VENT-FREE GAS HEATER

For more information, visit www.desatech.com

For more information, visit www.desatech.com

VN600BA, VP600BA

VN1000BT A, VP1000BTA

VN10A, VP10A

VN10T A, VP10T A

VN6D, VP5D

TM

OWNER’S OPERATION AND

INSTALLATION MANUAL

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing property damage, personal injury, or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

This appliance may be installed in an aftermarket*, permanently located, manufactured (mobile)

home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance

is not convertible for use with other gases.

*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this manual for correct

installation and operational procedures. For assistance or additional information consult a

qualified installer, service

agency, or the gas supplier.

WARNING: This is an unvented

gas-fired heater. It uses air (oxygen) from the room in which it is

installed. Provisions for adequate

combustion and ventilation air

must be provided. Refer to

Combustion and Ventilation

page 4 of this manual.

Air For

on

Save this manual for future reference.

Save this manual for future reference.

TABLE OF CONTENTS

SAFETY INFORMATION

2

TABLE OF CONTENTS

SAFETY INFORMATION ............................................................ 2

UNPACKING............................................................................... 3

PRODUCT IDENTIFICATION ..................................................... 3

PRODUCT FEATURES .............................................................. 3

LOCAL CODES........................................................................... 3

AIR FOR COMBUSTION AND VENTILATION ........................... 4

INSTALLATION ........................................................................... 6

OPERATING HEATER.............................................................. 10

INSPECTING BURNER ............................................................ 14

CLEANING AND MAINTENANCE ............................................ 15

TROUBLESHOOTING .............................................................. 16

SAFETY INFORMATION

WARNINGS

IMPORTANT: Read this owner’s manual carefully and

completely before trying to assemble, operate, or service this heater. Improper use of this heater can cause

serious injury or death from burns, fire, explosion,

electrical shock, and carbon monoxide poisoning.

SPECIFICATIONS .................................................................... 19

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST ....... 20

REPLACEMENT PARTS .......................................................... 30

SERVICE HINTS....................................................................... 30

TECHNICAL SERVICE ............................................................. 30

SERVICE PUBLICATIONS ....................................................... 30

ACCESSORY............................................................................ 30

OWNER’S REGISTRATION FORM.......................................... 31

PARTS CENTRALS .................................................................. 33

WARRANTY INFORMATION......................................Back Cover

Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

Do not place clothing or other flammable material on

or near the appliance. Never place any objects on the

heater.

DANGER: Carbon monoxide poisoning may lead

to death!

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble the flu, with headaches, dizziness, or nausea. If

you have these signs, the heater may not be working properly. Get

fresh air at once! Have heater serviced. Some people are more

affected by carbon monoxide than others. These include pregnant

women, persons with heart or lung disease or anemia, those under

the influence of alcohol, and those at high altitudes.

Natural and Propane/LP Gas: Natural and propane/LP gases are

fuel gases. Fuel gases are odorless. An odor-making agent is added

to fuel gases. The odor helps you detect a fuel gas leak. However,

the odor added to fuel gas can fade. Fuel gas may be present even

though no odor exists.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this heater.

WARNING: Any change to this heater or its

controls can be dangerous.

WARNING: Do not use any accessory not ap-

proved for use with this heater.

Surface of heater becomes very hot when running

heater. Keep children and adults away from hot surface to avoid burns or clothing ignition. Heater will

remain hot for a time after shutdown. Allow surface to

cool before touching.

Carefully supervise young children when they are in

the same room with heater.

Make sure grill guard is in place before running

heater.

Keep the appliance area clear and free from combustible materials, gasoline, and other flammable vapors

and liquids.

1. This appliance is only for use with the type of gas indicated on

the rating plate. This appliance is not convertible for use with

other gases.

2. Do not place propane/LP supply tank(s) inside any structure.

Locate propane/LP supply tank(s) outdoors.

3. Do not install 10,000 Btu units in a bathroom.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

SAFETY INFORMATION

UNPACKING

PRODUCT IDENTIFICATION

PRODUCT FEATURES

LOCAL CODES

3

3

SAFETY INFORMATION

Continued

4. If you smell gas

• Shut off gas supply

• Do not try to light any appliance

• Do not touch any electrical switch; do not use any phone in

your building

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions

• If you cannot reach your gas supplier, call the fire department

5. This heater needs fresh, outside air ventilation to run properly.

This heater has an Oxygen Depletion Sensing (ODS) safety

shutoff system. The ODS shuts down the heater if not enough

fresh air is available. See Air for Combustion and Ventilation,

pages 4 through 6.

6. Always run heater with control knob at LOW or HIGH locked

positions (VP10A) or ON position (VP5D). Never set control

knob between locked positions. Poor combustion may result.

7. Keep all air openings in the front and bottom of heater clear and

free of debris. This will insure enough air for proper combustion.

8. If heater shuts off, do not relight until you provide fresh, outside air. If heater keeps shutting off, have it serviced.

9. Do not run heater

• where flammable liquids or vapors are used or stored

• under dusty conditions

10. Before using furniture polish, wax, carpet cleaner, or similar

products, turn heater off. If heated, the vapors from these products may create a white powder residue within burner box or

on adjacent walls or furniture.

11. Do not use heater if any part has been under water. Immediately call a qualified service technician to inspect the room

heater and to replace any part of the control system and any

gas control which has been under water.

12. Turn off heater and let cool before servicing. Only a qualified

service person should service and repair heater.

13. Operating heater above elevations of 4,500 feet could cause

pilot outage.

14. T o prevent performance problems, do not use propane/LP fuel

tank of less than 100 lbs. capacity.

15. Provide adequate clearances around air openings.

UNPACKING

1. Remove heater from carton.

2. Remove all protective packaging applied to heater for shipment.

3. Check heater for any shipping damage. If heater is damaged,

promptly inform dealer where you bought heater.

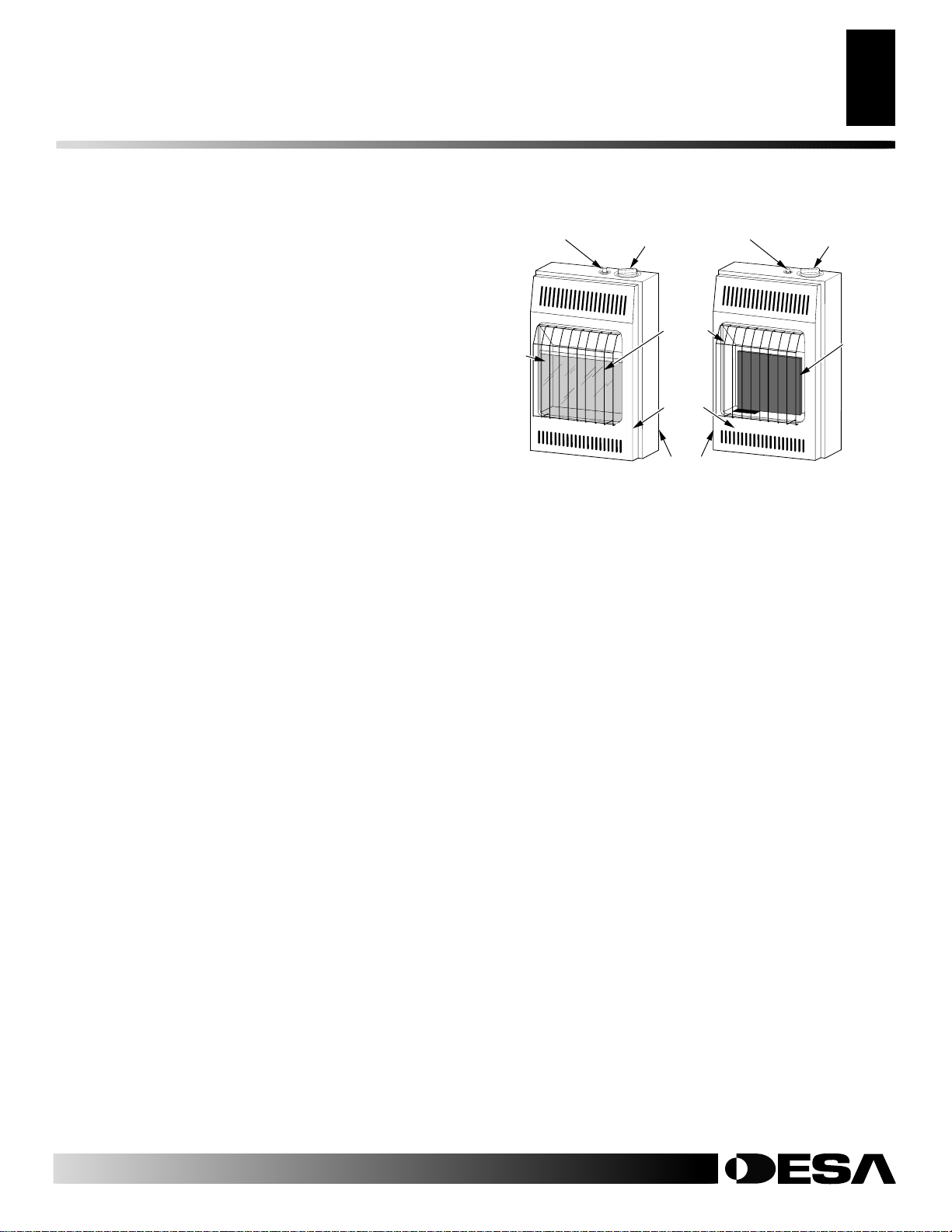

PRODUCT IDENTIFICATION

Piezo Ignitor

Button

Glass

Panel

Blue Flame Heater

Figure 1 - Vent-Free Gas Heater

Control Knob

Grill

Guard

Front

Panel

Heater

Cabinet

Piezo Ignitor

Button

Infrared Heater

Control Knob

Burners

PRODUCT FEATURES

SAFETY DEVICE

This heater has a pilot with an Oxygen Depletion Sensing (ODS)

safety shutoff system. The ODS/pilot is a required feature for ventfree room heaters. The ODS/pilot shuts off the heater if there is not

enough fresh air.

PIEZO IGNITION SYSTEM

This heater has a piezo ignitor. This system requires no matches,

batteries, or other sources to light heater.

LOCAL CODES

Install and use heater with care. Follow all local codes. In the absence

of local codes, use the latest edition of National Fuel Gas Code ANSI

Z223.1/NFPA 54*.

*Available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

110720-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

AIR FOR COMBUSTION AND VENTILATION

4

Providing Adequate Ventilation

Determining Fresh-Air Flow For Heater Location

AIR FOR COMBUSTION AND

VENTILATION

WARNING: This heater shall not be installed in a

confined space or unusually tight construction unless provisions are provided for adequate combustion and ventilation air. Read the following instructions to insure proper fresh air for this and other fuelburning appliances in your home.

Today’s homes are built more energy efficient than ever. New

materials, increased insulation, and new construction methods help

reduce heat loss in homes. Home owners weather strip and caulk

around windows and doors to keep the cold air out and the warm air

in. During heating months, home owners want their homes as

airtight as possible.

While it is good to make your home energy efficient, your home

needs to breathe. Fresh air must enter your home. All fuel-burning

appliances need fresh air for proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers, and fuel burning appliances

draw air from the house to operate. You must provide adequate fresh

air for these appliances. This will insure proper venting of vented

fuel-burning appliances.

