Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1C E1K EUT

Ver. 4

Please refer to the

MODIFICATION NOTICE.

DCD-F107

P

COMPACT DISC PLAYER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0164-1V04DM/DG1010

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerning important safety

parts

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

DCD-F107

Page 3

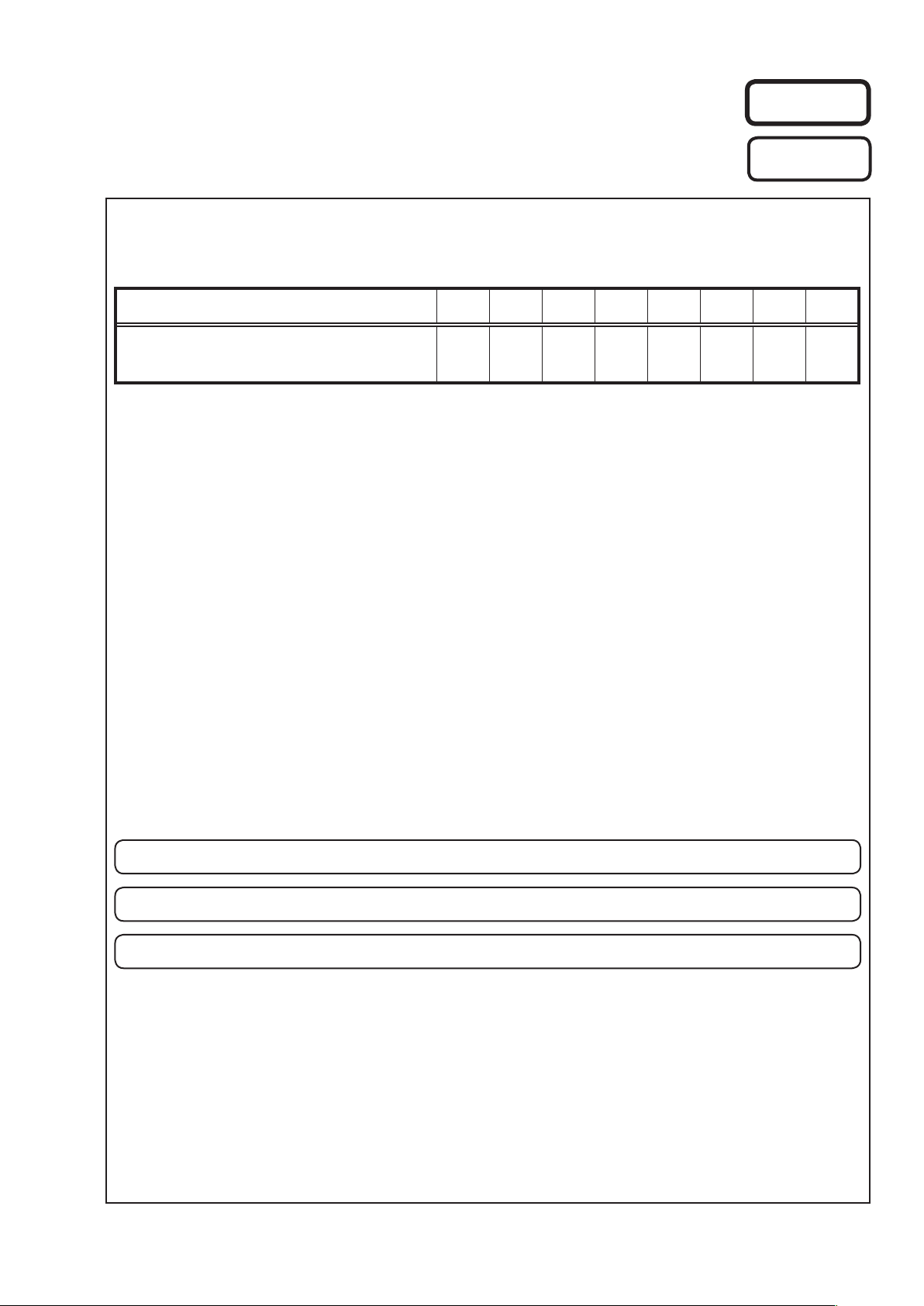

DIMENSION

3

DCD-F107

Page 4

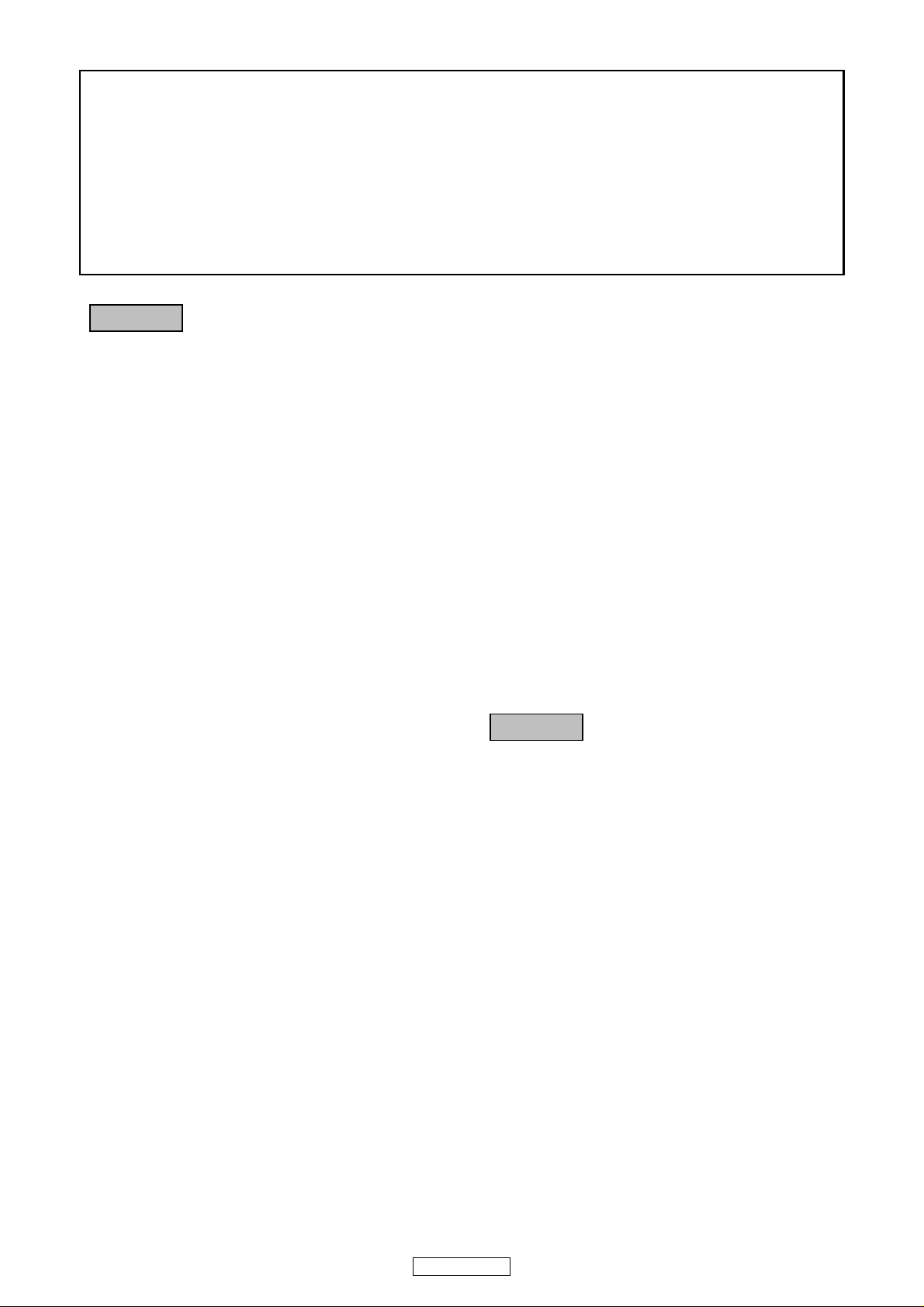

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or parts replacement etc.,be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

Front Panel side

Back Panel side

4

DCD-F107

Page 5

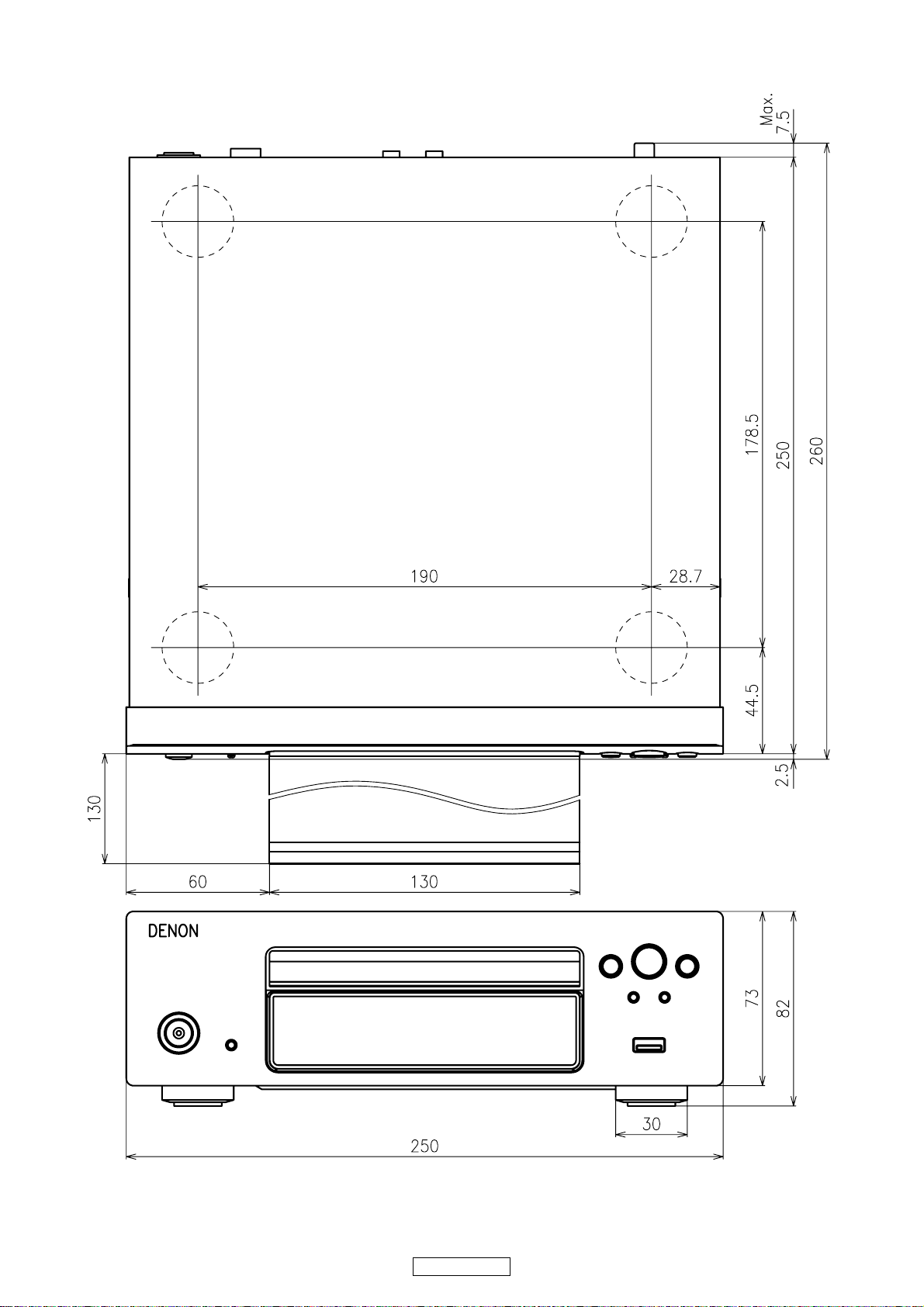

DISASSEMBLY

TOP COVER

LENAPRAERSNARTREWOPROOD

Refer to "DISASSEMBLY 1.DOOR" Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW"

Refer to "EXPLODED VIEW" LENAPRAERSNARTREWOP

)01M:WEIVDEDOLPXEfo.oN.feR()3C:WEIVDEDOLPXEfo.oN.feR(ROOD

(Ref. No. of EXPLODED VIEW : P1)

AUDIO PCB

FRONT PANEL ASSY

Refer to "EXPLODED VIEW"

Refer to "DISASSEMBLY 2.FRONT PANEL ASSY" INPUT PCB

Refer to "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : C7)

FRONT PCB

(Ref. No. of EXPLODED VIEW : C1)

POWER PCB

㩷

Refer to "EXPLODED VIEW"

MECHANISM

POWER PCB

Refer to "DISASSEMBLY

㩷

(Ref. No. of EXPLODED VIEW : C6)

3.MECHANISM"

Refer to "EXPLODED VIEW"

CD MECHANISM ASSY

(Ref. No. of EXPLODED VIEW : C5)

CD MAIN PCB

Refer to "EXPLODED VIEW"

CD MAIN PCB

(Ref. No. of EXPLODED VIEW : C4)

The viewpoint of each photograph

(photography direction)

[View from above]

Front side

Direction of photograph: A

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

About the photos used for descriptions in the “DISASSEMBLY” section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

DCD-F107

5

Page 6

1. DOOR

TOP COVER

DOOR

→

Proceeding :

Chucking plate

Drive gear

CD tray

DOOR

(1) Take off the Chucking plate after removing screws.

(2) Open the CD tray by turning the Drive gear clockwise.

(3) Detach the DOOR.

6

DCD-F107

Page 7

2. FRONT PANEL ASSY

TOP COVER

DOOR

→

FRONT PANEL ASSY

→

Proceeding :

View from bottom

CN97

cut

FFC Cable

CN52

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each PCB included in FRONT PANEL ASSY.

(1) Remove the screws.

(2) Cut the clamp bands, disconnect the connector wires and FFC Cable.

7

DCD-F107

Page 8

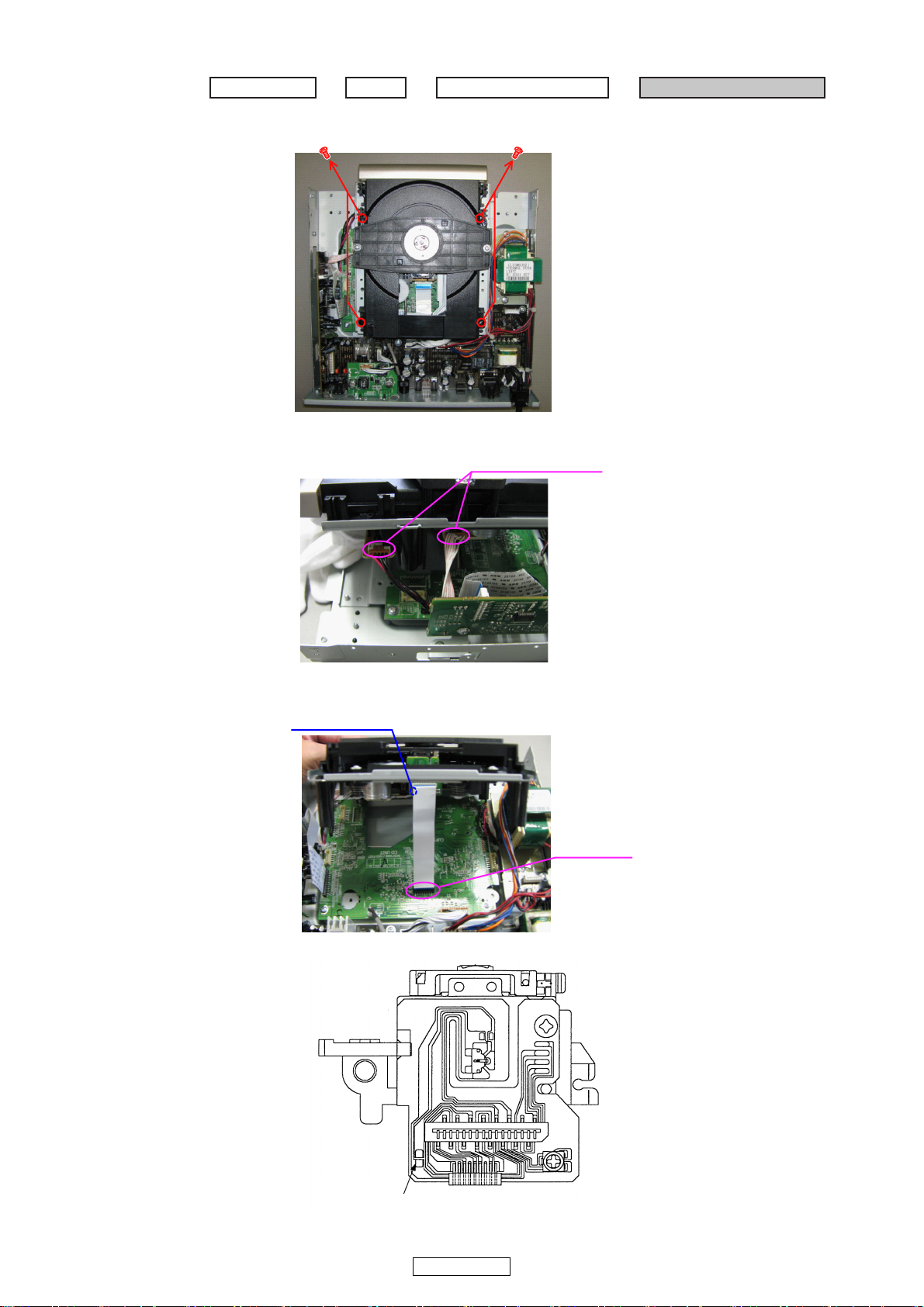

3. CD MECHANISM ASSY

Proceeding : CD MECHANISM ASSY

→

TOP COVER

DOOR

→

FRONT PANEL ASSY

→

ً

ً

Direction of photograph: A

Connector wires

Soldering place

Direction of photograph: A

FFC Cable

Laser short-circuit

(1) Cut the clamp bands, disconnect the connector wires. Remove the screws.

