Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D’UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO

Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

D25980

Heavy-Duty Pavement Breaker

Brise-béton robuste

Martillo rompedor para trabajos pesados

Page 2

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-D

EWALT (1-800-433-9258)

General Safety Rules

WARNING! To reduce risk of injury, user must read instruction manual.

Failure to follow all instructions listed below may result in electric shock, fire

English

and/or serious injury. The term “power tool” in all of the warnings listed below

refers to your mains-operated (corded) power tool or battery-operated (cordless)

power tool.

SAVE THESE INSTRUCTIONS

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock. Have damaged cords repaired by authorized service center immediately. Make sure your extension cord is in good condition. Use

only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles

that accept the tool’s plug.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

Make sure your extension cord is in good condition. Use of a cord suitable for outdoor

use.

use reduces the risk of electric shock. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. The following table shows

the correct size to use depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

610 18161412

10 12

12 16 14

Not More

Than

120V

240V

25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

16 16 14 12

12 Not Recommended

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts. Air vents often cover moving parts and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tools operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking

into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Instructions for Pavement Breakers

• Hold power tools by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the operator.

1

Page 3

Be certain that the material being worked does not conceal electric or gas service and that

their locations have been verified with the utility companies.

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

Keep a firm grip on the tool at all times. Do not attempt to operate this tool without

holding it with both hands. Operating this tool with one hand will result in loss of control.

Breaking through or encountering hard materials such as re-bar may be hazardous as well.

Tighten the side handle securely before use.

• Wear safety goggles or other eye protection. Hammering operations cause chips to

fly. Flying particles can cause permanent eye damage. Wear a dust mask or respirator for

applications that generate dust. Ear protection may be required for most applications.

• Do not operate this tool for long periods of time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure

by taking frequent rest periods.

• Do not recondition bits yourself. Chisel reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels could cause injury.

• Wear gloves when operating tool or changing bits. Accessible metal parts on the tool and

bits may get extremely hot during operation. Small bits of broken material may damage bare

hands.

• Never lay the tool down until the bit has come to a complete stop. Moving bits could

cause injury.

• Do not strike jammed bits with a hammer to dislodge them. Fragments of metal or

material chips could dislodge and cause injury.

• Slightly worn chisels can be resharpened by grinding.

• Keep the power cord away from the bit. Do not wrap the cord around any part of your

body. An electric cord wrapped around a bit may cause electric shock.

WARNING: ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: ALWAYS use respiratory protection. All users and bystanders must wear respi-

ratory protection that conforms to NIOSH/OSHA/MSHA standards.

WARNING: ALWAYS use eye protection. Everyday eyeglasses are NOT safety glasses. All

users and bystanders must wear eye protection that conforms to ANSI Z87.1.

WARNING: ALWAYS wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V .................. volts A .................... amperes

Hz ................ hertz W ................... watts

min .............. minutes

............ direct current

.................. alternating current

n

o ................... no load speed

................Class I Construction ................... earthing terminal

.................... (grounded) ................... safety alert symbol

................. Class II Construction …/min ............ revolutions or reciprocation

.................... (double insulated) ....................... per minute

BPM ............ beats per minute

SAVE THESE INSTRUCTIONS

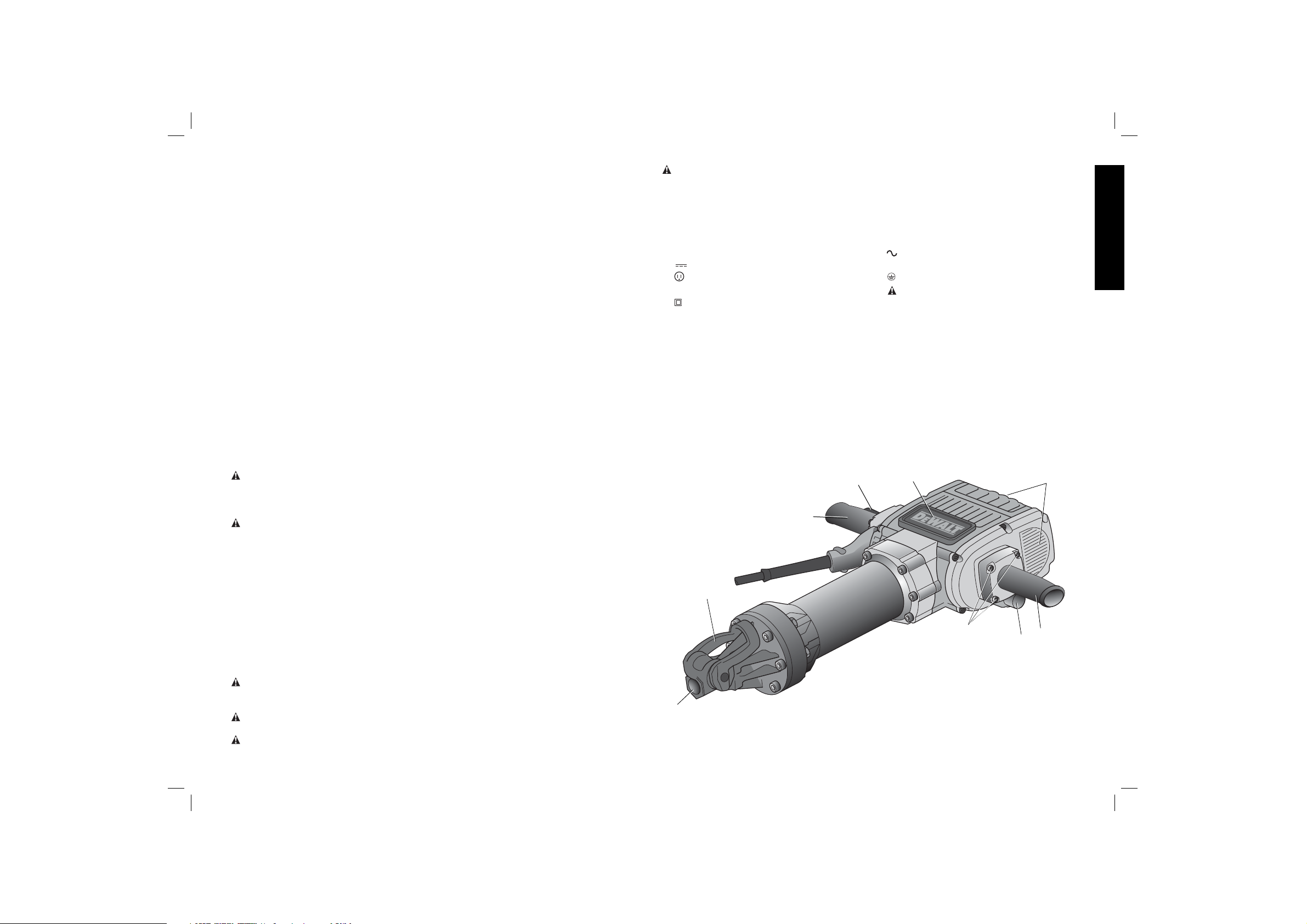

COMPONENTS (FIG. 1)

NOTE: Left and right describes the location of the part with the operator standing behind the

pavement breaker with the front of the tool facing away.

A. ON/OFF switch F. Active vibration control

B. Right side handle G. Front of tool

C. Left side handle H. Hex head screws

D. Bit retainer I. Air vents

E. Bit holder

FIG. 1

B

D

E

2

A

G

H

C

F

English

I

Page 4

ASSEMBLY

Side Handle (Fig. 1)

CAUTION: Always operate the tool with the side handle properly assembled. Hold tool

with both hands to maximize control.

Attach left side handle (C) with four hex head screws (H, supplied). Tighten with hex wrench

supplied.