PROVIDING ADEQUATE VENTILATION

The following are excerpts from National Fuel Gas Code, ANSI

Z223.1/NFPA 54, Section 5.3, Air for Combustion and Ventilation.

All spaces in homes fall into one of the three following ventilation

classifications:

1. Unusually Tight Construction

2. Unconfined Space

3. Confined Space

The information on pages 4 through 6 will help you classify your

space and provide adequate ventilation.

Unusually Tight Construction

The air that leaks around doors and windows may provide enough

fresh air for combustion and ventilation. However, in buildings of

unusually tight construction, you must provide additional fresh air.

Unusually tight construction is defined as construction

where:

a. walls and ceilings e xposed to the outside atmosphere

have a continuous water vapor retarder with a rating

of one perm (6 x 10

openings gasketed or sealed

b. weather stripping has been added on openable win-

dows and doors

-11

kg per pa-sec-m2) or less with

and

and

c. caulking or sealants are applied to areas such as

joints around window and door frames, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical,

and gas lines, and at other openings.

If your home meets all of the three criteria above, you

must provide additional fresh air. See

From Outdoors

, page 6

.

Ventilation Air

If your home does not meet all of the three criteria above,

proceed to

tion,

Determining Fresh-Air Flow For Heater Loca-

page 5.

Confined and Unconfined Space

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 defines a

confined space as a space whose volume is less than 50 cubic feet

per 1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating

of all appliances installed in that space and an unconfined space as

a space whose volume is not less than 50 cubic feet per 1,000 Btu per

hour (4.8 m3 per kw) of the aggregate input rating of all appliances

installed in that space. Rooms communicating directly with the

space in which the appliances are installed*, through openings not

furnished with doors, are considered a part of the unconfined space.

* Adjoining rooms are communicating only if there are doorless

passageways or ventilation grills between them.

DETERMINING FRESH-AIR FLOW FOR

HEATER LOCATION

Determining if You Have a Confined or

Unconfined Space

Use this work sheet to determine if you have a confined or unconfined space.

Space: Includes the room in which you will install heater plus any adjoining

rooms with doorless passageways or ventilation grills between the rooms.

1. Determine the volume of the space (length x width x height).

Length x Width x Height =___________ cu. ft. (volume of space)

Example:

height) = 3168 cu. ft. (volume of space)

If additional ventilation to adjoining room is supplied with grills or open-

ings, add the volume of these rooms to the total volume of the space.

2. Multiply the space volume by 20 to determine the maximum Btu/Hr

the space can support.

__________ (volume of space) x 20 = (Maximum Btu/Hr the space

Example:

Btu/Hr the space can support)

Space size 22 ft. (length) x 18 ft. (width) x 8 ft. (ceiling

can support)

2560 cu. ft. (volume of space) x 20 = 51,200 (maximum

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

Determining Fresh-Air Flow For Heater Location (Cont.)

AIR FOR COMBUSTION AND VENTILATION

Ventilation Air

5

5

AIR FOR COMBUSTION AND

VENTILATION

Continued

3. Add the Btu/Hr of all fuel burning appliances in the space.

Vent-free heater _____________ Btu/Hr

Gas water heater* _____________ Btu/Hr

Gas furnace _____________ Btu/Hr

Vented gas heater _____________ Btu/Hr

Gas fireplace logs _____________ Btu/Hr

Other gas appliances* + _____________ Btu/Hr

Total = _____________ Btu/Hr

* Do not include direct-vent gas appliances. Direct-vent draws combustion air from the outdoors and vents to the outdoors.

Example:

Gas water heater _____________ Btu/Hr

Vent-free heater + _____________ Btu/Hr

Total = _____________ Btu/Hr

4. Compare the maximum Btu/Hr the space can support with the actual

amount of Btu/Hr used.

__________________ Btu/Hr (maximum the space can support)

__________________ Btu/Hr (actual amount of Btu/Hr used)

Example:

51,200 Btu/Hr (maximum the space can support)

50,000 Btu/Hr (actual amount of Btu/Hr used)

The space in the above example is a confined space because the actual Btu/

Hr used is more than the maximum Btu/Hr the space can support. You must

provide additional fresh air. Your options are as follows:

A. Rework worksheet, adding the space of an adjoining room. If the ex-

tra space provides an unconfined space, remove door to adjoining

room or add ventilation grills between rooms. See V entilation Air Fr om

Inside Building.

B. Vent room directly to the outdoors. See Ventilation Air From

Outdoors.

C. Install a lower Btu/Hr heater, if lower Btu/Hr size makes room un-

confined.

If the actual Btu/Hr used is less than the maximum Btu/Hr the space can

support, the space is an unconfined space. You will need no additional fresh

air ventilation.

WARNING: If the area in which the heater may be

operated is smaller than that defined as an unconfined space or if the building is of unusually tight

construction, provide adequate combustion and ventilation air by one of the methods described in the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, Section 5.3

or applicable local codes.

40,000

10,000

50,000

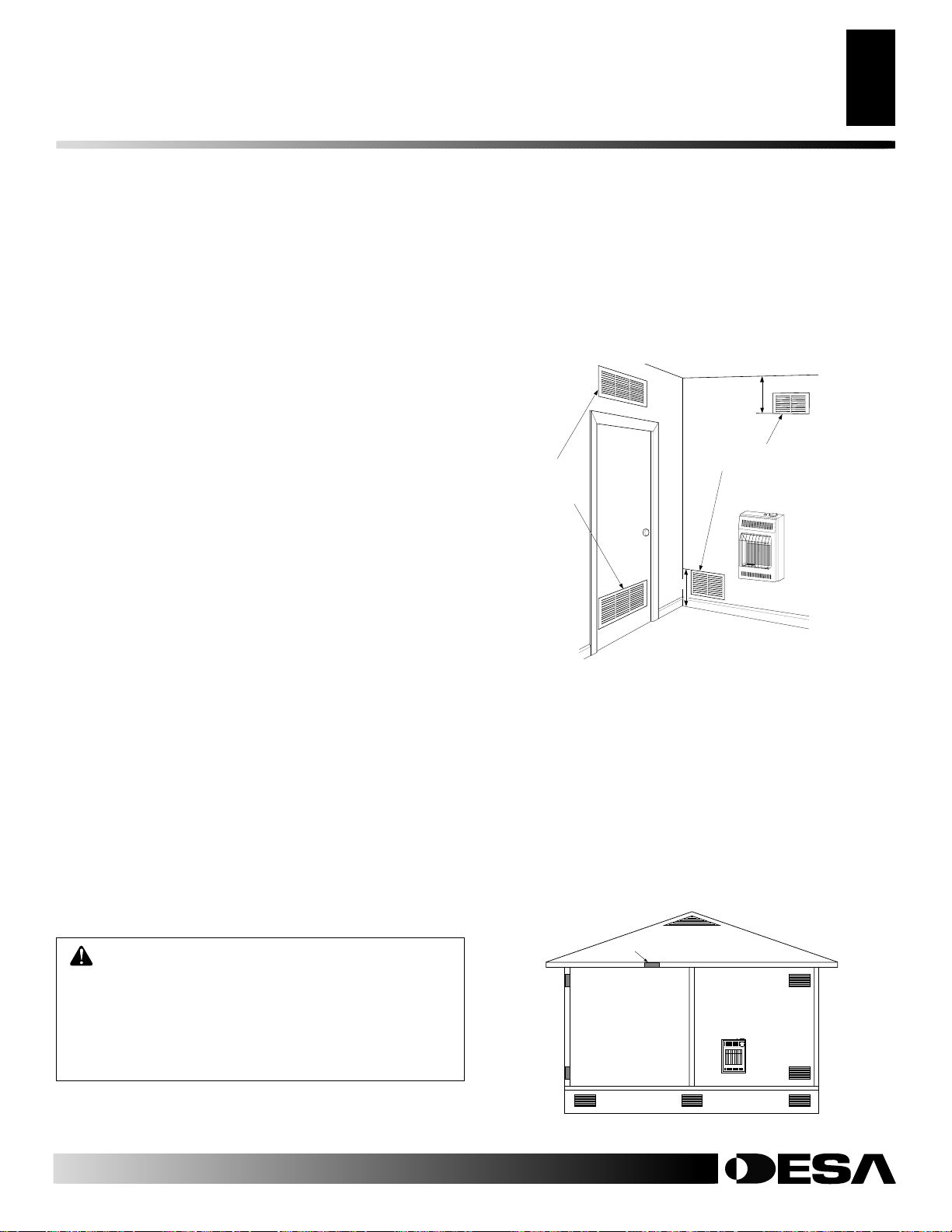

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining unconfined space.

When ventilating to an adjoining unconfined space, you must

provide two permanent openings: one within 12" of the ceiling and

one within 12" of the floor on the wall connecting the two spaces

(see options 1 and 2, Figure 2). You can also remove door into

adjoining room (see option 3, Figure 2). Follow the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Section 5.3, Air for Combustion

and Ventilation for required size of ventilation grills or ducts.

12"

