PENINSULA

MODEL VPN36

®

3-SIDED, WOODBURNING FIREBOX

INSTALLATION AND OPERATING INSTRUCTIONS

SAVE THIS BOOK

This book is valuable. In addition to instructing you

on how to install and maintain your appliance, it also

contains information that will enable you to obtain

replacement parts or optional accessory items when

needed. Keep it with your other important papers.

FOR YOUR SAFETY

• Do not store or use gasoline or any other flammable vapors or liquids in the vicinity of this or any

other appliance.

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

• Do not place clothing or other flammable materials

on or near the appliance.

• NEVER leave children unattended when a fire is

burning in the firebox.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE INJURY, PROPERTY DAMAGE, OR LOSS

OF LIFE. REFER TO THIS MANUAL. FOR ASSISTANCE OR ADDITIONAL INFORMATION CONSULT A

QUALIFIED INSTALLER OR LOCAL DISTRIBUTOR.

WARNING: THIS FIREBOX IS INTENDED FOR USE

WITH WOOD, OR IF A VENT-FREE OR DECORATIVE

GAS APPLIANCE IS INSTALLED, BURN PROPANE/

LP OR NATURAL GAS ONLY.

®

DESA INTERNATIONAL,

2701 INDUSTRIAL DRIVE

P.O. BOX 90004

BOWLING GREEN, KY

42102-9004

Model

Serial No.

Date Purchased

CHECK LOCAL CODES PRIOR TO INSTALLATION

55505

Rev. B

07/99

C O N T E N T S

1. INTRODUCTION......................................PG. 3

2. SELECTING LOCATION.........................PG. 3

3. CLEARANCES ........................................PG. 4

4. FRAMING ................................................PG. 4

5. HEARTH EXTENSIONS ..........................PG. 5

6. OUTSIDE AIR KIT INSTALLATION ........ PG. 6

7. GAS LINE INSTALLATION .....................PG. 6

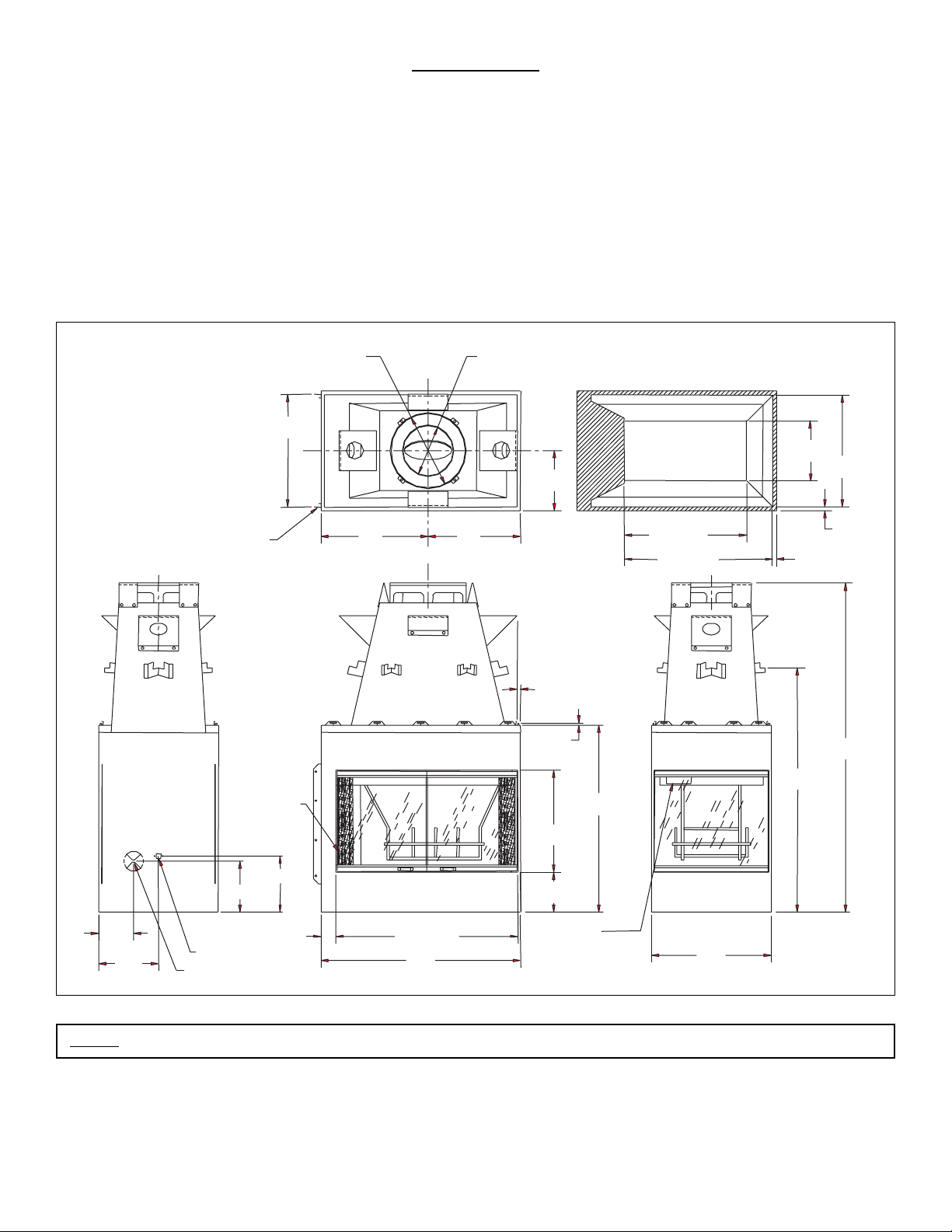

Ø15

O.D.

22 5/

8

NAILING

FLANGES

21

8. CHIMNEY PIPE INSTALLATION ............PG .7

9. FINISHING YOUR CHIMNEY SYSTEM .....PG. 9

10. TERMINATIONS .....................................PG. 11

11. FINISHING YOUR FIREBOX................. PG. 12

12. OPERATING GUIDELINES AND

MAINTENANCE INSTRUCTIONS......... PG. 13

13.

REPLACEMENT & ACCESSORY PARTS ...

Ø10

I.D.

