Page 1

Questions? See us on the World Wide Web at www.dewalt.com

¿Dudas? Visítenos en Internet: www.dewalt.com

Dúvidas? Visite-nos na Internet em www.dewalt.com.br

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR

EL PRODUCTO.

INSTRUÇÕES DE OPERAÇÃO, CENTRO DE SERVIÇOS E CERTIFICADO

DE GARANTIA. ADVERTÊNCIA: LEIA ESTAS INSTRUÇÕES ANTES DE

UTILIZAR O PRODUTO.

D25501

1-9/16" (40 mm) SDS Max

D25601

1-3/4" (45 mm) SDS Max

1-3/4" (45 mm) SDS Max

D25602

1-3/4" (45 mm) SDS Max

D25831, D25851

SDS Max

ranhura e SDS Max

®

and Spline Chipping Hammers / Martillos de burilado SDS Max® y estriados / Marteletes de raspagem de

®

®

Hammers / Martillo de 1-9/16" (40 mm) SDS Max® / Martelo 1-9/16" (40mm) SDS Max

®

Demolition Hammer / Martillo Demoledor de 1-3/4" (45 mm) SDS Max® / Martelo Demolidor

®

®

Hammers / Martillo de 1-3/4" (45 mm) SDS Max® / Martelo 1-3/4" (45 mm) SDS Max

®

®

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to these

symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

WARNING: To reduce the risk of injury, read the instruction

manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions

Failure to follow the warnings and instructions may result in

electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool" in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable,

use a ground fault circuit interrupter (GFCI) protected supply.

Use of a GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

English

1

Page 3

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in

the off position before connecting to power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising power

tools that have the switch on invites accidents.

English

d) Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding

of moving parts, breakage of parts and any other condition

that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Additional Safety Instructions for

Rotary Hammers

• Wear ear protectors. Exposure to noise can cause hearing

loss.

• Use auxiliary handles supplied with the tool. Loss of control

can cause personal injury.

• Hold power tools by insulated gripping surfaces when

performing an operation where the cutting tool may contact

hidden wiring or its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live” and shock the

operator.

2

Page 4

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by

hand or against your body is unstable and may lead to loss of

control.

• Wear safety goggles or other eye protection. Hammering

operations cause chips to fly. Flying particles can cause

permanent eye damage. Wear a dust mask or respirator for

applications that generate dust. Ear protection may be required

for most applications.

• Keep a firm grip on the tool at all times. Do not attempt

to operate this tool without holding it with both hands.

It is recommended that the side handle be used at all times.

Operating this tool with one hand will result in loss of control.

Breaking through or encountering hard materials such as re-bar

may be hazardous as well. Tighten the side handle securely

before use.

• Do not operate this tool for long periods of time. Vibration

caused by hammer action may be harmful to your hands and

arms. Use gloves to provide extra cushion and limit exposure by

taking frequent rest periods.

• Do not recondition bits yourself. Chisel reconditioning should

be done by an authorized specialist. Improperly reconditioned

chisels could cause injury.

• Wear gloves when operating tool or changing bits. Accessible

metal parts on the tool and bits may get extremely hot during

operation. Small bits of broken material may damage bare

hands.

• Never lay the tool down until the bit has come to a complete

stop. Moving bits could cause injury.

• Do not strike jammed bits with a hammer to dislodge them.

Fragments of metal or material chips could dislodge and cause

injury.

• Slightly worn chisels can be resharpened by grinding.

NOTE: Do not overheat the bit (discoloration) while grinding a

new edge. Badly worn chisels require reforging. Do not reharden

and temper the chisel.

• Keep the power cord away from the rotating bit. Do not

wrap the cord around any part of your body. An electric cord

wrapped around a spinning bit may cause personal injury and

loss of control.

• Air vents often cover moving parts and should be avoided.

Loose clothes, jewellery or long hair can be caught in moving

parts.

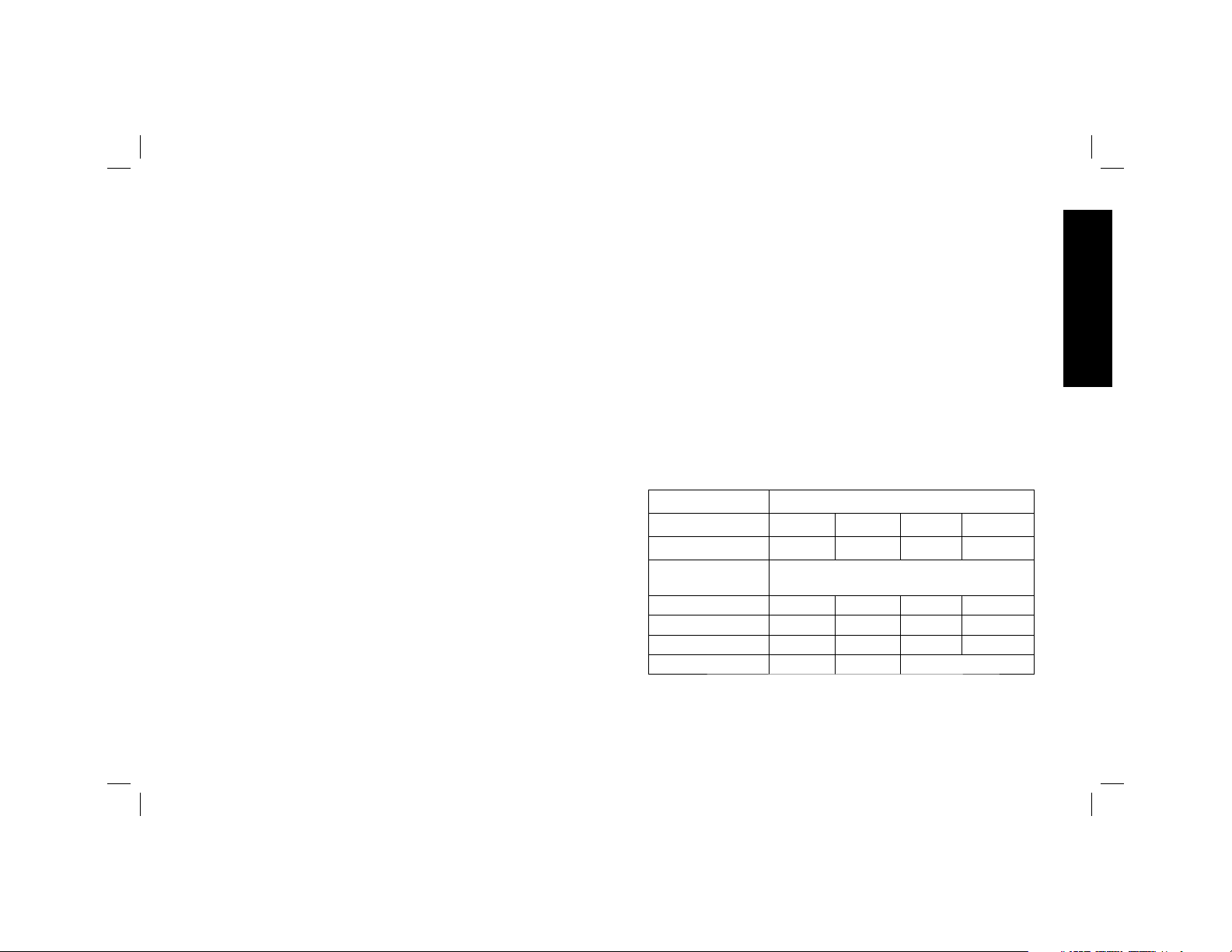

• An extension cord must have adequate wire size for safety.

An undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size. The following

table shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

Voltage (Volts)

Total length of cord in meters (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Rated Ampere

range

Minimal cross-sectional area of the

cord in meters (mm

2

)

0 - 6A 1.0 1.5 1.5 2.5

6 - 10A 1.0 1.5 2.5 4.0

10 - 12A 1.5 1.5 2.5 4.0

12 - 16A 2.5 4.0 Not Recommended

English

3

Page 5

WARNING: Always use eye protection. All users and

bystanders must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection

that conforms to ANSI S12.6 (S3.19) during use. Under some

conditions and duration of use, noise from this product may

contribute to hearing loss.

English

WARNING: ALWAYS use safety glasses. Everyday eyeglasses

are NOT safety glasses. Also use face or dust mask if cutting operation

is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed

to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face

and body.

• The label on your tool may include the following symbols. The

symbols and their definitions are as follows:

V ...........volts A ........ amperes

Hz .........hertz W....... watts

min ........ minutes

...... direct current ..... alternating or direct current

..........Class I Construction no ...... no load speed

.............. (grounded) ...... earthing terminal

..........Class II Construction ...... safety alert symbol

.............. (double insulated) BPM .. beats per minute

…/min ... per minute RPM .. revolutions per minute

IPM .......impact per minute

..... alternating current

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be

sure your power supply agrees with the nameplate markings.

Voltage decrease of more than 10% will cause loss of power and

overheating. All D

EWALT tools are factory tested.

