Page 1

• Do not overreach. Keep proper footing and balance at all times. Proper footing and bal-

ance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss

of control.

Do not force tool. Use the correct tool for your application. The correct tool will do the

job better and safer at the rate for which it is designed.

Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

_, with the switch is dangerous and must be repaired.

•m Disconnect the plug from the power source before making any adjustments, changing

4.a=... Check for misalignment or binding of moving parts, breakage of parts, and any other

"_ condition that may affect the tools operation. If damaged, have the tool serviced

accessories, or storing the tool. Such preventative safety measures reduce the risk of starting

the tool accidentally.

Store idle tools out of reach of children and other untrained persons. Tools are dan-

gerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind and are easier to control.

before using. Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on anoth-er tool.

_1_ Tool service must be performed only by qualified repair personnel. Service or mainte-

_ the Maintenance section of this manual. Use of unauthorized parts or failure to follow

,e= ADDITIONAL SPECIFIC SAFETY INSTRUCTIONS FOR

"_ • Hold tool by insulated gripping surfaces when performing an operation where the

_ cutting tools may contact hidden wiring or its own cord. Contact with a "live" wire will

_ make exposed metal parts of the tool "live" and shock the operator.

_._ _ chips to fly. Flying particles can cause permanent eye damage.

E

-- --_,. z_ CAUTION: DO NOT TOUCH ANY METAL PARTS OF THE TOOL when drilling or driving into

r_ *- P" walls, floors or areas where live electrical wires may be encountered. Hold the tool only by insulat-

_ &'" _ Z_CAUTION: Wear appropriate hearing protection during use. Under some conditions

I_) _,, and duration of use, noise from this product may contribute to hearing loss.

E "i_ d} _1_ _WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other con-

t__ _ rive harm. Some examples of these chemicals are:

_ struction activities contains chemicals known to cause cancer, birth defects or other reproduc-

_.,_ _ _._" E • ,eadfromlead-basedpaints,

(_._..___ Yourriskfromtheseexposuresvaries, dependingonhowoftenyoudothistypeofwork. To

DEWALT industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(APR03) Form No. 613712-00 D21007 Copyright©2003

The following are trademarks for one or more DEWALT power tools: the yellow and black color

scheme; the "D" shaped air intake grill; the array of pyramids on the handgrip; the kit box con-

figuration; and the array of lozenge-shaped humps on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

GENERAL SAFETY INSTRUCTIONS FOR ALL TOOLS

z_ WARNING! Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

• Keep your work area clean and well lit Cluttered benches and dark areas invite acci-

dents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Double insulated tools are equipped with a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized outlet only one way. ff the plug does not fit

fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the plug in any way. Double insulation []

eliminates the need for the three wire grounded power cord and grounded power supply

system.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

• Don't expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace dam-

aged cords immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use and reduce the risk of electric shock.

Volts

120V

240V

Ampere Rating

More Not more

Than Than

0 - 6

6 - 10

10 - 12

12 - 16

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use tool while tired or under the influence of drugs, alcohol, or medica-

tion. A moment of inattention while operating power tools may result in serious personal

injury,

• Dress properly. Do not wear loose clothing orjewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts. Air vents often cover moving parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with

your finger on the switch or plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

Minimum Gage for Cord Sets

Total Length of Cord in Feet

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommended

SERVICE

When servicing a tool, use only identical replacement parts. Follow instructions in

nance performed by unqualified personnel could result in a risk of injury.

Maintenance Instructions may create a risk of electric shock or injury.

DRILLS

• Wear safety goggles or other eye protection. Hammering and drilfing operations cause

• Keep handles dry, clean, and free from oil and grease. This will enable better control of the

tool.

ed grasping surfaces to prevent electric shock if you drill or drive into a live wire.

• crystalfine silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

reduce your exposure to these chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially designed to filter out microscop-

ic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

• The label on your tool may include the following symbols.

V.......................... volts

A .......................... amperes

Hz ........................ hertz

W ........................ watts

min ...................... minutes

"_ ........................ alternating current

.... . ................... direct current

no ........................ no load speed

[] .......................... Class II Construction

.../min .................. revolutions or reciprocation per minute

........................ earthing terminal

........................ safety alert symbol

Motor Brushes

DEWALT uses an advanced brush system which automatically stops the drill when the brush-

es wear out. This prevents serious damage to the motor.

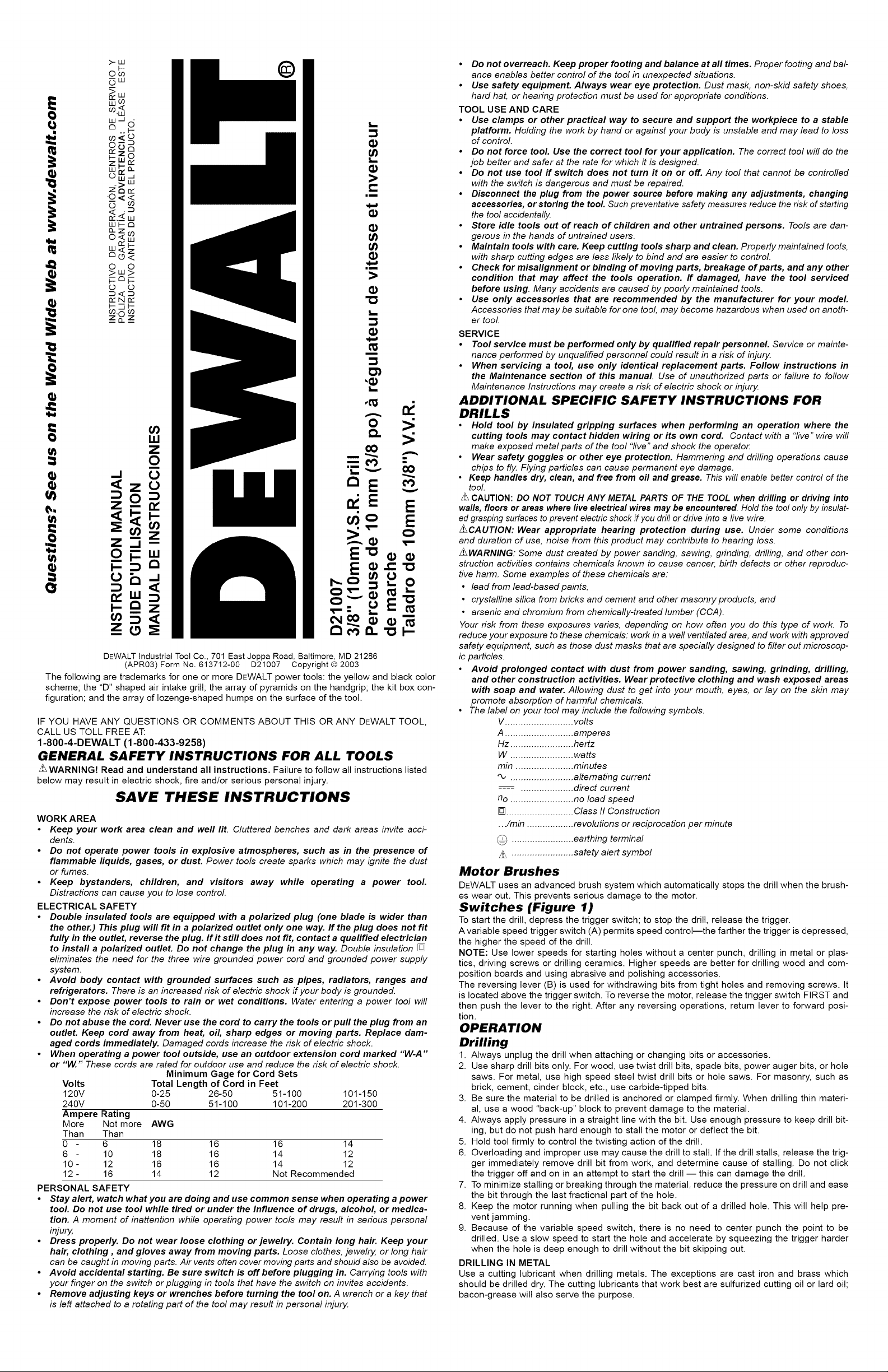

Switches (Figure 1)

To start the drill, depress the trigger switch; to stop the drill, release the trigger.

