Page 1

WORKSHOP MANUAL

MINIMOTO 50 C.C. 4T

Page 2

NACIONAL MOTOR, S.A., manufacturer of DERBI motorcycles and mopeds, has produced this manual with

PREFACE

the aim of documenting and simplifying as much as possible the work you need to do to in dismantling and

assembling the MINIMOTO 50 c.c. 4-stroke engine.

The intention is to provide as much assistance as possible to mechanics working in our brand’s dealers and

sub-dealers.

Due to its constant commitment to improving its products, DERBI - NACIONAL MOTOR, S.A.U. reserves the

right to introduce any modifications it deems fit, without prior warning.

All the information included in this manual is based on the latest data available at the time of its publication.

The drawings and photographs in this manual are for reference purposes only, and may therefore not be

exactly the same as the corresponding parts of the current model itself.

NACIONAL MOTOR, S.A.U.

1

Page 3

INDEX

GENER AL INFORMATION

Pág. 4

CARACTERISTICS

TIGHTENING TORQUES

MAINTENANCE

MAINETANCE CHART

ENGINE OIL

DISTRIBUTION

DISTRIBUTION - COMPRESSION

MOTOR

TRANSMISSION

CLUTCH

END GEAR SHAFT

STATOR-FLYWHEEL

REMOVING THEROCKER - ARMS COVER

CAM SHAFT

CYLINDER HEAD - VALVES

Pág. 5-6

Pág. 7

Pág. 10

Pág. 10-11

Pág. 11

Pág. 13

Pág. 14

Pág. 15

Pág. 16

Pág. 17

Pág. 18

Pág. 19

Pág. 20-21

CYLINDER - PISTON - SMALL END

INSPECTING THE CYLINDER HEAD

DISTRIBUTION CHAIN VALVES

INSPECTING THE CAM SHAFT

REFITTING THE TIMING CHAIN

ASSEMBLING THE TIMING CHAIN TENSIONER

REFITTING PICK-UP

REFITTING CARTER

REFITTING CRANKSHAFT

REFITTING THE CR ANKASE HALVES

OIL PUMP

CARBURETTOR

Pág. 21-28

Pág. 29

Pàg. 30-33

Pág. 34-36

Pág. 36-37

Pág. 37

Pág. 38

Pág. 39

Pág. 39-41

Pág. 42-43

Pág. 44-45

Pág. 46-47

3

Page 4

GENERAL INFORMATION

GENERAL INFORMATION

This section describes the general safety rules and service recommendations to be observed.

- Should it be necessary to run the engine in order to perform certain operations, please ensure the area is

adequately ventilated and, if required, use appropriate fume extractors; Never run the engine in an enclosed

space; exhaust gases are toxic.

- Petrol is extremely flammable and, under certain conditions, may be explosive. Do not smoke and do not

allow live flames or sparks in the work area.

- Use genuine PIAGGIO spare parts and recommended lubricants. Use of non-genuine spare parts may

damage the engine.

- For operations requiring special tools, use only those specifically designed for this engine.

- Always replace seals, gaskets and split pins with new ones, when refitting new or old components.

- After removal, clean the components with a non-flammable or high flash-point solvent. Lubricate all contact

surfaces and inspect taper fit couplings, before refitting.

- After refitting, ensure all components have been correctly fitted and work properly.

- Use only metric-sized tools for removing, repairing and refitting operations. Metric screw fasteners, nuts

and bolts are not interchangeable or compatible with Imperial-sized fasteners. Use of Imperialsized tools or

fasteners may damage the engine.

- For engine repairs involving the electric system, carefully inspect the refitting of the connections.

4

Page 5

CHARACTERISTICS

CHARACTERISTICS

DIRTBOY 10

DIRTKID 12

CHASSIS,

WHEELS AND

BRAKES

CHASSIS CODE

ZEMMR4CC24 ¿AXXXXXX?

ZEMMS4CC64 ¿AXXXXXX?

Frame Steel

Fork

Inner tube

Tyre

Front suspension

Rear suspension

Front brake

2,5 x 10”

3,00 x 10”

120mm travel

hydraulic fork

140mm

travel pneumatic

shock absorbers.

160mm mechanical disk.

Steel

ENGINE CODE

C391M ¿XXXX?

C391M ¿XXXX?

2,50 x 12”

3,00 x 10”

135mm travel

hydraulic fork

160mm

travel pneumatic

shock absorbers.

DIMENSIONS

Rear brake

Total lenght

Total width

Distance between axles

Seat height

Fuel tank capacity

Weight

90mm mechanical drum.

1290mm.

590mm.

905mm.

610mm.

44Kg.

1430mm

590mm

995mm

685mm

2,3L.

47Kg.

5

Page 6

CHARACTERISTICS

CHARACTERISTICS

SPECIFICATION

Engine

Bore per stroke

Displacement

Compression ratio

Carburettor Dell’orto

Recommended spark plug

Timing system

Valves play: induction

Valves play: exhaust

Lubrication

Fuel system

Transmission

Max. power

Engine oil

Grear-shaft teeth

DESC. / QUANTITY

Four-stroke mono-cyl-inder

39 x 41,8 mm.

49,93 mm.

11,5 ÷12,5:1

PHVA

Champion RG 4 HC

overhead single camshaft, two valves, chain controlled on l.h. side.

0,10 mm. (en cold)

0,10 mm. (en cold)

Engine lubrication by chain-driven lobe pump (in crankase) with gauze

strainer and centrifugal filter.

Gravity, unlead petrol (minimum octane number 95), through carburettor.

Automatic wet clutch and gear reducer.

3,3 Kw (4,6 CV ) 8500 rpm.

Capacity: ~ 600c.c.

10

Gearing retio

Transmission

6

1 / 4,1

SPECIFICATION DESC. / QUANTITY

Automatic wet clutch and gear reducer.

Page 7

TIGHTENING TORQUES

TIGHTENING TORQUES

NAME

Spark plug:

Head cover screw

Head-cylinder stud nut

Head-cylinder / crankcase fixing screw

Chain-tensioning pad screw

Timing chain tensioner screw

Timing chain tensioner central screw

Camshaft pulley screw

Rocker-arm shaft and camshaft bearing screw

Rocker-arm adjusting nuts

Engine oil pre-filter cap

Oil drain cap

Flywheel nut (electric starter version)

Stator screws

Pick-up screw

Mounting bracket / crankcase (flywheel side) fixing screws

TORQUE IN Nm

10 ÷ 15 Nm

8 ÷ 10 Nm

6 ÷ 7 + 135º+90º Nm for first fitting,

6 ÷ 7 90º+90º Nm for refitting/locking

8 ÷ 10 Nm

5 ÷ 7 Nm

8 ÷ 10 Nm

5 ÷ 6 Nm

12 ÷ 14 Nm

3 ÷ 4 Nm

7 ÷ 9 Nm

25 ÷ 28 Nm

25 ÷ 28 Nm

40 ÷ 44 Nm

2 ÷ 3 Nm

8 ÷ 10 Nm

8 ÷ 10 Nm

Oil pump /crankcase fixing screws

Intake manifold fixing screws

Carburettor manifold clamp screw

Starter motor fixing screw

Flywheel cover fixing screw

Transmission cover fixing screw

Oil conveying plate fixing screws

(half-crankcase transmission side)

Half-crankcase joining screws

When installing new studs, proceed as follows

7

2 ÷ 3 Nm

7 ÷ 9 Nm

1,5 Nm

11 ÷ 13 Nm

2,5 ÷ 3 Nm

8 ÷ 10 Nm

8 ÷ 10 Nm

8 ÷ 10 Nm

6 ÷ 7 Nm + 135º + 90º

following a diagonally crosswie sequence.

