Page 1

1

D27105

D27105V

www.

.eu

Page 2

2

Copyright DEWALT

Page 3

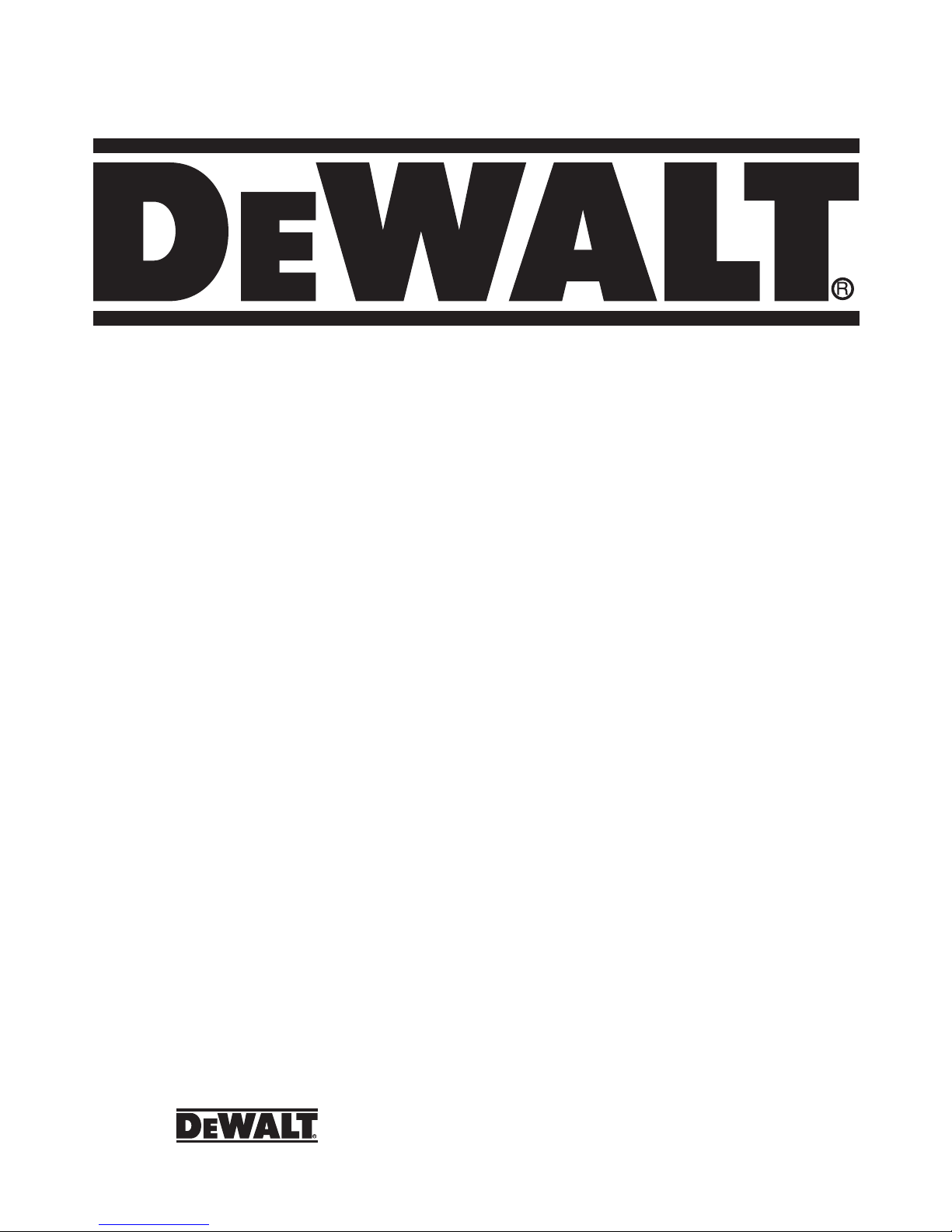

1

A2

A1

1

2

3

4

5

7

6

8

9

10

142

16

15

14

12

11

10

13

17

143

Page 4

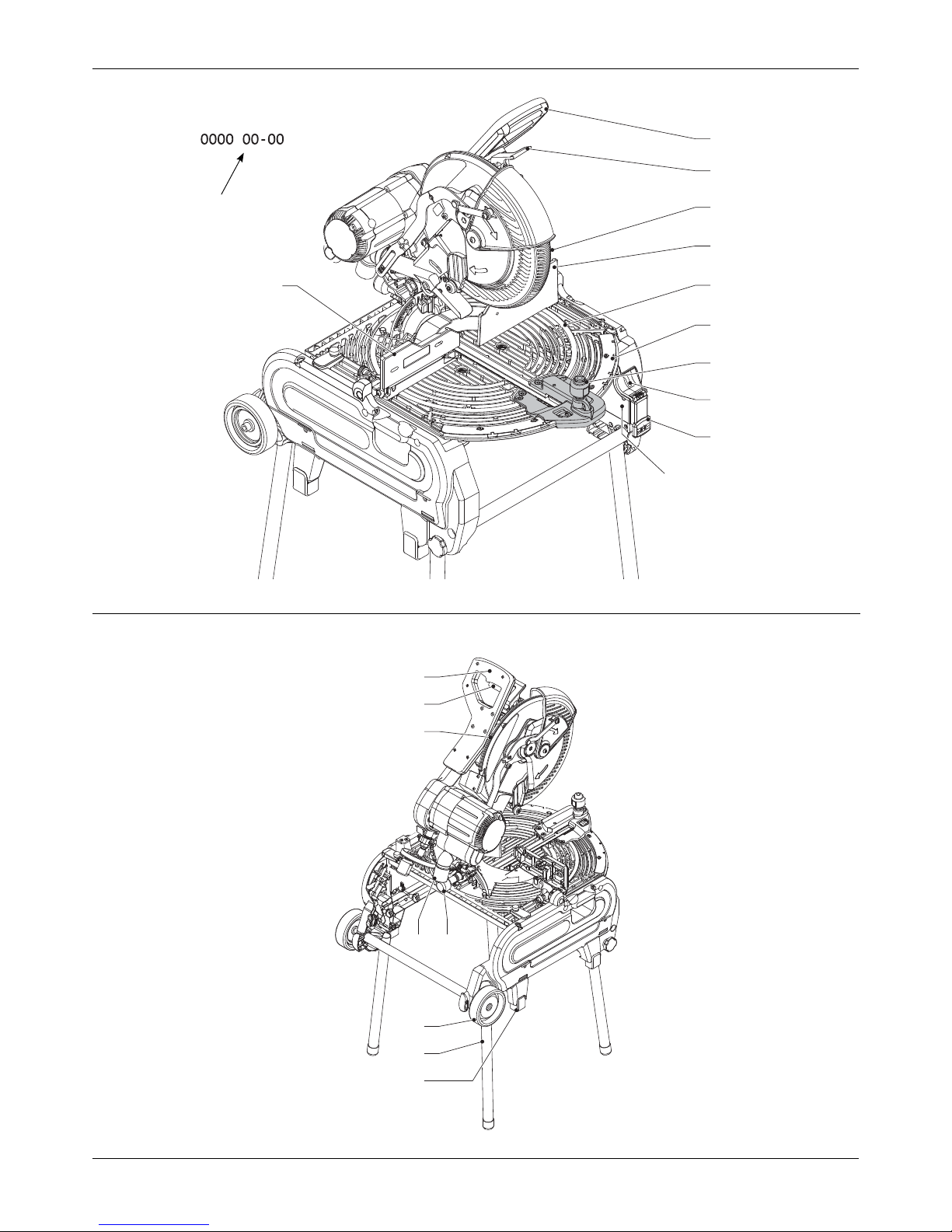

2

23

21 20 1922

17 18

A5

A3

30

A4

34

33

31

32

35 36

38 37

39

Page 5

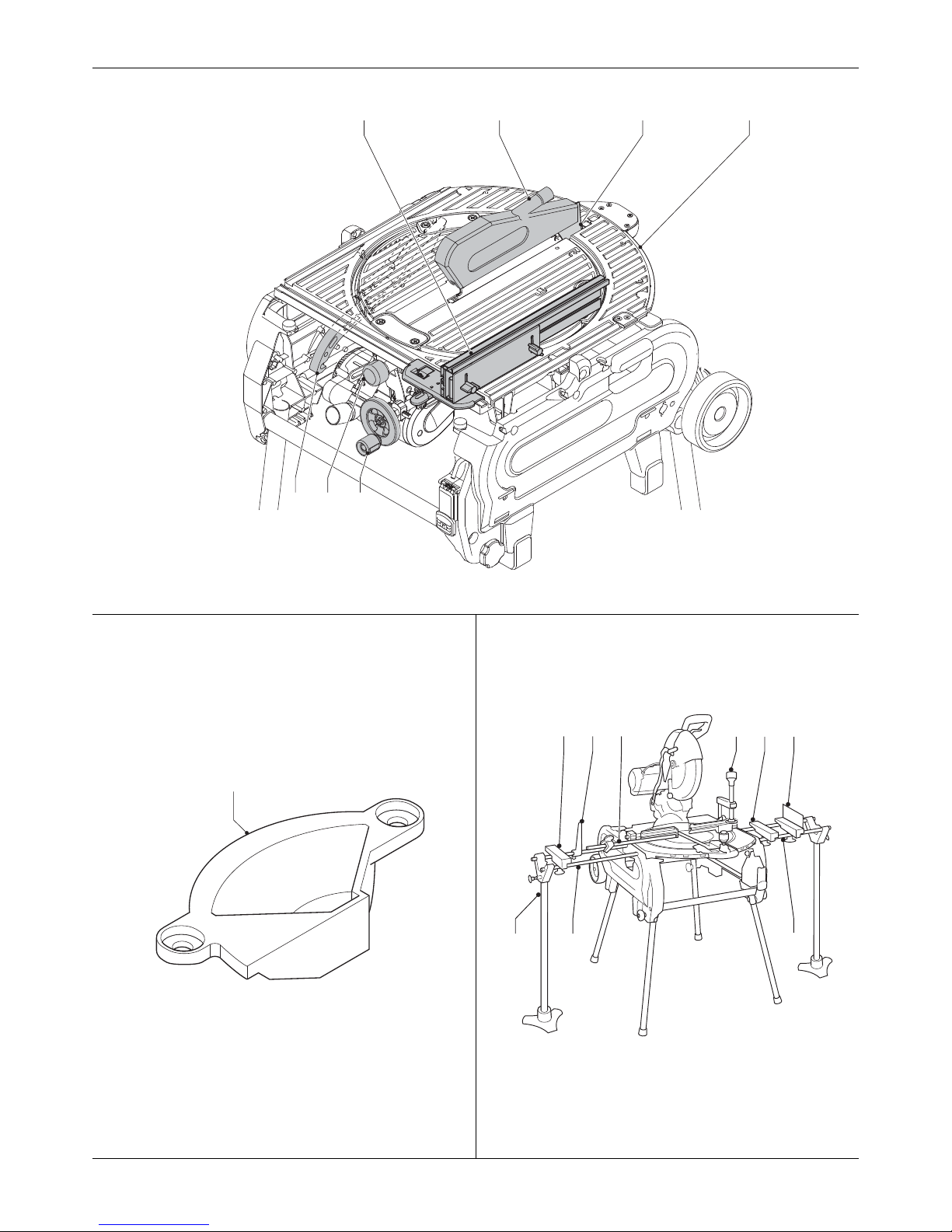

3

A6 A7

A8

41

32

42

43

A9

Page 6

4

44

15

58 5657

59

59 58

57

15 56

52

53

16

54

55

51

B

C1 C2

A10

B1

A11

144

Page 7

5

70

69

19

14

61 62

60

59

15

D

F3

C3 C4

E

63

6665 64

19

2

F2

F4

F1

68 67

Page 8

6

84 8685

7980815

83 8383

76827

H3

H2

H4

H1

73

75

76

77 78

8

9

74

G1

G2

G4

8

73

73

G3

Page 9

7

7

92

91

100

7

9799

8

98

20

88 93 96

95

94

88 88

89 8788 90

7682 81

I3

M1

I2

J

17

K

M2

L

I1

Page 10

8

108 107 22

20

105

106

21

N2

O

P1

103

104

20

3-8mm

2mm

68 67

4 2 68

70

102

69

102 101

M5

M3

M4

N1

Page 11

9

116115

7682117120

121

41

41

114

109

113

114

109

113

112 111

110

109

P4

Q3

P2

Q1

P3

P5

Q2

Q4

118119

Page 12

10

91

7

11

80

79

81

10

9

S3

79 80

S1

S2

T1

124

123

126

127

125

R3

1

R2

11

122

R1

Page 13

11

90°

U3

V2

A

T3T2

T4

0°-45°

45°

U1

U2

V1

23

Page 14

12

140

141

138139 139

Y2

Y3

Y1

X

13

63

128

W1

W2

21

13

Page 15

13

ENGLISH

FLIP-OVER SAW D27105, D27105V

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product

development and innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical data

D27105/D27105V

Type 3

Voltage V 115

Power input W 1730

Power output W 860

Max. blade speed min-1 3500

Blade diameter mm 305

Blade bore mm 30

Blade body thickness mm 3.2

Riving knife thickness mm 2.5

Automatic blade brake time s < 10

Weight kg 42

Cutting capacities

Mitre saw mode

Mitre (max. positions) left 48°

right 48°

Bevel (max. positions) left 48°

right 2°

Max. crosscut capacity at 90° mm 205

Max. mitre cut capacity at 45° mm 160

Max. depth of cut 90° mm 90

Max. depth of bevel cut 45° mm 60

Max. depth of cut at 45° bevel, 45° mitre mm 60

Saw bench mode

Max. ripping capacity left/right mm 120/320

Depth of cut at 90° mm 80

Depth of cut at 45° mm 56

LPA (sound pressure) dB(A) 95.0

K

PA

(sound pressure uncertainty) dB(A) 3.0

L

WA

(sound power) dB(A) 106.0

KWA (sound power uncertainty) dB(A) 3.0

Vibration total values (triax vector sum) determined according to EN 61029:

Vibration emission value a

h

ah

=

m/s²

2.1

Uncertainty K = m/s² 1.5

The vibration emission level given in this information sheet has been

measured in accordance with a standardised test given in EN 61029 and

may be used to compare one tool with another. It may be used for a

preliminary assessment of exposure.

WARNING: The declared vibration emission level represents

the main applications of the tool. However if the tool is used

for different applications, with different accessories or poorly

maintained, the vibration emission may differ. This may

significantly increase the exposure level over the total working

period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may

significantly reduce the exposure level over the total working

period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and

the accessories, keep the hands warm, organisation of work

patterns.

Fuses:

U.K. & Ireland 115 V tools 16 Amperes

NOTE: This device is intended for the connection to a power supply system

with maximum permissible system impedance Zmax of 0.25 Ω at the

interface point (power service box) of user’s supply.

The user has to ensure that this device is connected only to a power system

which fulfils the requirement above. If necessary, the user can ask the public

power supply company for the system impedance at the interface point.

Defi nitions: Safety Guidelines

The definitions below describe the level of severity for each signal word.

Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

Denotes risk of electric shock.

Denotes risk of fire.

EC-Declaration of Conformity

D27105/ D27105V

DEWALT declares that these products described under “technical data” are

in compliance with:

2006/42/EC, EN 61029-1, EN 61029-2-11.

These products also comply with Directive 2004/108/EC. For more

information, please contact DEWALT at the following address or refer to the

back of the manual.

The undersigned is responsible for compilation of the technical file and

makes this declaration on behalf of DEWALT.

Horst Grossmann

Vice President Engineering and Product Development

DEWALT, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

29.12.2009

Page 16

14

ENGLISH

Safety Instructions

WARNING! When using electric tools basic safety precautions

should always be followed to reduce

the risk of fire, electric shock and personal injury

including the following.

Read all these instructions before attempting to operate this product and

save these instructions.

SAVE THIS MANUAL FOR FUTURE REFERENCE

General Safety Rules

1. Keep work area clear.

Cluttered areas and benches invite injuries.

2. Consider work area environment.

Do not expose the tool to rain. Do not use the tool in damp or wet

conditions. Keep the work area well lit (250 - 300 Lux). Do not use

