Page 1

D28111S

Heavy-Duty 4-1/2" (115 mm) Small Angle Grinder

Mini-Esmeriladora Angular de 115 mm (4-1/2")

Mini-Esmerilhadeira Angular 4-1/2" (115 mm)

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

INSTRUÇÕES DE OPERAÇÃO, CENTRO DE SERVIÇOS E CERTIFICADO

DE GARANTIA. ADVERTÊNCIA: LEIA ESTAS INSTRUÇÕES ANTES DE

UTILIZAR O PRODUTO.

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

8

m

N

Page 2

Page 3

3

English

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool”in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool IN A DAmp location is unavoidable,

use a residual current device (RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

Page 4

4

English

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety instructions for all operations

a) This power tool is intended to function as a grinder,

sander, wire brush. Read all safety warnings, instructions,

illustrations and specifications provided with this power

tool. Failure to follow all instructions listed below may result

in electric shock, fire and/or serious injury.

b) Operations such as polishing or cutting-off are not

recommended to be performed with this power tool.

Operations for which the power tool was not designed may

create a hazard and cause personal injury.

Page 5

5

English

c) Do not use accessories which are not specifically

designed and recommended by the tool manufacturer.

Just because the accessory can be attached to your power

tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least

equal to the maximum speed marked on the power tool.

Accessories running faster than their rated speed can break

and fly apart.

e) The outside diameter and the thickness of your accessory

must be within the capacity rating of your power tool.

Incorrectly sized accessories cannon be adequately guarded

or controlled.

f) The arbour size of wheels, flanges, backing pads or

any other accessory must properly fit the spindle of

the power tool. Accessories with arbour holes that do not

match the mounting hardware of the power tool will run out of

balance, vibrate excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheel for chips

and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage or install an

undamaged accessory. After inspecting and installing an

accessory, position yourself and bystanders away from

the plane of the rotating accessory and run the power

tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

h) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and shop apron capable of stopping

small abrasive or workpiece fragments. The eye protection

must be capable of stopping flying debris generated by various

operations. The dust mask or respirator must be capable of

filtrating particles generated by your operation. Prolonged

exposure to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal

protective equipment. Fragments of workpiece or of a

broken accessory may fly away and cause injury beyond

immediate area of operation.

j) Hold power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory

contacting a “live” wire may make exposed metal parts of the

power tool “live” and shock the operator.

k) Position the cord clear of the spinning accessory. If you

lose control, the cord may be cut or snagged and your hand

or arm may be pulled into the spinning accessory.

l) Never lay the power tool down until the accessory has

come to a complete stop. The spinning accessory may grab

the surface and pull the power tool out of your control.

m) Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag

your clothing, pulling the accessory into your body.

n) Regularly clean the power tool’s air vents. The motor’s

fan will draw the dust inside the housing and excessive

accumulation of powdered metal may cause electrical

hazards.

o) Do not operate the power tool near flammable materials.

Sparks could ignite these materials.

p) Do not use accessories that require liquid coolants. Using

water or other liquid coolants may result in electrocution or

shock.

Page 6

6

English

Causes and Operator

Prevention of Kickback

• Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool to

be forced in the direction opposite of the accessory’s rotation

at the point of the binding.

• For example, if an abrasive wheel is snagged or pinched by

the workpiece, the edge of the wheel that is entering into the

pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either jump

toward or away from the operator, depending on direction

of the wheel’s movement at the point of pinching. Abrasive

wheels may also break under these conditions.

• Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a) Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up.

The operator can control torque reaction or kickback forces, if

proper precautions are taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool

in direction opposite to the wheel’s movement at the point of

snagging.

d) Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of

control.

Safety Warnings Specific for

Grinding Operations

a) Use only wheel types that are recommended for your

power tool and the specific guard designed for the

selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

b) The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. The guard

helps to protect operator from broken wheel fragments and

accidental contact with wheel.

c) Wheels must be used only for recommended applications.

For example: do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral grinding,

side forces applied to these wheels may cause them to

shatter.

d) Always use undamaged wheel flanges that are of correct

size and shape for your selected wheel. Proper wheel

flanges support the wheel thus reducing the possibility of

wheel breakage. Flanges for cut-off wheels may be different

from grinding wheel flanges.

e) Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the

higher speed of a smaller tool and may burst.

Safety Warnings Specific

for Wire Brushing Operations:

a) Be aware that wire bristles are thrown by the brush even

during ordinary operation. Do not overstress the wires by

applying excessive load to the brush. The wire bristles can

easily penetrate light clothing and/or skin.

Page 7

7

English

conditions and duration of use, noise from this product may

contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

WARNING: ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. Also use face or dust mask if

cutting operation is dusty. All users and bystanders MUST ALWAYS

wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

b) If the use of a guard is recommended for wire brushing,

do not allow any interference of the wire wheel or brush

with the guard. Wire wheel or brush may expand in diameter

due to work and centrifugal forces.

Additional Safety Warnings for Grinders

• An extension cord must have adequate wire size (AWG

or American Wire Gauge) for safety. The smaller the gauge

number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized

cord will cause a drop in line voltage resulting in loss of power

and overheating. When using more than one extension to

make up the total length, be sure each individual extension

contains at least the minimum wire size. The following table

shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

Voltage (Volts)

Total length of cord in meters (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

Minimal cross-sectional area of the

cord in meters (mm

2

)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

WARNING: Always use eye protection. All users and bystanders

must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

Page 8

8

English

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ............ volts A ............ amperes

Hz .......... hertz W ........... watts

min ......... minutes

..........alternating current

....... direct current

n

o ........... no load speed

........... Class I Construction ........... earthing terminal

............... (grounded) ...........safety alert symbol

............ Class II Construction …/min .... revolutions or

............... (double insulated) ............... reciprocation

BPM....... beats per minute

..............per minute

sfpm ...... surface feet

.............. per minute (sfpm)