A variable speed trigger switch (A) permits speed control--the farther the trigger is depressed,

the higher the speed of the drill.

NOTE: Use lower speeds for starting holes without a center punch, drilling in metal or plas-

tics, driving screws or drilling ceramics. Higher speeds are better for drilling wood and com-

position boards and using abrasive and polishing accessories.

The reversing lever (B) is used for withdrawing bits from tight holes and removing screws. It

is located above the trigger switch. To reverse the motor, release the trigger switch FIRST and

then push the lever to the right. After any reversing operations, return lever to forward posi-

tion.

OPERATION

Drilling

1. Always unplug the drill when attaching or changing bits or accessories.

2. Use sharp drill bits only. For wood, use twist drill bits, spade bits, power auger bits, or hole

saws. For metal, use high speed steel twist drill bits or hole saws. For masonry, such as

brick, cement, cinder block, etc., use carbide-tipped bits.

3. Be sure the material to be drilled is anchored or clamped firmly. When drilling thin materi-

al, use a wood "back-up" block to prevent damage to the material.

4. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill bit-

ing, but do not push hard enough to stall the motor or deflect the bit.

5. Hold tool firmly to control the twisting action of the drill.

6. Overloading and improper use may cause the drill to stall. If the drill stalls, release the trig-

ger immediately remove drill bit from work, and determine cause of stalling. Do not click

the trigger off and on in an attempt to start the drill -- this can damage the drill.

7. To minimize stalling or breaking through the material, reduce the pressure on drill and ease

the bit through the last fractional part of the hole.

8. Keep the motor running when pulling the bit back out of a drilled hole. This will help pre-

vent jamming.

9. Because of the variable speed switch, there is no need to center punch the point to be

drilled. Use a slow speed to start the hole and accelerate by squeezing the trigger harder

when the hole is deep enough to drill without the bit skipping out.

DRILLING IN METAL

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The cutting lubricants that work best are sulfurized cutting oil or lard oil;

bacon-grease will also serve the purpose.

Page 2

DRILLINGINWOOD

Holesinwoodcanbemadewiththesametwistdrillsusedformetal.Thesebitsmayover-

heatunlesspulledoutfrequentlytoclearchipsfromtheflutes.Forlargerholes,usepower

drillwoodbits.Workthatisapttosplintershouldbebackedupwithablockofwood.

DRILLINGINMASONRY

Usecarbidetippedmasonrybitsatlowspeeds.Keepevenforceonthedrillbutnotsomuch

thatyoucrackthebrittlematerials.Asmooth,evenflowofdustindicatestheproperdrilling

rate.

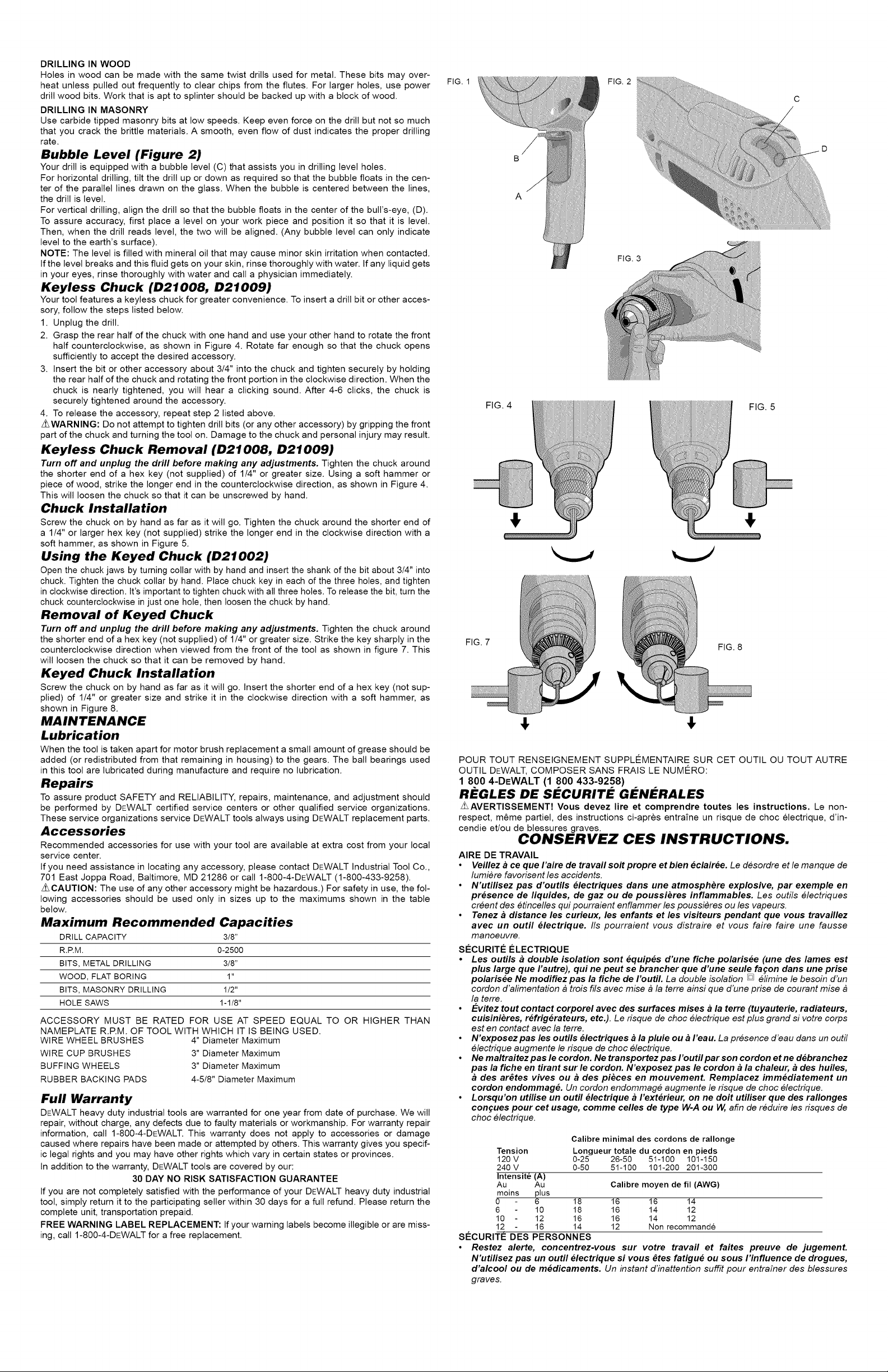

Bubble Level (Figure 2)

Your drill is equipped with a bubble level (C) that assists you in drilling level holes.

For horizontal drilling, tilt the drill up or down as required so that the bubble floats in the cen-

ter of the parallel lines drawn on the glass. When the bubble is centered between the lines,

the drill is level.

For vertical drilling, align the drill so that the bubble floats in the center of the bull's-eye, (D).

To assure accuracy, first place a level on your work piece and position it so that it is level.

Then, when the drill reads level, the two will be aligned. (Any bubble level can only indicate

level to the earth's surface).

NOTE: The level is filled with mineral oil that may cause minor skin irritation when contacted.

If the level breaks and this fluid gets on your skin, rinse thoroughly with water. If any liquid gets

in your eyes, rinse thoroughly with water and call a physician immediately.

Keyless Chuck (D21008, D21009)

Your tool features a keyless chuck for greater convenience. To insert a drill bit or other acces-

sory, follow the steps listed below.

1. Unplug the drill.

2. Grasp the rear half of the chuck with one hand and use your other hand to rotate the front

half counterclockwise, as shown in Figure 4. Rotate far enough so that the chuck opens

sufficiently to accept the desired accessory.

3. Insert the bit or other accessory about 3/4" into the chuck and tighten securely by holding

the rear half of the chuck and rotating the front portion in the clockwise direction. When the

chuck is nearly tightened, you will hear a clicking sound. After 4-6 clicks, the chuck is

securely tightened around the accessory.

4. To release the accessory, repeat step 2 listed above.

Z_WARNING: Do not attempt to tighten drill bits (or any other accessory) by gripping the front

part of the chuck and turning the tool on. Damage to the chuck and personal injury may result.