the tool where there is a risk of causing fire or explosion, e.g., in the

presence of flammable liquids and gases.

3. Guard against electric shock.

Avoid body contact with earthed surfaces (e.g., pipes, radiators,

cookers and refrigerators). When using the tool under extreme

conditions (e.g., high humidity, when metal swarf is being produced,

etc.), electric safety can be improved by inserting an isolating

transformer or a (FI) earth-leakage circuit-breaker.

4. Keep other persons away.

Do not let persons, especially children, not involved in the work, touch

the tool or the extension cord and keep them away from the work area.

5. Store idle tools.

When not in use, tools must be stored in a dry place and locked up

securely, out of reach of children.

6. Do not force the tool.

It will do the job better and safer at the rate to which it was intended.

7. Use the right tool.

Do not force small tools to do the job of a heavy duty tool. Do not use

tools for purposes not intended; for example do not use circular saws

to cut tree limbs or logs.

8. Dress properly.

Do not wear loose clothing or jewellery, as these can be caught in

moving parts. Non-skid footwear is recommended when working

outdoors. Wear protective hair covering to contain long hair.

9. Use protective equipment.

Always use safety glasses. Use a face or dust mask if working

operations create dust or flying particles. If these particles might be

considerably hot, also wear a heat-resistant apron. Wear ear protection

at all times. Wear a safety helmet at all times.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust extraction and

collecting equipment, ensure these are connected and properly used.

11. Do not abuse the cord.

Never yank the cord to disconnect it from the socket. Keep the

cord away from heat, oil and sharp edges. Never carry the tool by its

cord.

12. Secure work.

Where possible use clamps or a vice to hold the work. It is safer than

using your hand and it frees both hands to operate the tool.

13. Do not overreach.

Keep proper footing and balance at all times.

14. Maintain tools with care.

Keep cutting tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect

tools periodically and if damaged have them repaired by an authorized

service facility. Keep handles and switches dry, clean and free from oil

and grease.

15. Disconnect tools.

When not in use, before servicing and when changing accessories such

as blades, bits and cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches.

Form the habit of checking to see that adjusting keys and wrenches are

removed from the tool before operating the tool.

17. Avoid unintentional starting.

Do not carry the tool with a finger on the switch. Be sure that the tool is

in the “off” position before plugging in.

18. Use outdoor extension leads.

Before use, inspect the extension cable and replace if damaged.

When the tool is used outdoors, use only extension cords intended for

outdoor use and marked accordingly.

19. Stay alert.

Watch what you are doing. Use common sense. Do not operate the tool

when you are tired or under the influence of drugs or alcohol.

20. Check for damaged parts.

Before use, carefully check the tool and mains cable to determine

that it will operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or

replaced by an authorized service centre unless otherwise indicated

in this instruction manual. Have defective switches replaced by an

authorized service centre.

Do not use the tool if the switch does not turn it on and off.

Never attempt any repairs yourself.

WARNING! The use of any accessory or attachment or

performance of any operation with this tool other than those

recommended in this instruction manual may present a risk of

personal injury.

21. Have your tool repaired by a qualified person.

This electric tool complies relevant safety rules. Repairs should only be

carried out by qualified persons using original spare parts; otherwise this

may result in considerable danger to the user.

Additional safety rules for mitre saws

• Make sure all locking knobs and clamp handles are tight before starting

any operation.

• Do not operate the machine without the guard in position, or if the

guard does not function or is not maintained properly.

• Never place either hand in the blade area when the saw is connected to

the electrical power source.

• Never attempt to stop a machine in motion rapidly by jamming a tool or

other means against the blade; serious accidents can occur.

• Select the correct blade for the material to be cut.

• Never perform any cleaning or maintenance work when the machine is

still running and the head is not in the rest position.

• The front section of the guard is louvred for visibility while cutting.

Although the louvres dramatically reduce flying debris, there are

openings in the guard and safety glasses should be worn at all times

when viewing through the louvres.

• Never cut workpiece shorter than 20 mm.

• Without additional support the machine is designed to accept the

maximum workpiece size of:

– Height 63 mm by width 205 mm by length 500 mm

– Longer workpieces need to be supported by suitable additional

table, e.g. DE3474. Always clamp the workpiece safely.