Ventilation Grills

Ventilation

Grills

into Adjoining

Room,

Option 1

Or

Remove

Door into

Adjoining

Room,

Option 3

Figure 2 - Ventilation Air from Inside Building

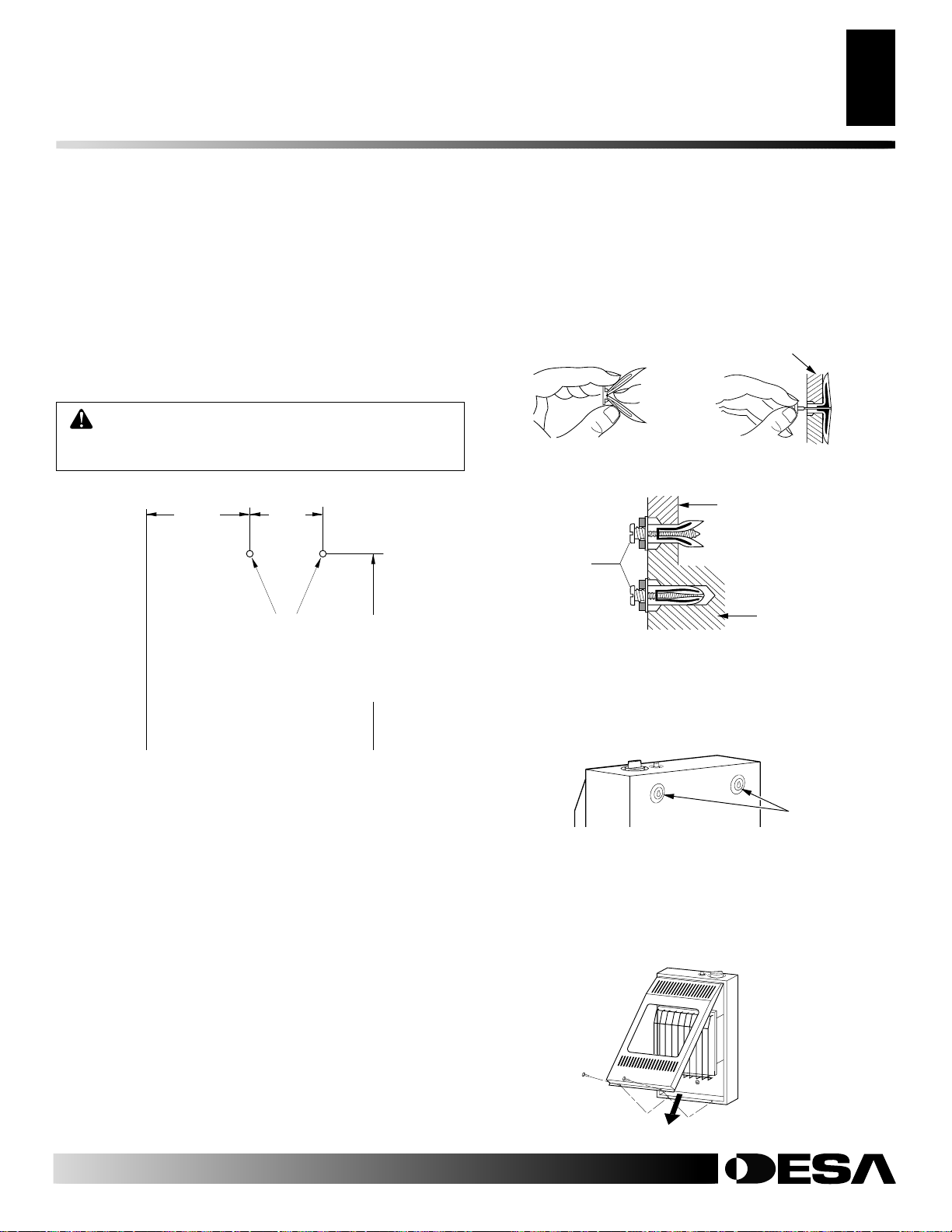

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills or ducts. You must

provide two permanent openings: one within 12" of the ceiling and

one within 12" of the floor. Connect these items directly to the

outdoors or spaces open to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel Gas Code, ANSI Z223.1/

NFPA 54, Section 5.3, Air for Combustion and Ventilation for

required size of ventilation grills or ducts.

IMPORTANT:

attic if attic has a thermostat-controlled power vent. Heated air

entering the attic will activate the power vent.

Outlet

Air

Do not provide openings for inlet or outlet air into

Outlet

Air

Inlet

Air

Inlet Air

Into Adjoining Room,

12"

Ventilated

Attic

Option 2

Ventilated

Crawl Space

To Attic

To

Crawl

Space

110720-01C

Figure 3 - Ventilation Air from Outdoors

For more information, visit www.desatech.com

For more information, visit www.desatech.com

T

INSTALLATION

6

Check Gas Type

Installation Items

Locating Heater

INSTALLATION

NOTICE: This heater is intended for use as supplemental heat. Use this heater along with your primary

heating system. Do not install this heater as your

primary heat source. If you have a central heating

system, you may run system’s circulating blower

while using heater. This will help circulate the heat

throughout the house. In the event of a power outage,

you can use this heater as your primary heat source.

WARNING: A qualified service person must in-

stall heater. Follow all local codes.

CHECK GAS TYPE

Use only the correct type of gas (natural or propane/LP). If your gas

supply is not the correct gas type, do not install heater. Call dealer

where you bought heater for proper type heater.

INSTALLATION ITEMS

Before installing heater, make sure you have the items listed below.

• for propane/LP gas, external regulator (supplied by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• ground joint union

• sediment trap

• tee joint

• pipe wrench

• for natural gas, test gauge connection*

* A CSA design-certified equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge connection. Purchase

the optional CSA design-certified equipment shutoff valve from

your dealer. See Accessory, page 30.

WARNING: Never install the heater

• in a bathroom (10,000 Btu/hr only. 6,000 Btu/hr models are allowed in a bathroom. Check local codes.)

• in a recreational vehicle

• where curtains, furniture, clothing, or other flam-

mable objects are less than 36 inches from the

front, top, or sides of the heater

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

CAUTION: This heater creates warm air currents.

These currents move heat to wall surfaces next to

heater. Installing heater next to vinyl or cloth wall

coverings or operating heater where impurities (such

as, but not limited to, tobacco smoke, aromatic

candles, cleaning fluids, oil or kerosene lamps, etc.)

in the air exist, may discolor walls or cause odors.

IMPORTANT:

Vent-free heaters add moisture to the air. Although this is beneficial, installing heater in rooms without enough

ventilation air may cause mildew to form from too much moisture.

See Air for Combustion and Ventilation, pages 4 through 6.

CAUTION: If you install the heater in a home

garage

• heater pilot and burner must be at least 18 inches

above floor

• locate heater where moving vehicle will not hit it

For convenience and efficiency, install heater

• where there is easy access for operation, inspection, and service

• in coldest part of room

CEILING

LOCATING HEATER

This heater is designed to be mounted on a wall.

WARNING: Maintain the minimum clearances

shown in Figure 4. If you can, provide greater clearances from floor, ceiling, and joining wall.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

6" Blueflame

8" Plaque

Minimum

From

Sides Of

Heater

Left

Side

Figure 4 - Mounting Clearances As Viewed From Front of Heater

36"

Minimum

Right

Side

3"

Minimum To

Minimum To Top

Of Carpeting,

Surface Of Carpeting,

Tile Or Other

Combustible Material

110720-01C

INSTALLATION

Continued

Thermostat Sensing Bulb (Thermostat Models Only)

INSTALLATION

Installing Heater To Wall

7

7

THERMOSTAT SENSING BULB (Thermostat

Models Only)

The thermostat sensing bulb is located inside the heater. Do not

move this bulb during installation or operation of the heater.

INSTALLING HEATER TO WALL

Marking Screw Locations

1. Determine where you will locate heater.

WARNING: Maintain minimum clearances shown

in Figure 5. If you can, provide greater clearances

from floor and joining wall.

2. Mark two mounting screw locations on wall (see Figure 5).

3

/4"

Mounting

Screw

Locations

FLOOR

7

1

20

/4"

Minimum To

Maintain 3"

Clearance

From Floor

8 7/8"

Blue Flame

7

/8" Plaque

10

Minimum To

Maintain 6"

Clearance

From Wall

JOINING WALL

Figure 5 - Mounting Screw Locations

4. For thin walls (1/2" or less), insert red key into wall anchor.

Push red key to “pop” open anchor wings (see Figure 7).

IMPORTANT:

Do not hammer key! For thick walls (over 1/2"

thick) or solid walls, do not pop open wings.

5. Tighten two screws until 1/16" space (thickness of penny) is

between screwheads and wall (see Figure 8).

Thin Walls (1/4" to 1/2" thick)

Figure 6 - Folding Anchor

1/16"

Space

Figure 8 - Tightening Anchors

Figure 7 - Popping Open Anchor

Wings For Thin Walls

Thin or

Thick Wall

(thick wall

shown)

Solid

Wall

Placing Heater On Mounting Screws

1. Locate two keyhole slots on back panel of heater (see Figure 9).

2. Place large openings of slots over screwheads. Slide heater

down until screws are in small portion of slots.

Installing Two Mounting Screws

Note:

Wall anchors and mounting screws are in hardware package.

The hardware package is provided with heater.

Attaching to wall stud method

For attaching mounting screw to wall stud

1. Drill hole at marked location using 9/64" drill bit.

2. Insert mounting screw into wall stud.

3. Tighten screw until 1/16" space (thickness of penny) is between screwhead and wall.

Attaching to wall anchor method

Follow instructions below to attach mounting screws to hollow walls

(wall areas between studs) or solid walls (concrete or masonry).

1. Drill holes at marked locations using 5/16" drill bit. For solid

walls (concrete or masonry), drill at least 1 1/4" deep.

2. Fold wall anchor (see Figure 6).

3. Insert wall anchor (wings first) into hole. Tap anchor flush to wall.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

Keyhole Slots

Figure 9 - Location Of Keyhole Slots On Back Panel Of Heater

Removing Front Panel Of Heater

1. Remove two screws near bottom corners of front panel.

2. Lift straight up on grill guard until it stops. Grill guard will slide

up about 1/4".

3. Pull bottom of front panel forward, then down.

Figure 10 - Removing Front Panel Of Heater

INSTALLATION

8

Installing Heater To Wall (Cont.)

Connecting To Gas Supply

INSTALLATION

Continued

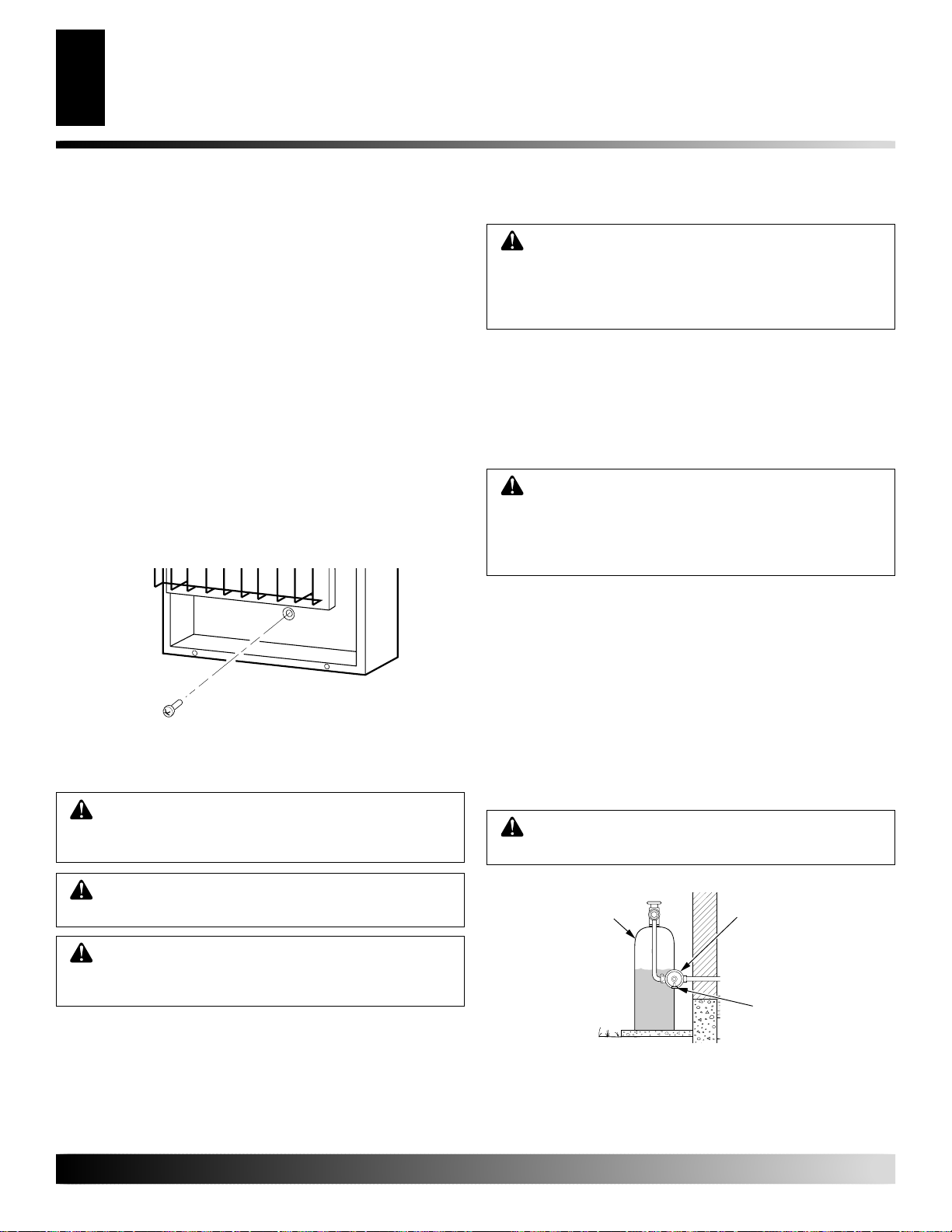

Installing Bottom Mounting Screw

1. Locate bottom mounting hole. This hole is near bottom on back

panel of heater (see Figure 11).

