Page 1

For U.S.A. & Canada model

SERVICE MANUAL

Ver. 1

MODEL

SPEAKER SYSTEM PACK

SYS-57HT

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

Denon Brand Company, D&M Holdings Inc.

●

●

●

●

TOKYO, JAPAN

本機の仕様は性能改良のため、予告なく変更すること

があります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

X0284 V.01 DE/CDM 0607

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power

cord is less than 460 kohms, the unit is defective.

SYS-57HT

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such as

the cabinet, parts, chassis, etc., have cautions indicated on

labels or seals. Be sure to heed these cautions and the cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching inter-

nal metal parts when the set is energized could cause

electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when

servicing while the set is energized, unplugging the power

cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra care

when the set is energized.

◎

Caution concerning disassembly and assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are moved

across them. Use gloves to protect your hands.

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked ! on wiring

diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange the

wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the

surface of printed circuit boards. Care is also taken with the

positions of the wires inside and clamps are used to keep

wires away from heating and high voltage parts, so be sure to

set everything back as it was originally.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation

check on the external metal connectors and between the

blades of the power plug, and otherwise check that safety is

ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the

antenna, plugs, etc., and turn the power switch on. Using a

500V insulation resistance tester, check that the insulation resistance between the terminals of the power plug and the externally exposed metal parts (antenna terminal, headphones

terminal, microphone terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and repaired.

CAUTION

Many of the electric and structural parts used in the set have

special safety properties. In most cases these properties are

difficult to distinguish by sight, and using replacement parts

with higher ratings (rated power and withstand voltage) does

not necessarily guarantee that safety performance will be preserved. Parts with safety properties are indicated as shown

below on the wiring diagrams and parts lists is this service

manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the ! mark.

(2) Parts lists ... Indicated by the ! mark.

Concerning important safety parts

Using parts other than the designated parts

could result in electric shock, fires or other

dangerous situations.

