Page 1

WORKSHOP MANUAL

GP1 125-250 c.c.

Page 2

DERBI - NACIONAL MOTOR, S.A.U., manufacturer of DERBI motorcycles and mopeds, has produced this

manual with the aim of documenting and simplifying as much as possible the work you need to do to in dismantling and assembling the GP1 125/250 c.c.

The intention is to provide as much assistance as possible to mechanics working for our brand’s dealers and

sub-dealers.

Due to its constant commitment to improving its products, DERBI - NACIONAL MOTOR, S.A.U. Sociedad

Unipersonal reserves the right to introduce any modifications it deems fit, without prior warning.

All the information included in this manual is based on the latest data available at the time of its publication.

The drawings and photographs in this manual are for reference purposes only, and may therefore not be

exactly the same as the corresponding parts of the current model itself.

NACIONAL MOTOR, S.A.U.

1

Page 3

Page 4

INTRODUCTION

GENERAL INFORMATION

GENERAL TECHNICAL DATA

RECOMMENDED TOOLS

PERIODIC MAINTENANCE

DISMANTLING

SEAT SIDE TRIM

COWLING

COWLING BOTTOM COVER

WATER-OIL TANK COVER

SIDE COVERS

SHIELD INNER COVER

BATTERY COVER

PETROL TANK COVER

HELMET CARRIER

FOOTRESTS

SIDE COVERS

SHIELD

ENGINE

EXHAUST ASSY - REMOVAL

REMOVAL OF THE WNGINE FROM THE VEHICLE

AUTOMATIC TRANSMISSION

AIR DUCT

REMOVING THE DRIVEN PULLEY SHOFT BEARING

REFFITING THE DRIVEN PULLEY SHOFT BEARING

BAFFLE ROLLER

REMOVING THE DRIVEN PULLEY

INSTEPTING THE CLUTCH DRUM

REMOVING THE CLUTCH

INSPECTING THE CLUTCH

PIN RETAINING COLLAR

REMOVING THE DRIVEN HALF-PULLEY BEARING

INSPECTING THE DRIVEN FIRED HALF-PULLEY

INSPECTING THE DRIVEN SUDING HALF-PULLEY

REFITTING THE DRIVEN HALF-PULLEY BEARING

REFITTING THE DRIVEN PULLEY

INSPECTING THE CLUTCH SPRING

Pág. 1

Pág. 8

Pág. 9

Pág. 30

Pág. 40

Pág. 64

Pág. 64

Pàg. 65

Pág. 65

Pág. 65

Pág. 66

Pág. 66

Pág. 66

Pág. 67

Pág. 68

Pág. 68

Pág. 68

Pág. 69

Pág. 69

Pág. 71

Pág. 71

Pág. 72

Pág. 72

Pág. 73

Pág. 73

Pág. 73

Pág. 74

Pág. 76

Pág. 76

Pág. 77

Pág. 77

Pág. 78

Pág. 78

Pág. 80

Pág. 81

3

Page 5

REFITTING THE CLUTCH

REFITTING THE DRIVEN PULLEY

DRIVE-VELT

REMOVING THE DRIVING PULLEY

INSPECTING THE ROLLERS CASE

REFTTING THE DRIVING PULLEY

REFITTING THE TRANSMISSION COVER

Pág. 82

Pág. 85

Pàg. 85

Pág. 86

Pág. 87

Pág. 88

Pág. 89

END GEAR

REMOVING THE WHEEL AXLE

REMOVING THE HUB BEARING

REMOVING THE WHEEL ASXLE BEARING

REMOVING THE DRIVEN PULLEY SHAFT BEARING

INSPECTING THE HUB SHAFT

INSPECTING THE HUB COVER

REFITTING THE WHEEL AXLE BEARING

REFITTING THE HUB COVER BEARING

REFITTING THE HUB BEARING

REFITTING THE HUB COVER

FLYWHEEL COVER

REMOVING THE STATOR

FLYWHEEL AND STARTING

REMOVING FLYWHEEL MAGNETO

INSPECTING THE FLYWHEEL COMPONENTS

REFITTING THE FLYWHEEL MAGNETO

REFITTING THE STATOR MOTOR

Pág. 90

Pág. 90

Pág. 92

Pág. 92

Pág. 92

Pág. 93

Pág. 93

Pág. 95

Pág. 95

Pág. 95

Pág. 96

Pág. 97

Pág. 97

Pág. 98

Pág. 99

Pág. 101

Pág. 101

Pág. 102

CYLINDER ASSY AND TIMING SYSTEM

REMOVING THE ROCKER ARMS COVER

REMOVING THE CAMSHAFT

REMOVING THE CYLINDER HEAD

REMOVING THE VALVES

REMOVING THE CYLINDER - PISTON ASSY

INSPECTING THE SMALL END

INSPECTING THE WRIST PIN

INSPECTING THE PISTON

INSPECTING THE CYLINDER

Pág. 103

Pág. 103

Pág. 105

Pág. 105

Pág. 106

Pág. 106

Pág. 107

Pág. 107

Pág. 107

Pág. 110

4

Page 6

INSPECTING THE PISTON RING

REMOVING THE PISTON RING

CHOOSING THE GASKET

COMPRESSION RATIO VERSION 250

REFITTING THE PISTON RINGS

REFITTING THE CYLINDER

INSPECTING THE CYLINDER HEAD

INSPECTING THE TIMING SYSTEM COMPONENTS

INSPECTING THE VALVE SEALINGS

INSPECTING THE VALVE HOUSINGS

INSPECTING THE VALVES

INSPECTING THE SPRINGS AND HALF-CONES

REFITTING THE VALVES

INSPECTING THE CAMSHAFT

REFITTING THE TIMING SYSTEM COMPONENTS

REFITTING THE ROCKER - ARMS COVER

REFITTING THE INTAKE MANIFOLD

REFITTING THE TIMING SYSTEM COMPONENTS

Pág. 111

Pág. 112

Pág. 113

Pág. 115

Pág. 116

Pág. 116

Pág. 117

Pág. 117

Pág. 118

Pág. 118

Pág. 118

Pág. 120

Pág. 120

Pág. 121

Pág. 122

Pág. 128

Pág. 128

Pág. 128

CRANKCASE - CRANKSHAFT

INSPECTING THE CRANSHFT ALIGNMENT

INSPECTING THE CRANKCASE HALVES

INSPECTING THE CRANKSHAFT PLAIN BEARING

REFITTING THE CRANKCASE HALVES

LUBRICATION

OIL PRESSURE CHACK

OIL PUMP

INSPECTION

REFITTING

REMOVING THE OIL - SUMP

INSPECTING THE BY-PASS VALVE

REFITTING THE OIL SUMP

SAS VALVE

INSPECTING THE CUT-OFF

FUEL SUPPLY

REFITTING THE CARBURETTOR

LEVEL CHECK

INSPECTING THE VALVE AND NEEDLE

INSPECTING THE AUTOMATIC CHOCKE DEVICE

Pág. 129

Pág. 133

Pág. 134

Pág. 135

Pág. 137

Pág. 139

Pág. 140

Pág. 143

Pág. 144

Pág. 145

Pág. 145

Pág. 146

Pág. 146

Pág. 147

Pág. 148

Pág. 149

Pág. 159

Pág. 164

Pág. 166

Pág. 169

5

Page 7

FORK, SHOCK ABSORBER. ENGINE SUPPORT AND STAND

DISMANTLING FRONT SUSPENSION

INSPECTING THE FRONT FORKS

DISMANTLING

INSPECTION

SWING-ARM

CHECKING THE SWINING ARM

EXHAUST BRACKET

OVERHAUL

REFITTING

CENTRE - STAND

FRONT WHEEL AND BRAKES

REAR WHEEL 125 C.C.

REAR WHEEL 250 C.C.

DISMANTLING

INSPECTING THE FRONT WHEEL

DISMANTLING THE FRONT DISCK CALLIPER

ASSEMBLING THE FRONT WHEEL

REAR WHEEL AND BRAKES

REAR WHEEL 125 C.C.

REAR WHEEL 250 C.C.

DISMANTLING

DISMANTLING THE REAR DISCK CALLIPER

INSPECTING THE REAR WHEEL

RIFTTING THE REAR WHEEL

Pág. 173

Pág. 175

Pág. 179

Pág. 179

Pág. 180

Pág. 181

Pág. 181

Pág. 182

Pág. 182

Pág. 183

Pág. 184

Pág. 185

Pág. 186

Pág. 186

Pág. 188

Pág. 194

Pág. 196

Pág. 197

Pág. 198

Pág. 198

Pág. 205

Pág. 205

CIRCUITO DE REFRIGERACIÓN

CIRCUIT DIAGRAM 250 C.C.

CIRCUIT DIAGRAM 150 C.C.

WATER PUMP - OVERHAUL

ELECTRICAL SYSTEM

ELECTRICAL SYSTEM GP1 125-250 C.C.

CHECK CONNECTORS

INSPECTIONS STEPS

DIGITAL INSTRUMENTS UNIT

IGNITION

LIGHTS AND AUTOMATIC CHOKE

RECHARGING THE BATTERY AND STARTTING

6

Pág. 206

Pág. 207

Pág. 208

Pág. 218

Pág. 219

Pág. 220

Pág. 220

Pág. 221

Pág. 222

Pág. 223

Page 8

SENSORS AND INDICATORS

TURN INDICATORS AND HORN

IGNITION CIRCUIT

SPARK PLUG

STATOR CHECK

VOLTAGE REGULATOR CHECK

FUSES

DISMANTLING THE BATTERY

BATTERY - INITIAL CHARGE

CAPACITY

INSPECTION THE CHARGING CONDITIONS

RECHARGING

CHARGING SYSTEM

TROUBLESHOOTING

ENGINE

REAR WHEEL TURNS WITH ENGINE TICKING OVER

DIFFICULTY STARTING

EXCESSIVE CONSUMPTION OF OIL/SMOKY EXHAUST

INSUFFICIENT LUBRICATION PRESSURE

THE ENGINE TENDS TO STOP AT MAX GAS OPENING

THE ENGINE TENDS TO STOP AT IDLE

HIGH CONSUMPTION

EXCESSIVELY NOISY WITH EXHAUST

SECONDARY AIR DEVICE ANOMALIES

TRANSMISSION AND BRAKES

INSUFFICIENT BRAKING

BRAKES OVERHEATING

VARIATIONS OR REFRAINED NOISINESS

BATTERY

FLASHING LICHTS NOT WORKING

HEARDENING STERRING

EXCESSIVE STEERING PLAY

NOIZY SUSPENSION

SUSPENSION OIL LEAKAGE

Pág. 224

Pág. 225

Pág. 226

Pág. 226

Pág. 227

Pág. 227

Pág. 230

Pág. 230

Pág. 232

Pág. 232

Pág. 233

Pág. 234

Pág. 235

Pág. 236

Pág. 237

Pág. 237

Pág. 238

Pág. 238

Pág. 239

Pág. 239

Pág. 240

Pág. 240

Pág. 240

Pág. 241

Pág. 241

Pág. 242

Pág. 242

Pág. 242

Pág. 243

Pág. 244

Pág. 244

Pág. 245

Pág. 245

7

Page 9

REGULATIONS

GU O S

S GUOS

MAINTENANCE REGULATIONS

This section describes the machine’s general safety and maintenance work rules.

