Page 1

UNVENTED (VENT-FREE) INFRARED GAS HEATER

SAFETY INFORMATION AND INSTALLATION MANUAL

MODELS CTR25NR, CTR22PR, VTN25R AND VTP22R

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

Save this manual for future reference.

For more information, visit www.desatech.com

Page 2

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual for correct installation

and operational procedures. For assistance or additional information consult a qualified installer, service

agency or the gas supplier.

WARNING: This is an unvented gas-fired heater. It uses

air (oxygen) from the room in which it is installed. Provisions for adequate combustion and ventilation air must

be provided. Refer to Air for Combustion and Ventilation

section on page 5 of this manual.

This appliance may be installed in an aftermarket,* permanently located, manufactured (mobile) home, where

not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use with other gases.

* Aftermarket: Completion of sale, not for purpose of resale, from the manufacturer

TABLE OF CONTENTS

Safety Information ............................................... 3

Local Codes ........................................................ 4

Product Identification ........................................... 4

Unpacking ........................................................... 4

Product Features ................................................. 4

Air For Combustion and ventilation ..................... 5

Installation ........................................................... 7

Operating Heater ............................................... 13

Inspecting Heater .............................................. 15

Cleaning and Maintenance ................................ 16

2

www.desatech.com

Service Hints ..................................................... 16

Technical Service .............................................. 16

Troubleshooting ................................................. 17

Illustrated Parts Breakdown .............................. 20

Parts List ........................................................... 21

Specifications ....................................................

Accessories ....................................................... 22

Service Publications .......................................... 22

Replacement Parts ............................................ 22

Parts Central ..................................................... 23

113261-01A

22

Page 3

SAFETY INFORMATION

WARNING: This product contains and/or generates chemicals

known to the State of California

to cause cancer or birth defects,

or other reproductive harm.

IMPORTANT: Read this owner’s

manual carefully and completely

before trying to assemble,

operate or service this heater.

Improper use of this heater can

cause serious injury or death

from burns, fire, explosion,

electrical shock and carbon

monoxide poisoning.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs of carbon

monoxide poisoning resemble the flu, with head

aches, dizziness or nausea. If you have these signs,

the heater may not be working properly. Get fresh

air at once! Have heater serviced. Some people

are more affected by carbon monoxide than others.

These include pregnant women, people with heart

or lung disease or anemia, those under the influ

ence of alcohol and those at high altitudes.

Natural and Propane/LP Gas: Natural and Propane/LP

gases are odorless. An odor-making agent is added

to these gases. The odor helps you detect a gas leak.

However, the odor added to the gas can fade. Gas

may be present even though no odor exists.

Make certain you read and understand all warnings. Keep this manual for reference. It is your

guide to safe and proper operation of this heater.

WARNING: Any change to

this heater or its controls can

be dangerous.

WARNING: Do not use a

blower insert, heat exchanger

insert or other accessory not approved for use with this heater.

Due to high temperatures, the

appliance should be located out

of traffic and away from furniture

and draperies.

Do not place clothing or other

flammable material on or near

the appliance. Never place any

objects on the heater.

Surface of heater becomes very

hot when running heater. Keep

children and adults away from

hot surface to avoid burns or

clothing ignition. Heater will

remain hot for a time after shut

down. Allow surface to cool

before touching.

Carefully supervise young children when they are in the same

room with heater.

-

Make sure grill guard is in place

before running heater.

Keep the appliance area clear

-

and free from combustible ma

terials, gasoline and other flammable vapors and liquids.

1. This appliance is only for use with the type of

gas indicated on the rating plate. This appliance

is not convertible for use with other gases.

2. Do not place propane/LP supply tank(s) in

side any structure. Locate propane/LP supply

tank(s) outdoors.

3. This heater shall not be installed in a bedroom

or bathroom.

4. If you smell gas

• Shut off gas supply

• Do not try to light any appliance

• Do not touch any electrical switch; do not

use any phone in your building

• Immediately call your gas supplier from a

neighborʼs phone. Follow the gas supplierʼs

instructions

• If you cannot reach your gas supplier, call

the fire department

-

-

-

www.desatech.com

3113261-01A

Page 4

SAFETY INFORMATION

Continued

5. This heater needs fresh, outside air ventilation

to run properly. This heater has an Oxygen

Depletion Sensing (ODS) safety shutoff

system. The ODS shuts down the heater if

not enough fresh air is available. See Air for

Combustion and Ventilation, page 5.

6. Keep all air openings in front and bottom of

heater clear and free of debris. This will insure

enough air for proper combustion.

7. If heater shuts off, do not relight until you

provide fresh, outside air. If heater keeps

shutting off, have it serviced.

8. Do not run heater

• where flammable liquids or vapors are used

or stored

• under dusty conditions

9. Do not use heater if any part has been under

water. Immediately call a qualified service

technician to inspect the room heater and to

replace any part of the control system and any

gas control which has been under water.

10. Turn off heater and let cool before servicing.

Only a qualified service person should service

and repair heater.

11. Operating heater above elevations of 4,500

feet (1372 m) could cause pilot outage.

12. To prevent performance problems, do not

use propane/LP fuel tank of less than 100

psi (690 kPa) capacity.

13. Before using furniture polish, wax, carpet

cleaner or similar products, turn heater off. If

heated, the vapors from these products may

create a white powder residue within burner

box or on adjacent walls or furniture.

14.

Provide adequate clearances around air

openings.

LOCAL CODES

Install and use heater with care. Follow all local

codes. In the absence of local codes, use the latest

edition of The National Fuel Gas Code, ANSI

Z223.1/NFPA 54

*Available from:

American National Standards Institute, Inc.

National Fire Protection Association, Inc.

*.