HEARTH AREA

DIMENSIONS

12

24 1/

29 1/

2

2

19

12

3/4

PG. 14

22 3/

3/4

8

5/8

3/8

48 1/

OUTSIDE AIR

HANDLE

OTHER SIDE

11 1/

1

10

7

12

GAS LINE CONDUIT

OUTSIDE AIR

4

/

4

36 1/

3

2

40

37 1/

2

20 1/

2

8 1/

8

UL LABEL

BEHIND DOOR

ON SMOKE SHELF

24

66 1/

2

NOTE: ALL DIMENSIONS IN THIS INSTALLATION MANUAL ARE IN INCHES UNLESS OTHERWISE SPECIFIED.

4

2

55505

INTRODUCTION

Model VPN36 series is a woodburning firebox intended and approved for installation in either residential homes or buildings of

standard construction.

This wood burning fireplace complies with UL 127 as a

FACTORY BUILT FIREPLACE and is listed and tested by

Underwriters Laboratory Inc.

This model is not for use in mobile homes.

This firebox system requires the utilization of a Vanguard 10"

double-wall, snap-lock flue pipe system.

BRUSHED BRASS GLASS DOORS are standard with this firebox.

Different style doors are offered as optional accessories (see last page).

BE SURE TO CHECK WITH YOUR LOCAL BUILDING

CODES FOR AREA REQUIREMENTS BEFORE INSTALLING THIS FIREBOX.

The model's serial number and any other specific rating information

may be found on the unit in the UL RATING PLATE located at the

interior of the firebox's opening (see Figure 1, page 2).

BEFORE YOU BEGIN

Before beginning the installation of your firebox, read these instructions through completely.

This firebox and its approved components are safe when installed

and operated according to this installation and operation manual.

Unless you use Vanguard approved components tested for this

firebox, YOU MAY CAUSE A FIRE HAZARD!

The DESA International warranty will be voided by, and DESA

International disclaims any responsibility for the following actions:

A) Modification of the firebox or any of the components manufac-

tured by DESA INTERNATIONAL unless otherwise permitted

by DESA INTERNATIONAL.

B) The use of a firebox insert or any other component part not ap-

proved by DESA INTERNATIONAL in combination with a

DESA INTERNATIONAL firebox.

C) Installation and/or operation in a manner other than instructed in

this manual.

D) The burning of any other fuel not tested or approved by DESA

INTERNATIONAL in this wood-burning firebox.

PROPER INSTALLATION is the most important step in ensur-

ing a safe and continuous operation of this firebox.

Although grounding may not be required by code in your area, it

must be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANS/

NFPA 70-1987.

This firebox is intended for installation in accordance with the

National Fire Protection Association Standard for Chimneys, Fireplaces, Vents, and Solid-Fuel Burning Fireplaces, NFPA 211, and in

accordance with codes such as the BOCA Basic/National Code, the

Standard Mechanical Code, and the Uniform Building Code.

NOTE: Installation and repair should be done by a qualified

installer. The firebox and chimney system should be inspected

and cleaned before use and periodically thereafter especially

during heating season to ensure a safe operating system.

This firebox is not intended to be used as a substitute for a

furnace to heat an entire home. Use for supplementary

heating only.

SELECTING LOCATION

To determine the safest and most efficient location for your firebox,

you must take into consideration the following guidelines:

1. The location must allow for all the proper clearances (see section on clearances, page 4).

2. Consider a location where the heat output would not be affected

by drafts, air conditioning ducts, windows or doors.

3. A location that avoids the cutting of joists or roof rafters will

make installation easier.

4. If an outside air kit is to be installed, accessibility to outside

combustion air must be considered. This can also be achieved

through a vented crawl space in some cases, for more details

refer to section on outside air kit installation.

