Page 1

KEROSENE/DIESEL

PORTABLE FORCED

AIR HEATERS

OWNER’S MANUAL

For more information, visit www.desatech.com

For more information, visit www.desatech.com

New

Straight

Shell

Design

Heater Sizes: 40,000 55,000 60,000 70,000 110,000 115,000

155,000 165,000 and 200,000 Btu/Hr Models

H.S.I. Series

IMPORTANT: Read and understand this manual before assembling, starting or servicing

heater. Improper use of heater can cause serious injury. Keep this manual for future reference.

TABLE OF CONTENTS

SAFETY INFORMATION ............................................................ 2

PRODUCT IDENTIFICATION ..................................................... 3

UNPACKING ............................................................................... 3

THEORY OF OPERATION ......................................................... 4

FUELS......................................................................................... 4

VENTILATION............................................................................. 4

ASSEMBLY ................................................................................. 5

OPERATION ............................................................................... 5

OPERATION WITH PORTABLE GENERATOR .......................... 6

STORING, TRANSPORTING, OR SHIPPING............................ 6

PREVENTATIVE MAINTENANCE SCHEDULE ......................... 6

TROUBLESHOOTING ................................................................ 7

SERVICE PROCEDURES.......................................................... 8

TECHNICAL SERVICE ............................................................. 15

REPLACEMENT PARTS .......................................................... 15

SPECIFICATIONS .................................................................... 16

WIRING DIAGRAMS................................................................. 16

ILLUSTRATED PARTS BREAKDOWN AND PARTS LIST ....... 18

WHEELS AND HANDLES ........................................................ 24

ACCESSORIES ........................................................................ 25

OWNER'S REGISTRATION FORM .......................................... 27

WARRANTY AND REPAIR SERVICE ........................ Back Cover

Fill In For Your Records

Model No. ___________________

(Located on side panel)

Serial No. ___________________

(Located on fuel tank)

Date of Purchase: ______________

Save this manual for future reference.

Save this manual for future reference.

®

Page 2

SAFETY INFORMATION

2

SAFETY INFORMATION

WARNINGS

WARNING: This product contains and/or generates

chemicals known to the State of California to cause

cancer or birth defects, or other reproductive harm.

IMPORTANT: Read this owner’s manual carefully and

completely before trying to assemble, operate, or service this heater. Improper use of this heater can cause

serious injury or death from burns, fire, explosion,

electrical shock, and carbon monoxide poisoning.

DANGER: Carbon monoxide poisoning may lead

to death!

Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble the flu, with headaches, dizziness, and/or nausea. If you have these signs, the heater may not be working properly.

Get fresh air at once! Have heater serviced. Some people are more

affected by carbon monoxide than others. These include pregnant

women, persons with heart or lung disease or anemia, those under

the influence of alcohol, and those at high altitudes.

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this heater.

• Use only kerosene, #1#2 diesel/fuel oil, JET A or JP-8 fuels to

avoid risk of fire or explosion. Never use gasoline, naphtha,

paint thinners, alcohol, or other highly flammable fuels.

• Fueling

a)Personnel involved with fueling shall be qualified and thor-

oughly familiar with the manufacturer's instructions and applicable regulations regarding the safe fueling of heating units.

b)Only the type of fuel specified on the heater's data plate shall

be used.

c) All flame, including the pilot light, if any, shall be extin-

guished and the heater allowed to cool, prior to fueling.

d)During fueling, all fuel lines and fuel-line connections shall

be inspected for leaks. Any leaks shall be repaired prior to

returning the heater to service.

e)At no time shall more than one day's supply of heater fuel

be stored inside a building in the vicinity of the heater . Bulk

fuel storage shall be outside the structure.

f) All fuel storage shall be located a minimum of 762cm (25

feet) from heaters, torches, welding equipment, and similar

sources of ignition (exception: the fuel reservoir integral with

the heater unit).

g)Whenever possible, fuel storage shall be confined to areas

where floor penetrations do not permit fuel to drip onto or

be ignited by a fire at lower elevation.

h)Fuel storage shall be in accordance with the authority hav-

ing jurisdiction.

• Use only the electrical voltage and frequency specified on

model plate.

• Heater must be grounded. Use only a properly grounded threewire extension cord. Plug into grounded outlet only.

• Use only in areas free of flammable vapors or high dust content.

• Minimum clearance from any combustible materials: 8 feet

(244 cm) from hot air outlet; 4 feet (122 cm) from top; and

4 feet (122 cm) from sides and inlet.

• Locate heater on a stable and level surface while hot or operating or a fire may occur.

• Use only in well-vented areas. Before using heater, pro vide at

least a 2800 square cm (three-square-foot) opening of fresh,

outside air for each 30 kw (100,000 Btu/Hr) of rating.

• Keep children and animals away from heater at all times.

• Never start heater when combustion chamber is hot or if fuel

has accumulated in combustion chamber.

• When used with thermostat, heater may start at anytime.

• When heater is moved or stored, it must be in a level position

or fuel spillage may occur.

• Use heater only in accordance with local ordinances and codes.

• Never use gasoline, crankcase drainings, naphtha, paint

thinners, alcohol, or other highly flammable fuels.

• Never use heater where gasoline, paint thinner , or other highly

flammable vapors are present.

• Never use heater in living or sleeping areas.

• Never leave a heater plugged in without adult supervision if

children or animals are likely to be present.

• Never move, handle, refuel, or service a hot, operating, or

plugged-in heater.

• Never attach duct work to front or rear of heater.

• Never attach heater to external fuel tank.

• Heaters used in the vicinity of tarpaulins, canvas, or similar

enclosure materials shall be located a safe distance from such

materials. The recommended minimum safe distance is

304.8cm (10 feet). It is further recommended that these enclosure materials be of a fire retardant nature. These enclosure

materials shall be securely fastened to prevent them from igniting or from upsetting the heater due to wind action.

• Unplug heater when not in use.

• Never block air inlet (rear) or air outlet (front) of heater.

• Warning to New York City Residents

For Use Only At Construction Sites in accordance with ap-

plicable NYC codes under NYCFD certificate of approval

#4803, #4899, #4908, #4909, or #4934.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 3

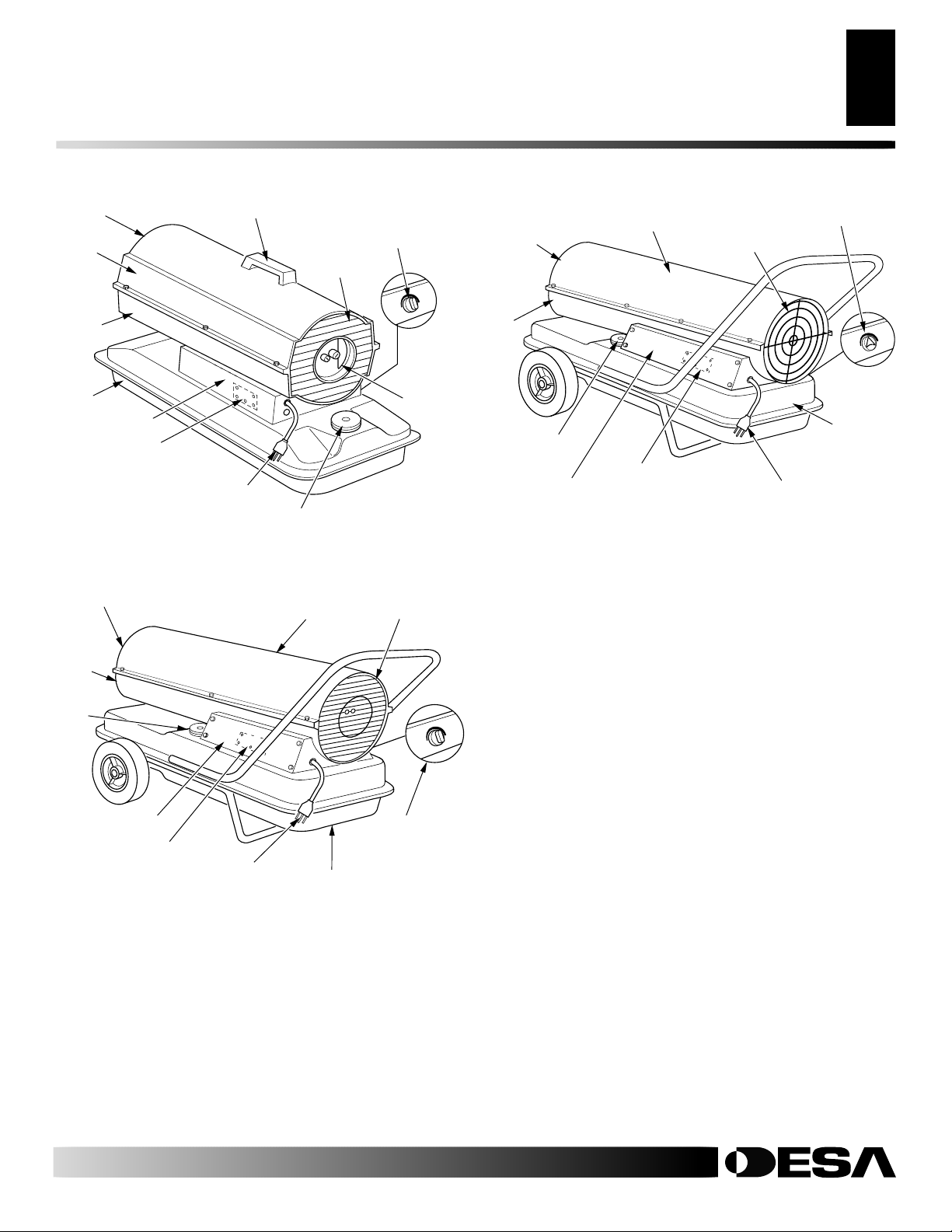

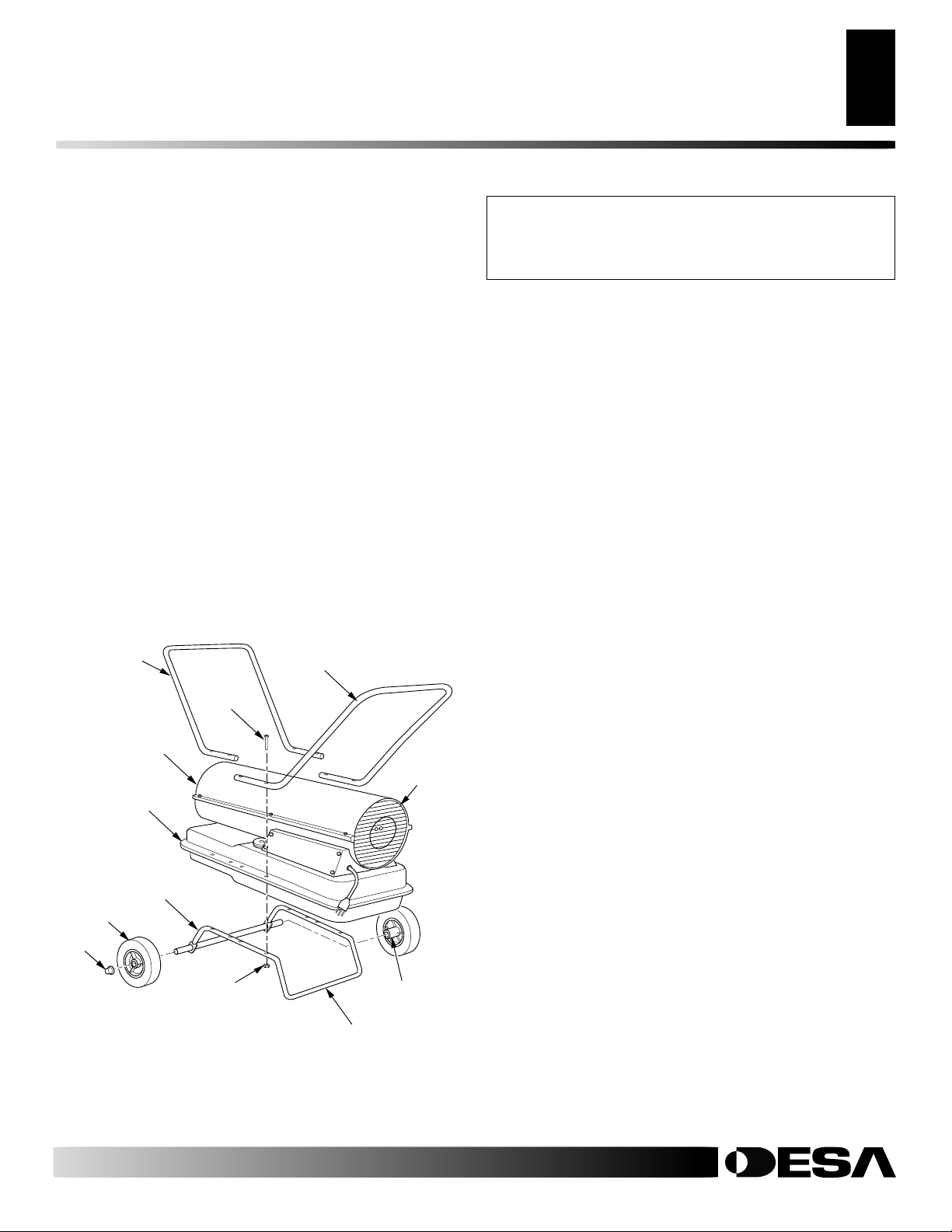

PRODUCT IDENTIFICATION

Hot Air

Outlet

Upper

Shell

Handle

Thermostat Knob

(Thermostat Models Only)

Fan Guard

Hot Air

Outlet

PRODUCT IDENTIFICATION

UNPACKING

Thermostat Knob

Upper Shell

(Thermostat Models Only)

Fan Guard

3

3

Lower

Shell

Fuel

Tank

Side Cover

Ignition Control

Assembly (On Inside

of Side Cover)

Power

Cord

Figure 1 - 40/55/60/70 Models

Hot Air Outlet

Lower

Shell

Fuel

Cap

Fuel Cap

Upper Shell

Air Filter

End

Cover

Fan

Guard

Lower

Shell

Fuel Cap

Side Cover

Figure 3 - 200 Model

Ignition Control

Assembly (On Inside

of Side Cover)

Fuel Tank

Power Cord

UNPACKING

1. Remove all packing items applied to heater for shipment.

2. Remove all items from carton.

3. Check items for any shipping damage. If heater is damaged,

promptly inform dealer where you bought heater.

