Page 1

UltraFlex™ Drying & Firing Furnace

OWNER’S MANUAL

C-229

VERSION 3

12/2010

Page 2

PREFACE UltraFlex Drying and Firing Furnace Owner’s Manual

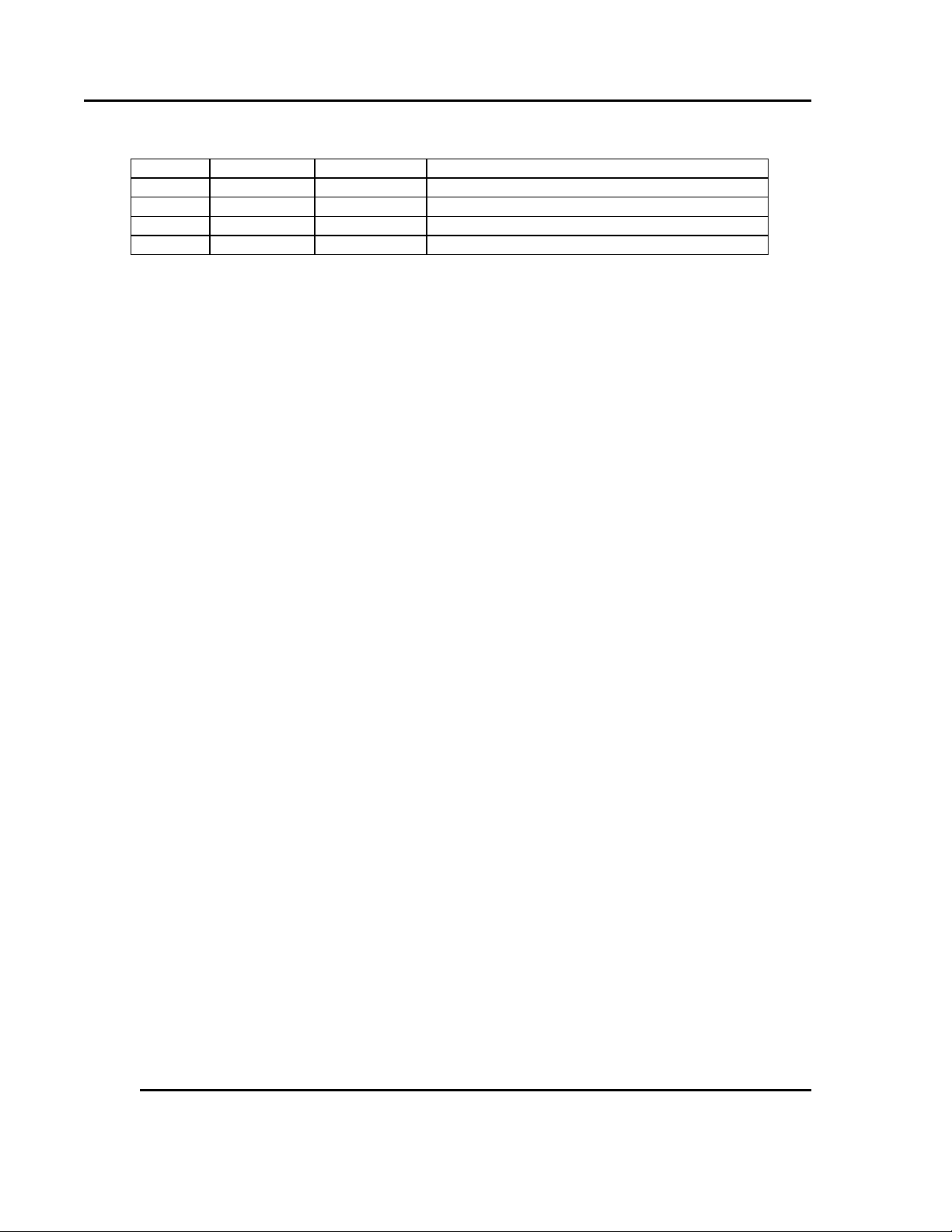

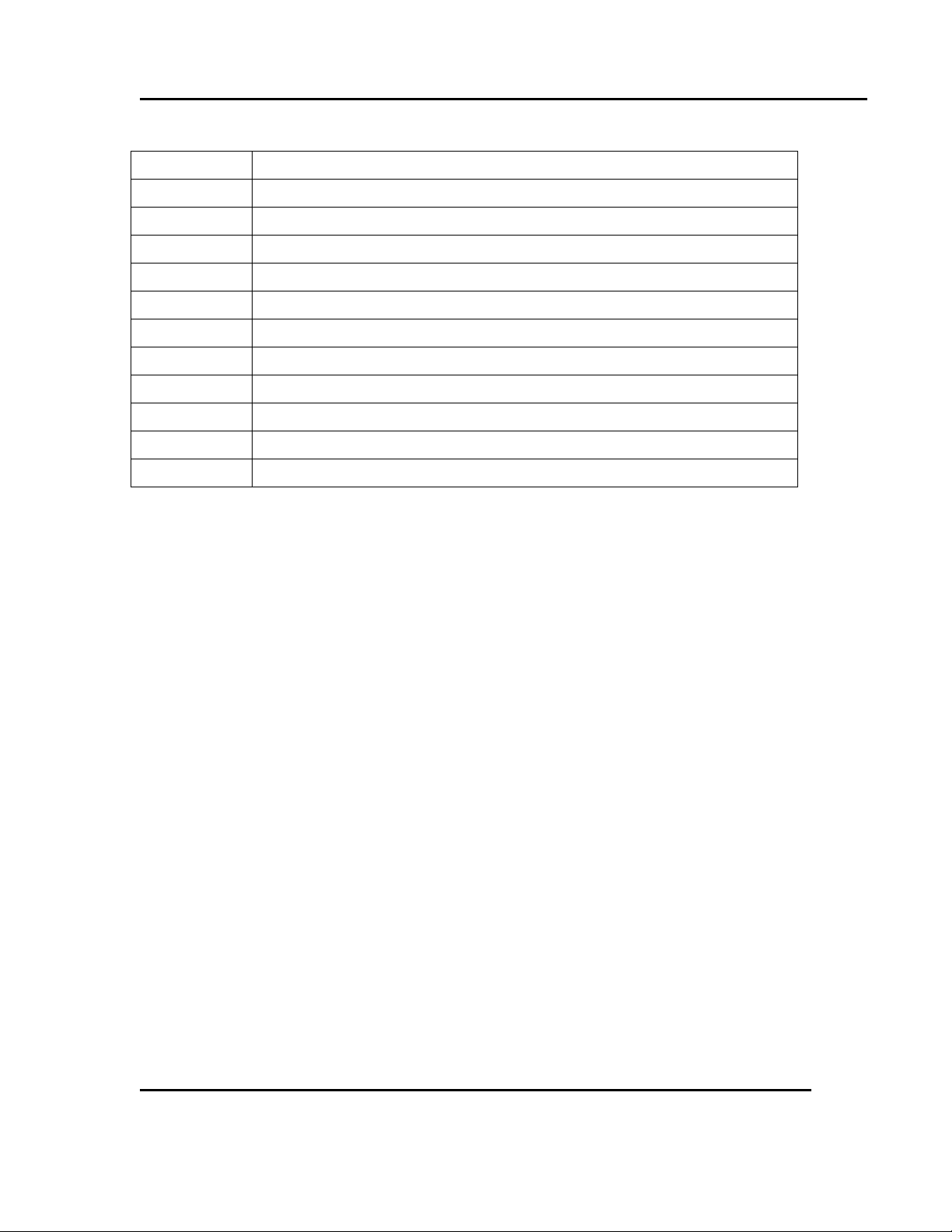

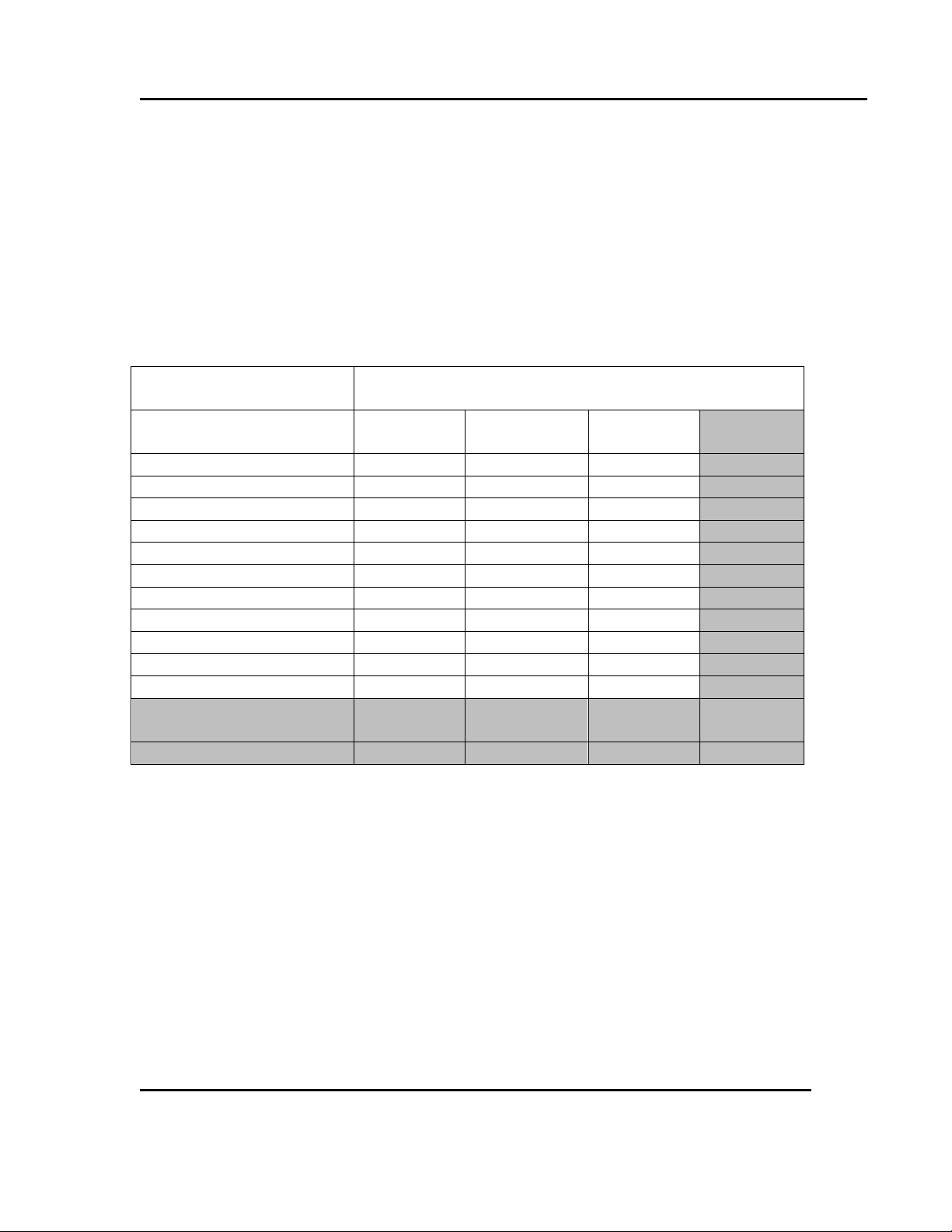

Revision

Date

Author

Description

1.0

11/2/2009

K. Livingston

Initial Release

1.1

5/24/2010

K. Livingston

Pre-Release Revisions

2.0

5/26/2010

K. Livingston

Revisions

3.0

12/6/2010

K. Livingston

Revisions

ii Version 3

Revision History

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for pu rchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 3