SAFETY REGULATIONS

- In the event of having to carry out work on the engine while this is running, ensure that the area is well

ventilated, where possible using extractor fans. Never leave engines running in closed spaces. Exhaust gases

are poisonous.

Petrol is extremely inflammable and in certain conditions may explode. Smoking must not be allowed in the

work area, nor should there be naked flames or sparks.

MAINTENANCE REGULATIONS

- Use genuine DERBI spare parts and lubricants recommended by the manufacturer. Non-genuine or unauthorised parts may damage the engine.

Always use new gaskets and oil seals during re-assembly.

After dismantling, clean the components with solvents that are non-inflammable or with a high flammability

point. Lubricate all working surfaces before assembling, excluding tapered joints.

After assembly, check that all components have been correctly fitted and that they are functioning perfectly.

For dismantling, checking and assembly operations, use only tools with metric measurements. Metric screws,

nuts and bolts are not interchangeable with imperial measurement joining devices. Using unsuitable tools

and joining devices may damage the engine.

- In the case of work on the engine involving the electrical circuitry, check that electrical connections have

been correctly fitted.

N.B.

Indicates a note that gives key information to make the procedure easier and clearer.

ATTENTION

Indicates specific procedures that must be carried out to avoid damage to the machine.

WARNING

Indicates specific procedures that must be followed to avoid possible accidents to the person repairing the

machine.

8

Page 10

G

5

c.c.

G

50

c.c.

MACHINE ENGINE PREFIX FRAME PREFIX

P1 12

GP1 125 c.c.

P1 2

GP1 250 c.c.

M434M

M237M

DIMENSIONS AND WEIGHT

VTHPS1A1A

VTHPT1A1A

SPECIFICATIONS

Maximum length

Maximum height

Length between axles

Handlebar width

Handlebar height

ENGINE

SPECIFICATIONS

Engine type

Timing

Int. diameter per stroke (125)

Int. diameter per stroke (250)

Cubic capacity (125)

Cubic capacity (250)

Compression ratio (125)

DESC. / QUANTITY

1930 mm.

1225 mm.

1375 mm.

705 mm.

1085 mm.

DESC. / QUANTITY

Single cylinder four-stroke and four valve water-cooled

Single overhead cam driven by a chain on the left-hand

side; rockers with three arms and with threaded adjuster.

57x 48,6mm

72 x 60 mm

124,015 cm

244,290 cm

3

3

12:1

9

Page 11

ENGINE

SPECIFICATIONS

Compresion ratio (250)

Keihin Carburettor (125 - 250)

Walbro Carburettor (125)

Walbro Carburettor (250)

Idle speed

Adjustment CO

Air filter

Starter system

Lubrication

Feeding

Max. power (crankshaft) 125cc

Max. power (crankshaft) 250cc

TRANSMISSION

DESC. / QUANTITY

10,5-11,5: 1

CVEK-30

WVF 7G* 0 29

WVF-7S*

1650 ±50 r.p.m.

3,8 ± 07

Sponge-type damped eith a 50% for filters.

Oil - 50% unleaded petrol misture

Electric starter motor

Engine lubrication with geared twin-screw pump (inside the

oil sump) coomanded by chain and double paper net filter.

With depression pump and petrol through carburettor

11 kw (15CV)at 9700p.r.m.

16,18 Kw (22CV) at 8250 p.r.m.

Transmission

CAPACITIES

Engine oil (125)

Engine oil (250)

Fuel tank

Rear hub oil

SPECIFICATIONS

SPECIFICATIONS

DESC. / QUANTITY

Automatic expandable pulley varistor with servosystem,

trapezoidal belt, self-ventilating dry automatic centrifugal clutch, gear reducer and transmission compartment

with forced air circulation.

DESC. / QUANTITY

~ 1100 cc

~ 1200 cc

~ 11 L. with reservation of 2,7 L.)

250 cc

10

Page 12

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS

SPECIFICATIONS

Ignition type

Ignition advance (before T.D.C) 125

(

Ignition advance

Spark plug (125)

Spark plug (250)

Battery

Fuses

Generator

before T.D.C

FRAME AND SUSPENSIONS

SPECIFICATIONS

Type

Front suspension

Front wheel max. travel

Rear suspension

DESC. / QUANTITY

Electronic with capacitive discharge (CDI) and variable

advance with separate HT coil.

10°±1° at 2000 r.p.m. - 34°±1° at 6000 r.p.m.

)

10° ± 1 at 2000g/min.

28° ± 1 at 6500 g/min.

CHAMPION RG4HC

CHAMPION RG4HC

12V-12Ah

N°1 15A / N°2 15A / N°3 15A

AC current

DESC. / QUANTITY

Aluminium alloy Delta Box type

Hydraulic telescopic fotk with forward-shifted pin and

Ø 40 mm rods.

100 mm

Engine functioning as swingarm pivoting on frame

through arm with two degrees of freedom. Pair of

double-acting hydraulic shock absorbers and coaxial

springs with preload adjustment.

Max. rear shock absorber travel

BRAKES

SPECIFICATIONS

Brakes front

Brakes rear

11

90/85 mm

DESC. / QUANTITY

Ø 245 mm disc with hydraulically operated dual piston

floating caliper (lever at right end of handlebar).

Ø 240 disc with hydraulically operated dual opposed

piston caliper (lever at left end of handlebar).

Page 13

WHEELS AND TYRES

SECONDARY AIR

SPECIFICATIONS

Front wheel rim

Rear wheel rim

Front tyre

Rear tyre

Tyre pressure front wheel (cold)

Tyre pressure rear wheel (cold)

Tyre pressure rear/front wheel (driver and

passenger). (cold)

N.B.

CHECK AND ADJUST TYRE PRESSURE WITH TYRES AT AMBIENT TEMPERATURE. ADJUST PRESSURE ACCORDING TO

THE WEIGHT OF THE RIDER AND ACCESSORIES.

Aluminium alloy

In light alloy

120 / 70 x 14”

120 / 60 x 14”

1,9 bar

2,0 bar

2,0 / 2.2 bar

SECONDARY AIR

DESC. / QUANTITY

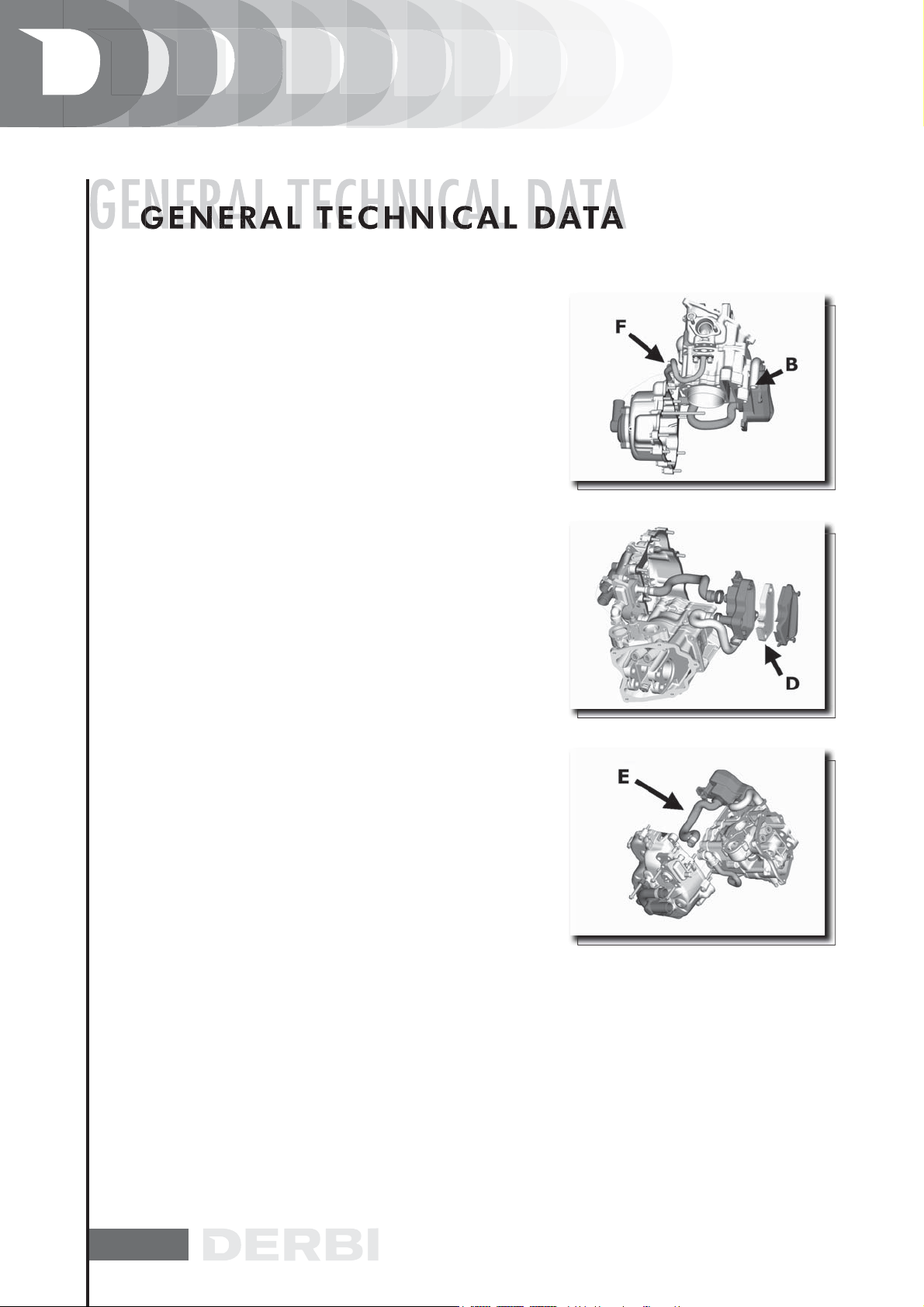

The working principie of the SAS for Leader 125 ce engines is

entirely similar to the SAS employed on 2-stroke engines.

The main differences are the following:

Secondary air enters directly into the exhaust duct on the

cylinder head, instead of entering through the exhaust pipe

as in two-stroke engines.

The reed valve found on 2-stroke engines is here replaced by

a membrane. The unit, indicated by an arrow in the figure, is

provided with a cut-off connected to the vacuum inlet on the

intake manifold to shut air intake during deceleraron, so to

prevent detonations in the silencer.

Air is sucked in through hole «A» and flowing through the

first filter is directed towards hole «B».

12

Page 14

Flowing through the hole shown in the figure, the air reaches

the second filter, «B», At this point, the tiltered air enters the

membrane device, so to be channelled towards the head.

Flowing through a rigid pipe, flanged to the head, the secondary air reaches the exhaust duct thus providing oxygen

addition to the unburnt gases just before they enter the cataiytic converter. The efficiency ofthe catalyzing process is

therefore increased.

