Desa SPV 12 EH Installation And Operation Manual

Installation and operation manual

SPLIT AIR CONDITIONER

SPV 12 EH

TABLE OF CONTENS

Technical specification 2

Safety instructions 3

Components 5

Assembly instructions installation 6

Assembly instructions connection 10

Assembly instructions disconnection 14

Remote control 16

Display panel 17

Operation 18

Remote control notes 21

Maintenance 22

Maintenance before and after the season 23

Troubleshooting 24

1

2

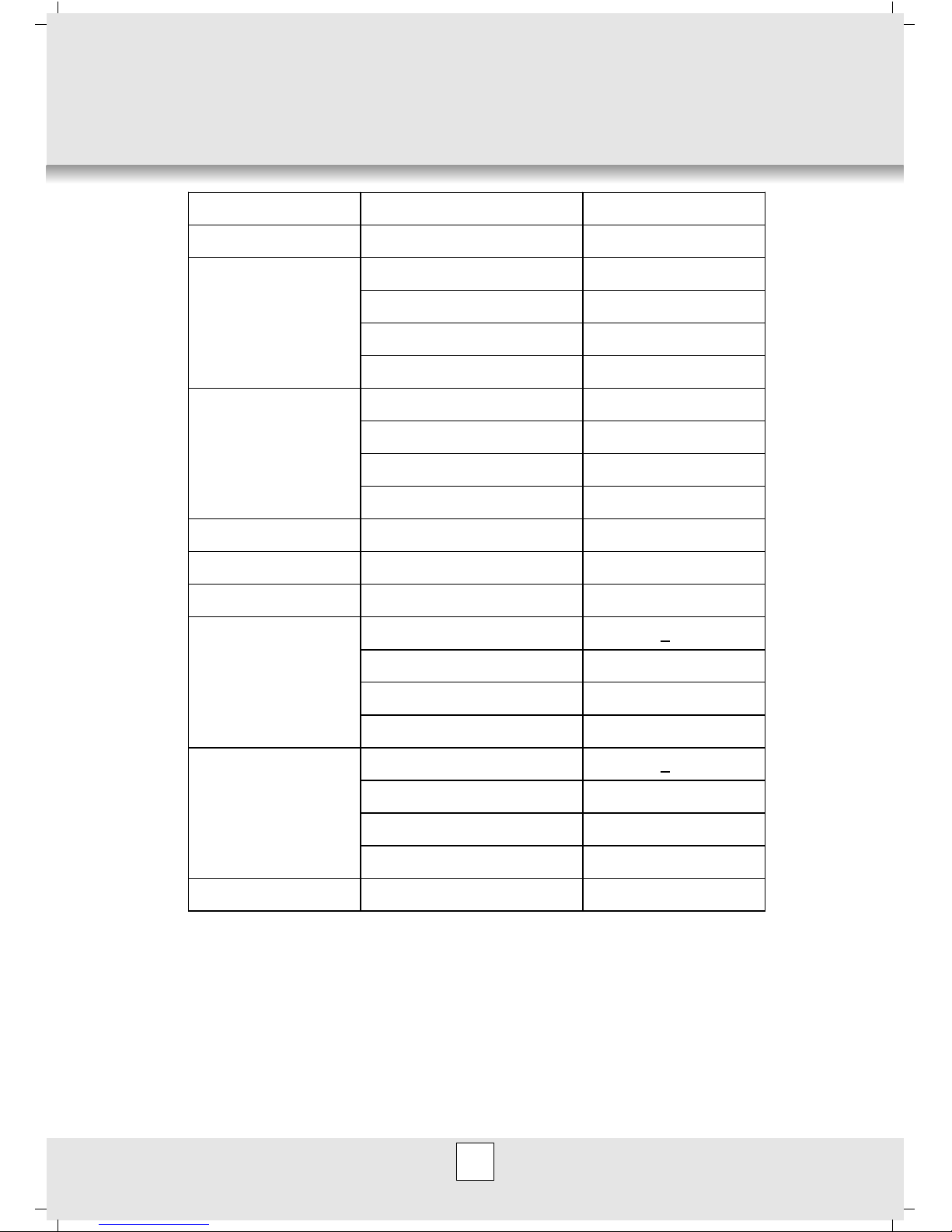

TECHNICAL SPECIFICATION

Please note:

1. Information may vary for technical reasons

2. Measuring condition for above is based on regulation EN14511

Model

SPV 12 EH

Power Supply

V/Hz 220÷240 / 50Hz

Capacity (W) 3500

Power Consumption (W) 1220

Operating Current (A) 5,5

Cooling

EER (W/W) 2,87

Capacity (W) 3800

Power Consumption (W) 1180

Operating Current (A) 5,4

Heating

COP (W/W) 3,22

Airflow Volume

m3/hr (Cooling/Heating) 520 / 560

Dehumidifying

l/h 1,0

Refrigerant

R407c (g) 850

Noise Level (db(A)) <43

Dimensions WxHxD (mm) 795x270x190

Packing WxHxD (mm) 860x320x400

Indoor Unit

Net/Gross Weight (kg) 11/16

Noise Level (db(A)) <53

Dimensions WxHxD (mm) 800x540x250

Packing WxHxD (mm) 888x590x344

Outdoor Unit

Net/Gross Weight (kg) 33/38

Suitable Area

m3 80

3

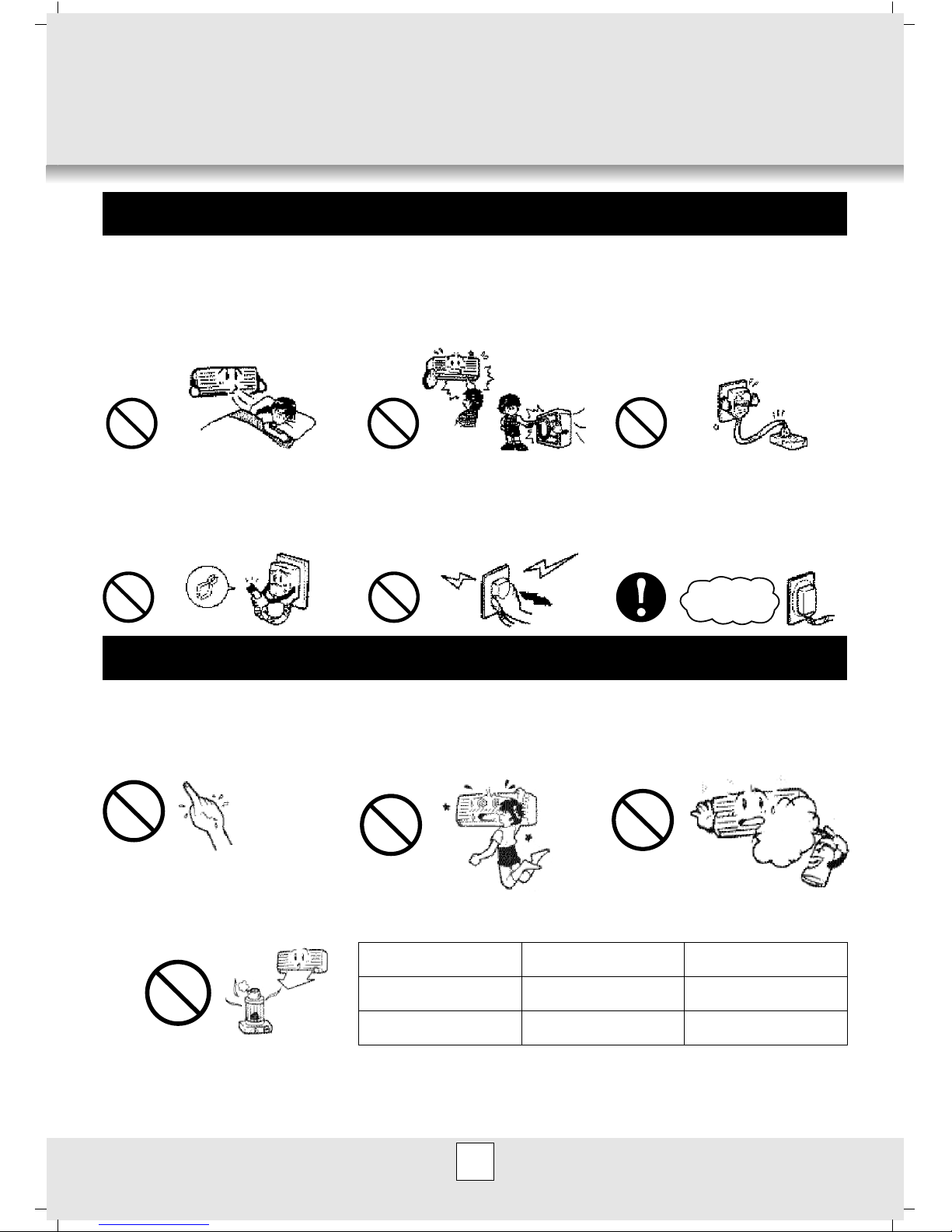

SAFETY INSTRUCTIONS

! Please read carefully this Manual and Safety Instructions before operating the

appliance.

! Warnings and instructions under the heading “CAUTION / NOTES” warn against occurrence

of serious problems, or inform on how to optimize appliance operation. Reading and

observing such notes is critical for ensuring safe and efficient operation of the appliance.

! Symbols used in this Manual have the following meanings:

Formal

prohibition

Follow the

instructions

Ensure continuity

of earthing

Disconnect

power supply

! After you read this Manual please keep it at hand and protect from damage or loss.

1. Do not install the appliance in places

exposed to leakage of flammable

gases.

Gas leaking and accumulating around the

appliance may cause fire.

1. Electric installation is to be fitted with

differential current switch.

When the appliance is connected to

improperly protected installation it may

cause electric shock.

2. Electric installation is to be fitted with

differential current switch.

When the appliance is connected to improperly

protected installation it may cause electric

shock.

3. Make sure the condensate tube is

placed correctly, so that water can drain

out.

Improper placement of condensate tube

can result in flooding of premises and

dampening of furniture.

4. Make sure the housing of external module

is earthed.

Earthing conductors cannot be running along

gas pipes, water pipes, lighting arrester wire or

telephone earthing wire. Improper installation of

earthing conductor may result in electric shock.

4

Never expose your body to

cold air for a long time, as it

may have adverse effect to

your health.

Never introduce any objects or

body parts to internal and

external parts of the appliance.

Never use extension cords

or branch-joints to connect

the appliance to power

supply.

OPERATION INSTRUCTIONS

Protect power cord from

damage.

Never switch the appliance on

or off by removing plug.

Before switching on, always

check if the appliance is

correctly connected to power

supply.

DANGER!!!

CAUTION!!!

Never touch switches or

buttons with wet hands.

Never hang on the

appliance.

Never spray flammable products

(such as insecticides) near the

appliance.

Never place combustion devices

(generating fire) near from the

air-conditioner air outlet.

Air-conditioner working range:

INSIDE OUTSIDE

COOLING

HEATING

O O

18 C - 43 C

O O

9 C - 43 C

O O

9 C - 30 C

O O

9 C - 30 C

Air-conditioner is designed to operate within temperature range as in the table above! The appliance

can be operated in below zero temperatures after prior adaptation by authorized service center. For details

contact your authorized service center or retailer.