Additional safety rules for saw benches

• Make sure that the blade rotates in the correct direction and the teeth

are pointing to the front of the saw bench.

• Make sure all locking knobs and clamp handles are tight before starting

any operation.

• Be sure all blade and flanges are clean and the recessed sides of the

collar are against the blade. Tighten the arbor nut securely.

• Use correctly sharpened saw blades. Observe the maximum speed

mark on the saw blade

Page 17

15

ENGLISH

• Never operate the saw without the upper and lower guards in place.

• Never place either hand in the blade area when the saw is connected to

the electrical power source.

• Disconnect the saw from the mains before changing blades or carrying

out maintenance.

• Use a push stick at all times, and ensure that you do not place hands

closer than 150 mm from the saw blade while cutting.

• Do not attempt to operate on anything but the designated voltage.

• Do not apply lubricants to the blade when it is running.

• Do not reach around behind the saw blade.

• Always keep the push stick in its place when not in use.

• Do not stand on top of the unit.

• During transportation make sure that the upper part of the saw blade is

covered, e.g. by the guard.

• Do not use the guard for handling or transportation.

• Rebating, slotting or grooving is not allowed.

• Ensure riving knife is adjusted correctly. Never cut without riving knife

assembled.

Never cut work-piece smaller than 30 mm.

• Without additional support the machine is designed to accept the

maximum workpiece size of:

– Height 81 mm by width 400 mm by length 600 mm

– Longer workpieces need to be supported by suitable additional

table, e.g. D271055 or D271058.

Additional safety rules for fl ip-over saws

• Ensure that the arm is securely fixed in the working position in the

bench sawing mode.

• Ensure that the arm is securely fixed when bevelling in the bench saw

mode.

• Ensure the table is correctly locked when changing the saw mode.

• Never saw ferrous or non-ferrous materials when ripping in the bench

saw mode.

• Before using any accessory consult the instruction manual. The

improper use of an accessory can cause damage.

• Observe the maximum speed marked on the saw blade.

• Use a holder or wear gloves when handling a saw blade.

• Ensure that the blade rotates in the correct direction. Keep the blade

sharp.

• The max. allowable speed of the saw blade must always be equal to or

greater than the no-load speed of the tool specified on the nameplate.

• Do not use saw blades that do not conform to the dimensions stated in

the technical data. Do not use any spacers to make a blade fit onto the

spindle. Use only the blades specified in this manual, complying with

EN 847-1.

• Consider applying specially designed noise-reduction blades.

• Do not use HSS blades.

• Do not use cracked or damaged saw blades.

• After completing the cut, release the switch and wait for the saw blade

to come to a complete stillstand before returning the head to its upper

rest position.

• Ensure that the arm is securely fixed when performing bevel cuts.

• Do not wedge anything against the fan to hold the motor shaft.

• The blade guard on your saw will automatically raise when the arm is

brought down; it will lower over the blade when the arm is raised.

The guard can be raised by hand when installing or removing saw

blades or for inspection of the saw. Never raise the blade guard

manually unless the saw is switched off.

• Keep the surrounding area of the machine well maintained and free of

loose materials, e.g. chips and cut-offs.

• Check periodically that the motor air slots are clean and free of chips.

• Disconnect the machine from the mains before carrying out any

maintenance work or when changing the blade.

• Do not use saw blades with a body thickness greater or a width of

tooth smaller than the thickness of the riving knife.

• Make sure the machine is placed on an even surface with sufficient

stability.

• Do not use abrasive or diamond disc.

• In case of an accident or machine failure immediately switch the

machine off and disconnect from power source.

Report the failure and mark the machine in suitable form to prevents

other persons from use the defective machine.

• When the saw blade is blocked due to abnormal feed force during

cutting, turn the machine off and disconnect it from power supply.

Remove the workpiece and ensure that the saw blade runs free. Turn

the machine on and start new cutting operation with reduced feed

force.

• Refrain from removing any cut-offs or other parts of the workpiece from

the cutting area while the machine is running and the saw head is not in

the rest position

• Do not use the machine without the legs mounted.

• Make sure your position is always left or right of the cutting line.

• Provide adequate general or localized lighting.

• Ensure the operator is adequately trained in the use, adjustment and

operation of the machine.

• Switch the machine off when unattended.

• A laser to indicate the cutting line is supplied with the D27107V, the

laser is of class 2 according to EN 60825-1. Do not replace a laser

diode with a different type. If damaged, have the laser repaired by an

authorised repair agent.

• Connect the saw to a dust collection device when sawing wood.

Always consider factors which influence exposure of dust such as:

-– type of material to be machined (chip board produces more dust

than wood);

-– sharpness of the saw blade;

-– correct adjustment of the saw blade,

-– dust extractor with air velocity not less than 20 m/s.

Ensure that the local extraction as well as hoods, baffles and chutes are

properly adjusted.

• Never cut light alloy, especially magnesium.

Residual risks

The following risks are inherent to the use of saws:

- injuries caused by touching the rotating parts

In spite of the application of the relevant safety regulations and the

implementation of safety devices, certain residual risks cannot be avoided.

These are:

- Impairment of hearing.

- Risk of accidents caused by the uncovered parts of the rotating saw

blade.

- Risk of injury when changing the blade.

- Risk of squeezing fi ngers when opening the guards.

- Health hazards caused by breathing dust developed when sawing

wood, especially oak, beech and MDF.

The following factors are of infl uence to noise production:

• The material to be cut

• The type of saw blade

• The feed force

The following factors increase the risk of breathing problems:

• No dust extractor connected when sawing wood

• Insuffi cient dust extraction caused by uncleaned exhaust fi lters

• Worn saw blade

• Workpiece not exactly guided

Page 18

16

ENGLISH

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

Carrying Point

Hands Away

O/I

When using the machine in the mitre saw mode, make

sure to operate the trigger switch in the handle when

switching ON and OFF. Do not operate the switchbox

in this mode. The ON/OFF switch located to machine

frame is foreseen for table saw mode only.

When using the machine in the mitre saw mode, make

sure the riving knife is secured in its rest position.

Never use as mitre saw when the guard is not in place.

DATE CODE POSITION (FIG. A1)

The Date Code (143), which also includes the year of manufacture, is printed

into the housing.

Example:

2010 XX XX

Year of Manufacture

Package contents

The package contains:

1 Partly assembled machine

1 Box containing:

1 Top guard for bench saw position

1 Under-table guard for mitre saw position

4 Legs

2 Wheels

4 Feet

1 Parallel fence

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or accessories which may have

occurred during transport.

• Take the time to thoroughly read and understand this manual prior to

operation.

Description (fi g. A1 - A11)

A1

1 On/off switch (saw bench mode)

2 Table release lever

3 Rotating table clamp

4 Mitre saw table

5 Rotating table

6 Fence right-hand side

7 Fence left-hand side

8 Moveable lower blade guard

9 Guard release lever

10 Operating handle

142 Circuit breaker reset button

143 Date code

A2

10 Operating handle

11 Trigger switch (mitre saw mode)

12 Fixed upper blade guard

13 Dust extraction adapter

14 Wheel

15 Leg

16 Foot

17 Bevel clamp handle

A3

17 Bevel clamp handle

18 Height adjuster

19 Saw bench table

20 Riving knife

21 Upper blade guard

22 Parallel fence

23 Push stick

Optional accessories

A4

For use in mitre saw mode:

30 Fence insert (DE7120)

A5

31 Adjustable stand 760 mm (max. height) (DE3474)

32 Support guide rails 1,000 mm (DE3494)

33 Support guide rails 500 mm (DE3491)

34 Inclinable support (DE3495)

35 Swivelling stop (DE3462)

36 Length stop for short workpieces (to be used with guide rails [33])

(DE3460)

37 Support with removable stop (DE3495)

38 Support with stop removed (DE3495)

39 Material clamp (D271051)

A6

40 Roller support table (DE3497)

For use in saw bench mode:

A7

41 Mitre fence (D271052)

A8

42 Extension table (D271058)

A9

43 Sliding table (D271055)

Push sticks (DE3454) (not shown)

Page 19

17

ENGLISH

For use in all modes:

A10

44 Three way dust extraction kit (D271054)

A11

144 Laser

INTENDED USE

Your D

EWALT D27105 flip-over saw has been designed to operate as a

mitre saw or a saw bench to perform the four main sawing operations of

ripping, cross-cutting, bevelling and mitring easily, accurately and safely.

This unit is designed for use with a nominal blade diameter 305 mm carbide

tip blade for professional cutting wood, wood products and plastics.

DO NOT use under wet conditions or in presence of flammable liquids or

gases.

These flip over saws are professional power tools.

DO NOT let children come into contact with the tool. Supervision is required

when inexperienced operators use this tool.

WARNING! Do not use the machine for purposes other than

intended.

Mitre saw mode

In mitre saw mode, the sawing machine is used in vertical, mitre or bevel

position.

Saw bench mode

Turned over on its central axis, the sawing machine is used to perform

the standard ripping operation and for sawing wide pieces by manually

feeding the workpiece into the blade.

Electrical Safety

The electric motor has been designed for one voltage only. Always check

that the power supply corresponds to the voltage on the rating plate.

Your tool is double insulated in accordance with EN 61029;

therefore no earth wire is required.

WARNING: 115 V units have to be operated via a fail-safe

isolating transformer with an earth screen between the primary

and secondary winding.

In case of cord replacement the tool must only be repaired by an authorized

service agent or by qualified electrician.

Fitting a Mains Plug to 115 V Units

(U.K. and Ireland Only)

• The plug fitted should be comply with BS EN 60309 (BS4343),

16 Amps, earthing contact position 4h.

WARNING: Always ensure that the cable clamp is correctly and

securely fitted to the sheath of the cable.

Using an Extension Cable

If an extension cable is required, use an approved 3–core extension cable

suitable for the power input of this tool (see technical data).

The minimum conductor size is 1.5 mm2. When using a cable reel, always

unwind the cable completely.

ASSEMBLY

WARNING: To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. Be sure the trigger switch

is in the OFF position. An accidental start-up can cause injury.

Unpacking the machine and its parts.

WARNING: To reduce the risk of injury, always seek assistance

when moving the machine.