Keyless Chuck Removal (D21008, D21009)

Turn off and unplug the drill before making any adjustments. Tighten the chuck around

the shorter end of a hex key (not supplied) of 1/4" or greater size. Using a soft hammer or

piece of wood, strike the longer end in the counterclockwise direction, as shown in Figure 4.

This will loosen the chuck so that it can be unscrewed by hand.

Chuck Installation

Screw the chuck on by hand as far as it will go. Tighten the chuck around the shorter end of

a 1/4" or larger hex key (not supplied) strike the longer end in the clockwise direction with a

soft hammer, as shown in Figure 5.

Using the Keyed Chuck (D21002)

Open the chuck jaws by turning collar with by hand and insert the shank of the bit about 3/4" into

chuck. Tighten the chuck collar by hand. Place chuck key in each of the three holes, and tighten

in clockwise direction. It's important to tighten chuck with all three holes. To release the bit, turn the

chuck counterclockwise in just one hole, then loosen the chuck by hand.

Removal of Keyed Chuck

Turn off and unplug the drill before making any adjustments. Tighten the chuck around

the shorter end of a hex key (not supplied) of 1/4" or greater size. Strike the key sharply in the

counterclockwise direction when viewed from the front of the tool as shown in figure 7. This

will loosen the chuck so that it can be removed by hand.

Keyed Chuck Installation

Screw the chuck on by hand as far as it will go. Insert the shorter end of a hex key (not sup-

plied) of 1/4" or greater size and strike it in the clockwise direction with a soft hammer, as

shown in Figure 8.

MAINTENANCE

Lubrication

When the tool is taken apart for motor brush replacement a small amount of grease should be

added (or redistributed from that remaining in housing) to the gears. The ball bearings used

in this tool are lubricated during manufacture and require no lubrication.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance, and adjustment should

be performed by DEWALT certified service centers or other qualified service organizations.

These service organizations service DEWALT tools always using DEWALT replacement parts.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

service center.

If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co.,

701 East Joppa Road, Baltimore, MD 21286 or call 1-800-4-DEWALT (1-800-433-9258).

Z_CAUTION: The use of any other accessory might be hazardous.) For safety in use, the fol-

lowing accessories should be used only in sizes up to the maximums shown in the table

below.

Maximum Recommended Capacities

DRI LL CAPACITY 3/8"

R.RM. 0-2500

BITS, METAL DRILLING 3/8"

WOOD, FLAT BORING 1"

BITS, MASONRY DRILLING 1/2"

HOLE SAWS 1-1/8"

ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO OR HIGHER THAN

NAMEPLATE R.RM. OF TOOL WITH WHICH IT IS BEING USED.

WIRE WHEEL BRUSHES 4" Diameter Maximum

WIRE CUP BRUSHES 3" Diameter Maximum

BUFFING WHEELS 3" Diameter Maximum

RUBBER BACKING PADS 4-5!8" Diameter Maximum

Full Warranty

DEWALT heavy duty industrial tools are warranted for one year from date of purchase. We will

repair, without charge, any defects due to faulty materials or workmanship. For warranty repair

information, call 1-800-4-DEWALT. This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others. This warranty gives you specif-

ic legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

30 DAY NO RISK SATISFACTION GUARANTEE

If you are not completely satisfied with the performance of your DEWALT heavy duty industrial

tool, simply return it to the participating seller within 30 days for a full refund. Please return the

complete unit, transportation prepaid.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are miss-

ing, call 1-800-4-DEWALT for a free replacement.

FIG. 1

A

FIG. 4

,!,

FIG. 7

FIG. 2

C

FIG. 3

FIG. 5

,I,

FIG. 8

,!, ,!,

POUR TOUT RENSEIGNEMENT SUPPLEMENTAtRE SUR CET OUTIL OU TOUT AUTRE

OUTIL DEWALT, COMPOSER SANS FRAtS LE NUM¢:RO:

1 800 4-DEWALT (1 800 433-9258)

REGLES DE sr:CURITr: Gr:Nr:RALES

ZLAVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le non-

respect, mGme partiel, des instructions ci-apres entraTne un risque de choc electrique, d'in-

cendie et/ou de blessures graves.

AIRE DE TRAVAIL

• Veillez ace que I'aire de travail soit propre et bien _clair_e. Le desordre et le manque de

lumiere favorisent les accidents.

• N'utilisez pas d'outils _lectriques dans une atmosphere explosive, par exemple en

presence de liquides, de gaz ou de poussi_res inflammables. Les outils electriques

creent des etincelles qui pourraient enflammer les poussieres ou les vapeurs.

• Tenez a distance les curieux, les enfants et les visiteurs pendant que vous travaillez

avec un outil _lectrique. IIs pourraient vous distraire et vous faire faire une fausse

manoeuvre.

SI_CURITI_ I_LECTRIQUE

• Les outils a double isolation sont _quip_s d'une fiche polaris_e (une des lames est

plus large que I'autre), qui ne peut se brancher que d'une seule fa¢on dans une prise

polaris_e Ne modiflez pas la fiche de I'outil. La double isolation [] elimine le besoin d'un

cordon d'alimentation a trois ills avec mise a la terre ainsi que d'une prise de courant mise

la terre.

• Evitez tout contact corporel avec des surfaces mises a la terre (tuyauterie, radiateurs,

cuisini_res, r_frig_rateurs, etc.). Le risque de choc electrique est plus grand si votre corps

est en contact avec la terre.

• N'exposez pas les outils _lectriques a la pluie ou a I'eau. La presence d'eau dans un outil

electrique augmente le risque de choc electrique.

• Ne maltraitez pas le cordon. Ne transportez pas I'outil par son cordon etne d_branchez

pas la fiche en tirant sur le cordon. N'exposez pas le cordon a la chaleur, a des huiles,

des ar_tes vives ou a des pi_ces en mouvement. Remplacez imm_diatement un

cordon endommag& Un cordon endommage augmente le risque de choc electrique.

• Lorsqu'on utilise un outil _lectrique a I'ext_rieur, on ne dolt utiliser que des rallonges

con¢ues pour cet usage, comme celles de type W-A ou W, afin de reduire les risques de

choc electrique.

S¢:CURITE DES PERSONNES

• Restez alerte, concentrez-vous sur votre travail et faites preuve de jugement.

N'utilisez pas un outil _lectrique si vous _tes fatigu_ ou sous I'influence de drogues,

d'alcool ou de m_dicaments. Un instant d'inattention suffit pour entra;ner des blessures

graves.

CONSERVEZ CES INSTRUCTIONS.

Tension

120 V

240 V

Intensite (A)

Au Au

moins plus

0 6

6 10

10 12

12 16

Calibre minimal des cordons de rallonge

Longueur totale du cordon en pieds

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

Calibre moyen de fil(AWG)

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Non recommande

Page 3

• Habillez-vous convenablement. Ne portez ni v_tements flottants ni bijoux. Confinez les

cheveux longs. N'approchez jamais les cheveux, les v_tements ou les gants des

pi_ces en mouvement. Des v_tements flottants, des bijoux ou des cheveux longs risquent

d'etre happes par des pieces en mouvement.. Se tenir eloigne des events puisque ces

demiers pourraient camoufler des pieces mobiles.

• Eviter les d_marrages accidentels; s'assurer que I'interrupteur est en position d'arr_t

avant de brancher I'outiL Ne pas transporter I'outil en laissant le doigt sur I'interrupteur ni le

brancher Iorsque I'interrupteur est en position de marche, car cela pourrait causer un acci-

dent.

• Enlevez les cl_s de r_glage ou de serrage avant de d_marrer I'outil. Une cle laissee dans

un piece toumante de I'outil peut provoquer des blessures.

• Ne vous penchez pas trop en avant. Maintenez un bon appui et restez en _quilibre en

tout temps. Un bonne stabilite vous permet de mieux reagir a une situation inattendue.

• Utilisez des accessoires de s_curit_. Portez toujours des lunettes ou une visi_re. Selon

les conditions, portez aussi un masque antipoussiere, des bottes de securite antiderapantes,

un casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

• Immobilisez le mat_riau sur une surface stable au moyen de brides ou de toute autre

fa_on adequate. Le fait de tenir la piece avec la main ou contre votre corps offre un stabilite

insuffisante et peut amener un derapage de I'outiL

• Ne forcez pas I'outil. Utilisez I'outil appropri_ a la t&che. Lbutil correct fonctionne mieux

et de fagon plus securitaire. Respectez aussi la vitesse de travail qui lui est propre.

