Page 1

SERVICE MANUAL

Copyright 2013 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver.1

S0768-1V01DM/DG1312

•

Some illustrations using in this service manual are slightly different from the actual set.

•

Please use this service manual with referring to the operating instructions without fail.

• For purposes of improvement, specications and design are subject to change without notice.

D&M Holdings Inc.

MODEL JP E3 E2 EK EA E1 E1K E1C

MC6000MK2EM

P P

Professional Digital Mixer and Controller

Page 2

CONTENTS

ABOUT THIS MANUAL .............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................6

NOTE FOR SCHEMATIC DIAGRAM .........................................7

NOTE FOR PARTS LIST ...........................................................7

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS

AND OPTICAL UNIT .................................................................7

TECHNICAL SPECIFICATIONS ................................................9

DIMENSION .............................................................................10

PRECAUTIONS DURING SERVICE .......................................11

Initializing This Unit .................................................................11

DISASSEMBLY ........................................................................12

SPECIAL MODE ......................................................................23

Special mode setting button ....................................................23

PROCEDURE AFTER REPLACING THE

MICROPROCESSOR, ETC ....................................................34

FIRMWARE UPDATE PROCEDURE ......................................34

TROUBLE SHOOTING ............................................................43

WAVEFORMS and TROUBLESHOOTING .............................51

BLOCK DIAGRAM ...................................................................55

POWER BLOCK DIAGRAM ....................................................56

LEVEL DIAGRAM ....................................................................57

WIRING DIAGRAM ..................................................................58

PRINTED WIRING BOARDS ...................................................59

SCHEMATIC DIAGRAMS (1/5) ...............................................63

MAIN UNIT ..............................................................................63

I/O ..........................................................................................64

CONTROL 1 ............................................................................65

CONTROL 2 ............................................................................66

FRONT ....................................................................................67

EXPLODED VIEW ....................................................................68

PACKING VIEW .......................................................................69

SEMICONDUCTORS ...............................................................70

1. IC's .....................................................................................70

Page 3

ABOUT THIS MANUAL

Read the following information before using the service manual.

What you can do with this manual

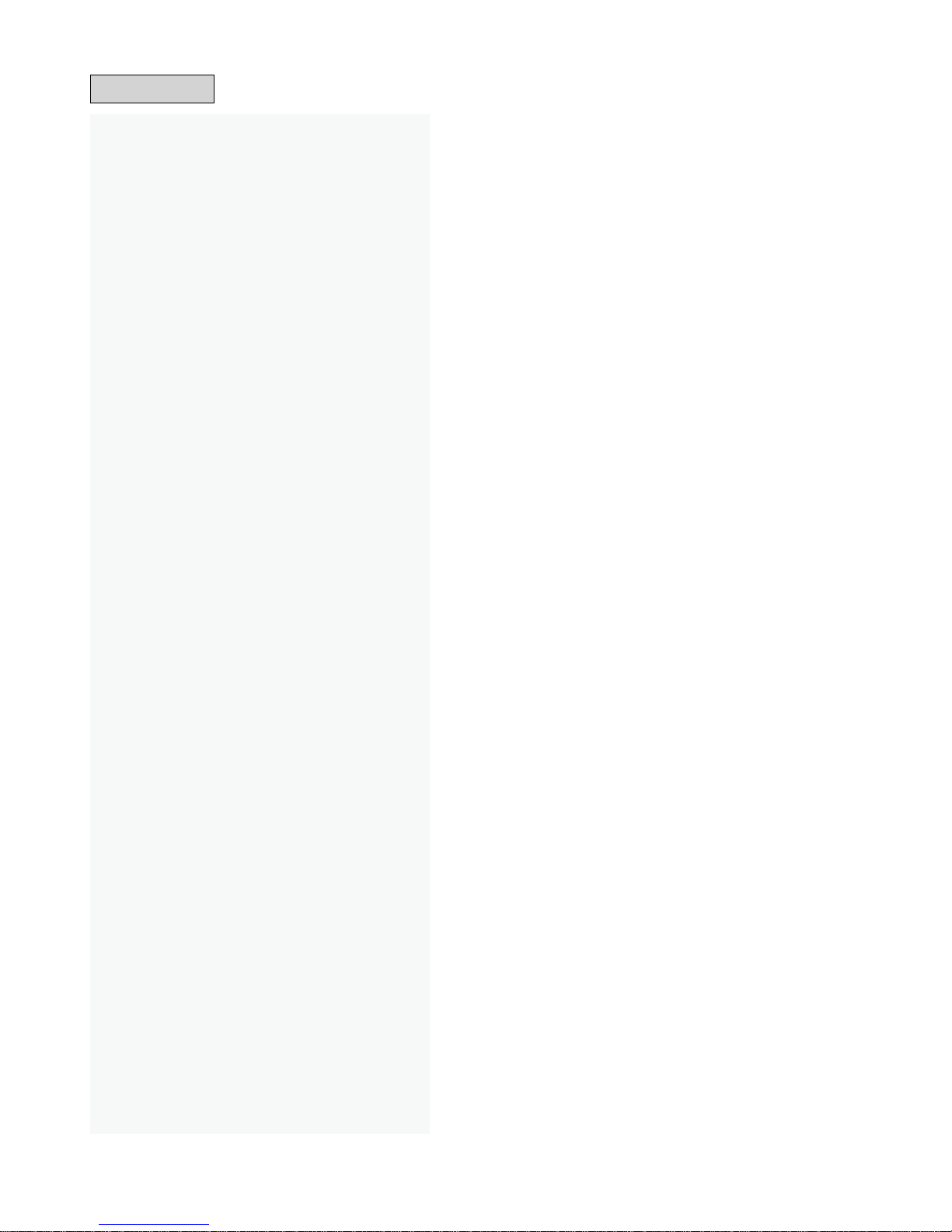

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in parts lists.

1.Press Ctrl+Shift+F on the keyboard.

• The Search window appears.

2.Enter the Ref. No. you want to search for in the

Search window, and then click the Search button.

•A list of search results appears.

3.Click an item on the list.

• The screen jumps to the page for that item, and the

search phrase is displayed.

Ctrl

Shift

F

Jump to the target of a schematic

diagram connector

Click the Ref. No. of the target connector in the red

box around a schematic diagram connector.

•The screen jumps to the target connector.

•Pagemagnicationstaysthesameasbeforethe

jump.

CP401

CP106

v

3

Page 4

Using Adobe Reader (Windows version)

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Page to print

Select the following checkbox.

"More Options" : "Current View"

• Page Sizing & Handling

Select the following checkbox.

"Size" / "Size Options" : "Fit"

Add notes to this data (Sign)

The Sign function lets you add notes to the data in

this manual.

Savetheleonceyouhavenishedaddingnotes.

[Example using Adobe Reader X]

On the "View" menu, click "Sign".

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "Document" menu, click "Sign".

Magnify schematic / printed wiring

board diagrams - 1

(Ctrl+Space, mouse operation)

Press Ctrl+Space on the keyboard and drag the

mouse to select the area you want to view.

• Theselectedareaismagnied.

• When you want to move the area shown, hold

down Space and drag the mouse.

• When you want to show a full page view, press

Ctrl+0 on the keyboard.

Ctrl Space

0

Print a magnied part of the manual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the "File" menu, click "Print".

3. CongurethefollowingsettingsinthePrintdialogbox.

4. Click the Print button to start printing.

4

Page 5

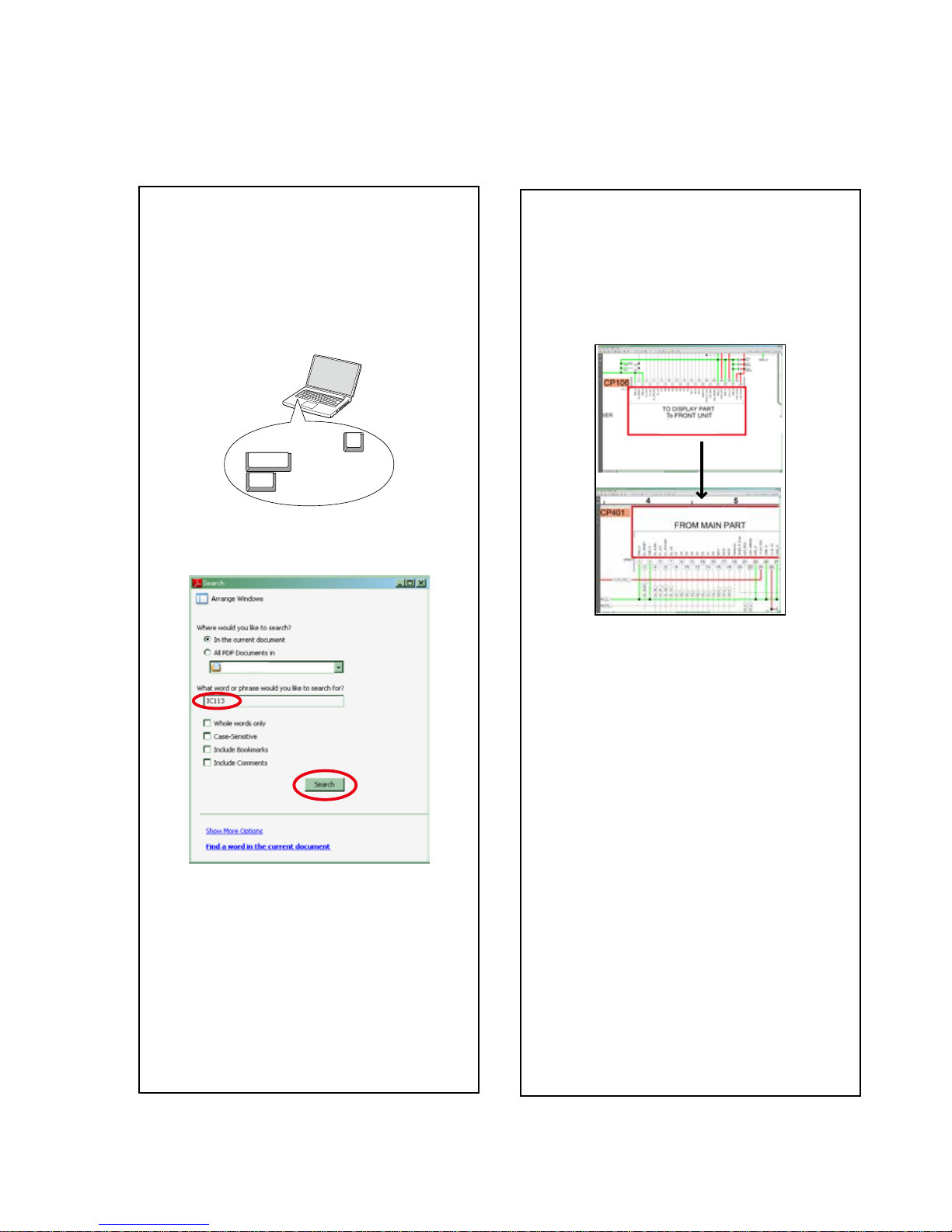

Magnify schematic / printed wiring

board diagrams - 2

(Pan & Zoom function)

The Pan & Zoom function lets you see which part of

amagnieddiagramisbeingshowninaseparate

window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Pan & Zoom".

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Pan & Zoom Window".

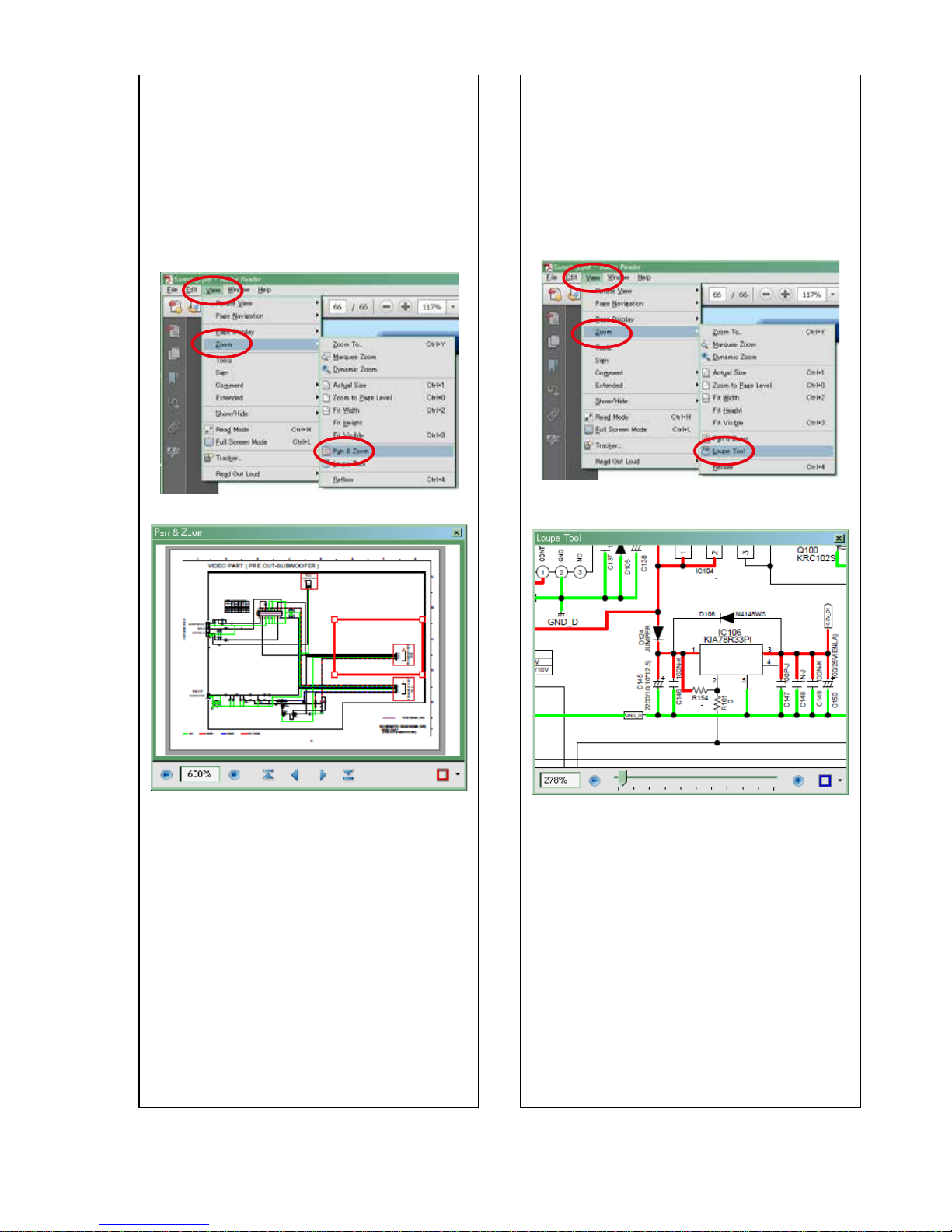

Magnify schematic / printed wiring

board diagrams - 3

(Loupe Tool function)

TheLoupeToolfunctionletsyoumagnifyaspecic

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Loupe Tool".

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select & Zoom", and

then click "Loupe Tool Window".

5

Page 6

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

leakage current check

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state

(on, off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if you

touch internal metal parts when the set is energized,

you may get an electric shock. Avoid getting an

electric shock, by using an isolating transformer

and wearing gloves when servicing while the set is

energized, or by unplugging the power cord when

replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs on

theedgesofparts.Theburrscouldcauseinjuryifngers

are moved across them in some rare cases. Wear gloves

to protect your hands.

◎Use only designated parts!

Theset'spartshavespecicsafetyproperties(re

resistance, voltage resistance, etc.). Be sure to use parts

which have the same properties for replacement. The

burrs have the same properties. In particular, for the

important safety parts that are indicated by the z mark

on schematic diagrams and parts lists, be sure to use

the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wires by arranging them

and using clamps to keep them away from heating and

high voltage parts, so be sure to set everything back as

it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in their

original positions, check that no serviced parts have

deteriorate the area around. Then make an insulation

check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and on the power. Using a 500V

insulation resistance tester, check that the insulation

resistance value between the inplug and the externally

exposed metal parts (antenna terminal, headphones

terminal,inputterminal,etc.)is1MΩorgreater.Ifitis

less, the set must be inspected and repaired.

Many of the electric and the structural parts used in the

set have special safety properties. In most cases these

propertiesaredifculttodistinguishbysight,andtheuse

of replacement parts with higher ratings (rated power

and withstand voltage) does not necessarily guarantee

that safety performance will be preserved. Parts with

safety properties are indicated as shown below on the

wiring diagrams and the parts list in this service manual.

Be sure to replace them with the parts which have the

designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks,resorotherdangerous

situations.

CAUTION

Concerning important

safety parts

6

Page 7

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check.

If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the

set is defective.

WARNING:

DONOTreturnthesettothecustomerunlesstheproblemisidentiedandremedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Besuretowearagroundingband(1MΩ)thatisproperlygroundedtoremoveanystaticelectricitythatmaybecharged

on the body.

