Page 1

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and bal-

ance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

• Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventative safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool’s operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow maintenance instructions may create a risk of electric shock or injury.

Additional Safety Instructions for Sanders

• Accessories must be rated for at least the speed recommended on the tool warning

label. Wheels and other accessories running over rated speed can fly apart and cause injury.

Accessory ratings must be above listed minimum wheel speed as shown on tool nameplate.

• Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

• Always wear eye protection and a respirator when sanding.

• Sanding of lead-based paint is not recommended. See Precautions To Take When

Sanding Paint for additional information before sanding paint.

• Do not operate the unit without the dust collection bag.

• Clean your tool out periodically.

• Empty dust bag frequently, especially when sanding resin coated surfaces such as

polyurethane, varnish, shellac, etc. Dispose of coated dust particles according to the finish

manufacturer’s guidelines, or place in a metal can with a tight-fitting metal lid. Remove coated

dust particles from the premises daily. The accumulation of fine sanding dust particles may

self ignite and cause fire.

• Replace worn CFS disc when it causes high tool rpm. High tool rpm caused by a worn

out CFS disc may result in separation of sanding pad from the sander, possibly causing personal injury. For instructions on replacing the CFS disc, see Tool Care.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

struction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and

duration of use, noise from this product may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V ..............volts A................amperes

Hz ............hertz W ..............watts

min............minutes ............alternating current

..........direct current

n

o..............no load speed

..............Class II Construction ..............earthing terminal

..............safety alert symbol .../min ........revolutions per minute

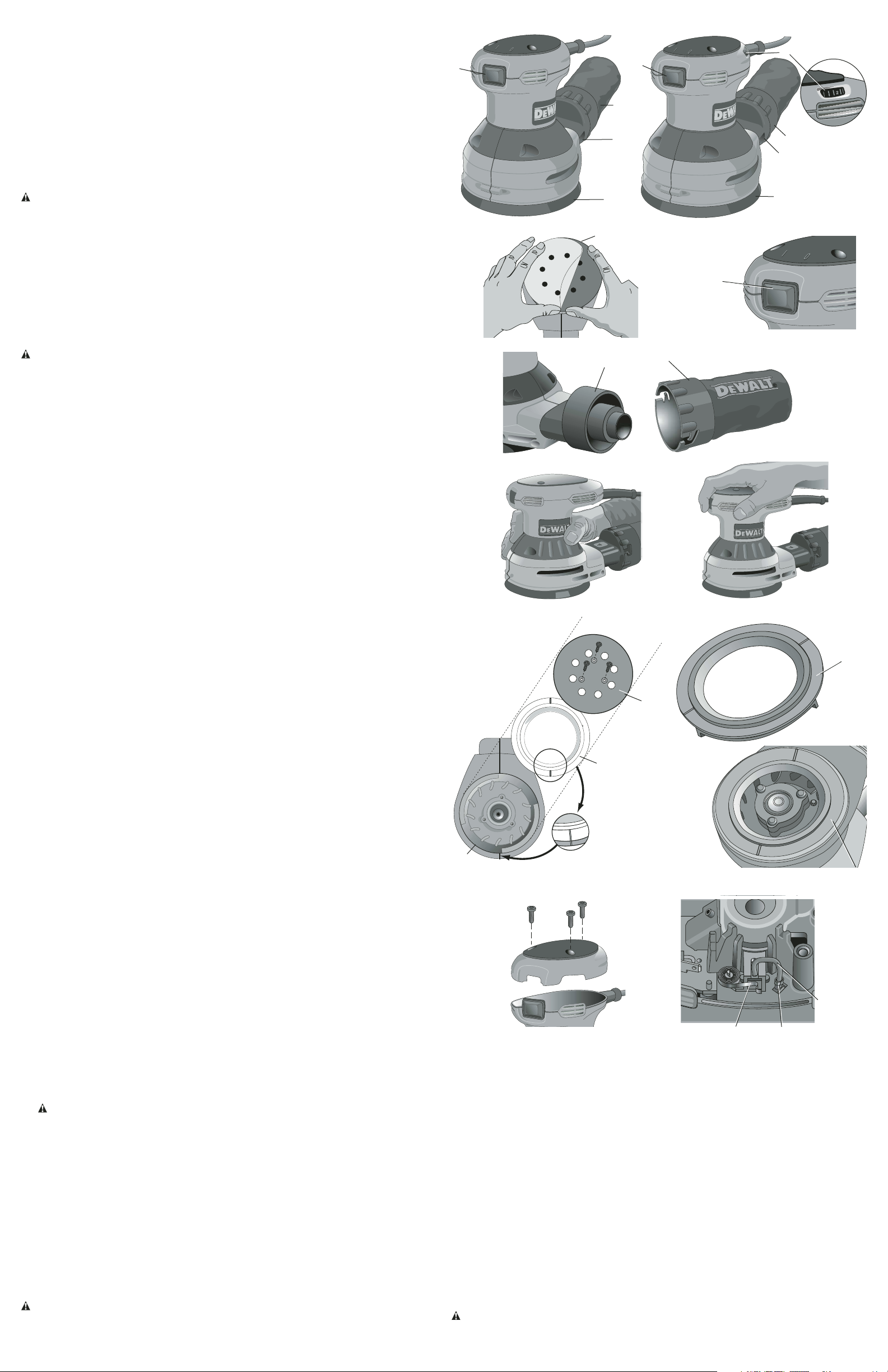

COMPONENTS (Fig. 1)

A. On/Off switch D. Dust collection bag

B. Speed control dial (D26453) E. Vac-adapter

C. Sanding pad F. CFS disc (Fig. 6)

Motor

Your DEWALT tool is powered by a DEWALT built motor. Be sure your power supply agrees with

the nameplate marking. (Volts, 120 AC only). Voltage decrease of more than 10% will cause loss

of power and overheating. All D

EWALT tools are factory tested; if this tool does not operate,

check the power supply.

Attaching Sanding Discs

Your sander is designed to use 5" (127mm) sanding discs with an 8-hole dust extraction pattern.

Sanding discs for the D26451 and D26453 attach with hook and loop. Sanding discs for the

D26450 attach using pressure sensitive adhesive (PSA).

TO ATTACH PAPER TO THE SANDING PAD (FIG. 2)

CAUTION: Turn off and unplug the tool before making any adjustments or removing

or installing attachments or accessories. Be sure the switch is in the OFF position.

1. Turn the sander over so that the sanding pad is facing upward.

2. Clean the dust from the vinyl pad face.

3. Hold the pad with one hand to keep it from rotating.

4. With the other hand, align the holes and place the disc directly on top of the pad.

REQUIRED SANDPAPERS

Model Disc Attachment Hole

Sander Size Method Pattern

D26450 5" PSA 8 Holes

D26451 5" Hook & Loop 8 Holes

D26453 5" Hook & Loop 8 Holes

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

D26450, D26451, D26453

Random Orbit Palm Sanders

Ponceuse de paume orbitale à mouvement aléatoire

Lijadoras planas de órbita aleatoria

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Instructions

WARNING! Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of flam-

mable liquids, gases, or dust. Power tools create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or

modify the plug in any way. Do not use any adaptor plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tools

should electrically malfunction or break down, grounding provides a low resistance path to

carry electricity away from the user. Applicable only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to

install a polarized outlet. Do not change the plug in any way. Double insulation elim-

inates the need for the three wire grounded power cord and grounded power supply system.

Applicable only to Class II (double insulated) tools.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”

or “W.” These cords are rated for outdoor use and reduce the risk of electric shock. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0-6 18 16 16 14

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothing, jewelry, or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(AUG04) Form No. 624291-00 D26450, D26451, D26453 Copyright © 2004 D

EWALT

The following are trademarks for one or more D

EWALT power tools: the yellow and black color

scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Questions? See us in the World Wide Web at www.dewalt.com

Page 2

NOTE: Do not use sanding screen (e.g., screen used for sanding drywall) directly on the hook

and loop pad. The screen will not hold and will damage the hooks on the pad. The hooks on the

pad will wear very rapidly if left in contact with the work surface while the tool is operating.

Switch (Fig. 3)

To turn the unit on, depress the side of the dust-protected switch (A) that corresponds to the

symbol “I”. To turn the tool off, depress the side of the switch that corresponds to the symbol “O”.