Side Cover

Ignition Control

Assembly (On Inside

of Side Cover)

Figure 2 - 110/115/155/165 Models

111167-01C

Power Cord

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Fuel Tank

Thermostat

Knob

(Thermostat

Models Only)

Page 4

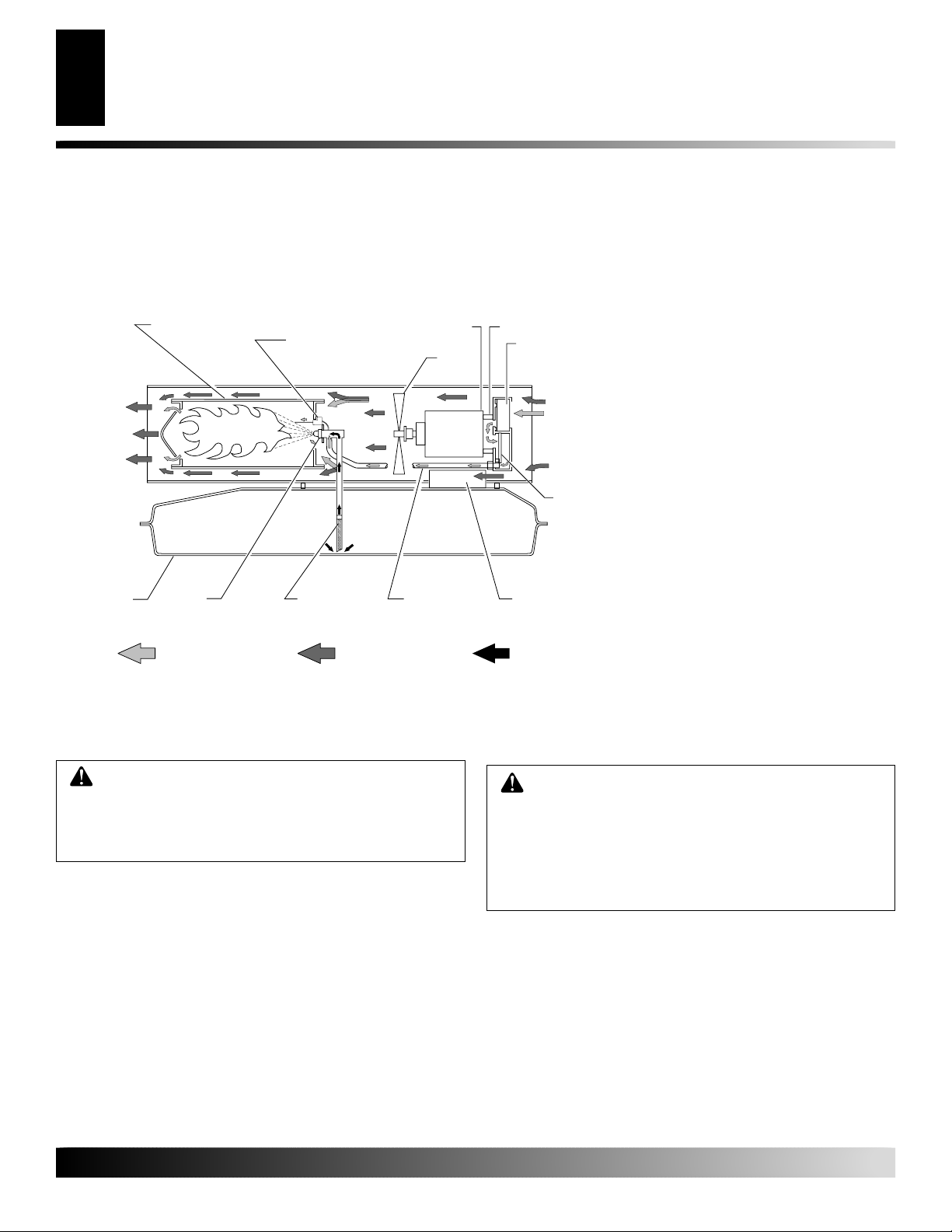

THEORY OF OPERATION

4

FUELS

VENTILATION

THEORY OF OPERATION

The Fuel System: The air pump forces air through the air line. The air

is then pushed through the nozzle. This air causes fuel to be lifted from

the tank. A fine mist of fuel is sprayed into the combustion chamber.

The Air System: The motor turns the fan. The fan pushes air into

and around the combustion chamber. This air is heated and provides

a stream of clean, hot air.

Clean

Heated

Air Out

Fuel

Tank

Combustion Chamber

Nozzle

Air For Fuel System

Ignitor

Fuel

Filter

Air For Combustion

And Heating

Motor

Fan

Air Line

To Burner

The Ignition System: The ignition control assembly provides

power to the ignitor. This ignites the fuel/air mixture in the combustion chamber.

The Flame-Out Control System: This system causes the heater to

shut down if the flame goes out.

Air Pump

Air Intake

Filter

Cool

Air

In

Air

Output

Filter

Ignition Control

Assembly

Fuel

Figure 4 - Cross Section Operational View

FUELS

WARNING: Use only kerosene, #1/#2 diesel/fuel

oil, JET A or JP-8 fuels to avoid risk of fire or explosion. Never use gasoline, oil drained from crankcases, naphtha, paint thinners, alcohol or other highly

flammable fuels.

Use only kerosene, #1/#2 diesel/fuel oil, JET A or JP-8 fuels.

Heavier fuels such as No. 2 fuel oil or No. 2 diesel fuel may also be

used but will result in:

• noticeable odor

• additional fuel filter maintenance

• the need for nontoxic, anti-icer additives in very cold weather

Do not use fuels heavier than No. 2 grade or heavy oils such as oil

drained from crankcases. These heavy oils will not ignite properly

and will contaminate the heater.

IMPORTANT:

(yellow ) storage container. Be sure storage container is clean. Foreign matter such as rust, dirt, or water will cause the ignition control

assembly to shut down heater. Foreign matter may also require

heater's fuel system to be frequently cleaned.

Use a KEROSENE ONLY (blue) or DIESEL ONLY

VENTILATION

WARNING: Provide a fresh air opening of at least

three square feet (2,800 square cm) for each 100,000

Btu/hr rating. Provide extra fresh air if more heaters

are being used. The minimum ventilation requirements must be followed to avoid risks associated

with carbon monoxide poisoning. Make certain these

requirements are met prior to operating heater.

Example:

following:

• a two-car garage door [4.88 meter (16 feet) opening] raised

12.7 cm (5 inches)

• a single-car garage door [2.74 meter (9 feet) opening] raised

20.3 cm (8 inches)

• two, 76.2 cm (30 inch) windows raised 38.1 cm (15 inches)

A 58.6kw (200,000 Btu/Hr) heater requires one of the

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 5

ASSEMBLY

OPERATION

5

5

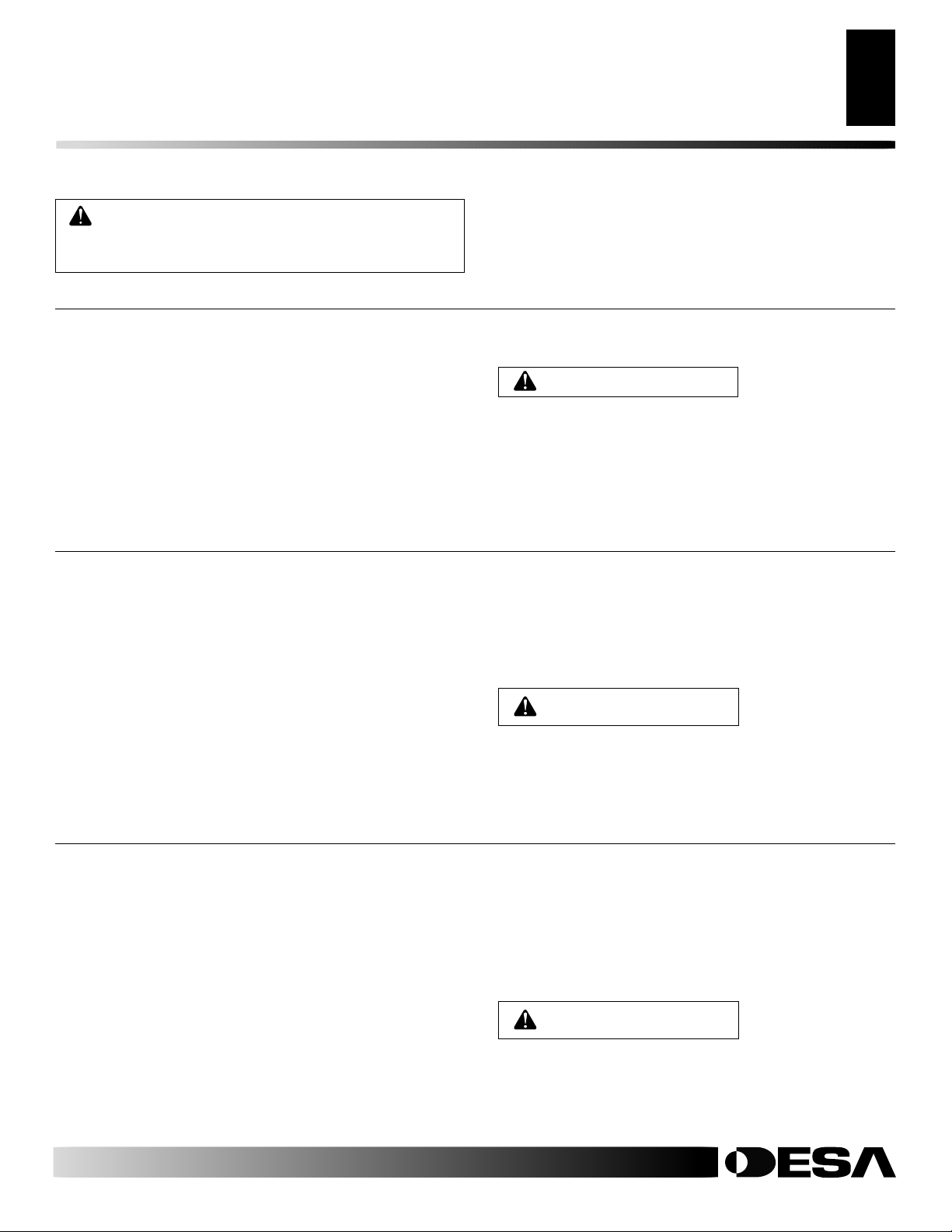

ASSEMBLY

(FOR 110/115/155/165/200 MODELS ONLY)

These models are furnished with wheels and a rear handle. Some

models are furnished with a front handle also. Wheels, handle(s),

and the mounting hardware are found in the shipping carton.

Tools Needed

• Medium Phillips Screwdriver

• 3/8" Open or Adjustable Wrench

• Hammer

1. Slide axle through wheel support frame. Install wheels on axle.

IMPORTANT:

wheels toward wheel support frame (see Figure 5).

2. Place cap nuts on axle ends. Gently tap with hammer to secure.

3. Place heater on wheel support frame. Make sure ho t a ir out let

end (fron t ) of heater is over wheels. Line up holes on fuel tank

flange with holes on wheel support frame.

4. Place rear handle (and front handle if provided) on top of fuel

tank flange. Insert screws through handle(s), fuel tank flange,

and wheel support frame. Attach nut finger tight after each

screw is inserted.

5. After all screws are inserted, tighten nuts firmly.

Front Handle

(If Provided)

Hot Air

Outlet

Fuel Tank

Flange

When installing wheels, point e xtended hub of

Handle

Screw

Air

Inlet

OPERATION

IMPORTANT: Review and understand the warnings

in the

needed to safely operate this heater. Follow all local

ordinances and codes when using this heater.

TO START HEATER

1. Follow all ventilation and safety information.

2. Locate heater to provide maximum circulation of the heated

3. Fill fuel tank with kerosene, #1#2 diesel/fuel oil, JET A or

4. Attach fuel cap.

5. For thermostat models, turn thermostat knob clockwise to the

6. Plug heater’s power cord into approved, grounded, three-wire

7. Plug extension cord into standard 120 volt/60 hertz, 3-prong

8. For thermostat models, adjust thermostat knob to the desired

Safety Information

air. Follow all location requirements noted in Safety Information, page 2.

JP-8 fuel.

high position.

extension cord. Extension cord must be at least six feet (1.8

meters) long.

Extension Cord Size Requirement

6 to 10 feet (1.8 to 3 meters) long, use 18 AWG (0.75 mm2)

rated cord

11 to 100 feet (3.3 to 30.5 meters) long, use 16 AWG (1.0 mm2)

rated cord

101 to 200 feet (30.8 to 61 meters) long, use 14 AWG (1.5 mm2)

rated cord

grounded outlet.

then heater will start.

setting.

This thermostat is a general-heating control. It is not intended

for precise temperature control. Adjust thermostat until heater

cycles at the desired setting.

Note:

Note:

A cold heater may af fect the thermostat setting.

section, page 2. They are

Ignitor will preheat for five seconds,

Wheel

Support

Wheel

Cap Nut

Figure 5 - Wheel and Handle Assembly, 110/115/155/165/200

Models Only

111167-01C

Frame

Nut

Axle

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Extended

Hub

TO STOP HEATER

Unplug extension cord from outlet.

TO RESTART HEATER

1. Unplug extension cord from outlet and wait 10 seconds. (Wait

two minutes if heater has been running.)