English

FEATURES (FIG. 1)

The D25980 Pavement Breaker has been designed for professional heavy-duty demolition,

applications in concrete, brick, stone and other masonry materials.

ON/OFF Switch

The weight of the hand will active/deactivate the ON/OFF switch. Firmly grasp pavement breaker

while applying pressure with the right hand to turn the pavement breaker on. To turn the tool off,

remove the right hand to relieve pressure from the switch.

Soft Start

Holding tool by both handles depress the ON/OFF switch (A). The Soft Start feature allows the

impact rate to build up more slowly preventing the bit or point from bouncing around on the surface. To stop the pavement breaker pull up on hand to relieve pressure from the switch to turn

the tool OFF.

SHOCKS™ – Active Vibration Control

The active vibration control (F) helps absorb the vibration transmitted to the user. This improves

user comfort and safety during operation.

Hold the tool firmly with one hand on the left side handle (C) and the other hand on the right

side handle (B). Using the right hand apply weight to the ON/OFF switch (A) to turn on. Apply

only enough pressure to the work area to engage the active vibration control. Applying too much

pressure will not make the pavement breaker chisel faster and the active vibration control will

not engage.

OPERATION

CAUTION: Always hold tool with both hands to maximize control. Allow the hammer to do the

work. Excessive added force shortens the life of the hammer and the accessory.

Bits

WARNING: ALWAYS turn off tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments or accessories. Such pre-

ventative safety measures reduce the risk of starting the tool accidentally.

WARNING: ALWAYS wear gloves when you change bits. Accessible metal parts on the tool

and bits may get extremely hot during operation.

WARNING: To reduce the risk of injury, only DEWALT recommended accessories should be

used with this product. A variety of bits are available from your local retailer.

NOTE: Insert bits with the front of tool (G) facing up.

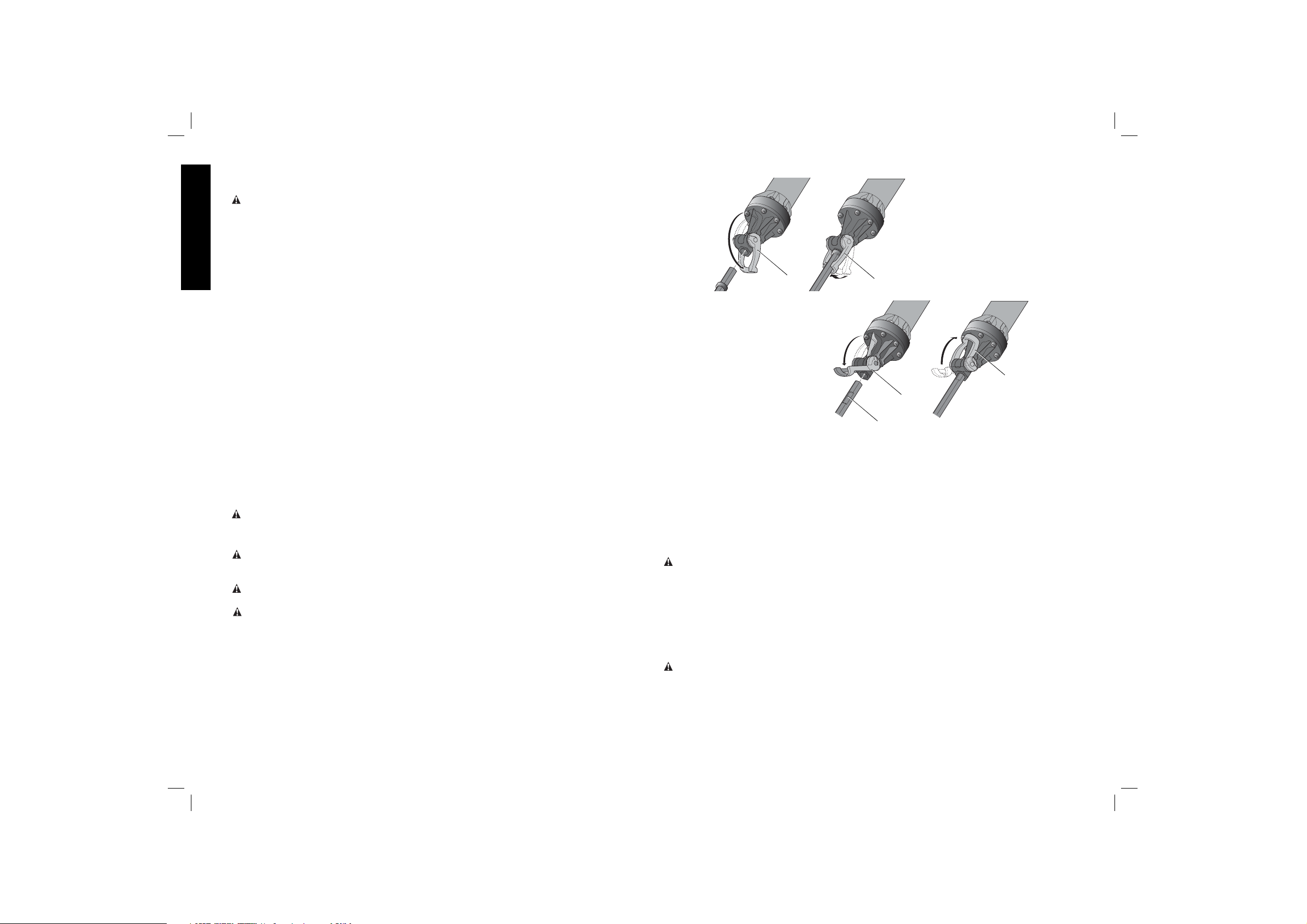

TO INSERT AIR STEEL BITS (RING-ONLY BIT)

1. Pull bit retainer (D) open as shown in Figure 2a.

2. Insert bit into bit holder (E) and close bit retainer onto bit as shown in Figure 2b.

TO INSERT TOOL STEEL BITS

(NOTCH-ONLY BIT)

1. Pull bit retainer (D) open as shown in Figure 3a.

2. Insert bit with notch (J) facing up into bit holder (E).

3. Pull bit retainer up to lock into position as shown in Figure 3b.

Use either of the above methods to insert combination steel (notch and ring bit)

FIG. 2A

FIG. 2B

D

FIG. 3A

D

FIG. 3B

D

D

J

To Operate

NOTE: Use sharp drill bits only.

1. Insert bit as described in Bits.

2. Standing behind the tool with both hands on the handles, depress the ON/OFF switch to start

the tool. Hold handles firmly to control tool.

3. Remove hand to relieve pressure from the ON/OFF switch to turn the tool OFF.

4. Place hands under handles and lift up to move tool.

MAINTENANCE

Cleaning

CAUTION: When cleaning, use only a damp cloth on plastic parts. Many household cleaners

contain chemicals which could seriously damage plastic. Also, do not use gasoline, turpentine,

lacquer or paint thinner, dry cleaning fluids or similar products which may seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Keep the air vents (I) clear and regularly clean the housing with a soft cloth.

Lubrication

The tool requires no additional lubrication.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk of

injury, only D

Recommended accessories for use with your tool are available at extra cost from your local

service center. If you need any assistance in locating any accessory, please contact D

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-D

433-9258) or visit our website www.dewalt.com.

EWALT recommended accessories should be used with this product.

EWALT

EWALT (1-800-

3

Page 5

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including

brush inspection and replacement) should be performed by a D

EWALT authorized service center or other qualified service personnel. Always use identical

a D

replacement parts.

EWALT factory service center,

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear

or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.

dewalt.com or call 1-800-4-D

sories or damage caused where repairs have been made or attempted by others. This warranty

gives you specific legal rights and you may have other rights which vary in certain states or

provinces.

