Page 1

D25980

Page 2

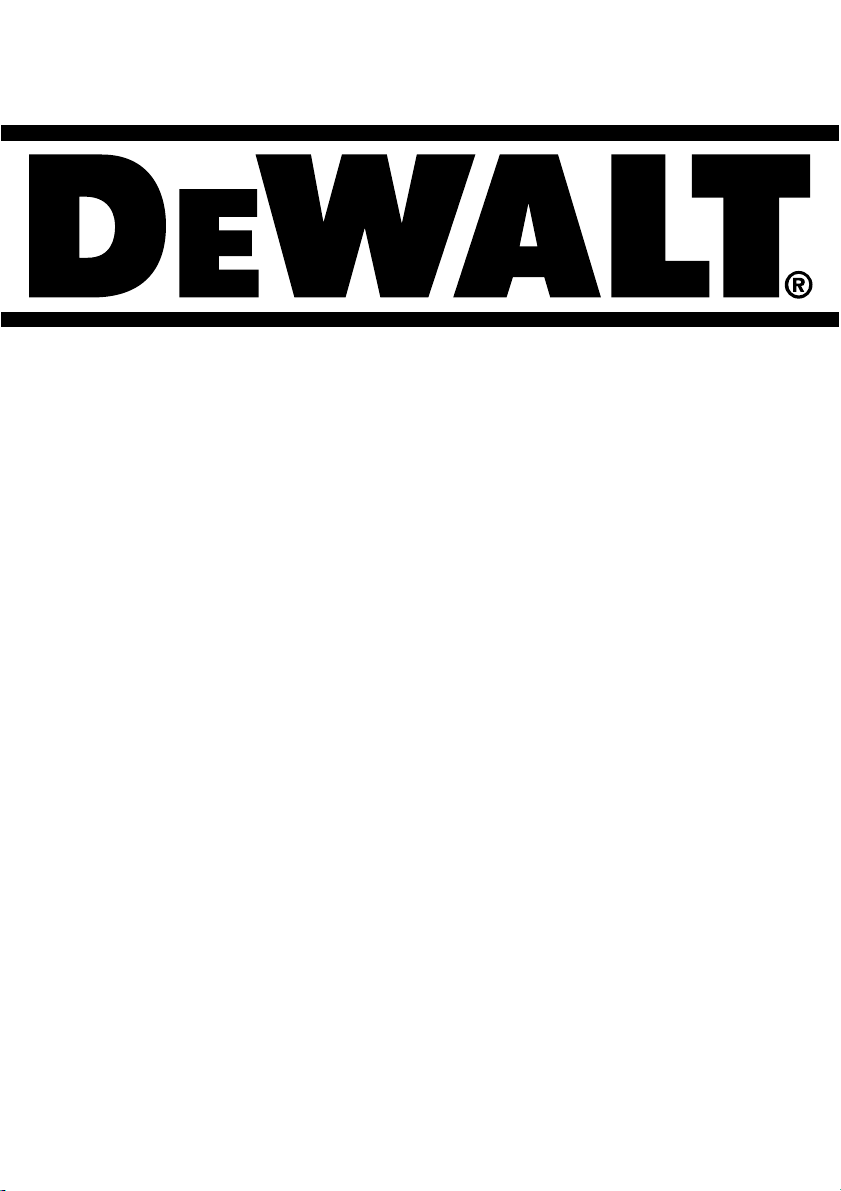

A1

12

2

4 3

5

6

A2

1

7

8

9

10

11

12

B1

Page 3

B2

3

3

13

4

B3

4

3

3

2

Page 4

C

3

14

E

15

16

Page 5

PAVEMENT BREAKER D25980

Congratulations!

You have chosen a D E WALT tool. Years of

experience, thorough product development and

innovation make D E WALT one of the most reliable

partners for professional power tool users.

Technical data

08952D

022 V egatloV

0-605 zH ycneuqerF

000,2 W tupni rewoP

nim etar tcapmI

13 gk thgieW

-1

870

86 J ygrene tcapmI

xeh mm 82 redloh looT

E N G L I S H

The following symbols are used throughout this

manual:

Denotes risk of personal injury, loss

Denotes risk of electric shock.

of life or damage to the tool in case of

non-observance of the instructions in

this manual.

4

Page 6

E N G L I S H

EC-Declaration of conformity

D25980 PAVEMENT BREAKER

D E WALT declares that these power tools have been designed in compliance with: 98/37/EC, 89/336/EEC,

73/23/EEC, 86/188/EEC, 2000/14/EC-Annex VIII, EN 60745-1, EN 60745-2-6, EN 55014-1, EN 55014-2,

EN 61000-3-2 & EN 61000-3-3.

For more information, please contact D E WALT at the address below, or refer to the back of the manual.

Level of acoustic power according to 2000/14/EC (Article 12, Annex III No. 10):

D25980

L

WA

L

WA

nim/078 = on )V 022( W 000,2 ,gk 13 snoitac fiiceps looT

210C40BA troper yrotarobaL

Notifi ed body, delivering the certifi )SPRT( HbmG ytefaS dna tcudorP dnalniehR VÜT etac

Am Grauen Stein 1

D-51105 Köln, Germany

401 )A(Bd )derusaem(

011 )A(Bd )deetnaraug(

Level of sound pressure measured according to EN 60745-1 & EN 60745-2-6:

08952D

L

pA

1)

at the operator's ear

1)

)A(Bd

93

Take appropriate measures for the protection of hearing.

Weighted root mean square acceleration value:

08952D

s/m 44105 NE ot gnidrocca derusaeM

Measured according to EN 60745-1 & EN 60745-2-6 m/s

1)

measurement uncertainty according to EN 12096: 1.5 m/s

Director Engineering and Product Development

Horst Großmann

2

5.4

2

6.6 1)

2

D E WALT, Richard-Klinger-Straße 11

D-65510, Idstein, Germany

5

Page 7

ENGLISH

Safety instructions

General power tool safety warnings

Warning! Read all safety warnings and

@

Save all warnings and instructions for future reference.

The term "power tool" in all of the warnings listed

below refers to your mains operated (corded) power

tool or battery operated (cordless) power tool.

1 Work area safety

a Keep work area clean and well lit.

b Do not operate power tools in explosive

c Keep children and bystanders away while

2 Electrical safety

a Power tool plugs must match the outlet.

b Avoid body contact with earthed or

c Do not expose power tools to rain or wet

d Do not abuse the cord. Never use the cord

all instructions. Failure to follow the

warnings and instructions listed below

may result in electric shock, fi re and/or

serious injury.

Cluttered or dark areas invite accidents.

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the

dust or fumes.

operating a power tool.

Distractions can cause you to lose control.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

grounded surfaces such as pipes, radiators,

ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

conditions.

Water entering a power tool will increase the

risk of electric shock.

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

e When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

3 Personal safety

a Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the infl uence of drugs, alcohol

or medication.

A moment of inattention while operating power

tools may result in serious personal injury.

b Use safety equipment. Always wear eye

protection.

Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c Avoid accidental starting. Ensure the switch

is in the off position before plugging in.

Carrying power tools with your fi nger on the

switch or plugging in power tools that have the

switch on invites accidents.

d Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

e Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

g If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used.

Use of dust collection can reduce dust-related

hazards.

4 Power tool use and care

a Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

6

Page 8

E N G L I S H

b Do not use the power tool if the switch does

not turn it on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

d Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

f Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions

and the work to be performed.

Use of the power tool for operations different

from those intended could result in a hazardous

situation.

5 Service

a Have your power tool serviced by a

qualifi ed repair person using only identical

replacement parts.

This will ensure that the safety of the power tool

is maintained.

Additional safety instructions for pavement

breakers

• Ensure the chisel is secured in place before

operating the tool.

• In cold-weather conditions or when the tool has not

been used for a longer period of time, let the tool

run with no load for several minutes before use.

• Always hold the tool fi rmly with both hands and

ensure a secure stance. Always operate the

tool with the side handle properly mounted.

• When working above ground level ensure the

area below is clear.

