Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1C E1K EUT

Ver. 2

Please refer to the

MODIFICATION NOTICE.

DCD-A100

P P P

SUPER AUDIO CD PLAYER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0175-1V02DM/DG1011

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be su re t o use part s whic h have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws , parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslat ion ch eck on the exter nal metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ...... Indicated by the z mark.

(2) Parts lists ...... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, res

or other dangerous situations.

2

Page 3

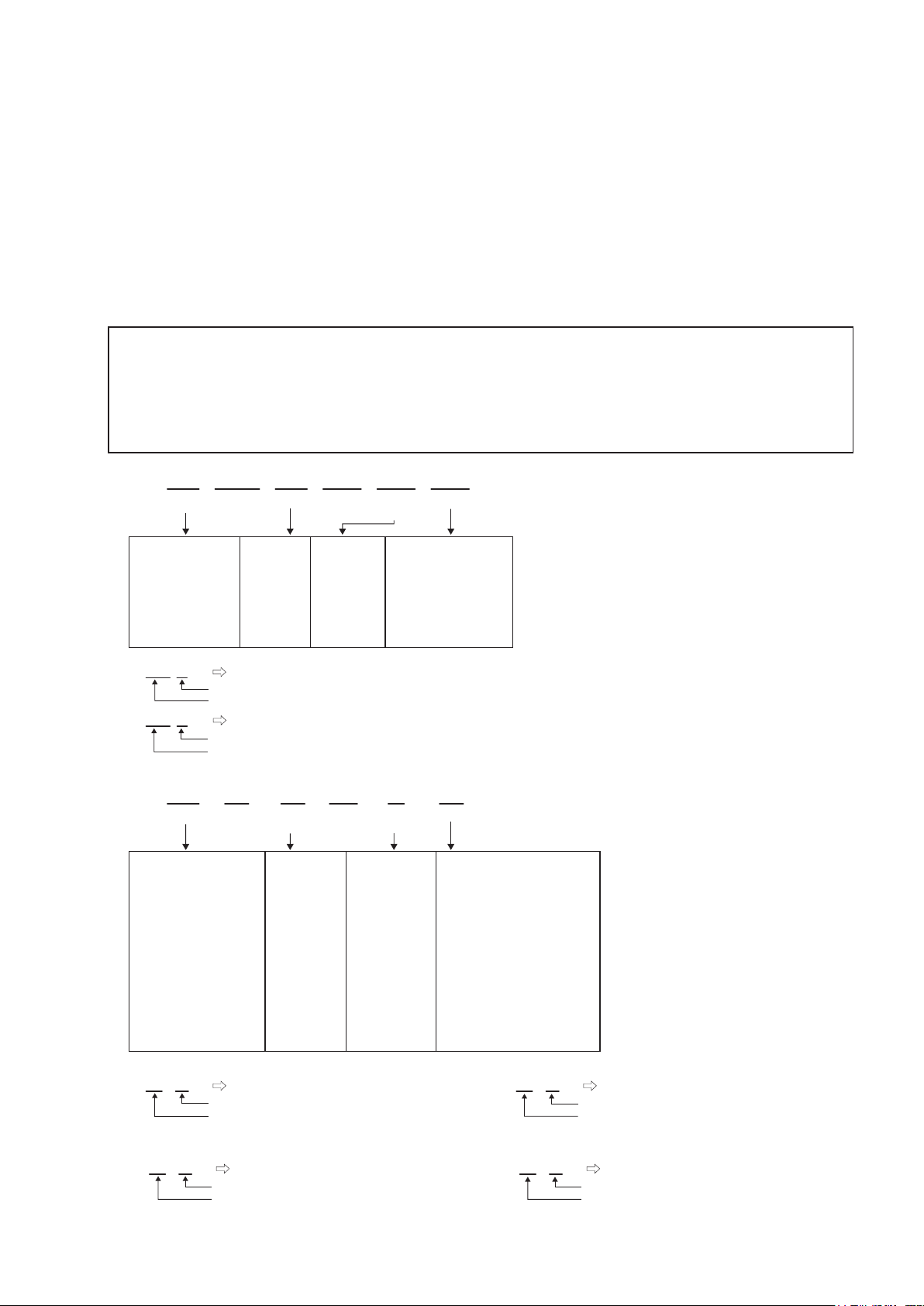

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

2.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

● Resistors

Ex.: RN

* Resistance

Capacitors

●

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ: Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

2

Indicates number of zeros after effective number.

・ Units:μF.

・ Units:pF

2-digit effective number.

2

14K

Shape

and performance

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

Z : ±80%

: - 20%

P : +100%

C : ±0.25pF

D : ±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

Page 4

WARNING AND LASER SAFETY INSTRUCTIONS

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are connected

with the same potential as the mass of the set via a

wrist wrap with resistance.

Keep components and tools also at this potential.

NL

Alle IC’s en vele andere halfgeleiders zijn gevoelig

voor elektrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de

levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een polsband

met weerstand verbonden bent met apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

WAARSCHUWING

F ATTENTION

Tous les IC et beaucoup d’autres semiconducteurs

sont sensibles aux décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est prise

a leur manipulation.

Lors de réparations, s’assurer de bien être relié au

même potentiel que la masse de l’appareil et enfiler

le bracelet serti d’une résistance de sécurité.

Veiller a ce que les composants ainsi que les outils

que l’on utilise soient également a ce potentiel.

D

WARNUNG

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

über ein Pulsarmband mit Widerstand mit auf

diesem Potential.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

“Pour votre sécurité, ces document s

doivent être utilisés par des

spécialistes agrées, se uls habilités à

réparer votre appareil en panne.”

F

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should

remove the cover or attempt to service this device, due to

possible eye injury.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili

alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente ridatta

in caso di non osservazione della piu grande

cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto a

resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo potenziale.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE

OF PROCEDURE OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will

increase eye hazard.

Repair handling should take place as much as possible with

a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION -CLASS 1M VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN.

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

VAROITUS -LUOKAN 1M NÄKYVÄÄ JA NÄKYMÄTÖNTÄ LASERSÄTEILYÄ. ÄVÄTUNA.

ÄLÄ KATSUO SÄDETTÄ SUORAAN PITISILLA LAITTEILLA.

VARNING -KLASS 1M SYNLIG OCH OSYNLIG LASERSTRÅLNING VID ÖPPNING.

BETRAKTA EJ STRÅLEN DIREKT MED OPTISKA INSTRUMENT.

ADVARSEL -KLASSE 1M USYNLIG OG SYNLIG LASERSTRÅLING VED ÅBNING.

MÅ IKKE BETRAGTES DIREKTE MED OPTISKEINSTRUMENTER.

4

100301DM

Page 5

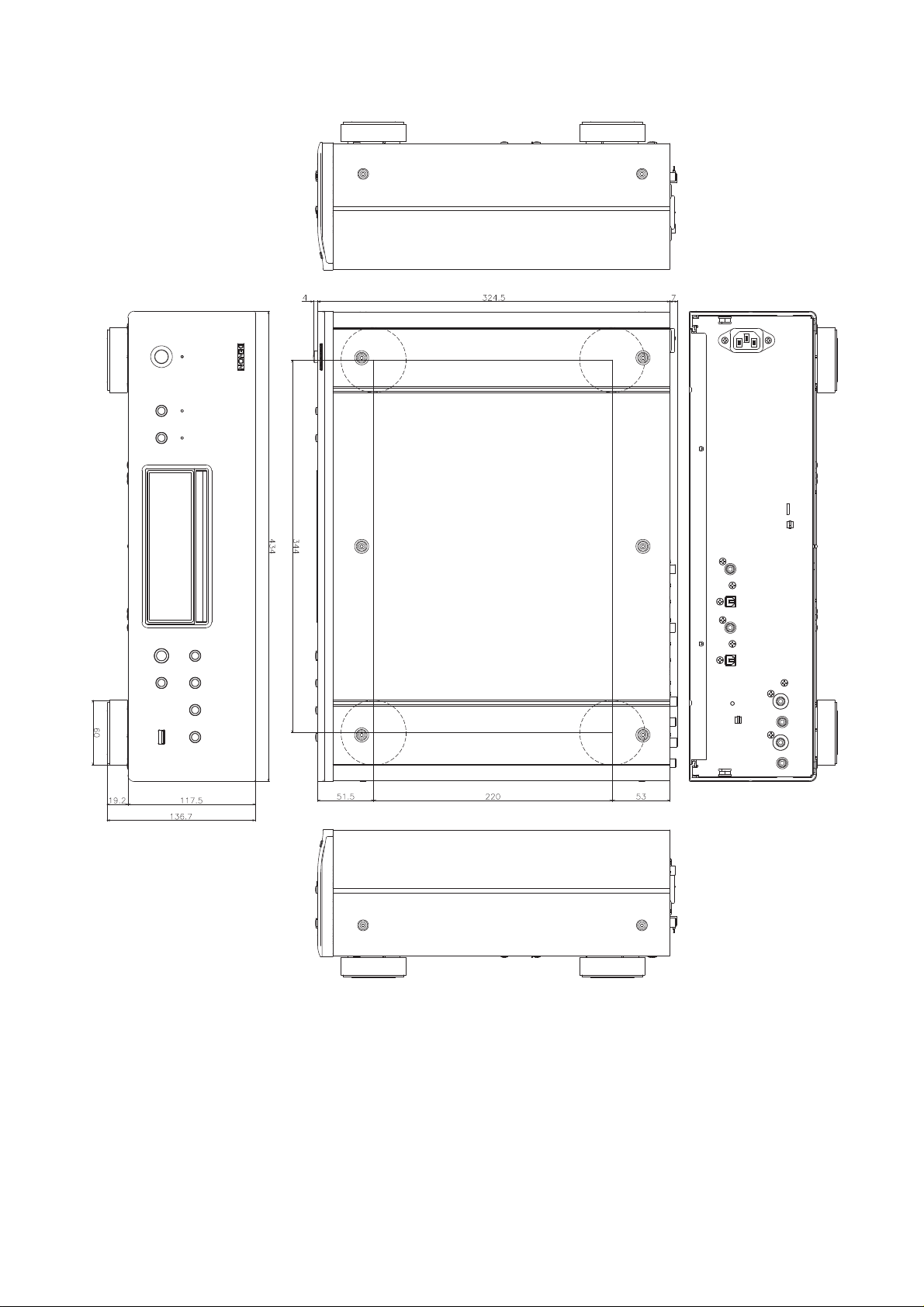

DIMENSION

5

Page 6

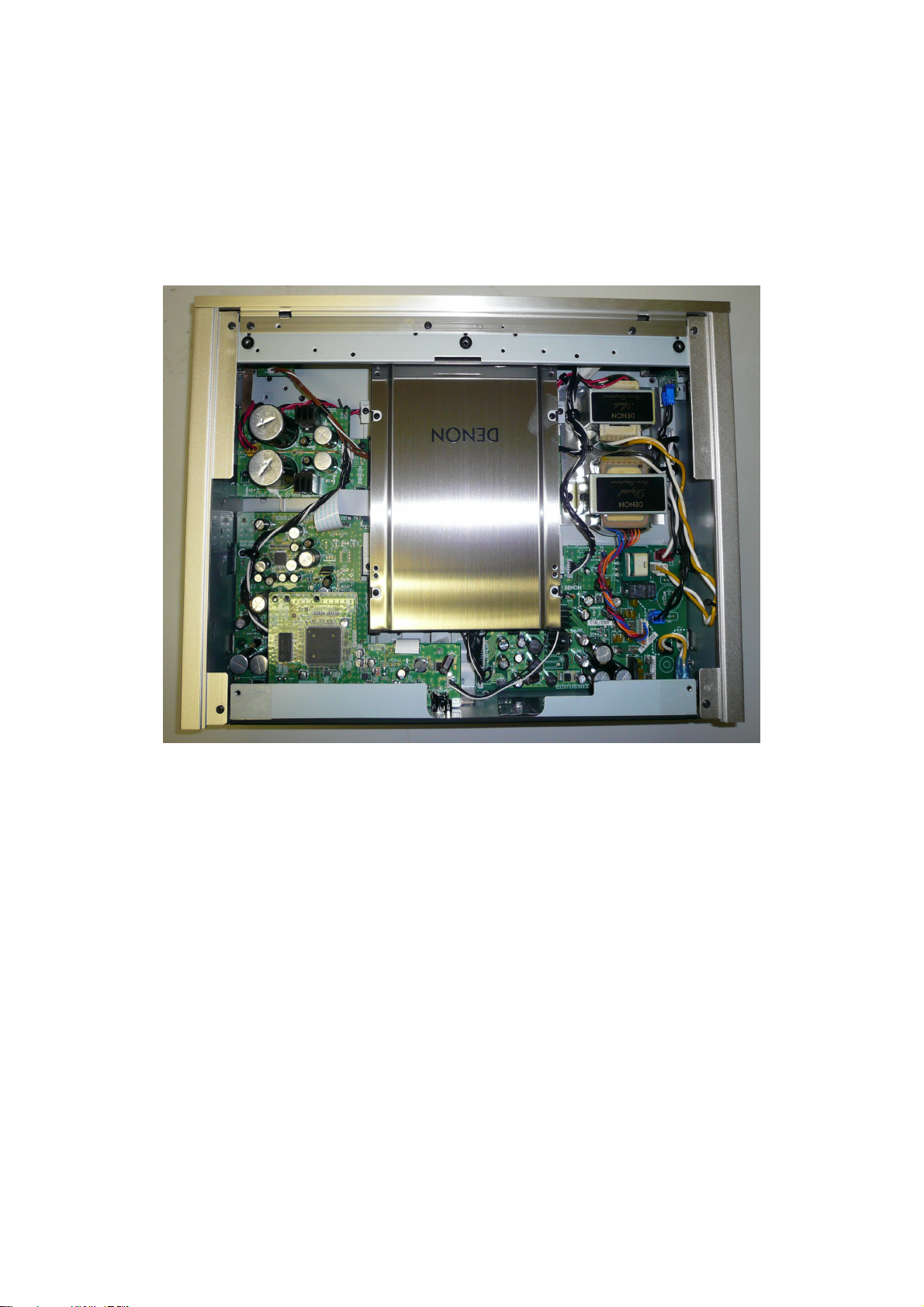

WIRE ARRANGEMENT

Front Panel side

Back Panel side

If wire bundles are untied or moved to perform adjustment or parts replacement etc.,be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

• The photograph is DCD-2010AE.

Wire arrangement viewed from the top

6

Page 7

DISASSEMBLY

TOP COVER

FRONT PANEL ASSY SACD/DVD MECHA UNIT ASSY DSP/DIGITAL-IO UNIT

Refer to "DISASSEMBLY 1.FRONT PANEL ASSY" Refer to "EXPLODED VIEW" Refer to "EXPLODED VIEW"

and "EXPLODED VIEW" SACD/DVD MECHA UNIT DSP/DIGITAL-IO UNIT

ANALOG PWR UNIT (Ref. No. of EXPLODED VIEW : 3A) (Ref. No. of EXPLODED VIEW : 1)

(Ref. No. of EXPLODED VIEW : 2-2) SACD/DVD MECHA UNIT

LED UNIT (Ref. No. of EXPLODED VIEW : 3B)

AUDIO UNIT

(Ref. No. of EXPLODED VIEW : 2-4) Refer to "EXPLODED VIEW"

USB UNIT

DISPLAY UNIT

AUDIOUNIT

(Ref. No. of EXPLODED VIEW : 2-5) Refer to "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : 2-7)

D.PWR UNIT DISPLAY UNIT

(Ref. No. of EXPLODED VIEW : 2-6) (Ref. No. of EXPLODED VIEW : 2-1)

POWER SW UNIT

Refer to "EXPLODED VIEW"

POWER SW UNIT

(Ref. No. of EXPLODED VIEW : 2-3)

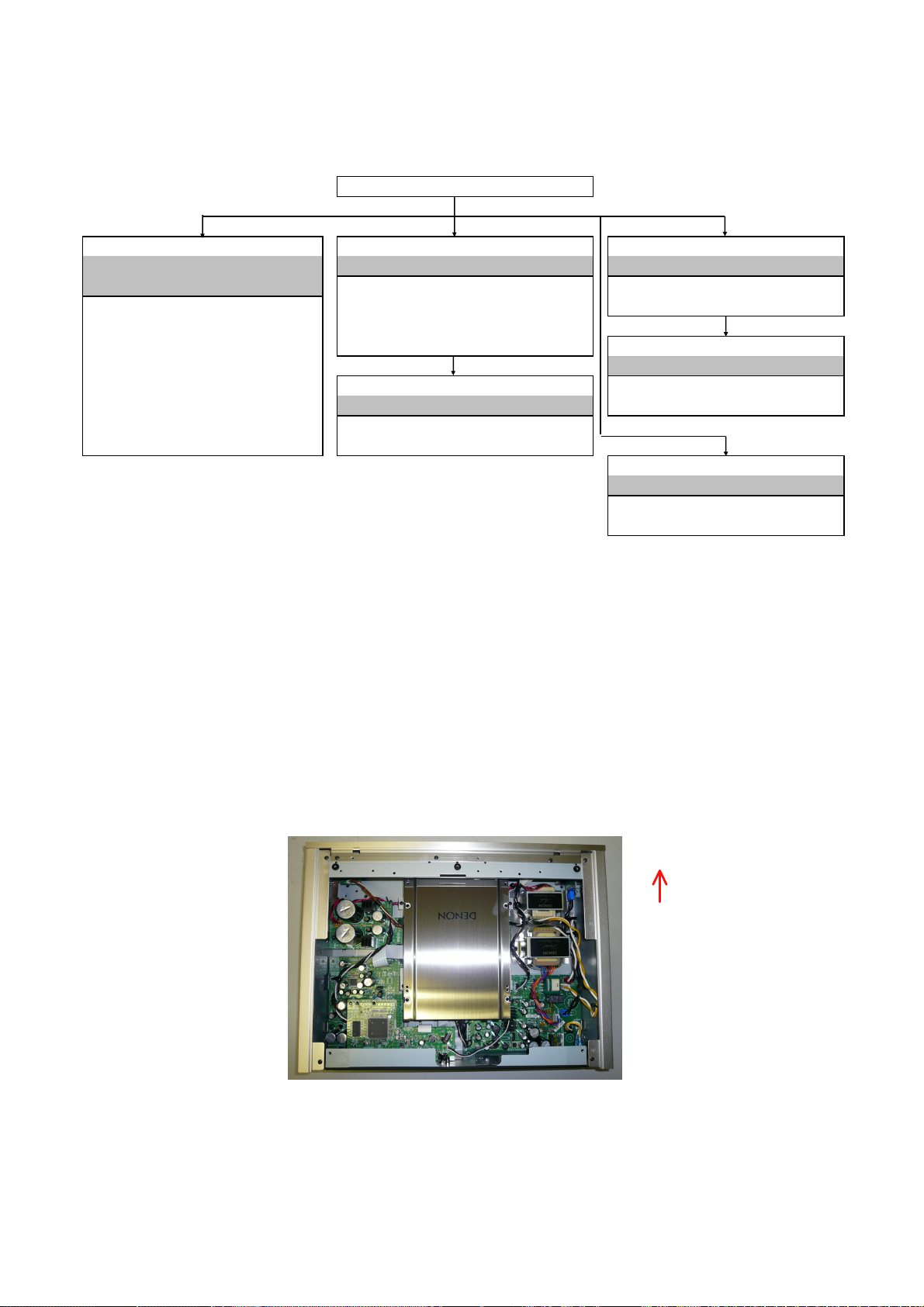

The viewpoint of each photograph

(Photografy direction)

[View from above]

Front side

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

About the photos used for descriptions in the “DISASSEMBLY” section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

• The photograph is DCD-2010AE.

7

Page 8

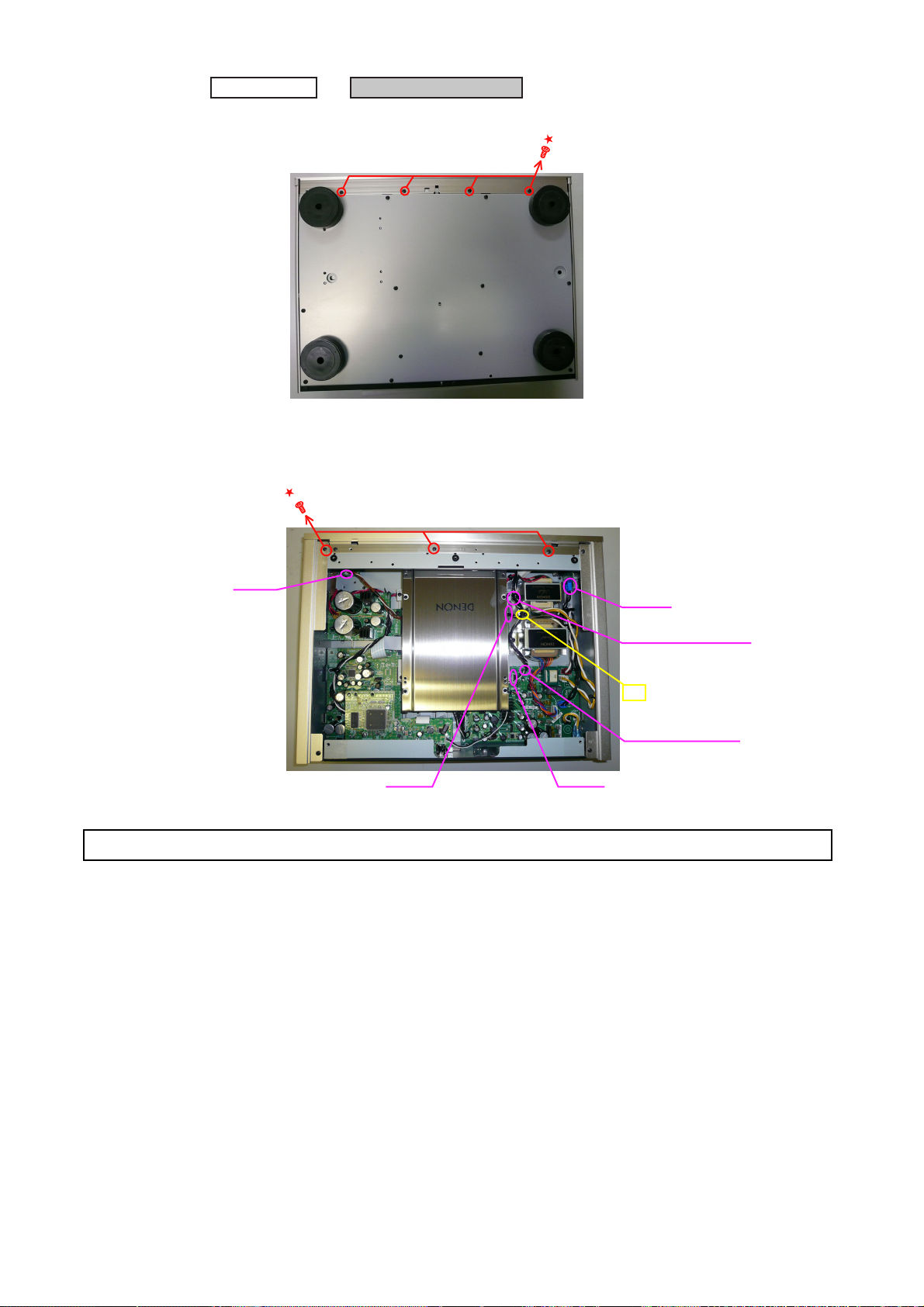

1. FRONT PANEL ASSY

Proceeding : TOP COVER

→

FRONT PANEL ASSY

View from bottom

Cord holder : Loose

CY034

Style pin : Loose

CX101 CX071

CY051

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

(1) Remove the screws.