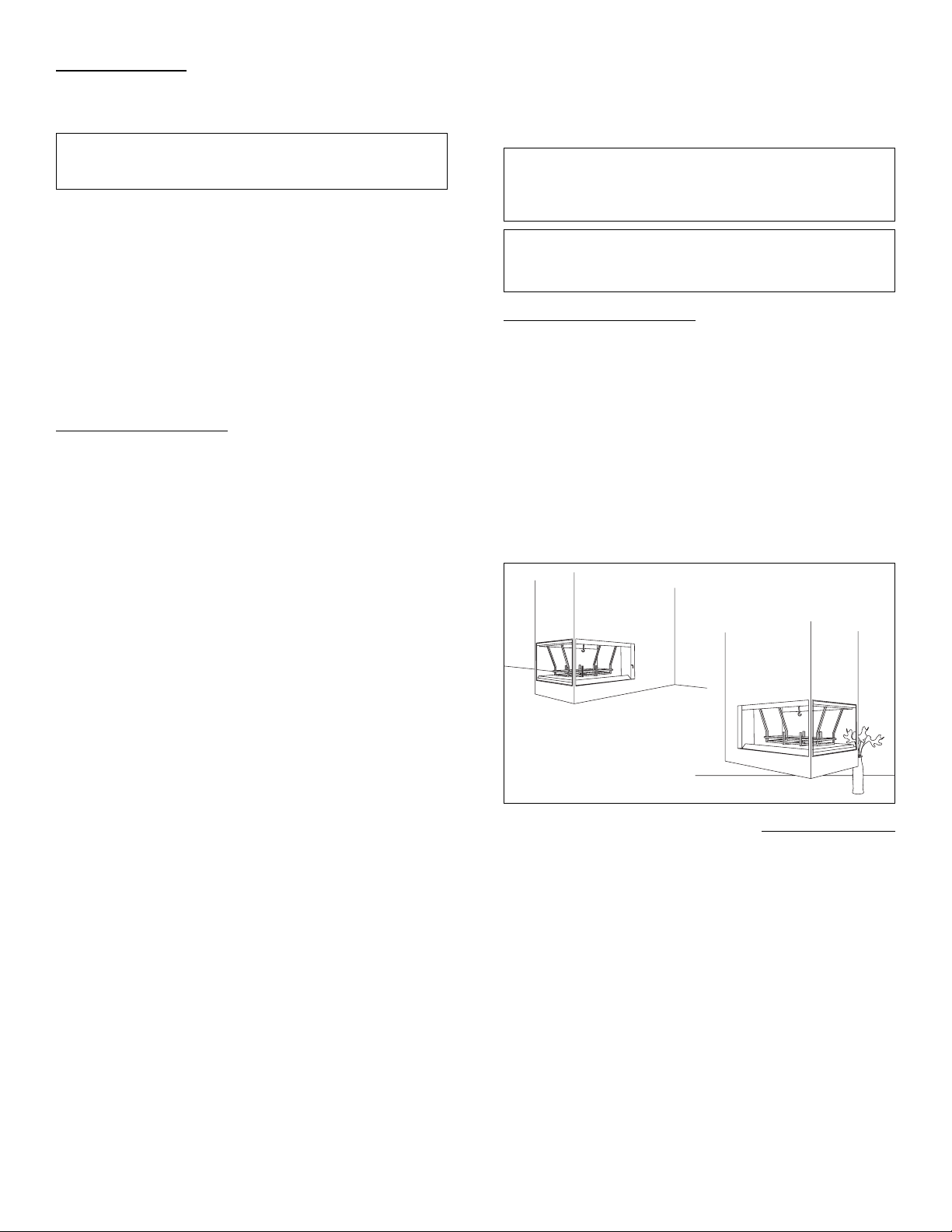

Figure 2

The typical installation for a peninsula is a

which allows you to extend the firebox any distance into the room. A

projection may be ideal for a new addition on an existing, finished wall.

projected installation,

55505

3

ALSO IN SELECTING A LOCATION, THE

FOLLOWING PRECAUTIONS MUST BE

OBSERVED;

1. Do not connect this firebox to a chimney system other than a

Vanguard chimney system.

2. Install in an area providing ventilation and adequate combustion air.

3. Due to high temperatures do not locate this firebox in high traffic areas or near furniture and draperies.

4. Provide adequate clearances around air openings into the combustion chamber. NEVER obstruct the front opening of the firebox or the flow of combustion and ventilation air.

5. Do not locate in or near an area where gasoline or other flammable liquids may be stored. The firebox area must be kept clear

and free from these combustible materials.

CLEARANCES

MINIMUM CLEARANCES TO COMBUSTIBLES ARE:

• BACK .................................................................. 1/2" MIN.

• ADJACENT WALL .............................................. 12" MIN.

• CHIMNEY OUTER PIPE SURFACES ................. 2" MIN.

• BOTTOM OF FIREBOX TO FLOOR................... 0" MIN.

SPACERS ON SIDES OF FIREPLACE

PROVIDE REQUIRED 1/2" CLEARANCE

MANTEL CLEARANCES

Woodwork, such as wood trims, mantels, and other combustible

materials, should not be placed within 9 inches of the effective

opening of this firebox.

The effective opening is considered the opening where actual

heat output may occur.

SPACERS

VIEW

"A"

1/2" MIN.

INSULATION

(DO NOT

REMOVE)

1

/2 inches

Combustible material above and projecting more than 1

from the front face of firebox (see Figure 4) should not be placed less

than 12 inches from the effective opening of the firebox (ref; NFPA

std. 7-3.3.3.)

"FALSE" HEADER

DRYWALL

COMBUSTIBLE

MATERIALS

ONLY BEYOND

LIMITS SHOWN

WITHIN 12"

OF EFFECTIVE

OPENING

SEAL 3/8 GAP FROM

TOP OF FIREPLACE

TO DRYWALL WITH

NONCOMBUSTIBLE

CAULKING

1

MAX.

1

12"

(NOM)

9" MIN.

/2"

11" MIN.

TO HEADER

2" MIN. TO

COMBUSTIBLES

VIEW "A"

1/2

MIN.

(3)

12

MINIMUM TO

ADJACENT WALL

Figure 3

WARNING: DO NOT BLOCK REQUIRED AIR SPACES

WITH INSULATION OR ANY OTHER MATERIAL. DO

NOT OBSTRUCT EFFECTIVE OPENING OF FIREBOX

WITH ANY TYPE OF FACING MATERIAL. COMBUSTIBLE MATERIAL MUST NOT BE IN CONTACT WITH

THE BLACK FRONT FACE OF THE FIREBOX.