• To prevent electric shock, check the working

area for live wires before operation.

• Do not touch the chisel or the parts close to the

chisel immediately after operation, as they may

be extremely hot and cause burns to the skin.

• Always direct the power cable to the rear, away

from the chisel.

• Keep the power cable away from the accessory.

A power cable wrapped around the bit may

cause electric shock.

• Do not wrap the power cable around your body.

• Do not allow children under 16 years of age to

use this tool.

• Wear ear protectors. Exposure to noise can

cause hearing loss.

• Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

• Do not strike jammed accessories with a

hammer to dislodge them. Fragments of metal or

material chips could dislodge and cause injury.

• Always switch off the tool when work is fi nished

and before unplugging.

• Do not recondition accessories yourself. Chisel

reconditioning should be done by a qualifi ed

specialist. Improperly reconditioned accessories

could cause injury. Only sligthly worn

accessories can be resharpened by grinding.

Residual risks

The following risks are inherent to the use of

pavement breakers:

- injuries caused by touching the rotating parts or

hot parts of the tool

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

- Impairment of hearing.

- Risk of squeezing fi ngers when changing the

accessory.

- Health hazards caused by breathing dust

developed when working in concrete and/or

masonry.

7

Page 9

E N G L I S H

- Physical trauma due to inappropriate lifting and

carrying of heavy equipment.

Package contents

The package contains:

1 Pavement breaker

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. A1 & A2)

D25980 pavement breaker has been designed for

professional heavy duty demolition, chipping and

chasing applications in concrete, brick, stone and

other masonry materials.

Fig. A1

1 On/off switch

2 Side handle

3 Tool retainer

4 Tool holder

Optional accessories (fi g. A2)

Various types of 28 mm hex. chisels are available

as an option.

Consult your dealer for further information on the

appropriate accessories.

5 Pointed chisel

6 Cold chisel

7 Scaling tool

8 Spade chisel

9 Asphalt cutter

10 Driver ground rod

11 Shank tamper

12 Plate tamper

Soft start feature

The soft start feature allows the impact rate to build

up more slowly, thus preventing the chisel or point

from "bouncing" around on the masonry when

starting up.

Fully vibration-dampened handles

The dampers in the handles (2) absorb the

vibrations transmitted to the user. This improves

user comfort during the operation.

Active vibration control

The active vibration control neutralises rebound

vibration from the hammer mechanism. Lowering

hand and arm vibration, it allows more comfortable

use for longer periods of time and extends the life

of the unit.

Electrical safety

The electric motor has been designed for a limited

voltage range. Always check that the power supply

falls within the voltage range on the rating plate.

Your D E WALT tool is double insulated

in accordance with EN 60745; therefore

no earth wire is required.

Using an extension cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see technical data). The minimum conductor

size is 1.5 mm

When using a cable reel, always unwind the cable

completely.

Also refer to the table below.

Conductor size (mm 2 ) Cable rating (amperes) )

0.75 6

1.00 10

1.50 15

2.50 20

4.00 25

)m( htgnel elbaC )

7.5 15 25 30 45 60

oltage Amperes Cable rating (amperes

115 0 - 2.0 6 6 6 6 6 10

2.1 - 3.4 6 6 6 6 15 15

3.5 - 5.0 6 6 10 15 20 20

5.1 - 7.0 10 10 15 20 20 25

7.1 - 12.0 15 15 20 25 25 -

12.1 - 20.0 20 20 25 - - 230 0 - 2.0 6 6 6 6 6 6

2.1 - 3.4 6 6 6 6 6 6

3.5 - 5.0 6 6 6 6 10 15

5.1 - 7.0 10 10 10 10 15 15

7.1 - 12.0 15 15 15 15 20 20

12.1 - 20.0 20 20 20 20 25 -

2

.

8

Page 10

E N G L I S H

Assembly and adjustment

Prior to assembly and adjustment

always unplug the tool.

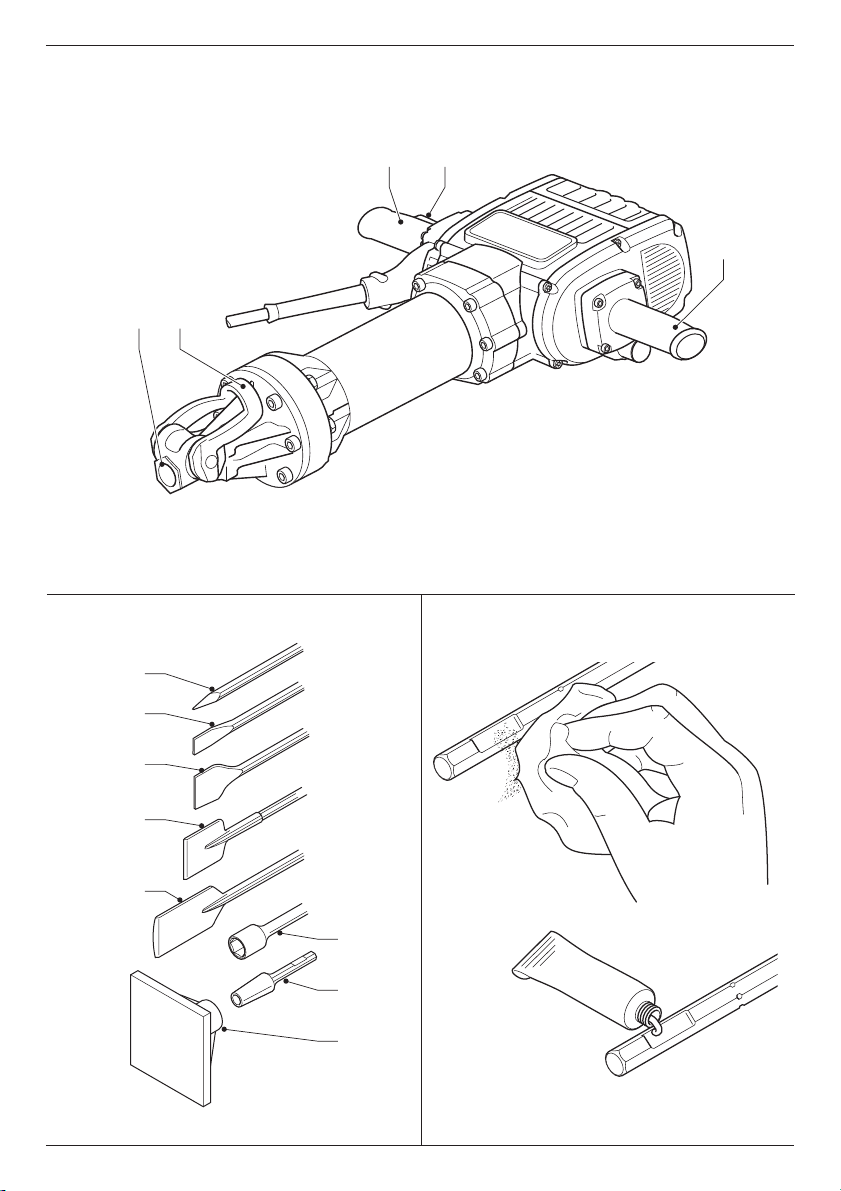

Inserting and removing 28 mm hex.

accessories (fi g. B1 - B3)

This machine uses chisels with a 28 mm hex.

shank.

We recommend to use professional accessories only.

Since accessories other than those offered

by D E WALT have not been tested with

this product, the use of such accessories

may entail hazardous situations. To reduce

the risk of injury, use only accessories

recommended by D E WALT.

• Clean and grease the chisel shank.

Do not apply lubricant to the machine.

• To fi t a chisel with groove in the shank, proceed

as follows (fi g. B2):

• Pull the tool retainer (3) to the unlock position.

• Hold the chisel in front of the tool holder with

the groove (13) facing upwards.

• Insert the chisel shank into the tool holder (4).

• Push the retainer (3) backwards to lock the

accessory in position.

• To fi t a chisel with collar on the shank, proceed

as follows (fi g. B3):

• Pull the tool retainer (3) to the unlock position.