• Remove the loose packaging material from the box.

• Lift the machine out of the box.

• Remove the parts box from the interior of the machine.

• Remove any remaining packing material from the machine.

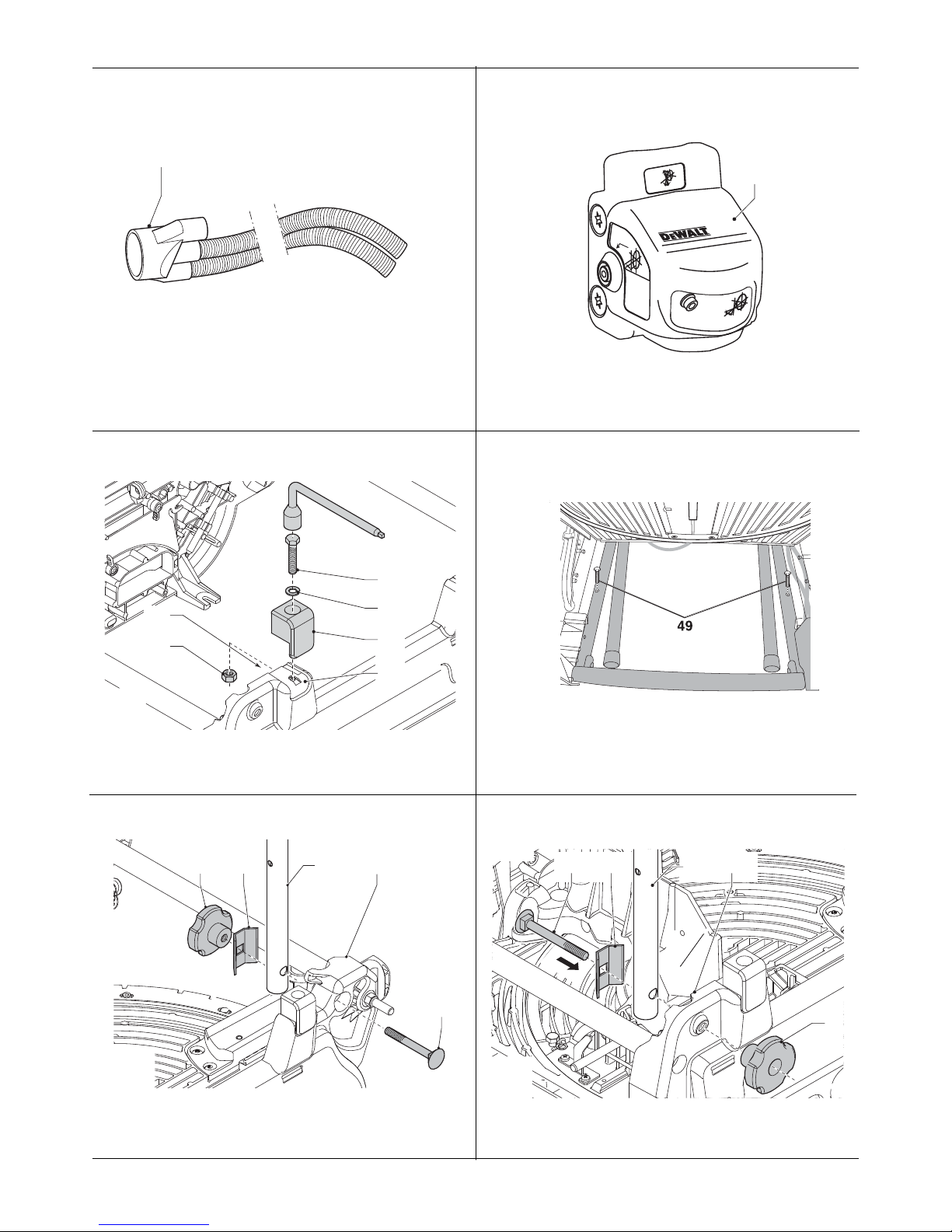

Mounting the feet (fi g. B, B1)

With the feet and legs mounted, alternatively the machine is suitable for

placement on a workbench. To ensure a safe operation, the machine must

be fastened to the workbench.

WARNING! Do never operate this machine when it is not

fastened to the workbench. The feed force will make the saw

unstable if not fastened to the workbench.

• Turn the machine upside down

• Place a foot (16) on each of the mounting locations (51) on the base

• Slide a nut (52) into the slots (53) located above the mounting locations

• Insert a bolt (54) fitted with a washer (55) into the feet

• Tighten the bolts

• Mount the legs as described below.

• Fold the legs as described below

• Turn the machine straight up

• Insert a bolt of 8 mm and 120 mm minimum length (49) into the feet on

each mounting location (fig. B1).

• Tighten the bolts

Mounting the legs (fi g. C1 & C2)

With the legs mounted, the machine is suitable for stand-alone placement.

• Turn the machine upside down.

• Mount the legs as described below. Beware that the front legs and the

rear legs have different lengths. The rear legs are slightly longer than

the front legs. Make sure to mount the legs in the correct place.

• Turn the machine straight up. Make sure it is level; adjust the leg

clamping height if required.

Rear legs

• Present a leg (15) to each of the mounting points (56) located at the

lower edges on the inside of the base (fi g. C1).

• Pass a coach bolt (57) from the outside through the holes into the

frame and the legs.

• Place a bracket (58) and a lock knob (59) onto the bolts.

• Tighten the lock knobs.

Front legs

• Present a leg (15) to each of the mounting points (56) located at the

upper edges on the inside of the base (fi g. C2).

• Place a bracket (58) over the legs.

• Pass a coach bolt (57) from the inside through the holes into the

brackets, the legs and frame.

• Place a lock knob (59) onto the bolts.

• Tighten the lock knobs.

Folding the legs (fi g. C3)

The legs can be folded into the base to make the machine suitable for use

on a workbench.

• Turn the machine upside down.

• Loosen the lock knob (59) of the fi rst leg (15).

• Fold the leg inwards.

• Tighten the lock knob.

• Repeat as for the other legs.

• Turn the machine straight up.

Mounting the wheels (fi g. D)

• Place a wheel (14) onto the axles (60) on each side of the machine.

• Place a fl at washer (61) and a nut (62) onto the threaded end of the axles.

• Tighten the nuts using the spanner supplied.

Page 20

18

ENGLISH

Assembly for mitre saw mode

Mounting the under-table guard (fi g. E)

The under-table guard (63) is fi tted to the top of the saw bench table.

• Place the two fasteners on the left of the guard into the slots (64) on

the left of the blade slot (65). Turn the plastic screws counterclockwise.

• Place the guard fl at on the table and press the fastener in the slot (66)

on the right of the blade slot. Turn the plastic screw counterclockwise.

• To remove, turn the screws clockwise and remove the guard.

Turning the sawhead and table over (fi g. F1 - F4)

• Withhold the saw table (19) with one hand and push the table release

lever (2) to the right (fi g. F1).

• Push the table downwards at the front (fi g. F2) and swing it over

completely until the motor assembly is uppermost and the plate (67)

engages in the table locking device (68) (fi g. F3).

• Push the release lever (69) to the rear whilst holding down the head

until the spring-loaded bearing unit (70) can be lifted out of its seating

(fi g. F4).

• Flip the bearing unit up.

• Holding the head fi rmly, allow the spring pressure to take the head

upwards into its rest position.

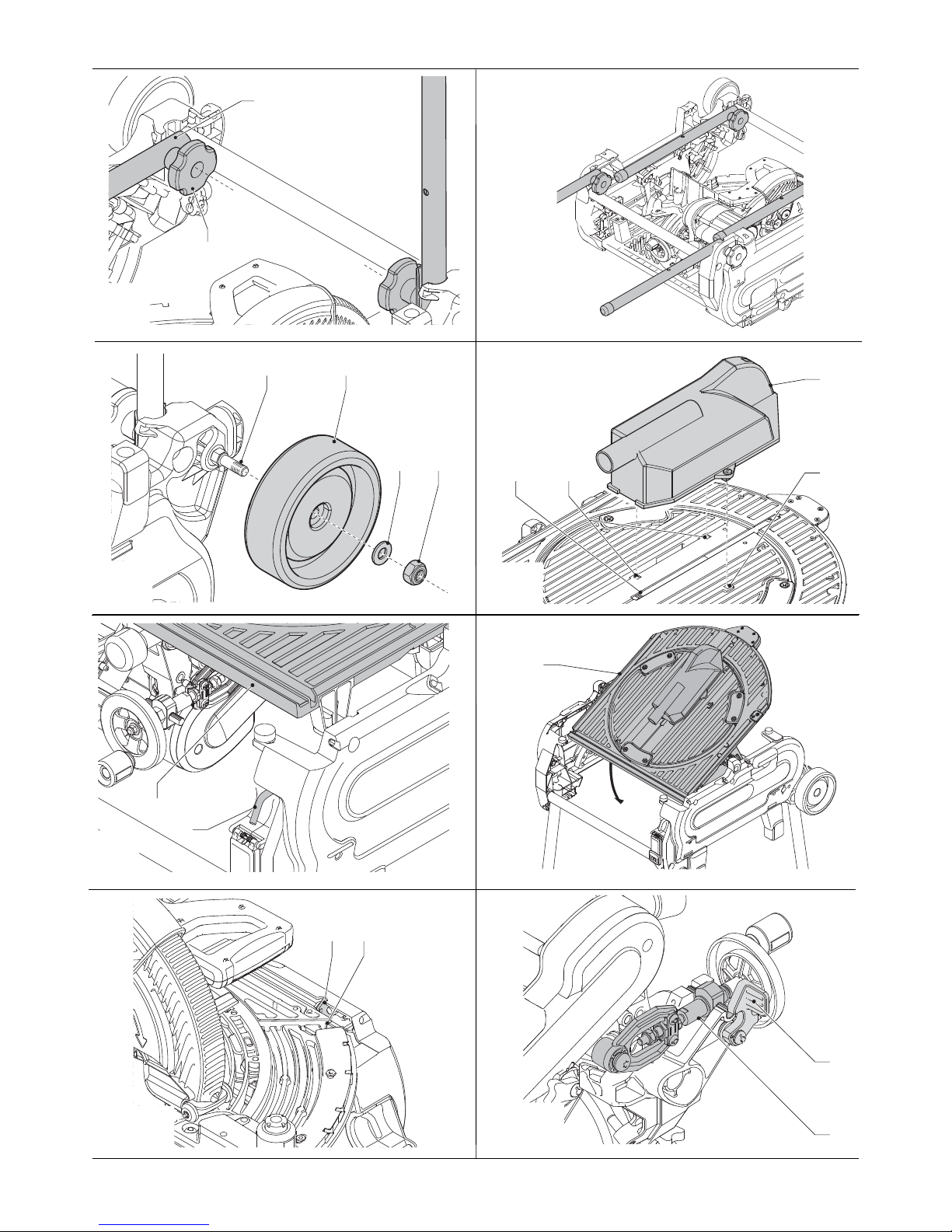

Mounting the saw blade (fi g. G1 - G4)

WARNING: To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. Be sure the trigger switch

is in the OFF position. An accidental start-up can cause injury.