1430 Broadway

New York, NY 10018

Batterymarch Park

Quincy, MA 02269

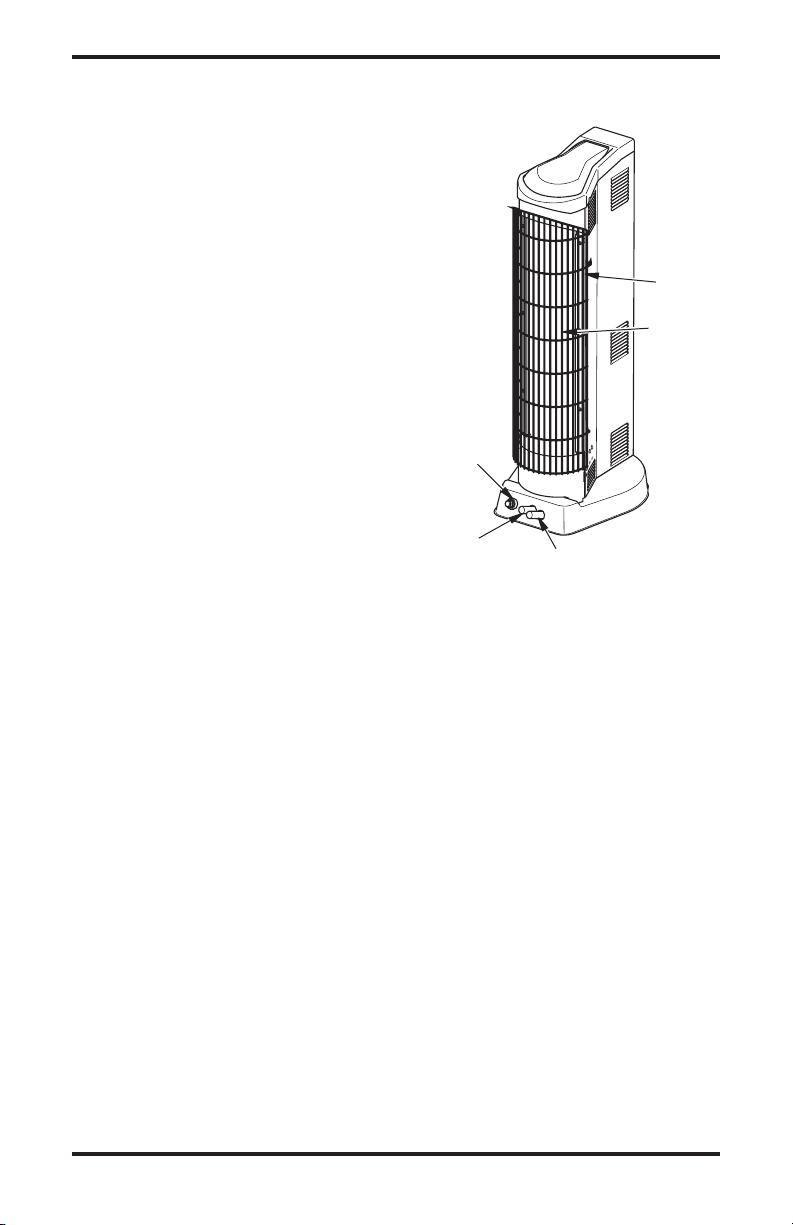

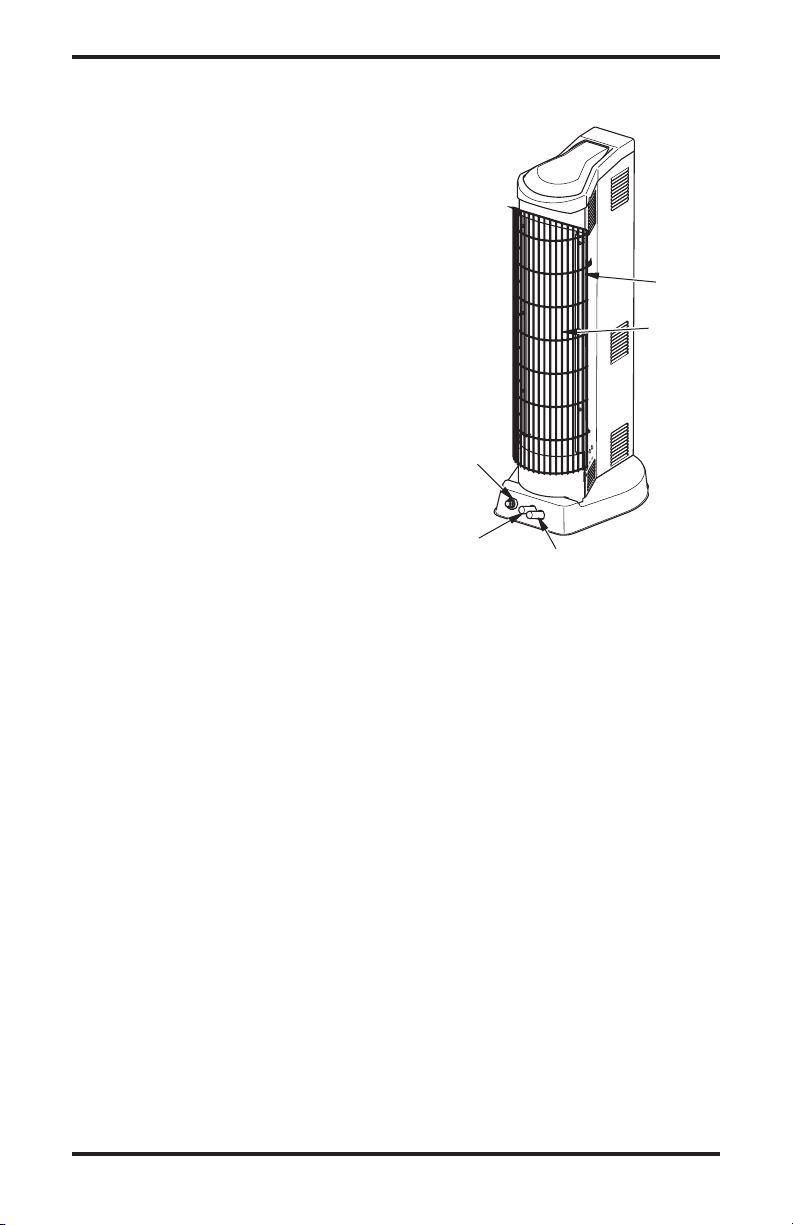

PRODUCT

IDENTIFICATION

Grill

Plaque

(behind

Grill)

Electronic

Ignitor

Manual/Auxiliary

Knob

Figure 1 - Infrared Tower Heater

On/Pilot/Off Knob

UNPACKING

1. Remove heater from carton.

2. Remove all protective packaging applied to

heater for shipment.

3. Check heater for any shipping damage. If

heater is damaged, promptly contact the dealer

to where you bought heater.

PRODUCT FEATURES

SAFETY DEVICE

This heater has a pilot with an Oxygen Depletion Sensing (ODS) safety shutoff system. The

ODS/pilot is a required feature for vent-free room

heaters. The ODS/pilot shuts off the heater if there

is not enough fresh air.

IGNITION SYSTEM

This heater has an electronic ignitor to light heater

fuel supply, which requires a AAA battery.

THERMOSTATIC HEAT CONTROL

Your unit is thermostatically controlled when heater and remote control are set to the proper modes.

This results in the greatest heater comfort.

4

www.desatech.com

113261-01A

Page 5

AIR FOR COMBUSTION

AND VENTILATION

WARNING: This heater shall

not be installed in a confined

space or unusually tight construction unless provisions are provided for adequate combustion and

ventilation air. Read the following

instructions to insure proper fresh

air for this and other fuel-burning

appliances in your home.

Todayʼs homes are built more energy efficient

than ever. New materials, increased insulation and

new construction methods help reduce heat loss

in homes. Home owners weather strip and caulk

around windows and doors to keep the cold air out

and the warm air in. During heating months, home

owners want their homes as airtight as possible.

While it is good to make your home energy effi

cient, your home needs to breathe. Fresh air must

enter your home. All fuel-burning appliances need

fresh air for proper combustion and ventilation.

Exhaust fans, fireplaces, clothes dryers and fuel

burning appliances draw air from the house to

operate. You must provide adequate fresh air for

these appliances. This will insure proper venting

of vented fuel-burning appliances.

PROVIDING ADEQUATE

VENTILATION

The following are excerpts from National Fuel

Gas Code, ANSI Z223.1/NFPA 54, Section 5.3,

Air for Combustion and Ventilation.

All spaces in homes fall into one of the three fol

lowing ventilation classifications:

1. Unusually Tight Construction

2. Unconfined Space

3. Confined Space

The information on pages 5 through 7 will help

you classify your space and provide adequate

ventilation.

Unusually Tight Construction

The air that leaks around doors and windows

may provide enough fresh air for combustion and

ventilation. However, in buildings of unusually

tight construction, you must provide additional

fresh air.

Unusually tight construction is defined as

construction where:

a. walls and ceilings exposed to the out

side atmosphere have a continuous

water vapor retarder with a rating of

one perm (6 x 10

less with openings gasketed or sealed

and

b. weather stripping has been added on

openable windows and doors and

c. caulking or sealants are applied to

areas such as joints around window

and door frames, between sole plates

and floors, between wall-ceiling joints,

between wall panels, at penetrations

for plumbing, electrical and gas lines

and at other openings.

If your home meets all of these three cri

teria, you must provide additional fresh

air. See Ventilation Air From Outdoors,

page 7.

If your home does not meet all of the three

-

criteria above, proceed to Determining

Fresh-Air Flow For Heater Location.

Confined and Unconfined Space

The National Fuel Gas Code, ANSI Z223.1/NFPA 54

defines a confined space as a space whose volume

is less than 50 cubic feet per 1,000 Btu per hour

3

per kw) of the aggregate input rating of all

(4.8 m

appliances installed in that space and an unconfined

space as a space whose volume is not less than 50

cubic feet per 1,000 Btu/Hr (4.8 m

aggregate input rating of all appliances installed in

that space. Rooms communicating directly with the

space in which the appliances are installed*, through

openings not furnished with doors, are considered

-

a part of the unconfined space.

* Adjoining rooms are communicating only if

there are doorless passageways or ventilation grills

between them.

-11

kg per pa-sec-m2) or

3

per kw) of the

DETERMINING FRESH-AIR FLOW

FOR HEATER LOCATION

Determining if You Have a Confined or

Unconfined Space

Use this work sheet to determine if you have a

confined or unconfined space.

Space: Includes the room in which you will install

heater plus any adjoining rooms with doorless passageways or ventilation grills between the rooms.

-

-

www.desatech.com

5113261-01A

Page 6

Or

Remove

Door into

Adjoining

Room,

Option 3

Ventilation Grills

Into Adjoining Room,

Option

2

12"

12"

Ventilation

Grills

into Adjoining

Room,

Option 1

AIR FOR COMBUSTION

AND VENTILATION

Continued

1. Determine the volume of the space (length x

width x height).

Length x Width x Height =__________cu. ft.

(volume of space)

Example: Space size 20 ft. (length) x 16 ft.

(width) x 8 ft. (ceiling height) = 2560 cu. ft.

(volume of space)

If additional ventilation to adjoining room is

supplied with grills or openings, add the volume

of these rooms to the total volume of the space.

2. Multiply the space volume by 20 to determine the

maximum Btu/Hr (kw) the space can support.

__________ (volume of space) x 20 = (Maxi-

mum Btu/Hr the space can support)

Example: 2560 cu. ft. (volume of space) x 20 =

51,200 (maximum Btu/Hr the space can support)

3. Add the Btu/Hr (kw) of all fuel burning appli

ances in the space.

Vent-free heater ________

Gas water heater* ________

Gas furnace ________

Vented gas heater ________

Gas fireplace logs ________

Other gas appliances* + ________

Total = ________

* Do not include direct-vent gas appliances. Di

rect-vent draws combustion air from the outdoors

and vents to the outdoors.

Example:

Gas water heater ___________

Vent-free heater ___________

Total ___________

4.

Compare the maximum Btu/Hr (kw) the space can

40,000 (11.7)

+ 22,000 (6.4)

= 62,000 (18.2)

support with the actual amount of Btu/Hr (kw) used.

___________

___________

Btu/Hr (kw) (maximum the space can support)

Btu/Hr (kw) (actual amount of Btu/Hr used)

Example: 51,200 Btu/Hr (15 kw) (maximum

the space can support)

62,000 Btu/Hr (18.2 kw) (actual

amount of Btu/Hr used)

The space in the above example is a confined space

because the actual Btu/Hr (kw) used is more than the

maximum Btu/Hr (kw) the space can support. You must

provide additional fresh air. Your options are as follows:

A. Rework worksheet, adding the space of an adjoin-

ing room. If the extra space provides an unconfined

space, remove door to adjoining room or add

ventilation grills between rooms. See Ventilation

Air From Inside Building.

B. Vent room directly to the outdoors. See Ventila

tion Air From Outdoors, page 7.

6

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

Btu/Hr (kw)

www.desatech.com

C. Install a lower Btu/Hr (kw) heater, if lower Btu/Hr

(kw) size makes room unconfined.

If the actual Btu/Hr (kw) used is less than the maxi

mum Btu/Hr (kw) the space can support, the space

is an unconfined space. You will need no additional

fresh air ventilation.