• Insert the chisel shank into the tool holder (4).

• Push the retainer (3) in line with the accessory

shank to lock the accessory in position.

• Pull on the chisel to check if it is properly

locked. The hammering function requires

the chisel to be able to move axially several

centimetres when locked in the tool holder.

• To remove a chisel pull back the retainer (3)

and pull the chisel out of the tool holder.

Always wear gloves when you change

accessories. The exposed metal parts

on the tool and accessory may become

extremly hot during operation.

Instructions for use

• Always observe the safety instructions

and applicable regulations.

• Be aware of the location of pipework

and wiring.

• Apply a pressure of approx. 20 - 30 kg

to the tool. Excessive force does not

speed up chiselling but decreases tool

performance and may shorten tool life.

Switching on and off (fi g. A)

• To run the tool, press the on/off switch (1).

• To stop the tool, release the switch.

Demolition, chasing and channelling (fi g. A)

• Select the appropriate chisel, and clean and

grease its shank.

• Insert the chisel and check whether it is

properly locked.

• Hold of the tool at both handles (2) and switch

on. The tool now runs in continuous operation.

Maintenance

Your D E WALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

• This machine is not user-serviceable. Take the

tool to an authorised D E WALT repair agent after

approximately 200 hours of use. If problems

occur before this time contact an authorised

D E WALT repair agent.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

Keep the ventilation slots clear and regularly clean

the housing with a soft cloth.

9

Page 11

E N G L I S H

Never use solvents or other harsh

chemicals for cleaning the non-metallic

parts of the tool. These chemicals may

weaken the plastic material used in

these parts. Use a cloth dampened only

with water and mild soap.

Accessory maintenance

Accessory maintenance at the right time

guarantees optimal results in application and a

long and effi cient accessory life.

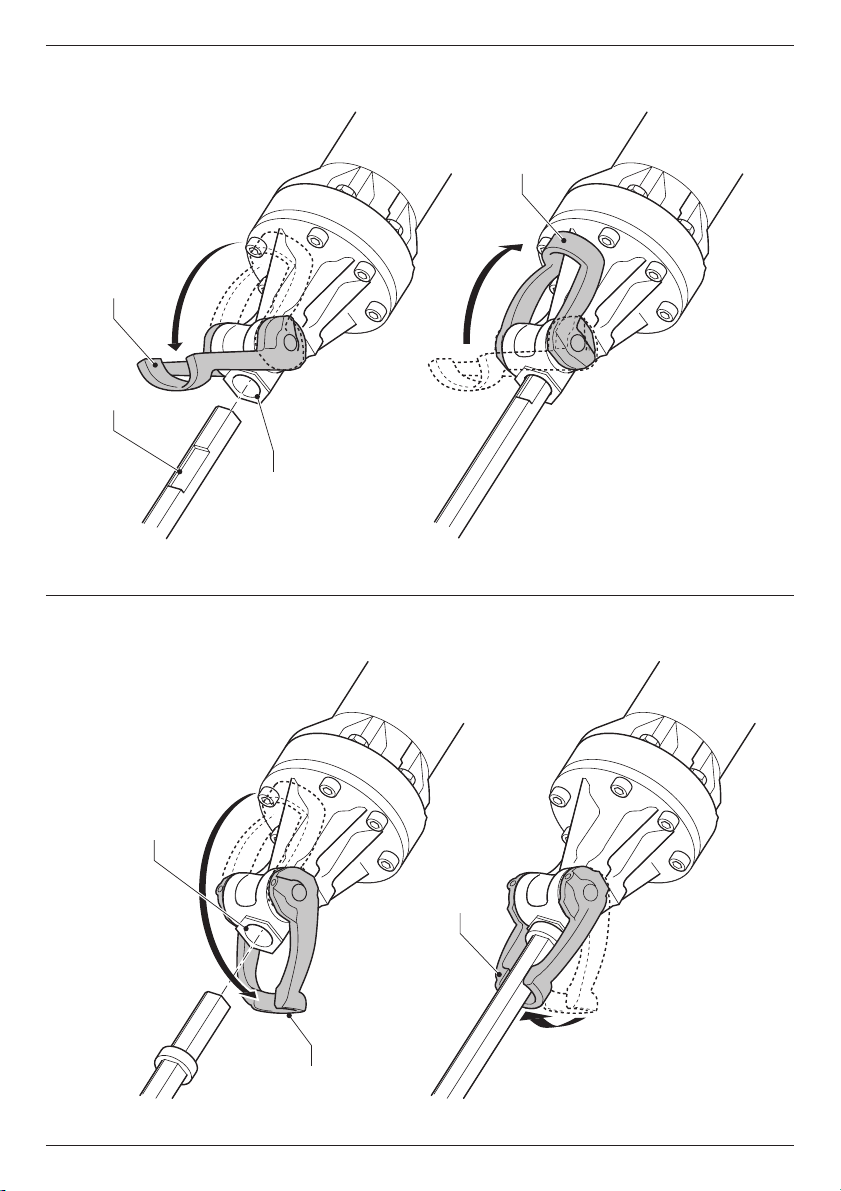

• Grind the chisels on grinding discs. Refer to fi g.

C for the appropriate angles of the following

chisels:

- spade-shaped chisel (14)

- cold chisel (15)

- pointed chisel (16)

These chisels can be reground

only a limited number of times. If

in doubt, contact your dealer for

recommendations.

Ensure that the cutting edge does not

show discolouration caused by too

much pressure. This may impair the

hardness of the accessory.

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you fi nd one day that your D E WALT product

needs replacement, or if it is of no further use to

you, do not dispose of it with household waste.

Make this product available for separate collection.

Separate collection of used products

and packaging allows materials to

be recycled and used again. Re-use

of recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by the

retailer when you purchase a new product.

10

Page 12

E S P A Ñ O L

!aneubarohnE¡

D atneimarreh anu rop odatpo ah detsU E WALT.

Muchos años de experiencia y una gran asiduidad

en el desarrollo y la innovación de sus productos

han convertido D E WALT en un socio muy fiable

para el usuario profesional.

Características técnicas

08952D

022VejatloV

0-605zHaicneucerF

adibrosba aicnetoP W 2.000

otcapmi ed ecidnÍ min

Energía del impacto J 68

1-

870

xehmm82atneimarrehatroP

13gkoseP

08952D SOTNEMIVAP EPMOR

siguientes:

11

launam etneserp le nE figuran los pictogramas

Indica peligro de lesiones, de

accidentes mortales o de averías en la

herramienta en caso de no respeto de

las instrucciones en este manual.

Indica tensión eléctrica.

Page 13

E S P A Ñ O L

Declaración de conformidad CE

D25980 SOTNEMIVAP EPMOR

D E WALT certifica que estas herramientas elétricas han sido diseñadas de conformidad a las normas

siguientes: 98/37/CE, 89/336/CEE, 73/23/CEE, 86/188/CEE, 2000/14/CE-Annex VIII, EN 60745-1,

EN 60745-2-6, EN 55014-1, EN 55014-2, EN 61000-3-2 & EN 61000-3-3.

D a etcatnoc ,adallated sám nóicamrofni araP

E WALT en la dirección indicada abajo o consulte el dorso

de este manual.

,21 olucítrA( EC/41/0002 núges acitsúca aicnetop ed leviN Anexo III No. 10):

D25980

L

WA

L

WA

itoN ficado a Organismo que hace entrega del certificado TÜV Rheinland Product and Safety GmbH (TRPS)

Am Grauen Stein 1

D-51105 Köln, Germany

L

pA

)1

al oído del usuario

)A(Bd

401)A(Bd)odidem(

011)A(Bd)odazitnarag(

nim/078=on)V022(W000.2,gk13atneimarrehaledsenoicacfiicepsE

210C40BAoirotaroballedemrofnI

:6-2-54706 NE y 1-54706 NE a dadimrofnoc ed odidem acitsúca nóiserp ed leviN

08952D

)1

93

Tome medidas adecuadas para la protección de los oídos.