• Always change blades with the machine in mitre saw mode.

• Never depress the spindle lock button while the blade is under

power or coasting.

• Do not cut ferrous metal (containing iron or steel) or masonry or

fibre cement product with this mitre saw.

• The teeth of a new blade are very sharp and can be dangerous.

• Always change blades with the machine in mitre mode.

• Depress the head lock up release lever (9) to release the lower

guard (8),then raise the lower guard as far as possible (Fig. G1).

• With the lower guard held in the raised position, depress the spindle

lock button (74) with one hand, then use the supplied blade spanner

in the other hand to loosen the left-hand threaded blade locking screw

(73) by turning clockwise.

WARNING! To use the spindle lock, press the button as shown

and rotate the spindle by hand until you feel the lock engage.

Continue to hold the lock button in to keep the spindle from turning (74,

fig. G1).

• Remove the blade locking screw (73) and the outside arbor collar (75).

• Install the saw blade (76) onto the shoulder (77) provided on the

inside arbor collar (78), making sure that the teeth at the bottom edge

of the blade are pointing toward the back of the saw (away from the

operator).

• Replace the outer arbor collar (75).

• Tighten the blade locking screw (73) carefully by turning counter-

clockwise while holding the spindle lock engaged with your other hand.

• Raise the lower guard.

WARNING! Be aware the saw blade shall be replaced in the

described way only. Only use saw blades as specified under

Technical Data; Cat.no.: DT4260 is suggested.

Adjustments for mitre saw mode

Your mitre saw was accurately adjusted at the factory. If readjustment due

to shipping and handling or any other reason is required, follow the steps

below to adjust your saw. Once made, these adjustments should remain

accurate.

Checking and adjusting the blade to the fence (fi g. H1 - H3)

• Loosen the mitre knob (79) and depress the mitre latch (80) to release

the rotating table (5) (fi g. H1).

• Swing the rotating table until the latch locates it at the 0° mitre position.

Do not tighten the knob.

• Pull down the head until the blade just enters the saw kerf (81).

• Place a square (82) against the left side (7) of the fence and blade (76)

(fi g. H2).

WARNING: Do not touch the tips of the blade teeth with the

square.

• If adjustment is required, proceed as follows:

• Loosen the screws (83) (fi g. H3) and move the scale/rotating table

assembly left or right until the blade is at 90° to the fence as measured

with the square (fi g. H2).

• Retighten the screws (83) (fi g. H3). Pay no attention to the reading of

the mitre pointer at this point.

Adjusting the mitre pointer (fi g. H1 & H4)

• Loosen the mitre knob (79) and depress the mitre latch (80) to release

the rotating table (5) (fi g. H1).

• With the mitre knob loose, allow the mitre latch to snap into place as

you rotate the mitre arm past zero.

• Observe the pointer (84) and mitre scale (85) (fi g. H4). If the pointer

does not indicate exactly zero, loosen the screw (86), move the pointer

to read 0° and tighten the screw.

Checking and adjusting the blade to the table (fi g. I1 - I3)

• Loosen the bevel clamp knob (17) (fi g. I1).

• Press the saw head to the right to ensure it is fully vertical and tighten

the bevel clamp handle.

• Pull down the head until the blade just enters the saw kerf (81).

• Place a set square (82) on the table and up against the blade (76) (fi g. I2).

WARNING: Do not touch the tips of the blade teeth with the

square.

• If adjustment is required, proceed as follows:

• Loosen the bevel clamp knob (17) (fi g. I1) and turn the vertical position

adjustment stop screw (87) (fi g. I3) in or out until the blade is at 90° to

the table as measured with the square (fi g. I2).

• If the bevel pointer (88) does not indicate zero on the bevel scale (89),

loosen the screw (90) that secures the pointer and move the pointer as

necessary (fi g. I3).

Adjusting the fence (fi g. J)

The upper part of the left side of the fence can be adjusted to the left to

provide clearance, allowing the saw to bevel to a full 48° left. To adjust the

fence (7):

• Loosen the fence clamping knob (91) and slide the upper part of the

side fence to the left.

• Make a dry run with the saw switched off and check for clearance.

Adjust the fence to be as close to the blade as practical to provide

maximum workpiece support, without interfering with the up and down

movement of the arm.

• Tighten the knob securely.

WARNING: The guide groove (92) can become clogged with

sawdust. Use a stick or some low pressure air to clear the guide

groove.

Checking and adjusting the bevel angle (fi g. I1, J K & L)

• Loosen the fence clamping knob (91) and slide the upper part of the

side fence to the left as far as it will go (fi g. J).

• Loosen the bevel clamp knob (17) (fi g. I1) and with the intermediate

bevel position stop (93) turned aside move the saw arm to the left until

the angle position stop (94) rests against the bevel position adjustment

stop (95) (fi g. K). This is the 45° bevel position.

Page 21

19

ENGLISH

• If adjustment is required, proceed as follows:

• Turn the bevel position adjustment stop screw (95) in or out as

necessary until the pointer (88) indicates 45° with the angle position

stop resting against the bevel position adjustment stop.

Checking and adjusting the intermediate bevel angle (fi g. I1, J & L)

The intermediate bevel angle is preset at 30°, enabling a quick setting for

the cutting of crown moulding.

• Loosen the fence clamping knob (91) and slide the upper part of the

side fence to the left as far as it will go (fi g. J).

• Loosen the bevel clamp knob (17) (fi g. I1) and with the intermediate

bevel position stop (93) turned into place move the saw arm to the left

until the angle position adjustment stop (96) rests on the intermediate

bevel position stop (93) (fi g. L). This is the 30° bevel position.

• If adjustment is required, proceed as follows:

• Turn the bevel position adjustment stop screw (96) in or out as

necessary until the pointer (88) indicates 30° with the bevel position

adjustment stop resting on the intermediate bevel position stop.

Assembly for saw bench mode

Changing from mitre saw to saw bench mode (fi g. A1, M1 - M5)

• Put the blade into 0° cross-cut position with the rotating table clamp (3)

secured (fi g. A1).

• Slacken the riving knife clamp knob (97) just enough to allow the riving

knife to enter the mounting slot (fi g. M1).

• Remove the riving knife (20) from its storage position in the inside of the

base.

• Depress the guard release lever (9) to release the blade guard (8),

then raise the blade guard as far as possible (fi g. A1).

• Slide the riving knife bracket (98) into the mounting slot (99) (fi g. M1).

Tighten the clamp knob.

• Push the lever (100) to allow the spring loaded upper part of the fence (7)

to rest against the rotating table (fi g. M2)

• Pull down the sawhead.

• Push the release lever (69) to the rear (fi g. M3).

• Push the bearing unit (70) down until notches (101) engage in the

locations (102) (fi g. M3).

WARNING: The blade should not foul the lower blade guard.

• Pull the table release lever (2) to the right, lift the front edge of the table

(4) fi g. M4) and fl ip it back through 180° until the plate of the tablelocking device (68) automatically engages the latch of the table locking

device to secure it in the saw bench mode (fi g. M5).

• Remove the under-table guard.

Adjusting the riving knife (fi g. N1 & N2)

WARNING: When adjustments to the riving knife (20) are to be

made, it is best to rotate the unit in mitre saw mode (fig. N2).

Proceed as described in the section “Changing from saw bench

to mitre saw mode”.

The correct position is for the top of the riving knife to be no more than 2 mm

below the highest tooth of the blade and the body of the radius to be a

maximum of 3 - 8 mm from the tips of the saw blade teeth (fi g. N1).

• If adjustment is required, proceed as follows:

• Slacken the bolts (104) to adjust the horizontal position of the riving knife.

• Slacken the bolts (103) to adjust the vertical position of the riving knife.

• Securely tighten the bolts.

Fitting the upper blade guard (fi g. O)

The upper blade guard (21) is designed to be quickly and easily attached

to the riving knife (20) once the machine has been set up for saw bench mode.

• Loosen the wingnut (105).

• Holding the guard vertically, align the slot in the rear of the guard with

the riving knife.

• Lower the guard over the riving knife (20), making sure that the shaft of

the bolt enters the recess.

• Turn the guard into horizontal position, which will lock the guard to the

riving knife by the locating screw (106).

• Tighten the wingnut.

WARNING: Never use your saw in saw bench mode without

the upper guard correctly fitted.