UltraFlex Drying and Firing Furnace Owner’s Manual PREFACE

Version 3 iii

Table of Contents

1. Abo ut This Manua l .............................................................................................. 9

1.1. Important User Information ........................................................................ 9

1.2. Manufacturer ............................................................................................ 10

1.3. Organization of this M anual ..................................................................... 10

1.4. Conventions Used in this Manual ............................................................. 10

1.5. Acronym Identifier ................................................................................... 11

2. Safety ................................................................................................................ 12

2.1. Safety I nforma tio n ................................................................................... 12

2.1.1. Lockout ................................................................................................ 12

2.1.1.1. Lockout Requirements ...................................................................... 12

2.1.1.2. Lockout Pro cedu r e ............................................................................ 12

2.1.2. Doors and Covers ................................................................................. 13

2.2. Maintenance ............................................................................................. 13

2.3. Electrical Power ....................................................................................... 13

2.4. Fire .......................................................................................................... 14

2.5. Equipment Lockout Requirements............................................................ 14

2.5.1. Emergency Sto p ................................................................................... 14

3. Theory of Operation........................................................................................... 16

3.1. UltraFlex Drying and Firing Furnace Machine States ............................... 17

3.1.1. Pow e r O ff ............................................................................................. 18

3.1.2. Initialization Mode ............................................................................... 18

3.1.3. Idle Mode ............................................................................................. 18

3.1.4. Loading Recipe Mode ........................................................................... 18

3.1.5. Stabilizat ion Mode ................................................................................ 19

3.1.6. Production Mode .................................................................................. 19

3.1.7. Cooldown Mode ................................................................................... 19

3.1.7.1. Quick Cooldown Mode ..................................................................... 19

3.1.8. Mainte nance Mod e ............................................................................... 20

3.2. Optimiz e d Recipes and Th erma l Profiling ................................................ 20

3.2.1. Thermal Profiling Pr ocess ..................................................................... 20

3.3. UltraFlex Dr yer ........................................................................................ 21

3.3.1. Overview .............................................................................................. 21

3.3.2. Transport System .................................................................................. 22

3.3.3. Heating System..................................................................................... 22

3.3.4. Process Ga s Syste m .............................................................................. 23

3.3.5. Oxidizer Airflow S ett ings ..................................................................... 24

3.4. Wafer Throughput .................................................................................... 24

3.5. VOC Ther mal Oxidize r ............................................................................ 25

3.6. Cha mber Lift Mecha n ism ......................................................................... 25

4. Software & Hardwar e S etu p .............................................................................. 27

4.1. Operation Overview ................................................................................. 27

4.2. Managing Use r s ....................................................................................... 29

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for pu rchaser's personal use.

Page 4

PREFACE UltraFlex Drying and Firing Furnace Owner’s Manual

iv Version 3

4.2.1. Security Levels ..................................................................................... 29

4.2.2. Adding a User or Changing User Privileges .......................................... 30

4.3. Recipe Setup and Optimization ................................................................ 31

4.3.1. UltraFlex Furnace Set po int Ranges ....................................................... 31

4.3.2. Optimize Recipe Pro cess w ith Example ................................................ 33

4.4. Dryer/Firing Fur nace Airf low Setup ......................................................... 37

4.4.1. Dryer Airflow Setup ............................................................................. 37

5. Operation ........................................................................................................... 39

5.1. Routine Operat ion .................................................................................... 39

5.1.1. Overview .............................................................................................. 40

5.1.1.1. Using the Ultr aFle x Fur nace T ouch Screen Interface ......................... 40

5.1.1.2. Using On-Screen Controls ................................................................. 41

5.1.1.3. Process Overview .............................................................................. 41

5.1.1.4. Furnace Status ................................................................................... 42

5.1.1.5. Navigation Bar .................................................................................. 44

5.1.1.6. UltraFlex Drying and Firing Furnace Modes ..................................... 44

5.1.2. Navigating the Home Scree n ................................................................ 45

5.1.3. Trending Screen ................................................................................... 46

5.1.4. Recipe Screen ....................................................................................... 48

5.1.5. Alarm Screen ........................................................................................ 49

5.1.6. Setup Screen ......................................................................................... 51

5.1.7. Maintenance Screen .............................................................................. 51

5.2. Startup and Run the UltraFlex Drying and Firing Furnace ........................ 53

5.2.1. Starting from Idle Mo de ........................................................................ 54

5.2.2. Stopping from Production Mode ........................................................... 55

5.2.3. Entering Maintenance Mode from Idle Mode ........................................ 56

5.2.4. Entering Maintenance Mode from Production or Cooldown Mode ........ 56

5.3. Wor king with Trending ............................................................................ 56

5.3.1. Wor king with H ourly Perfo rmance ....................................................... 57

5.3.2. Conveyor .............................................................................................. 57

5.3.3. Heat ...................................................................................................... 58

5.3.4. Airflow ................................................................................................. 59

5.3.5. Cooling ................................................................................................. 60

5.3.6. Data ...................................................................................................... 61

5.3.7. E10 St at istics ........................................................................................ 63

5.3.7.1. E10 States ......................................................................................... 63

5.3.7.2. Operator Initiat ed St at es .................................................................... 64

5.4. Wor king with R ecip es .............................................................................. 64

5.4.1. Enter a New Recipe .............................................................................. 65

5.4.2. Wor king with Existing Recip e s ............................................................. 65

5.4.2.1. Load Existing Recipe ........................................................................ 65

5.4.2.2. I mport a Recipe ................................................................................. 66

5.4.2.3. Change a Recipe Value ..................................................................... 66

5.4.2.4. Export a Recipe ................................................................................. 67

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 5

UltraFlex Drying and Firing Furnace Owner’s Manual PREFACE

Version 3 v

5.4.2.5. Edit a Recipe on a PC ........................................................................ 68

5.4.2.6. Save a Recipe .................................................................................... 69

5.4.2.7. Delete a Recipe ................................................................................. 69

5.4.3. Recipes and the PLC ............................................................................. 69

5.4.4. Help with Recip es ................................................................................. 69

5.5. Working with Alar ms ............................................................................... 70

5.5.1. Acknowledge Alarms ........................................................................... 70

5.5.2. Info ....................................................................................................... 71

5.5.3. Events................................................................................................... 71

5.5.4. Alarm History ....................................................................................... 71

5.5.5. Audit History ........................................................................................ 72

5.6. Wor king with Set up ................................................................................. 72

5.6.1. User Administ ration ............................................................................. 73

5.6.1.1. Export and Import ............................................................................. 73

5.6.1.2. Help .................................................................................................. 74

5.6.2. Tool Calibra tio n ................................................................................... 74

5.6.2.1. Import and Export ............................................................................. 75

5.6.3. Creating an UltraFlex Fur nace Screen Shot ........................................... 75

5.7. Wor king with M aint ena nce Mode ............................................................ 76

5.7.1.1. Cha mber Lift ..................................................................................... 76

5.7.1.2. Display ............................................................................................. 77

5.7.1.3. Status ................................................................................................ 77

5.7.1.4. Exit ................................................................................................... 78

6. Preventive M aintenance ..................................................................................... 79

6.1. Control Systems Maintenanc e .................................................................. 81

6.1.1. Touch Screen Maintena nce a nd Calibration .......................................... 81

6.1.2. Panels ................................................................................................... 81

6.1.3. Chamber Seals ...................................................................................... 81

6.2. Conveyor Systems Maintenance ............................................................... 81

6.2.1. Bearings ............................................................................................... 81

6.2.2. Dr ive R olle r .......................................................................................... 81

6.2.3. Encoder ................................................................................................ 82

6.2.3.1. Inspect & Clean ................................................................................ 82

6.2.4. Conveyor .............................................................................................. 82

6.2.4.1. Inspect .............................................................................................. 82

6.2.4.2. Clean ................................................................................................ 83

6.2.5. Motors .................................................................................................. 83

6.2.6. Conveyor Guides .................................................................................. 83

6.2.7. Quartz Rods .......................................................................................... 83

6.2.7.1. Inspect .............................................................................................. 83

6.2.7.2. Clean ................................................................................................ 83

6.2.8. Conveyor Take-up ................................................................................ 84

6.2.9. Process Plumbing Assembly ................................................................. 84

6.3. Chamber Systems ..................................................................................... 85

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 6

PREFACE UltraFlex Drying and Firing Furnace Owner’s Manual

vi Version 3

6.3.1. Heater Lamps ....................................................................................... 85

6.3.1.1. Inspect .............................................................................................. 85

6.3.1.2. Replace ............................................................................................. 85

6.3.2. Thermocouples ..................................................................................... 86

6.3.3. Insulation .............................................................................................. 87

6.3.4. Dryer Casing ........................................................................................ 88

6.3.5. Protective Glass Layer .......................................................................... 88

6.4. Cooling/ V entilation Syst ems .................................................................... 88

6.4.1. Coils ..................................................................................................... 88

6.5. Exha ust Syst ems ...................................................................................... 88

6.5.1. Duct Hoses (3” & 4”) ........................................................................... 88

6.5.2. Exhaust Venturi Port............................................................................. 88

6.5.3. Exhaust Flow Restrictor Plate ............................................................... 89

6.5.4. Water Filter .......................................................................................... 91

6.5.5. VOC ..................................................................................................... 91

6.6. Lift Systems ............................................................................................. 91

6.6.1. Inspect .................................................................................................. 92

6.6.2. Clean & Maintain ................................................................................. 92

6.6.3. Chamber Lift Troubleshooting .............................................................. 93

6.6.3.1. Chamber Does Not Lift ..................................................................... 93

6.6.3.2. Chamber Lifts But Does Not Close or Does Not Close Completely ... 93

6.7. Insulation B urn-off ................................................................................... 94

6.7.1. Procedure for I nsulat ion Burnoff .......................................................... 95

6.7.2. Recommendations for Reducing Paste Cont aminatio n .......................... 96

7. Appendices ........................................................................................................ 97

7.1. Using UltraFlex Furn ace Data Files: Data & Diagnostic Logs .................. 97

7.2. UltraFlex Furnace Alarms ........................................................................ 97

7.3. Ultrasonic Belt Cleaner ............................................................................ 98

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 7

UltraFlex Drying and Firing Furnace Owner’s Manual PREFACE

Version 3 vii

Figures

Figure 1. UltraFlex Fur nace E mergenc y Stop Locations. ............................................... 15

Figure 2. UltraFlex Infrared Firing and Drying Furnace in Manufacturing Line. ............ 16

Figure 3. UltraFlex Fur nace Machine States. ................................................................. 17

Figure 4. The UltraFlex Dr yer Transpo r ts Wafers through Multiple Chambers. ............. 22

Figure 5. Set Four Dryer Pro cess Air MFCs Using the Recipe Screen. ........................... 23

Figure 6. Despat ch VOC Ther mal Oxidizer Oper at io n. .................................................. 25

Figure 7. Typical Home Screen (UltraFlex). .................................................................. 27

Figure 8. UltraFlex Drying and Firing Furnace Software Navigation. ............................ 28

Figure 9. Press Setu p and then Users to Add o r Change User Information. .................... 30

Figure 10. Enter or Change User In formation with the Setup/User Administ r ation Screen.