(2) Cut the wire clamp bands, then loose the cord holder and style pin.

Disconnect the connector wires, then remove the screws.

8

Page 9

DIAGNOSTICS OF OPTICAL PICKUP AND REPLACING TRAVERSE UNIT

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (IOP) becomes more than 1.5 times of the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "IOP checked Method" of next page.

In case of replacing the Pickup, change the whole part of the Traverse Unit.

No mechanical adjustment is necessary after the replacement.

s

DVD :

(SACD)

CD :

DVD :

Laser drive current initial value:

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 2 3 - m m m m - -

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 2 1 - m m m m - -

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 6 D ± m m . m - -

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

HF wave form check

(Refer to WAVE FORMS)

Present value exceeds

the initial value by 1.5

times

Mecha Unit replacing

Laser current (Iop) memorizing after replacement

Disc no read, unsteady playback, etc.

FE balance value check

DVD: over ±15 %

Mecha Unit replacing

1. IOP checked Method

Select the laser ON/OFF(CD/DVD)mode of the test mode, and check the IOP value of DVD(SACD) laser or CD laser.

1.1 DVD(SACD) laser current check

(1) Press the

(2) Check the current value of IOP (nnnn)

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

or 9 button to display the laser current value, and then select “T24”.

8

- - - T 2 4 - n n n n - -

(- : Off, DVD(SACD) laser, Initial value: Current value: nn.nn [mA])

1.2 CD laser current check

(1) Press the

(2) Check the current value of IOP (nnnn)

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

or 9 button to display the laser current value, and then select “T22”.

8

- - - T 2 2 - n n n n - -

(- : Off, CD laser, Initial value: Current value: nn.nn [mA])

9

Page 10

2. Check the FE balance value

Load the DVD (TDV-520C) in the aging mode, and then select the "T3 Servo" mode of the test mode.

Select the mode and check FE balance value.

2.1 FE balance value(DVD) check

(1) Load the DVD (TDV-520C) in the aging mode, and then select the "T3 Servo" mode of the test mode. And press the

button. The FL display shows "T6D".

8

(2) Check the FE balance value (DVD).

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 6 D ± n n . n - -

(- : Off, FE balance value (DVD): nn.n [%])

3. Note for Handling the Laser Pick-Up

The protection for the damage of laser diode.

If you want to change the optical device unit from any other units, you must keep the following.

(1) It should be done at the desk already took measures the static electricity in care of removing the OPU's (Optical

device unit) connector cable.

(2) Workers should be put on the "Earth Band".

(3) It should be done to add the solder to the short land to prevent the broken Laser diode before removing the 24P FFC

cable.

(4) Don't touch OPU's connector parts carelessly.

4. Replacement of the Laser Pick-up (Mecha Unit)

In the following cases, change the mecha unit (FGDCD1650SES) to a new one.

(1) When the present IOP (current) value exceeds +150% of the initial value.

(2) When the FE balance value exceeds ±15% (DVD).

5. Rewriting the default value of the laser current

5.1 Store the current value of the laser current : DVD(SACD)

(1) Current value “T24” is selected.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 2 4 - n n n n - -

(2) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

button for at least 5 seconds, and "SAVE?" is displayed.

1/3

- - - T 2 4 S A V E ? - -

(3) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

or 9 button to select “T23”.

8

- - - T 2 3 - m m m m - -

(4) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

button and store the current value "T23". After “OK?” is displayed, stored value “T23” is displayed.

1/3

- - - T 2 3 - - O K ! - -

(5) Press the

button to display the current value “T24” without storing the current value “T23”.

2

10

Page 11

5.2 Store the current value of the laser current : CD

(1) Current value “T22” is selected.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T 2 2 - n n n n - -

(2) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

button for at least 5 seconds, and "SAVE?" is displayed.

1/3

- - - T 2 2 S A V E ? - -

(3) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

or 9 button to select “T21”.

8

- - - T 2 1 - m m m m - -

(4) Press the

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

button and store the current value "T21". After “OK?” is displayed, stored value “T21” is displayed.

1/3

- - - T 2 1 - - O K ! - -

(5) Press the

button to display the current value “T22” without storing the current value “T21”.

2

6. Resetting the accumulated laser on time

To clear the accumulated laser on time, press the 1/3 button while the accumulated laser on time is displayed until

" * CLR?" appears at the "nnnnn" position, then press the 8 or 9 button to select TB3. If the 1/3 button is

pressed while TB3 is displayed, the accumulated laser on time of CD and DVD(SACD) is cleared.When “TB1” or “TB2”

is selected with the 8 or 9 button, "nnnnn" is displayed as 0 so you can check.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T B Y n n n n n - -

(- : Off, Y:1: CD, 2: DVD(SACD), nnnnn: Hour [h])

11

Page 12

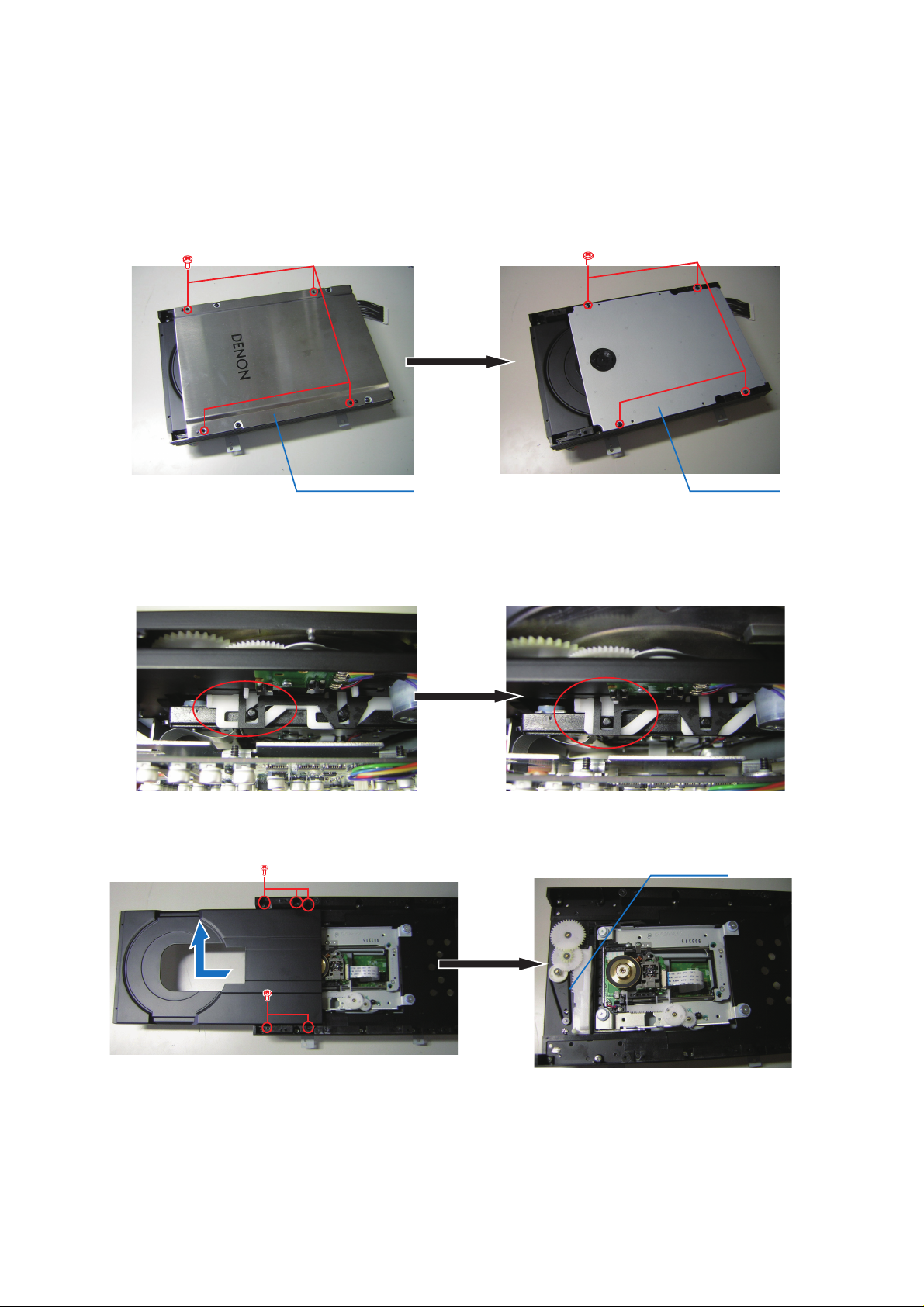

HOW TO REPLACE TRAVERSE UNIT

MECHA TOP PLATE GUIDE-CLAMP

BELT LOAD

Caution: The optical pickup can be damaged easily by static electricity charged on human body. Take necessary

anti-static measures when repairing around the optical pickup.

(Follow the procedure below in reverse order when reassembling.)

• The photograph is DCD-2010AE.

1. MECHA TOP PLATE GUIDE-CLAMP disassembly

(1) Remove 4 screws, then detach MECHA TOP PLATE.

(2) Remove 4 screws, then detach GUIDE-CLAMP.

2. Tray disassembly

(1) Push in the SLIDE CAM side underneath the MECHA front slowly securely. The Tray can now be pulled out.

(2) Pull out the tray, remove 5 screws of the tray rear. Remove the tray to direction of the arrow.

※ Check there is grease on the BELT LOAD. If there is grease on the BELT LOAD, wipe it off with alcohol.

12

Page 13

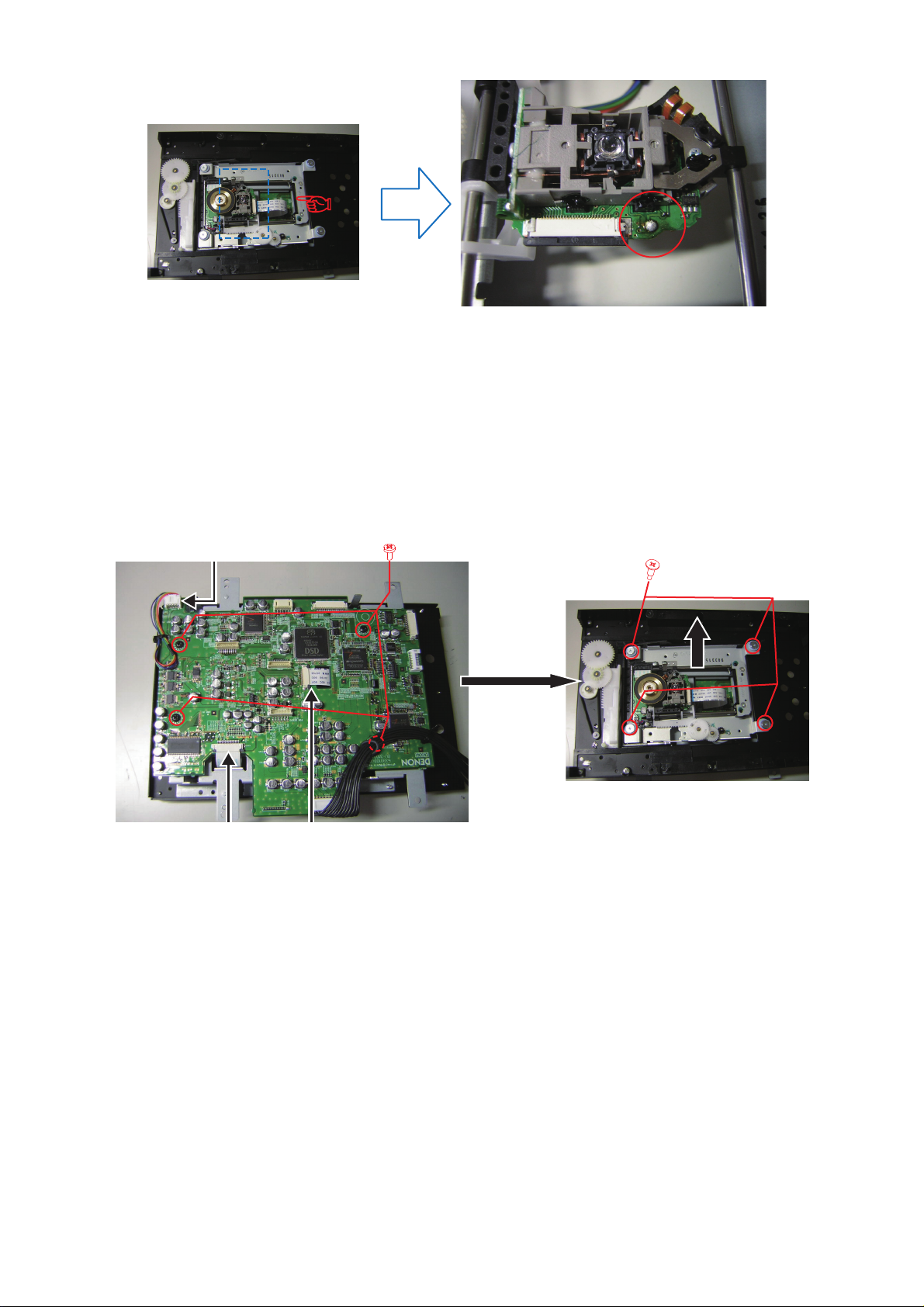

(3) Solder the short-circuit.

5P PH

15P FFC 24P FFC

3. Traverse Unit disassembly

(1) Remove 15P FFC, 24P FFC and 5P PH WIRE connecting with from the MECHA P.W.B. UNIT.

(2) Remove 4 screws then detach MECHA P.W.B. UNIT.

(3) Remove 4 screws fixing DAMPER.

(4) Remove Traverse Unit in the arrow direction.

13

Page 14

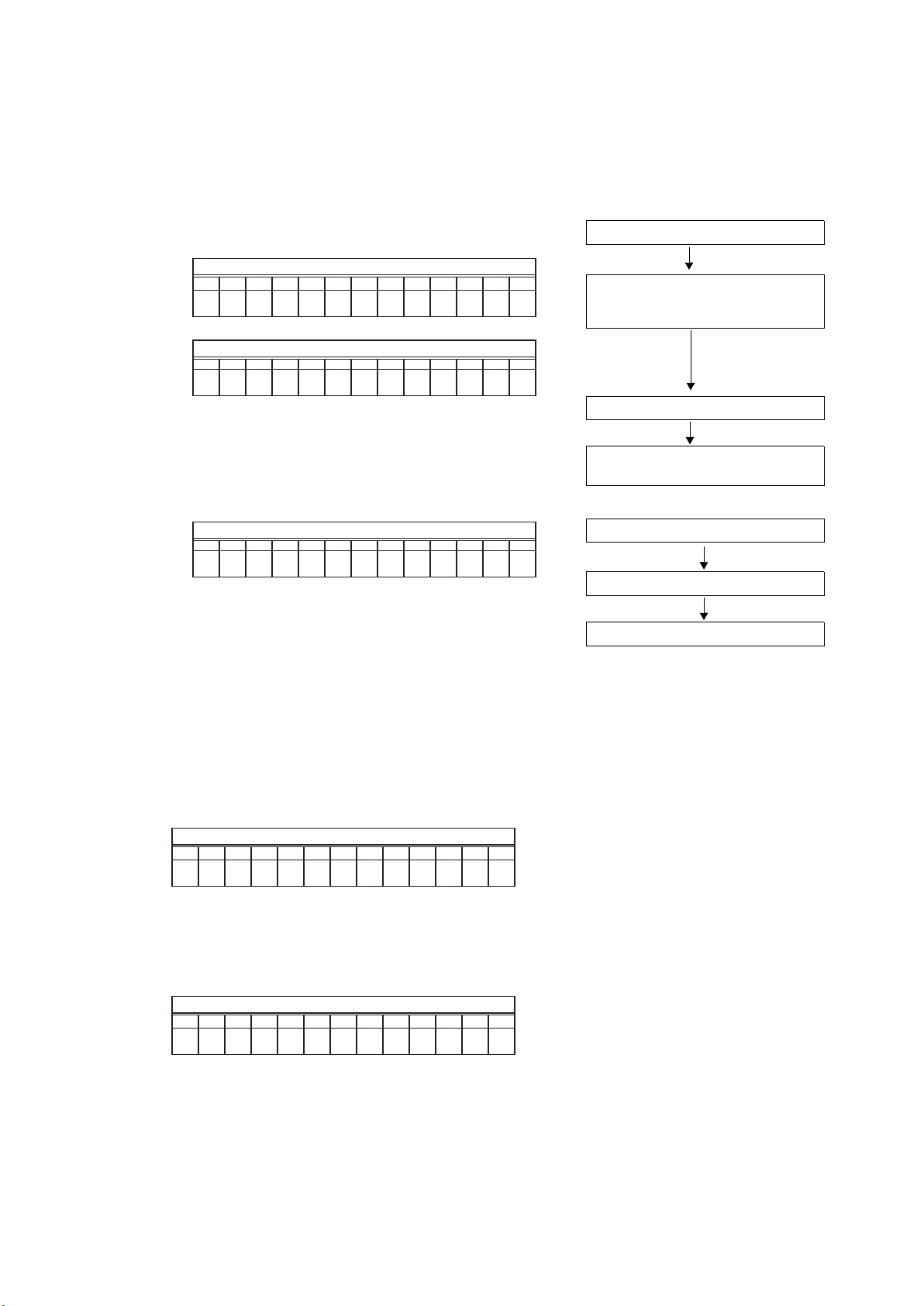

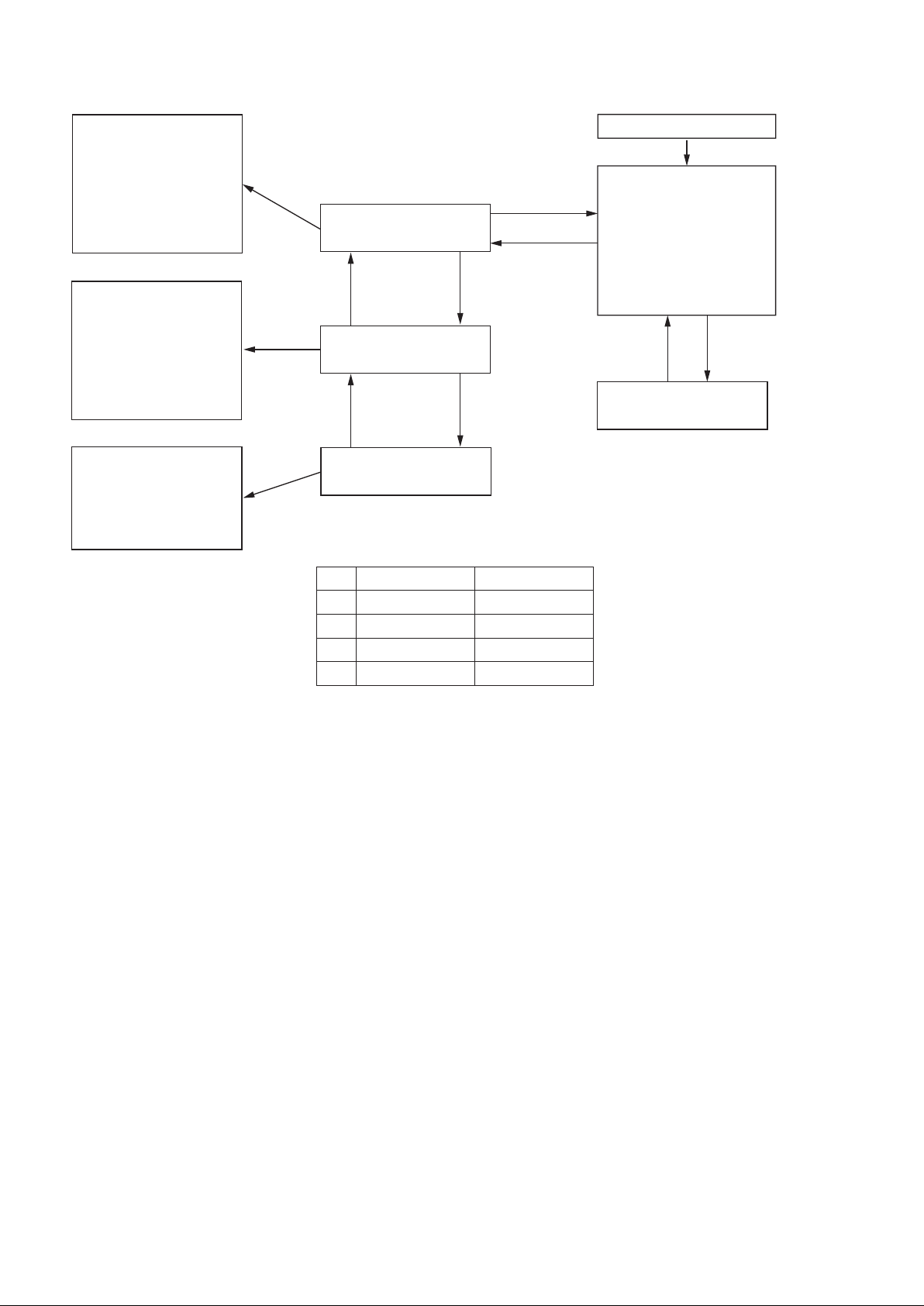

SPECIAL MODE TRANSITION DIAGRAM

H.R.NORMAL operation

TOC read → playback

title-all of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

H.R.SHORT operation

TOC read → playback

title-end of the disc. →

OPEN → CLOSE →

TOC read

It displays repeatedly.