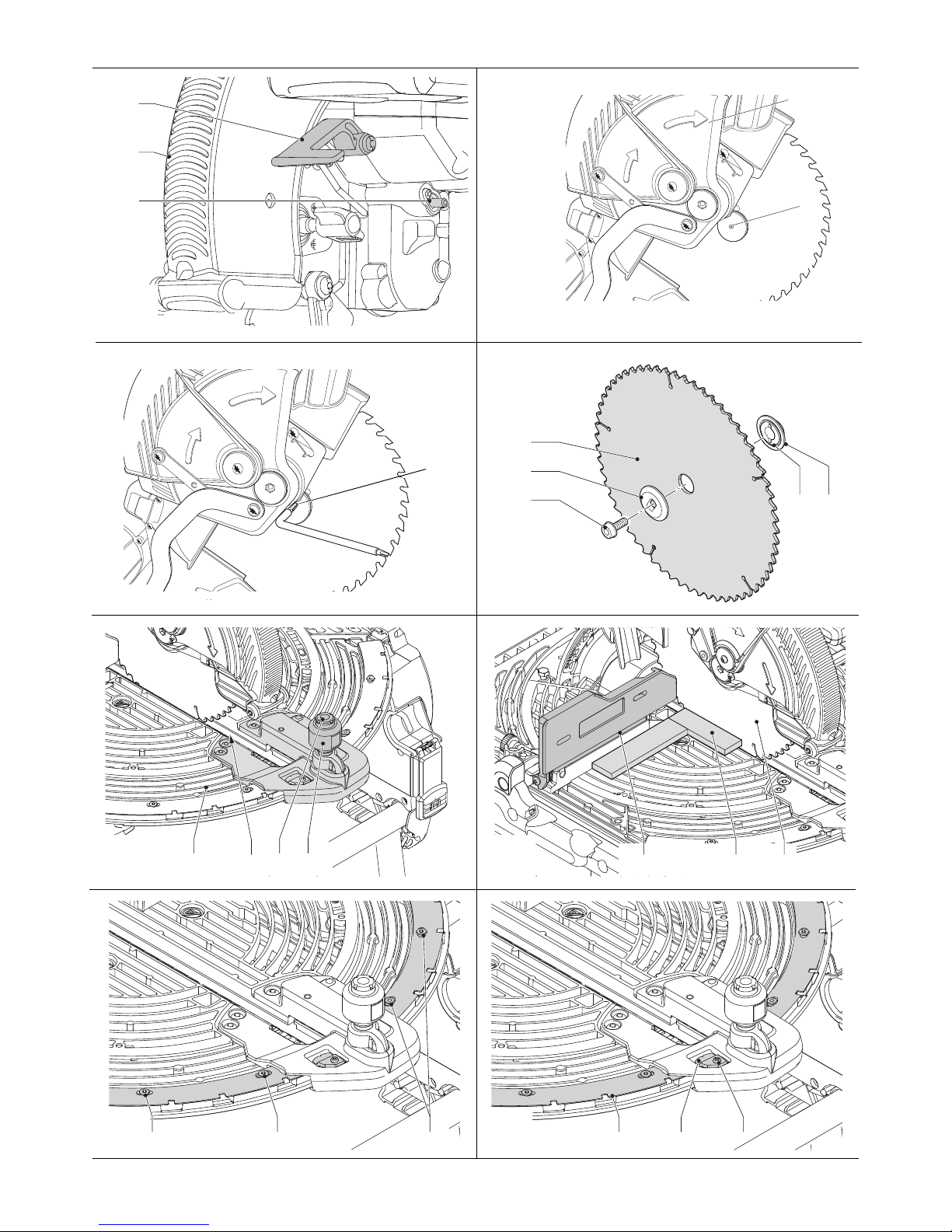

Mounting and adjusting the parallel fence (fi g. P1 - P5)

The parallel fence (22) can be mounted on either side of the blade.

• Slide the bracket (107) on from the left or the right (fi g. P1).

The clamping plate engages behind the front edge of the table.

• Slide the fence up against the blade.

• Push the lever (108) down to secure the fence in place.

• Check that the fence is parallel to the blade.

• If adjustment is required, proceed as follows:

• Loosen the lock knobs (109) and slide the fence backwards in order to

obtain access to the adjustment bolts (110) in the top of the fence (fi g. P2).

• Using the spanner, loosen the adjustment bolts fastening the fence

bracket to the fence support.

• Adjust the fence so that it is parallel to the blade by checking the

distance between the blade and the fence at the front and rear of the

blade.

• When the adjustment has been carried out, re-tighten the adjustment

bolts and check again that the fence is parallel to the blade.

• Check that the pointer (111) indicates zero on the scale (fi g. P3). If the

pointer does not indicate exactly zero, loosen the screw (112),

move the pointer to read 0° and tighten the screw.

The default set-up of the fence is to the right-hand side of the blade.

To prepare the fence for use to the left-hand side of the blade, proceed as

follows (fi g. P4):

• Remove the lock knobs (109).

• Slide the fence profi le (113) out of the clamping support.

• Turn the clamping support (114) round and re-fi t the lock knobs.

• Slide the fence onto the clamping support.

• Tighten the knobs.

The fence is reversible: the workpiece can be guided along the 75 mm or

along the 11 mm face to allow the use of a push stick when ripping thin

workpieces (fi g P5).

• To set for 11 mm, loosen the fence clamping knobs (109) and slide the

fence (113) out of the clamping support (114).

• Turn the fence and re-engage the clamping support in the slot as

shown (fi g. P5).

• To use with the full height of 75 mm, slide the fence into the clamping

support with the wide face in the vertical position (fi g. P4).

WARNING: Use the 11 mm profile for ripping low workpieces

to allow access between the blade and the fence for the push

stick. The rear end of the fence should be level with the front of

the riving knife.

Mounting and adjusting the mitre fence (fi g. Q1 - Q4)

The mitre fence (D271052) is available as an option. The mitre fence (41) can

be used for mitre cutting when the machine is in saw bench mode (fi g. Q1).

• Loosen the clamp knob (115) and swing the guide bar (116) out (fi g. Q2).

Tighten the clamp knob.

• Slide the fence on the left side on the table (fi g. Q3).

• Loosen the lock knob (117).

• Place a square (82) against the fence (41) and the blade (76).

• If adjustment is required, proceed as follows:

• Loosen the nut (118) a few turns and turn the right angle adjustment

stop screw (119) (fi g. Q4) in or out until the fence is at 90° to the blade

as measured with the square (fi g. Q3).

Page 22

20

ENGLISH

• Tighten the knob (117).

• Check that the pointer (120) indicates zero on the scale (121).

Adjust if necessary.

Changing from saw bench to mitre saw mode (fi g. A3, E & M1)

• Remove the parallel fence (22), or the mitre fence, if fi tted (fi g. A3).

• Remove the upper blade guard (21).

• Replace the under-table guard (63) (fi g. E).

• Proceed as described in the section “Turning the sawhead and table

over”.

• Slacken the riving knife clamp knob (97) and remove the riving knife (20),

while holding the blade guard (8) (fi g. M1).

• Lower the blade guard.

• Place the riving knife in its storage position in the inside of the base.

OPERATION

Instructions for Use

WARNING: Always observe the safety instructions and

applicable regulations.

• Ensure the material to be sawn is firmly secured in place.

• Apply only a gentle pressure to the tool and do not exert side

pressure on the saw blade.

• Avoid overloading.

The attention of UK users is drawn to the “woodworking machines

regulations 1974” and any subsequent amendments.

Ensure the machine is placed to satisfy your ergonomic conditions in terms

of table height and stability. The machine site shall be chosen so that the

operator has a good overview and enough free surrounding space around

the machine that allows handling of the workpiece without any restrictions.

To reduce effects of vibration make sure the environment temperature is not

too cold, machine and accessory is well maintained and the workpiece size

is suitable for this machine.

Prior to operation:

• Install the appropriate saw blade. Do not use excessively worn blades.

The maximum rotation speed of the tool must not exceed that of the

saw blade.

• Do not attempt to cut excessively small pieces.

• Allow the blade to cut freely. Do not force.

• Allow the motor to reach full speed before cutting.

• Make sure all locking knobs and clamp handles are tight.

Switching on and off (fi g. A1, R1 - R3)

This machine has two independent switching systems. In mitre saw mode,

the trigger switch (11) is used (fi g. R1). In saw bench mode, the on/off

switch (1) is used (fi g. R2). Integrated in the switch box is a motor overload

protector with manual reset. In case of a power shut-off, proceed as

follows:

- Make sure the machine has been switched off.

- Press the reset button (142).

Mitre saw mode (fi g. R1)

A hole (122) is provided in the trigger for insertion of a padlock to lock the

switch.

• To run the tool, press the trigger switch (11).

• To stop the tool, release the switch.

Saw bench mode (fi g. R2 & R3)

The on/off switch offers multiple advantages:

- no-volt release function: should the power be shut off for some reason,

the switch has to be deliberately reactivated.

- extra safety: the hinged safety enclosure plate (123) can be locked by

passing a padlock through the holes (124 & 125). The plate also serves

as an “easy to locate” emergency stop button as pressure on the front

of the plate will depress the stop button.

• To switch the machine on, press the green start button (126).

• To switch the machine off, press the red stop button (127).

Locking the switches

• In order to avoid unauthorised use of the machine, lock both switches

using padlocks.

Basic saw cuts

Sawing in mitre saw mode

It is dangerous to operate without guarding. Guards must be in position

when sawing.

• Make sure that the under-table guard does not become clogged with

sawdust.

• Always clamp the workpiece when cutting non-ferrous metals.

General handling

- In the mitre saw mode, the sawhead is automatically locked in the

upper “park”-position.

- Squeezing the guard release lever will unlock the sawhead. Moving the

sawhead down retracts the movable lower guard.

- Never seek to prevent the lower guard returning to its park position

when the cut is completed.

- The minimum length of offcut material is 10 mm.

- When cutting short material (min. 190 mm to the left or the right of the

blade), the use of the optional material clamp is recommended.

- When cutting UPVC sections, a supporting piece made out of timber

with a complementary profi le should be placed beneath the material

being cut to provide the correct level of support.

Vertical straight cross cut ( g. S1)

• Loosen the mitre knob (79) and depress the mitre latch (80).

• Engage the mitre latch at the 0° position and tighten the mitre knob.

• Place the wood to be cut against the fence (7).

• Take hold of the operation handle (10) and press in the guard release

lever (9).

• Press the trigger switch (11) to start the motor.

• Depress the head to allow the blade to cut through timber and enter

the saw kerf (81).

• After completing the cut, release the switch and wait for the saw blade

to come to a complete stillstand before returning the head to its upper

rest position.

Vertical mitre cross-cut ( g. S2)

• Loosen the mitre knob (79) and depress the mitre latch (80). Move the

rotating table left or right to the required angle.

• The mitre latch will automatically locate at 15°, 22.5°, 35.3° and 45°

both left and right. If any intermediate angle is required hold the head

fi rmly and lock by tightening the mitre knob.

• Always ensure that the mitre knob is locked tightly before cutting.

• Proceed as for a vertical straight cross-cut.