Figure 4

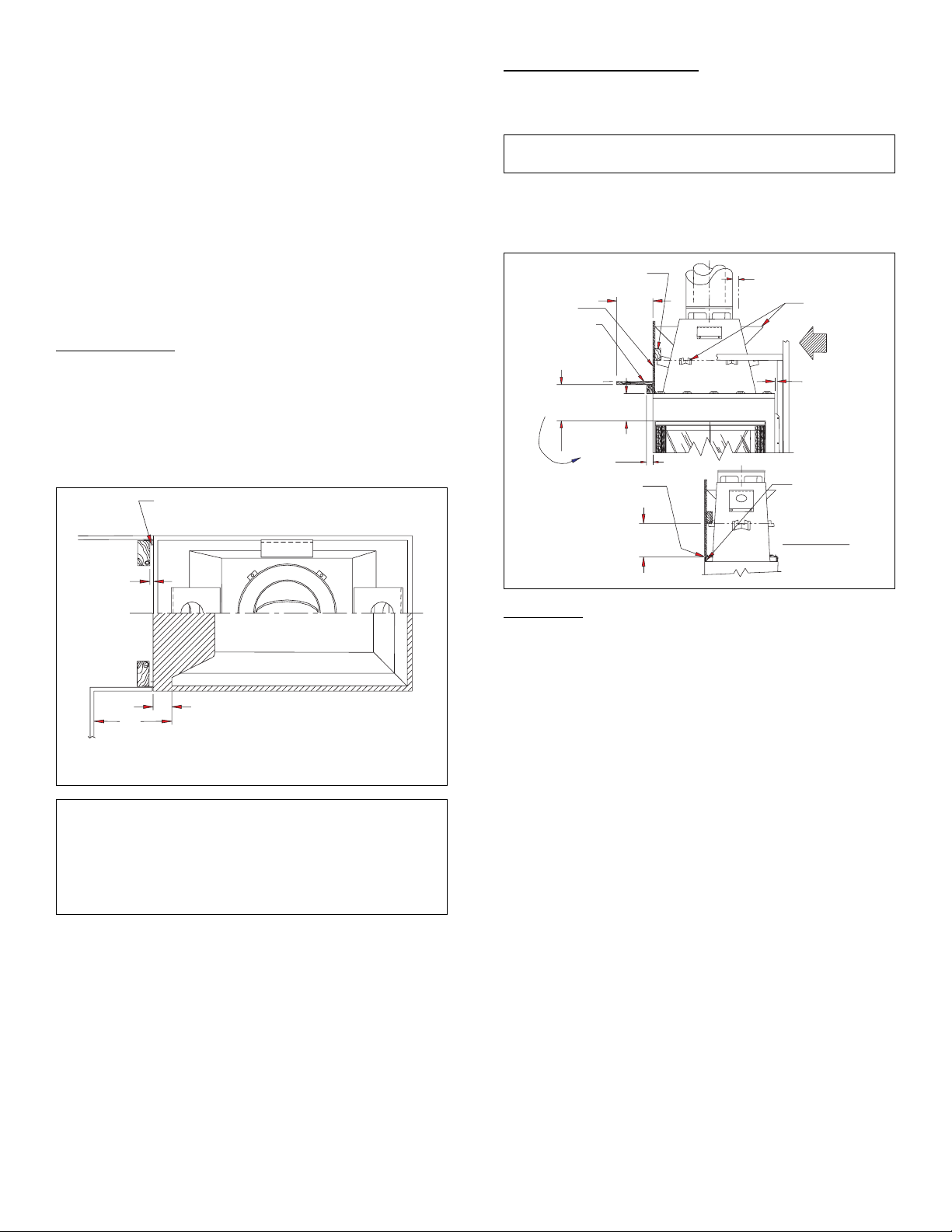

FRAMING

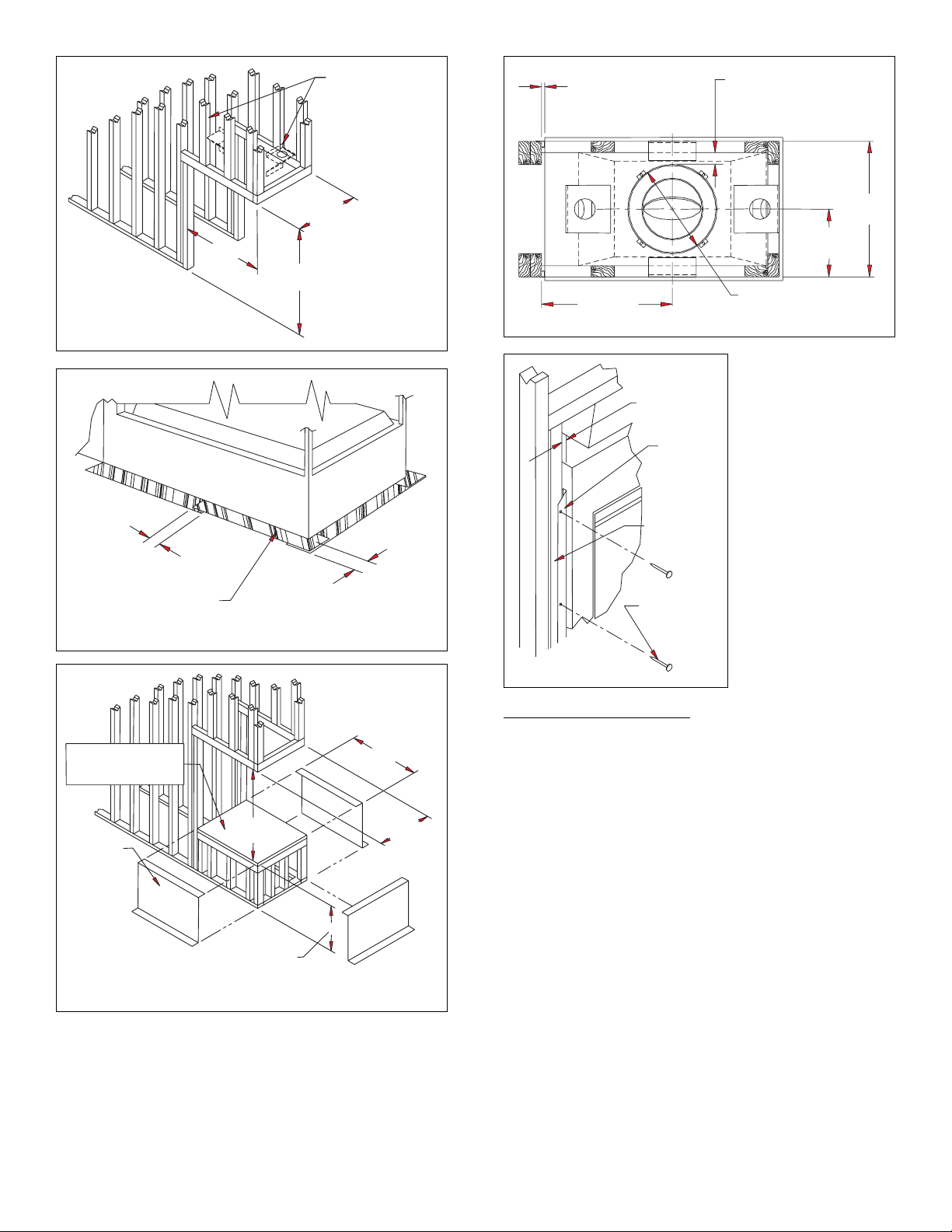

Construct framing using dimensions shown in Figures 5, 7, and 8,

page 5, depending on your particular installation.

If the firebox is to be installed directly on carpeting, tile (other than

ceramic), or any combustible material other than wood flooring; the

firebox must be installed upon a metal or wood panel extending the

full width and depth of the firebox.

Before securing firebox to prepared framing, metal safety strips

(provided) must be placed between hearth extensions (not supplied) and bottom front edge of firebox to protect against glowing

embers (Figure 6, page 5).

If the firebox is to be installed on a raised platform, a "Z-type" metal

safety shield (not supplied) must be fabricated to fit your required

platform height (see Figure 7, page 5). The shield must be made of

(26-28ga) galvanized sheet metal to prevent corrosion.