In addition to the warranty, D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

D

during the first two years after purchase.

If you are not completely satisfied with the performance of your D

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for

a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the packaging,

call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-D

EWALT for a free replacement

EWALT (1-800-433-9258). This warranty does not apply to acces-

EWALT tools are covered by our:

2 YEAR FREE SERVICE

90 DAY MONEY BACK GUARANTEE

EWALT Power Tool, Laser, or

Specifications

Voltage ............................. 120 V~

Current ............................. 15 A

Frequency ........................ 60 Hz

Power input ...................... 1800 W

Beats per minute ............. 870

Tool holder .......................28 mm

Weight .............................. 31 kg

English

4

Page 6

SI VOUS AVEZ DES QUESTIONS OU VOULEZ NOUS FAIRE PART DE VOS COMMENTAIRES

CONCERNANT CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSEZ SANS FRAIS

LE : 1 800 433-9258.

Règles générales de sécurité concernant les outils

à piles

AVERTISSEMENT ! Afin de réduire le risque de blessures, l’utilisateur doit

lire le mode d’emploi.

Tout manquement aux directives suivantes pose des risques de choc électrique,

d'incendie et/ou de blessure grave. Le terme « outil électrique » dans tous les

avertissements ci-après se rapporte à votre outil électrique à alimentation sur

secteur (avec fil) ou par piles (sans fil).

CONSERVER CES DIRECTIVES

1) SÉCURITÉ - AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner un outil électrique dans une atmosphère explosive, en

présence par exemple de poussières, gaz ou liquides inflammables. Les outils élec-

triques peuvent engendrer des étincelles qui pourraient enflammer toute émanation ou

poussière ambiante.

c) Tenir les enfants, ou toute autre personne, éloignés pendant l’utilisation d’un outil

électrique. Toute distraction pourrait vous faire perdre la maîtrise de ce dernier.

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit correspondre à la prise murale. Ne jamais modi-

fier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec un outil

électrique mis à la terre. L’utilisation de fiches d’origine et de prises appropriées réduira

Français

les risques de choc électrique.

b) Éviter tout contact corporel avec des éléments mis à la terre comme tuyaux, radia-

teurs, cuisinières ou réfrigérateurs. Les risques de choc électrique augmentent lorsque

le corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. Toute pénétration d’un

outil électrique par un liquide augmente les risques de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour trans-

porter, tirer ou débrancher un outil électrique. Protéger le cordon de la chaleur,

de l’huile et de tout bord tranchant ou pièce mobile. Les cordons endommagés ou

emmêlés augmentent les risques de choc électrique. Faire réparer immédiatement les

cordons endommagés par un centre de réparation autorisé. S’assurer que la rallonge est

en bon état. N’utiliser que des rallonges trifilaires munies de fiches tripolaires et des prises

tripolaires acceptant la fiche de l’outil.

e) Lors de l’utilisation d’un outil électrique à l’extérieur, n’utiliser que des ral-

longes conçues pour l’extérieur.

L’utilisation d’une rallonge conçue pour l’extérieur réduit les risques de choc électrique. En cas d’utilisation d’une rallonge, s’assurer que les valeurs nominales de

la rallonge utilisée correspondent bien à celles de l’outil alimenté. L’usage d’une

rallonge de calibre insuffisant causera une chute de tension entraînant perte de

puissance et surchauffe. Le tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge et l’intensité nominale indiquée sur la plaque signalétique. En cas de

doutes, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter de

courant.

S’assurer que la rallonge est en bon état.

Calibre minimum pour rallonge

Volts

Intensité nominale

Plus de Pas plus de AWG

0 6 5,5 (18) 4,9 (16) 4,9 (16) 4,3 (14)

6 10 5,5 (18) 4,9 (16) 4,3 (14) 3,7 (12)

10 12 4,9 (16) 4,9 (16) 4,3 (14) 3,7 (12)

12 16 4,3 (14) 3,7 (12) Non recommandé

3) SÉCURITÉ PERSONNELLE

a) Rester vigilant en tout temps et faire preuve de jugement pendant l’utilisation

d’un outil électrique. Ne pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Tout moment d’inattention pen-

dant l’utilisation d’un outil électrique pose des risques de blessure grave.

b) Utiliser le matériel de sécurité approprié. Toujours porter des lunettes de protection.

Le fait de porter un masque anti-poussières, des chaussures antidérapantes, un casque

de sécurité ou des protecteurs auditifs lorsque la situation le requiert réduira les risques de

blessure.

c) Éviter tout démarrage accidentel. S’assurer que l’interrupteur est en position

d’arrêt avant tout branchement. Transporter un outil le doigt sur l’interrupteur ou

brancher un outil électrique alors que l’interrupteur est en position de marche invite les

accidents.

d) Retirer toute clé de réglage avant de démarrer l’outil. Une clé laissée sur une pièce

rotative d’un outil électrique pose des risques de blessure.

e) Ne pas effectuer de travaux hors de portée. Les pieds doivent rester bien ancrés au

sol afin de maintenir son équilibre en tout temps. Cela permet de mieux maîtriser l’outil

électrique dans les situations imprévues.

f) Porter des vêtements appropriés. Ne pas porter de vêtements amples ni de bijoux.

Maintenir cheveux, vêtements et gants éloignés des pièces mobiles. Vêtements

amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces mobiles.

Prendre des précautions autour des évents car ils recouvrent des pièces mobiles.

g) Lorsque un dispositif de connexion à un système de dépoussiérage ou d’élimination

est fourni, s’assurer qu’il est connecté et utilisé correctement. L’utilisation de ces dis-

positifs peut réduire les risques engendrés par les poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser l’outil approprié au travail en cours. L’outil

approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse pour laquelle il a

été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout appareil dont

l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou le bloc-piles de l’outil électrique avant de faire

tout réglage ou changement d’accessoire, ou avant de ranger ce dernier. Ces mesures

préventives réduisent les risques de démarrage accidentel de l’appareil.

d) Après usage, ranger les outils électriques hors de la portée des enfants, et ne per-

mettre à aucune personne n’étant pas familière avec un outil électrique (ou son

manuel d’instruction) d’utiliser ce dernier. Les outils peuvent être dangereux entre les

mains des novices.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement, qu’elles sont en bon état et ne sont affec-

5

120V

240V

Longueur totale du cordon

en mètres (en pieds)

7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

Page 7

tées d’aucune condition susceptible de nuire au bon fonctionnement de l’outil. En

cas de dommage, faire réparer l’outil électrique avant toute nouvelle utilisation. Bien

des accidents sont causés par des outils mal entretenus.

f) Maintenir tout outil de coupe bien aiguisé et propre. Les outils de coupe bien entretenus

et affûtés sont moins susceptibles de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses accessoires, mèches, etc., conformément aux présen-

tes directives et suivant la manière prévue pour ce type particulier d’outil électrique,

en tenant compte des conditions de travail et du travail à effectuer. L’utilisation d’un

outil électrique pour toute opération autre que celle pour laquelle il a été conçu est dangereuse.

5) SERVICE

a) Faire entretenir les outils électriques par un réparateur qualifié en n’utilisant que des

pièces de rechange identiques. Cela permettra d’assurer l’intégrité de l’outil électrique et

la sécurité de l’utilisateur.

Autres directives de sécurité pour le brise-béton

•

Tenir l'outil par sa surface de prise isolée dans une situation où l'outil de coupe peut

entrer en contact avec un câblage caché ou avec son propre cordon d'alimentation.

Tout contact avec un fil « sous tension » mettra « sous tension » les pièces métalliques de

l'outil et causera un choc électrique à l'opérateur de l'outil.