H.R.CHACKING operation

TOC read → OPEN →

CLOSE → TOC read

It displays repeatedly.

1/3

1/3

1/3

H.R.NORMAL MODE

“NORMAL”

89

H.R.SHORT MODE

“SHORT”

89

H.R.CHACKING MODE

“CHACKING”

Heat run Error Code Table

No Error contents FL display

1 Tray Error ERROR 01

2 Bad Disc

3 Search Error

4 Read Error

9

8 or 1/3

ERROR 02

ERROR 03

ERROR 04

2 + 5 + POWER_ON

AGING MODE

“Aging Mode”

※ The tray opens and stops.

If loading an SACD, do not

carry out the next operation

until the title display ends

and “Aging Mode” is

displayed again.

2

TEST MODE

“Test Mode”

9

SERVICE MODE

1. Initial Setting Mode

1.1. procedure

(1)InitializetheCDplayerwhenμcom,peripheralpartsofμcom,orP.W.B.hasbeenreplacedinservicing.

(2)Allusersettingwillbelostanditsfactorysettingwillberestoredwhenthisinitializationismade.Besuretomemorize

yoursettingforrestoringagainaftertheinitialization.

(3)Carryoutthefollowingtorestorefactorysettingmode.

POWERswitchisturnedtoonwhilepressingthe

Display"RESET"ontheFLtube,thenkeeppressingthetwobuttonsuntil"RESET"turnsoff.

and

2

buttonssimultaneouslyonthemainunit.

9

14

Page 15

2. Version display

3. Test mode

3.1. Entering the test mode

To enter the test mode, press the 9 button in the heat run mode.

Basically, the test mode should be set in the stop mode after the disc is loaded in the heat run mode.

(The heat run mode is entered by pressing the 2 and 5 buttons simultaneously to turn on the POWER switch.

When the heat run mode is set, the “PLAY” and “PAUSE” indicators light.)

2.1. procedure

(1)POWERswitchisturnedtoonwhilepressingthe

1/3

and

theFLtube.Next,theversionofthesystemμcomisdisplayedonFLtube.

(2)Now,pressthe9button,followinginformationisdisplayedontheFLtube.

Display Order

<

>

VersionofBootLoader→VersionofB/E→MakedayofB/E→VersionofFPGA→VersionofUSBμ-com→

ChecksumcheckresultofEEPROM(Referetob1)→CommunicationresultwithB/E(Referetob2)→Theentire

FLtubeisashingwithanintervalofabout1second.

1ChecksumcheckresultofEEPROM

b

"EEPOK"

normal

:

"EEPErr1":Tuner/Timer-relatedchecksumerror

"EEPErr2":Amp-relatedchecksumerror

"EEPErr3":LastLine1,2selectchecksumerror

2CommunicationresultwithB/E

b

"BEOK"

normal

:

"BEErr":Communicationerror

buttonssimultaneously."Ver.Disp"isdisplayedon

8

3. Test mode

3.1. Entering the test mode

Toenterthetestmode,pressthe

Basically,thetestmodeshouldbesetinthestopmodeafterthediscisloadedintheheatrunmode.

(Theheatrunmodeisenteredbypressthe2and

Whentheheatrunmodeisset,the"1"and"3"indicatorslight.

buttonintheheatrunmode.

9

buttonssimultaneouslytoturnonthePOWERswitch.

5

Press 2 and 5 buttons simultaneously

POWER SW(h)

9 button

Test mode

8 or /1 3 button

Heat run mode

/

1 3 button

Excuting Heatrun

FLtubedisplaywhentestmodeentered

FLDisplay(Thedisplaypartof13digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

- - - T e s t M o d e - -

ThediscsplayableintheHeartRunModearethediscsshownonthetable.

Playable

discs

DVD-Audio DVD-Video Video CD CD CD-R CD-RW

DVD-R

DVD+R

DVD-RW

DVD+RW

SUPER

AUDIO CD

Mark

(logo)

15

Recordable

Page 16

3.2. Selecting the mode

Thefollowingmodesareavailable.

・

Pressthe8or9buttontoselecteachmodeandpressthe

Pressthe2buttontoreturntothemodeoriginallysetwhenthetestmodewasentered.

(1)FLtubelightingmode : T0

(2)Trayopen/closemode : T1

(3)Laseron/off(CD/DVD)mode : T2

(4)Servoadjustmentvaluedisplaymode : T3

(5)Tracemode(errorratedisplay) : T7

(6)Servopropertiesmeasurementmode : TA

(7)Accumulatedlaserontimedisplaymode : TB

(8)Monitorterminalsettingmode : TD

(9)SACDwatermarksignalqualitycheckingmode: TE

(10)Selftestmode : TF

buttontosetthatmode.

1/3

16

Page 17

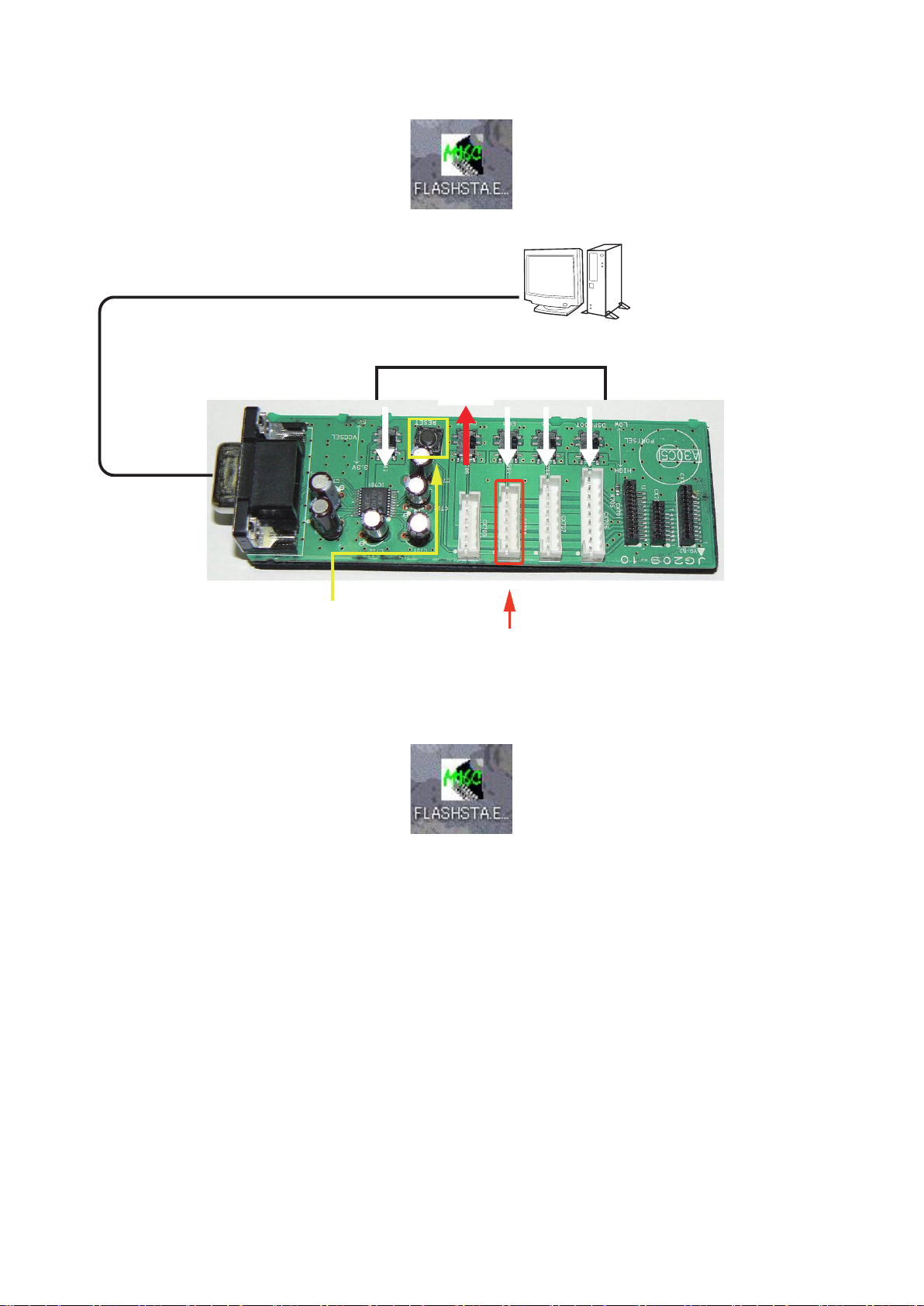

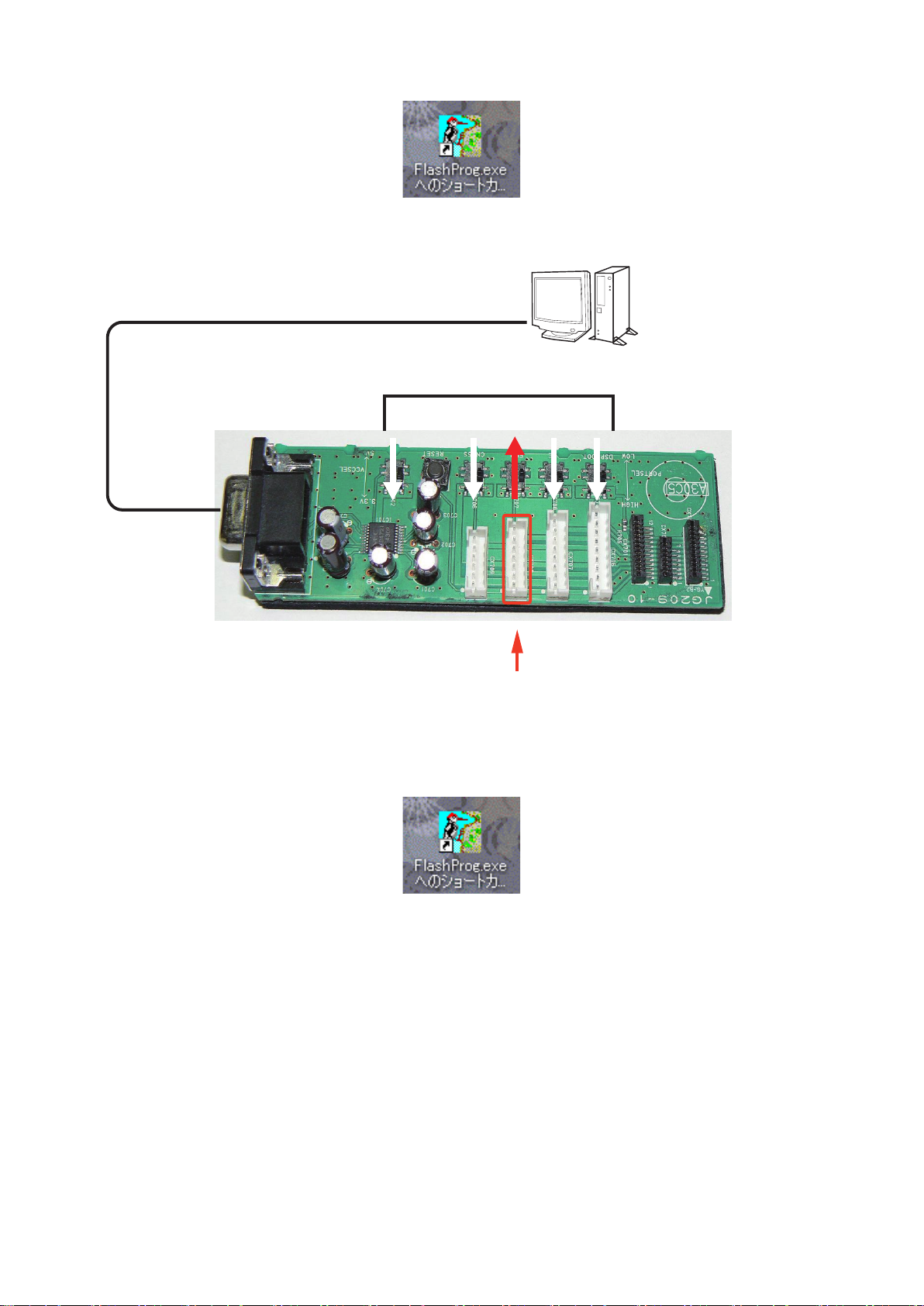

4.VERSION UPGRADE PROCEDURE OF FIRMWARE

PC

①Connect windows PC with RS-232C cable.

②Switch to the direction of the arrow.

③Connect CX072 on the 8U-310040 board

with 7P PH-PH CONN.CORD(00D2042971069)

④Turn on DCD-2010AE.

(Check connection CY141 on 8U-310040.)

⑤Press the RESET button.

CX708

S706

(CNVSS)

4.1. Update for IC502(M3062LFGPGP)

(1) PreparethewindowsPCthatinstalledtheFLASHSTA.EXE.

(2) ConnectSPK-581asfollows.

(3) DoubleclicktheFLASHSTA.EXE.AndlaunchtheM16FlashStart.

17

Page 18

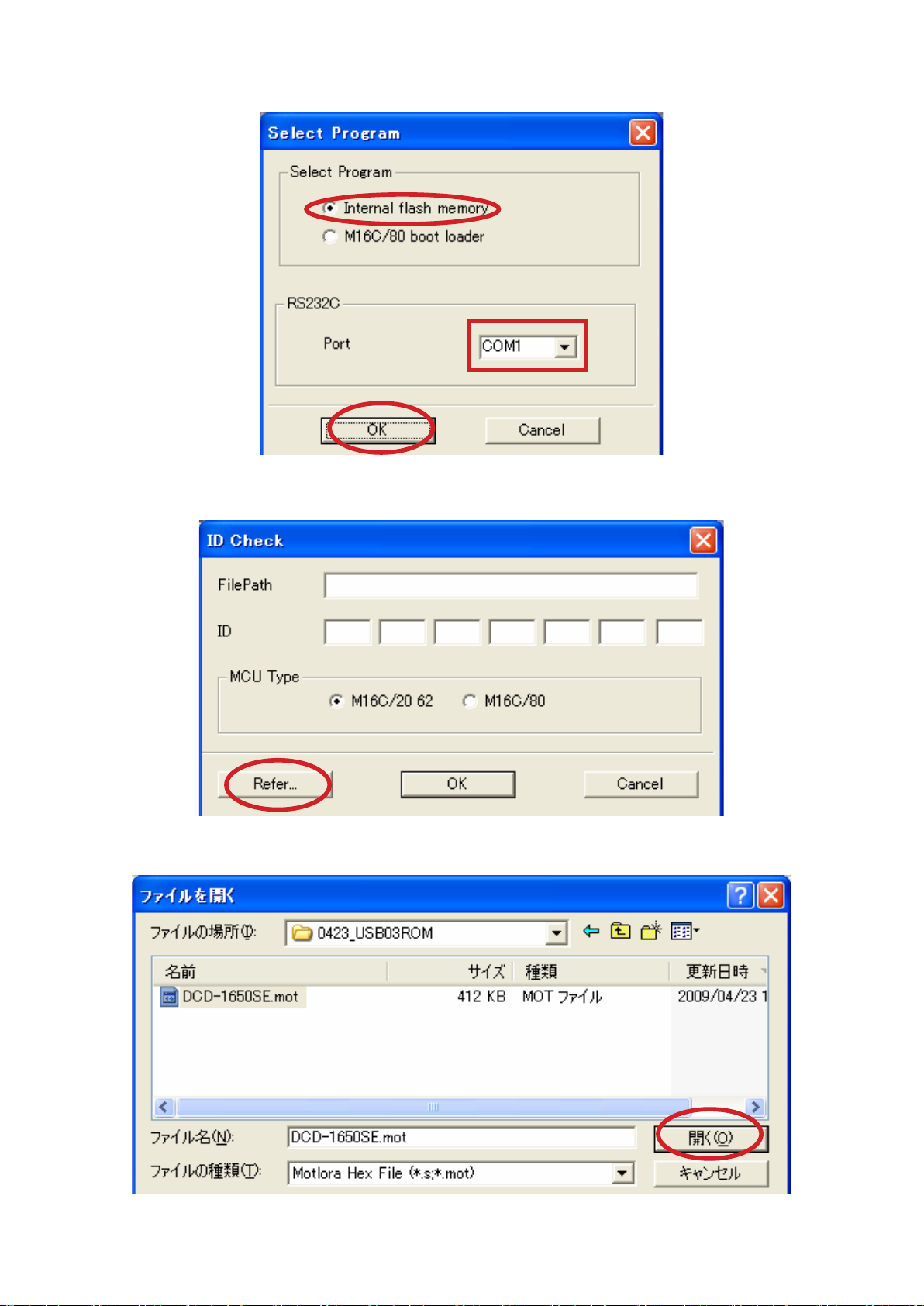

(4) ChecktheInternalashmemoryintheSelectProgram.

ChoosetheCOMPortnumber.

AndclicktheOK.

(5) ClicktheRefer....

(6) ChoosetheDCD-1650SE.mot.AndclicktheOpen.

18

Page 19

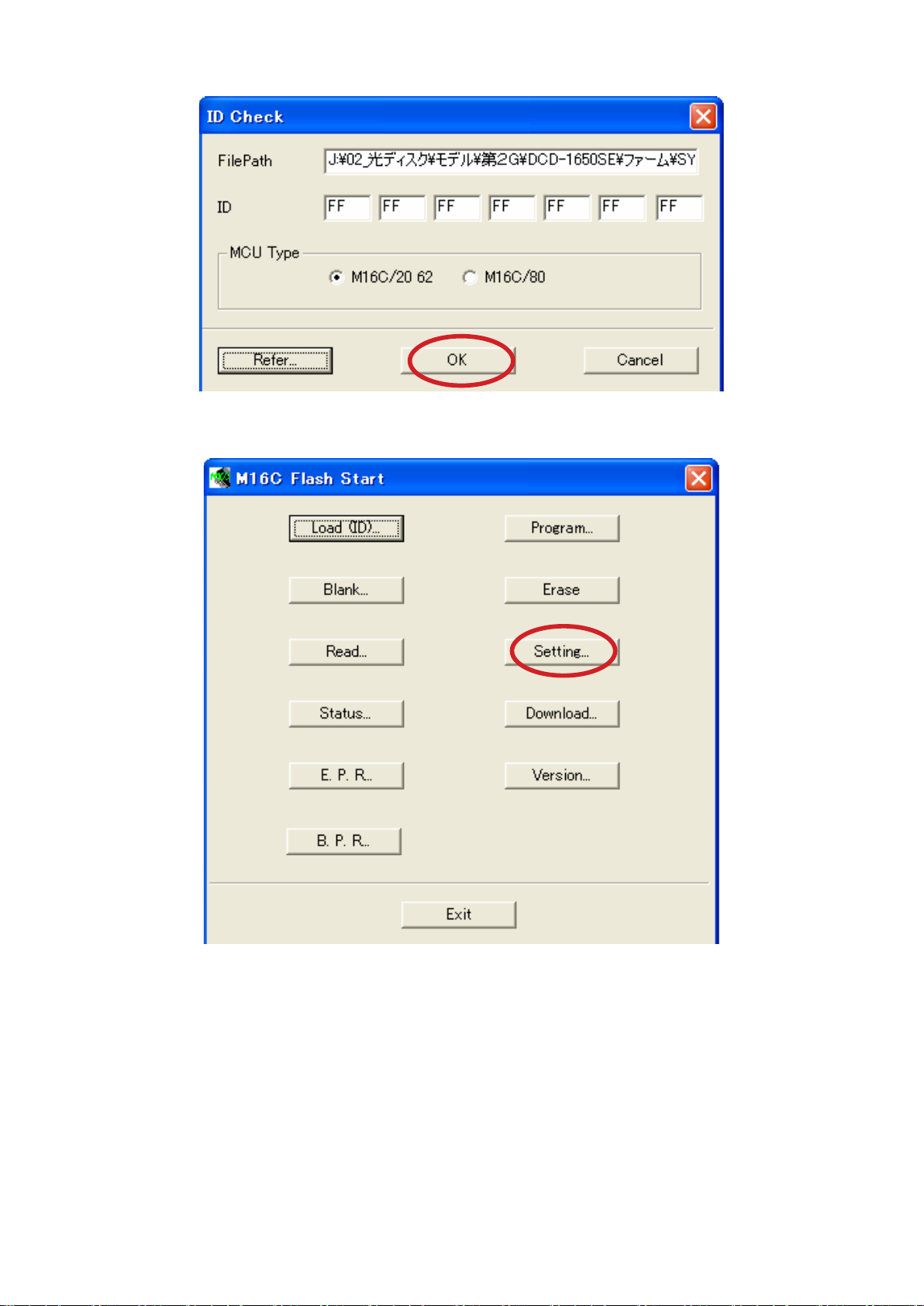

(7) TheFilePathandIDareinputtedautomatically,andtheMCUTypeisselectedtoM16C/2062automatically.

ClicktheOK.

(8) ClicktheSetting....