4

55505

Figure 5

39

TOP STUDS MUST

CLEAR SPACERS

ON TOP OF UNIT

22 5/

8

7

/

8

48 1/

2

MIN.

1/2

MIN. T O

COMBUSTIBLES

1

/

2

21

2 MIN. CLEARANCE

FROM OUTER PIPE

TO COMBUSTIBLES

11 5/

Ø15 OUTER PIPE

22 5/

8

16

Figure 8

Proceed to secure firebox

1/2" (12.7mm)

MIN. T O

COMBUSTIBLES

NAILING

FLANGES

to prepared framing at nailing flanges located at the

sides of the firebox as

shown in Figure 9.

1/2 MIN.

OVERLAP

METAL SAFETY STRIPS

(SUPPLIED)

Figure 6

PLATFORM MUST BE

SOLID, FLAT, AND

FULLY SUPPORTED

YPE

"Z" T

MET AL

SAFETY

SHIELDS

(NOT

SUPPLIED)

Figure 7

48 1/

2

MIN.

AS REQUIRED BY DESIGN

AS LONG AS CEILING

CLEARANCE IS

MAINTAINED

PREP ARED

1/2 MIN.

FRAMING

NAILS OR

SCREWS

Figure 9

HEARTH EXTENSIONS

A hearth extension is required to protect combustible floor surround-

39 7/

8

ing firebox. You may fabricate your own per the dimensions shown

in Figure 10, page 6.

The hearth extension must project 20 in. min. to the front and 12 in.

min. beyond each side of the firebox opening except on the end

22 5/

8

where projection is 16 in. min. to the front and 20 in. to the sides (see

Figure 10, page 6).

*

55505

5

NONCOMBUSTIBLE

SECURE TO

COLLARS WITH

DUCT T APE OR

SCREWS

VENTED CRAWL

SPACE INSTALLATION

CHECK WITH LOCAL AREA CODES PRIOR TO

INSTALLING IN A VENTED CRAWL SPACE

AIR INLET

EYEBROW

AIR INLET

LOCATION

MUST ALLOW

FOR BUSHES

OR SNOW

HEARTH EXTENSION

64 MIN.

20

MIN.

16

MIN.

65 MIN.

Figure 10

NONCOMBUSTIBLE

HEARTH EXTENSION

8" MAX

"Z" TYPE

EMBER PROTECTOR

NONCOMBUSTIBLE

HEARTH EXTENSION

"K" FACTOR

.84

EMBER PROTECTOR

Figure 11

1

1

1

/2" TYP

1

/2" TYP

FOR RAISED FIREPLACE SEE SECTION

ON FRAMING WITH A RAISED PLATFORM

If a hearth extension is to be field constructed, it must be made of

noncombustible, inorganic material having an effective thermal

conductivity "K" of .84 BTU In/Ft 2 Hr. F or less at 1" thickness.

Thermal conductivity "K" of materials can be obtained from the

manufacturer.

The minimum required thickness for any material could be obtained

by the following formula:

K factor x 1" = Thickness required

.84

If the hearth extension is to be raised, a "Z" type metal safety strip

must be used, see Figure 7, page 5 and Figure 11.

OUTSIDE AIR KIT INSTALLATION

The installation of the outside air kit must be installed during the

rough framing of the firebox due to the nature of its location. Outside

combustion air can be accessed through an exterior wall or a vented

crawl space (see Figure 12).

Figure 12

WARNING: AIR INLET DUCTS MUST NOT TERMINATE IN ATTIC SPACE.

Avoid installing outside air eyebrow in areas where inlet opening

may be blocked by snow, bushes or other obstacles. It should also be

located beyond the reach of small children.

The maximum height for the air inlet above platform of firebox is

within 3 feet below the termination flue gas outlet.

For further details on the installation of the outside air kit, please

refer to the instructions included with the kit. For operating instructions, please refer to your owner’s manual.

GAS LINE INSTALLATION

YOUR GAS SUPPLIER OR A QUALIFIED SERVICE PERSON SHOULD DO GAS LINE HOOKUP.

WARNING: BEFORE YOU PROCEED, MAKE SURE

YOUR GAS SUPPLY IS OFF!

A gas line may be installed for the purpose of installing a gas

appliance available through your local distributor. Use only 1/2"

black iron pipe and appropriate fittings. When installing a gas line,

a shut-off valve designed for installation outside the firebox is

recommended.

STEP 1: To install, remove the knockout indentation on the refractory (or firebrick) wall located approximately 2" above the refractory

hearth floor. The knockout indentation must be firmly tapped with

any solid object until it is released. Remove fragmented portion of

refractory (see Figure 13, page 7).

6

55505

OUTSIDE OF

FIREPLACE

GAS LINE

CONDUIT

REMOVE

INSULATION

TEMPORARILY

(DO NOT

DISCARD)

Figure 13

REMOVE

KNOCKOUT

AFTER REMOVING

GAS LINE COVER

PLATE, REPLACE

SCREWS

SIDE FIREBRICK

FINISHED SIDE

REFRACTORY

KNOCKOUT PLUG

REMOVE BY TAPPING

LIGHTL Y WITH A

1/2" DOWEL

STEP 2: Remove gas line cover plate on rear of firebox and pull out

insulation from gas line conduit sleeve, save insulation for reuse.

STEP 3: Run a 1/2" black iron gas line into the firebox through the

rear at 11

1

/4" from the floor and through gas line conduit sleeve (if

using a raised platform. Add height). Provide sufficient gas line into

firebox chamber for fitting connection (see Figure 14).

OUTSIDE OF

FIREPLACE

GAS LINE

CONDUIT

REPACK

INSULATION

Figure 14

INCOMING

1/2" BLACK

IRON PIPE

1

9

/4"

(235mm)

APPROX.

SIDE FIREBRICK

FINISHED SIDE

PROVIDE ENOUGH

THREADED END

FOR FITTING

CONNECTION

SEAL OPENING

WITH REFRACTORY

CEMENT

NOTE: Secure incoming line to wood framing to provide rigidity

for threaded end.

STEP 4: Repack insulation around gas line and into sleeve openings.

Seal any gaps between gas line and refractory knock out hole with

refractory cement or commercial furnace cement. Install the decorative gas appliance or cap-off gas line if desired.