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所についてはキャ

ビネット、部品、シャーシなどにラベルや捺印で注意事項を

表示しています。これらの注意書きおよび取扱説明書などの

注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電時

に内部金属部に触れると感電することがあります。従っ

て通電サービス時には、絶縁トランスの使用や手袋の着

用、部品交換には、電源プラグを抜くなどして感電にご

注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱に

は十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をして

おりますが、板金端面は鋭利となっている箇所が有りますの

で、部品端面に触れたまま指を動かすとまれに怪我をする場

合がありますので十分注意して作業して下さい。手の保護の

ために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持った

ものとなっています。従って交換部品は、使用されていたも

のと同じ特性の部品を使用してください。特に配線図、部品

表に!印で指定されている安全上重要な部品は必ず指定の

ものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、プ

リント基板から浮かして取付けた部品があります。また内部

配線は引きまわしやクランパーによって発熱部品や高圧部

品に接近しないように配慮されていますので、これらは必ず

元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元どお

りになっているか、またサービスした個所の周辺を劣化させ

てしまったところがないかなどを点検し、外部金属端子部

と、電源プラグの刃の間の絶縁チェックをおこなうなど、安

全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグな

どを外し、電源スイッチを入れます。500V 絶縁抵抗計を用

いて、電源プラグのそれぞれの端子と外部露出金属部[アン

テナ端子、ヘッドホン端子マイク端子、入力端子など]との

間で、絶縁抵抗値が1 MΩ 以上であること、この値以下の

ときはセットの点検修理が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安全

上、特別な特性を持っています。この特性はほとんどの場合、

外観では判別つきにくく、またもとの部品より高い定格(定

格電力、耐圧)を持ったものを使用しても安全性が維持され

るとは、限りません。安全上の特性を持った部品は、この

サービスマニュアルの配線図、部品表につぎのように表示し

ていますので必ず指定されている部品番号のものを使用願

います。

(1) 配線図…

(2) 部品表…

安全上重要な部品について

!マークで表示しています。

!マークで表示しています。

指定された部品と異なるものを使用した場合に

は、感電、火災などの危険を生じる恐れがあり

ます。

2

Page 3

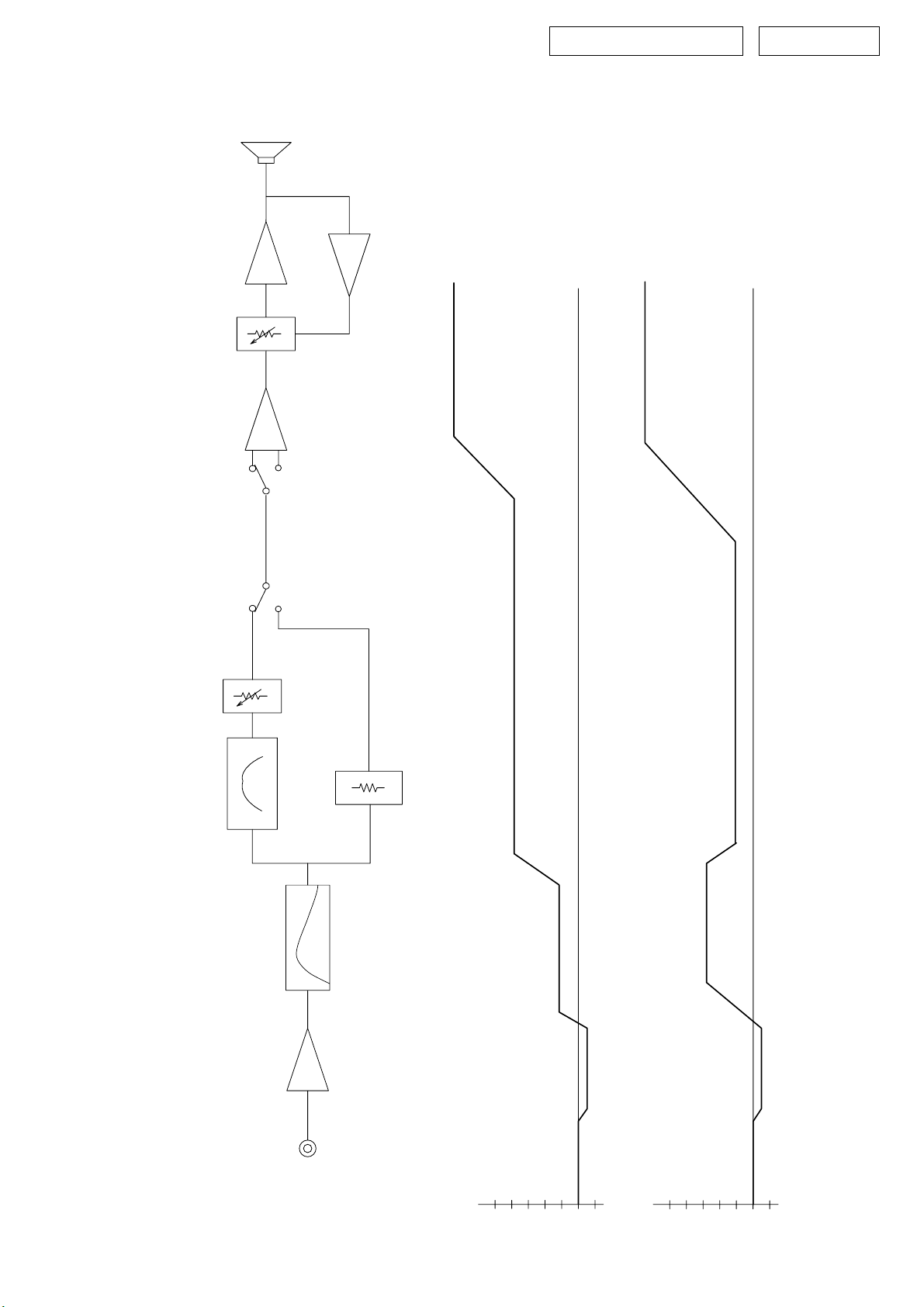

DSW-76(Black) BLOCK/LEVEL DIAGRAM

SPEAKER

U203

ALC

POWER AMPREVERSE PHASE

DSW-76(Black) Section

SYS-57HT

U203

NORMAL

SW202

DIRECT

VOL

MODE SW

at 55Hz

+50.5dB 20V/4ohrm THD 0.7% (ALCON)

at 55Hz

20V/4ohrm THD 0.7% (ALCON)

+27.2dB

+1.84dB

CONTROL

CROSSOVER

HPF

U201

LINE INPUT

ATT

DIRECT MODE

(dB)

+20dB

40

+4.34dB

75mV

0

20

-1dB

10

-

(dB)

+4.34dB

20

40

-1dB

830mV

0

10

-

3

Page 4

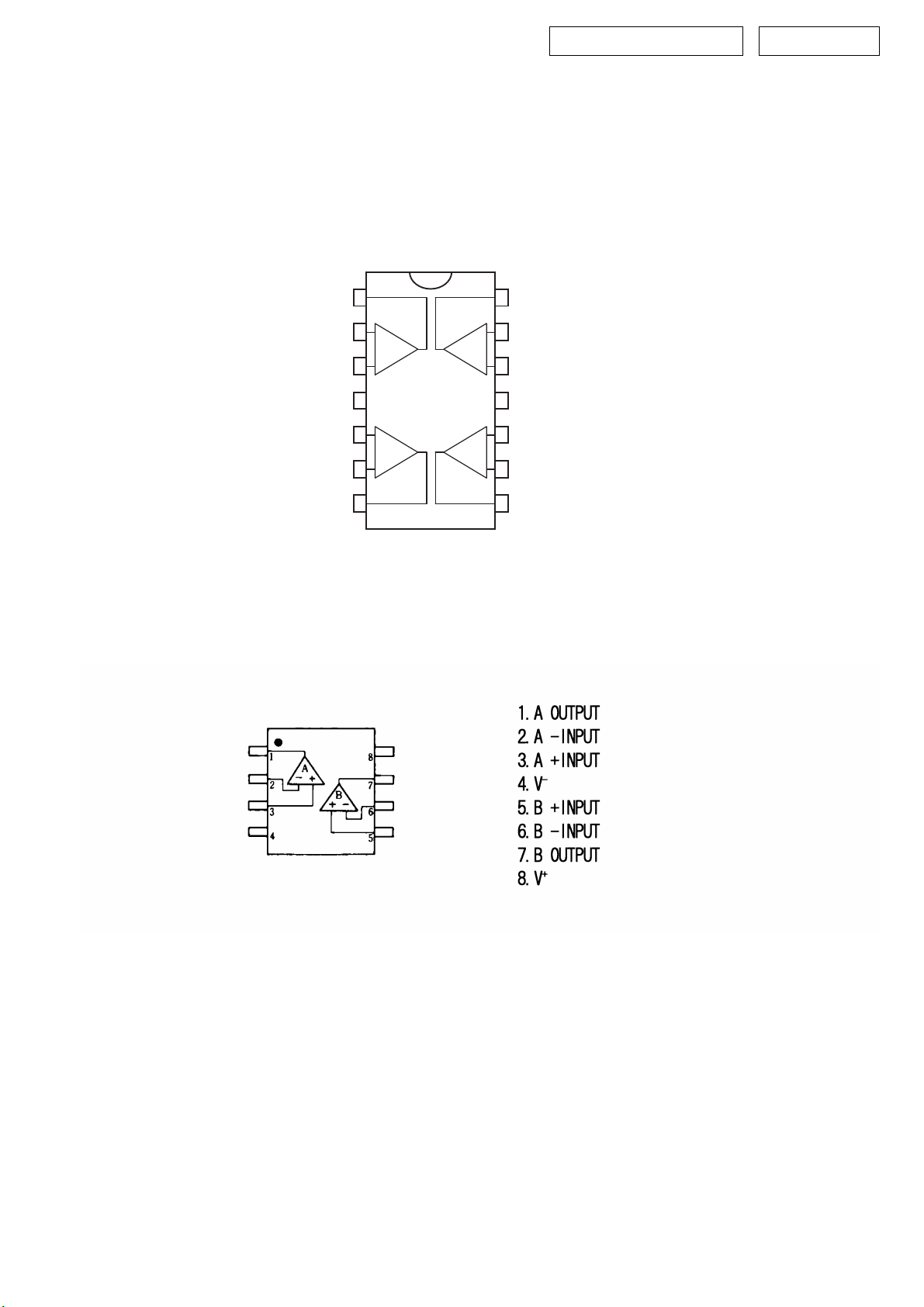

DSW-76(Black) SEMICONDUCTORS

Only major IC's are shown,generai IC's etc. are omitted to list.