Speed Control Dial (D26453)

The speed control dial (B), shown in Figure 1, allows you to increase or decrease speed from

7,000–12,000 Orbits Per Minute. The optimal speed setting for each application is very much

dependent on personal preference. Generally, you will want to use a higher setting on harder

materials and a lower setting on softer materials. Material removal rate increases as speed

increases.

Dust Extraction (Fig. 4)

CAUTION: Turn off and unplug the tool before making any adjustments or removing

or installing attachments or accessories. Be sure the switch is in the OFF position.

Your sander has two dust collection methods: a twist-on dust collection bag (D) and a built-in

vac-adapter (E) which can be hooked directly to a shop vaccum system.

TO EMPTY DUST BAG

1. While holding the sander, grasp the dust collection bag (D) at the end nearest the sander

and twist off of the vac-adapter (E).

2. Gently shake or tap the dust collection bag to empty.

3. Twist dust collection bag back onto the vac-adapter.

You may notice that all the dust will not come free from the bag. This will not affect sanding performance but will reduce the sander’s dust collection efficiency. To restore your sander’s dust

collection efficiency, depress the spring inside the dust bag when you are emptying it and tap it

on the side of the trash can or dust receptacle.

CAUTION: Never operate these tools unless the dust collector is in place. Sanding dust

exhaust may create a breathing hazard.

OPERATION (Fig. 5)

To operate your sander, grasp it as shown in Figures 5A or 5B and turn it on. Move the unit in

long, sweeping strokes along the surface being sanded, letting the sander do the work.

Pushing down on the tool while sanding actually slows the removal rate and produces an

inferior quality surface. Be sure to check your work often, this sander is capable of removing

material rapidly, especially with coarse paper.

The random orbital action of your sander allows you to sand with the grain or at any angle across

it for most sanding jobs. To produce the best finish possible, start with coarse grit sandpaper and

change gradually to finer and finer paper. Vacuum and wipe surface with a tack cloth between

grit steps.Your sander is designed to sand into small or confined areas. Its small size and light

weight make it ideal for overhead work.

The rate at which the dust collection bag fills up will vary with the type of material being sanded

and the coarseness of the sandpaper. For best results, empty the bag frequently. When sanding painted surfaces, (see the following for additional precautions when sanding paint) you may

find that the sandpaper loads up and clogs with paint. A heat gun will work much better to

remove paint before sanding. FOLLOW ALL SAFETY INSTRUCTIONS IN HEAT GUN

INSTRUCTION MANUAL.

NOTE (D26450 only): When using PSA sanding discs, remove the disc soon after operation.

PSA paper, if the disc is left on during tool storage, sometimes becomes difficult to remove. To

aid in the removal of old PSA paper, sand for a few minutes to soften the adhesive backing prior

to changing disc.

Precautions To Take When Sanding Paint

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without a chemical analysis,

we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

1. No children or pregnant women should enter the work area where the paint sanding is

being done until all clean up is completed.

2. A dust mask or respirator should be worn by all persons entering the work area. The filter

should be replaced daily or whenever the wearer has difficulty breathing. See your local

hardware store for the proper N.I.O.S.H. approved dust mask.

3. NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingest-

ing contaminated paint particles. Workers should wash and clean up BEFORE eating,

drinking or smoking. Articles of food, drink, or smoking should not be left in the work area

where dust would settle on them.

ENVIRONMENTAL SAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust generated.

2. Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils

thickness.

3. Sanding should be done in a manner to reduce tracking of paint dust outside the work

area.

CLEANING AND DISPOSAL

1. All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the

duration of the sanding project. Vacuum filter bags should be changed frequently.

2. Plastic drop cloths should be gathered up and disposed of along with any dust chips or

other removal debris. They should be placed in sealed refuse receptacles and disposed

of through regular trash pick-up procedures. During clean up, children and pregnant

women should be kept away from the immediate work area.

3. All toys, washable furniture and utensils used by children should be washed thoroughly

before being used again.

Tool Care

1. Keep your sander as clean as possible by wiping with a clean cloth and blowing air through

it after every 5 hours of use.

2. As part of CFS (Controlled Finishing System®), your sander is equipped with a replaceable disc (F) which is located between the pad (C) and the sander body (G). It is designed

to increase the dust collection efficiency and control the pad speed while the unit is off the

work surface. The disc is designed to be a consumable part and will occasionally need to be

replaced. Replacement is necessary when the pad speed increases very dramatically when

the unit is lifted from the work surface.

TO REPLACE YOUR CFS DISC (FIG. 6)

CAUTION: Turn off and unplug the tool before making any adjustments or removing

or installing attachments or accessories. Be sure the switch is in the OFF position.

a. Remove the three screws from the bottom of the pad.

b. Remove the pad (C).

c. Remove worn CFS disc (F).

d. To install the new CFS disc, place the spring side of the disc toward the sander.

e. Align the notches (H) on the CFS disc with the seams in the sander body.

f. Replace the pad and the three screws. Be careful not to over-tighten screws.

3. Don’t use harsh chemicals or solvents to clean the tool. These chemicals could seriously

damage the plastic components of your sander.

4. Avoid overloading your sander. Overloading will result in a considerable reduction in speed

and finish quality of your work. The unit may also become hot. In this event, run sander at a

no load condition for a minute or two.

5. If you wrap the cord around the tool when you store it, leave a generous loop of cord such

that the strain relief does not bend. This helps prevent premature cord failure.

Brush Replacement (Fig. 8, 9)

CAUTION: Turn off and unplug the tool before making any adjustments or removing or

installing attachments or accessories. Be sure the switch is in the OFF position.

FIG. 3

FIG. 2

FIG. 4

FIG. 5A

FIG. 5B

FIG. 6

FIG. 7

FIG. 8

TO REPLACE BRUSHES

1. Remove the three screws from the top cap and lift off top cap, as shown in Figure 8.

2. Pull the brush spring (I) back (be careful not to pull completely off) and slide out the old

brush.

3. Pull the brush wire (J) which is connected to the brush, out of the motor field (K).

4. Plug the new brush wire back into the motor field.

5. Still holding the brush spring back, slide in the new brush with the wire coming out the top

of the brush and release the brush spring.

6. Repeat steps 1–5 for the second brush.

7. Replace the top cap and tighten the three screws. Be careful not to over-tighten screws.

8. Always replace both brushes.

Lubrication

Self lubricating bearings are used in the tool and periodic relubrication is not required. However,

it is recommended that, once a year, you take or send the tool to a service center for a thorough

cleaning and inspection.

ACCESSORIES

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory for your

tool, contact: D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 or call

1-800-4-DEWALT (1-800-433-9258).

CAUTION: The use of any other accessory not recommended for use with this tool could be

hazardous.

G

FIG. 9

D26450, D26451 D26453

FIG. 1

A

D

E

A

A

B

C

F

J

I

K

F

F

C

H

C

C

E

E

D

D

Page 3

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be

performed by authorized service centers or other qualified service organizations, always using

identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

EWALT (1-800-433-9258). This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your D

EWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-D

EWALT for a free replacement.

SI VOUS AVEZ DES QUESTIONS OU VOUS VOULEZ NOUS FAIRE PART DE VOS COMMENTAIRES CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL D

EWALT, COMPOSEZ

SANS FRAIS LE : 1 800 433-9258 (1-800-4-DEWALT).

Règles de sécurité – Généralités

AVERTISSEMENT : Lire, comprendre et suivre toutes les directives précisées

ci-dessous, y compris les consignes de sécurité, afin d’éviter les risques de choc

électrique, d’incendie ou de blessure grave.

CONSERVER CES DIRECTIVES

AIRE DE TRAVAIL

• L’aire de travail doit être propre et bien éclairée. Les établis encombrés et les endroits

sombres peuvent entraîner des accidents.

• Ne pas faire fonctionner des outils électriques dans des atmosphères explosives,

comme en présence de liquides, de gaz et de poussières inflammables. Les outils électriques produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs

• Tenir les enfants, les visiteurs ou toute autre personne à l’écart lorsqu’on utilise un

outil électrique; les distractions peuvent faire perdre la maîtrise de ce dernier.