El sistema de funcionamiento del SAS para motor Quasar

250 Euro 2 es totalmente similar al funcionamiento del sistema SAS para motor 2T.

Las diferencias son las siguientes:

El aire secundario, en vez de entrar en el silenciador, como

sucede para el 2T entra directamente en el conducto de descarga sobre la culata.

13

Page 15

The working principie ofthe SAS for Quasar 250 cc Euro 2

engines is entirely similar to the SAS employed on 2-stroke

engines. The main differences are the following:

Secondary air enters directly into the exhaust duct on the

cylinder head, instead of entering through the exhaust pipe

as in two-stroke engines.

The reed valve found on 2-stroke engines is here replaced

by a membrane.

Unit «A», shown in the figure, is provided with a cut-off connected to the vacuum inlet on the intake manifold to shut air

inlet during deceleration, so to prevent detonations in the

silencer. Air is sucked in through hole «B» and flows inside

the duct into air-box «C» where it is filtered by filtering element «D».

The filtered air now enters membrane device «A», through

duct «E» and is then guided towards the head.

Flowing through pipe «F», flanged to the head, secondary

air reaches the exhaust duct thus providing oxygen addition

to the unburnt gases just before they enter the catalytic con

verter.

The efficiency of the catalyzing process is therefore increased.

14

Page 16

CARBURATTOR HEIHIN

Version 125

SPECIFICATION

Depresione type

Printing on the body

Device CUT-OFF

Max. jet

Minimum jet

Max. air jet

Minimum air jet

Idle mixture adjusment screw initial opening

Conical pin

Emulsifier nozzle

Starter air jet

Starter jet

Starter device resistance

Venturi choke

Throttle valve

Choke maximum cone

CARBURETTOR WALBRO

DESC. / QUANTITY

CVEK30

CVK

Not present

105

35

70

130

2 ±1/4

Ø 2,450

Ø 2,8

Ø 1,5

42

~20

Ø 29

Ø 30,5

Ø 47

SPECIFICATION

Type to depression

Printing on the body

Device CUT-OFF

Max jet

Minimum jet

Max air jet.

Minimum air jet

Gas valve spring

Idle mixture adjustment screw initial opening

Conical pin printing

Conical pin notches position from top

Emulsifier nozzle

Choke máximum cone

Starter air jet

Starter emulsifier jet

15

DESC. / QUANTITY

WVF-7G*

7G

Not present

108

36

115

100

100 gr

2 5/8 ± 1/2

51C

2

Ø 2,7

Ø 1,5

200

130

Page 17

CARBURADOR WALBRO

SPECIFICATION

Starter jet

Starter pin diameter

Starter device resistance

Choke

Throttie valve

Choke máximum cone

CARBURATTOR HEIHIN

Version 250

SPECIFICATION

Depression type

Printing on the body

CUT-OFF device

Max jet

Minimum jet

Max air jet

Mínimum air jet

Idle mixture adjustment screw initial opening

Conical pin

Emulsifier nozzle

Starter air jet

Starter jet

Starter device resistance

Venturi choke

Throttie valve

Choke máximum cone

DESC. / QUANTITY

50

Ø 1,78

~ 40Q

Ø 29 (30,3x27,0)

Ø 33

Ø 48,0

DESC. / QUANTITY

CVEK30

CVK

Present

100

38

70

115

2½ ± ¼

Ø 2,530

Ø 2,8

Ø 1,5

42

~ 20

Ø 29

Ø 30,5

Ø 47

16

Page 18

CARBURATTOR WALBRO

Version 250

SPECIFICATION

Depression type

Printing on the body

CUT-OFF device

Max jet

Minimum jet

Max air jet

Mínimum air jet

Gas valve spring

Idle mixture adjustment screw initial opening

Conical pin

Tacche dall’alto spillo cónico

Emulsitier nozzle

Choke máximum cone

Starter air jet

Starter emulsifier jet

Starter jet

Starter pin diameter

Starter device resistance

Choke

Throttie valve

Choke máximum cone

* The identification letter can vary every time the carburettor is updated.

WVF-7S*

7S

Presente

118

34

150

31

120 gr

3±½

465

3

Ø 2,7

Ø 1,5

200

130

50

Ø 1,78

~ 40

Ø 29 (30,3x27,0)

Ø 33

Ø 48,0

DESC. / QUANTITY

17

Page 19

CHASSIS TIGHTENING TORQUES

DESCRIPTION

M8X125 8.8 FRONT FRAME-CHASSIS SECUR.DEVICE

M8X125 8.8 SUBCHASSIS-CHASSIS SEC.DEVICE

M10x150 12.9 TOP SHOCK ABSOR.-CHASSIS SEC.DEVICE

M10x150 12.9 BOTTOM SHOCK ABSOR.-ENG. SEC.DEV.

M14x200 8.8 FRONT ENG. SUPPORT-CHASSIS SEC.DEV.

M10X150 8.8 REAR ENG.SUPP-FRONT ENG.SUPP. SEC.DEV.

M10X150 8.8 ENGINE-REAR SUPP. SEC.DEV.

M8X125 8.8 ENGINE SUPP. SILENTBLOC CLAMP SEC.DEV.

M8X125 8.8 SHOCK ABSORBER SUPP. SEC.DEV.

M8X125 12.9 SHOCK ABSOR. SUPP. TO CRANKCASE SEC.DEV.

M12X175 12.9 SHOCK ABSORBER SUPP. TO SUSP. ARM SEC.DEV. M12X175 12.9

M30,5X150 FORKS FLANGE SEC.DEV.

M6x100 HORN-CHASSIS SEC.DEV.

M10X150 8.8 STAND SEC.DEV.

M8Z125 8.8 FOOTREST SUPPORT-CHASSIS SEC.DEV.

M7x100 8.8 EXHAUST PIPE-CYLINDER SEC.DEV.

M8X125 8.8 SILENCER-SUSPENSION ARM SEC.DEV.

M6x100 8.8 STEERING LOCK-CHASSIS SEC.DEV.

M8x125 8.8 HANNDLEBARS-STEERING FORKS SEC. DEV.

M8x125 8.8 HANDLEBAR CLAMP SEC.DEV.

M5x80 8.8 COUNTERWEIGHT-HANDLEBAR SEC.DEV.

M14x150 FRONT WHEEL-FORKS SEC.DEV.

M8x125 FORK ARM LOCK SEC.DEV.

M6x100 10.9 BRAKE DISK-FRONT WHEEL SEC.DEV.

M10x150 8.8 FR. BRAKE CALLIPER-FORKS SEC.DEV.

M8X125 12.9 SUSP. ARM-ENGINE SEC. DEV.

M16X125 10.9 REAR HUB-ENGINE SEC.DEV.

M8X40 10.9 REAR WHEEL-HUB SEC.DEV.

M8X125 8.8 REAR CALLIPER SUPP.-CRANKCASE SEC.DEV.

M8X125 8.8 REAR CALLIPER-CALLIPER SUPP. SEC.DEV.

M6x100 10.9 BRAKE DISK-REAR HUB SEC. DEV.

M8x125 8.8 CLAMP-CHASSIS SEC.DEV.

M6x100 RADIATOR-CHASSIS SEC.DEV.

THERMOSTAT SWITCH-RADIADOR SEC.DEV.

M5X80 8.8 ELECT.FAN-CHASSIS SEC.DEV.

M5x80 VARIOUS METAL PARTS TO CHASSIS SEC.DEV

M6x100 VARIOUS METAL PARTS TO CHASSIS SEC.DEV.

M8x125 VARIOUS METAL PARTS TO CHASSIS SEC.DEV.

M5x80 VARIOUS PLASTIC PARTS TO CHASSIS SEC.DEV.

M6x100 VARIOUS PLASTIC PARTS TO CHASSIS SEC.DEV.

(•) Sellador the thread type locktite 243

TORQUES

(N.M)

1,7÷1,9

1,7÷1,9

4,5÷5,5

4,5÷5,5

7÷8

3÷4

3÷4

1,7÷1,9

1,7÷1,9

3÷3,5

6÷6,5

9÷13

0,8÷1

3÷4

1,7÷1,9

1÷1,3

1,7÷1,9

0,8÷1

1,7÷1,9

1,7÷1,9

0,35÷0,45

7÷8

1,5÷1,9

1÷1,2

3,5÷4

2,2÷2,5

11, 5÷12,5

2,7÷2,9

1,7÷1,9

1,7÷1,9

1÷1,2

1,7÷-1,9

0,8÷1

1,7÷2,2

0,4÷0,5

0,35÷0,45

0,8÷1

1,5÷1,9

0,1÷0,2

0,2÷0,35

TORQUES

(M.KG)

17÷19

17÷19

45÷55

45÷55

70÷80

30÷40

30÷40

17÷-19

17÷19

30÷35

60÷65

90÷130

8 ÷ 10

30÷40

17÷19

10÷13

17÷19

8÷10

17÷19

17÷19

3,5÷4,5

70÷80

15÷19

10÷12

35÷40

22÷25

115 ÷12 5

27÷29

17÷19

17÷19

10÷12

17÷19

8÷10

17÷22

4÷5

3,5÷4,5

8÷10

15÷19

1÷2

2÷3,5

SEALER

.

.

.

.

.

.

.

18

Page 20

EXAUST PIPE

NAME

Screw clamping manifold to silencer

Screw clamping heat shield to silencer

Exhaust gas intake screw

Screw fixing silencer support arm to crankcase

Exhaust pipe/support bracket fixing screw.

Exhaust pipe/cylinder head fixing nut.

ENGINE - LUBRICATION

NAME

Hub oilexhaust cap

Oil filter unión on crankcase

Engine oil / net filter drainage cap

Oil filter

Oil pump cover screws

Screws fixing the oil pump to the crankcase

Oil pump control rim screw

Oil pump cover píate screws

Oil sump screws

Minimum oil pressure sensor

TORQUE IN Nm

15,5 ÷ 18,5

5 ÷ 6

22 ÷ 26

33 ÷ 41

27 ÷ 30

16 ÷ 18

TORQUE IN Nm

15 ÷ 17

27 ÷ 33

24 ÷ 30

4 ÷ 6

0,7 ÷ 0,9

5 ÷ 6

10 ÷ 14

4 ÷ 6

10 ÷ 14

12 ÷ 14

CYLINDER HEAD

NAME

Spark plug

Cylinder head cover screw (1) (A)

Head fastening side screws

Start up mass screws

M5 side screw fastening washers on cam

shaft (125 cc)

19

TORQUE IN Nm

12 ÷ 14

9 ÷ 11 + 180°

11 ÷ 13

7 ÷ 8,5

7 ÷ 8,5

Page 21

CYLINDER HEAD

NAME

Tappet adjustment lock nut

Timing chain tightener sliding block screws

Start up mass bell screws

M6 central screw fastening washers on

cam shaft (125 cc)

Timing beit tightener support screw

Timing beit tightener central screw

Camshaft retain píate screw

TRANSMISSION

NAME

Beit support roller screw

Clutch assembly nut on driven pulley

Driving pulley screw

Transmission cover screw

Driven pulley axis

Hub cover screws

TORQUE IN Nm

6 ÷ 8

10 ÷ 14

11 ÷ 15

11 ÷ 15

11 ÷ 13

5 ÷ 6

4 ÷ 6

TORQUE IN Nm

11 ÷ 13

45 ÷ 50

75 ÷ 83

11 ÷ 13 Nm

54 ÷ 60

24 ÷ 27

FLYWHEEL

NAME

FIywheel cover fastening

Stator cover screws (°)

FIywheel nut (125)

FIywheel nut (250)

Pick-Up fixing screws

Free wheel fixing screws on the flywheel

20

TORQUE IN Nm

5 ÷ 6

3 ÷ 4

52 ÷ 58

94 ÷ 102

3 ÷ 4

13 ÷ 15

Page 22

ENGINE CRANKCASE AND SHAFT

NAME

Engine crankcase inside head screws

(transmission side half shaft)

Engine crankcase coupling screws

Starter motor screws

Crankcase timing cover screws

4 ÷ 6

11 ÷ 13

11 ÷ 13

3,5 ÷ 4,5

TORQUE IN Nm

COOLING

NAME

Water pump impeller cover

Water pump impeller drive joint screw

Thermostat cover screws

(°) Apply threadlocking LOCTITE médium, type 242.