(2) Disconnect the connector wires.

(3) Laser short-circuit in Pick-up of CD MECHANISM, then disconnect the FFC Cable.

8

DCD-F107

Page 9

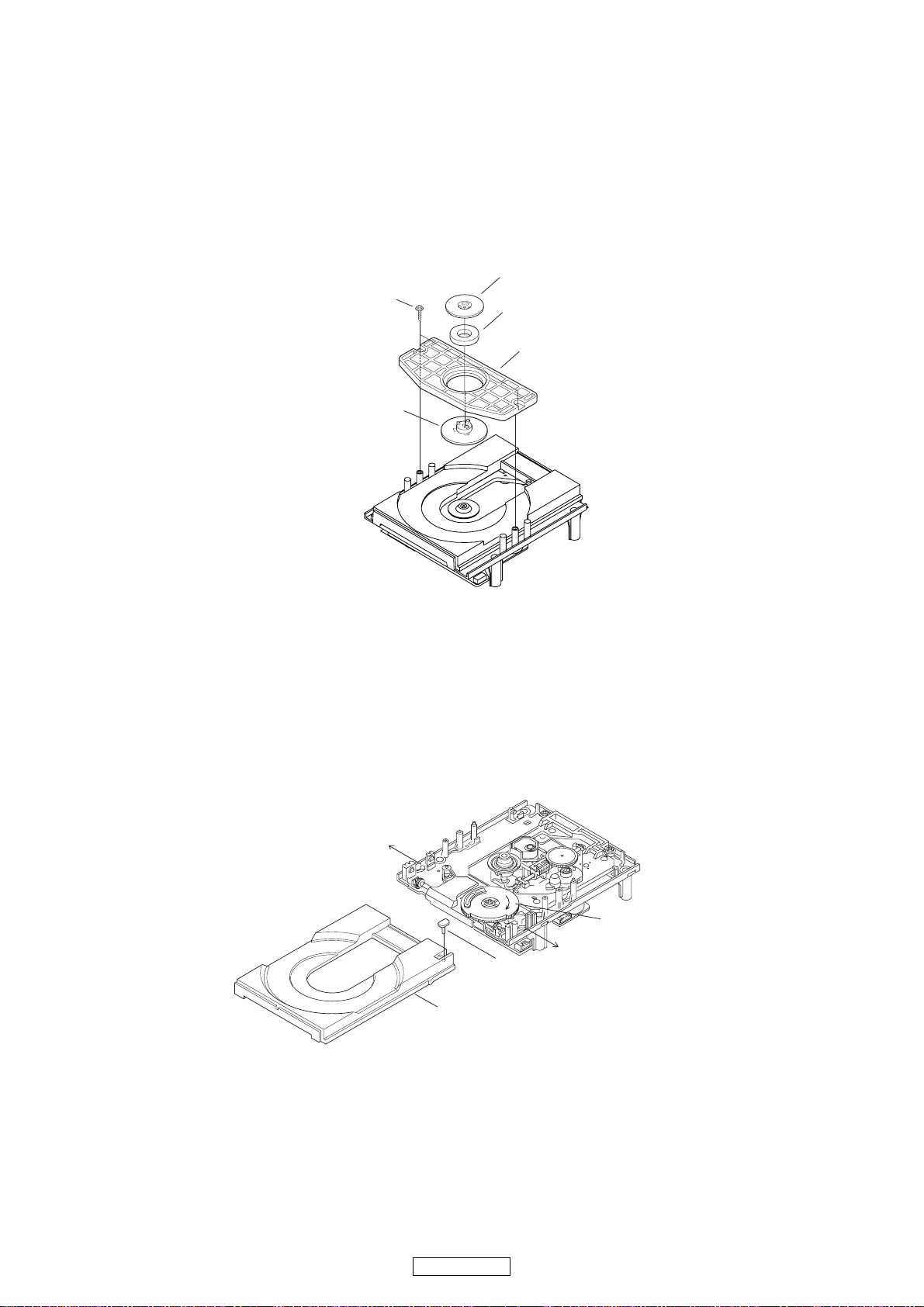

DISASSEMBLY OF MECHANIC

Chucking yoke

Chucking plate

Chucking pulley

Screws

Mugnet

(Follow the procedure below in reverse order when reassembling.)

Caution : The optical pickup can damaged by sassily by static electricity charged on human body. Take necessary anti-static

measures when repairing around the optical pickup.

1. Chucking plate

(1) Remove 2 top screws, then detach the Chucking plate.

(2) Detaching the Chucking pulley and chucking yoke by removing the 3 hooks, when abandoning CD MECHA ass’y.

2. CD tray

When abandoning CD MECHA ass’y, please detach the CD tray.

(1) Detach the Sw pin on the CD tray.

(2) Open the CD tray by turning the Drive gear clockwise.

(3) Open the Stopper as shown in the fig., then detach CD tray.

Stopper

CD tray

Drive gear

Stopper

Sw pin

9

DCD-F107

Page 10

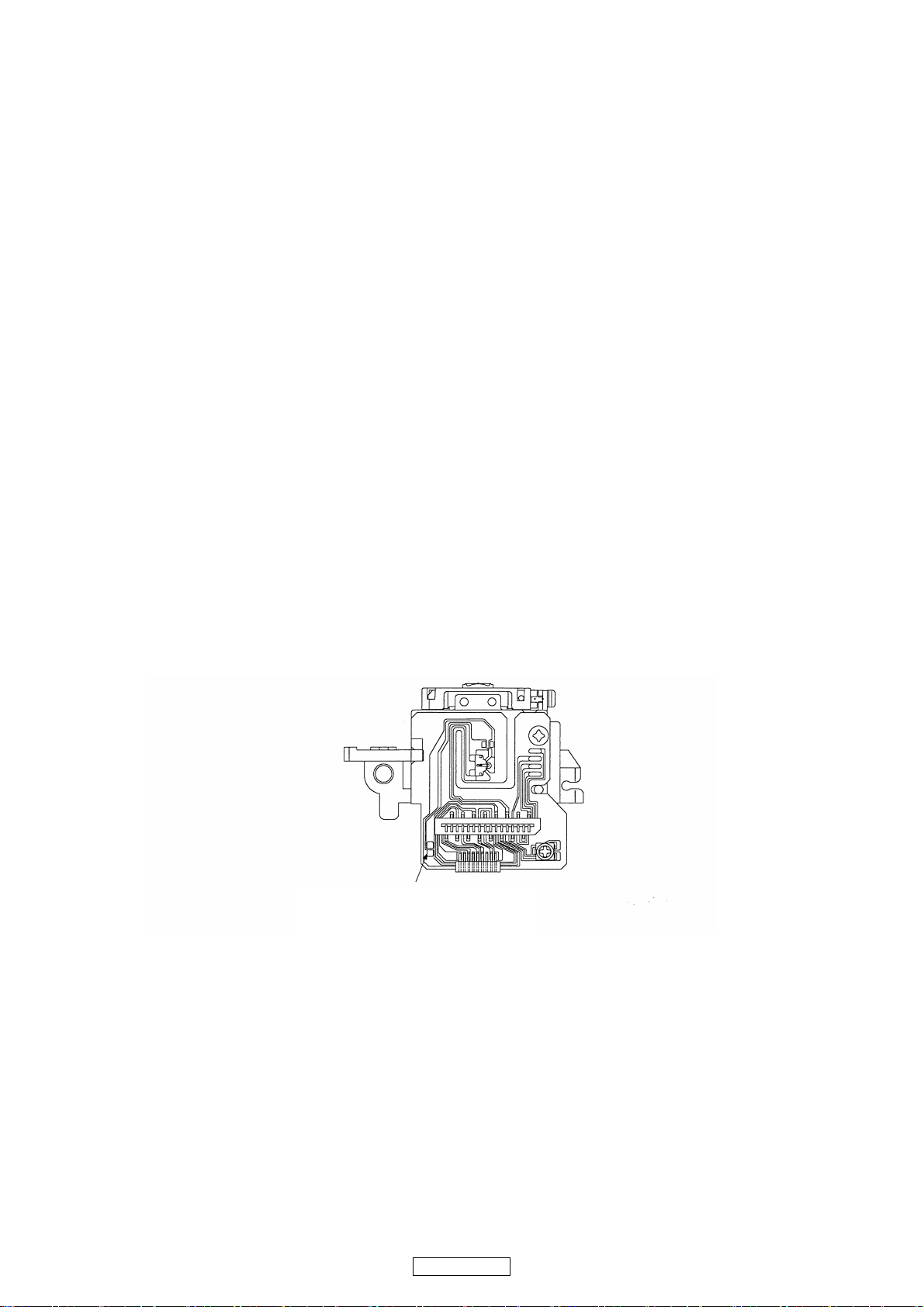

Note Handling and Replacement of the Laser pick-up

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the laser CD mechanism

• Handle the laser pick-up so that it is not exposed to dust.

• Do not leave the laser pick-up bare. Be sure to cover it.

• If dust adheres on lens of the pick-up, blow it off with a blower brush.

• Do not shock the laser pick-up.

• Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

• Be sure that to the bench, jig, head of soldering iron (with ceramic) and measuring instruments are well grounded.

• Workers who handle the laser pick-up must be grounded.

• The finished mechanism (prior to anchoring in the set) should be protected against static electricity and dust. The mechanism must be stored that damaging outside forces are not received.

• When carrying the finished mechanism, hold it by the

chassis body

• For proper operation, storage and operating environment should not contain corrosive gases. For example H

CI2 etc. In addition storage environment should not have materials that emit corrosive gases especially from silicic, cyanic,

formalin and phenol group. I the mechanism or the set, existence of corrosive gases may cause no rotation in motor.

2S, SO2, NO2,

4. Determining whether the laser pick-up is defective

•

Measure the waveform at RFO-VC on "MCU PCB Unit ".

( For measuring points and waveforms, see pages 26, 27.)

• The laser pick-up is OK if the amplitude level of the measured RFO waveform is between 0.4 and 1.1 Vp-p, defective otherwise.

Protective soldering place for laser diode.

10

DCD-F107

Page 11

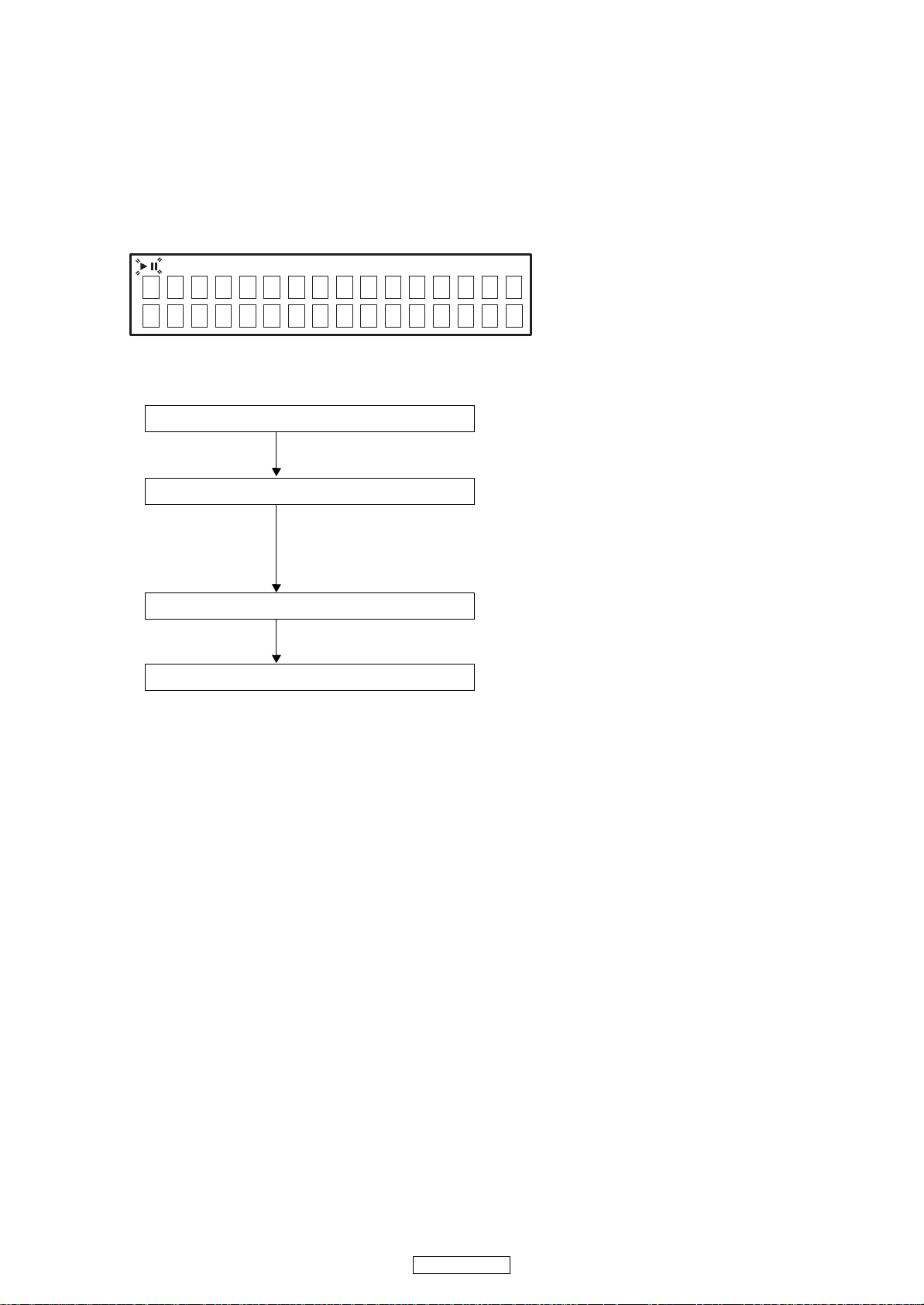

Diagnostics of optical pickup and replacing traverse unit d

S

/C: XXXmA/YYYmA

L

ASER CURRENT

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

Present value exceeds the initial value by 1.5 times

Traverse Unit replacing

Laser current (Iop) memorizing after replacement

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than 1.5 times of the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked Method" of next page.

In case of replacing the Pickup, change the whole part of the Traverse Unit.

No mechanical adjustment is necessary after the replacement.