S’assurer que le matériau, sur lequel les travaux seront exécutés, ne cache pas de conduite

électrique ou de gaz et que leur emplacement a été vérifié avec les entreprises de services

publiques.

• Porter des protecteurs d'oreilles. Une exposition au bruit peut entraîner une perte

auditive.

• Utiliser les poignées auxiliaires fournies avec l'outil. Une perte de maîtrise de l'outil peut

entraîner des blessures corporelles.

Tenir fermement l'outil en tout temps. Ne pas utiliser l'outil sans le tenir des deux

mains. Faire fonctionner cet outil d'une seule main risque de provoquer la perte de maîtrise

de l'outil. Il peut aussi être dangereux de percer ou de tomber sur des matériaux durs comme

une barre d'armature. Bien serrer la poignée latérale avant d'utiliser l'outil.

• Porter des lunettes de sécurité ou une autre protection oculaire. Les opérations de per-

cussion peuvent projeter les copeaux. Les particules projetées peuvent endommager les yeux

irréversiblement. Porter un masque antipoussières ou un appareil respiratoire. La plupart des

applications peuvent demander l'utilisation d'un dispositif de protection des oreilles.

• Ne pas faire fonctionner cet outil durant de longues périodes. Les vibrations causées par

la percussion du marteau peuvent être nuisibles pour vos mains et vos bras. Utiliser des gants

pour amortir davantage les vibrations et limiter l'exposition à l'outil par de fréquentes périodes

de repos.

• Ne pas remettre à neuf les mèches vous-même. La remise à neuf du burin doit être réalisée

par un spécialiste autorisé. Les burins mal remis à neuf peuvent causer des blessures.

• Porter des gants pour utiliser l'outil ou pour changer les mèches. Les pièces métalliques

accessibles de l'outil et les mèches peuvent devenir extrêmement chaudes durant le fonctionnement de l'outil. De petits morceaux de matériau qui se détachent peuvent endommager

les mains nues.

• Ne jamais déposer l'outil tant que la mèche ne s'est pas complètement arrêtée. Les

mèches mobiles peuvent provoquer des blessures.

• Ne pas frapper sur les mèches coincées avec un marteau pour les déloger. Des frag-

ments de métal ou des copeaux de matériau peuvent se déloger et causer des blessures.

• Les burins légèrement usés peuvent être réaffûtés par le meulage.

• Tenir le cordon d’alimentation loin de la mèche. Ne pas enrouler le cordon autour de

toute partie du corps. Un cordon d’alimentation enroulé autour d’une mèche risque de pro-

voquer un choc électrique.

AVERTISSEMENT : TOUJOURS porter un équipement de protection homologué :

• protection oculaire conforme à la norme ANSI Z87.1 (CAN/CSA Z94.3);

• protection auditive ANSI S12.6 (S3.19);

• protection des voies respiratoires conformes aux normes NIOSH/OSHA/MSHA.

AVERTISSEMENT : certaines poussières produites par les activités de ponçage, sciage,

meulage, perçage et autres activités de construction peuvent contenir des produits chimiques

pouvant causer le cancer, des anomalies congénitales ou d'autres problèmes liés aux fonctions

reproductrices. Voici quelques exemples de ces produits chimiques :

• le plomb contenu dans les peintures à base de plomb;

• la silice cristalline de la brique, du ciment et d'autres produits de maçonnerie; et

• l'arsenic et chrome provenant de bois traité chimiquement.

Les risques reliés à l'exposition à ces poussières varient selon la fréquence à laquelle l'utilisateur

travaille avec ce type de matériaux. Pour réduire votre exposition à ces produits chimiques :

travailler dans un endroit bien ventilé et porter un équipement de sécurité approuvé comme un

masque antipoussières conçu spécialement pour filtrer les particules microscopiques.

• Éviter le contact prolongé avec les poussières produites par les activités de ponçage,

sciage, meulage, perçage et autres activités de construction. Porter des vêtements de

protection et laver les parties du corps exposées avec une solution d'eau et de savon.

Laisser la poussière pénétrer dans la bouche, les yeux ou reposer sur la peau peut favoriser

l'absorption de produits chimiques nocifs.

AVERTISSEMENT : l'utilisation de cet outil peut produire et/ou dégager des poussières qui

risqueraient de causer des problèmes respiratoires graves et permanents ou d'autres problèmes

médicaux. Toujours porter un appareil respiratoire approuvé par la NIOSH/OSHA pour se protéger de la poussière. Diriger les particules loin du visage et du corps.

AVERTISSEMENT : TOUJOURS utiliser une protection respiratoire. Tous les utilisateurs

et les personnes à proximité doivent porter une protection respiratoire conforme aux normes de

la NIOSH, OSHA et MSHA.

AVERTISSEMENT : TOUJOURS utiliser une protection oculaire. Les lunettes de vue ne

constituent PAS des lunettes de sécurité. Tous les utilisateurs et personnes à proximité doivent

porter une protection oculaire conforme à la norme ANSI Z87.1.

AVERTISSEMENT : TOUJOURS porter une protection auditive appropriée conformément

à la norme ANSI S12.6 (S3.19) lors de l’utilisation du produit. Dans certaines conditions et selon

la durée d’utilisation, le bruit émis par ce produit peut contribuer à une perte auditive.

• L'étiquette apposée sur votre outil peut comprendre les symboles suivants. Les symboles et

leurs définitions sont indiqués ci-après :

V ............. volts A ...............ampères

Hz ........... hertz W ..............watts

min ......... minutes

....... courant continu

........... Construction de classe I ..............borne de terre

............... (mis à la terre) .............. symbole d'alerte à la sécurité

............ Construction de classe II …/min .......Rotations ou alternance par minute

............... (à double isolation) BPM ..........coups par minute

.............courant alternatif

n

o ..............vitesse à vide

CONSERVER CES DIRECTIVES

Français

6

Page 8

COMPOSANTS (FIG. 1)

REMARQUE : toutes les indications qui font référence à la droite ou la gauche correspondent au

point de vue de l’opérateur qui est debout, derrière le brise-béton. L’avant de l’outil est à l’opposé

de l’opérateur.

A. Interrupteur marche/arrêt F. Correcteur antivibrations actif

B. Poignée droite G. Avant de l’outil

C. Poignée gauche H. Vis à tête hexagonale

D. Dispositif de retenue de l’embout I. Évents

E. Porte-embout

FIG. 1

A

B

D

G

H

F

Français

E

SHOCKSTM – dispositif antivibrations actif

Le dispositif antivibrations actif (F) permet d’absorber les vibrations transmises à l’utilisateur.

Ainsi, le confort et la sécurité de l’utilisateur sont accrus durant le fonctionnement de l’outil.

Tenir fermement l’outil, une main étant sur la poignée gauche (C) et l’autre main, sur la poignée

droite (B). À l’aide de la main droite, enfoncer l’interrupteur MARCHE/ARRÊT (A) pour allumer

l’outil. Exercer uniquement la pression nécessaire à la zone des travaux pour engager le dispositif

antivibrations actif. Trop de pression n’accélèrera pas le trépan ordinaire du brise-béton, et le

dispositif antivibrations actif ne s’engagera pas.

FONCTIONNEMENT

MISE EN GARDE : tenir l’outil des deux mains pour obtenir une plus grande maîtrise de l’outil.

I

Laisser le marteau faire le travail. Toute force excessive réduit la durée de vie du marteau et de

l’accessoire.

Trépans

AVERTISSEMENT : TOUJOURS éteindre l’outil et le débrancher avant d’effectuer des

réglages, d’enlever ou de poser des pièces ou des accessoires. Une telle mesure de sécurité

préventive réduit le risque de mettre l’outil en marche accidentellement.