...................................................................................................................................... 30

Figure 11. Typical Firing Zone Setpoints vs. Actual Temperatures. ............................... 32

Figure 12. Adjusting Value on Detail Bo x. .................................................................... 36

Figure 13. UltraFlex Fur nace Home Screen. .................................................................. 39

Figure 14. Use On-Screen Keypad or Keyboard to Enter D ata. ...................................... 40

Figure 15. Using On-Screen Co ntrols. ........................................................................... 41

Figure 16. UltraFlex Fur nace Home Screen—Process Overv iew. .................................. 42

Figure 17. UltraFlex Fur nace Home Screen—Furnace Status. ....................................... 43

Figure 18. Typical Deta il Scree n for Furnace Temperature Zone 1. ............................... 43

Figure 19. UltraFlex Fur nace Home Screen—Navigation Bar. ....................................... 44

Figure 20. Trending Screen. .......................................................................................... 46

Figure 21. Histor y Trending/Furnace Zone 1 Screen. ..................................................... 47

Figure 22. Recipes Scree n and Pop-up Screen for Parameters Descr ipt ions. .................. 48

Figure 23. Alarms Screen and Close-up of Unacknowledged Alarms............................. 49

Figure 24. Alarm Histor y Scree n. .................................................................................. 50

Figure 25. System Event Alar m Screen. ........................................................................ 50

Figure 26. Setup Screen. ................................................................................................ 51

Figure 27. Maintenance Screen with Close-up. .............................................................. 52

Figure 28. Confirm LEL Settings Dialogue Window. .................................................... 53

Figure 29. Start Production Mode from Idle Mode. ........................................................ 54

Figure 30. LEL Dialogue Window. ................................................................................ 54

Figure 31. Stabilization Mode. ....................................................................................... 54

Figure 32. Tool in Production Mode. ............................................................................. 55

Figure 33. Trending Main Screen. ................................................................................. 56

Figure 34. Conveyor Trending Screen. .......................................................................... 57

Figure 35. Heat Trending Screen. .................................................................................. 58

Figure 36. Airflow Trending Screen. ............................................................................. 59

Figure 37. Cooling Trending Screen. ............................................................................. 60

Figure 38. Data Logging Screen. ................................................................................... 62

Figure 39. Front and Rear USB Ports. ............................................................................ 62

Figure 40. E10 Statistics Screen. ................................................................................... 63

Figure 41. Operato r Selects Equipment State. ................................................................ 64

Figure 42. Work with Exist ing or N ew Recipes Using the Recipe Screen. ..................... 65

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 8

PREFACE UltraFlex Drying and Firing Furnace Owner’s Manual

viii Version 3

Figure 43. Recipe with Comment Dialogue Box Open. .................................................. 67

Figure 44. Recipe File Saved as CSV File. .................................................................... 68

Figure 45. Alarms Screen. ............................................................................................. 70

Figure 46. Alarms Events Screen. .................................................................................. 71

Figure 47. Alarm Histor y Scree n. .................................................................................. 71

Figure 48. Audit History Screen. ................................................................................... 72

Figure 49. User Administr ation Screen. ......................................................................... 73

Figure 50. User Administr ation Help Screen. ................................................................. 74

Figure 51. Tool Calibration Screen. ............................................................................... 74

Figure 52. Press the Despat ch Log o to Cr eate a Screen Shot on the USB stick. .............. 75

Figure 53. Conveyor Chamber Lift Verify Screen. ......................................................... 76

Figure 54. Display Screen.............................................................................................. 77

Figure 55. Status Screen for Troubleshooting. ............................................................... 78

Figure 56. Listen for So unds o f Bearing Failur e every Three Months. ........................... 81

Figure 57. Inspect and C lean Encoder Weekl y. .............................................................. 82

Figure 58. Inspect Conveyor Take-up for Ease of Movement......................................... 84

Figure 59. Inspect Plumbing for Leaks every Six Months. ............................................. 84

Figure 60. Lamp Box Covers Removed. ........................................................................ 85

Figure 61. Attach Wago block. ...................................................................................... 86

Figure 62. Replace Thermoco u ple. ................................................................................ 86

Figure 63. Replace Insu lat ion "T" Piece. ....................................................................... 87

Figure 64. Restr ictor Plate. ............................................................................................ 89

Figure 65. Remove exhaust ho using to access restrictor plate. ....................................... 90

Figure 66. Inspect Wat er Filter Mo nt hly and Repla ce Filter as Necess ary. ..................... 91

Figure 67. Contaminated Dryer Zone Before (left) and After (right) Insulation Burn-off

procedure. ..................................................................................................................... 94

Tables

Table 1. UltraFlex Security Levels. ............................................................................... 29

Table 2. UltraFlex Furnace T ypical Setpoint Ranges. .................................................... 31

Table 3. Guideline to Determine Number of Firing Zones. ............................................ 34

Table 4. Determine LEL Alert and Alar m Levels. .......................................................... 38

Table 5. UltraFlex Firing & Drying Furnace Modes. ..................................................... 44

Table 6. Burnoff Recipe Settings. .................................................................................. 95

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 9

UltraFlex Drying and Firing Furnace Owner’s Manual ABOUT THIS MANUAL

Version 3 9

1. About This Manual

1.1. Important User Information

Copyright © 2010 by Despatch Industries.

All rights reserved. No p art of the cont ent s of this manual may be reproduced, copied, or

transmitted in any form or by any means including graphic, electronic, or mechanical

methods or photocopying, recording, or info rmation storage and re trieval syst ems w ithou t

the written permission of the publisher, unless it is for t he purchaser 's perso na l use.

Printed and bound in the United St at es of Amer ica.

The i nformation in this manu al is s ubje ct to change without notice and d oes not represent

a commitment on the part of Despatch Industries. Despatch Industries does not assume

any responsibility for any errors that may appear in this manual.

In no event will Despatch Industries be liable for technic al or editorial omissions made

herein, nor for direct, indirect, spe cial, inc identa l, or consequential damages resulting

from the use or defect of this manual.

Values displayed on screens are examples only. Though

O

O

The i nformation in this doc ument is not intended t o co ver all poss i ble c ond itions and

situations that might occur. The end user must exerc ise caut ion and common sens e when

installing or maintaining Despatch Industries products. If any questions or problems

arise, call Despatch Industries at 1-888-DESPATCH or 1-952-469-5424.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

those values may be typical , cont act Despatch Industries for

the final value.

Actual screens may vary from those published in this manual.

Copyright © 2010 by Despatch Industries.

Page 10

ABOUT THIS MANUAL UltraFlex Drying and Firing Furnace Owner’s Manual

This icon signifies information that describes an unsafe

Danger!

A condition that may result in death, serious injury or

damage to equipment.

Warning!

A condition that may result in serious injury or damage to

equipment.

Caution!

A condition that may res ult in da m a ge t o equipme nt or

product.

LOG OUT

Bold, 10pt Arial typeface indicates a specific key or butto n

on screen to click.

10 Version 3

1.2. Manufacturer

The UltraFlex Drying and Firing Furnace is manufact ur ed by:

Despatch Industries

8860 207th Street

Lakeville, MN 55044

1-952-469-5424 • 1-888-DESPATCH

www.despatch.com

Refer to the UltraFlex Drying and Firing Furnace name plate for a lis t o f machine

specifications a nd t echnical support contact infor mat ion.

1.3. Organization of this Manual

The Owner’s manual c ont ains the most comprehensive set of information for the

UltraFlex™ Firing and Drying Furnace.

1.4. Conventions Used in this Manual

O

This icon sig ni f ies imp o rtant information.

condition that may result in death, serious injury, or damage

to the equipment.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 11

UltraFlex Drying and Firing Furnace Owner’s Manual ABOUT THIS MANUAL

Acronym:

Refers to:

CDA

Clean, Dry Air

GUI

Graphical User Interface

HMI

Human-Machine Interface

IR

Infrared

Lpm

Liters per minute

MFC

Mass Flow Controller

PLC

Programmable Logic Controller

SSR

Solid State Rel ay

SCR

Silicon-Controlled Rectifier or Semiconductor-Controlled Rect ifier

VFD

Variable Frequenc y Drive

VOC

Volatile Organi c Com pound

Version 3 11

1.5. Acronym Identifier

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 12

SAFETY UltraFlex Drying and Firing Furnace Owner’s Manual

Danger!

12 Version 3

2. Safety

2.1. Safety Information

Do not wo rk on the UltraFlex D ryin g and Fir ing Furnac e without read ing and

understanding this section which contains important information and warnings. Ignoring

these warnings can result in death, serious injury or damage to the machine and product.

2.1.1. Lockout

Machine lockout places t he UltraFlex Drying and Firing Furnace into a zero energy state

and prevents accidental machine start up. Always fo llow the Lock out Procedure

described in this Section before cleaning, maintaining or repairing the U ltraFlex Drying

and Firing Furnace. An accidental start-up, wh ile wo rking on the Ult raFlex Drying and

Firing Furnace, can result in serious injury or death.

2.1.1.1. Lockout Requirements

1. Every power source that can energ ize an y element of the UltraFlex Drying and Firing

Furnace must be shut off at the closest po ss ible power source. This includes air, wa ter

and electricity.

2. After energy sources are locked out, test to ensure circuits are de-energized.

2.1.1.2. Lockout Procedure

Personnel author ized to lockout equipment must have the necessar y locks to perform the

lockout.

1. Physically disconnect all electrical power to the machine or lockout the appro pr iate

breaker or disconnects.

2. Close all valves for air or water sour ces and bleed off any pressure.

3. Test for power by attempt ing a start with the machine cont rols.

Electric a l pa ne ls conta in high voltage. Disconnec t a nd loc k o ut

the power supply before working inside any electrical panels.

Failure to lock out the power supply can result in death or injury.

4. Identify the Locko ut Co nd ition with a t ag o n the electr ical disco nnect and p neu matic

shut off valve .

5. When work is complete, r emove all tags and rest ore the machine to its working state.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 13

UltraFlex Drying and Firing Furnace Owner’s Manual SAFETY

Danger!

Danger!

Failure to lock out the power supply can result in death or injury.

Version 3 13

2.1.2. Doors and Covers

Doo rs and c overs on the UltraFlex D ryin g and Fir ing Furnace pr otect against the hazards

beh ind t hem. O pera tion withou t thes e sa fety devices in place creates hazards that the

doors and covers are intended to render safe for pers onne l . Inspect the U ltra Flex Drying

and Firing Furnace periodically to make sure the doo r s and covers are in place.

Electrical panels contain high v olt age. Disconnec t a nd loc k out

the power supply before working inside any electrical panels.

All doors on this machine have fast eners that latch to the frame and require a tool to

open. Panels and doo r s that req uire a too l to open are part of the safety system of the

UltraFlex Drying and Firing Furnace. Do not open any doors while the machine is

running.

2.2. Maintenance

Only qualified and trained personnel should perform maintenance or repair.

2.3. Electrical Power

Only qualified and trained personnel should perform electrical maintenance or electrical

repair.

• Before perfo rm ing maintenance, disco nnect all electrical power fro m the machine.