2. Ground for Workbench

Besuretoplaceaconductivesheetorcopperplatewithpropergrounding(1MΩ)ontheworkbenchorothersurface,

where the semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through the

body grounding band, be careful to avoid contacting semi-conductors with your clothing

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

NOTE FOR PARTS LIST

1. Parts indicated by "nsp" on this table cannot be supplied.

2. When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3. A part ordered without specifying its part number can not be supplied.

4. Part indicated by "★" mark is not illustrated in the exploded view.

WARNING: Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the

manufacturer.

7

Page 8

Personal notes:

8

Page 9

9

TECHNICAL SPECIFICATIONS

n

Audio

(0 dBu=0.775 Vrms, 0 dBV =1 Vrms)

・

PHONO inputs

2 Stereo

Unbalanced RCA terminal

Input impedance:

50 kΩ/kohms

Level:

–40 dBV(10 mV)

Signal to Noise ratio:

Over 82 dB

・

LINE 1, 2 inputs

2 Stereo

Unbalanced RCA terminal

Input impedance:

10 kΩ/kohms

Level:

0 dBV

Signal to Noise ratio:

Over 84 dB

・

LINE 3, 4 inputs

2 Stereo

Unbalanced RCA terminal

Input impedance:

10 kΩ/kohms

Level:

0 dBV

Signal to Noise ratio:

82 dB or later

・

Equalizer (CH)

3 Band

Channel EQ Adjustment Range:

HI (High Range) : –∞, –90 dB – +10 dB

MID (Medium Range) : –∞, –90 dB – +10 dB

LOW (Low Range) : –∞, –90 dB – +6 dB

・

MIC inputs

2 Monaural

MIC 1:

Combo jack

(terminal for balanced XLR and balanced 1/4 inch TRS)

(1: ground, 2: hot, 3: cold, chip: hot, ring: cold, sleeve: ground)

MIC 2:

Balanced 1/4 inch TRS terminal

Input impedance:

5 kΩ/kohms

Level:

–60 dBu – –16 dBu

・

Equalizer (MIC)

3 Band

Adjustment Range:

HI (High Range) : –15 – +15 dB

MID (Medium Range) : –15 – +15 dB

LOW (Low Range) : –15 – +15dB

・

USB audio inputs

2 Stereo (4 Monaural) 16 bit, Fs : 44.1 kHz USB B

・

MASTER output

Balanced:

Stereo, balanced XLR terminal

(1: Ground, 2: Hot, 3: Cold)

DA converter:

24 bit

Load impedance:

Over 600 Ω/ohms

Level:

+ 4 dBu (Max + 24 dBu)

When RL=100 kΩ/kohms

Frequency response:

20 Hz – 20 kHz (±1 dB)

THD:

Less than 0.05%

Crosstalk:

Less than –90 dB (1 kHz)

Unbalanced:

Stereo RCA terminal

Load impedance:

100 kΩ/kohms

Level:

0 dBu (Max + 20dBu)

・

BOOTH Output

Stereo balanced 1/4 inch TRS terminal

Load impedance:

Over 600 Ω/ohms

Level:

+ 4 dBu (Max + 24 dBu)

When RL=100 kΩ/kohms

・

Headphone output

Stereo

Load impedance:

40 Ω/ohms

Level:

100 mW

・

USB audio output

2 Stereo (4 Monaural) 16 bit, 44.1 kHz USB B

n

General

USB MIDI I/O:

IN: 1ch, OUT: 1ch MIDI 1.0, MIDI Clock USB B

CH/MASTER Meter:

PPM 7 Point LED –20 – +10 dB, Peak

CH Fader:

45 mm Slim Type Fader

Cross Fader:

45 mm Fader

・

Power voltage:

DC12V (the unit)

AC adapter input:

U.S.A. and Canada models:

AC 120 V, 60 Hz

European,U.K. and Asia/

Pacific models:

AC 230 V, 50 Hz

AC adapter output:

DC 12V 3A

Power consumption:

24 W

Operating temperature:

+5 °C – +35 °C

Operating humidity:

25 % – 85 %

Storage temperature:

–20 °C – 60 °C

For the purpose of improvement, the specications and design are subject to change without notice.

Page 10

10

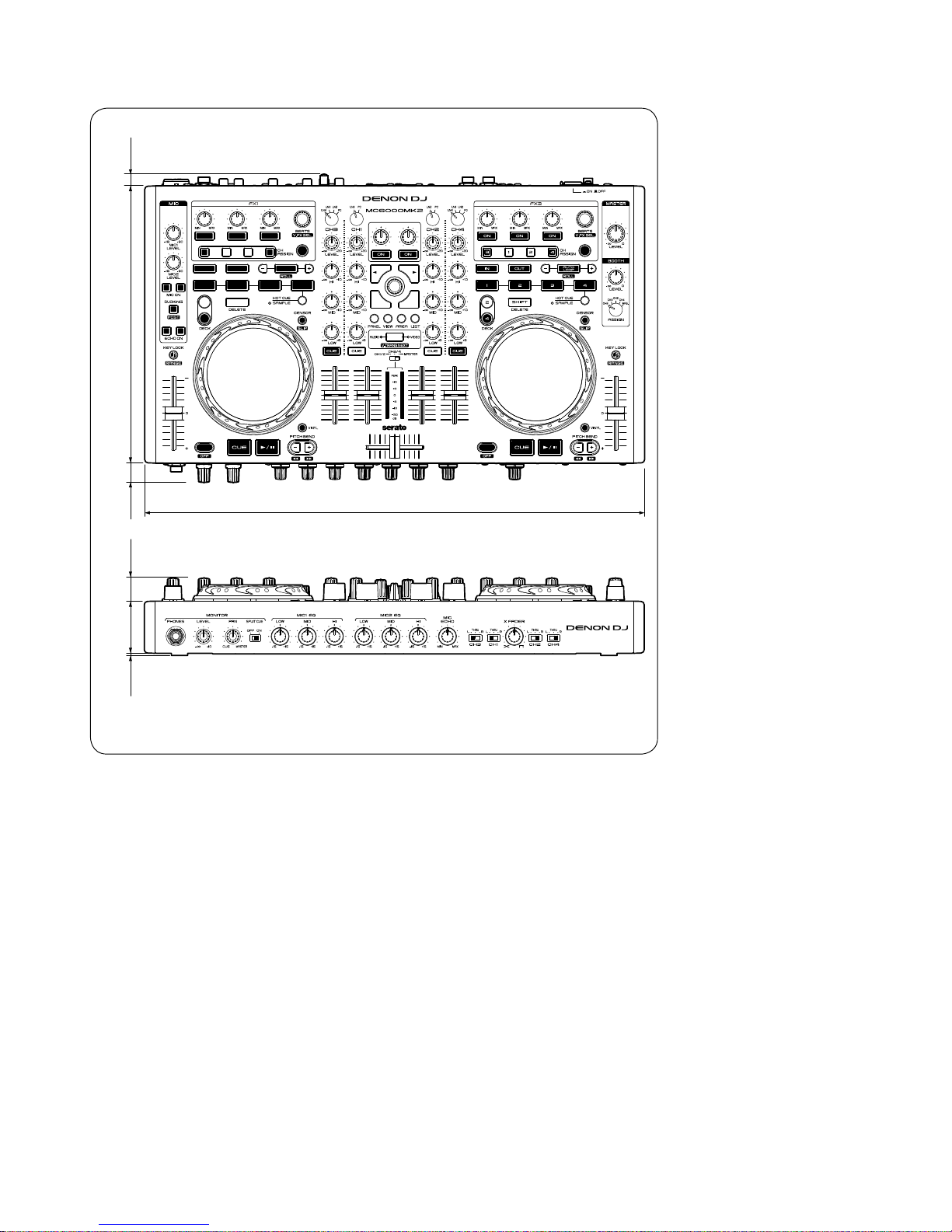

DIMENSION

Unit : in. (mm)

18 11/32

(460.0)

7/16

(11.0)

27/32

(21.5)

1 57/64

(48.0)

10 3/64

(255.0)

45/64

(17.7)

5/64

(2.0)

Weight : 9 lbs 8 oz (4.3 kg)

Page 11

11

Initializing This Unit

Initialize this unit if you have replaced the microprocessor, one of the parts around the microprocessor, or the main PWB.

1. Turn on the power while pressing the BACK, FWD and X-F LINK buttons simultaneously.

2. Return to default setting, and these data (as follows) turn to factory default setting.

Upon completion of the adjustment, it automatically restarts, start in Normal mode.

NOTE: • The parameters will be lost and the factory setting will be recovered after the set is initialized.

So make sure to note down your setting beforehand for restoring after the initialization.

PRECAUTIONS DURING SERVICE

Power operation switch

BACK FWD

X-F LINK

Page 12

12

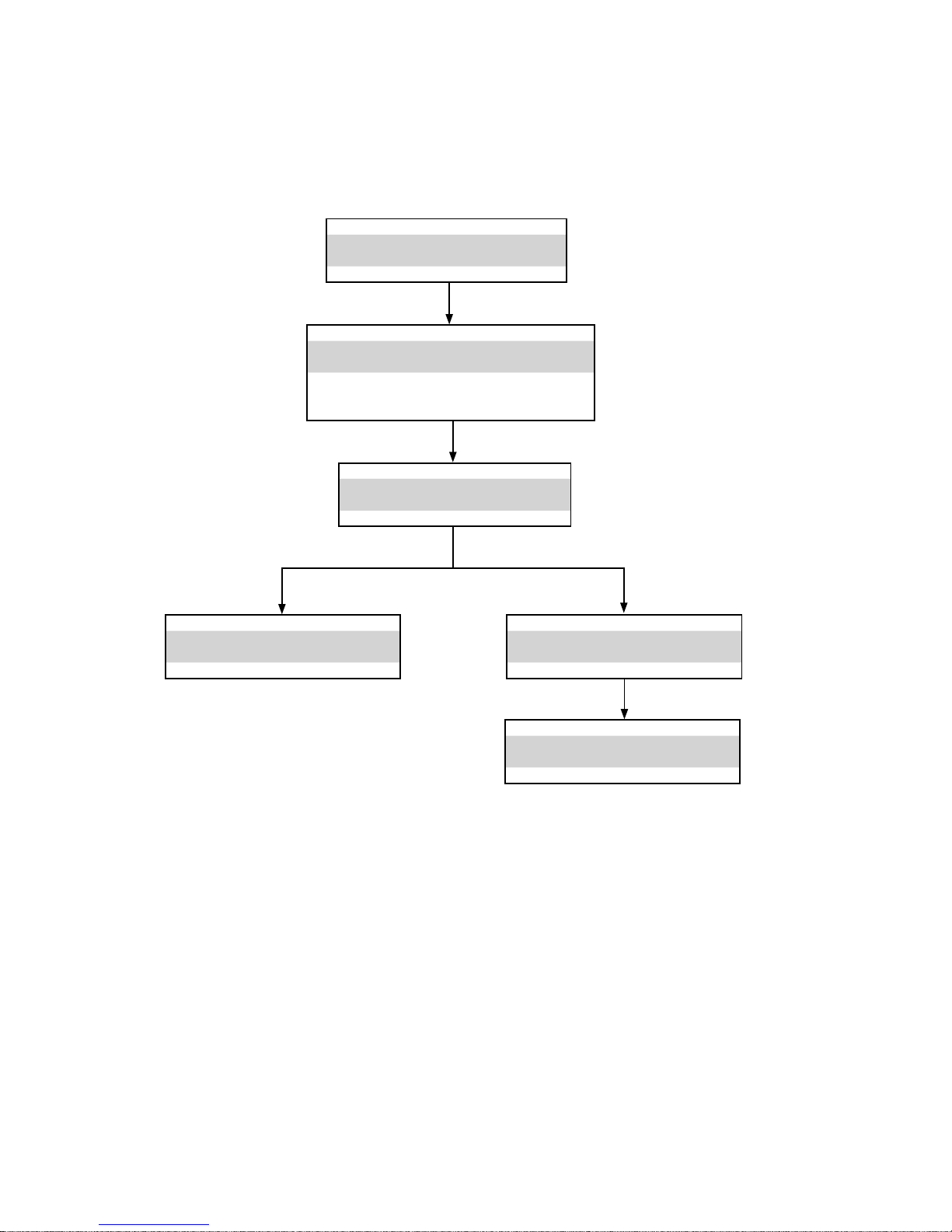

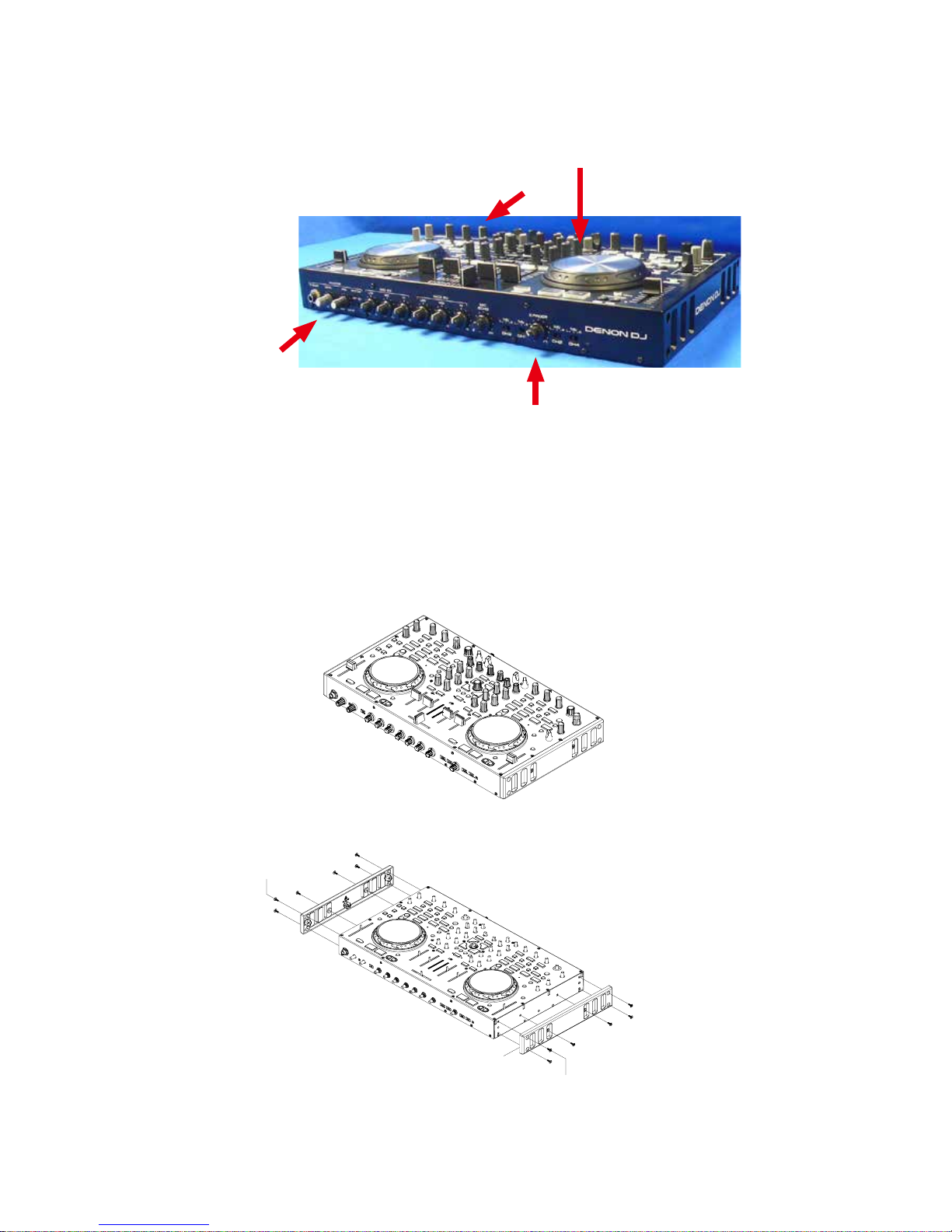

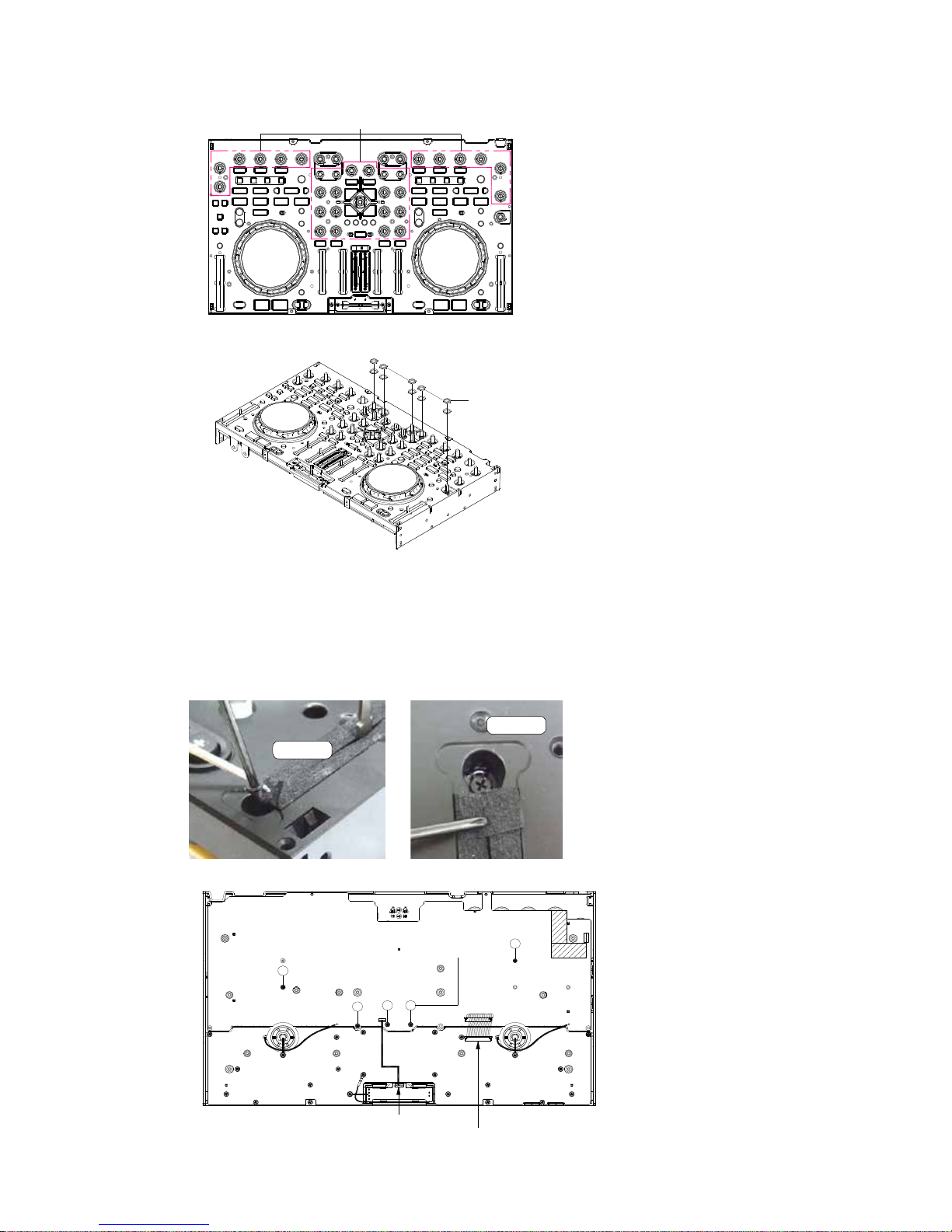

DISASSEMBLY

• Remove each part in the order of the arrows below.