19

Page 20

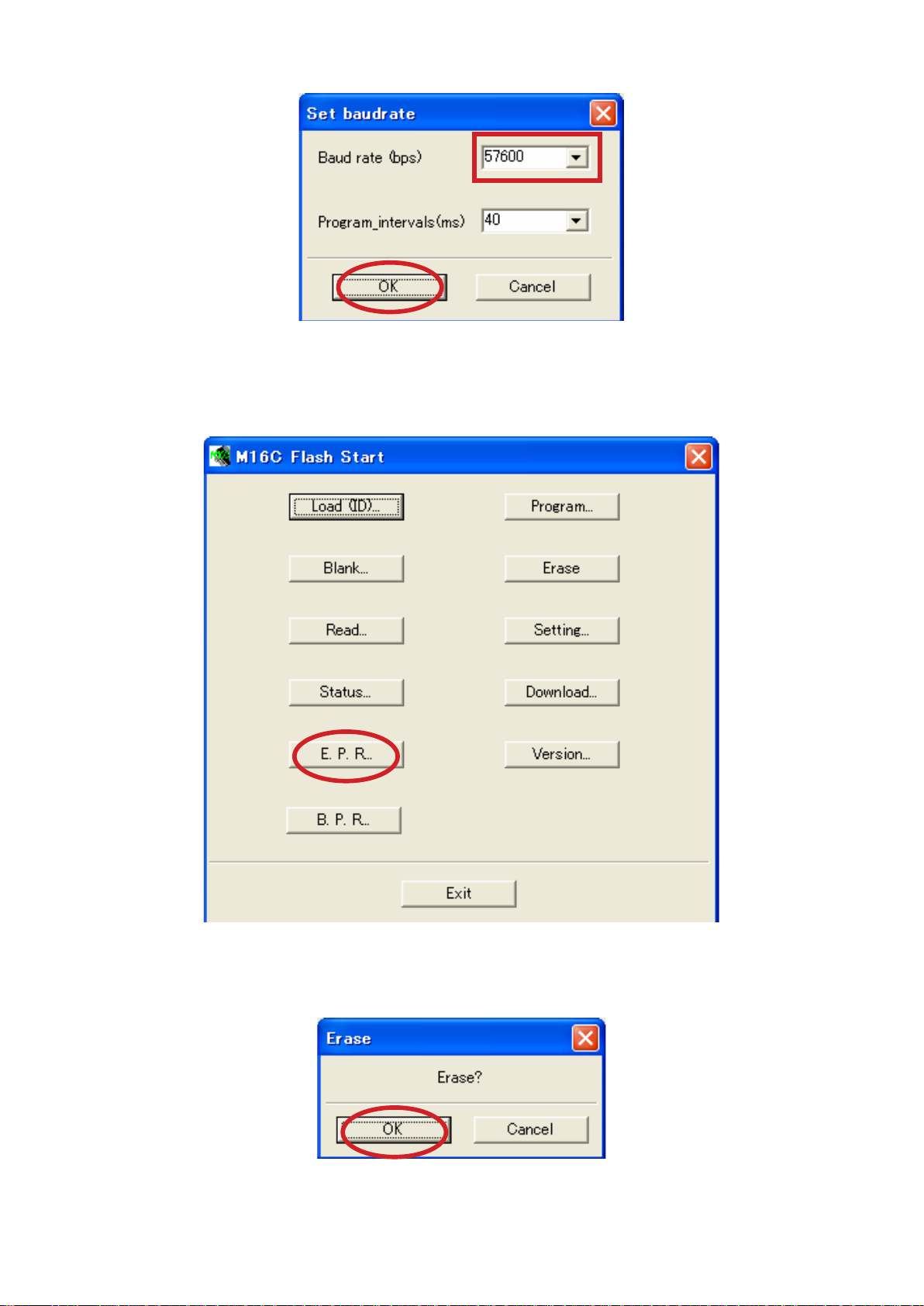

(9) Choosethe57600intheBaudrate.(DONOTchoosetheotherone!!)

ClicktheOK.

Thesettingismemorizedifitdoesonce.

※

Itisnecessarytosetittoconnectedfailureagainwhendoing.

(10)ClicktheE.P.R....

(11)ClicktheOK.

20

Page 21

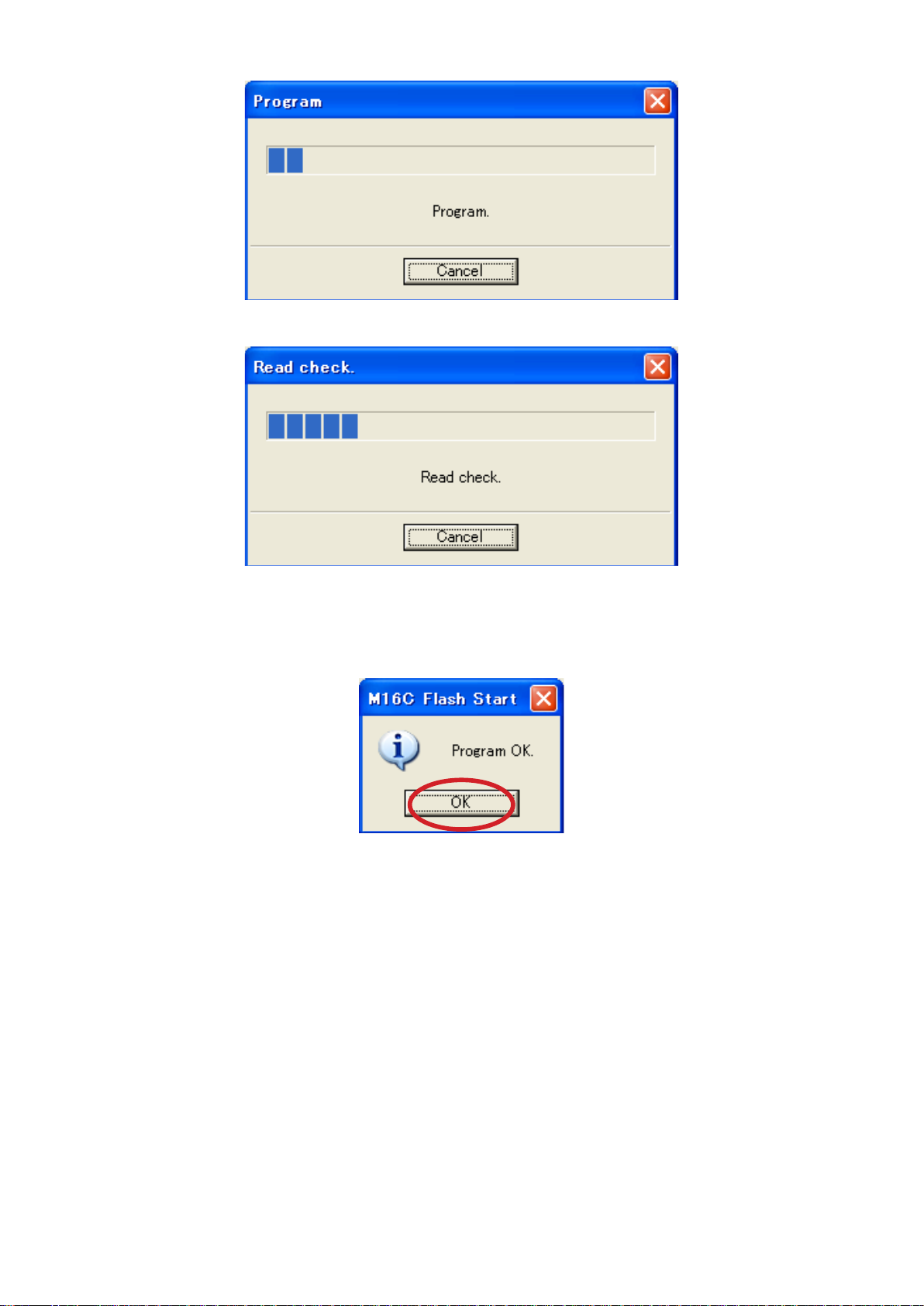

(12)SoftwareiswrittenintotheI-nternalFlash-ROM.

Thewritingofsoftwaretakesabout1minute30seconds.

Thecheckingofsoftwaretakesabout50seconds.

(13)ClicktheOK.

Pleaseretryitfrom(8)whenfailing.

21

Page 22

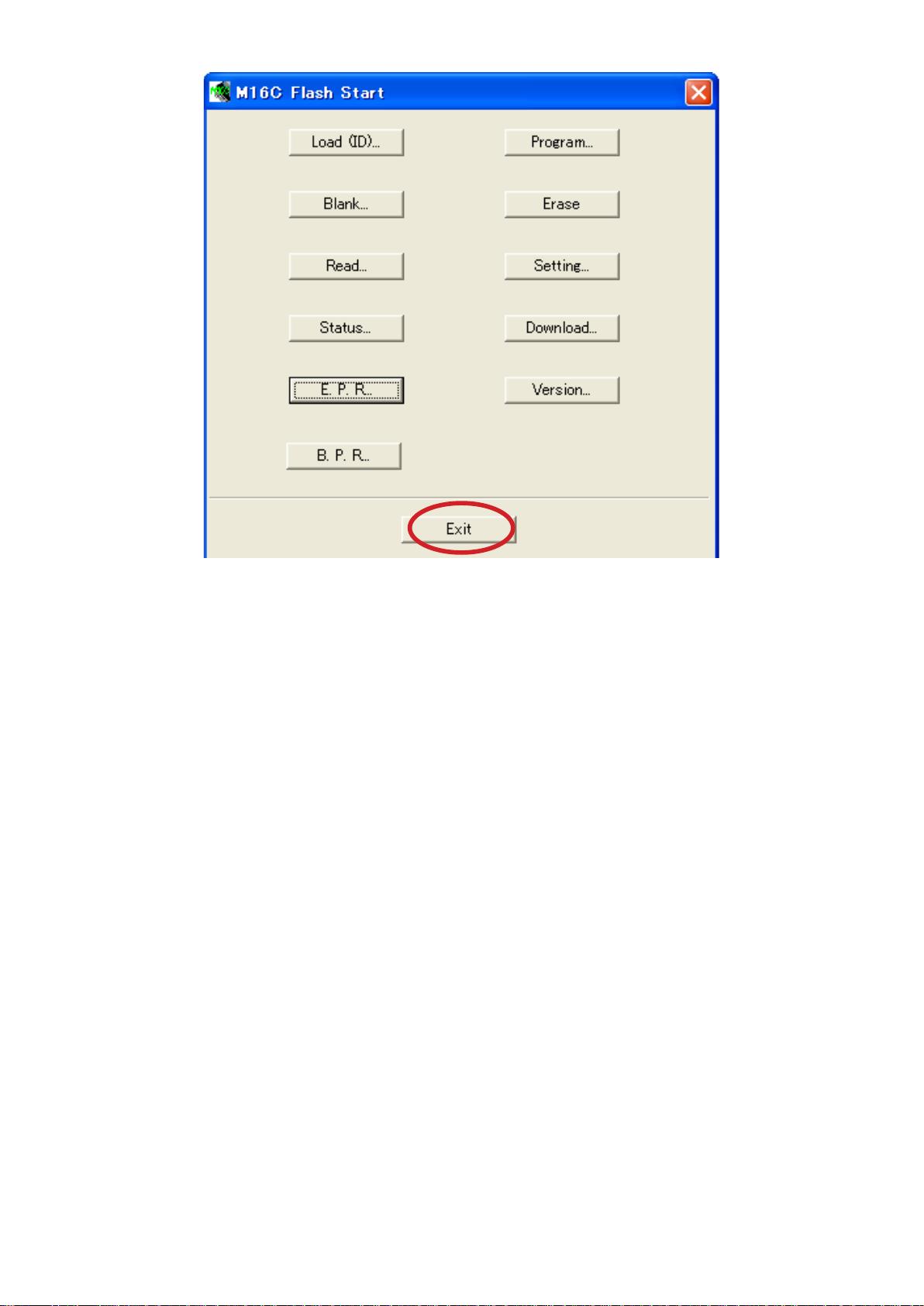

(14)ClicktheExit.

(15)TurnoffDCD-A100.

(16)RemovetheSPK-581formDCD-A100.

22

Page 23

4.2.UpdateforIC803(TMP92FD28AFG)

PC

①Connect windows PC with RS-232C cable.

②Switch to the direction of the arrow.

③Connect CX072 on the 8U-310040 board

with 7P PH-PH CONN.CORD(00D2042971069).

CX708

(1) PreparethewindowsPCthatinstalledtheFlashProg.EXE.

(2) ConnectSPK-581asforrows.

(3) DoubleclickFlashProg.exe,andlaunchtheFlashProgrammer.

23

Page 24

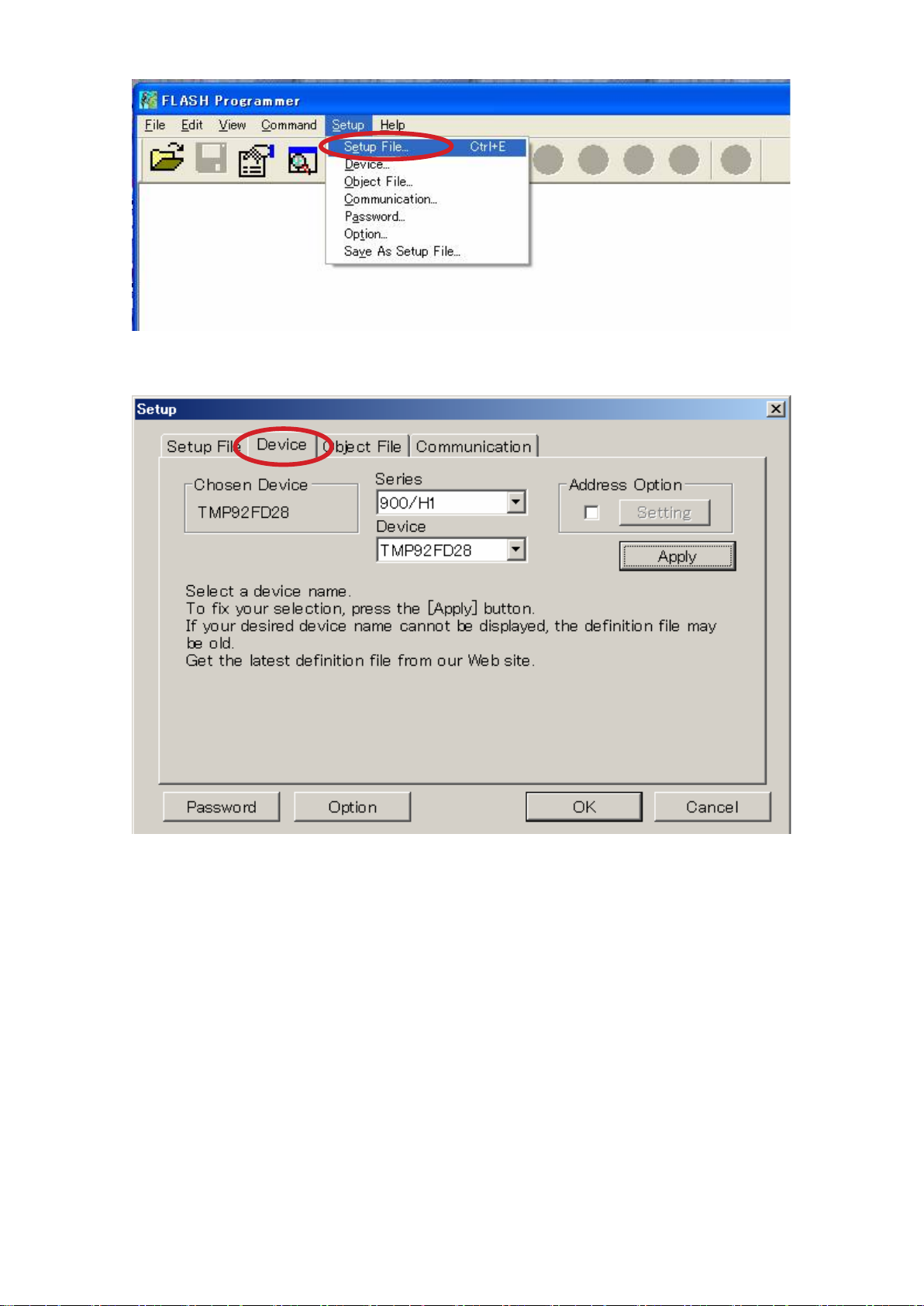

(4) ClicktheSetupinthemenubarandselecttheSetupFile.

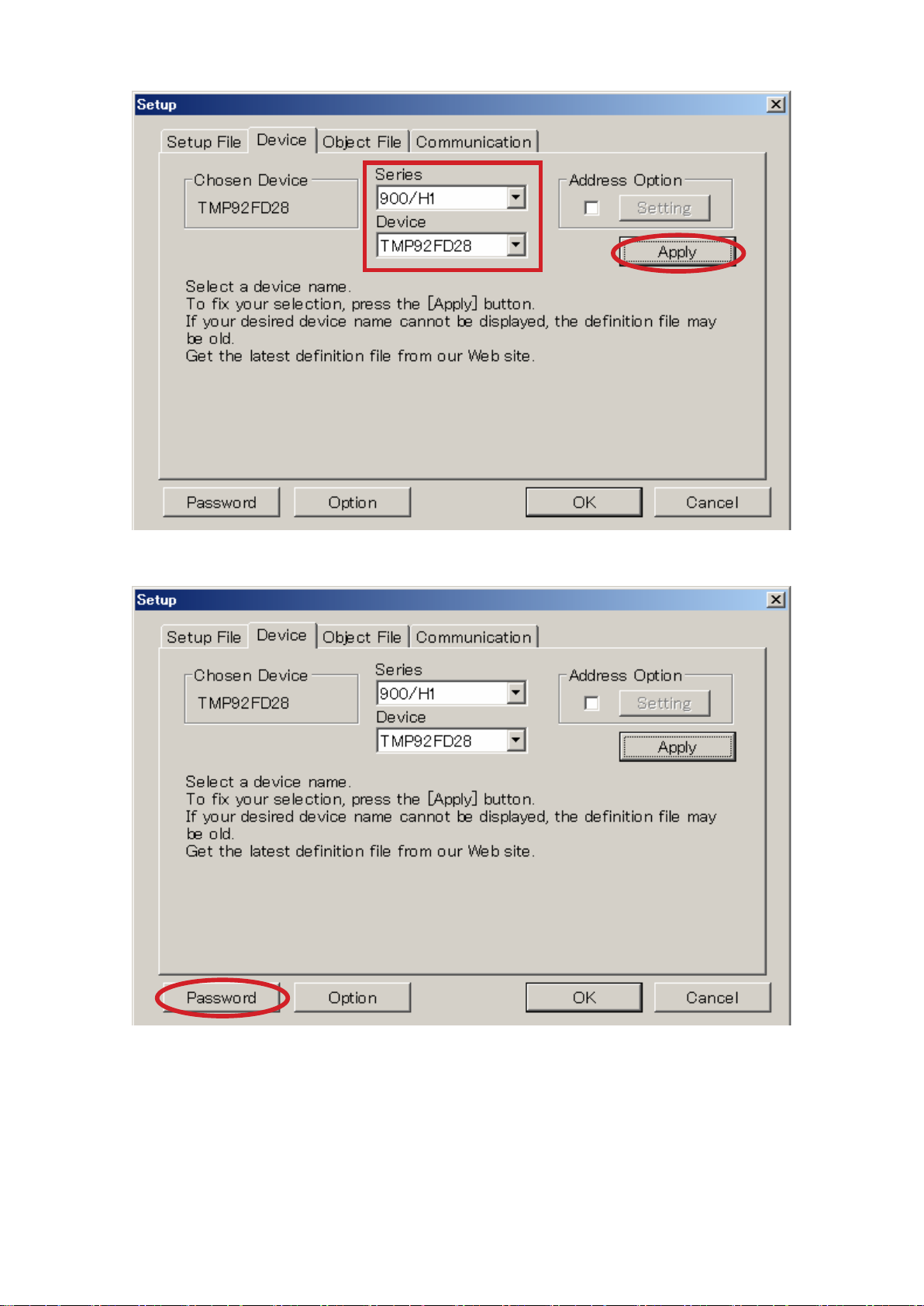

(5) ClickDevicetab.

24

Page 25

(6) ChoosetheTMP91FD28intheDevice,andchoosethe900/H1intheSeries.

ClickApply,anddisplaythechosenDvice.

(7) ClickPassword.

25

Page 26

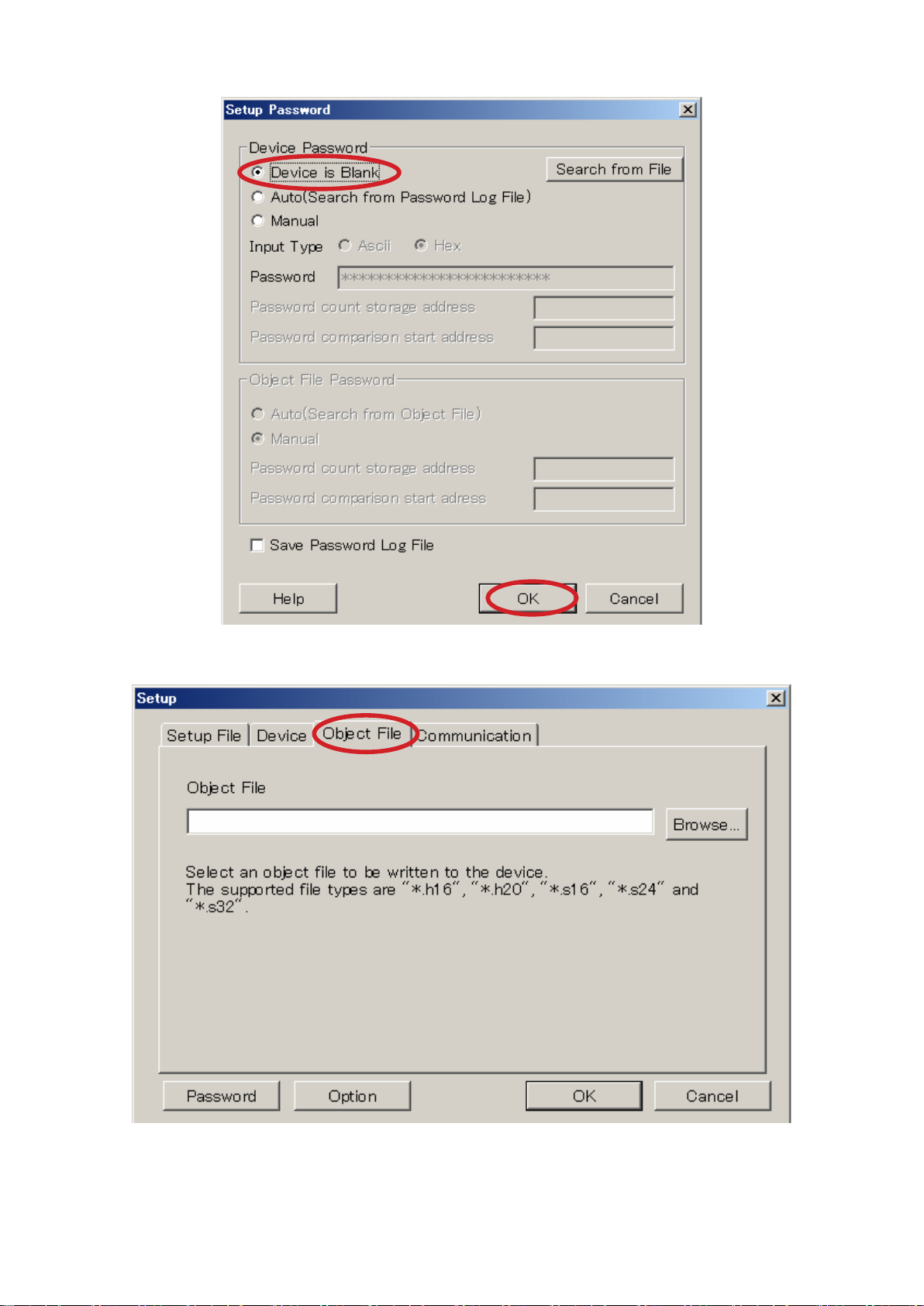

(8) ChoosetheDeviceisBlank.

