Page 1

y

®

and Spline

®

et cannelures,

®

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

y estriados D25831, D25851

®

et cannelures, D25831, D25851

®

and Spline Chipping Hammers

®

Si tiene dudas o comentarios, contáctenos.

If you have questions or comments, contact us.

and Spline Combination Hammers; D25602, D25651 1-3/4" (45 mm) SDS Max

®

y estriados de combinación D25501, D25553; Martillos de 1-3/4 pulg. (45 mm) SDS Max

®

Pour toute question ou tout commentaire, nous contacter.

1-800-4-DEWALT • www.dewalt.com

et cannelures, 40 mm (1-9/16 po), D25501, D25553; Marteaux mixtes, SDS Max

®

Combination Hammers; D25831, D25851 SDS Max

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(MAY10) Part No. N030713 D25501, D25553, D25602, D25651, D25831, D25851

The following are trademarks for one or more D

color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box

configuration; and the array of lozenge-shaped humps on the surface of the tool.

Copyright © 2010 D

EWALT power tools: the yellow and black

EWALT

D25501, D25553 1-9/16" (40 mm) SDS Max

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

WARNING: To reduce the risk of injury, read the instruction manual.

1-800-4-DEWALT (1-800-433-9258).

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury.

Martillos de 1-9/16 pulg. (40 mm) SDS Max

Marteaux mixtes, SDS Max

45 mm (1-3/4 po), D25602, D25651; Marteaux burineurs, SDS Max

estriados de combinación D25602, D25651; Martillos de burilado SDS Max

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Instructions for Rotary Hammers

• Wear ear protectors. Exposure to noise can cause hearing loss.

• Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal

injury.

• Hold power tools by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Cutting accessory

contacting a “live” wire may make exposed metal parts of the power tool “live” and could

give the operator an electric shock.

• Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

• Wear safety goggles or other eye protection. Hammering operations cause chips to

fly. Flying particles can cause permanent eye damage. Wear a dust mask or respirator for

applications that generate dust. Ear protection may be required for most applications.

• Keep a firm grip on the tool at all times. Do not attempt to operate this tool without

holding it with both hands. It is recommended that the side handle be used at all times.

Operating this tool with one hand will result in loss of control. Breaking through or encountering

hard materials such as re-bar may be hazardous as well. Tighten the side handle securely

before use.

• Do not operate this tool for long periods of time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure

by taking frequent rest periods.

• Do not recondition bits yourself. Chisel reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels could cause injury.

• Wear gloves when operating tool or changing bits. Accessible metal parts on the tool and

bits may get extremely hot during operation. Small bits of broken material may damage bare

hands.

• Never lay the tool down until the bit has come to a complete stop. Moving bits could

cause injury.

• Do not strike jammed bits with a hammer to dislodge them. Fragments of metal or

material chips could dislodge and cause injury.

• Slightly worn chisels can be resharpened by grinding.

NOTE: Do not overheat the bit (discoloration) while grinding a new edge. Badly worn chisels

require reforging. Do not reharden and temper the chisel.

• Keep the power cord away from the rotating bit. Do not wrap the cord around any part

of your body. An electric cord wrapped around a spinning bit may cause personal injury and

loss of control.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size. The following table shows the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also

use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY

EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscopic

particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always use eye protection. All users and bystanders must wear eye protection

that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V ........................volts A ....................... amperes

Hz ......................hertz W ...................... watts

min .................... minutes

................. direct current .................... alternating or direct current

......................Class I Construction

.......................... (grounded) ..................... earthing terminal

......................Class II Construction ..................... safety alert symbol

.......................... (double insulated) BPM .................beats per minute

…/min ...............per minute RPM ................. revolutions per minute

Not More

Than

120V

240V

25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

.................... alternating current

n

o ..................... no load speed

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees

with the nameplate markings. Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWALT tools are factory tested.

Page 2

FIG. 1

HAMMERDRILLING MODE

MODE DE MARTEAU PERFORATEUR

MODO TALADRO PERCUTOR

CHISEL BIT ADJUSTMENT MODE

MODE DE RÉGLAGE DU TRÉPAN ORDINAIRE

MODO DE AJUSTE DE LA BROCA DE CINCEL

CHIPPING MODE

MODE DE BURINAGE

MODO CINCEL

CHISEL BIT ADJUSTMENT MODE

MODE DE RÉGLAGE DU TRÉPAN ORDINAIRE

MODO DE AJUSTE DE LA BROCA DE CINCEL

E

I

F

D

A

J

B

G

H

E

C

D25602

FIG. 2

M

FIG. 3

I

K

N

O

P

L

J

H

FIG. 4

C

M

R

C

Q

P

FIG. 5

COMPLETE TORQUE CONTROL

CTC

1 3/4" (44mm) SDS MAX

TARY HAMMER

RO

D25XXX

SER.

S

T

U

TO REDUCE THE RISK OF INJUR

WARNING

USER MUST READ INSTRUCTION

MANUAL. A

ATO

RESPIR

LEA EL MANUAL DE

ADVERTENCIA

INSTRUCCIONES PARA

UN FUNCIONAMIENTO SEGURO. SIEMPRE UTILICE

PROTECCIÓN ADECUADA

A

RESPIR

AFIN DE MINIMISER

AVERTISSEMENT

LES RISQUES DE

BLESSURES,

D’UTILIS

OCULAIRE,

UTILISER LA POIGNÉE L

T INDUSTRIAL TOOL CO., BA

L

A

W

E

D

FOR SERVICE INFORMA

W

E

.D

w

ww

G

Y,

YS USE PROPER EYE, EAR AND

LWA

YS USE SIDE HANDLE.

A

LW

RY PROTECTION. A

PARA LOS OJOS, OÍDOS Y VÍAS

TORIAS. SIEMPRE UTILICE EL MANGO LATERAL.

TEUR DOIT LIRE LE GUIDE

A

’UTILIS

L

TE.

A

TOIRE ADÉQU

A

TION.TOUJOURS UTILISER UNE PROTECTION

A

AUDITIVE ET RESPIR

TÉRALE.