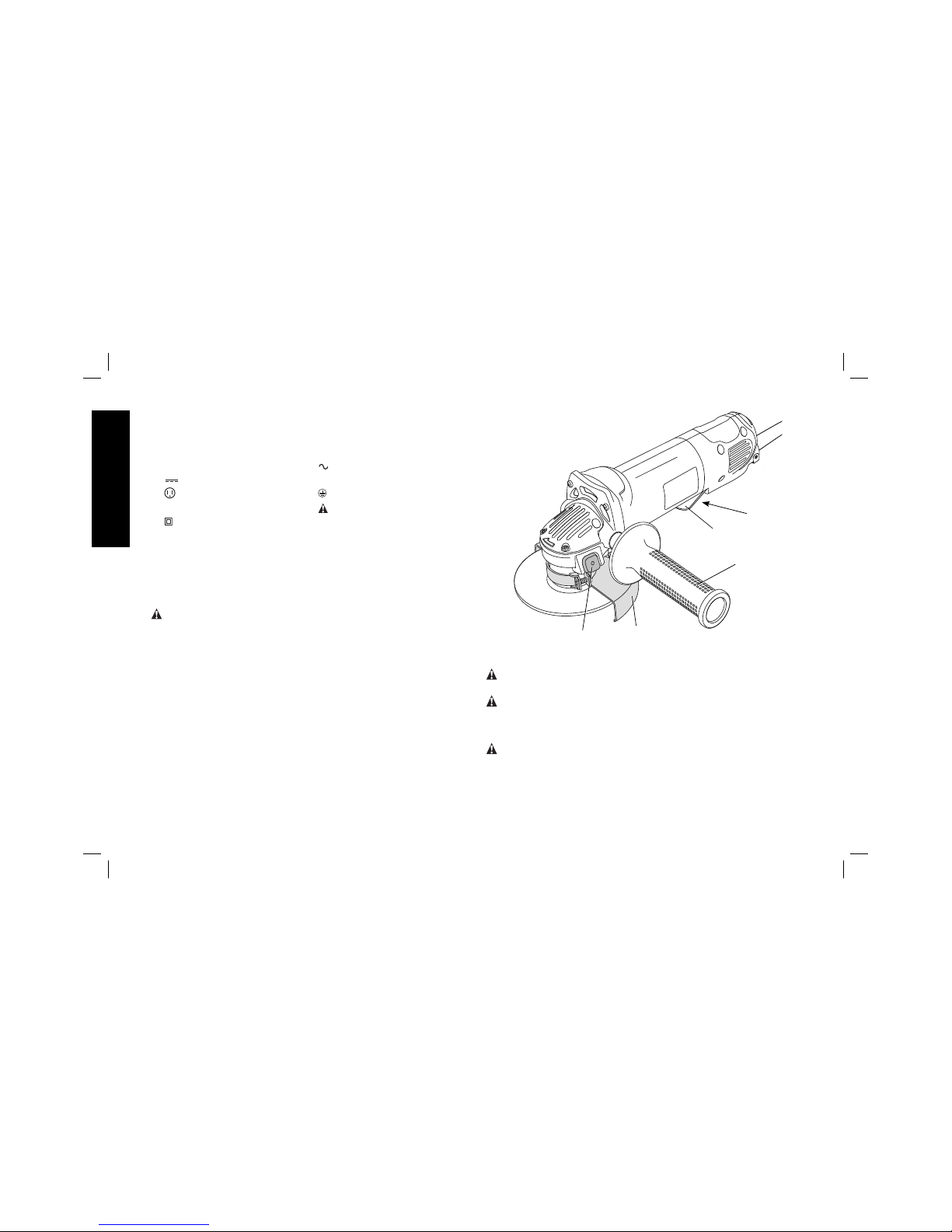

DESCRIPTION (FIG. 1)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury could result.

INTENDED USE

Your angle grinder has been designed for professional grinding and

cutting applications.

DO NOT use under wet conditions or in presence of flammable

liquids or gases.

DO NOT use grinding wheels other than center depressed wheels

and flap-disk.

This heavy-duty angle grinder is a professional power tool. DO NOT

let children come into contact with the tool. Supervision is required

when inexperienced operators use this tool.

A. Paddle switch D. Guard

B. Lock-off lever E. Side handle

C. Spindle lock

FIG. 1

D

E

A

C

B

ASSEMBLY AND ADJUSTMENTS

WARNING: Prior to assembly and adjustment, ALWAYS unplug

tool.

WARNING: Never use the tool without the guard in place.

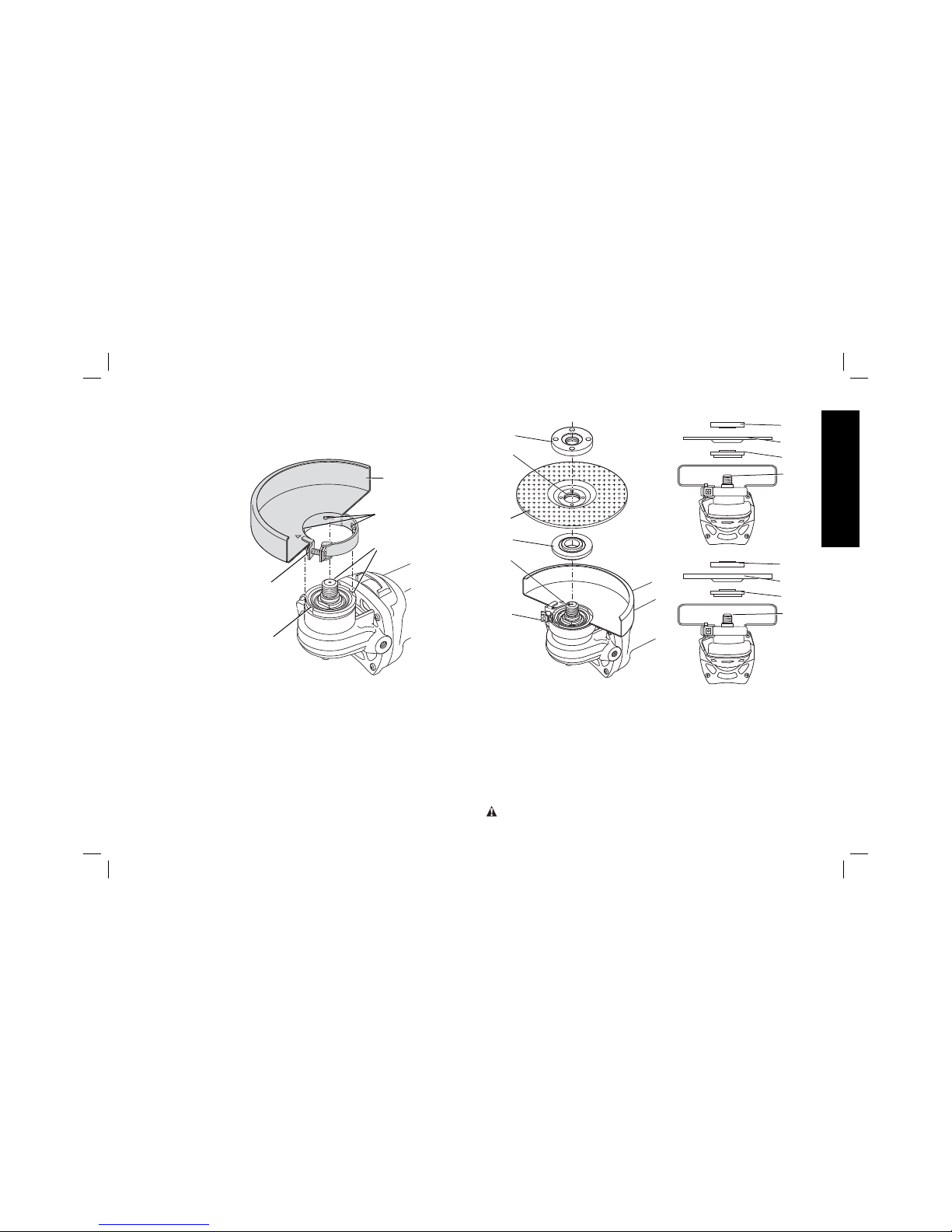

Mounting and Removing the Guard

(Fig. 2)

WARNING: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or

accessories. Before reconnecting the tool, depress and release

the paddle switch to ensure that the tool is off.

1. Place the angle grinder on a table, spindle up.

2. Align the lugs (F) with the notches (G).

Page 9

9

English

– the ring on the flange (M) must face away from the disc when

fitting a cutting disc (C).

5. Press the spindle lock (C) and rotate the spindle (J) until it locks

in position.

6. Tighten the flange (M) with the two-pin spanner supplied.

7. Release the spindle lock.

8. To remove the disc, loosen the flange (M) with the two-pin

spanner.

WARNING: Do not use a damaged disc.

3. Press the guard down and rotate it to the required position.

4. Securely tighten the screw (H).

5. To remove the guard, slacken the screw.

C

F

G

H

G

FIG. 2

Fitting and Removing a Grinding or

Cutting Disc (Fig. 3A, 3B)

1. Place the tool on a table, guard up.

2. Fit the inner flange (I) correctly onto the spindle (J) (fig. 3A).

3. Place the disc (K) on the flange (I). When fitting a disc with a

raised center, make sure that the raised center (L) is facing the

flange (I).

4. Screw the outer flange (M) onto the spindle (J) (fig. 3B):

– the ring on the flange (M) must face towards the disc when

fitting a grinding disc (K);

