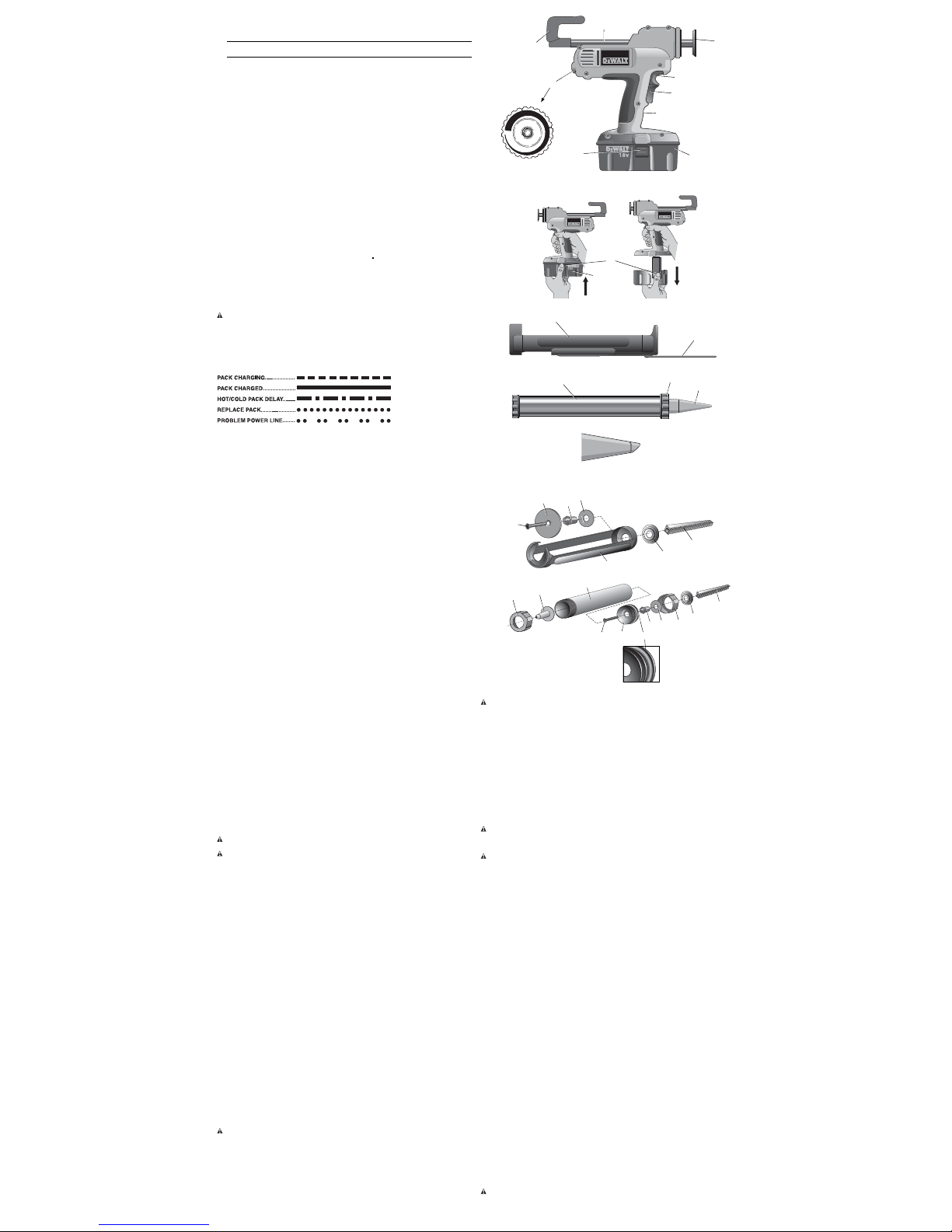

COMPONENTS (Fig. 1–4)

A.

Plunger rod release trigger G. Plunger rod

B. Trigger switch H. Plunger

C. Trigger switch lock-off I. Release buttons

D. Battery pack J. Cartridge holder

E. Variable speed dial K. Poker

F. Plunger rod handle L. Sausage holder

Electr

onic For

ce Control

The tool is designed to dispense a wide r

ange of adhesiv

e and caulk, and to detect when

material is not dispensing or dispensing slowly. In certain cases, the tool may not dispense

material properly due to solidified adhesive, puncture holes, frozen materials and the like. Always

follow the manufacturer’s recommendations regarding solidified adhesive , puncture holes, frozen

materials, etc. to reduce the risk of damaging the tube or casing.

Remove the battery pack and replace material tube/casing following the manufacturer’s

instructions and the instructions under To Insert Material. Take the tool to a D

E

WAL

T service

center if the tool continues to shut down.

Electronic Auto-r

everse

This tool has an auto-reverse feature that reverses the plunger in certain situations depending

on material used and speed of tool.

ASSEMBLY

The DC545, DC546 and the DC547 cordless adhesive guns come fully assembled.

The DC545 accepts 10 oz., 300-310 ml. or 1/10th gallon cartridges. The DC546 accepts 29 oz.

or quart cartridges. The DC547 accepts 10 oz./300 ml., or 20 oz./600 ml. sausage packs.

OPERATION

Installing and Removing the Batter

y Pack

NOTE:

Make sure your battery pack is fully charged.

CA

UTION:

To prevent inadvertant operation, lock trigger switch before removing or installing

battery.

To install the battery pack into the tool handle, align the base of the tool with the notch inside

the tool’s handle and slide the battery pack firmly into the handle until you hear the lock snap

into place (Fig. 2).

To remove the battery pack from the tool, press the release buttons (I) and firmly pull the

battery pack out of the tool handle. Insert it into the charger as described in the charger section

of this manual.

Trigger Switch (Fig. 1)

To tur

n the tool on, squeeze the trigger switch (B). To turn the tool off, release the trigger

switch. Your tool is equipped with a trigger switch lock-off (C) to safeguard against inadvertent

release of material.

Trigger Switch Lock-of

f (Fig. 1)

WARNING:

To reduce the risk of personal injury, turn unit off and disconnect battery

pack before installing and removing accessories, before adjusting or when making

repairs. T o prevent inadvertant operation, lock the trigger switch when the tool is not in use and

when storing the tool.

1. To lock the trigger switch, push trigger switch lock-off (C) up. The tool will not operate with

the switch in the locked position.

2. To unlock the trigger switch, push the trigger switch lock-off down.

Variable Speed Dial (Fig. 1)

1. Turn the variable speed dial (E) to an appropriate speed for your application. Turn the

dial counterclockwise for minimum flow of caulk or adhesive. Turn the dial clockwise for

maximum flow of caulk or adhesive.

2. Press the trigger switch (B) to start the flow of material.

3. Release trigger switch to stop the flow of material.

Rotating Cartridge Holder

The cartr

idge holder rotates 360˚ to apply material at any angle.

Plunger Rod Handle (Fig. 1)

WARNING:

To reduce the risk of personal injury, turn unit off and disconnect battery

pack before installing and removing accessories, before adjusting or when making

repairs. T o prevent inadvertant operation, lock the trigger switch when the tool is not in use and

when storing the tool.

W

ARNING:

To reduce the risk of serious personal injury, DO NOT use the plunger rod

handle as a hook to suspend objects from.

The plunger rod handle may be used to suspend tool from a stable location when not in use or

for storage.

To Adjust Plunger Rod (Fig. 1)

1. To manually adjust plunger rod (G), press and hold the plunger rod release trigger (A).

2. Push or pull plunger rod handle (F) to desirable position.

3. Release plunger rod release trigger.

To Inser

t Material

NOTE: Material left in the cartridge/sausage holder may dry if left unattended. Follow

manufacturer’s recommendations when using caulk or adhesive material.

CARTRIDGE HOLDER (FIG. 3)

1. Ensure that the proper cartridge holder is installed properly.

2. Use the trigger switch lock-off (C) to lock trigger switch (A).

3. Trim nozzle end of the caulk/adhesive tube (Fig. 5). Small openings require more force to

push the material possibly affecting battery life.

4. Break inner seal of caulking tube or adhesive material using the poker (K) located on the

under side of the cartridge holder.

CAUTION: If the inner seal is not broken, material could be forced out through the rear of the

tube and damage the tool.

CAUTION: Keep plunger rod, cartridge holder and cartridge clean of all material. Retracting a

plunger rod that is covered with dried material may damage the internal parts of the tool and

cause misalignment of tube.

5. Securely hold the tool, press plunger rod release trigger (A) to declutch and free the plunger

rod (G). Using the plunger rod handle (F), pull the plunger rod (G) back to allow the caulk/

adhesive tube to fit inside the cartridge holder.

6. Insert caulk/adhesive tube.

7. Press and hold plunger rod release tr igger (A) while pushing the plunger rod handle (F)

forward until the plunger (H) is against the tube.

8. Release the plunger rod release trigger.

9. Rotate cartridge holder to desired angle.

SAUSAGE HOLDER (FIG. 4)

1. Unscrew nozzle cap (M) and remove nozzle (N).

2. Press and hold plunger rod release trigger (A). Using the plunger rod handle (F), pull plunger

rod (G) back to allow the caulk/adhesive casing to fit inside the sausage holder (L).

3. Insert sausage pack into sausage holder and cut casing (closest end to the nozzle) according

to manufacturer’s instructions.

IMPORTANT: Insert sausage pack into sausage holder and cut casing (closest end to the

nozzle) according to manufacturer’s instructions. This sausage holder is designed to be

used only WITH sausage packs. DO NOT remove caulk/adhesive material from the casing.

NEVER dip the nozzle tip into any type of material.

4. With nozzle tip facing away from tool, screw nozzle cap back onto sausage holder.

5. Trim tip of nozzle cap for appropriate application (Fig. 5).

To Change Holders

WARNING:

To reduce the risk of personal injury, turn unit off and disconnect battery

pack before installing and removing accessories, before adjusting or when making

repairs. T o prevent inadvertant operation, lock the trigger switch when the tool is not in use and

when storing the tool.