A

TIMORE, MD 21286 USA

L

T

L

A

W

E

TION, CALL 1-800-4-D

.com

T

L

A

Service

Lock-On

rvice

ush Se

r

B

V

W

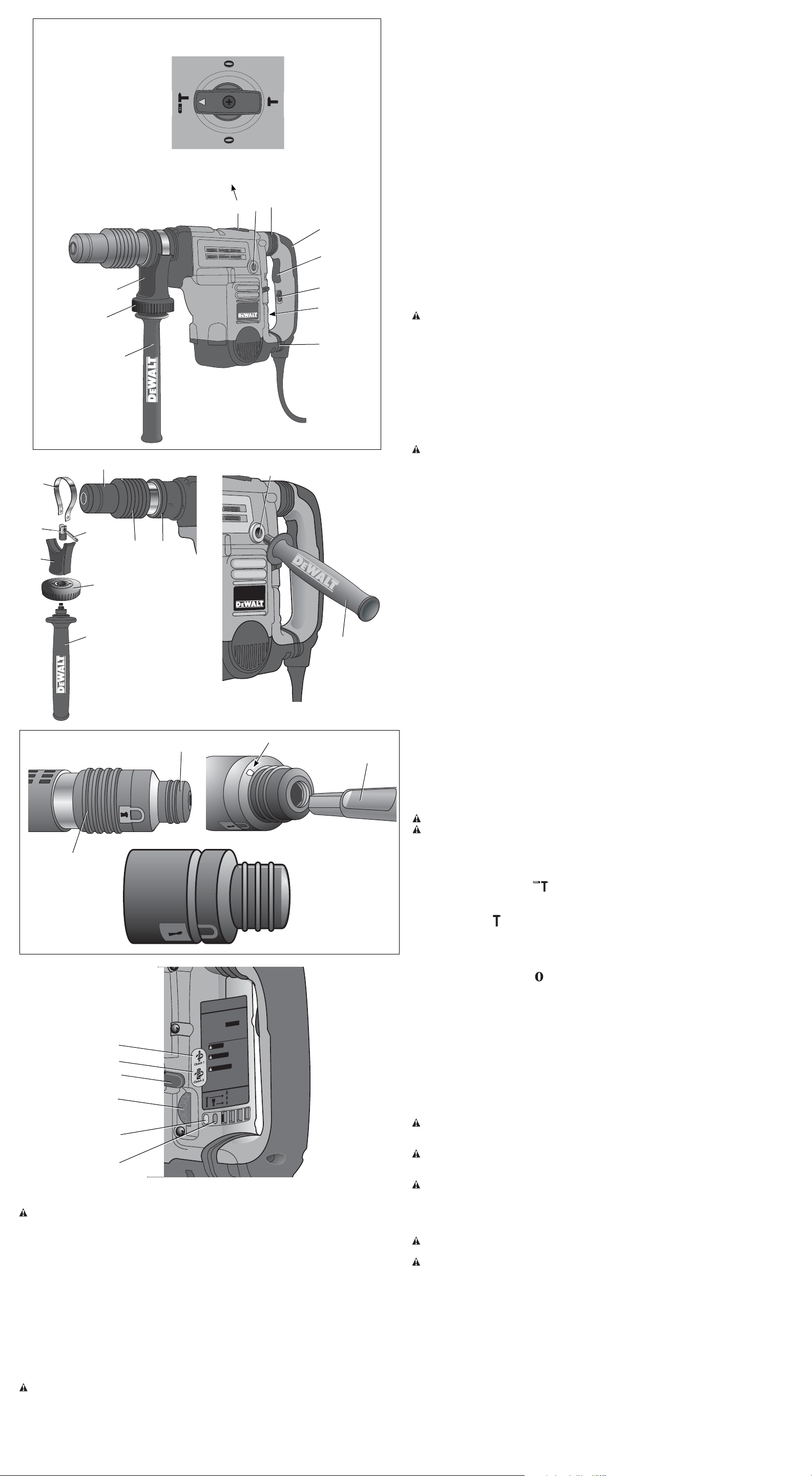

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result.

A. Trigger switch F. Mode selector

B. Lock-on slider G. Electronic Speed and impact control dial

C. Side handle H. Clamp knob

D. Main handle I. Rear side handle position

E. Active vibration control

INTENDED USE

These heavy-duty rotary hammers have been designed for professional hammerdrilling, and

chipping at various work sites (i.e., construction sites). DO NOT use under wet conditions or in

presence of flammable liquids or gases.

These heavy-duty rotary hammers are professional power tools. DO NOT let children come into

contact with the tool. Supervision is required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

Side Handle (Fig. 1)

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed and securely tightened. Failure to do so may result in the side handle

slipping during tool operation and subsequent loss of control. Hold tool with both hands to

maximize control.

The side handle clamps to the front barrel (collar) and may be rotated 360° to permit right

or left-hand use. For operating convenience, the side handle can be installed in front or rear

positions.

TO MOUNT IN FRONT POSITION (FIG. 2)

1. Unscrew the side handle (C) and disassemble the side handle clamp (J).

2. Snap the steel ring (K) over the collar (L) behind the tool holder (M). Squeeze both ends of

the steel ring together. Mount the bushing (N) and insert the pin (O).

3. Slide the side handle clamp (J) over the bushing and screw on the clamp knob (H)–do not

tighten.

4. Screw the side handle (C) into the clamp knob (H) and tighten.

5. Rotate the side handle mounting assembly to the desired position. For hammerdrilling

horizontally with a heavy drill bit, place the side handle assembly at an angle of approximately

20° to the tool for optimum control.

6. Lock the side handle mounting assembly in place by tightening the clamp knob (H).

TO MOUNT IN REAR POSITION (FIG. 3)

1. Unscrew the side handle (C) and remove it from the side handle mounting assembly. Leave

the side handle mounting assembly in the front position.

2. Screw the side handle directly into one of the rear side handle positions (I) on either side of

the tool.

Active Vibration Control (Fig. 1)

D25602, D25651, D25831, D25851

For best vibration control, hold the tool with one hand on the main handle (D) and the other hand

on the side handle (C). Apply just enough pressure so the damping device on the main handle

is approximately mid stroke. The hammer only needs enough pressure to engage the active

vibration control. Applying too much pressure will not make the tool drill or chip faster and active

vibration control will not engage.

Inserting and Removing Spline Drive Accessories

(Fig. 4)

D25553, D25651, D25851

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

1. Insert the bit shank into the tool holder (M) as far as it will go. The groove on the chisel shank

(Q) must be aligned with the symbol (R) on the toolholder. If inserted correctly, the locking

sleeve (P) moves back to the end position and shows a closed lock symbol.

2. Pull on the bit to be sure that it is properly locked.

3. If the chisel groove is not aligned with the symbol, or is not inserted to the complete depth

the lock symbol remains open.

To remove the bit, pull back the locking sleeve and pull the bit out.

Inserting and Removing SDS Max® Accessories

D25501, D25602, D25831

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

1. Pull back the locking sleeve (P) and insert the bit shank. The bit shank must be clean.

2. Turn the bit slightly until the sleeve snaps back into position.

3. Ensure the bit is properly engaged.

NOTE: The bit needs to move several centimeters in and out of the tool holder (M) when

properly engaged.

4. To remove the bit, pull back the locking sleeve and pull the bit out.

Complete Torque Control (Fig. 5)

D25602, D25651

NOTICE: Always turn the tool off before changing torque control settings or damage to tool may

result.

The Complete Torque Control (CTC) feature of this tool is designed to provide additional control

with a two-stage clutch mechanism.

Clutch Setting 1 (S) is designed for most hammerdrilling applications and is designed to easily

clutch out when the drill bit encounters re-bar or other foreign substances.

Clutch Setting 2 (T) is designed for higher torque applications such as core-bits and deep hole

hammerdrilling and is designed to clutch out at a higher torque threshold.

Move the torque control lever (U) to setting 1 or 2 as needed for application.

NOTE: Allow the motor housing to rotate a little while changing torque.