• N'utilisez pas un outil si son interrupteur est bloqu_. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et droit _tre repare.

• D_branchez la fiche de I'outil avant d'effectuer un r_glage, de changer d'accessoire ou

de ranger l'outil. De telles mesures preventives de securite reduisent le risque de demarrage

accidentel de IbutiL

• Rangez les outils hors de la pottle des enfantes et d'autres personnes

inexp_riment_es. Les outils sont dangereux dans les mains d'utilisateurs novices.

• Prenez soin de bien entretenir les outils. Les outils de coupe doivent _tre toujours bien

aff£/t_s et propres. Des outils bien entretenus, dont les ar_tes sont bien tranchantes, sont

moins susceptibles de coincer et plus faciles a diriger.

• Soyez attentif a tout d_salignement ou coincement des pi_ces en mouvement, a tout

bris ou a toute autre condition pr_judiciable au bon fonctionnement de I'outiL Si vous

constatez qu'un outil est endommag_, faites-le r_parer avant de vous en servir. De

nombreux accidents sont causes par des outils en mauvais etat.

• N'utilisez que des accessoires que le fabricant recommande pour votre module d'outil.

Certains accessoires peuvent convenir a un outil, mais _tre dangereux avec autre.

RC:PARATION

• La r_paration des outils _lectriques dolt _tre confi_e a un r_parateur qualifi_. L'entretien

ou la reparation d'un outil electrique par un amateur peut avoir des consequences graves.

• Pour la r_paration d'un outil, n'employez que des pi_ces de rechange d'origine. Suivez

les directives donn_es a la section _R_paratiom_ de ce manuel. L'emploi de pieces non

autorisees ou le non-respect des instructions d'entretien peut creer un risque de choc

electrique ou de blessures.

• Tenez I'outil par ses surfaces de prise isol_es pendant toute operation o_/I'outil de

coupe portrait venir en contact avec un c&blage dissimul_ ou avec son propre cordon.

En cas de contact avec un conducteur sous tension, les pieces metalliques a decouvert de

Ibutil transmettraient un choc electrique a I'utilisateur.

Mesures de s_curit_ de perceuses additionnelles

• Saisir les surfaces isol_es de I'outil Iorsqu'on s'en sert la o_/il pourrait y avoir des

ills sous tension et Iorsqu'il pourrait entrer en contact avec son propre ill. En cas de

contact avec un fil sous tension, les composantes metalliques a decouvert de I'outil

deviendraient sous tension et I'utilisateur subirait des secousses electriques.

• Porter des lunettes de s_curit_ ou autre dispositif de protection oculaire car le marte-

lage et le pergage peuvent faire projeter des particules et entrafner des dommages

irreversibles aux yeux.

• S'assurer que les poign_es sont propres, libres de toute tache d'huile et de graisse.

II est conseille de porter des gants en caoutchouc afin d'optimiser la maftrise de I'outiL

z_ MISE EN GARDE :Lorsqu'on perce ou on visse dans les murs, les planchers ou tout

autre endroit o_/ peuvent se trouver des ills sous tension, NE PAS TOUCHER A TOUT

COMPOSANT METALLIQUE DE L'OUTIL. Ne le saisir que par ses surfaces de prise en

plastique afin de se proteger des secousses electriques que provoqueraient le contact du foret

ou de la lame avec un fll sous tension.

z_ MISE EN GARDE : porter un dispositif de protection personnel anti-bruit approprie durant

I'utilisation. Sous certaines conditions et pendant toute la duree de I'utilisation, le bruit emanant

de ce produit pourrait contribuer a la perte d'audition.

z_AVERTISSEMENT : Certains outils, tels que les sableuses electriques, les scies, les meules,

les perceuses ou certains autres outils de construction, peuvent soulever de la poussiere con-

tenant des produits chimiques susceptibles d'entrafner le cancer, des malformations congeni-

tales ou pouvant _tre nocifs pour le systeme reproductif. Parmi ces produits chimiques, on

retrouve :

• le plomb dans les peintures a base de plomb;

• la silice cristalline dans les briques et le ciment et autres produits de magonnerie;

• I'arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique (CCA).

Le risque associe a de relies expositions peut varier selon la frequence avec laquelle on effectue

ces travaux. Pour reduire I'exposition a de tels produits, il faut travailler dans un endroit bien ven-

tile et utiliser I'equipement de securite approprie tel un masque anti-poussieres specialement

congu pour flitter les particules microscopiques.

• Eviter tout contact prolong_ avec la poussi_re soulev_e par cet outil ou autres outils

_lectriques. Porter des v_tements de protection et nettoyer les parties expos_es du

corps avec de I'eau savonneuse. S'assurer de bien se proteger afin d'eviter d'absorber

par la bouche, les yeux ou la peau des produits chimiques nocifs.

• L'etiquette de Ibutil peut comporter les symboles suivants.

V ...................... volts

A ...................... amperes

Hz ...................... hertz

W ...................... watts

min ...................... minutes

"_ ...................... courant altematif

.... ...................... courant continu

no .................................. sous vide

[] .................................. construction de classe II

/min ................................ tours ou courses a la minute

.................................... borne de mise a la terre

z_ .................................. symbole d'avertissement

Balais du moteur

Les outils DEWALT sont dotes d'un systeme perfectionne de verification des balais qui arr_te

automatiquement I'outil Iorsque les balais sont uses afin d'emp6cher d'endommager le

moteur.

Interrupteurs (Fig. 1)

Pour mettre la perceuse en marche, enfoncer I'interrupteur a detente; pour la mettre hors cir-

cuit, rel_cher I'interrupteur a detente.

Le regulateur de vitesse permet de contrSler la vitesse de I'outil. Plus on enfonce I'interrupteur

detente, plus I'outil fonctionne rapidement.

NOTE : Se servir des basses vitesses pour amorcer des trous sans poin£on ainsi que pour

percer les metaux, les plastiques et la ceramique, ainsi que pour enfoncer des vis. Les

vitesses elevees conviennent mieux au per£age du bois et des panneaux d'agglomeres, ainsi

qu'a I'utilisation d'accessoires pour le pon£age et le polissage.

L'inverseur de marche (B) sert a sortir les vis ou les forets coinces. 11se trouve au-dessus de

I'interrupteur a detente. Pour actionner la marche arriere, il faut D'ABORD rel_cher I'interrupteur

detente, puis faire glisser I'inverseur de marche vers la droite. Apres les travaux en marche

arriere, toujours remettre I'inverseur a la marche avant.

FONCTIONNEMENT

PerFage

1. Toujours debrancher I'outil Iorsqu'on en change les forets ou les accessoires.

2. N'utiliser que des forets bien affQtes. Pour le BOIS : forets helicofdaux, a langue d'aspic,

de tariere ou des emporte-piece; pour le M¢:TAL : forets helicofdaux en acier de coupe

rapide ou des emporte-piece; pour la MA(_ONNERIE (brique, ciment et beton, etc.) : fore-

ts au carbure.

3. Veiller ace que la piece a percer soit solidement retenue ou fixee en place. Afin d'eviter

les avaries aux materiaux minces, les adosser a un bloc de bois epais.

4. Toujours exercer la pression en ligne directe avec le foret. N'user que de la force qu'il faut

pour que le foret continue de percer; eviter de trop forcer, ce qui pourrait faire caler le

moteur ou devier le foret.

5. Saisir fermement la perceuse afin de contrer I'effet de torsion de I'outil en marche.

6. La perceuse s'etouffe habituellement Iorsqu'elle est surchargee ou utilisee de fa£on inappro-

priee. Relacher immediatement I'inerrupteur ,ik detante, retirer le foret du materiau et deter-

miner la cause du blocage, a eviter de mettre en marche et hors circuit I'outil a I'aide de I'in-

terrupteur a detente dans le but de faire demarrer la perceuse bloquee, cela pourrait I'en-

dommager.

7. Afin de minimiser I'etouffement du moteur ou le defoncement de la piece, reduire la pres-

sion et faire avancer plus doucement le foret vers la fin de sa course.