FIG. 3A FIG. 3B

M

L

K

I

J

C

A

B

J

M

K

I

J

M

K

I

Page 10

10

English

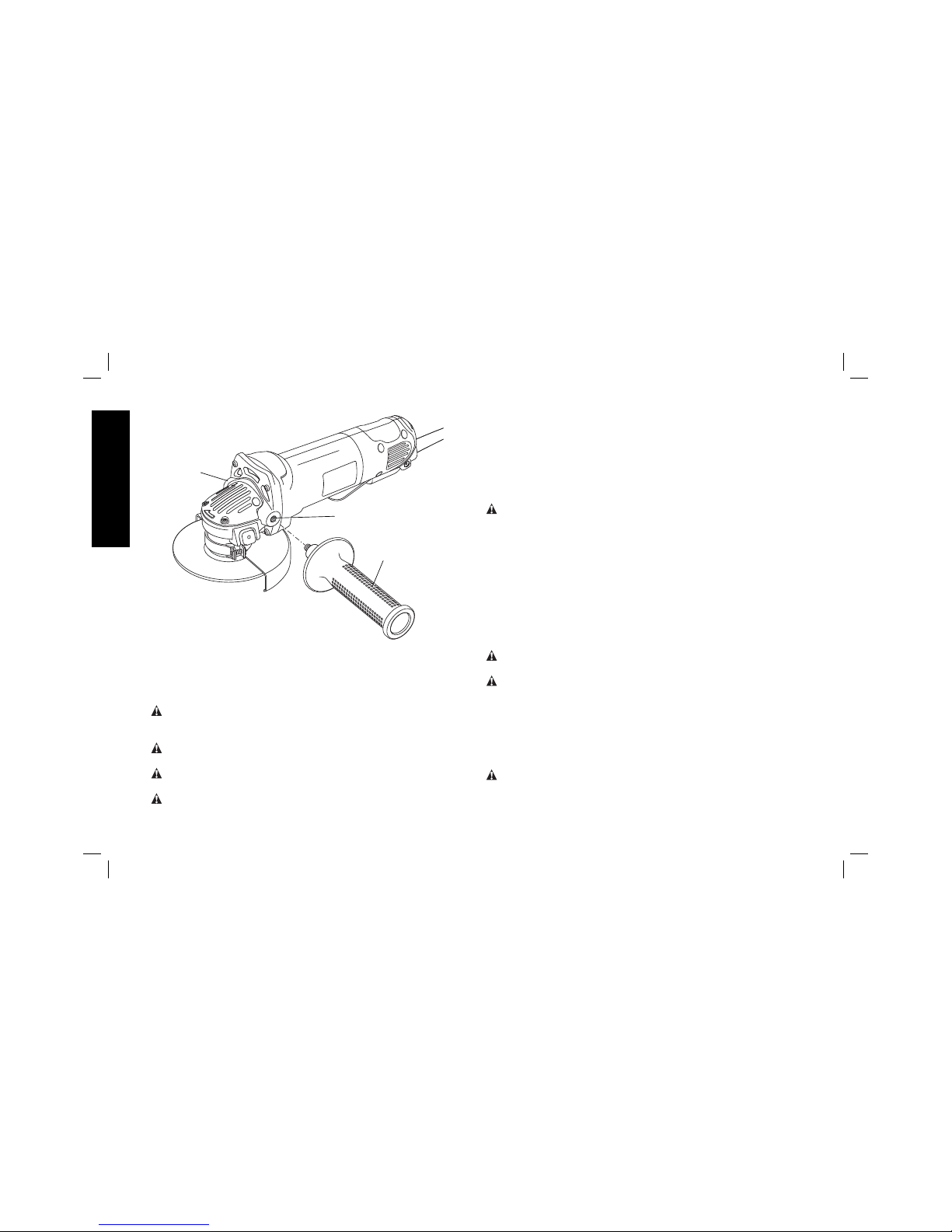

E

N

N

FIG. 4

Mounting the Side Handle (Fig. 4)

Screw the side handle (E) tightly into one of the holes (N) on either

side of the gear case.

OPERATION

WARNING: Allow the tool to reach full speed before touching tool

to the work surface. Lift the tool from the work surface before

turning the tool off.

WARNING: Ensure all materials to be ground or cut are secured

in place.

WARNING: Apply only a gentle pressure to the tool. Do not exert

side pressure on the disc.

WARNING: Avoid overloading. Should the tool become hot, let it

run a few minutes under no load condition.

PRIOR TO OPERATION

Install the guard and appropriate disc or wheel. Do not use

excessively worn discs or wheels.

Be sure the inner and outer flange are mounted correctly.

Make sure the disc or wheel rotates in the direction of the arrows

on the accessory and the tool.

Paddle Switch

WARNING: Before connecting the tool to a power source

depress and release the paddle switch (A) once without depressing

the lock-on button (B) to ensure that the switch is off. Depress and

release the paddle switch as described above after any interruption

in power supply to the tool, such as the activation of a ground fault

interrupter, throwing of a circuit breaker, accidental unplugging, or

power failure. If the paddle switch is locked on, the tool will start

unexpectedly when it is reconnected.

To turn the tool on, push the lock-off lever (B) toward the back of

the tool, then depress the paddle switch (A). The tool will run while

the switch is depressed. Turn the tool off by releasing the paddle

switch.

WARNING: Do not disable the lock-off lever. If the lock-off lever

is disabled, the tool may start unexpectedly when it is laid down.

WARNING: Do not switch the tool on or off when under load.

Metal Applications

When using the tool in metal applications, make sure that a residual

current device (RCD) has been inserted to avoid residual risks

caused by metal swarf.

If the power supply is shut off by the RCD, take the tool to authorised

D

EWALT repair agent.

WARNING: In extreme working conditions, conductive dust can

accumulate inside the machine housing when working with metal.

This can result in the protective insulation in the machine becoming

degraded with a potential risk of an electrical shock.

Page 11

11

English

WARNING: To avoid build-up of metal swarf inside the machine,

we recommend to clear the ventilation slots on a daily basis. Refer

to Maintenance.

Using Flap Discs

WARNING: Metal dust build-up.

Extensive use of flap discs in metal applications can result in the

increased potential for electric shock. To reduce this risk, insert an

RCD before use and clean the ventilation slots daily by blowing

dry compressed air into the ventilation slots in accordance with the

below maintenance instructions.

MAINTENANCE

Your DEWALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

Pop-off Brushes

The motor will be automatically shut off indicating that the carbon

brushes are nearly worn out and that the tool needs servicing.

The carbon brushes are not user-serviceable. Take the tool to an

authorised D

EWALT repair agent.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and removing

accessories, before making any adjustments or removing/installing

attachments or accessories.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of the main housing with dry

air as often as dirt is seen collecting in and around the air vents.

Wear approved eye protection and approved dust mask when

performing this procedure.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

EWALT, recommended accessories should be used

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center.

Page 12

12

Español

12

Definiciones: Normas

de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO:

indica una situación de peligro inminente que, si

no se evita,

provocará

la

muerte o lesiones graves.

ADVERTENCIA:

Indica una situación de peligro potencial

que, si no se evita,

podría

provocar la

muerte o lesiones

graves

ATENCIÓN:

Indica una situación de peligro potencial que, si

no se evita,

puede

provocar

lesiones leves o moderadas.

ATENCIÓN:

Utilizado sin el símbolo de alerta de seguridad

indica una situación de peligro potencial que, si no se evita,

puede provocar

daños en la

propiedad

.

ADVERTENCIA: para reducir el riesgo de lesiones, lea el

manual de instrucciones.

Advertencias generales de seguridad

para las herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones. El incumplimiento de las advertencias o instrucciones

puede provocar descargas eléctricas, incendios o lesiones graves.

GUARDE LAS ADVERTENCIAS E

INSTRUCCIONES PARA PODER

CONSULTARLAS EN EL FUTURO

El término “herramienta eléctrica” incluido en todas las advertencias

se refiere a su herramienta eléctrica conectada a la red (cable

eléctrico) o a su herramienta eléctrica accionada con baterías

(inalámbrica).

1) SEGURIDAD DEL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas u oscuras propician accidentes.

b) No haga funcionar las herramientas eléctricas en

atmósferas explosivas, como ambientes donde haya

polvo, gases o líquidos inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o

producir humo.

c) Mantenga alejados a los niños y a los espectadores

de la herramienta eléctrica en funcionamiento. Las

distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse

a la toma de corriente. Nunca modifique el enchufe de

ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con conexión a tierra. Los

enchufes no modificados y que se adaptan a las tomas de

corrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con toma de

tierra como, por ejemplo, tuberías, radiadores, cocinas y

refrigeradores. Existe mayor riesgo de descarga eléctrica si

su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. Si entra agua en una herramienta

eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable

para transportar, tirar o desenchufar la herramienta

eléctrica. Mantenga el cable alejado del calor, el aceite,

los bordes afilados o las piezas móviles. Los cables

dañados o enredados aumentan el riesgo de descarga

eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice

un cable prolongador adecuado para tal uso. Utilice un

Page 13

13

Español

13

cable adecuado para uso en exteriores a fin de reducir el

riesgo de descarga eléctrica.

f) Si no se puede evitar el uso de una herramienta eléctrica

en una zona húmeda, utilice un dispositivo de corriente

residual (residual current device, RCD) de seguridad.

El uso de un RCD reduce el riesgo de sufrir una descarga

eléctrica.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el

sentido común cuando emplee una herramienta eléctrica.