(*) Tighten the two screws after tightening the rear wheel spindie nut with the prescribed torque.

(A)Tighten the nuts ¡n two phases, following a crosswise pattern.

3 ÷ 4

3 ÷ 4

3 ÷ 4

TORQUE IN Nm

(1) Lubrícate nuts with engine oil before fitting.

21

Page 23

OVERHAUL DATA

ASSEMBLY CLEARANCES

CYLINDER - PISTON ASSY

CATEGORIES COUPLING 125

NAME

Cylinder

Cylinder

Piston

Piston

Cylinder first uprat.

Cylinder first uprat.

Piston first uprat.

Piston first uprat.

Cylinder second uprat.

Cylinder second uprat.

Piston second uprat.

Piston second uprat.

Cylinder third uprat.

Cylinder third uprat.

Piston third uprat.

Piston third uprat.

PLAY

57+0,025±0,003

57+0,025±0,003

56,959±0,014

56,959±0,014

57,2+0,025±0,003

57,2+0,025±0,003

57,159±0,014

57,159±0,014

57,4+0,025±0,003

57,4+0,025±0,003

57,359±0,014

57,359±0,014

57,6+0,025±0,003

57,6+0,025±0,003

57,559±0,014

57,559±0,014

INITIALS

A

B

C

D

A1

B1

C1

D1

A2

B2

C2

D2

A2

B3

3C

D3

CYLINDER

56,997 ÷ 57,004

57,004 ÷ 57,011

57,011 ÷ 57,018

57,018 ÷ 57,025

57,197 ÷ 57,204

57,204 ÷ 57,211

57,211 ÷ 57,218

57,218 ÷ 57,225

57,397 ÷ 57,404

57,404 ÷ 57,411

57,411 ÷ 57,418

57,418 ÷ 57,425

57,597 ÷ 57,604

57,604 ÷ 57,611

57,611 ÷ 57,618

57,618 ÷ 57,625

PISTON

56,945 ÷ 56,952

56,952 ÷ 56,959

56,959 ÷ 56,966

56,966 ÷ 56,973

57,145 ÷ 57,152

57,152 ÷ 57,159

57,159 ÷ 57,166

57,166 ÷ 57,173

57,345 ÷ 57,352

57,352 ÷ 57,359

57,411 ÷ 57,418

57,366 ÷ 57,373

57,545 ÷ 57,552

57,552 ÷ 57,559

57,559 ÷ 57,566

57,566 ÷ 57,573

PLAY ON

FITTING

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

0,045-0,059

22

Page 24

on

n

r

ylinder

COUPLING CATEGORIES ENGINE 250

NAME

Cylinder

C

Cylinde

Cylinder

Pisto

Piston

Pist

Piston

PISTON RINGS

PLAY

72+0,018±0,010

72+0,018±0,010

71,967±0,014

71,967±0,014

INITIAL

A

B

C

D

CYLINDER

71,990 ÷ 71,997

71,997 ÷ 72,004

72,004 ÷ 72,011

72,011 ÷ 72,018

PISTON

71,953 ÷ 71,960

71,960 ÷ 71,967

71,967 ÷ 71,974

71,974 ÷ 71,981

PLAY ON FITTING

0,030-0,044

0,030-0,044

0,030-0,044

0,030-0,044

UPRATING TABLE ENGINE 125

NAME

Compression lining

Scraper ring lining

Scraper ring lining

DESCRIPTION DIMENSIONS

57 x 1

57 x 1

57 x 2,5

INITIALS

A

A

A

QUANTITY

0,15 ÷ 0,30

0,10 ÷ 0,30

0,15 ÷ 0,35

23

Page 25

OVERSIZES ENGINE 250

NAME

Compression lining

Scraper ring lining

Scraper ring lining

DESCRIPTION DIMENSIONS

72 x 1,5

72 x 1

72 x 2,5

CRANKCASE - CRANKSHAFT - CONNECTING ROD

CRANKCASE - DRVING SHAFT - BENCH HALF BEARING

NAME

Half crankshaft bearing

Half crankshaft bearing

Half crankshaft bearing

Crankshaft cat. 1 - Crankcase cat. 1

Crankshaft cat. 1 - Crankcase cat. 2

Crankshaft cat. 2 - Crankcase cat. 1

Crankshaft cat. 2 - Crankcase cat. 2

Crankshaft

Crankshaft

Carter

Carter

DESCRIPTION DIMENSIONS INITIALS

INITIALS

A

A

A

Type A -red

Type B - blue

Type C - yellow

Category 1

Category 2

Category 1

Category 2

QUANTITY

0,15 ÷ 0,30

0,20 ÷ 0,40

0,20 ÷ 0,40

QUANTITY

1,970 ÷ 1,973

1,973 ÷ 1,976

1,976 ÷ 1,979

C - C

B -B

B - B

A -A

28,998 ÷ 29,004

29,004 ÷ 29,010

32,959 ÷ 32,965

32,953 ÷ 32,959

24

Page 26

FITTING CLEARANCE

Driving shaft/case axial clearance: Standard clearance 0,15 ÷ 0,40mm (cold engine).

CARNCSHAFT - CRANKCASE AXIAL CLEARANCE/CARTER

NAME

Half shaft transmission side

Half shaft flywheel side

Conecting rod

Spacing tool

DESCRIPTION DIMENSIONS INITIALS

16,6+0- 0,05

16,6+0- 0,05

18- 0,10-0,15

51,4+0,05

A

B

C

D

QUANTITY

D = 0,20 ÷ 0,50

D = 0,20 ÷ 0,50

D = 0,20 ÷ 0,50

D = 0,20 ÷ 0,50

25

Page 27

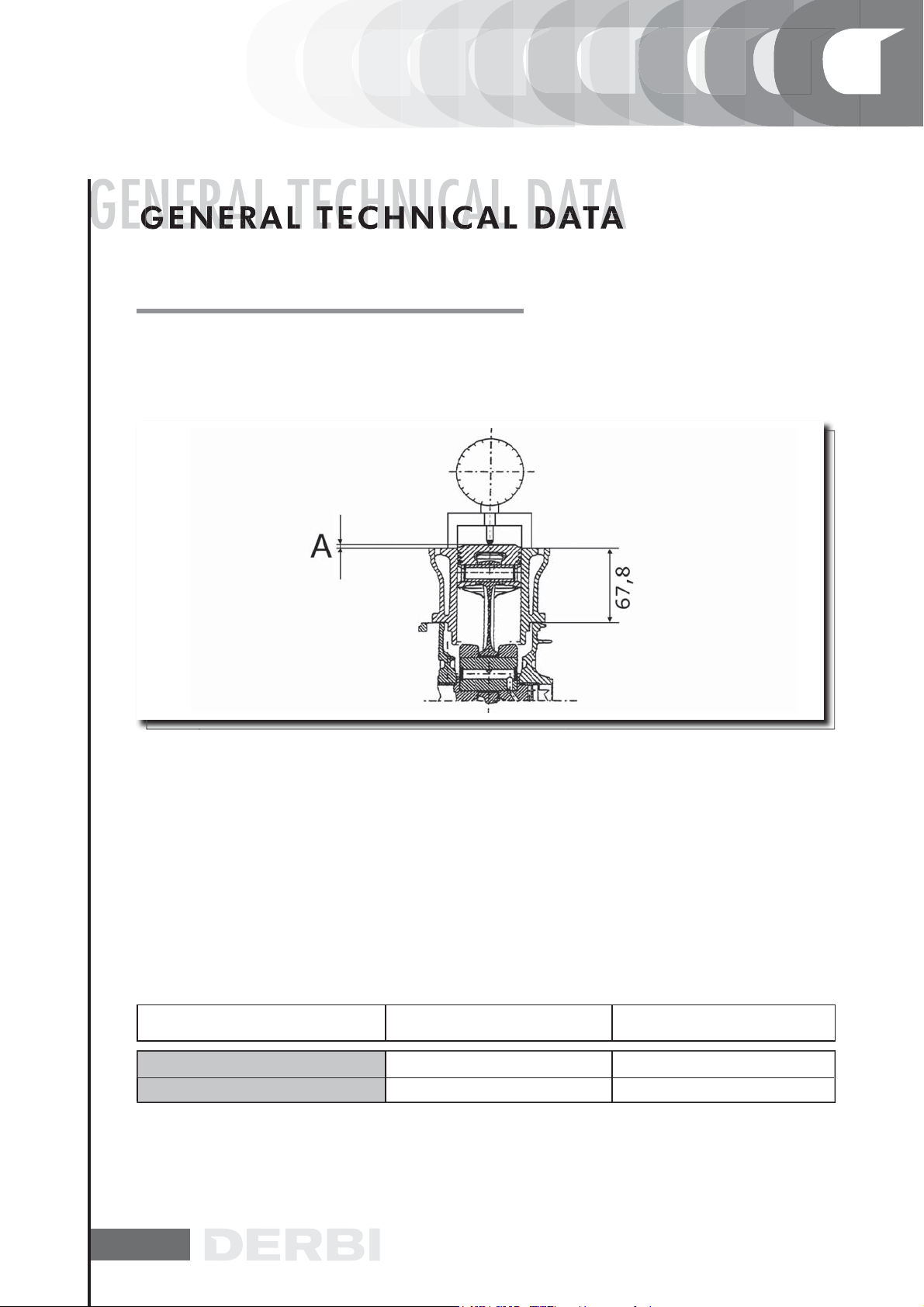

SLOT PACKING SYSTEM

Characteristics

Compresion ratio - 125cc verion

Rc: 11,50÷13:1

The length «A» to be measured refers to the pistón protrusion. It indicates the amount by which the surface formed

by the pistón crown tops the surface formed by the upper parí of the cylinder. The more the pistón descends into the

cylinder, the less the base gasket to be applied (to recover the compression ratio) will be and vice versa.