2. Repeat steps under To Start Heater.

Page 6

OPERATION WITH PORTABLE GENERATOR

6

STORING, TRANSPORTING, OR SHIPPING

PREVENTATIVE MAINTENANCE SCHEDULE

OPERATION WITH PORTABLE

GENERATOR

WARNING: Before operating heater or any appliance from a portable generator, verify that generator

has been properly connected to earth ground. Improper grounding or failure to ground generator can

result in electrocution if a ground fault occurs. Refer

to owner’s manual supplied by generator manufacturer for proper grounding procedures.

The operating voltage range of the heater is 108 to 132 Volts (120

Volts +/- 10%). Prior to plugging heater into generator the output

voltage should be verified (if generator is equipped with the automatic

idle feature, the output voltage should be measured with the generator

running at full speed). If the voltage does not measure in this range

the heater should not be plugged into the generator.

Refer to Operation, page 5, for starting, stopping, and resetting

heater procedures.

Alternator

Ground Lug

Copper or Brass

Grounding Point

STORING, TRANSPORTING,

OR SHIPPING

Note:

If shipping, transport companies require fuel tanks to be empty.

1. Drain fuel tank.

Note:

Some models have drain plug on underside of fuel tank.

If so, remove drain plug to drain all fuel. If heater does not

have drain plug, drain fuel through fuel cap opening. Be sure

all fuel is removed.

2. Replace drain plug if provided.

3. If any debris is noted in old fuel, add 1 or 2 quarts of clean

kerosene to tank, stir, and drain again. This will prevent excess debris from clogging filters during future use.

4. Replace fuel cap or drain plug. Properly dispose of old and

dirty fuel. Check with local automotive service stations that

recycle oil.

5. If storing, store heater in dry place. Make sure storage place is

free of dust and corrosive fumes.

IMPORTANT:

during next heating season. Using old fuel could damage heater.

Do not store kerosene over summer months for use

Ground Wire (#10 AWG Stranded-Copper)

Figure 6 - Typical Generator Grounding Method (Generator

construction may vary from that shown)

PREVENTATIVE MAINTENANCE SCHEDULE

WARNING: Never service heater while it is plugged in, operating, or hot. Severe burns and electrical shock

can occur.

Item

Fuel tank

Air output and lint filters

Air intake filter

Fuel filter

Ignitor

Fan blades

How Often

Flush every 150-200 hours of operation or as needed

Replace every 500 hours of operation or once a year

Wash and dry with soap and water every 500 hours

of operation or as needed

Clean twice a heating season or as needed

No maintenance required

Clean every season or as needed

How To

See Storing, Transporting, or Shipping, above

See Air Output, Air Intake, and Lint Filters, page 8

See Air Output, Air Intake, and Lint Filters, page 8

See Fuel Filter, pages 9 and 10

See Fan, page 8

Motor

Not required/permanently lubricated

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 7

TROUBLESHOOTING

WARNING: Never service heater while it is plugged

in, operating, or hot. Severe burns and electrical

shock can occur.

TROUBLESHOOTING

7

7

FAULT CONDITION

Motor does not start five seconds after

heater is plugged in

Motor starts and runs but heater does not

ignite

POSSIBLE CAUSE

1. No power to heater

2. If equipped, thermostat setting is too low

WARNING: High voltage!

3. Bad electrical connection between motor and ignition control assembly or ignition control assembly and power cord

4. Binding pump rotor

5. Defective ignition control assembly

6. Defective motor

7. Blown fuse or ignitor control assembly

1. No fuel in tank

2. Pump pressure incorrect

3. Dirty fuel filter

4. Obstruction in nozzle

5. Water in fuel tank

WARNING: High voltage!

6. Bad electrical connection between ignitor and ignition control assembly

7. Defective ignitor

8. Defective ignition control assembly

9. 200 Model Only: Defective fuel valve

(Models equipped with fuel valve only)

REMEDY

1. Check circuit breaker in electrical panel

2. Turn thermostat knob to a higher setting

3. Check all electrical connections. See

Wiring Diagrams, pages 16 and 17

4. If fan does not turn freely , see Pump Ro-

tor, page 14

5. Replace ignition control assembly

6. Replace motor

7. See Ignition Control Assembly, page 15

1. Fill tank with kerosene

2. See Pump Pressure Adjustment, page 9

3. See Fuel Filter, pages 9 and 10

4. See Nozzle Assembly, pages 12 and 13

5. Drain and flush fuel tank with clean

kerosene. See Storing, T ransporting , or

Shipping, page 6

6. Check electrical connections. See Wir-

ing Diagrams, pages 16 and 17

7. Replace ignitor, see page 11

8. Replace ignition control assembly

9. See Fuel Valve, page 10

Heater ignites but ignition control assembly shuts heater off after a short

period of time

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

1. Pump pressure incorrect

2. Dirty air intake, air output, and/or lint

filter

3. Dirty fuel filter

4. Obstruction in nozzle

5. Photocell assembly not properly installed (not seeing the flame)

6. Dirty photocell lens

WARNING: High voltage!

7. Bad electrical connection between photocell and ignition control assembly

8. Defective photocell

9. Defective ignition control assembly

1. See Pump Pressure Adjustment, page 9

2. See Air Output, Air Intake, and Lint Fil-

ters, page 8

3. See Fuel Filter, pages 9 and 10

4. See Nozzle Assembly, pages 12 and 13

5. Make sure photocell boot is properly

seated in bracket

6. Clean photocell lens

7. Check electrical connections. See Wir-

ing Diagrams, pages 16 and 17

8. Replace photocell

9. Replace ignition control assembly

Page 8

SERVICE PROCEDURES

8

SERVICE PROCEDURES

WARNING: To avoid risk of burn and electrical

shock, never attempt to service heater while it is

plugged in, operating, or hot.

Setscrew

Fan

Motor

Setscrew

Fan

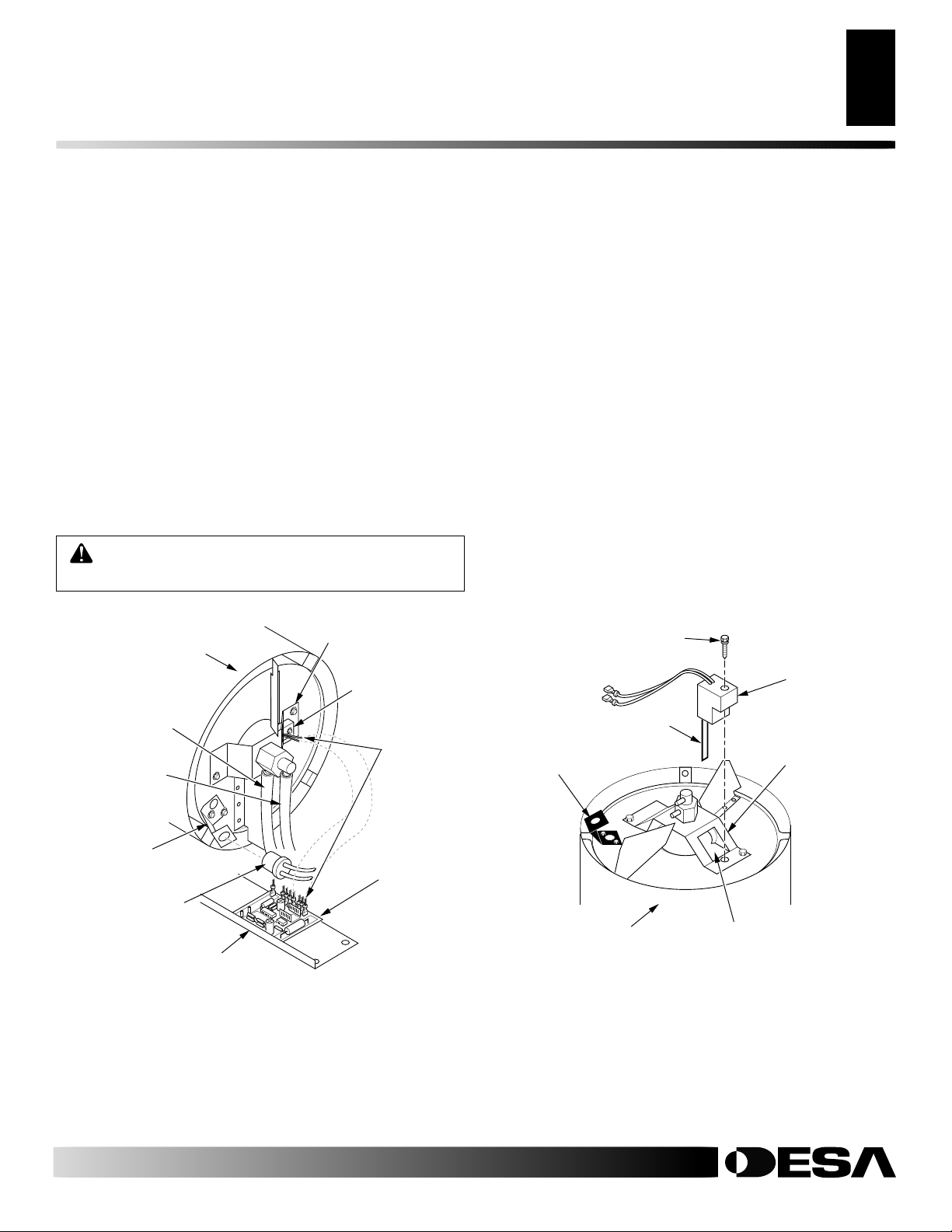

UPPER SHELL REMOVAL

1. Remove screws along each side of heater using 5/16" nut-dri ver .

These screws attach upper and lower shells together. See Figure 7 or 8.

2. Lift upper shell off.

3. Remove fan guard.

Screw

Upper Shell

Fan

Guard

Figure 7 - Upper Shell

Removal, 40/50/60/70

Models Only

Figure 8 - Upper Shell

Removal, 110/115/155/165/200

Models Only

Screw

Upper Shell

Fan

Guard

FAN

Flush

Motor

Shaft

Figure 9 - Fan, Motor Shaft,

and Setscrew Location

Figure 10 - Fan Cross Section

Motor

Shaft

AIR OUTPUT, AIR INTAKE AND LINT FILTERS

1. Remove upper shell (see Figure 7 or 8).

2. Remove filter end cover screws using 5/16" nut-driver (see

Figure 11 or 12).

3. Remove filter end cover.

4. Replace air output and lint filters.

5. W ash or replace air intake filter (see Pr eventative Maintenance

Schedule, page 6).

6. Replace filter end cover.

7. Replace fan guard and upper shell.

IMPORTANT:

Do not oil filters.

Air Intake

Filter

Filter End

Cover

IMPORTANT:

Remove fan from motor shaft before removing

motor from heater. The weight of the motor resting on the fan could

damage the fan pitch (see Figure 9).

1. Remove upper shell (see Figure 7 or 8).

2. Use 1/8" allen wrench to loosen setscrew which holds fan to

motor shaft.

3. Slip fan off motor shaft.

4. Clean fan using a soft cloth moistened with kerosene or solvent.

5. Dry fan thoroughly.

6. Replace fan on motor shaft. Place fan hub flush with end of

motor shaft (see Figure 10).

7. Place setscrew on flat of shaft. T ighten setscre w firmly (40-50

inch-pounds/4.5-5.6 n-m).

8. Replace fan guard and upper shell.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Lint Filter

Air Output

Filter

Figure 11 - Air Output, Air Intake, and Lint Filters, 40/55/60/70

Models Only

Air Intake

Filter

Filter End

Cover

Lint Filter

Air Output Filter

Figure 12 - Air Output, Air Intake, and Lint Filters, 110/115/155/

165/200 Models Only

111167-01C

Page 9

SERVICE PROCEDURES

Continued

SERVICE PROCEDURES

9

9

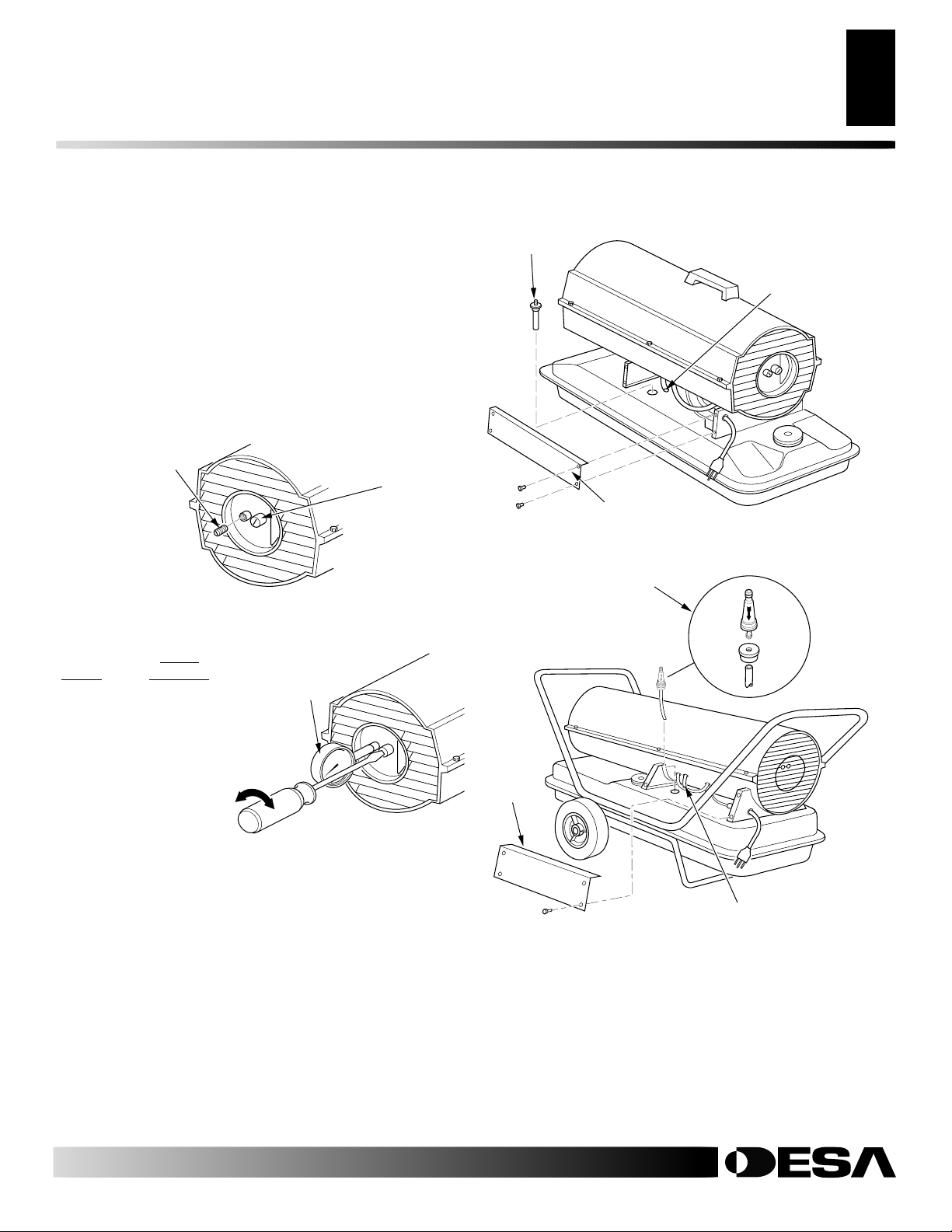

PUMP PRESSURE ADJUSTMENT

1. Remove pressure gauge plug from filter end cover (see Figure 13).

2. Install accessory pressure gauge (part number HA1180).

3. Start heater (see Operation, page 5). Allow motor to reach

full speed.