• Reassemble removed parts in the reverse order.

• Read“ SAFETY PRECAUTION” before reassembling removed parts.

• If wire bundles are removed or moved during adjustment or part replacement, reshape the wires after completing the

work. Failure to shape the wires correctly may cause problems such as noise.

SIDE COVER, BASE(BOTTOM PANNEL)

Refer to "DISASSEMBLY 1.- 4.3."

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 25, 31)

FRONT PANEL

Refer to "DISASSEMBLY 12."

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 4-2)

Caution

Tighten removed screws in the following steps.

1. Front(TOP) panel screws.(See DISASSEMBLY 11.)

2. Rear panel screws.(See DISASSEMBLY 4-2.)

3. Front panel screws.(See DISASSEMBLY 4-3.)

4. Bottom screws.(See DISASSEMBLY 4-1.)

5. Side cover screws.(See DISASSEMBLY 2.)

IO, MAIN and FRONT PWB

Refer to "DISASSEMBLY 5-1.-11."

and "EXPLODED VIEW"

IO PWB: (Ref. No. of :EXPLODED VIEW : 8)

MAIN PWB: (Ref. No. of :EXPLODED VIEW : 7)

FRONTIO PWB: (Ref. No. of :EXPLODED VIEW : 9)

CROSS FADER ASSY

Refer to "DISASSEMBLY 21"

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 10)

CONTROL1, CONTROL 2 PWB

Refer to "DISASSEMBLY 13-20"

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 5, 6)

WHEEL ASSY

Refer to "DISASSEMBLY 22"

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 3)

Page 13

13

Explanatory Photos for“ DISASSEMBLY”

• The angles from which the photos are taken are shown by“ Photo angle: A, B, C, D“ .

• See the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

1. Dismantle the packaging, taking out the machine.

2. Remove the screws*12 from side cover.

Reassemble the rear panel by the 5th step. Step of screw tightening.(1-6)

Side Cover*2

5

6

1

5

4

3

6

2

Screw*6

1

2

3

4

Screw*6

Shooting direction: B

(Rear side)

Shooting direction: D

(Top side)

Shooting direction: A

(Front side)

Shooting direction: C

(Bottom side)

Page 14

14

3. Remove the rotary knob *41 and push knob*6 from panel.

4-1. Remove the screws*12 from bottom base.

Reassemble the bottom base by the 4th step. Step of screw tightening from1 to 12.

Caution on assembly of the bottom panel.

To push one hande and hold at.

4-2. Remove the screws*6 from rear panel.

Reassemble the rear panel by the 2nd step. Step of screw tightening (1-6).

4-3. Remove the screws*6 from front panel.

Reassemble the front panel by the 3rd step. Step of screw tightening from (1-6).

1

screw*6

2

3

4

5

6

1

3

2

4

5

6

screw*6

screw*12

1

2

3

4

5

6

7

8

9

10

11

12

Page 15

15

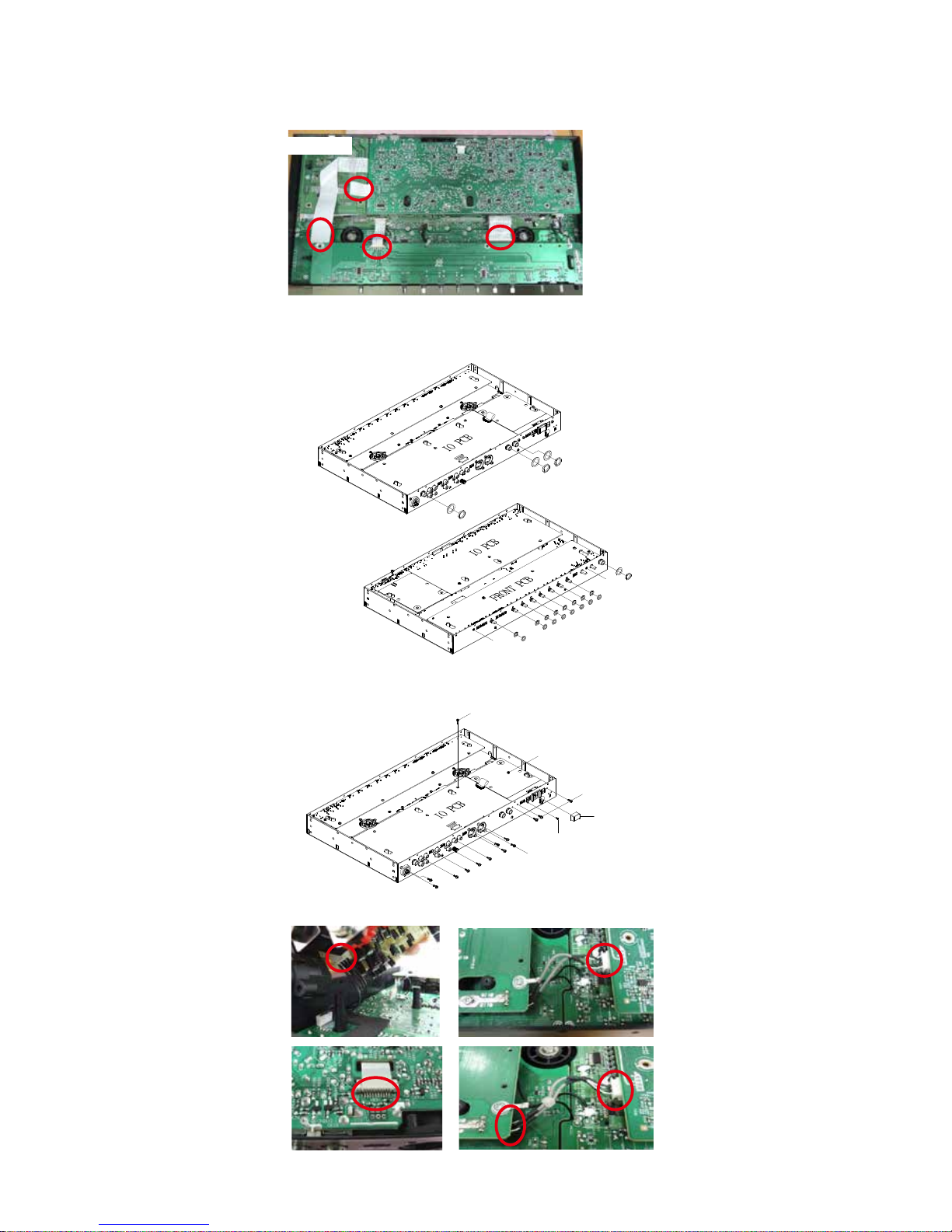

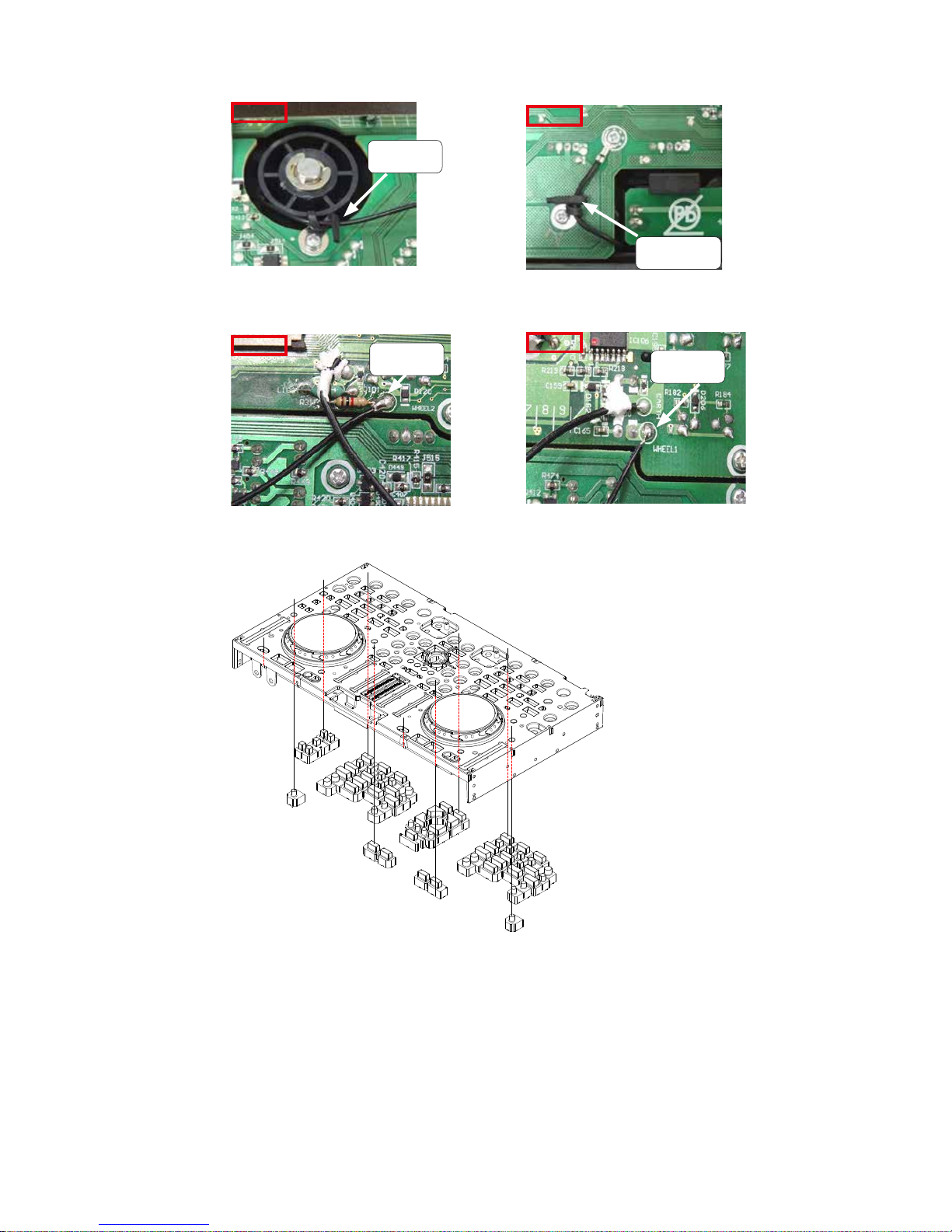

5-1. Disconnect the FCC cable(follow Figure A).

5-2. Remove the MAIN pcb ass'y.(follow Figure A).

Shooting direction: C (Bottom side)

6. Remove the nuts*12 and washer *12.

7. Remove the screws*15 and remove power button.

Step of screw tightening.(1-10)

8. Disconnect the FCC cable and connector wire and remove cable tie.(follow Figure B).

screw*1

MAIN pcb ass'y

Power button

screw*1

3

2

1

screw*3

screw*10

1

2

3

4

5

6

7

8

9

10

MAIN PWB ASSY

↓

Figure A

Figure B

Page 16

16

9. Disconnect the FCC cable and connector wire.(follow Figure C).

Shooting direction: C (Bottom side)

10. Remove the screw*4

Step of screw tightening.(1-4)

11. Remove the screws *14 from front panel.

Reassemble the front panel by the rst step. Step of screw tightening (1-14).

Caution on assembly of the button.

Adjust and assemble the top panel in the center of the hole.

Press a place other than the center of the button, to conrm that do not catch button on the panel. FAIL

4

3

2

1

Screw*2

FRONT pcb ass'y

Screw*2

1

8

2

3

4

5

6

7

14

13

12

11

10

9

screw*14

Figure C

Page 17

17

12. Remove the screws *10 from front panel.

Step of screw tightening.(1-10)

13-1. Remove screw .buckle and knob protector.

13-2. Remove gound pin . Washer and nut.

13-3. Remove screw*8. (①-⑤)

1

2

3

4

6

5

9

10

7

8

screw*2

screw*2

screw*6

Screw*1

Ground pin

Washer

Nut

Buckle*1

Knob protector

CONTROL 1 PCB

5

63

4

8

7

CN100

CN100

CONTROL 2 PCB

1

screw*8

2

1

2

3

4

6

5

9

10

7

8

screw*2

screw*2

screw*6

Page 18

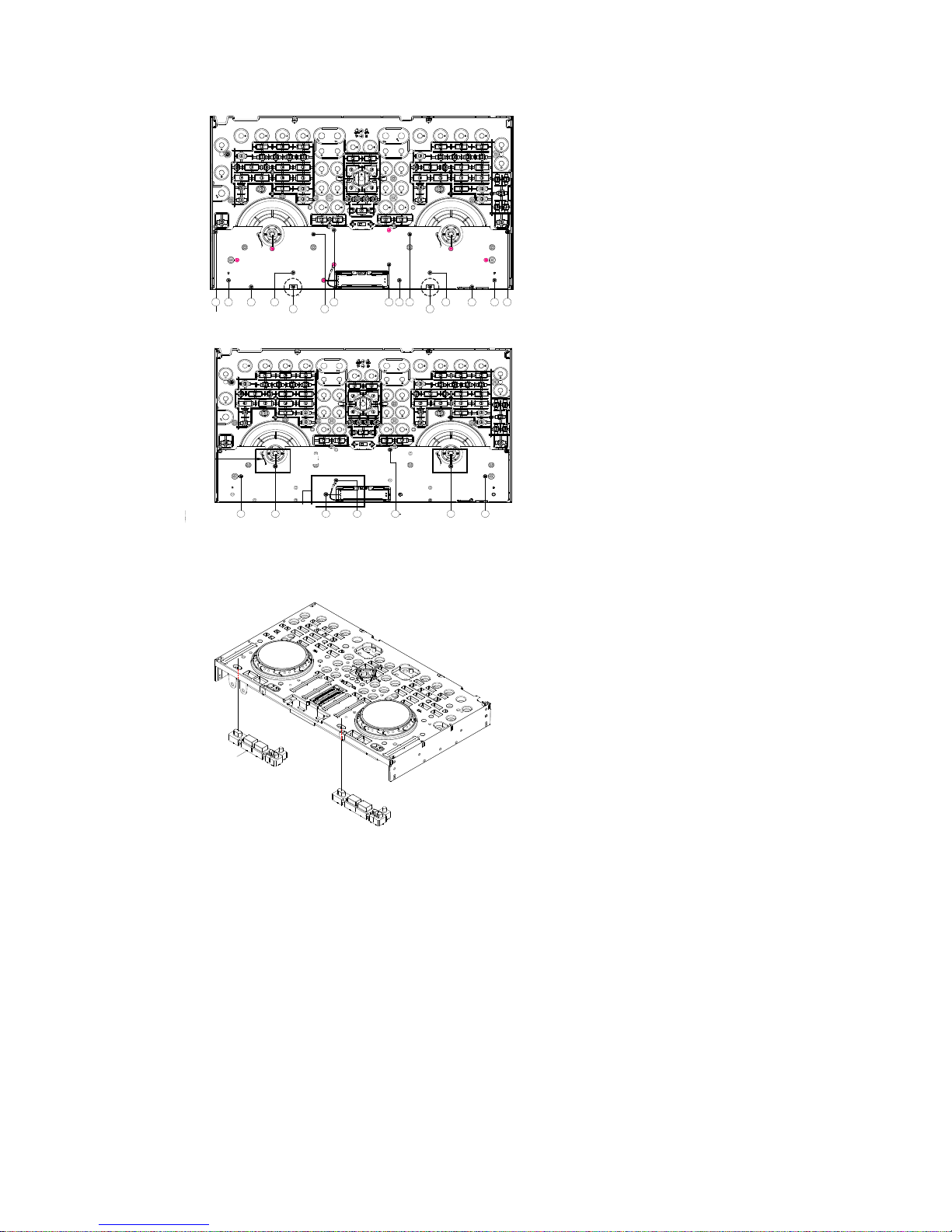

18

14. Remove nuts*36 and washers*36.

15-1. Remove screw*4. (SCREW*2x2)

15-2. Remove screw*5.(①-⑤)

15-3. Disconnect 32P FFC cable.