8. Laisser le moteur en marche Iorsqu'on retire le foret d'un trou afin d'eviter que le foret se

coince.

9. II n'est pas necessaire de pratiquer un creux de guidage avec les perceuses a regulateur

de vitesse. Utiliser plutSt la basse vitesse pour commencer le trou, puis accelerer en

enfon£ant plus profondement I'interrupteur a detente Iorsque le foret est suffisamment

insere dans la piece.

PER(_AGE DANS LES MC:TAUX

Utiliser de ]'huile de coupe pour percer dans ]es metaux, sauf ]a fonte et ]e ]alton qui se per-

cent a sec. L'huile de coupe ]a plus efficace est I'huile sulfurisee ou I'huile de lard; la graisse

de bacon est parfois suffisante.

PER(_AGE DANS LE BOIS

Les forets he]icofdaux a metal peuvent servir a percer ]e bois, mais il faut les retirer souvent

du trou pour chasser ]es copeaux et rognures des goujures afin d'eviter qu'ils ne surchauffent.

Pour percer de gros trous, utiliser les forets a bois d'une perceuse electrique. Adosser les

materiaux friables a un bloc de bois quelconque.

PER(_AGE DANS LA MA(_ONNERIE

Utiliser des forets a ma_onnerie aux basses vitesses. Exercer une pression constante, sans

forcer afin d'eviter de casser les materiaux friables. Une production uniforme de poussiere

debit moyen indique un per£age convenable.

Niveau a bulle (Fig. 2)

La perceuse est munie d'un niveau a bulle pour s'assurer que les trous perces sont de niveau

avec les plans horizontal ou vertical.

Dans le cas des trous perces a I'horizontale, placer la perceuse de sorte que la bulle se trou-

ve entre les reperes (comme le montre la figure 3A). ,ik ce moment-la, la perceuse est de

niveau avec le plan horizontal.

Pour percer des trous a la verticale, il suffit de placer la perceuse pour que la bulle flotte au

centre du verre indicateur, comme I'illustre la figure 3B.

Afin de s'assurer de la precision, mettre un niveau sur la piece a percer et placer cette

derniere de niveau. Puis, aligner la perceuse, qui est de niveau, sur la piece. (Tousles

niveaux n'indiquent que le niveau par rapport au champ de gravitation de la terre.)

NOTE : Le niveau contient de I'huile minerale qui peut causer une legere irritation au contact

de la peau. Si le niveau se brise et que I'huile entre en contact avec la peau, bien la rincer

avec de I'eau. Si le liquide entre en contact avec les yeux, les rincer a fond avec de I'eau,

puis telephoner immediatement a un medecin.

Mandrin sans cl_ (D21008, D21009)

L'outil est muni d'un mandrin sans cle pour plus de commodite. Pour y inserer un foret ou tout

autre accessoire, faire ce qui suit.

1. Debrancher I'outil.

2. Saisir la moitie arriere du mandrin d'une main et de I'autre, faire tourner la moitie avant

dans le sens antihoraire, comme le montre la figure 4. Faire tourner suffisamment pour

faire entrer I'accessoire voulu dans le mandrin.

3. Inserer environ 38 mm (3/4 po) du foret ou de I'accessoire dans le mandrin et bien serrer

en tenant la moitie arriere du mandrin et en faisant tourner la moitie avant dans le sens

horaire.

Pour degager I'accessoire, repeter I'etape 2 precedente.

Z_AVERTISSEMENT : Ne pas essayer de serrer les forets (ou tout autre accessoire) en sai-

sissant I'avant du mandrin et en mettant I'outil en marche; cela presente des risques de

blessures et de dommages au mandrin.

Retrait du mandrin (D21008, D21009)

Serrer le mandrin autour de la courte extremite d'une cle a six pans (non fournie) d'au moins

6 mm (1/4 po). ,ik I'aide d'un marteau leger ou d'un morceau de bois, frapper I'extremite la

Iongue extremite de la cle dans le sens horaire, de la fa£on illustree a la figure 5.

On desserre ainsi le mandrin de fa£on a pouvoir le retirer a la main.

Installation du mandrin

Visser a fond le mandrin a la main. Visser le mandrin autour de la courte extremite d'une cle

six pans d'au moins 6 mm (1/4 po) (non fournie) et frapper la Iongue extremite de la cle

dans le sens horaire a I'aide d'un marteau leger, de la fa£on illustree a la figure 6.

Mandrins a cl_ (D21002)

Ouvrir les m_choires du mandrin en tournant la bague a la main et y inserer environ 3/4 po

de I'arbre du foret. Resserrer la bague du mandrin a la main. Placer la cle du mandrin dans

chacun des trois trous et serrer dans le sens HORAIRE. II est essentiel de bien serrer les trois

trous du mandrin. Pour degager le foret, il suffit de faire tourner la cle du mandrin dans le sens

ANTtHORAIRE dans I'un des trous, puis de desserrer le mandrin a la main. Le personnel d'un

centre de service autorise peut remplacer un mandrin a cle par un mandrin sans cle.

Retrait du mandrin

Placer la cle du mandrin dans I'un des trois trous du mandrin de la fa_on illustree a la figure 7.

Frapper la cle dans le sens antihoraire (Iorsqu'on se place a I'avant de I'outil). On desserre

ainsi le mandrin de fa£on a pouvoir le retirer a la main.

Installation du mandrin

Visser a fond le mandrin a la main. Placer la cle du mandrin dans I'un des trois trous du man-

drin et la frapper dans le sens horaire (Iorsqu'on se place a I'avant de I'outil), comme le mon-

tre la figure 8.

ENTRETIEN

Lubrification

Quand I'outil est demonte pour le remplacement de brosse de moteur un peu de graisse devrait

6tre ajoute (ou redistribue de cela restant dans le Iogement) aux vitesses. Les roulements

billes utilises dans cet outil sont lubrifies pendant la fabrication et n'exigent aucune lubrification.

Rdparations

Pour assurer la SECURtT¢: D'EMPLOI et la FIABILIT¢: de I'outil, n'en confier la reparation,

I'entretien et les rajustements (y compris I'inspection et le remplacement des balais) qu'au

personnel d'un centre de service DEWALT ou d'un atelier d'entretien autorise n'utilisant que

des pieces de rechange identiques.

Accessoires

On peut se procurer separement les accessoires recommandes pour I'outil chez les detail-

lants ou au centre de service de la region.

LA VlTESSE NOMINALE DES ACCESSOIRES DOlT ETRE EGALE OU SUPERIEURE AU

REGtME DE L'OUTIL (INDIQU¢: SUR LA PLAQUE SIGNALETIQUE DE CE DERNIER)AVEC

LEQUEL ILS SONT UTILISES.

Page 4

Pourtrouverunaccessoire,prieredecommuniqueravecDEWALTIndustrialToolCo.,701

EastJoppaRoad,Baltimore,MD21286,E.-U.,oucomposersansfraisle1(800)4-DEWALT.

MISEENGARDE: L'utilisationdetoutaccessoirenonrecommandepeut6tredan-

gereuse.

Garantie compl_)te

Les outils industriels de service intensif DEWALT sont garantis pendant un an a partir de la

date d'achat. Toute piece d'un outil DEWALT qui s'averait defectueuse en raison d'un vice de

matiere ou de fabrication sera reparee ou remplacee sans frais. Pour obtenir de plus amples

renseignements sur les reparations couvertes par la garantie, composer le 1 (800) 4-DEWALT

(! (800) 433-9258). La ga rantie ne couvre pas les accessories ni les reparations tentees ou

effectuees par des tiers. Les modalites de la presente garantie donnent des droits legaux

specifiques. L'utilisateur peut egalement se prevaloir d'autres droits selon I'etat ou la province

qu'il habite.

En outre, la garantie suivante couvre les outils DEWALT.

GARANTIE DE SATISFACTION DE 30 JOUR80U ARGENT REMI8

Si, pour quelque raison que ce soit, I'outil industriel de service intensif DEWALT ne donne pas

entiere satisfaction, il suffit de le retourner chez le marchand participant dans les 30 jours

suivant la date d'achat afin d'obtenir un remboursement complet. II faut retourner, port pay&

I'outil complet. On peut exiger une preuve d'achat.