WARNING: If the area in which

the heater may be operated is

smaller than that defined as

an unconfined space or if the

building is of unusually tight

construction, provide adequate

combustion and ventilation air

by one of the methods described

in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 Section 5.3

or applicable local codes.

-

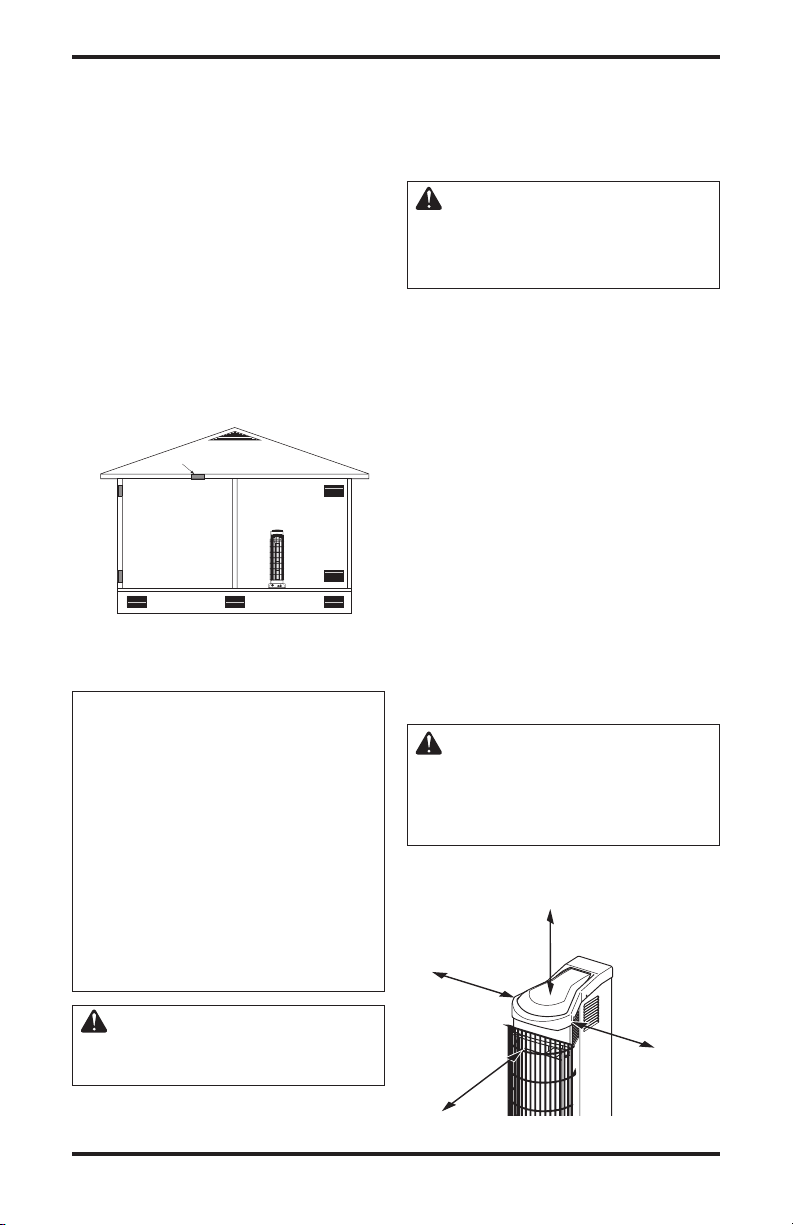

VENTILATION AIR

Ventilation Air From Inside Building

This fresh air would come from an adjoining un

confined space. When ventilating to an adjoining

unconfined space, you must provide two permanent openings: one within 12" (30.5 cm) of the

ceiling and one within 12" (30.5 cm) of the floor

on the wall connecting the two spaces (see options

1 and 2, Figure 2). You can also remove door into

-

adjoining room (see option 3, Figure 2). Follow the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

Section 5.3, Air for Combustion and Ventilation for

required size of ventilation grills or ducts.

12" (30,48 cm)

12" (30,48 cm)

Figure 2 - Ventilation Air from Inside

-

Building

113261-01A

-

-

Page 7

AIR FOR COMBUSTION

Outlet

Air

Ve

ntilated

Attic

Outlet

A

ir

Inlet

Air

Inlet Air

Ve

ntilated

Crawl Space

To

Crawl

Space

To Attic

AND VENTILATION

Continued

Ventilation Air From Outdoors

Provide extra fresh air by using ventilation grills

or ducts. You must provide two permanent open

ings: one within 12" (30.5 cm) of the ceiling and

one within 12" (30.5 cm) of the floor. Connect

these items directly to the outdoors or spaces

open to the outdoors. These spaces include attics

and crawl spaces. Follow the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, Section 5.3, Air for

Combustion and Ventilation for required size of

ventilation grills or ducts.

IMPORTANT: Do not provide openings for inlet

or outlet air into attic if attic has a thermostatcontrolled power vent. Heated air entering the attic

will activate the power vent.

Figure 3 - Ventilation Air from Outdoors

INSTALLATION

NOTICE: This heater is intended

for use as supplemental heat.

Use this heater along with your

primary heating system. Do not

install this heater as your pri

mary heat source. If you have a

central heating system, you may

run system’s circulating blower

while using heater. This will help

circulate the heat throughout the

house. In the event of a power

outage, you can use this heater

as your primary heat source.

-

CHECK GAS TYPE

Use only the correct type of gas (natural or propane/LP). If your gas supply is not the correct gas

type, do not install heater. Call dealer where you

bought heater for proper type heater.

-

WARNING: This appliance

is equipped for (natural or pro

pane/LP) gas. Field conversion

is not permitted.

INSTALLATION ITEMS

Before installing heater, make sure you have the

items listed below.

• for propane/LP gas, external regulator (supplied

by installer)

• piping (check local codes)

• sealant (resistant to propane/LP gas)

• equipment shutoff valve *

• ground joint union

• sediment trap

• tee joint

• pipe wrench

• for natural gas, test gauge connection*

* A CSA design-certified equipment shutoff valve

with 1/8" NPT tap is an acceptable alternative to

test gauge connection. The optional CSA designcertified equipment shutoff valve can be purchased

from your dealer. See

Accessories, page 22.

LOCATING HEATER

WARNING: Maintain the

minimum clearances shown

in Figure 4. If you can, provide

greater clearances from ceiling

and joining wall(s).

Heater may be installed either in a corner or along

the wall.

36"

10"

(25.4 cm)

(91.4 cm)

-

WARNING: A qualified service person must install heater.

Follow all local codes.

www.desatech.com

36"

(91.4 cm)

Figure 4 - Clearances to Combustibles

10"

(25.4 cm)

7113261-01A

Page 8

INSTALLATION

R

E

M

OT

E

OF

F

R

EM

O

T

E

OF

F

Continued

WARNING: Never install the

heater

• in a bedroom or bathroom

• in a recreational vehicle

• where curtains, furniture,

clothing or other flammable

objects are less than 36 inches

(91.4 cm) from the front or top

of the heater or less than 10"

(25.4 cm) from sides of heater

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

CAUTION: If you install the

heater in a home garage

• heater pilot and burner must

be at least 18 inches (45.7 cm)

above floor

• locate heater where moving

vehicle will not hit it

CAUTION: This heater creates

warm air currents. These currents

move heat to wall surfaces next

to heater. Installing heater next

to vinyl or cloth wall coverings or

operating heater where impurities

(such as, but not limited to, tobacco smoke, aromatic candles,

cleaning fluids, oil or kerosene

lamps, etc.) in the air exist, may

discolor walls or cause odors.

IMPORTANT: Vent-free heaters add moisture to

the air. Although this is beneficial, installing heater

in rooms without enough ventilation air may cause

mildew to form from too much moisture. See Air

for Combustion and Ventilation, page 5. If high hu

midity is experienced, a dehumidifier may be used

to help lower the water vapor content in the air.

For convenience and efficiency, install heater

• where there is easy access for operation, inspec

tion and service

• in coldest part of room

An optional fan kit is available from your dealer.

See Accessories, page 22. If planning to use fan,

locate heater near an electrical outlet.

INSTALLING REMOTE CONTROL

RECEIVER

Remote control receiver must be installed to operate the remote control.

1. Locate receiver bracket, two packages of

AA batteries, remote receiver and screws in

hardware bag included with your heater.

2. Remove battery cover on receiver and install

batteries as shown in Figure 5. Replace battery

cover.

3. Insert wire connector and wire through bush

ing on the back of heater (see Figure 6).

4.

Lay heater onto its side. Insert wire connector

into valve at location shown in Figure 7 page 9.

Feed extra wire from receiver into heater base.

Place heater back in upright position.

5. Attach bracket around receiver with screws

as shown in Figure 6.

Receiver

AA Batteries

Battery Cover

Figure 5 - Installing Batteries in Receiver

Receiver

-

Wire

Connector

-

Receiver

Bracket

Figure 6 - Installing Remote Receiver

Bushing

-

8

www.desatech.com

113261-01A

Page 9

INSTALLATION

RE

MOTE

OF

F

F

TEMPSET

ON

ROOM

OFF

MODE

SET

Continued

Bottom View

Slide Right to

REMOTE

LEARN Button (Inside)

ON

Button

Receiver Wire

Figure 7 - Connecting Receiver Wire

INSTALLING BATTERIES INTO

REMOTE

1. Locate hand-held remote control in hardware

bag included with your heater.

2. Remove battery cover and insert supplied batter

ies into remote control as shown in Figure 8.