MESURES DE SÉCURITÉ – ÉLECTRICITÉ

• Les outils mis à la terre doivent être branchés dans une prise correctement installée

et mise à la terre tel que l’indiquent les codes et règlements en vigueur. Ne jamais retirer la broche de mise à la terre ou modifier la prise en aucune façon. Ne pas utiliser de

fiche d’adaptation. Consulter un électricien qualifié s’il y a un doute en ce qui concerne la mise à la terre de la prise. En cas de défaillance électrique ou de bris de l’outil, la

mise à la terre procure un chemin de faible résistance au courant afin de réduire les risques

de choc électrique. Cette protection ne s’applique qu’aux outils de classe I (mis à la

terre).

• Les outils à double isolation sont munis d’une fiche polarisée (c’est-à-dire que l’une

des lames est plus large que l’autre), laquelle ne peut être raccordée qu’à une prise

polarisée et ce, dans un seul sens; on doit l’inverser si on est incapable de l’enfoncer

complètement. Si la fiche ne s’adapte toujours pas, on doit faire appel à un électricien

qualifié pour qu’il installe la prise appropriée. On ne doit jamais modifier la fiche. La

double isolation élimine le besoin d’installer un cordon d’alimentation trifilaire et un système d’alimentation électrique pourvus d’une mise à la terre; seuls les outils de classe II (à

double isolation) sont munis d’une telle protection.

• Éviter tout contact entre le corps et les éléments mis à la terre, comme les tuyaux,

les radiateurs, les cuisinières et les réfrigérateurs, afin de réduire les risques de choc

électrique.

• Ne pas utiliser l’outil électrique dans des endroits mouillés, ni l’exposer à la pluie; l’infiltration d’eau à l’intérieur de l’outil augmente les risques de choc électrique.

• Ne pas utiliser le cordon de manière abusive; on ne doit pas transporter l’outil en le

tenant par le cordon, ou utiliser ce dernier pour le débrancher. On doit tenir le cordon

à l’écart des sources de chaleur, de l’huile, des bords tranchants ou des pièces

mobiles. Remplacer immédiatement les cordons endommagés, car ces derniers aug-

mentent les risques de choc électrique.

• Lorsqu’on utilise un outil électrique à l’extérieur, on ne doit utiliser que des rallonges

conçues pour cet usage, comme celles de type « W-A » ou « W », afin de réduire les

risques de choc électrique. S’assurer que la rallonge est en mesure de porter le courant

nécessaire à l’outil. Une rallonge de calibre inférieur entraînera une chute de tension se

traduisant par une perte de puissance et une surchauffe. Le tableau ci-dessous illustre les

calibres que l’on doit utiliser selon la longueur de la rallonge et l’intensité nominale indiquée

sur la plaque signalétique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit,

plus la rallonge peut porter de courant.

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en mètres

120 V De 0 à 7 De 7 à 15 De 15 à 30 De 30 à 45

240 V De 0 à 7 De 7 à 15 De 15 à 39 De 30 à 45

Intensité (A)

Au Au Calibre moyen de fil

moins plus

0-618161614

SÉCURITÉ PERSONNELLE

• Rester vigilant en tout temps et faire preuve de jugement lorsqu’on utilise un outil

électrique. Ne pas utiliser l’outil lorsqu’on est fatigué ou sous l’influence de drogues,

d’alcool ou de médicaments, car un moment d’inattention pourrait entraîner des blessures

graves.

• Porter des vêtements appropriés. Ne pas porter des vêtements amples ou des bijoux.

Couvrir ou attacher les cheveux longs. Garder les cheveux, les vêtements, les bijoux

et les gants éloignés des pièces mobiles, car ceux-ci peuvent s’y coincer. Se tenir éloigné

des évents puisque ces derniers pourraient camoufler des pièces mobiles.

• Éviter les démarrages accidentels; s’assurer que l’interrupteur est en position

d’arrêt avant de brancher l’outil. Ne pas transporter l’outil en laissant le doigt sur l’interrupteur ni le brancher lorsque l’interrupteur est en position de marche, car cela pourrait

causer un accident.

• Retirer les clés de réglage avant de démarrer l’outil. Une clé laissée sur une pièce rota-

tive pourrait entraîner des blessures.

• Ne pas trop étendre les bras. Les pieds doivent rester ancrés fermement au sol afin de

maintenir son équilibre en tout temps et de mieux maîtriser l’outil dans des situations

imprévues.

• Utiliser le matériel de sécurité approprié; toujours porter des lunettes de protection.

Porter un masque anti-poussières, des chaussures antidérapantes, un casque de sécurité ou

des protecteurs auditifs lorsque la situation le requiert.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Fixer et soutenir la pièce sur une plate-forme stable au moyen d’une bride de serrage

ou de tout autre dispositif semblable. La pièce est instable lorsqu’on la retient manuelle-

ment ou qu’on l’appuie contre le corps, ce qui pourrait faire perdre la maîtrise de l’outil.

• Ne pas forcer l’outil ni l’utiliser pour des travaux autres que ceux pour lesquels il a été

conçu. Pour obtenir de meilleurs résultats et prévenir les risques de blessure, laisser l’outil

couper à la vitesse pour laquelle il a été conçu.

• Ne pas utiliser l’outil lorsque l’interrupteur marche-arrêt ne fonctionne pas. Tout outil

qui ne peut être commandé au moyen de l’interrupteur est dangereux et doit être réparé.

• Débrancher l’outil de la source d’alimentation électrique avant d’effectuer un réglage,

de changer les accessoires ou de ranger l’outil; ces mesures de sécurité préventives

réduisent les risques de démarrage accidentel.

• Lorsqu’on n’utilise pas l’outil, le ranger hors de la portée des enfants ou des person-

nes non qualifiées. Les outils sont dangereux entre les mains de personnes inexpérimentées.

• Bien entretenir l’outil; s’assurer qu’il est toujours bien propre et aiguisé. Les outils bien

entretenus et dont les bords sont bien tranchants sont moins susceptibles de rester coincés

et sont plus faciles à maîtriser.

• Vérifier les pièces mobiles afin de s’assurer qu’elles sont bien alignées et qu’elles ne

restent pas coincées. Vérifier également les pièces afin de s’assurer qu’il n’y a aucun

bris ni aucune autre condition susceptible de nuire au bon fonctionnement de l’outil.

Faire réparer l’outil si ce dernier est endommagé avant de s’en servir à nouveau, car

les accidents sont souvent causés par des outils mal entretenus.

• N’utiliser que les accessoires recommandés par le fabricant pour le modèle concerné.

Un accessoire destiné à un outil particulier peut devenir dangereux lorsqu’il est utilisé avec

un autre.

ENTRETIEN

• L’outil doit être entretenu par le personnel qualifié seulement; toute maintenance effec-

tuée par une personne non qualifiée pourrait entraîner des risques de blessure.

• Lors de l’entretien, n’utiliser que des pièces de rechange identiques et suivre les

directives précisées à la section « Entretien » du présent guide afin de prévenir les

risques de choc électrique ou de blessure.

Régles de sécurité additionnelles relatives aux

ponceuses

• La vitesse des accessoires doit correspondre à la vitesse minimale recommandée

indiquée sur l’étiquette d’avertissement de l’outil, car les meules et les accessoires

qui sont réglés à une vitesse trop élevée peuvent se briser et occasionner des

blessures lorsque des fragments de métal sont projetés. S’assurer que l’intensité nomi-

nale des accessoires utilisés est supérieure à la vitesse minimum des meules indiquée sur

la plaque signalétique.

• Tenir l’outil par les surfaces isolées prévues à cette fin lorsqu’il risque d’entrer en con-

tact avec des fils cachés ou son propre cordon, car de tels contacts peuvent mettre les

pièces métalliques de l’outil sous tension, engendrant des risques de choc électrique.

• Toujours porter des lunettes de protection et un appareil respiratoire antipoussière

pendant le ponçage.

• Le ponçage de peintures à base de plomb n’est pas recommandé. Se reporter à la sec-

tion Mesures de précaution concernant le ponçage de peinture pour plus d’informations

quant au ponçage des peintures.

• Ne pas utiliser l’appareil sans le sac à poussières.

• Nettoyer cet outil périodiquement.