REMPLACEMENT GRATUIT DE L'#TIQUETTE

Si vos etiquettes d'avertissement deviennent illisibles ou sont manquantes, composez le 1-800-

4-DEWALT pour obtenir une etiquette de remplacement gratuite.

Reglas generales de seguridad

ZLiADVERTENCIA! Lea y comprenda todas las instrucciones. No hacerlo puede originar

riesgos de choque electrico, incendio y lesiones personales de gravedad.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

• Conserve su _rea de trabajo limpia y bien iluminada. Las bancas amontonadas y/as

zonas oscuras propician los accidentes.

• No opere herramientas el_ctricas en atmGsferas explosivas, como en presencia de

liquidos, gases o polvos inflamables. Las herramientas e/ectricas producen chispas que

pueden originar la ignici6n de los polvos o los vapores.

• Conserve a observadores, nihos y visitantes alejados mientras opera una her-

ramienta el_ctrica. Las distracciones pueden ocasionar que pierda el control.

SEGURIDAD ELECTRICA

• Las herramientas con doble aislamiento est#n equipadas con una clavija polarizada

(con una pata m#s ancha que la otra.) Esta clavija se acoplar# #nicamente en una

toma de corriente polarizada de una manera. Si la clavija no se acopla al contacto,

invi_rtala. Si a#n asi no se ajusta, comuniquese con un electricista calificado para

que le instalen una toma de corriente polarizada apropiada. [] El doble aislamiento

elimina la necesidad de cables con tres hilos y sistemas de alimentaci6n con conexi6n a

tierra.

• Evite el contacto corporal con superficies aterrizadas tales como tuberias, radi-

adores, hornos y refrigeradores. Hay un gran riesgo de choque electrico si su cuerpo

hace tierra.

• No exponga las herramientas el_ctricas a la Iluvia o a condiciones de mucha

humedad. El agua que se introduce en las herramientas aumenta el riesgo de descargas

electricas.

• No maltrate el cable. Nunca tome el cable para transportar una herramienta ni para

desconectarla de la toma de corriente. Cons_rvelo alejado de calor aceite, bordes aft-

lados o piezas m6viles. Cambie inmediatamente los cables da#ados. Los cables daSa-

dos aumentan el riego de choque electrico.

• Cuando opere una herramienta el_ctrica a la intemperie, utilice una extensi6n marca-

da "W-A" o "W". Estas extensiones estan clasificadas para uso a la intemperie y para

reducir el riesgo de choques electricos.

Volts

120V

240V

AMPERAJE

Mas No mas

de de

0

6

10

12

SEGURIDAD PERSONAL

• Est_ alerta conc_ntrese en Io que est# haciendo. Recurra al sentido com#n cuando

opere una herramienta el_ctrica. No opere ninguna herramienta si se encuentra fati-

gado o bajo la influencia de drogas, alcohol o medicamentos. Un momento de desa-

tenci6n mientras se operan herramientas electricas puede ocasionar lesiones graves.

• Vistase de manera adecuada. No tenga puestas ropas o articulos de joyeria flojos.

Cubra su cabello si Io tiene largo. Conserve su cabello, sus ropas y guantes alejados

de las piezas m6viles. Las piezas de vestir flojas, las joyas y el cabello largo pueden resul-

tar atrapados por las piezas m6viles. Las rejillas de ventilaci6n cubren partes m6viles y

tambien deben evitarse.

• Evite el encendido accidental. Aseg#rese que el interruptor est_ en posici6n de apa-

gado antes de conectar. Sostener una herramienta con el dedo en el interruptor o conec-

tarla sin fijarse si el interruptor esta en posici6n de encendido propicia los accidentes.

• Retire las Ilaves de ajuste antes de encender la herramienta. Una Ilave que se deja en

una pieza giratoria puede ocasionar lesiones personales.

• No se sobreextienda. Conserve siempre los pies bien apoyados, al igual que el equi-

librio. La posici6n correcta de los pies y el equilibrio permiten controlar mejor la her-

ramienta en situaciones inesperadas.

• Utilice equipo de seguridad. Siempre utilice protecci6n en los ojos. Se deben utilizar

mascarillas contra polvo, zapatos antiderrapantes, casco o protectores para los oidos para

tener las condiciones apropiadas.

USO Y CUIDADOS DE LA HERRAMIENTA

• Utilice prensas u otros medios pr#cticos para asegurar y apoyar la pieza de trabajo

en una plataforma estable. Sujetar las piezas con la mano o contra su cuerpo es inestable

y puede originar la perdida de control

• No fuerce la herramienta. Emplee la herramienta correcta para su aplicaci6n. La her-

ramienta correcta hara el trabajo mejor y de manera mas segura y bajo las especificaciones

para las que rue diseSada.

• No utilice la herramienta si el interruptor no enciende y apaga. Cualquier herramienta

que no pueda controlarse por medio del interruptores peligrosa y debe reemplazarse.

• Desconecte la clavija de la toma de corriente antes de hacer cualquier ajuste, cam-

bio de accesorios o de guardar la herramienta. Tales medidas de seguridad preventivas

reduciran el riesgo de que la herramienta se encienda accidentalmente.

• Guarde las herramientas fuera del alcance de los ni#os y de otras personas no

capacitadas. Las herramientas son peligrosas en manos de personas no capacitadas.

• Cuide sus herramientas. Conserve las herramientas de corte afiladas y limpias. Las

herramientas que reciben un mantenimiento adecuado, con piezas de corte afiladas, difi-

cilmente se atascan y son mas faciles de controlar.

• Verifique la alineaci6n de las piezas m6viles, busque fracturas en las piezas y cua-

lesquiera otras condiciones que puedan afectar la operaci6n de las herramientas. Si

est_ dabada, Ileve su herramienta a servicio antes de usarla de nuevo. Muchos acci-

dentes se deben a herramientas con mantenimiento pobre.

• Solamente use accesorios que el fabricante recomiende para su modelo de her-

ramienta. Los accesorios que esten dise_ados para una herramienta, pueden volverse

peligrosos cuando se emplean con otra.

Calibre minimo para cordones de extensi6n

Longitud total del cord6n en metros

0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

0-15,2 15,2-30,4 30,4-60,9 60,9-91,4

Calibre del cord6n AWG

6 18 16 16 14

10 18 16 14 12

12 16 16 14 12

16- 14 12 No_comendado

SERVICIO

• El servicio a las herramientas Io debe efectuar #nicamente personal calificado. El ser-

vicio o mantenimiento realizado por personal no calificado puede originar riesgos de

lesiones.

• Cuando efectE/e servicio a una herramienta, utilice _nicamente refacciones id_nticas.

Siga las instrucciones de la secciGn de Mantenimiento de este manual. El emp/eo de

piezas no autorizadas o no seguir las instrucciones de mantenimiento puede originar riegos

de choque electrico o lesiones.

Reglas adicionales de seguridad

• Tome la herramienta por las superficies aislantes de sujeciGn cuando realice una

operaciGn en que la herramienta de corte pueda hacer contacto con cables ocultos o

con su propia extensi6n. El contacto con un cable "vivo" hara que las partes metalicas de

la herramienta queden "vivas" y descarguen hacia el operador.

• Utflice gafas de seguridad u otto tipo de protecci6n ocular. Las operaciones de mar-

tillado pueden ocasionar que salgan astillas despedidas. Las particulas voladoras pueden

ocasionar daSos oculares permanentes.

• Conserve los mangos secos, limpios, fibres de aceite y grasa. Se recomienda el uso

de guantes de goma. Esto le permitira controlar mejor, la herramienta.

PRECAUCION: NO TOQUE NINGUNA PARTE METALICA DE LA HERRAMIENTA

cuando perfore o atornflle en muros, pisos o dondequiera que pueda encontrar cables

el_ctricos vivos. Tome la herramienta solamente por las superficies de sujeci6n aislantes

para evitar el choque electrico en caso que perfore o atornille un cable electrico vivo.

PRECAUCION: utilice la protecci6n auditiva apropiada durante el uso. Bajo ciertas

condiciones de duraci6n de uso, el ruido producido por este producto puede contribuir a la

perdida auditiva.