主な半導体を記載しています。汎用の半導体は記載を省略しています。

IC's

TL074CN (U201-203) PRE-AMP P.W.B. UNIT

DSW-76(Black) Section

SYS-57HT

CC

1

2

-

+

3

+

4

5

+

-

6

7

-

+

+

-

Output 1

Inverting Input 1

Non-inverting Input 1

V

Non-inverting Input 2

Inverting Input 2

Output 2

NJM4558D (U101) AMP P.W.B. UNIT

14

Output 4

13

Inverting Input 4

12

Non-inverting Input 4

-

V

11

CC

10

Non-inverting Input 3

9

Inverting Input 3

8

Output 3

4

Page 5

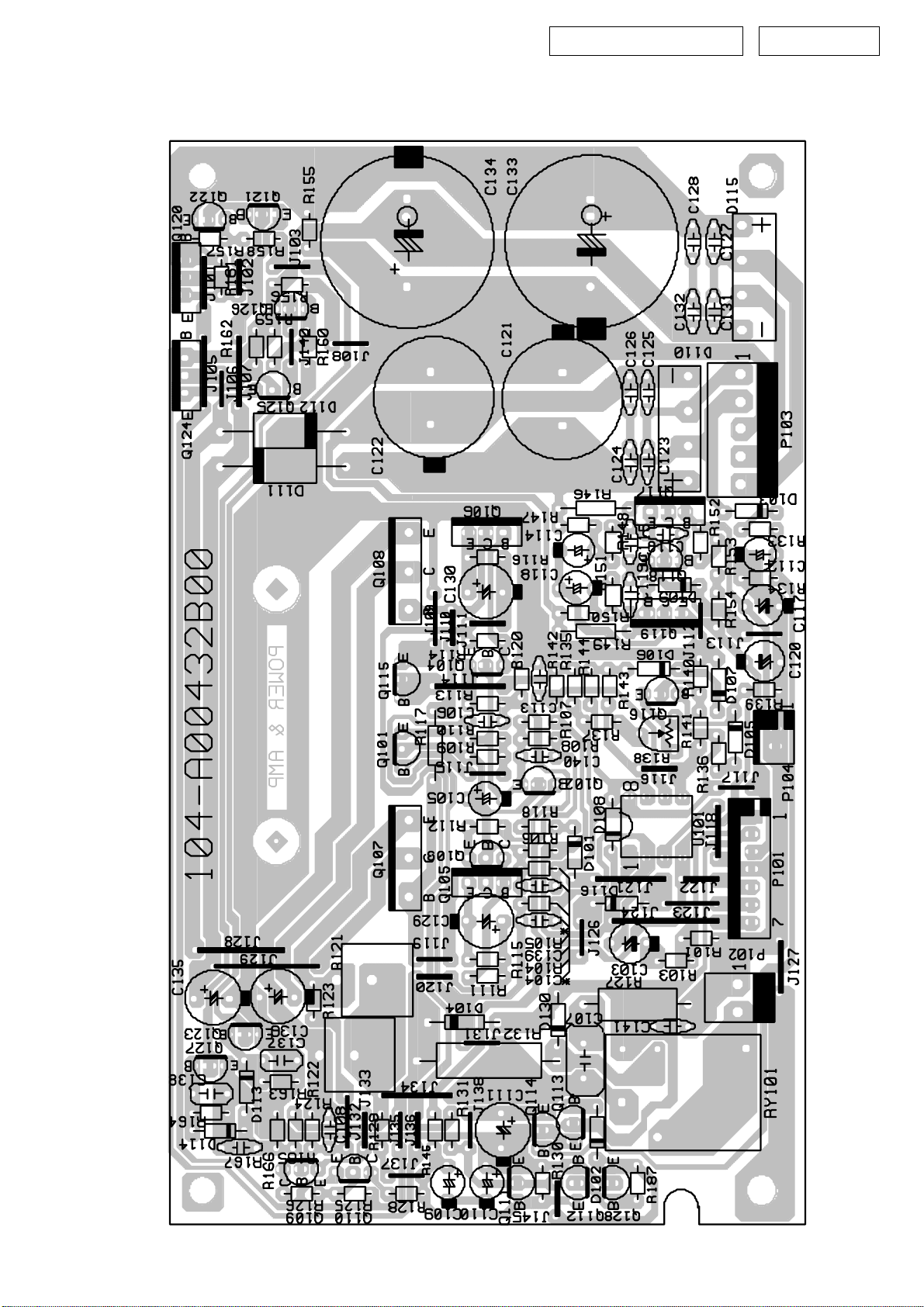

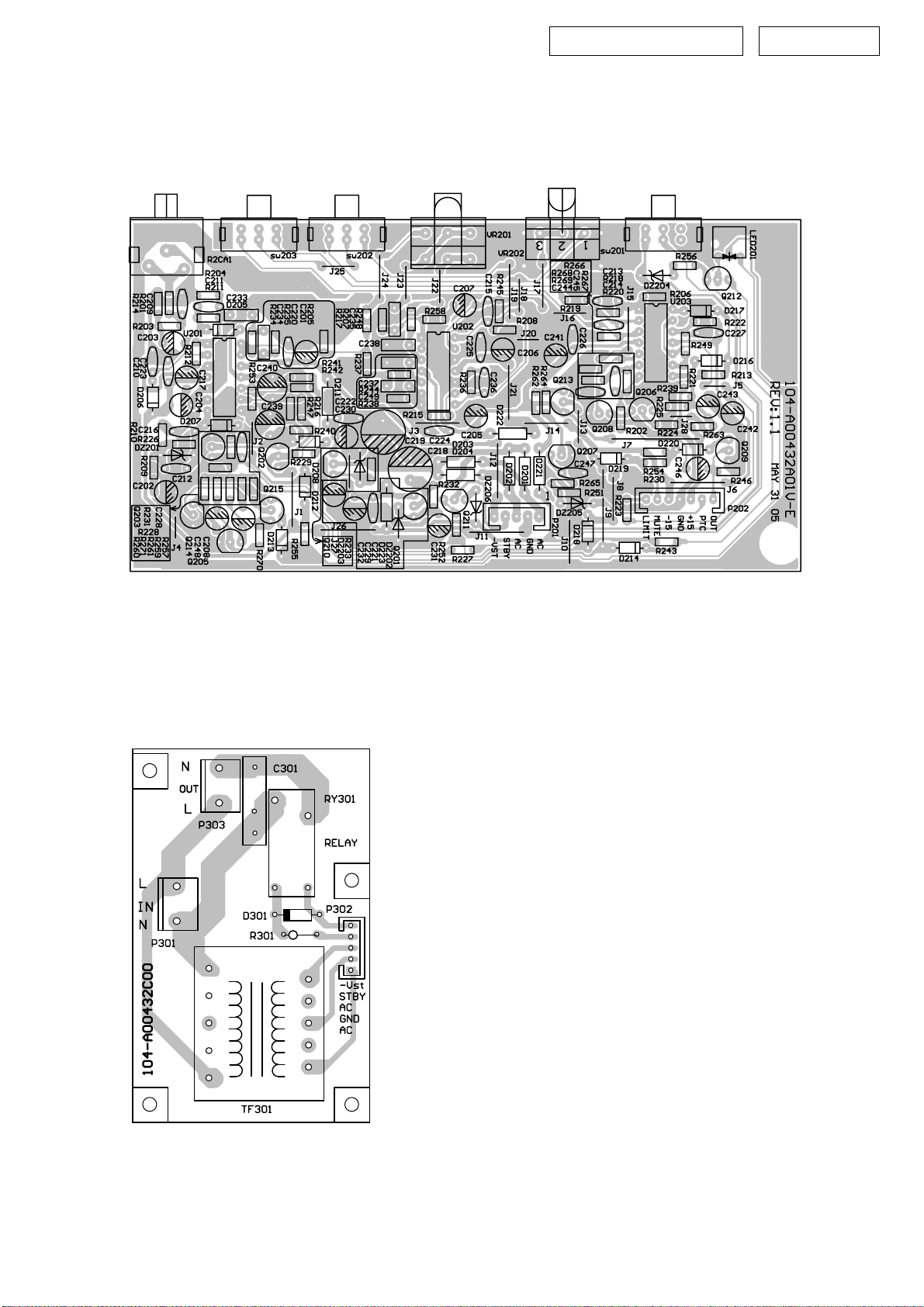

DSW-76(Black) PRINTED WIRING BOARDS (1/2)

AMP P.W.B. UNIT

DSW-76(Black) Section

SYS-57HT

5

Page 6

DSW-76(Black) PRINTED WIRING BOARDS (2/2)

PRE-AMP P.W.B. UNIT

DSW-76(Black) Section

SYS-57HT

POWER P.W.B. UNIT

6

Page 7

SYS-57HTDSW-76(Black) Section

NOTE FOR PARTS LIST

• Part indicated with the mark "nsp" are not always in stock and possibly to

take a long period of time for supplying, or in some case supplying of part

may be refused.

• When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-

supplying.

• Ordering part without stating its part number can not be supplied.

• Part indicated with the mark " ★ " is not illustrated in the exploded view.

• Not including General-purpose Carbon Film Resistor in the P.W.Board

parts list. (Refer to the Schematic Diagram for those parts.)

• Not including General-purpose Carbon Chip Resistor in the P.W.Board

parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol ! have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

] Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

部品表について

1.nsp 印の部品は常時在庫していませんので供給に長時間を要すること

があります。

場合によっては、供給をお断りすることがあります。

2.部品を発注する際は特に数字の " 1 " と英字の "I" との区別をはっき

り記入してください。

3.部品番号を表示していない部品は供給できません。

4.!印の部品は安全上重要な部品です。交換するときは、安全および性

能維持のため必ず指定の部品をご使用ください。

5.★印のついている部品は分解図中には記載していません。