AndClickOK.

(9) ClickObjectFiletab.

26

Page 27

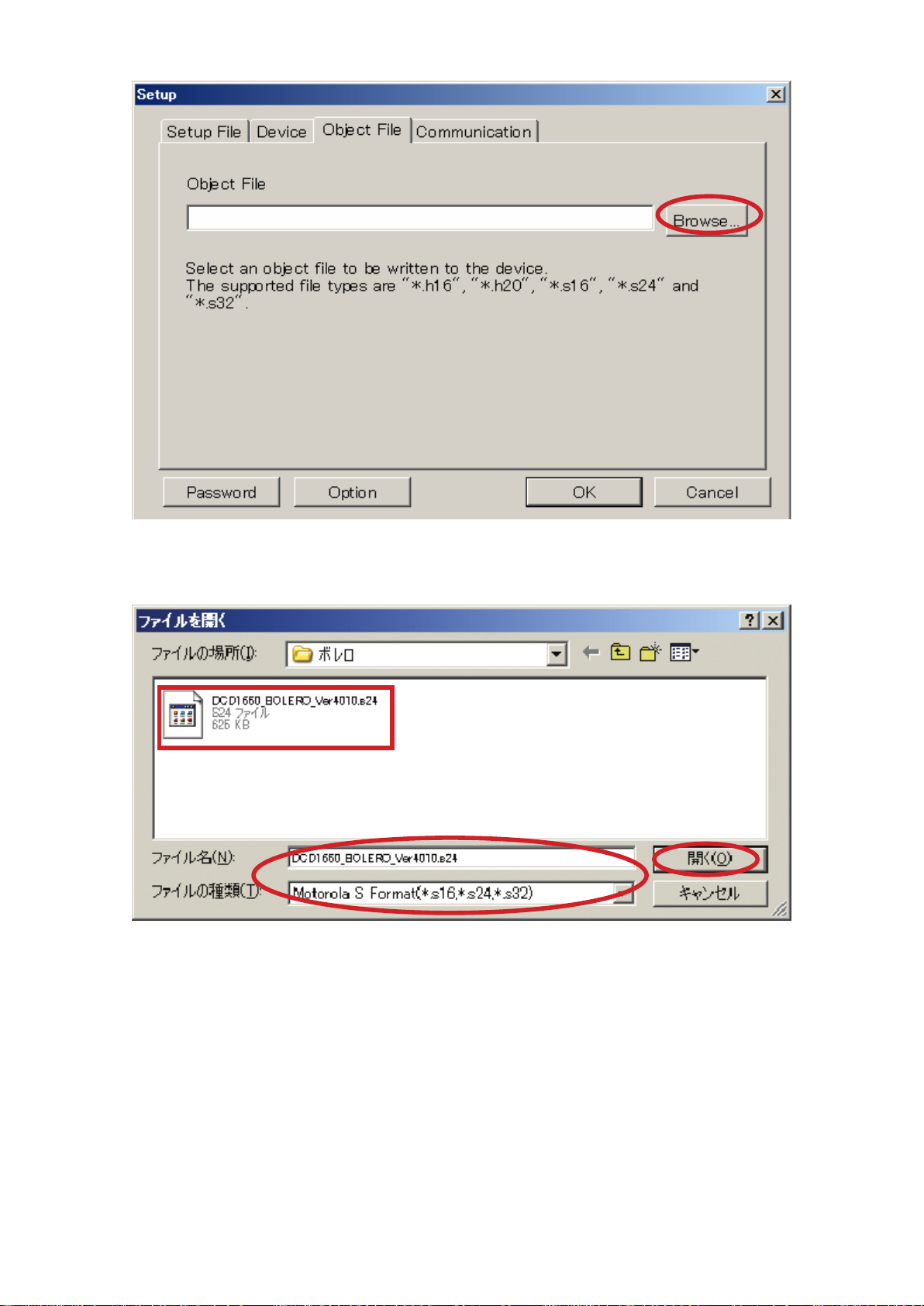

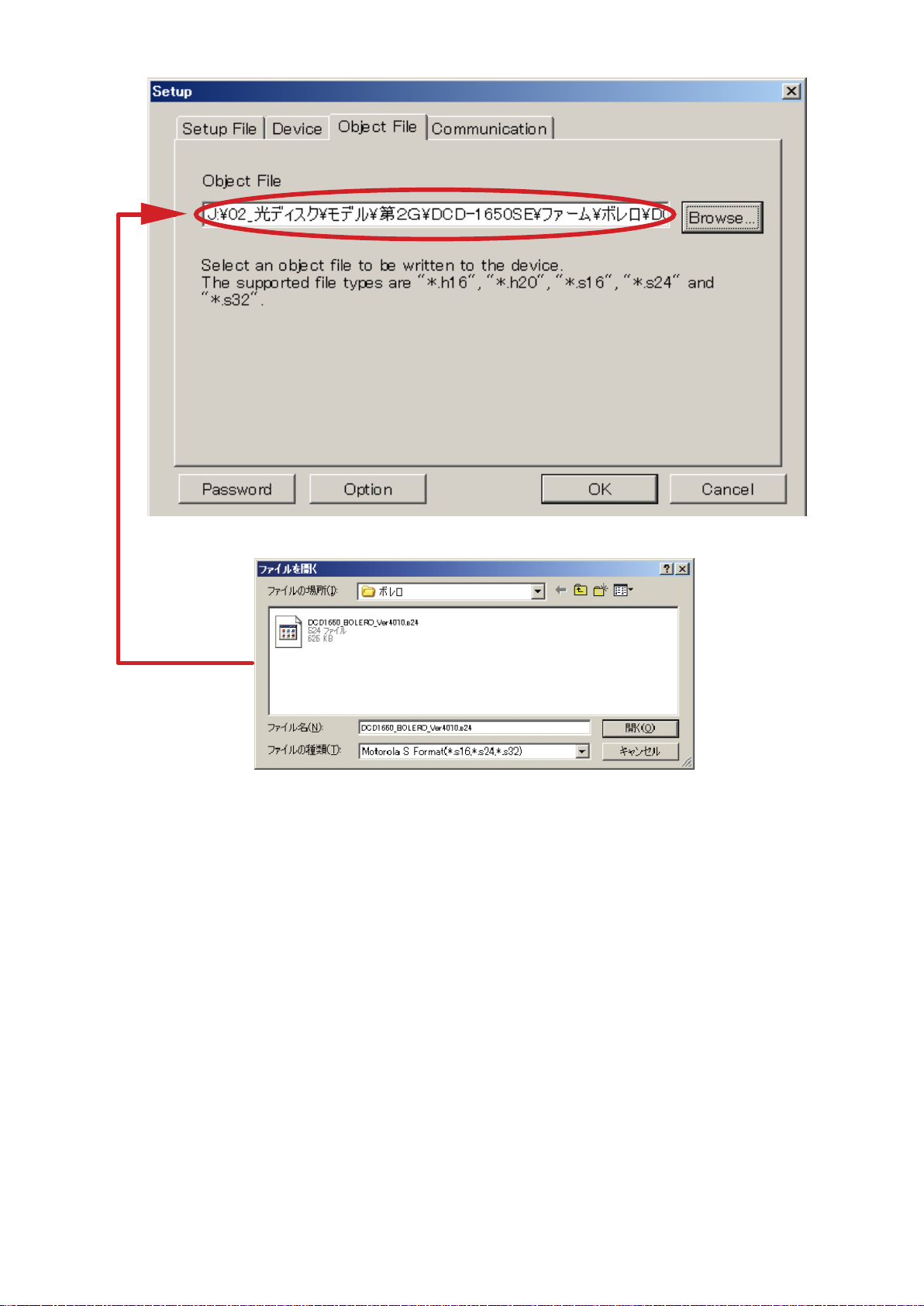

(10)ClickBrowse.

(11)ChoosetheMotorolaSFormat(*.s16,*.s24,*.s32)inFilesoftype.

ChoosetheDCD1650_BOLERO_Ver0_4010.s24,andclickOpen.

27

Page 28

(12)Theplaceoftheleisdisplayed.

28

Page 29

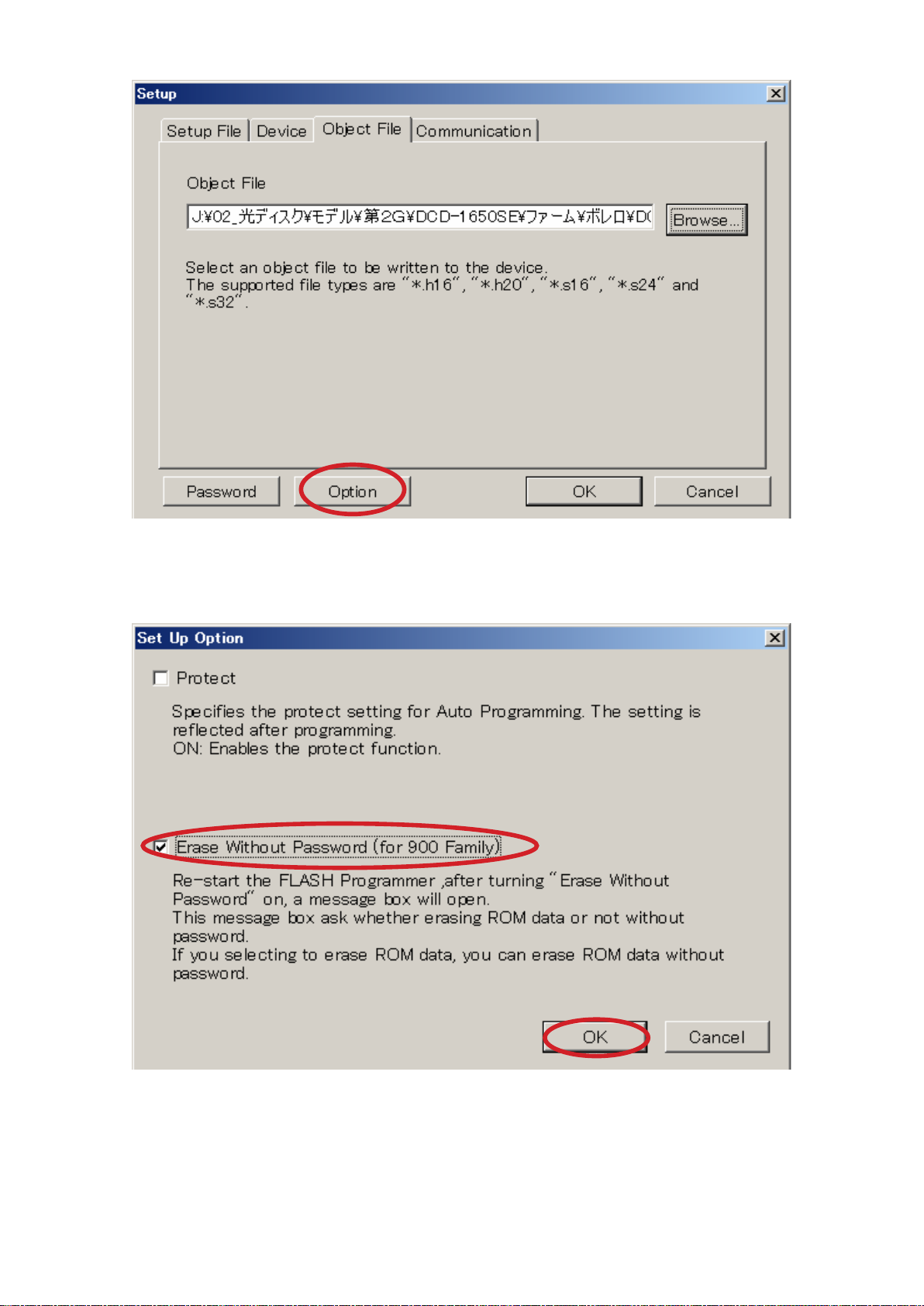

(13)ClickOption.

(14)ChooseEraseWithoutPassword(for900Family).

AndClickOK.

29

Page 30

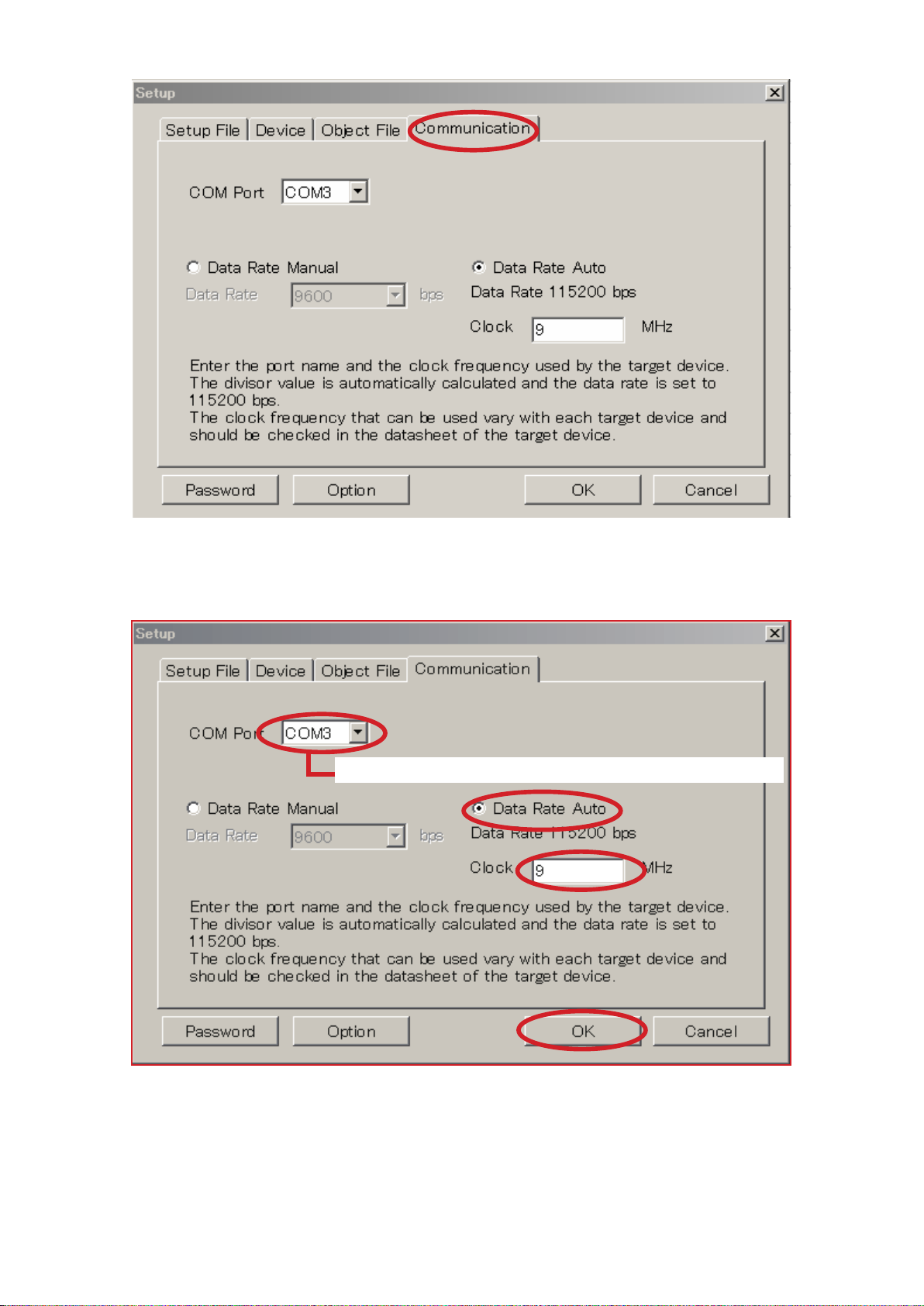

(15)ClickCommunicationtab.

(16)ChoosetheSerialportnumberintheCOMPort.ChecktheDataRateManual,andinput9intheClock.

AndClickOK.

Choose the Serial port that connect with 232C cable.

Thesettingiscompleted.

30

Page 31

(17)TurnonDCD-A100,andpresstheRESETbutton.

PC

①Turn on DCD-2010AE.

(Check connection CY141 on 8U-310040.)

②Press the RESET button.

CX708

(18)IftheconnectionwiththeFlashProgrammerissuccessfullymade,adialogueboxsaying"EraseAlldatainthis

devise?(Y/N)"appearsautomatically.Iftheconnectionfails,errormessagewillappear.(Ex.:E000)

ClickYes.

(19)ClickA(AutoPrograming)tostartwriting.

(20)TurnoffDCD-A100.

(21)RemovetheSPK-581formDCD-A100.

31

Page 32

TROUBLE SHOOTING

8U-210083-1(DIGITAL POWER UNIT)

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㪺㫆㫄㫇㫆㫅㪼㫅㫋㩷

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪪㪫㪘㪥㪛㪙㪰㩷㪫㪩㪘㪥㪪㪃㪛㪏㪈㪊㪃㪛㪏㪈㪋㪃㪛㪏㪈㪎㪃㪛㪏㪈㪏

䇭䊶㪠㪚㪏㪇㪊㪃㪚㪯㪇㪊㪈㪃㪚㪯㪇㪊㪋

䇭䊶㪚㪰㪇㪊㪋㪃㪪㪏㪇㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪛㪏㪉㪇㪃㪛㪏㪉㪈㪃㪫㪩㪏㪇㪉㪃㪫㪩㪏㪇㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪋㪈

䇭䊶㪚㪰㪈㪋㪈㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪠㪚㪌㪇㪉㪃㪠㪚㪌㪇㪊㪃㪯㪌㪇㪈㪃㪠㪚㪌㪇㪍㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪛㪠㪞㪠㪫㪘㪣㩷㪫㪩㪘㪥㪪

䇭䊶㪚㪯㪇㪊㪊㪃㪚㪯㪇㪏㪈㪃㪫㪩㪏㪇㪌㪃㪩㪏㪊㪏㪃㪩㪣㪐㪇㪈

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㪼㪺㫆㫅㪻㪸㫉㫐㩷㫉㪼㪺㫋㫀㪽㫀㪺㪸㫋㫀㫆㫅㩷㪺㫀㫉㪺㫌㫀㫋㩷㪸㫅㪻㩷㫋㪿㪼㩷㫊㫆㫃㪻㪼㫉

㫆㪽㩷㫋㪿㪼㩷㫉㪼㪾㫌㫃㪸㫋㫆㫉㪅

䇭䊶㪛㪏㪉㪌㪃㪛㪏㪊㪇㪃㪛㪏㪊㪈

䇭䊶㪠㪚㪏㪇㪈㪃㪏㪇㪉㪃㪠㪚㪏㪇㪌㪃㪠㪚㪏㪇㪍㪃㪠㪚㪏㪇㪎

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪋㪈

䇭䊶㪚㪰㪈㪋㪈㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪠㪚㪏㪇㪌㪃㪛㪏㪇㪊㪃㪣㪏㪇㪌

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪋㪈

䇭䊶㪚㪰㪈㪋㪈㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪠㪚㪏㪇㪎㪃㪛㪏㪇㪌㪃㪣㪏㪇㪍

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪋㪈

䇭䊶㪚㪰㪈㪋㪈㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪠㪚㪏㪇㪍㪃㪛㪏㪇㪋㪃㪣㪏㪇㪋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪋㪈

䇭䊶㪚㪰㪈㪋㪈㩷㪑㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪠㪚㪏㪇㪈㪃㪠㪚㪏㪇㪉㪃㪠㪚㪏㪇㪏

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪇㪎㪈

䇭䊶㪚㪰㪇㪎㪈㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪉

䇭䊶㪫㪩㪏㪇㪈㪃㪱㪛㪏㪇㪉㪃㪱㪛㪏㪇㪊㪃㪠㪚㪏㪇㪋

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪈

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪈㪈㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪥㪪㪮㩷㪑㩷㪊㪅㪊㪭

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪉

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪈㪉㪀㫇㫀㫅㩷㩷㩷㩷㩷㪧㪅㪛㪦㪮㪥㩷㪑㩷㪊㪅㪊㪭

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪊

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪈㪊㪀㫇㫀㫅㩷㩷㩷㩷㩷㪧㪶㪚㪦㪥㪫㩷㪑㩷㪊㪅㪊㪭

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪋

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪇㪏㪈㩷㩿㪊㪀㫇㫀㫅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪌

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪝㪬㪪㪜䇭㩿㪝㪏㪇㪈䇮㪝㪏㪇㪉㪃㪝㪏㪇㪊㪀㩷㩷㩷㩷㩷㪚㪿㪼㪺㫂㩷㪝㪬㪪㪜㩷㪚㫆㫅㪻㫀㫋㫀㫆㫅㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪍

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪈㪇㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪛㪌

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪎

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪍㪀㩿㪎㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪛㪈

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪏

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪈㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪌㪭㪶㪬㪪㪙

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪐

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪈㪋㪈㩷㩿㪉㪀㩿㪊㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪌㪭㪶㪤㪈㩷㩷㪑㩷㪌㪭

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪂㪈㪉㪭㪶㪤㪈㪑㩷㪈㪉㪭

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪈㪇

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈㩿㪛㪠㪞㪠㪫㪘㪣㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪇㪎㪈㩷㩿㪌㪀㩿㪍㪀㩿㪎㪀㫇㫀㫅㩷㩷㩷㩷㩷㩷㩷㪄㪊㪉㪭㪃㪝㪂㪃㪝㪄

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩿㪧㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㪽㫆㫉㩷㪝㪣㩷㪛㫀㫊㫇㫃㪸㫐㪀

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪜㪥㪛

㪦㪅㪢㪅

32

Page 33

8U-310040(SACD MODULE UNIT-FE/BE BLOCK)