_ADVERTENCIA " Parte del polvo creado al lijar, aserruchar, moler o perforar con maquina,

asi como al realizar otras actividades de la construcci6n, contiene substancias quimicas que se

sabe producen cancer, defectos congenitos u otras afecciones reproducfivas. Algunos ejemp-

los de esas substancias quimicas son:

• plomo de pinturas a base de plomo,

• silice cristalizado de ladrillos y cemento y otros productos de albaSileria, y

• arsenico y cromo de la madera quimicamente tratada (CCA).

El riesgo al contacto con estas substancias varia, segEm la frecuencia en que se haga este tipo

de trabajo. Para reducir la exposici6n a esas substancias quimicas: trabaje en un area bien ven-

tilada, y trabaje con equipos de seguridad aprobados, tales como mascaras contra el polvo

especialmente diseSadas para filtrar las particulas microsc6picas.

• Evite el contacto prolongado con polvos originados por lijar, aserrar, esmerilar, tal-

adrar y otras actividades constructivas. Vista ropas protectoras y lave las #reas

expuestas con agua yjab6n. Permitir que el polvo se introduzca en su boca, ojos, o dejar-

Io sobre la piel promueve la absorci6n de quimicos daSinos.

• La etiqueta de su herramienta puede incluir los siguientes simbolos.

V .......................... volts

A .......................... amperes

Hz .......................... hertz

W .......................... watts

min .......................... minutos

"x, .......................... corriente altema

.... .......................... corriente directa

no .............................. velocidad sin carga

[] .............................. construcci6n Clase II

/min .......................... revoluciones o reciprocaciones por minuto

............................ terminales de conexi6n a tierra

ZL .............................. symbole d'avertissement

Cepillos Del Motor

DeWalt utiliza un sistema avanzado del cepillo que pare automaticamente el taladro cuando

los cepillos desgastan hacia fuera. Esto previene daSo serio al motor.

Interruptores (Fig. 1)

Oprima el interruptor de gatillo para accionar el taladro; sueltelo para detenerlo.

El interruptor de gatillo de velocidad variable permite controlar la velocidad. Cuanto mas a fondo

se optima el gatillo, mas elevada sera la velocidad del taladro.

NOTA: Utilice velocidades bajas para perforar sin haber marcado el "punto" de centro, tal-

adrar en metal o plasticos, atornillar y perforar ceramica. Las altas velocidades son mejores

para barrenar madera y aglomerados de esta, y cuando se van a utilizar los accesorios abra-

sivos y de pulido.

La palanca de reversa (B) se utiliza para sacar las brocas atascadas en barrenos muy apreta-

dos y para destornillar. Se encuentra situada por arriba del interruptor de gatillo. Para activar el

motor en reversa, suelte PRtMERO el gatillo y, a continuaci6n, mueva la palanca hacia la

derecha. Despues de haber efectuado una operacion en reversa, devuelva la palanca hacia la

posicion de marcha hacia adelante.

OPERACION

Para Taladrar

1. Desconecte siempre el taladro antes de poner o cambiar brocas o accesorios.

2. Utilice exclusivamente brocas afiladas. Para taladrar MADERA emplee brocas heli-

coidales, brocas de horquilla o brocas sierra. Para taladrar METAL use brocas helicoidales

de alta velocidad o brocas sierra. Para taladrar MAMPOSTERIA, ladrillo, cemento, etc.,

utilice brocas con punta de carburo de tungsteno.

3. AsegQrese de que el material que va a taladrar este firmemente anclado o afianzado. Si

perfora material delgado, aplique al mismo un respaldo de madera para evitar daSarlo.

4. Aplique presion a la broca en linea recta. Haga suficiente presion para que la broca siga

perforando, pero no tanta para que el motor se atasque o la broca se desvie.

5. Sujete la herramienta firmemente para controlar la acci6n de torsion de la broca.

6. Si el taladro se traba, esto se debera posiblemente a que esta sobrecargado o que se esta

utilizando en forma indebida. Suelte el gatillo de inmediato, retire la broca del barreno y

determine la causa del atascamiento. No apriete el gatillo para hacer pruebas de encen-

dido y apagado pues podria da5arlo.

7. Para reducir el peligro de que se atasque el taladro, reduzca la presi6n y deje ir suave-

mente la broca hacia el final del barreno.

8. Conserve el motor trabajando al retirar la broca del interior del barreno. De esta manera

evitara que se atasque.

9. Con los taladros de velocidad variable no hay necesidad de poner un "punto" de centrado

para iniciar los barrenos. Utilice velocidad baja para iniciar la perforacion, y acelere oprim-

iendo el gatillo cuando el barreno tenga suficiente profundidad.

TALADRADO EN METAL

Utilice un lubricante para corte cuando perfore metales, excepto en los casos de hierro cola-

do o lat6n en los que se debera taladrar en seco. Los lubricantes mas adecuados para corte

son los de aceite sulfQrico y la manteca de cerdo.

TALADRADO EN MADERA

Los barrenos en madera pueden hacerse con las mismas brocas que se utilizan para metal.

Para evitar que las brocas se sobrecalienten, deben sacarse frecuentemente del barreno

para quitar las virutas acumuladas en las estrias. Para hacer perforaciones mas grandes,

emplee brocas de poder para madera. El material que podria astillarse debe protegerse con

un respaldo de madera.

TALADRADO EN MAMPOSTERJA

Utilice brocas con punta de carburo de tungsteno a bajas velocidades. Conserve uniforme la

presion sobre el taladro, pero no al grado que se despostillen los materiales. La salida con-

tinua de volutas de polvo indica que se esta aplicando la velocidad apropiada.

Page 5

Nivel de burbuja (Fig. 2)

Su taladro viene equipado con un nivel de burbuja, de utilidad para perforar barrenos a nivel.

Para el taladrado horizontal mueva su unidad hacia arriba o hacia abajo para que la burbuja,

al flotar, vaya desplazandose hacia las lineas paralelas grabadas en el vidrio. El taladro

estara nivelado una vez centrada la burbuja entre las lineas, como se ilustra.

Para el taladrado vertical, se debe alinear el taladro de manera que la burbuja flote en el cen-

tro del ojo de buey, como se ilustra.

Para garantizar la precision, coloque primero un nivel sobre la pieza en la que este trabajan-

do y nivelela; a continuacion, cuando el taladro se encuentre nivelado, Io estaran entre si este

y la pieza de trabajo. (Los dispositivos de burbuja pueden indicar s61o el nivel de la superfi-

cie de la tierra).

NOTA" el nivel contiene aceite mineral, sustancia que podria producir irritaciones menores de

la piel al entrar en contacto con ella. Si el nivel se rompiera y se derramara su contenido sobre

su piel,, lavesela con agua en abundancia. Si le cayera en los ojos, laveselos con agua en

abundancia y Ilame de inmediato al medico.

Portabrocas sin Ilave (D21008, D21009)

Su herramienta cuenta con un portabrocas sin Ilave para mayor comodidad. Para insertar una

broca u otro accesorio, siga los pasos descritos a continuacion.

1. Desconecte el taladro.

2. Tome la mitad trasera del portabrocas con una mano y utilice su otra mano para girar la

mitad delantera en sentido contrario alas manecillas del reloj, como se observa en la figu-

ra 4. Gire Io suficiente para que el portabrocas se abra Io necesario para aceptar el acce-

sorio deseado.

3. Inserte la broca u otro accesorio aproximadamente 19 mm (3/4") dentro del portabrocas

y apriete con firmeza sujetando la mitad trasera del portabrocas y girando la porcion frontal

en el sentido de las manecillas del reloj.

Para sacar el accesorio, pepita el paso 2 mencionado con anterioridad.

Z_ADVERTENClA: No intente apretar las brocas (ni ningQn otro accesorio) sujetando la

parte frontal del portabrocas y encendiendo la herramienta. Hay riesgos de lesiones person-

ales y dados a la herramienta.

Remoci6n del portabrocas (D21008, D21009)

Apriete el portabrocas alrededor del extremo mas corte de una Ilave allen (no suministrada)

de 1/4" o mayor. De un golpe al extremo mas grande con un marro de goma o una pieza de

madera en sentido opuesto a las manecillas del reloj, como se observa en la figura 4.

Esto aflojara el portabrocas para poder destornillarlo a mano.