3. Replace battery cover.

AAA

Batteries

Remote Control

Battery Cover

Figure 8 - Installing Batteries in Hand-

Held Remote Control

ACTIVATING COMMUNICATION

BETWEEN RECEIVER AND REMOTE

CONTROL

1. Set receiver selector switch to the remote

position (see Figure 9).

2. Push the ON button on hand-held remote

control. You should hear a beep. If not, use a

dull object to push the

receiver (see Figure 9). Push the ON button

on remote control once again. You should hear

a series of beeps.

If you have questions regarding the remote control

or receiver, call 1-888-673-8929.

LEARN button in the

Figure 9 - Receiver and Remote Control

REPLACING BATTERY IN IGNITOR

If the spark that lights the pilot lessons, you may need

Valve

to replace the battery in the ignitor. See Figure 10.

AAA Battery

Negative

towards cap

-

MOUNTING HEATER BASE TO

FLOOR (Where required by local codes)

1. Position heater in desired location. Mark holes

2. For carpeted floors, make a small cut with a

3. Drill 1/8" (diameter hole, 3/4" deep. (Do not

4. For concrete floors, use 1/4" diameter concrete

5. Position heater over holes. Secure to floor with

www.desatech.com

Setup

Figure 10 - Replacing Battery in

Electronic Ignitor

for drilling. Move heater aside.

sharp knife at the marked locations prior to

drilling.

use anchors in wood floors.)

drill bit. Drill 1

3

/

" deep. Insert anchors com-

8

pletely into holes.

wood screws. See Figure 11.

Wood

Screw

Mounting

Hole (One

each side)

Figure 11 - Mounting Heater to Floor

9113261-01A

Page 10

INSTALLATION

Continued

CONNECTING TO GAS SUPPLY

WARNING: This appliance

requires a 3/8" NPT (National

Pipe Thread) inlet connection to

the pressure regulator.

WARNIN G: A q ua li fi ed

service person must connect

heater to gas supply. Follow all

local codes.

WARNING: For natural gas,

never connect heater to private

(non-utility) gas wells. This

gas is commonly known as

wellhead gas.

IMPORTANT: For natural gas, check gas line

pressure before connecting heater to gas line. Gas

line pressure must be no greater than 10.5 inches

(2.6 kPa) of water. If gas line pressure is higher,

heater regulator damage could occur.

CAUTION: For propane/LP

gas, never connect heater directly to the propane/LP supply.

This heater requires an external

regulator (not supplied). Install

the external regulator between the

heater and propane/LP supply.

For propane/LP gas, the installer must supply an

external regulator. The external regulator will

reduce incoming gas pressure. You must reduce

incoming gas pressure to between 11 and 14 inches

(2.7 and 3.5 kPa) of water. If you do not reduce

incoming gas pressure, heater regulator damage

could occur. Install the external regulator with

the vent pointing down as shown in Figure 12.

Pointing the vent down protects it from freezing

rain or sleet.

CAUTION: Use only new,

black iron or steel pipe. Internally-tinned copper tubing may

be used in certain areas. Check

your local codes. Use pipe of

large enough diameter to allow

proper gas volume to heater. If

pipe is too small, undue loss of

volume will occur.

Typical Inlet Pipe Diameter

All models - 1/2" or greater

Installation must include equipment shutoff valve,

union and plugged 1/8" NPT tap. Locate NPT

tap within reach for test gauge hook up. NPT tap

must be upstream from heater (see Figure 13,

page 11).

IMPORTANT: Install an equipment shutoff valve

in an accessible location. The equipment shutoff

valve is for turning on or shutting off the gas to

the appliance.

Apply pipe joint sealant lightly to male NPT

threads. This will prevent excess sealant from

going into pipe. Excess sealant in pipe could result

in clogged heater valves.

WARNING: Use pipe joint

sealant that is resistant to liquid

petroleum (LP) gas.

Propane/LP

Supply Tank

Figure 12 - External Regulator With Vent

Pointing Down

External

Regulator

Vent

Pointing

Down

10

www.desatech.com

113261-01A

Page 11

INSTALLATION

Continued

Install sediment trap in supply line as shown in

Figure 13. Locate sediment trap where it is within

reach for cleaning. Locate sediment trap where

trapped matter is not likely to freeze. A sediment

trap traps moisture and contaminants. This keeps

them from going into heater controls. If sediment

trap is not installed or is installed wrong, heater

may not run properly.

IMPORTANT: Hold the pressure regulator with

wrench when connecting it to gas piping and/or

fittings. Do not over tighten pipe connection to

regulator. The regulator body could be damaged.

Pressure

Regulator

Regulator

Bracket

Heater

Cabinet

Tee Joint

Reducer

Bushing to

1/8" NPT

1/8" NPT

Plug Tap

Test Gauge Connection*

Tee Pipe Cap

Joint Nipple

Sediment Trap

Figure 13 - Gas Connection

* A CSA design-certified equipment shutoff valve

with 1/8" NPT tap is an acceptable alternative to

test gauge connection. Purchase the optional CSA

design-certified equipment shutoff valve from your

dealer. See

Accessories, page 22.

3"

(76 mm)

Min.

[7" (1.8 kPa) WC to

10.5" (2.6 kPa) WC

From External Regulator

[11" (2.7 kPa) WC to 14"

(3.5 kPa) WC Pressure]

3/8" NPT

Pipe

Nipple

Ground

Joint

Union

Equipment

Shutoff

Valve *

Natural Gas

From Gas Meter

Pressure]

Propane/LP

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping

and connections, internal and

external to unit, for leaks after

installing or servicing. Correct

all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply

a noncorrosive leak detection

fluid to all joints. Bubbles forming show a leak. Correct all leaks

at once.

CAUTION: For propane/LP

gas, make sure external regula

tor has been installed between

propane/LP supply and heater.

See guidelines under

Connect-

ing to Gas Supply, page 10.

PRESSURE TESTING GAS SUPPLY

PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1. Disconnect appliance with its appliance main

gas valve (control valve) and equipment

shutoff valve from gas supply piping system.

Pressures in excess of 1/2 psig (3.5 kPa) will

damage heater regulator.

2. Cap off open end of gas pipe where equipment

shutoff valve was connected.

3. Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve

located on or near gas meter for natural gas

or using compressed air.

4. Check all joints of gas supply piping system.

Apply a noncorrosive leak detection fluid to

all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

6.

Reconnect heater and equipment shutoff valve to

gas supply. Check reconnected fittings for leaks.

113261-01A

www.desatech.com

11

Page 12

INSTALLATION

Continued

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see Figure 14).

2. Pressurize supply piping system by either

opening propane/LP supply tank valve for

propane/LP gas or opening main gas valve

located on or near gas meter for natural gas

or using compressed air.

3. Check all joints from gas meter for natural gas

(see Figure 15) or propane/LP supply tank for

propane/LP gas, to equipment shutoff valve

(see Figure 16). Apply a noncorrosive leak

detection fluid to all joints. Bubbles forming

show a leak.

4. Correct all leaks at once.

PRESSURE TESTING HEATER GAS

CONNECTIONS

1. Open equipment shutoff valve (see Figure 14).

2. For natural gas open main gas valve located

on or near gas meter. For propane/LP gas open

propane/LP supply tank valve.

3. Make sure control knob of heater is in the OFF

position.

4. Check all joints from equipment shutoff valve

to thermostat gas valve (see Figure 15 or 16).

Apply a noncorrosive leak detection fluid to

all joints. Bubbles forming show a leak.

5. Correct all leaks at once.

Light heater (see Operating Heater, page 13).

6.

Check all other internal joints for leaks.

7. Turn off heater (see To Turn Off Gas to Appli-

ance, page 14).

8. Replace front panel.

Equipment

Shutoff Valve

Open

Equipment

Gas

Meter

Figure 15 - Checking Gas Joints for

Propane/LP

Supply Tank

Figure 16 - Checking Gas Joints for

Shutoff

Valve

Thermostat Gas Valve

(Inside Heater)

Natural Gas

Equipment

Shutoff

Valve

Thermostat Gas Valve

(Inside Heater)

Propane/LP Gas

Closed

Figure 14 - Equipment Shutoff Valve

12

www.desatech.com

113261-01A

Page 13

OPERATING HEATER

A

U

X

O

N

A

U

X

O

N

O

F

F

P

I

L

O

T

O

N

FOR YOUR SAFETY READ

BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly,

a fire or explosion may result

causing property damage, per

sonal injury or loss of life.

A. This appliance has a pilot which must be

lighted by hand. When lighting the pilot,

follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next

to the floor because some gas is heavier than

air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighborʼs phone. Follow the gas

supplierʼs instructions.

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the

gas control knob. Never use tools. If the

knob will not push in or turn by hand, donʼt

try to repair it, call a qualified service tech

nician or gas supplier. Force or attempted

repair may result in a fire or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

LIGHTING

INSTRUCTIONS

1. STOP! Read the safety information above.

2. Make sure equipment shutoff valve is fully

open.

3. Turn pilot knob clockwise

position.

4. Wait five minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information above. If you donʼt smell gas,

go to the next step.

-

to the OFF

5. Press in pilot knob and turn counterclock

wise to the PILOT position. Keep

pilot knob pressed in for five (5) seconds

(see Figure 17).

Note: You may be running this heater for

the first time after hooking up to gas supply.

If so, the pilot knob may need to be pressed

in for 30 seconds or more. This will allow

air to bleed from the gas system.

• If pilot knob does not pop up when re

leased, contact a qualified service person

or gas supplier for repairs.