2. Mark screw location on wall.

3. Remove heater from wall.

4. If installing bottom mounting screw into hollow or solid wall,

install wall anchor. Follow steps 1 through 5 under Attaching To

W all Anchor Method, page 7. If installing bottom mounting screw

into wall stud, drill hole at marked location using 9/64" drill bit.

5. Replace heater on wall.

6. Insert bottom anchor screw through back panel into bottom

anchor or drilled hole (see Figure 11).

7. Tighten screw until heater is firmly secured to wall. Do not

over tighten.

Note:

Do not replace front panel at this time. Replace front

panel after making gas connections and checking for leaks (see

pages 8 through 10).

Figure 11 - Installing Bottom Mounting Screw

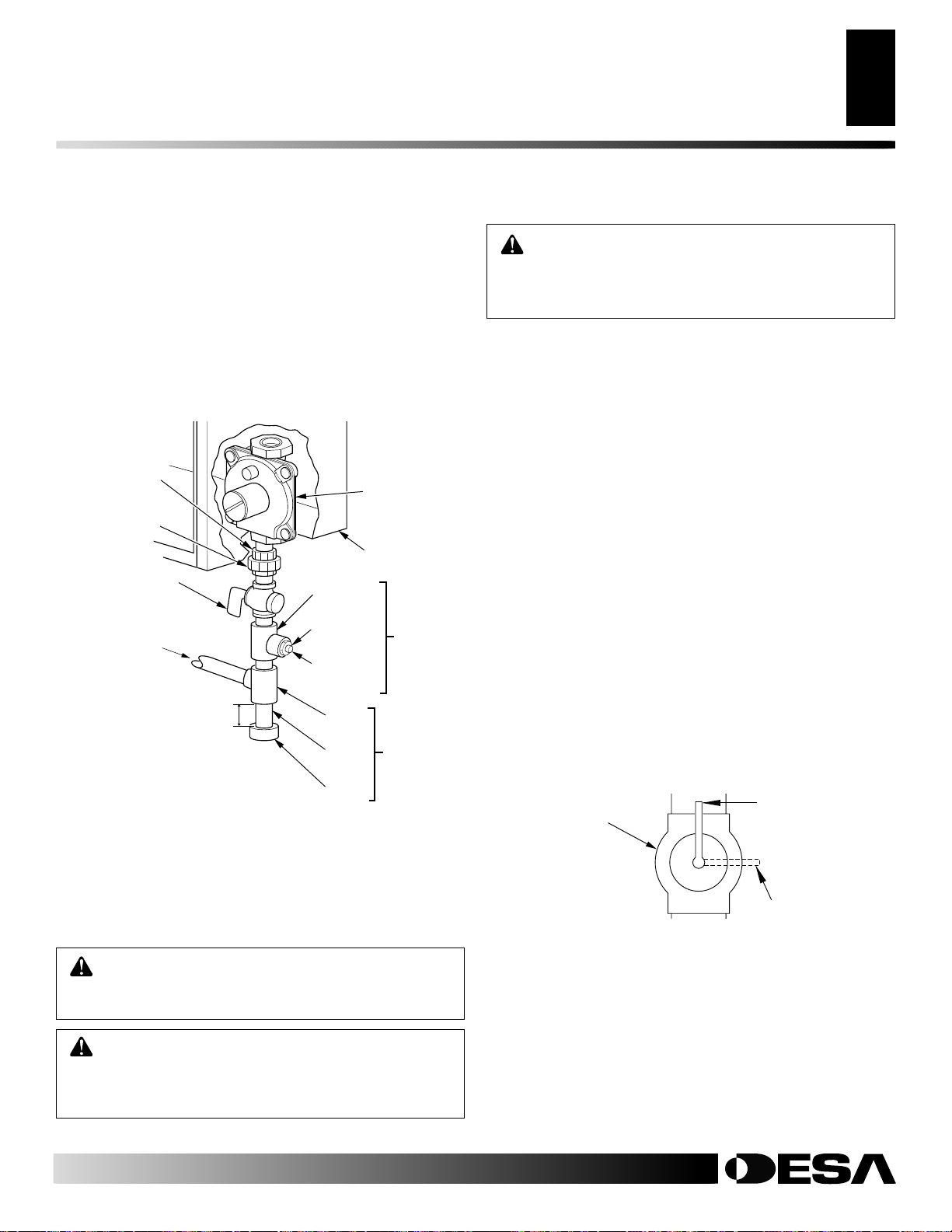

CONNECTING TO GAS SUPPLY

WARNING: This appliance requires a 3/8" NPT

(National Pipe Thread) inlet connection to the pressure regulator.

CAUTION: For propane/LP gas, never connect

heater directly to the propane/LP supply. This heater

requires an external regulator (not supplied). Install

the external regulator between the heater and propane/LP supply.

For propane/LP gas, the installer must supply an external regulator.

The external regulator will reduce incoming gas pressure. You must

reduce incoming gas pressure to between 11 and 14 inches of water.

If you do not reduce incoming gas pressure, heater regulator damage

could occur. Install external regulator with the vent pointing down

as shown in Figure 12. Pointing the vent down protects it from

freezing rain or sleet.

CAUTION: Use only new, black iron or steel pipe.

Internally-tinned copper tubing may be used in certain areas. Check your local codes. Use pipe of large

enough diameter to allow proper gas volume to heater.

If pipe is too small, undue loss of volume will occur.

Installation must include equipment shutoff valve, union, and plugged

1/8" NPT tap. Locate NPT tap within reach for test gauge hook up.

NPT tap must be upstream from heater (see Figure 13, page 9).

IMPORTANT:

location. The equipment shutoff valve is for turning on or shutting

off the gas to the appliance.

Check your building codes for any special requirements for locating

equipment shutoff valve to fireplaces.

Apply pipe joint sealant lightly to male NPT threads. This will

prevent excess sealant from going into pipe. Excess sealant in pipe

could result in clogged heater valves.

WARNING: Use pipe joint sealant that is resistant

to liquid petroleum (LP) gas.

Install an equipment shutoff valve in an accessible

WARNING: A qualified service person must con-

nect heater to gas supply. Follow all local codes.

WARNING: For natural gas, never connect heater to

private (non-utility) gas wells. This gas is commonly

known as wellhead gas.

IMPORTANT

connecting heater to gas line. Gas line pressure must be no greater than

14 inches of water. If gas line pressure is higher, heater regulator

damage could occur.

: For natural gas, check gas line pressure before

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Propane/LP

Supply Tank

Figure 12 - External Regulator With Vent Pointing Down

(propane/LP systems only)

External Regulator

Vent Pointing Down

110720-01C

ON

POSITIO

OF

POSI

INSTALLATION

Continued

We recommend that you install sediment trap in supply line as

shown in Figure 13. Locate sediment trap where it is within reach for

cleaning. Install in piping system between fuel supply and heater.

Locate sediment trap where trapped matter is not likely to freeze. A

sediment trap traps moisture and contaminants. This keeps them

from going into heater controls. If sediment trap is not installed or

is installed wrong, heater may not run properly.

IMPORTANT:

necting it to gas piping and/or fittings. Do not over tighten pipe

connection to regulator. The regulator body could be damaged.

3/8" NPT

Pipe Nipple

Ground

Joint Union

Equipment

Shutoff Valve*

Natural Gas

From Gas Meter

(4" W.C. to 10.5"

W.C. Pressure)

Propane/LP

From External

Regulator

(11" W.C. to 14"

W.C. Pressure)

Figure 13 - Gas Connection

* A CSA design-certified equipment shutoff valve with 1/8" NPT

tap is an acceptable alternative to test gauge connection. Purchase

the optional CSA design-certified equipment shutoff valve from

your dealer. See Accessory, page 30.

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping and connections

for leaks after installing or servicing. Correct all leaks

at once.

Hold pressure regulator with wrench when con-

Pressure

Regulator

Heater

Cabinet

Tee Joint

3"

Minimum

Reducer

Bushing to

1/8" NPT

1/8" NPT

Plug Tap

Tee

Joint

Pipe

Nipple

Cap

Test

Gauge

Connection*

Sediment

Trap

Connecting To Gas Supply (Cont.)

INSTALLATION

Checking Gas Connections

9

9

CAUTION: For propane/LP gas, make sure external regulator has been installed between propane/LP

supply and heater. See guidelines under

to Gas Supply

, page 8.

Connecting

Pressure Testing Gas Supply Piping System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1. Disconnect appliance with its appliance main gas valve (control

valve) and equipment shutoff valve from gas supply piping system. Pressures in excess of 1/2 psig will damage heater regulator.

2. Cap off open end of gas pipe where equipment shutoff valve

was connected.

3. Pressurize supply piping system by either opening propane/LP

supply tank valve for propane/LP gas or opening main gas valve

located on or near gas meter for natural gas, or using compressed air.

4. Check all joints of gas supply piping system. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming

show a leak.

5. Correct all leaks at once.

6. Reconnect heater and equipment shutoff valve to gas supply.

Check reconnected fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 14).

2. Pressurize supply piping system by either opening propane/LP

supply tank valve for propane/LP gas or opening main gas

valve located on or near gas meter for natural gas, or using

compressed air.

Equipment

Shutoff Valve

Figure 14 - Equipment Shutoff Valve

Open

Closed

WARNING: Never use an open flame to check for

a leak. Apply a noncorrosive leak detection fluid to all

joints. Bubbles forming show a leak. Correct all leaks

at once.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

10

INSTALLATION

Checking Gas Connections (Cont.)

OPERATING HEATER (Manual Control Blue Flame Models)

For Your Safety Read Before Lighting

Lighting Instructions

INSTALLATION

Continued

3. Check all joints from gas meter for natural or propane/LP

supply to equipment shutoff valve (see Figure 17 or 18).

Apply a noncorrosive leak detection fluid to all joints. Bubbles

forming show a leak.

4. Correct all leaks at once.

Pressure Testing Heater Gas Connections

1. Open equipment shutoff valve (see Figure 14, page 9).

2. Open main gas valve located on or near gas meter for natural

gas or open propane/LP supply tank valve.

3. Make sure control knob of heater is in the OFF position.

4. Check all joints from equipment shutoff valve to control valve

(see Figures 15 and 16). Apply a noncorrosive leak detection

fluid to all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6. Light heater (see Operating Heater pages 10 through 14).