No utilice una herramienta eléctrica si está cansado o

bajo el efecto de drogas, alcohol o medicamentos. Un

momento de descuido mientras se opera una herramienta

eléctrica puede provocar lesiones personales graves.

b) Utilice equipo de seguridad personal. Utilice siempre

protección ocular. El uso de equipo de seguridad, como

mascarillas para polvo, calzado de seguridad antideslizante,

cascos o protección auditiva en las condiciones adecuadas

reducirá las lesiones personales.

c) Evite poner en marcha la herramienta involuntariamente.

Asegúrese de que el interruptor está apagado antes de

conectar la fuente de alimentación y/o la batería, coger

o transportar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o

enchufar herramientas eléctricas con el interruptor en la

posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de

encender la herramienta eléctrica. Una llave de tuercas

o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones

personales.

e) No se estire demasiado. Conserve el equilibrio y

posiciónese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas

en movimiento.

g) Si se suministran dispositivos para la conexión de

accesorios con fines de recolección y extracción de

polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso del extractor de polvo puede

reducir los riesgos relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. La

herramienta eléctrica correcta hará el trabajo mejor, y de un

modo más seguro, a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla

o apagarla con el interruptor. Las herramientas que no

puedan ser controladas con el interruptor constituyen un

peligro y deben repararse.

c) Desconecte el enchufe de la fuente de alimentación o

la batería de la herramienta eléctrica antes de realizar

cualquier ajuste, cambio de accesorios o almacenar

las herramientas eléctricas. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta

eléctrica de forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios que no tienen

formación.

Page 14

14

Español

14

e) Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas,

piezas rotas o cualquier otra situación que pueda afectar

el funcionamiento de las herramientas eléctricas. Si

encuentra daños, haga reparar la herramienta eléctrica

antes de utilizarla. Se producen muchos accidentes a

causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de corte con mantenimiento adecuado y

con los bordes de corte afilados son menos propensas a

trabarse y son más fáciles de controlar.

g) Utilice las herramientas eléctricas, sus accesorios y

piezas, etc. de acuerdo con las presentes instrucciones,

teniendo siempre en cuenta las condiciones de trabajo y

el trabajo que deba llevar a cabo. El uso de la herramienta

eléctrica para operaciones diferentes de aquellas para las

que fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona cualificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica

y que solo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

NORMAS ESPECÍFICAS DE SEGURIDAD

ADICIONALES

Instrucciones de seguridad para

todas las operaciones

a) Esta herramienta eléctrica ha sido diseñada para

funcionar como esmeriladora, lijadora y cepillo metálico.

Lea todas las advertencias de seguridad, instrucciones,

ilustraciones y especificaciones que acompañan a esta

herramienta eléctrica. El incumplimiento de todas las

instrucciones enumeradas a continuación puede provocar

descargas eléctricas, incendios o lesiones graves.

b) Con esta herramienta eléctrica no se recomienda realizar

operaciones tales como pulir o serrar. El uso de esta

herramienta eléctrica para operaciones distintas a las

explícitamente previstas puede suponer un peligro y provocar

daños personales.

c) No utilice accesorios que no hayan sido específicamente

diseñados y recomendados por el fabricante de la

herramienta. Aunque el accesorio encaje en su herramienta

eléctrica, no significa que garantice su funcionamiento

seguro.

d) La velocidad nominal del accesorio debe ser como

mínimo igual a la velocidad máxima que figura en la

herramienta eléctrica. Aquellos accesorios que funcionen

más rápido que su velocidad nominal podrían partirse y salir

despedidos.

e) El diámetro exterior y el grosor de su accesorio debe

ajustarse al nominal de capacidad de su herramienta

eléctrica. Aquellos accesorios que no tengan las medidas

correctas no quedarán oportunamente protegidos o

controlados.

f) El tamaño de las ruedas, los flanges, las almohadillas

de apoyo o cualquier otro accesorio, deben ajustarse

perfectamente en el eje de la herramienta eléctrica. Los

accesorios con agujeros que no se ajusten al equipo de

montaje de la herramienta eléctrica, se descompensarán,

vibrarán excesivamente y podrían ser causa de la pérdida de

control.

g) No utilice accesorios deteriorados. Antes de su uso,

inspeccione los accesorios tales como los discos

abrasivos para grietas y desconchados, la almohadilla

para las grietas, manchas o un desgaste excesivo, el

Page 15

15

Español

15

cepillo de alambre para los cables sueltos o agrietados. Si

una herramienta eléctrica o accesorio se cae, inspeccione

si ha sufrido daños o instale un accesorio que no esté

dañado. Después de inspeccionar e instalar un accesorio,

colóquese usted mismo y los que puedan estar a su

alrededor lejos del plano de rotación del accesorio y

haga funcionar la herramienta eléctrica a la máxima

velocidad sin carga durante un minuto. Los accesorios

dañados normalmente se romperán y desprenderán durante

esta prueba.

h) Lleve equipo de protección personal. Según la

aplicación, utilice un protector facial, gafas de seguridad

o cristales de seguridad. Si es necesario, colóquese una

mascarilla antipolvo, protectores para los oídos, guantes

y un delantal de trabajo capaz de absorber pequeños

fragmentos abrasivos o de la pieza. La protección para los

ojos debe poder detener los restos que salgan despedidos

por las distintas operaciones. La mascarilla antipolvo o el

respirador debe poder filtrar las partículas generadas durante

el trabajo. Una exposición prolongada a ruidos de gran

intensidad podría ser causa de pérdida de audición.

i) Mantenga a las personas a una distancia segura, alejada

de la zona de trabajo. Cualquiera que entre en la zona de

trabajo debería llevar un equipo de protección personal.

Podrían salir despedidos fragmentos de las piezas o de un

accesorio roto y causar lesiones fuera de la zona de trabajo.

j) Coloque la herramienta eléctrica sólo en superficies

absorbentes aisladas cuando realice un trabajo en el que

accesorio de corte pueda entrar en contacto con cables

ocultos o con su propio cable. Un accesorio de corte que

entre en contacto con un cable “activo” podría hacer que

las piezas de metal expuestas de la herramienta eléctrica

transmitieran también corriente y electrocutaran al operario.

k) Coloque el cable lejos del accesorio giratorio. Si pierde el

control, el cable podría cortarse o enrollarse y su mano o su

brazo podrían verse atraídos por el accesorio giratorio.

l) Nunca deje la herramienta eléctrica sobre una superficie

hasta que el accesorio se haya parado del todo. El

accesorio giratorio podría engancharse en la superficie y tirar

de la herramienta eléctrica hasta quedar fuera de su control.

m) No haga funcionar la herramienta eléctrica mientras

la lleve a su lado. El contacto accidental con el accesorio

giratorio podría rasgar su ropa y empujar el accesorio hasta

su cuerpo.

n) Limpie con regularidad los respiraderos de la herramienta.

El ventilador del motor absorberá el polvo presente en

el interior de la carcasa y una excesiva acumulación de

metal en polvo podría convertirse en un peligro debido a la

electricidad

o) No haga funcionar esta herramienta eléctrica cerca de

materiales inflamables. Las chispas podrían incendiar estos

materiales.

p) No utilice accesorios que requieran refrigerantes líquidos.

La utilización de agua u otros líquidos refrigerantes podrían

causar electrocuciones o calambres.

Causas de la inversión de giro y su

prevención por parte del operario

• La inversión de giro es una reacción brusca a una rueda

giratoria, una almohadilla de repuesto, un cepillo o cualquier

otro accesorio que se encuentre comprimido o esté atascado

y que, a su vez, hace que la herramienta eléctrica se

descontrole y vaya en sentido opuesto al giro del accesorio

en el momento de la conexión.

• Por ejemplo, si una pieza engancha o comprime una muela

abrasiva, el borde de la rueda que entra en contacto con

el punto crítico puede quedarse clavado en la superficie

Page 16

16

Español

16

del material y hacer que la rueda salga despedida. La

rueda también puede escaparse de las manos del operario,

según el sentido del movimiento de la rueda en el punto de

compresión. En estas condiciones, las muelas abrasivas

también pueden romperse.