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪝㪜㪆㪙㪜㩷㪺㫆㫄㫇㫆㫅㪼㫅㫋

㪈㪅㪈㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪈㪅㪉㪛㫆㪼㫊㩷㫅㫆㫋㩷㪩㪼㪸㪻㩷㪛㫀㫊㪺

䇭㩿㪈㪀㪛㫀㫊㪺㩷㪻㫆㪼㫊㩷㫅㫆㫋㩷㪩㫆㫋㪸㫋㪼㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪈

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪰㪈㪋㪈㩷㩿㪊㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪌㪭㪶㪛㪈㩷㪑㩷㪌㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈

䇭䊶㪠㪚㪏㪇㪈㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪉

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪰㪈㪋㪈㩷㩿㪍㪀㩿㪎㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪊㪅㪊䌖㪶㪛㪈㩷㪑㩷㪊㪅㪊㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈

䇭䊶㪠㪚㪏㪇㪎㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪊

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪠㪚㪌㪇㪈㩷㩷㩷㩷㩷㩷㪂㪉㪅㪌㪶㪛㪈㪆㪶㪘㪈㩷㪑㩷㪉㪅㪌㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈㪃㪠㪚㪌㪇㪈

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪜㫄㫀㫊㫊㫀㫆㫅㩷㫆㪽㩷㪧㫀㪺㫂㪄㫌㫇㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪜㫄㫀㫊㫊㫀㫆㫅㩷㫆㪽㩷㪧㪅㪬㪅㩷㫃㪸㫊㪼㫉㩷㪦㪅㪢㪅㪖

䇭䊶㪫㪿㪼㩷㫋㪼㫊㫋㩷㫄㫆㪻㪼㩷㩹㪫㪉㩹㩷㫀㫊㩷㪼㫏㪼㪺㫌㫋㪼㪻㪅

㩷㩷䇭㪣㪸㫊㪼㫉㩷㪺㫌㫉㫉㪼㫅㫋㩷㪦㪅㪢㪅㪖

㩿㪈㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫃㪸㫊㪼㫉㩷㫊㫆㫃㪻㪼㫉㩷㫊㪿㫆㫉㫋㩷㫃㪸㫅㪻㩷㫆㪽㩷㪧㪅㪬㩷㪸㫅㪻

㩷㩷㩷㩷㩷㩷㪏㪬㪄㪊㪈㪇㪇㪋㪇㪅

㩿㪉㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪫㪩㪈㪇㪈㪴

㩷㩷㩷㩷㩷㩷㩷㪸㫅㪻㩷㪲㪫㪩㪈㪇㪌㪴㪅

㩿㪊㪀䇭㪚㪿㪼㪺㫂㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪅䊶䊶䊶㪧㪅㪬㪅㪄㪚㪯㪉㪋㪈

㩿㪋㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㪲㪠㪚㪈㪇㪈㪴㩷㪸㫅㪻㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㩷㩷㩷㩷㩷㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪠㪚㪈㪇㪈㪴

㩿㪌㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㪲㪠㪚㪈㪇㪎㪴㩷㪸㫅㪻㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㩷㩷㩷㩷㩷㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪠㪚㪈㪇㪎㪴

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫇㫀㫅㪻㫃㪼㩷㪻㫉㫀㫍㪼㩷㫊㫀㪾㫅㪸㫃㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪲㪪㪧㪠㪥㪛㪣㪜㪴䋺㩹㪟㩹㫃㪼㫍㪼㫃䋿

㩿㪈㪀䇭㪚㪿㪼㪺㫂㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪠㪚㪈㪇㪎㪴㪑㪏㪌㪃㩷㪐㪇㫇㫀㫅

㩿㪉㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪪㪧㪠㪥㪛㪣㪜㪴㪃

㩷㩷㩷㩷㩷㩷㪲㪝㪞㪠㪥㪴㩷㫊㫀㪾㫅㪸㫃㪅

㩿㪊㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㪅䊶䊶䊶㪤㪼㪺㪿㪸㪄㪚㪯㪈㪌㪈

㩿㪋㪀䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㪲㪠㪚㪈㪇㪈㪴㩷㪸㫅㪻㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㩷㩷㩷㩷㩷㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪠㪚㪈㪇㪈㪴

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪊

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪠㪚㪈㪇㪋㩷㩷㩷㩷㩷㪂㪈㪅㪉㪶㪛㪭㪊㪅㪉㩷㪑㩷㪈㪅㪉㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈㪃㪠㪚㪈㪇㪋

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪜㪥㪛

㪜㪥㪛

33

Page 34

䇭㩿㪉㪀㪚㪛㩷㫆㫉㩷㪪㪘㪚㪛㩿㪛㪭㪛㪀㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊

䇭㩿㪊㪀㩷㪪㪘㪚㪛㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊

㪈㪌㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪩㪝㩷㫊㫀㪾㫅㪸㫃㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪫㪼㫊㫋㪄㪧㫆㫀㫅㫋㩷㩿㪫㪧㪀㪀

䇭䊶㪫㪧㪲㫄㪘㪤㪦㪥㪈㪴㩷㪲㪘㪤㪦㪥㪉㪴㪑㩷㪻㫀㪽㪽㪼㫉㪼㫅㫋㫀㪸㫃㩷㫆㫌㫋㫇㫌㫋㩷㪸㪹㫆㫌㫋㩷㪎㪇㪇㫄㪭㫇㪄㫇

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㪲㪠㪚㪈㪇㪎㪴㩷㪸㫅㪻㩷㪺㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㩷㩷㩷㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾㩷㫆㪽㩷㪲㪠㪚㪈㪇㪎㪴

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪠㪚㪊㪇㪊㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫍㫆㫃㫋㪸㪾㪼㪅㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪛㪈㩷㩷㪑㩷㪊㪅㪊䌖

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷䇭㪂㪉㪅㪌㪶㪛㪈㪆㪶㪘㪈㩷㪑㩷㪉㪅㪌㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈㪃㪠㪚㪌㪇㪈

䇭䊶㪚㪯㪈㪋㪈㩷㪑㪏㪬㪄㪉㪈㪇㪇㪏㪊

㪚㪿㪼㪺㫂㩷㪦㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫎㪸㫍㪼㪽㫆㫉㫄㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪊㪇㪊㩷㩿㪈㪈㪀㫇㫀㫅㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪤㪚㪢㪈㩷㪑㩷㪊㪊㪅㪏㪎㪤㪟㫑㩷㩿㪊㪅㪊㪭㪀

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪊㪇㪊㪃㪩㪊㪉㪇㪃㪩㪍㪇㪊㪃㪠㪚㪌㪈㪇㪃㪚㪯㪉㪈㪈

䇭䊶㪚㪰㪉㪈㪈㪃㪠㪚㪈㪇㪋㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪎

㪚㪿㪼㪺㫂㩷㪩㪼㫊㪼㫋㩷㫊㫀㪾㫅㪸㫃㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪊㪇㪊㩷㩿㪐㪀㫇㫀㫅㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪠㪦㪶㪩㪪㪫㩷㪑㩷㩹㪟㩹㩷㫃㪼㫍㪼㫃㩷㩿㪊㪅㪊㪭㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪩㪊㪈㪏㪃㪩㪉㪊㪌㪃㪠㪚㪈㪇㪎

㪚㪿㪼㪺㫂㩷㪙㫌㫊㩷㪣㫀㫅㪼㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㪘㪻㪻㫉㪼㫊㫊㪃㩷㪛㪸㫋㪸㩷㪙㫌㫊㩷㪹㪼㫋㫎㪼㪼㫅㩷㪠㪚㪊㪇㪊㩷㪸㫅㪻㩷㪠㪚㪊㪇㪈㩿㪪㪛㪩㪘㪤㪀

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪘㪻㪻㫉㪼㫊㫊㪃㩷㪛㪸㫋㪸㪃㩷㪚㫆㫅㫋㫉㫆㫃㩷㪪㫀㪾㫅㪸㫃㪅

䇭䊶㪲㪛㪨㪇㪄㪎㪴㪃㪲㪛㪶㪤㪘㪇㪄㪈㪈㪴㪃㪲㪛㪚㪣㪢㪴㪃㪲㪛㪚㪢㪜㪴㪃㪲㪛㪮㪜㪴㪃

㩷㩷㩷㩷㪲㪥㪚㪘㪪㪴㪃㪲㪥㪩㪘㪪㪴

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㪛㪸㫋㪸㩷㪣㫀㫅㪼㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪲㪪㪛㪇㪄㪎㪴㪃㪲㪯㪪㪘㪢㪴㪃㪲㪯㪪㪟㪛㪴㪃㪲㪪㪛㪚㪢㪴㪃㪲㪪㪛㪜㪝㪴㪃㪲㪯㪪㪩㪨㪴

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪇㪎㩷㪑㩷㩿㪈㪐㪈㪀㪄㩿㪈㪐㪌㪀㫇㫀㫅

䇭䊶㪠㪚㪊㪇㪊㩷㪑㩷㩿㪈㪍㪋㪀㪄㩿㪈㪎㪍㪀㫇㫀㫅

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪮㪸㫋㪼㫉㩷㪤㪸㫉㫂㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪲㪧㪪㪧㪶㪮㪘㪛㪈㪄㪎㪴㪃㪲㪧㪪㪧㪶㪤㪚㪢㪴

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

䇭䊶㪫㪿㪼㩷㫋㪼㫊㫋㩷㫄㫆㪻㪼㩷㩹㪫㪜㩹㩷㫀㫊㩷㪼㫏㪼㪺㫌㫋㪼㪻㪅㩷㪈㪐㪇㩷㫆㫍㪼㫉㪖

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪇㪎㩷㪑㩷㩿㪐㪋㪀㪄㩿㪈㪇㪈㪀㫇㫀㫅

䇭䊶㪠㪚㪊㪇㪊㩷㪑㩷㩿㪈㪉㪊㪀㪃㩿㪈㪈㪎㪀㪄㩿㪈㪉㪇㪀㪃㩿㪈㪈㪉㪀㪄㩿㪈㪈㪋㪀㫇㫀㫅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪜㪥㪛

㪜㪥㪛

㪦㪅㪢㪅

34

Page 35

8U-310040(SACD MODULE UNIT-DIGITAL BLOCK)

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫊㫀㪾㫅㪸㫃㩷㫇㫉㫆㪺㪼㫊㫊㫀㫅㪾㩷㫌㫅㫀㫋㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪠㪚㪌㪈㪇㩷㩷㩷㩷㩷㩷㩷㪊㪊㪶㪭㪚㪚㪠㪦㩷㪑㩷㪊㪅㪊㪭

䇭䊶㪠㪚㪌㪇㪋㪃㪠㪚㪌㪇㪌㪃㪚㪰㪈㪋㪈㩿㪈㪇㪀㫇㫀㫅㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪌㪶㪭㪚㪚䇭㩷㩷㪑㩷㪉㪅㪌㪭

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪈㪉㪶㪭㪚㪚㩷㩷㩷㩷㩷㪑㩷㪈㪅㪉㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪿㪼㪺㫂㩷㪪㪟㪦㪩㪫㪆㪦㪧㪜㪥㩷㫊㫌㪺㪿㩷㪸㫊㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫀㪼㫊㩷㪸㫅㪻㩷㪞㪥㪛

㩷㩷㩷㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㫋㪼㫊㫋㪼㫉㩷㪼㫋㪺㪅

䇭䊶㪚㪿㪼㪺㫂㩷㫎㪿㪼㫋㪿㪼㫉㩷㫋㪿㪼㩷㫉㪼㪾㫌㫃㪸㫋㫆㫉㩷㫋㪿㪼㩷㫅㫆㫉㫄㪸㫃㫀㫋㫐㪅

䇭䊶㪚㪿㪼㪺㫂㩷㫎㪿㪼㫋㪿㪼㫉㩷㫋㪿㪼㩷㪼㫃㪼㫄㪼㫅㫋㩷㫆㪽㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐

㪚㪧㪬㩷㫊㫋㪸㫉㫋㫀㫅㪾㸢㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪤㪼㪺㪿㪸㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㪄㪈

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪌㪇㪉㩷㩿㪈㪇㪀㪃㩷㩿㪈㪏㪀㪃㩷㩿㪐㪊㪀㩷㫇㫀㫅㩷㫀㫊㩷㩹㪟㩹㪖

䇭䊶㪠㪚㪌㪇㪉㩷㩿㪈㪈㪀㩷㫇㫀㫅㩷㫀㫊㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫆㫉㪖䇭䇭䇭䇭㪈㪍䌍䌈㫑

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪿㪼㪺㫂㩷㪠㪚㪌㪇㪉㪃㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫆㪽㩷㪝㪜㪆㪙㪜㩷㫊㫀㪻㪼㪃

㩷㩷㩷㩷㪩㪜㪪㪜㪫㩷㩿㪠㪚㪌㪇㪊㪀㪅

䇭䊶㪚㪿㪼㪺㫂㩷㪸㫅㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪌㪇㪉䇭䇭䇭㪯㪌㪇㪈

㪚㪧㪬㩷㫊㫋㪸㫉㫋㫀㫅㪾㸢㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪤㪼㪺㪿㪸㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㪄㪉

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪌㪇㪉㩷㩿㪌㪏㪀㩷㫇㫀㫅㩷㫀㫊㩷㩹㪟㩹㪖㩷䋨㪮㪿㪼㫅㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㫆㪽㩷㪝㪜㪆㪙㪜㩷㫊㫀㪻㪼㩷㫀㫊㩷㪦㪢䋺㩹㪟㩹䋩

䇭䊶㪮㪿㪼㫅㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫇㫆㫎㪼㫉㩷㫊㫆㫌㫉㪺㪼㪃㩷㪠㪚㪌㪇㪉㩷㪸㫅㪻㩷㪠㪚㪌㪇㪏㩷㩿㪜㪜㪧㪩㪦㪤㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼

㩷㩷㩷㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫊㫋㪸㫋㪼㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪝㪜㪆㪙㪜㩷㫊㫀㪻㪼㩷㫋㫉㪸㫅㫊㫀㫋㪼㪻㩷㫀㫅㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㪸㫃㩷㫇㫆㫊㫊㫀㪹㫃㪼㩷㫊㫋㪸㫋㪼

䇭䇭㩿㪛㪭㪶㪪㪫㪙㪑㩷㩹㩷㪟㩹㩷㪀㩷㪛㪭㪶㪪㪫㪙㩹㩷㪣㩹㩷䋺㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜

䇭䇭㪬㪥㪠㪫㪄㪝㪜㪆㪙㪜㩷㪙㪣㪦㪚㪢㩷㪺㪿㪼㪺㫂㪅

䇭䊶㪠㪚㪌㪇㪏

㪚㪿㪼㪺㫂㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫆㫉㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪯㪉㪈㪈㩷㩿㪈㪏㪀㩷㪿㪸㫊㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫉㫀㫇㫇㫃㪼㩷㫄㪸㫉㫂㩷㪸㫇㫇㪼㪸㫉㪼㪻㩷㫀㫅㩷㫇㫀㫅㪖

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪉㪅㪌㪎㪐㪉㪤㪟㫑

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪯㪉㪈㪈

䇭䊶㪚㪰㪉㪈㪈㪃㪠㪚㪈㪇㪋䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪎

㪚㪿㪼㪺㫂㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫋㪿㪼㩷㪝㪧㪞㪘䋨㪠㪚㪌㪈㪇䋩㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪦㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫉㫀㫇㫇㫃㪼㩷㫄㪸㫉㫂㩷㪸㫇㫇㪼㪸㫉㪼㪻㩷㫀㫅㩷㪩㪌㪏㪌㪖㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪈㪍㪅㪐㪊㪋㪋㪤㪟㫑

䇭䊶㪦㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫉㫀㫇㫇㫃㪼㩷㫄㪸㫉㫂㩷㪸㫇㫇㪼㪸㫉㪼㪻㩷㫀㫅㩷㪩㪍㪇㪊䇮㪩㪍㪉㪉㪖䇭䇭㪊㪊㪅㪏㪍㪏㪏㪤㪟㫑

䇭䊶㪮㪿㪼㫅㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㫇㫆㫎㪼㫉㩷㫊㫆㫌㫉㪺㪼㪃㩷㪠㪚㪌㪈㪇㩷㪸㫅㪻㩷㪠㪚㪌㪇㪐㩷㩿㪜㪜㪧㪩㪦㪤㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼

㩷㩷㩷㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫊㫋㪸㫋㪼㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪿㪼㪺㫂㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫆㪽㩷㪠㪚㪌㪈㪇㪅䋨㪊㪅㪊㪭㪃㪉㪅㪌㪭㪃㪈㪅㪉㪭䋩

䇭䊶㪠㪚㪌㪇㪐㪃㪚㪯㪉㪈㪈㪃㪩㪍㪋㪇

䇭䊶㪚㪰㪉㪈㪈㪃㪠㪚㪈㪇㪋䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪎

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㪽㫉㫆㫄㩷㪝㪜㪆㪙㪜㪄㪈䇭䇭䇭䋨㪚㪸㫊㪼㩷㫆㪽㩷㪚㪛䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪩㪍㪇㪇䋺㪧㪚㪤㪶㪣㪩㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪩㪍㪇㪈䋺㪧㪚㪤㪶㪙㪚㪢㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪩㪌㪐㪐䋺㪧㪚㪤㪶㪛㪘㪫㪘䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪈㪍㪹㫀㫋㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

䇭䊶㪩㪍㪇㪉䋺㪪㪧㪛㪠㪝㩿㪛㪄㪦㪬㪫㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪇㪎㪃㪠㪚㪈㪇㪍㪃㪩㪉㪇㪌䌾㪩㪉㪈㪍㪃㪠㪚㪈㪈㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㪽㫉㫆㫄㩷㪝㪜㪆㪙㪜㪄㪉䇭䇭䇭䋨㪚㪸㫊㪼㩷㫆㪽㩷㪪㪘㪚㪛䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪩㪍㪎㪋䋺㪛㪪㪛㪶㪙㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪩㪌㪐㪎䋺㪛㪪㪛㪶㪤㪠㪯㪶㪣㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩿㪠㫋㩷㪺㪿㪸㫅㪾㪼㫊㩷㫀㫅㩷㫋㪿㪼㩷㪽㪸㫃㫃㩷㫆㪽㩷㪙㪚㪢㩷䋩

䇭䊶㪩㪌㪐㪏䋺㪛㪪㪛㪶㪤㪠㪯㪶㪩㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩿㪠㫋㩷㪺㪿㪸㫅㪾㪼㫊㩷㫀㫅㩷㫋㪿㪼㩷㪽㪸㫃㫃㩷㫆㪽㩷㪙㪚㪢㩷䋩

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪇㪎㩿㪐㪋䌾㪈㪇㪈㫇㫀㫅㪀㪃㪠㪚㪈㪇㪍㪃㪩㪉㪇㪌䌾㪩㪉㪈㪍㪃㪠㪚㪈㪈㪊

䇭䊶㪠㪚㪊㪇㪈㪃㪠㪚㪊㪇㪉㪃㪠㪚㪊㪇㪊㪃㪩㪊㪉㪎㪃㪩㪊㪊㪌㪃㪩㪊㪊㪍

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪈䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㪚㪸㫊㪼㩷㫆㪽㩷㪚㪛䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀䇭䇭䇭㪚㪿㪼㪺㫂㩷㪘㪬㪛㪠㪦㩷㪛㪘㪫㪘㪆㪚㪣㪢

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪯㪉㪈㪈㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃䇭䇭䇭㪮㪚㪢㪃㪙㪚㪢㪃㪧㪚㪤㪶㪛㪘㪫㪘㪶㪣㪆㪶㪩

䇭䊶㪠㪚㪌㪇㪉㩿㪏㪍㪀㫇㫀㫅㩷㪑㩹㪣㩹㩷㪖䇭㩿㪜㪯㪫㪶㪠㪥㪆㪬㪪㪙䋺㩹㪟㩹㪀

䇭䊶㪩㪍㪈㪏䋺㩹㪣㩹㩷㫃㪼㫍㪼㫃㩷㪦㪢㪖䇭䇭䇭䇭䇭䇭㩿㪪㪘㪚㪛䋺㩹㪟㩹㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪈㪉㪃㪠㪚㪌㪇㪉㪃㪠㪚㪌㪈㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪉䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㪚㪸㫊㪼㩷㫆㪽㩷㪪㪘㪚㪛䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀䇭䇭䇭㪚㪿㪼㪺㫂㩷㪘㪬㪛㪠㪦㩷㪛㪘㪫㪘㪆㪚㪣㪢

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪯㪉㪈㪈㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃䇭㩷㩷㩷㩷㪛㪪㪛㪶㪙㪚㪢㪃㪛㪪㪛㪶㪛㪘㪫㪘㪶㪣㪆㪶㪩

䇭䊶㪠㪚㪌㪇㪉㩿㪏㪍㪀㫇㫀㫅䋺㩹㪣㩹㪖䇭㩿㪜㪯㪫㪶㪠㪥㪆㪬㪪㪙䋺㩹㪟㩹㪀

䇭䊶㪩㪍㪈㪏䋺㩹㪟㩹㩷㫃㪼㫍㪼㫃㩷㪦㪢㪖䇭䇭䇭䇭䇭䇭㩿㪪㪘㪚㪛䋺㩹㪣㩹㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪈㪈㪉㪃㪠㪚㪌㪇㪉㪃㪠㪚㪌㪈㪇

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

35

Page 36

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩿㪚㪦㪘㪯㪆㪦㪧㪫㪀㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪈

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪠㪚㪋㪇㪈㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㩷㩷㩷㩷㩷㩷㩷㪊㪊㪶㪭㪚㪚㪶㪛㪠㪩䋺㪊㪅㪊䌖

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪠㪚㪋㪇㪈㩿㪋㪈㪀㫇㫀㫅㩷㪩㪜㪪㪜㪫䇭㩷䇭䇭䇭䇭㩷䇭㪯㪤㪦㪛㪜䇭䇭䋺㩹㪟㩹

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪋㪇㪈䇭䇭䇭䇭䇭䇭㩷䇭㪉㪋㪅㪌㪎㪐㪉㪤㪟㫑

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪋㪇㪈㩷㪸㫅㪻㩷㪠㪚㪌㪇㪉䇭䇭䇭㩷㪛㪜㪃㪛㪣㪃㪛㪠㪃㪛㪦

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪰㪈㪋㪈㪃㪝㪙㪌㪇㪍㪃㪯㪋㪇㪈㪃㪠㪚㪌㪇㪉

䇭䊶㪚㪯㪈㪋㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩿㪚㪦㪘㪯㪆㪦㪧㪫㪀㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪉䇭䇭䇭䇭㩷䋨㪚㪸㫊㪼㩷㫆㪽㩷㪚㪛䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㫊㩷㫋㪿㪼㩷㪪㪧㪛㪠㪝㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫀㫅㫋㫆㩷㪠㪚㪋㪇㪈㩿㪈㪇㪀㫇㫀㫅㪖