• Vider le sac à poussières fréquemment, particulièrement lors du ponçage de surfaces

enduites de résines synthétiques tels polyuréthanes, vernis, gommes laques, etc. Se

défaire des particules de poussières enrobées conformément aux directives du fabricant, ou

les mettre dans une boîte métallique à fermeture hermétique. Éliminer quotidiennement toute

particule de poussière enrobée des lieux de travail. L’accumulation de fines particules de

poussières poncées pourrait s’auto enflammer et causer un incendie.

• Changer tout disque CFS lorsqu’il oblige l’appareil à tourner trop rapidement. Un tour

par minute élevé causé par un disque CFS usé pourrait causer la séparation du tampon ponceur de la ponceuse, et poser de risques de blessure. Pour toute instruction relative au

changement du disque CFS, se reporter à la section Entretien de l’outil.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent produire de la poussière contenant des produits chimiques susceptibles d’entraîner le cancer, des malformations congénitales ou pouvant être nocifs pour le système reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures à base de plomb,

• la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

• l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (comme

l’arséniate de cuivre et de chrome).

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on effectue ces

travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un endroit bien aéré et

utiliser le matériel de sécurité approprié, tel un masque anti-poussières spécialement conçu

pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres outils

électriques. Porter des vêtements de protection et nettoyer les parties exposées du

corps à l’eau savonneuse. S’assurer de bien se protéger afin d’éviter d’absorber par la

bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière susceptible de causer

des dommages sérieux et permanents au système respiratoire. Toujours utiliser un appareil respiratoire anti-poussières approprié approuvé par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé du visage et du corps.

MISE EN GARDE : Porter un appareil de protection personnel anti-bruit approprié

durant l’utilisation. Sous certaines conditions et pendant toute la durée de l’utilisation, le bruit

émanant de ce produit pourrait contribuer à la perte d’audition.

• L’étiquette apposée sur l’outil peut afficher les symboles suivants. Ces symboles et leurs

définitions sont les suivants :

V ....................volts A ......................ampères

Hz ..................hertz W......................watts

min ................minutes ....................courant alternatif

..............courant continu

n

o ....................aucune option à vide

..................construction de classe II ......................borne de terre

....................symbole d’avertissement .../min ..............tours par minute

CONSERVER CES DIRECTIVES

Description (Fig. 1)

A. Interrupteur Marche/Arrêt D. Sac à poussières

B. Pressostat (D26453) E. Adaptateur de tube d’aspiration

C. Tampon ponceur F. Disque CFS (Fig. 6)

Moteur

Cet outil DEWALT est entraîné par un moteur fabriqué par DEWALT. S’assurer que l’intensité

nominale du cordon d’alimentation correspond à celle indiquée sur la plaque signalétique.

(Volts : 120 C.A. seulement). Une chute de tension de plus de 10 % entraînera une perte de

puissance et une surchauffe. Tous les outils D

EWALT sont soumis à un essai en usine; si cet

outil ne fonctionne pas, on doit d’abord vérifier l’intensité nominale du cordon d’alimentation.

Page 4

Installation des disques abrasifs

Cette ponceuse a été conçue pour fonctionner avec des disques abrasifs de 127 mm (5 po)

avec une configuration de dépoussiérage à 8 trous. Les disques des modèles D26451 et

D26453 sont rattachés par crochets et boucles. Les disques abrasifs pour le modèle D26450

sont auto-adhésifs (PSA).

INSTALLATION DU PAPIER SUR LE TAMPON PONCEUR (FIG. 2)

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retirer ou d’installer une pièce ou un accessoire. S’assurer que l’interrupteur est en

position d’arrêt.

1. Tourner la ponceuse de façon à ce que le tampon ponceur soit sur le dessus.

2. Éliminer toute poussière du tampon vinyle.

3. Maintenir le tampon d’une main pour l’empêcher de tourner.

4. De l’autre main, aligner les trous et placer le disque directement sur le tampon.

REMARQUE : Ne pas utiliser de filtre à poncer (ex. : les filtres utilisés pour poncer le

placoplâtre) directement sur un tampon à crochet et boucle. L’écran ne tiendra pas et endommagera les crochets du tampon. Les crochets du tampon s’useront très rapidement si laissés

en contact avec la surface à travailler pendant le fonctionnement de l’appareil.

Interrupteur (Fig. 3)

Pour mettre l’appareil en marche, appuyer sur le côté de l’interrupteur (A) étanche à la poussière correspondant au symbole « I ». Pour arrêter l’outil, appuyer sur le côté de l’interrupteur

correspondant au symbole « O ».

Bouton de réglage de la vitesse (D26453)

Le bouton de réglage de la vitesse (B), (Fig. 1), permet d’accélérer ou ralentir la vitesse de 7.000

à 12.000 tours par minute. La vitesse optimale de chaque application est une question de

préférence personnelle. Généralement, il est conseillé d’utiliser une vitesse élevée sur des

matériaux durs et basse sur des matériaux plus tendres. L’érosion du matériau augmente avec

la vitesse.

Dépoussiérage (Fig. 4)

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retirer ou d’installer une pièce ou un accessoire. S’assurer que l’interrupteur est en

position d’arrêt.

La ponceuse peut utiliser les deux modes d’élimination de la poussière suivants : un sac à

poussières verrouillable par rotation (D) et un adaptateur de tube d’aspiration intégré (E) pouvant être connecté directement sur un aspirateur d’atelier.

VIDANGE DU SAC À POUSSIÈRE

1. Tout en maintenant la ponceuse, saisir le sac à poussières (D) par son bout le plus près de

la ponceuse et dévisser l’adaptateur de tube d’aspiration (E).

2. Secouer doucement ou tapoter le sac à poussières pour le vider.

3. Reverrouiller le sac à poussières sur l’adaptateur de tube d’aspiration.

Il se peut que toute la poussière ne soit pas évacuée du sac. Cela n’affectera pas les performances de la ponceuse mais réduira l’efficacité d’aspiration de la poussière. Pour restaurer son

rendement d’aspiration, appuyer sur le ressort à l’intérieur du sac à poussière tout en vidant ce

dernier et en le tapotant sur les côtés du réceptacle de récupération utilisé, poubelle ou autre.

MISE EN GARDE : Ne jamais utiliser cet outil sans le système de dépoussiérage en place.

L’évacuation des poussières du ponçage pose des risques au système respiratoire.

FONCTIONNEMENT (Fig. 5)

Pour utiliser la ponceuse, la saisir comme illustré en Figure 5A ou 5B et la mettre en marche.

Déplacer la ponceuse par larges mouvements de balayage sur la surface à poncer, en la laissant effectuer le travail.

Le fait d’appuyer sur l’appareil pendant le ponçage ralentit le rendement et produit une surface

de qualité moindre. Vérifier souvent les progrès du travail, cette ponceuse est capable de poncer le matériau rapidement, surtout avec du papier à gros grains.

L’action orbiculaire aléatoire de la ponceuse permet de poncer dans le sens du grain ou à n’importe quel angle pour la plupart des travaux de ponçage. Pour le meilleur fini possible, commencer avec un papier abrasif à gros grains puis passer graduellement à du papier de plus en

plus fin. Passer l’aspirateur et nettoyer la surface avec un tampon gras entre chaque étape.

Cette ponceuse a été conçue pour poncer dans les endroits étroits ou difficiles d’accès. Sa

petite taille et son poids léger la rendent idéale pour les travaux en hauteur.

La vitesse à laquelle le sac à poussières se remplira dépendra du type de matériau poncé et

de la grosseur de grain du papier. Pour des résultats optimum, vider le sac à poussières

fréquemment. Lors du ponçage de surfaces peintes, (voir les précautions additionnelles suivantes relatives au ponçage de la peinture), il se peut que le papier abrasif s’entartre de peinture. Un pistolet à air chaud convient mieux pour retirer la peinture avant le ponçage. SUIVRE TOUTES LES DIRECTIVES DE SÉCURITÉ INCLUES DANS LE MANUEL DU PISTOLET

À AIR CHAUD.

REMARQUE (D26450 seulement) : Retirer rapidement tout disque abrasif PSA (auto-adhésif)

après toute utilisation. Le papier PSA, si laissé sur le disque après usage, est parfois difficile à

retirer. Pour faciliter le retrait de papier PSA usagé, poncer quelques minutes pour ramollir

l’adhésif avant de changer le disque.