Laser drive current initial value:

・13 flashing

XXX : Initial value : Stored data (EEPROM stored value)

YYY : Current value

11

DCD-F107

Page 12

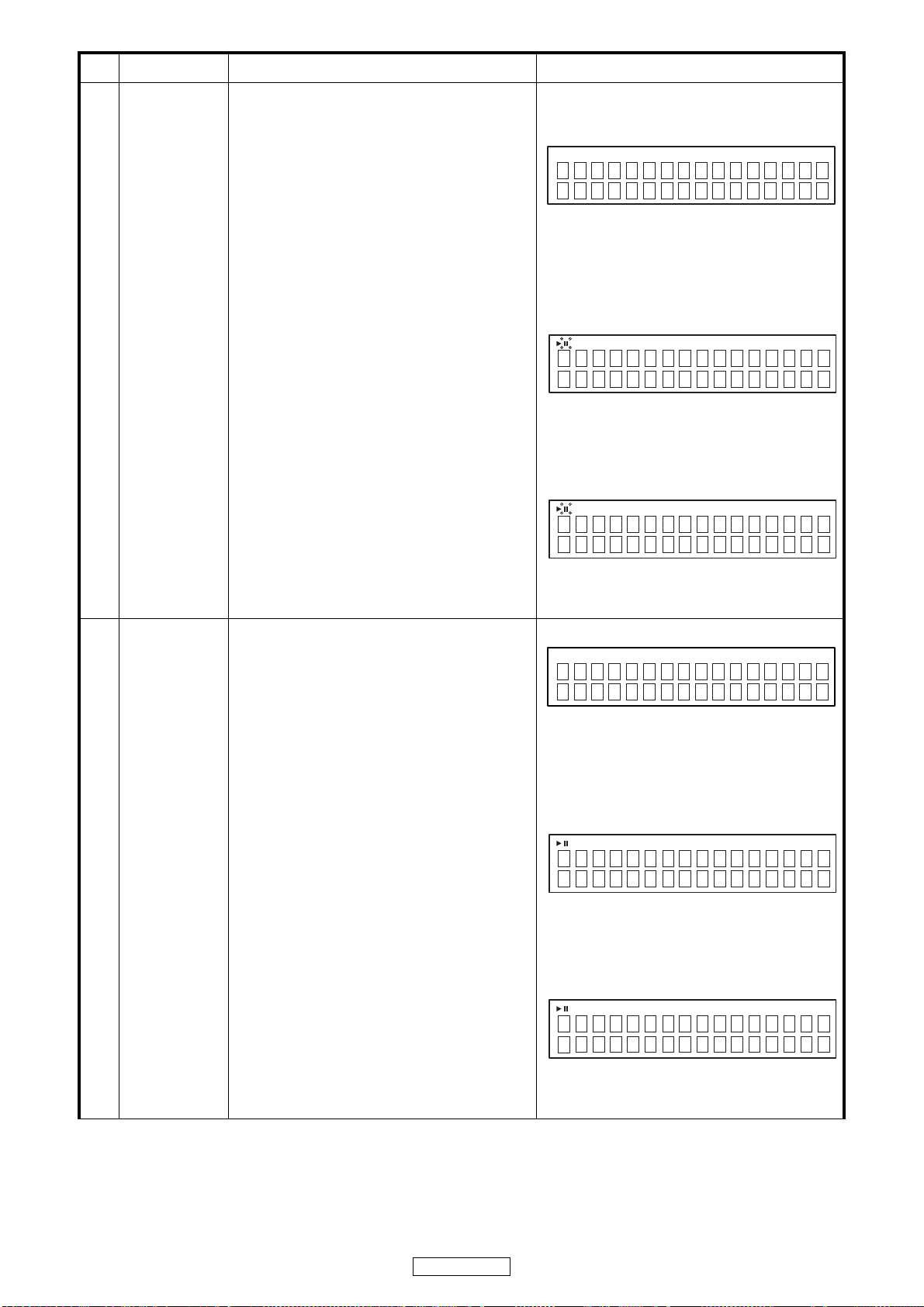

SPECIAL MODE

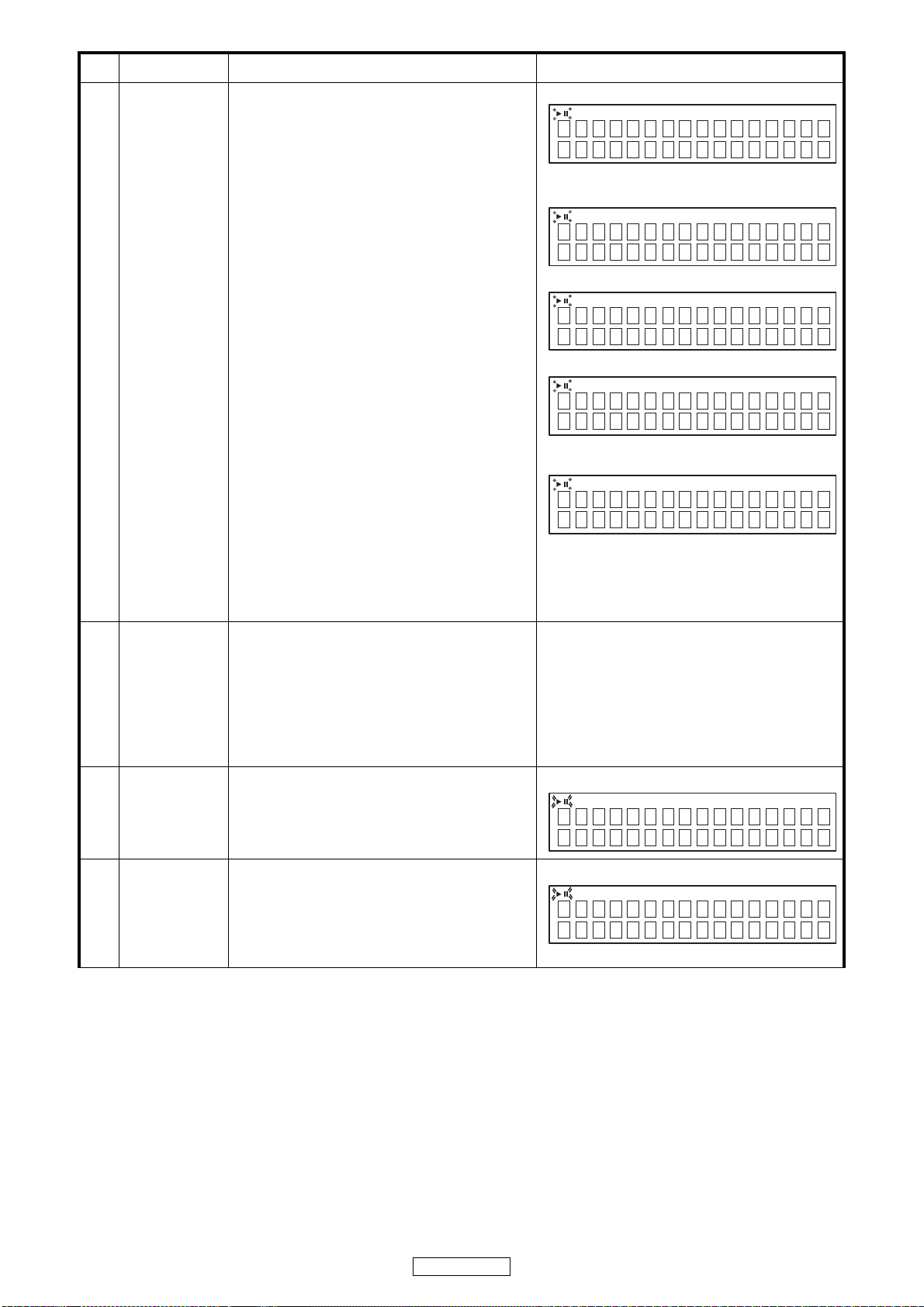

No Key name Function Display

• AC is turned on while pressing the 5 and 2 button

1

Service mode

same time on DCD-F107.(Model name display)

DCD-F107

Version No. of

1.1

main μ-com

Display mode

Version No. of

1.2

USB μ-com

Display mode

1.3 FLD check mode

2 CD test mode

2.1 Disc loading

• Press the 9 button.

• Press the 9 button while version No. of main

μ-com is displayed.

• When display is version No. of USB μ-com and

the 9 button is pressed, turn on the entire display is flashing with an interval of about 1 second.

• Press the 9 button again in the turn on each

grid of FLD. (Each grid is displayed at interval of 1

second.)

• AC is turned on while pressing the 5 and 2 button

same time on DCD-F107.(Entering the Service

mode)

• Press the 2 and

version display, FLD check mode and heat runmode.(CD TEST MODE display)

• Press the DISC/USB button continuously for over

3 seconds to display the version number of main

μ-com.

• Press the 5 button to open the tray.

• Set a disc on the tray, then press the 5 button

again to close the tray.

• Press the

steps.

q LD ON (with servo still stopped)

13 button. Execute the following

/

13 button same time while

/

Ver xxxx

"****" : Version number of main μ-com

USB_Ver ****

"****" : Version number of USB μ-com

13 flashing

00 CD TEST MODE

・13 flashing

q

2.2 Servo check

w FOCUS ON (disc rotation, tracking off)

If no disc loaded, retry then stop.

e CLV ON

12

DCD-F107

01 LD ON

w

02 Focus ON

e

03 CLV ON

Page 13

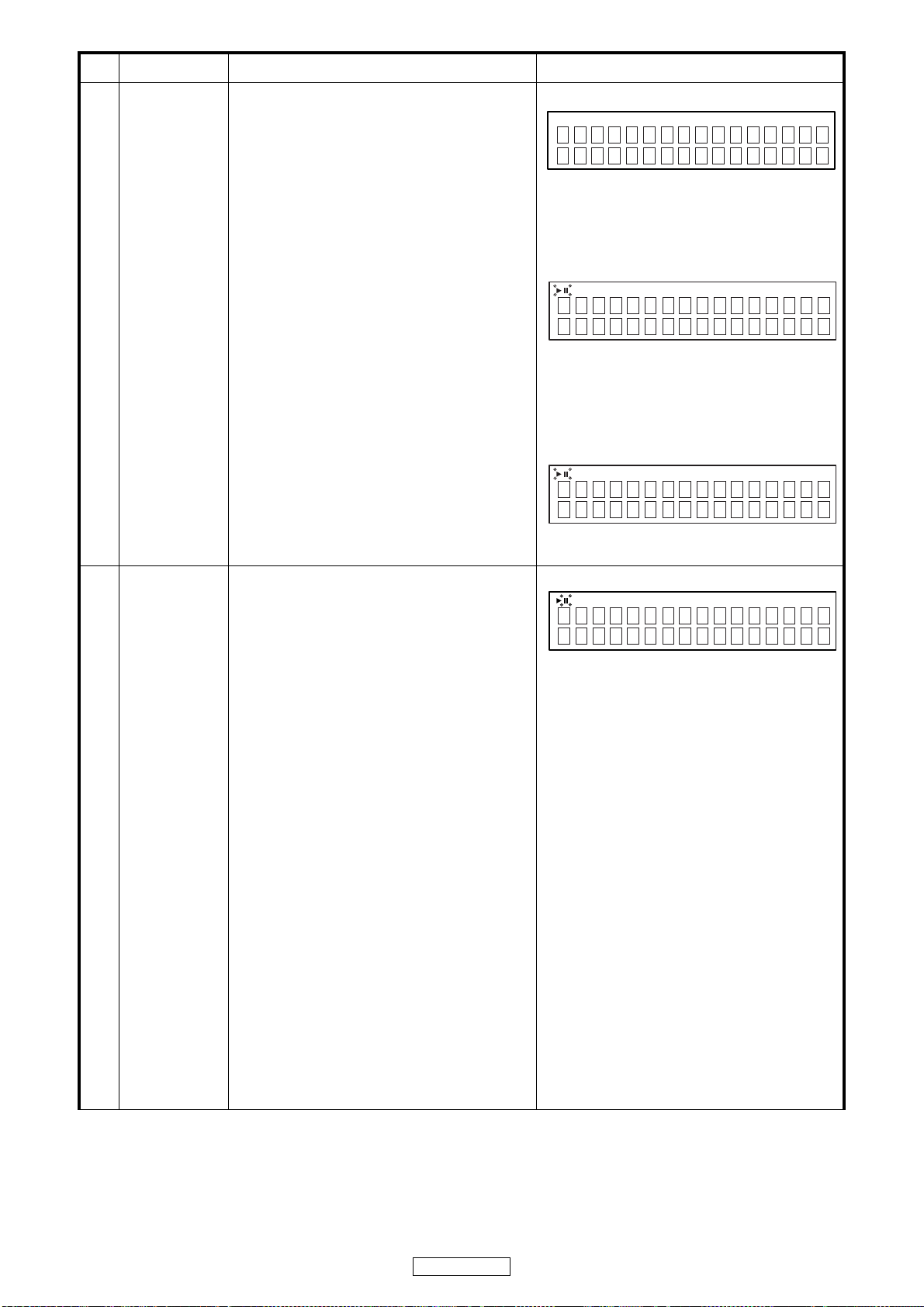

No

2.2 Servo check

2.3

Key name

Pickup

movement

Function Display

r TRACKING ON

t SUB CODE readout (playback sound output)

• The BER (Block Error Rate) generated in 1

second's time is displayed on the upper tier of

the display.

• The playback position (IN/MID/OUT) can be

changed by pressing the 8 or 9 button.

• The count of the errors that could not be

corrected with the C1 error correction system is

displayed.

y When display is as in t and the

pressed, conduct BER (Block Error Rate)

display for 2 seconds.

• The BER (Block Error Rate) generated in 10

second's time is displayed of the display.

bPress

second to switch directly to SUB CODE readout

in step

・In the stop mode, pickup moves in REV (inwards)

or FWD (outwards) direction when 8 or 9

button pressed.

・When 8 button pressed, move to stop

operation after detection that inner switch has

turned on.

・Pickup movement stops when button released.

(Pickup moves while button is pressed.)

/

13 button continuously for over 1

t.

/

13 button is

r

04 Tracking ON

t

[IN]

NERR######

I

05 @@

[MID]

ID ERR ######

M

05 @@

[OUT]

UT ERR ######

O

05 @@

###### : B.E.R., @@ : T.No, XX:XX : Time

y

PP ERR ######

P

Tr

Tr

Tr

XX:XX

XX:XX

XX:XX

ERR *** ***

PPP : Playback position (IN/MID/OUT)

###### : 1

Continuous display of previous time

second's B.E.R.

, *****:

10 second's B.E.R.

2.4 Stop

2.5 All servo on

・When 2 button is pressed, play operation and

servo stop.

・After stopping, conduct reading of auto adjust

values.

・When 2 and 5 button is pressed, all servos turn

on, auto adjustment is performed and switch to

playback operation. (Playback sound output)

(NOTE)When the 2 button is pressed for over 1

second while the laser turns on and the laser

current is measured.

・13 flashing

00 CD TEST MODE

・13 flashing

@@

Tr

@@ : T.No, XX:XX : Time

XX:XX

13

DCD-F107

Page 14

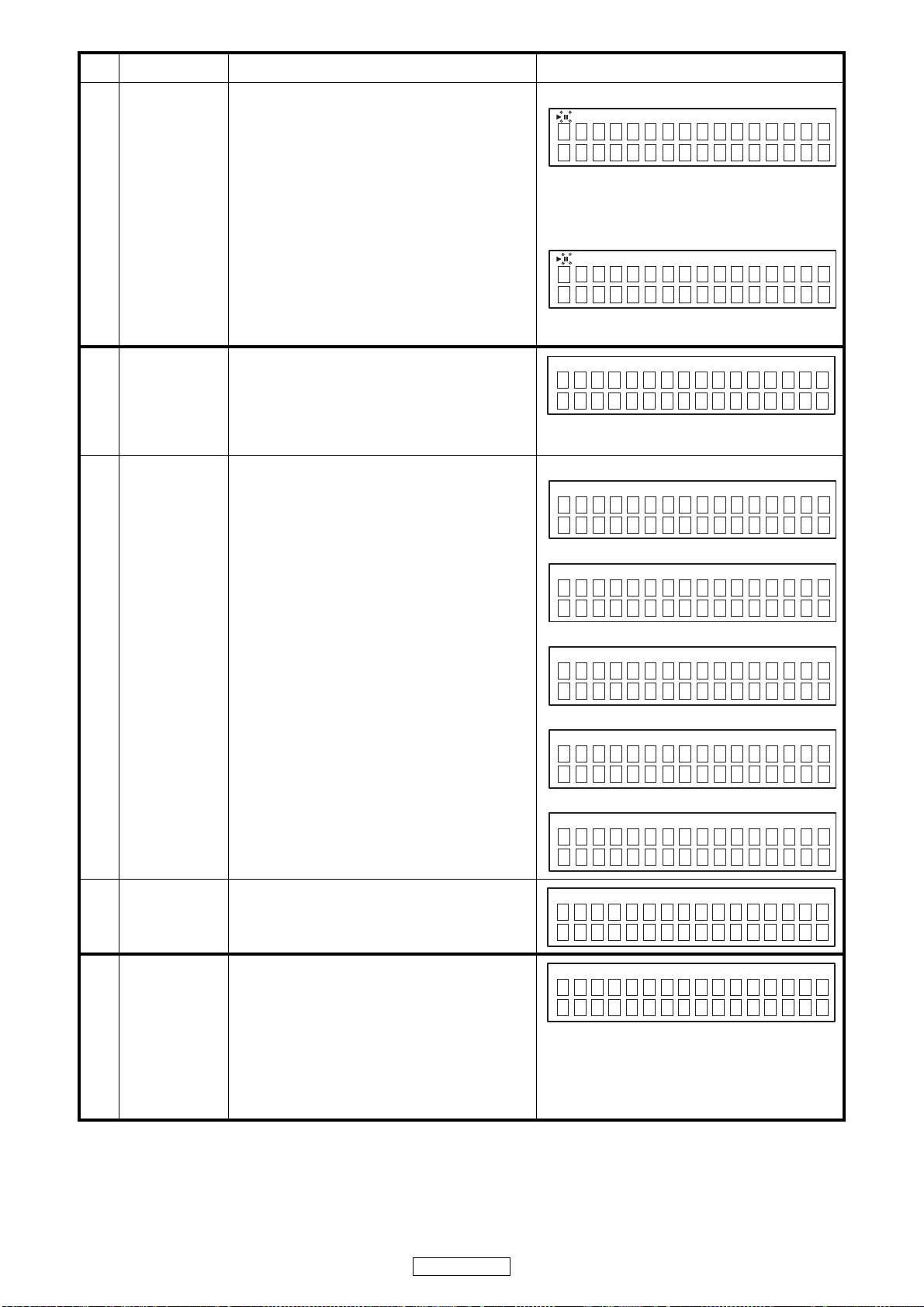

No

Key name

Function Display

Laser current is

2.6

display

・When the 2 button is pressed for over 1 second

while the DCD-F107 is in the stop mode, the

laser turns on and the laser current is measured.