15-4. Remove the control 1 pcb ass'y.

nut and washer

(10Φ,31P.S.)

nut and washer

(11Φ,5P.S.)

nut and washer

(10Φ,31P.S.)

nut and washer

(11Φ,5P.S.)

5

3P wire

CN100

CN100

32P FFC cable

CONTROL 1 PCB ASS'Y

3

1

screw*5

4

2

CONTROL 2 PCB ASS'Y

screw*2

screw*2

Page 19

19

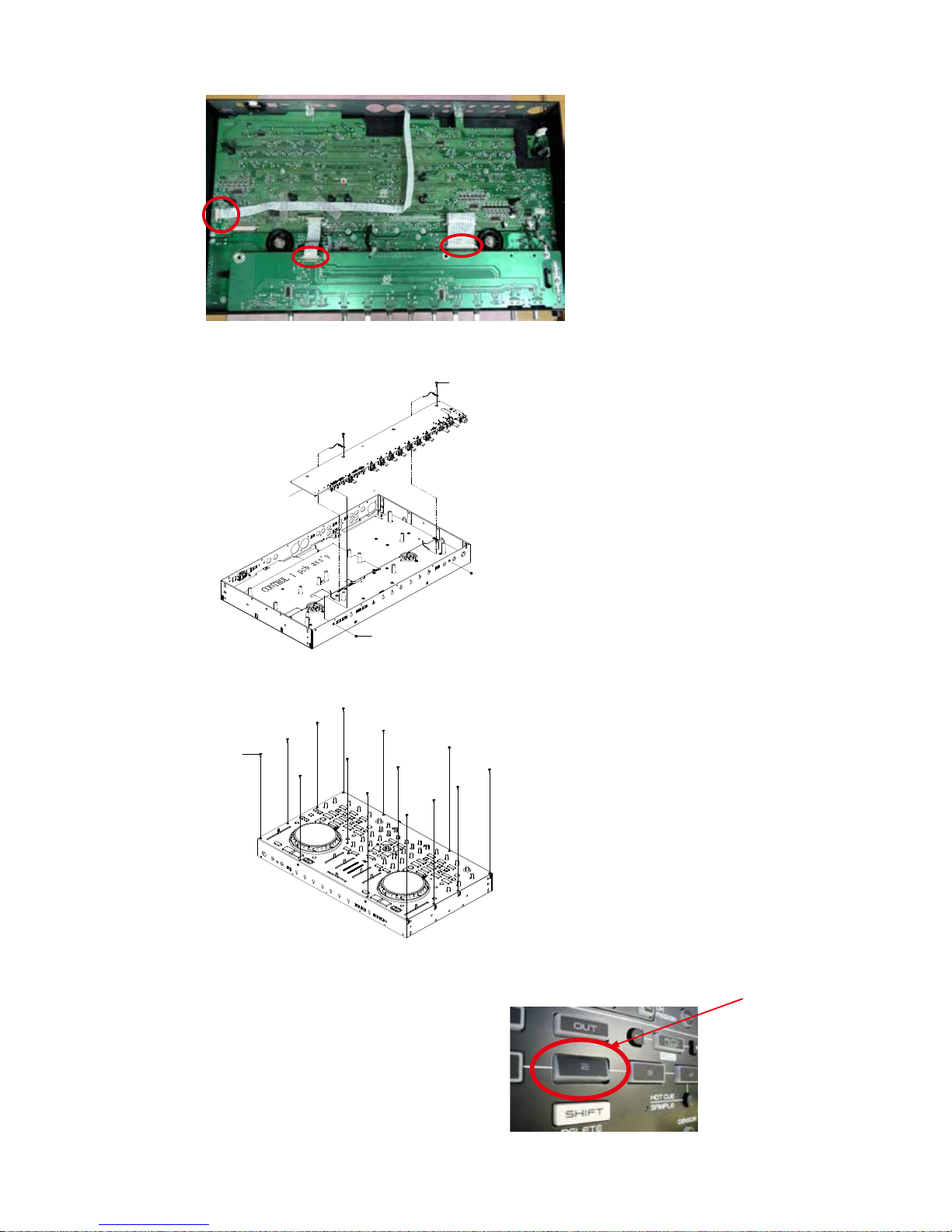

16-1. Release the clamp*2(follow Figure D&E).

16-2. Remove the solder *2.(follow Figure F&G) then remove the control 2 pcb ass'y.

17. Remove the square buttons and rotary buttons.

Release

the clamp

Figure D

Figure E

Figure F

Figure E

Release the

clamp

Remove

the solder

Remove

the solder

Page 20

20

18. Remove the screw*22.

19. Remove the square buttons*2.

1

602-SL24F-099

螺絲*7

3 42

板外

1P配線

控制2基板

56 7

如圖A

如圖B

如圖B

1

602-SL24F-099

螺絲*15

3 42

5

6 7 8

10 11 12

1415

如圖A 如圖A

控制2基板

9

13

CONTROL 2

Screw*15

CONTROL 2

Screw*

1

602-SL24F-099

螺絲*7

3 42

控制2基板

56 7

如圖A

如圖B如圖B

1

螺絲*15

3 42

5

6 7 8

10 11 12

1415

如圖A 如圖A

控制2基板

9

13

CONTROL 2

CONTROL 2

Screw*

Button*2

Page 21

21

20-1. Remove the screw*8.

20-2. Remove the ch xed plate *2

21. Remove the screw*2, then Remove the cross fader pcb ass'y.

22-1. Remove the wheel ass'y*2.

22-2. Remove the spring & wire ass'y *2.

control 2 pcb ass'y

screw*8

1

2

3

4

CH fixed plate *2

1

4

3

2

control 2 pcb ass'y

screw*8

1

2

3

4

CH fixed plate *2

1

4

3

2

screw*2

CROSS FADER pcb ass'y

Spring

&Wier Assy

E-RING

Page 22

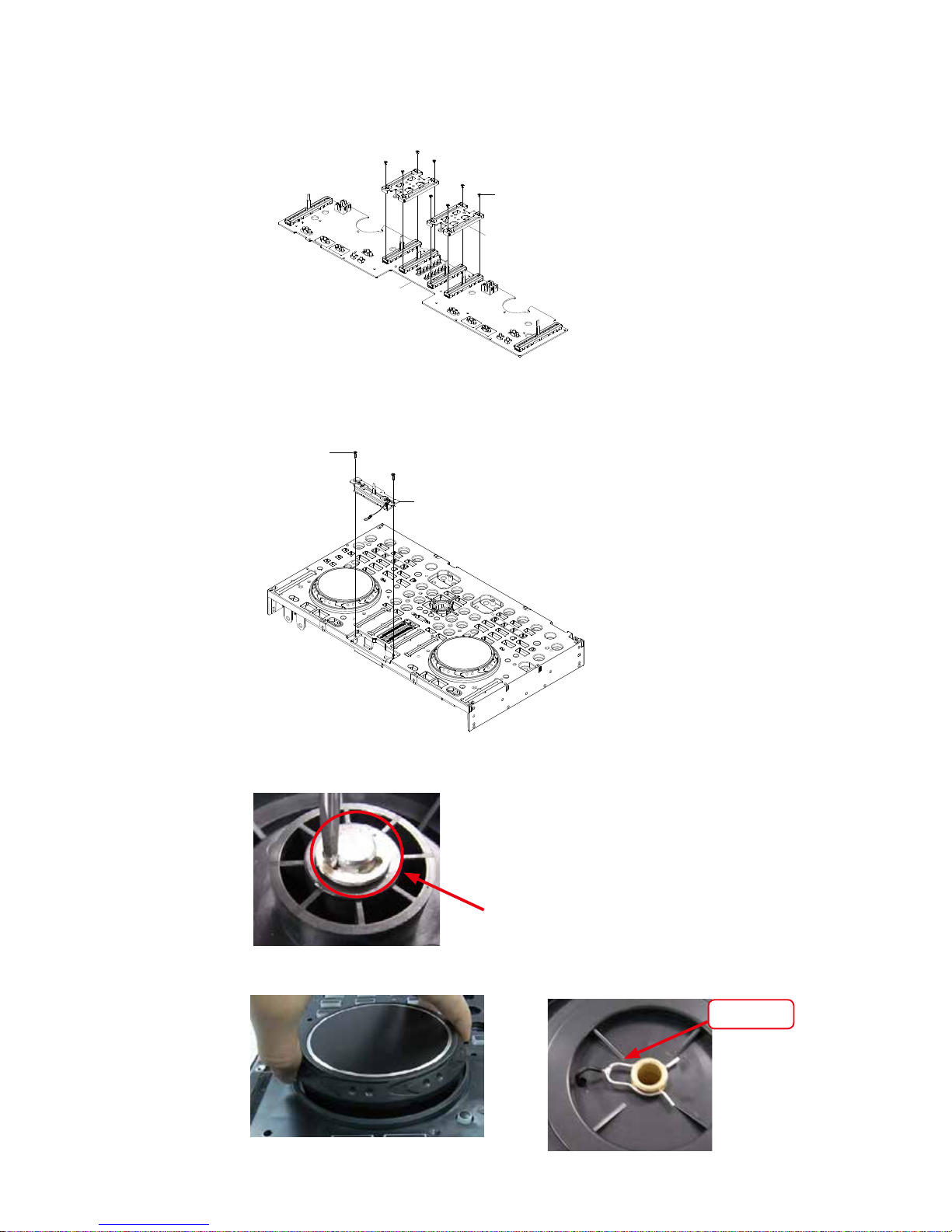

22

23. Remove the screw*4.

LED lens*2

screw*4

Page 23

23

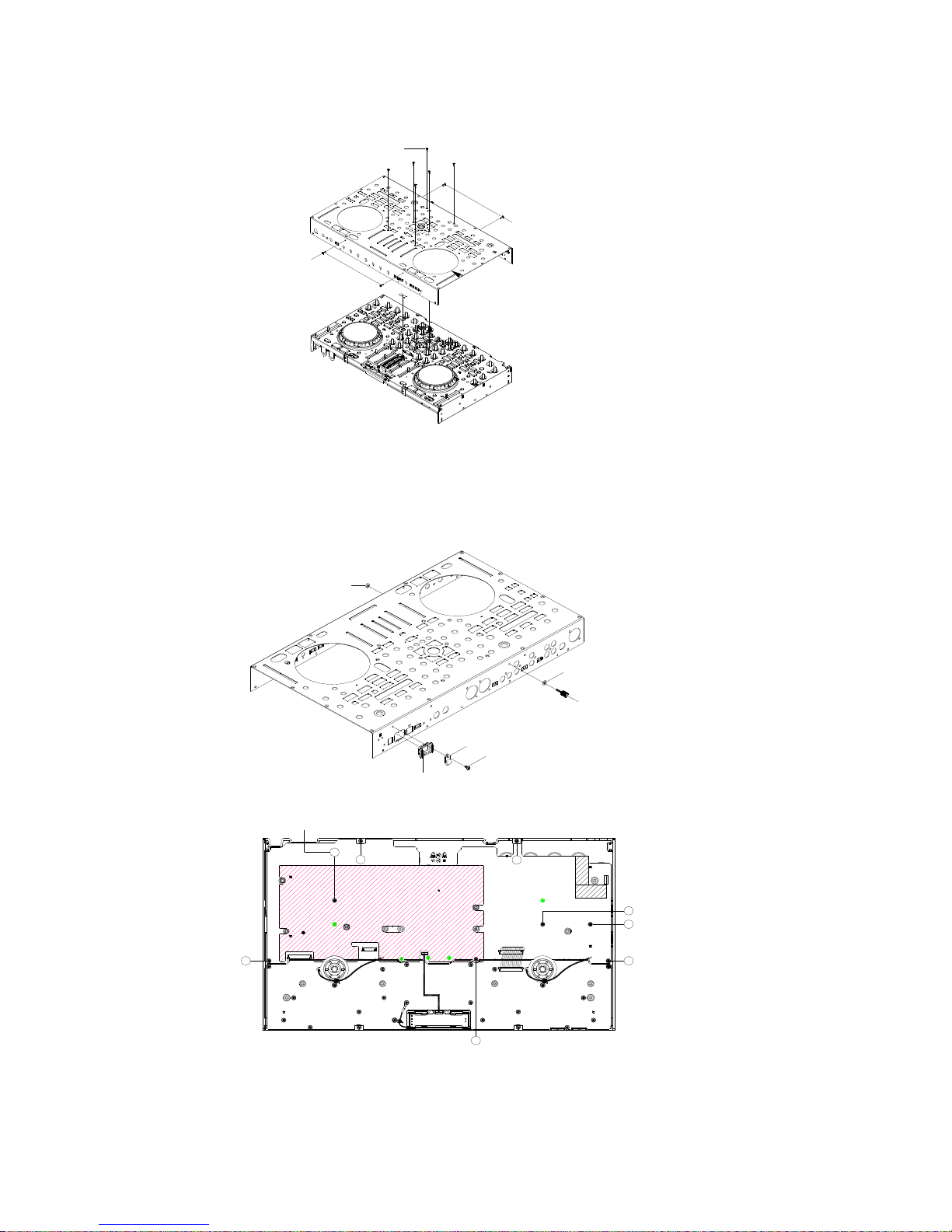

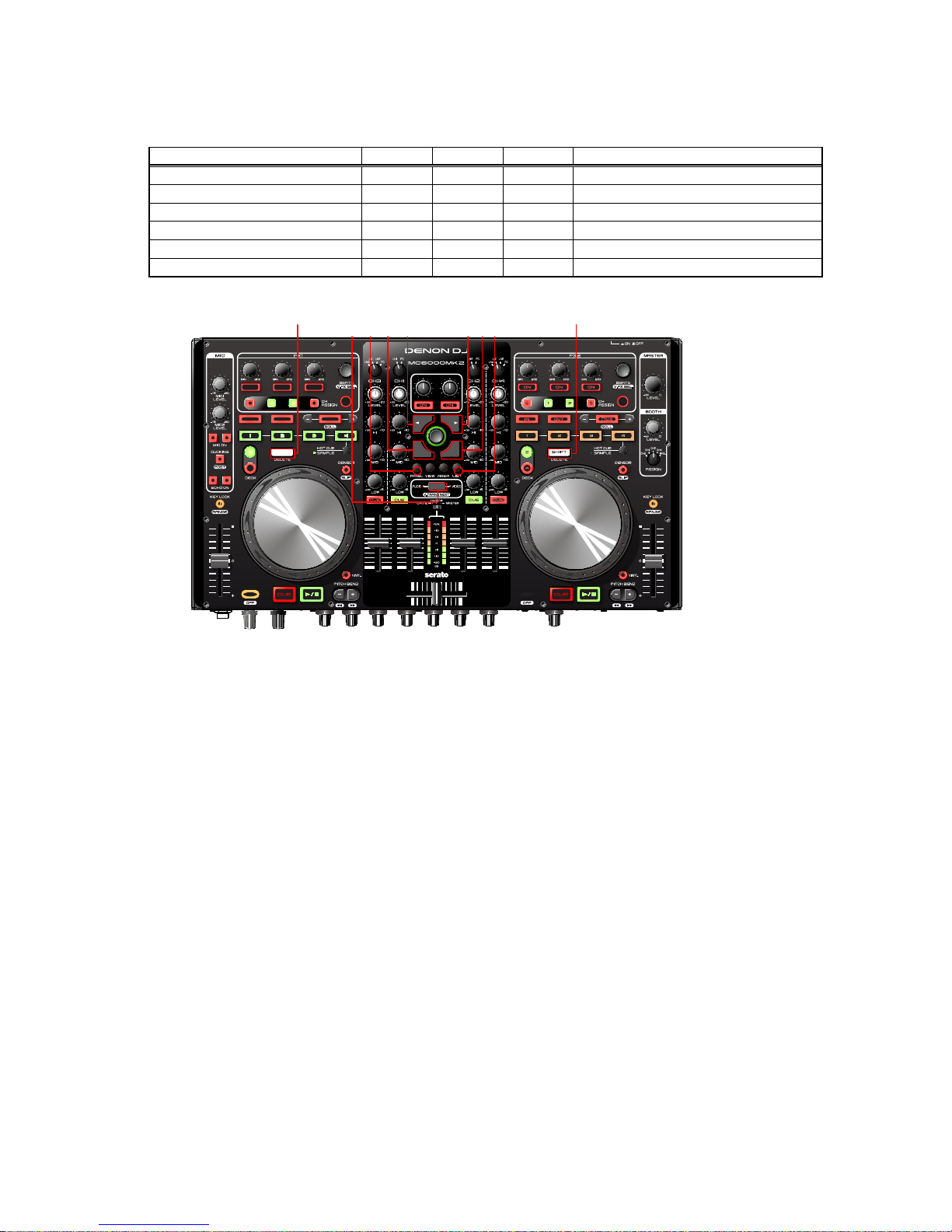

SPECIAL MODE

Special mode setting button

Hold down buttons A, B and C at the same time and press the power button to turn on the power.