Each time the tool is plugged in, it will automatically default to clutch setting 1, the most

sensitive setting.

Electronic Speed and Impact Control (Fig. 5)

D25602, D25651, D25831, D25851

The electronic speed and impact control allows the use of smaller drill bits without the risk of

bit breakage, hammerdrilling into light and brittle materials without shattering and optimal tool

control for precise chipping.

To set the control dial, turn the dial (G) to the desired level. The higher the number, the greater

the speed and impact energy. Dial settings make the tool extremely adaptable for many

different appli cations. The required setting depends on the bit size and hardness of material

being drilled.

Mode Selector (Fig. 1)

CAUTION: Never change the mode while the unit is running.

CAUTION: Do not change to hammerdrill mode with chisel bit in tool holder. Personal injury

and damage to tool may result.

The D25501, D25553, D25602, D25651 uses two operating modes. To select the required

operating mode, rotate the mode selector (F) until the arrow points to the hammerdrilling or the

chipping icon. The D25831 and D25851 use only the chipping mode.

HAMMERDRILLING MODE (

)

The tool simultaneously rotates and impacts the work. This mode is appropriate for all concrete

and masonry operations.

CHIPPING MODE (

)

The spindle lock is engaged during chipping mode so the tool impacts the work without

rotating. This mode is appropriate for light chipping, chiseling and demolition applications.

NOTE: In chipping mode, the hammerdrill can also be used as a lever to free a jammed drill

bit.

CHISEL BIT ADJUSTMENT (

)

Turn the mode selector to one of the chisel bit adjustment icons to adjust the chisel to the

desired position. There are 18 possible positions to set the angle of the chisel. After finding the

desired position, slightly maneuver the chisel bit back and forth to ensure the chisel is properly

engaged.

Power Indicator Lights (Fig. 5)

The yellow brush wear indicator LED (V) lights up when the carbon brushes are nearly worn out

indicating that the tool needs servicing within the next 8 hours of use.

The red indicator LED (W) lights up if the lock-on slider (B) is used in any mode except the

chipping mode.

The red indicator LED (W) flashes if there is a fault with the tool or if the brushes are completely

worn (refer to Brushes under Maintenance).

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored

or clamped firmly. If hammerdrilling thin material, use a wood “back-up” block to prevent

damage to the material.

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side

handle properly installed and securely tightened. Failure to do so may result in the side

handle slipping during tool operation and subsequent loss of control. Hold tool with both hands

to maximize control.

Proper Hand Position (Fig. 1)

WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position

as shown.

WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation

of a sudden reaction.

Proper hand position requires one hand on the side handle (C), with the other hand on the main

handle (D).

NOTE: Operating temperature of this tool is 19˚ to 104˚ F (-7 to +40˚ C). Using the tool outside

of this temperature range will decrease the life of the tool.

Trigger Switch (Fig. 1)

To turn the tool on, depress the trigger switch (A). To stop the tool, release the trigger switch.

D25602, D25651

In chipping mode only, lock the trigger switch on, push the lock-on slider (B) upwards while

depressing the trigger switch.

To deactivate the lock-on slider, depress the trigger switch once then release.

The lock-on slider may only be activated in chipping mode. The machine will stop running when

trying to engage the lock-on slider in hammerdrilling mode. The motor will stop if the lock-on slider is

activated when changing from chisel mode into hammerdrilling mode.

D25831, D25851

For continuous operation, move the toggle switch to the on position. To stop continuous

operation, move the toggle switch to the off position.

Page 3

SOFT START FEATURE

The soft start feature allows you to build up speed slowly, thus preventing the drill bit from

walking off the intended hole position when starting. The soft start feature also reduces the

immediate torque reaction transmitted to the gearing and the operator if the hammer is started

with the drill bit in an existing hole.

Hammerdrilling with a Solid Bit

D25501, D25553, D25602, D25651

NOTE: The D25831, D25851 have only chipping modes with no hammerdrilling capability.

1. Set the mode selector (F) to hammerdrilling mode.

2. For D25602 and D25651 only, move the torque control lever (U) to Setting 1 (S).

3. Set the speed and impact control dial (G).

4. Insert the appropriate drill bit.

5. Adjust the side handle (front or rear position) (C).

6. Mark the spot where the hole is to be drilled.

7. Place the drill bit on that mark and depress the trigger switch (A).

8. Apply only enough pressure to engage active vibration control (refer to Active Vibration

Control).

9. To stop the tool, release the trigger switch. Always turn the tool off when work is finished and

before unplugging.

Hammerdrilling with a Core Bit

D25501, D25553, D25602, D25651

CAUTION: Do not use a core bit for hammerdrilling wood. Personal injury and damage to tool

may result.

NOTE: The D25831, D25851 have only chipping modes with no hammerdrilling capability.

1. Set the mode selector (F) to hammerdrilling mode.

2. For D25602 and D25651 only, move the torque control lever (U) to Setting 2 (T).

3. Turn the speed and impact control dial (G) to the maximum speed (level 7).

4. Adjust the side handle (front or rear position) (C).

5. Assemble the centering bit and adapter shank into core bit.

6. Mark the spot where the hole is to be drilled.

7. Place the centering bit on that mark and depress the trigger switch (A).

NOTE: Some core drills require the removal of centering bit after about 1 cm of penetration. If

so, remove and continue hammerdrilling.

8. When hammerdrilling through a structure thicker than the depth of the core bit, break away

the round cylinder of concrete or core inside the bit at regular intervals. To avoid unwanted

breaking away of concrete around the hole, first drill a hole the diameter of the centering

bit completely through the structure. Then drill the cored hole halfway from each side of

the structure.

9. To stop the tool, release the trigger switch. Always turn the tool off when work is finished and

before unplugging.

Chipping

D25831, D25851

1. Set the mode selector (F) to chipping mode.

2. Set the impact control dial (G) to desired setting (refer to Electronic Speed and Impact

Control).

3. Insert the appropriate chisel and rotate it by hand to lock it into the desired position.

NOTE: For SDS Max

4. Adjust the side handle (front or rear position) (C).

5. Depress the trigger switch (A).

6. Apply only enough pressure to engage active vibration control (refer to Active Vibration

Control).

7. To stop the tool, release the trigger switch. Always turn the tool off when work is finished and

before unplugging.

®

models, only use SDS Max® bits.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments or

accessories.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear

proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA

respiratory protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months, depending

upon use, take or send your tool to an authorized service center for a complete cleaning,

inspection and lubrication. Tools used constantly on production jobs will need relubrication more

often. Also, tools “out of service” for long periods should be relubricated before being put back

to work.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested

with this product, use of such accessories with this tool could be hazardous. To reduce the risk

of injury, only D

Recommended accessories for use with your tool are available at extra cost from your local

dealer or authorized service center. If you need assistance in locating any accessory, please

contact D

1-800-4-D

D25501 D25553 D25602 D25651 D25831 D25851

Concrete 1-9/16" 1-9/16" 1-3/4" 1-3/4" – –

(40 mm) (40 mm) (45 mm) (45 mm) – –

RPM 490 490 210–415 210–415 – –

No load BPM 3300 3300 1430–2840 1430–2840 1430–2840 1430–2840

EWALT, recommended accessories should be used with this product.