• La inversión de giro es el resultado de un mal uso de

la herramienta y/o de unos incorrectos procedimientos o

condiciones de uso y se puede evitar tomando las medidas de

precaución adecuadas, tal y como se indica seguidamente:

a) Sujete fuertemente la herramienta eléctrica y coloque

su cuerpo y su brazo de manera que le permita resistir

la fuerza de la inversión de giro. Utilice siempre una

empuñadura auxiliar, si la hay, para controlar mejor

la inversión de giro o la reacción del par durante el

arranque. El operario puede controlar la reacción del par o la

fuerza de la inversión de giro siempre que tome las debidas

precauciones.

b) No coloque nunca su mano cerca del accesorio giratorio.

El accesorio puede golpearle la mano.

c) No coloque su cuerpo en la zona en la que se moverá la

herramienta eléctrica, de lo contrario podría golpearle.

En caso de atascarse, la inversión de giro empujará la

herramienta en el sentido opuesto al movimiento de la

rueda.

d) Tenga especial cuidado cuando trabaje curvas, bordes

afilados, etc. Evite el rebote y el enganche del accesorio.

Las curvas, los bordes afilados o los rebotes tienden a

atascar el accesorio giratorio y provocan la pérdida del control

o la inversión de giro.

e) No coloque una cuchilla para tallar madera en la sierra de

cadena ni una cuchilla de sierra dentada. Estas cuchillas

generan con frecuencia inversiones de giro y pérdidas de

control.

Advertencias específicas para las

operaciones de esmeriladoras

a) Utilice sólo los discos recomendados para su herramienta

eléctrica y la protección de seguridad específicamente

diseñada para el disco seleccionado. Los discos que

no hayan sido diseñados para esta herramienta eléctrica

no quedarán oportunamente protegidos y no ofrecerán

seguridad.

b) La protección debe quedar sujeta a la herramienta de

seguridad y estar perfectamente colocada para obtener

la máxima seguridad, de modo que el operador quede

expuesto a una mínima superficie de la herramienta. La

protección sirva para proteger al operario de los fragmentos

de disco rotos o del contacto adicional con el disco

c) Los discos deben utilizarse sólo para las aplicaciones

recomendadas. Por ejemplo: no realice operaciones de

esmerilado con el lateral del disco de corte. Los discos de

cortar han sido diseñados para los esmerilados periféricos,

por lo que las fuerzas laterales aplicadas a estas muelas

podrían hacer que se partieran.

d) Utilice siempre flanges que no estén dañadas, que

tengan el tamaño y la forma correctas para el disco

seleccionado. Unos flanges adecuados para el disco sujetan

la muela y así reducen la posibilidad de su rotura. Los flanges

para los discos de corte pueden ser distintas a los flanges

para las muelas.

e) No utilice discos gastados de herramientas eléctricas

más grandes. Los discos diseñados para una herramienta

eléctrica más grande no resultan adecuados para la mayor

velocidad de una herramienta más pequeña y podrían

quemarse.

Page 17

17

Español

17

Advertencias específicas para las

operaciones de cepillado metálico

a) No olvide que el cepillo desprende cerdas metálicas

durante su funcionamiento habitual. No sobrecargue los

alambres mediante la aplicación de una carga excesiva en

el cepillo. Las cerdas metálicas pueden penetrar fácilmente en

ropas ligeras y/o en la piel.

b) Si se recomienda el uso de una protección para el cepillado

metálico, no permita ninguna interferencia de la rueda

metálica o del cepillo metálico con la protección. La rueda

metálica o el cepillo metálico pueden sufrir un aumento en su

diámetro debido al trabajo y a las fuerzas centrífugas.

Advertencias de seguridad adicionales

para esmeriladoras

• Los cables de extensión deben ser de un calibre apropiado

(AWG o American Wire Gauge) para su seguridad. Mientras

menor sea el calibre del cable, mayor la capacidad del cable.

Es decir, un cable calibre 16 tiene mayor capacidad que uno

de 18. Un cable de un calibre insuficiente causará una caída

en la tensión de la línea dando por resultado una pérdida de

energía y sobrecalentamiento. Cuando se utilice más de un

alargador para completar el largo total, asegúrese que los

cables de cada alargador tengan el calibre mínimo. La tabla

siguiente muestra el tamaño correcto a utilizar, dependiendo

de la longitud del cable y del amperaje nominal de la placa de

identificación. Si tiene dudas sobre cuál calibre usar, use un

calibre mayor. Cuanto más pequeño sea el número del calibre,

más resistente será el cable.

Ténsion (Volts) Longitud del cable en metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente nominal

(Ampéres)

Sección nominal mínima del cable

en milímetros quadrados (mm

2

)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 No recomendado

ADVERTENCIA: Siempre use protección ocular. Todos los

usuarios y las personas circunstantes deben llevar protección

ocular en conformidad con ANSI Z87.1.

ADVERTENCIA: Siempre lleve la debida protección auditiva

personal en conformidad con ANSI S12.6 (S3.19) durante el

uso de esta herramienta. Bajo algunas condiciones y duraciones

de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

ADVERTENCIA: Parte del polvo generado al lijar, serrar,

esmerilar o taladrar, así como al realizar otras actividades del

sector de la construcción, contienen productos químicos que

pueden producir cáncer, defectos congénitos u otras afecciones

reproductivas. Ejemplos de estos químicos son:

• plomo de algunas pinturas,

• polvo de sílice proveniente de ladrillos y cemento y otros

productos de albañilería, y

• arsénico y cromo provenientes de maderas tratadas con

químicos (arseniato de cobre cromado).

Page 18

18

Español

18

Su riesgo de exposición a estos químicos varía, dependiendo de

la frecuencia con la cual realiza usted este tipo de trabajo. Para

reducir la exposición a esas sustancias químicas: trabaje en una

zona bien ventilada y llevando equipos de seguridad aprobados,

como mascarillas antipolvo especialmente diseñadas para filtrar

partículas microscópicas.

• Evite el contacto prolongado con polvo generado por el

lijado, serruchado, pulido y taladrado eléctrico y otras

actividades de construcción. Vista ropa protectora y lave

las áreas de la piel expuestas con agua y jabón. Si permite

que el polvo se introduzca en la boca u ojos o quede sobre

la piel, puede favorecer la absorción de productos químicos

peligrosos.

ADVERTENCIA: La utilización de esta herramienta puede

generar polvo o dispersarlo, lo que podría causar daños graves y

permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH (Instituto

Nacional de Seguridad y Salud en el Trabajo) u OSHA

(Administración de Seguridad y Salud en el Trabajo) apropiada

para la exposición al polvo. Dirija las partículas en dirección

contraria a la cara y el cuerpo.

ADVERTENCIA: USE SIEMPRE LENTES DE SEGURIDAD.

Los anteojos de diario NO SON lentes de seguridad. Utilice

además una máscara para la cara o guardapolvo si la operación

de corte genera demasiado polvo. Todo usuario y persona

circunstante DEBE SIEMPRE llevar equipo de seguridad

certificado:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3),

• Protección auditiva ANSI S12.6 (S3.19),

• Protección respiratoria NIOSH/OSHA/MSHA.

• La etiqueta de su herramienta puede incluir los siguientes

símbolos. Estos símbolos y sus definiciones son:

V ........... voltios A .........amperes

Hz ......... hercios W ........vatios

min ....... minutos

......corriente alterna

...... corriente directa

n

o .......velocidad sin carga

........... Construcción Clase I ........ terminal de tierra

............... (tierra) ........ símbolo de advertencia

............ Construcción Clase II ....... de seguridad

.............. (doble aislamiento) …/min .revoluciones o

sfpm ..... pies de superficie

........... por minuto

............ por minuto (sfpm) BPM ...golpes por minuto

DESCRIPCIÓN (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica ni

ninguna pieza de esta. Puede producir daños o lesiones

corporales.

USO PREVISTO

La esmeriladora de ángulo de alto rendimiento D28111 fue

diseñada para realizar amolamientos profesionales en distintos

tipos de trabajo (por ejemplo, obras de construcción).

NO use la herramienta bajo condiciones de humedad o en

presencia de gases o líquidos inflamables.

NO utilice otras muelas que las ruedas de centro deprimido y

discos con protección.

Estas esmeriladoras de alto rendimiento son herramientas

profesionales. NO permita que los niños tengan contacto con la

herramienta. Cuando la hagan funcionar operarios sin experiencia,

es necesaria su supervisión.