4. Adjust pressure. Tur n relief valve to right to increase pressure.

Turn relief valve to left to decrease pressure. See specifications correct pressure for each model (see Figure 14).

5. Remove pressure gauge. Replace pressure gauge plug in filter

end cover.

Pressure

Gauge

Plug

Figure 13 - Pressure Gauge Plug Removal (40/55/60/70 Models

Shown)

Pump

Model Pressure

40 3.0 PSI

55 3.4 PSI

60 3.4 PSI

70 4.7 PSI

110 5.1 PSI

115 5.1 PSI

155 5.2 PSI

165 5.6 PSI

200 6.2 PSI

Pressure

Gauge

Relief

Valve

Fuel Filter

and Bushing

Upper Fuel Line

Side Cover

Figure 15 - Fuel Filter Removal, 40/55/60/70 Models

Fuel Filter, Bushing,

and Lower Fuel Line

Side

Cover

Figure 14 - Adjusting Pump Pressure (40/55/60/70 Models Shown)

FUEL FILTER

(For 40/55/60/70/110/115/155/165 Models Only)

1. Remove side cover screws using 5/16" nut-driver.

2. Remove side cover.

3. Pull upper fuel line off fuel filter neck (see Figure 15 or 16).

4. Carefully pry bushing, fuel filter , and lower fuel line (110/115/

155/165 Models only) out of fuel tank (see Figure 16).

5. Wash fuel filter with clean fuel and replace in tank.

6. Attach upper fuel line to fuel filter neck.

7. Replace side cover.

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Upper Fuel Line

Figure 16 - Fuel Filter Removal, 110/115/155/165 Models

Page 10

10

SERVICE PROCEDURES

SERVICE PROCEDURES

Continued

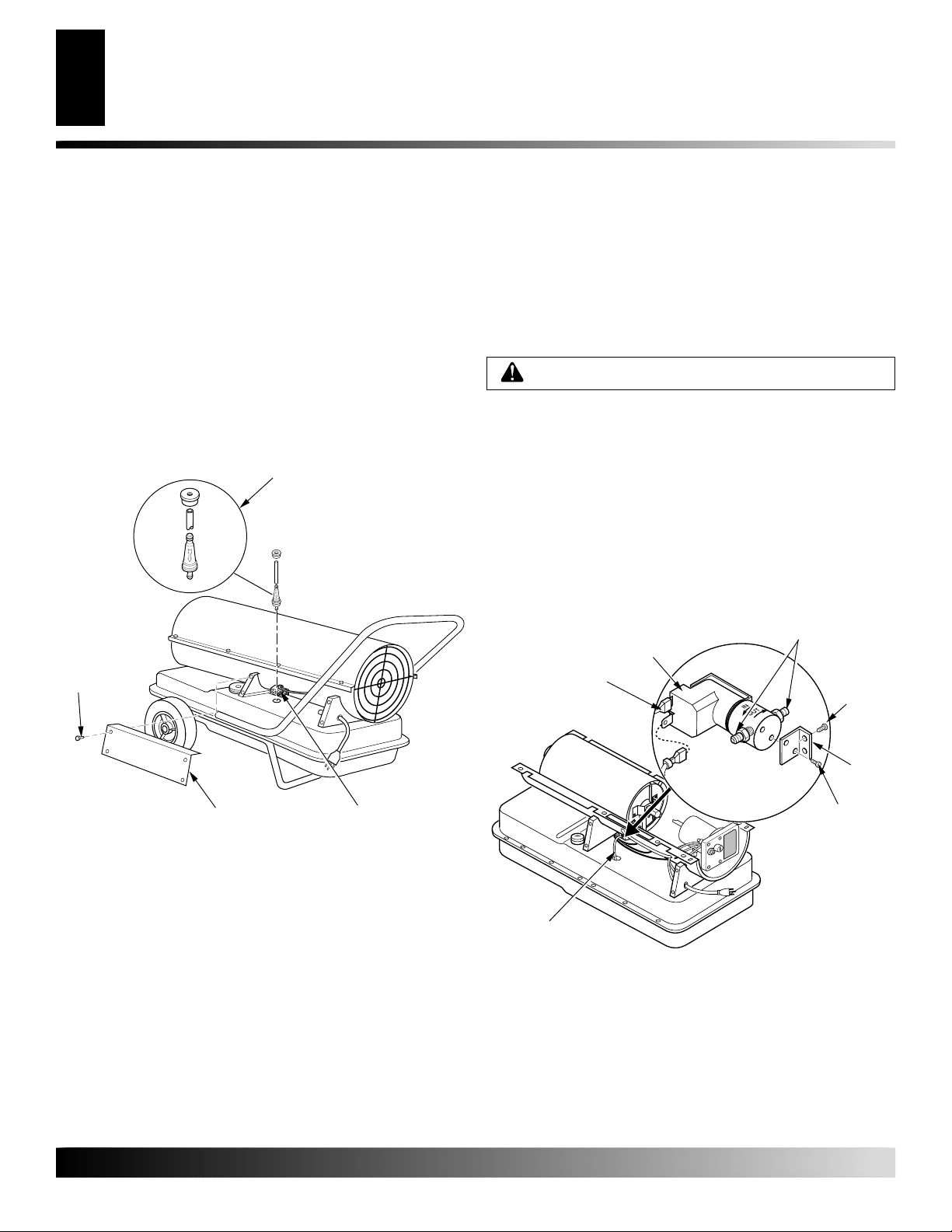

(For 200 Model Only)

1. Remove side cover screws using 5/16" nut-driver.

2. Remove side cover (see Figure 17).

3. Pull low er fuel line of f the fuel v alve fitting (se e Figu re 17) .

Note:

See Figure 16, page 9 if your model does not come

equipped with a fuel valve.

4. Carefully pry bushing, lower fuel line, and fuel filter out of

fuel tank.

5. Wash fuel filter with clean fuel and replace in tank.

6. Attach lower fuel line to fuel valve fitting.

7. Replace side cover.

Bushing, Lower Fuel

Line, and Fuel Filter

Screw

FUEL VALVE

For 200 Models Equipped with Fuel Valve

1. Remove side cover (see Figure 17), fan guard, and upper

shell (see Figure 8, page 8) screws using 5/16" nut-driver.

2. Remove fan (see Fan, page 8).

3. Pull lower fuel line off the fuel valve fitting (see Figure 18).

WARNING: High Voltage

4. Disconnect red and white wires from fuel valve (see Figure 18).

5. Using 1/4" nut driver remove 2 screws holding fuel valve and

bracket to lower shell (see Figure 18). Save these screws.

6. Using 1/4" nut driver remove 2 screws holding fuel valve to

bracket. Save these screws.

7. Attach new fuel valve to bracket with 2 screws.

8. Install new fuel valve and bracket on lower shell with 2 screws.

9. Connect red and white wires (polarity not important). Connect

upper and lower fuel lines to fuel valve (see Figure 18).

10. Replace fan, fan guard, upper shell, and side cover.

Valve Fittings

Fuel Valve

Electrical Wires

Screw

Side Cover

Figure 17 - Fuel Filter Removal, 200 Model Only (Model with Fuel

Valve Assembly Shown)

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Fuel Valve Fitting

Bracket

Screw

Lower Fuel Line

Figure 18 - Fuel Valve Replacement, 200 Model Only

111167-01C

Page 11

SERVICE PROCEDURES

Continued

IGNITOR

1. Remove upper shell and fan guard (See Upper Shell Removal,

page 8).

2. Remove fan (see page 8).

3. Remove 4 side cover screws with a 5/16" nut driver. Remove

side cover (see Figures 15 or 16, page 9 or Figure 17, page 10).

4. Disconnect ignitor wires from ignition control assembly (see

Figure 19). Pull the ignitor wires up through the hole in the

lower shell.

5. Disconnect fuel line hose and air line hose. Remove photocell

from photocell bracket (see Figure 19).

6. Remove combustion chamber. Stand combustion chamber on

end with nozzle adapter bracket on top (see Figure 20).

7. Remove ignitor screw with a 1/4" nut dri ver . Carefully remov e

ignitor from nozzle adapter bracket.

CAUTION: Do not bend or strike ignitor element.

Handle with care.

SERVICE PROCEDURES

11

11

8. Carefully remove replacement ignitor from styrofoam packing.

9. Carefully guide ignitor into opening in nozzle adapter bracket.

Do not strike ignitor element. Attach ignitor to nozzle adapter

bracket with screw using a 1/4" nut driver (see Figure 20).

Torque .90 to 1.69 N-m (8 to 15 in-lbs) Do not over torque.

10. Replace combustion chamber.

11. Route the ignitor wires back down through the hole in the lower

shell. Connect wires to the ignition control assembly (see Figure 19).

12. Replace side cover (see Figures 15 or 16, page 9 or Figure 17,

page 9).

13. Connect and route fuel line hose and air line hose to nozzle

adapter assembly. See Fuel and Air Line Replacement and

Proper Routing, page 13.

14. Replace photocell in photocell bracket. Route wires as shown in

either (see Figures 21 or 22, page 12 or Figure 25, page 13).

15. Replace fan (see page 8).

16. Replace fan guard and upper shell (see page 8).

Nozzle Adapter

Combustion

Chamber

Air Line Hose

Fuel Line Hose

Photocell

Bracket

Photocell

Assembly

Side Cover

Figure 19 - Disconnecting Ignitor Wires from Ignition Control

Assembly (40/55/60/70/110/115/155/165 Models Shown)

Bracket

Ignitor

Ignitor Wire

Ignition

Control

Assembly

Ignitor Screw/

Washer Assembly

Ignitor Element

Photocell

Bracket

Combustion

Chamber

Figure 20 - Ignitor Replacement

Ignitor

Nozzle Adapter

Bracket

Nozzle Adapter

Bracket Opening

111167-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 12

SERVICE PROCEDURES

12

SERVICE PROCEDURES

Continued

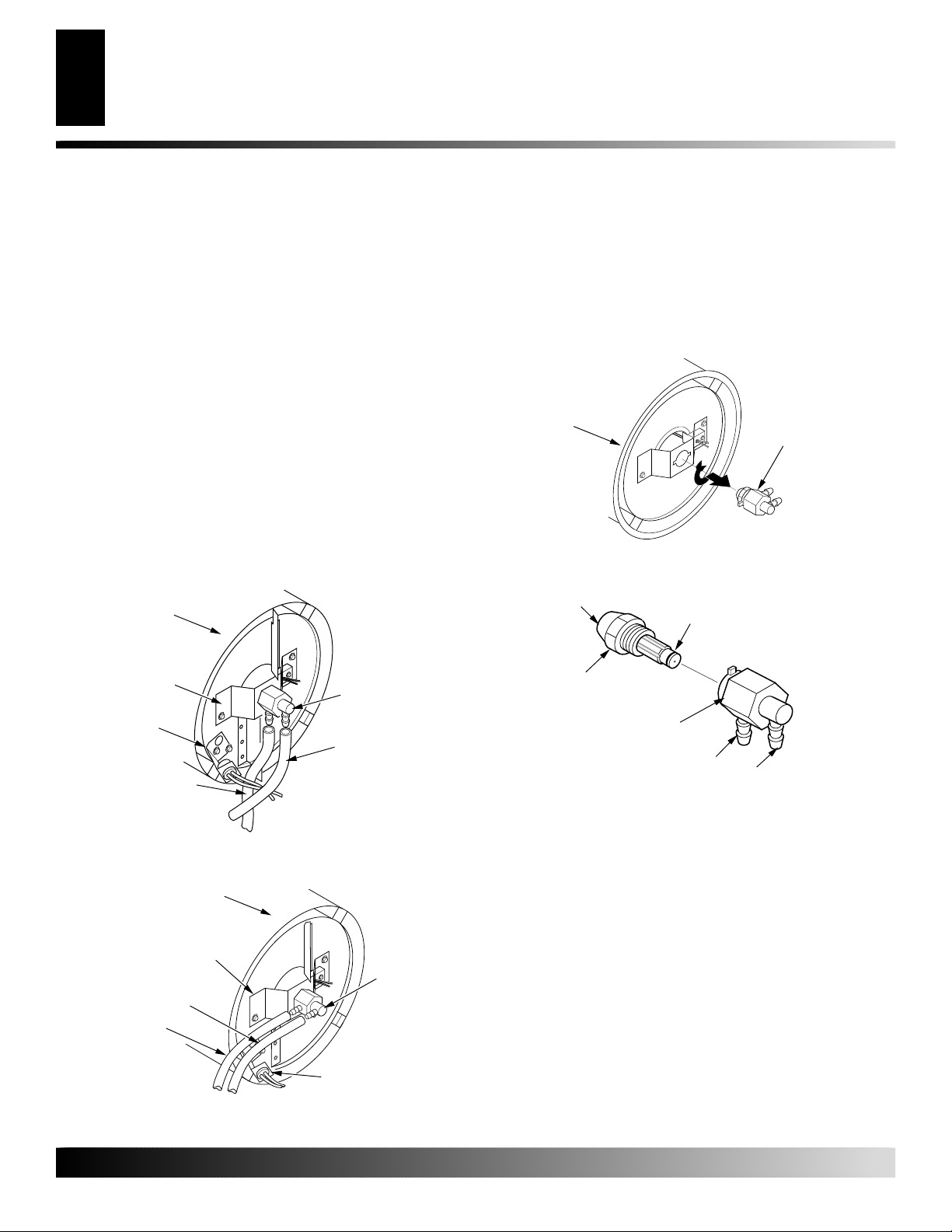

NOZZLE ASSEMBLY

(For 40/55/60/70/110/115/155/165 Models Only)

1. Remove upper shell (see Upper Shell Removal, page 8).

2. Remove fan (see Fan, page 8).

3. Remove fuel and air line hoses from nozzle assembly (see Figure 21 or 22).

4. Turn nozzle assembly 1/4 turn to left and pull to ward motor to

remove (see Figure 23).