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

EWALT (1-800-433-9258) or visit our website www.dewalt.com.

MAXIMUM CAPACITY

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a D

EWALT authorized service center or other qualified service personnel. Always use identical

a D

replacement parts.

EWALT factory service center,

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4-D

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

D

during the first two years after purchase.

EWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

D

during the first year after purchase.

If you are not completely satisfied with the performance of your D

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are

missing, call 1-800-4-D

EWALT for a free replacement.

EWALT (1-800-433-9258). This warranty does not apply to

EWALT tools are covered by our:

2 YEARS FREE SERVICE

D25602, D25651, D25831, D25851

1 YEAR FREE SERVICE

D25501, D25553

90 DAY MONEY BACK GUARANTEE

EWALT Power Tool, Laser, or

Définitions : lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur

employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée pourrait se solder par des blessures mineures ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages

matériels.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIF À CET OUTIL OU À

PROPOS DE TOUT AUTRE OUTIL D

(1-800-433-9258).

AVERTISSEMENT : afin de réduire le risque de blessures, lire le mode d’emploi de

l’outil.

Avertissements de sécurité généraux pour les outils

électriques

AVERTISSEMENT! Lire tous les avertissements de sécurité et les directives. Le

non-respect des avertissements et des directives pourrait se solder par un choc

électrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte à votre outil électrique à

alimentation sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, tel qu’en

présence de liquides, de gaz ou de poussières inflammables. Les outils électriques

produisent des étincelles qui pourraient enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les personnes à proximité pendant l’utilisation d’un outil

électrique. Une distraction pourrait en faire perdre la maîtrise à l’utilisateur.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais modifier

la fiche d’aucune façon. Ne jamais utiliser de fiche d’adaptation avec un outil

électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation de fiches

non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des tuyaux,

des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique est

plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à l’humidité. La pénétration de l’eau

dans un outil électrique augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné de

la chaleur, de l’huile, des bords tranchants et des pièces mobiles. Les cordons

endommagés ou enchevêtrés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge convenant

à cette application. L’utilisation d’une rallonge conçue pour l’extérieur réduira les risques

de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit humide,

brancher l’outil dans une prise ou sur un circuit d’alimentation dotés d’un disjoncteur de

fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur réduit les risques de choc

électrique.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un outil

électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un simple moment d’inattention

en utilisant un outil électrique peut entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve à la

position d’arrêt avant de relier l’outil à une source d’alimentation et/ou d’insérer un

bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil électrique alors

que le doigt repose sur l’interrupteur ou brancher un outil électrique dont l’interrupteur est

à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé avant de démarrer l’outil. Une clé ou une clé de

réglage attachée à une partie pivotante de l’outil électrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet de

mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de bijoux.

Garder les cheveux, les vêtements et les gants à l’écart des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux longs risquent de rester coincés dans les

pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de dépoussiérage

et de ramassage, s’assurer que ceux-ci sont bien raccordés et utilisés. L’utilisation

d’un dispositif de dépoussiérage peut réduire les dangers engendrés par les poussières.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche de la source d’alimentation et/ou du bloc-piles de l’outil

électrique avant de faire tout réglage ou changement d’accessoire ou avant de

ranger l’outil. Ces mesures préventives réduisent les risques de démarrage accidentel de

l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants et ne permettre à

aucune personne n’étant pas familière avec un outil électrique ou son mode

d’emploi d’utiliser cet outil. Les outils électriques deviennent dangereux entre les mains

d’utilisateurs inexpérimentés.

e) Entretien des outils électriques. Vérifier si les pièces mobiles sont mal alignées ou

coincées, si des pièces sont brisées ou présentent toute autre condition susceptible

de nuire au bon fonctionnement de l’outil électrique. En cas de dommage, faire

réparer l’outil électrique avant toute nouvelle utilisation. Beaucoup d’accidents sont

causés par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à

maîtriser.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail à

effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle

il a été conçu est dangereuse.

5) RÉPARATION

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que des

pièces de rechange identiques. Cela permettra de maintenir une utilisation sécuritaire

de l’outil électrique.

Consignes de sécurité additionnelles propres aux

marteaux rotatifs

• Porter un dispositif de protection auditif. Le bruit en résultant pourrait occasionner une

perte de l’acuité auditive.

• Utiliser la/les poignée(s) auxiliaire(s) si fournie(s) avec l'outil. Une perte de contrôle de

l’outil pourrait occasionner des dommages corporels.

• Tenir l’outil par les surfaces isolées prévues à cet effet pendant toute utilisation où

l’organe de coupe pourrait entrer en contact avec des fils électriques cachés ou son

propre cordon. Tout contact de l’organe de coupe avec un fil sous tension mettra les parties

métalliques exposées de l'outil sous tension et électrocutera l'utilisateur.

• Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le matériau

sur une surface stable. Tenir la pièce à la main ou contre son corps offre une stabilité

insuffisante qui pourrait vous en faire perdre le contrôle.

• Porter des lunettes de protection ou toute autre protection oculaire. Le martelage

pourrait faire voltiger des éclats. Ces particules volantes pourraient occasionner des

dommages oculaires permanents. Porter un masque anti-poussières ou un appareil de

protection des voies respiratoires pour toute application productrice de poussières. Une

protection auditive peut s’avérer nécessaire pour la plupart des applications.

EWALT, COMPOSER SANS FRAIS LE : 1-800-4-DEWALT

Page 4

• Maintenir systématiquement l’outil fermement. Ne pas tenter d’utiliser cet outil sans

.....................

le maintenir à deux mains. Il est recommandé d’utiliser systématiquement la poignée

latérale. Le fait d’utiliser cet outil à une main pourra vous en faire perdre le contrôle. Traverser

ou rencontrer des matériaux durs comme les armatures peut aussi s’avérer dangereux.

Resserrer soigneusement la poignée latérale avant toute utilisation.

• Ne pas utiliser cet outil pendant des périodes de temps prolongées. Les vibrations

causées par la percussion peuvent poser des risques pour les mains ou les bras. Porter des

gants pour amortir les vibrations, et pour limiter les risques, faire des pauses fréquentes.

• Ne pas remettre à neuf les forets soi-même. La remise à neuf de tout burin doit être

effectuée par un spécialiste agréé. Tout burin remis à neuf incorrectement pose des risques

de dommages corporels.

• Porter des gants lors de l’utilisation de l’outil ou le changement de mèche. Les parties

métalliques accessibles de l’outil et des mèches/forets pourraient s’avérer brûlantes lors de

l’utilisation. De petits débris de matériau pourraient aussi blesser les mains nues.

• Attendre systématiquement l’arrêt complet de la mèche/foret avant de déposer

l’outil où que ce soit. Des forets/mèches en rotation posent des risques de dommages

corporels.