WARNING: When mitring the end of a piece of wood with a

small off-cut, position the wood to ensure that the off-cut is to

the side of the blade with the greater angle to the fence:

left mitre, off-cut to the right

right mitre, off-cut to the left.

Bevel cross-cut ( g. A2, S3)

Bevel angles can be set from 48° left to 2° right and can be cut with the

rotating table set between zero and a maximum of 45° mitre position left

or right.

Page 23

21

ENGLISH

• Loosen the fence clamping knob (91) and slide the upper part of the

side fence to the left as far as it will go.

• Loosen the bevel clamp knob (17) and set the bevel as desired.

• Tighten the bevel clamp knob fi rmly.

• Proceed as for a vertical straight cross-cut.

Compound mitre ( g T1 - T4)

A compound mitre is a cut made using a mitre angle (fi g. T1) and a bevel

angle (fi g. T2) at the same time. This is the type of cut used to make

frames or boxes with slanting sides like the one shown in fi g. T3.

WARNING: If the cutting angle varies from cut to cut, check

that the bevel clamp knob and the mitre lock knob are securely

tightened. These knobs must be tightened after making any

changes in bevel or mitre.

• The chart shown below will assist you in selecting the proper bevel

and mitre settings for common compound mitre cuts. To use the chart,

select the desired angle “A” (fi g. T4) of your project and locate that

angle on the appropriate arc in the chart. From that point follow the

chart straight down to fi nd the correct bevel angle and straight across

to fi nd the correct mitre angle.

• Set your saw to the prescribed angles and make a few trial cuts.

• Practice fi tting the cut pieces together.

• Example: To make a 4 sided box with 25° exterior angles (angle “A”)

(fi g. T4), use the upper right arc. Find 25° on the arc scale. Follow the

horizontal intersecting line to either side to get the mitre angle setting

on the saw (23°). Likewise follow the vertical intersecting line to the top

or bottom to get the bevel angle setting on the saw (40°). Always try

cuts on a few scrap pieces of wood to verify the settings on the saw.

SET THIS BEVEL ANGLE ON SAW

SET THIS MITER ANGLE ON SAW

ANGLE OF SIDE OF BOX (ANGLE"A")

SQUARE BOX

6 SIDED BOX

8 SIDED BOX

Cutting base mouldings

The cutting of base moulding is performed at a 45° bevel angle.

• Always make a dry run without power before making any cuts.

• All cuts are made with the back of the moulding laying fl at on the saw.

Inside corner

- Left side

• Position the moulding with top of the moulding against the fence.

• Save the left side of the cut.

- Right side

• Position the moulding with the bottom of the moulding against the

fence.

• Save the left side of the cut.

Outside corner

- Left side

• Position the moulding with the bottom of the moulding against the

fence.

• Save the right side of the cut.

- Right side

• Position the moulding with top of the moulding against the fence.

• Save the right side of the cut.

Cutting crown mouldings

The cutting of crown moulding is performed in a compound mitre. In

order to achieve extreme accuracy, your saw has pre-set angle positions

at 35.3° mitre and 30° bevel. These settings are for standard crown

mouldings with 45° angles at the top and 45° angles at the bottom.

• Make test cuts using scrap material before doing the fi nal cuts.

• All cuts are made in a left bevel and with the back of the moulding

against the base.

Inside corner

- Left side

• Top of the moulding against the fence.

• Mitre right.

• Save the left side of the cut.

- Right side

• Bottom of the moulding against the fence.

• Mitre left.

• Save the left side of the cut.

Outside corner

- Left side

• Bottom of the moulding against the fence.

• Mitre left.

• Save the right side of the cut.

- Right side

• Top of the moulding against the fence.

• Mitre right.

• Save the right side of the cut.

Sawing in the bench mode

• Always use the riving knife.

• Always ensure that the riving knife and blade guard are correctly

aligned.

• Always ensure that the mitre saw is set and locked in 0° mitre.

WARNING: Do not cut metal in this mode.

Ripping (fi g. U1 & U3)

• Set the bevel angle to 0°.

• Adjust the saw blade height.

• Set the parallel fence to the required distance.

• Hold the workpiece fl at on the table and against the fence. Keep the

workpiece approx. 25 mm away from the saw blade.

• Keep both hands away from the path of the saw blade.

• Switch the machine on and allow the saw blade to reach full speed.

• Slowly feed the workpiece underneath the upper blade guard, keeping

it fi rmly pressed against the fence. Allow the teeth to cut, and do not

force the workpiece through the saw blade. The saw blade speed

should be kept constant.

• Remember to use the push stick (23) when close to the blade.

Page 24

22

ENGLISH

• After completing the cut, switch the machine off, allow the saw blade

to stop and remove the workpiece.

WARNING: Never push or hold the free or cut-off side of the

workpiece.

WARNING: Always use a push stick when ripping small

workpieces.

Bevel cuts (fi g. U2)

• Set the required bevel angle.

• Proceed as for ripping.

Cross-cutting (fi g. V1)

• Set the bevel angle to 0°.

• Adjust the saw blade height.

• Set the mitre fence to 0°.

• Proceed as for ripping, only use the mitre fence to push the workpiece

through the blade.

Bevel cross-cutting

• Set the required bevel angle.

• Proceed as for cross-cutting.

Mitre cuts ( g. V2)

• Set the mitre fence to the required angle.

• Proceed as for cross-cutting.

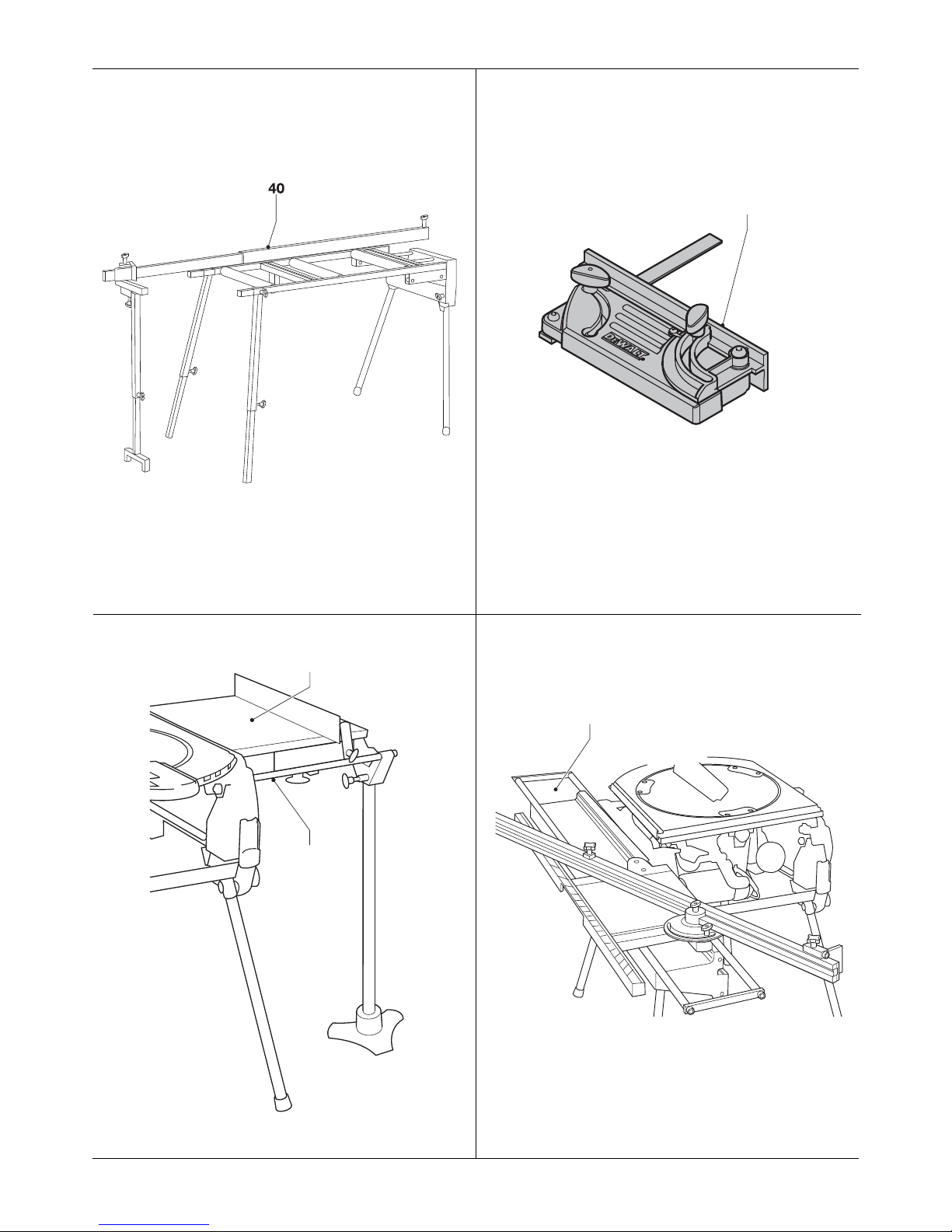

Optional attachments

WARNING: Prior to assembling any accessories always unplug

the machine.

Dust extraction kit (fi g. W1 & W2)

WARNING! This machine is provided with two dust extraction

points for use in each mode.

WARNING! Whenever possible, connect a dust extraction

device designed in accordance with the relevant regulations

regarding dust emission.

WARNING! When sawing wood, connect a dust extraction

device designed in accordance with the relevant regulations

regarding dust emission.

Connect a dust collection device designed in accordance with the relevant

regulations. The air velocity of externally connected systems shall be 20

m/s ±2 m/s. Velocity to be measured in the connection tube at the point of

connection, with the tool connected but not running.tion tube at the point of

connection, with the tool connected but not running.

Connecting - mitre saw position (fi g. W1)

• Connect the one end of the fi rst hose to the dust extraction adaptor (13).

• Insert the other end of the hose into the middle inlet port of the

manifold (128).

• Connect the one end of the other hose to the under-table guard (63).

• Insert the other end of the hose into the outer inlet port of the manifold.

Connecting - saw bench position (fi g. W2)

• Proceed as for mitre saw position, only connect the hose from the

under-table guard to the saw blade guard (21).

Mitre saw extra support/length stop (fi g. A5)

The extra support and length stop can be mounted on the left-hand side

or on the right-hand side, or with two sets on either side.