WARNING: All gas piping and connections must be

tested for leaks after the installation is completed.

After ensuring that the gas valve is on, apply a soap and water

solution to all connections and joints. If bubbles appear, leaks

can be detected and corrected.

DO NOT USE AN OPEN FLAME FOR LEAK TESTING

AND DO NOT OPERATE ANY APPLIANCE IF A LEAK

IS DETECTED.

The gas pipe is intended for connection to an unvented gas log set or

to a decorative gas appliance.

If you will install an unvented gas log set, ONLY UNVENTED GAS

LOG SETS WHICH HAVE BEEN FOUND TO COMPLY WITH THE

STANDARD FOR UNVENTED ROOM HEATERS, ANS/IAS/AGA

Z21.11.2, ARE TO BE INSTALLED IN THIS FIREPLACE.

NOTE: An appropriate Vanguard hood must be installed when

using an unvented gas log set.

WARNING: DO NOT OPERATE AN UNVENTED GAS

LOG SET IN THIS FIREPLACE WITH THE CHIMNEY

REMOVED.

If you will install a decorative gas appliance, the decorative gas

appliance must comply with the Standard for Decorative Gas

Appliances for Installation in solid Fuel burning Fireplaces,

ANS Z21.60-1996 and shall also be installed in accordance with the

National Fuel Gas code, ANS Z223.1-1996.

WARNING: WHEN USING A DECORATIVE APPLIANCE,

THE DAMPER MUST BE REMOVED OR PERMANENTLY

LOCKED IN THE FULLY OPEN POSITION.

CHIMNEY PIPE INSTALLATION

The Vanguard chimney system is a snap-lock, double-wall pipe. It

consists of a stainless steel inner flue pipe, a galvanized outer pipe,

and a wire spacer.

Each section of pipe comes in lengths of 12", 18", 24", 36", and 48"

but the actual lineal gain for each is measured after each section is

fully connected.

Lineal gain is the actual measurable length of a part after two or more

parts are connected.

LINEAL GAIN

PART # NO. DESCRIPTION GAIN (inches)

VPN36 PENINSULA 66 1/4"

FIREBOX

V12-10DM FLUE PIPE 10 3/8"

V18-10DM FLUE PIPE 16 3/8"

V24-10DM FLUE PIPE 23 3/8"

V36-10DM FLUE PIPE 34 3/8"

V48-10DM FLUE PIPE 46 3/8"

VETL-10DM CHASE STYLE 7" to 17"

TERMINATION

VRTL-10DM ROUND TOP 6"

TERMINATION

PIPE INSTALLATION

Place pipe assembly (inner and outer with wire spacer) over starting

collar. Inner pipe fits inside inner pipe, outer pipe fits outside

outer pipe.

Begin by aligning hemmed-end of inner flue pipe into the inner starting

flue pipe of firebox. Push down until hem "snap-locks" with lances. The

outer pipe is just the opposite; female end has the lances. Continue the

same procedure for the outer pipe (see Figure 15, page 8).

55505

7

HEMMED

V12S-10DM

SUPPORT

REQUIRED

30 FT.

(9.14m)

30 FT.

(9.14m)

RETURN

ELBOW

END

15" (381 mm)

DIA. GALVANIZED

OUTER PIPE

10" (254 mm)

STAINLESS

INNER PIPE

LANCED SIDE UP

SCREW

(TYP. OF 8)

ATTIC SPACE

ABOVE CEILING

Figure 17

FIRESTOP

SPACER

EXISTING CEILING

FRAME

Figure 15

It is important to assure that the joint between the chimney sections

is fully locked. Check by pulling chimney upward after locking.

The chimney should not come apart if properly locked. It is not

necessary to add screws to keep vertical or angled chimney runs

together.

WARNING: THE OPENINGS AROUND THE STARTING COLLAR ON TOP OF THE FIREBOX MUST NEVER

BE OBSTRUCTED. NEVER USE BLOWN INSULATION TO FILL THE CHIMNEY ENCLOSURE.

FIREBOX SPACER

Firebox spacers are required at each point where the chimney

penetrates a floor or ceiling, joist space. Their purpose is two fold;

they establish and maintain the required clearance between the outer

pipe and combustible materials, and they also serve as a shield

between floors as required by most codes.

When the pipe passes through a framed opening into a living space

above, a firestop must be placed on the ceiling below (Figure 16).

LIVING SPACE

ABOVE CEILING

EXISTING CEILING

FRAME

SUPPORT SECTIONS

The chimney support section is a 4 strap, 12-inch length of pipe. A

chimney support is required every 30 feet above the firebox after

a straight chimney run, or above a return elbow after a straight

chimney run (Figure 18).

This support is designed to relieve the extra weight load on the

firebox and elbows when high chimneys are installed.

Figure 18

ELBOW OFFSET INSTALLATION

Chimney weight above offset rests on return elbow. Straps must be

secured with nails to rafters or joists (see Figure 19).

FIRESTOP SPACER

SCREW

(TYP. OF 8)

Figure 16

When the pipe passes through a framed opening into an attic space

above, a firestop must be placed on the attic floor above (Figure 17).

8

STRAPS

Figure 19

2" (50.8mm)

MINIMUM

ANGLE

FIRESTOP

CEILING SUPPORT

PIPE V12S-10DM

RETURN

ELBOW

55505

RETURN

ELBOW

CEILING

SUPPORT

PIPE

V12S-10DM

RETURN

ELBOW

RETURN

ELBOW

RETURN

ELBOW

OFFSET

ELBOW

OFFSET

ELBOW

OFFSET

ELBOW

6' MAX

6' MAX

6' MAX

6' MAX

6' MAX

6' MAX

TYPICAL OFFSET INSTALLATIONS

To achieve desired offset, you may install combinations of 12, 18,

10 FOOT RULE

2' MIN.

2' MIN.

LEVEL OF FLUE

GAS OUTLET

10'

3' MIN.

3' MIN.

10'

OR LESS

36, or 48 inch lengths of double wall pipe (see Figure 20 and Rise

and Offset Chart).