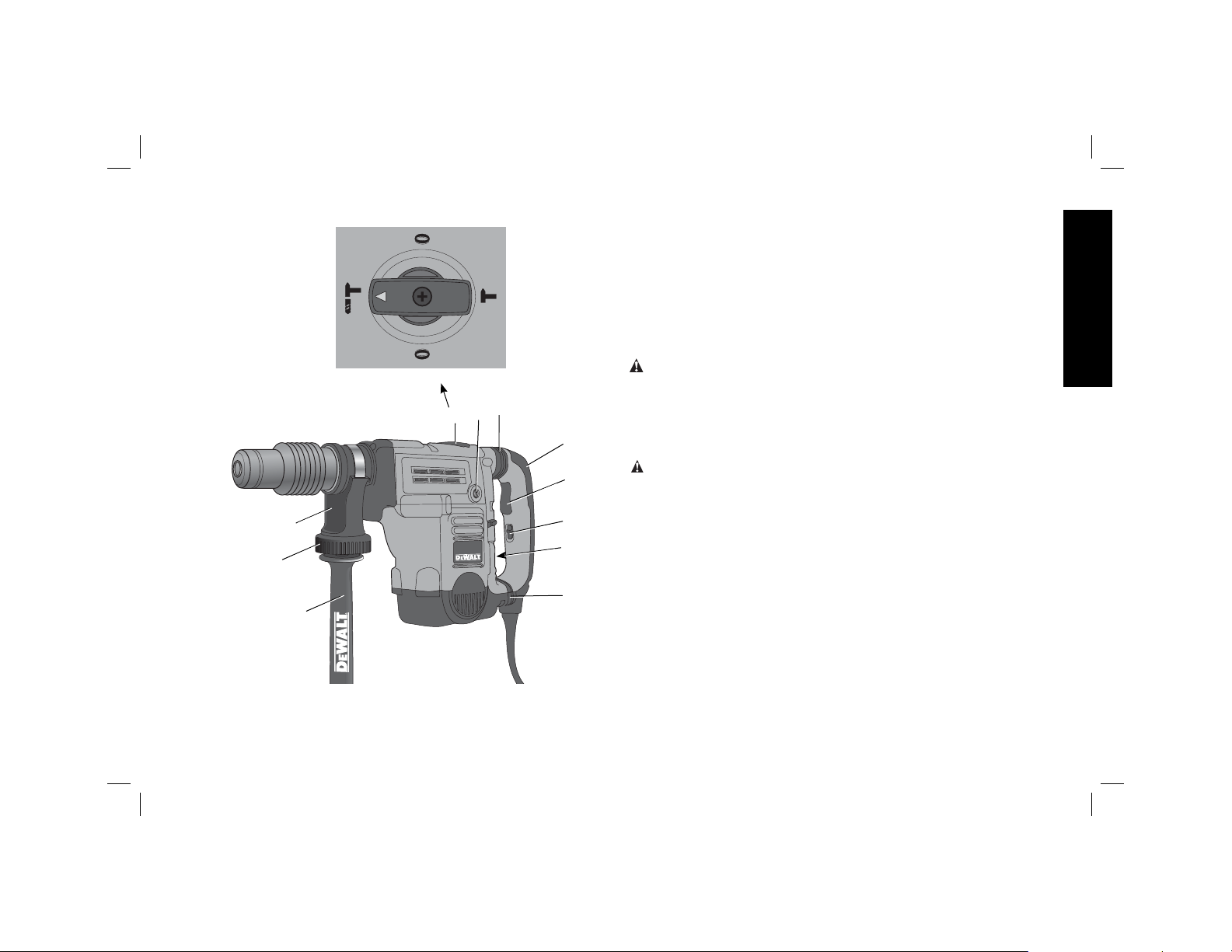

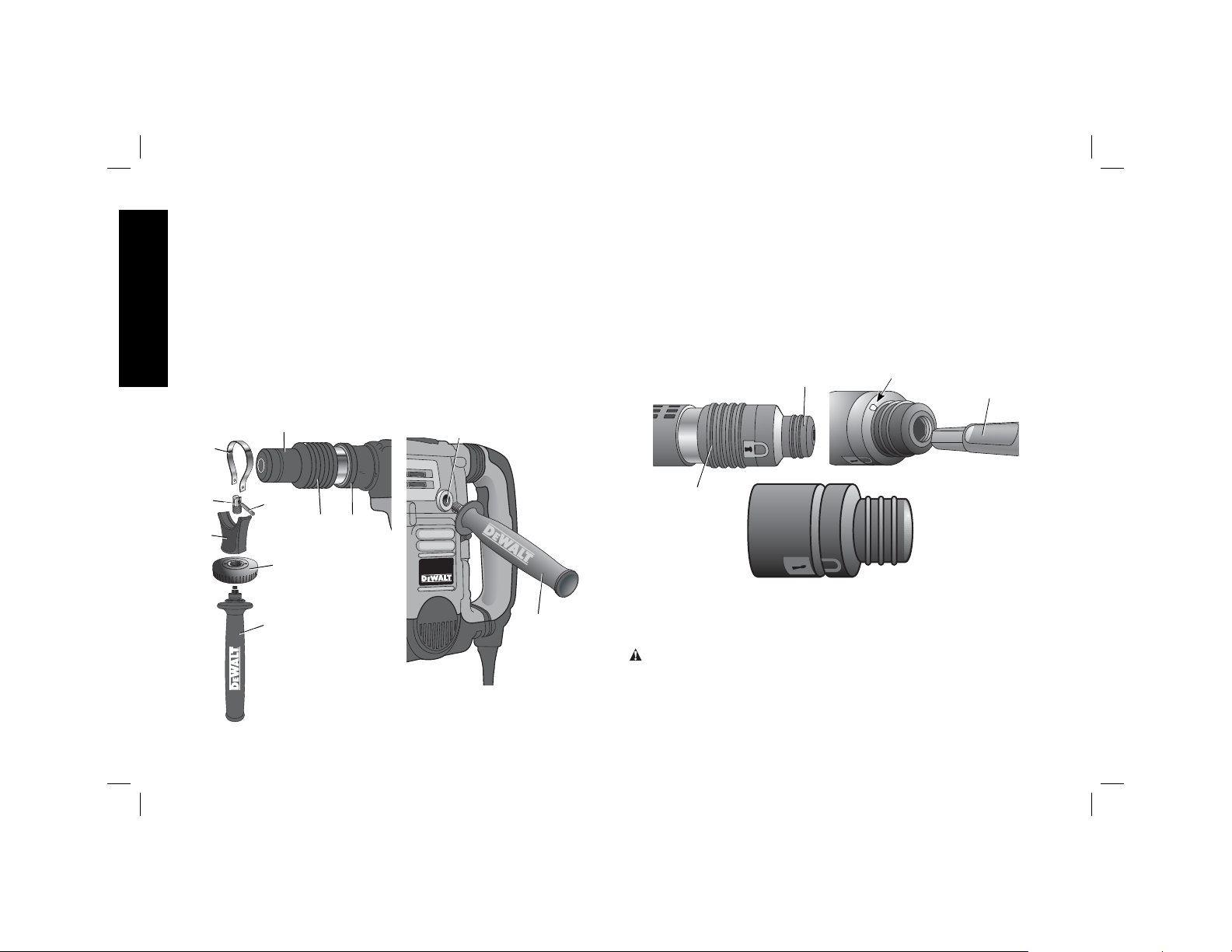

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Trigger switch F. Mode selector

B. Lock-on slider G. Electronic Speed and

C. Side handle impact control dial

D. Main handle H. Clamp knob

E. Active vibration control I. Rear side handle position

4

Page 6

FIG. 1

HAMMERDRILLING

MODE

J

H

C

CHISEL BIT ADJUSTMENT MODE

CHISEL BIT ADJUSTMENT MODE

I

F

D25602

CHIPPING

MODE

E

INTENDED USE

These heavy-duty rotary hammers have been designed for

professional hammerdrilling, and chipping at various work sites

(i.e., construction sites). DO NOT use under wet conditions or in

English

presence of flammable liquids or gases.

This heavy-duty rotary hammer is a professional power tool. DO

NOT let children come into contact with the tool. Supervision is

required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of injury, turn unit off and

disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or

when making repairs. Be sure the trigger switch is in the OFF

D

A

B

G

E

position. An accidental start-up can cause injury.

Side Handle (Fig. 1)

WARNING: To reduce the risk of personal injury, ALWAYS

operate the tool with the side handle properly installed and securely

tightened. Failure to do so may result in the side handle slipping

during tool operation and subsequent loss of control. Hold tool with

both hands to maximize control.

The side handle clamps to the front barrel (collar) and may be rotated

360° to permit right or left-hand use. For operating convenience, the

side handle can be installed in front or rear positions.

TO MOUNT IN FRONT POSITION (FIG. 2)

1. Unscrew the side handle (C) and disassemble the side handle

clamp (J).

2. Snap the steel ring (K) over the collar (L) behind the tool holder

(M). Squeeze both ends of the steel ring together. Mount the

bushing (N) and insert the pin (O).

3. Slide the side handle clamp (J) over the bushing and screw on

the clamp knob (H) –do not tighten.

4. Screw the side handle (C) into the clamp knob (H) and tighten.

5

Page 7

5. Rotate the side handle mounting assembly to the desired

position. For hammerdrilling horizontally with a heavy drill bit,

place the side handle assembly at an angle of approximately

20° to the tool for optimum control.

6. Lock the side handle mounting assembly in place by tightening

the clamp knob (H).

TO MOUNT IN REAR POSITION (FIG. 3)

English

1. Unscrew the side handle (C) and remove it from the side handle

mounting assembly. Leave the side handle mounting assembly

in the front position.

2. Screw the side handle directly into one of the rear side handle

positions (I) on either side of the tool.

FIG. 2

K

M

FIG. 3

I

Active Vibration Control (Fig. 1)

D25602, D25831, D25851

For best vibration control, hold the tool with one hand on the main

handle (D) and the other hand on the side handle (C). Apply just

enough pressure so the damping device on the main handle is

approximately midstroke. The hammer only needs enough pressure

to engage the active vibraton control. Applying too much pressure

will not make the tool drill or chip faster and active vibration control

will not engage.