Mode A B C Contents

Version Up mode 3 6 8 Firmware Upgrade

Version Display Mode 1 6 8 Firmware version display

Adjusting mode of the touch sense sensitivity 1 4 5 Adjust sensitivity of JOG wheel.

Initialize mode 1 3 6 Return to factory default setting.

MIDI transmission time mode 1 2 7 MIDI command transmission interval time

SW, VOLUME, ENCODER and LED TEST - - - Test of each function. (Use PC)

8

1 2 3 4 5 6 7

8

2. Version Up mode

Version up processing

*See "FIRMWARE UPDATE PROCEDURE" (34 page) for the procedure of the rmware update.

Page 24

24

3. Version Display Mode

Displays the version of F/W or DSP.

Hold down buttons "SHIFT" "FWD"and "X-F LINK" at the same time and press the power button to turn on the power.

DSP version display by pressing the PLAY button.

F/W version display by pressing the CUE button.

Press [SHIFT] to return to Normal Mode.

How to read the version number

Firmware Version LED (Ver A.XYZ. After Ver1.000, it is commercial version).

A : LEFT DECK (for commercial version No.)

X, Y, Z : RIGHT DECK

1 2 3 4 5 6 7 8 9

A (LEFT

DECK)

FX1-L FX1-M FX1-R DECK3 DECK1 DECK2 DECK4 TAP -

X (RIGHT

DECK)

FX2-L FX2-M FX2-R - - - - - -

Y (RIGHT

DECK)

DECK3 DECK1 DECK2 DECK4 TA P - - - -

1 2 3 4 5 6 7 8 9

Z (RIGHT

DECK)

LOOP IN LOOP OUT AUTO LOOP HOT CUE1 HOT CUE2 HOT CUE3 HOT CUE4 - -

Example : Ver1.132

DECK A side : FX1-L.

DECK B side : FX2-L, DECK3, DECK1, DECK2, LOOP IN, LOOP OUT

Seven places of LED turns on.

1 2 3

4 5 86 7

1 2 3

1

65

7

8

1 2 3

4

2 3

A: The 1st digit numeric display. X: The 2nd digit numeric display.

Y: The 3rd digit numeric display.

Z: The 3rd digit numeric display.

54

CUE:System version

PLAY: DSP version

Page 25

25

4. Adjusting mode of the touch sense sensitivity

The unit can be controlled the sensitivity of the touch sensor for the Jog Wheel in 9 steps (-4 to 0 to +4).

“-4” is the lowest sensitivity, and “+4” is the highest sensitivity.

The default setting is “0”.

(1) Pressing (X-F LINK+LOAD A+LOAD B) at the same time, then turn on MC6000MK2.

(2) Press CUE, and switch the jog wheel that you want to adjust.

(e.g.)If you press CUE of the left side, only CUE of the left side turns on, and jog wheel of the left deck is chosen to

adjust it.

(3) Rotate the track selection knob, and adjust the sensitivity. The button lights according to the set sensitivity

Buttons HOT CUE 1 HOT CUE 2 HOT CUE 3 LOOP IN LOOP OUT AUTO LOOP FX1-L FX1-M FX1-R

Sensitivity -4 -3 -2 -1 0 1 2 3 4

(4) Press the track selection knob to memorize adjustment data.

(5) Press SHIFT, then the mode switches back from the sensitivity adjustment mode to the normal mode.

5. Initialization of parameters

Return to factory default setting.

(1) Pressing (BACK+FWD+X-F LINK) at the same time, then turn on MC6000MK2.

(2) Return to default setting, and these data (as follows) turn to factory default setting.

Upon completion of the adjustment, it automatically restarts, start in Normal mode.

Initialize Data Factory default Range

JW transmission interval time 4ms 3ms

<->

20ms

Sensitivity of JOG Wheel 0 -4

<->

4

Filter/Video mode Filter Filter

<->

Video

-1

2 3 4

0 1

-2

2 3

-1

8

0

1

Left deck

Right deck

4

-3

-4

-4

-2-3

Page 26

26

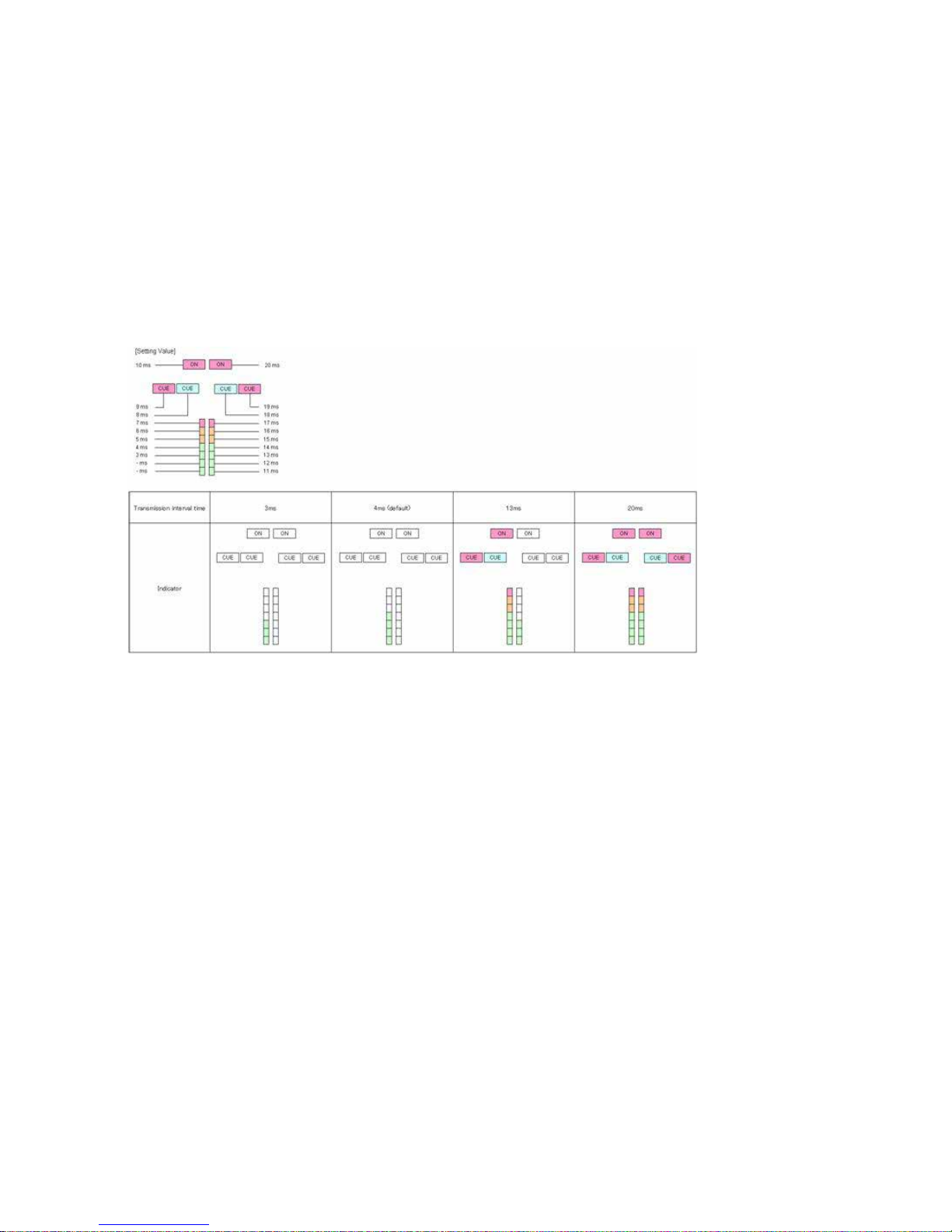

6. Adjusting interval time of MIDI command transmission

Depending on the computer specications and OS type, the computer may not be able to receive the MIDI commands

transmitted from this unit correctly.

In this case, use the following operation to set the MIDI command transmission interval time to a suitable value.

(1) Pressing (PANEL+LIST+X-F LINK) at the same time, then turn on MC6000MK2.

The following LED turns on, and the unit switches to the setting mode for MIDI command transmission interval time.

(2) Rotate SEL.

The relationship between LED display position and the MIDI command transmission interval time is as shown in the

diagram as follows. The factory setting is 4 msec.

(3) Press SEL.

The MIDI command transmission interval time is entered.

(4) Press SHIFT.

The settings are completed, and unit exits the setting mode.

How to read the interval time

Page 27

27

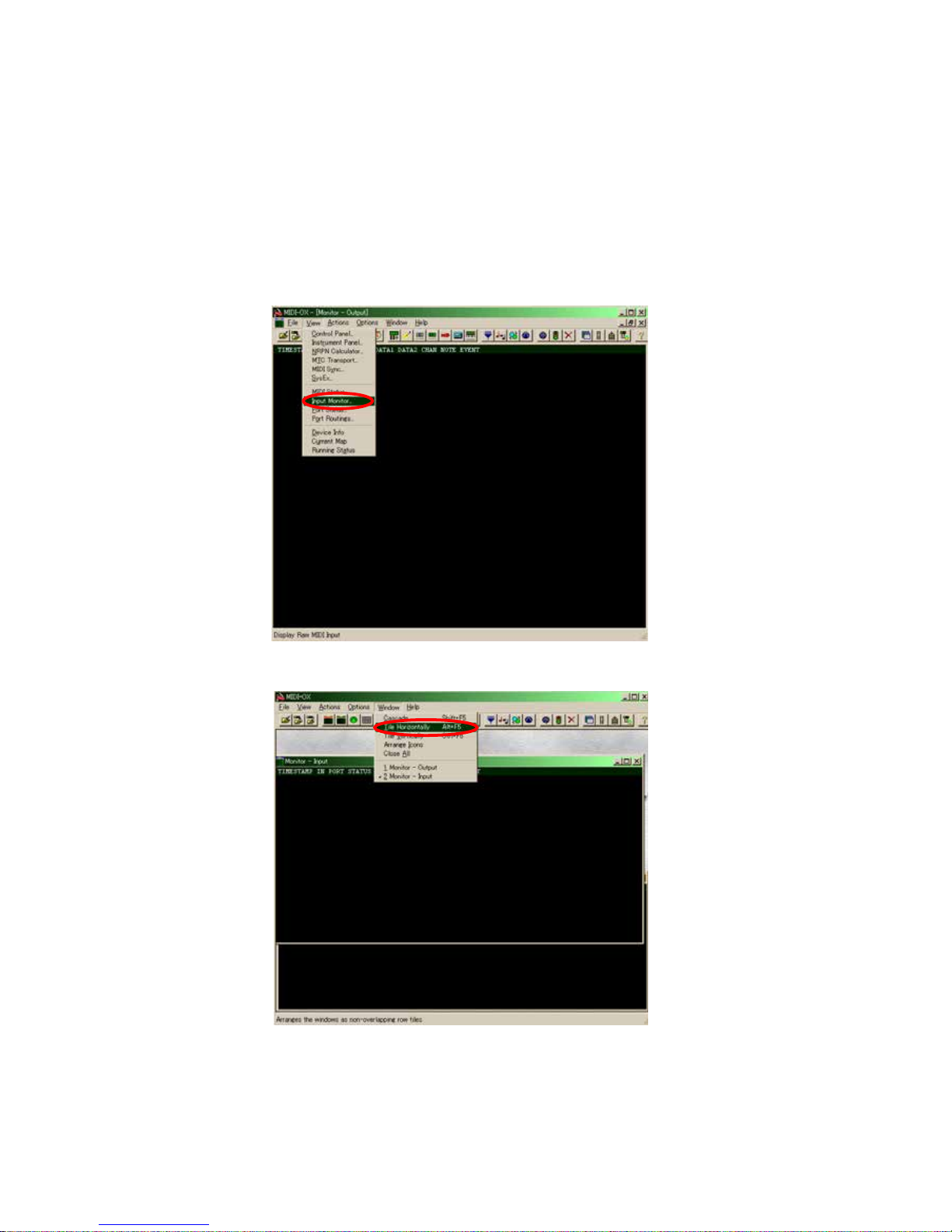

7. SW, VOLUME, ENCODER and LED TEST

Operating check procedure for the SW/VOLUME/ENCODER and LEDs on this unit with MIDI-OX.

[1] MIDI-OX Installation and Settings

Install MIDI-OX on the PC, and congure the PC environment.

(1) Download MIDI-OX (freeware).

Download from the URL below.

URL: www.midiox.com/

(2) Install MIDI-OX on the PC.

(3) Connect this unit to the PC, and switch the power on.

(4) Start MIDI-OX that you installed on the PC.

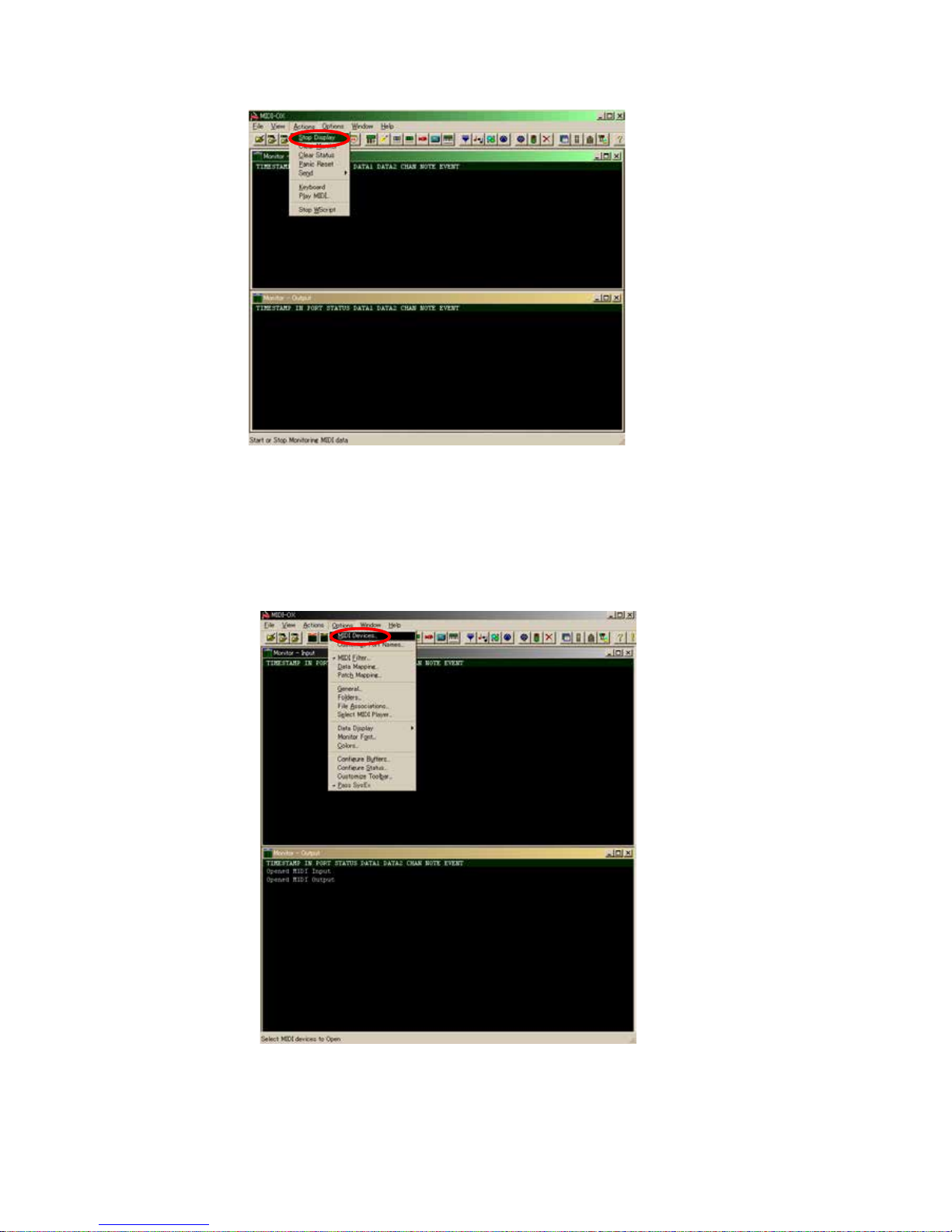

(5) In MIDI-OX, select [View] menu - [Input Monitor].