B

Figure 20

A

RISE AND OFFSETS

A B 48 36 18 12

3

4

/8 163/8

91/2 251/4 1

1

12

/2 303/8 1

3

14

/8 34 2

5

17

/8 391/4 11

1

21

/2 46 1

3

22

/4 481/8 12

3

26

/8 547/8 1

3

26

/8 60 1 1

3

31

/4 633/4 11

3

34

/4 69 1 1

5

38

/8 755/8 2

397/8777/

433/

4 84

463/

4 87

487/

8 93

8 111

1

/2 11

3

/4 21

3

/8 2

Figure 21

FINISHING YOUR CHIMNEY SYSTEM

10 FOOT RULE

All chimney termination must extend a minimum of 3 feet

above the highest point where it passes through the roof and

must be at least 2 feet above the roof within a 10 foot horizontal

span (see Figure 22).

Figure 22

IMPORTANT: If an exposed portion of chimney is greater than 4

feet above the roof line, use support wires to keep chimney secure.

The support wires may be attached to the outer pipe of the chimney

with screws, provided the screws do not penetrate the inner flue pipe.

Maximum length of pipe between supports is 6 feet of angled run.

A maximum of two 6 foot angled run sections per chimney system

(see Figure 21).

55505

9

VSC-10

FLASHING

VFS-10DM

VRTL-10D

MINIMUM

HEIGHT

15 FT.

VRTL-10D

VFS-10DM

VETL-10D

MAXIMUM

HEIGHT

CHASE

TERMINATION

50 FT.

MAXIMUM CHIMNEY HEIGHT

The maximum height approved for any chimney run with this

firebox system is 50 feet measured from bottom of firebox to flue

outlet-end of pipe.

CHIMNEY MAINTENANCE

Have your chimney system cleaned and inspected regularly to

ensure safe and efficient operation. Refer to your Owner's

Manual for further guidelines on maintenance and operation.

Using Figure 24 and the chart below, determine the opening that will

be required for the pitch of your particular roof.

19" MIN.

(482.6mm)

2" MIN.

(50.8mm)

2" MIN.

(50.8mm)

2" MIN.

(50.8mm)

30" MIN.

(762mm)

V30FS-10DM

V30E-10DM

Figure 23

MINIMUM CHIMNEY HEIGHT

The minimum chimney height (measured from bottom of firebox to

flue gas outlet-end of pipe) is 15 feet for a straight run, 16 feet min.

for a run with 1 elbow set (a set consists of one starter elbow and one

return elbow).

Uncommon circumstances such as neighboring hills, tall trees, or

strong wind areas can cause downdrafts in the chimney system. In

such cases going beyond the minimum recommended height would

be preferable to provide a better draw.

OPENING

"A"

Figure 24

ROOF OPENING CHART

PITCH OPENING "A" USE FLASHING NO.

FLAT 19 V6F10

6/12 23

(26.6 DEG. SLOPE)

12/12 30

(45 DEG. SLOPE)

Before cutting hole, temporarily remove shingles around area to be

opened. After preparing the opening on the roof, continue to add

sections of pipe until it extends a minimum of 30 inches above

highest point of roof cutout (see Figure 24).

With the termination the minimum height should add up 3 feet (see

10-Foot Rule and Figure 22).

1

/4 V6F10

3

/4 V12F10

10

55505

FLASHING INSTALLATION

30" MIN.

30" MIN.

18" MIN. TYP.

Determine the flashing to be used with the roof-opening chart. Slide

flashing over pipe until base is flat against roof. Replace as many

shingles as needed to cover exposed area and flashing base. Secure

in position by nailing through shingles.

DO NOT NAIL THROUGH FLASHING CONE.

The terminations approved for this firebox are VRTL-10D which can

be used for flashing or chase and VETL-10D for chase style termination only. Figure 27 shows an VRTL-10D round top termination.

STAINLESS

INNER FLUE

PIPE

VRTL-10D

CHIMNEY PIPE

OVERLAP

SHINGLES

TOP AND

SIDES ONLY

FLASHING

NAIL ONLY

OUTER

PERIMETER

OF FLASHING

Figure 25

STORM

COLLAR

UNDERLAP

SHINGLES

AT BOTTOM

STORM COLLAR INSTALLATION

Place storm collar over pipe and slide down until snug against the

open edge of the flashing (see Figure 26).

CHIMNEY

PIPE

SECURE

TERMINATION

TO OUTER

PIPE WITH

(3) SCREWS

APPL Y WA TERPR OOF

OVERLAP

SHINGLES

(TOP AND

SIDES OF

FLASHING BASE)

CAULKING

STORM COLLAR

FLASHING

UNDERLAP

SHINGLES

Figure 27

CAUTION: DO NOT SEAL OPENINGS ON THE ROOFTOP FLASHING. FOLLOW THE INSTALLATION INSTRUCTIONS PROVIDED WITH THE TERMINATION

BEING USED.

CHASE INSTALLATIONS

Instructions for chase installations are included with the chase style

termination chosen although it is worthy to mention here that in a

multiple chase installation, provide adequate distance between terminations or smoke spillage from one termination to another may

occur. We suggest they be separated at least 30" center to center and

stacked at a vertical height difference of 18" vertically from one

termination to the other (see Figure 28).

Figure 26

Apply waterproof caulking to all seams and notched around storm

collar and also at base around shingles.

TERMINATIONS

The firebox system must be terminated with the listed round top or

chase terminations, In any case, refer to the installation instructions

supplied with the termination.

55505

Figure 28

11

FINISHING YOUR FIREBOX

CABINET DOOR INSTALLATION

Brushed brass glass doors have been provided with this firebox. A set

includes the front glass panel assembly. They come in different

styles, check with your local distributor for availability and options.

To install doors and front panel, simply insert top door pin(s) up into

hole(s) on top frame, and insert bottom pin (D) into hole (S) on

bottom frame until door is fully seated.

No alignments or adjustments are necessary (see Figure 29).

TOP SLOT

UNDERNEATH

FRAME

ADJUSTMENT

CLIP

BOTTOM PIN

SHORT PIVOT PIN

BOTTOM SLOT

Use only heat resistant, noncombustible mortar or adhesive when

securing facing material to the front of the firebox.

When placing facing at the upper edge of the effective opening of the

firebox, provide an "L" shaped piece of metal extending the full

width of the opening.