Page 19

19

Español

19

A. Interruptor de paleta D. Guarda

B. Palanca de bloqueo de encendido E. Mango lateral

C. Seguro del eje

FIG. 1

D

E

A

C

B

MONTAJE Y AJUSTES

ADVERTENCIA: Desenchufe la herramienta antes de proceder

con el montaje y los ajustes.

ADVERTENCIA: Nunca utilice la herramienta sin el protector

colocado en su lugar.

Protector con tornillo de fijación (fig. 2)

ADVERTENCIA: Apague y desenchufe la herramienta antes

de realizar cualquier ajuste o de poner o quitar cualquier

accesorio. Antes de volver a conectar la herramienta, presione y

suelte el interruptor de paleta para asegurarse de que la

herramienta esté apagada.

1. Coloque la esmeriladora angular en una mesa, con el eje hacia

arriba.

2. Haga coincidir las orejetas (F) con las ranuras (G).

3. Presione el protector y gírelo hasta la posición deseada.

4. Apriete firmemente el tornillo (H).

5. Para retirar el protector, afloje el tornillo.

C

F

G

H

G

FIG. 2

Page 20

20

Español

4 Enrosque la brida exterior (M) en el eje (J) (fig. 3B):

– el aro del eje (M) debe quedar hacia el disco cuando se

instala un disco de esmerilar (K);

– el aro del eje (M) debe quedar al lado contrario del disco

cuando se instala un disco de corte (C).

5. Presione el bloqueo del eje (C) y haga girar el eje (J) hasta que

encaje en su posición.

6. Apriete el eje (M) con la llave doble para tuercas suministrada.

7. Suelte el bloqueo del eje.

8. Para retirar el disco, afloje el eje (N) con la llave doble para

tuercas.

ADVERTENCIA: No utilice el disco si está dañado.

E

N

N

FIG. 4

Montaje y Desmontaje de un Disco de

Esmerilado o De Corte (Fig. 3A, 3B)

1. Coloque la herramienta en una mesa, con el protector hacia

arriba.

2. Fije la brida interior (I) correctamente en el eje (J) (fig. 3A).

3. Coloque el disco (K) sobre la eje (I). Cuando instale un disco

con el centro elevado, asegúrese de que el centro elevado (L)

quede hacia la brida (I).

FIG. 3A FIG. 3B

M

L

K

I

J

C

A

B

J

M

K

I

J

M

K

I

Page 21

21

Español

Montaje de la empuñadura lateral (Fig. 4)

Atornille la empuñadura lateral (E) firmemente en uno de los

orificios (N) de cualquiera de los lados de la caja de engranajes.

FUNCIONAMIENTO

ADVERTENCIA: Deje que la herramienta alcance su velocidad

total antes de tocar con ella la superficie de la pieza de trabajo.

Levante la herramienta de la superficie de trabajo antes de

apagarla.

ADVERTENCIA: Asegúrese de que todos los materiales que se

vayan a amolar o cortar estén sujetos en su posición.

ADVERTENCIA: Sólo se debe ejercer una ligera presión sobre

la herramienta. No ejerza presión lateral sobre el disco.

ADVERTENCIA: Evite la sobrecarga. En caso de calentamiento

de la herramienta, hágala funcionar unos minutos sin carga.

ANTES DE TRABAJAR

Montar el protector adecuado y un disco o una muela. No use

discos o muelas excesivamente desgastados.

Asegúrese de que los ejes interior y exterior estén correctamente

instaladas.

Asegúrese de que el disco o la muela gira en el sentido indicado

por las flechas en el accesorio y la herramienta.

Interruptor de paleta

ADVERTENCIA: Antes de enchufar la herramienta, presione y

suelte el interruptor de paleta (A) una vez sin presionar el botón

de bloqueo de encendido (B), para asegurarse de que el

interruptor esté apagado. Siempre que ocurra una interrupción al

suministro eléctrico de la herramienta, tal como la activación de

un interruptor de falla a tierra, el disparo de un interruptor de

circuito, el desenchufado accidental o una falla eléctrica, presione

y suelte el interruptor de paleta tal como se ha indicado. Si el

interruptor de paleta está con el botón de bloqueo de encendido

activado, la herramienta se pondrá en marcha súbitamente al

volver a conectarla.

Para encender la herramienta, empuje la palanca de bloqueo de

encendido (B) hacia atrás y luego presione el interruptor de paleta

(A). La herramienta funcionará mientras el paleta esté presionado.

Para apagar la herramienta, suelte la palanca.

ADVERTENCIA: No inhabilite la palanca de bloqueo de

encendido. Si se inhabilita la palanca de bloqueo de encendido,

la herramienta puede ponerse en marcha súbitamente al ponerla

a un lado.

ADVERTENCIA: No encienda ni apague la herramienta cuando

esté con carga.

Aplicaciones metálicas

Cuando utilice la herramienta en aplicaciones metálicas, asegúrese

de insertar un dispositivo de corriente residual (RCD) para evitar los

riesgos residuales provocados por el polvo metálico.

Si el RCD desconecta el suministro eléctrico, lleve la herramienta a

un servicio técnico autorizado de D

EWALT.

ADVERTENCIA:En condiciones de trabajo extremas, el polvo

conductor puede acumularse en el interior del alojamiento de la

máquina al trabajar con metal. Esto puede hacer que el aislamiento

protector de la máquina se degrade con el riesgo potencial de una

descarga eléctrica.

ADVERTENCIA: Para evitar la acumulación de polvo metálico

en el interior de la máquina, le recomendamos que limpie las

ranuras de ventilación diariamente. Consulte Mantenimiento.

Uso de discos laminados

ADVERTENCIA: Acumulación de polvo metálico.

El uso abundante de discos laminados en aplicaciones metálicas

puede provocar el aumento del potencial de descarga eléctrica.

Para reducir este riesgo, inserte un dispositivo de corriente residual

(RCD) antes del uso y limpie las ranuras de ventilación diariamente,

Page 22

22

Español

soplando con aire comprimido en las ranuras según las siguientes

instrucciones de mantenimiento.

MANTENIMIENTO

Su herramienta DEWALT ha sido diseñada para funcionar

durante un largo período con un mínimo de mantenimiento.

Un funcionamiento continuo satisfactorio depende del cuidado

adecuado de la herramienta y de una limpieza periódica.

Desgaste de carbones

El motor se apagará automáticamente indicando que los carbones

están casi desgastadas y que la herramienta necesita mantenimiento.

Los carbones no pueden ser sustituidas por el usuario. Confíe la

herramienta al servicio técnico autorizado D

EWALT.

ADVERTENCIA: Para minimizar el riesgo de graves lesiones

personales, apague la herramienta y desconecte la batería

antes de realizar ajustes o quitar/instalar los acoples o accesorios.

Un encendido accidental puede causar lesiones.

Lubricación

La herramienta eléctrica no requiere lubricación adicional.

Limpieza

ADVERTENCIA: Sople la suciedad y el polvo de la carcasa

principal con aire seco siempre que vea acumularse el polvo

alrededor de los respiraderos. Utilice protección ocular y mascarillas

antipolvo aprobadas cuando realice este procedimiento.

ADVERTENCIA: no use nunca disolventes ni otros agentes

químicos agresivos para limpiar las piezas no metálicas de la

herramienta. Estos agentes químicos pueden debilitar los materiales

de dichas piezas. Use un trapo humedecido sólo con agua y jabón

suave. No deje que penetre ningún líquido dentro de la herramienta

y no sumerja ninguna pieza de la herramienta en líquidos.

Accesorios

ADVERTENCIA: Dado que algunos accesorios, diferentes de

los ofrecidos por D

EWALT, no se han probado con este producto,

el empleo de tales accesorios podría constituir un riesgo. Para

reducir el riesgo de lesiones, sólo deben usarse con el producto los

accesorios recomendados D

EWALT.

Si desea más información sobre los accesorios adecuados,

consulte a su distribuidor.

Especificaciones

D28111S

Frecuencia de operación: 50-60 Hz

Potencia nominal: 850W

Rotación sin carga: 10000 rev/min

Page 23

23

Português

Definições: Diretrizes de

Segurança

As definições abaixo apresentadas descrevem o grau de

gravidade correspondente a cada palavra de advertência.