5

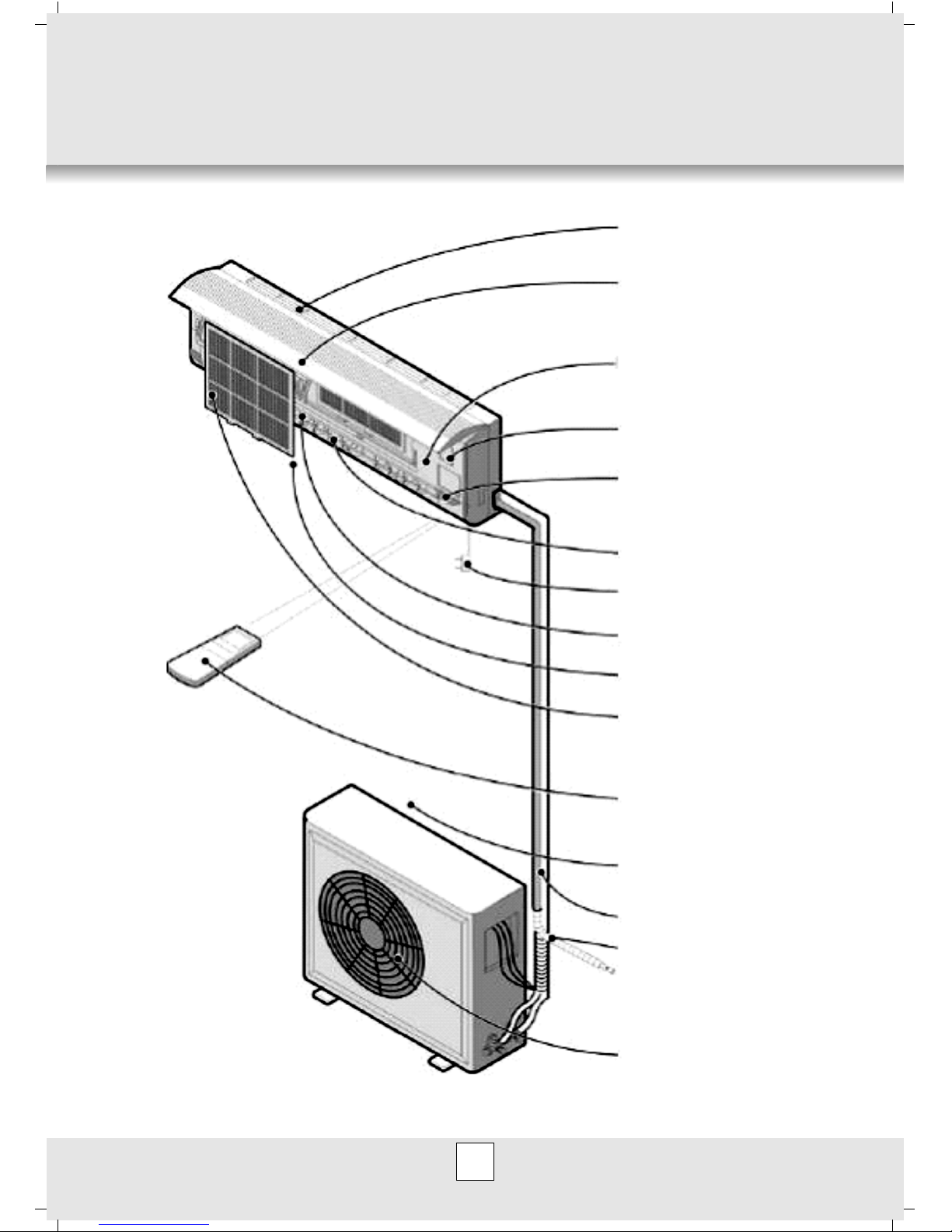

COMPONENTS

Indoor unit

Outdoor unit

Air outlet

Drainage hose

Connecting pipe and cable

Air inlet

Remote controller

Air filter

Air outlet

Vertical louver

Power plug

Horizontal louver

Indicate lamp & signal

receiving window

Emergency switch

Temperature sensor

Air intake grilles

Air inlet

Fig. 1

6

ASSEMBLY MANUAL

– INSTALLATION

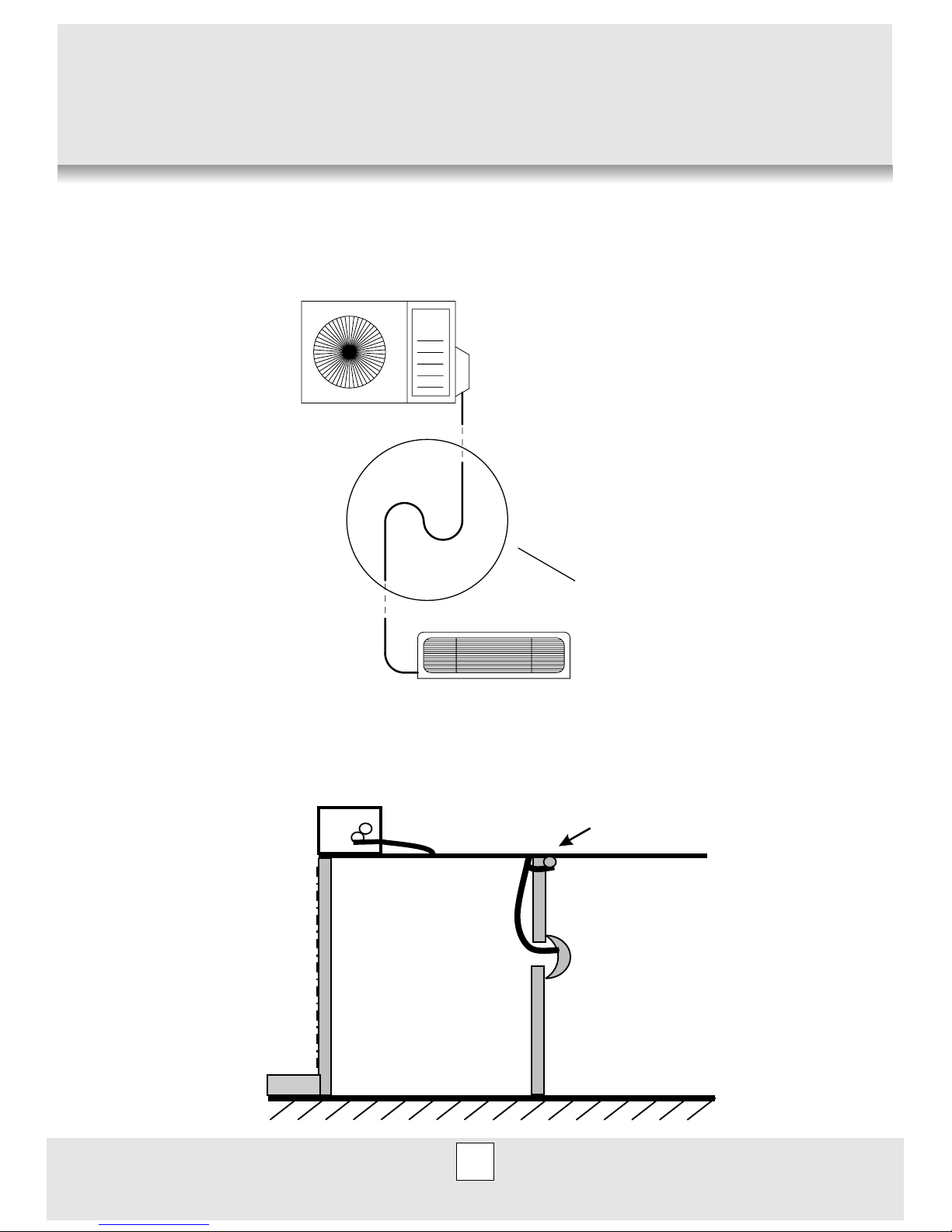

1. Installation and connection.

A. External module

External module is to be installed in horizontal position

Option A Option B

Standing on

ground / platform

Wall-mounted

on support

(optional)

External module is to

be installed keeping

the minimum offsets

from walls, ceilings, etc.

0,6m

min

0,15m

min

0,6m

min

0,15m

min

0,6m

min

Note:

To en sure s elf -d rai nin g of

condensate (water restored from

air in air-conditioned premises) the

external module is to be mounted

below the Internal module see

Fig.6 “Basic Installation”. It is

however possible to mount the

modules as in Fig.7 “Optional

Installation”.

External

module

Pipeline

(optional)

Basic

installation

Optional

installation

External

module

Internal

module

Internal

module

Bracket spacing

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

A = 140 mm

B = 510 mm

C = 130 mm

7

Should you choose optional installation (Fig.7), with external module above the internal

module, bear in mind application of so-called “oil trap” Fig.8.

In case of any installation problems please contact authorized service center or retailer.

Should you decide for esthetics to lead the condensate tube upwards to external module

(see Fig.9), always apply condensate pump. For details contact authorized service center or

retailer.