N.B.

THE MEASUREMENT OF «A» MUST BE CARRIED WITH THE PISTÓN AT THE TDC, WITHOUT ANY GASKET

INSTALLED BETWEEN THE CRANKCASE AND THE CYLINDER, AND AFTER RESETTING THE COMPARATOR,

COMPLETE WITH SUPPORT, ON A RECTIFIED SURFACE.

125CC VERSIÓN WITH FIBRE HEAD GASKET (1.1)

NAME

Thicknesses 125

Thicknesses 125

MEASURE A THICKNESS

2,20÷2,45

2,45÷2,70

0,4 ± 0,05

0,6 ± 0,05

26

Page 28

SLOT PACKING SYSTEM

Characteristics

Compresion ratio - 125cc verion

Re: 11,50÷13:1

The length «A» to be measured refers to the pistón protrusion. It indicates the amount by which the surface formed

by the pistón crown tops the surface formed by the upper part of the cylinder. The more the pistón descends into the

cylinder, the less the base gasket to be applied (to recover the compression ratio) will be and vice versa.

N.B.

THE MEASUREMENT OF «A» MUST BE CARRIED WITH THE PISTÓN AT THE TDC, WITHOUT ANY GASKET

INSTALLED BETWEEN THE CRANKCASE AND THE CYLINDER, AND AFTER RESETTING THE COMPARATOR,

COMPLETE WITH SUPPORT, ON A RECTIFIED SURFACE.

125CC VERSIÓN WITH METALLIC HEAD GASKET (0.3)

NAME

Thicknesses 125

Thicknesses 125

MEASURE A THICKNESS

1,40÷1,65

1,65 ÷1,90

0,4 ± 0,05

0,6 ± 0,05

27

Page 29

SISTEMA DE MONTAJE DE ESPESORES

Características Técnicas

Relación de compresión versión 250

Re: 10,5-11,5

MEASUREMENT (A)

(WITH PISTON AT T.D.C.)

NOTE

MEASUREMENT (A) MUST BE TAKEN WITHOUT TRIM MOUNTED BETWEEN THE

CASING AND THE CYLINDER, AFTER HAVING PUT THE COMPARATOR TO ZERO,

WITH ITS SUPPORT, ON A FLAT PLANE.

NOTE

MOUNT ACCORDING TO THE

MEASUREMENT (A) OBTAINED

N.B.

THE MEASURE «A» TO TAKE IS A PISTÓN PROTRUSION VALUÉ THAT INDICATES HOW MUCH THE PLAÑE

FORMED BY THE PISTÓN TOP PROTRUDES FROM THE PLAÑE FORMED BY THE TOP OF THE CYLINDER.

THE MORE THE PISTÓN PROTRUDES FROM THE CYLINDER, THE MORE THE BASE GASKET TO APPLY (TO

RECOVER THE COMPRESSION RATIO) AND VICE VERSA.

SHIMMING 250

NAME

Shimming 250

Shimming 250

Shimming 250

MEASURE A THICKNESS

2,60÷2,50

2,50÷2,30

2,30÷2,20

0,4 ±0,05

0,6 ± 0,05

0,8 ± 0,05

28

Page 30

OVERSIZES

OVERSIZES ENGINE

NAME

Compression lining 1° greater

First uprated scraper ring lining

First uprated scraper ring lining

Second uprated compression lining

Second uprated scraper ring lining

Second uprated scraper ring lining

Third uprated compression lining

Third uprated scraper ring lining

Third uprated scraper ring lining

DESCRIPTION DIMENSION

57,2 x 1

57,2 x 1

57,2x 2,5

57,4 x 1

57,4 x 1

57,4 x 2,5

57,6 x 1

57,6 x 1

57,6 x 2,5

RECOMENDEDS PRODUCTS

DESCRIPTION SPECIFICATIONS

Rear hub oil

Air filter sponge oil

Complex calcium soap grease NLGI 1-2

Engine oil

Brake fluid

Cooling fluid

Grease for driven pulley shaft compensating ring and

mobile driven pulley sliding seat

Grease for steering wheel bearings and pin seats

Oil for four stroke engines

Oil SAE 80W/90 of higher quality than API GL3 Specifications

Mineral oil with specific additives to increase adhesión ISO

VG

Grease (brake command levers, Gas)

Synthetic oil SAE 5W/40 of higher quality than API SJ Specifications

Synthetic fluid SAE J1703, NHTSA 116 DOT 4, ISO 4925

Mono-ethyiene glycol based anti-freeze, CUNA NC 956-16 fluid

Molybdenum bisulphide grease

Lithium soap and zinc oxide grease NLGI2 for the oscillating arm

Oil for flexible transmission lubrication (gas control)

INITIALS

A

A

A

A

A

A

A

A

A

QUANTITY

0,15 ÷ 0,30

0,10 ÷ 0,30

0,15 ÷ 0,35

0,15 ÷ 0,30

0,10 ÷ 0,30

0,15 ÷ 0,35

0,15 ÷ 0,30

0,10 ÷ 0,30

0,15 ÷ 0,35

29

Page 31

PPREPARATION FOR REMOVAL AND DISMANTLING

1. Remove all the dirt, grime, dust and other foreign material

before removing and dismantling.

2. Use properly cleaned tools and equipment.

See “SPECIAL TOOLS”.

3. On dismantling the motorcycle, always keep paired parts

together. This includes gears, cylinders, pistons and other

parts submitted to natural wear in pairs. Paired parts must

always be reassembled or replaced together.

4. While dismantling the motorcycle, clean all the parts and

lay them out on trays in the order dismantled. This speeds up

reassembly and ensures the correct fitting of all the parts.

5. Keep all parts away from any contact with fire.

30

Page 32

REPLACEMENT PARTS

C S

TAB/SPACER WASHERS AND SPLIT PINS

1. Use only genuine DERBI spare parts. For all lubrication

tasks use oils and greases recommended by DERBI. Other

makes make seem similar in their function and appearance,

but are inferior in quality.

SEALS, RETAINING RINGS AND O-RINGS

1. Replace all seals, retaining rings and O-rings when servi-

cing the engine.

All surfaces receiving seals, retaining ring edges and O-rings

must be cleaned.

2. Apply oil to all paired parts and bearing during reassembly. Apply grease to the retaining ring edges.

TAB/SPACER WASHERS AND SPLIT PINS

1. After removing them, replace all tab/spacer washers (1)

and split pins Bend the tabs to fit the flat surfaces of the

bolt or nut once they have been tightened to the specified

torque.

BEARINGS AND RETAINING RINGS

1. Fit bearings and retaining rings in such a way that the ma-

nufacturers marks remain visible. On fitting retaining rings,

applying a thin film of light lithium soap based grease to

their edges. Where required, apply oil generously when fitting bearings.

WARNING

DO NOT USE COMPRESSED AIR TO DRY BEARINGS. THIS

DAMAGES THE BEARING SURFACES.

31

Page 33

LOCKING RINGS

OC G GS

1. Examine all the locking rings carefully before fitting.

Always replace the gudgeon pin circlips after every use. Replace distorted locking rings. On fitting a locking ring (1),

ensure that the sharp edge (2) is on the opposite side to the

force to be applied to it.

See the figure on the side, (4) Axle.

SPECIAL TOOLS

1. The following special tools are needed for assembly and

for complete and exact adjustments. Only use the proper

special tools; thereby avoiding damage caused by the use of

unsuitable tools or improvised techniques.

020151Y

020331Y

020333Y

020334Y

STORES CODE

IMAGEDESCRIPTION

Air heater

Digital multimeter

Single battery charger

Multiple battery charger

001467Y014

32

15 mm plier s

Page 34

STORES CODE

DESCRIPTION

IMAGE

020412Y

020335Y

020565Y

020439Y

020359Y

15mm guide

Magentic stand and

comparator

Compass flywheel stop

spanner

17mm guide

42 x 47mm hub bearing fitting

adaptor

020363Y

002095Y

008564Y

020434Y

33

20mm guide

Engine support

Flywheel extractor

Oil presure gauge connection

Page 35

STORES CODE

IMAGEDESCRIPTION

020382Y011

020424Y

020431Y

020193Y

020306Y

Bushing (valve remover)

Driven pulley roller casing drift

Valve oil seal extractor

Oil pressure gauge

Valve sealing ring drift

020360Y

020364Y

020375Y

34

52 x 55mm adaptor

25mm guide

Adapter 28 x 30mm

Page 36

STORES CODE

IMAGEDESCRIPTION

020376Y

020444Y

020330Y

001467Y035

020368Y

Handle for punches

Driven half pulley spring compressor tool

Stroboscopic gun fot two-and

four-stroke engines

Bell

Driving pulley stop wrench

020319Y

020287Y

020263Y

35

Immobilizer control test

Piston band clamps (engine

125 c.c)

Protective sheath

Page 37

STORES CODE

IMAGEDESCRIPTION

020262Y

020430Y

020428Y

020426Y

020425Y

Crankcase detachment plate

Pin retainers installation tool

(engine 125cc)

Piston position check support

Piston fitting fork

Flywheel-side oil guard punch

36

020423Y

020414Y

020393Y

Driven pulley stop key

28 mm guide - Hub bearing

asembly

Piston band clamps

(Engine 200-250cc)

Page 38

STORES CODE

IMAGEDESCRIPTION

020382Y

020455Y

020442Y

020440Y

020329Y

Tool for removing valve cotters

equipped with part 012

10mm guide

Pulley stop wrench

Water pump overhaul tool

Pump

020357Y

020409Y

020456Y

37

32 x 35 mm adaptor

Multimeter adpater (Peak voltage measurement)

Ø 24mm adaptor

Page 39

STORES CODE

IMAGEDESCRIPTION

020332Y

020074Y

002465Y

020454Y

020622Y

Digital rpm counter

Crankshaft aligning tool

Pliers dor snap rings

Pin retainers installation tool

Transmission-side oil guard

punch

020444Y011

020444Y009

001467Y

38

Adapter ring

45 x 55 wrench

Bell

Page 40

STORES CODE

IMAGEDESCRIPTION

001467Y013

020444Y008

020244Y

020115Y

020271Y

15mm pliers

Adapter ring

Drift Ø 15

Drift Ø 18

Slient-block installation / removal tool

020627Y

020467Y

020626Y

39

Flywheel stop key

Flywheel estractor

Driving pulley stop key

Page 41

MAINTENANCE CHART

C C

S

3000

VERY

EVERY 3000 KM

ACTION

Engine Oil Level Check/Top up

EVERY 2 YEAR

EVERY 2 YEARS

ACTION

Cooling Fluid Replacement

Brake fluid Change

Secondary air filter (external - internal) - Cleaning (125)

AT 1.000 KM OR 4 MONTHS

ACTION

Engine oil Replacement

Hub Oil Replacement

Oil filter Replacement

Idling speed Adjustment

Acceleration command Adjustment

Steering Adjust

Brake levers Grease

Brake pads Check condition + wear

Brake fluid level Check

Nuts, bolts and fasteners Check

Electrical system and battery Check

Tires-inflation and wear Check

Vehicle and brake test Road test

KM

AT 6.000 KM OR 12 MONTHS

ACTION

Engine oil Replacement (125)