・The laser drive current undergoes A/D

conversion for calculation. Decimal values are

discarded.

・The first current value is measured 3 seconds

after the laser turns on.

・The current value is updated every 3 seconds.

・Press the 2 button, CD test mode display (2)

reappears.

・Stored data is not cleared, even when the DCD-

F107 is reset.

q Overwriting the stored data

・When the

seconds while the laser current is displayed, the

current value is stored in the EEPROM

(overwriting the stored data).

・Once rewriting is completed, the display in 2.6

reappears.

・Rewriting is performed upon shipment from the

factory and when the mechanism is replaced.

・Press the 2 button after executing the servo auto

adjustment.

・When 9 button is pressed, the adjustment

values are displayed in the following order.

q FOCUS BALANCE

w FOCUS GAIN

/

13 button is pressed for over 5

・ 13 flashing

/C: XXXmA/YYYmA

S

ASER CURRENT

L

XX : Stored data : EEPROM Stored value

YY : Current value

q

TORED

S

ASER CURRENT

L

・13 flashing

q

X

X

OCUS BALANCE

F

XX : Adjustment value

w

Adjustment value

2.7

display

e TRACKING BALANCE

r TRACKING GAIN

tFOCUS OFFSET

y TRACKING OFFSET

X

X

OCUS GAIN

F

XX : Adjustment value

e

X

X

RACKING BALANCE

T

XX : Adjustment value

r

X

X

RACKING GAIN

T

XX : Adjustment value

t

X

X

OCUS OFFSET

F

XX : Adjustment value

y

X

X

RACKING OFFSET

T

XX : Adjustment value

14

DCD-F107

Page 15

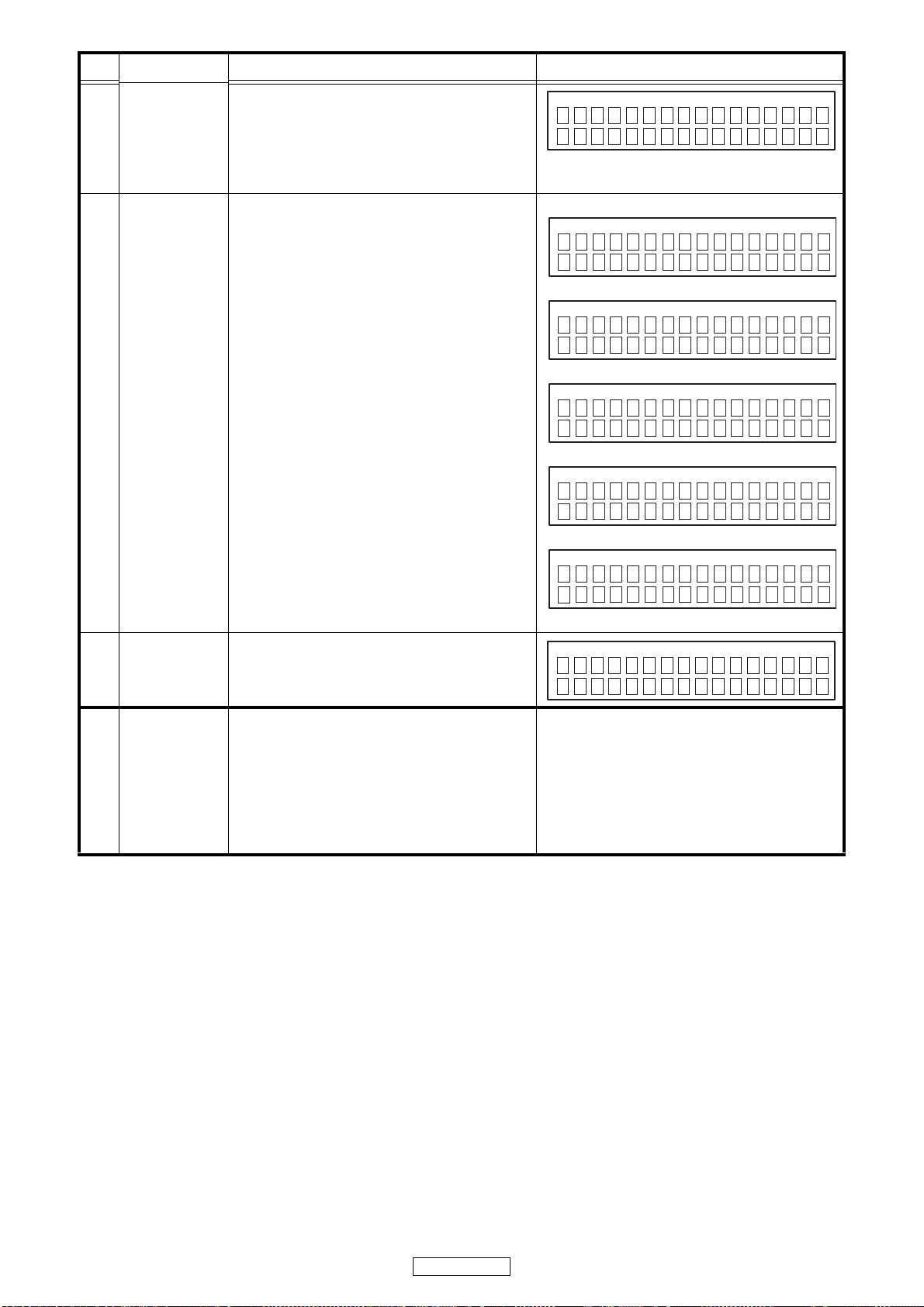

No

Key name

Function Display

Adjustment value

2.7

display

Accumulated

2.8

laser on time

display

u RFRP

i Return to q.

(Note)If auto adjustment is not completed, proper

values are not displayed.

・When the DISC/USB and 5 button is pressed

while the DCD-F107 is in the stop mode, the

accumulated laser on time is displayed.

・The laser drive times are added and the result is

displayed.

・One count corresponds to 10 minutes. (Values

under 10 minutes are discarded.)

・Count values are stored in the EEPROM every 10

minutes.

・The accumulated laser on time is displayed in

hours.

・Laser ON/OFF is monitored and counted.

・Press the 2 button, CD test mode display (2)

reappears.

・The count values are not cleared, even when the

set is reset.

・Minimum display specification

• No. digits stored in EPROM: 4, 0xFFFF

• No. digits displayed: 5

• When the time exceeds 10922 hours, the

stored data is not updated and the value is

fixed to 0xFFFF.

(The display is fixed to 10922 hours.)

u

X

X

FRP

R

XX : Adjustment value

・13 flashing

XXXX hour

X

ASER ON TIME

L

3

CD heat run

mode

q Count value is reset

・When the

seconds while the accumulated laser on time is

displayed, the count value is reset.

・After resetting is completed, the display in 2.6

(00000 hours on the top line) reappears.

・Count value is reset upon shipment from the

factory and when the mechanism is replaced.

・AC is turned on while pressing the 5 and 2 button

same time on DCD-F107.

・Switches to mode according to button input.

・Press the reverse button to switch the mode while

displaying the version of the main μcom.

(Normal heat run mode, Heat run short mode,

Automatic mounting mode.) d

・If an error occurs, display the error and stop

operation at that point.

・Number of operations held.

・While heat run, the operation of each button is not

valid except the ON/STANDBY button and

pressing the 5 and 2 button same time.

/

13 button is pressed for over 5

q

LEAR

C

ASER ON TIME

L

15

DCD-F107

Page 16

No

Key name

Function Display

Normal heat run

3.1

mode

・Press the

displayed or H.R.NORMAL is displayed.

・Count this as the 0th heat run repetition.

q Play from the first to last track on disc.

w After disc playback has finished, move pickup

to innermost position and open tray.

e When loader open status detected, close tray

again, re-read TOC and start playback from the

first track on the disc.

r The heat run repetition no. is incremented

(increased by 1) when the tray is opened.

※ If the 2 and 5 button is pressed while operat-

/

13 button while name of the model is

ing, number of heat run is displayed for 3 seconds.

・Model Name display

・H.R.NORMAL display

.R.NORMAL

H

・Normal heat run mode

Normal display except when 1 light, 3 flashing

q Normal display except when 1 light, 3 flashing

w

CD XXXX

XXXX : No. of heat run repetitions

e Normal display except when 1 light, 3 flashing

r

CD XXXX

XXXX : No. of heat run repetitions

Heat run Short

3.2

mode

t Conduct q to e repeatedly.

/

・Press the

H.R.SHORT is displayed.

・Count this as the 0th heat run repetition.

q Play the last track only on disc.

w After disc playback has finished, move pickup

to innermost position and open tray.

e When loader open status detected, close tray

again, re-read TOC and start playback from the

first track on the disc.

r The heat run repetition no. is incremented

(increased by 1) when the tray is opened.

※ If the 2 and 5 button is pressed while oper-

13 button while name of the

ating, number of heat run is displayed for 3

seconds.

・H.R.SHORT display

.R.SHORT

H

・Heat run Short mode

Normal display except when 1 light, 3 light

q Normal display except when 1 light, 3 light

w

CD XXXX

XXXX : No. of heat run repetitions

e Normal display except when 1 light, 3 light

r

CD XXXX

XXXX : No. of heat run repetitions

t Conduct q to e repeatedly.

16

DCD-F107

Page 17

No

Key name

Function Display

Automatic

3.3

mounting mode

3.4 Error display

・Press the

H.R.CHACKING is displayed.

・Count this as the 0th heat run repetition.

q Play the last track only on disc.

w The heat run repetition no. is incremented

(increased by 1) when the tray is opened.

※ If the 2 and 5 button is pressed while oper-

ating, number of heat run is displayed for 3

seconds.

e Conduct q repeatedly.

E1-00 : Disc cannot be detected

E1-01 : Tracking offset adjustment not possible

E1-02 : Focus offset adjustment not possible

E2-00 : Focus servo dropped during playback.

E2-01 : Focus servo dropped during searching.

E2-03 : Focus servo dropped during TOC reading.

E2-05 : Focus servo dropped during manual

E2-10 : Subcode can no longer be read during

E2-11 : Subcode can no longer be read during

E2-12 : Subcode can no longer be read during

E2-14 : Subcode cannot be read during pause

E2-15 : Subcode cannot be read during manual

E3-00 : TOC could not be read within specified

E3-01 : PVD/SVD analysis could not be

E4-04 : Search time out

E4-05 : Error in communications with CD decoder

E5-00 : Inner switch not on

E6-00 : Inner switch not off

E8-00 : Tray is not opened by the specified time.

E8-01 : Tray is not closed by the specified time.

E9-01 : Other error

/

13 button while name of the

search.

playback

searching

TOC reading

search

time

completed within specified time

・H.R.CHACKING display

.R.CHACKING

H

・Heat run short mode

Normal display except when 1 flashing, 3 flashing

qNumber of heat run is display

CD XXXX

XXXX : No. of heat run repetitions

・READING, CLOSEdisplay

Normal display except when 1 flashing, 3 flashing

wNumber of heat run is display

CD XXXX

XXXX : No. of heat run repetitions

,

・

13 with mode light or flashing

CD EX-XX

X-XX : Error cord

17

DCD-F107

Page 18

No

Key name

Function Display

3.4 Error display

Main μ-com

4

Version up

mode

q Number of heat run is display

・Press the 9 button while the error is displayed.

・ No. heat runs is displayed for 5 seconds, the error

display reappears.

w The track no. and time when the error occurred is

displayed

・Press the 8 button while the error is displayed.

・ The track no. and time when the error occurred is

displayed for 5 seconds, then error display

reappears.

・AC is turned on while pressing the 5 and 2 button

same time on DCD-F107.(Entering the Service

mode)

・ While displaying model name, when 2 and the

ON/STANDBY button are pressed simultaneously,

the tray opens.

• If an the 5 or

closed, a disc will be loaded and Version up will be

started.

• " FileError" is displayed when not found upgrade

file and the tray is opened.

/

13 button is pushed and a tray is

,

q

13 with mode light or flashing

CD XXXX

XXXX : No. of heat run repetitions

・Error display reappears after 5 seconds. See 3.4.

,

13 with mode light or flashing.

w

CD 01

・Error display reappears after 5 seconds. See 3.4.

YSTEM VUP ALL

S

etDisc -> Close

S

q During a file search

YSTEM VUP ALL

S

ileSearch

F

w During a file check

Tr

01:47

4.1 Start version up

4.2 End version up

Cold start

5

(Initialize)

・After Version UP is completed, a tray is opened

and it stops in

・AC is turned on while pressing the 5 and 9

button same time on DCD-F107.

・The system is reset, and once this is completed

the unit is set to the normal mode.

DIMMER : 100%

DISC/USB : DISC

REMOTE/BROWSE : REMOTE

・The laser current initial value and laser

accumulated on time is not cleared.

YSTEM VUP ALL

S

ileCheck

F

e During deletion

YSTEM VUP ALL

S

rasig

E

r Writing

YSTEM VUP ALL

S

riting

W

t When a file is not found

YSTEM VUP ALL

S

ileError

F

YSTEM VUP ALL

S

omplete

C

INITIALIZE

18

DCD-F107

Page 19

No

6

Key name

USBμ-com

Version up

mode

Function Display

・AC is turned on while pressing the 5 and 2 button

same time on DCD-F107.(Entering the Service

mode)

・ While displaying model name, when 9 and the

ON/STANDBY button are pressed simultaneously,

the tray opens.

• If an the 5 or

closed, a disc will be loaded and Version up will

be started.

• "FileError" is displayed when not found upgrade

file and the tray is opened.

/

13 button is pushed and a tray is

OLERO VUP

B

etDisc -> Close

S

q During a file search

YSTEM VUP ALL

S

ileSearch

F

w During a file check

YSTEM VUP ALL

S

ileCheck

F

e During deletion

6.1 Start version up

6.2 End version up

EEPROM TEST

7

mode

・After Version UP is completed, a tray is opened

and it stops in

・Press POWER SW while simultaneously pressing

ON/STANDBY and DISC/US button.

・POWER LED lights to the orange (TEST start).

・After EEPROM TEST, in the case of OK, LED

lights to the green.

・After EEPROM TEST, in the case of NG, LED

lights to the red.

・Mode is cancelled with POWER OFF.