Check the rest of the internal joints for leaks.

7. Turn off heater (see To Turn Off Gas to Appliance, pages 11,

12 or 14, depending on your model).

8. Replace front panel.

Control Valve Location

Gas

Meter

Equipment

Shutoff Valve

OPERATING HEATER

MANUAL CONTROL

BLUE FLAME MODELS

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance ar ea

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, don’t try to repair it, call a qualified service technician or gas supplier. Force or attempted repair may result

in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

Figure 15 - Checking Gas Joints for Natural Gas

Propane/LP

Supply Tank

Figure 16 - Checking Gas Joints for Propane/LP Gas

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Control

Valve Location

Equipment

Shutoff Valve

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information above.

2. Make sure equipment shutoff valve is fully open.

3. Turn control knob clockwise

4. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B” in the safety information, above. If y ou don’t smell

gas, go to the next step.

5. Press in control knob and turn counterclockwise

to the PILOT position. Keep control knob pressed in for

five (5) seconds (see Figure 17, page 11).

Note:

You may be running this heater for the first time

after hooking up to gas supply . If so, the control knob may

need to be pressed in for 30 seconds or more. This will allow air to bleed from the gas system.

• If control knob does not pop up when released, contact a

qualified service person or gas supplier for repairs.

to the OFF position.

Clockwise

C-clockwise

110720-01C

OPERATING HEATER

Continued

OPERATING HEATER (Manual Control Blue Flame Models)

Lighting Instructions (Cont.)

To Turn Off Gas To Appliance

Manual Lighting Procedure

OPERATING HEATER (Manual Control Infrared Models)

For Your Safety Read Before Lighting

11

11

6. With control knob pressed in, push do wn and release ignitor button. This will light pilot. The pilot is attached to the

front of burner. If needed, keep pressing ignitor button until

pilot lights.

Note:

If pilot does not stay lit, refer to Troubleshooting,

pages 16 through 18. Also contact a qualified service person or gas supplier for repairs. Until r epairs are made, light

pilot with match. To light pilot with match, see Manual

Lighting Procedure.

7. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

Note:

If pilot goes out, repeat steps 3 through 7.

8. T urn contr ol knob counterclockwise

C-clockwise

to the HIGH

position. The main burner should light. Set control knob

to any heat level between HIGH and LO W . To turn control

knob from HIGH to a lower setting, press in the control

knob and turn counterclockwise

Note:

Both HIGH and LOW ar e locked positions. You must

C-clockwise

.

press in control knob befor e turning it from these positions.

CAUTION: Do not try to adjust heating levels by

using the equipment shutoff valve.

Ignitor Button

Control Knob

PILOT

OFF

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

1. Tur n control knob clockwise

2. Press in control knob and turn clockwise

OFF position.

Clockwise

to the PILOT position.

Clockwise

to the

Shutting Off Burner Only (pilot stays lit)

Turn control knob clockwise

to the PILOT position.

Clockwise

MANUAL LIGHTING

PROCEDURE

1. Remove front panel (see Figure 10, page 7).

2. Follow steps 1 through 5 under Lighting Instructions, page 10.

3. With control knob pressed in, strik e match. Hold match to

pilot until pilot lights.

4. Keep control knob pressed in for 30 seconds after pilot is

lit. After 30 seconds, release control knob. Follow step 8

under Lighting Instructions.

5. Replace front panel.

MANUAL CONTROL INFRARED MODELS

IGNITOR

Figure 17 - Control Knob In The OFF Position

Figure 18 - Pilot

110720-01C

HIGH

LOW

Thermocouple

Ignitor Electrode

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Pilot Burner

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance ar ea

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your g as supplier, call the fire department.

OPERATING HEATER (Manual Control Infrared Models)

12

For Your Safety Read Before Lighting (Cont.)

Lighting Instructions

To Select Heating Level

To Turn Off Gas To Appliance

OPERATING HEATER

Continued

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, don’t try to repair it, call a qualified service technician or gas supplier. Force or attempted repair may result

in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information page 11, column 2.

2. Make sure equipment shutoff valve is fully open.

3. Turn control knob clockwise to the OFF position.

4. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B” in the safety information, page 11, column 2. If

you don’t smell gas, go to the next step.

5. Press in control knob, and turn counterclockwise to

pilot position. Keep control knob pressed for five seconds.

Note:

You may be running this heater for the first time

after hooking up to gas supply . If so, the control knob may

need to be pressed in for 30 seconds or more. This will allow air to bleed from the gas system.

• If control knob does not pop up when released, contact a

qualified service person or gas supplier for r epairs.

6. With control knob pressed in, push down and release ignitor

button. This will light pilot. The pilot is attached to the front of

burner . If needed, keep pr essing ignitor button until pilot lights.

Note:

If pilot does not light, refer to Troubleshooting, pages

17 through 19. Also contact a qualified service person or

gas supplier for repairs. Until repairs ar e made, light pilot

with match, see Manual Lighting Procedure, page 13.

7. Keep control knob pressed in for 10 seconds after lighting

pilot. After 10 seconds, release control knob.

Note:

If pilot goes out, repeat steps 3 through 7.

Piezo Ignitor

Button

IGNITOR

Figure 19 - Control Knob In

The OFF Position

Control Knob

PILOT

LOW

OFF

HIGH

Thermocouple

Figure 20 - Pilot, Infrared

Heaters

Ignitor Electrode

Pilot

Burner

TO SELECT

HEATING LEVEL

WARNING: When running heater, set control

knob at LOW or HIGH locked positions for double

burner heater, or ON position for single burner heater..

Never set control knob between locked positions.

Poor combustion and higher levels of carbon monoxide may result.

CAUTION: Do not try to adjust heating levels by

using the equipment shutoff valve.

Slightly press in control knob and turn

counterclockwise to the LOW or HIGH positions for

double burner heater, or ON position for single burner heater.

IMPORTANT:

Release downward pressure while turning con-

trol knob. Control knob will lock at the desired position.

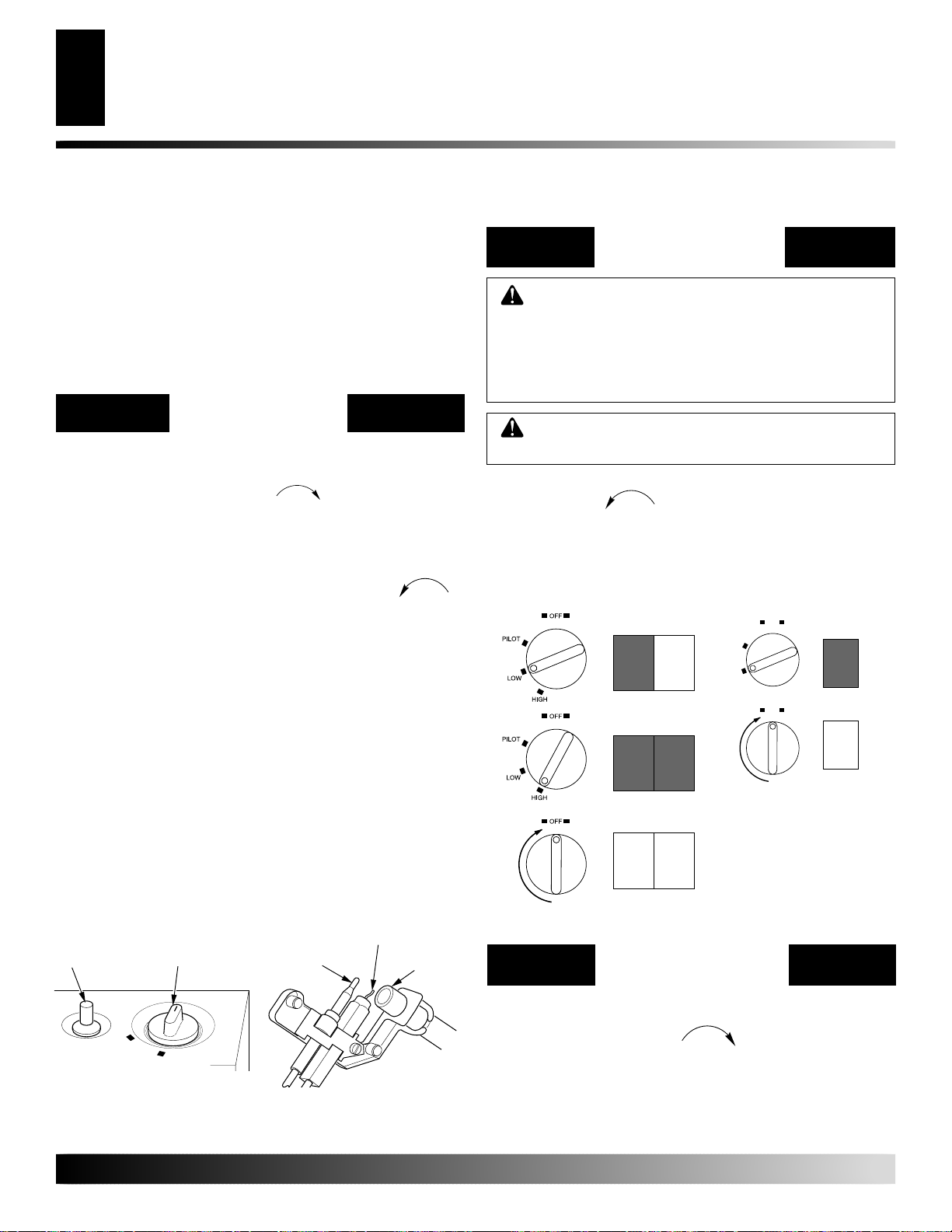

Control Double

Knobs Burners

Figure 21 - Burner Patterns

Control Single

Knob Burner

OFF

PILOT

ON

OFF

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

Turn control knob clockwise to the OFF position.

Shutting Off Burner Only

(pilot stays lit)

Turn control knob clockwise to the PILOT position.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

OPERATING HEATER (Thermostat Control Blue Flame and Infrared Models)

OPERATING HEATER

Continued

OPERATING HEATER (Manual Control Infrared Models)

Manual Lighting Procedure

For Your Safety Read Before Lighting

Lighting Instructions

13

13

MANUAL LIGHTING

PROCEDURE

1. Remove front panel (see Figure 10, page 7).

2. Follow steps 1 through 5 under Lighting Instructions,

page 12.

3. With control knob pressed in, strike ma tch. Hold match to

pilot until pilot lights.

4. Keep control knob pressed in for 10 seconds after pilot is

lit. After 10 seconds, release control knob.

5. Replace front panel.

THERMOSTAT CONTROL BLUE FLAME

AND INFRARED MODELS

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance ar ea

for gas. Be sure to smell next to the floor because some gas

is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by

hand, don’t try to repair it, call a qualified service technician or gas supplier. Force or attempted repair may result

in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

3. Turn control knob clockwise

to the OFF position

Clockwise

(see Figure 22).

4. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you smell gas, STOP! Follow “B” in the safety information, column 1. If you don’t

smell gas, go to the next step.

5. T urn control knob counterclockwise

C-clockwise

to the PILOT

position. Press in control knob for five (5) seconds

(see Figure 22).