AVERTISSEMENT : TOUJOURS porter des gants pour changer les trépans. Les pièces

métalliques accessibles de l’outil et les trépans peuvent devenir extrêmement chauds durant le

fonctionnement de l’outil.

AVERTISSEMENT : pour réduire le risque de blessures, utiliser exclusivement les accessoires

EWALT recommandés avec le présent produit. Divers trépans sont offerts chez votre détaillant

D

local.

REMARQUE : insérer les trépans alors que le devant de l’outil (G) est redressé.

C

POUR INSÉRER DES TRÉPANS MÉTALLIQUES PNEUMATIQUES (TRÉPAN À ANNEAU

SEULEMENT)

1. Retirer le dispositif de retenue du trépan (D) comme il est indiqué à la figure 2a.

2. Insérer le trépan dans le porte-mèche (E), puis fermer le dispositif de retenue sur le trépan

comme le montre la figure 2b.

FIG. 2A

FIG. 2B

ASSEMBLAGE

Poignée latérale (Fig. 1)

MISE EN GARDE : TOUJOURS utiliser l’outil avec la poignée latérale bien assemblée. Tenir

l’outil des deux mains pour obtenir une plus grande maîtrise de l’outil.

Fixer la poignée gauche (C) à l’aide de quatre vis à tête hexagonale (H, fournies). Les serrer avec

la clé hexagonale fournie.

CARACTÉRISTIQUES (FIG. 1)

Le brise-béton D25980 a été conçu pour la démolition industrielle et pour être utilisé sur le béton,

la brique, la pierre et d’autres matériaux de maçonnerie.

Interrupteur MARCHE/ARRÊT

Le poids de la main activera/désactivera l’interrupteur MARCHE/ARRÊT. Saisir fermement le

brise-béton tout en exerçant une pression de la main droite pour allumer le brise béton. Pour

éteindre l’outil, retirer la main droite pour enlever la pression exercée sur l’interrupteur.

Démarrage souple

En tenant l’outil des deux mains, enfoncer l’interrupteur MARCHE/ARRÊT (A). La fonction de

démarrage souple permet une augmentation plus lente de la vitesse de percussion, ce qui évite

au trépan ou à la pointe de rebondir sur la surface. Pour arrêter le brise béton, soulever la main

pour libérer la pression exercée sur l’interrupteur et éteindre l’outil.

D

FIG. 3A

7

D

FIG. 3B

D

D

J

Page 9

POUR INSÉRER DES TRÉPANS MÉTALLIQUES (TRÉPAN À ENCOCHE SEULEMENT)

1. Retirer le dispositif de retenue du trépan (D) comme le montre la figure 3a.

2. Insérer le trépan de manière à ce que l’encoche (J) soit vers le haut, dans le portemèche (E).

3. Relever le dispositif de retenue du trépan pour le verrouiller en place comme le montre la

figure 3b.

Utiliser une des méthodes précédentes pour insérer les trépans métalliques combinés (encoche

et anneau).

Fonctionnement

REMARQUE : utiliser uniquement des trépans tranchants.

1. Insérer le trépan comme il est décrit à la section Trépans.

2. Debout derrière l’outil, les deux mains sur les poignées, enfoncer l’interrupteur MARCHE/

ARRÊT pour démarrer l’outil. Tenir fermement les poignées pour maîtriser l’outil.

3. Retirer la main pour libérer la pression exercée sur l’interrupteur MARCHE/ARRÊT et ainsi

éteindre l’outil.

4. Mettre les mains sous les poignées, puis soulever l’outil pour le déplacer.

ENTRETIEN

Nettoyage

MISE EN GARDE : lors du nettoyage, utiliser exclusivement un chiffon humide sur les com-

posants en plastique. Bon nombre de nettoyants domestiques renferment des produits chimiques

pouvant grandement endommager le plastique. En outre, ne pas utiliser d’essence, de térébenthine, de diluant à peinture ou à laque, de liquides pour nettoyage à sec ou tout autre produit

semblable qui pourrait endommager gravement les composants en plastique. Ne jamais laisser

de liquide pénétrer dans l’outil et n’immerger aucune partie de l’outil dans un liquide.

Tenir les grilles d’aération (I) libres de toute obstruction et nettoyer régulièrement le boîtier avec

un chiffon doux.

Lubrification

L’outil ne requiert pas d’autre lubrification.

Accessoires

AVERTISSEMENT : puisque les accessoires autres que ceux offerts par DEWALT n’ont pas

été testés avec ce produit, l’utilisation de ceux-ci avec l’outil pourrait s’avérer dangereuse. Pour

réduire le risque de blessures, utiliser exclusivement les accessoires DEWALT recommandés

avec le présent produit.

Les accessoires recommandés pour être utilisés avec l'outil sont disponibles auprès du centre

de réparation de votre région. Pour toute demande d'assistance pour trouver un accessoire,

contacter D

composer le 1(800) 4-D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, États-Unis,

EWALT (1-800-433-9258) ou visiter notre site Web à www.dewalt.com.

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l'entretien et les réglages

(y compris l'inspection et le remplacement de la brosse) doivent être réalisés par un centre de

réparation en usine D

réparation professionnel. Toujours utiliser des pièces de rechange identiques.

EWALT, un centre de réparation autorisé DEWALT ou par un personnel de

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un défaut de matériel ou de fabrication pour une période de trois ans à compter de la date d’achat. La présente garantie ne couvre pas les pièces dont la défectuosité a été causée par une usure normale ou l’usage abusif de

l’outil. Pour obtenir de plus amples renseignements sur les pièces ou les réparations couvertes

par la présente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne vise pas les dommages

causés par des réparations effectuées par un tiers. Cette garantie confère des droits légaux

particuliers à l’acheteur, mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état

ou d’une province à l’autre.

En plus de la présente garantie, les outils D

SERVICE D’ENTRETIEN GRATUIT DE 2 ANS

EWALT entretiendra l’outil et remplacera les pièces usées par une utilisation normale, et ce,

D

gratuitement, en tout temps, pendant deux ans à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que ce soit, du rendement de

l’outil électrique, du laser ou de la cloueuse D

d’un reçu, dans les 90 jours à compter de la date d’achat, pour obtenir un remboursement

intégral, sans aucun problème.

AMÉRIQUE LATINE : Cette garantie ne s'applique aux produits vendus en Amérique latine.

Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique présente dans

l'emballage, appeler l'entreprise locale ou consulter le site Web pour les informations relatives

à cette garantie.

REMPLACEMENT GRATUIT DE L'ÉTIQUETTE : Si vos étiquettes d'avertissement deviennent illisibles ou sont manquantes, composez le 1-800-4-D

de remplacement gratuite.

EWALT sont couverts par notre :

EWALT, celui-ci peut le retourner, accompagné

EWALT pour obtenir une étiquette

Fiche technique

Tension ...............................120 V~

Courant ...............................15 A

Fréquence ...........................60 Hz

Puissance absorbée ...........1 800 W

Frappe par minute ..............870

Porte-outil ............................28 mm

Poids ...................................31 kg

Français

8

Page 10

Reglas de seguridad generales

¡ADVERTENCIA! Para reducir el riesgo de lesiones, el usuario debe leer el

manual de instrucciones.

El incumplimiento de todas y cada una de las instrucciones descritas debajo

puede provocar descarga eléctrica, incendio o lesiones graves. El término

“herramienta eléctrica” incluido en todas las advertencias descritas a

continuación hace referencia a su herramienta eléctrica operada con corriente

(alámbrica) o a su herramienta eléctrica operada con baterías (inalámbrica).