Hub oil level Check

Spark Plug/Electrodes distance Check

Air Filter Cleaning

Oil filter Replacement (125)

125 cc Valve Play Check

Roller support sliding blocks / Varistor rollers Check

40

Page 42

AT 6.000 KM OR 12 MONTHS

ACTION

Transmission Belt Check

Cooling fluid level Check

Brake pads Check condition + wear

Brake fluid level Check

Electrical system and battery Check

Tires-inflation and wear Check

Vehicle and brake test Road test

AT 12.000 KM OR 24 MONTHS AND 60.000 KM

ACTION

Engine oil Replacement

Hub oil level Check

Spark plug/Electrode gap Check/Change

Air Filter Cleaning

Oil filter Replacement

Idling speed S& Adjustment

Roller support sliding blocks / Varistor rollers Change

Acceleration command Adjustment

Cooling fluid level Check

Steering Adjust

Brake levers Grease

Brake pads Check condition + wear

Brake fluid level Check

Transmissions Lubricate

Nuts, bolts and fasteners Check

Suspensions Check

Electrical system and battery Check

Headlight Adjust

Tires-inflation and wear Check

Vehicle and brake test Road test

Transmission Belt (125 cc) Replacement

Transmission Belt Check (250)

41

Page 43

AT 18.000 KM AND 54.000 KM

ACTION

Engine oil Replacement (125)

Hub oil level Check

Spark Plug/Electrodes distance Check

Air Filter Cleaning

Oil filter Replacement (125)

125 cc Valve Play Check

250 cc Valve Play Check

Roller support sliding blocks / Varistor rollers Check

Cooling fluid level Check

Radiator External cleaning/Check

Brake pads Check condition + wear

Brake fluid level Check

Electrical system and battery Check

Tires-inflation and wear Check

Vehicle and brake test Road test

Secondary air filter (250) Cleaning

Transmission Belt Replacement (250)

Transmission Belt (125 cc) Replacement

AT 24.000 KM AND 48.000 KM

ACTION

Engine oil Replacement

Hub Oil Replacement

Spark plug/Electrode gap Check/Change

Air Filter Cleaning

Oil filter Replacement

Idling speed Adjustment

Roller support sliding blocks / Varistor rollers Change

Acceleration command Adjustment

Cooling fluid level Check

Steering Adjust

Brake levers Grease

Brake pads Check condition + wear

Brake fluid level Check

Transmissions Lubricate

Nuts, bolts and fasteners Check

Suspensions Check

42

Page 44

AT 24.000 KM AND 48.000 KM

ACTION

Electrical system and battery Check

Headlight Adjust

Tires-inflation and wear Check

‘ Vehicle and brake test Road test

Transmission Belt Check (250)

AT 30.000 KM. 42.000 KM AND 66.000 KM

ACTION

Hub oil level Check

Spark Plug/Electrodes distance Check

Air Filter Cleaning

Varistor rollers Check or Replacement

Transmission Belt Check

Cooling fluid level Check

Brake pads Check condition + wear

Brake fluid level Check

Electrical system and battery Check

Tires-inflation and wear Check

Vehicle and brake test Road test

Engine oil Replacement (125)

Oil filter Replacement (125)

AT 36.000 KM

ACTION

Engine oil Replacement

Hub oil level Check

Spark plug/Electrode gap Check/Change

Air Filter Cleaning

Oil filter Replacement

125 cc Valve Play Check

250 cc Valve Play Check

Idling speed Adjustment

Roller support sliding blocks / Varistor rollers Change

Acceleration command Adjustment

Transmission Belt Replacemen

43

Page 45

AT 36.000 KM

ACTION

Cooling fluid level Check

Radiator External cleaning/Check

Steering Adjust

Brake levers Grease

Brake pads Check condition + wear

Flexible brake lines Change

Brake fluid level Check

Transmissions Lubricate

Nuts, bolts and fasteners Check

Suspensions Check

Electrical system and battery Check

Headlight Adjust

Tires-inflation and wear Check

Secondary air filter (250) Cleaning

Vehicle and brake test Road test

AT 72.000 KM

ACTION

Engine oil Replacement

Hub Oil Replacement

Spark plug/Electrode gap Check / Change

Air Filter Cleaning

Oil filter Replacement

125 cc Valve Play Check

250 cc Valve Play Check

Idling speed Adjustment

Roller support sliding blocks /Varistor rollers Change

Acceleration command Adjustment

Transmission Belt Replacemen

Cooling fluid level Check

Radiator External cleaning/Check

Steering Adjust

Brake levers Grease

Brake pads Check condition + wear

Flexible brake lines Change

Brake fluid level Check

44

Page 46

AT 72.000 KM

ACTION

Transmissions Lubricate

Nuts, bolts and fasteners Check

Suspensions Check

Electrical system and battery Check

Headlight Adjust

Tires-inflation and wear Check

Secondary air filter (250) Cleaning

Vehicle and brake test Road test

45

Page 47

ENGINE OIL

ENGINE OIL 125 C.C.

ENGINE OIL 250 C.C.

HUB OIL LEVER

DRIVE BELT 125 C.C.

DRIVE BELT 250 C.C.

TRANSMISSION

OIL FILTER 125 C.C.

OIL FILTER 250 C.C.

AIR FILTER

SECONDARY OIL FILTER 125 C.C.

SECONDARY OIL FILTER 250 C.C.

SPARK PLUG / ELECTRODE GAP

ELECTRICAL SYSTEM AND BATTERY

VALVE CLEARANCE

WHEEL BEARINGS

IDLE SPEED / FUEL – AIR MIXTURE

THROTTLE CONTROL

STEERING

BRAKE LEVERS

BRAKE PADS/SHOES

BRAKE FLUID

LEVEL BRAKE FLUID

FLEXIBLE BRAKE FLUID PIPELINES

TYRE PRESSURE AND CONDITION

SUSPENSION

HEADLIGHT

COOLING LIQUID

RADIATOR

NUTS, BOLTS AND AND FASTENINGS

VEHICLE AND BRAKE TEST

1000 km - 2 Months

6000 km - 12 Monthse

12000 km - 24 Monthse

18000 km - 36 Monthse

24000 km

30000 km

36000 km

42000 km

48000 km

Check level / top up every 3000 km

Check every 2 years

Replace every 2 years

Replace every 2 years

54000 km

60000 km

66000 km

72000 km

REMPLACE CHECK CLEAN LUBRICATION ADJUSTMENT

46

Page 48

CARBURETTOR

- Disassemble all carburettor components, accurately wash

them in solvent, then dry them with compressed air. To ensure thorough cleaning, pay special attention to the passages

in the carburettor body.

- Carefully check the condition of all components.

- The throttle must slide freely in the chamber, if the play is

excessive because or wear-replace the throttle.

- Replace the carburettor if the chamber shows signs of wear

as to prejudice the valve’s regular seal or free sliding (though

it is new).

- When reassembling the carburettor, it is a good rule to

replace the gaskets.

WARNING

PETROL IS HIGHLY EXPLOSIVE. ALWAYS FIT NEW SEALS

AND GASKETS TO PREVENT LEAKAGE.

Diaphragm cover

Throttle valve spring

Conical needle support

Conical needle spring

Conical needle

Throttle valve diaphragm

Automatic starting device

Idle speed adjusting screw

Accelerating pump rocker

Idle mixture adjusting screw

Float pin

Accelerating pump assembly

Float

Float chamber

Idling Jet

Main jet

Diffuser

Float chamber drain screw

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

47

Page 49

CHECKING THE SPARK ADVANCE

- To check the ignition advance, use the stroboscopic lamp

with induction collet connected to the spark plug power supply cable.

- Connect the induction collet according to the right polarity

(the arrow on the collet must be facing the spark plug).’

- Set the lamp selector to the central position (1 spark = 1

driving shaft revolution as in 2 stroke engines).

- Start the engine and check that the lamp is in good working

order and that the rpm counter reads high speeds too (e.g.

8,000 rpm).

- If you detect abnormal flashes or rpm reads, increase the

resistive load on the spark plug supply line (10 - 15 KQ in

series with the H.V. cable).

Version 125

- Remove the slit plastic cap on the flywheel cover.

- Adjust the lamp flash dephasing corrector to make the reference on the flywheel cover collimate with the level on the

water pump drive. Read the advance degrees indicated by

the stroboscopic lamp.

Characteristic

Ignition advance (before T.D.C) 125

10° ± 1° at 2000 r.p.m. - 34° ± 1° at 6000 r.p.m

Version 250

- Remove the spark plug.

- Remove the plastic cover from the slotted hole on the

flywheel cover, indicated in the picture.

48

Page 50

- Remove the transmission cooling air inlet, shown in the picture.

- Using a screwdriver rotate the fan, mounted onto the drive

pulley, until the marking on the flywheel is aligned with that

stamped on the fly-wheel cover, as shown in the picture.

- Mark the alignment between fan and transmission cover on

the transmission side, as shown in the picture.

- Refit the spark plug.

- Refit the plastic cover on the flywheel cover.

Characteristic

Spark advance check, 250cc

from 10°±1°a2000 rpm

through 28°±1°a6500 rpm

49

Page 51

- Check that the advance degrees match the revolution speed as indicated in the tables.

- In case of abnormal values, check the Pick-Up and the control unit supplies (positive-negative); replace the

control unit, if required.

- A new control unit prevents the engine from rotating at over 2,000 rpm.

- The programmed control unit allows the engine revolution within the prescribed limits.

Specific tooling

020330Y Stroboscopic gun for two- and four-stroke engines

VERSION 125

SPARK ADVANCE VARIATION

SPECIFICATION DESC./QUANTITY

Tripping threshold

Restoration threshold

Spark suppression

First threshold: 10700 ±50

Second threshold: 11000 ±50

First threshold: 10600 ±50

Second threshold: 10900 ±50

First threshold: 1 spark out of 7

Second threshold: 2 sparks out of 3

50

Page 52

VERSION 250

SPARK ADVANCE VARIATION

SPECIFICATION DESC./QUANTITY

Tripping threshold

Restoration threshold

Spark suppression

First threshold : 9600 ±50

Second threshold : 9800 ±50

First threshold : 9500 ±50

Second threshold : 9700 ±50

First threshold : 1 spark out of 7

Second threshold: 2 sparks out of 3

51

Page 53

SPARK PLUG

- Put the vehicle on the central stand.

- Open the door on the left side of the vehicle by levering in

the recess in the lower part of the door after removing the

screw.

- Disconnect the spark plug HV cable cap. - Unscrew the

spark plug with the spanner provided.

- Check the spark plug to see if the insulator is cracked, the

electrodes are worn out or excessively sooty. Also check the

condition of the seal washer and measure the spark gap with

a suitable thickness gauge.

- If necessary adjust the spark gap by carefully bending the

side electrode. If the spark plug has any of the defects mentioned above, replace it with a plug of the recommended

type.