Use a padlock and lockout all disco nnect s feeding power to the machine.

• Never clean, lubricate or repair the furnace whe n in operation.

Contact with energized electrical sources may result in serio us

injury or death.

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 14

SAFETY UltraFlex Drying and Firing Furnace Owner’s Manual

Danger!

Danger!

14 Version 3

• Unauthorized alterations o r modifications to UltraFlex Drying and Firing Furnace are

strictly forbidde n. Never modify any electrical circuits. Unaut ho r ized mod ifications

can impair the funct ion and saf e ty of the UltraFlex Drying and Firing Furnace.

Systems equipped with an uninterruptible power supply (UPS)

may require that the UPS be powered OFF manually to

disconnect all elect rical power.

2.4. Fire

Keep the UltraFlex Drying and Firing Furnace clean and free o f scrap mat er ials, oil or

solvents to pre vent the poss i bility of f ire. In the eve nt o f fire, use a fire extinguisher as

follows.

1. De-energize the machine immediately by pushing an Emergency Stop push button

2. Turn off the remote main disconnect (customer supplied disco nnect ) .

3. Extinguish the f ire.

2.5. Equipment Lockout Requirements

2.5.1. Emergency Stop

Always disconne c t a ll power before extinguishing a fire.

Attempting to extinguish a fire in a machine connected to

electrical power can result in serious injury or death!

To prevent injury or equipment damage during inspection or repair, the UltraFlex Drying

and Firing Furnace must be locked out.

When a risk of personal injury or d amage to the Ult r aFlex Drying and Firing Furnace

exists, push an Emergency Stop operator. This shuts off all electrical power to the

machine. Figure 1 shows lo ca tion of Emergency Stop operators.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 15

UltraFlex Drying and Firing Furnace Owner’s Manual SAFETY

Unload

View

Load End

Product

Flow

Emergency Stop Loc ations

UltraFlex

Figure 1. UltraFlex Furnace Emergency Stop Locations.

Version 3 15

Furnace

Emergency

Stop

View

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 16

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

Furnace

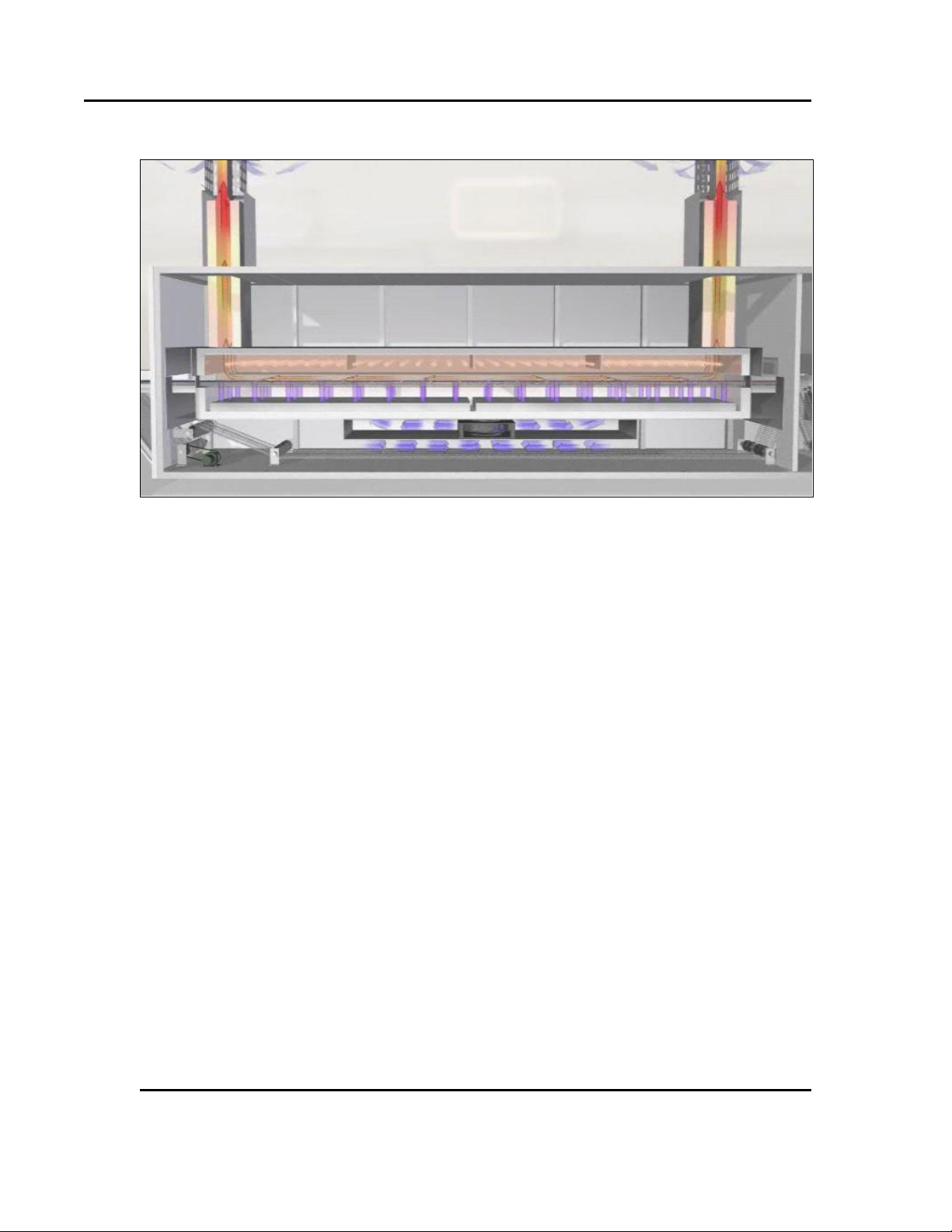

Figure 2. Ultra Flex Infrared Firi ng and Dryi ng Furnace in Manufact uri ng Line.

16 Version 3

3. Theory of Operation

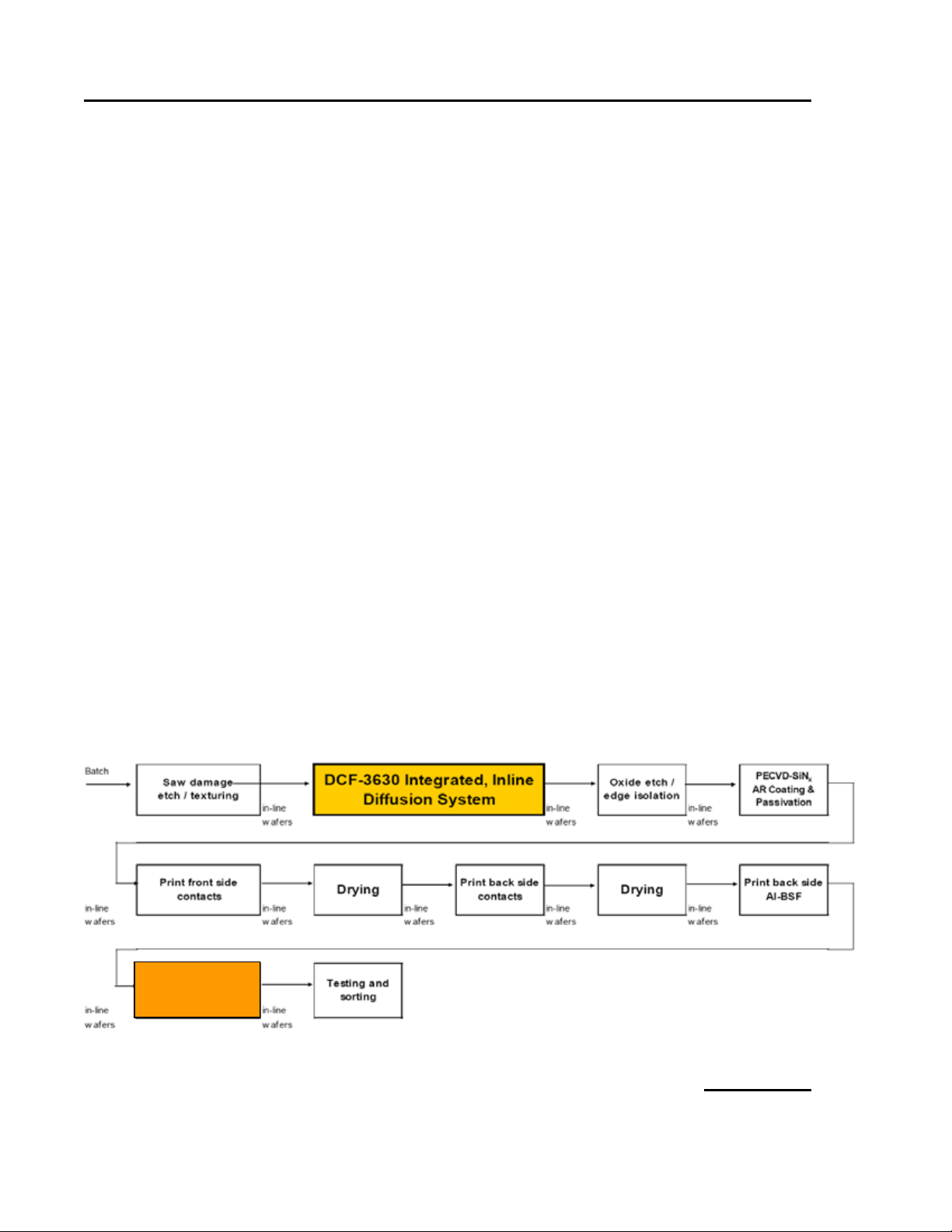

The Despatch UltraFlex fur nace is a second generation in-line (co nveyor ized) furnace

(following the Despatch C F/CDF series). It is designed for use in photovoltaic

manufacturing lines for the express purpose of drying and firing metalized paste to

silicon substr ates. The furnace process immediate ly follows the last scr een printing step

(typical manufacturing process ste ps sho wn in Figure 2).

The UltraFlex furnace is avai la ble as a firing fur nace alone (Model FF) or wit h a n

inte gral dryer (Model DFF). The func tion of the dryer portion of the machine is to

liberate Volatile Orga nic Compounds (VOCs) from the scree n printed substrate to

prevent firing ano malies. I nfrared r adiation and resistant heaters pro vide the heat source

for the drying process. T he U ltraF lex dr yer inco r porates a self-co ntained oxidation

system that incinerates VOCs at the point of evacuat ion or exhaust. VOCs are exhausted

near the entrance and exit o f the dryer d irect ly into individua l Thermal Oxidizers. Each

Ther ma l Ox id iz er is ind ep e nd e ntly mo nit o r e d and cont rolled to ensure t emperature and

flow are maintained within proper limits to achieve VOC destruction.

The function of the furnace is to sinter t he screen-printed and dried paste to the

silicon substr ate as the final manu fact u r ing step in producing a solar cell. T he furnace

uses infrared r adiation as a heat source and a combination rad iant/convective chiller to

remove heat from the product and belt prior to exiting the machine.

From beginning to end the drying/firing process entails drying, binder (polymer)

burn-out, sinte ring and co ol-down. Production speeds are approximately 457.2- 698.5

cm per minute (180-275 inches per min ute ).

Both the dryer and furnace use an in d u s trial pro gr am mab le logic controller (PLC)

and Microsoft Windows t ouc h s c reen PC (human-machine interface, or HMI) as the

primary control platform and human/machine inter face respectively. All so ftwar e is

proprietar y to Despatch Industries.