GUARDE ESTAS INSTRUCCIONES

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga su área de trabajo limpia y bien iluminada. Los accidentes abundan en las

áreas de trabajo desordenadas u oscuras.

b) No opere máquinas herramienta en ambientes explosivos, tales como en presencia

de líquidos, gases o polvos inflamables. Las máquinas herramienta generan chispas

que pueden inflamar el polvo o los gases.

c) No use máquinas herramienta en presencia de niños u otras personas circunstantes.

Las distracciones pueden hacerle perder el control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de las máquinas herramienta deben poder acoplarse a la toma de cor-

riente. Jamás modifique el enchufe de ninguna manera. No emplee adaptadores de

enchufe con máquinas herramienta conectadas a tierra. Los enchufes no modificados

y las tomas de corriente que correspondan al enchufe reducirán el riesgo de descarga

eléctrica.

b) Evite el contacto corporal con superficies conectadas a tierra, tales como tuberías,

radiadores, cocinas y refrigeradores. Existe un mayor riesgo de descarga eléctrica

cuando su cuerpo está conectado a tierra.

c) No exponga máquinas herramienta a condiciones lluviosas o húmedas. Si entra agua

a la máquina herramienta, aumentará el riesgo de descarga eléctrica.

d) No abuse del cable. Jamás transporte, arrastre o desenchufe la máquina herramienta

por el cable. Mantenga el cable alejado de fuentes de calor, aceite, bordes afilados o piezas en movimiento. Los cables dañados o enredados aumentan el riesgo de

descarga eléctrica. Repare los cables dañados en un centro de mantenimiento autorizado de

inmediato. Verifique que su alargador esté en buenas condiciones. Utilice sólo alargadores

de 3 hilos con enchufes de 3 patas, con conexión a tierra y tomas de corriente de 3 polos

que acepten el enchufe de la herramienta.

e) Cuando opere una máquina herramienta a la intemperie, use un alargador

diseñado para uso a la intemperie. Verifique que su alargador esté en buenas condicio-

nes. El uso de un alargador diseñado para uso a la intemperie reduce el riesgo de descarga

eléctrica. Cuando use un alargador, asegúrese de usar uno de un calibre suficiente como

para cargar con la corriente que requerirá su producto. Un alargador de menor calibre

causará una caída en el voltaje de la línea lo que resultará en pérdida de potencia y sobrecalentamiento. El siguiente cuadro muestra el tamaño correcto a utilizar, dependiendo del

largo del cable y el amperaje nominal. En caso de duda, utilice el de mayor calibre. Mientras

menor el número del calibre, mayor la capacidad del cable.

Español

Calibre mínimo para juegos de cables

Capacidad nominal

en amperios

Desde Hasta AWG

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 No recomendado

3) SEGURIDAD PERSONAL

a) Manténgase alerta, fíjese en lo que está haciendo y utilice su sentido común cuando

opere una máquina herramienta. No utilice una máquina herramienta si está cansado

o bajo la influencia de drogas, alcohol o medicamentos Sólo hace falta un momento de

distracción durante la operación de máquinas herramienta para causar lesiones corporales

serias.

b) Use equipo de seguridad. Utilice siempre protección ocular. El uso de un equipo de

seguridad apropiado a las condiciones de trabajo, tal como máscaras antipolvo, calzado

de seguridad anti-derrapante, cascos o protección auditiva, reducirá la posibilidad de sufrir

lesiones corporales.

c) Evite encender la máquina herramienta en forma accidental. Verifique que el

conmutador esté apagado antes de enchufar la máquina herramienta. El sujetar una

máquina herramienta con el dedo en el conmutador o enchufar máquinas herramienta con

el conmutador encendido se presta para que ocurran accidentes.

d) Retire toda llave de ajuste antes de encender la máquina herramienta. Si se deja

alguna llave en una pieza giratoria de la máquina herramienta, podría provocar lesiones.

e) No se sobreextienda. Manténgase siempre bien apoyado y equilibrado. Esto permite

tener un mayor control de la máquina herramienta en situaciones inesperadas.

f) Vístase debidamente. No se ponga ropa suelta o joyas. Mantenga su pelo, ropa y

guantes alejados de piezas móviles. La ropa suelta, las joyas y el pelo largo pueden

quedar atrapados en las piezas móviles. Los orificios de ventilación suelen cubrir piezas en

movimiento, por lo que también se deben evitar.

g) Si la máquina herramienta viene con algún dispositivo de conexión para la extrac-

ción y colección de polvo, asegúrese que este sea debidamente conectado y

utilizado. El uso de estos dispositivos puede reducir los peligros relacionados a la gen-

eración de polvo.

4) USO Y CUIDADO DE LA MÁQUINA HERRAMIENTA

a) No fuerce la máquina herramienta. Use la máquina herramienta correcta para su apli-

cación. La máquina herramienta apropiada hará un trabajo mejor y más seguro si se usa

de la forma para la cual fue diseñada.

b) No use la máquina herramienta si el conmutador no puede encenderla y apagarla.

Cualquier máquina herramienta que no pueda ser controlada con el conmutador es

peligrosa y debe ser reparada.

c) Desenchufe la máquina herramienta de la toma de corriente y/o de la unidad de

alimentación antes de ajustarla, cambiar de accesorio o guardarla. Estas medidas

de seguridad preventiva reducen el riesgo de poner en marcha la máquina herramienta

accidentalmente.

d) Guarde su máquina herramienta fuera del alcance de niños cuando no la esté

usando y no permita que personas que no estén familiarizadas con la máquina

herramienta o estas instrucciones la usen. Las máquinas herramienta son peligrosas en

manos de personas no capacitadas.

9

Voltios Largo total del cable en metros (en pies)

120V

240V

7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

Page 11

e) Mantenga su máquina herramienta. Revise la máquina herramienta para verificar

que no esté mal alineada, que sus piezas móviles no estén trabadas o rotas y que no

exista otra condición que pudiera afectar su operación. Si está dañada, haga reparar

la máquina herramienta antes de utilizarla. Muchos accidentes son causados por usar

máquinas herramienta que no han sido bien mantenidas.

f) Mantenga máquinas herramienta que son usadas para cortar afiladas y limpias. Las

máquinas herramienta de corte debidamente mantenidas y afiladas tienen menos probabilidades de trabarse y son más fáciles de controlar.

g) Use la máquina herramienta, sus accesorios, etc., en cumplimiento con estas instruc-

ciones y en la manera para la cual la máquina herramienta fue diseñada, tomando

en cuenta las condiciones de trabajo y el trabajo a realizar. El uso de una máquina

herramienta para operaciones fuera de aquellas para las que fue diseñada podría resultar

en una situación peligrosa.

5) SERVICIO

a) Haga reparar su máquina herramienta por un técnico de reparación calificado,

utilizando sólo repuestos originales. Esto garantizará la seguridad de la máquina

herramienta.

Instrucciones de seguridad adicionales para los Martillos

rompedores

•

Sostenga la herramienta por las superficies de agarre aisladas cuando realice una oper-

ación en la que la herramienta de corte pueda tocar cables eléctricos ocultos o el cable

de ésta. El contacto con un cable con corriente eléctrica hará que las partes expuestas de la

herramienta tengan corriente y que el operador reciba una descarga eléctrica.

Asegúrese de que el material a trabajar no contenga cableados o tuberías de gas ocultos,

cuyas ubicaciones deben haber sido constatadas con las empresas de servicios públicos correspondientes.

• Use protectores auditivos. La exposición al ruido puede ocasionar la pérdida de la

audición.

• Use los mangos auxiliares que se suministran con la herramienta. La pérdida del control

podría ocasionar lesiones personales.

Sujete la herramienta firmemente en todo momento. No intente hacer funcionar esta

herramienta sin sostenerla con ambas manos. Si intenta hacerla funcionar con una sola

mano, podría perder el control de la herramienta. También podría ser peligroso perforar o

encontrar materiales duros, como barras de refuerzo. Ajuste firmemente el mango lateral

antes de utilizar la herramienta.