Valor de aceleración media cuadrática ponderada:

s/m44105NEnúgesnóicideM

6-2-54706 NE & 1-54706 NE núges nóicideM m/s

)1

incertidumbre de medición de conformidad a EN 12096: 1,5 m/s

tnempoleveD tcudorP dna gnireenignE rotceriD

nnamßorG tsroH

D E WALT, Richard-Klinger-Straße 11,

D-65510, Idstein, Alemania

D25980

2

5,4

2

1)

6,6

2

12

Page 14

E S P A Ñ O L

Instrucciones de seguridad

ed dadiruges erbos selareneg saicnetrevdA

herramientas eléctricas

¡Atención! Lea todas las advertencias

de seguridad, así como todas las

instrucciones. En caso de no atenerse

a las advertencias e instrucciones de

seguridad siguientes, ello puede dar

lugar a una descarga eléctrica, incendio

o lesión grave.

Guarde las advertencias y las instrucciones para

consultas posteriores.

El término "herramienta eléctrica" empleado en las

advertencias indicadas a continuación se refi ere

a la herramienta eléctrica con alimentación de red

(con cable) o alimentada por batería (sin cable).

1 Seguridad del área de trabajo

a Mantenga limpia y bien iluminada el área de

trabajo.

El desorden o una iluminación defi ciente en las

áreas de trabajo pueden provocar accidentes.

b No utilice la herramienta eléctrica en un

entorno con peligro de explosión, en el que

se encuentren combustibles líquidos, gases

o material en polvo.

Las herramientas eléctricas producen chispas

que pueden llegar a infl amar los materiales en

polvo o vapores.

c Mantenga alejados a los niños y otras

personas del área de trabajo al emplear la

herramienta eléctrica.

Una distracción le puede hacer perder el

control sobre la herramienta.

2 Seguridad eléctrica

a El enchufe de la herramienta eléctrica

debe corresponder a la toma de corriente

utilizada. No es admisible modifi car el

enchufe en forma alguna. No emplee

adaptadores en herramientas eléctricas

dotadas con una toma de tierra.

Los enchufes sin modifi car adecuados a las

respectivas tomas de corriente reducen el

riesgo de una descarga eléctrica.

b Evite que su cuerpo toque partes

conectadas a tierra como tuberías,

radiadores, cocinas y refrigeradores.

El riesgo a quedar expuesto a una descarga

eléctrica es mayor si su cuerpo tiene contacto

con tierra.

c No exponga las herramientas eléctricas a

la lluvia y evite que penetren líquidos en su

interior.

Existe el peligro de recibir una descarga

eléctrica si penetran líquidos en la herramienta

eléctrica.

d Cuide el cable eléctrico. No utilice el

cable eléctrico para transportar o colgar

la herramienta eléctrica, ni tire de él para

sacar el enchufe de la toma de corriente.

Mantenga el cable eléctrico alejado del

calor, aceite, bordes afi lados o piezas

móviles.

Los cables eléctricos dañados o enredados

pueden provocar una descarga eléctrica.

e Al trabajar con la herramienta eléctrica

en la intemperie utilice solamente cables

alargadores homologados para su uso en

exterior.

La utilización de un cable alargador adecuado

para su uso en exterior reduce el riesgo de una

descarga eléctrica.

3 Seguridad personal

a Esté atento a lo que hace y emplee la

herramienta eléctrica con prudencia.

No utilice la herramienta eléctrica si

estuviese cansado, ni tampoco después

de haber consumido alcohol, drogas o

medicamentos.

El no estar atento durante el uso de una

herramienta eléctrica puede provocarle

lesiones graves.

b Utilice un equipo de protección y en todo

caso unas gafas de protección.

El riesgo a lesionarse se reduce

considerablemente si, dependiendo del tipo

y la aplicación de la herramienta eléctrica

empleada, se utiliza un equipo de protección

adecuado como una mascarilla antipolvo,

zapatos de seguridad con suela antideslizante,

casco o protectores auditivos.

13

Page 15

E S P A Ñ O L

c Evite una puesta en marcha accidental de la

herramienta. Compruebe que el interruptor

esté en la posición de apagado antes de

enchufar la herramienta.

Transportar la herramienta eléctrica con el dedo

sobre el interruptor o enchufarla con el interruptor

encendido puede provocar accidentes.

d Retire las herramientas de ajuste o llaves

fijas antes de conectar la herramienta

eléctrica.

giratoria de la herramienta eléctrica puede

producir lesiones al ponerse a funcionar.

e Sea precavido. Mantenga un apoyo firme

sobre el suelo y conserve el equilibrio en

todo momento.

eléctrica en caso de presentarse una situación

inesperada.

f Utilice la indumentaria adecuada. No lleve

vestidos anchos ni joyas. Mantenga su pelo,

vestimenta y guantes alejados de las piezas

móviles.

aL vestimenta suelta, las joyas y el pelo largo se

pueden enganchar con las piezas en movimiento.

g Siempre que sea posible utilizar unos

equipos de aspiración o captación de polvo,

asegúrese que éstos estén montados y que

sean utilizados correctamente.

ovlop ed nóicatpac ed sopiuqe ed oelpme lE

reduce los riesgos derivados del polvo.

4 Uso y cuidado de herramientas eléctricas

a No sobrecargue la herramienta eléctrica.

Use la herramienta eléctrica adecuada para

el trabajo a realizar.

Con la herramienta eléctrica adecuada podrá

trabajar mejor y más seguro dentro del margen

de potencia indicado.

b No utilice herramientas eléctricas con un

interruptor defectuoso.

conectar o desconectar son peligrosas y deben

ser reparadas.

c Desconecte el enchufe de la toma de

corriente y/o la batería de la herramienta

eléctrica antes de realizar ajustes, cambiar

accesorios o almacenar las herramientas

eléctricas.

atsE medida preventiva reduce el riesgo de

conectar accidentalmente la herramienta eléctrica.

d Guarde las herramientas eléctricas fuera del

alcance de los niños y de las personas que

no estén familiarizadas con su uso.

personas inexpertas son peligrosas.

e Cuide sus herramientas eléctricas

con esmero. Controle si funcionan

correctamente, sin atascarse, las partes

azeip anu ne adacoloc evall o atneimarreh anU

móviles de la herramienta eléctrica, y si

existen partes rotas o deterioradas que

pudieran afectar al funcionamiento de la

herramienta. Si la herramienta eléctrica

estuviese defectuosa haga que la reparen

antes de volver a utilizarla.

atneimarreh al rojem ralortnoc áritimrep el ollE

eléctricas con un mantenimiento deficiente.

f Mantenga las herramientas de corte limpias

y afiladas.

correctamente se dejan guiar y controlar mejor.

g Utilice la herramienta eléctrica, accesorios,

útiles de la herramienta, etc. de acuerdo con

estas instrucciones. Considere en ello las

condiciones de trabajo y la tarea a realizar.

diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

5 Servicio técnico

a Haga reparar su herramienta eléctrica sólo

por personal técnico autorizado que emplee

exclusivamente piezas de repuesto originales.

herramienta eléctrica.

rompe pavimentos

• Asegúrese de que el cincel esté bien sujeto en

su posición antes de utilizar la herramienta.

nadeup es on euq sacirtcéle satneimarreh saL

• En condiciones de frío o cuando la herramienta

no se haya utilizado durante un largo periodo

de tiempo, deje en marcha la herramienta sin

carga durante varios minutos antes de utilizarla.

• Sujete siempre firmemente la herramienta

con ambas manos y mantenga una postura

segura. Utilice siempre la herramienta con la

empuñadura lateral adecuadamente montada.

rop sadazilitu sacirtcéle satneimarreh saL

satneimarreh a nebed es setnedicca sohcuM

sadinetnam etroc ed satneimarreh saL

sojabart arap sacirtcéle satneimarreh ed osu lE

al ed dadiruges al azitnarag es ísa etnemaloS

arap selanoicida dadiruges ed senoiccurtsnI

14

Page 16

E S P A Ñ O L

• Cuando trabaje por encima del nivel del suelo,

asegúrese de que el espacio situado debajo

esté despejado.