Leia cuidadosamente o manual e preste atenção a estes

símbolos.

PERIGO: Indica uma situação de risco iminente que, se

não for evitada, resultará em morte ou ferimentos graves.

AVISO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em morte ou ferimentos

graves.

CUIDADO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em ferimentos leves ou

moderados.

CUIDADO: Usado sem o símbolo de alerta de segurança

indica uma situação de risco potencial que, se não evitada,

poderá resultar em danos à propriedade.

ATENÇÃO: para reduzir o risco de ferimentos, leia o manual

de instruções.

Avisos de segurança gerais relativos a

ferramentas elétricas

ATENÇÃO! Leia todos os avisos de segurança e todas as

instruções. O não cumprimento dos avisos e instruções

poderá resultar em choque elétrico, incêndio e/ou lesões

graves.

GUARDE TODOS OS AVISOS E

INSTRUÇÕES PARA FUTURAS CONSULTAS

Em todos os avisos que se seguem, o termo “ferramenta elétrica”

refere-se à sua ferramenta accionada por alimentação da rede

elétrica (com fio) ou por bateria (sem fio).

1) SEGURANÇA DA ÁREA DE TRABALHO

a) Mantenha a área de trabalho limpa e bem iluminada.

As áreas desorganizadas ou escuras são propensas a

acidentes.

b) Não utilize as ferramentas elétricas em ambientes

explosivos ou na presença de líquidos, gases ou poeiras

inflamáveis. As ferramentas elétricas criam faíscas que

podem inflamar as poeiras ou os fumos.

c) Mantenha crianças e outras pessoas à distância quando

utilizar a ferramenta elétrica. As distracções podem levar à

perda de controle.

2) SEGURANÇA ELÉTRICA

a) Os plugues das ferramentas elétricas têm de ser

compatíveis com a tomada. Nunca modifique os plug

de forma alguma. Não utilize Plugues adaptadoras

com ferramentas elétricas ligadas à terra. Plugues não

modificadas e tomadas compatíveis reduzem o risco de

choque elétrico .

b) Evite o contato corporal com superfícies ligadas à terra,

como tubos, radiadores, fogões e frigoríficos. Se o seu

corpo estiver ligado à terra, o risco de choque elétrico é

maior.

c) Não exponha as ferramentas elétricas à chuva ou

a condições de humidade. A entrada de água numa

ferramenta elétrica aumenta o risco de choque elétrico .

d) Não utilize indevidamente o cabo. Nunca o utilize par

carregando, arrastar ou desligar a ferramenta elétrica.

Mantenha o cabo afastado de calor, óleo, pontas

afiadas ou peças em movimento. Cabos danificados ou

emaranhados aumentam o risco de choque elétrico .

e) Ao operar a ferramenta elétrica fora de casa, utilize

uma extensão adequada para a utilização ao ar livre. A

utilização de um cabo adequado para o ar livre reduz o risco

de choque elétrico .

Page 24

24

Português

f) Se não for possível evitar trabalhar com uma ferramenta

elétrica num local húmido, utilize uma alimentação

protegida por um dispositivo de corrente residual (DCR).

A utilização de um DCR reduz o risco de choque elétrico .

3) SEGURANÇA PESSOAL

a) Mantenha-se atento, preste atenção ao que está a fazer

e faça uso de bom senso ao operar uma ferramenta

elétrica. Não utilize uma ferramenta elétrica quando

estiver cansado ou sob o efeito de drogas, álcool

ou medicamentos. Um momento de desatenção durante

a utilização de ferramentas elétricas poderá resultar em

ferimentos graves.

b) Use equipamento de proteção pessoal. Use sempre

proteção ocular. O equipamento de proteção , como

máscara anti-poeira, sapatos de segurança antiderrapantes,

capacete de segurança ou proteção auricular, usado nas

condições apropriadas, reduz o risco de lesões.

c) Evite um acionamento acidental. Certifique-se de que o

interruptor esteja na posição de desligado antes de ligar

a fonte de alimentação elétrica e/ou bateria ou antes de

levantar ou transportar a ferramenta. Se mantiver o dedo

sobre o interruptor ao transportar a ferramenta elétrica ou se

ligar aparelhos que estejam com o interruptor ligado, poderá

originar acidentes.

d) Retire qualquer chave de ajuste ou chave de porcas

antes de ligar a ferramenta elétrica. Uma chave de porcas

ou chave de ajuste colocada numa parte móvel do aparelho

poderá resultar em lesões.

e) Não se estique muito. Mantenha-se sempre em posição

firme e equilibrada. Desta forma, será mais fácil controlar o

aparelho em situações inesperadas.

f) Use roupa apropriada. Não use roupa larga nem jóias.

Mantenha o cabelo, roupa e luvas afastados de partes

em movimento. Roupas largas, jóias ou cabelos compridos

podem ficar presos nas peças em movimento.

g) Se for prevista a montagem de dispositivos de aspiração

de pó e de dispositivos de recolha, assegure-se de

que estejam ligados e sejam utilizados corretamente. A

utilização de dispositivos de recolha do pó pode reduzir os

riscos provocados por poeiras.

4) UTILIZAÇÃO E MANUTENÇÃO DE FERRAMENTAS

ELÉTRICAS

a) Não sobrecarregue a ferramenta elétrica. Utilize

a ferramenta elétrica correta para o seu trabalho. A

ferramenta elétrica adequada fará um trabalho melhor e mais

seguro ao ritmo para que foi concebida.

b) Não utilize a ferramenta elétrica se o interruptor não

puder ser ligado nem desligado. Qualquer ferramenta

elétrica que não possa ser controlada através do interruptor

de ligar e desligar é um perigo e tem de ser reparada.

c) Retire os plug da tomada e/ou a bateria da ferramenta

elétrica antes de efetuar quaisquer ajustes no aparelho,

substituir acessórios ou armazenar a ferramenta elétrica.

Estas medidas de segurança evitam que a ferramenta elétrica

seja ligada acidentalmente.

d) Guarde as ferramentas elétricas que não estiverem

sendo utilizadas fora do alcance de crianças e não

permita que o aparelho seja utilizado por pessoas não

familiarizadas com o mesmo ou com estas instruções.

As ferramentas elétricas são perigosas nas mãos de pessoas

sem formação.

e) Faça a manutenção das ferramentas elétricas. Verifique

se as partes móveis do aparelho estão alinhadas e não

emperram, se existem peças partidas ou danificadas

e qualquer outra situação que possa interferir com

o funcionamento do aparelho. Caso existam peças

Page 25

25

Português

danificadas, devem ser reparadas antes da utilização do

aparelho. Muitos acidentes têm como causa a manutenção

insuficiente das ferramentas elétricas.

f) Mantenha as ferramentas de corte sempre afiadas e

limpas. Ferramentas de corte devidamente tratadas, com

arestas de corte afiadas, emperram com menos frequência e

controlam-se com maior facilidade.

g) Utilize a ferramenta elétrica, os acessórios e as peças,

etc., de acordo com estas instruções, tendo em conta

as condições de trabalho e a tarefa sendo efetuada. A

utilização da ferramenta elétrica para fins diferentes dos

previstos poderá resultar em situações perigosas.

5) ASSISTÊNCIA

a) A sua ferramenta elétrica só deve ser reparada por

pessoal qualificado e só devem ser utilizadas peças

sobressalentes originais. Desta forma, é assegurada a

segurança da ferramenta elétrica.