(6) Select [Window] menu - [Tile Horizontally].

Page 28

28

(7) Open the [Actions] menu and check that “Stop Display” is shown.

If “Start Display” is shown, click “Start Display” so that “Stop Display” is shown.

[2] Check the SW/VOLUME/ENCODER

When SW/VOLUME/ENCODER is operated on this unit, the corresponding MIDI command is shown on MIDI-OX.

If the MIDI command is not shown on MIDI-OX even when the panel of this unit is operated, check the following.

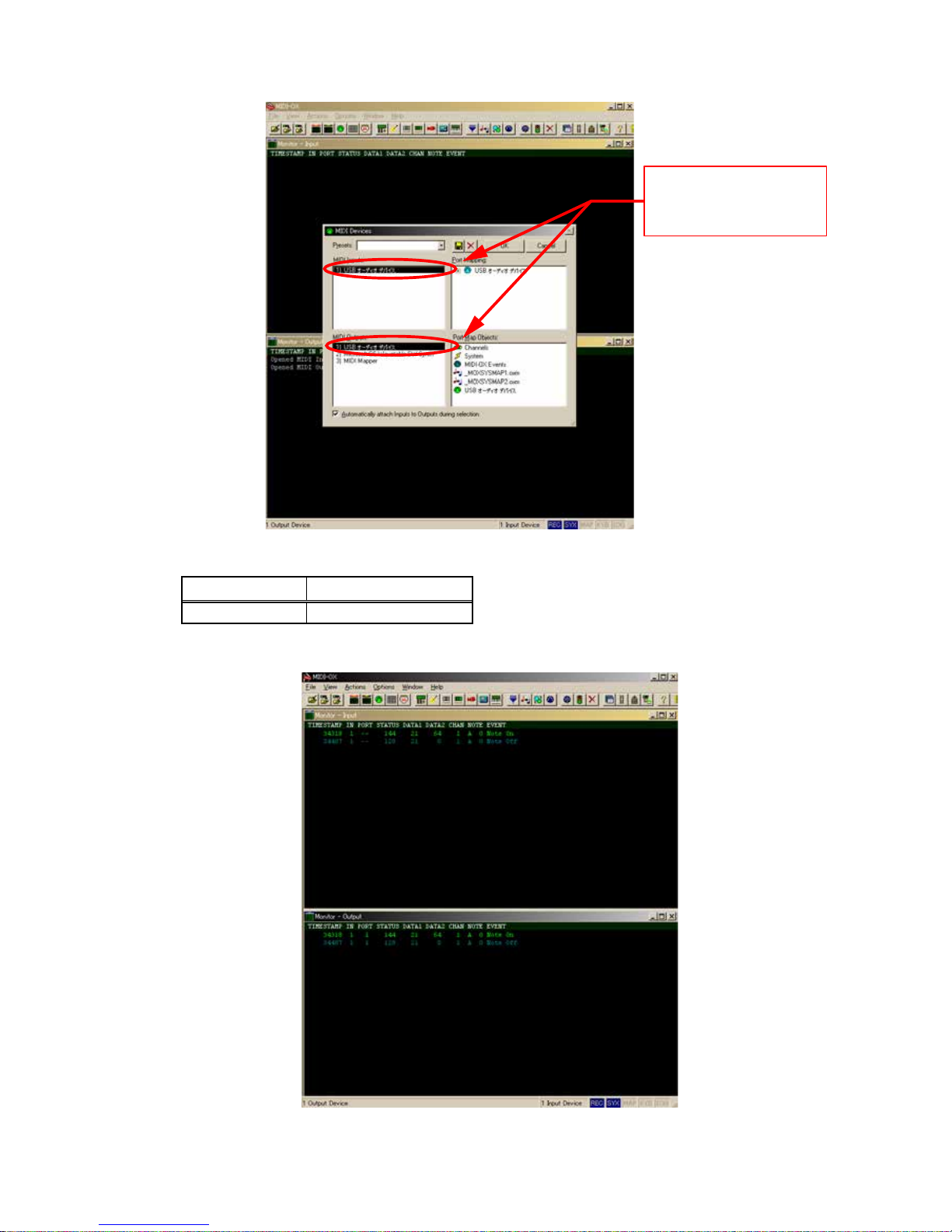

(1) Select [Options] menu - [MIDI Device].

Page 29

29

(2) Check whether the USB audio device is selected.

(3) Screen display when the EFX.1 button on this unit is switched ON-OFF.

Pressed button DATA1 column display

EFX.1 (FX1) 21

For details on the correspondence between operation on this unit and the contents of the screen display, see the

"MIDI command list" in the instruction manual.

Check that it is highlighted black.

If it is not highlighted, select it

so that it is highlighted black.

Page 30

30

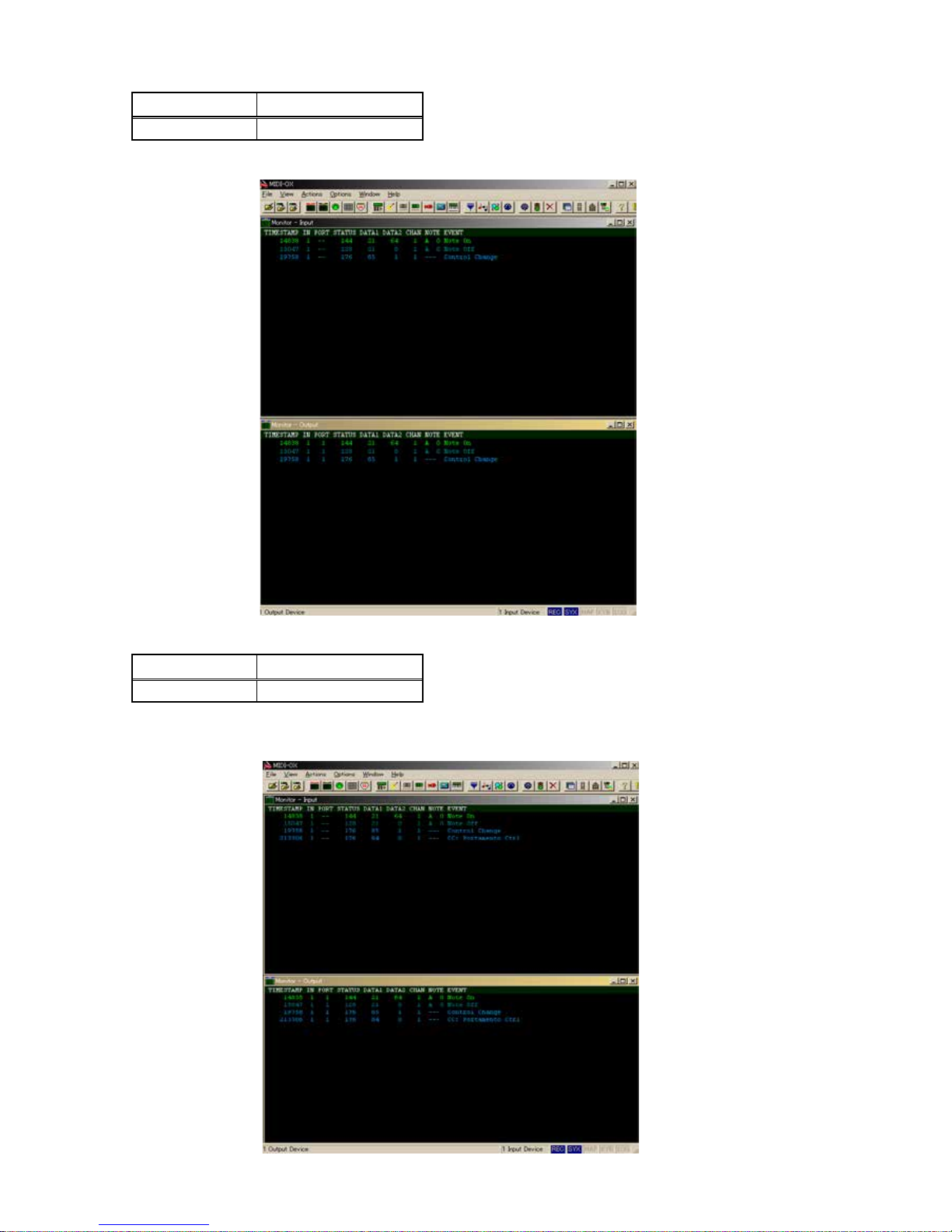

(4) Next, this is the screen display when the EFX.1 knob is moved either to the left or right.

Operated knob DATA1 column display

EFX.1 85

For details on the correspondence between operation on this unit and the contents of the screen display, see the

"MIDI command list" in the instruction manual.

(5) Next, this is the screen display when the TRACK SELECT knob on the unit is moved 1click to the right.

Operated knob DATA1 column display

TRACK SELECT 84

For details on the correspondence between operation on this unit and the contents of the screen display, see the

"MIDI command list" in the instruction manual.

Page 31

31

[3] Check the LED

When the MIDI command is sent from MIDI-OX, the LED lights/ashes/off/Dimmer.

(1) Select [View] menu - [Control Panel].

(2) These are explained in order of LED lights/off/ashes/Dimmer.

Example1 : When lighting the EFX.1 button on DECK A

In the MIDI-OX Control Panel, set the following parameters.

Control Event Channel Value

74) Brightness 1 92

When the Enter button on the PC keyboard is pressed, the EFX.1 button on the unit lights.

Page 32

32

Example2 : When ashing the EFX.1 button on DECK A

In the MIDI-OX Control Panel, set the following parameters.

Control Event Channel Value

76) --- 1 92

When the Enter button on the PC keyboard is pressed, the EFX.1 button on the unit ashes.

Example3 : When off the EFX.1 button on DECK A

In the MIDI-OX Control Panel, set the following parameters.

Control Event Channel Value

75) -- 1 92

When the Enter button on the PC keyboard is pressed, the EFX.1 button on the unit off.

Page 33

33

Example4 : When dimming the EFX.1 button on DECK A

In the MIDI-OX Control Panel, set the following parameters.

Control Event

Channel

Value

74) Brightness 1 44

When the Enter button on the PC keyboard is pressed, the EFX.1 button on the unit dims.

b

Some of the LEDs such as those for Meter or Ducking use the following parameters to light/switch off.

Control Event

Light

80) ---

Off 81) ---

For details, see the “MIDI command list” in the instruction manual.

Page 34

34

PROCEDURE AFTER REPLACING THE MICROPROCESSOR, ETC

The procedure after replacing the u-COM (Microprocessor), ash ROM, etc. is as follows.

PWB

Name

Ref. No. Description

After

replaced

Remark

CONTROL

IC100 STM8S207M8T6 B 704-6K2-A620

CONTROL

IC105 IC(EN25F1-100GIPTR) B 417-DDJLE-1084

After replacing

A : The software has been written. The software is not written at the time of replacement.

B : The software has been written. The software may need to be rewritten by version updates. Check the version.

C : The software has not been written. The software needs to be written after replacement. See “Firmware Update

Procedure” for information on writing the software.

D : The software has been written. Be sure to rewrite with the latest software for your service region. See “Firmware

Update Procedure” for information on writing the software.

FIRMWARE UPDATE PROCEDURE

1. Items to Be Prepared

(1) Connect the computer by USB cable.

MC6000MK2 : Type B

(2) UPDATER

Dowload Dennon SDI site.

for Windows : DDJUpdater-2.0.msi

for Mac : DDJ Updater.app

(3) Latest Firmware

Dowload Dennon SDI site.

le : MC6000MK2_vX.YYY

(X.YYY: Ver.No.)

2. InstallingthermwareupdateprogramforWindows

b

Upgrade program for Macintosh is installed on your Mac by copied the DDJ Updater.app.

(1) Double click the DDJUpdater-2.0.msi

MC3000

Page 35

35

(2) Click the Next.

(3) Check the I accept the terms of the license agreement,and Click the Next.

(4) Click the Next.

Page 36

36

(5) Click the Next.

(6) Click the Next.

(7) The Setup Status bar appears.

Page 37

37

(8) Click the Close.

3. UpdateFirmware

[Caution]

During the loading and upgrading the power OFF and set, PC or please do not remove the cable connection.

Also, please press the button of a keyboard and computer sets.

(1) Connect the USB cable from PC to the unit.

(2) Press the POWER button to turn on while pressing buttons BACK, FWD and SHIFT.

(3) MC6000MK2 will enter versionup mode. CUE 1 will light.

(4) Run the "DDJ Updater” on desktop of PC.

M6000MK2

Page 38

38

(5) Click the File menu. And click the Open. Select the latest rmware.

(6) Click the Load.

MC6000MK2

MC6000MK2

MC3000

MC6000MK2

Page 39

39

(7) The Setup Status bar appears.

(8) Click the OK.

MC6000MK2

MC3000

MC6000MK2

MC6000MK2

Page 40

40

(9) Click the Execute.

(10) The Setup Status bar appears.

MC6000MK2 indicates state of updating.

CUE 1: Update Ready, CUE 2: Update Data(0%),

CUE 3: Update Data(50%), CUE 4: Update Data(100%)

MC6000MK2

MC6000MK2

MC6000MK2

MC6000MK2

Ver.1.100

Page 41

41

(11) Click the OK.

(12) When version up nished, this unit is usual mode automatically.

Failure to upgrade to the PC "Version up was not completed." is displayed.

Then "Execute" click again.

MC6000MK2

Page 42

42

4. Errormessage&trabuleshooting

Message Solution

File is invalid. Please select the update le for this unit.

Load failed. Check the connection, and retry Please try again step (1).

Loaded data is invalid. Check the le Please select the update le for this unit.

Version up was not completed Please try again step (1).

(1) Unit is not connected or if the unit is not upgraded mode as shown below. Please try again step (1).

(2) If the le version is not loaded "File is not ready." Is displayed. Please try again step (5).

[Caution]

During the loading and upgrading the power OFF and set, PC or please do not remove the cable connection. Also, please

press the button of a keyboard and computer sets.

MC6000MK2

Page 43

43

TROUBLE SHOOTING

1. FLOW CHART NO.1 (704-6K2-A617 : MAIN PCB ASS'Y)

FLOW CHART NO.2 (704-6K2-A617 : MAIN PCB ASS'Y)

The unit does not power on

Has a fuse broken?

Are the FFC(24 pin:CN102), FFC(20 pin:CN801),

and PH(6 pin:CN1) correctly connected?

Is a voltage of +5V supplied to 7 pin of IC100(CPU)?

Replace IC100.

See FLOW CHART NO.2 <Broken fuse>.

Connect the connectors correctly.

NO

NO

NO

YES

YES

YES

Broken fuse

Are +12V, D5V and D3.3V voltage line supply being correctly?

Replace the fuse after repair.

Replace any faulty parts.

NO

YES

Check the circuits around the IC100 and replace any faulty

parts. (L1, SW1, Q1, L5, IC2, L7, L4, IC105)

Page 44

44

FLOW CHART NO.3 (704-6K2-A617 : MAIN PCB ASS'Y)

FLOW CHART NO.4 (704-6K2-A617 : MAIN PCB ASS'Y)

D3.3V is not outputted

Is +12V voltage line supply being correctly?

NO

D5V is not outputted

Is +12V voltage line supply being correctly?

Check the circuits around the IC1 and replace any faulty

parts.

See FLOW CHART NO.2 <Broken fuse>.

NO

YES

FLOW CHART NO.5 (704-6K2-A618 : IO PCB ASS'Y)

A5V is not outputted

Is +12V voltage line supply being correctly?

Check the circuits around the Q40 and replace any faulty

parts.

See FLOW CHART NO.2 <Broken fuse>.

NO

YES

See FLOW CHART NO.2 <Broken fuse>.

YES

Check the circuits around the IC2 and replace any faulty

parts.

Page 45

45

FLOW CHART NO.6 (704-6K2-A618 : IO PCB ASS'Y)

FLOW CHART NO.7 (704-6K2-A618 : IO PCB ASS'Y)

+A12V is not outputted

Is +12V voltage line supply being correctly? See FLOW CHART NO.2 <Broken fuse>.

NO

YES

Check the circuits around the Q41 and replace any faulty parts.

-A12V is not outputted

Is +12V voltage line supply being correctly?

Check the circuits around the U741 and replace any faulty

parts.

See FLOW CHART NO.2 <Broken fuse>.

NO

YES

FLOW CHART NO.8 (704-6K2-A618 IO PCB ASS'Y)

A3.3V is not outputted

Is +12V voltage line supply being correctly?

Check the circuits around the U40 and replace any faulty

parts.

See FLOW CHART NO.2 <Broken fuse>.

NO

YES

Page 46

46

FLOW CHART NO.9 (704-6K2-A615 CONRTOL 1 PCB ASS'Y)

NO

NO

The keys cannot be operated

Are the contact point and the installation state of the key

switches (SW100~SW170) and rotary encoder (SW150, 154,

158) nomal?

Does LED (D153~D180, D207~D287) light correctly?