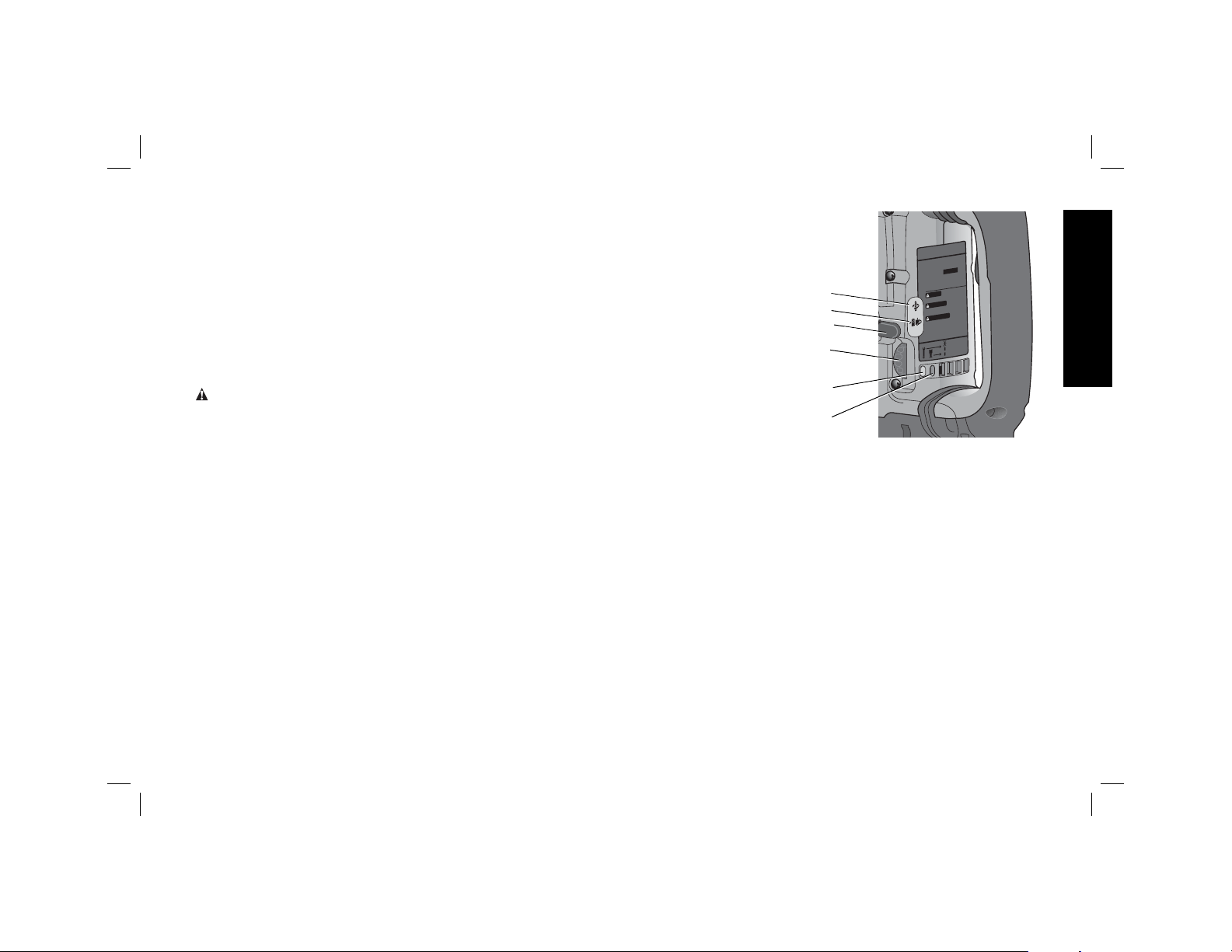

FIG. 4

M

R

Q

N

J

O

P

L

H

P

Inserting and Removing Spline Drive

C

C

Accessories (Fig. 4)

D25851

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments

or accessories.

1. Insert the bit shank into the tool holder (M) as far as it will go.

The groove on the chisel shank (Q) must be aligned with the

6

Page 8

symbol (R) on the toolholder. If inserted correctly,the locking

sleeve (P) moves back to the end position and shows a closed

lock symbol.

2. Pull on the bit to be sure that it is properly locked.

3. If the chisel groove is not aligned with the symbol, or is not

inserted to the complete depth the lock symbol remains open.

To remove the bit, pull back the locking sleeve and pull the bit out.

Inserting and Removing SDS Max®

Accessories

D25501, D25602, D25831

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments

or accessories.

1. Pull back the locking sleeve (P) and insert the bit shank. The bit

shank must be clean.

2. Turn the bit slightly until the sleeve snaps back into position.

3. Ensure the bit is properly engaged.

NOTE: The bit needs to move several centimeters in and out of

the tool holder (M) when properly engaged.

4. To remove the bit, pull back the locking sleeve and pull the bit

out.

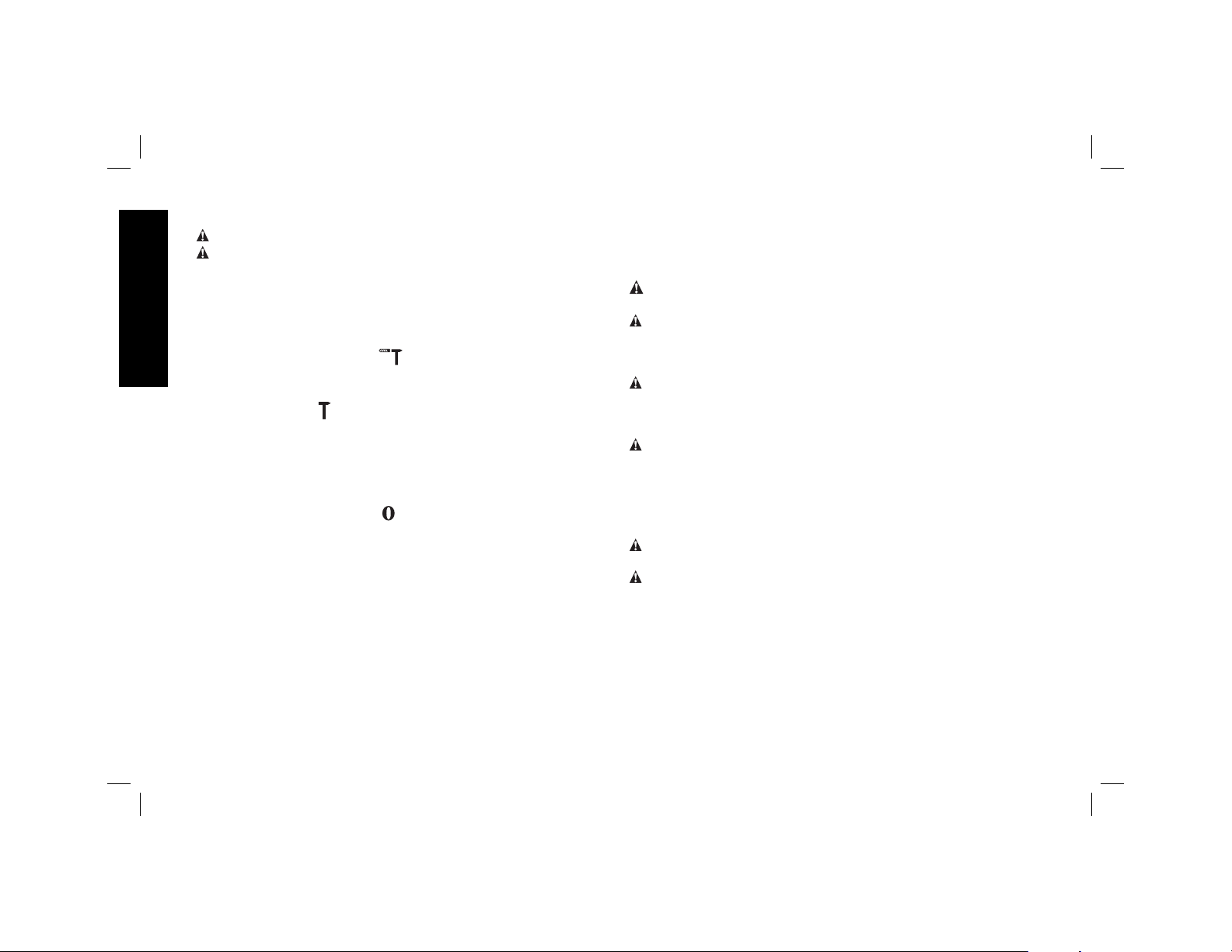

Complete Torque Control (Fig. 5)

D25602

NOTICE: Always turn the tool off before changing torque control

settings or damage to tool may result.

The Complete Torque Control (CTC) feature of this tool is designed

to provide additional control with a two-stage clutch mechanism.

Clutch Setting 1 (S) is designed for most hammerdrilling applications

and is designed to easily clutch out when the drill bit encounters

re-bar or other foreign substances.

Clutch Setting 2 (T) is

FIG. 5

designed for higher torque

applications such as corebits and deep hole

hammerdrilling and is

designed to clutch out at a

higher torque threshold.

Move the torque control

lever (U) to setting 1 or 2

as needed for application.

NOTE: Allow the motor

housing to rotate a little

S

T

U

G

V

COMPLETE TORQUE CONTROL

CTC

1 3/4" (44mm) SDS MAX

ROTARY HAMMER

D25XXX

SER.

TO REDUCE THE RISK OF INJUR

WARNING

USER MUST READ INSTRUCTION

YS USE PROPER EYE, EAR AND

LWA

LW

MANUAL. A

RY PROTECTION. A

ATO

RESPIR

LEA EL MANUAL DE

ADVERTENCIA

INSTRUCCIONES PARA

PARA LOS OJOS, OÍDOS Y VÍAS

UN FUNCIONAMIENTO SEGURO. SIEMPRE UTILICE

PROTECCIÓN ADECUADA

TORIAS. SIEMPRE UTILICE EL MANGO LATERAL.