Mesures de précaution concernant le ponçage

de peinture

1. Le ponçage de peintures à base de plomb n’est PAS RECOMMANDÉ puisqu’il est trop difficile de maîtriser la poussière contaminée. Les enfants et les femmes enceintes courent le

plus grand risque d’intoxication par le plomb.

2. Puisqu’il est difficile de savoir, sans effectuer une analyse chimique, si une peinture contient

du plomb, on recommande de suivre les mesures de précaution décrites ciaprès :

SÉCURITÉ PERSONNELLE

1. S’assurer que les enfants et les femme enceintes n’entrent pas dans l’aire de travail avant

qu’elle n’ait été nettoyée à fond.

2. Toute personne qui entre dans l’aire de travail doit porter un masque anti-poussière ou un

appareil respiratoire; le filtre doit être remplacé chaque jour ou lorsque la respiration

devient difficile. Se renseigner auprès de son quincaillier local pour obtenir la liste des

masques anti-poussières approuvés par le NIOSH.

3. NE PAS MANGER, BOIRE OU FUMER sur les lieux de travail pour prévenir l’ingestion

de particules de peinture contaminées. Il est recommandé aux ouvriers de se laver et nettoyer AVANT de manger, boire ou fumer. Ne pas laisser sur les lieux de travail, là où la

poussière pourrait s’y déposer, toute nourriture, boisson, cigarette ou autre produit de

consommation.

RESPECT DE L’ENVIRONNEMENT

1. Enlever la peinture de manière à réduire au minimum la quantité de poussière générée.

2. Sceller les zones où on enlève la peinture au moyen de grandes feuilles de plastique

d’une épaisseur de 4 mils.

3. Effectuer le ponçage de manière à éviter autant que possible de traîner de la poussière

à l’extérieur de l’aire de travail.

ENTRETIEN ET RANGEMENT

1. Passer quotidiennement l’aspirateur sur les lieux de travail et les nettoyer soigneusement

pendant toute la durée du projet de ponçage. Changer fréquemment les filtres d’aspirateur.

2. Recueillir toute toile de protection plastifiée utilisée et s’en défaire avec toute particule de

poussière ou autre débris à éliminer. Les placer dans un contenant pour déchets et s’en

défaire suivant la procédure normale d’élimination des ordures. Pendant le nettoyage,

maintenir éloigné de la zone immédiate de travail les enfants ou les femmes enceintes.

3. Nettoyer soigneusement jouet, meuble lavable ou tout ustensile utilisé par les enfants

avant toute nouvelle réutilisation.

PAPIERS ABRASIFS REQUIS

Modèle de Taille Méthode Configuration

ponceuse de disque d’attachement des trous

D26450 127 mm (5 po) PSA 8 trous

D26451 127 mm (5 po) Crochet et boucle 8 trous

D26453 127 mm (5 po) Crochet et boucle 8 trous

Entretien de l’outil

1. Maintenir la ponceuse aussi propre que possible en la nettoyant avec un chiffon propre et

en y propulsant de l’air toutes les 5 heures d’utilisation.

2. Intégré au système CFS (Controlled Finishing System®), cette ponceuse est équipée

d’un disque remplaçable (F) situé entre le tampon (C) et le corps de la ponceuse (G). Il a

été conçu pour augmenter l’efficacité du système de dépoussiérage et contrôler la vitesse

du tampon lorsque l’appareil n’est en contact avec aucune surface. Ce disque est un objet

périssable et doit être remplacé périodiquement. Remplacer ce disque chaque fois que la

vitesse du tampon augmente dramatiquement lorsque l’appareil perd contact avec la surface de travail.

REMPLACEMENT DU DISQUE CSF (FIG. 6)

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retirer ou d’installer une pièce ou un accessoire. S’assurer que l’interrupteur est en

position d’arrêt.

a. Retirer les trois vis dessous le tampon.

b. Retirer le tampon (C).

c. Retirer le disque CFS (F).

d. Pour installer le nouveau disque CFS, disposer le côté du disque avec le ressort contre

la ponceuse.

e. Aligner les encoches (H) sur le disque CFS avec les rainures sur le corps de la ponceuse.

f. Remettre le tampon et les trois vis. Faire attention à ne pas trop serrer les vis.

3. Ne pas utiliser de produits chimiques ou solvants décapants pour nettoyer l’appareil. Ces

produits pourraient endommager sérieusement les parties plastifiées de la ponceuse.

4. Éviter de surcharger la ponceuse. Toute surcharge aura pour résultat de diminuer la vitesse

et la qualité du fini du travail. L’appareil peut aussi chauffer. Dans cette éventualité, faire

fonctionner la ponceuse à vide une minute ou deux.

5. Si le cordon est enroulé autour de l’appareil après usage, ne pas le serrer pour éviter de tordre le réducteur de tension. Cela permet d’éviter d’endommager le cordon prématurément.

Remplacement des brosses (FIg. 8, 9)

MISE EN GARDE : Arrêter et débrancher l’outil avant d’effectuer un réglage ou de

retirer ou d’installer une pièce ou un accessoire. S’assurer que l’interrupteur est en

position d’arrêt.

POUR REMPLACER LES BROSSES

1. Retirer les trois vis du capuchon puis soulever se dernier (Fig. 8).

2. Tirer le ressort de la brosse (I) vers l’arrière en faisant attention à ne pas le retirer complètement et retirer la brosse usagée.

3. Tirer la tige métallique de la brosse (J) rattachée à la brosse, hors de l’orifice du moteur (K).

4. Insérer la nouvelle tige dans l’orifice du moteur.

5. Toujours en maintenant le ressort de la brosse vers l’arrière, insérer la nouvelle brosse avec

la tige dépassant sur le dessus de la brosse puis relâcher le ressort.

6. Répéter les étapes 1 à 5 pour la deuxième brosse.

7. Remettre le capuchon et resserrer les trois vis. Faire attention à ne pas trop serrer les vis.

8. Toujours remplacer les deux brosses en même temps.

Lubrification

Des roulements auto-lubrifiants sont utilisés dans cet appareil et aucune lubrification périodique

n’est nécessaire. Il est cependant recommandé d’amener ou d’envoyer l’appareil une fois par

an dans un centre de service autorisé pour y être soigneusement nettoyé et inspecté.

ACCESSOIRES

Les accessoires recommandés avec cet outil sont vendus séparément chez votre distributeur

local ou dans les centres de service autorisés. Pour obtenir plus d’information sur les accessoires, communiquer avec D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286, aux États-Unis ou composer le 1 800 433-9258 (1-800-4-D

EWALT).

MISE EN GARDE : L’usage de tout autre accessoire non recommandé avec cet outil peut

présenter un danger.

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ de ce produit, toutes les opérations de réparation,

d’entretien et de réglage doivent être effectuées dans un centre de service autorisé ou par du

personnel qualifié ; on ne doit utiliser que des pièces de rechange identiques.

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un défaut de matériel ou de fabrication pour une période de trois ans à compter de la date d’achat. La présente garantie ne couvre pas les pièces dont la défectuosité a été causée par une usure normale ou l’usage abusif

de l’outil. Pour obtenir de plus amples renseignements sur les pièces ou les réparations couvertes par la présente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258

(1 800 4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne vise pas les dom-

mages causés par des réparations effectuées par un tiers. Cette garantie confère des droits

légaux particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un

état ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

D

EWALT entretiendra l’outil et remplacera les pièces usées au cours d’une utilisation normale et

ce, gratuitement, pendant une période d’un an à compter de la date d’achat, et la

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que ce soit, du rendement de

l’outil électrique, du laser ou de la cloueuse D

EWALT, celui-ci peut le retourner, accompagné

d’un reçu, dans les 90 jours à compter de la date d’achat, pour obtenir un remboursement intégral, sans aucun problème.

REMPLACEMENT GRATUIT DE L’ÉTIQUETTE D’AVERTISSEMENT : En cas de perte ou

d’endommagement des étiquettes d’avertissement, composer le 1 800 433-9258 afin d’en

obtenir de nouvelles sans frais.