When pressing each key switches, turning rotary switches

and turning rotary encoder, does the voltage of each pin of

IC100 (shown below) decrease?

-------------------------------------------------------------------------------SW100, SW106, SW111, SW116, SW121, SW126, SW131,

SW136, SW141: IC100 60pin

SW101, SW109, SW114, SW119, SW124, SW129, SW134,

SW139, SW144: IC100 61pin

SW102, SW108, SW113, SW118, SW123, SW128, SW133,

SW138, SW143: IC100 62pin

SW103, SW105, SW110, SW115, SW120, SW125, SW130,

SW135, SW140: IC100 63pin

SW104, SW107, SW112, SW117, SW122, SW127, SW132,

SW137, SW142: IC100 64pin

SW147, SW153, SW157, SW162, SW166, SW167, SW168,

SW169, SW170: IC100 65pin

SW148, SW151, SW155, SW159, SW163: IC100 66pin

SW149, SW152, SW156, SW160, SW164: IC100 67pin

SW161, SW165: IC100 70pin

Rotary encoder

SW150, SW154, SW158: IC100 70pin

Re-paste the switches correctly or replace the poor switches.

YES

YES

YES

Check the Q100~Q120, IC101, IC102, IC107 and surrounding,

and replace any faulty parts.

NO

Check the key switches and the rotary encoder and and

surrounding, and replace any faulty parts.

YES

Replace IC100.

Page 47

47

NO

Slide switches cannot be operated.

Are the contact point and the installation state of the Slide

switche (SW174) normal?

When switching Slide switch (SW174), does the voltage of 11

pin of IC109 increase?

Re-paste the switches correctly or replace the poor switches.

YES

FLOW CHART NO.10 (704-6K2-A615 CONRTOL 1 PCB ASS'Y)

FLOW CHART NO.11 (704-6K2-A616 CONRTOL 2 PCB ASS'Y)

The keys cannot be operated

Is the FFC(CN100) correctly connected ?

Are the contact point and the installation state of the key

switches (SW400~SW411) nomal?

YES

NO

Connect the FFC correctly.

NO

Check A3.3V is output.

YES

Replace IC109.

NO

Re-paste the switches correctly or replace the poor switch.

YES

Does LED (D412~D431, D434~D445 ) light correctly?

NO

Check the Q403~Q414, IC401 and surrounding, and

replace any faulty parts.

When pressing each key switches, turning rotary switches

and turning rotary encoder, does the voltage of each pin of

IC100 (shown below) decrease?

-----------------------------------------------------------------------------SW400, SW401, SW402, SW403: IC100 66pin

SW404, SW406, SW408, SW410: IC100 67pin

SW405, SW407, SW409, SW411: IC100 70pin

Replace IC100.

YES

YES

NO

Check the key switches and the rotary encoder and and

surrounding, and replace any faulty parts.

Page 48

48

FLOW CHART NO.12 (704-6K2-A618 IO PCB ASS'Y, 704-6K2-A617 : MAIN PCB ASS'Y)

Audio is not output from the Master output.

Are the PH(6pin:CN1), FFC(24pin:CN102), and

FFC(20pin:CN801) correctly connected?

YES

• Set the channel input source switch to "LINE"

• Set the CROSS FADER CONTOUR to "THRU"

• Set the input level volume to "12:00"

• Set the Cannel FADER to "MAX".

• Set the master level volume to "14:30".

Are audio signals output to 18pin(Lch), 15pin(Rch) of U755

when an audio signal of 1kHz 0dBV is input externally to the

LINE input?

Are the audio signals outputted to 7 pin(Lch), 1 pin(Rch) of

U507?

Are the audio signals outputted to 7 pin(Lch), 1 pin(Rch) of

U508?

Check surrounding circuit of JK504, JK505 from 1 pin(Rch), 7

pin(Lch) of U508, and replace any faulty parts.

Is base terminal of Q42(MUTE control signal) +3.3V, and has

been base terminal of Q518~Q521(MUTE drive signal) L

(-12V)?

YES

YES

YES

YES

NO

Connect the connector cable and FFCs correctly.

NO

Check surrounding circuit of U755, and service it if defective.

When the surrounding circuit is correct, replace U755.

NO

Check surrounding circuit of U507, and service it if defective.

When the surrounding circuit is correct, replace U507.

NO

Check surrounding circuit of U508, and service it if defective.

When the surrounding circuit is correct, replace U508.

NO

Check surrounding circuit of Q42, Q518~Q521 and replace

any faulty parts.

Page 49

49

FLOW CHART NO.14 (704-6K2-A616 CONRTOL 2 PCB ASS'Y, 704-6K2-A615 CONRTOL 1 PCB ASS'Y)

JOG WHEEL is no operating

(BEND functions is not operating)

Is D3.3V being output from 27 pin of CN100?

Is encoder waveform(0-3.3V) outputted to 14pin, 15pin, 16pin,

17pin of CN100, when JOG WHEEL is turned.(See Fig.1-6 of

the 52 page.)

Is encoder waveform(0-3.3V) outputted to 9pin, 10pin, 11pin,

12pin of IC100 from CN100, when JOG WHEEL is turned.(See

Fig.1-6 of the 52 page.)

Connect the FFC (32pin:CN100) correctly.

Check surrounding circuit of CN100 from D432/D433/D443/

D444, and service it if defective.When the surrounding circuit

is correct, replace FFC cabel.

NO

NO

YES

YES

FLOW CHART NO.13 (704-6K2-A618 IO PCB ASS'Y, 704-6K2-A617 : MAIN PCB ASS'Y)

Sound of LINE input is not being output correctly

Are the PH(6pin:CN1), FFC(24pin:CN102), and

FFC(20pin:CN801) correctly connected?

YES

• Set the channel input source switch to "LINE"

• Set the CROSS FADER CONTOUR to "THRU"

• Set the input level volume to "12:00"

• Set the Cannel FADER to "MAX".

• Set the master level volume to "14:30".

Are audio signals output to 7pin(Lch), 1pin(Rch) of U505

when an audio signal of 1kHz 0dBV is input externally to the

LINE input?

Are the audio signals outputted to 11 pin and 12 pin of U751?

Are the digital audio signals (0-3.3V) outputted from 4 pin of

U751?

Check surrounding circuit of 88 pin of IC902 from 4 pin of

U751, and replace any faulty parts.

YES

YES

YES

NO

Connect the connector cable and FFCs correctly.

NO

Check surrounding circuit of U505 from K500, and service it if

defective.

When the surrounding circuit is correct, replace U505.

NO

Check periphery circuit of U751 from U505, and replace any

faulty parts.

When the periphery circuit is correct, replace U751.

NO

Replace any faulty parts.

NO

Check surrounding circuit of IC100 from CN100, and service it

if defective.

YES

Replace IC100.

Page 50

50

FLOW CHART NO.15 (704-6K2-A615 CONRTOL 1 PCB ASS'Y)

JOG WHEEL is not operating

(SCRATCH function is not operating)

Is BEND function operating?

YES

Is reference waveform outputted at 2pin, 6pin and 12pin of

IC106 and IC111?

(See Fig.1-7-1 of the 52 page.)

When JOG WHEEL is touched, is wavelength of 2pin, 6pin

and 12pin changing of IC106 and IC111?

(See Fig.1-7-2 of the 52 page.)

Is waveform inputed to 2pin of IC104 and 5pin of IC110?

(See Fig.1-7-3 of the 52 page.)

Replace IC100.

When the top of JOG WHEEL is touched, is waveform inputed

to 20pin and 28pin of IC100 changed?

YES

YES

YES

YES

NO

See FLOW CHART NO.14 <JOG WHEEL is not

operating. (BEND function is not operating.)>.

NO

Check the surrounding circuit of IC106 and IC111 and rreplace

any faulty parts.

When the surrounding circuit is correct, replace IC106 and

IC111.

NO

Check the surrounding circuit of JOG WHEEL form IC106

and IC111 and replace any faulty parts When the surrounding

circuit is correct, replace JOG WHEEL.

NO

Replace IC104 and IC110.

NO

Check surrounding circuit of IC100 from IC104 and IC110,

and replace any faulty parts.When the surrounding circuit is

correct, replace IC104 and IC110.

Page 51

51

WAVEFORMS and TROUBLESHOOTING

1-1 Power failure

Symptom: The DECK1&2 LED and DECK1&2 VINYL does not light. Status of

The product: The power circuit failure

Diagnostic procedure:

1. Connect the DC12V/3A adaptor, Turn on the power switch, as gure 1-1.

2. Check each DC voltage, measure C21 positive to ground is +12V C18 positive to ground is D5V, C17 positive to ground is D3.3V, C46

positive to ground is 3.3V, C47 positive to ground is A3.3V, C51 negative to ground is A-12V, C50 positive to

ground is A+12V.

1-2Nokeyfunction

Symptom: No key function

Diagnostic procedure:

1.Measure if there is operating wave for pin of tact sw, as gure 1-2

If it is not, please check tact sw. status.

1-3 Rotary selector not controllable

Symptom: Rotary selector not controllable

Diagnostic procedure:

1.Measure if there is operating wave for pin of EN1~EN6, Check IC100 PIN42 ~ PIN46&PIN52,

as gure 1-3

If it is always on high level, please check if Rotary selector is controlled.

1-1 C21 +12V

1-3 ROTARY ENCODER PIN

1-2 TACT SW PIN

1-1 C50 A+12V1-1 C51 A-12V1-1 C47 A3.3V

1-1 C46 3.3V1-1 C17 D3.3V1-1 C18 D5V

Page 52

52

1-4Slidervolumenotcontrollable

Symptom: Slider volume not controllable

Diagnostic procedure:

1.Measure if there is operating wave for pin of AD10~AD11, Check IC402 PIN3&PIN13, as gure 1-4

If it is always on high level, please check if Rotary selector is controlled.

1-5Selectswitchcannotwork

Symptom: Select switch can not work

Diagnostic procedure:

1.Measure if there is operating wave for pin, Check IC380 PIN9&PIN10, as gure 1-5

If it is always on high level, please check if selector switch is controlled.

1-6 Jog rotation can not be dectected

Symptom: Jog rotation can not be detected

Diagnostic procedure:

1.Turn the jog to measure if there is operating wave for pin, Check IC403 PIN2&PIN4&PIN8&PIN10, as gure 1-6

1-7Jogtouchcannotbedetected

Symptom: Jog touch can not be detected

Diagnostic procedure:

1.Touch the jog to measure if it is Hi to Low for pin, Check IC106&IC111 PIN5, as gure 1-7-4

If the wave is unexpected, please check IC106&IC111

1-6 JOG ROTATION PIN

1-5 SLIDER SWITCH PIN

1-4 SLIDER VOLUME PIN

1-7-31-7-21-7-1

1-7-4

Page 53

53

1-8Nosoundinput/outputfromUSB

Symptom: Audio is not input/output :

Diagnostic procedure:

1.Connect PC with USB cable.

2.Is there clock 6MHz to ground IC901->PIN51&50 If it is not, IC901、X900 is damaged.

3.Is a signal input to the USB D+ & D- ? IC901 USB IN->PIN7& PIN8 , as gure 1-8

4.If it is not, IC901 is damaged.

1-9NosoundoutputfromMASTEROUT

Symptom: Audio is not output & MASTER level meter is not light up :

Diagnostic procedure:

1.Is a signal output to the DAC? U755:MASTER->PIN15&PIN18

A. If it is, something is wrong with the analog -circuit block. Check if output amplier (U515:MASTER) is

working normally. Check if each MUTE transistor (Q512~513) BASE PIN is -12V.

B. If it is not, something is wrong with the digital-circuit block. Check if there is CLOCK signal for

U755 :MASTER->PIN1 & PIN2 & PIN3 & PIN4 , as gure 1-9.

1-10NosoundoutputfromBOOTH

Symptom: Audio is not output :

Diagnostic procedure:

1. Is a signal output to the DAC? U756:BOOTH->PIN15 & PIN18

A. If it is, something is wrong with the analog -circuit block. Check if output amplier (U510)

is working normally. Check if each MUTE transistor (Q526~Q529) BASE PIN is -12V.

B. If it is not, something is wrong with the digital-circuit block. Check if there is CLOCK signal for

U756:BOOTH ->PIN1 & PIN2 & PIN3 & PIN4, as gure 1-9.

1-9 U755 PIN 21-9 U755 PIN 1

1-8 IC901 PIN7& PIN8

1-9 U755 PIN 4

1-9 U755 PIN 3

Page 54

54

1-11NosoundoutputfromPHONES

Symptom: Audio is not output :

Diagnostic procedure:

1. Is a signal output to the DAC? U759:PHONES->PIN15 & PIN18

A. If it is, something is wrong with the analog -circuit block. Check if output amplier (U512: PHONES) is

working normally. Check if each MUTE transistor (Q550~Q553:PHONES)BASE PIN is -12V.

B. If it is not, something is wrong with the digital-circuit block. Check if there is CLOCK signal for

U759 :PHONE->PIN1 & PIN2 & PIN3 & PIN4, as gure 1-9.

1-12NosoundinputfromMIC1

Symptom: Audio is not input:

Diagnostic procedure:

1. Is a signal input to the ADC ? MIC(U752) ->PIN10

A. If it is not, something is wrong with the analog-circuit block. Check if OPA MIC(U513) is working

normally.

B. If it is, something is wrong with the digital-circuit block. Check if there is CLOCK signal for MIC(U752) >PIN2 & PIN4 & PIN7 & PIN8, as gure 1-9

1-9 U755 PIN 21-9 U755 PIN 1

1-9 U755 PIN 4

1-9 U755 PIN 3

Page 55

55

BLOCK DIAGRAM

LINE1 L/R

LINE3/PHONO

L/R

0dBV

(-40dBV)PHONO

-11.48dB

ADC

CS5341

-16.93dB

ADC

PCM1803

LINE4/PHONO

L/R

(-40dBV)PHONO

LINE2 L/R

0dBV ADC

CS5341

2

3

1

L

T

R

R

G

S

MIC1

MIC2

-40dBu

-40dBu

Balance(mono)

Balance(mono)

ADC

CS5341

+40dB

+40dB

+12.25dB

DAC

CS4351

MASTER OUT(RCA)

BAL ANCE

+4dB

2

3

1

MASTER OUT(Balance)

+12.25dB

BAL ANCE

+4dB

BOOTH OUT(Balance)

L

3

R

2

G

1

+4.19dB

REC OUT(RCA)

+16.9dB Headphone(40 ohm)

L

3

R

2

G

1

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM8080G

NJM2068

NJM8080G

DSP56724

FLASH ROM

EN25F10

USB PortB

TUSB3200

DC POWER

+12V/3A

STM8S207MBT6

MCU

1 2

POWER

MOSFET SW

TPS54232

TPS54232

D3.3V

D5V

A+12V

SPI

I2C

EXT. AD

TC4052*6

CROSS* 1

PITCH* 4

FADER* 4

ROTARY* 28

FUNCTI ON*4

PIC16F616*2

PWM

TOUCH PLAT* 2

ENCODER* 6

LED* 152

DI0 DI1

DI2

DI3

DI4

DI5

DI6

DO0 DO1

DO2

DO3

DO4

DO5

URST

DRST

6M

512fs for A/D,D/A)

(I2S format for audio data)

(245.76MHz)

24.576M

(12MHz)

(24MHz )

Switching P ower

Front PCB

I/O PCB

Control PC B

-16.93dB

NJM8080G

-11.48dB

NJM8080G

BCK

ST/MO SW*1

WHEEL *4

EXT. AD

TC4052*2

Booth EQ*2

MIC EQ*6

Front PCB

TPS54232A5V

XFADER* 1

CH SW*4

MIC ECHO*1

Monitor*2

12pAD

4pAD

Split Cue*1

USB Audio*1

Tact/Push SWsend

*81

return9p9p

Hysteresis

74HC14

RIAA

2C11

LN/PH

RIAA

2

C1

1

LN/PH

MUTE

MUTE

MUTE

MUTE

MUTE

MUTE

MUTE

LRCK

BD4745

A+12V

A-12V

Compare

Power Delay

Buck boost

Buck

Buck

KTC3228Y

ADC

PCM1803

D3.3VA5V

D3.3VA5V

D3.3VA5V

D3.3VA5V

D3.3VA5V

D3.3VD5V

D3.3V

D3.3V D5V

D5V

D3.3V

DAC

CS4351

DAC

CS4351

DAC

CS4351

SER.- ->PAL.

74HCT595*5

D3.3V

D5V

USB SW.

D3.3VA+12V

Tr. AMP

3 1

2

+16.39~ +60 dB

NJM2068

3 1

2

+16.39~ +60 dB

-11.48dB

-11.48dB

Tr. Buffer

Tr. Bufer

I2S Buffer

74HC4050

BCK ,LRCK

SCK

24M

MAIN PCB

I/O PC B

MAIN PCB

2SA2127

2SD1207S

A+12V

MTZJ6.8B

A3.3V

BU33TD3

A3.3V

LDO

D3.3VA+12VA3.3V

D3.3VA+12VA3.3V

D3.3VA+12VA3.3V

INT

Page 56

56

POWER BLOCK DIAGRAM

A

B

C

D

AC/DC Adapertor

+12V/3A

MOSFET SW

TPS54232

AC IN

Main Power Cont.