YSTEM VUP ALL

S

rasig

E

r Writing

YSTEM VUP ALL

S

riting

W

t When a file is not found

YSTEM VUP ALL

S

ileError

F

OLERO VUP

B

omplete

C

19

DCD-F107

Page 20

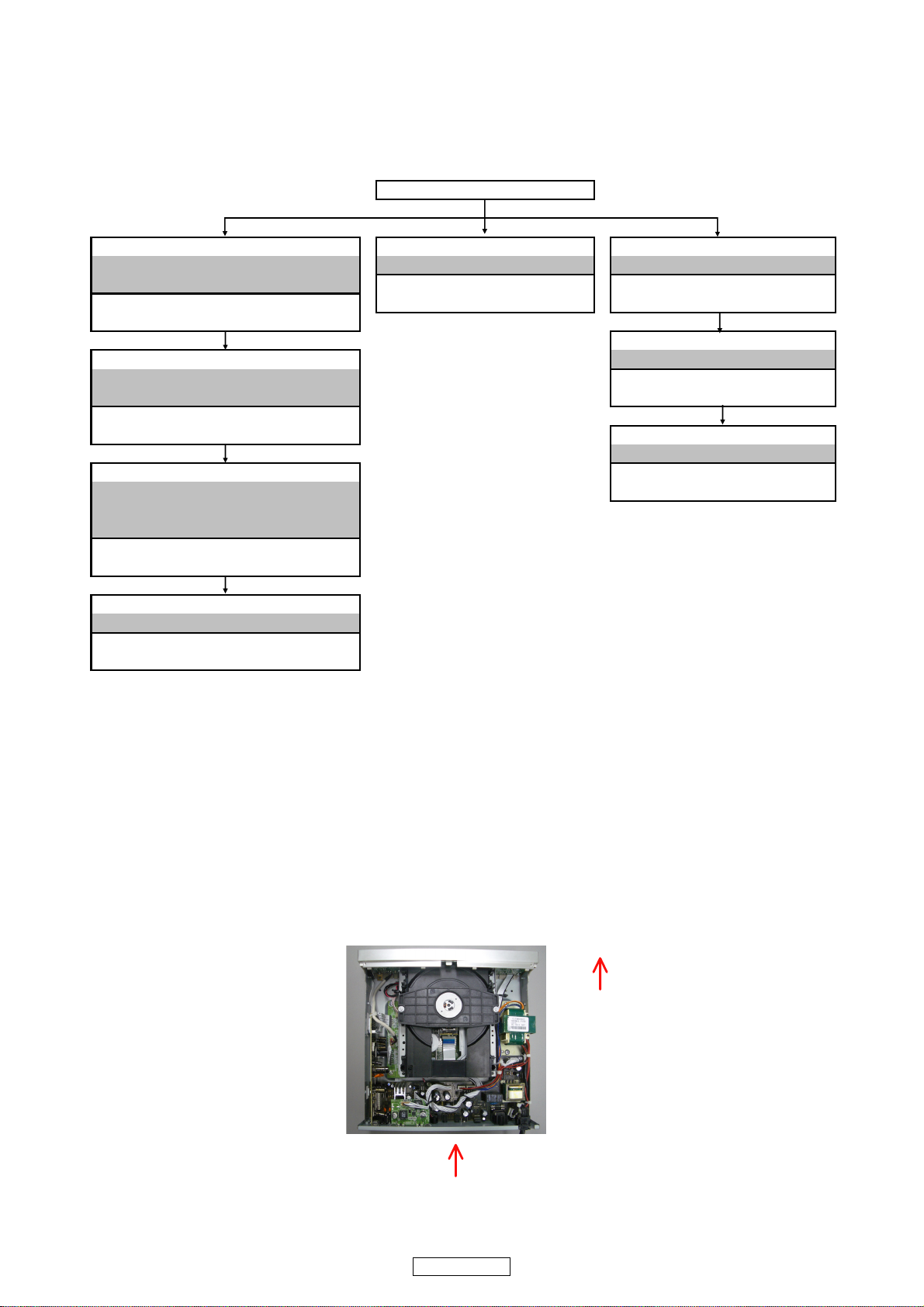

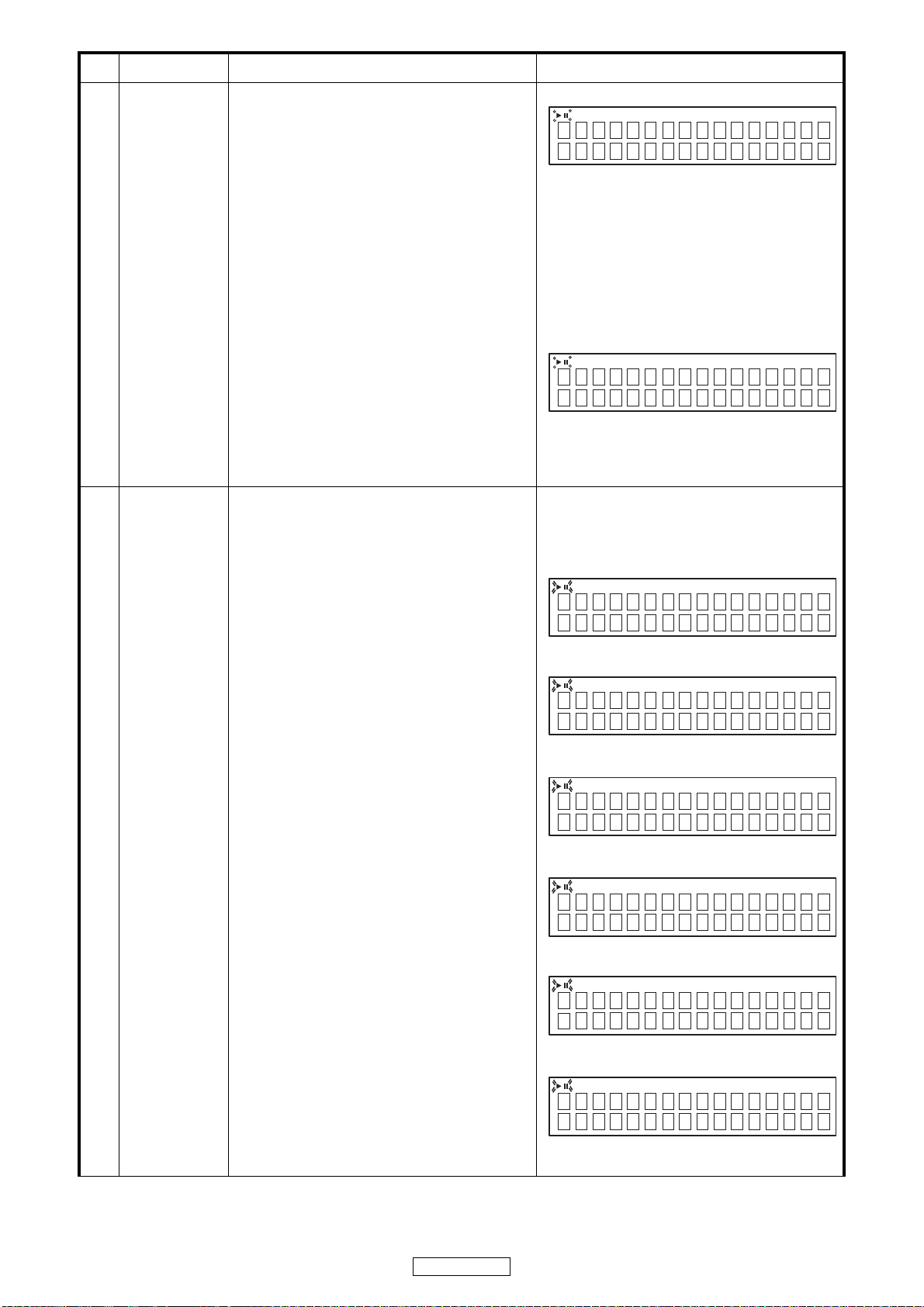

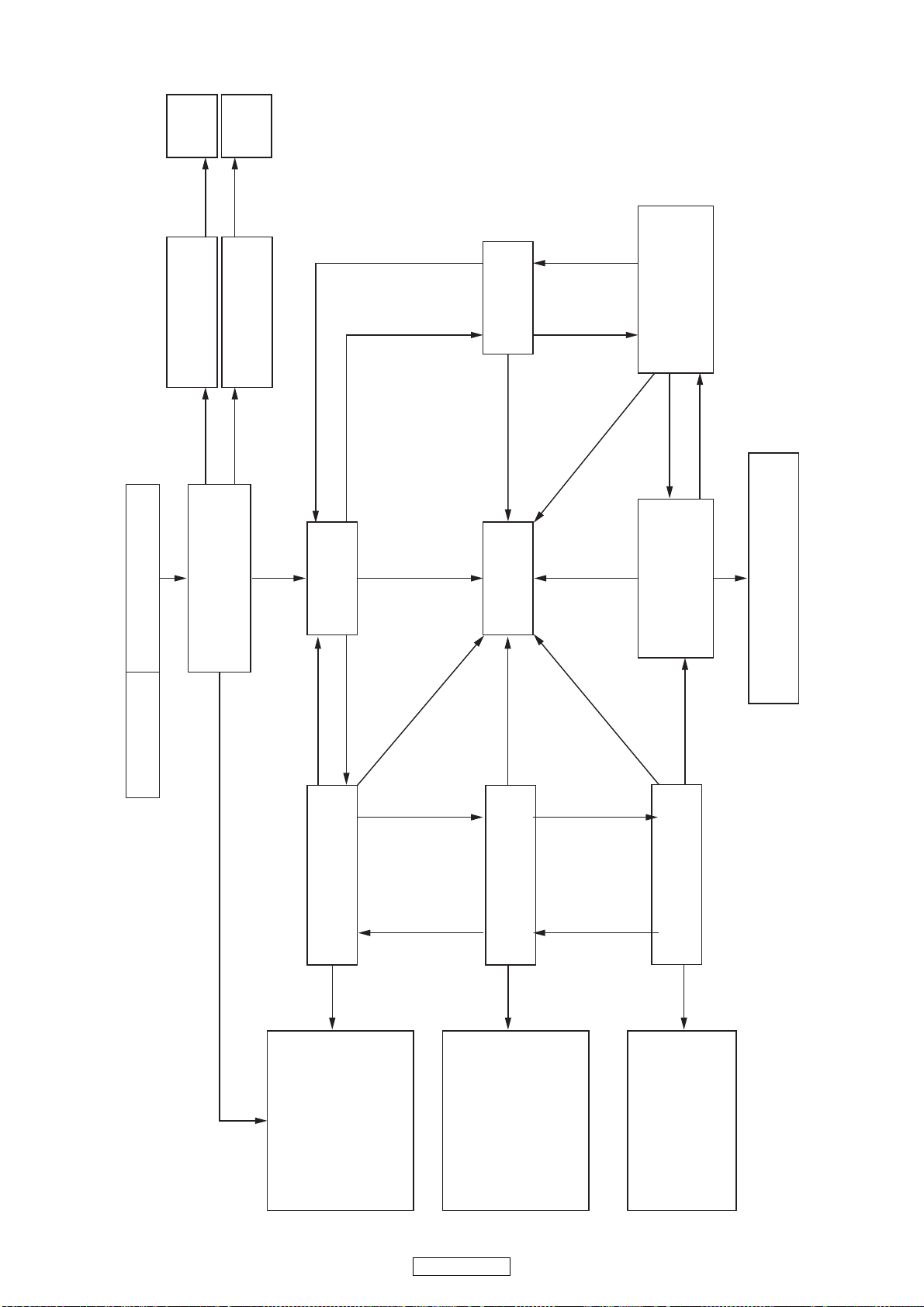

Special mode transition diagram

Start

Ver UP

5

1/3 or

USB Ver UP mode

“Ver UP USB” display

9 +

ON/STANDBY

Start

Ver UP

5

1/3 or

Main Ver UP mode

“Ver UP Main” display

+

ON/STANDBY

2

8

9

Ver.display

USB μ-com

2+1/3

8

9

2+1/3

FL all light

The entire display is

flashing with an interval

of about 1 second.

9

8

5+2+AC_ONService mode

Model Name display

1/3

8 or 9

“DCD-F107”

Main μ-com

Ver.display

9

8

H.R.NORMAL display

1/3

2+1/3

8

9

2+1/3

9

CD test mode

FL tube

The display for each grid.

(It displays at intervals

of 1 second.)

Main Ver. display reappears.

2+1/3

2+1/3

2+1/3

8

8

H.R.SHORT display

9

1/3

H.R.CHACKING display

1/3

H.R.NORMAL operation

TOC read → playback

title-all of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

DCD-F107

H.R.SHORT operation

20

TOC read → playback

title-end of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

H.R.CHACKING operation

TOC read → OPEN →

CLOSE → TOC read

It displays repeatedly.

Page 21

TROUBLE SHOOTING

FLOW CHART NO.1

The power cannot be turned on.

㸣

Is Power LED lit? 㸢No

㸣Yes

Is the +3.3V_NSW line voltage normal? 㸢No

㸣Yes

Is the +5_SYS line voltage normal? 㸢No

㸣Yes

Is the "H" level MCU Reset to Pin(77) of IC11? 㸢No

㸣Yes

Is normal state restored when once unplugged power

cord is plugged again after several seconds?

㸣Yes

Check each voltage regulator circuit and service it if defective.

㸢No

FLOW CHART NO.2

+3.3V_D is not outputted.

㸣

Is +7V_DRV voltage supplied to Pin(1) of IC93? 㸢No

Check if there is any leak or short-circuiting rectifier circuit

of SUB Power transformer, and service it if defective.

(T901,IC94,IC95,Q905-Q909,D930,D931,D934-D936)

Check IC11,IC12and the periphery circuit, and service it if

defective.

Check if there is any leak or short-circuiting rectifier circuit

of Power transformer, and service it if defective.

(Main Trans,IC81,D917-D923)

㸣Yes

Check IC93 and the periphery circuit, and service it if

defective.

FLOW CHART NO.3

The fluorescent display tube does not light up.

㸣

Is +3.3V_D. voltage supplied to Pins(37) of F701? 㸢No Check the +3.3V_D line and service it if defective.

㸣Yes

Is the voltage of approximately +42V supplied to

Pin(38) of F701?

㸣Yes

Is the voltage of approximately +7V supplied to

Pin(1),(43) of F701?

㸣Yes

Check the fluorescent display tube control signal of a

microcomputer. (FL_RST,FL_CS,FL_CLK,FL_MDT)

㸢No

㸢No Check the FL1/FL2 line and service it if defective.

Check D924-927,Q904 and periphery circuit, and service

it if defective.

21

DCD-F107

Page 22

FLOW CHART NO.4

The key operation is not functioning.

㸣

Are the contact point and the installation state of the

key switches (S701-S704,S706-S708) normal?

㸣Yes

When pressing each switches (S701-S704,S706S708), do the voltage of Pin (4),(5),(6),(99),(100) of

IC11 decrease?

㸣Yes

Replace IC11.

㸢No

㸢No

FLOW CHART NO.5

No operation is possible from the remote control unit.

㸣

Are the System Connector (DENON BUS) Cables

nomal?

㸣Yes

Is +5V_SYS voltage supplied to Pin(8) of IC96? 㸢No

㸣Yes

Re-install the switches (S701-S704,S706-S708) correctly

or replace the poor switch.

Check the switches (S701-S704,S706-S708) and their

periphery, and service it if detective.

Check IC94 and the periphery circuit, and service it if

defective.

Check Control Signal Pin(2) DBTXD,Pin(3) DBRXD of

JK93,JK94

㸣Yes

Refer to DRA-F107 TROUBLESHOOTING_Remote Control

㸢No

FLOW CHART NO.6

The disc tray cannot be opened and closed.

㸣

Is the normal control voltage inputted to Pin(6) of

IC11? Refer to "FLOW CHART NO.4" <The key

operation is not functioning.>

㸣Yes

Check the line between CN23 and IC14, and service it if

defective.

㸢No Replace the "OP/CL" button (S706).

Check IC96,IC11 and the periphery circuit, and service it

if defective.

22

DCD-F107

Page 23

FLOW CHART NO.7

Audio is not outputted normally.

㸣

Set the disc on the disc tray, and playback.

㸣

Are the analog audio signals outputted to Pin(1),(7) of

IC41,IC42

IC41Pin(1),(7) : AUDIO (L-),(L+)

IC42Pin(1),(7) : AUDIO (R-),(R+)

㸣Yes 㸣Yes

Is the "H" level MUTE line to Pin(21) of CY11? Is the "H" level Reset Signal for DAC to Pin(14) of IC31?

㸣Yes 㸣Yes

Check A_MUTE line and service it if defective.

IC44 Pin(25) A_MUTE H : mute / L : play 㸣Yes

㸢No

Check AUDIO+V(+6V) and AUDIO-V(-6V) line and

service it if defective.

Check the DAC(IC31) digital audio data signal from a

DSP (IC17). (BCK,LRCK,DATA_S1L,DATA_S1R)

Check the DAC(IC31) control signal from a

microcomputer (IC11). (DAC_CS,DAC_MCK,DAC_MDT)

㸣Yes

Check DAC(IC31)_Vcc(+3.3V_D2) line and service it if

defective.

㸣Yes

Replace IC31.

FLOW CHART NO.8

DIGITAL OUT(OPTICAL) Audio is not outputted normally.

㸣

Is +5VA voltage supplied to Pin(2) of JK91? 㸢No

㸣Yes

Check Data Signal Pin(3) D_OUT of JK91. 㸢No

Check IC71 and the periphery circuit, and service it if

defective.

Check Pin(33) DOUT of IC17 and the periphery circuit,

and service it if defective.

23

DCD-F107

Page 24

FLOW CHART NO.9

USB PLAY don't work normally.

㸣

Is VBUS(+5V) voltage supplied to Pin(1) of JK71? 㸢No

㸣Yes

Check Data Signal from USB UNIT.

JK71 2,3pin䇭䇭+D,-D

㸢No

FLOW CHART NO.10

CD PLAY don't work normally.

㸣

Is +7V_DRV voltage supplied to Pin(21),(22) of IC14? 㸢No

㸣Yes

Is +3.3V_D voltage supplied to Pin(3) of IC20? 㸢No

㸣Yes

Is the "H" level CD Reset to Pin(69) of IC17? 㸢No

㸣Yes

Is the "H" level CD Reset to Pin(1) of IC15? 㸢No

㸣Yes

Check IC71 and the periphery circuit, and service it if

defective.