• Ne pas donner des coups de marteau sur des forets/mèches coincés pour les déloger.

Des fragments de métal ou de matériau pourraient être éjectés et causer des dommages

corporels.

• Les burins légèrement usés peuvent être réaffutés.

REMARQUE : ne pas surchauffer une mèche (jusqu’à sa décoloration) pendant le réaffutage.

Les burins très émoussés doivent être remartelés. Ne pas retremper un burin ou en faire un

revenu.

• Maintenir le cordon d’alimentation à l’écart d’une mèche en rotation. Ne pas enrouler

le cordon autour d’une partie quelconque de votre corps. Un cordon électrique enroulé

autour d’une mèche en rotation pose des risques de dommages corporels et de perdre le

contrôle de l’outil.

• Prendre des précautions à proximité des évents, car ils cachent des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces

mobiles.

• Pour la sécurité de l’utilisateur, utiliser une rallonge de calibre adéquat (AWG,

American Wire Gauge [calibrage américain normalisé des fils électriques]). Plus le

calibre est petit, et plus sa capacité est grande. Un calibre 16, par exemple, a plus de capacité

qu’un calibre 18. L’usage d’une rallonge de calibre insuffisant causera une chute de tension

entraînant perte de puissance et surchauffe. Si plusieurs rallonges sont nécessaires pour

obtenir une certaine longueur, s’assurer que chaque rallonge présente au moins le calibre de

fil minimum. Le tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge

et l’intensité nominale indiquée sur la plaque signalétique. En cas de doute, utiliser le calibre

suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

Volts Longueur totale de cordon en mètres (pieds)

Intensité (en ampères)

Plus de Pas plus de AWG

0 6 18 16 16 14

610 18161412

10 12 16 16 14 12

12 16 14 12 Non recommandé

AVERTISSEMENT : Porter SYSTÉMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque antipoussières si la

découpe doit en produire beaucoup. PORTER SYSTÉMATIQUEMENT UN ÉQUIPEMENT DE

SÉCURITÉ HOMOLOGUÉ :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3 ;

• Protection auditive ANSI S12.6 (S3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : Les scies, meules, ponceuses, perceuses ou autres outils de

construction peuvent produire des poussières contenant des produits chimiques reconnus pour

causer cancers, malformations congénitales ou être nocifs au système reproducteur. Parmi ces

produits chimiques, on retrouve :

• le plomb dans les peintures à base de plomb ;

• la silice cristallisée dans les briques et le ciment ou autres articles de maçonnerie ; et

• l’arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associé à de telles expositions varie selon la fréquence à laquelle on effectue ces

travaux. Pour réduire toute exposition à ces produits : travailler dans un endroit bien aéré, en

utilisant du matériel de sécurité homologué tel un masque antipoussières spécialement conçu

pour filtrer les particules microscopiques.

• Limiter tout contact prolongé avec les poussières provenant du ponçage, sciage,

meulage, perçage ou toute autre activité de construction. Porter des vêtements de

protection et nettoyer à l’eau savonneuse les parties du corps exposées. Le fait de

laisser la poussière pénétrer dans la bouche, les yeux ou la peau peut provoquer l’absorption

de produits chimiques dangereux.

AVERTISSEMENT : Cet outil peut produire et/ou répandre de la poussière susceptible de

causer des dommages sérieux et permanents au système respiratoire. Toujours utiliser un

appareil respiratoire antipoussières homologué par le NIOSH ou l’OSHA. Diriger les particules

dans le sens opposé au visage et au corps.

AVERTISSEMENT : Porter systématiquement une protection oculaire. Tout utilisateur ou

individu présent doit porter une protection oculaire homologuée ANSI Z87.1.

AVERTISSEMENT : Pendant l’utilisation, porter systématiquement une protection

auditive individuelle adéquate homologuée ANSI S12.6 (S3.19). Sous certaines conditions

et suivant la longueur d’utilisation, le bruit émanant de ce produit pourrait contribuer à une perte

de l’acuité auditive.

• L’étiquette apposée sur votre outil peut inclure les symboles suivants. Les symboles et leur

définition sont définis ci-après :

V ...................volts A .................... ampères

Hz .................hertz W ................... watts

min ............... minutes

............ courant continu ................. courant alternatif ou continu

.................Classe / Fabrication

..................... (mis à la terre) ..................borne de terre

.................Classe II Fabrication .................. symbole d’avertissement

..................... (double isolation) BPM .............. battements par minute

…/min ..........par minute R/MIN ............ tours par minute

120V

240V

7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

................. courant alter natif

n

o .................. vitesse à vide

Moteur

Votre outil DEWALT est équipé d’un moteur d’origine DEWALT. S’assurer que le courant utilisé

correspond bien à celui indiqué sur la plaque signalétique. Une baisse de tension de plus de

10% causera perte de puissance et surchauffe. Tous les outils D

EWALT sont testés en usine.

DESCRIPTION (Fig. 1)

AVERTISSEMENT : Ne jamais modifier l’outil électrique ni aucun de ses composants. Il y a

risques de dommages corporels ou matériels.

A. Gâchette F. Sélecteur de mode

B. Glissière de verrouillage G. Régulateur électronique de vitesse et d'impact

C. Poignée latérale H. Bouton de fixation

D. Poignée principale I. Position arrière de la poignée latérale

E. Système d'amortissement des vibrations

USAGE PREVU

Ces marteaux rotatifs industriels ont été conçus pour le martelage-perforage et le burinage

professionnels sur des chantiers divers (ex. : chantiers de construction). NE PAS les utiliser en

milieu ambiant humide ou en présence de liquides ou de gaz inflammables.

Ces marteaux rotatifs industriels sont des outils de professionnels. NE PAS les laisser à la portée

des enfants. Une supervision est nécessaire auprès de tout utilisateur non expérimenté.

ASSEMBLAGE ET REGLAGES

Poignée latérale (Fig. 1)

AVERTISSEMENT: pour réduire tout risque de dommages corporels, utiliser

SYSTÉMATIQUEMENT l’outil avec sa poignée latérale installée correctement et solidement

arrimée. Tout manquement à cette directive pourrait faire que la poignée latérale glisse pendant

l’utilisation de l’outil et entraîner la perte du contrôle de celui-ci. Maintenir l’outil fermement à

deux mains pour un contrôle optimal.

La poignée latérale se fi xe sur le barillet avant (collier) et peut effectuer une rotation de

360° pour permettre d’être utilisée par un gaucher ou un droitier. Pour faciliter l’utilisation, la

poignée latérale peut être installée sur la position avant ou arrière.

INSTALLATION EN POSITION AVANT (FIG. 2)

1. Dévissez la poignée latérale (C) et démontez le dispositif de fixation de la poignée latérale

(J).

2. Enclenchez la bague d'acier (K) sur le collier (L) derrière le porte-outil (M). Appuyez en

même temps sur les deux extrémités de la bague d'acier. Installez la bague (N) puis insérez

la goupille (O).

3. Poussez le dispositif de fixation de la poignée latérale (J) sur l’anneau et vissez sur le bouton

de fixation (H), (ne pas resserrer).