Note:

You may be running this heater for the first time

after hooking up to gas supply . If so, the control knob may

need to be pressed in for 30 seconds or more. This will allow air to bleed from the gas system.

6. With control knob pressed in, push down and release ignitor button. This will light pilot. The pilot is attached to the

front of burner. The pilot can be seen through the glass panel.

If needed, keep pressing ignitor button until pilot lights.

Note:

If pilot does not stay lit, refer to Troubleshooting,

pages 16 through 18. Also contact a qualified service person or gas supplier for repairs. Until r epairs are made, light

pilot with match. To light pilot with match, see Manual

Lighting Procedure, page 14.

7. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

• If control knob does not pop up when released, contact a

qualified service person or gas supplier for repairs.

Note:

If pilot goes out, repeat steps 3 through 7. This heater

has a safety interlock system. Wait one (1) minute before

lighting pilot again.

8. Turn control knob counterclockwise

C-clockwise

to desired

heating level. The main burner should light. Set control

knob to any heat level between HI and LO.

CAUTION: Do not try to adjust heating levels by

using the equipment shutoff valve.

Ignitor Button

IGNITOR

Control Knob

T

LO

ILO

P

O

F

F

H

I

Thermocouple

Ignitor Electrode

Pilot Burner

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information above.

2. Make sure equipment shutoff valve is fully open.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

Figure 22 - Control Knob In

The OFF Position

Figure 23 - Pilot (Infrared Heater

Shown)

OPERATING HEATER (Thermostat Control Blue Flame and Infrared Models)

14

To Turn Off Gas To Appliance

Thermostat Control Operation

Manual Lighting Procedure

INSPECTING BURNER

Pilot Flame Pattern

Burner Flame Pattern Blue Flame Models

OPERATING HEATER

Continued

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

1. Turn control knob clockwise

2. Turn off all electric power to the appliance if service is to

be performed.

to the OFF position.

Clockwise

Shutting Off Burner Only (pilot stays lit)

Turn control knob clockwise

to the PILOT position.

Clockwise

THERMOSTAT CONTROL

OPERATION

The thermostatic control used on these models differs from

standard thermostats. Standard thermostats simply turn on and

off the burner. The thermostat used on this heater senses the

room temperature. The thermostat adjusts the amount of gas

flow to the burner. This increases or decreases the burner flame

height. At times the room may exceed the set temperature. If so,

the burner will shut off. The burner will cycle back on when room

temperature drops below the set temperature. The control knob

can be set to any heat level between HI and LO.

Note:

The thermostat sensing bulb measures the temperature of

air near the heater cabinet. This may not always agree with room

temperature (depending on housing construction, installation

location, room size, open air temperatures, etc.). Frequent use of

your heater will let you determine your own comfort levels.

MANUAL LIGHTING

PROCEDURE

1. Remove front panel (see Figure 10, page 7).

2. Follow steps 1 through 5 under Lighting Instructions,

page 13.

3. With control knob pressed in, strike ma tch. Hold match to

pilot until pilot lights.

4. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, r elease contr ol knob. Follow step 8

under Lighting Instructions, page 13.

5. Replace front panel.

INSPECTING BURNER

If pilot flame pattern is incorrect, as shown in Figure 25

• turn heater off (see To Turn Off Gas to Appliance, pages 11, 12

or 14 depending on your model)

• see Troubleshooting, pages 16 through 18

Note:

The pilot flame on natural gas units will have a slight curve,

but flame should be blue and have no yellow or orange color.

Pilot

Pilot Burner

Thermocouple

GRH/OV 007GOOD PILOT/LP

Figure 24 - Correct Pilot Flame

Pattern

Thermocouple

Figure 25 - Incorrect Pilot Flame

Pattern

Burner

GRH/OV 008BAD PILOT/LP

BURNER FLAME PATTERN

BLUE FLAME MODELS

Figure 26 shows a correct burner flame pattern. Figure 27 shows an

incorrect burner flame pattern. The incorrect burner flame pattern

shows yellow tipping of the flame. It also shows the flame higher

than 1/2 the glass panel height.

WARNING: If yellow tipping occurs, your heater

could produce increased levels of carbon monoxide.

If burner flame pattern shows yellow tipping, proceed

with the following instructions.

NOTICE: Do not mistake orange flames with yellow

tipping. Dust or other fine particles enter the heater

and burn causing brief patches of orange flame.

1/2 GLASS HEIGHT

(Models VN600A and VP600A will be

lower due to lower input rating)

Figure 26 - Correct Burner Flame Pattern

Check pilot flame pattern and burner flame pattern often.

PILOT FLAME PATTERN

Figure 24 shows a correct pilot flame pattern. Figure 25 shows an

incorrect pilot flame pattern. The incorrect pilot flame is not touching

the thermocouple. This will cause the thermocouple to cool. When the

thermocouple cools, the heater will shut down.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Yellow

Tipping

1/2 GLASS HEIGHT

Figure 27 - Incorrect Burner Flame Pattern

110720-01C

INSPECTING BURNER

Continued

Burner Flame Pattern Blue Flame Models (Cont.)

INSPECTING BURNER

Burner Flame Pattern Infrared Models

CLEANING AND MAINTENANCE

ODS/Pilot and Burner Orifice

Cleaning Burner Pilot Air Inlet Hole

Cabinet

15

15

If burner flame pattern is incorrect, as shown in Figure 27, page 14

• turn heater off (see To Turn Off Gas to Appliance, page 1 1 or 14

depending on your model)

• see Troubleshooting, pages 16 through 18

BURNER FLAME PATTERN

INFRARED MODELS

Figure 28 shows a correct burner flame pattern. Figure 29 shows an

incorrect burner flame pattern.

If burner flame pattern is incorrect, as shown in Figure 29

• turn heater off (see To Turn Off Gas to Appliance, page 12)

• see Troubleshooting, pages 16 through 18

Figure 28 - Correct Burner

Flame Pattern (Dual Burner

Shown)

Figure 29 - Incorrect Burner

Flame Pattern (Dual Burner

Shown)

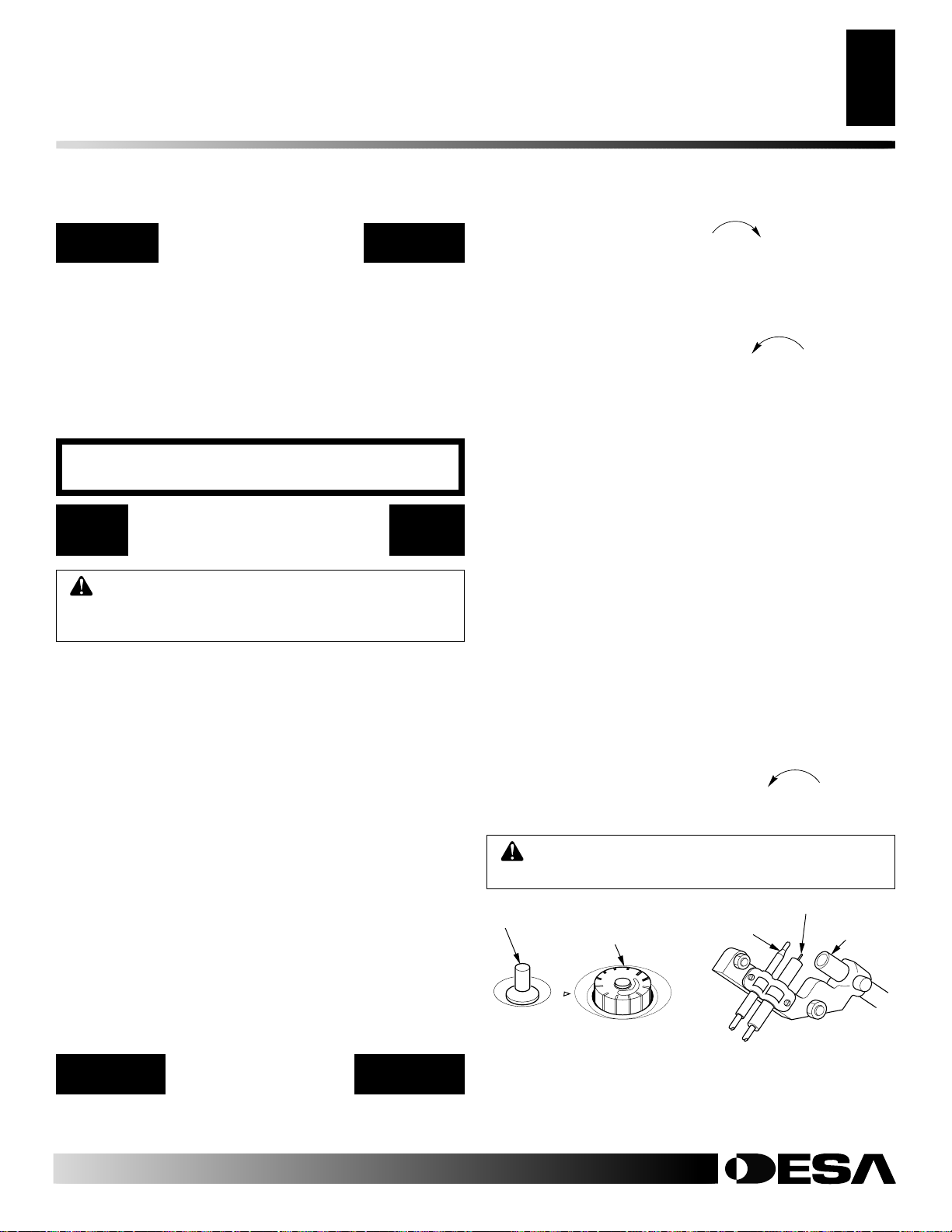

CLEANING BURNER PILOT AIR INLET HOLE

The primary air inlet holes allow the proper amount of air to mix with

the gas. This provides a clean burning flame. Keep these holes clear

of dust, dirt, and lint. Clean these air inlet holes prior to each heating

season. Blocked air holes will create soot. We recommend that you

clean the unit every three months during operation and have heater

inspected yearly by a qualified service person.

We also recommend that you keep the burner tube and pilot

assembly clean and free of dust, dirt, lint and pet hair. To clean these

parts we recommend using compressed air no greater than 30 PSI.

Your local computer store, hardware store, or home center may

carry compressed air in a can. You can use a vacuum cleaner in the

blow position. If using compressed air in a can, please follow the

directions on the can. If you don't follow directions on the can, you

could damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow the unit to cool for

at least thirty minutes.

2. Inspect burner, pilot for dust and dirt.

3. Blow air through the ports/slots and holes in the burner.

Clean the pilot assembly also. A yellow tip on the pilot flame

indicates dust and dirt in the pilot assembly. There is a small pilot

air inlet hole about two inches from where the pilot flame comes out

of the pilot assembly (see Figure 30). With the unit off, lightly blow

air through the air inlet hole. You may blow through a drinking straw

if compressed air is not available.

Pilot Assembly

CLEANING AND

MAINTENANCE

WARNING: Turn off heater and let cool before

cleaning.

CAUTION: You must keep control areas, burner,

and circulating air passageways of heater clean. Inspect these areas of heater before each use. Have

heater inspected yearly by a qualified service person.