Secure with sheet metal screws at a distance high enough from the

edge as to not interfere with the operation of doors. This assures that

the facing material, in time, should not block the opening if it were

to lose cohesion.

FLASHING MANTELS

Mantels, combustible or noncombustible, may be constructed (see

Figure 31), as long as the proper clearances are observed (refer to

page 4 for clearance).

ADJUSTMENT CLIP

Figure 29

FIREBOX FACING

Any noncombustible material may be used for facing (glass, title,

brick, etc.) as long as the proper clearances are adhered to (refer to

section on clearances) and the firebox opening are not blocked or

obstructed in any way (see Figure 30).

NONCOMBUSTIBLE

FACING MATERIAL

DO NOT

BLOCK

EFFECTIVE

"L" SHAPED

METAL SUPPORT

NONCOMBUSTIBLE

FACING MATERIAL

OPENING

Figure 31

Figure 30

12

55505

OPERATING GUIDELINES AND MAINTENANCE

INSTRUCTIONS

GLASS DOORS

Only the cabinet type doors can be opened, the front glass panel

assembly is stationary and must be installed with doors.

When firebox is in operation, both sets of cabinet doors on each side

of firebox, must be in the FULLY OPEN or FULLY CLOSED

position only or a fire hazard may be created (see Figure 32).

CABINET DOORS MUST EITHER BE FULLY OPEN (AS SHOWN)

OR FULLY CLOSED WHEN FIREPLACE IS IN OPERATION

SIDE PANEL IS

STATIONARY

CABINET GLASS

DOOR (TYP. OF 4)

Figure 32

DAMPER MECHANISM

The damper control lever is located inside the fire chamber (see

Figure 33). Make sure lever is cool before handling. Pull down to

CLOSE, push up to OPEN. The damper must be open when lighting

a fire; not doing so will cause smoke spillage into the room.

When the firebox is not in use, close the damper to prevent downdrafts

from entering room.

The damper mechanism should be per the following figure.

OUTSIDE AIR MECHANISM

The outside air handle is located at the right hand side of the firebox

rear refractor (Figure 33). Pull to close, push to open, Always open

the mechanism when starting a fire, this provides adequate outside

combustion air. Close the mechanism when not in use to prevent cold

air from entering the room.

Periodically check your outside air intake vent hood for any possible

obstructions (snow, bushes, etc.).

OUTSIDE AIR

GRATE

Figure 33

DAMPER CONTROL LEVER

PULL DOWN TO CLOSE

PUSH UP TO OPEN

HANDLE

PULL TO CLOSE

PUSH TO OPEN

GRATE

The grate is designed to provide you with the maximum solid fuel

capacity, do not attempt to defeat its purpose, doing so may cause

smoke spillage and may cause a fire hazard.

Do not overload the grate or obstruct the required air space beneath

it. Always keep ashes from building up under the grate.

WARNING: RISK OF FIRE! REPLACE GRATE WITH

VANGUARD MODEL 36PNGR GRATE ONLY.

Never obstruct the flow of combustion and ventilation air.

Keep the front of the firebox clear of all obstacles and

materials.

WARNING: CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH SURFACE

TEMPERATURES AND TO STAY AWAY FROM THESE

TO AVOID BURNS OR CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM AS

THE FIREBOX.

FOR FURTHER OPERATING GUIDELINES, INSTRUCTIONS AND WARRANTY INFORMATION PLEASE REFER TO YOUR OWNER'S MANUAL OR CONTACT YOUR

AUTHORIZED DEALER.

55505

13

REPLACEMENT AND ACCESSORY PARTS

Purchase replacement parts or accessories from your local dealer. If they can not supply these accessories, call DESA International's Parts

Department at 1-800-972-7879 for referral information. You can also write to the address listed on the front cover of this manual. When calling

DESA International, have ready

• model number of your heater

• the replacement part number

NOTE: USE OF ANY OTHER GLASS DOOR ASSEMBLY NOT TESTED WITH THIS FIREPLACE MAY CONSTITUTE A FIRE

HAZARD AND WILL VOID THE DESA INTERNATIONAL WARRANTY.

STORM COLLAR

VSC2-20-10DM (20 PACK)

FLASHING

ROOF PITCH

V6F-10DM - 0 to 6/12

COMES WITH

WIRE SPACER

V12F-10DM - 6/12 to 12/12

RETURN

ELBOW

ROUND TOP TERMINATION

VRTL-10D

ECONO-TOP TERMINATION

VETL-10D

10" CHIMNEY PIPE

ASSEMBLY

(INCLUDES OUTER

AND INNER PIPES)

V12-10DM (12" LONG)

V18-10DM (18" LONG)

V24-10DM (24" LONG)

V36-10DM (36" LONG)

V48-10DM (48" LONG)

EMBER PROTECTORS (5)

ADJUSTABLE HOOD

BLACK - GA6050

POLISHED BRASS - GA6052

ANTIQUE BRASS - GA6053

STARTER

ELBOW

VENT HOOD

ELBOW SET

V30E-10DM

PIPE SUPPORT

ASSEMBLY

V12S-10DM

OUTSIDE AIR KIT VAK4 (900147)

VENT PLASTER

COLLAR

VDGPN36 (Cabinet Doors (2 sets) and end panel (1) - Brushed Brass)

VDPPN36 (Cabinet Doors (2 sets) and end panel (1) - Polished Brass)

VDG36PNFPC (Pyroceramic Fixed Glass Doors - Brushed Brass) Includes one piece of glass only

VDP36PNFPC (Pyroceramic Fixed Glass Doors - Polished Brass) Includes one piece of glass only

VDG36PNFP (Tempered Fixed Glass Doors - Brushed Brass) Includes one piece of glass only

VDP36PNFP (Tempered Fixed Glass Doors - Polished Brass) Includes one piece of glass only

CONNECTOR DUCT - 4" X 3'

FRONT PANEL

ASSEMBLY

VPN36 GLASS DOOR SETS

CABINET DOOR SET

(LEFT & RIGHT)

FIRESTOP SPACERS

VFS-10DM FOR STRAIGHT PIPE

V30FS-10DM FOR ANGLED RUN

GRATE 36PNGR

14

55505

Loading...

Loading...