• Use lentes de seguridad u otra protección similar para los ojos. Al martillar se producen

astillas. Las partículas volátiles pueden provocar lesiones oculares permanentes. Utilice una

máscara para polvo o una mascarilla de respiración en aplicaciones que generen polvo. La

mayoría de las aplicaciones pueden requerir protección auditiva.

• No haga funcionar esta herramienta durante períodos prolongados. La vibración

que produce la acción de percusión puede ser perjudicial para las manos y los brazos.

Use guantes que provean amortiguación extra y limite la exposición tomando descansos

frecuentes.

• No reacondicione las brocas usted mismo. El reacondicionamiento del cincel debe

ser realizado por un especialista autorizado. Los cinceles reacondicionados de manera incorrecta pueden provocar lesiones.

• Use guantes cuando utilice la herramienta o cambie las brocas. Mientras la herramienta

se encuentra en funcionamiento, las piezas metálicas accesibles de la misma y las brocas

pueden sobrecalentarse. Los trozos pequeños de material roto pueden dañar las manos sin

guantes.

• Nunca apoye la herramienta hasta que la broca se haya detenido completamente. Las

brocas en movimiento podrían provocar lesiones.

• No golpee las brocas atascadas con un martillo para desatascarlas. Los fragmentos de

metal o astillas del material podrían desprenderse y provocar lesiones.

• Los cinceles levemente gastados pueden afilarse con una esmeriladora.

• Mantenga el cable eléctrico alejado de la broca. No enrosque el cable alrededor de ninguna parte del cuerpo. Un cable eléctrico enroscado alrededor de una broca puede provocar

una descarga eléctrica.

ADVERTENCIA: UTILICE SIEMPRE equipos de seguridad certificados:

• Protección para los ojos ANSI Z87.1(CAN/CSA Z94.3)

• Protección auditiva según la norma ANSI S12.6 (S3.19)

• Protección respiratoria según las normas NIOSH/OSHA/MSHA.

ADVERTENCIA: Algunas partículas originadas al lijar, aserrar, amolar, taladrar y realizar otras

actividades de construcción contienen productos químicos que producen cáncer, defectos de

nacimiento y otros problemas reproductivos. Algunos ejemplos de estos productos químicos

son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería, y

• el arsénico y el cromo de la madera con tratamiento químico.

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este

tipo de trabajo. Para reducir la exposición a estos productos químicos, se recomienda trabajar

en áreas bien ventiladas y usar equipos de seguridad aprobados, como las máscaras para polvo

especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con las partículas de polvo originadas al lijar, aserrar,

esmerilar, taladrar y realizar demás actividades de la construcción. Use indumentaria

protectora y lave las áreas expuestas con agua y jabón. Evite que el polvo entre en la

boca y en los ojos o se deposite en la piel, para impedir la absorción de productos químicos

nocivos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar partículas de polvo,

que pueden causar lesiones respiratorias permanentes y graves u otras lesiones. Use siempre

protección respiratoria apropiada para la exposición al polvo aprobada por el Instituto Nacional

de Salud y Seguridad Ocupacional de EE.UU. y la Administración de Salud y Seguridad

Ocupacional de EE.UU. (NIOSH y OSHA respectivamente, por sus siglas en inglés). Aleje la cara

y el cuerpo del contacto con las partículas.

ADVERTENCIA: UTILICE siempre protección respiratoria. Todos los usuarios y especta-

dores deben utilizar protección respiratoria conforme con las normas NIOSH/OSHA/MSHA.

ADVERTENCIA: Utilice SIEMPRE protección para los ojos. Los anteojos de uso diario NO

son lentes de seguridad. Todos los usuarios y espectadores deben utilizar protección para los

ojos conforme con las normas ANSI Z87.1.

ADVERTENCIA: Durane el uso SIEMPRE utilice una protección auditiva adecuada que

cumpla con la norma ANSI S12.6 (S3.19). Bajo ciertas circunstancias y según el período de

uso, el ruido producido por este producto puede contribuir a la pérdida de audición.

• La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y sus definiciones son los siguientes:

V ............. voltios A ...............amperios

Hz ........... hertz W ..............vatios

min ......... minutos

....... corriente directa

........... Construcción Clase I ..............terminal a tierra

............... (con conexión a tierra) ..............símbolo de alerta de seguridad

.............corriente alterna

n

o ..............velocidad sin carga

Español

10

Page 12

............ Construcción Clase II …/min .......Revoluciones o reciprocidad por minuto

............... (con aislamiento doble) BPM ..........golpes por minuto

GUARDE ESTAS INSTRUCCIONES

COMPONENTES (FIG. 1)

NOTA: Izquierda y derecha describen la ubicación de la pieza con el operador parado detrás del

martillo rompedor y el frente de la herramienta en dirección opuesta a él.

A. Interruptor de encendido/apagado F. Control activo de vibración

B. Mango lateral derecho G. Frente de la herramienta

C. Mango lateral izquierdo H. Tornillos de cabeza hexagonal

D. Dispositivo de retención de la broca I. Orificios de ventilación

E. Portabrocas

FIG. 1

A

B

D

G

H

F

I

C

Arranque suave

Si sostiene la herramienta con ambos mangos se oprime el interruptor de ENCENDIDO/

APAGADO (A). La función de arranque suave permite que la velocidad de impacto se acumule

más lentamente para evitar que la broca o punta rebote en la superficie. Para detener el martillo,

tire con la mano para liberar la presión del interruptor para APAGAR la herramienta.

Control activo de vibración SHOCKS™

El control activo de vibración (F) absorbe la vibración que se transmite al usuario. Esto mejora la

comodidad del usuario y la seguridad durante el funcionamiento.

Sostenga firmemente la herramienta con una mano por el mango del lado izquierdo (C) y la

otra mano en el mango del lado derecho (B). Con la mano derecha presione el interruptor de

ENCENDIDO/APAGADO (A) para encender la herramienta. Aplique sólo la presión suficiente en

el área de trabajo para activar el control activo de vibración. Si se aplica demasiada presión, la

herramienta no cincelará más rápido y no se activará el control activo de vibración.

FUNCIONAMIENTO

PRECAUCIÓN: Sostenga la herramienta con ambas manos para un máximo control. Permita

que la herramienta realice el trabajo. Aplicar una fuerza excesiva puede acortar la vida útil del

martillo y del accesorio.

Brocas

ADVERTENCIA SIEMPRE apague la herramienta y desconéctela de la fuente de alimen-

tación antes de realizar ajustes o de retirar o instalar cualquier dispositivo o accesorios.

Estas medidas de seguridad preventivas reducen el riesgo de encender la herramienta en forma

accidental.

ADVERTENCIA: SIEMPRE use guantes cuando cambie las brocas. Mientras la herramienta

se encuentra en funcionamiento, las piezas metálicas accesibles de la misma y las brocas

pueden sobrecalentarse.

ADVERTENCIA: Para reducir el riesgo de lesiones, con este producto deben usarse sólo

los accesorios DEWALT recomendados. Una amplia variedad de brocas está disponible en su

comercio minorista local.

NOTA Inserte las brocas con la parte frontal de la herramienta (G) hacia arriba.

FIG. 2A

FIG. 2B

E

ENSAMBLAJE

Mango lateral (Fig. 1)

PRECAUCIÓN: Opere siempre la herramienta con el mango lateral montado correctamente.

Sostenga la herramienta con ambas manos para un máximo control.

Instale el mango del lado izquierdo (C) con cuatro tornillos de cabeza hexagonal (H, suministrados) Ajuste con una llave hexagonal suministrada.