• Para evitar descargas eléctricas, compruebe si

existen cables eléctricos en la zona de trabajo

antes de la utilización.

• No toque el cincel ni las piezas cercanas

al cincel inmediatamente después de la

utilización, ya que pueden estar muy calientes y

pueden provocar quemaduras en la piel.

• Dirija siempre el cable de alimentación hacia la

parte posterior, alejándolo del cincel.

• Mantenga el cable eléctrico alejado del

accesorio. Si el cable eléctrico se enredara

alrededor de la punta podría provocar una

descarga eléctrica.

• No enrolle el cable eléctrico alrededor de su

cuerpo.

• No permita que los niños menores de 16 años

de edad utilicen esta herramienta.

• Use protección acústica. La exposición al ruido

puede provocar la pérdida de audición.

• Utilice las empuñaduras auxiliares que se

suministran con la herramienta. La pérdida de

control puede provocar lesiones personales.

• No golpee los accesorios atascados con un

martillo para sacarlos. Podrían desprenderse

fragmentos de metal o virutas de material y

provocar lesiones.

• No reafile los accesorios usted mismo.

El reafilado de los cinceles debe realizarlo un

especialista cualificado. Los accesorios afilados

incorrectamente pueden provocar lesiones.

Únicamente es posible reafilar los accesorios

desgastados con un afilador.

selaudiser sogseiR

nos nóicaunitnoc a sodacidni sogseir soL

inherentes al uso de rompe pavimentos:

- lesiones provocadas al tocar las piezas que

giran o piezas calientes de la herramienta

A pesar del cumplimiento de la normativa

de seguridad correspondiente y del uso de

dispositivos de seguridad, existen determinados

riesgos residuales que no pueden evitarse. Son los

siguientes:

- Dificultades auditivas.

- Riesgo de que los dedos queden atrapados al

cambiar el accesorio.

- Riesgos de salud causados por la inhalación

del polvo producido cuando se trabaja en

hormigón y/o mampostería.

- Trauma físico debido a una elevación y

transporte inadecuados de equipos pesados.

Verificación del contenido del embalaje

:eneitnoc eteuqap lE

1 Rompe pavimentos

1 Manual de instrucciones

1 Dibujo despiezado

• Compruebe si la herramienta, piezas o

accesorios han sufrido algún daño durante el

transporte.

• Tómese el tiempo necesario para leer y

comprender este manual antes de utilizar la

herramienta.

Descripción (fig. A1 & A2)

sotnemivap epmor etsE D25980 ha sido

diseñado para aplicaciones profesionales, tales

como obras de demolición, cincelado y embutido

en hormigón, ladrillo, piedra y otros materiales de

albañilería.

.giF A1

1 Interruptor de marcha/parada

2 Empuñadura lateral

3 Retenedor de herramientas

4 Portaherramienta

Accesorios opcionales (fig. A2)

ed sopit soirav nóicpo omoc selbinopsid yaH

cinceles hexagonales de 28 mm..

Consulte a su proveedor si desea información más

detallada sobre los accesorios apropiados.

5 Cincel puntiagudo

6 Cincel de plano

7 Herramienta desincrustadora

8 Cincel de pala

9 Cortador de asfalto

10 Clavador de varillas enterradas

11 Apisonador de vástago

12 Apisonador de placa

15

Page 17

E S P A Ñ O L

evaus euqnarra ed nóicnuF

El arranque suave permite una aceleración suave,

evitando así que el cincel o la punta "rebote" de un

lado a otro de la mampostería cuando se inicie el

trabajo.

vibraciones

Los amortiguadores de las empuñaduras (2)

absorben las vibraciones transmitidas al usuario.

Esto aumenta el nivel de comodidad durante el

manejo.

ovitca nóicarbiv ed lortnoC

El control de vibración activo neutraliza la vibración

producida por los rebotes del mecanismo percutor.

Al reducir la vibración de la mano y el brazo,

permite un uso más cómodo durante periodos de

tiempo más largos y alarga la vida útil del equipo.

Seguridad eléctrica

El motor eléctrico ha sido diseñado para una

gama limitada de tensiones. Compruebe siempre

con la placa de características nominales que la

alimentación de corriente cae dentro de la gama

de tensiones.

Su herramienta D E WALT tiene doble

aislamiento, conforme a la norma

EN 60745; por consiguiente, no se

requiere conexión a tierra.

Sustitución de cable o enchufe

Al sustituir el cable o el enchufe hágalo con sumo

cuidado: un enchufe con conectores de cobre

desprotegidos es peligroso si se conecta a una

toma de corriente activa.

Utilización de un cable de prolongación

En caso de que sea necesario utilizar un cable de

prolongación, deberá ser un cable de prolongación

aprobado, adecuado para la potencia de esta

herramienta (véanse las características técnicas).

La sección mínima de conductor es de 1,5 mm

Si utiliza un carrete de cable, desenrolle siempre el

cable completamente.

2

.

setsuja y ejatnoM

Desenchufe la herramienta antes de

proceder con el montaje y los ajustes.

artnoc sadaugitroma etnemlatot sarudañupmE

28 mm (fi g. B1 - B3)

Esta máquina utiliza cinceles con un vástago

hexagonal de 28 mm.

Recomendamos utilizar accesorios para

profesionales únicamente.

• Limpie y engrase el vástago del cincel.

No aplique lubricante a la máquina.

• Para instalar un cincel con ranura en el

• Ponga el retenedor de herramientas (3) en la

• Sujete el cincel delante del portaherramientas

• Inserte la cola de cincel en el portaherramientas

• Empuje el retenedor (3) hacia atrás para

• Para instalar un cincel con collarín en el

• Ponga el retenedor (3) en la posición de

• Inserte la cola de cincel en el portaherramientas

• Empuje el retenedor (3) en línea con el vástago

• Tire del cincel para verifi car si está bien

Puesto que los accesorios ajenos

a D

vástago, haga lo siguiente (fi g. B2):

posición de desbloqueo.

con la ranura (13) orientada hacia arriba.

(4).

bloquear el accesorio en su posición.

vástago, haga lo siguiente (fi g. B3):

desbloqueo.

(4).

del accesorio para bloquear el accesorio en su

posición.

bloqueado. La función de martillar requiere

que el cincel se pueda mover axialmente sobre

varios centímetros mientras se encuentre

bloqueado en el portaherramientas.

E WALT no se han probado con

este producto, la utilización de los

mismos puede dar lugar a situaciones

peligrosas. Para reducir el riesgo de

lesiones, utilice únicamente accesorios

recomendados por D

E WALT.

ed .xeh soirosecca ed nóiccartxe y nóicresnI

16

Page 18

E S P A Ñ O L

• Para desmontar un cincel, tire hacia atrás

del retenedor (3) y saque el cincel del

portaherramientas.

Lleve siempre guantes cuando cambie

los accesorios. Las piezas metálicas

expuestas de la herramienta y el accesorio

pueden calentarse extremadamente

durante el funcionamiento.

osu le arap senoiccurtsnI

• Respete siempre las instrucciones de

seguridad y las normas de aplicación.

• Infórmese sobre la ubicación de

tuberías y de cables eléctricos.

• Sólo se debe ejercer una ligera presión

sobre la herramienta (20 - 30 kg).

Una presión excesiva no acelera el

cincelado, sino que reduce la efectividad

de la herramienta e incluso puede

reducir su vida útil.

Encendido y apagado (fi g. A)

• Para poner en marcha la herramienta, presione

el interruptor de encendido/apagado (1).

• Para parar la herramienta, suelte el interruptor.

fi( ralanaca y ralecnic ,relomeD g. A)

• Seleccione el cincel apropiado, y limpie y

engrase el vástago.

• Inserte el cincel y verifi que si está bloqueado

como es debido.

• Sujete la herramienta por las dos empuñaduras

(2) y enciéndala. La herramienta funcionará en

modo continuo.

otneiminetnaM

Su herramienta eléctrica D E odis ah TLAW

diseñada para funcionar mucho tiempo con un

mínimo de mantenimiento. El funcionamiento

satisfactorio depende del buen cuidado de la

herramienta y de una limpieza frecuente.