• Fit the items 31 - 39 onto the two guide rails (32 & 33).

• Use the inclinable support (34) for cross-cutting 210 mm wide boards

(15 mm thick).

Roller support table (fi g. A6)

The roller support table (40) is used to support long workpieces. In mitre

saw mode, the roller support table can be mounted on the left-hand side

or on the right-hand side, or with two sets on either side. In saw bench

mode, it can also be mounted in front or at the rear of the saw table.

Side extension table (fi g. A8)

The side extension table increases the distance from the rip fence to

the blade to 600 mm or more, depending on the rod length fi tted to the

machine and the clamped position of the table. The side extension table

must be used in conjunction with guide rails (32) (option). The adjustable

table is equipped with an engraved scale along its front edge and

mounted on a sturdy base which clamps to the guide rods.

• Fit the extension table to the right-hand side of the machine for

continuity of the distance scale on both tables.

Sliding table (fi g. A9)

This sliding table (43) allows for board sizes to the left of the blade up to

1200 x 900 mm.

The guide rods are mounted on a sturdy alloy extrusion which is quickly

detachable from the machine and yet fully adjustable is all planes.

The fence incorporates a full length measuring tape for quick positioning

of an adjustable stop and an adjustable support for narrow workpieces.

Transporting (fi g. X)

WARNING: Always transport the machine in saw bench mode

with the upper blade guard fitted.

The castor wheels provide an easier transport of the machine.

• Put the machine on the right base side.

• Fold the rear legs into the base

• Fold the front legs out of the base

• Turn the machine straight up.

• Lift the machine by the front legs up to the wheels are in contact with

the floor.

WARNING: When carrying the machine, always seek

assistance.

Maintenance

Your DEWALT power tool has been designed to operate over a long

period of time with a minimum of maintenance. Continuous satisfactory

operation depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing

and removing accessories, before adjusting or changing

set-ups or when making repairs. Be sure the trigger switch

is in the OFF position. An accidental start-up can cause injury.

Lubrication

The bearings of the motor are pre-lubricated and watertight.

• Slightly oil the rotating table bearing surface where it slides on the lip of

the fi xed table at regular intervals.

• Periodically lubricate the depth of cut screwthread.

• Clean the parts subject to accumulation of sawdust and chips

periodically with a dry brush.

Cam adjustment (fi g. Y1 - Y3)

To take out the clearance between the two tables, proceed as follows:

• Rotate the machine into saw bench mode.

• Remove the screws (138) and the retainer plate (139).

Page 25

23

ENGLISH

• Loosen the screw (140) of the adjustment cam (141).

• Rotate the adjustment cam using a pair of needle nose pliers.

• Hold the adjustment cam with the pliers and tighten the screw.

• Replace the retainer plate and tighten the screws.

• Rotate the machine into mitre saw mode. Check the force that is

needed to mitre the saw. Repeat the above steps if the force needed is

too high.

Cleaning

Before use, carefully check the upper blade guard, movable lower blade

guard as well as the dust extraction tube to determine that it will operate

properly. Ensure that chips, dust or workpiece particle cannot lead to

blockage of one of the functions.

In case of workpiece fragments jammed between saw blade and guards

disconnect the machine from the power supply and follow the instructions

given in section Mounting the Saw Blade. Remove the jammed parts and

reassembling the saw blade.

WARNING: Blow dirt and dust out of the main housing with dry

air as often as dirt is seen collecting in and around the air vents.

Wear approved eye protection and approved dust mask when

performing this procedure.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals

may weaken the materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool into a

liquid.

WARNING:: To reduce the risk of injury, regularly clean the

table top.

WARNING: To reduce the risk of injury, regularly clean the

dust collection system.

Optional Accessories

WARNING: Since accessories, other than those offered by

DEWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the

risk of injury, only DEWALT, recommended accessories should

be used with this product.

LASER WARNING:

LASER RADIATION: DO NOT STARE INTO BEAM

CLASS 2 PRODUCT

MAXIMUM OUTPUT POWER

P = < 1 mW;

peak

= 630 nm –680 nm

IEC 60825-1: 2007

Consult your dealer for further information on the appropriate accessories.

Protecting the Environment

Separate collection. This product must not be disposed of with

normal household waste.

Should you find one day that your DEWALT product needs replacement, or

if it is of no further use to you, do not dispose of it with household waste.

Make this product available for separate collection.

Separate collection of used products and packaging allows

materials to be recycled and used again. Re-use of recycled

materials helps prevent environmental pollution and reduces the

demand for raw materials.

Local regulations may provide for separate collection of electrical products

from the household, at municipal waste sites or by the retailer when you

purchase a new product.

DEWALT provides a facility for the collection and recycling of DEWALT

products once they have reached the end of their working life. To take

advantage of this service please return your product to any authorised repair

agent who will collect them on our behalf.

You can check the location of your nearest authorised repair agent by

contacting your local D

EWALT office at the address indicated in this manual.

Alternatively, a list of authorised DEWALT repair agents and full details

of our after-sales service and contacts are available on the Internet at:

www.2helpU.com.

GUARANTEE

DEWALT is confident of the quality of its products and offers an

outstanding guarantee for professional users of the product.

This guarantee statement is in addition to and in no way

prejudices your contractual rights as a professional user or

your statutory rights as a private non-professional user. The

guarantee is valid within the territories of the Member States of

the European Union and the European Free Trade Area.

• 30 DAY NO RISK

SATISFACTION GUARANTEE •

If you are not completely satisfied with the performance of your

DEWALT tool, simply return it within 30 days, complete with all

original components, as purchased, to the point of purchase,

for a full refund or exchange. The product must have been

subject to fair wear and tear and proof of purchase must be

produced.

• ONE YEAR FREE SERVICE CONTRACT •

If you need maintenance or service for your DEWALT tool,

in the 12 months following purchase, it will be undertaken

free of charge at an authorised DEWALT repair agent. Proof

of purchase must be produced. Includes labour. Excludes

accessories and spare parts unless failed under warranty.

• ONE YEAR FULL WARRANTY •

If your DEWALT product becomes defective due to faulty

materials or workmanship within 12 months from the date of

purchase, DEWALT guarantees to replace all defective parts

free of charge or – at our discretion – replace the unit free of

charge provided that:

• The product has not been misused;

• The product has been subject to fair wear and tear;

• Repairs have not been attempted by unauthorised

persons;

• Proof of purchase is produced;

• The product is returned complete with all original

components.

If you wish to make a claim, contact your seller or check the

location of your nearest authorised DEWALT repair agent in

the DEWALT catalogue or contact your DEWALT office at the

address indicated in this manual. A list of authorised DEWALT

repair agents and full details of our after-sales service is

available on the Internet at: www.2helpU.com.

Page 26

24

01/10

N047925

Belgique et Luxembourg Black & Decker - DEWALT Tel: +32 (0)015 - 15 47 9211

België en Luxemburg Nieuwlandlaan 7, IZ Aarschot B156 Fax: +32 (0)015 - 15 47 9210

B-3200 Aarschot www.dewalt.be

Danmark D

EWALT Tlf: 70201511

Sluseholmen 2-4 Fax: 70224910

2450 København SV www.dewalt.dk

Deutschland D

EWALT Tel: 06126-21-1

Richard-Klinger-Straße Fax: 06126-21-2770

65510 Idstein www.dewalt.de

Ελλάς Black & Decker (Hellas) S.A. Τηλ: (01) 8981-616

Στράβωνος 7 & Βουλιαγμένης 159 Φαξ: (01) 8983-570

Γλυφάδα 16674, Αθήνα Service: (01) 8982-630

España D

EWALT Tel: 934 797 400

Parque de Negocios “Mas Blau” Fax: 934 797 439

Edificio Muntadas, c/Bergadá, 1, Of. A6 www.dewalt.es

08820 El Prat de Llobregat (Barcelona)

France D

EWALT Tel: 04 72 20 39 20

5, allée des hêtres Fax: 04 72 20 39 00

BP 30084, 69579 Limonest Cedex www.dewalt.fr

Schweiz D

EWALT Tel: 01 - 730 67 47

Suisse In der Luberzen 40 Fax: 01 - 730 70 67

Svizzera 8902 Urdorf www.dewalt.ch

Ireland D

EWALT Tel: 00353-2781800

Calpe House Rock Hill Fax: 00353-2781811

Black Rock, Co. Dublin www.dewalt.ie

Italia D

EWALT Tel: 800-014353

Viale Elvezia 2 Fax: 039-2387592

20052 Monza (Mi) www.dewalt.it

Nederlands Black & Decker - D

EWALT Tel: 0164 283000

Joulehof 12 Fax: 0164 283100

4600 AB Bergen Op Zoom www.dewalt.nl

Norge D

EWALT Tel: 22 90 99 00

Postboks 4814, Nydalen Fax: 22 90 99 01

0422 Oslo www.dewalt.no

Österreich D

EWALT Tel: 01 - 66116 - 0

Werkzeugevertriebs GmbH Fax: 01 - 66116 - 14

Erlaaerstraße 165, Postfach 320,1231 Wien www.dewalt.at

Portugal D

EWALT Tel: 214 66 75 00

Rua Egas Moniz 173 Fax: 214 66 75 75

João do Estoril, 2766-651 Estoril www.dewalt.pt

Suomi D

EWALT Oy Puh: 010 400 430

Tekniikantie 12 Faksi: 0800 411 340

02150 Espoo, Finland www.dewalt.fi

D

EWALT Oy Tel: 010 400 430

Teknikvägen 12 Fax: 0800 411 340

02150 Esbo, Finland www.dewalt.fi

Sverige D

EWALT Tel: 031 68 61 00

Box 94 Fax: 031 68 60 08

431 22 Mölndal www.dewalt.se

Türkiye

KALE Hırdavat ve Makina A.Ş. Tel: 0212 533 52 55

Defterdar Mah. Savaklar Cad. No:15 Faks: 0212 533 10 05

Edirnekapı / Eyüp / İSTANBUL 34050 TÜRKİYE www.dewalt.com.tr

United Kingdom D

EWALT Tel: 01753-56 70 55

210 Bath Road Fax: 01753-57 21 12

Slough, Berks SL1 3YD www.dewalt.co.uk

Loading...

Loading...