- Insert the plug into the hole with the proper inclination,

screw it in fully by hand and then tighten itwitizthe specially

designed spanner.

- Push the spark plug cap all the way down onto the spark

plug and then proceed to the reassembly.

CAUTION

THE SPARK PLUG MUST BE REMOVED WITH COLD ENGINE. THE SPARK PLUG SHOULD BE REPLACED EVERY 12,000

KM. THE USE OF NONCONFORMING IGNITION CONTROLLERS, AND SPARK PLUGS OTHER THAN THOSE PRESCRIBED CAN SERIOUSLY DAMAGE THE ENGINE.

Characteristic

Spark plug (250)~’^Z.S- iz5c)

CHAMPION RG4HC

Distance between the electrodes

mm 0,7 - 0,8

Pares de apriete (N.m)

Spark plug 12 ÷ 14

52

Page 54

HUB OIL

Check that there is oil in the rear hub. (quantity of oil contained ~ 250 cc). Proceed as follows in order to check the hub

oil level:

1) Take the vehicle to a flat area and rest it on the support.

2) Unscrew the oil bar «A», dry it with a clean cloth and reinsert it, screwing it in completely.

3) Extract the rod and check that the level is up to the mark

indicated in the image.

4) Screw the bar back in, checking that it is tightly in place.

N.B.

THE NOTCHES ON THE HUB OIL LEVEL BAR, WITH THE EXCEPTION OF THAT INDICATING THE MAX LEVEL, REFER TO

SOME OF THE MANUFACTURER’S OTHER MODELS AND

HAVE NO SPECIFIC FUNCTION AS FAR AS REGARDS THIS

VEHICLE.

WARNING

USING THE VEHICLE’S HUB WITH INSUFFICIENT LUBRICATION OR WITH CONTAMINATED OR IMPROPER LUBRICANTS, ACCELERATES THE WEAR AND TEAR OF THE MOVING PARTS AND CAN CAUSE SERIOUS DAMAGE.

ENVIRONMENT

THE OIL USED CONTAINS ENVIRONMENTALLY HARMFUL

SUBSTANCES. FOR THE REPLACEMENT OF THE HUB OIL

WE RECOMMEND TURNING TO AN AUTHORIZED PIAGGIO

SERVICE CENTRE THAT IS EQUIPPED FOR THE DISPOSAL

OF USED OIL IN RESPECT OF NATURE AND LEGAL REGULATIONS.

WARNING

WHEN REPLACING THE HUB OIL PREVENT IT FROM COMING

INTO CONTACT WITH THE REAR BRAKE DISC.

Recommended products

SAE 80W/90 Oil that passes API GL3 specifications

53

Page 55

CHECK

- Move the vehicle to a flat ground and rest it on the stand.

- Unscrew the oil bar, dry it with a clean cloth and reinsert it,

screwing it in thoroughly.

- Extract the bar and check that the oil level reaches the second notch of the bar from the bottom.

- Screw the oil bar back on, checking that it is tightly in place.

Recommended products

Oil SAE 80W/90 of higher quality than API GL3 specifications

Locking torques (N*m)

Hub oil exhaust cap 15÷17

REPLACEMENT

- Remove oil filler plug “A”.

- Unscrew oil drain plug “B” and drain all the oil.

- Retighten the oil drain plug and then fill the hub with fresh

oil.

Recommended products

Rear hub oil

SAE 80W/90 Oil that passes API GL3 specifications

Locking torques (N*m)

Hub oil drain screw 15 - 17 Nm

AIR FILTER

- Remove the left footboard and the left side pan- el as described in Chapter Bodywork.

- Remove the cleaner cap after loosening the 9 fixing

screws.

- Pull out the filter element.

- Replace the air filter with a new one.

54

Page 56

N.B.

CHECK AND IF NECESSARY BLOW THE AIR FILTER EVERY

6,000 KM. DIRECT THE AIR JET FROM THE INSIDE TO THE

OUTSIDE OF THE FILTER (I.E. IN THE OPPOSITE DIRECTION

TO THE AIR FLOW DURING NORMAL ENGINE OPERATION).

EVERY 6,000 KM, DURING THE SCHEDULED SERVICE, REMOVE THE RETAINER, TAKE OFF THE RUBBER CAP FROM

UNDER THE FILTER BOX AS SHOWN IN THE FIGURE AND

DRAIN ANY OIL RESIDUES.

Cleaning (Every 12,000 Km):

- Wash with water and shampoo.

- Dry with light jets of compressed air and wipe with a clean

cloth.

- Soak with a 50 fuel-oil mixture for filters.

- Let the filter cartridge drip and then squeeze it between the

hands without wringing.

- Refit the filter element.

CAUTION

DO NOT RUN THE ENGINE IF THE AIR FILTER IS NOT IN

PLACE AS THIS WOULD RESULT IN EXCESSIVE WEAR OF

THE CYLINDER AND PISTON AS WELL AS IN DAMAGE TO

THE CARBURETTOR.

CAUTION

IF THE VEHICLE HAS RIDDEN ON DUSTY ROADS, THE AIR

FILTER MUST BE CLEANED MORE FREQUENTLY THAN WHAT

INDICATED IN THE SCHEDULED MAINTENANCE TABLE.

Recommended products

Air filter sponge oil

Mineral oil with specific additives to increase adhesion

ISO VG 150

55

Page 57

ENGINE OIL

REPLACEMENT

The engine oil should be replaced after the first 1,000 km,

and then every 6,000 km for the 125cc version and 12,000

km for the 250cc version. The engine must be drained

through the net filter draining cap «B» on flywheel side; in

addition, to facilitate the drainage, oil dipstick «A» should be

loosen. Once the engine oil has been drained, remove oil

cartridge «C».

Since a certain oil quantity remains inside the circuit, the fillup must be carried out with 600-650cc of fresh oil poured

through filler cap «A». Hence start the vehicle, let the engine run for a few minutes, and then shut it back down; after

approx. five minutes, check the level and top-up if necessary, without exceeding the MAX mark.

N.B.

RENEW THE OIL WHEN THE ENGINE IS HOT.

Recommended products

Engine oil

Synthetic oil SAE 5W/40 of higher quality than API SJ

specifications

Locking torques (N*m)

Engine oil drain plug 24 - 30 N.m

CHECK

In four-stroke engines oil is used to lubricate the valve gear

components, the crankshaft bearings and the power plant. A

lack of engine oil can cause serious damage to the engine.

In all four-stroke engines, oil deterioration and consumption

are, to some extent, normal, especially during running-in.

Consumption partly depends on the riding style (for example,

constantly riding at full throttle increases oil consumption).

56

Page 58

Perform this operation when the engine cold, as des-

G O

cribed below:

1) Put the vehicle on its central stand on a flat surface.

2) Unscrew dipstick “A”, dry it with a clean cloth and refit by

screwing it completely.

3) Remove the dipstick again and check that the oil level is

between the MAX and MIN marks on the dipstick; top up if

necessary.

The MAX level mark indicates an amount of about 1100 cc

of engine oil. The level will be lower if checked after using

the vehicle (i.e. when the engine is hot). To obtain a correct

indication of the oil level, wait for at least 10 minutes after

switching off the engine.

Characteristic

Engine oil (125)

-1100 cc

Engine oil (250)

-120 0 cc

If the oil level is too low, top up by adding fresh oil without

exceeding the MAX level.

Approximately 400 cc of oil are needed to restore the level

between the MIN and MAX marks.

ENGINE OIL FILTER

The oil cartridge must be replaced with every oil replacement. For top-ups and replacements only use fresh oil of the

recommended type.

Check that the net filter O-rings and drainage cap are not

worn out and in good conditions. Lubricate O-rings and replace net filter and oil drainage cap; tighten at the prescribed torque. Install the new cartridge filter after lubricating

the O-ring. Fill with fresh engine oil.

Recommended products

Engine oil 4T

Synthetic oil SAE 10W/40 of higher quality than API SJ

specifications

57

Page 59

OIL PRESSURE WARNING LIGHT

Oil pressure warning light. A warning light on the instrument

panel comes on when the ignition key is turned to the “ON”

position. The light must go out after the engine has started.

Should the warning light come on while braking, idling

or cornering, check the oil level and the lubrication

system as soon as possible.

CHECKING THE IGNITION TIMING

- Remove the four fixing screws and detach the flywheel cover, with the water pump and hoses, from the engine.

- Turn the flywheel until the reference mark reaches the fine

machining on the crankcase, as shown in the picture (TDC).

Ensure the 4V mark, stamped on the camshaft drive pulley,

is aligned with the reference mark on the head, as shown

in the second figure. If the mark is on the opposite side of

the sign stamped on the head, crank the engine so that the

crankshaft computes a complete revolution.

- The TDC reference mark is also shown on the flywheel

cooling fan and cover.

In order to use these markings, remove the spark plug and

crank the crankshaft backwards, using a retaining tool to

hold the camshaft driving pulley.

N.B.

IF THE TIMING ASSEMBLY IS NOT IN PHASE, ADJUST IT AS

REQUIRED.

58

Page 60

CHECKING THE VALVE CLEARANCE

-To check the valve clearance, you have to make the point

references coincide

-Check that the clearance between the valve and register corresponds to the values shown using a proper thickness gauge. If the values of the valve clearances - intake and discharge, respectively are different than those given below, adjust

them by loosening the lock nut and using a screwdriver on

the register as shown in the figure.

Air intake: 0,10 mm (cold)

Discharge: 0,15 mm (cold)

COOLING SYSTEM

TOP-UP

The fluid level inspection should be carried out every 6,000

km when the motor is cold, following the methods indicated

below:

- Rest the vehicle on the central stand and on a flat ground.

Accessing the coolant level indicator

To check the level of coolant, remove the cap on top (remove

screws 1 and 2).

- Top up, if ffie fluid leveT is near to or below the MIN level

into the expansion tank. The fluid level should always be between the MIN and MAX level.

- The cooling fluid consists of a mixture of 50 demineralised water and ethylene glycol and corrosion inhibitors based

anti-freeze solution.

ATENCIÓN

TO PREVENT THE COOLANT FROM LEAKING OUT OF THE

EXPANSION TANK DURING USE, BE SURE TO NEVER EXCEED THE MAX LEVEL WHEN REFILLING

59

Page 61

BRAKING SYSTEM

Level check

Proceed as follows:

- Rest the vehicle onto its centre-stand and align the handlebars;

- Check the liquid level through the inspection hole «A».

A certain decrease in the liquid level is due to the wear of

the pads.

Top-up

Use the following procedure:

Loosen the two screws, remove the reservoir cap, remove

the gasket and top up only with the prescribed fluid without

exceeding the maximum level.

CAUTION

USE ONLY DOT 4 BRAKE FLUID.

CAUTION

KEEP THE BRAKE FLUID AWAY FROM THE SKIN, THE EYES

AND CLOTHING. IN CASE OF CONTACT, RINSE GENEROUSLY WITH WATER.

CAUTION

THE BRAKE FLUID IS HIGHLY CORROSIVE. TAKE CARE NOT

TO SPILL IT ON THE PAINTWORK.