5. Place plastic hex-body into vise and lightly tighten.

6. Carefully remove nozzle from the nozzle adapter using 5/8"

socket wrench (see Figure 24).

7. Blow compressed air through face of nozzle. This will free

any dirt in nozzle area.

8. Inspect nozzle sleeve for damage.

9. Replace nozzle into nozzle adapter until nozzle seats. Tighten

1/3 turn more using 5/8" socket wrench 4.5 to 5.1 N-m (40 to

45 in-lbs). See Figure 24.

Combustion

Chamber

Nozzle

Adapter

Bracket

Photocell

Bracket

Air Line

Hose

Figure 21 - Removing Air and Fuel Line Hoses

(40/55/60/70 Models Only)

Nozzle/Adapter

Assembly

Fuel Line Hose

10. Attach nozzle assembly to burner strap (see Figure 23).

11. Attach fuel and airline hoses to nozzle assembly . See Fuel and

Airline Replacement and Proper Routing, page 13.

12. Replace fan (see Fan, page 8).

13. Replace fan guard and upper shell (see Upper Shell Removal,

page 8).

Combustion

Chamber

Figure 23 - Removing Nozzle/Adapter Assembly

Nozzle

Face

Nozzle

Nozzle Adapter

Figure 24 - Nozzle and Nozzle Adapter

Nozzle Sleeve

Air Line

Fitting

Nozzle/Adapter

Assembly

Fuel Line

Fitting

Combustion

Chamber

Nozzle Adapter

Bracket

Air Line Hose

Fuel Line

Hose

Photocell Bracket

Figure 22 - Removing Air and Fuel Line Hoses

(110/115/155/165 Models Only)

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Nozzle/

Adapter

Assembly

111167-01C

Page 13

SERVICE PROCEDURES

Continued

SERVICE PROCEDURES

13

13

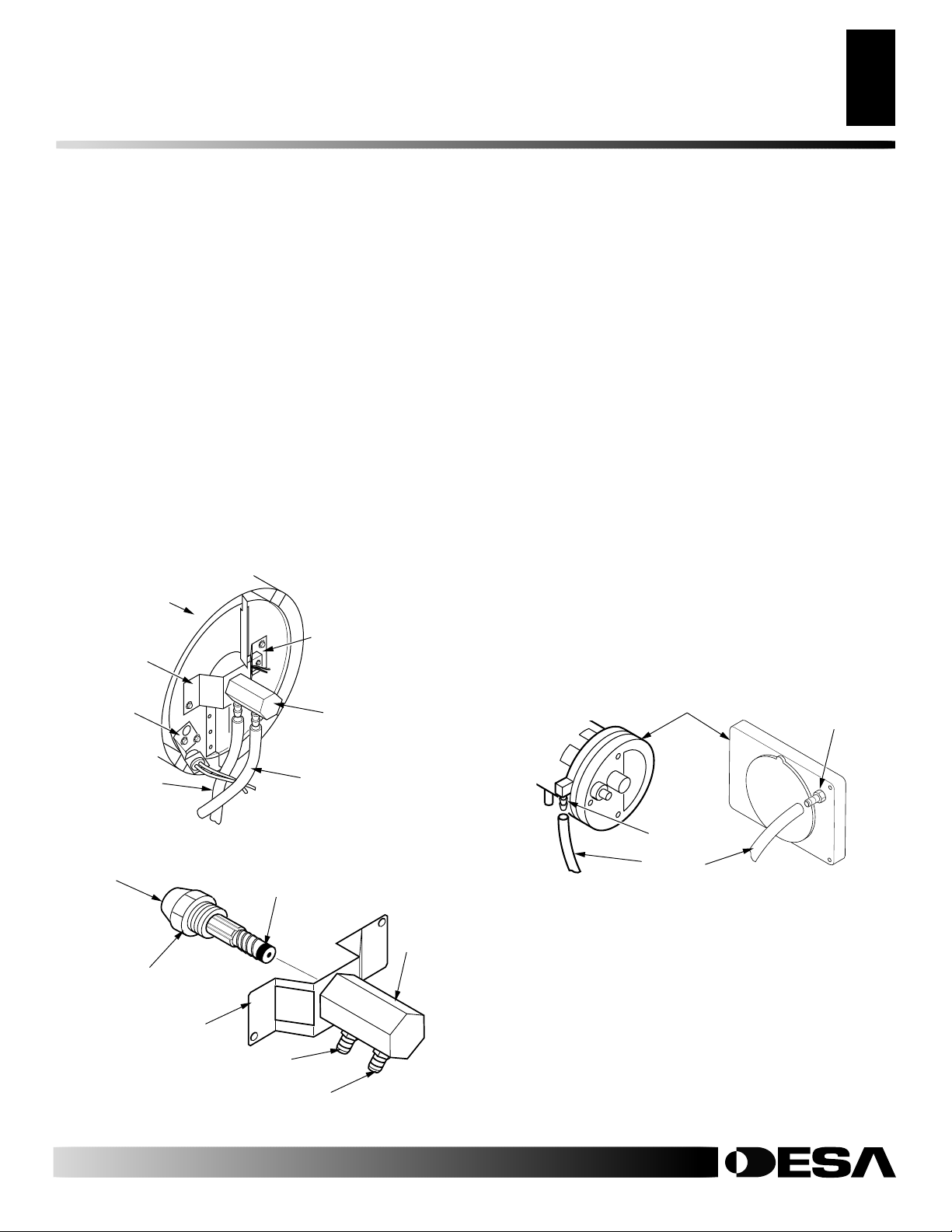

(For 200 Model Only)

1. Remove combustion chamber and ignitor by following steps 1

through 7 under Ignitor, page 11.

2. Carefully place the ignitor in a safe location.

3. Remove two nozzle adapter bracket screws (see Figure 25).

4. Place hex-shaped aluminum nozzle adapter into vise (do not

overtighten).

5. Carefully remove nozzle from nozzle adapter using 5/8" socket

wrench (see Figure 26).

6. Blow compressed air through face of nozzle. This will remove any debris in nozzle.

7. Inspect nozzle seal for damage.

8. Replace nozzle into nozzle adapter until nozzle seats. Tighten

80-110 inch-pounds.

9. Attach nozzle adapter bracket to combustion chamber with two

screws removed in step 3.

10. Repeat steps 9 through 16 under Ignitor, page 11.

Combustion

Chamber

Nozzle Adapter

Nozzle

Adapter

Bracket

Bracket

Screw

FUEL AND AIR LINE REPLACEMENT AND

PROPER ROUTING

1. Remove upper shell (see Upper Shell Removal, page 8).

2. Remove side cover screws using 5/16" nut driver (see Figure 15

or 16, page 9 or Figure 17, page 10).

3. Remove side cover.

4. Inspect fuel and air line hoses for cracks and/or holes. If fuel line

hose is damaged, disconnect from nozzle adapter (see Figure 21

or 22, page 12, or Figure 25) and from fuel filter (see Fuel Filter ,

pages 9 and 10). If air line hose is damaged, disconnect from

nozzle adapter (see Figure 21 or 22, page 12, or Figure 25) and

from barb fitting on pump end cover (see Figure 27).

5. Install new air and/or fuel line. Attach one end of air line hose to

barb fitting on pump end cover (see Figure 27) and the other

end to nozzle adapter (see Figure 21 or 22, page 12, or Figure

25). Attach one end of fuel line hose to fuel filter (see Fuel Fil-

ter, pages 9 and 10) and the other end to nozzle adapter (see

Figure 21 or 22, page 12, or Figure 25).

Note:

Route hoses as shown in see Figure 21 or 22, page 12,

or Figure 25, according to model. Hoses are not to touch photocell bracket.

6. Replace side cover.

7. Replace upper shell and fan guard (see Upper Shell Removal,

page 8).

Photocell

Bracket

Air Line

Hose

Figure 25 - Removing Air and Fuel Line Hoses (200 Model Only)

Nozzle Face

Nozzle

Nozzle

Adapter

Bracket

Figure 26 - Nozzle and Nozzle Adapter

Nozzle

Sleeve

Air Line

Fitting

Fuel Line Fitting

Nozzle/

Adapter

Assembly

Fuel Line Hose

Nozzle

Adapter

Pump End Cover

Barb

Fitting

Air Hose

40/55/60/70

Models

Figure 27 - Air Hose to Barb Fitting

Barb Fitting

110/115/155/165/200

Models

111167-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 14

14

SERVICE PROCEDURES

SERVICE PROCEDURES

Continued

PUMP ROTOR

(Procedure if Rotor is Binding)

1. Remove upper shell (see Upper Shell Removal, page 8).

2. Remove filter end cover screws using 5/16" nut driver (see Figure 28 or 29).

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16" nut-driver.

5. Remove pump plate.

6. Remove rotor, insert, and blades (see Figure 28 or 29).

7. Check for debris in pump. If debris is found, blow out with

compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to .076/.101 mm (.003"/.004") if

needed (see Figure 30).

Note:

Rotate rotor one full turn to ensure the gap is .076/.101 mm

(.003"/.004") at tightest position. Adjust if needed.

10. Install blades, pump plate, air filters, and filter end cover.

11. Replace fan guard and upper shell (see Upper Shell Removal,

page 8).

12. Adjust pump pressure (see Pump Pressure Adjustment, page 9).

Note:

If rotor is still binding, proceed as follows.

13. Perform steps 1 through 6.

14. Place fine grade sandpaper (600 grit) on flat surface. Sand rotor lightly in “figure 8” motion four times (see Figure 31).

15. Reinstall insert and rotor.

16. Perform steps 10 through 12.

Blade

Pump Plate

Air Intake Filter

Filter End

Cover

Blade

Pump Plate

Air Intake

Filter

Rotor

Insert

Air Output

Filter

Figure 29 - Rotor Location, 110/115/155/165/200 Models

Gap Adjusting Screw

.003"/.004"

(.076-.101 mm)

Gap Measured

Blade

Gap Adjusting Screw

Figure 30 - Gap Adjusting Screw Locations

Sandpaper

With Feeler

Gauge

Rotor

Filter End

Cover

Insert

Figure 28 - Rotor Location, 40/55/60/70 Models

Rotor

Air Output

Filter

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Figure 31 - Sanding Rotor

111167-01C

Page 15

SERVICE PROCEDURES

TECHNICAL SERVICE

REPLACEMENT PARTS

15

15

SERVICE PROCEDURES

Continued

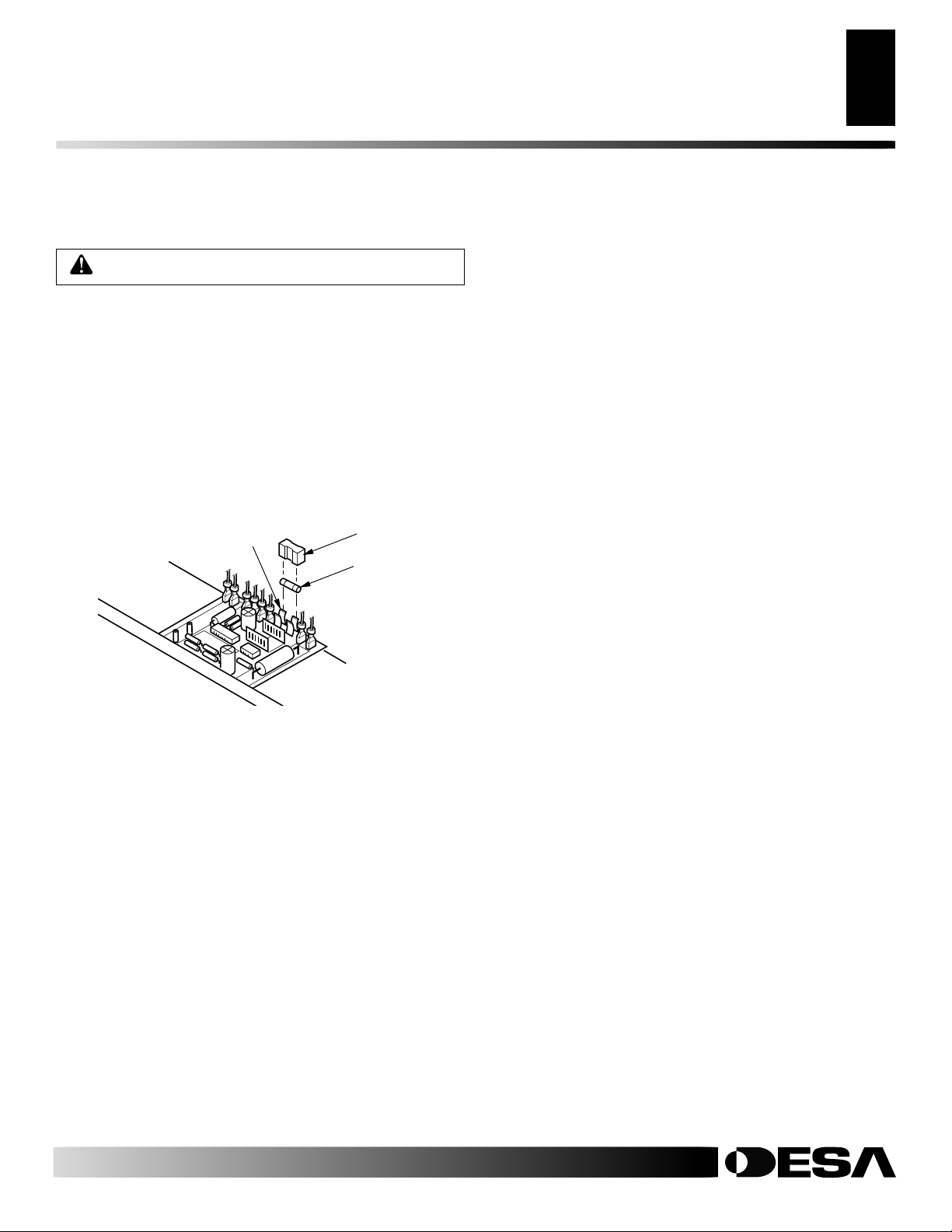

IGNITION CONTROL ASSEMBLY

WARNING: High voltage!