4. Vissez la poignée latérale (C) sur le bouton de fixation (H) puis serrez à fond.

5. Faites tourner le dispositif de la poignée latérale sur la position désirée. Pour le martelageperforage horizontal avec un foret épais, placez le dispositif de la poignée latérale à un angle

approximatif de 20 ° de l’outil pour optimiser le contrôle de ce dernier.

6. Verrouillez le dispositif de fixation de la poignée latérale en place en resserrant le bouton de

fixation (H).

INSTALLATION EN POSITION ARRIERE (FIG. 3)

1. Dévissez la poignée latérale (C) et retirez-la du dispositif de fixation de la poignée latérale.

Laissez le dispositif de la poignée latérale sur la position désirée.

2. Vissez directement la poignée latérale sur l’une de ses positions arrière (I) d’un côté ou de

l’autre de l’outil.

Système d'amortissement des vibrations (Fig. 1)

D25602, D25651, D25831, D25851

Pour optimiser le contrôle des vibrations, maintenez l'outil une main sur la poignée principale (D)

et l'autre sur la poignée latérale (C). Appliquez juste assez de pression sur le marteau de façon à

ce que le dispositif amortisseur de la poignée principale tourne à mi-régime. Seule une quantité

limitée de pression sur le marteau est nécessaire pour activer le système d'amortissement.

Appliquer une pression excessive sur l’outil ne le fera ni percer ni buriner plus rapidement et

préviendra l’activation du système d'amortissement.

Installation et retrait d’accessoires à douille de

cannelures (Fig. 4)

D25553, D25651, D25851

AVERTISSEMENT: pour réduire tout risque de dommages corporels graves, arrêter et

débrancher l'outil avant tout réglage ou avant de retirer ou installer toute pièce ou tout

accessoire.

1. Insérez la tige de mèche dans le porte-outil (M) aussi loin que possible. La rainure sur la tige

du burin (Q) doit s’aligner sur le symbole (R) sur le porte-outil. S’il est inséré correctement,

le manchon de verrouillage (P) retournera sur sa position extrême et affichera un symbole

de verrou fermé.

2. Tirez sur la mèche pour vous assurer qu’elle est correctement verrouillée.

3. Si la rainure du burin n’est pas alignée sur le symbole, ou s’il n’est pas inséré à fond, le

symbole du verrou restera ouvert.

Pour retirer la mèche, tirez le manchon de verrouillage vers l’arrière et sortez la mèche.

Installation et retrait des accessoires SDS Max

D25501, D25602, D25831

AVERTISSEMENT: pour réduire tout risque de dommages corporels graves, arrêter et

débrancher l'outil avant tout réglage ou avant de retirer ou installer toute pièce ou tout

accessoire.

1. Tirez vers l’arrière le manchon de verrouillage (P) et insérez une tige de mèche. La tige de

mèche doit être propre.

2. Tournez la mèche légèrement jusqu’à ce que le manchon s’enclenche en position.

3. Assurez-vous que la mèche est correctement arrimée.

REMARQUE: la mèche doit pouvoir bouger de quelques centimètres, vers l’avant ou

l’arrière, dans le porte-outil (M) pour être correctement installée.

4. Pour retirer la mèche, tirez le manchon de verrouillage vers l’arrière et sortez la mèche.

®

Correcteur de couple intégral (Fig. 5)

D25602, D25651

AVIS: arrêter systématiquement l’outil avant de changer les paramètres de couples pour éviter

d’endommager l’outil.

La fonctionnalité de correcteur de couple intégral (CCI) de cet outil a été conçue pour permettre

d’optimiser le contrôle grâce à un mécanisme d’embrayage à deux phases.

Le réglage de couple 1 (S) a été conçu pour la plupart des applications de martelage-perforage

et pour débrayer facilement lorsque la mèche rencontrera une armature ou tout autre matériau

étranger.

Le réglage de couple 2 (T) a été prévu pour des applications nécessitant un couple élevé comme

le perçage à percussion avec trépans carottiers ou mèches demi-rondes, et conçu pour débrayer

à un seuil plus élevé de couple.

Déplacez le levier du régulateur de couple (U) sur les réglages 1 ou 2 en fonction de

l’application.

REMARQUE: laisser le boîtier du moteur tourner un peu avant de changer le couple.

Chaque fois que l’outil sera branché, il retournera automatiquement par défaut sur le réglage

d’embrayage 1, le réglage le plus sensible.

Régulateur électronique de vitesse et d'impact (Fig. 5)

D25602, D25651, D25831, D25851

Le régulateur électronique de vitesse et d'impact permet l’utilisation de mèches plus petites

sans risquer de les briser, le perçage à percussion de matériaux légers ou fragiles sans les

faire éclater, et l’optimisation du contrôle de l’outil pour le ciselage de préci-sion.

Pour l’ajuster, tournez le régulateur (G) sur le niveau désiré. Plus le chiffre est élevé, plus la

vitesse et l’énergie d'impact seront grandes. Les paramètres du régulateur donnent à l’outil

une adaptabilité extrême pour se prêter à différentes applications. Le réglage requis dépendra

de la taille de la mèche et de la dureté du matériau à percer.

Sélecteur de mode (Fig. 1)

ATTENTION: ne jamais changer de mode alors que l’appareil tourne.

ATTENTION: ne pas passer au mode martelage-perforage avec un foret dans le porte-outil

pour prévenir tout risque de dommages corporels ou matériels.

Les modèles D25501, D25553, D25602 et D25651 possèdent deux modes d’opérations.

Pour choisir le mode d'utilisation requis, tournez le sélecteur de mode (F) jusqu’à ce que la

flèche pointe sur l’icône martelage-perforage ou burinage. Les modèles D25831 et D25851 ne

possèdent que le mode burinage.

MODE MARTELAGE-PERFORAGE (

L’outil tourne et percute simultanément la pièce à travailler. Ce mode est approprié pour travailler

le béton et la maçonnerie.

MODE BURINAGE (

Le verrou de la broche est activé en mode burinage de façon à permettre la percussion sans

rotation. Ce mode est approprié pour la démolition, le burinage et le ciselage légers.

REMARQUE: en mode burinage, le marteau-perforateur peut aussi être utilisé comme levier

pour débloquer une mèche enrayée.

REGLAGE DU FORET ( )

Tournez le sélecteur de mode sur l’une des icônes de réglage de foret pour l’ajuster sur la

position désirée. Le burin peut être réglé sur 18 positions d’angles. Une fois la position désirée

choisie, déplacez légèrement d’avant en arrière le foret pour vous assurer qu’il est correctement

arrimé.

)

)

Voyants d’alimentation (Fig. 5)

Le voyant DEL jaune (V) d’usure des balais s’allumera lorsque les balais de charbon seront

presque usés pour indiquer que la maintenance de l’outil devrait être effectuée dans les 8 heures

d’utilisation.

Le voyant DEL rouge (W) s’allumera lorsque la glissière de verrouillage (B) sera activée, dans

tous les modes, excepté celui de burinage.