UltraFlex Drying

and Firing

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 17

UltraFlex Drying and Firing Furnace Owner’s Manual THEORY OF OPERATION

Figure 3. UltraFlex Furnace Machine States.

Version 3 17

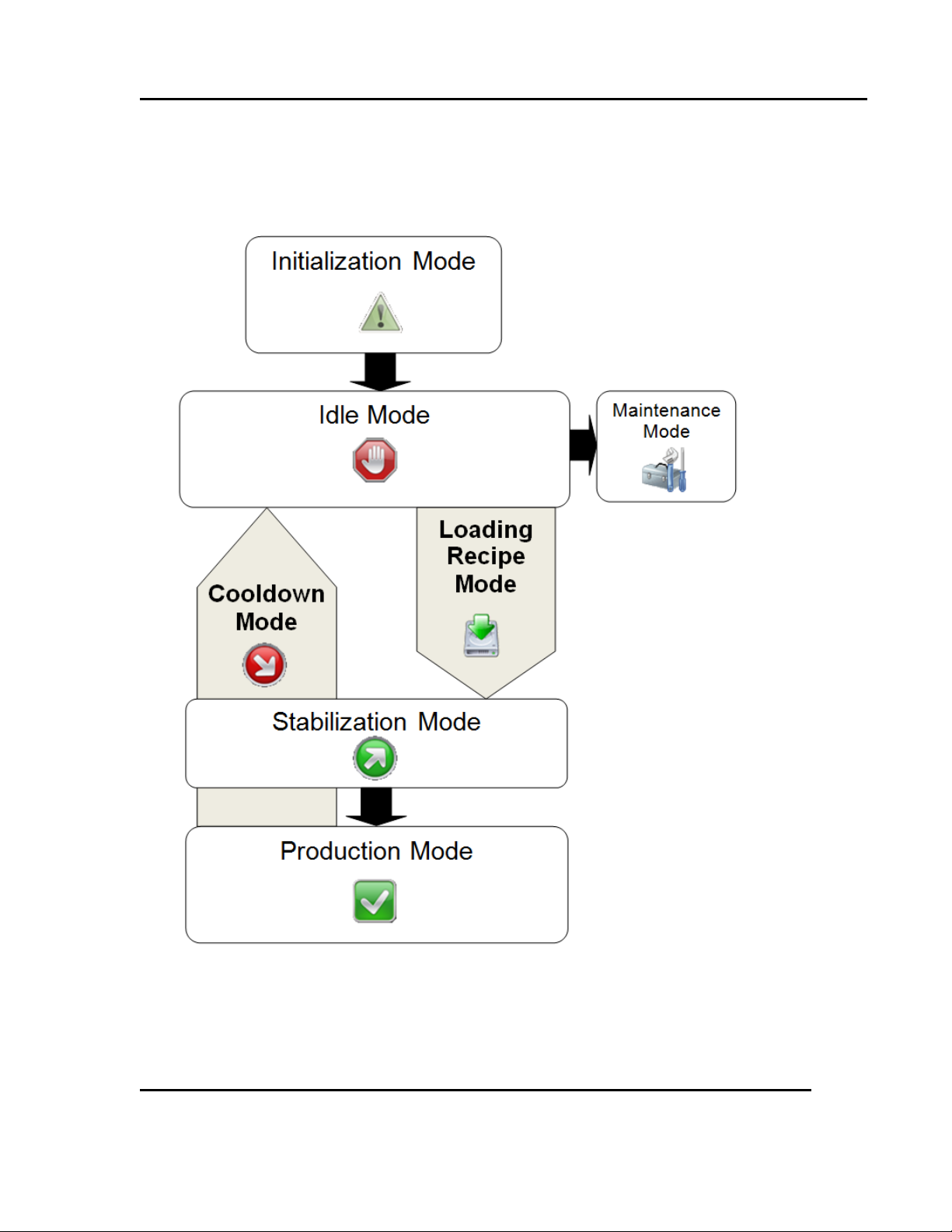

3.1. UltraFlex Drying and Firing Furnace Machine States

The UltraFlex Drying and Firing Furnace operates using a series of seven modes. The

tool dries and diffuses wafers using the Production Mode (Figure 3).

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 18

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

18 Version 3

3.1.1. Power Off

Tool is OFF. Power the tool ON at the main breaker.

3.1.2. Initialization Mode

Initial entry state when st arting the pro gram. During Initialization, t he system performs

startup sequences such as:

• Diagnostic routines check for hardware er rors

• System checks for local/remote I /O st atu s. If necessar y, erro r messages display and

program remains in Initialization Mode.

• The Human Machine Interface (HMI) and t he Pro gra mmable Logic Controller (PLC)

are both powered u p into the “Run” state. Recipe values are matched and the last

running recipe is loaded. Note that a default recipe is de fined at t he first start up

• After successful diagnostic rout ines and checks, the system sets displays and o utputs

to defa ult co nd itions and ente rs t he Idle Mode

3.1.3. Idle Mode

The Idle Mode allows for recipe creation, editing and selection, withou t need to run the

entire system. Idle Mode includes these conditions:

• The t o ol is idl e .

• If alarm conditions exist (for instance wait ing because of E-stop, high temperat ur e

limit or power low), those conditions must be acknowledged before starting the tool.

In fa c t, exception condit io ns may cause t he syst em to switch to the Stabilization or

Cooldown states. A separat e HMI “E-STOP Reset” sets a relay output that re sets the

safety circuit.

• All alarms are enabled

3.1.4. Loading Recipe Mode

The Loading Recipe Mode simply begins the load ing process for the selected recipe.

After loading a recipe, t he user can star t Production Mode.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 19

UltraFlex Drying and Firing Furnace Owner’s Manual THEORY OF OPERATION

Version 3 19

3.1.5. Stabilization Mode

In Stabilizat ion Mode the system monitor s the process values until they a re within a

defined window and then proceeds to the Product io n Read y stat e when the system is

stable.

3.1.6. Production Mode

Production Mode is the machine state used for production and maintains process values

status with respect to r ecipe-specified target set points and deviation limits.

• Deviatio n exceptions and physical input exception conditions may cause the system

to automatically switch t o t he St ab ilization or Cooldown states.

• If the user selects to stop the process using the HMI console, the system enters the

Cooldown state.

3.1.7. Cooldown Mode

In the Cooldown state, dr yer and furnace heating is disabled while other systems

(including coo ling water, airflow, and oxidizer) hold the t hresho ld temperature.

• When heat zones have cooled below the Cooldown thres hold, the system shuts

everything off and enters t he Idle Mode.

• Using the Rapid Cool option, the system opens the chamber to approximately one

inch for rapid cooling.

3.1.7.1. Quick Cooldown Mode

In quick Cooldown mode, the chamber opens slightly for more rapid cooling. Quick

Cooldown mode follows this process:

• Audible alarm sounds

• Casing lowers roughly 80 mm

• The conve yor is O N

• The tool goes to Idle Mode

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 20

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

Warning!

20 Version 3

3.1.8. Maintenance Mode

Manually select Maintenance Mode to serv ice the too l:

• Maintenance state is open loop control mode only. 0-100% power control is

available.

• User inputs are blocked to ensure safe oper ation of the tool.

• General alarms (for instance, temperatu re hi gh and low) are

not active in Maintenance Mode.

• Safety interlocks remain active in Maintenance Mode.

Only qualified and trained personnel should perform

O

O

maintenance or repai r

Access to Maintenance Mode is available only when the

chamber temperature is below the Cooldown threshold.

.

3.2. Optimized Recipes and Thermal Profiling

The UltraFlex furnace optimizes hea t transfer for firing so s etpoints may be lower

compared to other furnaces. During UltraFlex furnace fast firing and cooling profiles

(those greater than 125°C/second), a wafer measured with a light gauge thermocouple

spring typicall y under-reports true wafer temperature. Contact Despatch Global

Headquarters for:

• A method to optimize the efficiency of a wafer through design o f experiments

• The Despatch measure me nt to ol that more reliably reports wafer temperature

3.2.1. Thermal Profiling Process

Thermal profiling co nsist s o f these general steps:

1. Determine the pro file windo w. What needs to be accomplished with each wafer as it

mo v es f r om drying to burnout to firing to cooling?

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 21

UltraFlex Drying and Firing Furnace Owner’s Manual THEORY OF OPERATION

Version 3 21

2. Determine process speeds: Conveyor maximum and minimum speeds based on the

entire line as well as the paste manufactu r er ’s process window.

3. Determine the number o f firing zones req uired for the profile.

4. Determine airflow rates (dryer and furnace), cooling r at es and burno ut t emperature.

Due to the use of Microzone™ technology, conventiona l high

temperatures and fast bel t speeds are not required.

O

While eight zones using Microzone technology are available,

typical profiles make use of three to four zones.

Additio n al s teps may include:

• Adjusting Micro zone™ technology to optimize the profile

• Adjusting the final wafer t emperat ur es

• Testing the process using thermoco u ple assemb lies and samp les

• Reviewing cell electrical results, adjusting settings and rerunning the process

Refer to Recipe Setup and Optimization (4.3) for specific setup instructions.

3.3. UltraFlex Dryer

3.3.1. Overview

To achieve the desired rheo log ica l and other compositional qualities, all photovoltaic

(PV) metallization pastes contain volatile organ ic co mpounds ( VOC) . After printing with

these pastes, the printed ce lls must be properly dried to avoid the release of hazardous

fumes into the furnace, to avo id excessive equipment contamination and to achieve

VOCs max imum cell pe rformanc e .