Instrucciones de seguridad generales

¡ADVERTENCIA! Lea todas las instrucciones hasta comprenderlas. No

ajustarse a las instrucciones siguientes puede ser causa de choque eléctrico,

incendio o lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

ÁREA DE TRABAJO

• Mantenga el área de trabajo limpia y bien iluminada. Las bancadas desordenadas y las

zonas oscuras propician los accidentes.

• No opere herramientas eléctricas en atmósferas explosivas, como en presencia de

líquidos, gases o polvos inflamables. Las herramientas eléctricas producen chispas que

pueden originar la ignición del polvo o los vapores.

Page 5

• Mientras opere una herramienta eléctrica, mantenga lejos a los observadores, niños y

visitantes. Las distracciones pueden ocasionar que pierda el control

SEGURIDAD ELÉCTRICA

• Las herramientas con conexión a tierra deben conectarse a una toma de corriente

debidamente instalada y con conexión a tierra, de acuerdo con todos los códigos y

ordenanzas aplicables. Nunca quite la pata de conexión a tierra ni modifique el enchufe

en ninguna manera. No emplee ningún adaptador para enchufes. Si tiene alguna duda

acerca de si la toma de corriente está debidamente conectada a tierra, consulte a un

electricista calificado. Si las herramientas presentasen fallas eléctricas o averías, la conex-

ión a tierra ofrece una vía de baja resistencia para alejar la corriente eléctrica del usuario. Sólo

es aplicable a las herramientas de Clase I (con conexión a tierra).

• Las herramientas con doble aislamiento están equipadas con una clavija polarizada

(una pata es más ancha que la otra). Esta clavija se acoplará a un enchufe polarizado

de una sola manera. Si la clavija no se acopla al contacto, inviértala. Si aún así no se

ajusta, comuníquese con un electricista cualificado para que instale un enchufe polarizado apropiado. Nunca cambie la clavija. El doble aislamiento elimina la necesidad de

cables con tres hilos y sistemas de suministro eléctrico con conexión a tierra. Sólo es aplicable a las herramientas de Clase II.

• Evite el contacto del cuerpo con superficies conectadas a tierra, tales como tuberías,

radiadores, registros y refrigeradores. El riesgo de choque eléctrico aumenta si su cuer-

po hace tierra.

• No exponga las herramientas eléctricas a la lluvia o a condiciones de mucha humedad.

Si entra agua en una herramienta eléctrica, aumenta el riesgo de choque eléctrico.

• No maltrate el cable. Nunca tome el cable para transportar la herramienta ni para

desconectarla del enchufe. Mantenga el cable alejado de las fuentes de calor, el aceite,

las orillas afiladas o las piezas en movimiento. Cambie inmediatamente los cables

dañados. Los cables dañados aumentan el peligro de choque eléctrico.

• Cuando opere una máquina herramienta a la intemperie, utilice un alargador marca-

do “W-A” o “W”. Estos alargadores están clasificados para ser usados a la intemperie y

reducen el riesgo de descarga eléctrica. Al usar un alargador, asegúrese de que tenga el

calibre necesario para llevar la corriente que su producto requerirá. Un alargador de un calibre insuficiente causará una caída en la tensión de la línea dando por resultado la pérdida

de energía y sobrecalentamiento. La tabla siguiente muestra el tamaño correcto para utilizar

dependiendo de la longitud del alargador y del amperaje nominal de la placa de identificación. En caso de duda, utilice el de mayor calibre. Cuanto más pequeño es el número del

calibre, más resistente es el alargador.

Calibre mínimo para cordones de extensión

Voltios Longitud total del cordón en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

Amperaje

Más No más Calibre del cordón AWG

de de

0-6 18 16 16 14

SEGURIDAD PERSONAL

• Al utilizar una herramienta eléctrica, esté atento, concéntrese en lo que hace y aplique

el sentido común. No utilice la herramienta si se encuentra fatigado o bajo la influencia de drogas, alcohol o fármacos. Mientras se utilizan herramientas eléctricas, basta un

instante de distracción para sufrir lesiones graves.

• Lleve ropa adecuada. No utilice ropa suelta ni joyas. Recójase el cabello largo.

Mantenga el cabello, la ropa y los guantes apartados de las piezas en movimiento. Las

partes móviles pueden atrapar las prendas de vestir sueltas, las joyas y el cabello. Los orificios de ventilación suelen cubrir piezas en movimiento, por lo que también se deben evitar.

• Evite puestas en marcha accidentales. Asegúrese de que el interruptor esté apagado

antes de enchufar la máquina. Transportar las herramientas con el dedo sobre el interruptor

o enchufarlas con el interruptor encendido favorece los accidentes.

• Antes de poner en marcha la herramienta, retire las llaves de ajuste. Una llave que se

deje en una pieza giratoria de la herramienta puede provocar lesiones.

• No ponga en peligro su estabilidad. Manténgase siempre bien apoyado y equilibrado.

Un buen apoyo y equilibrio permiten controlar mejor la herramienta si se produce algún

imprevisto.

• Utilice el equipo de seguridad. Lleve siempre lentes protectores. Cuando sea adecuado, también se debe usar mascarilla antipolvo, zapatos de suela antideslizante, casco o protectores auditivos.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice abrazaderas u otro elemento adecuado para sujetar y apoyar la pieza de trabajo en una plataforma estable. Sujetar la pieza con la mano o contra el cuerpo es inestable

y facilita la pérdida de control.

• No fuerce la herramienta. Emplee la herramienta correcta para cada aplicación. La

herramienta correcta hace el trabajo mejor y más seguro dentro del rango para el que ha

sido diseñada.

• No utilice la herramienta si el interruptor no la enciende y apaga. Cualquier herramienta

que no pueda controlarse con el interruptor es peligrosa y se debe reparar.

• Desconecte la clavija del enchufe antes de proceder a cualquier ajuste, cambiar un

accesorio o guardar la herramienta. Estas medidas de seguridad preventiva reducen el

riesgo de poner en marcha la herramienta accidentalmente.

• Cuando no las utilice, guarde las herramientas fuera del alcance de los niños o de

cualquier persona no capacitada. Las herramientas son peligrosas en manos de usuar-

ios no capacitados.

• Cuide las herramientas. Conserve las herramientas de corte afiladas y limpias. Unas

herramientas adecuadamente cuidadas y con los bordes de corte afilados se atascan menos

y son más fáciles de controlar.

• Compruebe si las piezas móviles se desalinean o atascan, si hay alguna pieza rota o

cualquier otra circunstancia que pueda afectar la operación de la herramienta. Si la

herramienta está dañada, hágala reparar antes de usarla. Muchos accidentes los provo-

can unas herramientas mal cuidadas.

• Utilice únicamente los accesorios recomendados por el fabricante para su modelo. Un

mismo accesorio puede ser adecuado para una herramienta, pero peligroso si se usa en

otra.

SERVICIO

• El servicio a la herramienta sólo debe realizarlo personal cualificado. El servicio o man-

tenimiento realizados por personal no calificado puede dar como resultado un riesgo de

lesiones.

• Al proceder al mantenimiento de una herramienta, utilice únicamente refacciones

idénticas. Siga las instrucciones de la sección “Mantenimiento” de este manual. La uti-

lización de piezas no autorizadas, o no respetar las instrucciones de mantenimiento, puede

suponer un peligro de choque eléctrico o de lesiones.

Instrucciones de seguridad adicionales para lijadoras

• Los accesorios deben estar clasificados por lo menos para la velocidad recomendada

en la etiqueta de advertencia de la herramienta. Si funcionan a velocidades superiores a

la prevista, los discos y otros accesorios pueden deshacerse y provocar lesiones. Las

especificaciones de los accesorios deben encontrarse a una velocidad de disco superior a

la mínima registrada en la placa nominal de la herramienta.

• Sujete la herramienta por sus empuñaduras aisladas si lleva a cabo una operación en

que la herramienta pueda tocar cables eléctricos ocultos o su propio cable. El contacto

con un cable activo provocará que las piezas metálicas de la herramienta se carguen y que

el operador reciba una descarga eléctrica.

• Al lijar, lleve siempre protección ocular y respiratoria.

• No se recomienda el lijado de pintura con base de plomo. Ver Precauciones para el

lijado de pintura para mayor información antes de lijar pintura.