1. Unplug heater.

2. Remove side cover screws (4) using 5/16" nut-driver to expose ignition control assembly.

3. Remove fuse cover (see Figure 32).

4. Remove fuse from fuse clips (see Figure 32).

5. Replace fuse with fuse of the same type and rating (GMA-10).

Do not substitute a fuse with a higher current rating.

6. Replace fuse cover (see Figure 32).

7. Replace side cover (see Figures 15 or 16, page 9 or Figure 17,

page 10).

Fuse Clips

Fuse

Cover

Fuse

TECHNICAL SERVICE

You may have further questions about installation, operation, or

troubleshooting. If so, contact DESA Heating Products’ Technical

Service Department at 1-866-672-6040. When calling please have

your model and serial numbers of your heater ready.

You can also visit DESA Heating Products’ technical services web

site at www.desatech.com.

REPLACEMENT PARTS

Note:

Use only original replacement parts. This will protect your

warranty coverage for parts replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If they can’t supply

original replacement part(s), call DESA Heating Products’ Technical Service Dept. at 1-866-672-6040.

When calling DESA Heating Products, have ready:

• your name

• your address

• model and serial numbers of your heater

• how heater was malfunctioning

• purchase date

Usually, we will ask you to return the part to the factory.

Figure 32 - Replacing Fuse

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If they can’t supply original

replacement part(s), call DESA Heating Products at 1-866-672-6040

for referral information. Parts dealers are listed in the Authorized

Service Center booklet supplied with heater.

When calling DESA Heating Products, have ready:

• model and serial numbers of your heater

• the replacement part number

111167-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 16

16

SPECIFICATIONS

WIRING DIAGRAMS

SPECIFICATIONS

Model Size 40 55/60 70 110/115 155 165 200

Output Rating (Btu/Hr) 40,000 55,000 70,000 110,000 155,000 165,000 200,000

and 60,000 and 115,000

Fuel Use only kerosene, #1/#2 diesel/fuel oil, JET A or JP-8 fuels*

Fuel Tank Capacity

(U.S. Gal./Liters) 3/11.3 5/18.9 5/18.9 9/34 13.5/51 13.5/51 13.5/51

Fuel Consumption

(Gal. Per Hr/Liters Per Hr) .3/1.14 .44/1.67 .52/1.97 .85/3.00 1.14/4.31 1.2/4.54 1.4/5.3

Pump Pressure (psi) 3.0 3.4 4.7 5.1 5.2 5.6 6.2

Electric Requirements 120 V/60 HZ (Same All Models)

Amperage (Normal Run) 2.0 2.0 2.8 3.6 3.6 3.6 3.6

Motor RPM 1725 1725 3440 3400 3400 3400 3400

Hot Air Output (CFM) 170 180 360 490 550 575 600

Motor HP 1/15 1/15 1/8 1/5 1/5 1/5 1/4

Shipping Weight 32/14.5 33/15 35/15.9 54/24.5 63/28.6 65/29.5 77/35

(Approximate Pounds/Kilograms)

Heater Weight without Fuel 28/12.7 29/13.1 31/14 46/21 54/24.5 55/25 66/30

(Approximate Pounds/Kilograms)

* Use of #2 diesel & fuel oil will result in noticeable odor and could require additional fuel filter maintenance. Use in extreme cold

temperatures may require nontoxic anti-icer additives.

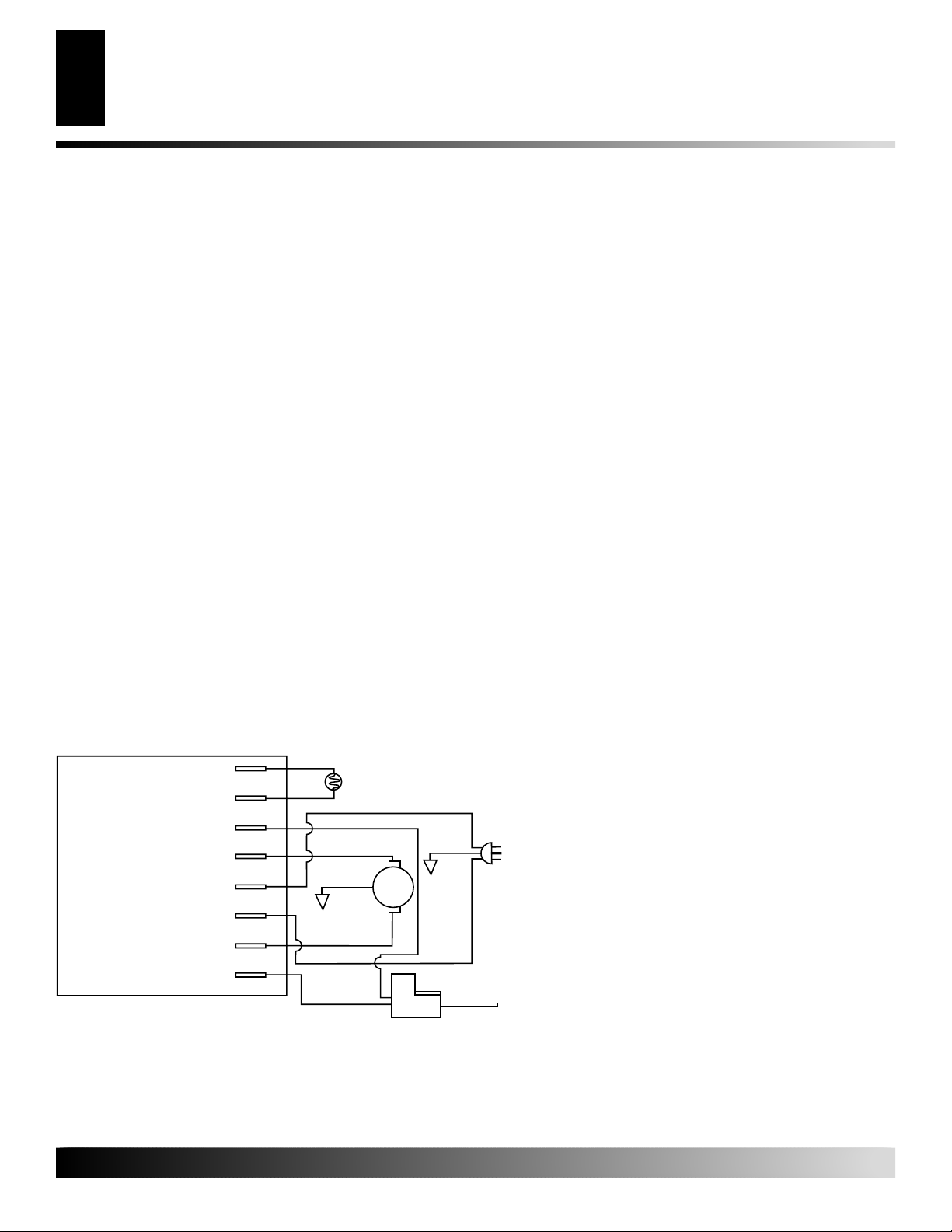

WIRING DIAGRAMS

Photocell

Photocell

Ignitor

Ignition Control Assembly

Figure 34 - Wiring Diagram without Thermostat (40/55/60/70/110/115/155/165 Models)

Motor Return

AC Neutral (L2)

120V (L1)

Motor

Ignitor

Blue

Blue

Red

Black

White

Green

Yellow

Photocell

White

Motor

Green

Power Plug

120V/60Hz

Yellow

Ignitor

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 17

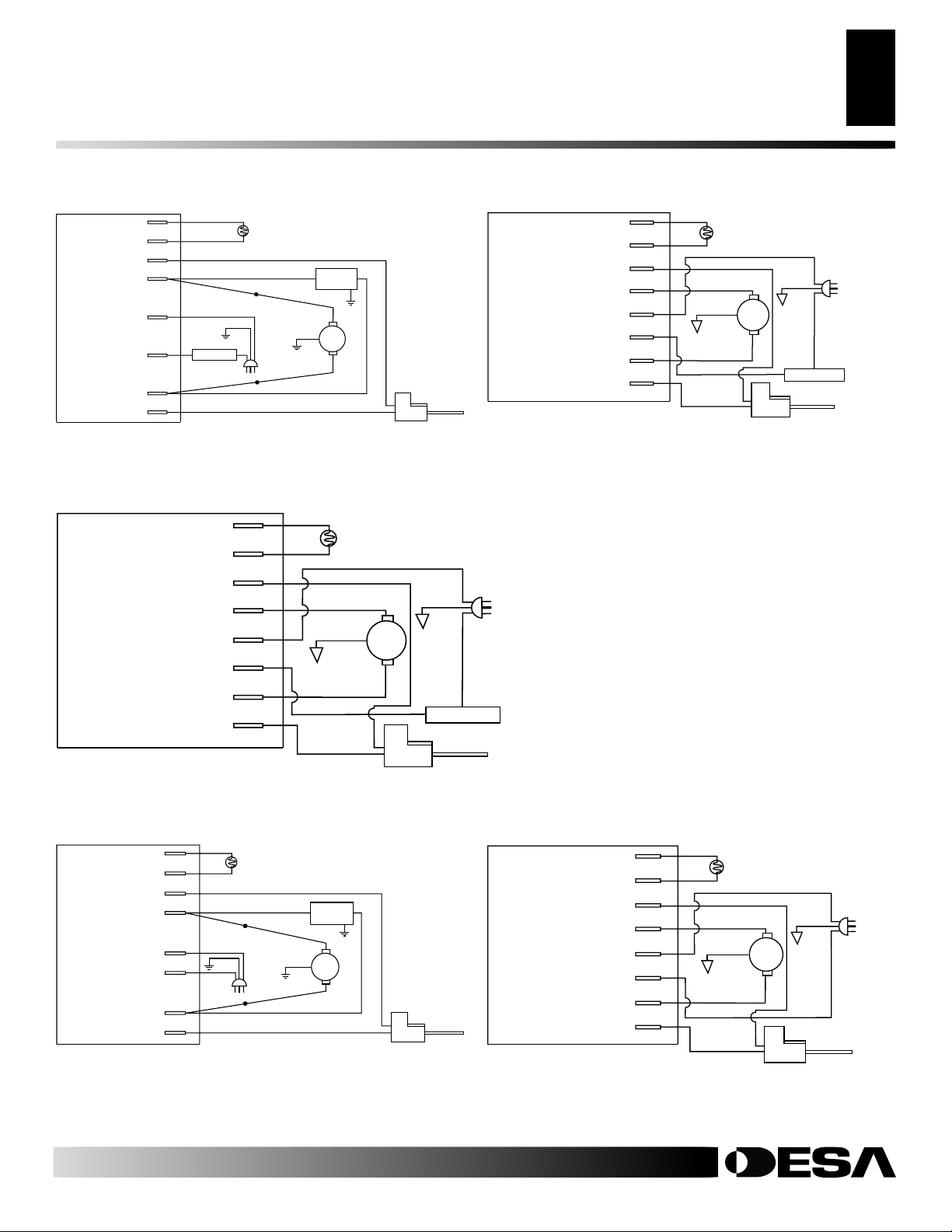

WIRING DIAGRAMS

Continued

White

Black

Thermostat

Red

Blue

Blue

White

Green

Photocell

120V/60Hz

Black

White

White

Power Plug

Green

Solenoid

Red

Valve

Motor

Yellow

Yellow

Red

Ignitor

Photocell

Photocell

Ignitor

Motor Return

AC Neutral (L2)

AC Hot (L1)

Ignition Control Assembly

Motor

Ignitor

(Heater with Fuel Valve Assembly) (Heater without Fuel Valve Assembly)

Figure 35 - Wiring Diagram with Thermostat for 200 Model

WIRING DIAGRAMS

Photocell

Photocell

Ignitor

Motor Return

AC Neutral (L2)

120V (L1)

Ignition Control Assembly

Motor

Ignitor

Blue

Blue

White

Green

Red

Black

Y ellow

Photocell

White

Green

Motor

Yellow

Thermostat

Ignitor

17

17

lug

er P

ow

P

120V

Black

/60H

z

Photocell

Photocell

Blue

Blue

Photocell

White

Ignitor

Ignitor

Green

Yellow

Thermostat

Power Plug

120V/60Hz

Black

Motor Return

AC Neutral (L2)

White

Green

Motor

120V (L1)

Ignition Control Assembly

Motor

Red

Black

Ignitor

Y ellow

Figure 36 - Wiring Diagram with Thermostat (40/55/60/70/110/115/155/165 Models)

Blue

Blue

White

White

Black

Red

Green

Photocell

White

Power Plug

120V/60Hz

Green

Solenoid

Valve

White

Motor

Red

Black

Red

Black

Ignitor

Photocell

Photocell

Motor Return

AC Neutral (L2)