CARACTERÍSTICAS (FIG. 1)

El Martillo Rompedor D25980 está diseñado especialmente para demoliciones para trabajo

pesados, aplicaciones en hormigón, ladrillos, piedras y otros materiales de mampostería.

Interruptor de ENCENDIDO/APAGADO (ON/OFF)

El peso de la mano activará o desactivará el interruptor de ENCENDIDO/APAGADO. Sujete

Español

el martillo rompedor con firmeza mientras ejerce presión con la mano derecha para encender

el martillo. Para apagar la herramienta, retire la mano derecha para liberar la presión del

interruptor.

11

D

FIG. 3A

D

FIG. 3B

D

D

J

Page 13

PARA INSERTAR AIRE EN LAS BROCAS DE ACERO (BROCA DE UN SÓLO ANILLO)

1. Tire para abrir el dispositivo de retención de la broca (D) como se observa en la Figura 2.

2. Inserte la broca en el portabrocas (E) y cierre el dispositivo de retención en la broca como se

observa en la Figura 2b.

PARA INSERTAR BROCAS DE ACERO DE LA HERRAMIENTA (BROCA DE UNA MUESCA)

1. Tire para abrir el dispositivo de retención de la broca (D) como se observa en la

Figura 3a.

2. Inserte la broca con la muesca (J) hacia arriba en el portabrocas (E).

3. Tire del dispositivo de retención hacia arriba para trabarlo en su posición como se observa

en la Figura 3b.

Use cualquiera de los métodos anteriores para insertar la combinación del acero (broca de anillo

y muesca)

Para operar

NOTA: Utilice solamente brocas de taladro afiladas.

1. Inserte la broca como se detalla en la sección Brocas.

2. Párese detrás de la herramienta con ambas manos en los mangos y oprima el interruptor de

ENCENDIDO/APAGADO para encenderla. Sostenga los mangos firmemente para controlar

la herramienta.

3. Retire la mano para liberar la presión del interruptor de ENCENDIDO/APAGADO para

APAGAR la herramienta.

4. Coloque las manos por debajo de los mangos y levante para mover la herramienta.

MANTENIMIENTO

Limpieza

PRECAUCIÓN: Sólo use una tela humedecida para limpiar las partes plásticas. Muchos lim-

piadores para uso doméstico pueden contener sustancias químicas que podrían dañar el plástico

considerablemente. Tampoco utilice gasolina, aguarrás, barniz o solvente, líquidos para limpieza en

seco o productos similares, que podrían dañar seriamente las piezas de plástico. Nunca permita que

penetre líquido dentro de la herramienta ni sumerja ninguna de las piezas en un líquido. Mantenga

limpios los conductos de ventilación (I) y limpie la caja en forma regular con un paño húmedo.

Lubricación

La herramienta no necesita lubricación adicional.

Accesorios

ADVERTENCIA: debido a que no se han probado con este producto otros accesorios

que no sean los que ofrece D

reducir el riesgo de lesiones, con este producto deben usarse sólo los accesorios D

EWALT, el uso de dichos accesorios podría ser peligroso. Para

EWALT

recomendados.

Los accesorios que se recomiendan usar con su herramienta están disponibles a un costo adicional en su centro de servicio local. Si usted necesita ayuda para encontrar un accesorio para

su herramienta, contacte a: D

21286, llame al 1-800-4-D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

EWALT (1-800-433-9258) o visite nuestro sitio web www.dewalt.com.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán hacerse reparaciones, mantenimiento y ajustes de esta herramienta en los centros autorizados de servicio D

organizaciones autorizadas. Estas organizaciones prestan servicio a las herramientas D

y emplean siempre refacciones legitimas D

EWALT.

EWALT u otras

EWALT

PARA REPARACIÓN Y SERVICIO DE SUS HERRAMIENTAS ELÉCTRICAS, FAVOR DE

DIRIGIRSE AL CENTRO DE SERVICIO MÁS CERCANO

CULIACAN, SIN

Av. Nicolás Bravo #1063 Sur - Col. Industrial Bravo (667) 7 12 42 11

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero No.831 - Col. Centro (81) 8375 2313

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. Madero 139 Pte. - Col. Centro (442) 214 1660

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES LLAME AL: (55) 5326 7100

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: _______________________ Mod./Cat.: ________________________

Marca: _______________________________ Núm. de serie:_________________________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: ________________________________________

Nombre y domicilio del distribuidor donde se adquirió el producto:_________________________

_________________________________________________________________________

Este producto está garantizado por un año a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, así como en materiales y mano de obra empleados para su fabricación. Nuestra garantía incluye la reparación o reposición del producto y/o componentes sin

cargo alguno para el cliente, incluyendo mano de obra, así como los gastos de transportación

razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y esta póliza sellada por el

establecimiento comercial donde se adquirió el producto, de no contar con ésta, bastará la factura

de compra.

EXCEPCIONES

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompaña;

• Cuando el producto hubiese sido alterado o reparado por personas distintas a las enlistadas al final de este certificado.

Español

12

Page 14

Anexo encontrará una relación de sucursales de servicio de fábrica, centros de servicio autorizados y franquiciados en la República Mexicana, donde podrá hacer efectiva su garantía y adquirir

partes, refacciones y accesorios originales.

Garantía limitada por tres años

DEWALT reparará, sin cargo, cualquier falla que surja de defectos en el material o la fabricación

del producto, por hasta tres años a contar de la fecha de compra. Esta garantía no cubre fallas

de las piezas causadas por su desgaste normal o abuso a la herramienta. Para mayores detalles

sobre la cobertura de la garantía e información acerca de reparaciones realizadas bajo garantía,

visítenos en www.dewalt.com o dirígase al centro de servicio más cercano. Esta garantía no

aplica a accesorios o a daños causados por reparaciones realizadas o intentadas por terceros.

Esta garantía le otorga derechos legales específicos, además de los cuales puede tener otros

dependiendo del estado o provincia en que se encuentre.

Además de la garantía, las herramientas D

SERVICIO GRATUITO DE 2 AÑOS

EWALT realiza el mantenimiento de la herramienta y reemplaza las piezas gastadas tras el

D

uso normal, sin costo alguno, en cualquier momento durante los primeros dos años después de

la compra.

GARANTÍA DE REEMBOLSO DE SU DINERO POR 90 DÍAS

Si no está completamente satisfecho con el desempeño de su máquina herramienta, láser o clavadora DEWALT, cualquiera sea el motivo, podrá devolverlo hasta 90 días de la fecha de compra

con su recibo y obtener el reembolso completo de su dinero – sin necesidad de responder a

ninguna pregunta.

AMÉRICA LATINA: Esta garantía no se aplica a los productos que se venden en América

Latina. Para los productos que se venden en América Latina, debe consultar la información de

la garantía específica del país que viene en el empaque, llamar a la compañía local o visitar el

sitio Web a fin de obtener esa información.

REEMPLAZO GRATUITO DE LAS ETIQUETAS DE ADVERTENCIA: Si las etiquetas de advertencia se tornan eligibles o se pierden, llame al 1-800-4-D

alguno.

EWALT están cubiertas por:

EWALT para reemplazarlas sin costo

Especificaciones

Voltaje ........................................120 V ~

Corriente ....................................15 A

Frecuencia .................................60 Hz

Entrada ......................................1800 W

Goples por minuto ..................... 870

Soporte de la herramienta ........28 mm

Peso ...........................................31 kg

Español

13

Page 15

Page 16

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (OCT06) Form No. 491663-01 D25980

Copyright © 2002, 2005, 2006 D

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box

configuration; and the array of lozenge-shaped humps on the surface of the tool.

EWALT

Loading...

Loading...