䇭䊶㪠㫊㩷㫋㪿㪼㩷㪪㪧㪛㪠㪝㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㩷㫀㫅㫋㫆㩷㪠㪚㪋㪇㪈㩿㪈㪀㫇㫀㫅㪖

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪠㪚㪌㪈㪇㪃㪠㪚㪌㪈㪈㪃㪚㪯㪈㪏㪈

䇭䊶㪚㪰㪈㪏㪈㪃㪚㪰㪇㪊㪌㪃㪠㪚㪈㪈㪉㪃㪫㪈㪇㪈㪃㪠㪚㪈㪈㪎㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪋

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪜㪥㪛

36

Page 37

8U-21003-7(AUDIO UNIT)

㪚㪿㪼㪺㫂㩷㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪅㩷

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪇㪌㪉

䇭䊶㪚㪯㪇㪌㪉㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪊

䇭䊶㪠㪚㪐㪇㪈㪃㪠㪚㪐㪇㪉㪃䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䇭䊶㪚㪿㪼㪺㫂㩷㪪㪟㪦㪩㪫㪆㪦㪧㪜㪥㩷㫊㫌㪺㪿㩷㪸㫊㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫀㪼㫊㩷㪸㫅㪻

㪞㪥㪛

㩷㩷㩷㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㫋㪼㫊㫋㪼㫉㩷㪼㫋㪺㪅

䇭䊶㪚㪿㪼㪺㫂㩷㫎㪿㪼㫋㪿㪼㫉㩷㫋㪿㪼㩷㫉㪼㪾㫌㫃㪸㫋㫆㫉㩷㫋㪿㪼㩷㫅㫆㫉㫄㪸㫃㫀㫋㫐㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪉㪈㪈㪃㪩㪈㪇㪌㪃㪠㪚㪈㪇㪋

䇭䊶㪚㪯㪉㪈㪈㩷㪑㩷㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪉㪈㪈

䇭䊶㪚㪯㪉㪈㪈㩷㪑㩷㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪉㪈㪈

䇭䊶㪚㪯㪉㪈㪈㩷㪑㩷㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪈㪇㪍㩷㪸㫉㫆㫌㫅㪻㩷㫎㫀㫋㪿㩷㪚㪃㩷㪩

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪈㪇㪏㪃㪠㪚㪈㪇㪐㪃㪠㪚㪈㪈㪇㩷㪸㫅㪻㩷㪠㪚㪈㪈㪊㩷㪸㫉㫆㫌㫅㪻㩷㫎㫀㫋㪿㩷㪚䇮㪩

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪇㪌㪉㪃㪫㪩㪈㪇㪏㪃㪩㪣㪈㪇㪉

䇭䊶㪚㪯㪇㪌㪉㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪡㪢㪈㪇㪋㪃㪡㪢㪈㪇㪌

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪈

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪚㪯㪇㪌㪉㩷㩿㪈㪀㩿㪊㪀㫇㫀㫅㩷㩷㩷㩷㩷㪂㪈㪉㪭㪶㪘㩷㪑㩷㪈㪉㪭

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪄㪈㪉㪭㪶㪘㩷㪑㩷㪈㪉㪭

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㪄㪉

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪠㪚㪈㪇㪈䇭䇭䇭䇭䇭䇭䇭㩷㩷㪂㪌㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㫌㫅㫀㫋㪄㪈

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪈㪇㪋㩷㩿㪊㪀㫇㫀㫅

䇭䊶㪚㪿㪼㪺㫂㩷㪚㪰㪉㪈㪈㩷㩿㪈㪏㪀㫇㫀㫅㩷㪤㪚㪣㪢㪅䇭䇭䇭䇭䇭䇭㪉㪉㪅㪌㪎㪐㪉㪤㪟㫑

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㫌㫅㫀㫋㪄㪉

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀䇭䇭䇭䇭䇭䇭䇭㪚㪿㪼㪺㫂㩷㪘㪬㪛㪠㪦㩷㪛㪘㪫㪘㪆㪚㪣㪢㪅

䇭䊶㪚㪿㪼㪺㫂㩷㪸㩷㪚㪰㪉㪈㪈㩷㫊㫀㪾㫅㪸㫃㪅䇭䇭䇭㪚㪸㫊㪼㩷㫆㪽㩷㪧㪚㪤㩷䋺㪮㪚㪢䇮㪙㪚㪢䇮㪪㪛㪘㪫㪘㪶㪣㪆㪶㪩

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷䇭㪚㪸㫊㪼㩷㫆㪽㩷㪪㪘㪚㪛䋺㪛㪪㪛㪙㪚㪢䇮㪛㪪㪛㪶㪣㪆㪶㪩

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㫌㫅㫀㫋㪄㪊

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀䇭䇭䇭䇭䇭䇭䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪘㪚㩷㪺㫆㫅㫋㫉㫆㫃㩷㫊㫀㪾㫅㪸㫃㪅

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪰㪉㪈㪈㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅䇭䇭䇭䇭䇭䇭㩷㩷㪩㪪㪫䇮㪤㪪䇮㪤㪚䇮㪤㪛㪠

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪸㫅㪸㫃㫆㪾㩷㫊㫀㪾㫅㪸㫃㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㪸㪽㫋㪼㫉㩷㪛㪘㪚㪅㪄㪈

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪈㪇㪍㩷㩿㪉㪉㪀㩿㪉㪊㪀㩿㪊㪊㪀㩿㪊㪋㪀㫇㫀㫅䇭䇭䋺䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪘㪚㩷㪸㫅㪸㫃㫆㪾㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪸㫅㪸㫃㫆㪾㩷㫊㫀㪾㫅㪸㫃㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㪸㪽㫋㪼㫉㩷㪛㪘㪚㪅㪄㪉

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪦㪧㩷㪘㫄㫇㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪤㪬㪫㪜㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㪅

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀䇭䇭䇭䇭䇭䇭䇭㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪤㪬㪫㪜㩷㪺㫆㫅㫋㫉㫆㫃㩷㫊㫀㪾㫅㪸㫃

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪰㪇㪌㪉㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㩷㩷㩷㩷㪤㪬㪫㪜䇮㪄㪈㪌㪭㪶㪩㪣䇮㪞㪥㪛㪶㪩㪣

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷㩷㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪤㪬㪫㪜㩷㫉㪼㫃㪸㫐㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫋㪼㫉㫄㫀㫅㪸㫃㪅

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㪩㪚㪘㩷㪧㪠㪥㩷㪡㪘㪚㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪜㪥㪛

37

Page 38

8U-310040(SACD MODULE UNIT-USB BLOCK)

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㪺㫆㫄㫇㫆㫅㪼㫅㫋㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫌㫋㫇㫌㫋㩷㫍㫆㫃㫋㪸㪾㪼㩷㫆㪽㩷㪠㪚㪏㪇㪉㪃㪠㪚㪏㪇㪊㪃㪚㪯㪇㪌㪈

䇭䇭䇭㪊㪊㪶㪭㪚㪚㪶㪬㪪㪙㪆㪂㪊㪅㪊㪭㪶㪘㪆㪂㪊㪅㪊㪭㪶㪛㪅㪆㪂㪊㪅㪊㪭㪶㪛㪊㩷㪑㩷㪊㪅㪊㪭

䇭䇭䇭㪂㪈㪅㪌㪭㪶㪛㪅㪆㪂㪈㪅㪌㪭㪶㪛㪅㪅䇭㪑㩷㪉㪅㪌㪭䇭䇭䇭䇭䇭㩷䇭㪂㪌㪭㪶㪬㪪㪙䋺㪌䌖

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪏㪇㪈㪃㪚㪰㪈㪋㪈㪃㪚㪯㪇㪌㪈

䇭䊶㪚㪯㪈㪋㪈㪃㪠㪚㪏㪇㪍㪃㪛㪏㪇㪋㪃㪣㪏㪇㪋䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

䇭䊶㪚㪰㪇㪌㪈㪃㪱㪛㪍㪇㪎㪃㪱㪛㪍㪇㪊㪃㪡㪢㪍㪇㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪍

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪏㪇㪊㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪈㪀㫇㫀㫅䋺㪩㪜㪪㪜㪫䇮㪃㩿㪍㪐㪀㫇㫀㫅䋺㪙㪦㪦㪫㩷㫀㫊㩷㩹㪟㩹䋿

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪎㪊㪀㫇㫀㫅㩷㫀㫊㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫆㫉㪖䇭䇭䇭䇭䇭㪐䌍䌈㫑

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪏㪇㪊㩷㪸㫅㪻㩷㪠㪚㪌㪇㪉㪅㩷㩷㩷㩷㪉㪏㪫㪯㪛㪃㪉㪏㪩㪯㪛

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪌㪇㪉㪃㪠㪚㪌㪇㪍㪃㪠㪚㪌㪇㪎㪃㪯㪏㪇㪈

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪏㪇㪉

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪍㪐㪀㫇㫀㫅䋺㪩㪜㪪㪜㪫㩷㫀㫊㩷㩹㪟㩹䋿

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪋㪏㪀㩷㫇㫀㫅㩷㪤㪚㪢㩷㫀㫅㫇㫌㫋㩷㪦㪢㪖䇭䇭䇭䇭㪬㪪㪙㪶㪤㪚㪢䋺㪈㪍㪅㪐㪊㪋㪋㪤䌈㫑

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪏㪇㪉㩷㪸㫅㪻㩷㪠㪚㪏㪇㪊

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪌㪈㪇㪃㪠㪚㪏㪇㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㪅

䋨㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪎㪐㪀㩿㪏㪇㪀㫇㫀㫅䋺㩷㪚㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫎㪸㫍㪼㪽㫆㫉㫄㩷㫀㫊㩷㪦㪢㪖䇭䇭䇭㪛㪂㩷㪃㩷㪛㪄

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪇㪌㪈

䇭䊶㪚㪰㪇㪌㪈㪃㪱㪛㪍㪇㪋㪃㪱㪛㪍㪇㪌㪃㪡㪢㪍㪇㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪍

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㪅㪄㪈㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷䋨㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪎㪈㪀䇭㪣㪩㪚㪢㫆㫌㫋㫇㫌㫋

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪐㪉㪀䇭㪙㪚㪢㫆㫌㫋㫇㫌㫋

䇭䊶㪠㪚㪏㪇㪊㩷㩿㪐㪊㪀䇭㪛㪘㪫㪘㫆㫌㫋㫇㫌㫋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪏㪌㪐㪃㪩㪐㪇㪊㪃㪩㪐㪇㪋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㪅㪄㪉㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷䋨㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪊㪍㪀䇭㪣㪩㪚㪢㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪊㪌㪀䇭㪙㪚㪢㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪊㪋㪀䇭㪛㪘㪫㪘㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪈㪍㪹㫀㫋㩷㪸㪽㫋㪼㫉

䇭䊶㪠㪚㪏㪇㪉㩷㩿㪊㪊㪀䇭㪛㪄㪦㪬㪫㩷㫆㫌㫋㫇㫌㫋䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷㩷㪪㪧㪛㪠㪝

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶䌒㪏㪋㪍㪄㪏㪋㪐

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㪅㪄㪊㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷䋨㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀䇭䇭㩷㪠㪚㪌㪈㪇㩷㩿㪝㪧㪞㪘㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㪅

䇭䊶㪩㪌㪏㪍䇭㪣㪩㪚㪢㩷㫀㫅㫇㫌㫋䇭㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪩㪌㪏㪎䇭㪙㪚㪢㩷㫀㫅㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪩㪌㪏㪏䇭㪛㪘㪫㪘㩷㫀㫅㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪈㪍㪹㫀㫋㩷㪸㪽㫋㪼㫉

䇭䊶㪩㪌㪏㪐䇭㪛㪄㪦㪬㪫㩷㫀㫅㫇㫌㫋䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷㩷㩷䇭䇭䇭䇭㩷㩷㩷㪪㪧㪛㪠㪝

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶䌒㪌㪏㪍㪄㪌㪏㪐㪅䌒㪏㪋㪍㪄㪏㪋㪐

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㪅㪄㪋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷䋨㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪌㪇㪉㩿㪏㪍㪀㫇㫀㫅䋺㩹㪟㩹㪖䇭㩷㩷㩷㩷㩷㩷㩷㩿㪜㪯㪫㪶㪠㪥㪆㪬㪪㪙䋺㩹㪟㩹㪀

䇭䊶㪩㪍㪍㪋㩿㪝㪧㪞㪘㪶㪚㪋㪀䋺㩹㪟㩹㩷㪖䇭䇭㩿㪜㪯㪫㪶㪠㪥䋺㩹㪣㩹㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪌㪇㪉

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪙㪼㫃㫆㫎㩷㫀㫊㩷㫋㪿㪼㩷㫊㪸㫄㪼㩷㪸㫊䇭㪛㪠㪫㪘㪣㪶㪙㪣㪦㪚㪢䋺㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃

㫆㫌㫋㫇㫌㫋㪄㪈

38

Page 39

㪚㪿㪼㪺㫂㩷㫀㪧㫆㪻㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㪅

㪘㫊㩷㪽㫆㫉㩷㪬㪪㪙㩷㫄㪼㫄㫆㫉㫐㩷㫆㫇㪼㫉㪸㫋㫀㫆㫅㩷㫆㫅㫃㫐㩷㪦㪢㩷㪸㫅㪻㩷㫀㪧㫆㪻㩷㪥㪞

㪚㪿㪼㪺㫂㩷㫀㪧㫆㪻㪅䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㫀㪧㫆㪻㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪌㪇㪊㩷㪸㫅㪻㩷㪠㪚㪏㪇㪋㩷㩿㫀㪧㫆㪻㩷㪺㪼㫉㫋㫀㪽㫀㪺㪸㫋㫀㫆㫅㩷㪺㪿㫀㫇㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼

㩷㩷㩷㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㪹㪼㫋㫎㪼㪼㫅㪅

㪰㪼㫊

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪏㪇㪋㩷㪸㫅㪻㩷㪸㫉㫆㫌㫅㪻㩷㪚㪃㩷㪩

㪦㪅㪢㪅

㪜㪥㪛

39

Page 40

8U-210084(DSP DIGITAL I-O UNIT)

㪫㪿㪸㫋㩷㪩㪜㪪㪫㪦㪩㪜㪩㩷㫀㫊㩷㫋㫌㫉㫅㪼㪻㩷㫋㫆㩷㪦㪥㩷㩿㪤㪦㪛㪜㪈㪄㪊㪀㪃㩷㫎㪿㪼㫅㩷㫊㫆㫌㫅㪻㩷㪻㫆㪼㫊㩷㫅㫆㫋㩷㪺㫆㫄㪼㩷㫆㫌

㫋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪝㪧㪞㪘㩷㪺㫆㫅㫋㫉㫆㫃㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪩㪍㪍㪊䋺㪝㪧㪞㪘㪶㪚㪊䋺㩹㪟㩹㪖䇭䋨㪩㪜㪪㪫㪦㪩㪜㪩㩷㪦㪝㪝䋺㩹㪣㩹䋩

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪌㪇㪉㪃㪩㪍㪍㪊

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪝㪧㪞㪘㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪅

䋨㪤㪧㪊㩷㫆㫉㩷㪮㪤㪘㩷㫆㫉㩷㫀㪧㫆㪻㩷㫇㫃㪸㫐㪹㪸㪺㫂㩷䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪯㪈㪏㪈㩿㪈㪊㪀䇭㪣㪩㪚㪢㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪚㪯㪈㪏㪈㩿㪈㪉㪀䇭㪙㪚㪢㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪚㪯㪈㪏㪈㩿㪈㪋㪀䇭㪛㪘㪫㪘㩷㫆㫌㫋㫇㫌㫋㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪌㪍㪋㪃㪩㪌㪍㪌㪃㪩㪌㪍㪎㪃㪚㪯㪈㪏㪈

䇭䊶㪚㪰㪈㪏㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫆㪽㩷㪛㪪㪧

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫆㫌㫉㪺㪼㩷㫆㪽㩷㪠㪚㪉㪇㪊㪃㪠㪚㪉㪇㪋㪃㪠㪚㪉㪇㪌㩷㩷㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪛䋺㪊㪅㪊䌖

䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪂㪈㪅㪉䌖㩷䇭䋺㪈㪅㪉㪭

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪇㪊㪌㪃㪠㪚㪏㪇㪌㪃㪛㪏㪇㪌㪃㪣㪏㪇㪐㪃㪠㪚㪉㪇㪉

䇭䊶㪚㪯㪇㪊㪌䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㪛㪪㪧㩷㪄㪈䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㪩㪜㪪㪫㪦㪩㪜㪩㩷㪦㪥䋩

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪰㪈㪏㪈㩿㪉㪀㩿㪊㪀䋺㩷㪩㪜㪪㪜㪫㩷㫀㫊㩷㩹㪟㩹㪖

䇭䊶㪠㪚㪉㪇㪋㩿㪏㪊㪀㫇㫀㫅䋺㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪣㪢㪠㪥㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪇㪅㪏㪈㪌㪤㪟㫑䋨㪈㪅㪉㪭䋩

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪯㪉㪇㪈䇮㪫㪩㪉㪇㪊㪄㪉㪇㪍㪃㪚㪰㪈㪏㪈

䇭䊶㪚㪯㪈㪏㪈䋺㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㪛㪪㪧㩷㪄㪉䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㪩㪜㪪㪫㪦㪩㪜㪩㩷㪦㪥䋩

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㪹㪼㫋㫎㪼㪼㫅㩷㪠㪚㪉㪇㪋㩷㪸㫅㪻㩷㪠㪚㪉㪇㪌

㩷㩷㩷䋨㪘㪽㫋㪼㫉㩷㫋㪿㪼㩷㪩㪜㪪㪜㪫㩷㪺㪸㫅㪺㪼㫃㫃㫀㫅㪾䋩

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪉㪇㪌㩷㪸㫅㪻㩷㫇㪼㫉㫀㫇㪿㪼㫉㪸㫃㩷㫇㪸㫉㫋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫊㫋㪸㫉㫋㫀㫅㪾㩷㪛㪪㪧㩷㪄㪊䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䋨㪩㪜㪪㪫㪦㪩㪜㪩㩷㪦㪥㪀

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㪹㪼㫋㫎㪼㪼㫅㩷㪠㪚㪉㪇㪋㩷㪸㫅㪻㩷㪠㪚㪉㪇㪊䇭䇭䇭䋨㪧㫃㪸㫐㪹㪸㪺㫂䋩

䇭䊶㪜㪛㪇㪄㪊㪈㪃㪜㪘㪈㪄㪈㪇㪃㪜㪘㪈㪎㪃㪜㪘㪈㪏㪃㪚㪣㪢㪃㪮㪜㪃㪚㪘㪪㪃㪩㪘㪪

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪉㪇㪊㩷㪸㫅㪻㩷㫇㪼㫉㫀㫇㪿㪼㫉㪸㫃㩷㫇㪸㫉㫋

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫋㫉㫆㫃㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪛㪪㪧

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪰㪈㪏㪈㩿㪋㪀㪄㩿㪏㪀䋺㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫉㫀㫇㫇㫃㪼㩷㫄㪸㫉㫂㪅

䇭㩹㪟㩹㹤㩹㪣㩹㩷㫊㫎㫀㫋㪺㪿㫀㫅㪾

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪉㪊㪋㪄㪉㪊㪎㪃㪚㪰㪈㪏㪈

䇭䊶㪚㪯㪈㪏㪈䋺㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪛㪪㪧

䋨㪤㪧㪊㩷㫆㫉㩷㪮㪤㪘㩷㫆㫉㩷㫀㪧㫆㪻㩷㫇㫃㪸㫐㪹㪸㪺㫂䋩

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪉㪇㪋㩿㪈㪋㪊㪀㩿㪈㪋㪋㪀䋺㪣㪩㪚㪢㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪠㪚㪉㪇㪋㩿㪈㪊㪎㪀㩿㪈㪋㪍㪀䋺㪙㪚㪢㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪠㪚㪉㪇㪋㩿㪈㪉㪌䇭䇭䇭㩷㩷䋺㪛㪘㪫㪘㪄㪠㪥㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪊㪇㪇㪄㪊㪇㪊㪃㪚㪰㪈㪏㪈㪃㪩㪉㪍㪇㪃㪩㪉㪍㪊㪃㪩㪉㪍㪌㪃㪩㪉㪎㪈㪃㪩㪉㪏㪌

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪛㪪㪧

䋨㪤㪧㪊㩷㫆㫉㩷㪮㪤㪘㩷㫆㫉㩷㫀㪧㫆㪻㩷㫇㫃㪸㫐㪹㪸㪺㫂䋩

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪉㪇㪋㩿㪈㪊㪊㪀䇭䇭䇭㩷㩷䋺㪛㪘㪫㪘㪄㪦㪬㪫㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪉㪎㪍㪃㪚㪰㪈㪏㪈

䇭䊶㪚㪯㪈㪏㪈䋺㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

40

Page 41

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫀㫅㫇㫌㫋㪅㩷

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪝㪧㪞㪘㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋

䋨㪤㪧㪊㩷㫆㫉㩷㪮㪤㪘㩷㫆㫉㩷㫀㪧㫆㪻㩷㫇㫃㪸㫐㪹㪸㪺㫂䋩

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪩㪌㪍㪍䇭䇭䇭䇭䇭䇭䇭䇭䋺㪛㪘㪫㪘㩷䇭㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪙㪼㫃㫆㫎㩷㫀㫊㩷㫋㪿㪼㩷㫊㪸㫄㪼㩷㪸㫊䇭㪛㪠㪫㪘㪣㪶㪙㪣㪦㪚㪢䋺㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪈

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪌㪍㪍㪃㪚㪯㪈㪏㪈

䇭䊶㪚㪰㪈㪏㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪋

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫆㪽㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪥㪧㪬㪫㩷㪙㪣㪦㪚㪢㪅

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㫆㪽㩷㪠㪚㪈㪈㪏㩷㪸㫅㪻㩷㪠㪚㪈㪈㪉㩷㩷㩷㩷㩷㩷㩷㪂㪊㪅㪊㪭㪶㪛䋺㪊㪅㪊䌖

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪇㪊㪌㪃㪠㪚㪏㪇㪌㪃㪛㪏㪇㪌㪃㪣㪏㪇㪐㪃㪠㪚㪉㪇㪉

䇭䊶㪚㪯㪇㪊㪌䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅㩷㪄㪈

㪏㪬㪄㪉㪈㪇㪇㪏㪋㩿㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪄㪦㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪰㪈㪏㪈㩿㪈㪍㪀䋺㪚㪦㪘㪯㪠㪘㪣㩷㪠㪥