A+12V

Buck Boost

DC Convertor

A-12V

Pre-OPA

NJM8080G

Phones Driver

LDO

BU33TD3

DAC

CS4351

A. Mute

2SD2704K

DC/DC Buck

TPS54232

D5V

D3.3V

DC/DC Buck

TPS54232

DC Convertor

USB Controller

TUSB3200 logic

USB Controller

TUSB3200 Core

AD Switch

Flash Memory

EN25F10

LED Scan

74HCT595

Hysteresis

74HC14

POWER BLOCK DIAGRAME

74HC4052

ADC

CS5341

ADC

PCM1803

MCU

STM8S207

PWM

PIC16F616

DAC

CS4351

DC Convertor

LDO

NJM79L09

MIC-OPA

NJM2068

A-9V

Phones Driver

Pre-OPA

NJM8080G

DAC

CS4351

LDO

KTC3228Y

ADC

CS5341

ADC

PCM1803

A5V

A3.3V

A. Mute

2SD2704K

2SC1815GR

2SA1015GR

MIC-OPA

NJM2068

A-12V

D5V

D3.3V

Page 57

57

LEVEL DIAGRAM

Line3,4/Phono

-17.5

A/D

dBV

LINE Max Input Level

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

limit -0.1dBV

PCM1803

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

dBFS

ANALOG

31

2

TRIM EQ

31

2 3

1

2

CH.Fader * CR.Fader

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

DR:105dB

-140

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

D/A

DR:112dB

CS4351

0dBFS=6dBV

31

2

Master Level

NJM8080G

Master Out

ANALOG

DIGITAL

DR:112dB

-16.93

NJM8080G

15dBV

CS5341

+6

231

NJM8080G

dBV

0

10

20

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

+10.24

BALANCE Max. 23.6dBu

+8~ -12 dB

-144dBFS@24bit

Noise Level

PC-->DA@-77.76dBV

@-121dBV

Clip=17.41dBV

Clip=17.41dBV

Balance Clip=23.41dBV

MIC VR Min. position

-16dBu

+16.39

-60dBu

Phono Level

-40dBV

+40

D/A

DR:112dB

CS4351

0dBFS=6dBV

31

2

CUE Level

+11.9

Mic. Max. Noise -68.36dBV

Unbalance Max. 19.6dBu

L

3

R

2

G

1

PHONES

RIAA

LN:0

PH:+40

+20~0~ -∞ dB

+10~ -∞ dB

0~ -∞ dB +10~ -∞ dB

LINE1,2

A/D

limit -0.1dBV

CS5341

-17.5

NJM8080G

NJM8080G

ADC

CS5341

L

3

R

2

G

1

S

4

MIC.

NJM2068

-17.5

NJM8080G

EQ

+15~ -15 dB

31

2

GAIN

+16.39~ +60 dB

Booth EQ

+15~-15dB

PCM1803

D/A

DR:112dB

CS4351

0dBFS=6dBV

31

2

Booth Level

NJM8080G

+10~ -∞ dB

XLR

RCA

+8

-12

+10.24

+15

Phones Max. 120mW

Phono Noise

-97.93dBV

Phono@-82.76dBV

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

dBFS

+10.24

MIC Noise(VR.Min.)

@-127dBu

Max.Phono Level

-25dBV

Max. MIC Level 3dBu

DR:105dB

DR:103dB

DR:105dB

1:30 position

+20

Unbalance Out 0.45dBu(Ref.)Reference LINE3/4 level 0dBV

-15

MIC VR Max. position

+60

LINE1/2

LINE3/4

-16.93

CS5341

-17.5

15.05dBV

L

3

R

2

G

1

Booth Out

+6

-5dBFS

+10.24

-20dBFS

-40dBu

MIC VR 2:30 position

LINE1,2@-86.76dBV

Max. position

+10

Tr. AMP

limit +0.5dBV

+11.9

MIC

-17.5

-0.2dBFSMIC Max. IN

-16.93

+40

PCM1803

DR:103dB

LINE1/2 Noise

-132.48dBV

MIC Noise(VR.Max.)

MIC Noise(VR 2:30)

-86.71dBV

-106.71dBV

-130.32dBV

-86.61dBFS

-14dBV

Phones 4dBm(Ref.)

-0.65dBV

-100.99dBFS

LINE3,4@-84.76dBV

LINE:-2.56

LINE Max. IN

LINE 1/2

5.16dBV

Max.

+2

+2

+2

+6

-1.7

-3.52

+13.35

-4.9dBV

+9.1

14:30

Phones Min. noise -97.11dBu

Page 58

58

WIRING DIAGRAM

N380

N802

N1

FRONT PCB

W380

CN104

MAIN PCB

CN102

CN801

CN1

N105

N801

I/O PCB

CN100

CN100

CONTROL 1 PCB

CONTROL 2 PCB

W101

WHEEL1

EARTH

TO CS FIXED PLATE

WHEEL2

EARTH

CN105

CN102

CN104

W103

CN103

CROSS FADER PCB

Page 59

59

IO PWB (A SIDE)

IO PWB (B SIDE)

MAIN (A SIDE)

MAIN (B SIDE)

PRINTED WIRING BOARDS

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

A

B

C

D

E

F

G

H

J

K

L

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Page 60

60

FRONT PWB (A SIDE)

FRONT PWB (B SIDE)

FADER PWB(A, B SIDE)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

A

B

C

D

E

F

G

H

J

K

L

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Page 61

61

CONTROL 1 (A SIDE)

CONTROL 1 (B SIDE)

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

A

B

C

D

E

F

G

H

J

K

L

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Page 62

62

CONTROL 2 PWB (A SIDE)

CONTROL 2 PWB (B SIDE)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

A

B

C

D

E

F

G

H

J

K

L

M

1

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Page 63

COREVDD1COREGND2LAL E3LCS04LCS15LCS26LCS37LCS48LCS59LCS610LCS711IOVDD12IOGND13COREVDD14GOREGND15LWE16LOE17LGP518LSDA1019LCK E20LCLK21LBCTL22LSDWE23LSDCAS24LGTA25LA026LA127LA228IOVDD29IOGND30PLLP1GND31PLLP1VDD32PLLD1GND33PLLD1VDD34PLLA1GND35PLLA1VDD

36

LSY NCI N

37

LSY NCOU T

38

LAD 23

39

LAD 22

40

LAD 21

41

LAD 20

42

LAD 19

43

LAD 18

44

LAD 17

45

CORE VD D

46

CORE GND

47

IOV DD

48

IOGND

49

LAD 16

50

LAD 15

51

LAD 14

52

LAD 13

53

LAD 12

54

LAD 11

55

LAD 10

56

LAD 9

57

IOV DD

58

IOGND

59

CORE VD D

60

CORE GND

61

LAD 8

62

LAD 7

63

LAD 6

64

LAD 5

65

LAD 4

66

LAD 3

67

LAD 2

68

LAD 1

69

LAD 0

70

IOGND

71

IOV DD

72

PLLPVDD

73

PLLAVDD74PLLAGND75PLLDVDD76PLLDGND

77

PLLPGND

78

XTAL

79

EXTAL

80

IOVDD81IOGND

82

SPDIDIN1

83

SPDIFOUT1

84

SDO5/I0

85

SDO4/I1

86

SDO3/I2

87

SDO2/I3

88

HCKT

89

FST

90

SCKT

91

HCKR

92

SCKR

93

FSR

94

COREVDD95COREGND

96

SDO5_1/I0_197SDO4_1/I1_198SDO3_1/I2_199SDO2_1/I3_1

100

TMS

101

TCK

102

TDI

103

TDO

104

PINIT/NMI

105

WDT

106

IOVDD

107

IOGND

108

CORE VD D

109

CORE GND

110

RES ET

111

SS_1/HA2_1

112

MISO/SDA

113

MOSI/HA 0

114

SCK /SCL

115

HRE Q/PH4

116

SS/HA2

117

SDO5_3/I0_3

118

SDO4_3/I1_3

119

SDO3_3/I2_3

120

SDO2_3/I3_3

121

SDO5_2/I0_2

122

SDO4_2/I1_2

123

SDO3_2/I1_2

124

SDO2_2/I3_2

125

MODD1/PG2

126

M

ODC1/NMI_1

127

MODB1/IR QD

128

MODA1/IR QC

129

CORE VD D

130

CORE GND

131

IOV DD

132

IOGND

133

HCK T_3

134

FST_3

135

SCK T_3

136

HCK R_3

137

SCK R_3

138

FSR_3

139

MODD0/PG1

140

MODC0/PLOC K

141

MODB0/IR QB

142

MODA0/IR QA

143

SCAN

144

IC902

DSP56724

C919

0.1

C921

0.1

C920

0.1

C931

0.1

C932

0.1

C929

0.1

C930

0.1

C933

0.1

C934

0.1

C935

0.1

C936

0.1

C937

0.1

C939

0.1

C940

0.1

C938

0.1

C927

0.1

C928

0.1

C926

0.1

C925

0.1

C922

0.1

C923

0.1

X901

24.576M

C941

33P

C942

33P

R967

1M

C902

220/10

C903

220/10

C901

0.1

R966

NC

R930

10K

TP2

R935 NC

R933 NC

R932 NC

R931 NC

R934 N C

R942

10K

R938

10K

R941

10K

R936

10K

R929

10K

R928

NC

R937

NC

R939

NC

R940

NC

R916

10K

R917

NC

R915 10K

R914

10K

R911NCR910

10K

R909 NC

R913

NC

TP9

R965

10K

R964

NC

SCK

C924

0.1

R954

220

/CS7

VB

1D-2D+3

DGND

4

CHASSI S5CHASSI S

6

JK900

USB (DEVI CE)

D

HRE Q

MOSI

/CS2

1 2

3 4

5 6

7 8

9 10

1112

1314

JP900

P=2.5X14P

JTAG

D

TDO

TDI

TCK

TMS

TDO

TDI

TCK

TMS

D3.3V

TP17TP15 TP14

TP16

TP13

TP6

TP8

TP7

DI1

DI0

DI6

BCK 1

LRCK 1

DI4

DI5

DI2

DI3

D3.3V

TP3

TP4

TP5

DO3

DO4

DO1R 950 47

R943

150

R944

150

R946

100

R948

100

DI2

DI3

DI4

DI5

DI6

DO2

DO3

DO4

DO5

PFO1AVDD2PWMO3PLLO4DVSS5PUR6DP7DM8DVDD9/MRST10TEST11EXTEN12/RSTO

13

P30

14

P31

15

DVSS

16

/XINT

17

P33

18

P34

19

P35

20

DVDD

21

NC

22

PLL OEN

23

P10

24

P11

25

P12

26

DVDDS

27

P1328P1429P1530P1631P17

32

DVSS

33

CSCLK

34

CSYNC

35

CDATO

36

DVDD

37

CDATI

38

/CRST

39

CSC

40

SDA

41

SCL

42

DVDD S

43

MCL KO

44

MCL LO2

45

DVSS

46

MCL KI

4

7

MCL KI 2

48

AV SS

49

XTO

50

XTI

51

PFI

52

IC901

TUSB3200

R905 33

R906

33

R907 1.5K

C918

1000P

R912

3.09K

C917

100P

X900

6M

C915

33P

C916

33P

R923 100

R920 100

C909

0.1

C911

0.1

C912

0.1

C910

0.1

C908

0.1

R904

220

R922

100

R921

100

D5V

SCL

SDA

D

DI0

DO0

DI1

DO1

D902

RSB6.8S

D904

RSB6.8S

1

2 3

4

L902

ACM2012

D

C905

0.1

D903

RSB6.8S

D901

RSB6.8S

C907

0.1

R945

100

R947

100

DO2

DO5

R949 47 D O0

TP12

R962 150

R963 150

R958 47

R959 47

R960 47

R961 47

R955 47

R956 47

R957 47

LRC K 1

BCK 1

/INT

R918

10K

C906

0.1

\RESET

1.2V

R952 150

R951 150

R953 150 MISO

R926

150

R919

820

R925

150

R927

150

R924

150

LRCK 1

LRCK 2

BCK 1

BCK 2

MCLK

LRCK 2

BCK 2

IN

I

NC

OUT

O

FIN

G

IC900

BD12KA5FP

R903

1

C913

10/10

C914

10/10

C904

0.1

D3.3V

L901

22uH/1A

ZD900

EDZCTE61 6.8B

D905

SMAJ6.0A

ZD901

EDZCTE61 6.8B(NC)

ZD904

EDZCTE61 6.8B(NC)

ZD902

EDZCTE61 6.8B(NC)

ZD903

EDZCTE61 6.8B(NC)

D906

SMAJ6.0A

C900

0.1

L900

22uH/1A

MCLK

1.2V

D

E

UADC1

123

SW900

USB Audio SW.

MIC

CH3/4

DVS

R902

7.5K

AD3.3V

R900

3.3K

R901

3.3K

AD

/URST

5V

PD

D3.3V

D

SDA

SCL

D5V

SCK

MOSI

MISO

/CS2

/URST

HREQ

UAD

AD AD3.3V

/INT

D907

SMAJ6.0A

D

P

+12V

D3.3V

D

Q900

C124TKA

D3.3V

R908

1.5K

/MST

/MST

1234567891011121314151617181920212223

24

CN102

TO CTRL1

12345678910111213141516171819

20

CN801

TO IO

C18

470/10

C15

22/16

L3

Bead

C3

0.1

BOOT1VIN

2EN3SS4

VSNS

5

COMP

6

GND

7PH8

IC1 T PS54232

C7

0.1uF

C11

22/16

C5

0.015uF

R2

43K

R3

47K

R1

8.2K

C13

33P

C9

390P

C1

10/25

L2

Bead

D1

SM5819A

L6

15uH/1.95A

D5V

C16

22/16

L4

Bead

C4

0.1

BOOT1VIN

2EN3SS4

VSNS

5

COMP

6

GND

7PH8

IC2 T PS54232

C8

0.1uF

C12

22/16

C6

0.015uF

R7

4.7K

R8

39K

R6

1.5K

C14

33P

C10

390P

C2

10/25

L5

Bead

D2

SM5819A

L7

15uH/1.95A

D3.3V

D

C17

330/10(L)

D

F2

1.5A/63V

F1

1A/32V

R4

100K

Q1

PMN3603

1

2

C1

SW1

POWER SW.

123

JK1

DC12V/3A

C19

0.1

L1

BEAD

C21

2200/25

F3

2.5A/63V

C20

0.1

5V

L8

22uH/1A

C22

4.7/25

R5

68K

OFF

ON(3)

PD

P

+12V

E

12345

6

CN1

TO IO

DGND

DGND

D

E

C944

0.01

C943

0.01

R969

10K

R968

10K(NC)

C948

1000P(NC)

C946

0.01(NC)

R970

3.3K

R971

3.3K

C950

0.1

C949

0.1

C951

0.1

R972

820(NC)

D3.3V

C953

0.01(NC)

X1/IN1VDD2GND3S1

4

OCLK

5S06OE7X28

IC903

ICS501(NC)

C952

10/25(NC)

L903

BEAD(32/NC)

R973

820(NC)

D900

SM5817A

POWER +GND AUDIO SIGNAL LINE

63

SCHEMATIC DIAGRAMS (1/5)

MAIN UNIT

CN801

TO N105

A1

TO 1A

CN1

TO N802

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

B

C

D

E

F

G

H

J

K

L

M

A

B

C

D

E

F

G

H

J

K

L

M

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Page 64

POWER +GND AUDIO SIGNAL LINEPOWER -

4

AV=-16.93dBAV PH=40dB

321

L

R

K502

LINE3

C530

470P

C531

470P

LN=0dB

7

6

5

4 8

U500B

8080

R515

270K/0.5%

R517

22K/0.5%

R513

270/0.5%

C521

.012

C523

.0033

A-12V

C513

100/16

C527

330P

1

2

3

U500A

8080

R521

4.7K/0.5%

R514

270K/0.5%

C526

330P

R516

22K/0.5%

A+12V

R512

270/0.5%

A-12V

C520 .012

7

6

5

4 8

U502B

8080

C522

.0033

C512

100/16

R520

4.7K/0.5%

1

2

3 U502A

8080

R519

33K/0.5%

R518

33K/0.5%

LN3

R523

100/0.5%

C518

0.1

R522

100/0.5%

A+12V

R504

47K

R505

47K

R511

1K/0.5%

R510

1K/0.5%

PH

R506

2.7K

Q501

2SD2704K

R507

2.7K

Q502

2SD2704K

LN3-G

2C11

S500

LN/PH SW

R509

51K

R508

100K

A-12V

Q500

DTA124EK

LN3-SW

C519

0.1

C515

100P

C514

100P

C511

470P

C510

470P

C517

220P

C516

220P

C529

10/25

C528

10/25

C525

0.1

C524

0.1

D500

1SS355

A3.3V

DI2

DI3

DI4

DI5

DI6

DO2

DO3

DO4

DO5

LRCK2

BCK2

MCLK