Page 8

MAINTENANCE

MAINTENANCE

ACTION

Engine Oil - Level Check/Top up

Spark plug/electrode gap - Check

Air Filter - Cleaning

Idle speed / Fuel - Adjust

Acceleration command - Adjustment

Clutch - Check

Oil filter - Clean

Engine oil - Replacement

Engine Oil - Level Check/Topup

Spark plug/electrode gap - Check

Idle speed / Fuel - Change

Oil filter - Clean

Oil filter - Replacement

Air Filter - Cleaning

FREQUENCY

Every 3 month

Every 3 month

Every 3 month

Every 3 month

Every 6 month

Every 6 month

Every engine oil replacement

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

Valve clearance” Check

Idle speed / Fuel - Adjust

Acceleration command -Adjustment

Clutch - Check

Eletrical system - Check

Engine oil - Replacement

Engine oil - Replacement

Idle speed / Fuel - Change

Oil filter - Replacement

Valve clearance - Check

Clutch - Replacement

Eletrical system - Check

Engine oil - Replacement

8

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 5 hours or 1 month

At 20 hours or 6 month

At 40 hours or 12 month

At 40 hours or 12 month

At 40 hours or 12 month

At 40 hours or 12 month

At 40 hours or 12 month

At 40 hours or 12 month

At 60 hours or 18 month

Page 9

MAINTENANCE

MAINTENANCE

ACTION

Engine oil - Replacement

Idle speed / Fuel - Change

Filtro aceite - Sustitución

Valve clearance - Check

Clutch - Replacement

Eletrical system - Check

Engine oil - Replacement

Engine oil - Replacement

Idle speed / Fuel - Change

Oil filter - Replacement

Valve clearance - Check

Clutch - Replacement

Eletrical system - Check

FREQUENCY

At 80 hours or 24 month

At 80 hours or 24 month

At 80 hours or 24 month

At 80 hours or 24 month

At 80 hours or 24 month

At 40 hours or 12 month

At 100 hours or 30 month

At 120 hours or 36 month

At 120 hours or 36 month

At 120 hours or 36 month

At 120 hours or 36 month

At 120 hours or 36 month

At 120 hours or 36 month

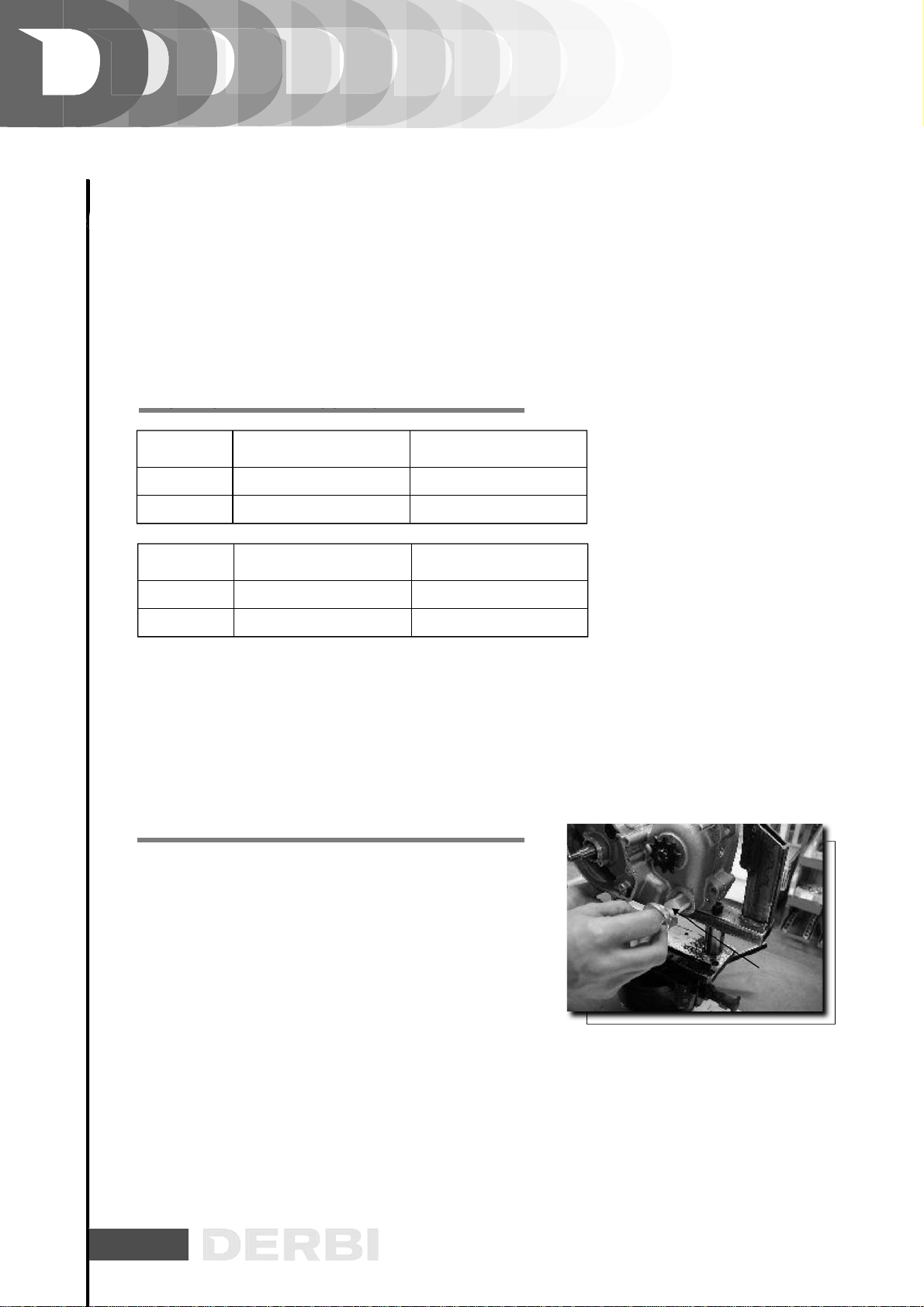

The spark plug inspection must be carried out with the engine cold and as described below:

- Detach the spark plug cap at the end of the HT cable.

- The spark plug must be unscrewed using the supplied box spanner.

- Carefully inspect the insulator; replace if dented or damaged.