• Esta máquina no está diseñada para que la

repare el usuario. Lleve la herramienta a un

agente D E WALT autorizado después de unas

200 horas de operación. En caso de problemas

antes del término de dicho plazo,

póngase en contacto con un agente D

autorizado.

nóicacirbuL

Su herramienta eléctrica no requiere lubricación

adicional.

azeipmiL

Evite que se obturen las ranuras de ventilación

y limpie el exterior con regularidad utilizando un

paño suave.

Nunca utilice disolventes ni otros

materiales químicos para la limpieza

de las piezas no metálicas de la

herramienta. Estos productos químicos

pueden debilitar el material plástico

utilizado en estas piezas. Utilice

únicamente un paño humedecido en

agua y jabón suave.

Un buen mantenimiento puntual de los accesorios

garantiza resultados óptimos durante el uso, así

como una larga vida útil de estos accesorios.

• Afi le los cinceles en discos de afi lado. Véase

la fi g. C para los ángulos apropiados para los

siguientes cinceles:

- cincel de pala (14)

- cincel de plano (15)

- cincel puntiagudo (16)

Estos cinceles sólo pueden ser afi lados

cierto número de veces. En caso de

duda, póngase en contacto con su

suministrador para que le aconseje

cómo proceder.

Asegúrese de que el extremo de

corte no pierda color por una presión

excesiva, ya que esto puede perjudicar

la dureza del accesorio.

E WALT

soirosecca sol ed otneiminetnaM

17

Page 19

Protección del medio ambiente

Separación de desechos. Este producto

no debe desecharse con la basura

doméstica normal.

E WALT o éste ha dejado de tener utilidad para

D

usted, no lo deseche con la basura doméstica

normal. Asegúrese de que este producto se

deseche por separado.

La separación de desechos de

productos usados y embalajes permite

que los materiales puedan reciclarse

y reutilizarse. La reutilización de

materiales reciclados ayuda a evitar

la contaminación medioambiental y

reduce la demanda de materias primas.

de desechos de productos eléctricos de uso

doméstico en centros municipales de recogida

de desechos o a través del distribuidor cuando

adquiere un nuevo producto.

E S P A Ñ O L

otcudorp us razalpmeer ed otnemom le agell iS

nóicarapes al reverp edeup lacol avitamron aL

18

Page 20

P O R T U G U Ê S

AM RTELO DEMOLIDOR D25980

Parabéns!

DatnemarrefamuuehlocsE E WALT. Muitos anos

de experiência, um desenvolvimento contínuo

de produtos e o espírito de inovação fizeram da

DE WALT um dos parceiros mais confiáveis para os

utilizadores profissionais.

Dados técnicos

08952D

022VmegatloV

06zHaicnêuqerF

adivrosbaaicnêtoP W 2.000

agracedotcapmI min

Energia de impacto J 68

Suporte de ferramenta 28 mm

1-

870

lanogaxeh

13gkoseP

:launametsensodasuoãssolobmíssetniugessO

Indica risco de ferimentos, perda de

vida ou danos à ferramenta no caso do

não-cumprimento das instruções deste

manual.

Indica tensão elétrica.

19

Page 21

P O R T U G U Ê S

Declaração CE de conformidade

D25980 Martelo demolidor

A D E WALT declara que estas ferramentas elétricas foram concebidas em conformidade com: 98/37/CE,

89/336/CEE, 73/23/CEE, 86/188/CEE, 2000/14/CE-Annex VIII, EN 60745-1, EN 60745-2-6, EN 55014-1,

EN 55014-2, EN 61000-3-2 & EN 61000-3-3.

Daratlusnocarieuq,seõçamrofnisiamaraP E WALT na parte de trás do presente

manual.

,21ogitrA(EC/41/0002amronamocodrocaedacitsúcaaicnêtopedlevíN Anexo III Nº. 10):

08952D

L

WA

L

WA

Corpo notificado, entrega de certifi )SPRT(HbmGytefaSdnatcudorPdnalniehRVÜTodac

L

pA

)1

no ouvido do operador

Am Grauen Stein 1

D-51105 Köln, Germany

)1

)A(Bd

401)A(Bd)odidem(

011)A(Bd)oditnarag(

nim/078=on)V022(W000.2,gk13atnemarrefadseõçacfiicepsE

210C40BAoirótarobalodoirótaleR

:6-2-54706NE&1-54706NEamocodrocaedodidemodíuredoãsserpedlevíN

08952D

93

Use protectores auditivos.

Valor médio quadrático ponderado em frequência de aceleração:

D25980

2

)1

imprecisão de medição conforme a EN 12096: 1,5 m/s

6-2-54706NE&1-54706NEmocedadimrofnocmeodideM m/s

2

s/m44105NEmocedadimrofnocmeodideM

2

5,4

6,6

1)

tnempoleveDtcudorPdnagnireenignErotceriD

nnamßorGtsroH

D E WALT, Richard-Klinger-Straße 11,

D-65510, Idstein, Alemanha

20

Page 22

P O R T U G U Ê S

Instruções de segurança

satnemarrefarapsiaregaçnarugesedsosivA

elétricas

Advertência! Leia todos os avisos

de segurança e instruções. O não

cumprimento dos avisos e instruções

a seguir pode resultar em choque

elétrico, incêndio e/ou graves lesões.

arutufarapseõçurtsniesosivasosodotedrauG

referência.

iugesaodazilitu,"acirtéleatnemarref"omretO r,

refere-se a ferramentas elétricas com ligação à

corrente elétrica (com fios) ou operadas a bateria

(sem fios).

1 Segurança na área de trabalho

a Mantenha a sua área de trabalho limpa e

bem iluminada.

acarfmocohlabartedsaeráuomedroseD

iluminação podem causar acidentes.

b Não trabalhe com a ferramenta elétrica

em áreas com risco de explosão, nas

quais se encontrem líquidos, gases ou pós

inflamáveis.

sacsíafmezudorpsacir As ferramentas elét

que podem provocar a ignição de pó e vapores.

c Mantenha crianças e outras pessoas

afastadas durante a utilização da ferramenta

elétrica.

o controle da ferramenta.

2 Segurança elétrica

a O plugue da ferramenta elétrica deve caber

na tomada. O plugue não deve ser modificada

de modo algum. Não utilize quaisquer plugues

de adaptação com ferramentas elétricas

ligadas à terra.

sadauqedasadamotesadaretlaniPlugues

reduzem o risco de choques elétricos.

b Evite que o corpo entre em contacto

com superfícies ligadas à terra, como

por exemplo tubos, radiadores, fogões e

frigoríficos.

,socirtéleseuqohcedodaveleocsirmuáH

caso o corpo seja ligado à terra.

c A ferramenta elétrica não deve ser exposta

à chuva nem a humidade.

A penetração de água na ferramenta elétrica

aumenta o risco de choques elétricos.

d Manuseie o cabo com cuidado. O cabo da

ferramenta não deve ser utilizado para o

transporte, para puxar a ferramenta, nem

para retirar o plugue da tomada. Mantenha o

cabo afastado de calor, óleo, cantos afiados

ou peças em movimento.

Cabos danificados ou torcidos aumentam o

risco de choques elétricos.

e Ao trabalhar com a ferramenta elétrica

ao ar livre, use um cabo de extensão

apropriado para áreas externas.

externas reduz o risco de choques elétricos.

3 Segurança pessoal

a Mantenha-se atento, observe o que está

fazendo e seja prudente ao trabalhar

com a ferramenta elétrica. Não use a

ferramenta elétrica se estiver cansado

ou sob a influência de drogas, álcool ou

medicamentos.

utilização da ferramenta elétrica pode causar

graves lesões.

b Use equipamento pessoal de proteção.