• No haga funcionar la unidad sin la bolsa de recolección de polvo.

• Limpie su herramienta periódicamente.

• Vacíe la bolsa de recolección de polvo con frecuencia, especialmente cuando lije

superficies recubiertas con resinas como poliuretano, esmalte, laca, etc. Disponga de

las partículas de polvo recubiertas según las pautas del fabricante del acabado o póngalas

en un contenedor de metal con una tapa de metal hermética. Retire las partículas de polvo

recubiertas del local a diario. La acumulación de partículas de polvo provenientes del lijado

fino, puede encenderse y causar incendios.

• Cambie el disco CFS desgastado cuando produzca un índice rpm alto en la herra-

mienta. Los índices rpm altos causados por un disco CFS desgastado pueden resultar en

la separación del disco de lijado de la lijadora, posiblemente causando lesiones corporales. Para obtener instrucciones acerca de cómo cambiar el disco CFS, vea Cuidado de

la herramienta.

ADVERTENCIA: Parte del polvo generado al lijar, serrar, esmerilar y taladrar con máquinas

herramienta, así como al realizar otras actividades del sector de la construcción, contienen

productos químicos que pueden producir cáncer, defectos congénitos u otras afecciones

reproductivas. Ejemplos de esas substancias químicas son:

• plomo procedente de pinturas a base de plomo,

• óxido de silicio cristalino procedente de ladrillos, cemento y otros productos de mampostería y

• arsénico y cromo procedentes de madera tratada químicamente (CCA).

El peligro derivado de estas exposiciones que usted enfrente varía en función de la frecuencia

con que se realice este tipo de trabajo. Para reducir la exposición a esas sustancias químicas:

trabaje en una zona bien ventilada y llevando equipos de seguridad aprobados, como mascarillas antipolvo especialmente diseñadas para filtrar partículas microscópicas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado, esmerilado

y taladrado eléctricos, así como de otras actividades del sector de la construcción.

Lleve ropa protectora y lave con agua y jabón las zonas expuestas. Si permite que el

polvo se introduzca en la boca o los ojos o quede sobre la piel, puede favorecer la absorción

de productos químicos peligrosos

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo lo cual puede

causar lesiones respiratorias serias y permanentes y otros tipos de lesión. Siempre use protección respiratoria aprobada por NIOSH/OSHA para la exposición al polvo. Dirija las partículas en

dirección opuesta a su cara y cuerpo.

PRECAUCIÓN: Utilice una protección auditiva apropiada durante el uso. En determi-

nadas condiciones y con utilizaciones prolongadas, el ruido generado por este producto

puede favorecer la pérdida de audición.

• La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y sus

definiciones son los siguientes:

V ................voltios A ..............amperios

Hz ..............hertzios W ..............vatios

min ............minutos ............corriente alterna

..........corriente directa

n

o ............velocidad sin carga

..............construcción de Clase II ..............terminal con conexión a tierra

................símbolo de alerta de seguridad .../min........revoluciones por minuto

COMPONENTES (Fig. 1)

A. Conmutador de encendido y apagado D. Bolsa de recolección de polvo

B. Cuadrante de control de velocidad (D26453) E. Adaptador para aspiradoras

C. Disco de lijado F. Disco CFS (Fig. 6)

Motor

Su herramienta DEWALT tiene un motor DEWALT. Asegúrese que el suministro eléctrico concuerde con el indicado en la placa nominal (voltios, sólo 120 CA). Una reducción de voltaje

superior a 10% provocará pérdida de potencia y sobrecalentamiento. Todas las herramientas

D

EWALT vienen probadas de fábrica; si esta herramienta no funciona, revise el abastecimiento

eléctrico.

Fijación de los discos de lijado

Su lijadora está diseñada para usar discos de lijado de 127 mm (5 pulg.) con un patrón de

extracción de polvo de 8 huecos. Los discos de lijado para el D26451 y D26453 se adhieren

con velcro. Los discos de lijado para el D26450 se adhieren usando un adhesivo a presión

(PSA).

PARA FIJAR EL PAPEL A LA ALMOHADILLA DE LIJADO (FIG. 2)

PRECAUCIÓN: Apague y desenchufe la herramienta antes de hacer cualquier ajuste

o de quitar o instalar accesorios. Asegúrese que el conmutador esté en posición OFF

(apagada).

1. Ponga la lijadora boca abajo para que la almohadilla de lijado quede hacia arriba.

2. Limpie el polvo de la cara de la almohadilla de vinilo.

3. Sujete la almohadilla con una mano para que no gire.

4. Con la otra mano, alinee los huecos y ponga el disco directamente sobre la almohadilla.

NOTA: No use una rejilla de lijado (por ejemplo, las rejillas usadas para lijar muro seco) directamente sobre la almohadilla de velcro. La rejilla no se sujetaría y dañaría los ganchos de la

almohadilla. Los ganchos de la almohadilla se desgastarán muy rápido si se dejan en contacto

con la superficie de trabajo con la herramienta funcionando.

Conmutador (Fig. 3)

Para encender la unidad, presione el conmutador protegido contra polvo (A) por el lado con el

símbolo “I”. Para apagarla, presione el lado del conmutador con el símbolo “O”.

Cuadrante de control de velocidad (D26453)

El cuadrante de control de velocidad (B), que aparece en la Figura 1, le permite aumentar o disminuir la velocidad de 7,000-12,000 órbitas por minuto. El ajuste de velocidad óptimo para cada

aplicación depende en gran medida de su preferencia personal. En general, es preferible un

valor alto en materiales duros y un valor menor en los blandos. La velocidad de eliminación de

material aumenta con la velocidad.

Extracción de polvo (Fig. 4)

PRECAUCIÓN: Apague y desenchufe la herramienta antes de hacer cualquier ajuste

o de quitar o instalar accesorios. Asegúrese que el conmutador esté en posición OFF

(apagada).

Su lijadora tiene dos métodos de recolección de polvo: una bolsa de recolección de polvo

enroscable (D) y un adaptador para aspiradoras integrado (E) el cual puede ser conectado

directamente a un sistema de aspiradoras de taller.

PARA VACIAR LA BOLSA DE POLVO

1. Mientras sujeta la lijadora, sostenga la bolsa de recolección de polvo (D) del extremo más

cercano a la lijadora y desenrosque el adaptador de la aspiradora (E).

2. Sacuda o golpee ligeramente la bolsa de recolección de polvo para vaciarla.

3. Enrosque la bolsa de recolección de polvo en el adaptador para aspiradoras.

Existe la posibilidad de que no todo el polvo se salga solo de la bolsa. Esto no afectará el

desempeño de la lijadora pero sí reducirá la eficiencia en la recolección de polvo de la lijadora.

Para restaurar la eficiencia de recolección de polvo de su lijadora, presione el resorte dentro de

la bolsa de recolección de polvo cuando la esté vaciando y golpéela contra el lado del basurero

o recipiente de polvo.

PRECAUCIÓN: Nunca opere estas herramientas si no tiene el colector de polvo instalado.

La expulsión de polvo de lijado podría provocar un riesgo para la respiración.

OPERACIÓN (FIG. 5)

Para operar su lijadora, tómela como aparece en las Figuras 5A o 5B y gírela para encenderla.

Mueva la unidad con desplazamientos de barrido amplios a lo largo de la superficie a lijar, dejando que la lijadora haga el trabajo.

Apretar hacia abajo la herramienta mientras se lija disminuye de hecho la velocidad de eliminación y genera una superficie de menor calidad. Verifique los resultados a menudo: esta lijadora puede eliminar material muy rápidamente, especialmente si utiliza papel grueso.

PAPELES DE LIJA REQUERIDOS

Modelo de Tamaño de Método de Patrón de

lijadora disco adhesión huecos

D26450 127 mm (5 pulg.) PSA 8 Huecos

D26451 127 mm (5 pulg.) Velcro 8 Huecos

D26453 127 mm (5 pulg.) Velcro 8 Huecos

Page 6

La acción orbital aleatoria de la lijadora le permitirá lijar en la dirección del grano, o en cualquier

ángulo respecto a él, en la mayoría de los trabajos de lijado. Para que el acabado sea el mejor

posible, empiece con papel de lija grueso y cambie progresivamente a otros cada vez más

finos. Pase una aspiradora por la superficie y límpiela con un trapo antiestático entre pasada y

pasada. La lijadora ha sido diseñada para lijar zonas pequeñas o de difícil acceso. Su reducido tamaño y su poco peso la hacen ideal para trabajos en altura.