- Measure the spark gap using a suitable thickness gauge and, if necessary, adjust it by carefully bending

the outer electrode.

- Ensure the seal washer is in good conditions.

- Refit the spark plug by screwing it in carefully by hand, and then locking it with the supplied box spanner.

CHARACTERISTICS

Recommended spark plug

Champion RG 4 HC

9

Page 10

G

MAINTENANCE

M

MAINTENANCE

ELECTRICAL CHARACTERISTICS

Distance between electrodes

0.8 ÷ 0.9 mm

RED

EARTH

BLACK

EARTH

Locking torques (N*m)

Spark plug: 10 ÷ 15Nm

EN

INE OIL

REPLACEMENT

YELLOW

55 ± 10%

Infinite

BROWN

100 ± 10%

100 ± 10%

EARTH

Infinite

EARTH

0-1

Renew the oil when the engine is hot. Place a container

under the oil sump and remove the oil drain plug. After

draining the oil, clean the gauze strainer with a suitable

solvent and then blow it with compressed air. To gain access

to the gauze strainer, remove plug «A» (see figure). Refit the

strainer and tighten the oil plug with the prescribed torque

using a new O-ring.

10

A

Page 11

MAINTENANCE

MAINTENANCE

Fill up the engine with the recommended oil, using the filler

hole on the RHS engine cover.

Tighten the cap manually.

N.B.

LET THE ENGINE RUN FOR A FEW MINUTES, THEN

CHECK THE OIL LEVEL AGAIN, WITH THE ENGINE COLD;

THIS MUST ALWAYS BE AT THE LOWER EDGE OF THE

INSPECTION HOLE.

N.B.

WHEN REPLENISHING FOR THE FIRST TIME, OR AFTER

AN OVERHAUL, POUR IN 600 CC OF ENGINE OIL. IN ALL

OTHER CASES USE 550 CC AND IF NECESSARY TOP UP.

Recommended products

AGIP CITY 4 T

Synthetic oil 20W40

The oil level must be at the lower edge of the filler cap.

Therefore, before starting the «cold» engine, it is necessary

to check the oil level using the inspection hole on the RHS

engine cover.

CHARACTERISTIC

Engine oil

Capaciity: ~ 600c.c.

Turn the magnetic flywheel in a clockwise direction until the

mark on it is lined up with the reference mark on the Pickup/Stator bracket, as shown in the figure, always bearing in

mind that the mark on the magnetic flywheel is the reference

for the first magnet (in a clockwise direction).

11

Page 12

MAINTENANCE

MAINTENANCE

Ensure the reference mark on the camshaft control ring is

aligned with that machined on the head, as shown in the

second figure.

If the marking is on the side opposite to the reference on the

head, perform a complete revolution of the crankshaft, since

the piston must be at the TDC of the ignition phase.

HECKING THE VALVE CLEARANCE

In order to carry out the inspection of the valve clearances,

align the reference marks as for the valve timing point,

described earlier.

Using a thickness gauge, ensure the clearance between the

valve and the valve adjuster is within the indicated values.

If the valve clearance values differ from those shown below

(for intake and exhaust respectively), proceed with the

adjustment, by loosening the counter nut and then, with the

aid of a screwdriver, loosening or tightening the adjusting

screw as shown in the figure.

CHARACTERISTIC

Valves play:

induction 0,10mm (cold)

Valves play:

exhaust 0,15mm (cold)

Locking torques (N*m)

Rocker-arm adjusting nuts: 7 ÷ 9 Nm

12

Page 13

CO

SSU

MAINTENANCE

MAINTENANCE

HECKING THE END

- With the engine cold, remove the spark plug cap.

- Remove the spark plug.

- Using a 10mm adapter, install a compression test manometer on the spark plug housing, and tighten at

the prescribed torque.

- Crank the engine using the starter motor and with the carburettor fully opened, as long as the manometer

reading has stabilized. If the pressure is within the prescribed limits, remove the manometer and refit the

components following the removal procedure in the reverse order.

- If the pressure is below the min allowable pressure, check the engine speed in test conditions. If this is too

low, check the starting system, if this is acceptable, or slightly faster, ensure the proper cylinder base gasket

is installed, and inspect the sealing of the thermal components (piston rings, valves, head, timing system,

etc.).

CHARACTERISTIC

Compression pressure

Min allowable value: 10,5 Kgr

MPRESSION PRE

RE

Engine revs:

~ 630 rpm (starting speed).

Locking torques (N*m)

Tightening torque ~ 10 ÷15 M m

13

Page 14

SMISSIO

CO

ENGINE

ENGINE

AUTOMATIC TRANSMISSION

TRAN

- Remove the seven cover fixing screws.

- Remove the screw and the kick-start.

- Remove the seeger ring and the washer shown in the figure.

- Remove the sector gear.

- Search for excessive wear in the toothed segment, the toothed

segment shaft, the gear shaft and its housing in the crankcase,

and the return spring.

- Replace any damaged part.

- Refit the toothed segment as show in the

figure, pre-loading the spring by hand.

N

VER

- Using the special tool, retain the engine gear shaft.

- Remove the lock nut and then the gear shaft.