Utilize sempre óculos de proteção.

exemplo, máscara de proteção contra pó,

adrepeuqamegiroradmedopseõçcartsidsA

sapatos de segurança anti-derrapantes,

capacete de segurança ou proteção auricular,

de acordo com o tipo e aplicação da ferramenta

elétrica, reduz o risco de lesões.

c Evite um accionamento involuntário.

Assegure-se de que o interruptor está na

posição de desligado antes de ligar o plugue.

Otransporte de ferramentas elé

dedo no interruptor ou a ligação das mesmas

à corrente elétrica com o interruptor ligado

provoca acidentes.

d Retire eventuais chaves de ajuste ou

chaves de fenda, antes de ligar a ferramenta

elétrica.

se encontre numa peça móvel da ferramenta,

pode dar origem a lesões.

t

saeráarapodairporpaobacmuedosuO

aetnarudoãçnetaedatlafedotnemommU

ropomoc,açnarugesedotnemapiuqE

omocsacir

euq,etsujaedevahcuoadnefedevahcamU

21

Page 23

P O R T U G U Ê S

e Não se incline. Mantenha-se sempre bem

posicionado e em equilíbrio.

aralortnoclicáfsiamresáredop,amrofatseD

ferramenta em situações inesperadas.

f Utilize vestuário adequado. Não utilize

roupas largas nem jóias. Mantenha o

cabelo, roupa e luvas afastados de peças

em movimento.

ficar presos nas peças em movimento.

4 Utilização e manutenção da ferramenta

elétrica

a Não sobrecarregue a ferramenta elétrica.

Utilize a ferramenta elétrica correcta para o

trabalho que irá realizar.

A ferramenta correcta realizará o trabalho de

forma melhor e mais segura dentro da potência

indicada.

b Não utilize a ferramenta elétrica se o

interruptor não puder ser ligado nem

desligado.

assopoãneuqacirtéleatnemarrefreuqlauQ

ser controlada através do interruptor de ligar/

desligar é perigosa e deve ser reparada.

c Desligue o plugue da tomada e/ou a bateria

da ferramenta elétrica antes de efectuar

quaisquer ajustes, substituir acessórios ou

armazenar a ferramenta elétrica.

aeuqativeaçnarugesedadidematsE

ferramenta elétrica seja ligada acidentalmente.

d Mantenha as ferramentas elétricas que não

estiverem sendo utilizadas fora do alcance de

crianças. Não permita que a ferramenta seja

utilizada por pessoas não familiarizadas

com a mesma ou que não tenham lido estas

instruções.

essasogirepoãssacir As ferramentas elét

utilizadas por pessoas não qualificadas.

e Efetue a manutenção da ferramenta

elétrica. Verifi que se as peças móveis

da ferramenta funcionam perfeitamente

e não emperram, bem como se há peças

quebradas ou danificadas que possam

influenciar o funcionamento da ferramenta.

As peças danificadas devem ser reparadas

antes da utilização da ferramenta.

manutenção insuficiente das ferramentas

elétricas.

f Mantenha as ferramentas de corte sempre

medopsognolsolebacuosaiój,sagralsapuoR

afiadas e limpas.

manutenção adequada e com extremidades

de corte afiadas, emperram com menos

frequência e podem ser controladas com maior

facilidade.

g Utilize a ferramenta elétrica, os acessórios

e as brocas da ferramenta etc., de acordo

com estas instruções. Considere também

as condições de trabalho e o trabalho a ser

efectuado.

A utilização da ferramenta elétrica para outros

fins que não os previstos pode resultar em

situações perigosas.

5 Reparação

a A sua ferramenta elétrica só deve ser

reparada por pessoal qualificado e só devem

ser colocadas peças sobressalentes originais.

ferramenta elétrica.

martelos demolidores

• Assegure-se de que o cinzel esteja na

posição correta antes de começar a utilizar a

ferramenta.

• Em climas frios ou quando a ferramenta tenha

estado fora do uso durante um período de

tempo longo, deixe-a a funcionar sem carga

durante vários minutos antes de iniciar a

utilização.

• Segure a ferramenta firmemente sempre com

ambas as mãos e com uma postura firme.

Utilize a ferramenta sempre com o punho

lateral devidamente montado.

• Quando for trabalhar acima do nível do chão,

assegure-se de que a área abaixo esteja limpa.

• Para evitar choques elétricos, verifique se há

fios eletrificados na área de trabalho antes de

iniciar a operação.

amuasuacomocmêtsetnedicasotiuM

amuasatiejus,etrocedsatnemarrefsA

adaçnarugesaadarugessaé,amrofatseD

arapaçnarugeserbossianoicidaseõçurtsnI

22

Page 24

P O R T U G U Ê S

• Não toque o cinzel ou as peças próximas ao

mesmo imediatamente após a operação, já que

podem estar extremamente quentes e provocar

queimaduras.

• Mantenha o cabo de alimentação sempre na

parte traseira, longe do cinzel.

• Mantenha o cabo de alimentação afastado do

acessório. Um cabo de alimentação enrolado

em volta da ferramenta pode resultar em choques

elétricos.

• Não enrole o cabo em volta do seu corpo.

• Não permita a utilização desta ferramentas por

crianças com idade inferior a 16 anos.

• Utilize protetores auriculares. A exposição ao

ruído poderá provocar perda de audição.

• Utilize os punhos auxiliares fornecidos com

a ferramenta. A perda de controle da mesma

pode provocar ferimentos pessoais.

• Não bata em acessórios encravados com um

martelo para os desencravar. Poderão soltar-se

fragmentos de metal ou lascas de material e

causar ferimentos.

• Não proceda você mesmo ao

recondicionamento de acessórios. O

recondicionamento do cinzel deverá ser

efectuado por um especialista com a devida

formação. Os acessórios indevidamente

recondicionados poderão causar ferimentos.

Apenas os acessórios ligeiramente gastos

poderão ser afiados através de rebarbamento.

siaudisersocsiR

edosuoasetnerenioãssocsirsetniugessO

martelos demolidores:

-ferimentos causados pelo contato físico com

peças giratórias ou peças quentes da ferramenta.

edsotnemalugersodoãçacilpaadrasepA

segurança relevantes e da implementação de

instrumentos de segurança, certos riscos residuais

não podem ser evitados. Estas são:

-Diminuição da audição.

-Risco de trilhamento dos dedos ao substituir o

acessório.

-Problemas de saúde provocados pela inalação

do pó produzido ao trabalhar em concreto e/o

alvenaria.

-Lesões físicas provocadas pela elevação

e transporte inadequados de equipamento

pesado.

Verificação do conteúdo da embalagem

A embalagem contém:

1 Martelo demolidor

1 Manual de instruções

1 Vista dos componentes destacados

• Verifique se a ferramenta, as peças ou os

acessórios apresentam sinais de danos que

possam ter ocorrido durante o transporte.

• Antes de utilizar a ferramenta, dedique o tempo

necessário à leitura e compreensão deste

manual.

Descrição (fig. A1 & A2)

rodilomedoletramuesO D25980 foi concebido

para aplicações profissionais pesadas de

cinzelamento em concreto, tijolo, pedra e outros

materiais de alvenaria.

.giF A1

1 Interruptor on/off

2 Punho lateral

3 Retentor da ferramenta

4 Suporte de ferramenta

Acessórios opcionais (fig. A2)

A pedido, encontram-se disponíveis vários tipos de

cinzéis com hastes hexagonais de 28 mm como

opção.

soiróssecasoerbosseõçamrofnisiamaraP

apropriados, consulte o seu revendedor

autorizado.

5 Ponteiro

6 Cinzel

7 Ferramenta de dimensionamento

8 Pá

9 Cortador de asfalto

10 Cravador de elétrodos de terra

11 Amortecedor da haste

12 Amortecedor da placa

evauseuqnarraedoãçnuF

A função de arranque suave permite aumentar

gradualmente a taxa de impacto evitando que o

cinzel ou a broca se desloquem da posição de

furos pretendida na alvenaria quando a máquina

começa a funcionar.