A

RESPIR

1

AFIN DE MINIMISER

AVERTISSEMENT

TEUR DOIT LIRE LE GUIDE

LES RISQUES DE

A

’UTILIS

L

BLESSURES,

TION.TOUJOURS UTILISER UNE PROTECTION

A

D’UTILIS

AUDITIVE ET RESPIR

TÉRALE.

A

OCULAIRE,

2

UTILISER LA POIGNÉE L

T INDUSTRIAL TOOL CO., BA

L

A

W

E

TION, CALL 1-800-4-D

D

FOR SERVICE INFORMA

.com

T

L

A

W

E

.D

w

ww

YS USE SIDE HANDLE.

A

TOIRE ADÉQU

A

TIMORE, MD 21286 USA

L

T

L

A

W

E

Service

Lock-On

rvice

ush Se

r

B

Y,

TE.

A

while changing torque.

Each time the tool

W

is plugged in, it will

automatically default to

clutch setting 1, the most

sensitive setting.

Electronic Speed and Impact Control

(Fig. 5)

D25602, D25831, D25851

The electronic speed and impact control allows the use of smaller

drill bits without the risk of bit breakage, hammerdrilling into light

and brittle materials without shattering and optimal tool control for

precise chipping.

To set the control dial, turn the dial (G) to the desired level. The

higher the number, the greater the speed and impact energy. Dial

settings make the tool extremely adaptable for many different

appli cations. The required setting depends on the bit size and

hardness of material being drilled.

English

7

Page 9

Mode Selector (Fig. 1)

CAUTION: Never change the mode while the unit is running.

CAUTION: Do not change to hammerdrill mode with chisel bit in

tool holder. Personal injury and damage to tool may result.

The D25501, D25553, D25601, D25602 uses two operating modes.

To select the required operating mode, rotate the mode selector (F)

until the arrow points to the hammerdrilling or the chipping icon. The

English

D25831 uses only the chipping mode.

HAMMERDRILLING MODE (

The tool simultaneously rotates and impacts the work. This mode is

appropriate for all concrete and masonry operations.

CHIPPING MODE (

The spindle lock is engaged during chipping mode so the tool

impacts the work without rotating. This mode is appropriate for

light chipping, chiseling and demolition applications.

NOTE: In chipping mode, the hammerdrill can also be used as a

lever to free a jammed drill bit.

CHISEL BIT ADJUSTMENT (

Turn the mode selector to one of the chisel bit adjustment icons

to adjust the chisel to the desired position. There are 18 possible

positions to set the angle of the chisel. After finding the desired

position, slightly maneuver the chisel bit back and forth to ensure

the chisel is properly engaged.

)

)

)

Power Indicator Lights (Fig. 5)

The yellow brushwear indicator LED (V) lights up when the carbon

brushes are nearly worn out indicating that the tool needs servicing

within the next 8 hours of use.

The red indicator LED (W) lights up if the lock-on slider (B) is used

in any mode except the chipping mode.

The red indicator LED (W) flashes if there is a fault with the tool

or if the brushes are completely worn (refer to Brushes under

Maintenance).

OPERATION

WARNING: Always observe the safety instructions and applicable

regulations.

WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

making any adjustments or removing/installing attachments

or accessories.

WARNING: To reduce the risk of personal injury, ALWAYS

ensure workpiece is anchored or clamped firmly. If drilling thin

material, use a wood “back-up” block to prevent damage to the

material.

WARNING: To reduce the risk of personal injury, ALWAYS

operate the tool with the side handle properly installed and

securely tightened. Failure to do so may result in the side handle

slipping during tool operation and subsequent loss of control. Hold

tool with both hands to maximize control.

Proper Hand Position (Fig. 1)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce therisk of serious personal injury, ALWAYS

hold securely in anticipation of a sudden reaction.

Proper hand position requires one hand on the side handle (C), with

the other hand on the main handle (D).

NOTE: Operating temperature of this tool is 19˚ to 104˚ F (-7

to +40˚ C). Using the tool outside of this temperature range will

decrease the life of the tool.

Trigger Switch (Fig. 1)

To turn the tool on, depress the trigger switch (A). To stop the tool,

release the trigger switch.

8

Page 10

D25602

In chipping mode only, lock the trigger switch on, push the lock-on

slider (B) upwards while depressing the trigger switch.

To deactivate the lock-on slider, depress the trigger switch once

then release.

The lock-on slider may only be activated in chipping mode. The

machine will stop running when trying to engage the lock-on slider

in hammerdrilling mode. The motor will stop if the lock-on slider is

activated when changing from chisel mode into hammerdrilling

mode.

D25831, D25851

For continuous operation, move the toggle switch to the on position.

To stop continuous operation, move the toggle switch to the off

position.

SOFT START FEATURE

The soft start feature allows you to build up speed slowly, thus

preventing the drill bit from walking off the intended hole position

when starting. The soft start feature also reduces the immediate

torque reaction transmitted to the gearing and the operator if the

hammer is started with the drill bit in an existing hole.

Hammerdrilling with a Solid Bit

D25501, D25601, D25602

NOTE: The D25831, D25851 has only chipping modes with no

hammerdrilling capability.

1. Set the mode selector (F) to hammerdrilling mode.

2. For D25602 only, move the torque control lever (U) to Setting 1

(S).

3. Set the speed and impact control dial (G).

4. Insert the appropriate drill bit.

5. Adjust the side handle (front or rear position) (C).

6. Mark the spot where the hole is to be drilled.

7. Place the drill bit on that mark and depress the trigger switch

(A).

8. Apply only enough pressure to engage active vibration control

(refer to Active Vibration Control).

9. To stop the tool, release the trigger switch. Always turn the tool

off when work is finished and before unplugging.

Hammerdrilling with a Core Bit

D25501, D25601, D25602

CAUTION: Do not use a core bit for hammerdrilling wood.

Personal injury and damage to tool may result.

NOTE: The D25831, D25851 has only chipping modes with no

hammerdrilling capability.

1. Set the mode selector (F) to hammerdrilling mode.

2. For D25602 only, move the torque control lever (U) to Setting 2

(T).

3. Turn the speed and impact control dial (G) to the maximum

speed (level 7).

4. Adjust the side handle (front or rear position) (C).

5. Assemble the centering bit and adapter shank into core bit.

6. Mark the spot where the hole is to be drilled.

7. Place the centering bit on that mark and depress the trigger

switch (A).

NOTE: Some core drills require the removal of centering bit

after about 1 cm of penetration. If so, remove and continue

hammerdrilling.

8. When hammerdrilling through a structure thicker than the

depth of the core bit, break away the round cylinder of

concrete or core inside the bit at regular intervals. To avoid

unwanted breaking away of concrete around the hole, first drill

English

9

Page 11

a hole the diameter of the centering bit completely through the

structure. Then drill the cored hole halfway from each side of

the structure.

9. To stop the tool, release the trigger switch. Always turn the tool

off when work is finished and before unplugging.

Chipping

D25831, D25851

English

1. Set the mode selector (F) to chipping mode.

2. Set the impact control dial (G) to desired setting (refer to

Electronic Speed and Impact Control).

3. Insert the appropriate chisel and rotate it by hand to lock it into

the desired position.

NOTE: For SDS Max

4. Adjust the side handle (front or rear position) (C).

5. Depress the trigger switch (A).

6. Apply only enough pressure to engage active vibration control

(refer to Active Vibration Control).

7. To stop the tool, release the trigger switch. Always turn the tool

off when work is finished and before unplugging.

®

models, only use SDS Max® bits.

MAINTENANCE

Your DEWALT power tool has been designed to operate over a

long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular

cleaning.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and removing

accessories, before making any adjustments or removing/installing

attachments or accessories.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at

least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye

protection and proper NIOSH/OSHA/MSHA respiratory protection

when performing this.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from

two to six months, depending upon use, take or send your tool to

an authorized service center for a complete cleaning, inspection

and lubrication. Tools used constantly on production jobs will need

relubrication more often. Also, tools “out of service” for long periods

should be relubricated before being put back to work.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center.

D25501 D25601 D25602 D25831

Concrete 1-9/16" 1-9/16" 1-3/4" –

(40 mm) (40 mm) (45 mm) –

RPM 490 490 210–415 –

No load BPM 3300 3300 1430–2840 1430–2840

EWALT, recommended accessories should be used

MAXIMUM CAPACITY

10

Page 12

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement)

should be performed by authorized service centers or other

qualified service personnel, always using identical replacement

parts.

English

D25501 D25601 D25602 D25831

Voltage: 120 V AC

Current 12 A 12 A 13.5 A 13.5 A

Frequency: 50–60 Hz 50–60 Hz 50–60 Hz 50–60 Hz

Watts 1100 W 1200 W 1200 W 1200 W

RPM: 490/min 210–415/min 210–415/min –

Beats per

minute (BPM) 3300 1430–2840 1430–2840 1430–2840 bpm

SPECIFICATIONS

120 V AC 120 V AC 120 V AC

11

Page 13

Definiciones: Normas

de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO:

no se evita,

ADVERTENCIA:

que, si no se evita,

graves

ATENCIÓN:

no se evita,

AVISO: Se refiere a una práctica

corporales

propiedad.

Español

ADVERTENCIA: para reducir el riesgo de lesiones, lea el

manual de instrucciones.

indica una situación de peligro inminente que, si

provocará

puede

que de no evitarse

la

muerte o lesiones graves.

Indica una situación de peligro potencial

podría

Indica una situación de peligro potencial que, si

provocar

provocar la

lesiones leves o moderadas.

puede resultar

muerte o lesiones

no relacionada a lesiones

en

daños a la

Advertencias generales de seguridad

para las herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e

instrucciones.

instrucciones puede provocar descargas eléctricas, incendios o

lesiones graves.