Specific tooling

020288Y Gear shaft retaining tool

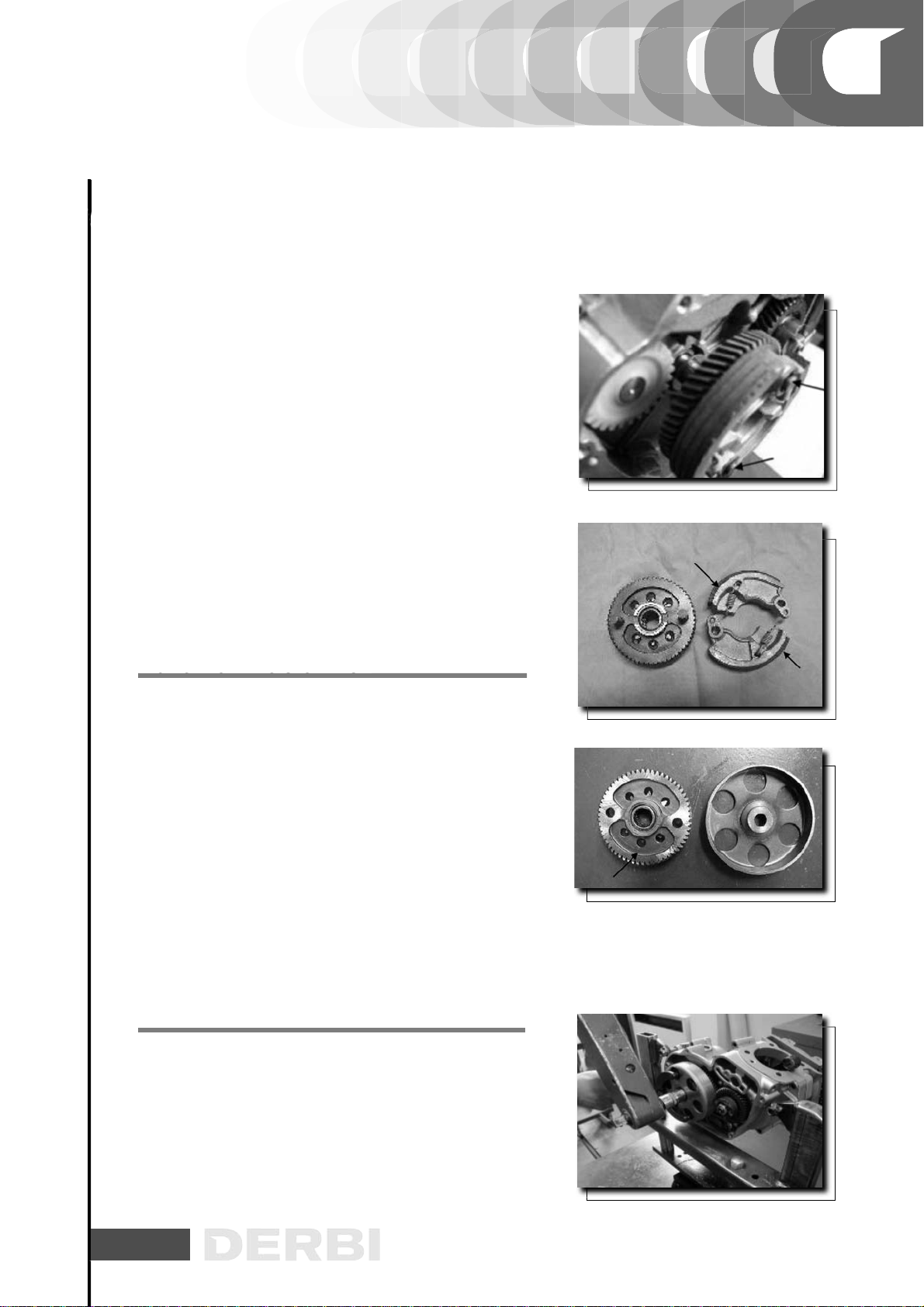

- Remove the clutch masses with their gear.

- Remove the two circlips so to free the clutch masses.

- Ensure the teeth are not deformed and/or worn.

14

Page 15

ENGINE

ENGINE

- Check the thickness of the friction material of the masses.

If the friction material of the mass is found to be missing

the circumferential grooves or cleats, the clutch is to

be considered excessively worn and the masses should

therefore be replaced.

N.B.

WHILE RUNNING-IN, THE MASSES SHOULD SHOW A

CENTRAL CONTACT SURFACE AND MUST DIFFER ONE

FROM THE OTHER. DIFFERENT CONDITIONS MAY CAUSE

A CLUTCH GRABBING PHENOMENON.

CAUTION

DO NOT USE TOOLS TO OPEN THE MASSES, SO TO AVOID

LOAD VARIATIONS IN THE SPRINGS.

- Check that the clutch bell housing is not worn or

damaged.

- Measure the inside diameter of the clutch bell housing.

N.B.

CHECK THE ECCENTRICITY OF THE CLUTCH DRUM AND

ITS KEYING: M AX 0.15 mm.

CHARACTERISTIC

Standard value:

Ø 92 +0,2 -0 mm

Max allowable value:

Ø 92,3 mm

EMOVING THE CLUTCH

- Lock the clutch bell housing with the specific tool.

- Remove the nut, the clutch bell housing and the whole of

the driven pulley assembly.

Specific tooling

020565Y Compass fly wheel stop spanner

15

Page 16

ENGINE

ENGINE

- Before refitting the assembly, carefully grease the roller

bearing inside the gear housing.

- Refit the clutch assembly, the drum washer, and the nut

using the special tool.

-After refitting, ensure the drum spins freely.

Specific tooling

020565Y Compass fly wheel stop spanner

Locking torques (N*m)

Coppia di bloccaggio 40-44 Nm

Insert the chain gear shaft and secure with its circlip, as

shown in the figure.

- Refit the gasket (new).

- Refit the cover tightening the seven screws at the prescribed

torque.

- Refit the oil filler cap.

Locking torques (N*m)

Transmission cover fixing screw: 8 ÷ 10 Nm.

REMOVING THE HUB COVER

Remove the shroud by acting upon the four fittings, as shown

in the figure.

16

Page 17

G

ENGINE

ENGINE

SG

- Remove the two stator fixing screws as shown in the figure.

According to the versions (kick-start/electric). Locking

torques ( N*m)

Flywheel cover fixing screw: 2,5 - 3 Nm

LYWHEEL AND STARTIN

- Restrain the rotation of the flywheel using the special tool.

- Remove the M10X1.25 flanged nut.

- Extract the flywheel with the specially designed extractor.

Specific tooling

020565Y Compass fly wheel stop spanner.

Flywheel tool: 2-claw universal extractor.

Locking torques (N*m)

Flywheel nut 15 Nm

Removing the pick-up:

Remove the two pick-up screws, as shown in the figure.

17

Page 18

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

-

Remove the four tappet cover fastenings; remove the cover

complete with the 0-ring.

N.B.

IN THE CASE OF LONG MILEAGE OR POOR MAINTENANCE,

CLEAN THE OIL BREATER TUBE.

- Remove the chain tensioner central screw, together with its

spring, washer and O-ring.

- Loosen the chain tensioner central screw and remove it

with the spring and the washer.

18

Page 19

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Remove the tappet cover.

- Remove the central screw and the belleville washer shown

in the figure using the specific tool to lock camshaft ring

gear.

- Remove the camshaft drive pulley and the shim below it.

N.B.

TO FACILITATE THE REMOVAL OF THE CYLINDER HEAD

COMPONENTS, IT IS ADVISABLE TO BRING THE CRANKSHAFT TO THE TDC, AT THE END OF THE COMPRESSION

STROKE.

Specific tooling

020565Y Compass fly wheel stop spanner

Remove the bearing check screw shown in the figure.

Remove the camshaft complete with the bearing using the

specific tool shown in the figure.

Eject the bearing from the camshaft using the specific tool

and taking care to fit a screw on the camshaft so as to protect

the camshaft thread.

N.B.

WHENEVER THE BEARING IS SEPARATED FROM THE

CAMSHAFT, REPLACE IT WITH A NEW ONE.

19

Page 20

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

Specific tooling

020450Y Camshaft fitting/removing tool

004499Y Bearing extractor

Remove the rocker arm pivot through the hole on the flywheel side and simultaneously remove the rocker arms.

N.B.

MARK THE INSTALLING POSITION OF EACH ROCKER ARM

SO AS TO AVOID FIT TING THE INTAKE ROCKER AR M IN

PLACE OF THE EXHAUST ROCKER ARM OR VICE VERSA.

- Remove the timing assembly, the camshaft, and the rockerarms.

- Remove the spark plug.

- Remove the two side fastenings shown in the figure.

- Loosen the four cylinder head locknuts in two or three

phases following a crosswise pattern.