Check IC15 and the periphery circuit, and service it if

defective.

Check if there is any leak or short-circuiting rectifier circuit

of Power transformer, and service it if defective.

(Main Trans,IC81,D917-D923)

Check IC93,D917,D918 and the periphery circuit, and

service it if defective.

Check IC11,IC15 and the periphery circuit, and service it

if defective.

Pin(57) RST1,Pin(26) USB_RST of IC11OK?

Pin(68) RST2 of IC15 OK?

Check CD Controle wave and service it if defective.

RFEQO,RFO,FSMONIT,FOO,TEI,TRO,FMO,DMO of

IC17

24

DCD-F107

Page 25

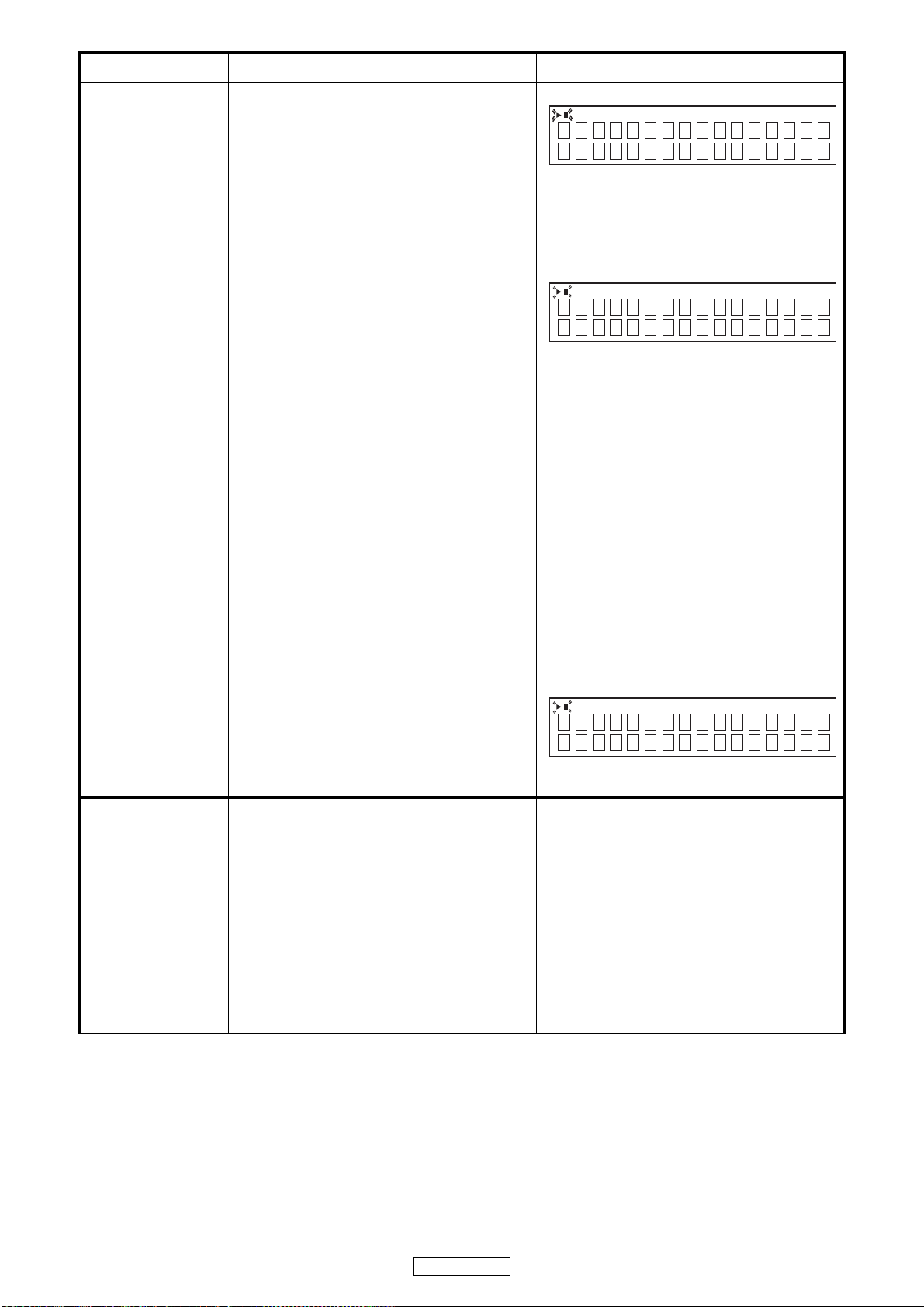

MEASURING POINT AND WAVEFORMS

MEASURING POINT

CUP12202 MAIN PCB ASSY (Component side)

o OPSW

Q0 CLSW

u FMO

i DMO

r FOO

w RFOq RFEQO

y TRO

Q2 LOAD-

Q1 LOAD+

CUP12202 MAIN PCB ASSY (Foil side)

e FSMONIT

(IC17 : 21pin)

t TEI

(IC17 : 24pin)

25

DCD-F107

Page 26

WAVEFORMS

y

y

㧕

y

T

①RFEQO

㽲RFEQO

1. DISC PLAY RF WAVEFORM㧔EYE-PATTERN

1.1 CD㧔TCD-784㧕Pla

③FSMONIT

1.2 CD-R㧔TCD-R000RM㧕Pla

③FSMONIT

②RFO

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

②RFO

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

2. DISC DETECTION

2.1 CD㧔TCD-784㧕DISC DETECTION

1V

200mV

2V

500Mv

2V

1V

2V

2.2 CD-R䋨TCD-R000RM䋩DISC DETEC

1V

200mV

2V

500Mv

2V

1V

2V

㽲RFEQO

1.3 CD-RW䋨TCD-W000RM 䋩Pla

②RFO

③FSMONIT

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

2.3 CD-RW䋨TCD-W000RM䋩DISC DETECTION

1V

200mV

2V

500Mv

2V

1V

2V

26

DCD-F107

Page 27

3. TOC READ

3.1 CD㧔TCD-784㧕TOC READ

4. FOCUS ADJUSTMENT

4.1 CD㧔TCD-784㧕FOCUS ADJUSTMENT

②RFO

③FSMONIT

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

②RFO

③FSMONIT

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

1V

200mV

2V

500Mv

2V

1V

2V

3.2 CD-R䋨TCD-R000RM䋩TOC READ 4.2 CD-R䋨TCD-R000RM䋩FOCUS ADJUSTMENT

¬

1V

200mV

2V

500Mv

2V

1V

2V

3.3 CD-RW㧔TCD-W000RM 㧕TOC READ 4.3 CD-R䋨TCD-R000RM䋩FOCUS ADJUSTMENT

②RFO

③FSMONIT

④FOO

⑤TEI

⑥ TRO

⑦FMO

⑧DMO

⑨OPSW

⑩CLSW

⑪LOAD+

5. LOADER OPEN-CLOSE

OPEN

CLOSE

¬1V

200mV

2V

500Mv

2V

1V

2V

5V

5V

5V

⑫LOAD-

5V

27

DCD-F107

Page 28

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

TMP92FD23AFG (IC11)

TMP92FD23AFG Terminal Function

Pin

No

IC Terminal ame Terminal name

1 AVSS/VREFL Power

supply(GND)

2 AVCC/VREFH Power

supply(+3.3V)

3 PC0/TA0IN Non(PU) I Non(PU) Port only for input (Schmitt)

4 PC1/INT1 Non(PU) I POWER KEY (F107 only) Port only for input (Schmitt)

5 PC2/INT2 PLAY KEY I PLAY KEY Port only for input (Schmitt)

6 PC3/INT3 OP/CL KEY I OP/CL KEY Port only for input (Schmitt)

7 PF0/TXD0 FL_MDT O FL tube communication line (data) (Schmitt I input)

8 PF1/RXD0 OPEN O Non (NC) (Schmitt I input)

9 PF2/SCLK0/CTS0/CLK FL_CLK O FL tube communication line (clock) (Schmitt I input)

10 PF3/TXD1/HSSO [TXD] O DENON BUS [Communication lines for

11 PF4/RXD1/HSSI [RXD] I DENON BUS [Communication lines for

I/O

setting

P Power supply (GND)

P Power supply (+3.3V)

writing](F107 only)

writing](F107 only)

Terminal function Remarks

(Schmitt I input)

(Schmitt I input)

28

DCD-F107

Page 29

Pin

No

IC Terminal ame Terminal name

12 PF5/SCLK1/CTS1/

HSCLK

13 PN0/SCK0 CONT1 O Reserved (Schmitt I input), When resetting it, it

14 PN1/SO0/SDA0 CONT2 I Reserved (Schmitt I input and open drain output),

15 PN2/SI0/SCL0 CONT3 O Reserved (Schmitt I input and open drain output),

16 PN4/SO1/SDA1 E2P_DI O Cereal data output for E2PROM (Schmitt I input and open drain output),

17 PN5/SI1/SCL1 E2P_DO I Cereal data input for E2PROM (Schmitt I input and open drain output),

18 PN3/SCK1 E2P_CLK O Serial clock output for E2PROM (Schmitt I input)§When resetting it, it

19 PD0/TB0OUT0/INT4 PU I DENON BUS (F107 only) (Schmitt I input)

20 DVSS Power supply

21 P74/INT0 REMOCON I Remote control input (710only) Port only for input (Schmitt)

22 DVCC Power supply

23 P00/D0 OPEN_F O Tray OPEN control P0x : Setting is possible by 1bit unit

24 P01/D1 CLSE_F O Tray CLOSE control

25 P02/D2 A_Mute O DAC output audio mute L; Mute, H; Mute cancel

26 P03/D3 DRVMUTE O CD drive mute output L; Mute, H; Mute cancel (Cancels

27 P04/D4 INSW I CD drive limit SW input

28 P05/D5 CLSW I CD drive close SW input

29 P06/D6 OPSW I CD drive opening SW input

30 P07/D7 (USB_DET) PU I Reserved

31 P10/D8 FL_RST O FL tube communication line (reset) P1x : Setting is possible by 1bit unit

32 P11/D9 FL_CS O FL tube communication line (chip

33 P12/D10 E2P_CS O Chip selection for E2PROM (Act:H)

34 P13/D11 MODEL SEL I Model select H : 710AE / L : F107

35 P14/D12 14BUS0 (DSP) O *TC94A92FG bus control

36 P15/D13 14BUS1 (DSP) O *TC94A92FG bus control

37 P16/D14 BUS2 (DSP) O *TC94A92FG bus control

38 P17/D15 92BUS3 (DSP) O *TC94A92FG bus control

39 DVSS Power supply

40 NMI

41 DVCC Power supply

42 P40/A0 MODE0 I Select destination P4x : Setting is possible by 1bit unit

43 P41/A1 MODE1 I Select destination 00 : E2, 01 : E3, 10 : JP, 11 : E1C

44 P42/A2 LED_R O STB is red LED H;ON L;OFF

45 P43/A3 LED_G O P.ON is green LED H;ON L;OFF

46 P44/A4 DAC_CS O DAC1796 CS

47 P45/A5 (DAC_MDO) I (DAC1796 MDO) No control

48 P46/A6 DAC_RST O DAC1796 RST 710; PD in 1M

49 P47/A7 MDT_DAC/DXP/

50 P50/A8 MCK_DAC/DXP/

51 P51/A9 DXP_CS O Chip selector for DXP6000

52 P52/A10 DXP_RST O Reset for DXP6000

53 P53/A11 BU_CS O Chip selector for BU2630

54 P54/A12 MCK_SEL O MCLK selector

55 P55/A13 POWER O MainTRANS on / off

56 P56/A14 USBRST(DSP) O Reset for TMP92FD28FG

57 P57/A15 DECRST O Reset for TC94A92FG

58 P60/A16 OPEN O Non P6x : Setting is possible by 1bit unit

100K

Ω

/PD

(GND)

(+3.3V)

(GND)

PULL DOWN (0

(+3.3V)

BU

BU

I/O

setting

I DENON BUS(F107 only) (Schmitt I input)

P Power supply (GND)

P Power supply(+3.3V)

selection)

P Power supply (GND)

INMI

Ω

)

P Power supply(+3.3V)

O DAC1796 MDI

O DAC1796 MCK P5x : Setting is possible by 1bit unit

Terminal function Remarks

becomes output latch 1.

When resetting it, it becomes output

latch 1.

When resetting it, it becomes output

latch 1.

When resetting it, it becomes output

latch 1.

When resetting it, it becomes output

latch 1.

becomes output latch 1.

above 3V)

BaseModel is PULL DOWN(0Ω).

RESET in OR of D305 and D306

RESET in +3.3V_D

→

29

DCD-F107

Page 30

Pin

No

100 PG0/AN0/KI0 KEY0 I KEY input 10 Port only for input(Schmitt )/Key on

IC Terminal ame Terminal name

59 P61/A17 (SRAMSTB) I Reserved

60 P62/A18 PWR_DET I "AC power OFF detection input

61 P63/A19 DOUT_MUTE O Mute output of digital data

62 P64/A20 DOUT_SEL O Digital data output selection

63 P65/A21 92SBSY I OASIS system busy input Connection with Borelo (4) pin.

64 P66/A22 28INT0 O Reserved

65 P67/A23 BOOT_CONT I Reserved

66 P80/CS0/

TA1 O UT[BO O T ]

67 P81/CS1/TA3OUT OPEN O Non Only the output port

68 P82/CS2 5V_REG_SW O Reserved Only the output port

69 P83/CS3/WAIT/

TA5 OUT

70 PD1/TB1IN0/INT5 92DREQ(MP3) I OASIS DREQ input (Schmitt I input) only for input

71 PD2/TB1IN1/INT6/

TXD2

72 AM1

73 X2 Oscillator

74 DVSS Power supply

75 X1 Oscillator

76 DVCC Power supply

77 RESET RESET I

78 AM0

79 P77/XT2

80 P76/XT1 92CCE(DSP) O *TC94A92FG bus control Open drain output R644(OPEN);GND

81 DVCC Power supply

82 P70/RD

83 P71/SRWR

84 P72/SRLLB

85 P73/SRLUB

86 PD3/TB1OUT0/RXD2/

INT7

87 PD4/TB1OUT1/SCLK2/

CTS2

88 DVSS Power

89 PL3/AN11/ADTRG

90 PL2/AN10

91 PL1/AN9

92 PL0/AN8

93 PG7/AN7/KI7

94 PG6/AN6/KI6

95 PG5/AN5/KI5

96 PG4/AN4/KI4

97 PG3/AN3/KI3

98 PG2/AN2/KI2 LD_CHCK I Input for LD check Port only for input(Schmitt )/Key on

99 PG1/AN1/KI1 KEY1 I KEY input 1 Port only for input(Schmitt )/Key on

BOOT O BOOT (for farm writing) Only the output port

92BUCK(DSP) O *TC94A92FG bus control Schmitt input

28TXD O For TMP92FD28FG communication (Schmitt I input)

PULL UP(0

connection pin

(GND)

connection pin

(+3.3V)

PULL UP(0

PULL UP(47k

(+3.3V)

CHECKIN(100K

PD)

CHECK1(100K

PD)

CHECK2(100K

PD)

CHECK3(100K

PD)

28RXD I For TMP92FD28FG communication (Schmitt I input)

OPEN O Non (Schmitt I input)

supply(GND)

100K

100K

100K

100K

100K

100K

100K

100K

100K

Ω

)

Ω

)

Ω

Ω

PD

Ω

/PD

Ω

/PD

Ω

/PD

Ω

/PD

Ω

/PD

Ω

/PD

Ω

/PD

Ω

/PD

I/O

setting

(When it is unplugged AC : L)"

I AM1 Pull UP Fixed H

O Oscillator connection pin

P Power supply (GND)

I Oscillator connection pin

P Power supply (+3.3V)

Reset input of

I AM0 Pull UP Fixed H

O Non Open drain output

)

P Power supply (+3.3V)

I P.W.B. check mode Schmitt input and with PU resistance

Ω

/

Ω

Ω

Ω

I P.W.B. check mode Schmitt input and with PU resistance

/

I P.W.B. check mode Schmitt input and with PU resistance

/

I P.W.B. check mode Schmitt input

/

P Power supply(GND)

I Non Port only for input(Schmitt )

I Non Port only for input(Schmitt )

I Non Port only for input(Schmitt )

I Non Port only for input(Schmitt )

I Non Port only for input(Schmitt )/Key on

I Non Port only for input(Schmitt )/Key on

I Non Port only for input(Schmitt )/Key on

I Non Port only for input(Schmitt )/Key on

I Non Port only for input(Schmitt )/Key on

Terminal function Remarks

μ

-com

W.U P

W.U P

W.U P

W.U P

W.U P

W.U P

W.U P

W.U P

30

DCD-F107

Page 31

TMP92CD28AFG (IC15)