Le voyant DEL rouge (W) clignotera en cas de problème avec l’outil ou si les balais sont

complètement usés (se reporter à la section Balais sous Maintenance).

FONCTIONNEMENT

AVERTISSEMENT : Pour réduire tout risque de dommages corporels graves, arrêter et

débrancher l’outil avant tout réglage ou avant de retirer ou installer toute pièce ou tout

accessoire.

AVERTISSEMENT : Pour réduire tout risque de dommages corporels, s’assurer

SYSTÉMATIQUEMENT que la pièce est ancrée ou arrimée solidement. Pour percer des

matériaux fins, utiliser un morceau de bois « de renfort » pour éviter de les endommager.

AVERTISSEMENT : Pour réduire tout risque de dommages corporels, utiliser

SYSTÉMATIQUEMENT l’outil avec sa poignée latérale installée correctement et solidement

arrimée. Tout manquement à cette directive pourrait faire que la poignée latérale glisse pendant

l’utilisation de l’outil et entraîner la perte du contrôle de celui-ci. Maintenir l’outil fermement à

deux mains pour un contrôle maximum.

Position correcte des mains (Fig. 1)

AVERTISSEMENT : Pour réduire tout risque de dommages corporels graves, adopter

SYSTÉMATIQUEMENT la position des mains illustrée.

AVERTISSEMENT : Pour réduire tout risque de dommages corporels graves, Maintenir

SYSTÉMATIQUEMENT l’outil fermement pour anticiper toute réaction soudaine.

La position correcte des mains requiert une main sur la poignée latérale (C), et l’autre sur la

poignée principale (D).

REMARQUE: il est recommandé d’utiliser cet outil à des températures entre -7 ° et +40 °C (19 °

et 104 °F). L’utilisation de cet outil en dehors de ces températures en réduira la durée de vie.

Gâchette (Fig. 1)

Pour mettre l’outil en marche, appuyez sur la gâchette (A). Pour arrêter l'outil, relâchez la

gâchette.

D25602, D25651

En mode burinage seulement, verrouillez la gâchette en marche, poussez la glissière de

verrouillage (B) vers le haut tout en appuyant sur la gâchette.

Pour désactiver la glissière de verrouillage, réappuyez rapidement une fois sur la gâchette.

La glissière de verrouillage ne peut être activée qu’en mode burinage. L’appareil s’arrêtera de

fonctionner si on tente d’activer la glissière de verrouillage en mode martelage-perforage. Le

moteur s’arrêtera de tourner si la glissière de verrouillage est activée pour passer du mode

ciselage au mode martelage-perforage.

Page 5

D25831, D25851

Pour un travail continu, mettez l’interrupteur à bascule en position de marche. Pour arrêter le

travail continu, mettez l’interrupteur à bascule en position d’arrêt.

FONCTION DEMARRAGE EN DOUCEUR

La fonction démarrage en douceur permet d’accroître la vitesse progressivement, pour prévenir

que la mèche quitte la position désirée pour le trou au démarrage. La fonction démarrage

en douceur réduit aussi la transmission immédiate de retour de couple à l’engrenage et à

l’utilisateur si le marteau venait à démarrer alors que la mèche est dans un trou existant.

Martelage à percussion avec un trépan plein

D25501, D25553, D25602, D25651

REMARQUE: les modèles D25831 et D25851 ne possèdent que le mode burinage et pas de

martelage-perforage.

1. Réglez le sélecteur de mode (F) sur le mode martelage-perforage.

2. Pour les modèles D25602 et D25651 seulement, ajustez le levier du régulateur de couple

(U) sur le réglage 1 (S).

3. Réglez le régulateur électronique de vitesse et d’impact (G).

4. Insérez la mèche appropriée.

5. Ajustez la poignée latérale (C), (position arrière ou avant).

6. Marquez l’endroit où le trou doit être percé.

7. Placez la mèche sur le tracé et appuyez sur la gâchette (A).

8. Appliquez seulement une quantité limitée de pression sur le marteau pour activer le système

d'amortissement (se reporter à la section Système d'amortissement des vibrations).

9. Pour arrêter l'outil, relâchez la gâchette. Mettez systématiquement l’interrupteur en position

d’arrêt une fois le travail terminé et avant de débrancher l’outil.

Perçage à percussion avec un trépan carottier

D25501, D25553, D25602, D25651

ATTENTION: ne pas utiliser un trépan carottier pour le perçage à percussion du bois pour

prévenir tout risque de dommages corporels ou matériels.

REMARQUE: les modèles D25831 et D25851 ne possèdent que le mode burinage et pas de

martelage-perforage.

1. Réglez le sélecteur de mode (F) sur le mode martelage-perforage.

2. Pour les modèles D25602 et D25651 seulement, ajustez le levier du régulateur de couple

(U) sur le réglage 2 (T).

3. Tournez le régulateur électronique de vitesse et d'impact (G) sur la position de couple

maximum (niveau 7).

4. Ajustez la poignée latérale (C), (position arrière ou avant).

5. Installez la mèche de centrage et l’adaptateur de tige sur le trépan carottier.

6. Marquez l’endroit où le trou doit être percé.

7. Placez la mèche de centrage sur le tracé et appuyez sur la gâchette (A).

REMARQUE: certains trépans carottiers nécessitent le retrait de la mèche de centrage après

1 cm de pénétration. Si c’est le cas, retirez-la puis continuez le perçage à percussion.

8. Pour le perçage à percussion à travers une structure plus épaisse que la longueur du trépan

carottier, cassez le cylindre de béton, ou carotte, à l’intérieur du trépan à intervalles réguliers.

Pour éviter tout fendillement indésirable du béton autour du trou, percez tout d’abord un trou

du diamètre de la mèche de centrage au travers de la structure. Puis percez le trou moulé

de moitié, de chaque côté de la structure.

9. Pour arrêter l'outil, relâchez la gâchette. Mettez systématiquement l’interrupteur en position

d’arrêt une fois le travail terminé et avant de débrancher l’outil.

Burinage

D25831, D25851

1. Réglez le sélecteur de mode (F) sur le mode burinage.

2. Réglez le régulateur électronique d’impact (G) sur le paramètre désiré (se reporter à la

section Régulateur électronique de vitesse et d'impact).

3. Insérez le burin approprié et faites le tourner manuellement pour le verrouiller sur la position

requise.

REMARQUE: pour les modèles SDS Max

SDS Max®.

4. Ajustez la poignée latérale (C), (position arrière ou avant).

5. Appuyez sur la gâchette (A).

6. Appliquez seulement une quantité limitée de pression sur le marteau pour activer le système

d'amortissement (se reporter à la section Système d'amortissement des vibrations).

7. Pour arrêter l'outil, relâchez la gâchette. Mettez systématiquement l’interrupteur en position

d’arrêt une fois le travail terminé et avant de débrancher l’outil.

®

, utiliser exclusivement des accessoires

MAINTENANCE

AVERTISSEMENT : Pour réduire tout risque de dommages corporels graves, arrêter et

débrancher l’outil avant tout réglage ou avant de retirer ou installer toute pièce ou tout

accessoire.