FIG. 1

I

D

FIG. 2

L

N

M

FIG. 4

FIG. 3

K

J

FIG. 5

D

F

G

E

B

A

C

H

I

10 OZ./29 OZ. CARTRIDGE HOLDER

PORTE-CARTOUCHE DE 300 ML / 857 ML (10 OZ. / 29 OZ.)

SOSTENEDOR DEL CARTUCHO DE 300 ML / 857 ML (10 OZ. / 29 OZ).

FIG. 6

FIG. 7

S

J

R

Q

G

O

P

N

L

Q

R

U

T

G

W

V

X

600 ML SAUSAGE HOLDER

PORTE-BÂTON DE 600 ML

SOSTENEDOR DEL POMO DE 600 ML

M

Page 3

TO REMOVE CARTRIDGE HOLDER (FIG. 1, 6)

1. Remove the plunger screw (O) and cartridge plunger (P) from inside of cartridge holder (J).

2. Press and hold the plunge rod release trigger (A) and pull plunger rod handle (F) back to

access the barrel nut (Q). Release plunger rod release trigger.

3. With a 1/2" square drive tool, turn the barrel nut (Q) counterclockwise to remove.

4. The rear end washer (R), spacer (S) and cartridge holder (J) are now easily removed.

For installation of the cartridge holder, reverse the above procedure.

TO INSTALL SAUSAGE HOLDER (FIG. 1, 7)

1. Position the rear cap spacer (T) and the rear end cap (U) [fine threads] onto nose of the

tool.

NOTE: The side of the rear cap spacer (T) with the double collar faces away from the tool.

2. Place the rear end washer (R) on top of the rear end cap (U) and thread barrel nut (Q) into

the nose of the tool. Tighten and secure the barrel nut with a 1/2" square drive tool. This caulk

gun is designed to allow the rear end cap to rotate freely.

3. Press and hold the plunger rod release trigger and push the plunger rod (G) completely

forward. Release the trigger.

4. Thread the sausage holder (L) onto the rear end cap (U).

5. Assemble the barrel plunger (V) onto the plunger rod (G) and thread the plunger screw (W)

into the plunger rod. This will secure the barrel plunger (V) in place. Tighten securely.

NOTE: Pr ior to assembly of the sausage holder (L), ensure the o-ring (X) has been fully

lubricated. If not, use the lubricant included to completely lubricate the o-ring prior to assembly.

Periodic lubrication of the plunger o-ring (X) may be needed during the life of the caulk gun.

To maintain smooth operation while dispensing material, apply a light coating of the proviced

lubricant to the outside surface of the o-ring.

IMPORTANT:

• Under normal use, the lubricant included with the caulk gun is not expected to cause

eye irritation. Eye irritation may occur under direct contact or in poorly ventilated

areas.

• Short term skin contact with the lubricant is not expected to cause irritation. Direct,

repeated or prolonged exposure may result in skin irritation and redness.

6. Press and hold the plunge rod release trigger and pull the plunger rod handle back before

loading material. Pulling the barrel plunger back will lubricate the inside of the sausage

holder (L). Initial resistance of the plunger rod is expected until the barrel plunger has been

pulled completely back.

7. Place the nozzle (N) onto the sausage holder (L) and thread the nozzle cap (M) over the

nozzle.

To remove the sausage holder, reverse the above procedure.

NOTE: The barrel nut (Q) may ocassionally need to be retighten to ensure the tool functions

properly. If the barrel nut in the carrier becomes loose, use a 1/2" square drive tool to retighten.

MAINTENANCE

WARNING: T o reduce the risk of personal injury, turn unit off and disconnect battery

pack before installing and removing accessories, before adjusting or when making

repairs. T o prevent inadvertant operation, lock the trigger switch when the tool is not in use and

when storing the tool.

Cleaning

CAUTION: To reduce the risk of damaging the tool, material left in the cartridge/sausage holder

may dry if left unattended. Do not attempt to dispense material under this condition. Follow the

manufacturer’s recommendations when using caulk or adhesive material to reduce the risk of

property damage.

To clean the cartridge holder, follow man ufacturer’s recommendations for cleaning material from

nozzle, barrel plunger and plunger rod.

To clean the sausage holder, unscrew nozzle cap (M) and sausage holder (L) and remove

from tool. Follow the manufacturer’s recommendations for cleaning material from nozzle, barrel

plunger, plunger rod and sausage holder.

NOTE: The barrel nut (Q) may ocassionally need to be retighten to ensure the tool functions

properly. If the barrel nut in the carrier becomes loose, use a 1/2" square drive tool to retighten.

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when

performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; nev er immerse

any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt

and grease may be removed from the exterior of the charger using a cloth or soft non-metallic

brush. Do not use water or any cleaning solutions.

De

Walt electric

Po

wer tools

Loading...

Loading...