6. With pilot knob pressed in, push in ignitor

button. This will light pilot. The pilot is

located at the bottom of plaque burners. If

needed, keep pressing ignitor button until

pilot lights.

Note: If pilot does not stay lit, refer to

Troubleshooting, page 17. Also contact a

qualified service person or gas supplier for

repairs. Until repairs are made, light pilot

with a match. To light pilot with a match,

see Manual Lighting Procedure, page 14.

7. Keep pilot knob pressed in for 30 seconds

after lighting pilot. After 30 seconds, release

pilot knob.

• If pilot knob does not pop up when re

leased, contact a qualified service person

or gas supplier for repairs.

Note: If pilot goes out, repeat steps 3

through 7.

-

8.

With the auxiliary knob in the ON position, turn pilot knob counterclockwise

to start the heater. The main burner

should light.

Electronic Ignitor

Button

Auxiliary

Knob

Figure 17 - Pilot Knob In The ON Position

Thermocouple

Ignitor Electrode

Pilot

Burner

-

-

-

Pilot

Knob

Figure 18 - Pilot

www.desatech.com

13113261-01A

Page 14

F

TEMPSETONROOM

OFF

MODE

SET

OPERATING HEATER

Continued

9. With the auxiliary knob in the AUX posi

tion, push the ON button on the remote

control. To adjust the temperature with the

remote control, follow the instructions on

page 15. When the temperature surround

ing the remote control drops below the set

temperature, the burner should light. The

remote receiver behind the unit must be in

the REMOTE position.

CAUTION: Do not try to adjust heating levels by using the

equipment shutoff valve.

TO TURN OFF GAS

TO APPLIANCE

Shutting Off Heater

1. Press in and turn pilot knob clockwise

2. Unplug any electrical power to the appli

Shutting Off Burner Only (pilot stays lit)

If auxiliary knob is in AUX position, push OFF

button on remote control.

If auxiliary knob is in ON position, turn pilot

knob clockwise to the PILOT position.

The thermostat used on this heater senses the

room temperature at the location of the handheld remote control. At times the room may

exceed the set temperature. If so, the burner will

shut off. The burner will cycle back on when

room temperature drops below the set temperature. All plaques will turn off and on.

1. Follow steps 1 through 5 under Lighting

2. With pilot knob pressed in, strike match.

3. Keep pilot knob pressed in for 30 seconds

14

to the OFF position.

ance if service is to be performed.

THERMOSTAT

OPERATION

MANUAL LIGHTING

PROCEDURE

Instructions, page 13.

Hold match to pilot until pilot lights.

after lighting pilot. After 30 seconds, release

pilot knob. Continue with step 8 under

Lighting Instructions, above.

1. Slide selector switch on remote receiver to

-

the REMOTE position.

2. Slightly pull and turn auxiliary knob so the

AUX is to the left and right and ON is to the

top and bottom positions.

-

3. Light the pilot. Follow steps 1 through 6

under Lighting Instructions, page 13.

DISPLAY

The LCD display on the remote control indi

cates current room temperature in Fahrenheit

or Celsius. The small flame indicates burner/

valve in operation. ROOM indicates remote

is in thermo operation. TEMP appears during

manual operation. SET appears during the

time of setting the desired temperature in the

thermo operation.

Changes heater

-

from Manual

Mode to

Thermo Mode

Sets

temperature in

Thermo Mode

Figure 19 - Hand-Held Remote Control Unit

SETTING FAHRENHEIT AND CELSIUS SCALE

The factory setting for temperature is Fahrenheit. To change this setting to Celsius, press

the ON and OFF buttons on remote at the same

time. Follow the same procedure to change from

Celsius back to Fahrenheit.

MANUAL FUNCTION

On Operation

When the ON button is pressed the appliance

flame will come on. The LCD screen will show

ON for three seconds, then default to room

temperature and the word TEMP and flame

icon will show.

Off Operation

When the OFF button is pressed the appliance

flame will shut off. The LCD screen will show

OF for three seconds, then default to room tem

perature and the word TEMP will show.

www.desatech.com

HAND-HELD REMOTE

CONTROL OPERATION

-

Turns

heater

ON

Turns

heater

OFF

-

113261-01A

Page 15

OPERATING HEATER

Continued

THERMOSTAT FUNCTION

Setting Desired Room Temperature

This remote control system can be thermostati

cally controlled when the remote control is in

the thermo mode. The word ROOM must be

displayed on the screen.

1. Press MODE button on remote control until

ROOM appears. This sets the remote to the

thermostat mode.

2. Press and hold the SET button until the

desired temperature is displayed. The

numbers will increase from 45° to 99° then

restart over at 45°. After releasing the SET

button, the set room temperature will dis

play for 3 seconds, then default to display

the room temperature.

Changing Set Temperature

1. Follow step two under Setting Desired Room

Temperature

2. Press the MODE button to disengage the

thermo mode. The word ROOM does

not display when thermo mode is not in

operation.

above.

INSPECTING HEATER

Check pilot flame pattern and burner flame pattern often.

PILOT FLAME PATTERN

Figure 20 shows a correct pilot flame pattern.

Figure 21 shows an incorrect pilot flame pattern.

The incorrect pilot flame is not touching the

thermocouple. This will cause the thermocouple

to cool. When the thermocouple cools, the heater

will shut down.

If pilot flame pattern is incorrect, as shown in

Figure 21

•

turn heater off (see To Turn Off Gas to Appliance,

page 14)

• see Troubleshooting, page 17

Note: The pilot flame on natural gas units will

have a slight curve, but flame should be blue and

have no yellow or orange color.

Blue Flame

Thermocouple

-

Figure 20 - Correct Pilot Flame Pattern

Thermocouple

Figure 21 - Incorrect Pilot Flame Pattern

-

Pilot Burner

Yellow Flame

Pilot Burner

BURNER FLAME PATTERN

Figure 22 shows a correct and incorrect burner flame

pattern. If burner flame pattern is incorrect

• turn heater off (see To Turn Off Gas to Appli

ance, page 14)

• see Troubleshooting

Correct

Flame

Pattern

Figure 22 - Burner Operation

, page 17

Incorrect

Flame

Pattern

-

www.desatech.com

15113261-01A

Page 16

CLEANING AND

MAINTENANCE

WARNING: Turn off heater

and let cool before cleaning.

CAUTION: You must keep control areas, burner and circulating

air passageways of heater clean.

Inspect these areas of heater

before each use. Have heater

inspected yearly by a qualified

service person. Heater may need

more frequent cleaning due to

excessive lint from carpeting,

bedding material, pet hair, etc.

WARNING: Failure to keep

the primary air opening(s) of

the burner(s) clean may result in

sooting and property damage.

ODS/PILOT AND BURNER

Use a vacuum cleaner, pressurized air or small,

soft bristled brush to clean.

BURNER PILOT AIR INLET

The primary air inlet holes allow the proper

amount of air to mix with the gas. This provides a

clean burning flame. Keep these holes clear of dust,

dirt and lint. Clean these air inlet holes prior to each

heating season. Blocked air holes will create soot.

We recommend that you clean the unit every three

months during operation and have heater inspected

yearly by a qualified service person.

We also recommend that you keep the burner

tube and pilot assembly clean and free of dust and

dirt. To clean these parts we recommend using

compressed air no greater than 30 PSI (200 kPa).

Your local computer store, hardware store or home

center may carry compressed air in a can. You can

use a vacuum cleaner in the blow position. If using

compressed air in a can, please follow the direc

tions on the can. If you don't follow directions on

the can, you could damage the pilot assembly.

1. Shut off the unit, including the pilot. Allow

the unit to cool for at least thirty minutes.

2. Inspect burner, pilot for dust and dirt.

3. Blow air through the ports/slots and holes in

the burner.

4. Never insert objects into the pilot tube.

Clean the pilot assembly also. A yellow tip on the

pilot flame indicates dust and dirt in the pilot as

sembly. There is a small pilot air inlet about two

inches from where the pilot flame comes out of

the pilot assembly (see Figure 23). With the unit

off, lightly blow air through the air inlet. You may

blow through a drinking straw if compressed air

is not available.

Pilot Assembly

Pilot Air Inlet

Figure 23 - Pilot Air Inlet

CABINET

Air Passageways

Use a vacuum cleaner o r pressurized air to

clean.

Exterior

Use a soft cloth dampened with a mild soap and

water mixture. Wipe the cabinet to remove dust.

BATTERIES

During long periods of time when the heater is

not being used, take batteries out of receiver and

ignitor. Remove exhausted batteries immediately.

Do not mix old and new batteries.

SERVICE HINTS

When Gas Pressure Is Too Low

• pilot will not stay lit

• burner will have delayed ignition

• heater will not produce specified heat

• propane/LP gas supply may be low

You may feel your gas pressure is too low. If so, con

tact your local natural or propane/LP gas supplier.

TECHNICAL SERVICE

-

You may have further questions about installation,

operation or troubleshooting. If so, contact DESA

Heating Productsʼ Technical Service Department

at 1-866-672-6040. When calling please have your

model and serial numbers of your heater ready.

You can also visit DESA Heating Productsʼ techni

cal service web site at www.desatech.com.

-

-

-

16

www.desatech.com

113261-01A

Page 17

TROUBLESHOOTING

WARNING: Turn off and unplug heater and let cool before servicing.

Only a qualified service person should service and repair heater.

CAUTION: Never use a wire, needle or similar object to clean

ODS/pilot. This can damage ODS/pilot unit.

Note: All troubleshooting items are listed in order of operation.