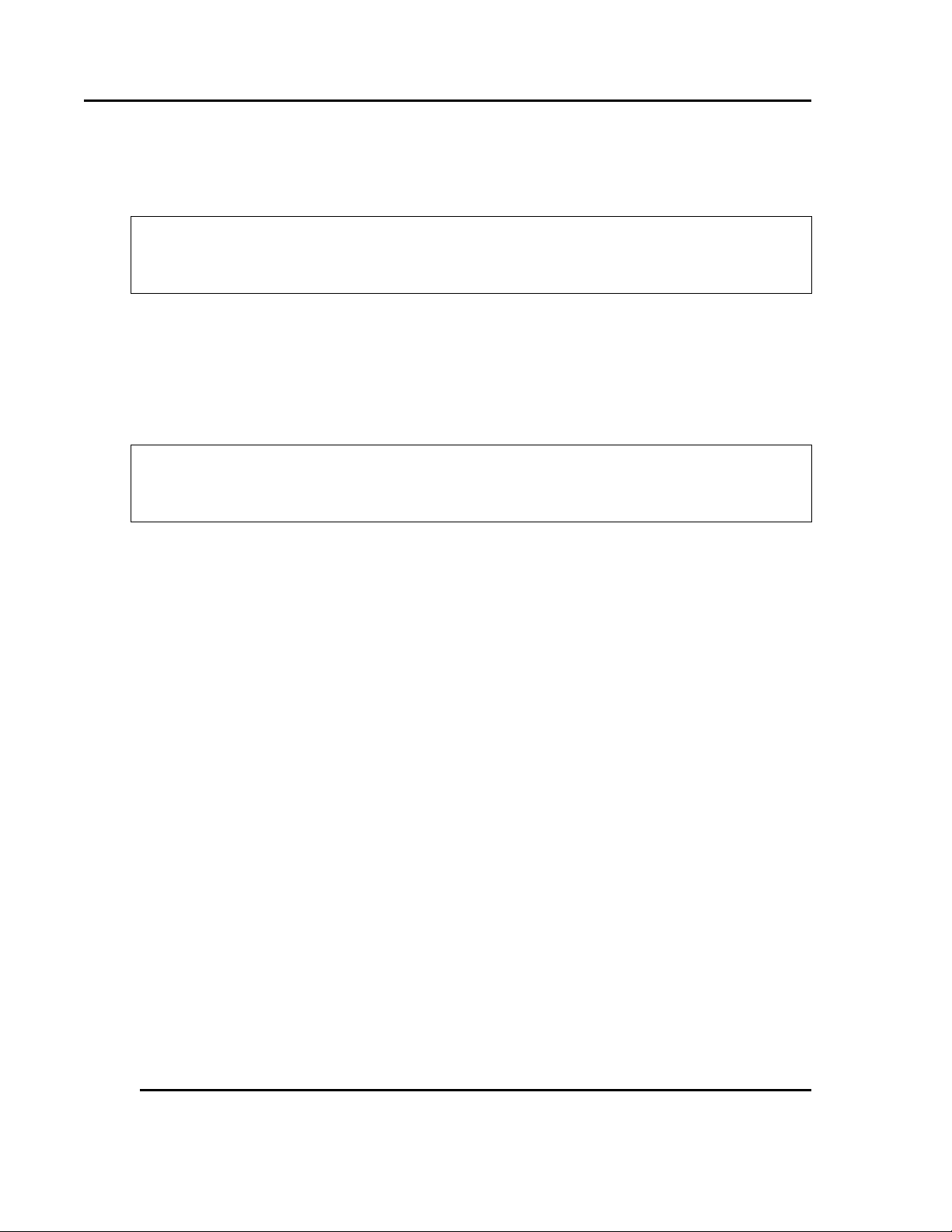

The UltraFlex Dryer tr anspo rts printed cells (wafers) through multiple integrated,

independently-controlled heating chambers using a variable-speed conveyor (Figure 4).

The wafers are heated to a temperat u r e that liberat es volatiles from the paste and

evacuates the VOCs fro m the heat ing chamber us i ng a c losed-loop control process gas

system. The VO Cs are then exhausted into the integr ated thermal oxidizer where they are

destroyed leaving only CO and HO byproducts. The wafer is then transferred d irectly

into the firing furnace for furt her pr ocessing.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 22

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

Figure 4. The UltraFlex Dryer Transports Wafer s t hrough Multi ple Chambers.

22 Version 3

3.3.2. Transport System

The wafer transport syste m co ns ists of a me sh b e lt, drive motor, progra mma ble logic

controller (PLC), variable fre que ncy drive s (VFDs), encoders, wafer senso r s, prec ision

gu ides and an internal s upport syst em. The mesh be lt is desig ned to contact the wafers

o n l y a t the outer extre m ities, minimizing surface damage and allowing uniform heating

w ith out inf lue nce from belt contact. Belt speed is cont rolled with a clo sed loop syste m

including the PLC, VFD, motor and encoder. The transport system is designed t o operate

from 64-635 cm/min with an accuracy of ± 0.5%. The conveyor is supported within the

chamber by a series o f quartz rods secured by glass plates within the refractory. Wafer

sensor photo-eyes are secured on the entrance and exit of the chamber t o ensure sa fe

operation of the machine below the lower explosive limit of the pro cessed VOCs.

3.3.3. Heating System

The heating s ys tem includes three separat e yet integ r ated systems. The lower portion of

the chamber has resistance-coil heating for preheating t he process gas introduced in the

chamber. The dryer upper chamber contains infrar ed ( IR) lamps to heat t he wafers to the

point of solvent evacuation as they pass through the chamber. T he o xidizer resistance coil

heaters destro y the VOCs remo ved from the wafer in the process. All three heat ing

syste ms are close-loop controlled via PLC, thermocouples, SSR and SCRs. T he typical

operation temperatu r e of the lower cha mber pr ehe ater is approximately 350 °C. IR lamp

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 23

UltraFlex Drying and Firing Furnace Owner’s Manual THEORY OF OPERATION

Figure 5. Set Four Dryer Process Air MFCs Using the Rec ipe Scree n.

Version 3 23

heaters operat e in a typical range of 200-550 °C and the oxidizer operates at 760 °C.

Set points and toleranc es for a ll heating systems are a function of setting the recipe.

3.3.4. Process Gas System

Process gas is delivered using a cont rol system made up of the PLC, mass f low

controllers (MFC), proportioning valves and monito r ing pressure transducers. Air i s

introduced into the upper and lower dryer heating chambers by the M FCs, whe re it is

preheated and delivered t o t he chamber ca vity. MFCs provide exhaust air flow to each

dryer zone to clear the VOCs. O xidizer s evacuate contaminated p ro cess a ir at t he ends of

the chambers and destro y the VOCs, leaving only CO2 and H2O byproducts.

Note:

• Two proportioning valves are facto r y set to achieve and maintain the required flow

for oxidizer air. Tw o additional facto ry-set proportioning valves provide dryer

entrance and exit air sparges (air curtains).

• Set any of the four dryer process air MFCs by using the Recipe screen (Set Four

Dryer Pr ocess Air MFCs U sing the Recipe Screen.).

• The PLC uses pressure transducers (there are several) to convert pressure to flow

numbers for control, display and alarm purposes.

Only Despatch personnel are permitted to change proportionin g

O

valves.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 24

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

24 Version 3

3.3.5. Oxidizer Airflow Settings

The exhaust set-point adjusts with the Oxidizer flow set-point

O

The dryer is shipped with factory airflow and pressure settings which produce balancedconditions, that is, the dryer is ba lanc e d from end to end—equal amounts of exhaust

flow t hrough ea ch oxidizer, and the dr yer runs at a very slig ht negat ive pressure

compared to the r oom. Keep the dryer in a balanced condition by always using the

factory settings.

O

and does not require separate ad ju stment .

Consult Despatch for assistance befo re using non-standard

oxidizer airflow settings.

3.4. Wafer Throu g hp ut

The UltraFlex Drying and Firing Furnace is designed for a specific solvent load. Dilution

air volume dictat es the a mount o f flammable solvent that can be safely processed in the

furnace. The dr yer is equipped wit h an airflow safety switch to ensure the introduction of

the minimum volume of d ilu tion air. The MF C ensures the introduct ion of the proper

volume of dilution air.

As the tool moves into P ro d uct ion Mode, scr eens pro mpt t he user to ent er infor mat ion

necessary for det ermining the proper LEL (lower explosive limit) le vels. See S ection 5.2

for more information.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 25

UltraFlex Drying and Firing Furnace Owner’s Manual THEORY OF OPERATION

Figure 6. Despatch VOC Thermal Oxidizer Operat i on.

Version 3 25

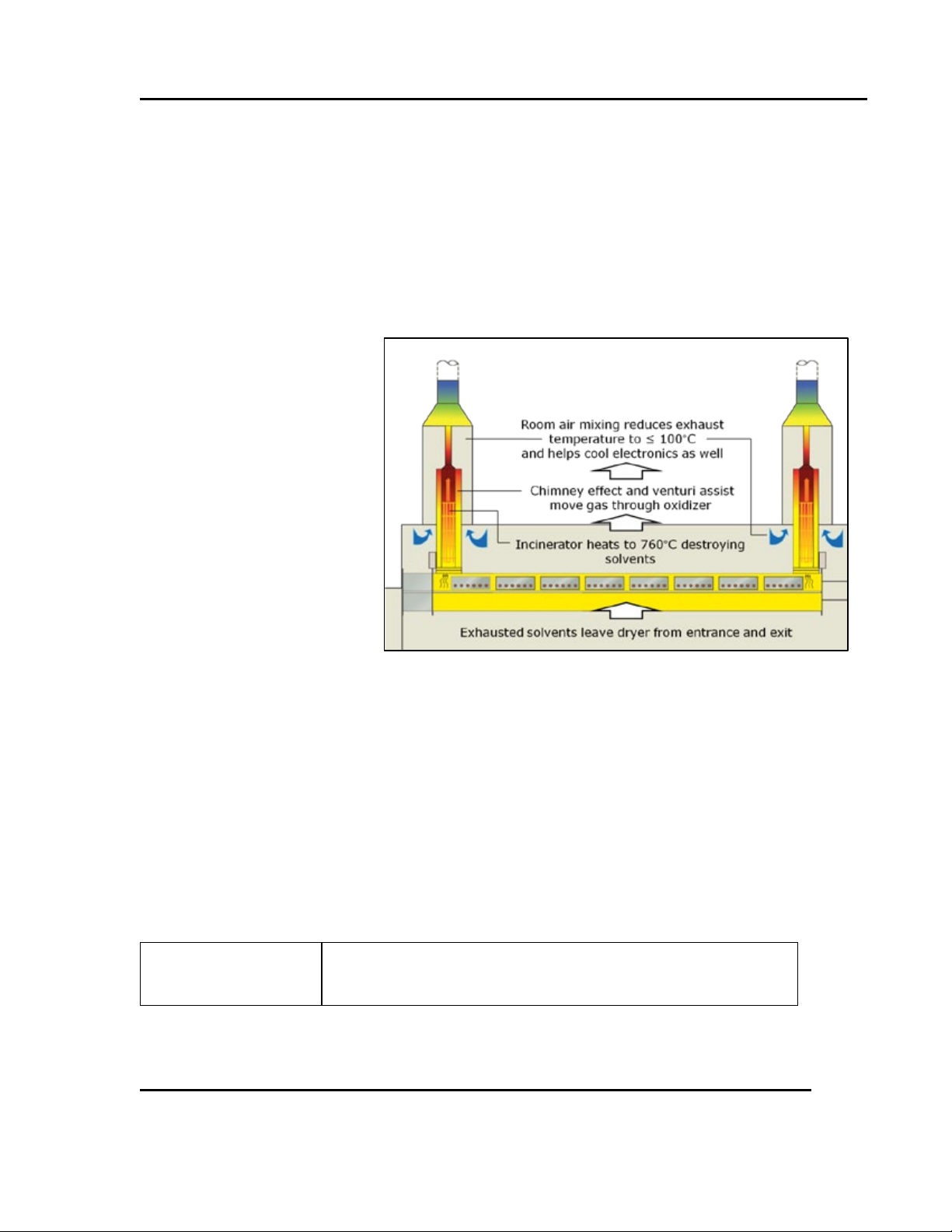

3.5. VOC Thermal Oxidizer

Paste used in the metallizat ion pro cess can pro d uce harmful byproducts cont aining

volatile organic co mpounds (VOCs) that vaporize into t he at mosphere. In the Unit ed

Sta tes, the Environmental Protection Agency (E P A) requires effective abateme nt of

VOCs.

The Despatch VOC Thermal Oxid izer was des ig ned to eliminat e o ver 99% of VOCs

from gasses exhausted during solar cell manufacturing. Destroying the VOCs using the

Oxidizer eliminates the need to collect and dispose of this waste in a separate process.

The exhaust exiting from t he VOC Oxidizer c ontains only CO2 and water vapor.