- Remove the cylinder head, the two dowel bolts and the

gasket.

N.B.

SHOULD IT BE NECESSARY, THE HEAD MAY BE REMOVED

WITH THE CAM SHAFT AND RACOKERARM PIN. IT SHOULD

BE REMEMBERED, HOWEVER, THAT IT IS THEN NECESSARY

TO HOLD THE CHAIN IN PLACE WITH A METALLIC WIRE AND

CARRY OUT THE CHAIN ADJUSTMENT WHEN REFITTING,

AS DESCRIBED IN THE PARAGRAPH “REFITTING THE TIMING

COMPONENTS”.

- Ensure the chain correctly engages the timing gear-shaft

keyed to the crankshaft, on the flywheel-side.

20

Page 21

-

.

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

OG C SO SS .

Using the specific tool with the part shown in the figure, remove the cotter halves, the caps and the springs from both

valves.

Specific tooling

020382Y Valve fitting/removing tool

EMOVING THE CYLINDER

- Remove the cylinder minding the aligning pin on the crankcase.

- Remove the cylinder base gasket.

CAUTION

TO AVOID DAMAGING THE PISTON, SUPPORT IT WHILE

REMOVING THE CYLINDER.

- Remove the two circlips, the piston pin and the piston.

- Remove the three piston rings.

N.B.

TAKE CARE NOT TO DAMAGE THE PISTON RINGS WHILE

REMOVING THEM.

PISTON ASSY

21

Page 22

N

SC G S

SC G S

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

NSPECTING THE SMALL END

Using an inside micrometer, measure the small end diameter.

N.B.

IF THE DIAMETER OF THE SMALL END IS GREATER THAN

THE MAX ALLOWABLE DIAMETER, OR SHOWS SIGNS OF

WEAR OR OVERHEAT, REPLACE THE CRANKSHAFT.

CHARACTERISTIC

Standard diameter:

13+0,025+0,015 mm

Max. allowable diameter:

13,030mm

NSPECTING THE WRIST PI

Measure the piston pin outside diameter.

CHARACTERISTIC

Standard diameter:

13-0 -0,0 0 4 mm

Minimum allowable diameter:

12,990 mm

Calculate the mating play between the piston pin and the

piston.

CHARACTERISTIC

Piston standard diameter:

13+0,010+0,005 mm

Fitting clearance

Wrist-pin/piston fitting clearance (standard): 0,005 - 0,014 mm

22

Page 23

SPEC

ON

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Measure the piston outside diameter perpendicularly to the

piston pin axis.

- Take the measurement 27 mm from the piston top as

shown in the figure.

CHARACTERISTIC

Piston diameter:

38,982 - 38,954

- Using a bore meter, measure the cylinder inside diameter

at three different heights in the directions shown in the figure.

- Check that the mating surface with the cylinder head is not

worn or distorted.

CHARACTERISTIC

Standard cylinder diameter:

39,024 - 38,996

Maximum allowable runout:

0,05 mm

Pistons and cylinders are classified according to diameter.

Mating is obtained by matching class letters (A-A, B-B, C-C,

D-D).

IN

- Fit a comparator on the specific tool and then place both

parts on a surface plate.

- Reset the comparator on the surface plate. While maintaining the resetting position, fit the tool to the cylinder and

fasten it with two nuts as shown in the figure.

- Rotate the crankshaft to the TDC (comparator rotation inversion point).

TING THE PIST

23

Page 24

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Measure the piston protrusion compared to the head plane

and use the chart below, to determine the proper base gasket thickness. The proper base gasket thickness guarantees

the engine will run at the correct compression ratio.

- Remove the specific tool and the cylinder.

CHARACTERISTIC

Compression ratio:

11,5÷ 12,5:1

Cylinder height:

57,15 ± 0,15

Cylinder base gasket thickness:

0,5

Measured value: - 0,40 / - 0,25

Gasket thickness: 0,25 ± 0,05

Measured value: - 0,25 / - 0,05

Gasket thickness: 0,35 ± 0,05

- Carefully clean the piston ring grooves using an old piston

ring.

- Using a reed thickness gauge, measure the play between

the piston rings and the grooves as shown in the figure.

- If any play is found to be greater than specified in the table

below, replace the piston and the piston rings.

24

Page 25

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

STANDARD MATING PLAY

NAME

1º Ring

2º Ring

Scraper

DIMENSIONS

0,030 ÷ 0,065 mm

0,020 ÷ 0,055 mm

0,040 ÷ 0,160 mm

MAXIMUM ALLOWABLE PLAY AFTER USE

NAME

1º Ring

2º Ring

Scraper

DIMENSIONS

0,080 mm

0,070 mm

0,20 mm

INITIALS

INITIALS

QUANTITY

QUANTITY

- Alternately insert the three piston rings into the cylinder, in

the area where it retains its original diameter.

- Using the piston, insert the rings perpendicularly to the

cylinder axis

- Using a thickness gauge (see figure), measure the gaps of

the piston rings.

- If any measurements are greater than prescribed, replace

the piston rings.

25

Page 26

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

N.B.

BEFORE REPLACING THE PISTON RINGS ONLY, ENSURE

THAT THE CLEARANCE BETWEEN THE PISTON RINGS AND

THE PISTON RING GROOVES, AND BETWEEN THE PISTON

AND THE CYLINDER, IS AS SPECIFIED. IN ANY CASE, NEW

PISTON RINGS USED IN COMBINATION WITH A USED CYLINDER MAY HAVE DIFFERENT BEDDING CONDITIONS THAN

THE STANDARD.

STANDARD GAP

NAME

1º Ring

2º Ring

Scraper

MAXIMUM GAP

NAME

1º Ring

2º Ring

Scraper

DIMENSIONS

0,08 ÷ 0,20 mm

0,05 ÷ 0,20 mm

0,20 ÷ 0,70 mm

DIMENSIONS

0,35 mm

0,30 mm

0,8 mm

INITIALS

INITIALS

QUANTITY

QUANTITY

26

Page 27

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Fit the piston and the piston pin to the connecting rod. The

arrow on the piston must face the exhaust side.

- Insert the piston pin circlip into the specially designed tool.

- With the gap in the position shown on the tool, fit the circlip

into the tool by means of the drift.

- Rest the tool on the piston taking care that the side with the

90° bevel always faces upwards as shown in the figure.

- Fit the piston pin circlip using the tommy.

CAUTION

USING A HAMMER TO FIT THE CIRCLIPS CAN DAMAGE THE

CIRCLIP SEATS.

Specific tooling

0204484YIIK Piston pin circlip fitting tool

27

Page 28

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Fit the scraper starting with the spring. Ensure that the scraper ends do not overlap.

- Fit the two piston rings so that their gaps and that of the

scraper are never aligned.

- Fit the 2nd piston ring with the identification letter «T» facing the piston top.

- Fit the 1st piston ring with the «T» reference mark facing

the piston top.

N.B.