OBSERVED PROBLEM

When ignitor button is pressed

in, there is no spark at ODS/

pilot

When ignitor button is pressed

in, there is a spark at ODS/Pilot

but no ignition

POSSIBLE CAUSE

1. Ignitor electrode positioned

wrong

2. Ignitor electrode broken

3. Ignitor elect rode not con

nected to ignitor cable

4. Ignitor cable pinched or wet

5. Broken ignitor cable

6. Bad ignitor

7. Battery not installed, battery

power low or battery not in

stalled correctly

1. Gas supply turned off or equip

ment shutoff valve closed

2. Pilot knob not fully pressed in

while pressing ignitor button

3. Air in gas lines when in

stalled

4. Depleted gas supply (propane/

LP gas)

5. ODS/pilot is clogged

6. Gas regulator setting is not

correct

REMEDY

1. Replace pilot assembly

2. Replace pilot assembly

3. Reconnect ignitor cable

-

4. Free ignitor cable if pinched

by any metal or tubing. Keep

ignitor cable dry

5. Replace ignitor cable

6. Replace ignitor

7. Install new alkaline battery in

electronic ignitor. Verify bat

tery is installed correctly. See

page 9

1. Turn on gas supply or open

equipment shutoff valve

2. Turn to PILOT/IGN position.

Fully press in pilot knob while

pressing ignitor button

-

3. Continue holding down pilot

knob. Repeat igniting operation until air is removed

4. Contact local propane/LP gas

company

5. Clean ODS/pilot (see Cleaning

and Maintenance, page 16) or

replace ODS/pilot assembly

6. Replace gas regulator

-

www.desatech.com

17113261-01A

Page 18

OBSERVED PROBLEM

ODS /pilot lights but flame

goes out when control knob is

released

TROUBLESHOOTING

Continued

POSSIBLE CAUSE

1.

Pilot knob not fully pressed in

2. Pilot knob not pressed in long

enough

3. Equipment shutoff valve not

fully open

4. Thermoco upl e conne ction

loose at control valve

5. Pilot flame not touching ther

mocouple, which allows ther

mocouple to cool, causing

pilot flame to go out. This

problem could be caused by

one or both of the following:

A) Low gas pressure

B) Dirty or partially clogged

ODS/pilot

6. Thermocouple damaged

7. Valve damaged

-

-

REMEDY

1. Press in pilot knob fully

2. After ODS/pilot lights, keep pilot knob pressed in 30 seconds

3. Fully open equipment shutoff

valve

4. Hand tighten until snug, then

tighten 1/4 turn more

5. A) Contact local natural or

propane/LP gas company

B) Cle a n ODS/pi l ot (see

Cleaning and Maintenance

page 16) or replace ODS/pilot

assembly

6. Replace pilot assembly

7. Replace valve

,

Burner(s) does not light after

ODS/pilot is lit

Delayed ignition of burner(s)

Burner backfiring during com

bustion

Burner plaque(s) does not glow

Slight smoke or odor during

initial operation

Heater produces a clicking/tick

ing noise just after burner is lit

or shut off

1. Burner orifice(s) is clogged

2. Inlet gas pressure is too low

1. Manifold pressure is too low

2. Burner orifice(s) is clogged

1. Burner orifice(s) is clogged or

damaged

2. Burner damaged

3. Gas regulator defective

1. Plaque damaged

2. Inlet gas pressure is too low

1. Residues from manufacturing

processes

1. Metal expanding while heating

or contracting while cooling

1.

Clean burner orifice(s) (see

Cleaning and Maintenance, page

16) or replace burner orifice(s)

2. Contact local natural or propane/LP gas company

1. Contact local natural or pro

pane/LP gas company

2.

Clean burner orifice(s) (see

Cleaning and Maintenance, page

16) or replace burner orifice(s)

1.

Clean burner orifice(s) (see

Cleaning and Maintenance, page

16) or replace burner orifice(s)

2. Replace burner

3. Replace gas regulator

1. Replace burner

2. Contact local natural or pro

pane/LP gas company

1. Problem will stop after a few

hours of operation

1. This is common with most heat

ers. If noise is excessive, contact

qualified service person

-

-

-

18

www.desatech.com

113261-01A

Page 19

TROUBLESHOOTING

Continued

WARNING: If you smell gas

• Shut off gas supply.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

IMPORTANT: Operating heater where impurities in air exist may create odors. Cleaning supplies,

paint, paint remover, cigarette smoke, cements and glues, new carpet or textiles, etc., create fumes.

OBSERVED PROBLEM

Remote does not function

POSSIBLE CAUSE

1. Battery is not installed or batter power is low

REMEDY

1. Replace AA batteries in receiver

and remote hand set

White powder residue forming

within burner box or on adjacent

walls or furniture

Heat er pr oduce s u nwant ed

odors

Heater shuts off in use (ODS

operates)

Gas odor even when pilot knob

is in OFF position

Gas odor during combustion

1. When heated, vapors from

furniture polish, wax, carpet

cleaner, etc., may turn into

white powder residue

1. Heater burning vapors from

paint, hair spray, glues, etc.

See IMPORTANT statement

above

2. Low fuel supply (propane/LP

gas)

3. Gas le ak. Se e War ning

statement at top of page

1. Not enough fresh air is avail

able

2. Low line pressure

3. O D S/ p il ot i s p a rt ia ll y

clogged

1. Gas le ak. Se e War ning

statement at top of page

2. Valve defective

1. Foreign matter between valve

and burner

2. Gas le ak. Se e War ning

statement at top of page

1. Turn heater off when using

furniture polish, wax, carpet

cleaners or similar products

1. Ventilate room. Stop using

odor causing products while

heater is running

2. Refill supply tank

3. Locate and correct all leaks

(see Checking Gas Connec

tions, page 11)

1. Open window and/or door for

ventilation

2. Contact local natural or pro

pane/LP gas company

3. Clean ODS/pilot (see Cleaning

and Maintenance, page 16)

1. Locate and correct all leaks

(see Checking Gas Connec

tions, page 11)

2. Replace valve

1. Take apart gas tubing and

remove foreign matter

2. Locate and correct all leaks

(see Checking Gas Connec

tions, page 11)

-

-

-

-

Moisture/condensation noticed

on windows

1. Not enough combustion/ven

tilation air

www.desatech.com

1. Refer to Fresh Air for Com

bustion and Ventilation re

quirements (page 5)

-

-

19113261-01A

Page 20

ILLUSTRATED PARTS BREAKDOWN

2

3

4

5

6

14

15

16

17

16

19

18

25

26

22

24

12

13

21

20

20

7

8

9

10

31

37

34

35

36

32

33

1

11

27

28

29

30

28

23

F

T

E

M

P

S

E

T

O

N

RO

O

M

O

F

F

M

O

D

E

S

E

T

MODELS

CTR25NR, VTN25R, CTR22PR AND VTP22R

20

www.desatech.com

113261-01A

Page 21

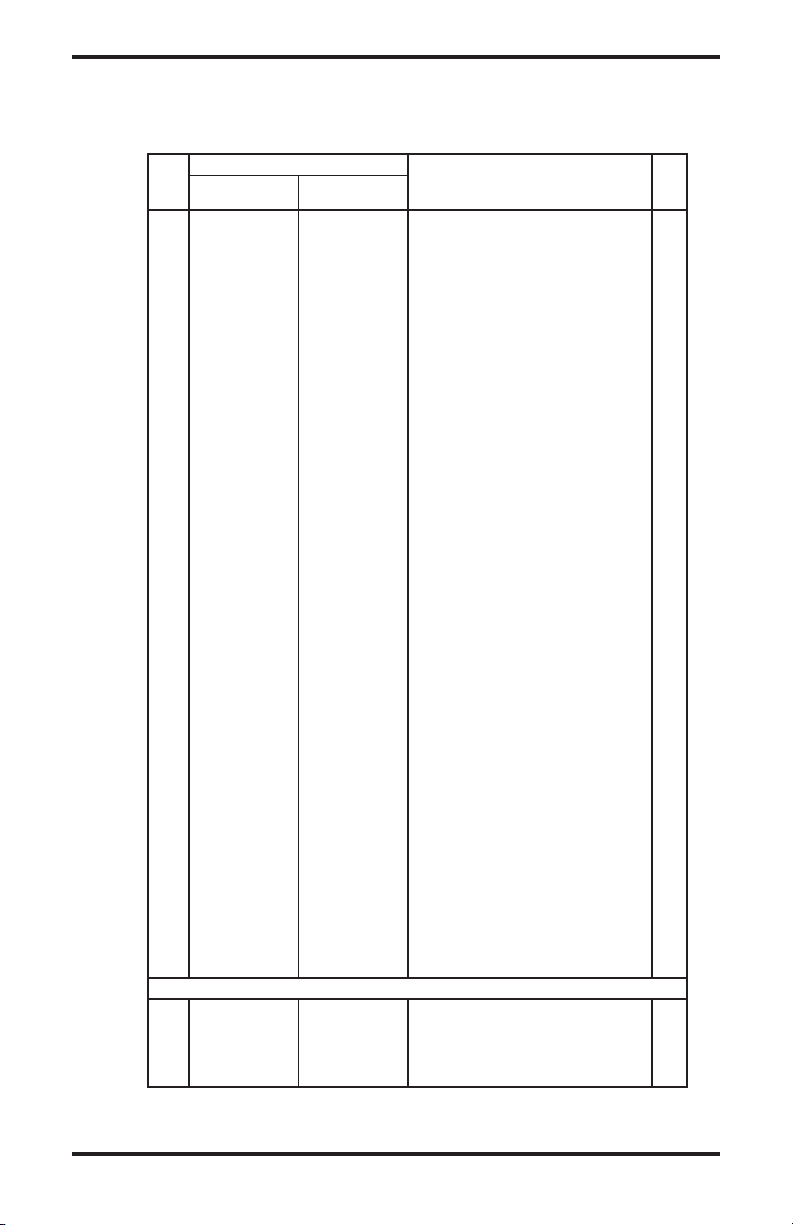

PARTS LIST

This list contains replaceable parts used in your heater. When ordering parts, follow the instructions

listed under Replacement Parts on page 22 of this manual.