GUARDE LAS ADVERTENCIAS E

INSTRUCCIONES PARA PODER

CONSULTARLAS EN EL FUTURO

El término “herramienta eléctrica” incluido en todas las advertencias

se refiere a su herramienta eléctrica conectada a la red (cable

eléctrico) o a su herramienta eléctrica accionada con baterías

(inalámbrica).

El incumplimiento de las advertencias o

1) SEGURIDAD DEL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas u oscuras propician accidentes.

b) No haga funcionar las herramientas eléctricas en

atmósferas explosivas, como ambientes donde haya

polvo, gases o líquidos inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o

producir humo.

c) Mantenga alejados a los niños y a los espectadores de la

herramienta eléctrica en funcionamiento. Las distracciones

pueden provocar la pérdida de control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse

a la toma de corriente. Nunca modifique el enchufe de

ninguna manera. No utilice ningún enchufe adaptador

con herramientas eléctricas con conexión a tierra. Los

enchufes no modificados y que se adaptan a las tomas de

corrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies con toma de

tierra como, por ejemplo, tuberías, radiadores, cocinas y

refrigeradores. Existe mayor riesgo de descarga eléctrica si

su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. Si entra agua en una herramienta

eléctrica, aumentará el riesgo de descarga eléctrica.

d) No use el cable indebidamente. Nunca utilice el cable para

transportar, tirar o desenchufar la herramienta eléctrica.

Mantenga el cable alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Los cables dañados o

enredados aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice

un cable prolongador adecuado para tal uso. Utilice un

cable adecuado para uso en exteriores a fin de reducir el

riesgo de descarga eléctrica.

12

Page 14

f) Si no se puede evitar el uso de una herramienta eléctrica

en una zona húmeda, utilice un dispositivo de corriente

residual (residual current device, RCD) de seguridad.

El uso de un RCD reduce el riesgo de sufrir una descarga

eléctrica.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el

sentido común cuando emplee una herramienta eléctrica.

No utilice una herramienta eléctrica si está cansado o

bajo el efecto de drogas, alcohol o medicamentos. Un

momento de descuido mientras se opera una herramienta

eléctrica puede provocar lesiones personales graves.

b) Utilice equipo de seguridad personal. Utilice siempre

protección ocular. El uso de equipo de seguridad, como

mascarillas para polvo, calzado de seguridad antideslizante,

cascos o protección auditiva en las condiciones adecuadas

reducirá las lesiones personales.

c) Evite poner en marcha la herramienta involuntariamente.

Asegúrese de que el interruptor está apagado antes de

conectar la fuente de alimentación y/o la batería, coger

o transportar la herramienta. Transportar herramientas

eléctricas con su dedo apoyado sobre el interruptor o

enchufar herramientas eléctricas con el interruptor en la

posición de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de

encender la herramienta eléctrica. Una llave de tuercas

o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta eléctrica puede provocar lesiones

personales.

e) No se estire demasiado. Conserve el equilibrio y

posiciónese adecuadamente en todo momento. Esto

permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas

en movimiento.

g) Si se suministran dispositivos para la conexión de

accesorios con fines de recolección y extracción de

polvo, asegúrese de que estén conectados y que se

utilicen correctamente. El uso del extractor de polvo puede

reducir los riesgos relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. La

herramienta eléctrica correcta hará el trabajo mejor, y de un

modo más seguro, a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla

o apagarla con el interruptor. Las herramientas que no

puedan ser controladas con el interruptor constituyen un

peligro y deben repararse.

c) Desconecte el enchufe de la fuente de alimentación o

la batería de la herramienta eléctrica antes de realizar

cualquier ajuste, cambio de accesorios o almacenar

las herramientas eléctricas. Estas medidas de seguridad

preventivas reducen el riesgo de encender la herramienta

eléctrica de forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios que no tienen

formación.

Español

13

Page 15

e) Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas,

piezas rotas o cualquier otra situación que pueda afectar

el funcionamiento de las herramientas eléctricas. Si

encuentra daños, haga reparar la herramienta eléctrica

antes de utilizarla. Se producen muchos accidentes a

causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias.

Las herramientas de corte con mantenimiento adecuado y

con los bordes de corte afilados son menos propensas a

trabarse y son más fáciles de controlar.

g) Utilice las herramientas eléctricas, sus accesorios y

piezas, etc. de acuerdo con las presentes instrucciones,

teniendo siempre en cuenta las condiciones de trabajo y

el trabajo que deba llevar a cabo. El uso de la herramienta

eléctrica para operaciones diferentes de aquellas para las que

fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

Español

a) Solicite a una persona cualificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica

y que solo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

Instrucciones de seguridad adicionales

para los rotomartillos

• Utilice protectores auditivos. La exposición a ruidos puede

causar pérdida auditiva.

• Utilice los mangos auxiliares que vienen con la herramienta.

Perder el control de la herramienta podría causar lesiones

corporales.

• Sostenga la herramienta eléctrica por sus superficies de

empuñadura aisladas cuando realice una operación en la

cual la herramienta para cortar pudiera entrar en contacto

con instalaciones eléctricas ocultas o con su propio

cable. El contacto con un conductor “activo” hará que las

piezas metálicas de la herramienta que estén expuestas a él

conduzcan electricidad y que el operador reciba una descarga

eléctrica.

• Use abrazaderas u otra manera práctica de fijar y sujetar la

pieza de trabajo a una plataforma estable. Sujetar la pieza

con la mano o contra el cuerpo es inestable y resultará en que

pierda el control.

• Lleve lentes de seguridad u otra protección ocular. Las

operaciones de martilleo provocan la expulsión de virutas. Las

partículas despedidas pueden provocar lesiones irreversibles en

los ojos. Lleve una mascarilla antipolvo o un respirador cuando

realice aplicaciones que generen polvo. En la mayoría de las

aplicaciones puede ser necesaria una protección auditiva.

• Mantenga siempre la herramienta bien sujeta. No opere la

herramienta si no puede sujetarla con ambas manos. Es

recomendable usar siempre el mango lateral. Si opera esta

herramienta con una sola mano, perderá el control de la misma.

Atravesar o topar con materiales duros, tales como un refuerzo

posterior, también podría resultar peligroso. Ajuste bien el

mango lateral antes de usar la herramienta.

• No opere esta herramienta durante períodos largos de

tiempo. La vibración provocada por la acción de percusión

puede ser peligrosa para sus manos y brazos. Utilice guantes

para mayor amortiguación y descanse con frecuencia para

limitar el riesgo de exposición.

• No renueve las brocas usted mismo. La renovación de las

brocas debe realizarla un especialista autorizado. Una broca

mal renovada puede provocar lesiones.

• Lleve guantes al operar la herramienta y al cambiar las

brocas. Las piezas metálicas de la herramienta y las brocas

14

Page 16

pueden calentarse mucho durante la operación. Los pequeños

trozos de material roto pueden dañar las manos desprotegidas.

• Nunca suelte la herramienta hasta que la broca haya

dejado de girar totalmente. Las brocas en movimiento pueden

provocar lesiones.

• Si una broca se atasca, no la golpee con un martillo para

desbloquearla. Podrían saltar fragmentos de metal o virutas de

material y provocar lesiones.

• Las brocas ligeramente desgastadas pueden afilarse de

nuevo.

NOTA: No sobrecaliente la broca (decoloración) mientras la afila

de nuevo. Las brocas muy gastadas precisan un reforjado. No

reendurezca ni temple la broca.

• Mantenga el cable alejado de la broca en movimiento. No

enrolle el cable alrededor de ninguna parte de su cuerpo.

Un cable eléctrico enrollado alrededor de una broca que gira

puede provocar lesiones y pérdida de control.

• Los orificios de ventilación suelen cubrir piezas en

movimiento, por lo que también se deben evitar. Las partes

móviles pueden atrapar las prendas de vestir sueltas, las joyas

y el cabello.

• Los hilos del alargador deben ser de un calibre apropiado

para su seguridad. Un cable de un calibre insuficiente causará

una caída en la tensión de la línea dando por resultado una

pérdida de energía y sobrecalentamiento. Cuando se utilice más

de un alargador para completar el largo total, asegúrese que

los hilos de cada alargador tengan el calibre mínimo. La tabla

siguiente muestra el tamaño correcto a utilizar, dependiendo

de la longitud del cable y del amperaje nominal de la placa de

identificación. Si tiene dudas sobre cuál calibre usar, use un

calibre mayor.

Ténsion (Volts) Longitud del cable en metros (m)

120 - 127V 0 - 7 7 - 15 15 - 30 30 - 50

220 - 240V 0 - 15 15 - 30 30 - 60 60 - 100

Corriente

nominal

(Ampéres)

0 - 6A 1,0 1,5 1,5 2,5

6 - 10A 1,0 1,5 2,5 4,0

10 - 12A 1,5 1,5 2,5 4,0

12 - 16A 2,5 4,0 No recomendado

ADVERTENCIA: Siempre use protección ocular. Todos los

usuarios y personas circunstantes deben llevar protección ocular

en conformidad con ANSI Z87.1.

ADVERTENCIA: Siempre lleve la debida protección auditiva

personal en conformidad con ANSI S12.6 (S3.19) durante el

uso de esta herramienta. Bajo algunas condiciones y duraciones

de uso, el ruido producido por este producto puede contribuir a la

pérdida auditiva.

ADVERTENCIA: Use SIEMPRE lentes de seguridad. Los

anteojos de uso diario NO son lentes de seguridad. Utilice también

máscaras faciales o para polvo si los cortes producen polvillo.

UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• Protección para los ojos ANSI Z87.1 (CAN/CSA Z94.3),

• Protección auditiva ANSI S12.6 (S3.19),

• Protección respiratoria según las normas NIOSH/OSHA/

MSHA.