6.汎用カーボン抵抗器は記載していません。定数は回路図を参照願いま

す。

7.汎用カーボンチップ抵抗器は記載していません。定数は回路図を参照

願います。

8.部品表の抵抗器、コンデンサの品名記号の読み方は表を参照してくだ

さい。

RN 14K 2E 182 G FR

RD : 2B : 1/8 W F : ±1% P :

RC : 2E : 1/4 W G : ±2% NL :

RS : 2H : 1/2 W J : ±5% NB :

RW : 3A : 1 W K : ±10% FR :

RN : 3D : 2 W M : ±20% F :

RK : 3F : 3 W

∗

18 2

1R 2

3H : 5 W

1800

Ö

2

1.2

Ö

1

2 R

=1.8k

0

ll

l Capacitors

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR : Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL par t

CP : Oil 2A : 100V –20% C : CSA par t

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

] Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

] Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

2-digit effective number.

2-digit effective number.

requency

CE 04W 1H 2R2 M BP

CE : 0J : 6.3 V F : ±1% HS :

CA : 1A : 10 V G : ±2% BP :

CS : 1C : 16 V J : ±5% HR :

CQ : 1E : 25 V K : ±10% DL :

CK : 1V : 35 V M : ±20% HF :

CC : 1H : 50 V Z : +80% U : UL

CP : 2A : 100 V −20% C : CSA

CM : 2B : 125 V P : +100% W : UL-CSA

CF : 2C : 160 V − 0% F :

CH : 2D : 200 V C : ±0.25pF

2E : 250 V D : ±0.5pF

2H : 500 V = :

2J : 630 V

∗

22 2

22 2

2200µF

Ö

2

µ

F

2200pF=0.0022µF

Ö

(0 2 )

2

p

F

0

0

2R 2

22 1

Ö

1

2 R

µ

F

Ö

(0 0 1 )

2

p

F

AC

2.2µF

220pF

0

7

Page 8

DSW-76(Black) Section

SYS-57HT

DSW-76(Black) PARTS LIST OF P.W.B. UNIT ASS’Y

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

PRE-AMP P.W.B. UNIT ASS'Y

Ref. No nsp Part No. Part Name Remark Q'ty New

SEMICONDUCTORS GROUP

U201-203 00D DSW 7601 025 TL074CN 190-16t1074cn-e

Q201-203 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q205-209 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q214-215 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q210-213 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