PART NUMBER

KEY CTR25NR CTR22PR

NO. VTN25R VTP22R DESCRIPTION QTY

1 113079-01 113079-01 Grill 1

2 113601-02DC 113601-02DC Cast Top 1

3 113602-01CK 113602-01CK Perforated Top 1

4 113078-02CK 113078-02CK Deflector Trim Plate 1

5 ** ** Wrapper 1

6 113651-01CK 113651-01CK Top Trim 1

7 113600-03DC 113600-03DC Back Door 1

8 114659-01 114659-01 Grill Screws 2

9 114032-01 114032-01 Receiver Remote 1

10 113255-01DC 113255-01DC Remote Receiver Plate 1

11 M50104-06 M50104-06 Bushing 1

12 114254-01 114254-01 Top Burner Assembly 1

13 114254-02 114254-02 Bottom Burner Assembly 1

14 114255-01 114255-01 Reflector Assembly 1

15 113175-01CK 113175-01CK Top Baffle 1

16 113175-02 113175-02 Mid Burner Baffle 2

17 113175-03 113175-03 Between Burner Baffle 1

18 113176-01 113176-01 Plaque Clip 6

19 113074-02DC 113074-02DC Bottom Trim 1

20 099056-24 099056-25 Injector 2

21 113258-01 113258-01 Outlet Tube 1

22 113650-02CK 113650-02CK Trim Deflector Plate 1

23 113173-01 113173-01 Pilot Bracket 1

24 110803-03 110803-02 ODS Pilot 1

25 109121-02 109121-02 Pilot Shield 1

26 098271-11 098271-11 Ignitor Cable 1

27 099387-13 099387-13 Pilot Tube 1

28 111435-01 111435-01 Electronic Ignitor 1

29 114021-01 114021-01 Auxiliary Knob Extension 1

30 114021-02 114021-02 Pilot Knob Extension 1

31 ** ** Base 1

32 113172-01 113172-01 Regulator Bracket 1

33 099415-21 099415-18 Gas Regulator 1

34 114250-01 114250-01 Inlet Tube 1

35 098264-02 098264-02 Male Connector 2

36 114012-01 114012-01 Valve 1

37 114031-01 114031-01 Hand-Held Remote 1

PARTS AVAILABLE - NOT SHOWN

113262-01 113262-01 Control Decal 1

113264-01 113264-01 Lighting Inst Hang Tag English 1

113264-02 113264-02 Lighting Inst Hang Tag Spanish 1

105345-01 105345-01 Wire Tie 1

** Not a field replaceable part.

www.desatech.com

21113261-01A

Page 22

SPECIFICATIONS

CTR25NR CTR22PR

VTN25R VTP22PR

Btu/hr (kW) 25,000 (7.3) 22,000 (6.4)

Type Gas Natural Only Propane/LP Only

Ignition Electronic Electronic

Pressure Regulator Setting 6" W.C. (1.5 kPa) 8" W.C. (2.0 kPa)

Inlet Gas Pressure* (in. of water)

Maximum 10.5" (7.6 kPa) 14" (3.5 kPa)

Minimum 7" (1.8 kPa) 11" (2.7 kPa)

Dimensions (H x W x D)

Heater 40

102.9 x 38.1 x 48.3 cm 102.9 x 38.1 x 48.3 cm

Carton 45

115.9 x 44.5 x 55.2 cm 115.9 x 44.5 x 55.2 cm

Weight

Heater 28 lbs. (12.7 kg) 28 lbs. (12.7 kg)

Shipping 33 lbs. (15 kg) 33 lbs. (15 kg)

Note: Dimensions listed are outer most points on the heater (includes control knobs and grill).

* For purposes of input adjustment.

1

/2" x 15" x 19" 40 1/2" x 15" x 19"

5

/8" x 17 1/2" x 21 3/4" 45 5/8" x 17 1/2" x 21 3/4"

ACCESSORIES

Purchase these heater accessories from your local

dealer. If they can not supply these accessories, either

contact your nearest Parts Central (see page 23) or

call DESA Heating Products at 1-866-672-6040 for

referral information. You can also write to the address

listed on the back page of this manual.

EQUIPMENT SHUTOFF VALVE

GA5010

For all models. Equipment shutoff valve with

1/8" NPT tap.

FAN KIT - GA3220T

For all models. Provides better heat distribution.

Makes heater more efficient. Complete installation

and operating instructions included.

Thermostatically-controlled, blower turns itself on

and off as required.

SERVICE PUBLICATIONS

You can purchase a service manual from the address

listed on the back page of this manual. Send a check

for $5.00 payable to DESA Heating Products.

REPLACEMENT PARTS

Note: Use only original replacement parts. This

will protect your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product. If

they canʼt supply original replacement part(s),

call DESA Heating Productsʼ Technical Service

Department at 1-866-672-6040.

When calling DESA Heating Products, have ready

• your name

• your address

• model and serial numbers of your heater

• how heater was malfunctioning

• type of gas used (propane/LP or natural gas)

• purchase date

Usually, we will ask you to return the part to the

factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product. If they

canʼt supply original replacement part(s), either

contact your nearest Parts Central (see page 23)

or call DESA Heating Products at 1-866-672-6040

for referral information.

When calling DESA Heating Products, have ready

• model number of your heater

• the replacement part number

22

www.desatech.com

113261-01A

Page 23

PARTS CENTRAL

These Parts Centrals are privately owned businesses. They have agreed to support our customerʼs needs

by providing original replacement parts and accessories.

Tools & Equipment Co.

5 Manila Ave

Hamden, CT 06514-0322

1-800-397-7553

203-248-7553

Portable Heater Parts

342 N. County Rd. 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-888-619-7060

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

Fax: 1-800-846-0090

franktalk@aol.com

Master Parts Dist.

1251 Mound Ave. NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

www.nbmc.com

Washer Equipment Co.

1715 Main Street

Kansas City, MO 64108-2195

KS, MO, AR

816-842-3911

www.washerparts.com

East Coast Energy

707 Broadway

W. Long Branch, NJ 07764-1542

732-870-8809

1-800-755-8809

www.njplaza.com/ecep

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

800-325-4828

Laporte’s Parts & Service

2444 N. 5th Street

Hartsville, SC 29550-7704

843-332-0191

Parts Department

Cans Unlimited

P.O. Box 645

Taylor, SC 29687-0013

803-879-3009

1-800-845-5301

cuisales@aol.com

www.desatech.com

23113261-01A

Page 24

Patent Pending

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

Page 25

CALENTADOR DE GAS INFRARROJO NO VENTILADO

(SIN VENTILAS)

INFORMACIÓN DE SEGURIDAD Y MANUAL DE INSTALACIÓN

MODELOS CTR25NR, CTR22PR, VTN25R Y VTP22R

ADVERTENCIA: Si la información contenida en este manual

no se sigue al pie de la letra, se puede producir un incendio

o una explosión que podría ocasionar daños a la propiedad,

lesiones personales o la pérdida de la vida.

— No guarde ni utilice gasolina u otros vapores y líquidos

inflamables cerca de este aparato ni de cualquier otro.

— QUÉ HACER SI PERCIBE OLOR A GAS

• No intente encender ningún aparato.

• No toque ningún interruptor eléctrico; no use ningún

teléfono en el edificio.

• Llame inmediatamente a su proveedor de gas desde

el teléfono de algún vecino. Siga las instrucciones del

proveedor de gas.

• Si no puede localizar al proveedor de gas, llame al

departamento de bomberos.

— La instalación y el servicio deben ser realizados por un

instalador capacitado, agencia de servicio o por el pro

-

veedor de gas.

Guarde este manual para futuras referencias.

Para obtener más información, visite www.desatech.com

Page 26

ADVERTENCIA: La instalación, ajuste, alteración, servicio o

mantenimiento inadecuados pueden provocar lesiones o daños a la propiedad. Consulte este manual para conocer los procedimientos correctos de instalación y operación. Para obtener

asistencia o información adicional consulte a un instalador

capacitado, agencia de servicio o al proveedor de gas.

ADVERTENCIA: Este es un calentador de llama de gas sin

ventilación. Utiliza aire (oxígeno) del cuarto en el que se instala. Se deben tomar las medidas necesarias para asegurar la

cantidad de aire para una ventilación y combustión adecuadas. Consulte la sección Aire para combustión y ventilación,

en la página 5 de este manual.

Este aparato puede ser instalado en una casa móvil con ubicación permanente y adquirida en el mercado de posventa*,

siempre que no esté prohibido por los códigos locales.

Este aparato está diseñado para usarse únicamente con el tipo

de gas indicado en la placa de clasificación. Este aparato no

se puede convertir para su uso con otros gases.