ADVERTENCIA: Parte del polvo creado al lijar, aserruchar,

moler o perforar con máquina, así como al realizar otras actividades

de la construcción, contiene substancias químicas que se sabe

producen cáncer, defectos congénitos u otras afecciones

reproductivas. Algunos ejemplos de esas substancias químicas

son:

• plomo de pinturas a base de plomo,

Sección nominal mínima del cable en

milímetros cuadrados (mm2 )

Español

15

Page 17

• sílice cristalizado de ladrillos y cemento y otros productos de

albañilería, y

• arsénico y cromo de la madera químicamente tratada (CCA).

El riesgo al contacto con estas substancias varía, según la

frecuencia en que se haga este tipo de trabajo. Para reducir la

exposición a esas substancias químicas: trabaje en un área bien

ventilada, y trabaje con equipos de seguridad aprobados, tales

como máscaras contra el polvo especialmente diseñadas para filtrar

las partículas microscópicas.

• Evite el contacto prolongado con polvos originados por lijar,

aserrar, esmerilar, taladrar y otras actividades constructivas.

Vista ropas protectoras y lave las áreas expuestas con agua

y jabón. Permitir que el polvo se introduzca en su boca, ojos,

o dejarlo sobre la piel promueve la absorción de químicos

dañinos.

ADVERTENCIA: La utilización de esta herramienta puede

originar polvo o dispersarlo, lo que podría causar daños graves y

permanentes al sistema respiratorio, así como otras lesiones.

Siempre use protección respiratoria aprobada por NIOSH/OSHA,

Español

apropiada para su uso en condiciones de exposición al polvo.

Procure que las partículas no se proyecten directamente sobre su

rostro o su cuerpo.

• La etiqueta de la herramienta puede incluir los siguientes

símbolos. A continuación se indican los símbolos y sus

definiciones:

V ......... voltios A ...........amperios

Hz ....... hertz W ..........vatios

min ...... minutos

... corriente directa .........corriente alterna o

........ Construcción Clase I .............. directa

........... (con conexión a tierra) no ..........velocidad sin carga

......... corriente alterna

........ Construcción Clase II ..........terminal a tierra

............ (con aislamiento doble) ..........símbolo de alerta de

…/min . por minuto

IPM .....impactos por minutos GPM .....golpes por minuto

RPM .... revoluciones o

reciprocidad por

minuto

.............. seguridad

Motor

Esta herramienta DEWALT está impulsada por un motor fabricado

por D

EWALT. Compruebe que el suministro eléctrico concuerde

con el indicado en la placa de características. Una reducción

del voltaje superior al 10% provocará pérdida de potencia y

sobrecalentamiento. Todas las herramientas D

de fábrica.

EWALT se prueban

DESCRIPCIÓN (Fig. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica ni

ninguna pieza de esta. Puede producir daños o lesiones corporales.

A. Interruptor de gatillo G. Selector de control

B. Pieza deslizante de bloqueo electrónico de la velocidad

C. Agarradera lateral y el impacto

D. Agarradera principal H. Perilla de soporte

E. Control de vibración activa I. Posición trasera de la

agarradera lateral

F. Selector de modalidad

USO DEBIDO

Estos rotomartillos para trabajos pesados han sido diseñados

para el taladrado con percusión y corte por capas realizado a

nivel profesional en diversos sitios de trabajo (por ejemplo, sitios

de construcción). NO utilice la herramienta en condiciones de

humedad o en la presencia de líquidos o gases inflamables.

16

Page 18

Este rotomartillo es una herramienta eléctrica profesional. NO

permita que los niños toquen la herramienta. Si el operador no

tiene experiencia operando esta herramienta, su uso deberá ser

supervisado.

FIG. 1

MODO TALADRO

PERCUTOR

MODO DE AJUSTE DE LA BROCA DE CINCEL

MODO DE AJUSTE DE LA BROCA DE CINCEL

F

J

H

C

MODO

CINCEL

E

I

D

A

B

G

E

D25602

MONTAJE Y AJUSTES

ADVERTENCIA: Para reducir el riesgo de lesiones, apague y

desconecte la máquina de la fuente de energía antes de

instalar y de retirar los accesorios, antes de regular o cambiar

los ajustes o cuando se realicen reparaciones. Compruebe que

el interruptor esté en la posición OFF. Un encendido accidental

puede causar lesiones.

Mango lateral (Fig. 1)

ADVERTENCIA: Para reducir el riesgo de lesiones corporales,

SIEMPRE opere la herramienta con el mango lateral debidamente

instalado y ajustado. El incumplimiento con lo anterior podría

resultar en que el mango lateral se suelte durante la operación

de la herramienta y que el operador pierda el control como

consecuencia. Sostenga la herramienta con ambas manos para

maximizar control.

La agarradera lateral se sujeta al cilindro frontal (collarín) y se

puede girar 360° para permitir su uso con la mano derecha o

izquierda. Para mayor comodidad, la agarradera lateral puede

montarse en las posiciones delantera o trasera.

MONTAJE EN LA POSICIÓN DELANTERA (FIG. 2)

1. Desatornille la agarradera lateral (C) y desmonte el soporte de

la agarradera lateral (J).

2. Cierre el anillo de acero (K) sobre el collarín (L) situado detrás

del portaherramientas (M). Apriete ambos extremos del anillo

de acero uno contra el otro. Monte el casquillo (N) e inserte la

clavija (O).

3. Deslice la abrazadera de la agarradera lateral (J) sobre el

casquillo y atornille sobre la perilla de soporte (H); no apriete.

4. Atornille la agarradera lateral (C) en la perilla de soporte (H) y

apriete.

Español

17

Page 19

5. Haga girar el conjunto de montaje de la agarradera lateral

hasta la posición deseada. Si debe taladrar con percusión

horizontalmente con una broca para trabajos pesados, para

lograr un control óptimo coloque el conjunto de la agarradera

con un ángulo de unos 20° respecto a la herramienta.

6. Fije en su sitio el conjunto de montaje de la agarradera lateral

apretando la perilla de soporte (H).

FIG. 2

K

N

J

M

O

P

H

FIG. 3

L

I

Español

C

MONTAJE EN LA POSICIÓN TRASERA (FIG. 3)

1. Desatornille la agarradera lateral (C) y retírela del conjunto de

montaje de la agarradera lateral. Deje el conjunto de montaje

de la agarradera lateral en la posición frontal.

2. Atornille la agarradera lateral directamente en una de las

posiciones traseras (I) situadas a uno y otro lado de la

herramienta.

Control de vibración activa (Fig. 1)

D25602, D25831, D25851

Para un mejor control de la vibración, sostenga la herramienta

con una mano en la agarradera principal (D) y la otra en la

agarradera lateral (C). Aplique solamente suficiente presión para

que el dispositivo amortiguador sobre la agarradera principal

quede aproximadamente a la mitad de su recorrido. El martillo sólo

requiere una cantidad suficiente de presión para activar el control

de vibración activa. La herramienta no taladrará ni cortará con

mayor rapidez, ni se activará el control de vibración activa si se

aplica más presión de la necesaria.

FIG. 4

C

P

M

R

Q

Inserción y desmontaje de accesorios

estriados (Fig. 4)

D25851

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente

de alimentación antes de realizar ajustes o de quitar o poner

accesorios.

18

Page 20

1. Inserte el vástago de la broca en el portaherramientas (M) tanto

como pueda. El surco sobre el vástago del cincel (Q) debe estar

alineado con el símbolo (R) sobre el portaherramientas. Si está

insertado correctamente, el manguito de bloqueo (P) retrocede

a la posición extrema y muestra un símbolo de candado

cerrado.

2. Tire de la broca para comprobar que esté bien sujeta.

3. Si el surco del cincel no está alineado con el símbolo, o no está

completamente insertado, el símbolo de candado permanece

abierto.

Para retirar la broca, tire del manguito de bloqueo y extraiga la

broca.

Inserción y desmontaje de accesorios

SDS Max

D25501, D25602, D25831

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente de

alimentación antes de realizar ajustes o de quitar o poner

accesorios.

1. Tire hacia atrás del manguito de bloqueo (P) e inserte el

vástago de la broca. El vástago de la broca debe estar limpio.

2. Gire ligeramente la broca hasta que el manguito vuelva a su

posición.

3. Cerciórese que la broca esté engranada en forma apropiada.

NOTA: La broca necesita moverse varios centímetros adentro

y afuera del portaherramientas (M) cuando está engranado en

forma apropiada.

4. Para retirar la broca, tire del manguito de bloqueo y extraiga la

broca.

®

Control completo del par de torsión

(Fig. 5)

D25602

AVISO: Siempre apague la herramienta antes de cambiar los

ajustes de control del par de torsión o podría dañar la herramienta.

La función de Control completo del par de torsión (CTC) de esta

herramienta está diseñada para proporcionar control adicional

con un mecanismo de embrague en dos etapas.

La configuración de embrague 1 (S) está orientada a la mayoría

de aplicaciones de taladrado de percusión y está diseñada para

desembragar fácilmente cuando la broca encuentre varillas de

refuerzo u otras sustancias extrañas.

La configuración de

embrague 2 (T) está

orientada a aplicaciones

con mayor par de

torsión, tales como

barrenas huecas y

taladrado de percusión

de orificios profundos, y

está diseñada para

FIG. 5

S

T

U

G

COMPLETE TORQUE CONTROL

CTC

1 3/4" (44mm) SDS MAX

TARY HAMMER

RO

D25XXX

SER.