Heater may need more frequent cleaning due to excessive lint from carpeting, bedding material, pet hair, etc.

ODS/PILOT AND BURNER ORIFICE

• Use a vacuum cleaner, pressurized air, or small, soft bristled

brush to clean.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

Pilot Air Inlet

Figure 30 - Pilot Inlet Air (Propane/LP Pilot Shown)

CABINET

Air Passageways

• Use a vacuum cleaner or pressurized air to clean.

Exterior

• Use a soft cloth dampened with a mild soap and water mixture.

Wipe the cabinet to remove dust.

16

TROUBLESHOOTING

TROUBLESHOOTING

Note:

For additional help, visit DESA

International’s technical service web site

at www.desatech.com.

Note:

All troubleshooting items are listed in

order of operation.

OBSERVED PROBLEM

When ignitor button is pressed, there is no

spark at ODS/pilot

When ignitor button is pressed, there is

spark at ODS/pilot but no ignition

WARNING: Turn off heater

and let cool before servicing. Only

a qualified service person should

service and repair heater.

POSSIBLE CAUSE

1. Ignitor electrode positioned wrong

2. Ignitor electrode broken

3. Ignitor electrode not connected to ignitor cable

4. Ignitor cable pinched or wet

5. Piezo ignitor nut is loose

6. Broken ignitor cable

7. Bad piezo ignitor

1. Gas supply turned off or equipment

shutoff valve closed

2. Control knob not in PILOT position

3. Control knob not pressed in while in

PILOT position

4. Air in gas lines when installed

5. Depleted gas supply (propane/LP only)

6. ODS/pilot is clogged

7. Gas regulator setting is not correct

CAUTION: Never use a wire,

needle, or similar object to clean

ODS/pilot. This can damage ODS/

pilot unit.

REMEDY

1. Replace pilot assembly

2. Replace pilot assembly

3. Reconnect ignitor cable

4. Free ignitor cable if pinched by any

metal or tubing. Keep ignitor cable dry

5. Tighten nut holding piezo ignitor to

heater cabinet. Nut is located inside

heater cabinet at top

6. Replace ignitor cable

7. Replace piezo ignitor

1. Turn on gas supply or open equipment

shutoff valve

2. Turn control knob to PILOT position

3. Press in control knob while in PILOT

position

4. Continue holding down control knob.

Repeat igniting operation until air is removed

5. Contact local propane/LP gas company

6. Clean ODS/pilot (see Cleaning and

Maintenance, page 15) or replace ODS/

pilot assembly

7. Replace gas regulator

ODS/pilot lights but flame goes out when

control knob is released

For more information, visit www.desatech.com

For more information, visit www.desatech.com

1. Control knob not fully pressed in

2. Control knob not pressed in long enough

3. Equipment shutoff valve not fully open

4. Thermocouple connection loose at control valve

5. Pilot flame not touching thermocouple,

which allows thermocouple to cool,

causing pilot flame to go out. This problem could be caused by one or both of

the following:

A) Low gas pressure

B) Dirty or partially clogged ODS/pilot

6. Thermocouple damaged

7. Control valve damaged

1. Press in control knob fully

2. After ODS/pilot lights, keep control

knob pressed in 30 seconds

3. Fully open equipment shutoff valve

4. Hand tighten until snug, then tighten 1/4

turn more

5. A) Contact local natural or propane/LP

gas company

B) Clean ODS/pilot (see Cleaning and

Maintenance, page 15) or replace ODS/

pilot assembly

6. Replace pilot assembly

7. Replace control valve

110720-01C

TROUBLESHOOTING

Continued

TROUBLESHOOTING

17

17

OBSERVED PROBLEM

Burner does not light after ODS/pilot is lit

Delayed ignition of burner

Burner backfiring during combustion

Burner plaque(s) does not glow (Infrared

models only)

Yellow flame during burner combustion

POSSIBLE CAUSE

1. Burner orifice is clogged

2. Inlet gas pressure is too low

1. Manifold pressure is too low

2. Burner orifice is clogged

1. Burner orifice is clogged or damaged

2. Burner damaged

3. Gas regulator defective

1. Control knob set between locked positions

2. Inlet gas pressure is too low

3. Plaque damaged

1. Not enough air

2. Inlet gas pressure is too low

3. Gas regulator defective

REMEDY

1. Clean burner orifice (see Cleaning and

Maintenance, page 15) or replace burner

orifice

2. Contact local natural or propane/LP gas

company

1. Contact local natural or propane/LP gas

company

2. Clean burner orifice (see Cleaning and

Maintenance, page 15) or replace burner

orifice

1. Clean burner orifice (see Cleaning and

Maintenance, page 15) or replace burner

orifice

2. Replace burner

3. Replace gas regulator

1. Turn control knob until it locks at desired setting

2. Contact local natural or propane/LP gas

company

3. Replace burner

1. Check burner for dirt and debris. If

found, clean burner (see Cleaning and

Maintenance, page 15)

2. Contact local natural or propane/LP gas

company

3. Replace gas regulator

Slight smoke or odor during initial operation

Heater produces a whistling noise when

burner is lit

Heater produces a clicking/ticking noise

just after burner is lit or shut off

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

1. Residues from manufacturing processes

1. Turning control knob to HIGH position

when burner is cold

2. Air in gas line

3. Air passageways on heater blocked

4. Dirty or partially clogged burner orifice

1. Metal expanding while heating or contracting while cooling

1. Problem will stop after a few hours of

operation

1. Turn control knob to LOW position and

let warm up for a minute

2. Operate burner until air is removed from

line. Have gas checked by local natural

or propane/LP gas company

3. Observe minimum installation clearances (see Figure 4, page 7)

4. Clean burner (see Cleaning and Mainte-

nance, page 15) or replace burner orifice

1. This is common with most heaters. If

noise is excessive, contact qualified service person

TROUBLESHOOTING

18

TROUBLESHOOTING

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

IMPORTANT:

supplies, paint, paint remover, cigarette smoke, cements and glues, new carpet or textiles,

etc., create fumes. These fumes may mix with combustion air and create odors.

Operating heater where impurities in air exist may create odors. Cleaning

OBSERVED PROBLEM

White powder residue forming within burner

box or on adjacent walls or furniture

Heater produces unwanted odors

Heater shuts off in use (ODS operates)

Gas odor even when control knob is in OFF

position

POSSIBLE CAUSE

1. When heated, vapors from furniture polish, wax, carpet cleaners, etc. may turn

into white powder residue

1. Heater burning vapors from paint, hair

spray, glues, etc. (See

statement above)

2. Low fuel supply (propane/LP only)

3. Gas leak. See W arning statement at

top of page

1. Not enough fresh air is available

2. Low line pressure

3. ODS/pilot is partially clogged

1. Gas leak. See W arning statement at

top of page

2. Control valve defective

IMPORTANT

REMEDY

1. Turn heater off when using furniture

polish, wax, carpet cleaners, or similar

products

1. Ventilate room. Stop using odor -causing

products while heater is running

2. Refill supply tank (propane/LP only)

3. Locate and correct all leaks (see Check-

ing Gas Connections, pages 9 and 10)

1. Open window and/or door for ventilation

2. Contact local natural or propane/LP gas

company

3. Clean ODS/pilot (see Cleaning and

Maintenance, page 15)

1. Locate and correct all leaks (see Check-

ing Gas Connections, pages 9 and 10)

2. Replace control valve

Gas odor during combustion

Moisture/condensation noticed on windows

For more information, visit www.desatech.com

For more information, visit www.desatech.com

1. Foreign matter between control valve

and burner

2. Gas leak. See W arning statement at

top of page

1. Not enough combustion/ventilation air

1. Take apart gas tubing and remove foreign matter

2. Locate and correct all leaks (see Check-

ing Gas Connections, pages 9 and 10)

1. Refer to Fresh Air for Combustion and

Ventilation requirements (page 4)

110720-01C

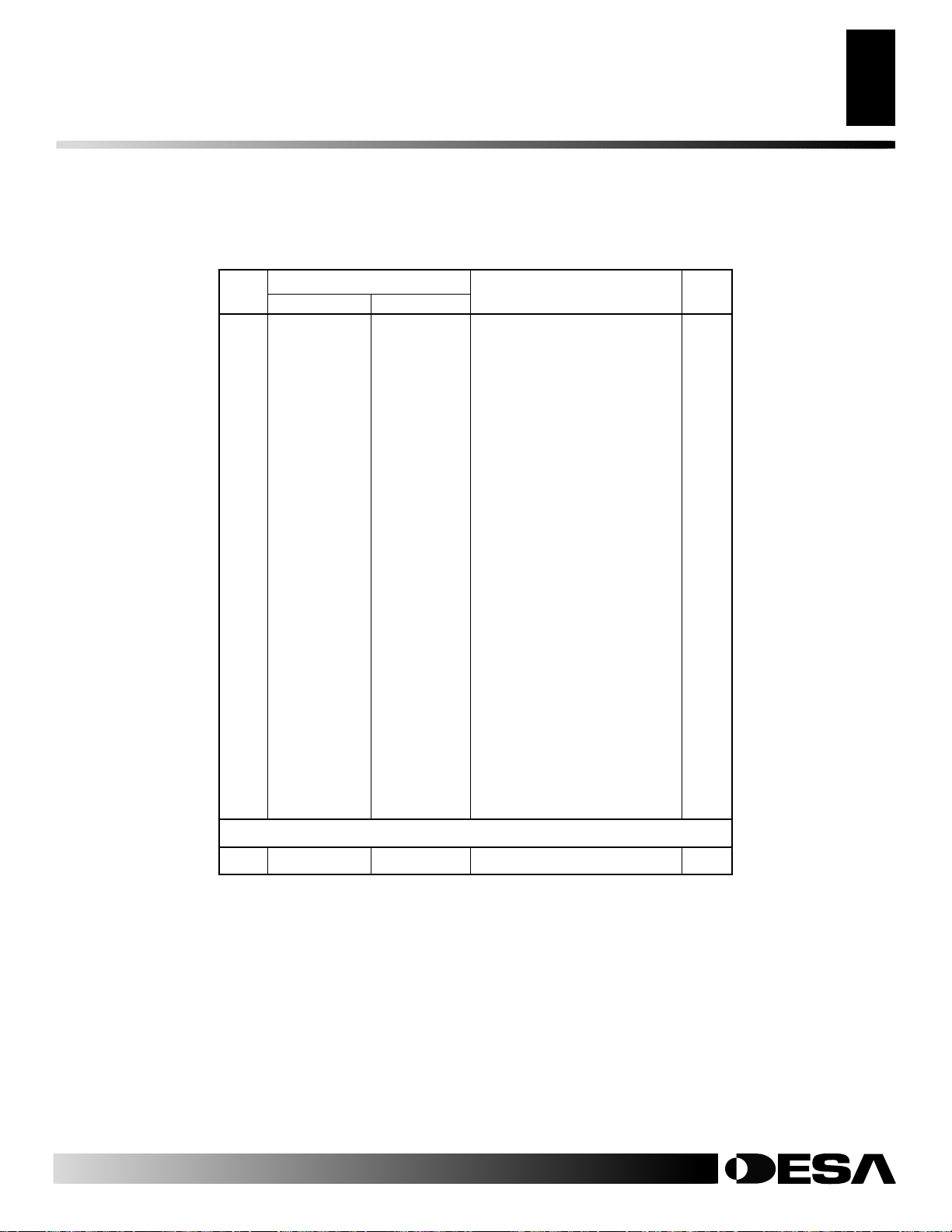

SPECIFICATIONS

19

19

SPECIFICATIONS

VP600BA VP5D VP10A VP10TA VP1000BTA

Btu (Variable) 4,400/6,000 5,500 5,500/10,000 10,000 5,000/10,000

Type Gas Propane/LP Only Propane/LP Only Propane/LP Only Propane/LP Only Propane/LP Only

Ignition Piezo Piezo Piezo Piezo Piezo

Pressure Regulator Setting 8" W.C. 8" W.C. 8" W.C. 8.5" W.C. 8" W.C.