* Mercado de posventa: venta completada por parte del fabricante, sin fines de reventa

TABLA DE CONTENIDO

Información de seguridad .................................... 2

Códigos locales .................................................. 4

Identificación del producto ................................... 4

Desempaque ...................................................... 4

Características del producto ................................ 4

Aire para combustión y ventilación ..................... 5

Instalación .......................................................... 7

Funcionamiento del calentador ......................... 13

Inspección del calentador ................................. 15

Limpieza y mantenimiento ................................. 16

INFORMACIÓN DE SEGURIDAD

ADVERTENCIA: Este producto

contiene y/o genera químicos que el

Estado de California reconoce que

causan cáncer, defectos de nacimiento u otros daños relacionados

con la reproducción.

2

www.desatech.com

Consejos para reparaciones ............................ 16

Servicio técnico ................................................ 16

Solución de problemas ...................................... 17

Clasificación ilustrada de piezas y lista de piezas

Especificaciones ................................................ 22

Accesorios ........................................................ 22

Publicaciones para servicio .............................. 22

Piezas de repuesto ........................................... 23

Central de piezas ............................................. 23

.. 20

IMPORTANTE: Lea este manual del

propietario cuidadosa y completamente antes de intentar ensamblar, operar

o dar servicio a este calentador. El uso

inadecuado de este calentador puede

causar lesiones graves o la muerte

por quemaduras, incendio, explosión,

electrocución e intoxicación con mo

nóxido de carbono.

113261-01A

-

Page 27

INFORMACIÓN DE SEGURIDAD

Continuación

PELIGRO: La intoxicación

con monóxido de carbono puede

resultar en la muerte!

Intoxicación con monóxido de carbono: Los síntomas

iniciales de la intoxicación con monóxido de carbono son

semejantes a los de la gripe, con dolores de cabeza, mareos

y/o náusea. Si usted presenta estos síntomas, es posible que

el calentador no esté funcionando correctamente. ¡Respire

aire fresco inmediatamente! Haga que le den servicio al

calentador. El monóxido de carbono afecta más a algunas

personas que a otras. Las más afectadas incluyen a mujeres

embarazadas, personas con enfermedades del corazón o

de los pulmones o anemia, aquellas bajo la influencia del

alcohol y aquellas a grandes altitudes.

Gas natural y propano o gas LP: Los gases natural y

propano o gas LP son gases inodoros. A estos gases se

les agrega un agente oloroso. El olor le ayuda a detectar

las fugas de gas. Sin embargo, el olor que se añade al gas

puede desvanecerse. Es posible que haya gas presente

aunque no haya ningún olor.

Asegúrese de leer y comprender todas las advertencias.

Conserve este manual para consulta. Es su guía para la

operación segura y correcta de este calentador.

ADVERTENCIA: Cualquier

cambio a este calentador o a los

controles puede ser peligroso.

ADVERTENCIA: No utilice

un aditamento de ventilador, de

intercambio de calor ni otro accesorio que no esté aprobado para

su uso con este calentador.

Debido a las altas temperaturas,

el aparato debe situarse fuera de

las rutas de paso y alejado de los

muebles y cortinas.

No ponga ropa ni otros materiales

inflamables sobre el aparato o cerca

del mismo. Nunca coloque ningún

objeto sobre el calentador.

La superficie del calentador alcanza

temperaturas muy altas cuando éste

está funcionando. Mantenga niños y

adultos alejados de las superficies

calientes para evitar quemaduras o

que la ropa se encienda. El calentador permanecerá caliente durante

algún tiempo después de que se

haya apagado. Deje que la superficie

se enfríe antes de tocarla.

Supervise con sumo cuidado a los

niños pequeños cuando estén en el

mismo cuarto que el calentador.

Asegúrese que el resguardo de la

rejilla esté puesto antes de hacer

funcionar el calentador.

Mantenga el área del aparato limpia

y libre de materiales combustibles,

gasolina y otros vapores y líquidos

inflamables.

1. Este aparato está diseñado para usarse únicamente con el tipo de gas indicado en la placa de

clasificación. Este aparato no se puede convertir

para su uso con otros gases.

2. No ponga los tanques de suministro de propano

o gas LP dentro de ninguna estructura. Sitúe los

tanques de suministro de propano o gas LP en el

exterior.

3. Este calentador no se debe instalar en un recá

mara o en un baño.

4. Si percibe olor a gas

• Cierre el suministro de gas

• No intente encender ningún aparato

• No toque ningún interruptor eléctrico; no use

ningún teléfono en el edificio

• Llame inmediatamente a su proveedor de gas

desde el teléfono de algún vecino. Siga las

instrucciones del proveedor de gas

• Si no puede localizar al proveedor de gas, llame

al departamento de bomberos

5. Este calentador necesita de ventilación de aire

fresco del exterior para poder funcionar correc

tamente. Este calentador tiene un sistema de

apagado de seguridad con Sensor de agotamiento

de oxígeno (ODS). El ODS apaga el calentador

cuando éste no cuenta con suficiente aire fresco.

Consulte Aire para combustión y ventilación,

página 5.

-

-

www.desatech.com

3113261-01A

Page 28

INFORMACIÓN DE SEGURIDAD

Continuación

6. Mantenga limpias y libres de residuos todas las

aberturas de las partes anterior e inferior del ca

lentador. Esto asegurará que haya suficiente aire

para lograr una combustión adecuada.

7. Si el calentador se apaga, no lo vuelva a encender

hasta que éste cuente con aire fresco del exterior. Si el

calentador se sigue apagando, haga que lo reparen.

8. No haga funcionar el calentador

• Donde se utilicen o almacenen líquidos o vapores

inflamables

• En condiciones con mucho polvo

9. No use el calentador si cualquiera de sus partes ha

estado sumergida bajo el agua. Llame inmediatamente

a un técnico capacitado de servicio para que inspec

cione el calentador de cuartos y para que reemplace

las piezas del sistema de control o los controles de gas

que hayan estado sumergidos en el agua.

10. Apague el calentador y deje que se enfríe antes de

repararlo. Sólo una persona de servicio capacitada

debe repararlo o darle servicio.

11. Hacer funcionar el calentador a alturas superiores

a 1.371 metros (4.500 pies) puede ocasionar que

el piloto se apague.

12. Para prevenir problemas de rendimiento, no use

tanques de propano o gas LP de menos de 690 kPa

(100 psi) de capacidad.

13. Apague el calentador antes de usar pulidores de

muebles, ceras, limpiadores de alfombras o pro

ductos parecidos. Si se calientan, los vapores que se

desprenden de estos productos pueden producir un

residuo de polvo blanco en el interior de la caja del

calentador o en las paredes o muebles adyacentes.

14. Procure que se cumplan las distancias mínimas

alrededor de las aberturas para el aire.

CÓDIGOS LOCALES

Instale y use el calentador con cuidado. Siga todos

los códigos locales. A falta de códigos locales,

utilice la última edición del Código Nacional de

Gas Combustible, ANSI Z223.1/NFPA 54*.

*Lo puede obtener de:

American National Standards Institute, Inc.

National Fire Protection Association, Inc.

4

1430 Broadway

New York, NY 10018, EE.UU.

Batterymarch Park

Quincy, MA 02269, EE.UU.

www.desatech.com

IDENTIFICACIÓN DEL

PRODUCTO

-

Placa

(detrás de

la parrilla)

-

Encendedor

electrónico

Perilla manual

auxiliar

Figura 1. Calentador infrarrojo en torre

Perilla de On (encendido)/

Pilot (piloto)/Off (apagado)

DESEMPAQUE

1. Saque el calentador de la caja.

-

2. Retire todo el empaque de protección que se

agregó al calentador para su envío.

3.

Revise el calentador para ver si hay algún daño debido

al transporte. Si el calentador está dañado, contacte

de inmediato al distribuidor a quien lo compró.

CARACTERÍSTICAS DEL

PRODUCTO

DISPOSITIVO DE SEGURIDAD

Este calentador tiene un piloto con un sistema de

apagado de seguridad con Sensor de agotamiento de

oxígeno (ODS, por sus siglas en inglés). El piloto con

ODS es una característica necesaria de los calentadores

sin ventilación para cuartos. El piloto con ODS apaga

el calentador cuando no hay suficiente aire fresco.

SISTEMA DE ENCENDIDO

Este calentador tiene un encendedor electrónico

para prender el suministro de combustible del

calentador, lo cual requiere de una batería AAA.

CONTROL DE CALOR TERMOSTÁTICO

Su unidad está controlada de manera termostática

cuando el calentador y su control remoto están

configurados en los modos apropiados. Esto ofrece

la mayor comodidad de uso del calentador.

113261-01A

Parrilla

Page 29

AIRE PARA COMBUSTIÓN

Y VENTILACIÓN

ADVERTENCIA: Este calentador

no debe instalarse en un espacio con

finado o en una construcción inusualmente sellada a menos que se hayan

tomado medidas para proporcionar

el aire adecuado para combustión y

ventilación. Lea las instrucciones a

continuación para asegurarse de que

su hogar cuente con la cantidad ade

cuada de aire fresco para éste y otros

aparatos que quemen combustible.

Hoy más que nunca, las casas están diseñadas para ser más

eficientes en términos de energía. Los nuevos materiales,

un mejor aislamiento y los nuevos métodos de construcción ayudan a reducir la pérdida de calor en las casas. Los

propietarios de las casas colocan tiras aislantes y sellan los

bordes de las ventanas para mantener el aire frío afuera

y el aire caliente adentro. Durante los meses cálidos, los

propietarios de las casas quieren que éstas estén lo más

aisladas que sea posible de filtraciones de aire.

Aunque es bueno hacer que su casa sea eficiente en

términos energéticos, ésta también necesita respirar. Es