TO REDUCE THE RISK OF INJUR

WARNING

USER MUST READ INSTRUCTION

YS USE PROPER EYE, EAR AND

LWA

LW

MANUAL. A

RY PROTECTION. A

ATO

RESPIR

LEA EL MANUAL DE

ADVERTENCIA

INSTRUCCIONES PARA

PARA LOS OJOS, OÍDOS Y VÍAS

UN FUNCIONAMIENTO SEGURO. SIEMPRE UTILICE

PROTECCIÓN ADECUADA

TORIAS. SIEMPRE UTILICE EL MANGO LATERAL.

A

RESPIR

1

AFIN DE MINIMISER

AVERTISSEMENT

TEUR DOIT LIRE LE GUIDE

LES RISQUES DE

A

’UTILIS

L

BLESSURES,

TOUJOURS UTILISER UNE PROTECTION

TION.

A

D’UTILIS

AUDITIVE ET RESPIR

TÉRALE.

A

OCULAIRE,

2

UTILISER LA POIGNÉE L

T INDUSTRIAL TOOL CO., BA

L

A

W

E

TION, CALL 1-800-4-D

D

FOR SERVICE INFORMA

.com

T

L

A

W

E

.D

w

ww

YS USE SIDE HANDLE.

A

TOIRE ADÉQU

A

TIMORE, MD 21286 USA

L

T

L

A

W

E

Service

Lock-On

rvice

ush Se

r

B

Y,

TE.

A

desembragar al pasar

un mayor umbral de par

de torsión.

Desplace la palanca de

control del par de torsión

V

W

(U) a la configuración 1 ó 2 según lo requiera la aplicación.

NOTA: Permita que la carcasa del motor gire un poco al cambiar

el par de torsión.

Cada vez que se enchufa la herramienta se pondrá

automáticamente en la configuración de embrague 1, la

configuración más sensible.

Español

19

Page 21

Control electrónico de la velocidad y el

impacto (Fig. 5)

D25602, D25831, D25851

El control electrónico de la velocidad y el impacto permite usar

brocas más pequeñas sin riesgo de romperlas; taladrar con

percusión en materiales ligeros y frágiles sin astillarlos, y tener un

control óptimo para un burilado preciso.

Para fijar el selector de control, gire el selector (G) al nivel

deseado. Cuanto más alto sea el número, mayores serán la

velocidad y la energía de impacto. Los valores del selector

permiten que la herramienta resulte extremadamente adaptable

para muchas aplicaciones diversas. El valor adecuado depende

del tamaño de la broca y la dureza del material taladrado.

Selector de modo (Fig. 1)

ATENCIÓN: Nunca cambie el modo mientras que la unidad esté

funcionando.

Español

ATENCIÓN: No cambie a la modalidad de taladro percutor con la

broca para cincelado en el portaherramientas. Podrían presentarse

lesiones corporales y daños a la herramienta.

Los D25501, D25553, D25601, D25602 utilizan dos modos

operativos. Para seleccionar el modo operativo requerido, gire el

selector de modalidad (F) hasta que la flecha apunte al ícono de

taladrado de percusión o de burilado. El D25831 solamente utiliza

el modo de burilado.

MODO DE TALADRADO DE PERCUSIÓN (

La herramienta gira e impacta el trabajo simultáneamente. Este

modo es adecuado para todas las operaciones sobre hormigón y

mampostería.

MODO DE BURILADO (

El seguro del eje está engranado durante el modo de burilado de

tal modo que la herramienta impacta el trabajo sin rotación. Este

)

)

modo es adecuado para trabajos livianos de burilado, cincelado

y demolición.

NOTA: En modo de burilado, el taladro percutor también puede

usarse como palanca para liberar una broca atascada.

AJUSTE DE LA BROCA PARA CINCELADO ( )

Gire el selector de modalidad hasta uno de los íconos de ajuste

de la broca para cincelado para ajustar el cincel a la posición

deseada. Existen 18 posiciones posibles para ajustar el ángulo

del cincel. Después de encontrar la posición deseada, maniobre

suavemente la broca para cincelado hacia atrás y hacia adelante

para cerciorarse de que el cincel esté engranado en forma

apropiada.

Luces indicadoras de energía (Fig. 5)

El indicador LED amarillo del desgaste de escobillas (V) se

enciende cuando las escobillas de carbón estén casi desgastadas,

indicando que la herramienta necesita servicio dentro de las

próximas 8 horas de uso.

El indicador LED rojo (W) se enciende si la pieza deslizante de

bloqueo (B) es utilizada en cualquier modo distinto al modo de

burilado.

El indicador LED rojo (W) destella si se presenta una avería en la

herramienta, o si las escobillas están completamente desgastadas

(refiérase a Escobillas bajo Mantenimiento).

FUNCIONAMIENTO

ADVERTENCIA: Respete siempre las instrucciones de seguridad

y la reglamentación aplicable.

ADVERTENCIA: Para reducir el riesgo de lesiones corporales

graves, apague la herramienta y desconéctela de la fuente de

alimentación antes de realizar ajustes o de quitar o poner

accesorios.

20

Page 22

ADVERTENCIA: Para reducir el riesgo de lesiones

corporales, SIEMPRE asegúrese de que la pieza de trabajo

esté debidamente sujeta. Si va a perforar un material delgado,

utilice un bloque de madera como “respaldo” para evitar dañarlo.

ADVERTENCIA: Para reducir el riesgo de lesiones

corporales, SIEMPRE opere la herramienta con el mango

lateral debidamente instalado y ajustado. El incumplimiento con

lo anterior podría resultar en que el mango lateral se suelte durante

la operación de la herramienta y que el operador pierda el control

como consecuencia. Sostenga la herramienta con ambas manos

para maximizar control.

Bien colocar las manos (Fig. 1)

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

SIEMPRE coloque bien las manos, tal como se muestra.

ADVERTENCIA: Para reducir el riesgo de lesiones personales,

SIEMPRE debe de sujetar la herramienta correctamente para

anticipar reacciones súbitas.

Mantenga una mano sobre el mango lateral (C) y la otra sobre el

mango principal (D) para sujetar la máquina correctamente.

NOTA: La temperatura de operación de esta herramienta es -7 a

+40 ˚C (19˚ a 104 ˚F). El utilizar la herramienta por fuera de este

rango de temperatura disminuirá la vida útil de la herramienta.

Interruptor de gatillo (Fig. 1)

Para encender la herramienta, apriete el interruptor de gatillo (A).

Para detener la herramienta, suelte el interruptor de gatillo.

D25602

Sólo en el modo de burilado, bloquee el interruptor de gatillo,

empuje la pieza deslizante de bloqueo (B) hacia arriba mientras

presiona el interruptor de gatillo.

Para desactivar la pieza deslizante de bloqueo, presione una vez

el interruptor de gatillo y suelte a continuación.

La pieza deslizante de bloqueo solamente puede ser activada

en el modo de burilado. La máquina dejará de operar cuando se

intente engranar la pieza deslizante de bloqueo en el modo de

taladrado de percusión. El motor se detendrá si la pieza deslizante

para bloqueo en encendido es activada al cambiar del modo de

cincelado al modo de taladrado de percusión.

D25831, D25851

Para operación continua, desplace el conmutador basculante a

la posición de encendido. Para detener la operación continua,

desplace el conmutador basculante a la posición de apagado.

FUNCIÓN DE ARRANQUE PROGRESIVO

La función de arranque progresivo permite aumentar la velocidad

lentamente, de modo que la broca no se mueva de la posición de

taladrado al arrancar. La función de arranque progresivo también

reduce la reacción de par inmediata transmitida al engranaje y al

operador si el martillo arranca con la broca en un agujero que ya

exista.

Taladrado con brocas sólidas

D25501, D25601, D25602

NOTA: Los D25831, D25851 solamente tienen modos de burilado,

sin capacidad para taladrado de percusión.

1. Coloque el selector de modalidad (F) en el modo de taladrado

de percusión.

2. Únicamente para D25602, mueva la palanca de control del par

de torsión (U) a la configuración 1 (S).

3. Fije el selector de control de la velocidad y el impacto (G).

4. Inserte la broca adecuada.

5. Ajuste la agarradera lateral (posición frontal o trasera) (C).

6. Marque el punto donde debe taladrarse el agujero.

7. Coloque la broca sobre esa marca y presione el interruptor de

gatillo (A).

Español

21

Page 23

8. Aplique solamente suficiente presión para engranar el control

de vibración activa (Refiérase a Control de vibración activa).

9. Para detener la herramienta, suelte el interruptor de gatillo.

Siempre apague la herramienta al terminar el trabajo y antes

de desenchufar.

Taladrado con barrenas huecas

D25501, D25601, D25602

ATENCIÓN: No utilice una barrena hueca para taladrado de

percusión en madera. Podrían presentarse lesiones corporales y

daños a la herramienta.

NOTA: Los D25831, D25851 solamente tienen modos de burilado,

sin capacidad para taladrado de percusión.

1. Coloque el selector de modalidad (F) en el modo de taladrado

de percusión.

2. Únicamente para D25602, mueva la palanca de control del par

de torsión (U) a la configuración 2 (T).

3. Gire el selector de control de impacto (G) a la velocidad

Español

máxima (nivel 7).

4. Ajuste la agarradera lateral (posición frontal o trasera) (C).

5. Monte la broca de centrado y el adaptador en la barrena hueca.

6. Marque el punto donde debe taladrarse el agujero.

7. Coloque la broca de centrado sobre esa marca y presione el

interruptor de gatillo (A).

NOTA: Algunas barrenas huecas precisan que se quite la broca de

centrado después de una penetración de aproximadamente 1 cm.

Si es así, retire y continúe con el taladrado de percusión.

