Page 1

INSTALLATION INSTRUCTIONS FOR

PCBM-325 CONVERSION KIT

CONVERTING FROM NATURAL GAS TO PROPANE/LP GAS

For Use When Converting Model (V)P325(B)

Vented Decorative Fireplace

This conversion kit must be

installed by a qualied service

person.

Read these instructions completely before

installing this conversion kit.

Before proceeding, make sure the gas control valve is in the OFF position, all electrical

power to the appliance is OFF, and the replace is cool to the touch.

CAUTION: The gas supply

shall be shut off prior to disconnecting the electrical power

before proceeding with the

ACCESSING FIREPLACE

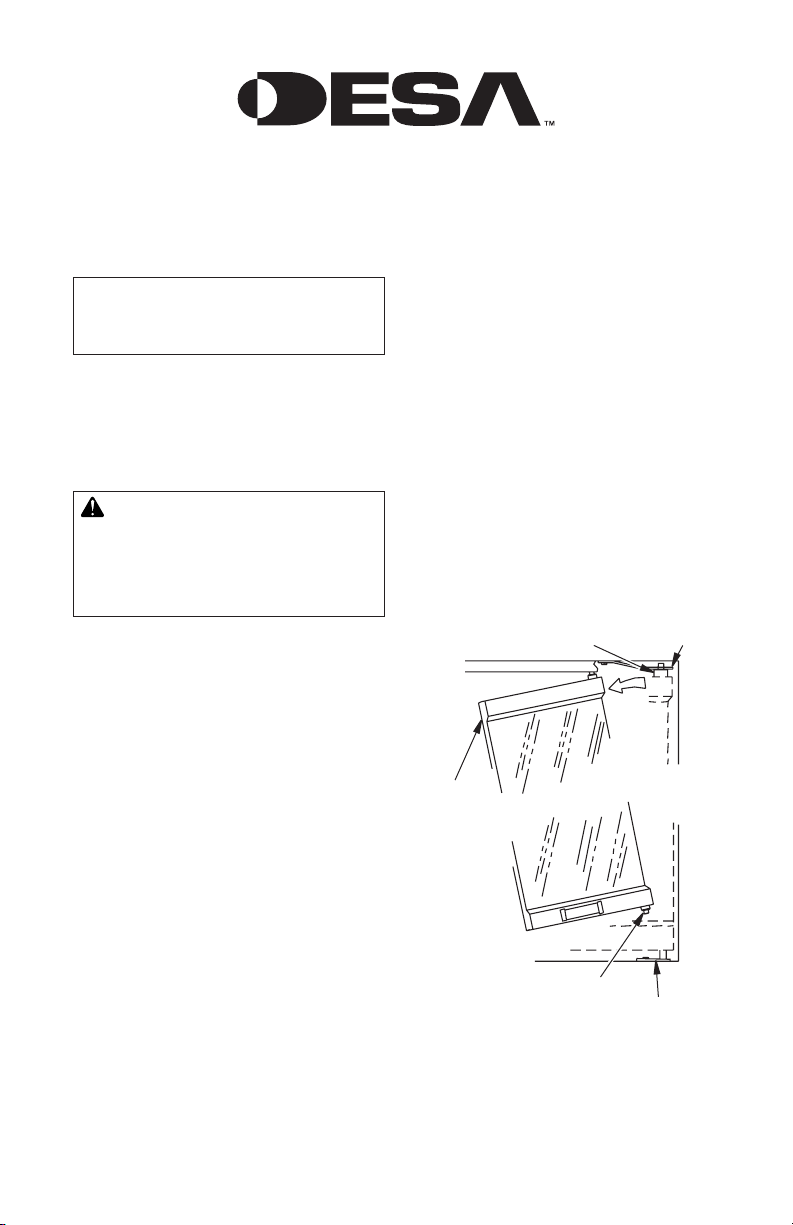

You may access burner system through opening in front of unit.

1. Remove front glass panels (if installed).

This will keep them from being damaged.

To remove, partially open doors. Press

up on upper spring clip of one door panel

with a screwdriver until outer top pivot pin

is free of clip (see Figure 1). Repeat with

second door panel. Place glass panels

safely out of your work area.

2. Slide open screens and tuck inside outer

pockets on rebox.

3. Remove front refractory access panel by

lifting up and angling out of rebox opening (see Figure 2, page 2).

conversion.

Parts included with this kit:

Part No. Description Qty.

108805-01 Instruction Sheet 1

108085-02 Pilot Orice LP 1

901065-09 Main Burner Orice LP 1

901066-02 Air-Mixer Brass LP 1

106380-01 Gas Valve Regulator 1

108808-02 Conversion Label, English 1

108809-02 Conversion Label, French 1

106080-01

Tools Required:

• 7/8" Open End Wrench or Adjustable

• 3/4" Open End Wrench or Adjustable

• 3/8" Deep Socket Drive

• Torx T20 or Slotted Screwdriver

• 5/32" Allen Wrench

• #2 Short Phillips Screwdriver

• Thread Sealant (Resistant to Propane/LP )

Conversion Information Label

Wrench

Wrench

1

Depress Spring Clip to

Release Pivot Pin

Fold Bi-Fold

Door After

Releasing

Spring Clip

and Slide

Door Out

of Upper

Track

Remove Bottom Pin From

Pivot Plate While Sliding Door

Out of the Upper Track

Figure 1 - Removing Glass Doors

Spring

Clip

Pivot

Plate

www.desatech.com

Page 2

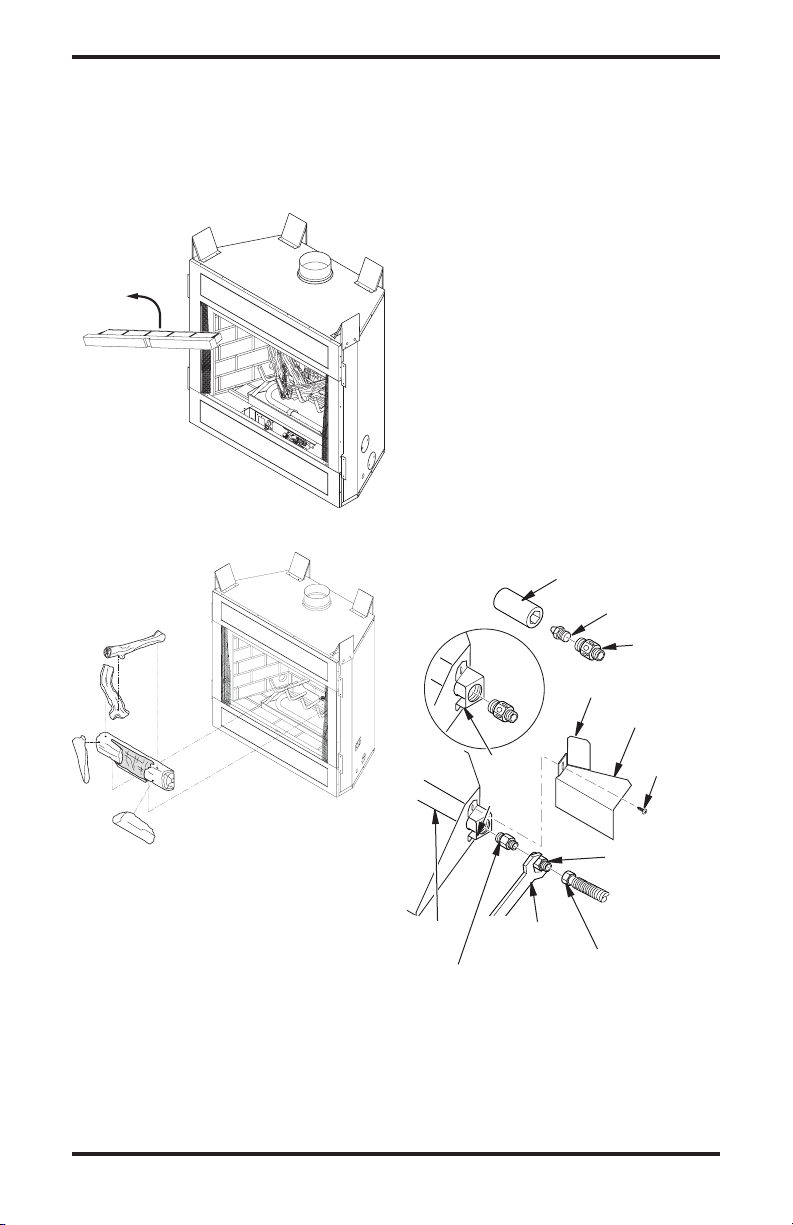

4. Remove logs. Care fully lift top logs

straight up until pins are clear of lower logs

(see Figure 3). Continue removing logs

one at a time. The rear log is very heavy

and should be lifted with both hands.

Place logs away from your work area. Be

careful not to damage logs.

Figure 2 - Removing Front Refractory

Access Panel

4. Separate the 3/8" male are adapter from

the existing natural gas orice tting and

save for later reassembly.

5. Thread the propane/LP gas orice into the

propane/LP gas air-mixer tting using a

3/8" deep socket driver. Note: LP gas air-

mixer tting has six (6) holes. The natural

gas tting has no holes.

6. Apply a light amount of propane/LP resistant sealant to both threaded ends of LP

air-mixer tting.

7. Thread large threaded end of propane/

LP air-mixer tting into burner tube and

tighten with 7/8" wrench until ange is

fully-seated into bracket.

8. Replace 3/8" are adapter onto exposed

thread on propane/LP gas air-mixer tting. Use 7/8" back-up wrench on tting

to prevent turning burner tube.

9. Retighten are tting on exible manifold

tube with the 3/4" open-end wrench and

7/8" back-up wrench.

10. Reattach pilot shield onto burner bracket

with screw removed in step 1.

3/8" Deep Socket

Propane/LP

Gas Orice

Propane/LP

Gas Air-

Flange

Burner

Bracket

Mixer Fitting

Pilot Burner

Shield

#10 Phillips

Screw

Figure 3 - Removing Logs Set

MAIN BURNER ORIFICE

CONVERSION

1. Using a #10 short Phillips screwdriver,

remove top mounting screw holding pilot

burner shield in place (see Figure 4).

2. With orice mount exposed, use a 7/8"

open-end back-up wrench on 3/8" are

adapter and remove 3/8" are tting at the

end of 3/8" are adapter. This will prevent

spinning and damage to the exible tube

(see Figure 4).

3. Using the 7/8" wrench, remove the remain-

ing orice assembly from the burner tube.

www.desatech.com

3/8" Flare

Adapter

Burner

Tube

Natural Gas

Orice Fitting

7/8" Back-Up

Wrench

Figure 4 - Removing/Replacing Main

Burner Orice

3/8" Flare Fitting

108805-01C2

Page 3

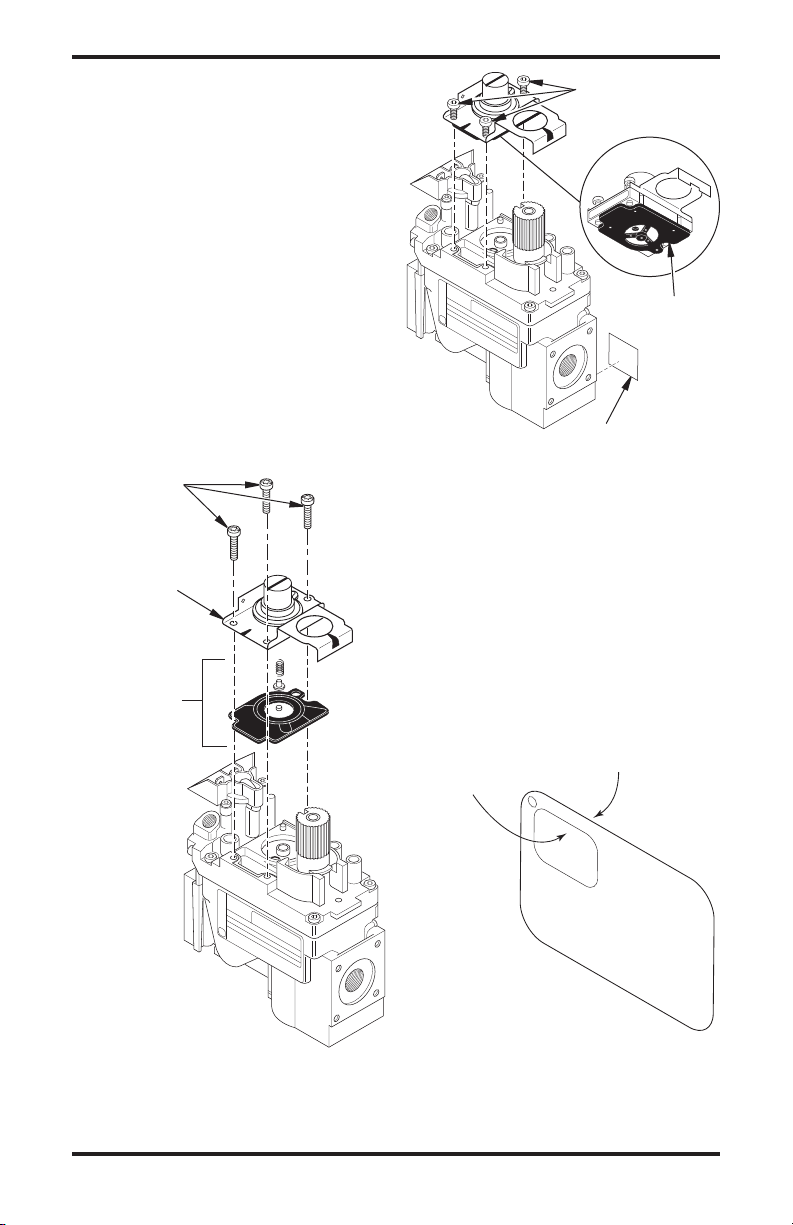

GAS CONTROL VALVE

O

F

F

P

I

L

O

T

O

N

O

F

F

P

I

L

O

T

O

N

CONVERSION

Convert gas control valve by changing out the

valve regulator portion of gas valve.

1. Using a TORX T20 or slotted screwdriver,

remove and discard thr ee mounting

screws, pressure regulator tower, and

diaphragm/spring components (see Fig-

ure 5).

2. Insure rubber gasket is properly positioned on new pressure regulator assembly. Install new pressure regulator

assembly to valve using new mounting

screws supplied with kit. Tighten screws

securely (approximately 25 in-lbs.) See

Figure 6.

3. Install the identication label enclosed with

gas valve regulator to valve body where it

can easily be seen (see Figure 6).

Mounting

Screws

Pressure

Regulator

Tower

Diaphragm/

Spring

Components

Mounting Screws

Rubber Gasket

Identication

Label

Figure 6 - Installing Pressure Regulator

Assembly

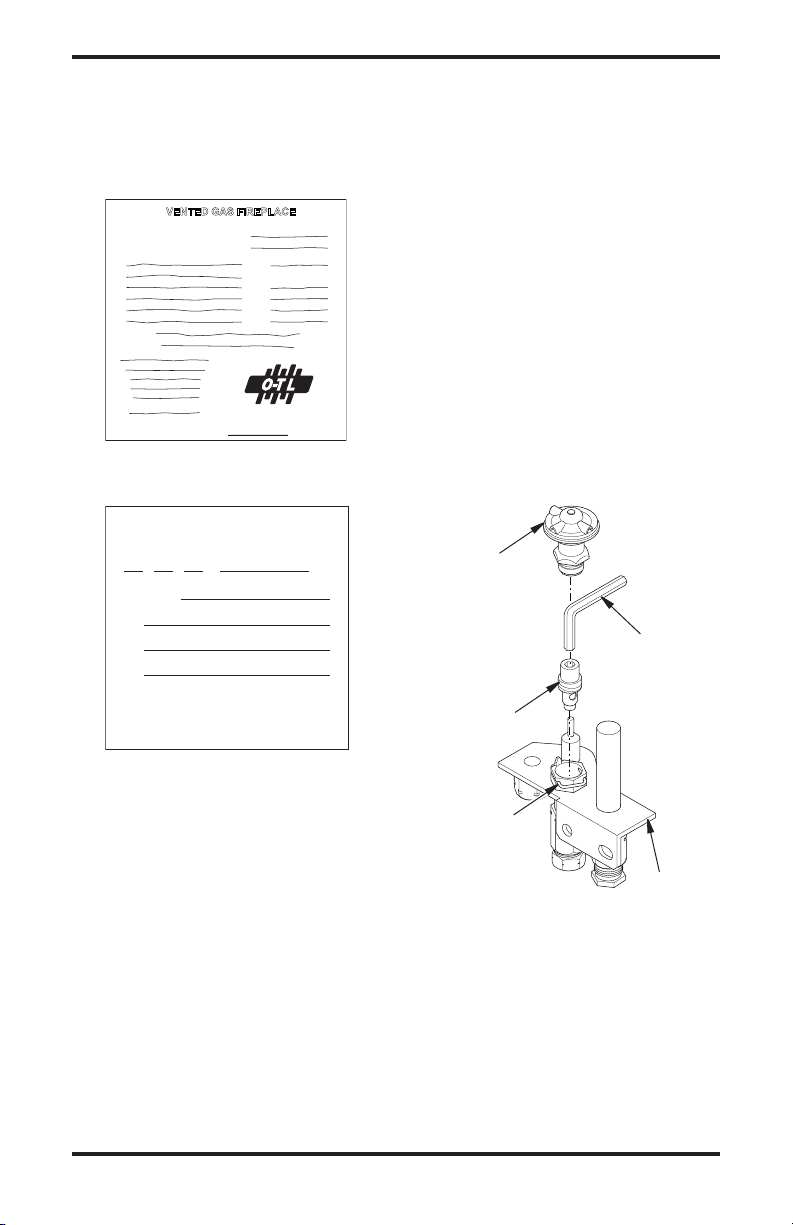

CONVERSION LABELING AND

PLACEMENT

1. Apply the English and French conversion

labels over the top of existing certication

labels (see Figure 7). Existing certication

labels are located on the lighting instruction plate inside the gas valve compart-

ment area. With permanent ink, print the

previous model number on the label in the

space provided (see Figure 8, page 4).

French This

Side

English This

Side

Lighting

Instruction

Plate

Figure 5 - Removing Mounting Screws,

Pressure Regulator Tower, and

Diaphragm/Spring Components

108805-01C 3

www.desatech.com

Figure 7 - Applying English and French

Conversion Labels Over Existing

Certication Labels on Lighting

Instruction Plate

Page 4

2. After lling in the data required on the

CONVERSION INFORMATION LABEL

This appliance was converted on

(name and address of organization making

this conversion), which accepts the

responsibility that this conversion has been

properly made.

Day Month Year

– – to gas

with Kit No.

by

106080-01

VENTED GAS FIREPLACE

Conversion Kit Model

Type of Gas

Previous Model #

conversion information label, afx it to

the oor of the appliance where it is easily

seen when the control cover is removed

(see Figure 9).

Figure 8 - Print Previous Model Number

on Conversion Labels

PILOT ORIFICE CONVERSION

1. Remove pilot hood assembly by pulling up

until it disengages from barrel. DO NOT

remove barrel clip (see Figure 10).

2. Remove pilot orice from inside barrel

using a 5/32" allen wrench to unscrew the

orice.

3. Repl ace pilot orifice wit h LP orif ice

supplied with this kit. The number 30 is

stamped on the sleeve for identication.

Insert small end of new pilot orice into

barrel and thread until tight with allen

wrench.

4. Line up notch on pilot hood assembly

to positioning tab on barrel receiver and

snap back into position.

IMPORTANT: Be careful not to bend or

kink aluminum tubing during conversion.

Make sure pilot hood and orice are properly mated and aligned after nishing this

conversion.

Pilot Hood

5/32" Allen

Wrench

Figure 9 - Conversion Information Label

Pilot Orice

Barrel Clip

Figure 10 - Converting Pilot Orice

www.desatech.com

Pilot Bracket

108805-01C4

Page 5

FINAL PREPARATION

1. Replace any vermiculite and ember material if displaced. Refer to Ember and Pan

Material Placement in owner’s manual.

2. Reinstall logs starting with the rear log,

front logs, then remaining top logs. Refer

to Log Placement in owner’s manual.

3. Leak check gas control and any connections you've made before operating

appliance. Refer to Gas Supply Hook-up

in owner’s manual.

4. Replace refractory access panel and lava

rock.

5. Replace glass doors if previously installed. Refer to Installing Optional Glass

Doors in owner’s manual.

The conversion is now complete.

To operate your replace, refer to Operating

Fireplace in your appliance owner’s manual.

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

leaks at once.

WARNING: Never use an

open ame to check for a leak.

Apply commercial leak test solution to all gas joints. Bubbles

forming show a leak. Correct all

leaks at once.

WARNING: This conversion

kit shall be installed by a qualied service agency in accordance with the manufacturer’s

instructions and all applicable

codes and requirements of the

authority having jurisdiction. If

the information in these instruction is not followed exactly, a

re, explosion, or production

of carbon monoxide may result

causing property damage, personal injury, or loss of life. The

qualied service agency is responsible for the proper installation of this kit. The installation is

not proper and complete until the

operation of the converted appli-

ance is checked as specied in

the manufacturer’s instructions

supplied with the kit.

108805-01C 5

www.desatech.com

Page 6

NOTES

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

www.desatech.com

108805-01C6

Page 7

NOTES

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

108805-01C 7

www.desatech.com

Page 8

108805 01

2701 Industrial Drive

Bowling Green, KY 42101

www.desaint.com

NOT A UPC

108805-01

Rev. C

02/07

Loading...

Loading...