TO ENSURE OPTIMUM BEDDING, THE TWO PISTON RINGS

HAVE CONICAL SECTIONS IN THE AREAS OF CONTACT

WITH THE CYLINDER. FOR THIS REASON, IT IS IMPORTANT

THAT THE RINGS SHOULD BE FITTED WITH THE «T» FACING

UPWARDS. STAGGER THE PISTON RING GAPS BY 120 DEGREES AS SHOWN IN THE FIGURE. LUBRICATE THE PARTS

WITH ENGINE OIL.

Install the base gasket with the previously determined thickness. Carry out the refitting procedure for the cylinder as

shown in the figure.

Ensure to drive the timing chain through its housing while

maintaining it engaged on the timing gearshaft.

CHARACTERISTIC

Cylinder base gasket thickness:

0,5

28

Page 29

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

N.B.

SEE “REFITTING THE TIMING CHAIN”, TO BE CARRIED OUT

BEFORE RECOUPLING THE HALFCR ANKCASES.

- Insert the spacer on the camshaft.

- Using the markings on flywheel and stator mounting bracket, position the piston at the TDC.

- Insert the chain tensioning rod and secure it in its housing.

It is possible to hold the piston out of the crankcase plane,

using the special tool.

N.B.

BEFORE REFITTING THE CYLINDER, CAREFULLY BLOW THE

LUBRICATION DUCT AND OIL THE CYLINDER BARREL.

Specific tooling

020288Y Fork for fitting piston to cylinder

Locking torques (N*m)

Timing chain tensioner screw: 8 ÷ 10 Nm

NSPECTING THE CYLINDER HEAD

Using a trued bar, check that the cylinder head surface is not

worn or distorted.

CHARACTERISTIC

Maximum allowable runout:

0,05 mm

- Ensure that the camshaft and rocker arm pivot bearings

show no signs of wear.

- Check that the cylinder head cover surface, the intake manifold and the exhaust manifold are not worn.

29

Page 30

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

STANDARD DIAMETER

SPECIFICATIONS

Standrad diameter A:

Standrad diameter B:

Standrad diameter C:

- Check that the guide shoe and the tensioner shoe are not

worn out.

DESC. / QUANTITY

Ø 32,015 ÷ 32,025 mm

Ø 16,0 ÷ 16,018 mm

Ø 11,0 ÷ 11,018 mm

- Ensure that the camshaft drive pulley, the chain assembly

and the pinion are not worn.

- Replace any worn components. If the chain, pinion or

pulley are worn, replace the whole assembly.

- Removing the central screw with the O-ring and the chaintensioner spring. Ensure the unidirectional mechanism is not

worn.

- Check the condition of the tensioner spring.

- If any worn components are found, replace the whole

assembly.

30

Page 31

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

Measure the width of the sealing surface on the valve seats.

CHARACTERISTIC

Sealing surface width

Intake: 1,5 m m

Exhaust: 1,6 m m

- Remove any carbon formation from the valve guides.

- Measure the inside diameter of each valve guide.

- Take the measurement at three different heights in the rocker arm push direction.

EXHAUST GUIDE

SPECIFICATION

Standard diameter:

Wear limit:

INTAKE GUIDE

SPECIFICATION

Standard diameter:

Wear limit:

- If the width of the impression on the valve seat or the diameter of the valve guide exceed the prescribed limits, replace the cylinder head.

- Measure the width of the impression on valve seat «V», the

wear limit being 1.6 mm.

DESC. / QUANTITY

5 + 0 + 0,012 mm

5,022 mm

DESC. / QUANTITY

5 + 0 + 0,012 mm

5,022 mm

31

Page 32

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Insert the valves into the cylinder head.

- Alternately test the intake and exhaust valves.

- The test is carried out by filling the manifold with petrol and

checking that no petrol oozes through the valves when these

are pressed with one finger.

- Measure the diameter of the valve stem at the three positions shown in the figure.

- Calculate the clearance between the valve and the valve

guide.

- Check that the mating surface with the adjuster articulated

terminal is not worn.

- Should the valve sealing area be greater than the prescribed limit, or if any bending or gaps are noted, replace the

valve.

- If no anomalies are found during the above checks, the

same valves can be reused.

- For best sealing results, it is advisable to grind the valves.

- Grind the valves gently with a fine-grained lapping compound.

- During the grinding, keep the cylinder head in a horizontal

position. This will prevent the lapping compound residues

from penetrating between the valve stem and the guide.

CAUTION

TO AVOID SCORING THE MATING SURFACE, DO NOT KEEP

ROTATING THE VALVE WHEN NO LAPPING COMPOUND

IS LEFT. CAREFULLY WASH THE CYLINDER HEAD AND THE

VALVES WITH A SUITABLE PRODUCT FOR THE TYPE OF LAPPING COMPOUND BEING USED.

32

Page 33

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

CHARACTERISTIC

Minimum allowable diameter - Intake:

4,970 mm

Minimum allowable diameter - Exhaust:

4,960 mm

Standard clearance - Intake:

0,015 ÷ 0,042 mm

Standard clearance - Exhaust:

0,025 ÷ 0,052 mm

Maximum allowable clearance - Intake:

0,052 mm

Maximum allowable clearance - Exhaust:

0,062 mm

Valve standard length - Intake:

70,1 mm

Valve standard length - Exhaust:

69,2 mm

-

Check that the upper spring caps and the cotter halves show

no signs of abnormal wear.

- Lubricate the valve guides with graphitized oil.

- Position the valve spring lower caps on the cylinder head.

- Using the specific drift, alternately insert the two seal

rings.

- Fit the valves, the springs and the upper caps.

- Using the specific tool, compress the springs and insert the

cotter halves into their seats.

Specific tooling

020306Y Valve oil seal fitting drift

020382Y Valve fitting/removing tool

33

Page 34

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Ensure that the camshaft bearings are not abnormally

worn.

- If any measurements or values are not as specified, proceed to replace the defective parts.

N.B.

A BALL BEARING IS PITTED ON BEARING «A»; CONSEQUENTLY, BEARING «B» IS MORE IMPORTANT BECAUSE IT

WORKS DIRECTLY ON THE ALUMINIUM OF THE CYLINDER

HEAD.

CHARACTERISTIC

Standard diameter - Bearing A:

Ø 12+0,002+0,010 mm

Standard diameter - Bearing B:

Ø 16-0,015-0,023mm

Minimum allowable diameter - Bearing A:

Ø 11,98mm

Minimum allowable diameter - Bearing B:

Ø 15,96 mm

Standard height - Intake:

25,935 mm

Standard height - Exhaust:

25,935 mm

Maximum allowable axial play:

0,5 mm

- Ensure that the rocker arm pivot is not worn or scored.

- Measure diameter «A».

- Measure the inside diameter of each rocker arm «B».

- Check that the cam contact shoe and the adjuster articulated cap are not worn.

34

Page 35

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Replace any damaged parts.

CHARACTERISTIC

Minimum allowable diameter «A»:

Ø 10,970mm

Minimum allowable diameter «B»:

Ø 11,030 mm

- Rest the cylinder head steadily on a worktable.