8. Al efectuar taladrado de percusión a través de una estructura

más gruesa que la profundidad de la barrena hueca, quite

periódicamente el cilindro de hormigón o el núcleo del interior

de la barrena. Para evitar la rotura del hormigón alrededor del

orificio, taladre antes un agujero del diámetro de la broca de

centrado a lo largo de toda la estructura. Luego barrene el

agujero, la mitad desde cada lado de la estructura.

9. Para detener la herramienta, suelte el interruptor de gatillo.

Siempre apague la herramienta al terminar el trabajo y antes

de desenchufar.

Burilado

D25831, D25851

1. Coloque el selector de modalidad (F) en el modo de burilado.

2. Coloque el selector de control de impacto (G) en la configuración

deseada (refiérase a Control electrónico de la velocidad y el

impacto).

3. Inserte el cincel adecuado y gírelo a mano para fijarlo en la

posición deseada.

NOTA: Utilice solamente brocas SDS Max® para los modelos

SDS Max®.

4. Ajuste la agarradera lateral (posición frontal o trasera) (C).

5. Presione el interruptor de gatillo (A).

6. Aplique solamente suficiente presión para engranar el control

de vibración activa (Refiérase a Control de vibración activa).

7. Para detener la herramienta, suelte el interruptor de gatillo.

Siempre apague la herramienta al terminar el trabajo y antes

de desenchufar.

MANTENIMIENTO

Su herramienta DEWALT ha sido diseñada para funcionar

durante un largo período con un mínimo de mantenimiento.

Un funcionamiento continuo satisfactorio depende del cuidado

adecuado de la herramienta y de una limpieza periódica.

ADVERTENCIA: Para minimizar el riesgo de graves lesiones

personales, apague la herramienta y desconecte la batería

antes de realizar ajustes o quitar/instalar los acoples o accesorios.

Un encendido accidental puede causar lesiones.

22

Page 24

Limpieza

ADVERTENCIA: Limpie la suciedad y el polvo de las rejillas

de ventilación con aire seco al menos una vez por semana.

Lleve protección ocular ANSI Z87.1 (CAN/CSA Z94.3) debida y

protección respiratoria NIOSH/OSHA/MSHA debida cuando haga

esto.

ADVERTENCIA: Nunca utilice solventes u otros químicos fuertes

cuando limpie las piezas no metálicas de la herramienta. Estos

químicos pueden debilitar los materiales de plástico utilizados en

estas piezas. Use un paño humedecido con agua y jabón suave.

Jamás permita que le entre líquido a la herramienta; nunca sumerja

ninguna parte de la herramienta.

Lubricación

Su herramienta fue debidamente lubricada antes de dejar la

fábrica. Lleve o envíe la herramienta a un centro de servicio

certificado en dos a seis meses, dependiendo del nivel de uso

para que se le haga una limpieza e inspección minuciosa. Las

herramientas utilizadas constantemente en tareas de producción

pueden requerir una lubricación más frecuente. Las herramientas

que no son utilizadas por períodos largos de tiempo deberían

volverse a lubricar antes de usarse nuevamente.

Accesorios

ADVERTENCIA: Dado que algunos accesorios, diferentes de los

ofrecidos por D

empleo de tales accesorios podría constituir un riesgo. Para reducir

el riesgo de lesiones, sólo deben usarse con el producto los

accesorios recomendados D

Si desea más información sobre los accesorios adecuados,

consulte a su distribuidor.

EWALT, no se han probado con este producto, el

EWALT.

CAPACIDADES MÁXIMAS RECOMENDADAS

D25501 D25601 D25602 D25831

Hormigón 40 mm 40 mm 45 mm –

(1-9/16") (1-9/16") (1-3/4") –

RPM 490 490 210–415 –

BPM

sin carga 3 300 3 300 1 430–2 840 1 430–2 840

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta

herramienta en los centros autorizados de servicio D

organizaciones autorizadas. Estas organizaciones prestan servicio

a las herramientas D

legitimas D

EWALT.

EWALT y emplean siempre refacciones

EWALT u otras

Español

23

Page 25

D25501-AR D25501-B2 D25601-B3 D25601-B2 D25602-AR D25602-B2

Voltagem 220V~ 220V~ 120V~ 220V~ 220V~ 220V~

Frequencia 50 Hz 50–60 Hz 50–60 Hz 50–60 Hz 50 Hz 50–60 Hz

Watts 1 100W 1 100W 1 200 W 1 200 W 1 200 W 1 200 W

RPM 490/min 490/min 210–415/min 210–415/min 210–415/min 210–415/min

Impactos por min (imp) 3 300 3 300 3 300 3 300 1 430–2 830 1 430–2 830

D25831-AR D25831-B2

Voltagem 220V~ 220V~

Frequencia 50 Hz 50–60 Hz

Watts 1 200 W 1 200W

RPM – –

Impactos por min (imp) 1 430–2 840 1 430–2 840

ESPECIFICACIONES

Español

24

Page 26

Definições: Diretrizes de

Segurança

As definições abaixo apresentadas descrevem o grau de

gravidade correspondente a cada palavra de advertência.

Leia cuidadosamente o manual e preste atenção a estes

símbolos.

PERIGO: Indica uma situação de risco iminente que, se

não for evitada, resultará em morte ou ferimentos graves.

AVISO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em morte ou ferimentos

graves.

CUIDADO: Indica uma situação de risco potencial que,

se não evitada, poderá resultar em ferimentos leves ou

moderados.

AVISO: Se refiere a una práctica no relacionada a

lesiones corporales que de no evitarse puede resultar en

daños a la propiedad.

AVISO: para reduzir o risco de ferimentos, leia o manual de

instruções.

Regras Gerais de Segurança

AVISO! Leia todas as instruções. Falha no seguir de todas as

instruções listadas abaixo pode resultar em choque elétrico,

fogo e/ou em ferimento sério. O termo "ferramenta" em todos os

avisos listados abaixo referem-se a ferramenta alimentada através

de seu cordão ou a ferramenta operada a bateria (sem cordão).

GUARDE ESTAS INSTRUÇÕES

1) ÁREA DE TRABALHO

a) Mantenha a área de trabalho limpa e iluminada. As áreas

desorganizadas e escuras são um convite aos acidentes.

b) Não opere ferramentas em atmosferas explosivas, como

na presença de líquidos inflamáveis, gases ou poeira. As

ferramentas criam faíscas que podem inflamar a poeira ou os

vapores.

c) Mantenha crianças e visitantes afastados ao operar

uma ferramenta. As distrações podem fazer você perder o

controle.

2) SEGURANÇA ELÉTRICA

a) Os plugues da ferramenta devem ser compatíveis com

as tomadas. Nunca modifique o plugue. Não use nenhum

plugue adaptador com as ferramentas aterradas. Os

plugues sem modificações aliados a utilização de tomadas

compatíveis reduzirão o risco de choque elétrico

b) Evite o contato do corpo com superfícies ligadas ao terra

ou aterradas tais como as tubulações, radiadores, escalas

e refrigeradores. Há um aumento no risco de choque elétrico

se seu corpo for ligado ao terra ou aterramento.

c) Não exponha a ferramentas à chuva ou às condições

úmidas. A água entrando na ferramenta aumentará o risco

de choque elétrico.

d) Não force o cabo elétrico. Nunca use o cabo elétrico para

carregar, puxar ou o para desconectar a ferramenta da

tomada. Mantenha o cabo elétrico longe do calor, óleo,

bordas afiadas ou das partes em movimentos

danificados ou emaranhados aumentam o risco de choque

elétrico.

e) Ao operar uma ferramenta ao ar livre, use um cabo de

extensão apropriado para o uso ao ar livre. O uso de um

cabo apropriado ao ar livre reduz o risco de choque elétrico.

3) SEGURANÇA PESSOAL

a) Fique atento, olhe o que você está fazendo e use o bom

senso ao operar uma ferramenta. Não use a ferramenta

. Os cabos

Português

25

Page 27

b) Use equipamento de segurança. Sempre use óculos de

c) Evite acidente inicial. Assegure que o interruptor está na

d) Remova qualquer chave de ajuste antes de ligar a

e) Não force além do limite. Mantenha o apoio e o equilíbrio

f) Vista-se apropriadamente. Não use roupas

g) Se os dispositivos são fornecidos com conexão para

Português

quando você estiver cansado ou sob a influência de

drogas, álcool ou de medicamentos. Um momento de

desatenção enquanto opera uma ferramenta pode resultar

em grave ferimento pessoal.

segurança. O equipamento de segurança tais como a máscara

contra a poeira, sapatos de segurança antiderrapantes,

capacete de segurança, ou protetor auricular usados em

condições apropriadas reduzirão os ferimentos pessoais.

posição desligada antes de conectar o plugue na tomada.

Carregar a ferramentas com seu dedo no interruptor ou

conectar a ferramenta que apresenta o interruptor na posição

“ ligado” são um convite à acidentes.

ferramenta. Uma chave de boca ou de ajuste unida a uma

parte rotativa da ferramenta pode resultar em ferimento

pessoal.

adequado todas as vezes que utilizar a ferramenta.

Isto permite melhor controle da ferramenta em situações

inesperadas.

demasiadamente largas ou jóias. Mantenha seus cabelos,

roupas e luvas longe das peças móveis. A roupa folgada,

jóias ou cabelos longos podem ser presos pelas partes em

movimento.

extração e coleta de pó, assegure que estes estão

conectados e usados corretamente. O uso destes

dispositivos pode reduzir riscos relacionados a poeira.

4) USO E CUIDADOS DA FERRAMENTA

a) Não force a ferramenta. Use a ferramenta correta para

sua aplicação. A ferramenta correta fará o trabalho melhor

e mais seguro se utilizada dentro daquilo para a qual foi

projetada.

b) Não use a ferramenta se o interruptor não ligar e desligar.

Qualquer ferramenta que não pode ser controlada com o

interruptor é perigosa e deve ser reparada.