Instalacibn del portabrocas

Atornille el portabrocas a mano tanto como sea posible. Apriete el portabrocas alrededor del

extremo menor de una Ilave allen de 1/4" (no suministrada). De un golpe al extremo mayor en

el sentido de las manecillas del reloj con un marro suave, como se ilustra en la figura 5.

Uso del portabrocas con Ilave (D21002)

Abra las mordazas del broquero girando el collarin a mano e inserte el vastago de la broca

aproximadamente 2 cm (3/4") en el portabrocas. Apriete el collarin del portabrocas a mano.

Coloque la Ilave en cada uno de los tres orificios del portabrocas y apriete en el sentido de las

manecillas del reloj. Es importante apretar el portabrocas en los tres orificios. Para sacar la

broca, gire el portabrocas en sentido opuesto alas manecillas del reloj en un solo orificio,

despues afloje el portabrocas a mano.

Remoci6n del portabrocas con Ilave

Apague y desconecte el taladro antes de hacer cualquier ajuste. Apriete el portabrocas alrede-

dor del extremo corto de una Ilave hexagonal (no suministrada) de 1/4" o mas grande. De un

golpe seco en sentido opuesto alas manecillas del reloj, viendo la herramienta como se

muestra en la Figura 7. Esto aflojara el portabrocas para poder sacarlo con la mano.

Instalaci6n del portabrocas con Ilave

Enrosque el portabrocas a mano tanto como sea posible, lnserte el extremo corto de una Ilave

hexagonal (no suministrada) de 1/4" o mas grande y de un golpe seco en el sentido de las

manecillas del reloj con un marro suave, como se muestra en la Figura 8.

MANTENIMIENTO

Lubricaci6n

Cuando la herramienta se separa para el reemplazo del cepillo del motor una cantidad pequeda

de grasa se debe agregar (o redistribuir de eso restante en la cubierta) a los engranajes. Los

rodamientos de bolitas usados en esta herramienta se lubrican durante la fabricacion y no

requieren ninguna lubricacion.

PARA REPARACION Y SERVIClO DE SUS HERRAMIENTAS ELECTRICAS FAVOR DE DIRIGIRSE

AL CENTRO DE SERVlCIO MAS CERCANO

CULIACAN

Av. Nicolas Bravo #1063 Sur (91 671 ) 242 10

GAU DALAJARA

Av. La Paz #1779 (91 3) 826 69 78.

MEXICO

Eje L&zaro Cardenas No. 18 Local D, Col. Obrera 588-9377

MERIDA

Calle 63 #459-A (91 99) 23 54 90

MONTERREY

Av. Francisco I. Madero Pte. 1820-A (91 83) 72 11 25

PUEBLA

17 Norte #205 (91 22) 46 37 14

QUERETARO

Av. Madero 139 Pte. (91 42) 14 16 60

SAN LOUIS POTOSl

Pedro Moreno #100 Centro (91 48) 14 25 67

TORREON

Blvd. Independencia, 96 pte. (91 17) 16 52 65

VERACRUZ

Prolongacion Diaz Miron #4280 (91 29) 21 70 16

VlLLAHERMOSA

Constitucion 516-A (91 93) 12 53 17

PARA OTRAS LOCALIDADES LLAME AL: 326 7100

Importante

Para garantizar la SEGURtDAD y la CONFIABtLIDAD, deberan hacerse reparaciones, man-

tenimiento y ajustes de esta herramienta en los centros autorizados de servicio DeWALT u otras

organizaciones autorizadas. Estas organizaciones prestan servicio alas herramientas DeWALT

y emplean siempre refacciones legitimas DeWALT.

Accesorios

Dispone usted de los accesorios recomendados para su herramienta con cargo adicional con

su distribuidor o en su centro de servicio locales. Se incluye una lista completa de los centros

de servicio con su herramienta. Si necesita usted ayuda para encontrar algQn accesorio para

su herramienta, por favor haga contacto con:

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

PRECAUCION: El empleo de cualquier accesorio no recomendado para esta herramien-

ta puede ser peligroso.

Capacidades m_ximas recomendadas

CAPAClDAD DEL TALADRO 9,5 mm (3/8")

R.RM 0-2500

BROCAS PARA METAL 9,5 mm (3/8")

BROCAS PARA MADERA 25,4 mm (1")

BROCAS PARA MAMPOSTERtA 12,7 mm (1/2")

BROCAS SIERRA 28,5 mm (1-1/8")

EL ACCESORIO DEBE ESTAR CLASIFICADO PARA UTtLIZARSE A UNA VELOClDAD

IGUAL O MAYOR QUE LAS R.PM. SENALADAS EN LA PLACA DE IDENTIFICAClON DE

LA HERRAMIENTA QUE SE ESTE EMPLEANDO.

CEPILLOS DE ALAMBRE Diametro maximo 101,6 mm (4")

CEPILLOS DE COPA Diametro maximo 76,2 mm (3")

BONETES PARA PULtR Diametro maximo 76,2 mm (3")

RESPALDOS DE GOMA Diametro maximo 117,4 mm (4-5/8")

P61iza de GarantJia

IDENTtFICACl0N DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: Mod./Cat.:

Marca: NQm. de serie:

(Datos para ser Ilenados por el distribuidor)

Fecha de compra y/o entrega del producto:

Nombre y domicilio del distribuidor donde se adquirio el producto:

Este producto esta garantizado por un ado a partir de la fecha de entrega, contra cualquier

defecto en su funcionamiento, asi como en materiales y mano de obra empleados para su fab-

ricaci6n. Nuestra garantia incluye la reparacion o reposicion del producto y/o componentes sin

cargo alguno para el cliente, incluyendo mano de obra, asi como los gastos de transportacion

razonablemente erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantia debera presentar su herramienta y esta p61iza sellada por

el establecimiento comercial donde se adquirio el producto, de no contar con esta, bastara la

factura de compra.

EXCEPCIONES.

Esta garantia no sera valida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con el instructivo de uso que se

acompada;

• Cuando el producto hubiese sido alterado o reparado por personas distintas alas enlistadas

al final de este certificado.

Anexo encontrara una relacion de sucursales de servicio de fabrica, centros de servicio autor-

izados y franquiciados en la RepOblica Mexicana, donde podra hacer efectiva su garantia y

adquirir partes, refacciones y accesorios originales.

Garantia Completa

Las herramientas industriales DEWALT estan garantizadas durante un ado a partir de la fecha

de compra. Repararemos, sin cargos, cualquier falla debida a material o mano de obra defec-

tuosos. Por favor regrese la unidad completa, con el transporte pagado, a cualquier Centro de

Servicio para Herramientas Industriales de DEWALT o alas estaciones de servicio autorizado

enlistadas bajo "Herramientas Electricas" en la Seccion Amarilla. Esta garantia no se aplica a

los accesorios ni a dados causados por reparaciones efectuadas por terceras personas. Esta

garantia le otorga derechos legales especificos, y usted puede tener otros derechos que

pueden variar de estado a estado.

En adicion a la garantia, las herramientas DEWALT estan amparadas por nuestra:

GARANTiA DE SATISFACCION SIN RIESGO POR 30 DiAS

Si usted no se encuentra completamente satisfecho con el desempedo de su herramienta

industrial DEWALT, sencillamente devuelvala a los vendedores participantes durante los

primeros 30 dias despues de la fecha de compra para que le efectOen un reembolso completo.

Por favor regrese la unidad completa, con el transporte pagado. Se puede requerir prueba de

compra.REEMPLAZO DE LAS ETIQUETAS DE ADVERTENClA GRATUlTO: Si sus etiquetas

de advertencia se tornan ilegibles o se pierden, Ilame al 1-800-4-DEWALT para que se las reem-

placen sin cost.

Epecificaciones

Tension de alimentacion

Potencia nominal:

Frecuencia de operacion:

Consumo de corriente:

IMPORTADO: DEWALT S.A. DE C.V.

BOSQUES DE CIDROS ACCESO RADIATAS NO. 42

COL. BOSQUES DE LAS LOMAS.

Para servicio y ventas consulte

"HERRAMIENTASELECTRICAS"

05120 MEXICO, D.F

TEL. 326-7100

en la seccionamarilla. SECCICN

(D21002, D21008,D21009)

120 V CA ~

558 W

50/60 Hz

5,0A

AM_JLLA

Loading...

Loading...