D201-204 00D DSW 7601 043 D 1N4002 197-101n4002-e

D205-208 00D DSW 7601 042 D 100mA 1N4148/75V 197-031n4148-e

D211 00D DSW 7601 043 D 1N4002 197-101n4002-e

D212-220 00D DSW 7601 042 D 100mA 1N4148/75V 197-031n4148-e

D221-223 00D DSW 7601 043 D 1N4002 197-101n4002-e

DZ201 00D DSW 7601 048 ZD 1/2W/3.3V 199-15000335-e

DZ202,203 00D DSW 7601 046 ZD 1/2W/12V 199-05001203j-e

DZ204-206 00D DSW 7601 044 ZD 1/2W/2.4V 199-05000243j-e

LED201 00D DSW 7601 040 LED 195-10339evg-e

RESISTER GROUP

VR201 00D DSW 7601 010 VAR R 115-h203b214-e

VR202 00D DSW 7601 011 VAR R 115-h503a102-e

CAPACITORS GROUP

C201-204 - ERECTRIC C 10uF/16V 135-3106m16-e

C205,206 - ERECTRIC C 10uF/25V 135-3106m25-e

C207 - ERECTRIC C 10uF/16V 135-3106m16-e

C208 - ERECTRIC C 47U/25V 135-3476m25-e

C209-215 - CERAMIC C 220P/50V 130-2b221k503-e

C216 - CERAMIC C 47P/50V 130-2b470k503-e

C217 - ERECTRIC C 1UF/16V 135-3105m16-e

C218,219 - ERECTRIC C 220uF/25V 135-3227m25-e

C220-228 - CERAMIC C 0.1U/50V 130-3f104z503-e

C229,230 - ERECTRIC C 47U/25V 135-3476m25-e

C231,232 - ERECTRIC C 10uF/16V 135-3106m16-e

C233-235 - FILM C 0.1U/63V 129-a104j633-e

C236 - CERAMIC C 1000P/50V 130-2b102k503-e

C237 - FILM C 0.22uF/63V 129-a223j633-e

C238 - FILM C 0.047U/63V 129-a473j633-e

C239 - ERECTRIC C 100uF/16V 135-3107m16-e

C240 - ERECTRIC C 4.7U/16V 135-3475m16-e

C241,242 - ERECTRIC C 10uF/25V 135-3106m25-e

8

Page 9

DSW-76(Black) Section

SYS-57HT

Ref. No nsp Part No. Part Name Remark Q'ty New

C243 - ERECTRIC C 100UF/25V 135-3107m25-e

C244,245 - FILM C 10NF/63V 129-a103j633-e

C246 - ERECTRIC C 47U/25V 135-3476m25-e

C247 - CERAMIC C 0.01U/50V 130-2b103k503-e

C248 - ERECTRIC C 47U/25V 135-3476m25-e

C249 - FILM C 0.15U/63V 129-a154j633-e

OTHER PARTS GROUP

P201 - 7PIN WIRE/BLK/WHT 162-5015d005-e *

P201 - 5PIN CONNECTOR 175-1c05v01-e

RCA1 - RCA-209A/BLK 174-0rca209u-e *

SW201-203 00D DSW 7601 023 MS7210V/6PIN 180-tms7210v-e *

- LED HOLDER7.5*7.1*8.25

361-NYL-05012-0BAE

*

AMP P.W.B. UNIT ASS'Y

Ref. No nsp Part No. Part Name Remark Q'ty New

SEMICONDUCTORS GROUP

U101 00D DSW 7601 024 4558D 190-06m4558d-e

Q101,102 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q103 00D DSW 7601 032 TR2N5551 192-1572n5551-e

Q104 00D DSW 7601 033 TR2N5401 192-1582n5401-e

Q105 00D DSW 7601 039 TRHSB649T 192-992b649t-e

Q106 00D DSW 7601 038 TRHSD669A 192-991d669a-e

Q107 00D DSW 7601 026 TRTIP35C 192-021tip35c-e

Q108 00D DSW 7601 027 TRTIP36C 192-022tip36c-e

Q109 00D DSW 7601 032 TR2N5551 192-1572n5551-e

Q110 00D DSW 7601 033 TR2N5401 192-1582n5401-e

Q111-113 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q114 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

Q115 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q116 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

Q117 00D DSW 7601 034 TRTIP31C 192-161tip31c-e

Q118 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q119 00D DSW 7601 037 TRKSB772Y 192-202b772y-e

Q120 00D DSW 7601 036 TRTIP42C 192-162tip42c-e

Q121 00D DSW 7601 029 TR2SC2235Y 192-027c2235y-e

Q122 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

Q123 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q124 00D DSW 7601 035 TRTIP41C 192-161tip41c-e