Entretien

AVERTISSEMENT : Expulser tout débris ou poussière des évents à l’aide d’un jet d’air sec

au moins une fois par semaine. Porter une protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) et

respiratoire NIOSH/OSHA/MSHA adéquates pour effectuer cette opération.

AVERTISSEMENT : Ne jamais utiliser de solvants ou tout autre produit chimique décapant

pour nettoyer les parties non métalliques de l’outil. Ces produits chimiques pourraient attaquer

les matériaux plastiques utilisés. Utilisez un chiffon humidifié avec de l’eau et un savon doux.

S’assurer qu’aucun liquide ne pénètre dans l’outil ; ne jamais immerger aucune partie de l’outil

dans un liquide.

Lubrification

Votre outil a été parfaitement lubrifié avant son départ d’usine. Entre deux à six mois, selon

la fréquence d’utilisation, amenez ou envoyez votre outil dans un centre de réparation agréé

D

EWALT pour entretien, inspection et lubrification complets. Les outils utilisés constamment pour

des travaux de production nécessiteront d’être lubrifiés plus souvent. Les outils inutilisés pendant

des périodes prolongées doivent être relubrifiés avant réutilisation.

Accessoires

AVERTISSEMENT : Comme les accessoires autres que ceux fournis par DEWALT n’ont pas

été testés avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour

réduire tout risque de dommages corporels, seuls des accessoires D

doivent être utilisés avec cet appareil.

Les accessoires recommandés pour cet outil sont vendus séparément chez les distributeurs

locaux ou dans les centres de réparation agréés. Si vous avez besoin d’aide pour localiser ces

accessoires, veuillez contacter D

MD 21286 ou appeler 1-800-4-D

dewalt.com.

CAPACITÉS MAXIMALES RECOMMANDÉES

D25501 D25553 D25602 D25651 D25831 D25851

Béton 40 mm 40 mm 45 mm 45 mm – –

(1-9/16") (1-9/16") (1-3/4") (1-3/4") – –

R/MIN 490 490 210–415 210–415 – –

BPM à vide 3300 3300 1430–2840 1430–2840 1430–2840 1430–2840

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

EWALT (1-800-433-9258) ou vous rendre sur notre site www.

EWALT recommandés

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations, l’entretien et les réglages

(y compris l’inspection et le remplacement de la brosse) doivent être réalisés par un centre de

réparation en usine D

réparation professionnel. Toujours utiliser des pièces de rechange identiques.

EWALT, un centre de réparation autorisé DEWALT ou par un personnel de

Garantie limitée trois ans

DEWALT réparera gratuitement tous les problèmes dus à des défauts de matériau ou de

fabrication pendant trois ans à compter de la date d’achat. Cette garantie ne couvre pas des

défaillances de pièce dues à une usure normale ou à une mauvaise utilisation de l’outil. Pour

plus de détails relatifs à la couverture de la garantie et aux réparations sous garantie, visiter le

site Web www.dewalt.com ou composer le 1 (800) 4-D

ne s’applique pas aux accessoires ni aux dommages causés par des réparations réalisées ou

tentées par des tiers. Cette garantie vous accorde des droits légaux spécifiques et il est possible

que vous ayez d’autres droits qui varient d’un État ou d’une province à l’autre.

En plus de la garantie, les outils D

SERVICE D'ENTRETIEN GRATUIT DE 2 ANS

EWALT entretiendra l'outil et remplacera les pièces usées par une utilisation normale et ce,

D

gratuitement, en tout temps, pendant deux ans à compter de la date d'achat.

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

EWALT entretiendra l’outil et remplacera les pièces usées par une utilisation normale et ce,

D

gratuitement, à tout instant pendant la première année à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances de votre outil électrique, laser ou de

votre cloueuse D

d’un reçu dans les 90 jours suivant la date d’achat et nous vous rembourserons entièrement –

sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits vendus en Amérique latine.

Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique présente dans

l’emballage, appeler l’entreprise locale ou consulter le site Web pour les informations relatives

à cette garantie.

EWALT pour quelque raison que ce soit, vous pouvez le retourner accompagné

EWALT sont couverts par notre :

D25602, D25651, D25831, D25851

D25501, D25553

EWALT (1 (800) 433-9258). Cette garantie

REMPLACEMENT GRATUIT DES ÉTIQUETTES D’AVERTISSEMENT : si les étiquettes

d’avertissement deviennent illisibles ou sont manquantes, composer le 1 (800) 4-D

en obtenir le remplacement gratuit.

EWALT pour

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de cada palabra de

señal. Lea el manual y preste atención a estos símbolos.

PELIGRO: indica una situación de peligro inminente que, si no se evita,

provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se

evita, podría provocar la muerte o lesiones graves.

ATENCIÓN: indica una situación de peligro potencial que, si no se evita,

posiblemente provocaría lesiones leves o moderadas.

AVISO: se refiere a una práctica no relacionada a lesiones corporales que

de no evitarse puede resultar en daños a la propiedad.

SI TIENE ALGUNA DUDA O ALGÚN COMENTARIO SOBRE ÉSTA U OTRA HERRAMIENTA

D

EWALT, LLÁMENOS AL NÚMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258).

ADVERTENCIA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Advertencias generales de seguridad para herramientas

eléctricas

¡ADVERTENCIA! Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA FUTURAS CONSULTAS

El término “herramienta eléctrica” incluido en las advertencias hace referencia a las herramientas

eléctricas operadas con corriente (con cable eléctrico) o a las herramientas eléctricas operadas

con baterías (inalámbricas).

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y oscuras

propician accidentes.

b) No opere las herramientas eléctricas en atmósferas explosivas, como ambientes

donde haya polvo, gases o líquidos inflamables. Las herramientas eléctricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los niños y a los espectadores de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con conexión a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con descargas a tierra como, por ejemplo,

tuberías, radiadores, cocinas eléctricas y refrigeradores. Existe mayor riesgo de

descarga eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

entra agua a una herramienta eléctrica, aumentará el riesgo de descarga eléctrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes

filosos y las piezas móviles. Los cables dañados o enredados aumentan el riesgo de

descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable prolongador

adecuado para tal uso. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de evitar,

utilice un suministro protegido con un interruptor de circuito por falla a tierra (GFCI). El uso

de un GFCI reduce el riesgo de descargas eléctricas.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta eléctrica puede provocar lesiones personales

graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los ojos. En

las condiciones adecuadas, el uso de equipos de protección, como máscaras para polvo,

calzado de seguridad antideslizante, cascos o protección auditiva, reducirá las lesiones

personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la posición

de apagado antes de conectarlo a la fuente de energía o paquete de baterías, o antes

de levantar o transportar la herramienta. Transportar herramientas eléctricas con el

dedo apoyado en el interruptor o enchufar herramientas eléctricas con el interruptor en la

posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de encender la herramienta

eléctrica. Una llave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y párese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en situaciones inesperadas.