The Despatch VOC (Figure 6)

uses elevated temperatures to

cause organic compounds to

co mbust when exposed to

oxygen. Thermal destruction

of most organic compounds

takes place at 350 °C to 450

°C. Thermal oxidizers

typ ic all y maintain a

temperature of 760 °C to

ensure destruc tion of all

VOCs. The process releases

heat and so contributes to

maintaining the t emperat ur e

of the oxidizer.

3.6. Chamber Lift Mechanism

The chamber lift mechanism is o per ated by a pneumatic cylinder and a set of lift c hains

which lift t he chamber into place and seal the upper and lower casings. The pneu matic

cylinder applies a lower pressure to lift the casing. When the casing is within roughly 50

mm, the cylinder applies a higher pressure to seal the casing. Pr essure is c ontinuousl y

applied to the casing while the tool is in Production Mode.

Use of the pneumatic cylinder t o close and op en the chamber

O

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

means no clamps are required for op erat ion.

Copyright © 2010 by Despatch Industries.

Page 26

THEORY OF OPERATION UltraFlex Drying and Firing Furnace Owner’s Manual

26 Version 3

Operation of the chamber lift is accomplished through the scree ns provided (Section 5.7).

Operating the Chamber Lift mechanism requires that the tool

O

Warnings and alerts for the chamber li ft mec hanis m inc lu d e:

• Audible and on-screen warning before opening

• Alert if the chamber opening or closing does not complete the cycle

O

be in Maintenance Mode.

If the chamber is open, neither heaters nor conveyor will run

(except in Cooldown mode when casing opens 80 mm).

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 27

UltraFlex Drying and Firing Furnace Owner’s Manual SOFTWARE & HARDWARE SETUP

Version 3 27

4. Software & Hardware Setup

Always read and underst and Section 2—Safety before

O

4.1. Operation Overview

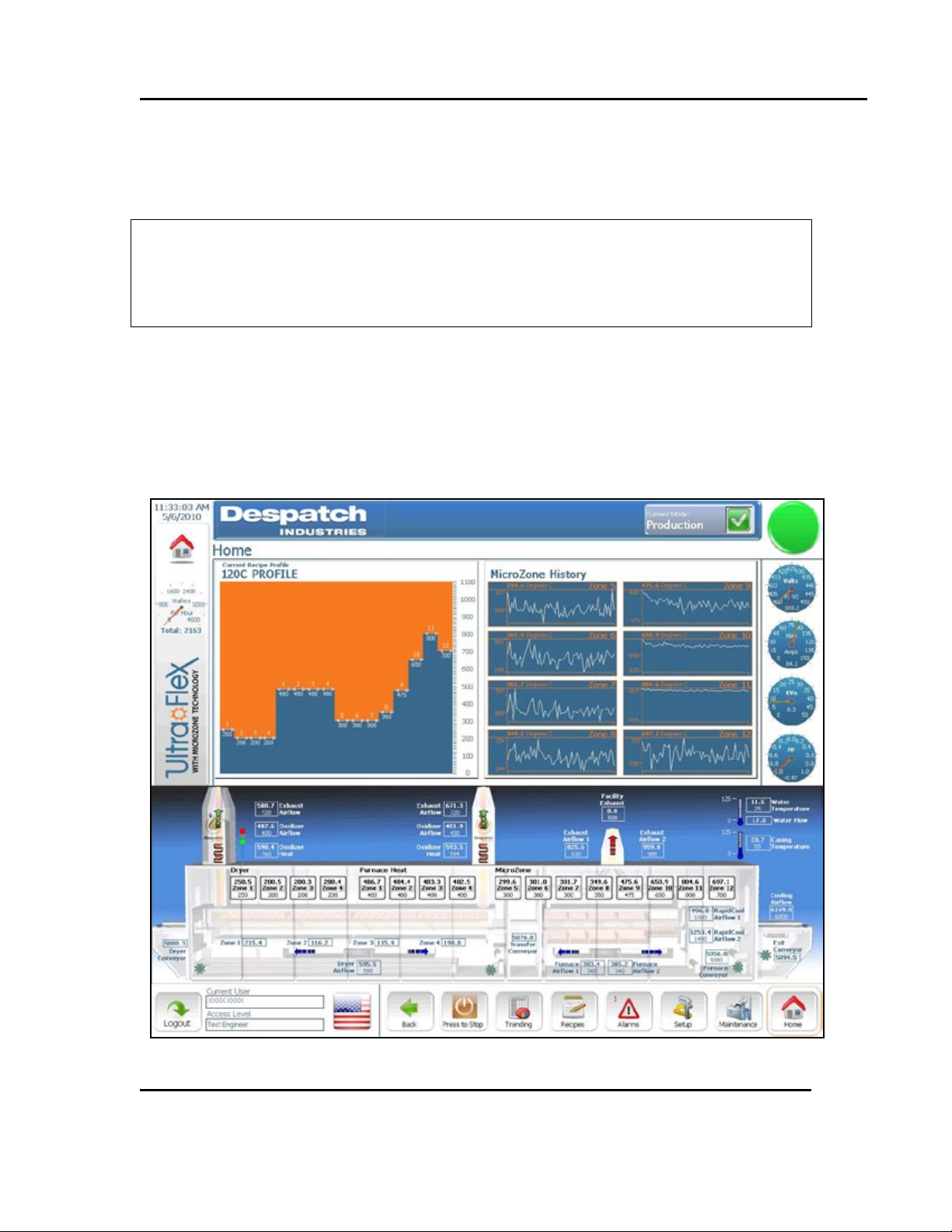

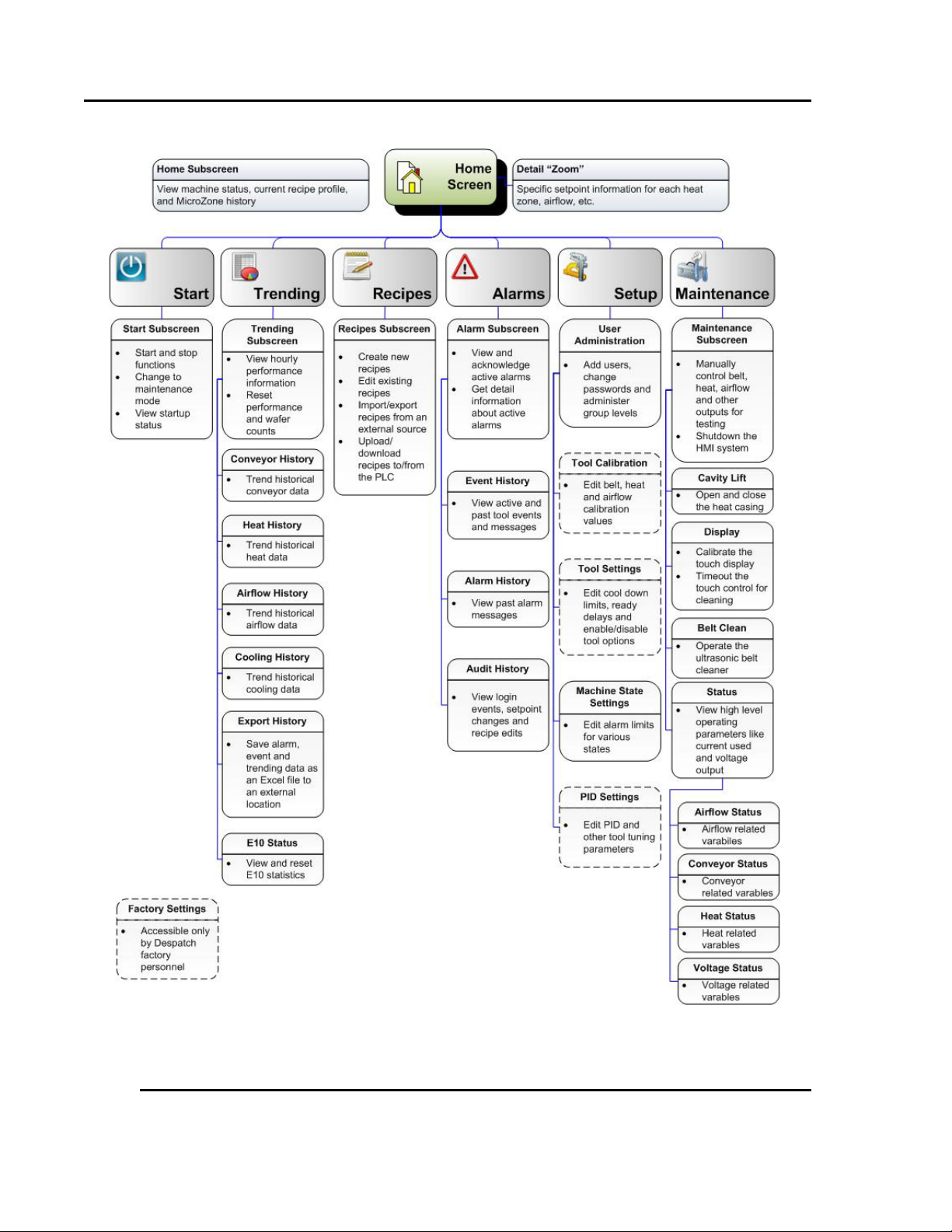

The Ho me Scree n of the UltraFlex Drying and Firing Furnace is the system d ef ault

screen, the screen that app ear s after boot-up ( Figure 7). Navigat e fro m the Home Scr een

to all other screens and modes (including Ready, Stabilization, Cooldown and Idle) used

to operate the UltraFlex Drying and Firing Furnace (Figure 8).

installing, performing maintenance or adjusting the UltraFlex

Drying and Firing Furnace.

Figure 7. Typical Home Screen (UltraFlex).

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 28

SOFTWARE & HARDWARE SETUP UltraFlex Drying and Firing Furnace Owner’s Manual

Figure 8. UltraFlex Drying and Firing Furnace Software Navigation.

28 Version 3

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

Copyright © 2010 by Despatch Industries.

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 29

UltraFlex Drying and Firing Furnace Owner’s Manual SOFTWARE & HARDWARE SETUP

UltraFlex Furnace

Function

Security Level

Operator

Maintenance

Process

Engineer

Despatch

Users

Load Recipes/Run S yste m

X X X

X

Acknowledge Alarms

X X X

X

Change Languages

X X X

X

Edit Recip es

X X X

Mainte nance Mod e

X X X

Open Chamber

X X X

Enable Remote Access

X X X

Edit Data logging

X X X

Expo rt/I mport Use rs

X

X

Export/Import Calibrations

X

X

Exit System

X

X

Export/I mport Machine

Constants

X

Edit P ID Va lues

X

Version 3 29

4.2. Managing Users

After launching the UltraFlex Drying and Firing Furnace, login to g a in access to syst em

functions.

4.2.1. Security Levels

Security to the various functions of the UltraFlex fur nace (Table 1):

Table 1. UltraFlex Security Levels.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 30

SOFTWARE & HARDWARE SETUP UltraFlex Drying and Firing Furnace Owner’s Manual

Setup

Users

Figure 9. Press Setup and

User Information.

Figure 10. Enter or Change User Information with the Setup/User Admini stration Screen.