23

Page 25

P O R T U G U Ê S

seõçarbivedotnemicetromamocsohnuP

samevrosba)2(sohnupsonserodecetromasO

vibrações transmitidas ao utilizador. Isto melhora

o conforto para o utilizador durante a utilização da

ferramenta.

aoãçarbivedelortnoC

ovit

oãçarbivaazilartuenovitaoãçarbivedelortnocO

de retorno proveniente do mecanismo do martelo.

Mediante a redução da vibração da mão e do

braço é possível utilizar a ferramenta com maior

conforto por períodos de tempo mais longos, além

de prolongar o tempo de vida útil do instrumento.

Segurança elétrica

edlevínmuarapodibecnociofocirtélerotomO

voltagem limitado. Verifique sempre se a fonte de

alimentação está dentro da voltagem permitida na

placa de características.

A sua ferramenta D E WALT tem duplo

isolamento em conformidade com

o estipulado na norma EN 60745,

não sendo, por isso, necessária uma

ligação à terra.

Substituição do cabo ou plugue

uoobacoriutitsbusoA plugue,elimine-os de forma

segura; um plugue com condutores de cobre a

descoberto é perigoso quando entra em contacto

com uma tomada com corrente.

Extensões

muoirásseceniofeS fio de extensão, use um

cabo especial, conveniente para a corrente desta

ferramenta (Veja os dados técnicos). A dimensão

mínima do condutor é 1,5 mm2.

todo.

Montagem e afinação

profissionais.

• Limpe e lubrifique a haste do cinzel.

Não aplique lubrificante na máquina.

• Para encaixar um cinzel com ranhura na haste,

proceda da seguinte forma (fig. B2):

• Pressione o retentor da ferramenta (3) até à

posição de desbloqueio.

• Segure o cinzel à frente do suporte da

ferramenta com a ranhura (13) virada para

cima.

• Insira o haste do cinzel para dentro do

suporte da ferramenta (4).

• Empurre o retentor (3) para trás para fixar o

acessório em posição.

• Para encaixar um cinzel com aro na haste,

proceda da seguinte forma (fig. B3):

• Pressione o retentor da ferramenta (3) até à

posição de desbloqueio.

• Insira o haste do cinzel para dentro do

encabadouro (4).

• Empurre o retentor (3) alinhado com a haste do

acessório para fixar o acessório em posição.

• Puxe o cinzel para verificar se está

devidamente bloqueado. A função de impacto

requer que o cinzel tenha um movimento axial

de vários centímetros quando preso no suporte

de ferramenta.

• Para retirar o cinzel puxe o retentor (3) para

trás e retire o cinzel do suporte da ferramenta.

Utilize sempre luvas para a substituição

obacoelornesed,anibobamurasuesedosacoN

de acessórios. As peças metálicas

expostas na ferramenta e no acessório

poderão aquecer extremamente

durante a sua utilização.

soiróssecasanepaezilitueuqsomadnemoceR

Antes da montagem de acessórios e da

afinação retire sempre o plugue da tomada.

28 mm (fig. B1 - B3)

hexagonal de 28 mm.

edsianogaxehsoiróssecarevomereriresnI

etsahamumocsiéznicazilituaniuqámatsE

24

Page 26

P O R T U G U Ê S

ogerpmeedodoM

• Cumpra sempre as instruções

de segurança e os regulamentos

aplicáveis.

• Esteja informado sobre a localização

de tubagens e de fios eléctricos dentro

da parede.

• Aplique apenas uma ligeira pressão

na ferramenta (20 - 30 kg). O excesso

de força não irá acelerar a operação

de cinzelamento e sim diminuir o

rendimento da ferramenta, podendo

reduzir o seu período de vida útil.

Ligar e desligar (fig. A)

• Para ligar a máquina pressione o interruptor (1).

• Para desligar a máquina, liberte o interruptor.

meD olição, abertura de roças e de canais (fig. A)

• Seleccione o cinzel apropriado e limpe e

lubrifique a haste do mesmo.

• Insira o cinzel e verifique se está devidamente

preso.

• Segure a ferramenta pelos punhos (2) e liguea. A ferramenta está agora pronta para funcionar

de forma

contínua.

oãçnetunaM

A sua Ferramenta Elétrica D E WALT foi concebida

para funcionar durante muito tempo com um

mínimo de manutenção. O funcionamento

satisfatório contínuo depende de bons cuidados e

limpeza regular da ferramenta.

azepmiL

Conserve livres as aberturas de ventilação e limpe

regularmente o corpo da máquina utilizando um

pano macio.

Nunca utilize solventes ou outros

químicos agressivos para limpar as

peças não metálicas da ferramenta.

Estes químicos poderão enfraquecer o

material plástico utilizado nessas peças.

Utilize um pano humedecido apenas em

água e um detergente suave.

• Rectifique os cinzéis. Consulte a fig. C quanto

aos ângulos apropriados dos seguintes cinzéis:

- pá (14)

- cinzel (15)

- ponteiro (16)

Estes cinzéis só podem ser rectificados

um certo número de vezes. Se tiver

dúvidas, contacte o seu revendedor

autorizado D

Certifique-se de que a aresta cortante

não apresenta sinais de descoloração

devido a pressão demasiada. Isto

poderá prejudicar a dureza do

acessório.

E WALT.

Proteção do meio ambiente

• Esta ferramenta não deve ser reparada pelo

utilizador. Leve-a a um centro de reparações

autorizado da D E WALT após cerca de 200

horas de utilização. Caso haja problemas antes

de cumprir esse prazo, contacte um centro de

reparações autorizado da D E WALT.

Lubrificação

A sua Ferramenta Elétrica não precisa de

lubrificação suplementar.

25

Recolha em separado. Não deve deitar

este produto fora juntamente com o lixo

doméstico normal.

Caso chegue o momento em que um dos seus

produtos D E WALT precise de ser substituído ou

decida desfazer-se do mesmo, não o deite fora

juntamente com o lixo doméstico.

Page 27

A recolha separada de produtos

e embalagens utilizados permite

que os materiais sejam reciclados e

reutilizados. A reutilização de materiais

reciclados ajuda a evitar a poluição

ambiental e a reduzir a procura de

matérias-primas.

A D E WALT oferece um serviço de recolha e

reciclagem de produtos D E WALT que tenham

atingido o fim das suas vidas úteis. Para usufruir

deste serviço, entregue o seu produto em qualquer

agente de reparação autorizado que o irá recolher

em nosso nome.

irevaraP ficar a localização do agente de

reparação mais próximo contate o escritório

local da D E WALT no endereço indicado neste

manual. Se preferir, consulte a lista de agentes

autorizados da D E WALT e os dados completos

dos nossos serviços de atendimento pós-venda na

Internet no endereço: www.dewalt.com.br

P O R T U G U Ê S

26

Page 28

SOLAMENTE PARA PROPÓSITO DE ARGENTINA:

IMPORTADO POR: BLACK & DECKER ARGENTINA S.A.

COLECTORA ESTE DE RUTA PANAMERICANA

IMPORTADO POR: BLACK & DECKER S.A. DE C.V.

BOSQUES DE CIDROS, ACCESO RADIATAS NO. 42

PACHECO TRADE CENTER

KM. 32.0 EL TALAR DE PACHECO

PARTIDO DE TIGRE

BUENOS AIRES (B1618FBQ)

REPÚBLICA DE ARGENTINA

NO. DE IMPORTADOR: 1146/66

TEL. (011) 4726-4400

SOLAMENTE PARA PROPÓSITO DE MÉXICO:

3A. SECCIÓN DE BOSQUES DE LAS LOMAS

DELEGACIÓN CUAJIMALPA,

05120, MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

IMPORTED BY/IMPORTADO POR:

BLACK & DECKER DO BRASIL LTDA.

ROD. BR 050, S/N° - KM 167

DIST. INDUSTRIAL II

UBERABA – MG – CEP: 38056-580

CNPJ: 53.296.273/0001-91

INSC. EST.: 701.948.711.00-98

S.A.C.: 0800-703-4644

MADE IN ITALY

HECHO EN ITALIA

FABRICADO NA ITALIA

491661-02 12/06

Loading...

Loading...