120V (L1)

Ignition Control Assembly

Ignition Control Assembly

AC Neutral (L2)

Photocell

Photocell

Ignitor

Motor Return

AC Hot (L1)

Motor

Ignitor

(Heater with Fuel Valve Assembly) (Heater without Fuel Valve Assembly)

Ignitor

Motor

Ignitor

Blue

Blue

Red

Black

White

Green

Yellow

Photocell

White

Motor

Ignitor

Green

Yellow

ow

P

120V

er P

/60H

lug

z

Figure 37 - Wiring Diagram without Thermostat for 200 Model

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 18

18

ILLUSTRATED PARTS BREAKDOWN

40/55/60/70 Models

ILLUSTRATED PARTS

BREAKDOWN

40/55/60/70 MODELS

Standard Thermostat

Models Models

R40 R40T

REM40 REM40T

R55B R55BT

R60 R60T

B55B B55BT

REM60 REM60T

R70D R70DT

B70D B70DT

RM60 RM60T

22

4

5

35

3

9

7

8

6

21

10

20

23

18

1

2

9-1

9-2

9-5

11

9-4

9-3

12

13

16

24

12-18

12-17

12-1

12-16

12-2

12-5

12-3

12-4

12-15

12-14

17

12-6

19

34

12-7

31

12-8

12-9

28

30

29

32

12-13

12-10

36

25

27

39

26

37

38

33

15

14

Motor and Pump Assembly

For more information, visit www.desatech.com

For more information, visit www.desatech.com

12-12

12-19

12-11

111167-01C

Page 19

PARTS LIST

40/55/60/70 Models

19

19

PARTS LIST

40/55/60/70 MODELS

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 M51104-01 Handle 1

2 098511-67 Upper Shell (Service Part 1

Will Be Black)

3 M11084-29 Screw, #10-16 x 3/4" 2

4 M15823-27 Screw, #10-16 x 1

5 098512-58 Combustion Chamber (40) 1

098512-50 Combustion Chamber (55/60) 1

098512-51 Combustion Chamber (70) 1

6 M10908-2 Screw, #6-32 x 3/8" 2

7 103154-03 Photocell Bracket 1

8 M16656-24 Photocell Assembly 1

9 ∆ Burner Head Assembly

9-1 HA3006 Nozzle Assembly (40) 1

HA3024 Nozzle Assembly (55/60) 1

HA3026 Nozzle Assembly (70) 1

9-2 102548-03 Ignitor Kit 1

9-3 104056-01 Nozzle Adapter 1

9-4 102336-01 Nozzle Adapter Bracket 1

9-5 M10908-75 Screw, Hex Head, Tapping 1

9-6 103347-01 Belleville Washer 1

10 M11084-26 Screw, #10-16 x 3/8" 2

11 103684-01 Fan (40/55/60) 1

M29678 Fan (70) 1

12 ∆ Motor and Pump Assembly

12-1 102001-28 Motor (40/55/60) 1

102001-29 Motor (70) 1

12-2 079975-03 Pump Body (55/60) 1

079975-02 Pump Body (40/70) 1

12-3 M22009**, *** Insert 1

12-4 M22456-2** Rotor (55/60) 1

M22456-1*** Rotor (40/70) 1

12-5 M29608 Pump End Cover 1

12-6 M29632 ⊕ Lint Filter 1

12-7 M29633 ⊕ Intake Filter 1

12-8 M29609 Filter End Cover 1

12-9 M12461-31 Screw, #10-32 x 1" 3

12-10 M27694 ∞ Adjusting Screw 1

12-11 M10993-1 ∞ Pressure Relief Spring 1

12-12 M22997 ∞ Plug 1

12-13 M8940 ∞ Steel Ball, 1/4" Diameter 1

12-14 M29612-01 ⊕ Output Filter 1

12-15 M12461-32 Screw, #10-32 x 1

M12461-31 Screw, #10-32 x 1" (40/70) 6

12-16 103676-01 Nylon Elbow, 90° 1

12-17 M8643-2** Blade (55/60) 4

M8643*** Blade (40/70) 4

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

1

/2"6

1

/8" (55/60) 6

KEY PART

NO. NUMBER DESCRIPTION QTY.

12-18 FHPF3-6C Screw, #10-32 x 3/4" (55/60) 2

FHPF3-5C Screw, #10-32 x 5/8" (40/70) 2

12-19 105780-01 Plastic Cap 1

13 M51105-01 Fan Guard 1

14 098219-38 Power Cord 1

15 M11143-1 Strain Relief Bushing 1

16 NTC-4C Hex Lock Nut, 1/4-20 2

17 M11084-26 Screw, #10-16 x 3/8" 8

18 M50631 Rubber Bumper 2

19 097461-16 Side Cover 2

20 101205-01 Motor Bracket 1

21 M50104-06 Bushing 1

22 M11271-8 Clip Nut 6

23 M50104-02 Bushing 1

24 M11084-26 Screw, #10-16 x 3/8" 6

25 M10908-14 Screw, #8-32 x 3/8" 1

26 098511-234 Lower Shell (Service Part 1

Will Be Black) 1

27 M50814-06 Rubber Airline 1

28 079973-01 Fuel Line 1

29 M50876-04 Fuel Filter with bushing (40) 1

M50876-05 Fuel Filter with bushing

(55/60/70) 1

30 M10990-3 Rubber Bushing 1

31 102349-01 PCB Support 5

32 104068-02 Ignition Control Assembly 1

33 097702-01 Fuel Cap (Includes Gasket) 1

097663-04 Fuel Gauge (Includes Gasket

RM60 Only, If Equipped) 1

34 108088-01 Fuel Tank (40) 1

108088-03 Fuel Tank (55/60/70) 1

108088-16 Fuel Tank (RM60 Only, if

Equipped with Fuel Gauge) 1

35 M51108-01 Shell Heat-Shield 1

36 104458-01 Thermostat 1

37 M12461-18 Screw, #8-32 x 7/8" 1

38 104460-01 Thermostat Knob 1

39 WLE-2 Lock Washer, EXT #8 1

PARTS AVAILABLE - NOT SHOWN

103814-01

M9900-170 Wire Assembly

Wire Tie

Control Assembly) 1

(Thermostat to Ignition

Control Assembly) 1

(For Ignition

∆ Not available as an assembly ⊕ Included in Filter Kit (Part No. HA3014)

** Included in Rotor Kit (Part No. HA3005) ∞ Included in Pump Adjustment Kit (Part No. HA3020)

*** Included in Rotor Kit (Part No. HA3004)

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 20

20

1

2

3

23

19

9

10

16

11

12

15

25

27

24

28

29

20

22

21

30

31

17

14

14

33

34

35

36

32

26

18

5

4

6

7

8

7-2

7-1

7-5

7-4

7-3

37

13

39

38

7-6

110/115/155/165 Models

ILLUSTRATED PARTS

BREAKDOWN

110/115/155/165 MODELS

Standard Thermostat

Models Models

R110C R110CT

ILLUSTRATED PARTS BREAKDOWN

R115C R115CT

B115C B115CT

REM115C REM115CT

RM115C RM115CT

B155C B155CT

REM155C REM155CT

R165C R165CT

RM155C RM155CT

B165C B165CT

R155C R155CT

B110C B110CT

RM110C RM110CT

RM165C RM165CT

REM110C REM110CT

REM165C REM165CT

SB115CT

SB155CT

10-1

10-2

10-3

10-17

10-16

10-15

10-13

Motor and Pump Assembly

For more information, visit www.desatech.com

For more information, visit www.desatech.com

10-4

10-14

10-5

10-13

10-6

10-12

10-7

10-8

10-9

10-10

10-11

111167-01C

Page 21

PARTS LIST

110/115/155/165 Models

21

21

PARTS LIST

110/115/155/165 MODELS

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 098511-292 Upper Shell (Service Part Will

Be Black) 1

2 M15823-27 Screw, #10-16 x 1/2" 8

3 098512-71 Combustion Chamber (110/115) 1

098512-74 Combustion Chamber (155) 1

098512-75 Combustion Chamber (165) 1

4 103154-05 Photocell Bracket (110/115) 1

M16660-02 Photocell Bracket (155/165)

5 M10908-2 Screw, #6-32 x 3/8" 2

6 M16656-24 Photocell Assembly 1

7

7-1 HA3027 Nozzle Assembly (110/115) 1

7-2 102548-03 Ignitor Kit 1

7-3 M10908-75 Screw, #6-32 x 7/8" 1

7-4 102336-01 Nozzle Adapter Bracket 1

7-5 104054-01 Nozzle Adapter 1

7-6 103347-01 Washer 1

8 M11084-26 Screw, #10-16 x 3/8" 2

9 097293-01 Fan (110/115/155) 1

10

10-1 102001-30 Motor 1

10-2 079975-02 Pump Body 1

10-3 FHPF3-5C Screw, #10-32 x 5/8" 2

10-4 M22009** Rotor Insert 1

10-5 M22456-1** Pump Rotor 1

10-6 M50545 Pump End Cover 1

10-7 M12179*** Intake Filter 1

10-8 M16545 Filter End Cover 1

10-9 M8940

10-10 M10993-1

10-11 M27694

10-12 M22997

10-13 M12461-31 Screw, #10-32 x 1" 10

10-14 M12244-1*** Output Filter 1

10-15 M11637*** Lint Filter 1

10-16 104096-01 Fitting, Straight Nylon Barb 1

10-17 M8643** Blade 4

11 M50631 Rubber Bumper 2

∆ Burner Head Assembly 1

HA3028 Nozzle Assembly (155/165) 1

102042-01 Fan (165) 1

∆ Motor and Pump Assembly 1

∞ Steel Ball, 1/4" Diameter 1

∞ Relief Spring 1

∞ Adjusting Screw 1

∞ Plug 1

This list contains replaceable parts used in your heater. When ordering parts, be sure to

provide the correct model and serial numbers (from the model plate), then the part number

and description of the desired part.

KEY PART

NO. NUMBER DESCRIPTION QTY.

12 101206-01 Motor Mounting Bracket 1

13 M12461-18 Screw, #8-32 x 7/8" 1

14 104068-02 Ignition Control Assembly 1

15 NTC-4C Hex Lock Nut, 1/4-20 2

16 111037-01 Fan Guard 1

17 M27417 Drain Plug (Includes “o” Ring) 1

18 107878-02 Button Plug 1

19 M51345-06 Fuel Line 1

20 106896-01*** Fuel Filter 1

21 M51151-01 Fuel Line Tube (110/115) 1

M51151-02 Fuel Line Tube (155/165) 1

22 M10990-3 Rubber Bushing 1

23 M50814-03 Airline 1

24 098511-293 Lower Shell (Service Part Will

Be Black) 1

25 M50104-06 Bushing 1

26 M50104-01 Bushing 1

27 M11084-26 Screw, #10-16 x 3/8" 6

28 M11271-8 Clip Nut 8

29 M10908-14 Screw, #8-32 x 3/8" 1

30 108088-04 Fuel Tank (110/115) 1

108088-11 Fuel Tank (RM115CT Only) 1

108088-05 Fuel Tank (155/165) 1

31 097702-01 Fuel Cap (Includes Gasket) 1

097663-02 Fuel Gauge (Includes Gasket,

RM115CT Only) 1

32 102349-01 P.C. Board Support 5

33 M11143-1 Strain Relief Bushing 1

34 098219-38 Power Cord 1

35 M51077-18 Side Cover 2

36 M11084-26 Screw, #10-16 x 3/8" 8

37 104460-01 Thermostat Knob 1

38 104458-01 Thermostat 1

39 WLE-2 Lock Washer, EXT #8 1

103814-01 Wire Tie (Not Shown) - Groups 1

wires connected to Ignition

Control Assembly

M9900-77 Wire (Connects thermostat to

Ignition Control Assembly)

(Not Shown) 1

∆ Not available as an assembly ∗∗∗ Included in Filter Kit (Part No. HA3017)

** Included in Rotor Kit (Part No. HA3004) ∞ Included in Pump Adjustment Kit (Part No. HA3020)

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 22

22

ILLUSTRATED PARTS BREAKDOWN

Standard Model R200A

Thermostat Models RM200AT, B200AT, and REM200AT

ILLUSTRATED PARTS

BREAKDOWN

200 MODELS

39-1

39-4

39-5

39-2

39-3

7-1

39-6

39-4

39-7

Fuel Valve Assembly

(Models Equipped with

Fuel Valve Only)

7-2

7-3

7-4

7-5

7-6

2

1

3

37

9

10

16

12

15

13

26

27

(On models

18

without Fuel

Valve Assy,

filter will be

located on top

of fuel tank.)

42

41

44

7-7

7-8

38

7-9

7

4

6

24

28

5

8

23 19

39

21

30

20

31

11

25

29

22

Nozzle Assembly

10-1

10-2

10-3

10-4

10-17

10-16

10-15

10-18

Motor and Pump Assembly

For more information, visit www.desatech.com

For more information, visit www.desatech.com

7-11

10-5

10-14

10-6

10-13

10-7

10-12

7-10

35

10-8

10-11

36

10-9

32

10-10

10-19

40

43

33

14

17

14

34

111167-01C

Page 23

PARTS LIST

Standard Model R200A

Thermostat Models RM200AT, B200AT, and REM200AT

23

23

PARTS LIST

200 MODELS

KEY PART

NO. NUMBER DESCRIPTION QTY.