30 Version 3

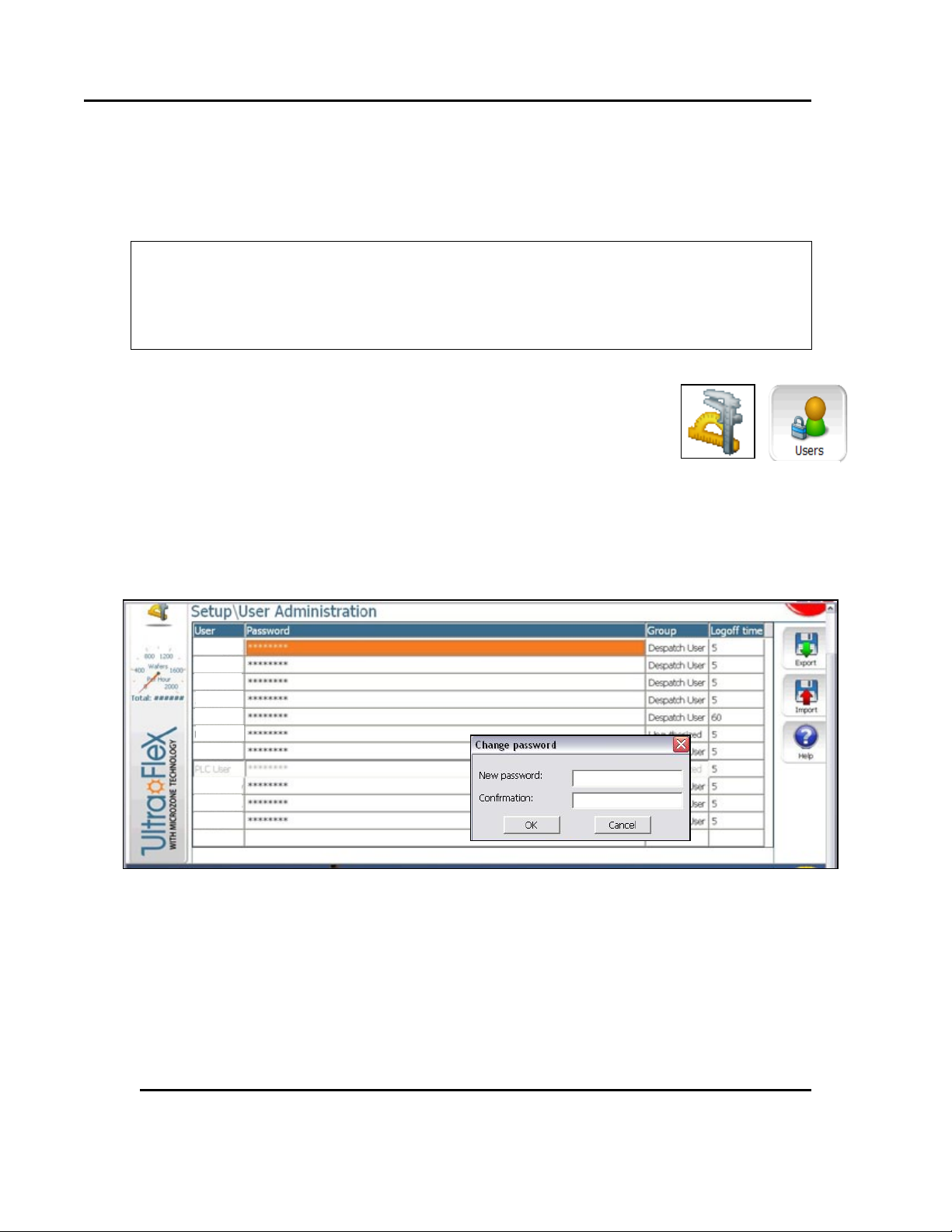

4.2.2. Adding a User or Changing User Privileges

Adding a user or changing user privileges requires use of the user administration

functions. Adding or changing functions includes user names, passwords, user group

identification a nd s pecifying a lo goff time.

The UltraFlex Drying and Firing furnace keeps an audit trail

O

1. From the Home screen, press Setup (Figure 9).

2. Press Users in the User Administrat ion section of the Setup

screen.

a. Press Help at any time for more I n formation

3. Using arrow keys go to the last row on the screen.

4. Double-click (or press Enter) on that row until the blinking

cursor appears

which requires that every change be logged in by a user with a

val id user name.

then Users to Add or Change

a. Ente r Use r name

b. Use t he full first and last name for t he User name entry.

c. Enter New password and Confirmat ion

5. Passwords must be at least four characters

a. Under Group, assign the group appro pr iate to t he tasks required for t he user.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 31

UltraFlex Drying and Firing Furnace Owner’s Manual SOFTWARE & HARDWARE SETUP

UltraFlex Furnace

UltraFlex Furnace Setpoints

Lower Setpoint

Upper Setpoint

Dryer Zones 1-4

25°C

500°C

Furnace Zone 1

25°C

600°C

Furnace Zones 2-4

25°C

750°C

Furnace Zones5-12

25°C

1050°C

Conveyor Speed

100 cm/min

635 cm/min

Oxidizer

25°C

780°C

Version 3 31

b. Enter Logoff t ime (maximu m time the sys te m can remain idle u ntil it

automatic ally log s out.

4.3. Recipe Setup and Optimization

Traditional recipes for solar cell production often adjust conveyor or belt speed to reach

the desired profile. The UltraF lex furna ce uses Mi cr ozone technology to prec isely heat or

cool wafers to the desired t emperat ur e. Microzone technology combines op timized

radiant wavele ngths with custom lamps to provide accurate profiles—independent of

conveyor or belt speed. Microzone technology allows for u nprecedent ed p r ecision in

achieving profiles without changing conveyor or belt speed and thus affecting the rest of

the line.

4.3.1. UltraFlex Furnace Setpoint Ranges

The s e tpoint ranges in Table 2 are based on typical pro d uct temperat u r es rat her than oven

temperatures. Figure 11 shows example f iring zo n e setpoints versus actua l temperatur es

for belt speeds of 508 cm/min and 635 cm/min. Actual zone temperatures (as measured at

the wafer or wafer facsimile) will vary with belt speed and temperature dis p a rity f r om

adjacent zones. The same recipe will produce different measured temperatures at varying

belt speeds. Measure t he t emperat ur e profile following each recipe change.

Lamp zo ne s etpoints les s than 300 °C may adversely affect

O

lamp li fe .

Table 2. UltraFlex Furnace Typical Setpoint Ranges.

Process Area

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 32

SOFTWARE & HARDWARE SETUP UltraFlex Drying and Firing Furnace Owner’s Manual

Figure 11. Typical Firing Zone Setpoints vs. Actual Temperatures.

32 Version 3

Copyright © 2010 by Despatch Industries.

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Page 33

UltraFlex Drying and Firing Furnace Owner’s Manual SOFTWARE & HARDWARE SETUP

Version 3 33

4.3.2. Optimize Recipe Process with Example

Precise profile cont ro l is achieved using UltraFlex furnace

O

While the UltraFlex furnace o ffers a variety of flexible optimization options, the typical

UltraFlex furnace burno ut-fire-cool pro file includes these steps:

1. Determine process speed ( conveyor minimum and maximum speed), based on:

a. The minimum transport speed based o n the speed of the slowest element in

the production line.

Example Transport Speed:

• W hile y our li ne m ay be different, in this example the printer is the slowest element in

the line with a speed of 1 wafer ever y 2.2 seconds.

.

%

• At 85% loading with a wafer length of 15.6 cm, the minimum transport speed i n the

furnace = 500.5 cm/min.

b. Minimu m a nd maximu m pro cess speed s based o n the recommended process

window supp lie d by the paste co mpany.

Example Minimum & Maximum Process Speed:

In this example, the recommended paste process time of 24-36 seconds includes

heating, burno ut and f iring. The heated length o f the U ltraFlex furnace is 183 cm.

Maximum pr ocess speed:

Minimum process speed:

Microzone technolo gy rather tha n the traditional control of

co nveyor or belt speed .

.

(

(

= /

)

= .

)

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 34

SOFTWARE & HARDWARE SETUP UltraFlex Drying and Firing Furnace Owner’s Manual

Number of F iring Zones Required at:

342.9- 381.0 cm/min

(135-150 inch/min)

482.6-558.8 cm/min

(190-220 inch/min)

584.2-635 cm/min

(230-250 inch/min)

Typical Profile

100-125°C/sec

4 5 6

Rapid Firing Profile

125-150°C/sec

3 4 5

Very Rapid Firing Profiles

>150°C/sec

2 3 4

34 Version 3

(

= ./

)

Example: Belt speeds fast er than 500.5 cm/minu te will not

O

increase production speed.

Example Final Process Speed:

Using the process speed (500.5 cm/minute) may limit production. Only conveyor

speeds between 610 cm/minute and 500.5 cm/minute should be considered.

2. Determine the number o f firing zones (Table 3)

Microzone t echno logy allows for an infinite amount of profile change s, ind epe nde nt

of belt speed.

Table 3. Guideline to Determine Number of Firing Zones.

Heating Slopes

Example Number of Firing Zones:

In t his exa mple, a typical profile (100 °C -125°C/second) would require five to six

firing zones.

3. Set airflow in dryer and furnace. Whi le greater volumes of air h elp clean the furnace,

they also elevate electricity consumption and re quire greater exhaust flows.

Example Airflow:

In t his exa mple of a sin gle lane tool, the H M I (inflow ) is s e t to :

• Low end: 190 Lpm

• High end: 380 Lpm

All rig hts reserved. No part of th e contents of th is m anual may b e r ep roduced, copied or t r ans mi t t ed i n any for m or b y any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries , unless for purchaser's personal use.

Copyright © 2010 by Despatch Industries.

Page 35

UltraFlex Drying and Firing Furnace Owner’s Manual SOFTWARE & HARDWARE SETUP

Version 3 35

4. Determine single lane o r dual lane cooling rates. Rapid Cooling 1 and Rapid Cooling

2 blow air downward from above t he wa fer and provide top and bo ttom radiant

cooling. The cooling rate depends on fan speeds, cooling water temperature, wafer

mass and belt sp e ed . Faster belt speeds requ ire more cooling, because more mass

needs more co oling. The rapid cooling fans 1 and 2 run between 4% and 100% when

ON. Eve n at a 0% setting ther e will be a 4% minimum speed, which is r equired for

stable fan operation. Typic al cooling rates are 50° to 65°C / second. Adjust fan speeds

to obtain the desired cooling. I f wafers are blown out of position or if excess vibration

is observed, reduce fan speed.

5. Determine burnout temperature

a. In general, lower temperatur es and longer bur no ut times are more p ro du ctive.

But final results are also based on t he past e manuf acturer recommendat ions.

b. If burnout is insufficient, increase t he t emperat ures or reduce belt speed and

use.

Example Burnout Temperature:

In this example, typical burnou t temperatures range fro m more than 300°C to less

than 800°C.

6. Adjust Microzo ne™ t echno logy for desired peak temperature and profile . Microzone

technology is typica lly set to higher setp oints in the center of the firing zones to

optimize heat transfers—based o n shared view fact ors with adjacent zones.

7. Adjust final wafer temperat ure using the exit conveyor coo ling blower volume. On

the Recipe screen (Figure 12):

a. Press Recipe.

b. Press Exit Conveyor Cooling Airflow and adjust blower speeds (to roughly

75%) until the wafers begin to move.

c. Reduce the setpoint by 1-2%.

d. Press Save to use in the currently running recipe.