- Screw on the camshaft fitting tool to its abutting end on the

bearing inner race.

- Push the camshaft in its housing, fitted with the bearing, as

far as it goes. Remove the tool.

- After having carefully cleaned all the contact surfaces,

install a new head gasket with the same thickness as the old

one.

- Insert the cylinder holding-down studs into the cylinder

head and tighten the four locknuts with a torque indicate.

N.B.

REPLACE THE CAMSHAFT BEARING WITH A NEW ONE

WHENEVER IT IS REMOVED.

Specific tooling

020450y Camshaft fitting/removing tool

Locking torques (N*m)

Head-cylinder stud nut:

6-7 +135° +90° N-m for first fitting, 6 - 7 90° +90° N-m for

refitting/locking

- Loosen the rocker arm adjusters.

- Fit the pivot and the intake and exhaust rocker arms.

- Lubricate the two rocker arms through the holes.

35

Page 36

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Tighten the pivot and camshaft check screw complete with

the washer shown in the figure.

Locking torques (N*m)

Rocker-arm shaft and camshaft bearing screw: 3 - 4 Nm

- To complete the fastening of the cylinder head, tighten the

four cylinder head nuts in two phases in a crosswise pattern

to a torque of 8 -10 N-m.

- Lock with the same torque used for the two side fixings.

- Continue tightening the nuts by giving them three 90-degree turns, following in a crosswise pattern. First locking: 6

- 7 Nm +135° +90° Relocking: 6 - 7 Nm +90° +90°FoIlowing the order indicated

N.B.

SEE “REFITTING THE TIMING CHAIN”, TO BE CARRIED OUT

BEFORE RECOUPLING THE HALFCR ANKCASES.

- Insert the spacer on the camshaft.

- Using the markings on flywheel and stator mounting bracket, position the piston at the TDC.

- Insert the chain tensioning rod and secure it in its housing.

- Ensure the chain correctly engages the timing gear-shaft

keyed to the crankshaft, on the flywheel-side.

- While keeping the piston in position, fit the chain on the

camshaft drive pulley, while maintaining the reference notch

aligned with the mark on the cylinder head.

36

Page 37

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

- Fit the pulley on the camshaft.

- Fit the belleville washer so that its outer rim is in contact

with the pulley.

- Turn in the screw until it makes contact, without tightening

it fully.

- Slightly press the tensioner shoe to verify the valve gear

timing.

- Using the specific tool, lock the camshaft ring gear and

then tighten the screw.

- Carry out the valve clearance adjustment procedure as

described in the «lnspecting/adjusting the valve clearance»

paragraph.

- Replace the 0-ring on the tappet cover.

- Fit the tappet cover and fasten it using the four fixing screws

shown in the figure.

Specific tooling

020565Y Compass fly wheel stop spanner

Locking torques (N*m)

Camshaft pulley screw:

12 - 14 Nm Head cover screw: 8-10 Nm

- Set the tensioner slider in its home position.

- Install the tensioner on the cylinder using a new gasket;

hence tighten the screws with the prescribed torque.

- Insert the spring with the central screw and the O-ring,

hence tighten the cap with the prescribed torque.

- Fit the spark plug.

CHARACTERISTIC

Recommended spark plug

Champion RG 4 HC

Electric characteristic

Electrode gap

mm 0,7 ÷ 0,8

Locking torques (N*m)

Timing chain tensioner screw:

8 ÷ 10 Nm

Timing chain tensioner central screw:

5 ÷ 6 Nm

Spark plug:

10 ÷ 15 Nm

37

Page 38

P

ENGINE

- CYLINDER ASSY. AND TIMING SYSTEM

ENGINE - CYLINDER ASSY. AND TIMING SYSTEM

SC G G

NSPECTING THE RADIAL AIR GA

Inspecting the kick-starter:

- Using a thickness gauge, measure the two metallic protrusions. Values: 0.2 ÷ 0.3 mm.

- Ensure the pick-up air is between 2.0 and 2.6 mm

- The pick-up refitting procedure does not include the adjustment of the air gap.

- Values different from the above, are due to deformations of

the pick-up mounting bracket.

Locking torques (N*m)

Stator/mounting bracket fixing screws: (M4x16) 2 ÷ 3 Nm

Pick-up/flywheel-side halfcrankcase fixing screws: (M6x16)

8 ÷ 10 Nm Mounting bracket for stator assy ./flywheel-side

half-crankcase fixing screws: (M6x20) 8 ÷ 10 Nm Flywheel fixing flanged-nut: (M10x1,25) 15 Nm Flywheel cover/

flywheel-side half-crankcase fixing screw: (M5x20) 2,5 ÷

3 Nm.

Follow the removal operations in the reverse order, tightening the four screws with the prescribed torque.

N.B.

FIT A NEW 0-RING ON THE ROCKER-ARMS COVER.

Locking torques (N*m)

Head cover screw: 8 ÷ 10 Nm

38

Page 39

ENGINE

- CRANKCASE - CRANKSHAFT

ENGINE - CRANKCASE - CRANKSHAFT

- Remove the following assemblies: Transmission cover,

clutch, gears, as described in the related paragraphs: «Removing the transmission cover», «Removing the clutch», and

«Removing the gear-shafts.

- For kick-start versions, remove the flywheel shroud, the

flywheel, the stator mounting, and the pick-up, as described

in the related paragraphs «Removing the flywheel shrouds,

«Removing the fly wheel magnetos, and «Removing the stator».

- For electric starter versions, remove the Bendix mounting

and the starter motor as described in the paragraph «Removing the starter motors.

- Remove the cylinder-piston-head assembly as described in

the related paragraphs.

- Remove the ten half-crankcase coupling screws. Split the

crankcase-halves, with the crankshaft remaining installed in

the flywheel-side half.

- Remove the crankshaft, by heating the halfcrankcase up to

about 120 °C with the aid of a heat gun.

N.B.

MIND THE LOOSE COMPONENTS INSIDE THE CR ANKCASE: CLUTCH SHAFT, TIMING CHAIN GEAR-SHAFT, AND

TWO REFERENCE PINS.

- Remove the flywheel-side oil seal from the crankcase,

paying attention in avoiding scratching or scoring the crankcase.

- Abundantly lubricate the new oil seal and its housing on

the crankcase with engine oil, before fitting.

- Position the crankshaft on the base of the support.

- Install the bearing.

- Using the special tool, refit the timing gearshaft.

39

Page 40

ENGINE

- CRANKCASE - CRANKSHAFT

ENGINE - CRANKCASE - CRANKSHAFT

ALIGNMENT

- Rest the flywheel-side crankcase-half on a flat surface,

adequately supported and with the crankshaft vertical.

- Insert the timing chain positioning it at the edge of its

housing so that in won’t interfere with the refitting of the

crankshaft assembly, the bearing, and the timing gearshaft.

- Heat the crankcase-half up to approx. 120 °C, using a heat

gun.