1 107353-10 Upper Shell (Service Part

Will Be Black) 1

2 M15823-27 Screw, #10-16 x 1/2" 8

3 098512-69 Combustion Chamber 1

4 103154-05 Photocell Bracket 1

5 M10908-2 Screw, #6-32 x 3/8" 2

6 M16656-24 Photocell Assembly 1

7

7-1 100735-13 Nozzle Assembly 1

7-2 M10659-1 Nozzle Washer 2

7-3 M10809-1 Nozzle Spring 1

7-4 M8882 Nozzle Sleeve 1

7-5 107272-01 Retaining Ring 1

7-6 102336-03 Nozzle Adapter Bracket 1

7-7 102548-03 Ignitor Kit 1

7-8 103347-01 Belleville Washer 1

7-9 M10908-75 Screw, #6-32 x .88 1

7-10 107273-01 Nozzle Adapter 1

7-11 M50820-02 Barb Fitting 1

8 M11084-26 Screw, #10-16 x 3/8" 2

9 102042-01 Fan 1

10 Motor and Pump Assembly 1

10-1 102001-27 Motor 1

10-2 079975-03 Pump Body 1

10-3 FHPF3-6C Screw, #10-32 x 5/8" 2

10-4 M22009** Rotor Insert 1

10-5 M22456-2** Pump Rotor 1

10-6 M50545 Pump End Cover 1

10-7 M12179*** Intake Filter 1

10-8 M16545 Filter End Cover 1

10-9 M8940

10-10 M10993-1

10-11 M27694

10-12 M22997∞ Plug 1

10-13 M12461-31 Screw, #10-32 x 1" 4

10-14 M12244-1*** Output Filter 1

10-15 M11637*** Lint Filter 1

10-16 M50820-02 Barb Fitting 1

10-17 M8643-2** Blade 4

10-18 M12461-32 Screw, #10-32 x 1.12" 6

10-19 105780-01 Plastic Cap 1

11 M50631 Rubber Bumper 2

12 101206-01 Motor Mounting Bracket 1

13 097785-04 Foam Gasket 2

14 104068-02 Ignition Control Assembly 1

15 NTC-4C Hex Lock Nut, 1/4-20 2

16 102756-01 Fan Guard 1

∆ Not available as an assembly ∗∗∗ Included in Filter Kit (Part No. HA3017)

** Included in Rotor Kit (Part No. HA3005) ∞ Included in Pump Adjustment Kit (Part No. HA3020)

111167-01C

∆ Burner Head Assembly 1

∞ Steel Ball, 1/4" Diameter 1

∞ Relief Spring 1

∞ Adjusting Screw 1

For more information, visit www.desatech.com

For more information, visit www.desatech.com

This list contains replaceable parts used in your heater. When ordering parts, be sure to provide

the correct model and serial numbers (from the model plate), then the part number and description

of the desired part.

KEY PART

NO. NUMBER DESCRIPTION QTY.

17 M27417 Drain Plug (Includes “o” Ring) 1

18 103523-01 Rubber Bushing 1

19 M51345-03 Fuel Line (Models with Fuel

Valve Assy) 1

M51345-04 Fuel Line (Models without Fuel

Valve Assy) 1

20 M51150-01*** Fuel Filter 1

21 M51345-04 Fuel Line Tube (Models with

Fuel Valve Assy) 1

M51151-02 Fuel Line Tube (Models without

Fuel Valve Assy) 1

22 M10990-3 Rubber Bushing 1

23 M50814-03 Airline 1

24 107353-11 Lower Shell (Service Part

Will Be Black) 1

25 M50104-06 Bushing 2

26 M50104-01 Bushing 1

27 M11084-26 Screw, #10-16 x 3/8" 6

28 M11271-8 Clip Nut 8

29 M10908-14 Screw, #8-32 x 3/8" 1

30 108088-06 Fuel Tank 1

31 097702-01 Fuel Cap (Includes Gasket) 1

32 102349-01 P.C. Board Support 5

33 M11143-1 Strain Relief Bushing 1

34 098219-38 Power Cord 1

35 107333-04AA Side Cover 1

36 M11084-26 Screw, #10-16 x 3/8" 8

37 099230-01 Screw, Special 2

38 M11084-27 Screw, #10-16 x 1/2" 2

39

39-1 107643-01 Fuel Valve 1

39-2 107336-01 Fuel Valve Bracket 1

39-3 M12461-13 Hex Head Screw, #8-32 x 1/4" 2

39-4 M50820-02 Fitting Barb 2

39-5 102432-01 Screw Hex Hd Sems Ext "B"

39-6 107274-01 Wire Assembly, Red 1

39-7 107274-02 Wire Assembly, White 1

40 104458-01 Thermostat 1

41 M12461-18 Screw, #8-32 x 7/8" 1

42 104460-01 Thermostat Knob 1

43 079010-35 Wire Assembly 1

44 WLE-2 Lock Washer, EXT #8 1

Fuel Valve Assembly 1

(MODELS EQUIPPED WITH FUEL VALVE ONLY)

#10-16 x 1/2" 2

103814-01 Wire Tie (Not Shown) 1

(For Ignition Control Assembly)

100621-06 Thermostat Decal (Not Shown) 1

Page 24

24

WHEELS AND HANDLES

110/115/155/165/200 Models

WHEELS AND HANDLES

WHEELS AND HANDLE PARTS LIST

KEY PART PART

NO. NUMBER DESCRIPTION QTY.

1 HA2203 Handle (110/115) 2 (If Equipped)

HA2204 Handle (155/165/200) 2 (If Equipped)

2 M12345-33 Screw, #10-24 x 1 3/4"6 or 8

3 M12342-3 Wheel Support Frame (110/115) 1

M12831-3 Wheel Support Frame (155/165/200) 1

4 NTC-3BZ Hex Nut, #10-24 6 or 8

5 107426-01 Wheel Kit (Contains 2 Wheels

and Cap Nuts) —

6 M28526 Cap Nut 2

7 M51015-01 Axle (110/115) 1

M16801-2 Axle (155/165/200) 1

1

2

3

7

5

6

4

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 25

ACCESSORIES

Purchase accessories and parts from your nearest dealer or service

center. If they can not supply these accessories or parts, either contact

your nearest parts dealer or DESA Heating Products at 1-866-672-6040

for referral information. Parts Centrals are listed in the Authorized

Service Center booklet supplied with heater.

AIR GAUGE KIT - HA1180

For all models. Special tool to check pump pressure.

ACCESSORIES

25

25

IGNITION CONTROL ASSEMBLY/PHOTOCELL

TESTER - HA1170

Special tool used to test the ignition control assembly and photocell.

HEAVY DUTY WHEELS AND HANDLE KIT

HA1202

For 40/55/60/70,000 Btu Models. For heavy duty applications.

Makes your heater even more portable and convenient.

STANDARD WHEELS AND HANDLE KIT

HA1206

For 40/55/60/70,000 Btu Models. Makes heater even more portable and convenient. Easy to assemble.

THERMOSTAT KIT - HA1210

Keeps your building at the temperature you select day and night.

Helps economize on fuel.

FUEL TANK FILLER NECK SCREEN - HA2210

This screen/filter drops in fuel tank filler neck. This prefilter allows

for easy cleaning and provides two-stage filtering advantage.

111167-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 26

26

NOTES

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

_______________________________________________________________________________________________

For more information, visit www.desatech.com

For more information, visit www.desatech.com

111167-01C

Page 27

27

OWNER'S REGISTRATION FORM

27

Complete registration form and mail or complete on-line registration at www.desatech.com within 30 days after purchase.

Brand:

Model:

Date Purchased:

Serial Number:

(Reddy Heater, Master, Remington, etc.)

(R60, HD15, etc.)

Note:

Keep receipt for warranty verification.

7 or 9 digit number located on product or identification tag.

First Name: Last Name:

Address:

City: State: Zip: Country:

Phone: ( ) - E-Mail:

Please answer the following questions to register your product with DESA Heating Products:

1. Who will heater be used by? ❍ Individual ❍ Business

2. Will you use your heater in more than one location? ❍ Yes ❍ No

3. Where will the product be used? (You may select more than one.) ❍ Workshop ❍ Barn ❍ Residential Construction

❍ Commercial Construction ❍ Garage ❍ Factory ❍ Recreation ❍ Warehouse ❍ Utility Shed/Outbuilding

❍ Other ______________________________ (Specify)

4. Cost of product (excluding sales tax)? $________________________________

5. Maintenance/service work will be performed by: ❍ Self ❍ Service Center ❍ Other ___________________________________

6. If you bought this product yourself, did you plan to purchase this type of product before going into the store? ❍ Yes ❍ No

7. Type of store where product was purchased? ❍ Hardware ❍ Propane Dealer ❍ Natural Gas/Utility Co. ❍ Home Center or Builder’s Supply

❍ Farm/Ag. Supply ❍ Auto Parts ❍ Warehouse Club ❍ Industrial/Contractor Supply ❍ Rental Store

❍ Discount Store ❍ HVAC Dealer ❍ Other _________________________________________________

8. What is your primary source of heat? ❍ Propane (LP Gas) ❍ Natural Gas ❍ Kerosene ❍ Diesel ❍ Electric ❍ Other________________

9. What motivated you to buy this product? ❍ Sudden Cold Weather ❍ Replace Older Model ❍ D.I.Y. Home Project ❍ Emergency Back-Up Heat

❍ Heater on Sale ❍ Construction Project ❍ Hard to Heat Location ❍ Other ________________________________

10. How did you learn about this product brand? ❍ Advertisement ❍ Relative or Friend ❍ Co-Worker ❍ Store Representative

❍ Store Display ❍ Previously Owned a Heater ❍ Other _________________________________________________(Specify)

11. What other brands did you consider? ❍ None ❍ Master ❍ Remington ❍ All-Pro ❍ Dayton ❍ Universal ❍ Mr. Heater ❍ L.B. White Tradesman

❍ John Deere ❍ Dyna-Glo ❍ Dura-Heat ❍ Paulin ❍ Coleman ❍ Vogelzang American ❍ Other ___________________________________

12. Who selected the product? ❍ Male ❍ Female ❍ Both

13. Level of Education of Purchaser: ❍ High School ❍ Vocation/Technical School ❍ Some College ❍ Completed College ❍ Graduate School

14. Age of Purchaser: ❍ Under 20 ❍ 20 - 29 ❍ 30 - 39 ❍ 40 - 49 ❍ 50 - 59 ❍ 60 or Over

15. Buyer’s total annual household income: ❍ Under $19,999 ❍ $20,000 to $34,999 ❍ $35,000 to $49,999

❍ $50,000 to $74,999 ❍ $75,000 to $99,999 ❍ $100,000 and Over

16. What is the population of your area? ❍ Under 10,000 ❍ 10,000 to 25,000 ❍ 25,000 to 50,000 ❍ 50,000 to 100,000

❍ 100,000 to 250,000 ❍ Over 250,000

17. Store where product was purchased:

Name: ______________________________________ City: _____________________________________ State: __________

18. In choosing this product, how important were the following:

Availability

Price

Brand Name

Overall Quality

Heat Output (Btu/Hr Rating)

Variable Heat Output (Btu/Hr)

Made in USA

Warranty

Local Service

Value for Price

Not Somewhat Very

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

Size

Prior Brand Experience

Built-In Thermostat

Ease of Operation

Special Features

Salesperson’s Recommendation

Friend/Relative’s Recommendation

Portability

Quiet Operation

Not Somewhat Very

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

19. This question will allow us to better understand the demographic profile of our customers. Which of the following best describes you? (not required)

❍ African American ❍ Asian American ❍ Mexican ❍ Puerto Rican ❍ Cuban ❍ Other Hispanic ❍ White ❍ Other ___________________

111167-01C

For more information, visit www.desatech.com

For more information, visit www.desatech.com

Page 28

TAPE

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

Postage

Required

TAPE

Page 29

OTHER OUTDOOR HEATING PRODUCTS

PROPANE/LP FORCED AIR HEATERS

PROPANE/LP CONVECTION HEATERS

l

;

l

d

l

;

l

p

l

;

;

l

l

d

;

l

;

l

;

l

d

p

;

d

d

p

;

e

;

;

p

l

p

;

;

;

g

;

d

;

e

;

o

l

p

e

;

;

;

g

e

,

;

e

;

,

g

;

o

l

g

;

o

g

l

,

e

e

o

l

;

,

;

l

o

,

l

;

k

,

;

g

,

,

e

,

o

l

,

o

l

e

k

k

l

;

e

,

l

e

i

k

o

l

,

k

h

k

o

k

l

o

e

i

k

o

k

l

k

i

h

k

k

e

l

i

h

i

o

k

o

l

h

l

h

k

k

e

l

b

k

i

l

e

k

o

j

e

h

i

o

e

l

e

b

o

i

l

h

k

o

l

j

l

b

u

;

l

e

b

j

e

l

k

l

b

s

i

j

l

l

o

e

j

e

d

i

u

k

e

i

e

b

o

p

s

u

i

l

l

l

;

;

j

u

s

l

u

;

l

k

l

b

s

;

e

l

s

l

l

d

i

l

k

l

j

;

k

l

d

p

u

e

l

k

e

;

;

;

l

s

i

l

d

p

;

l

;

l

;

l

;

g

d

l

p

;

u

k

;

d

o

p

d

;

e

s

l

l

;

;

l

;

p

;

l

;

p

e

;

,

;

;

g

k

;

,

d

;

e

l

;

g

o

;

l

p

e

l

;

e

;

;

g

o

e

l

,

l

;

e

;

d

;

,

;

g

o

l

,

k

g

p

;

,

g

o

l

,

e

;

e

o

o

l

;

,

;

l

o

;

l

,

e

;

k

k

l

;

,

g

,

,

e

,

i

k

o

l

,

o

e

l

e

k

;

h

k

o

l

;

e

l

,

l

e

i

k

k

o

g

l

,

k

k

i

h

k

k

o

o

l

e

o

l

e

i

h

k

o

k

l

l

;

k

o

,

i

h

k

k

k

e

l

,

i

i

h

o

k

e

o

b

l

h

l

e

l

h

k

k

e

o

j

l

l

b

k

i

l

k

e

o

e

k

j

b

i

e

h

l

e

o

l

o

j

e

b

o

u

i

l

k

o

k

j

e

b

s

i

u

l

e

b

l

i

j

e

l

b

s

i

u

j

l

l

o

k

j

e

h

s

l

i

u

l

k

e

l

;

i

e

b

s

i

u

l

k

k

l

l

j

u

s

u

e

d

k

l

s

e

WARNING

l

s

i

k

o

p

l

k

;

u

k

;

l

b

s

;

l

l

j

k

e

e