31

DCD-F107

Page 32

TMP92CD28AFG Block Diagram

TMP92CD28AFG Terminal Function

Pin

IC Terminal name

No

1 /RESET RESETTerminal I I I - PU Port only for input

2 PC0/INT0 Reserved I - I - PD Port only for input (with Schmidt input)

3 PC1/INT1 Non (PD) I - I - PD Port only for input (with Schmidt input)

4 PC2/INT2/TB1IN0/

TB0IN0

5 PC3/INT3 STREQ input I - I - Port only for input (with Schmidt input)

6 DVCC3B Power supply (+3.3V) P P P P - Power supply (+3.3V)

7 XT1 Non (NC) I I I - - Input port

8 XT2 Non (NC) O O I - - Output port

DCD-710AE/755SE

Terminal name

SYSTEM BUSY input I - I - Port only for input (with Schmidt input)

I/O RST INIT STB

Pull

U/D

(Schmitt input and PU resistance)

Port function

32

DCD-F107

Page 33

Pin

IC Terminal name

No

9 PWE Non (NC) O - O - - Output port

10 DVSS Power supply (GND) P P P P - Power supply (GND)

11 DVCC1B Power supply (+1.5V) P P P P - Power supply (+1.5V)

12 RVOUT1 Built-in +1.5V Regulator

13 RVIN Built-in +1.5V Regulator

14 RVIN Built-in +1.5V Regulator

15 RVOUT2 Built-in +1.5V Regulator

16 DVCC1A Power supply (+1.5V) P P P P - Power supply(+1.5V)

17 DVSS Power supply (GND) P P P P - Power supply(GND)

18 P00/D0 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

19 P01/D1 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

20 P02/D2 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

21 P03/D3 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

22 P04/D4 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

23 P05/D5 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

24 P06/D6 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

25 P07/D7 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

26 DVSS Power supply (GND) P P P P - Power supply (GND)

27 DVCC3A Power supply (+3.3V) P P P P - Power supply (+3.3V)

28 P10/D8 Non (NC) O - O(L) - PD P1x : Setting is possible by 1bit unit

29 P11/D9 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

30 P12/D10 Non (NC) O - O(L) - - P0x : Setting is possible by 1bit unit

31 P13/D11 MODEL ID L ; F107 H ;7

32 P14/D12 CHECK IN 100k PD O - O(L) - - P0x : Setting is possible by 1bit unit

33 P15/D13 CHECK 1 100k PD O - O(L) - - P0x : Setting is possible by 1bit unit

34 P16/D14 CHECK 2 100k PD O - O(L) - - P0x : Setting is possible by 1bit unit

35 P17/D15 CHECK 3 100k PD O - O(L) - - P0x : Setting is possible by 1bit unit

36 P40/A0 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

37 P41/A1 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

38 P42/A2 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

39 P43/A3 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

40 P44/A4 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

41 P45/A5 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

42 P46/A6 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

43 P47/A7 Non (NC) O - O(L) - - P4x : Setting is possible by 1bit unit

44 DVSS Power supply (GND) P P P P - Power supply (GND)

45 DVCC3A Power supply (+3.3V) P P P P - Power supply (+3.3V)

46 P50/A8 Non (NC) O - O(L) - - P5x : Setting is possible by 1bit unit

47 P51/A9 Non (NC) O - O(L) - - P5x : Setting is possible by 1bit unit

48 P52/A10 Non (NC) O - O(L) - - P5x : Setting is possible by 1bit unit

49 P53/A11 Non (NC) O - O(L) - - P5x : Setting is possible by 1bit unit

50 P54/A12 Non (NC) O - O(L) - - P5x : Setting is possible by 1bit unit

51 P55/A13 Reserved I - I - PU P5x : Setting is possible by 1bit unit

52 P56/A14 Reserved O - O(L) - PU P5x : Setting is possible by 1bit unit

53 P57/A15 Reserved I - I - PU P5x : Setting is possible by 1bit unit

54 P60/A16 Non (NC) O - O(L) - - P6x : Setting is possible by 1bit unit

55 P61/A17 Non (PD) O - O(L) - PD P6x : Setting is possible by 1bit unit

56 P62/A18 CCE O - I - PU P6x : Setting is possible by 1bit unit

57 P63/A19 BUCK O - I - PU P6x : Setting is possible by 1bit unit

58 P64/A20 BUS0 I/O - I - PU P6x : Setting is possible by 1bit unit

59 P65/A21 BUS1 I/O - I - PU P6x : Setting is possible by 1bit unit

60 P66/A22 BUS2 I/O - I - PU P6x : Setting is possible by 1bit unit

61 P67/A23 BUS3 I/O - I - PU P6x : Setting is possible by 1bit unit

62 DVSS Power supply (GND) P P P P - Power supply (GND)

63 DVCC3A Power supply (+3.3V) P P P P - Power supply (+3.3V)

64 P70/RD Non (NC) O - O(L) - - Port only for input

65 P71/SRWR Non (NC) O - O(L) - - Port only for input

66 P72/SRLLB Non (PD) O - O(L) - PD Port only for input

DCD-710AE/755SE

Terminal name

output

input

input

output

10AE

I/O RST INIT STB

O - O - - Voltage output is not in the Flash version

I - I - - Flash version is a terminal Power supply

I - I - - Flash version is a terminal Power supply

O - O - - Voltage output is not in the Flash version

I - O(L) - - P0x : Setting is possible by 1bit unit

Pull

U/D

(Schmitt input and PU resistance)

(Schmitt input and PU resistance)

(Schmitt input and PU resistance)

Port function

33

DCD-F107

Page 34

Pin

IC Terminal name

No

67 P73/SRLUB Non (NC) O - O(L) - - Port only for input

68 P74/TA0IN RESET output for

69 P80/CS0/TA1OUT/

BOOT

70 P82/CS2 Reserved O - O(H)- - Port only for input

DCD-710AE/755SE

Terminal name

TC94A92FG

Flash writing BOOT O I O(H)- PU Port only for input

I/O RST INIT STB

O-O(H)- - I/O port (Schmitt input )

Pull

U/D

(Schmitt input and PU resistance)

Port function

71 P83/CS3/WAIT/

TA5 OUT

72 AM1 Operational mode (PU) I - I - PU Port only for input (Fixed H)

73 X2 Oscillator connection

74 DVSS Power supply (GND) P P P P - Power supply (GND)

75 X1 Oscillator connection

76 DVCC3A Power supply (+3.3V) P P P P - Power supply (+3.3V)

77 P75/USBOC USB OC (overcurrent

78 P76/USBPON Non (NC) O - O(H)- - I/O port (Schmitt input )

79 D+ USB connection terminal I/O - I/O - - I/O port

80 D- USB connection terminal I/O - I/O - - I/O port

81 AM0 Operation mode (PU) I - I - PU Port only for input (Fixed H)

82 P77/X1USB Non (PD) O - O(H)- - I/O port (Schmitt input )

83 DVSS Power supply (GND) P P P P - Power supply (GND)

84 PF0/TXD0 Reserved I - I - PD I/O port (Schmitt input )

85 PF1/RXD0 Reserved I - I - PD I/O port Schmitt input )

86 PF2/SCLK0/CTS0/

CLK/TB0OUT0

87 PF3/TXD1/SPDO

88 PF4/RXD1/SPDI

89 PF5/SCLK1/CTS1/

SPCLK

90 PN1/SDA0/TA3OUT Co-PRO communication line

91 PN2/SCL0/TA2IN Co-PRO communication line

92 PN3/HSCLK/SCK1 TC94A92FG communication

93 PN4/HSSO/SDA1/

SO1

94 PN5/HSSI/SCL1/SI1 TC94A92FG communicatio n

95 DVCC3A Power supply (+3.3V) P P P P - Power supply (+3.3V)

96 PG3/KI3 Non (PD) I - I - PD Port only for input (Schmitt )/Key on W.UP

97 PG2/KI2 Non (PD) I - I - PD Port only for input (Schmitt )/Key on W.UP

98 PG1/KI1 Non (PD) I - I - PD Port only for input (Schmitt )/Key on W.UP

99 PG0/KI0 TC94A92FG DREQ input I - I - PD Port only for input (Schmitt )/Key on W.UP

100 DVSS Power supply (GND) P P P P - Power supply( GND)

TC94A92FG communication

LRCK

terminal (9.000MHz)

terminal (9.000MHz)

detection Act L) input

Non (PD) I - I - PD I/O port (Schmitt input )

SYS μ-com communication

line TXD/Flash writing TXD

SYS μ-com communication

line TXD/Flash writing TXD

Co-PRO RESET O - O - PU I/O port

I2C_SDA

I2C_SCL

BCK

TC94A92FG communication

DATA

GATE

O-O(H)- - I/O port

O - O - - Output port

I - I - - Input port

I - I - - I/O port (Schmitt input )

O - O - PU I/O port (Schmitt input )

I - I - PU I/O port

I/O - I/O - PU I/O port (Schmitt input, open drain)

O - O - PU I/O port (Schmitt input, open drain)

O - O - - I/O port (Schmitt input )

O - O - - I/O port Schmitt input, open drain)

O - O - - I/O port (Schmitt input, open drain)

34

DCD-F107

Page 35

TC94A92FG (IC17)

䎷䎲䎶䎫䎬䎥䎤䎃䎦䏒䏑䏉䏌䏇䏈䏑䏗䏌䏄䏏

㪫㪚㪐㪋㪘㪐㪉㪝㪞

㩿㪫㫆㫇㩷㪭㫀㪼㫎㪀

㩷

㪧㫀㫆㪎

㪧㫀㫆㪍

㪧㫀㫆㪌

㪧㫀㫆㪋

㪧㫀㫆㪊

㪧㫀㫆㪉

㪧㫀㫆㪈

㪧㫀㫆㪇

㩷

㩷

㪭㪪㪪㪄㪉

㪭㪛㪛㪈㪄㪉

㪯㪭㪛㪛㪊㪯㫆㪯㫀

㪯㪭㪪㪪㪊

㪛㪭㪪㪪㪊㪣㪣㫆㪛㪭㪛㪛㪊㪣

㪛㪭㪛㪛㪊㪩㪩㫆

㪛㪭㪪㪪㪊㪩

㪭㪛㪛㪊

㪙㪬㪪㪇

㪙㪬㪪㪈

㪙㪬㪪㪉

㪙㪬㪪㪊

㪙㪬㪚㪢

㪆㪚㪚㪜

㪤㪪

㪆㪩㪪㪫

㪫㪜㪪㪫

㪭㪛㪛㪈㪄㪈

㪭㪪㪪㪄㪈

㪆㪪㪩㪘㪤㪪㪫㪙

㪭㪛㪛㪤㪈

㪧㪛㫆

㪫㪤㪘㪯

㪣㪧㪝㪥

㪣㪧㪝㫆

㪧㪭㪩㪜㪝

㪭㪚㫆㪝

㪍㪇㪌㪐㪌㪏㪌㪎㪌㪍㪌㪌㪌㪋㪌㪊㪌㪉㪌㪈㪌㪇㪋㪐㪋㪏㪋㪎㪋㪍㪋㪌㪋㪋㪋㪊㪋㪉

㪍㪈 㪋㪇

㪍㪉 㪊㪐

㪍㪊 㪊㪏

㪍㪋 㪊㪎

㪍㪌 㪊㪍

㪍㪍 㪊㪌

㪍㪎 㪊㪋

㪍㪏 㪊㪊

㪍㪐 㪊㪉

㪎㪇 㪊㪈

㪎㪈 㪊㪇

㪎㪉 㪉㪐

㪎㪊 㪉㪏

㪎㪋 㪉㪎

㪎㪌 㪉㪍

㪎㪍 㪉㪌

㪎㪎 㪉㪋

㪎㪏 㪉㪊

㪎㪐 㪉㪉

㪏㪇 㪉㪈

㪈㪉㪊㪋㪌㪍㪎㪏㪐

㪈㪇㪈㪈㪈㪉㪈㪊㪈㪋㪈㪌㪈㪍㪈㪎㪈㪏㪈㪐㪉㪇

㪋㪈

㪚㪛㪤㫆㪥㪊

㪧㫀㫆㪈㪋㩷㪆㩷㪚㪛㪤㫆㪥㪉

㪧㫀㫆㪈㪊㩷㪆㩷㪚㪛㪤㫆㪥㪈

㪧㫀㫆㪈㪉㩷㪆㩷㪚㪛㪤㫆㪥㪇㩷㪆㩷㪝㪞㫀㪥

㪧㫀㫆㪈㪈

㪧㫀㫆㪈㪇

㪧㫀㫆㪐

㪧㫀㫆㪏

㪭㪛㪛㪈㪄㪊

㪛㪤㫆

㪝㪤㫆㪪

㪝㪤㫆

㪭㪪㪪㪄㪊

㪫㪩㫆

㪝㫆㫆

㪘㪭㪛㪛㪊

㪫㪜㫀

㪩㪝㪩㪧

㪩㪝㪱㫀

㪝㪪㪤㫆㪥㫀㪫

㪪㪣㪚㫆

㪩㪭㪛㪛㪊

㪩㪝㫀

㪩㪝㪩㪧㫀

㪩㪝㪜㪨㫆

㪛㪚㫆㪝㪚

㪘㪞㪚㫀

㪭㪚㫆㫀

㪩㪝㫆

㪩㪭㪪㪪㪊

㪫㪧㫀

㪝㪧㫀㪉

㪝㪥㫀㪉

㪝㪥㫀㪈

㪫㪥㫀

㪝㪧㫀㪈

㪭㪩㫆

㪤㪛㫀

㪘㪭㪪㪪㪊

㪣㪛㫆

35

DCD-F107

Page 36

TC94A92FG Terminal Function

p

Pin

No.

Symbol I/O Description

VCoi

1

RVDD3 -

2

SLCo

3

RFi

4

RFRPi

5

RFEQo

6

DCoFC

7

AGCi

8

RFo

9

RVSS3 -

10

FNI2

11

FNI1

12

FPI2

13

FPI1

14

TPi

15

TNi

16

VRo

17

AVSS3 -

18

MDi

19

LDo

20

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

Default Remarks

DSP VCO - EFM and PLCK Phase difference

O

signal output pin.

(DSP VCO control voltage inputr pin.)

CD-DSP-Power supply for 3.3V RF

amplifier core and PLL circuit

O

EFM slice level output pin㩷

I

RF signal input pin㩷

I

㪩㪝㩷㫉㫀㫇㫇㫃㪼㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅 I

O

㪩㪝㩷㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㪺㫀㫉㪺㫌㫀㫋㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

O

RFEQo offset compensation LPF output O

I

㪩㪝㩷㫊㫀㪾㫅㪸㫃㩷㪘㪞㪚㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅 I

O

㪩㪝㩷㫊㫀㪾㫅㪸㫃㩷㪾㪼㫅㪼㫉㪸㫋㫀㫆㫅㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅 O

㪞㫉㫆㫌㫅㪻㫀㫅㪾㩷㫇㫀㫅㩷 㪽㫆㫉㩷 㪊㪅㪊㩷 㪩㪝㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷 㪺㫆㫉㪼㩷and PLL

circuit

I

㪤㪸㫀㫅㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪚㪅

I

㪤㪸㫀㫅㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪘㪅

I

㪤㪸㫀㫅㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪛㪅㩷

I

㪤㪸㫀㫅㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪙㪅

I

㪪㫌㪹㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪝㪅

I

㪪㫌㪹㩷㪹㪼㪸㫄㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅㩷

㪫㫆㩷㪹㪼㩷㪺㫆㫅㫅㪼㪺㫋㪼㪻㩷㫋㫆㩷㪧㪠㪥㩷㪻㫀㫆㪻㪼㩷㪜㪅

O

㪈㪅㪍㪌㩷㪭㩷㫉㪼㪽㪼㫉㪼㫅㪺㪼㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

Grounding pin for 3.3V CD analog circuits.

I

㪤㫆㫅㫀㫋㫆㫉㩷㫇㪿㫆㫋㫆㪻㫀㫆㪻㪼㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅㪅 I

O

㪣㪸㫊㪼㫉㩷㪻㫀㫆㪻㪼㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅 O

O

3 state output

-

Connect capacitor according with se

O

rvo frequency band.

I

Selectable Zin 20/10 k:

Connect to RFRPi by 0.1uF, to RFi by

4700pF.

Connect to Vro by more than 0.015uF

-

I

I

I

I

I

I

Connected to PVREF,

And connect to GNG by

0.1uF+100uF.

-

Reference Voltage=178mVtyp.

36

DCD-F107

Page 37

Pin

No.