- Install the bearing on the crankcase with utmost care in

order to avoid damaging the bearing housing.

Place the crankshaft on the stand and measure the runout at

the three points shown in the figure.

Check the condition of the crankshaft cone, the tab seat, the

oil seal bearing, the knurled pin and the threaded tangs. If

any anomalies are found, replace the crankshaft.

NB

IF THE RUNOUT MEASUREMENTS SLIGHTLY EXCEED THE

SPECIFIED LIMITS, TRY TO STR AIGHTEN THE CRANKSHAFT

BY INSERTING A WOODEN WEDGE BETWEEN THE SHAFTS

OR, IF NECESSARY, BY CLAMPING THEM IN A VICE. IF,

DESPITE THE STR AIGHTENING, THE VALUES ARE NOT AS

SPECIFIED, PROCEED TO REPLACE THE CRANKSHAFT.

Specific tooling

020074Y Crankshaft aligning tool

020335Y Magnetic stand and comparator

CHARACTERISTIC

Max allowable misalignments:

A = Ø 0,05 mm

B = Ø 0,04 mm

C = Ø 0,04 mm

40

Page 41

ENGINE

- CRANKCASE - CRANKSHAFT

ENGINE - CRANKCASE - CRANKSHAFT

- Check the connecting rod axial play.

- While holding the crankshaft manually, check the connecting rod radial play. Measure the play with a comparator placed on the tip of the connecting rod small end while moving

the connecting rod vertically as shown in the figure.

- Check that the surface of both crankshaft halves is not scored. Using a calliper, measure the width of the crankshaft as

shown in the figure.

CHARACTERISTIC

Standard crankshaft width:

Fitting clearance

45 mm

Standard axial clearance:

0,15-0,30 mm

Standard radial clearance:

0,006 - 0,018 mm

Max allowable radial clearance:

0,25 mm

41

Page 42

ENGINE

- CRANKCASE

ENGINE - CRANKCASE

- Using a heat gun, heat the bearing housing on the

transmission-side crankcase-half up to approximately 120

°C. Install the bearing and the oil conveying plate with its

gasket, tightening the three screws at the prescribed torque,

as shown in the figure. Install the clutch shaft bearing and

secure with the circlip, as indicated in the figure.

Pay attention in positioning the clutch shaft and the chain

gear-shaft.

- Refit the oil pump on the crankcase and secure it by

tightening the two screws with the prescribed torque.

- Install the two locating pins, preferably on the transmissionside crankcase-half.

- Lubricate the housings with the engine oil as shown in the

figure. Install the gasket using the two pins as a reference.

- Adjoin the two crankcase-halves and tighten the ten screws

with the prescribed torque.

Locking torques (N*m)

Oil conveying plate fixing screws (half-crankcase transmission

side): 8 ÷ 10 Nm

Oil pump / crankcase fixing screws: 2 ÷ 3 Nm

42

Page 43

ENGINE

- CRANKCASE

ENGINE - CRANKCASE

- Lubrificare con olio motore Ie rispettive sedi come

indicate in figura. Montare la guarnizione utilizzando come

riferimento i due grani.

- Accostare i due carter e montare Ie 10 viti e bloccare alia

coppia prescritta.

Locking torques (N*m)

Half-crankcase joining screws: 8 ÷ 10 Nm

43

Page 44

ENGINE

- OIL PUMP

ENGINE - OIL PUMP

CRANKSHAFT OIL SEALS

Removal

- Extract the flywheel-side oil seal from the crank- case

taking care not to damage or score the crankcase.

- Pour engine oil over the oil seal and its seat in the

crankcase.

- Operating from the outside with the specific drift, push the

oil seal fully home into its seat in the crankcase.

Specific tooling

020340Y Fly wheel-side oil seal fitting drift Oil pump

INSPECTION

- Remove the two oil pump fixing screws.

- Remove the inner rotor circlip.

- Remove the rotors and carefully clean them with a

degreasing solvent and compressed air.

- Refit the two impellers with pump body and install the

circlip.

Using a thickness gauge, measure the distance between the

rotors (inner rotor - outer rotor) at the position shown in the

figure.

CHARACTERISTIC

Maximum allowable clearance:

0,15 mm

44

Page 45

ENGINE

- OIL PUMP

ENGINE - OIL PUMP

Measure the distance between the outer rotor and the pump

body (see figure).

CHARACTERISTIC

Maximum allowable clearance:

0,20 mm

Check the axial play of the rotors using a trued bar as shown

in the figure.

N.B.

ENSURE THAT THE TRUED BAR RESTS PROPERLY ON TWO

POINTS OF THE PUMP BODY PLANE.

CHARACTERISTIC

Maximum allowable clearance:

0,09 mm

- Check that the pump cover is not worn or scored.

- If any measurement is not as specified, or if any part is

scored, replace the part or the assembly.

- Fit the oil pump to the crankcase and tighten the two fixing

screws with the prescribed torque.

- Ensure that the pulley rotates smoothly, with no jerks or

friction.

Locking torques (N*m)

Oil pump / crankcase fixing screws:

2 ÷ 3 Nm

45

Page 46

ENGINE

- CARBURETTOR

ENGINE - CARBURETTOR

REMOVING THE CARBURETTOR

- In order to detach the carburettor from the engine, loosen

the intake manifold and reed-valve pipe clamp screw.

- To carry out further operations on the carburettor, disconnect the throttle cable and the fuel supply tube.

- Loosen the two fixing screws indicated in the figure and

remove the float bowl with its seal.

- Remove the jets (main and idling) and ensure they are not

obstructed.

- Remove the float with the fuel needle.

- Remove the throttle valve cover, paying attention to the

attached components (throttle valve, conical needle, and

return spring).

CAUTION

DO NOT ATTEMPT REMOVING COMPONENTS ATTACHED

TO THE CARBURETTOR BODY, SUCH AS: FUEL SUPPLY

DUCT, NEEDLE HOUSING, STARTER JET, AND ATOMISER.

- Before refitting the carburettor, carefully clean the carburettor body with a degreasing solvent and compressed air.

- Pay special attention to the fuel intake duct and the needle

seat.

- Wash and carefully blow the idling and main jets, the starter jet on the float bowl, the throttle valve, and the conical

needle.

46

Page 47

ENGINE

- CARBURETTOR

ENGINE - CARBURETTOR

- Should anomalies be observed for these components, proceed with the replacement.

- Refit the throttle valve cover.

- Refit the main and idling jets.

- Refit the float and its conical needle.

- Refit the float bowl ensuring the seal is properly positioned

in its housing.

WARNING

TO AVOID DAMAGE, DO NOT INSERT METAL OBJECTS IN

THE CALIBRATED SECTIONS.

ADJUSTING THE CARBURETTOR

Main jet

Minimum jet

Position-needle

Emulsifier

Air Screw

80

32

A-2 at the 2nd

210 GA

2 Turns

47

Page 48

create by: www.ciandisseny.com

Loading...

Loading...