Q125 00D DSW 7601 031 TR2SA965Y 192-028a965y-e

Q126 00D DSW 7601 028 TR2SC1815GR 192-027c1815gr-e

Q127 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

Q128 00D DSW 7601 030 TR2SA1015GR 192-028a1015gr-e

D101 00D DSW 7601 042 D 1N4148 197-031n4148-e

D102 00D DSW 7601 049 ZD 3.3V 199-15000335-e

9

Page 10

DSW-76(Black) Section

SYS-57HT

Ref. No nsp Part No. Part Name Remark Q'ty New

D103 00D DSW 7601 042 D 1N4148 197-031n4148-e

D105 00D DSW 7601 042 D 1N4148 197-031n4148-e

D106,107 00D DSW 7601 050 ZD 6.2V 199-15000625-e

D108 00D DSW 7601 042 D 1N4148 197-031n4148-e

D109 00D DSW 7601 051 ZD 16V 199-15001605-e

D110 00D DSW 7601 041 D KBL405/500V 197-00kbl405-e

D111,112 00D DSW 7601 055 D 1N5402 97-101n5402-e

D113,114 00D DSW 7601 042 D 1N4148 197-031n4148-e

D115 00D DSW 7601 041 D KBL405/500V 197-00kbl405-e

D117,118 00D DSW 7601 042 D 1N4148 197-031n4148-e

D130 00D DSW 7601 047 D 500mW/24V 199-05002403j-e

RESISTER GROUP

R121,122 00D DSW 7601 008 R 0.1ohm/5W 113-500r1j10-e

R132 00D DSW 7601 006 R 1K/2W 110-20102jk2-e

R138 00D DSW 7601 009 SEMI VAR. R 3K/0.3W 114-03302m0-e

R167 00D DSW 7601 005 R TTC-802(JS)/NTC 109-1ttc802j0-e

CAPACITORS GROUP

C103 - ERECTRIC C 47U/25V 135-3476m25-e

C104 - CERAMIC C 100P/50V 130-sl101k503-e

C105 - ERECTRIC C 1U/50V 135-3105m50-e

C106 - CERAMIC C 0.047U/50V 130-3f473m503-e

C107 - FILM C 0.1U/50V 132-104j503-e

C108 - CERAMIC C 0.1U/50V 30-3f104z503-e

C109,110 - ERECTRIC C 100uF/16V 135-3107m16-e

C111 - ERECTRIC C 220U/16V 135-3227m16-e

C112 - ERECTRIC C 4.7U/50V 135-3475m50-e

C113 - CERAMIC C 0.1U/50V 30-3f104z503-e

C114 - ERECTRIC C 22U/50V 135-3226m50-e

C115 - CERAMIC C 0.1U/50V 30-3f104z503-e

C116 - CERAMIC C 1000P/50V 130-2b102k503-e

C117 - ERECTRIC C 100U/25V 135-3107m25-e

C118 - ERECTRIC C 22U/50V 135-3226m50-e

C119 - CERAMIC C 0.1U/50V 30-3f104z503-e

C120 - ERECTRIC C 100U/25V 135-3107m25-e

C121,122 00D DSW 7601 012 ERECTRIC C 4700uF/35V 135-4478m35-e

C123-128 - FILM C 0.022uF/100V 132-223ja03-e

C129,130 - ERECTRIC C 220U/10V 135-3227m10-e

C131,132 - FILM C 0.022uF/100V 132-223ja03-e

C133,134 00D DSW 7601 013 ERECTRIC C 4700uF/63V 135-4478m63-e

C135,136 - ERECTRIC C 100U/50V 135-3107m50-e

C137,138 - CERAMIC C 0.1U/50V 30-3f104z503-e

C139,140 - CERAMIC C 100P/50V 130-sl101k503-e

C141 - CERAMIC C 1000P/50V 130-2b102k503-e

OTHER PARTS GROUP

P101 - 7PIN CONNECTOR 175-1c07v01-e

P102 - 2PIN CONNECTOR 175-1d02v01-e

P103 - 5PIN CONNECTOR 175-1d05v01-e

P104 - 2PIN CONNECTOR 175-1c02v01-e

RY101 00D DSW 7601 054 RELAY/24V 71-udhss124d-e *

10

Page 11

DSW-76(Black) Section

Ref. No nsp Part No. Part Name Remark Q'ty New

- TUBE 1M*10mm 156-h010010-e

- SHEET 361-NYL-00054-0LAE *

- TR BLACKET 361-FE-00051-0LAE *

- HEAT SINK 323-AL-00020-0LAE *

- M3*14 SCREW 351-AM03014A094-J

- M3*8 SCREW 352-AM03008D040-J *

POWER P.W.B. UNIT ASS'Y

Ref. No nsp Part No. Part Name Remark Q'ty New

SEMICONDUCTORS GROUP

D301 00D DSW 7601 045 D 1/2W/12V 199-05001200j-e

RESISTER GROUP

R301 00D DSW 7601 007 R 0.56K/2W 110-20561jk3-e

SYS-57HT

CAPACITORS GROUP

C301 - FILM C 0.01uF/275V 132-103kb74-e

OTHER PARTS GROUP

P301 - 3PIN CONNECTOR 175-1d03v04-e

P302 - 5PIN CONNECTOR WIRE 162-5026d001-e *

P303 - 3PIN CONNECTOR 175-1d03v02-e

RY301 00DDSW 7601 056 RELAY 171-cs112lmr-e *

! 00D DSW 7601 015 SUB TRANS 150-e0351201-e *

- TUBE 1M*10mm 156-h010010-e

11

Page 12

DSW-76(Black) EXPLODED VIEW

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by

the manufacturer.

WARNING:

印の部分は安全を維持するために重要

な部品です。従って交換時は必ず指定の

部品を使用してください。

1

DSW-76(Black) Section

2

SYS-57HT

104

103

101

29

28

30

101

4

3

6

5

34

32

31

33

35

11

14

15

16

17

27

12

18

13

19

101

23

22

20

21

102

101

24

105

26

7

102

8

25

12

Page 13

SYS-57HTDSW-76(Black) Section

DSW-76(Black) PARTS LIST OF EXPLODED VIEW

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

Ref. No. nsp Part No. Part Name Remarks Q'ty New

1 nsp 00D DSW 76BK 001 Cabinet Ass'y BHQBDN155001 1 *

2 00D DSW 7600 002 Woofer LB7430400001 1

3 nsp 00D DSW 7600 003 Oak Feet JD5081000014 4

4 00D DSW 76BK 002 Spikes JZ0010000003 4 *

5 nsp 00D DSW 7600 005 Screw LS1215010004 8

6 nsp 00D DSW 7600 006 Screw LS1215B07002 4

7 - Rear Sticker YS0480610020 1 *

11 nsp 00D DSW 7601 001 PREAMP P.W.B. UNIT 051-A00432A-E 1

12 nsp 00D DSW 7601 002 AMP P.W.B. UNIT 051-A00432B-E 1

13 nsp 00D DSW 7601 004 POWER P.W.B. UNIT 051-A00434C-E 1

14 - EVA 333-EVA-00783-0BAE 2

15 - WIRE CLAMP 163-11009-e 2

16 - EVA 333-EVA-00807-0BAE 2

17 - CASE 306-ABS-00206-1BBE 1

18 - BRACKET Large-R 361-FE-05008-0LBE 1

19 - HEAT SINK 309-ABS-05003-0BAE 1

! 20 00D DSW 7601 015 SUB TRANS 150-e0351201-e 1

21 - BRACKET Small-L 361-FE-05010-0LAE 1

22 - BRACKET Small-R 361-FE-05011-0LAE 1

23 nsp 00D DSW 7601 053 BACK PANEL 302-AL-05021-2BBE 1

! 24 00D DSW 7601 022 POWER SWITCH 180-prf1003s-e 1

! 25 00D DSW 7601 018 AC COARD 152-u75201601-e 1

26 - COVER 309-ABS-05003-0BAE 1

27 - HEAT SINK 323-AL-00019-0BBE 1

28 - BUSH 335-NYL-00002-0BAE 2

29 - RUBBER SHEET 25*21*2T 336-RUB-00263-0BAE 4

! 30 00D DSW 7601 017 MAIN TRANS 150-e0865005-e 1

31 - M4 NUT 354-GM04002-J 4

32 - PWB HOLDER 61-FE-05013-0LAE 1

33 - EVA 333-EVA-00835-0BAE 2

34 - BRACKET Large-L 361-FE-05008-0LAE 1

35 - EVA 333-EVA-00826-0BAE 2

! 36 00D DSW 7601 020 FUSE 125V 154-u25002t0-e 1

! 37 - CERAMIC C 4700P 130-3f472md00-e 1

38 - FUSE HOLDER R3-11 155-520020-e 1

39 - TUBE 20mm*40mm 156-h200040-e 1

40 - TUBE 20mm*60mm 156-h200060-e 1

41 - TUBE 7mm*120mm 156-h070120-e 1

43 - LED HOLDER7.5*7.1*8.25 361-NYL-05012-0BAE 1

45 - EVA 333-EVA-00220-0BAE 6

46 - EVA 333-EVA-05052-0BAE 4

101 - M3*8 SCREW 351-AM03008A079-J 19

102 - M3*8 SCREW 352-AM03008D040-J 14

103 - M3*10 SCREW 352-BM03010D064-J 2

104 - M3*14 SCREW 351-BM03014A093-J 1

105 - M4*16 SCREW 351-HM04016A218-J 4

106 - M3*10 SCREW 352-AM03010D065-J 1

107 - M3*14 SCREW 351-BM03014A093-J 1

108 - 4M*12 SCREW 350-EM04012D024-J 10

13

Page 14

DSW-76(Black) WIRING DIAGRAM

LI MI T

MUTE

-15V

AGND

+15V

PTC

in

AMP P.W.B. UNIT

AC2

AC4

PGND

AC3

AC1

PGND

PGND

DSW-76(Black) Section

SYS-57HT

PRE AMP P.W.B. UNIT

POWER P.W.B. UNIT

SIGNAL IN

SI GNAL I N

12VAC

LI MI T

-12V

-12V

MUTE

STBY

STBY

AC

-15V

AGND

AC1

AC2

12VA C

12VA C

PGND

AC

PTC

+15V

PGND

PGND

OUT

AC-ST

AC

12VAC

POW ER

14

Page 15

DSW-76(Black) Section

SYS-57HT

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you make

either (1) a leakage current check or (2) a line to chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if

the resistance from chassis to either side of the power cord is

less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM

M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD.

P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT

NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE.

!

配線図について

!

印の部品は安全を維持するために重要な部品です。

従って交換時は必ず指定の部品を使用してください。

注)

(1) 指定なき抵抗値は Ω、k は kΩ、M は MΩ を示す。

(2) 指定なきコンデンサーの値は µF、p は pF を示す。

(3) 各部の電圧は無信号の値を示す。

(4) この配線図は基本配線図です。改良等のため変更する

ことがありますのでご了承ください。

15

Page 16

DSW-76(Black) SCHEMATIC DIAGRAMS (1/2)

DSW-76(Black) Section

SYS-57HT

12

C217

1.5k

R201

-12.3V

C201

10u/16V /20%

R203

20k

C209

220p/10%

R209

150

R210

47k

6

5

STBY

-V st

C220

0.1u

C210

220p/10%

C203

10u/16V /20%

R214

220K

DZ 201

1N4733/3.3V

C212

220p/10%

150k

C216

47p/50v/10%

U201B

TL 074

D207

1N4148

11 4

D202

1N4001

D201

1N4001

D204

1N4001

R226

7

D203

1N4001

R231

1k

+13.3V

C218

220u/25V

-13.3V

C232

10u/16v

D205

1N4148

3

2

D206

1N4148

sw201

2

1

3

SW-4

R228

22k

Q201

C1815

C231

10u/16v

220u/25V

U201A

TL 074

411

R211

18K

C211

220p/10%

0.15u/5%

R237

10k 1%

5

4

R229

6

10K

R227

22k

R232

1k

C219

R233

1k

Q210

A 1015

DZ 203

12V

R2CA 1*

1

2

3

R212

33k

C202

10u/16V /20%

1u/16V /20%

TO P104

P201

5

4

3

2

1

*

TO P302

1

C249

D208

1N4148

Q203

C1815

C228

0.1u/10%

DZ 202

12V

3

R204

20K

C204

10u/16V /20%

R244

10k 1%

C237

0.022u/5%

R240

2M EG

C229

47u/25V

C221

0.1U

C230

47u/25V

C233

0.1u/5%

C223

0.1u

6

5

Q202

C1815

C239

100u/16V

D223

1N4001

D211

1N4001

C222

0.1U

R234

10.5K/1%

C234

0.1u/5%

U202B

TL074

11 4

R241

4.7k

R242

100k

+12.3V

-12.3V

-15V

U201C

13

R235

135K/1%

7

+12.3V

C240

4.7u/16V

D221

1N4001

D222

1N4001

12

R215

10k

R238

20k

+15V

R216

6.8k

R247

18k

R205

20k

411

45

8

14

411

D216

1N4148

D217

1N4148

R260

15k

10u/16V /20%

U202A

TL074

C248

47u

DZ206

2.2v

14

TL074

R236

7.5K

1000p/50v/10%

9

10

Q211

A1015

9

10

R253

1M EG

R243

100k

Q212

A1015

1

D214

1N4148

R217

10k

C236

U202D

TL074

11 4

STBY

R252

27K

U201D

11 4

LED201

R2ED/GR2EEN

3

2

1

C

B

E

2

R256

1.2k

DZ204

2.2v

+12.3V

8

TL074

8

3

VR201

20KB

C206

10u/16V /20%

R221

10k

R249

18k

R222

10k

st hi

play low

D212

1N4148

2k

R255

D213

1N4148

-15V

R257

1.2k

Q215

C1815

C235

0.1u/5%

R248

18k

0.047u/5%

C225

0.1u

9

10

13

12

R223

10k

R259

1k

C208

47u/16V

R270

20k Q214

C1815

C238

10u/16v/20%

C241

U203D

TL074

11 4

411

U203C

TL074

C242

10u/16v/20%

R261

15k

2

3

C205

1

R207

20K

+15V

C226

0.1u

R213

33k

C243

22u/25V /20%

-15V

C227

0.1u

R

271

1k

Q205

C1815

R258

5.1K

D218

1N4148

6

+15V

C224

0.1u

C207

10u/16V /20%

R263

12meg

R225

10k

R239

470k

D219

1N4148

TL074

Q207

C1815

VR202

50KA

R245

100k

13

12

Q213

A1015

C215

R224

10k

Q206

C1815

R264

3.3k

220p/10%

411

Q208

C1815

U202C

R208

20k

R266

7.5K/1%

R262

30k

C247

0.01u

14

R265

39K

R251

51K

0.01u/5%

R268

750/1%

2

1

3

+15V

sw202

SW-4

C244

+15V

7

5

6

5

4

6

R267

R269

750/1%

DZ205

2.2v

sw203

2

1

3

SW-4

114

U203B

TL074

7.5k/1%

C245

0.01u/5%

PTC

+0.1V

R219

10k

220P/10%

5

4

6

7

R202

150R

R230

D220

22K

1N4148

R254

1M EG

LI MI T

MU TE

-15V

AGND

+15V

PTC

OUT

SIGNAL LINE

10k

R218

C213

220p/10%

C214

R220

10k

C246

47u/25V /20%

Q209

1815

C

2

3

-15V

+15V

R206

20k

LI MI T

MU TE

411

R246

100K

-15V

U203A

TL074

OUT

P202

*

TO P101

AMP UNIT

8

A

1

B

C

1

2

3

4

5

6

7

D

E

16

Page 17

DSW-76(Black) SCHEMATIC DIAGRAMS (2/2)

DSW-76(Black) Section

SYS-57HT

12

-13.6V

+0.1V

3

45

+23.4V

+48.5V

6

7

8

A

B

-48.5V

-23.4V

+23.8V

+23.4V

-23.8V

+48.5V

E1 : 230V 50Hz

E1C : 220V 50Hz

E1T : 120V 60Hz

C

C301

0.01u/250V AC

P303

2

1

TO CON104

F301

HI

C303

4.7n/250V AC

S1

TF301

A

1

2

1

2 1

P301

L

2

N

K1

12VDC RELAY

D301

12V

R301

560R/2W

AC10.5V

GND

AC10.5V

STBY

-V st

TO P201

P302

1

2

3

4

5

D

TO P104

-23.4V

17

-48.5V

POWER INPUT: FUSE: T RANSFORMER:

AC120V(60HZ)

AC230V (50HZ)

SIGNAL LINE

F301 TF301

1.25A 125VAC

1.25A 250VAC

INPUT 120VAC

INPUT 230AC

POWER UNIT

PRE-AMP UNIT

E

Page 18

SC-A76(Black) EXPLODED VIEW

101

8

SYS-57HTSC-A76(Black) Section

6

4

102

7

1

3

101

2

5

SC-A76(Black) PARTS LIST OF EXPLODED VIEW

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

Ref. No. nsp Part No. Part Name Remarks Q'ty New

1 nsp 00D SCA 76BK 001 Cabinet Ass'y BHKXDN117000 1 *

2 00D SCA 76BK 002 Tweeter Ass'y BHXGDN117001 1 *

3 00D SCA 7600 001 Woofer LB0300610005 1

4 - Crossover Ass'y BHFYDN053000 1

5 00D SCA 76BK 003 Grille Ass'y BHBKDN117000 1 *

6 - Rear Sticker for FL YS0480610021 1 *

6 - Rear Sticker for FR YS0480610022 1 *

6 - Rear Sticker for SL YS0480610023 1 *

6 - Rear Sticker for SR YS0480610024 1 *

7 - Wall Bracket GG1510000006 1

8 nsp 00D SCA 76BK 004 Grille Catcher MK0014000001 4 *

101 nsp 00D SCC 7600 007 Screw 4X20 LS4212707001 8

102 - Screw 3.5X16 LS4211905001 4

18

Page 19

SC-C76(Black) EXPLODED VIEW

SYS-57HTSC-C76(Black) Section

7

6

4

102

3

7

1

101

3

101

5

8

2

SC-C76(Black) PARTS LIST OF EXPLODED VIEW

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

Ref. No. nsp Part No. Part Name Remarks Q'ty New

1 nsp 00D SCC 76BK 001 Cabinet Ass'y BHKXDN124000 1 *

2 00D SCC 76BK 002 Tweeter Ass'y BHXGDN124001 1 *

3 00D SCC 7600 001 Woofer LB0301210005 2

4 - Crossover Ass'y BHFYDN054000 1

5 00D SCC 76BK 003 Grille Ass'y BHBKDN124001 1 *

6 - Rear Sticker YS0480610025 1 *

7 - Wall Bracket GG1510000006 2

8 nsp 00D SCA 76BK 004 Grille Catcher MK0014000001 4 *

101 nsp 00D SCC 7600 007 Screw 4X20 LS4212707001 12

102 - Screw 3.5X16 LS4211905001 8

19

Page 20

PACKING VIEW

SC-C76(Black)

202

SYS-57HT

208204

220

SC-A76(Black)

201

219

210

209

FR

DSW-76(Black)

FL

203

218

215212

PARTS LIST OF PACKING & ACCESSORIES

*本表に記載されている部品は、補修用部品のため製品に使用している部品とは一部、形状、寸法などが異なる場合があります。

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

209

SW

209

SR

SL

C

209

216

217

211

*"nsp" 印の部品は常時在庫していませんので供給に長時間を要することがあります。場合によっては、供給をお断りする場合があります。

* Part indicated with the mark “nsp” are not always in stock and possibly to take a long period of time for supplying, or in some case supplying of part may be refused.

Ref. No. nsp Part No. Part Name Remarks Q'ty New

201 nsp 00D SYS 57HT BK1 Microfoam 360X580 BHSHDN156001 4 *

202 nsp 00D SYS 57HT BK2 Microfoam 450X580 BHSHDN156002 1 *

203 nsp 00D SYS 57HT BK3 Microfoam 1300X690 BHSHDN156003 1 *

204 00D SYS 6500 005 Oak Feet JD5081000001 5

205 00D SYS 57HT BK4 Owner's Manual YS0170200213 1 *

206 nsp 00D SYS 6500 007 Service Station list YS1670210002 1

207 - Warranty Card TS0270200013 1

208 - PE Bag BZ1400000002 1

209 nsp 00D SYS 76HT 005 Polyfoam Ass'y BHBLDN056000 1

- Polyfoam (Top) BZ06DN056001 1

- Polyfoam (Mid) BZ06DN056002 1

- Polyfoam (Mid) BZ06DN056003 1

- Polyfoam (Bottom) BZ06DN056004 1

210 nsp 00D SYS 57HT BK5 Paper Oversleeve BZ10DN156001 1 *

211 nsp 00D SYS 57HT BK6 Carton Box BZ01DN156001 1 *

212 00D SYS 6500 013 Speaker Wire (L=10m) DX2022357001 2

213 00D SYS 6500 014 RCA Wire (L=3m) DX4000020002 1

214 00D SYS 76HT 003 Speaker Wire (L=3m) BHSJ00000018 3

215 - PE Bag BZ1400000002 1

216 - Bar Code Label YS1370210259 1 *

217 - Control Card YS0570210067 2 *

218 - Caution Label YS1770200005 1

219 - Microfoam 184X130 BHSHDN117001 4 *

220 - Microfoam 276X124 BHSHDN11701 1 *

20

Loading...

Loading...