REGRAS DE SEGURANÇA ESPECÍFICAS

ADICIONAIS

Instruções de segurança para todas as

operações

a) Esta ferramenta elétrica destina-se a funcionar como

uma rectificadora, lixadeira ou escova de arame. Leia

todos os avisos de segurança, instruções, ilustrações

e especificações fornecidos em conjunto com esta

ferramenta elétrica. O não cumprimento das instruções

enumeradas em seguida poderá resultar em choque eléctrico,

incêndio e/ou lesões graves.

b) Não se recomenda a realização de operações como

polimento ou corte com esta ferramenta elétrica. Operações

para as quais a ferramenta elétrica não foi concebida podem

constituir um perigo e causar lesões físicas.

c) Não utilize acessórios que não tenham sido

especificamente concebidos e recomendados pelo

fabricante da ferramenta. Apesar de ser possível aplicar um

acessório na sua ferramenta elétrica, tal não significa que a

sua utilização é segura.

d) A velocidade nominal do acessório tem que corresponder,

no mínimo, à velocidade máxima indicada na ferramenta

elétrica. Os acessórios que funcionam a uma velocidade mais

rápida do que a sua velocidade nominal podem partir-se e

soltar-se.

e) O diâmetro externo e a espessura do seu acessório

devem situar-se dentro da classificação de capacidade da

ferramenta elétrica. Não é possível proteger nem controlar de

forma adequada os acessórios com um tamanho incorrecto.

f) O tamanho do encaixe dos discos, flanges, almofadas de

apoio ou qualquer outro acessório tem que corresponder

correctamente ao eixo da ferramenta elétrica. Os

acessórios com orifícios de encaixe que não correspondem

ao equipamento de montagem da ferramenta elétrica irão

funcionar de forma desequilibrada, irão vibrar excessivamente

e poderão resultar na perda de controlo.

g) Não utilize um acessório danificado. Antes de cada

utilização, verifique o acessório para verificar a existência

de, por exemplo, lascas e fendas no disco abrasivo,

fendas, rasgos ou desgaste excessivo na almofada de

apoio e arames soltos ou quebrados na escova de arame.

Se a ferramenta elétrica ou acessório forem deixados

cair, inspeccione-os quanto à existência de danos ou

instale um acessório que não esteja danificado. Depois

de inspeccionar e instalar um acessório, o operador,

bem como qualquer pessoa presente, deve manter

uma posição afastada do plano do acessório rotativo e

utilizar a ferramenta elétrica na velocidade máxima sem

carga durante um minuto. Normalmente, os acessórios

danificados irão partir-se durante este período experimental.

Page 26

26

Português

h) Use equipamento de protecção pessoal. Consoante a

aplicação, use um escudo facial, viseiras de protecção

ou óculos de segurança. Conforme apropriado, use

uma máscara de protecção contra poeiras, protectores

auriculares, luvas e um avental de oficina com capacidade

para o proteger contra pequenos fragmentos abrasivos

ou da peça de trabalho. A protecção ocular tem que ter

capacidade para o proteger contra a projecção dos detritos

gerados em diversas operações. A máscara de protecção

contra poeiras tem que ter capacidade para filtrar as partículas

geradas pelas operações. A exposição prolongada a um ruído

de elevada intensidade pode causar perda de audição.

i ) Mantenha as outras pessoas presentes no local a uma

distância segura da área de trabalho. Qualquer pessoa

que entre na área de trabalho tem que usar o equipamento

de protecção pessoal. Os fragmentos da peça de trabalho

ou de um acessório partido podem ser projectados e causar

lesões para além da área imediata de operação.

j) Quando realizar uma operação em que o acessório de

corte possa entrar em contacto com fios escondidos ou

com o seu próprio cabo, segure a ferramenta elétrica com

as superfícies do punho isoladas. O contacto do acessório

de corte com um fio condutor também pode carregar partes

metálicas expostas da ferramenta elétrica e provocar um

choque no operador.

k) Posicione o cabo afastado do acessório em rotação.

Se perder o controlo, o cabo poderá ficar cortado ou preso

e a sua mão ou braço podem ser puxados para o acessório

em rotação.

l) Nunca poise a ferramenta elétrica sem que o acessório

tenha parado completamente. O acessório em rotação

pode ficar preso à superfície e puxar a ferramenta elétrica para

fora do seu controlo.

m) Não tenha a ferramenta elétrica a funcionar quando a

transportar ao seu lado. O contacto acidental com o acessório

em rotação poderia prender o vestuário, aproximando o

acessório do corpo.

n) Limpe regularmente os respiradores da ferramenta

elétrica. A ventoinha do motor irá aspirar a poeira para

dentro do alojamento e uma acumulação excessiva de metal

carregado pode resultar em perigos eléctricos.

o) Não opere a ferramenta elétrica próximo de materiais

inflamáveis. As faíscas poderiam inflamar estes materiais

p) Não utilize acessórios que requerem a utilização de

refrigerantes líquidos. A utilização de água ou de outros

refrigerantes líquidos pode resultar em electrocussão ou

choque.

Causas e prevenção do operador em

relação ao efeito de retorno

• O retorno é uma reacção súbita a um disco giratório, almofada

de apoio, escova ou qualquer outro acessório comprimido ou

preso, que por sua vez força a ferramenta elétrica na direcção

contrária à da rotação do acessório no ponto de união.

• Por exemplo, se um disco abrasivo for comprimido ou preso

pela peça de trabalho, a extremidade do disco que está a

entrar no ponto de preensão pode mergulhar na superfície do

material, fazendo com que o disco levante ou salte para fora.

O disco pode saltar na direcção do operador ou para longe do

mesmo, consoante o sentido do movimento do disco no ponto

de preensão. Nestas condições, os discos abrasivos também

podem partir.

• Este efeito resulta da utilização indevida da ferramenta e/ou

de condições ou procedimentos de operação incorrectos que

podem ser evitados seguindo as precauções apropriadas

descritas em seguida:

Page 27

27

Português

a) Agarre a ferramenta elétrica com firmeza e posicione

o corpo e os braços de modo a resistir às forças de

retorno. Utilize sempre a pega auxiliar, se fornecida, para

um máximo controlo de reacções de retorno ou torção

durante o arranque. O operador pode controlar as forças

de reacção de torção ou de retorno, se forem tomadas

precauções adequadas.

b) Nunca coloque a mão próximo do acessório rotativo. O

acessório pode retornar sobre a sua mão.

c) Não coloque o seu corpo na zona para onde a ferramenta

elétrica se irá deslocar em caso de retorno. O retorno

impulsionará a ferramenta no sentido oposto ao movimento

do disco no ponto de preensão.

d) Use de especial atenção ao trabalhar em cantos, arestas

aguçadas, etc. Evite fazer ressaltar e prender o acessório.

Cantos, arestas aguçadas ou ressaltos têm tendência a

prender o acessório rotativo e dar origem a perda de controlo

ou retorno.

e) Não fixe uma lâmina de serra de corrente de corte de

madeira nem uma lâmina de serra dentada. Tais lâminas

causam retornos e perdas de controlo frequentes.

Avisos de segurança específicos para

operações de rectificação

a) Utilize apenas discos do tipo recomendado para

a ferramenta elétrica e a protecção especificamente

concebida para o disco seleccionado. A utilização de

discos para os quais a ferramenta não foi concebida não

garante uma protecção e segurança adequadas.

b) A protecção deve estar devidamente presa à ferramenta

elétrica e posicionada de forma a garantir a segurança

máxima, de modo ao disco ficar o mínimo exposto

possível na direcção do operador. A protecção ajuda a

proteger o operador contra fragmentos do disco partidos e o

contacto acidental com o disco.

c) Os discos têm que ser utilizados para as aplicações

recomendadas. Por exemplo: não proceda à rectificação

com o lado do disco de corte. Os discos de corte abrasivos

destinam-se à rectificação periférica, sendo que a aplicação

de forças laterais neste tipo de discos poderá fazer com que

se desfaçam.

d) Utilize sempre flanges de disco não danificadas com o

tamanho e forma correctos para o disco seleccionado. As

flanges de disco proporcionam um apoio correcto, reduzindo

a possibilidade de ruptura do disco. As flanges para os discos

de corte podem ser diferentes das flanges de discos de

rectificação.

e) Não utilize discos gastos de ferramentas elétricas maiores.

Um disco destinado a uma ferramenta elétrica maior não é

adequado para a velocidade superior de uma ferramenta

menor e, por conseguinte, pode rebentar.

Avisos de segurança específicos para

operações com escovas de arame

a) Tenha em atenção que cerdas de arame são projectadas

pela escova mesmo durante uma utilização normal. Não

aplique demasiada pressão nas cerdas ao colocar uma

carga excessiva sobre a escova. As cerdas de arame

podem penetrar facilmente através de vestuário leve e/ou da

pele.

b) Se a utilização de uma protecção for recomendada para

operações com escovas de arame, não permita qualquer

interferência do disco ou da escova de arame com a

protecção. O disco ou a escova de arame pode expandir-se

em diâmetro devido às forças de trabalho e centrífugas.

Page 28

28

Português

Instruções de segurança adicionais

para esmerilhadeiras