Inlet Gas Pressure

(inches of water)

Maximum 14" 14" 14" 14" 14"

Minimum 11" 11" 11" 11" 11"

Dimensions, Inches

(H x W x D)

Heater 20

Carton 25 x 16

Weight (pounds)

Heater 13.5 13 14 14

Shipping 19 17 18 18 19

1

/2 x 13 1/2 x 5 20 1/2 x 13 1/2 x 5 20 1/2 x 13 1/2 x 5 21 1/2 x 13 1/2 x 7 21 1/2 x 13 1/2 x 7

11

/16 x 7 1/2 25 x 16 11/16 x 7 1/2 25 x 16 11/16 x 7 1/2 25 1/4 x 16 3/4 x 7 1/2 25 1/4 x 16 3/4 x 7 1/2

VN600BA VN6D VN10A VN10TA VN1000BTA

Btu (Variable) 4,400/6,000 6,000 5,000/10,000 10,000 5,000/10,000

Type Gas Natural Only Natural Only Natural Only Natural Only Natural Only

Ignition Piezo Piezo Piezo Piezo Piezo

Pressure Regulator Setting 3" W.C. 3" W.C. 3" W.C. 3.5" W.C. 3" W.C.

Inlet Gas Pressure

(inches of water)

Maximum 10.5" 10.5" 10.5" 10.5" 10.5"

Minimum 4" 4" 5" 5" 5"

Dimensions, Inches

(H x W x D)

Heater 20 1/2 x 13 1/2 x 5 20 1/2 x 13 1/2 x 5 20 1/2 x 13 1/2 x 5 21 1/2 x 13 1/2 x 7 20 1/2 x 13 1/2 x 7

Carton 25 x 16 11/16 x 7 1/2 25 x 16 11/16 x 7 1/2 25 x 16 11/16 x 7 1/2 24 3/4 x 16 3/4 x 7 1/2 25 1/4 x 16 3/4 x 7 1/2

Weight (pounds)

Heater 13.5 13 14 14

Shipping 17 17 18 18 19

110720-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

20

ILLUSTRATED PARTS BREAKDOWN

VN600BA, VP600BA

ILLUSTRATED PARTS

BREAKDOWN

VN600BA

VP600BA

7

6

21

20

13

12

10

4

9

11

14

15

18

22

10

16

25

19

23

24

26

3

1

5

8

2

17

PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 30 of this manual.

KEY PART NUMBER FOR

NO. VP600BA VN600BA DESCRIPTION QTY.

1 098304-01 098304-01 Screw, #10 x 3/8" 2

2 099467-07 099467-07 Front Panel 1

3 099318-04 099318-04 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 102017-02 102017-02 Bottom Glass Retainer 1

6 098260-11 098260-11 Glass Panel 1

7 098532-06AA 098532-06AA Top Glass Retainer 1

8 M11084-38 M11084-38 Screw, #8 x 3/8" 8

9 099317-02 099317-02 Deflector Unit 1

10 098271-09 098271-09 Ignitor Cable 1

11 098249-01 098249-01 Nut, M5 2

12 110803-02*** 110803-01*** ODS/Pilot Assembly 1

12-1 110186-01 110186-01 Thermocouple Kit 1

13 104263-02 104263-01 Burner 1

14 099387-05 099387-05 Pilot Tubing 1

15 104259-04 104259-03 Injector, 1 piece 1

16 NJF-8C NJF-8C Hex Nut 1

17 099415-18 099415-17 Pressure Regulator 1

18 099462-01 099462-01 Burner Tubing 1

19 099391-02 099391-02 Regulator Tubing 1

20 099413-02 099413-01 Control Valve 1

21 ** **

22 097159-04 097159-04 Piezo Ignitor 1

23 099393-02 099393-02 Control Knob 1

24 098508-01 098508-01 Valve Retainer Nut 1

25 098303-02 098303-02 Screw, #6 x 5/16" 2

26 099818-01 099818-01 Internal Tooth Washer 1

Cabinet Assembly

VN600BA, VP600BA

PARTS LIST

21

21

110720-01C

PARTS AVAILABLE - NOT SHOWN

099395-09 099395-09 Control Position Label 1

100642-02 100642-02 Assembly, Hardware 1

** Not a field replaceable part.

*** If replacing ODS pilot and your model is pre 2002, your part number will be

099440-03 for natural gas models, 099059-03 for propane/LP models.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

22

ILLUSTRATED PARTS BREAKDOWN

VP10A, VN10A

ILLUSTRATED PARTS

BREAKDOWN

VP10A

VN10A

22

15

23

8

4

7

5

A

B

6

20

23

14

19

18

21

17

16

6

3

2

7-1

1

7-2

9

11

10

9

13

12

ODS/PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 30 of this manual.

KEY PART NUMBER

NO. VP10A VN10A DESCRIPTION QTY.

1 098304-01 098304-01 Screw, #10 x 3/8" 2

2 ** ** Front Panel Assembly 1

3 099318-03 099318-03 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 099469-02 099469-02 Reflector Assembly 1

6 M15823-37 M15823-37 Screw Hex #8 x 1/4" 10

7 099059-03 503329 ODS/Pilot Assembly 1

7-1 098514-01 098514-01 Thermocouple 1

7-2 098594-01 098594-01 Ignitor Electrode 1

8 099884-02 099884-02 Burner Assembly 1

9 099056-01 099056-06 Injector 2

10 099390-02 099390-02 Tubing - Valve to plaque A 1

11 099387-05 099387-05 Pilot Tubing - Valve to pilot 1

12 099392-01 099392-01 Tubing - Valve to plaque B 1

13 099391-02 099391-02 Tubing - Regulator to valve 1

14 100432-01 100432-01 Control Valve 1

15 ** ** Cabinet Assembly 1

16 099415-18 099415-17 Gas Regulator 1

17 098303-02 098303-02 Screw, #6 x 5/16" 2

18 098508-01 098508-01 Valve Retainer Nut 1

19 099393-02 099393-02 Control Knob 1

20 M11084-26 M11084-26 Screw, #10 x 3/8" 2

21 099818-01 099818-01 Internal Tooth Washer 1

22 097159-04 097159-04 Piezo Ignitor 1

23 098271-03 098271-03 Ignitor Cable 1

PARTS LIST

VP10A, VN10A

23

23

110720-01C

PARTS AVAILABLE - NOT SHOWN

100642-02 100642-02 Assembly, Hardware 1

** Not a field replaceable part.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

24

ILLUSTRATED PARTS BREAKDOWN

VP10TA, VN10TA

ILLUSTRATED PARTS

BREAKDOWN

VP10TA

VN10TA

15

17

16

8

4

7

5

A

B

6

12

16

14

18

19

6

3

11

2

1

7-1

7-2

10

13

9

ODS/PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 30 of this manual.

KEY PART NUMBER

NO. VP10TA VN10TA DESCRIPTION QTY.

1 098304-01 098304-01 Screw, #10 x 3/8" 2

2 ** ** Front Panel Assembly 1

3 099318-03 099318-03 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 099275-01 099275-01 Reflector Assembly 1

6 M15823-37 M15823-37 Screw Hex #8 x 1/4" 10

7 099059-03 503329 ODS/Pilot Assembly 1

7-1 098514-01 098514-01 Thermocouple 1

7-2 098594-01 098594-01 Ignitor Electrode 1

8 099884-03 099884-03 Burner Assembly 1

9 099056-25 099056-24 Injector 2

10 104087-01 104087-01 Tubing - Burner 1

11 099387-11 099387-11 Pilot Tubing - Valve to pilot 1

12 M11084-26 M11084-26 Screw, #10 x 3/8" 2

13 104084-01 104084-01 Tubing - Inlet 1

14 098522-16 098522-16 Control Valve 1

15 097159-04 097159-04 Piezo Ignitor 1

16 098271-03 098271-03 Ignitor Cable 1

17 ** ** Cabinet Assembly 1

18 099415-18 099415-12 Gas Regulator 1

19 098303-02 098303-02 Screw, #6 x 5/16" 2

PARTS LIST

VP10TA, VN10TA

25

25

110720-01C

PARTS AVAILABLE - NOT SHOWN

100642-02 100642-02 Assembly, Hardware 1

** Not a field replaceable part.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

26

ILLUSTRATED PARTS BREAKDOWN

VP5D, VN6D

ILLUSTRATED

PARTS

BREAKDOWN

VP5D

VN6D

21

18

14

22

8

4

7

6

19

22

5

13

17

20

16

15

6

3

2

1

7-1

7-2

11

10

9

12

ODS/PILOT

For more information, visit www.desatech.com

For more information, visit www.desatech.com

110720-01C

PARTS LIST

This list contains replaceable parts used in your heater. When

ordering parts, follow the instructions listed under Replacement

Parts on page 30 of this manual.

KEY PART NUMBER

NO. VP5D VN6D DESCRIPTION QTY.

1 098304-01 098304-01 Screw, #10 x 3/8" 2

2 ** ** Front Panel Assembly 1

3 099318-03 099318-03 Grill Guard 1

4 101108-01 101108-01 Grill Guard Clip 2

5 099469-01 099469-02 Reflector Assembly 1

6 M15823-37 M15823-37 Screw Hex #8 x 1/4" 9

7 099059-03 503329 ODS/Pilot Assembly 1

7-1 098514-01 098514-01 Thermocouple 1

7-2 098594-01 098594-01 Ignitor Electrode 1

8 099884-01 099884-01 Burner Assembly 1

9 099056-04 099056-01 Injector 1

10 099390-01 099390-01 Tubing - Valve to burner 1

11 099387-05 099387-05 Pilot Tubing - Valve to pilot 1

12 099391-02 099391-02 Tubing - Regulator to valve 1

13 100829-01 100829-01 Control Valve 1

14 ** ** Cabinet Assembly 1

15 099415-18 099415-17 Gas Regulator 1

16 098303-02 098303-02 Screw, #6 x 5/16" 2

17 098508-01 098508-01 Valve Retainer Nut 1

18 099393-02 099393-02 Control Knob 1

19 M11084-26 M11084-26 Screw, #10 x 3/8" 2

20 099818-01 099818-01 Internal Tooth Washer 1

21 097159-04 097159-04 Piezo Ignitor 1

22 098271-03 098271-03 Ignitor Cable 1

PARTS LIST

VP5D, VN6D

27

27

110720-01C

PARTS AVAILABLE - NOT SHOWN