Condensate

tube

Room 1 Room 2

Condensate

pump

Fig. 8

Fig. 9

oil trap

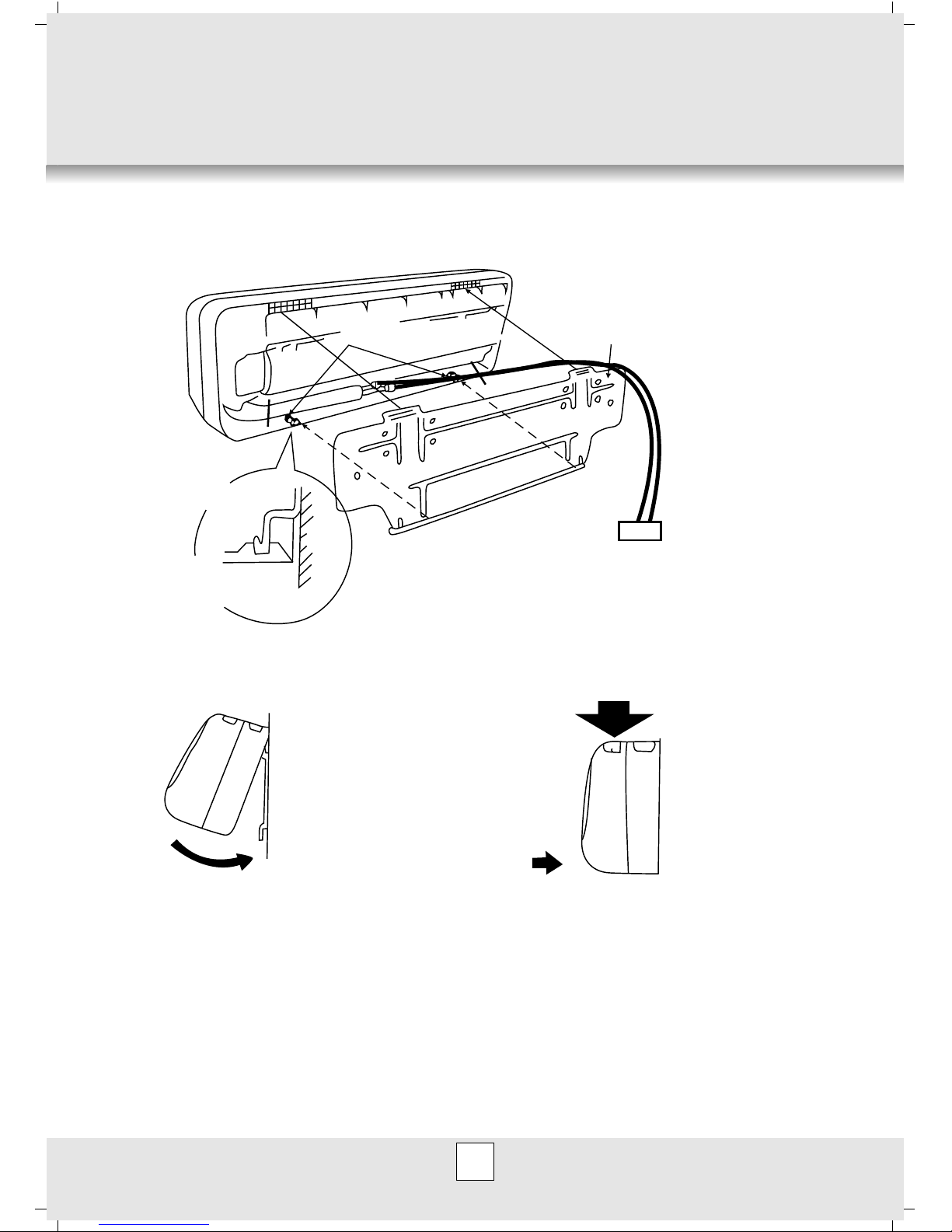

B. Installation of internal module using mounting plate

Internal module is to be mounted in horizontal position.

8

Indoor unit

Mounting plate

Mounting plate

Wall

)

Fixing on internal

module supports

ASSEMBLY

1. Hang upper part of

internal module on

mounting plate

2. Press the module till

its fixed

2 fixt ures2 fixt ures

Fig. 10

Fig. 11

Fig. 12

Loading...

Loading...