CAUTION

THE BRAKE FLUID IS HYGROSCOPIC, I.E. IT ABSORBS HUMIDITY FROM THE AIR. IF THE HUMIDITY CONTAINED IN THE

FLUID EXCEEDS A GIVEN CONCENTRATION, THE BRAKING

ACTION BECOMES INSUFFICIENT.

NEVER DRAW THE FLUID FROM OPEN OR PARTLY EMPTY

CONTAINERS.

UNDER NORMAL CLIMATIC CONDITIONS THE FLUID

SHOULD BE RENEWED EVERY 20,000 KM, OR IN ANY CASE

EVERY TWO YEARS.

N.B.

CHANGE THE BRAKE FLUID AND BLEED THE SYSTEM AS

DESCRIBED IN CHAPTER BR AKING SYSTEM

Recommendede products

Synthetic fluid SAE J 1703 NHTSA 116 DOT 4, ISO 4925

60

Page 62

HEADLIGHT ADJUSTMENT

INSPEC

TION AND CLEANING

Proceed as follows:

1. Position the vehicle in riding conditions, and with the tyres

inflated at the prescribed pressure, on a horizontal surface

10m away from a half-lit white screen, ensuring the vertical

axis of the vehicle is perpendicular to the screen;

2. Turn on the headlight and check the distance between the

ground and the horizontal line which separates the lit area

from the dark region, is no more than 9/10 and not less than

7/10 of the height of the headlight, measured from the

ground;

3. If this is not the case, adjust the headlight via screw «A»,

which may be reached by removing the front grid.

WARNING

THE PROCEDURE DESCRIBED ABOVE COMPLIES WITH THE

“EURONORM” CONCERNING THE MAX. AND MIN. HEIGHT OF THE LIGHT BEAM OF A ROAD VEHICLE. PLEASE

CHECK WITH THE LOCAL AUTHORITIES FOR WHAT REQUIREMENTS MUST BE FULFILLED IN EVERY SINGLE COUNTRY

WHERE THE VEHICLE IS TO BE USED.

SAS FILTERS INSPECTION AND CLEANING

ENGINE 250

- Remove the two screws shown in the picture.

61

Page 63

- Remove the two screws shown in the picture.

- Remove the filter shown in the picture.

- Inspect the gasket.

- Ensure the SAS filter box is not cracked or deformed.

- Accurately clean the SAS filter. In the event of break-ups or

abnormal deformations, proceed with the replacement.

For the reassembly, follow the above operations in the reverse order.

CAUTION

IF THE VEHICLE HAS RIDDEN ON DUSTY ROADS, THE AIR

FILTER MUST BE CLEANED MORE FREQUENTLY THAN WHAT

INDICATED IN THE SCHEDULED MAINTENANCE TABLE.

CAUTION

NEVER LET THE ENGINE RUN WITHOUT THE SECONDARY

AIR FILTER.

Engine 125

- Remove the flywheel cover.

- Remove the two SAS valve fixing screws, as shown in the

figure, and remove the SAS valve with its O-ring from the

bracket.

- Remove the plastic bracket with its packing as shown in the

picture.

62

Page 64

- Ensure the SAS filter box is not cracked or deformed.

- Inspect the packing.

-Accurately clean external and internal filters. In the case

of break-ups or abnormal deformations, proceed with the

replacement

- Ensure the manifold channelling secondary air into the

head is not cracked, deformed, or has undergone overheats.

Replace as necessary.

- Ensure the metallic manifold is not cracked. For the reassembly, follow the above operations in the reverse order, taking particular care in correctly installing the rubber manifold connecting the SAS valve to the exhaust system.

CAUTION

LEAKS FROM THE MATING PLANE BETWEEN SAS VALVE

AND FLYWHEEL, RESULT IN AN INCREASE IN NOISE EMISSIONS FROM THE SAS.

CAUTION

IF THE VEHICLE HAS RIDDEN ON DUSTY ROADS, THE AIR

FILTER MUST BE CLEANED MORE FRE- QUENTLY THAN

WHAT INDICATED IN THE SCHEDULED MAINTENANCE TABLE.

CAUTION

NEVER LET THE ENGINE RUN WITHOUT THE SECONDARY

AIR FILTER.

63

Page 65

1. SEAT SIDE TRIM

• Extract the 3 securing screws (2 Philips 3.6x14 selftappers and one 5x16 Allen M3) from each cover.

2. COWLING

• Extract the 6 screws (5x12 Allen M3) from under the

cowling.

- Extract the drawer for the tool kit and its cover, by

removing the 2 Philips screws with washers.

• Extract the 8 top screws (Philips 3.6x14 self-tappers

with washer) and the 2 side screws (Philips

6x16 with washer).

• Pull the cowling backwards slightly to access the turn

indicator connections and disconnect them.

• Extract the cowling backwards.

N.B.

TO REPLACE THE PILOT LIGHTS IT IS ONLY NECESSARY

TO EXTRACT THE TWO PILOT LIGHT SCREWS.

64

Page 66

3. LOWER COWLING COVER

• Extract the 2 securing screws (Philips 6x16 with washer)

N.B.

TO CONTINUE WITH THE HELMET HOLDER WE NEED

TO CONTINUE DISMANTLING THE FRONT PART, SINCE THE PETROL TANK FRONT BREATHER PIPE PASSES

THROUGH THE HELMET HOLDER.

4. WATER-OIL TANK COVER

• Extract the 2 top screws (Philips 5x12).

5. SIDE COVERS

• Pull them gently backwards.

65

Page 67

6. SHIELD INNER COVER

• Extract the 2 screws (5x12 Allen M3).

• Extract the 3 top screws (2 Philips 3.6x14 self-tappers

and one6x16 Allen screw with washer).

7. BATTERY COVER

• Extract the Philips screw and separate the cover from

the 2 securing flaps.

8. PETROL TANK COVER

• Extract the bottom covers (left and right), by removing the 6 screws (Philips 5x16 with washer) and the two

air inputs, 3 screws (1 Philips 3x10 self-tapper, 1 Philips

3.6x10 self-tapper and 1 Philips 5x16), as there are 2

screws (Philips 6x16 with washer) that are inaccessible

without carrying out this step.

66

Page 68

• After extracting the 6 side screws and the central

(Allen M3 5x12) screw from the tank cover, lift up the

tank cover.

8. HELMET CARRIER

• Remove the battery and cables.

• Extract the 6 securing screws (2 Philips 8x45, 2 Philips

6x19 with washer and 2 8x25 bolts), the petrol tank cover, the breather pipe and the seat opening cable.

67

Page 69

9. FOOTRESTS

• Remove the 5 securing screws (2 Philips 6x16 with

large washer, 2 Philips 6x16 with small washer and 1

Philips 4.8x25 self-tapper), and the one joining the two

fairings.

10. SIDE COVERS

• Remove the 2 securing screws (1 Philips 6x16 with l

washer and 1 Philips 3.6x10 self-tapper), and the turn

indicator wire.

11. SHIELD

• Remove the helmet carrier.

• Extract the securing screw (Philips 6x16 with washer).

68

Page 70

EXHAUST ASSY. REMOVAL

O O G O C

- Unloose the two fixings of the exhaust manifold on the

head.

- Unloose the 3 screws fixing the muffler to the supporting

arm.

- Remove the muffler assembly.

- For the reassembly, follow the operations indicated above

in the reverse order, complying with the tightening torques.

Locking torques (N*m)

Exhaust pipe/support bracket fixing screw 27 ÷ 30

Exhaust pipe/cylinder head fixing nut 16 ÷ 18

REMOVAL OF THE ENGINE FROM THE VEHICLE

- Disconnect the battery.

- Remove seat, side fairings

- Drain coolant.

- Remove the silencer assembly.

- Remove the silencer mounting bracket.

- Remove the rear wheel.

- Remove the bottom securing devices, shock absorbers and

the left and right-hand brackets corresponding to the rear

wheel flange.

69

Page 71

- Remove the throttle cable.

- Detach the air filter bellow and manifold shown in the figure.

- Detach engine earth cable.

- Disconnect the electrical devices on the carburettor and the

starter motor power cord.

- Detach the inlet and outlet carburettor fuel lines and the

cooling circuit hoses (head outlet and thermostat inlet).

- Detach the spark plug H.T. cable.

- Detach the generator wiring from the vehicle’s electrical

circuit.

- Remove the swing-arm from the engine pivoting.

- The engine may now be removed.

WARNING

PERFORM THESE OPERATION WITH THE ENGINE COLD.

WARNING

BE VERY CAREFUL WHEN HANDLING FUEL.

ATENCIÓN

WHEN INSTALLING THE BATTERY, CONNECT THE POSITIVE

CABLE BEFORE CONNECTING THE NEGATIVE ONE

- For refitting the engine onto the vehicle, follow the above

operations in the reverse order, complying with the tightening torques given in the Characteristics chapter.

- Check engine oil level and top-up with recommended type

as required.

- Fill-up the cooling system.

- Carry out the inspection of throttle and electrical devices.

CAUTION

TAKE CARE NOT TO INVERT THE POSITION OF THE TWO

ACCELERATOR CONTROL TRANSMISSIONS. CHECK THAT

BOTH SHOW A SLIGHT PLAY WITH THE VALVE IN CONTACT

WITH THE REGISTER.

70

Page 72

AUTOMATIC TRANSMISSION

AUTOMATIC TRANSMISSION

AIR DUCT

TRANSMISSION COVER

To remove the transmission cover it is necessary to remove

the plastic cover first, using a screwdriver on the special guides. Using the clutch bell lock wrench shown in the figure,

remove the driven pulley axle locking nut and washer.

Specific tooling

020423Y driven pulley stop key

- Remove the cap/bar of the engine oil filling hole.

- Remove the 10 screws.

- Remove the transmission cover. If this operation is performed directly on the vehicle, it is necessary to remove the

transmission compartment cooling air sleeve first.

AIR DUCT

- Remove the transmission cooling air inlet, shown in the picture.

Version 125

- Remove the 4 screws and the case.

71

Page 73

- Remove the 5 screws located on two different surfaces and

the case.

REMOVING THE DRIVEN PULLEY SHAFT BEARING

- Remove the snap ring from the cover internalside.

- Remove the bearing from the case using:

Specific tooling

020376Y Handle for punches

020375Y Adapter 28 x 30 mm

020412Y 15 mm guide

REFITTING THE DRIVEN PULLEY SHAFT BEARING

- Slightly warm the inside of the case to prevent damaging

the painted surface.

- Install the bearing into its seat

- Replace the snap ring.

CAUTION

USE AN APPROPRIATE REST SURFACE TO AVOID DAMAGING THE COVER PAINT.

N.B.

ALWAYS REPLACE THE BEARING WITH A NEW ONE UPON

REASSEMBLY.

Specific tooling

020376Y Handle for punches

020357Y 32 x 35 mm adaptor

020412Y 15 mm guide

72

Page 74

BAFFLE ROLLER

O

PLASTIC ROLLER

- To reassemble, install the roller with the containment edge

on the engine crankcase side.