Symbol I/O Description

Default Remarks

FSMoNiT

21

RFZi

22

RFRP

23

TEi

24

AVDD3 -

25

FOo

26

TRo

27

VSS-3 -

28

FMo

29

FMoS

30

DMo

31

VDD1-3

32

Pio8

33

Pio9

34

Pio10

35

Pio11

36

Pio12/

CDMoN0/

37

FGiN

Pio13/

38

CDMoN1

Pio14/

39

CDMoN2

CDMoN3

40

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

3AI/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

3I/F

O

O

O

O

O

O

O

O

O

Focus Error signal / Sub beam add signal

output pin(monitor pin/GND)

I

㪩㪝㩷㫉㫀㫇㫇㫃㪼㩷㫑㪼㫉㫆㪄㪺㫉㫆㫊㫊㩷㫊㫀㪾㫅㪸㫃㩷㪠㫅㫇㫌㫋㩷㫇㫀㫅 I

㪩㪝㩷㫉㫀㫇㫇㫃㪼㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

㪫㫉㪸㪺㫂㫀㫅㪾㩷㪼㫉㫉㫆㫉㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

Power supply pin for 3.3 V CD analog circuits.

㪝㫆㪺㫌㫊㩷㫊㪼㫉㫍㫆㩷㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

㪫㫉㪸㪺㫂㫀㫅㪾㩷㫊㪼㫉㫍㫆㩷㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

Grounding pin for 1.5V Decoder-DSP

CD circuit

㪝㪼㪼㪻㩷㫊㪼㫉㫍㫆㩷㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

Feed servo 㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅

䋨Stepper motor application䋩

㪛㫀㫊㪺㩷㫊㪼㫉㫍㫆㩷㪼㫈㫌㪸㫃㫀㫑㪼㫉㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅 O

Power supply pin for 1.5V Decoder-DSP

/CD circuit

Port 8䋨General Input/Output Port 䋩 I

Port 9䋨General Input/Output Port 䋩 I

Port 10䋨General Input/Output Port 䋩 I

Port 11䋨General Input/Output Port 䋩 I

Port 12䋨General Input/Output Port 䋩

/ CD Monitor 0 / FG signal input

Port 13䋨General Input/Output Port 䋩

/ CD Monitor1

Port 14䋨General Input/Output Port 䋩

/ CD Monitor 2

CD Monitor3 (Default output : SBSY) O

O

Bulit-in serises R=500:㪅

Connect to VRo by

capacitor.

-

Bulit-in serises R=3.3 k:

Bulit-in output R=3.3 k:

-

Bulit-in output R=3.3 k:

O

Bulit-in output R=3.3 k:

Bulit-in output R=3.3 k:

-

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

I

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

I

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

I

Refer to [1.2 Pin Assinment Table]

CMOS Port

Refer to [1.2 Pin Assinment Table]

㩷

37

DCD-F107

Page 38

Pin

No.

41

Symbol I/O Description

DVSS3R - Grounding pin for 3.3V Muiti-Bit DAC circuit -

Default Remarks

Ro

42

DVDD3R - Power supply pin for 3.3V Audio DAC circuit. -

43

DVDD3L - Power supply pin for 3.3V Audio DAC circuit. -

44

Lo

45

DVSS3L - Grounding pin for 3.3V Muiti-Bit DAC Circuit -

46

XVSS3 - Grounding pin for 3.3V clock oscillator circuit -

47

Xi

48

Xo

49

XVDD3 -

50

VDD1-2 - Power Supply pin for 1.5V Digital circuit -

51

VSS-2 - Grounding pin for 1.5V digital circuit -

52

Pio0

53

Pio1

54

Pio2

55

Pio3

56

Pio4

57

Pio5

58

Pio6

59

Pio7

60

O

3AI/F

O

3AI/F

3AI/F

O

3AI/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

R channel audio output pin of Audio DAC. O

L channel audio output pin of Audio DAC O

I

System clock Input pin I

System clock Output pin O

Power Supply pin for 3.3V clock

oscillator circuit

Port 0䋨General Input/Output Port 䋩 I

Port 1䋨General Input/Output Port 䋩 I

Port 2䋨General Input/Output Port 䋩 I

Port 3䋨General Input/Output Port 䋩 I

Port 4䋨General Input/Output Port 䋩 I

Port 5䋨General Input/Output Port 䋩 I

Port 6䋨General Input/Output Port䋩 I

Port 7䋨General Input/Output Port 䋩 I

Xtal oscillation circuit.

Connect feedback resistor 1

between Xo and Xi

M:

-

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

38

DCD-F107

Page 39

Pin

No.

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

3A I/F : 3 V analog circuit input/output pin.

1.5 I/F : 1.5Vdigital input/output pin.

3 I/F : 3 V digital input/output pin.

Symbol I/O Description

VDD3 - Power Supply pin for 3.3V Digital circuit -

BUS0

BUS1

BUS2

BUS3

BUCK

/CCE

MS

/RST

Te st

VDD1-1 - Power Supply pin for 1.5V Digital circuit -

VSS-1 - Grounding pin for 1.5V Digital circuit -

/SRAMSTB

VDDM1 - Power Supply for 1.5V 1Mbit SRAM circuit -

PDo

TMAX

LPFN

LPFo

PVREF - 㪧㪣㪣㩷㪺㫀㫉㪺㫌㫀㫋㩷㪈㪅㪍㪌㩷㪭㩷㫉㪼㪽㪼㫉㪼㫅㪺㪼㩷㫍㫆㫃㫋㪸㪾㪼㩷㫇㫀㫅㪅 -

VCoF

I/O

3I/F

I/O

3I/F

I/O

3I/F

I/O

3I/F

I

3I/F

I

3I/F

I

3I/F

I

3I/F

I

3I/F

I

3I/F

O

3AI/F

O

3AI/F

I

3AI/F

O

3AI/F

O

3AI/F

Microprocessor I/F data input/output pin 0 I

Microprocessor I/F data input/output pin 1 I

Microprocessor I/F data input/output pin 2 I

Microprocessor I/F data input/output pin 3 I

Microprocessor I/F BUS clock Input pin I

Microprocessor I/F chip enable input pin I

Microprocessor I/F mode selection pin.

“H”: Parallel I/F, “L”: Serial I/F

Reset Input pin I

Test pin 䋨”L” fixed䋩 I

1Mbit SRAM stand by pin䋨/SRAMSTB="L"䋩 I

㪜㪝㪤㩷㪸㫅㪻㩷㪧㪣㪚㪢㩷㪧㪿㪸㫊㪼㩷㪻㫀㪽㪽㪼㫉㪼㫅㪺㪼㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅㪅 O

㪫㪤㪘㪯㩷㪻㪼㫋㪼㪺㫋㫀㫆㫅㩷㫉㪼㫊㫌㫃㫋㩷㫆㫌㫋㫇㫌㫋㩷㫇㫀㫅 O

㪧㪣㪣㩷㪺㫀㫉㪺㫌㫀㫋㩷㪣㪧㪝㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㫀㫅㫍㪼㫉㫊㫀㫆㫅㩷㫀㫅㫇㫌㫋㩷㫇㫀㫅 I

㪧㪣㪣㩷㪺㫀㫉㪺㫌㫀㫋㩷㪣㪧㪝㩷㪸㫄㫇㫃㫀㪽㫀㪼㫉㩷㪦㫌㫋㫇㫌㫋㩷㫇㫀㫅 O

㪭㪚㪦㩷㪽㫀㫃㫋㪼㫉㩷㫇㫀㫅 O

Default Remarks

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

CMOS Port

Schmitt input

Refer to [1.2 Pin Assinment Table]

Schmitt input

Refer to [1.2 Pin Assinment Table]

Schmitt input

Refer to [1.2 Pin Assinment Table]

I

Refer to [1.2 Pin Assinment Table]

Schmitt input

Connect to GND for normal operation

4-state output ( RVDD3,

RVSS3,PVREF, Hiz)

3-state output ( RVDD3, RVSS3, Hiz)

Connected to VRO. Connect to

GND by 0.1uF and 100uF.

Connect to GND by 0.01uF

39

DCD-F107

Page 40

IP4001 (IC14)CR

Pin Discriptions

Block Diagram

NOGGGG SYMBOLGGGG I/O GGGG DESCRIPTIONGGGG

1G DO1-G OG CH1 OUTPUT (-)G

2G DO1+G OG CH1 OUTPUT (+)G

3G IN1G IG CH1 INPUT 1G

4G IN1AG IG CH1 INPUT 2G

5G N / CG -G NO-CONNECTIONG

6G REO50G OG

7G MUTEG IG

8G SGNDG -G

9G FWDG IG CH5 INPUT 1G

10G IN2G IG CH2 INPUTG

11G DO2+G OG CH2 OUTPUT (+)G

12G DO2-G O

13G PGND1G -GGGPOWER GROUND 1G

14G REVG IG CH5 INPUT 2G

5.0V REGULATOR

OUTPUTG

MUTE

INPUTG

SIGNAL

GROUNDG

G CH2 OUTPUT (-)G

NOGGGG SYMBOLGGGG I/OGGGG DESCRIPTIONGGGG

15G DO5+G OG CH5 OUTPUT (+)G

16G DO5-G OG CH5 OUTPUT (-)G

17G DO3-G OG CH3 OUTPUT (-)G

18G DO3+G OG CH3 OUTPUT (+)G

19G IN3G IG CH3 INPUT G

20G CTLG IG

21G VCC1G IG

22G VCC2G IG

23G REFG IG CH BIAS INPUTG

24G IN4AG IG CH4 INPUT 1G

25G IN4G IG CH4 INPUT 2G

26G DO4+G

27G DO4-G OG CH4 OUTPUT (-)G

28G PGND2G -GGGPOWER GROUND 2G

GGCH5 MOTOR SPEED

CONTROLG

SUPPLY VOLTAGE 1

(CH2,CH3,CH5)G

SUPPLY VOLTAGE 2

(CH1,CH4,SIGNAL,REG)G

OG CH4 OUTPUT (+)G

VBG

40

DCD-F107

Page 41

PCM1796DB (IC31)

L

R

PCM1796DB Block Diagram

LRCK

BCK

DATA

RST

MDO

MDI

MC

MS

MSEL

Audio

Data Input

I/F

Function

Control

I/F

ZEROL

ZEROR

MSEL

LRCK

DATA

BCK

SCK

DGND

V

DD

MS

MDI

MC

MDO

RST

8

Oversampling

Digital

Filter

and

Function

Control

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Advanced

Segment

DAC

Modulator

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC2L

AGND3L

I

OUT

I

OUT

AGND2

V

V

V

I

REF

AGND1

I

OUT

I

OUT

AGND3R

V

Current

Segment

DAC

Bias

and

Vref

Current

Segment

DAC

CC

COM

COM

CC

L–

L+

1

R–

R+

2R

L

R

I

OUT

I

OUT

V

COM

I

REF

V

COM

I

OUT

I

OUT

L–

L+

R–

R+

V

OUT

L

R

I/V and Filter

V

OUT

ZEROL

ZEROR

Zero

Detect

System

Clock

Manager

SCK

DGND

Power Supply

DD

V

AGND1

AGND2

AGND3L

1

CC

V

AGND3R

2L

V

CC

2R

V

I/V and Filter

CC

41

DCD-F107

Page 42

PCM1796DB Pin Discriptions

I/O

DESCRIPTIONS

TERMINAL

NAME PIN

AGND1 19 – Analog ground (internal bias)

AGND2 24 – Analog ground (internal bias)

AGND3L 27 – Analog ground (L-channel DACFF)

AGND3R 16 – Analog ground (R-channel DACFF)

BCK 6 I Bit clock input

DATA 5 I Serial audio data input

DGND 8 – Digital ground

I

L+ 25 O L-channel analog current output+

OUT

I

L– 26 O L-channel analog current output–

OUT

I

R+ 17 O R-channel analog current output+

OUT

I

R– 18 O R-channel analog current output–

OUT

I

REF

LRCK 4 I Left and right clock (fS) input

MC 12 I Mode control clock input

MDI 11 I Mode control data input

MDO 13 I/O Mode control readback data output

MS 10 I/O Mode control chip-select input

MSEL 3 I I2C/SPI select

RST 14 I Reset

SCK 7 I System clock input

VCC1 23 – Analog power supply, 5 V

VCC2L 28 – Analog power supply (L-channel DACFF), 5 V

VCC2R 15 – Analog power supply (R-channel DACFF), 5 V

V

L 22 – L-channel internal bias decoupling pin

COM

V

R 21 – R-channel internal bias decoupling pin

COM

V

DD

ZEROL 1 I/O Zero flag for L-channel

ZEROR 2 I/O Zero flag for R-channel

(1)

Schmitt-trigger input, 5-V tolerant

(2)

Schmitt-trigger input and output. 5-V tolerant input and CMOS output

(3)

Schmitt-trigger input and output. 5-V tolerant input. In I2C mode, this pin becomes an open-drain 3-state output; otherwise, this pin is a CMOS

output.

20 – Output current reference bias pin

9 – Digital power supply, 3.3 V

(1)

(1)

(1)

(1)

(1)

(3)

(2)

(1)

(1)

(1)

(2)

(2)

42

DCD-F107

Page 43

2. FL DISPLAY

7RRGT .QYGT

VFD (HCA-18MS03T) (F701)

1 43

PIN CONNECTION

GRID ASSIGNMENT

43

DCD-F107

Page 44

ANODE CONNECTION

44

DCD-F107

Page 45

45

DCD-F107

Page 46

LEVEL DIAGRAM

㪚㪛

㪛㪘㪚 㪝㫀㫃㫋㪼㫉 㫄㫌㫋㪼

㪧㪤㪚㪈㪎㪐㪍

㪈㪇㪻㪙

㪌㪅㪍㪻㪙㩿㪈㪅㪐㪭㪀

㪇㪻㪙

㪄㪈㪇㪻㪙

㪌㪅㪈㪻㪙

㩿㪈㪅㪏㪇㪭㪀

㪄㪇㪅㪌㪻㪙

46

DCD-F107

Page 47

BLOCK DIAGRAM

RESET IC

(SEIKO)

80130ALMC

SPI EEPROM 4K

(ST)

M95040

MAIN MCU

(TOSHIBA)

TMP92FD23FG

9MHz

X'TAL

KEY0

KEY1

FL RST

FL DATA

FL CLK

FL CS

OPEN_SW, CLOSE_SW

CD RST

AMUTE

BUS2

BUS3

BUS CK

BUS CE

CD DSP

(TOSHIBA)

TC94A92FG

BCK

LRCK

GATE

DATA

BLOCK DIAGRAM

LD

16.9344MHz

X'TAL

FC+/TR+/-

FMG

DMG

SYS_CLK

MOTOR

DRIVER

(INTERPION)

IP4001CR

INVERTER

KIC7SH04FU

LOAD+/-

BCK/LRCK/A_OUT

SPIN+/SLED+/-

F+/-,TR+/-

DAC_RST

OPEN/CLOSE

CD MECHA

(SANYO)

(BURBROWN)

AUDIO DAC

PCM1796

CD/MP3/WMA DISC

DIGITAL OUT

OP AMP

NJM2068

DB_TXD

INVERTER

TC7WHU04FU

OP AMP

NJM2068

DB_CLK

DB_RXD

DB_TXD

SYSTEM

IN/OUT

OPTICAL

OUT

AUDIO

OUT

MUTE

KEY

FLT

(SAMSUNG)

HCA-18MS03T

USB RST

DISP DATA(I2C)

USB MCU

(TOSHIBA)

TMP92CD28FG

D+/D-

IPOD

USB DEVICE

9MHz

X'TAL

USB JACK

I2CSCL

I2CSDA

AMUTE

IPOD CP 2.0b

MFI341S2161

LPP

DAC_CS

MCK_DAC

MDT_DAC

47

DCD-F107

Page 48

PRINTED WIRING BOARDS

AUDIO/POWER PCB ASSY (1/2)

48

DCD-F107

COMPONENT SIDE

Page 49

AUDIO/POWER PCB ASSY (2/2)

49

DCD-F107

FOIL SIDE

Page 50

MAIN PCB ASSY

COMPONENT SIDE

FOIL SIDE

50

DCD-F107

Page 51

NOTE FOR PARTS LIST

Parts for which "nsp" is indicated on this table cannot be supplied.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

Ordering part without stating its part number can not be supplied.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

Part indicated with the mark "★" is not illustrated in the exploded view.

WARNING:

1.

2.

3.

4.

5.

6.

● Resistors

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Ex.: RN

Type

14K

Shape

and performance

2E

Power

182

Resistance

G

Allowable

error

FR

Others

* Resistance

1800ohm=1.8kohm18

2

Indicates number of zeros after effective number.

2-digit effective number.

1.2ohm1R 2

2-digit effective number, decimal point indicated by R.

1-digit effective number.

: Units: ohm

● Capacitors

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

F:±1%