La velocidad a la cual se llena la bolsa de colección de polvo variará de acuerdo al tipo de material a lijar y el grosor del papel de lija. Para conseguir los mejores resultados, limpie la bolsa con

frecuencia. Al lijar superficies pintadas (consulte las precauciones adicionales siguientes al

respecto) puede suceder que el papel de lija se cargue y tape con la pintura. Es mucho mejor

usar una pistola térmica para eliminar la pintura antes de lijar. SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD DEL MANUAL DE INSTRUCCIONES DE LA PISTOLA TÉRMICA.

NOTA (sólo D26450): Si utiliza discos de lijado PSA, retire pronto el disco al terminar la

operación. Con el papel PSA, si el disco se deja puesto durante el almacenamiento de la herramienta, a veces se hace difícil de retirar. Para facilitar la retirada del papel de PSA viejo, lije

unos minutos para ablandar la capa adhesiva antes de cambiar el disco.

Precauciones a tomar cuando lije pintura

1. El lijado de pinturas con base de plomo NO SE RECOMIENDA debido a la dificultad de control del polvo contaminado. El envenenamiento por plomo es más peligroso para niños y

mujeres embarazadas.

2. Ya que es difícil identificar si una pintura contiene plomo o no, sin antes hacer un análisis

químico, le recomendamos que se tomen las siguientes precauciones cuando lije cualquier

pintura:

SEGURIDAD PERSONAL

1. Ningún niño o mujer embarazada debería entrar al área de trabajo donde se está lijando

la pintura hasta que se termine de limpiar el área.

2. Toda persona que entre al área de trabajo debe usar una máscara antipolvo o respirador.

El filtro debería ser reemplazado a diario o cuando el usuario tenga dificultades para respirar. Visite su ferretería local para obtener una máscara antipolvo apropiada, aprobada

por N.I.O.S.H.

3. NO se debe COMER, BEBER ni FUMAR en la zona de trabajo, para evitar la ingestión

de partículas de pintura contaminadas. Los trabajadores deberán lavarse bien ANTES de

comer, beber o fumar. No debe dejarse comida, bebida ni tabaco en la zona de trabajo,

donde el polvo se podría posar sobre ellos.

SEGURIDAD MEDIOAMBIENTAL

1. La pintura debe ser quitada de tal manera que se minimice la cantidad de polvo gen-

erada.

2. Aquellas áreas en las que se está quitando pintura deberían ser selladas con láminas de

plástico de 4 mm de grosor.

3. El lijado debería hacerse de modo que se reduzca la cantidad de polvo de pintura que se

lleve afuera.

LIMPIEZA Y ELIMINACIÓN

1. Todas las superficies de la zona de trabajo deben de ser aspiradas y limpiadas en pro-

fundidad todos los días mientras dure el proyecto de lijado. Las bolsas de filtrado de la

aspiradora se deben cambiar con frecuencia.

2. Disponga de cubiertas plásticas junto con cualquier astilla de polvo u otro desecho del

proceso de lijado. Deberán colocarse en un recipiente para desechos sellado y eliminarse

de acuerdo con los procedimientos de eliminación de la basura normal. Durante la

limpieza, mantenga alejados a niños y mujeres embarazadas de la zona de trabajo.

3.Todos los juguetes, muebles lavables y utensilios usados por niños deberán lavarse a

fondo antes de volverlos a usar.

Cuidado de la herramienta

1. Mantenga la lijadora tan limpia como sea posible, pasándole un trapo limpio y soplando aire

a través de ella cada cinco horas de funcionamiento.

2. Como parte del sistema de acabado controlado CFS (Controlled Finishing System®), su

lijadora viene con un disco cambiable (F) ubicado entre la almohadilla (C) y el cuerpo de la

lijadora (G). Este disco está diseñado para aumentar la eficacia de recolección del polvo y

para controlar la velocidad de la almohadilla cuando la unidad se aparta de la superficie de

trabajo. El disco es, por diseño, una pieza consumible y será necesario sustituirlo de vez en

cuando. Habrá que cambiarlo si, al levantar la unidad de la superficie de trabajo, la velocidad de la almohadilla aumenta dramáticamente.

PARA SUSTITUIR SU DISCO CFS (FIG. 6)

PRECAUCIÓN: Apague y desenchufe la herramienta antes de hacer cualquier

ajuste o de quitar o instalar accesorios. Asegúrese que el conmutador esté en

posición OFF (apagada).

a. Retire los tres tornillos de la parte inferior de la almohadilla.

b. Retire la almohadilla (C).

c. Retire el disco CFS gastado (F).

d. Para instalar el disco CFS nuevo, ponga el lado del disco que tiene el resorte, contra la

lijadora.

e. Alinee las muescas (H) del disco CFS con las juntas del cuerpo de la lijadora.

f. Reponga la almohadilla y los tres tornillos. Tenga cuidado de no ajustar los tornillos

demasiado.

3. No utilice químicos o solventes fuertes para limpiar la herramienta. Estos productos podrían

dañar gravemente los componentes de plástico de la lijadora.

4. Evite sobrecargar la lijadora. La sobrecarga reducirá considerablemente la velocidad y la

calidad de acabado del trabajo. Además, podría sobrecalentarse la herramienta. En tal

caso, haga funcionar la lijadora sin carga durante uno o dos minutos.

5. Si enrolla el cable alrededor de la herramienta al guardarla, deje un buen lazo de cable suelto, para que la tensión no deforme el protector. Así se evita que el cable falle prematuramente.

Sustitución de las escobillas (Fig. 8, 9)

PRECAUCIÓN: Apague y desenchufe la herramienta antes de hacer cualquier ajuste

o de quitar o instalar accesorios. Asegúrese que el conmutador esté en posición OFF

(apagada).

PARA CAMBIAR LAS ESCOBILLAS

1. Retire los tres tornillos de la tapa superior y levante la tapa, como lo muestra la Figura 8.

2. Tire el resorte de la escobilla (I) hacia atrás (cuidando de no sacarla completamente) y

deslice de él la escobilla vieja.

3. Tire del alambre de la escobilla (J) el cual está conectado a la escobilla, para sacarlo del

campo inductor del motor (K).

4. Enchufe el alambre nuevo de la escobilla de vuelta en el campo inductor del motor.

5. Mientras sostiene aún el resorte de la escobilla, deslice la nueva escobilla con el alambre

saliendo de la parte de arriba de la escobilla y suelte el resorte de la escobilla.

6. Repita los pasos 1–5 para la segunda escobilla.

7. Cambie la tapa superior y ajuste los tres tornillos. Tenga cuidado de no ajustar los tornillos

demasiado.

8. Sustituya siempre ambas escobillas.

Lubricación

La herramienta incorpora cojinetes autolubricantes, por lo que no requiere lubricación periódica. Sin embargo, se recomienda que una vez al año un centro de servicio proceda a una inspección y limpieza a fondo de la herramienta.

ACCESORIOS

Los accesorios recomendados para su herramienta están disponibles por un cargo adicional en

su distribuidor local o en el centro de servicio autorizado. Si necesita ayuda para encontrar un

accesorio para su herramienta, contacte a: D

EWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286 (1-800-4-DEWALT).

PRECAUCIÓN: La utilización de cualquier accesorio no recomendado para esta herramien-

ta puede ser peligrosa.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán hacerse reparaciones, mantenimiento y ajustes de esta herramienta en los centros autorizados de servicio D

EWALT u otras

organizaciones autorizadas. Estas organizaciones prestan servicio a las herramientas D

EWALT

y emplean siempre refacciones legitimas D

EWALT.

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: ________________________ Mod./Cat.: _______________________

Marca: ____________________________ Núm. de serie:___________________________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: ________________________________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

__________________________________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, así como en materiales y mano de obra empleados para su fabricación. Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin

cargo alguno para el cliente, incluyendo mano de obra, así como los gastos de transportación

razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por

el establecimiento comercial donde se adquirió el producto, de no contar con ésta, bastará la

factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompaña;