D25413

D25415

D25430

English (original instructions) 3

Français (traduction de la notice d’instructions originale) 12

2

Copyright DEWALT

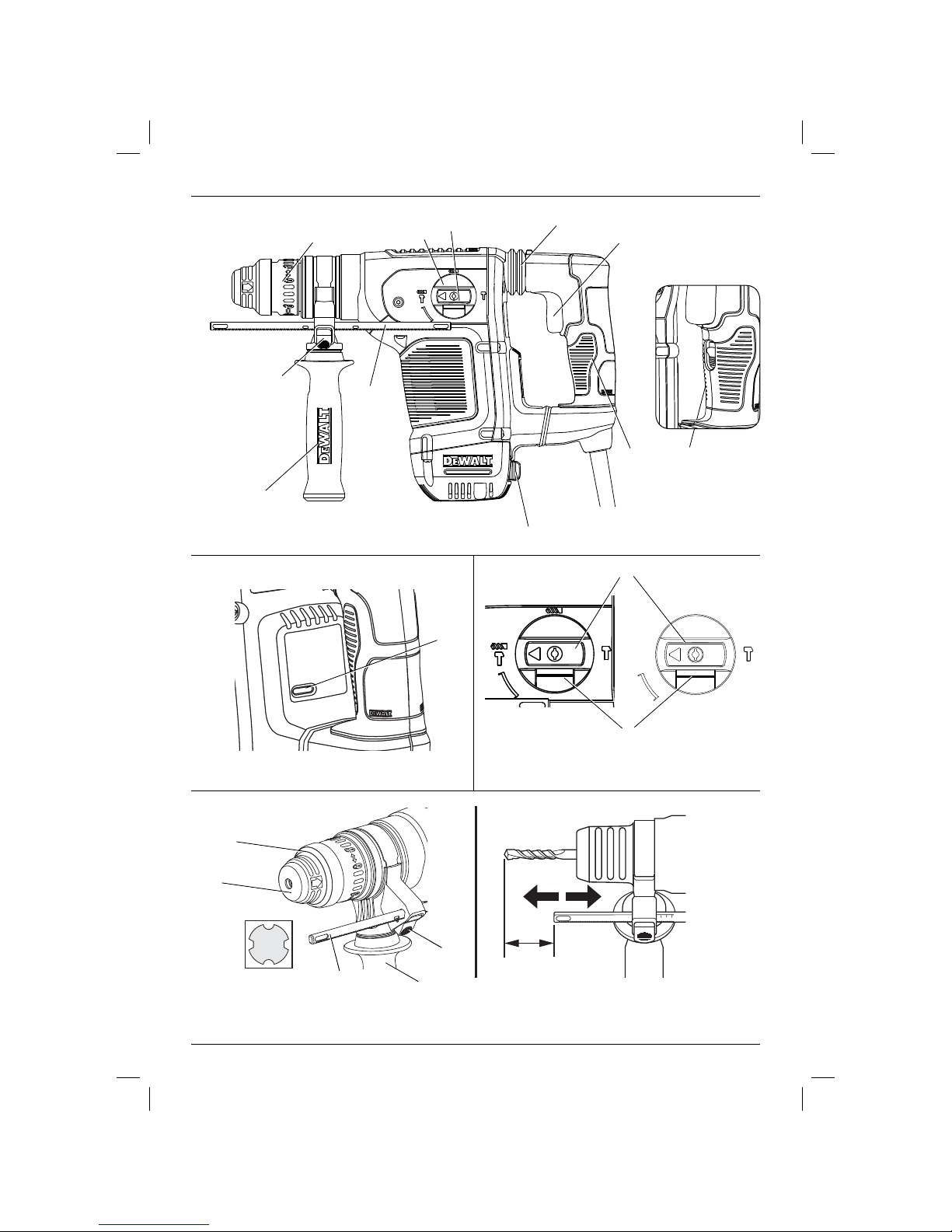

Figure 1

e

l

d

h

a

Figure 2

Figure 4

k

f

j

b

c

Figure 3

i

D25415

d

e

o

D25430D25413

g

n

k

j

f

1

Figure 5

c

Figure 6

Figure 7

l

g

m

b

f

2

ENGLISH

HEAVY-DUTY ROTARY HAMMER

D25413, D25415, D25430

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make

DEWALT one of the most reliable partners for professional power tool users.

Technical Data

D25413 D25415 D25430

Voltage V

Type 1 1 1

Power Input W 1000 1000 1000

No load speed min

Beats per minute bpm 0 – 4700 0 – 4700 0 – 4700

Impact energy

Hammerdrilling J 4.9 4.9 –

Chiselling J 4.9 4.9 4.9

Maximum drilling range in steel/wood/concrete

Chisel positions 12 12 12

Core drilling capacity in soft brick mm 100 100 –

Tool holder SDS Plus

Collar diameter mm 60 60 60

Weight kg 4.2 4.3 4.0

-1

mm 13 / 32 / 32 13 / 32 / 32 –

220–240

120

0 – 820 0 – 820 –

220–240

120

®

SDS Plus

220–240

120

®

SDS Plus

®

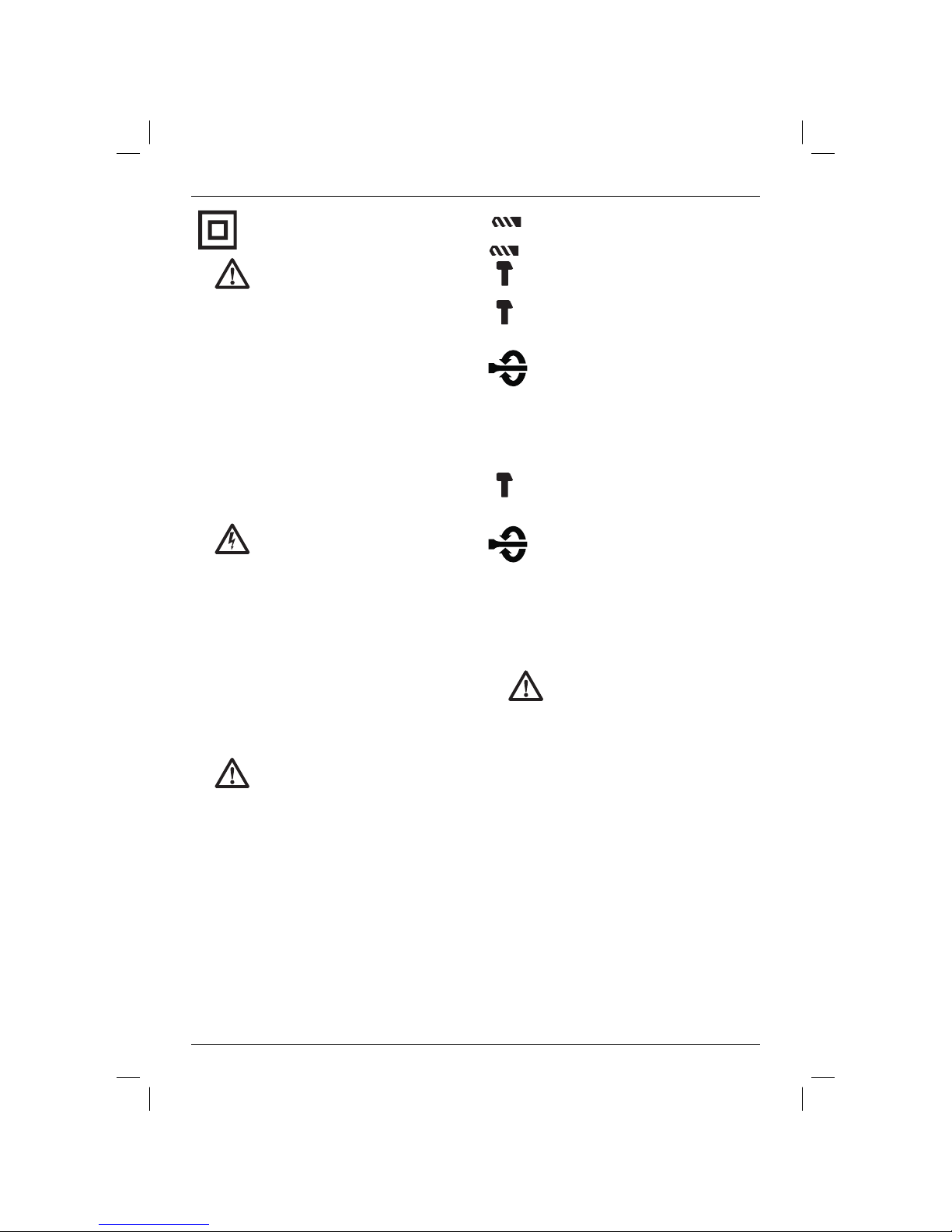

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTICE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

Denotes risk of fire.

WARNING: To reduce the risk of injury,

Denotes risk of electric shock.

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

3

ENGLISH

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

4

ENGLISH

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Additional Specifi c Safety Rules for

Rotary Hammers

• Wear ear protectors. Exposure to noise can

cause hearing loss.

• Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

• Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live”

wire will make exposed metal parts of the tool

“live” and shock the operator.

• Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

• Wear safety goggles or other eye protection.

Hammering operations cause chips to fly. Flying

particles can cause permanent eye damage.

Wear a dust mask or respirator for applications

that generate dust. Ear protection may be

required for most applications.

• Keep a firm grip on the tool at all times.

Do not attempt to operate this tool

without holding it with both hands. It is

recommended that the side handle be used at

all times. Operating this tool with one hand will

result in loss of control. Breaking through or

encountering hard materials such as re-bar may

be hazardous as well. Tighten the side handle

securely before use.

• Do not operate this tool for long periods of

time. Vibration caused by hammer action may

be harmful to your hands and arms. Use gloves

to provide extra cushion and limit exposure by

taking frequent rest periods.

• Do not recondition bits yourself. Chisel

reconditioning should be done by an authorized

specialist. Improperly reconditioned chisels

could cause injury.

• Wear gloves when operating tool or

changing bits. Accessible metal parts on the

tool and bits may get extremely hot during

operation. Small bits of broken material may

damage bare hands.

• Never lay the tool down until the bit has

come to a complete stop. Moving bits could

cause injury.

• Do not strike jammed bits with a hammer to

dislodge them. Fragments of metal or material

chips could dislodge and cause injury.

• Slightly worn chisels can be resharpened by

grinding.

• Keep the power cord away from the rotating

bit. Do not wrap the cord around any part of

your body. An electric cord wrapped around a

spinning bit may cause personal injury and loss

of control.

Residual Risks

The following risks are inherent to the use of rotary

hammers:

– injuries caused by touching the rotating parts or

hot parts of the tool.

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of squeezing fingers when changing the

accessory.

– Health hazards caused by breathing dust

developed when working in concrete and/or

masonry.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

5

ENGLISH

DATE CODE POSITION

The date code, which also includes the year of

manufacture, is printed into the housing.

Example:

2013 XX XX

Year of Manufacture

Package Contents

The package contains:

1 Heavy-duty rotary hammerdrill

1 Side handle

1 Depth adjustment rod (D25413, D25415 only)

1 Kitbox

1 Keyless chuck (D25415 only)

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1-4, 6)

WARNING: Never modify the power

tool or any part of it. Damage or

personal injury could result.

a. Variable speed switch

b. Main handle

c. Forward / reverse slider

d. Mode selector

e. Safety lock

f. Side handle

g. Tool holder / locking sleeve

h. Shocks

i. LED Indicator (D25415 only)

j. Depth adjustment rod (D25413, D25415 only)

k. Depth stop clamp

l. Locking collar

m. Chuck (D25415 only)

n. Dust cover

o. Lock on button (D25430 only)

INTENDED USE

These heavy-duty rotary hammers have been

designed for professional drilling and hammerdrilling,

screwdriving and light chipping.

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

These hammerdrills are professional power tools.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

ACTIVE VIBRATION CONTROL (FIG. 1)

The active vibration control neutralises rebound

vibration from the hammer mechanism. Lowering

hand and arm vibration allows for more comfortable

use for longer periods of time and extends the life of

the unit.

For best vibration control, hold the tool with one

hand on the main handle (b) and the other hand on

the side handle (f). Apply just enough pressure so

the hammer is approximately mid-stroke.

The hammer only needs enough pressure to engage

the active vibraton control. Applying too much

pressure will not make the tool drill or chip faster and

active vibration control will not engage.

TORQUE LIMITING CLUTCH

WARNING: The user must always

maintain a firm grip on the tool when in

operation.

The torque limiting clutch reduces the maximum

torque reaction transmitted to the operator in case

of jamming of a drill bit. This feature also prevents

the gearing and electric motor from stalling.

NOTICE: Always turn the tool off before

changing torque control settings or

damage to tool may result.

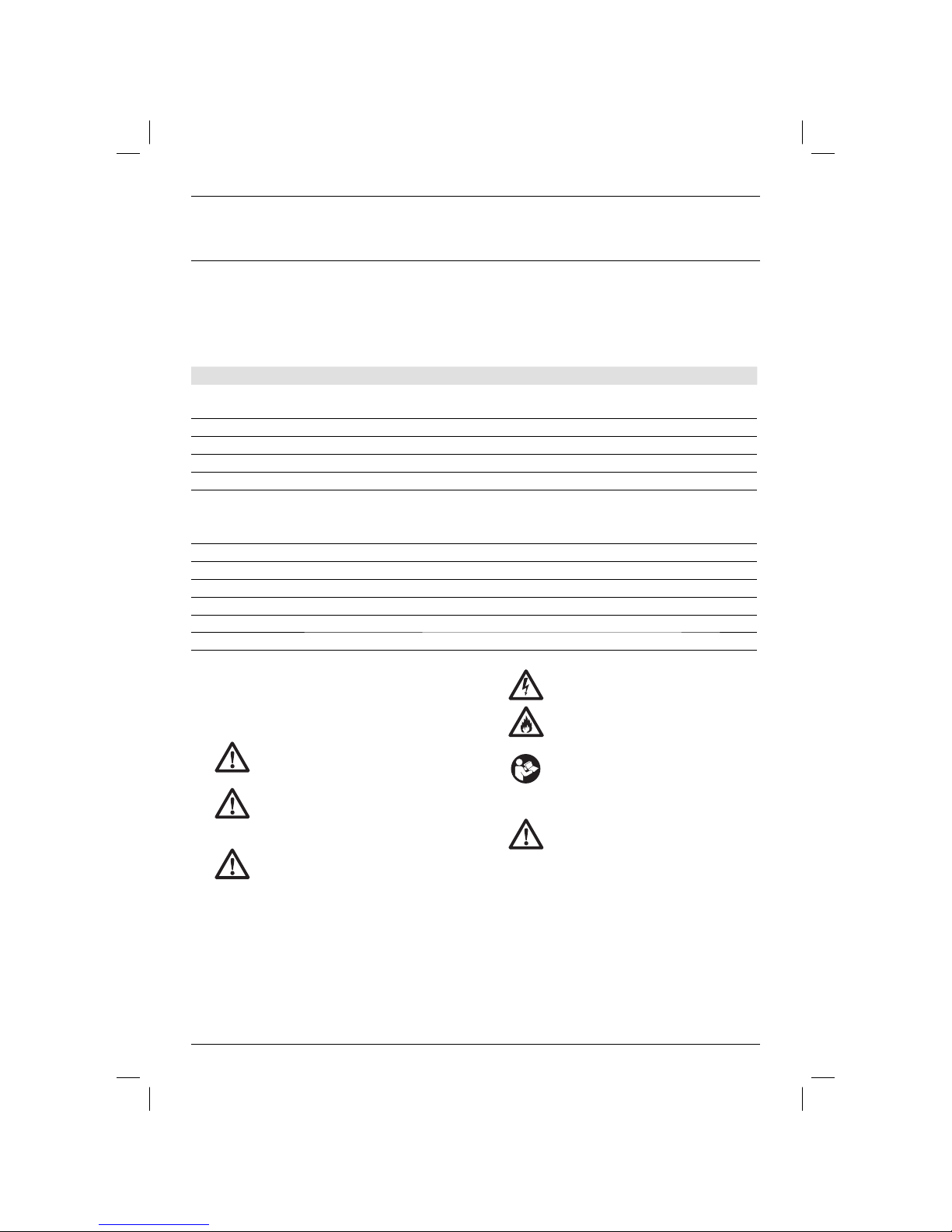

ANTI ROTATION SYSTEM D25415 (FIG. 2)

The anti rotation system offers increased user

comfort and safety through an on-board, antirotation technology capable of detecting if the

user loses control of the hammer. When a jam

is detected, the torque and speed are reduced

instantly. This feature prevents self rotation of the tool

reducing the occurrence of wrist injuries. The red

LED indicator (i) lights up if the anti-rotational device

is activated.

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

6

ENGLISH

Your DEWALT tool is double insulated in

accordance with EN 60745; therefore no

earth wire is required.

WARNING: 120 V units have to

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

EWALT service organisation.

D

be operated via a fail-safe isolating

transformer with an earth screen

between the primary and secondary

winding.

Mains Plug Replacement

(Middle East and Africa)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

made to the earth terminal.

Using an Extension Cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see Technical Data). The minimum conductor

size is 1 mm2; the maximum length is 30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing

set-ups or when making repairs.

Be sure the trigger switch is in the OFF

position. An accidental start-up can

cause injury.

Selecting the Operating Mode

(fig. 3)

D25413, D25415

The tool can be used in the following operating

modes:

Rotary drilling: for screwdriving and for

drilling into steel, wood and plastics.

Hammerdrilling: for concrete and masonry

drilling operations.

Hammering only: for light chipping,

chiselling and demolition applications. In

this mode the tool can also be used as a

lever to free a jammed drill bit.

Bit rotation: non-working position used

only to rotate a flat chisel into the desired

position.

D25430

The tool can be used in the following operating

modes:

Hammering only: for light chipping,

chiselling and demolition applications. In

this mode the tool can also be used as a

lever to free a jammed drill bit.

Bit rotation: non-working position used

only to rotate a flat chisel into the desired

position.

1. To select the operating mode, press the safety

lock (e) and rotate the mode selector switch

(d) until it points to the symbol of the required

mode.

2. Release the safety lock and check that the

mode selector switch is locked in place.

WARNING: Do not select the operating

mode when the tool is running.

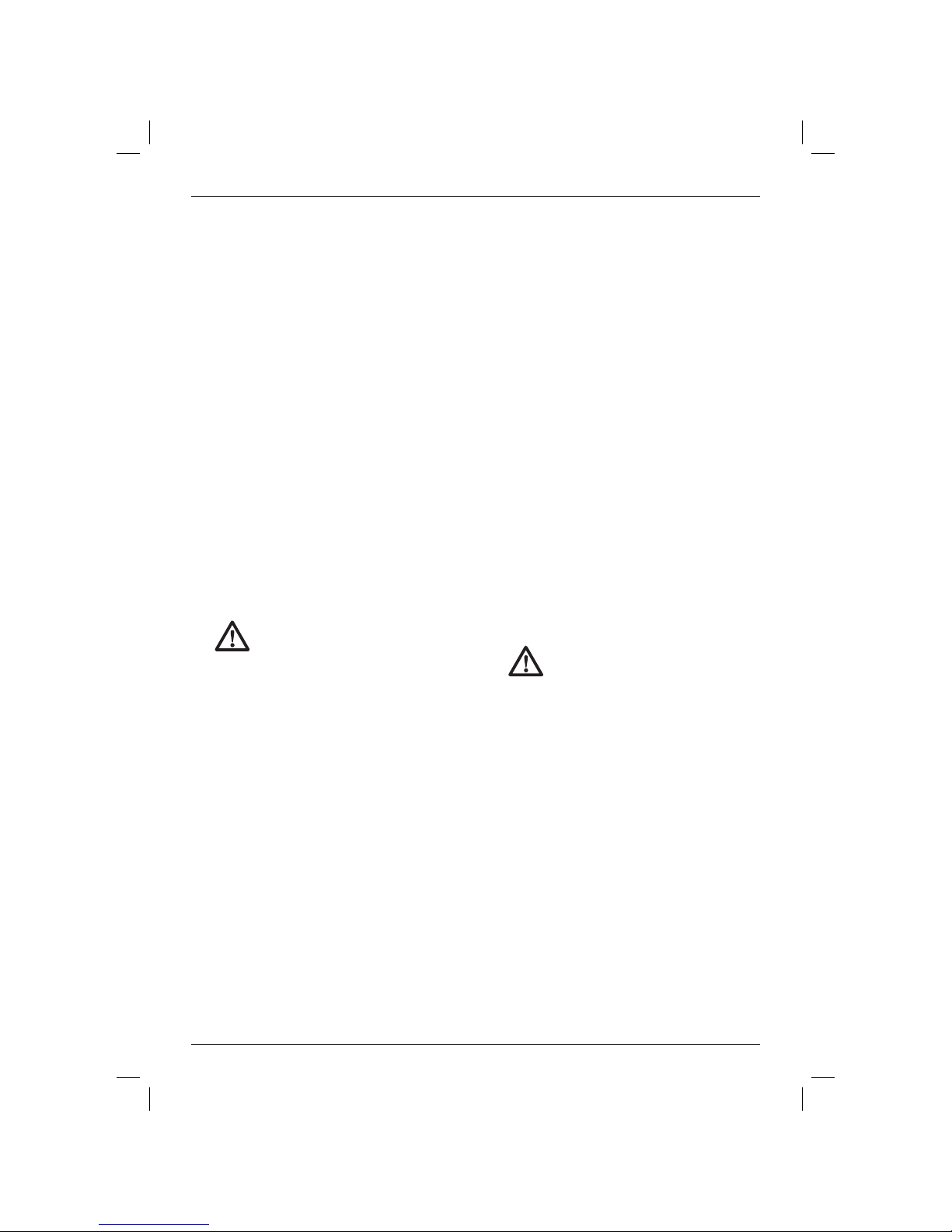

Indexing the Chisel Position (fi g. 3)

The chisel can be indexed and locked into 12

different positions.

1. Rotate the mode selector switch (d) until it

points to the bit rotation symbol. Refer to

Selecting the Operating Mode in Assembly

and Adjustments.

2. Rotate the chisel in the desired position.

3. Set the mode selector switch (d) to the

hammering only position.

4. Twist the chisel until it locks in position.

Inserting and Removing SDS Plus®

Accessories (fig. 4)

This tool uses SDS Plus® accessories (refer to

the inset in figure 4 for a cross-section of an SDS

Plus® bit shank). We recommend using professional

accessories only.

7

Loading...

Loading...