䇭䊶㪚㪰㪈㪏㪈㩿㪈㪎㪀䋺㪦㪧㪫㪠㪚㪘㪣㩷㪠㪥

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪠㪚㪈㪈㪉㪃㪠㪚㪈㪈㪏㪃㪡㪢㪈㪇㪈㪃㪚㪰㪈㪏㪈

䇭䊶㪚㪯㪈㪏㪈䋺㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㩷㩿㪛㪠㪩㪀㪄㪉

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪠㪚㪋㪇㪈㩷㫇㫆㫎㪼㫉㩷㫊㫌㫇㫇㫃㫐㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪊㪊㪶㪭㪚㪚㪶㪛㪠㪩䋺㪊㪅㪊䌖

䇭䊶㪠㪚㪋㪇㪈㩷㩿㪋㪈㪀㩷㪺㪿㪼㪺㫂㩷㫇㫀㫅㩷㪩㪜㪪㪜㪫㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㪯㪤㪦㪛㪜䇭䇭䋺㩹㪟㩹

䇭䊶㪠㪚㪋㪇㪈㩷㩿㪉㪏㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼㩷㫇㫀㫅㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㪅䇭䇭䇭䇭䇭䇭䇭㩷䇭㪉㪋㪅㪌㪎㪐㪉㪤㪟㫑

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫄㫄㫌㫅㫀㪺㪸㫋㫀㫆㫅㩷㫆㪽㩷㪠㪚㪋㪇㪈㩷㪸㫅㪻㩷㪠㪚㪌㪇㪉㪅㩷㩷㩷㩷㩷㪛㪜㪃㪛㪣㪃㪛㪠㪃㪛㪦

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪈㪋㪈㪃㪝㪙㪌㪇㪍㪃㪯㪋㪇㪈㪃㪠㪚㪌㪇㪉

䇭䊶㪚㪯㪈㪋㪈䋺㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㩷㩿㪛㪠㪩㪀㪄㪋

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪋㪇㪈㩿㪊㪊㪀䋺㪛㪠㪩㪈㪶㪘㪬㪛㪠㪦㩷㫀㫊㩷㩹㪟㩹㪖䇭䇭㩷㪥㪦㪫㩷㪘㪬㪛㪠㪦䋺㩹㪟㩹

䇭䊶㪠㪚㪋㪇㪈㩿㪊㪍㪀䋺㪛㪠㪩㪈㪶㪜㪩㪩㪦㪩㩷㫀㫊㩷㩹㪣㩹㪖䇭㩷㩷㪬㪥㪣㪦㪚㪢䇭䇭䋺㩹㪟㩹

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㫄㪸㫋㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪺㫆㫉㫉㫌㪾㪸㫋㪼㪻㩷㫈㫌㪸㫃㫀㫋㫐㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㩷㫆㪽㩷㪛㪠㪩㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪋㪇㪈㩿㪈㪍㪀䋺㪛㪠㪩㪈㪶㪤㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㪉㪋㪅㪌㪎㪍㪤㪟㫑

䇭䊶㪠㪚㪋㪇㪈㩿㪉㪇㪀䋺㪛㪠㪩㪈㪶㪣㪩㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪋㪋㪅㪈㪢㪟㫑

䇭䊶㪠㪚㪋㪇㪈㩿㪈㪎㪀䋺㪛㪠㪩㪈㪶㪙㪚㪢㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶㪠㪚㪋㪇㪈㩿㪉㪈㪀䋺㪛㪠㪩㪈㪶㪛㪘㪫㪘䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪈㪍㪹㫀㫋㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪋㪇㪈㪄㪋㪇㪋

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪛㪠㪞㪠㪫㪘㪣㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㩷㩿㪛㪠㪩㪀㪄㪊

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪋㪇㪈㩷㩿㪏㪀㩷㩿㪋㪀㫇㫀㫅㩷㫀㫊㩷㫋㪿㪼㩷㪪㪧㪛㪠㪝㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㪖

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪯㪈㪏㪈

䇭䊶㪚㪰㪈㪏㪈㪃㪚㪰㪇㪊㪌㪃㪠㪚㪈㪈㪉㪃㪫㪈㪇㪈㪃㪠㪚㪈㪈㪎㩷㪑㩷㪏㪬㪄㪉㪈㪇㪇㪏㪋

㪥㪅㪞㪅

㪦㪅㪢㪅

㪜㪥㪛

41

Page 42

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶䌒㪍㪇㪏䋺㪛㪠㪩㪈㪶㪤㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㪉㪋㪅㪌㪎㪍㪤㪟㫑

䇭䊶䌒㪍㪈㪇䋺㪛㪠㪩㪈㪶㪣㪩㪚㪢䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪋㪋㪅㪈㪢㪟㫑

䇭䊶䌒㪍㪇㪐䋺㪛㪠㪩㪈㪶㪙㪚㪢㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪉㪅㪏㪉㪉㪋㪤㪟㫑

䇭䊶䌒㪍㪈㪈䋺㪛㪠㪩㪈㪶㪛㪘㪫㪘䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪈㪍㪹㫀㫋㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪍㪇㪏㪄㪍㪈㪈

㪥㪅㪞㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶㪠㪚㪌㪇㪉㩿㪏㪍㪀㫇㫀㫅䋺㩹㪟㩹䋿䇭㩿㪜㪯㪫㪶㪠㪥㪆㪬㪪㪙䋺㩹㪟㩹㪀

䇭䊶㪩㪍㪍㪋㩿㪝㪧㪞㪘㪶㪚㪋㪀䋺㩹㪟㩹䋿䇭䇭㩿㪜㪯㪫㪶㪠㪥䋺㩹㪣㩹㪀

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪍㪇㪏㪄㪍㪈㪈㪃㪠㪚㪌㪇㪉

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫀㫅㫇㫌㫋㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪇㩿㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫㪀

䇭䊶䌒㪍㪋㪈䋺㪤㪚㪢㪉㪶㪦㪬㪫㪶㪛㪘㪚䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㩷㩷㪉㪉㪅㪌㪎㪐㪉㪤㪟㫑

䇭䊶䌒㪍㪋㪋䋺㪮㪚㪢㪶㪦㪬㪫䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪎㪇㪌㪅㪍㪢㪟㫑

䇭䊶䌒㪍㪋㪉䋺㪧㪚㪤㪶㪙㪚㪢㩷㩷䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭䇭㪉㪉㪅㪌㪎㪐㪉㪤㪟㫑

䇭䊶䌒㪍㪋㪌㪃㪍㪋㪎䋺㪧㪚㪤㪶㪛㪘㪫㪘㪶㪣㪆㪶㪩㩷䇭䇭䇭䇭䇭䇭䇭㪊㪉㪹㫀㫋㩷㪠㪉㪪㩷㪽㫆㫉㫄㪸㫋

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪩㪍㪇㪏㪄㪍㪈㪈㪃㪠㪚㪌㪇㪉

㪥㪅㪞㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫎㫀㫋㪿㩷㫋㪿㪼㩷㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪧㪅㪮㪅㪙㪅㫌㫅㫀㫋㪅

㪏㪬㪄㪉㪈㪇㪇㪊㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀䇭䇭䇭䇭䇭䇭䇭㪚㪿㪼㪺㫂㩷㪘㪬㪛㪠㪦㩷㪛㪘㪫㪘㪆㪚㪣㪢

䇭䊶㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪚㪰㪉㪈㪈㩷㫊㫀㪾㫅㪸㫃㪅䇭䇭䇭㪚㪸㫊㪼㩷㫆㪽㩷㪧㪚㪤䋺㪮㪚㪢䇮㪙㪚㪢䇮㪪㪛㪘㪫㪘㪶㪣㪆㪶㪩

䇭䊶㪠㪚㪈㪇㪍㩷㩿㪋㪉㪀㩷㪺㪿㪼㪺㫂㩷㫋㪿㪼㩷㫆㫊㪺㫀㫃㫃㪸㫋㫀㫆㫅㩷㫀㫅㫇㫌㫋㪅䇭䇭䇭䇭䇭䇭䇭䋺㩷㪉㪉㪅㪌㪎㪐㪉㪤㪟㫑

㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪺㪸㪹㫃㪼㩷㪸㫅㪻㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㫆㪽㩷㫋㪿㪼㩷㪺㫆㫅㫅㪼㪺㫋㫆㫉㪅

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䇭䊶㪚㪰㪉㪈㪈

䇭䊶㪚㪯㪉㪈㪈㩷㪑㩷㪏㪬㪄㪊㪈㪇㪇㪋㪇

䇭䊶㪚㪯㪉㪈㪈㩿㪊㪀䋺㪤㪚㪢㪶㪚㪦㪥㪫䋺㩹㪟㩹䋿

㪥㪅㪞㪅

㪙㪼㫃㫆㫎㩷㫀㫊㩷㫋㪿㪼㩷㫊㪸㫄㪼㩷㪸㫊䇭㪛㪠㪫㪘㪣㪶㪙㪣㪦㪚㪢䋺㪚㪿㪼㪺㫂㩷㫋㪿㪼㩷㪘㪬㪛㪠㪦㩷㫊㫀㪾㫅㪸㫃㩷㫆㫌㫋㫇㫌㫋㪄㪈

㪦㪅㪢㪅

42

Page 43

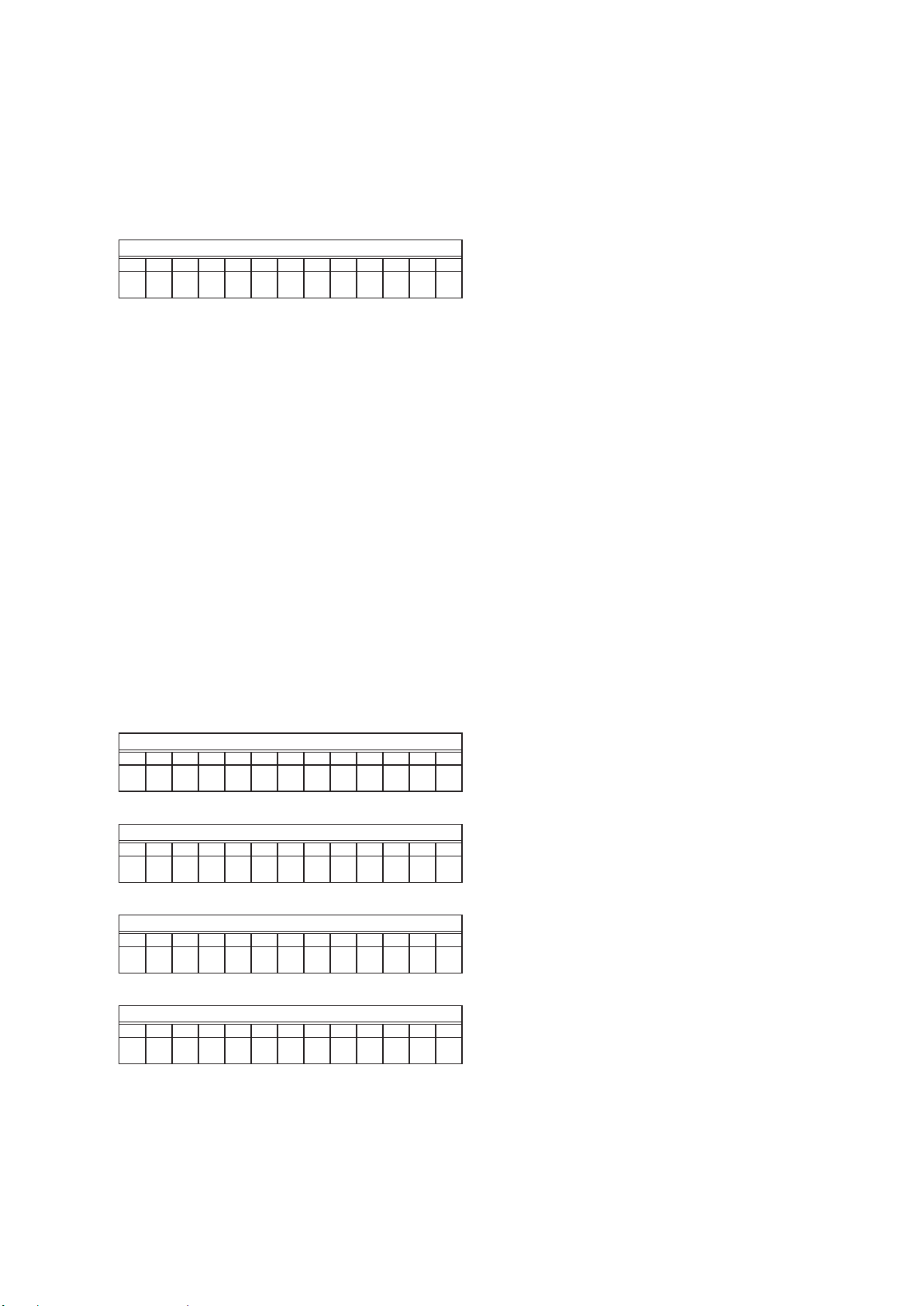

BLOCK DIAGRAM

䌄㫀㪾㪅㪠㪥 䌄㫀㪾㪅㪦㪬㪫

㪚㪰㪇㪊㪌

㪚㪰㪈㪏㪈

㪚㪯㪇㪎㪉

㪚㪯㪈㪏㪈

㪩㪪㪫㪆㪛㪠㪩㪶㪛㪠㪆㪚㪪㪆㪚㪝㪣㪬㪞

㪚㪰㪈㪋㪈 㪛㪠㪩㪶㪛㪦㪆㪚㪣㪢

㪤㪚㪢㩿㪈㪍㪅㪐㪊㪋㪋㪤

㪀

㪛㪤㪠㪯㪣

㪱㪛㪝㪣 㪛㪤㪠㪯㪩

㪛㪦㪬㪫 㪙㪚㪢㪃㪣㪩㪚㪢

㪱㪛㪝㪩 㪥㪩㪪㪫

㩿

㪪㪧㪛㪠㪝

㪀

㪘 㪦㪬㪫

㪦㪢 㪱㪛㪝㪚 㪛㪪㪘㪣㪪

㪚㪮㪇㪊㪌 㪱㪛㪝㪣㪝㪜 㪛㪪㪮

㪦㪢 㪱㪛㪝㪣㪪 㪛㪪㪘㪩㪪

㪱㪛㪝㪩㪪

㪚㪯㪇㪊㪈

㪛㪪㪧㪧㪮㪩

㪊㪧㪄㪭㪟 㩷 㪙㪚㪢㪘㪦

㪬㪪㪙㪩㪪㪫 㪛㪪㪧㪩㪪㪫

㪛㪪㪘㪚

㪚㪛㩷㩷㪛㪪㪧 㪛㪪㪧㪩㪦㪤㪩㪪㪫

㪛㪪㪘㪩

㪠㪆㪦 㪫㪚㪐㪋㪘㪐㪉㪝㪞㪄㪊㪇㪈 㪛㪪㪧㪚㪣㪢

㪚㪰㪇㪎㪉 㪛㪪㪘㪣

㪛㪠㪪㪧㩷㪻㪸㫋㪸㩿㪠㪉㪚

㪀

㪛㪪㪧㪤㪦㪪㪠

㪬㪪㪙 㪛㪜㪫 㪤㪧㪊

㪆㪮㪤㪘

㪛㪪㪧㪪㪠㪤㪦

㪚㪯㪇㪎㪊 㪚㪯㪈㪌㪈

㪛㪪㪧㪚㪪

㪬㪧㪛㪘㪫㪜

㪛㪪㪧㪝㪣㪘㪞㪇

㪧㪚㪤㪶㪛㪘㪫㪘㪇

㪛㪪㪧㪝㪣㪘㪞㪈

㪚㪯㪉㪋㪈 㪧㪚㪤㪶㪣㪩㪚㪢

㪧㪚㪤㪶㪙㪚㪢

㪛㪩㪭㪶㪤㪬㪫㪜㪈㪆㪉 㪪㪧㪛㪠㪝

㪙㪬㪪㪉㪙㪚㪢㪃㪣㪩㪚㪢

㪪㪤㪬㪫㪜 㪤㪦㪛㪜㪉

㪙㪬㪪㪊㪞㪘㪫㪜㪃㪛㪘㪫

㪘

㪚㪯㪇㪌㪊 㪤㪦㪛㪜㪊

㪙㪬㪪㪚㪢

㪦㪧㪜㪥㪶㪪㪮 㪤㪚㪢㪉 㪤㪚㪢㪉

㪙㪬㪪㪚㪜

㪚㪣㪦㪪㪜㪶㪪㪮

㪣㪛㪂 㪎㪪㪟㪬㪇㪋

㪛㪩㪠㪭㪜㩷㪤㪜㪚㪟㪘㩷㪬㪥㪠㪫 㪣㪛㪄 㪎㪪㪟㪬㪇㪋

㪤㪚㪢

㪚㪯㪈㪋㪈

㪬㪪㪙㪆㪤㪧㪬

㪤㪚㪣㪢

㪫㪤㪧㪐㪉㪚㪛㪉㪏㪘㪝㪞

㪫㪩㪚㪚㪣㪢

㪩㪦㪤㪆㪩㪘㪤㪑㪌㪈㪉㪢㪆㪉㪇

㪢

㪛㪘㪚㪚㪢

㪎㪮㪟㪬㪇㪋

㪬㪪㪙㪑㪉㪌㪍㪢

㪛㪝㪩㪪㪫

㩷 㪚㪛㪑㪉㪇㪢 㪠㪉㪚 㪚㪧

㪛㪂

㪤㪝㪠㪊㪋㪈㪪㪉㪈㪍㪈

㪬㪪㪙 㪛㪄

㪣㪘㪈

㪣㪘㪉

㪐㪤㪟㫑

㪣㪘㪊

㪣㪮㪩

㪣㪛㪇㪄㪈㪌 㪚㪪㪈

㪣㪦㪜

㪛㪘㪚㩷㪺㫆㫅㫋㫉㫆㫃

㩿㪛㪘㪃㪚㪢㪃㪚㪪㪀

㪤㪬㪫㪜

㪚㪯㪇㪌㪈

㪚㪯㪇㪊㪋 㪚㪯㪈㪇㪈 㪚㪯㪉㪈㪈 㪤㪪

㪚㪯㪇㪎㪈 㪤㪚

㪊㪧㩷㪭㪟 㪤㪛㪠 㪚㪰㪇㪌㪈 㪬㪪㪙┵ሶ

㪩㪜㪪㪜㪫

㪚㪰㪉㪈㪈 㪤㪦㪛㪜㪊

㪚㪯㪇㪏㪈

㪚㪯㪇㪊㪊 㪚㪯㪇㪊㪉 㪛㫀㪾㫀㩷㪦㪬㪫

㪚㪰㪈㪇㪈 㪤㪬㪫㪜

㪤㪚㪢㪉

㪚㪰㪇㪎㪈 㪤㪦㪛㪜㪊

㪤㪚㪢

㪧㪚㪤㪆㪛㪪㪛㪶㪤㪚㪢

㪣㪜㪛㪊㪒㩷㪦㪥

㪣㪜㪛㪋㪒㩷㪪㪫㪘㪥㪛㪙㪰 㪣㪺㪿

㪚㪮㪇㪊㪎 㪚㪯㪇㪊㪎 㪛㪪㪛㪶㪙㪚㪢

㪧㪚㪤㪄㪣㪺㪿

㩿㪩㪼㫄㫆㪺㫆㫅㪀

㪛㪪㪛㪄㪣㪺㪿

㪣㪜㪛㪈㪒㩷㪘㪛㩷㪘㪣㪊㪉 㪮㪚㪢㪆㪛㪪㪛㪄㪣㩾㪺㪿 㪩㪺㪿

㪣㪜㪛㪉㪒㩷㪪㪘㪚㪛 㪚㪯㪇㪌㪉 㪚㪰㪇㪌㪉 㪧㪚㪤㪄㪙㪚㪢

㪤㪪

㪤㪛㪠

㪚㪰㪇㪊㪋 㪚㪯㪇㪊㪏 㪚㪛㪫㪠

㪊㪧㩷㪭㪟 㪧㪛㪥㩷㩿㪩㪪㪫㪀

㪧㪦㪮㪜㪩㩷㪪㪮㩷㪬㪥㪠㪫

㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫

㪤㪸㫊㫋㪼㫉

㪚㫃㫆㪺㫂

㪉㪉㪅㪌㪎㪐㪉㪤㩿㪌㪈㪉㪝㪪㪀

㪓㪝㪣㩷㪛㫀㫊㫇㫃㪸㫐㪕

㪤㪦㪛㪜㪈

㪧㪦㪮㪜㪩㩷㪣㪜㪛㩷㪬㪥㪠㪫

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪌

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪈

㪫㪚㪎㪪㪱㪈㪉㪌㪝

㪙㪩㪉㪋㪣㪊㪉

㪜㪜㪧㪩㪦㪤

㪉㪎㪤㪟㫑

㪚㪧㪬

㩿㪙㪆㪜㪀

㪜㪤㪍㪊㪏㪈㪍㪌

㪍㪋㪤

㪪㪛㪩㪘㪤

㪤㪯㪉㪐㪣㪭㪊㪉㪇

㪈㪍㪤

㪝㪣㪘㪪㪟㩷㪩㪦㪤

㪠㪥㪫㪅㪧㪣㪣

㪩㪝㩷㪘㫄㫇

㪚㪧㪬

㩿㪝㪆㪜㪀

㪊㪉㪙㪠㪫㩷㪛㪘㪚

㪘㪢㪋㪊㪐㪐

㪝㪣㩷㪛㫉㫀㫍㪼㫉㩷㪒㩷㪧㪫㪍㪊㪇㪉

㪛㪠㪪㪧㪣㪘㪰㩷㪬㪥㪠㪫

㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪎

㪘㪥㪘㪣㪦㪞㩷㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪊

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪉

㪝㫉㫆㫅㫋

㪜㫅㪻

㪈㪍㪤

㪛㪩㪘㪤

㪙㪩㪉㪋㪣㪊㪉

㪜㪜㪧㪩㪦㪤

㫖

㪝㪧㪞㪘

㪜㪧㪊㪚㪈㪍

㪚㪯㪛㪉㪎㪌㪊

㪛㪪㪛

㪛㪜㪚㪦㪛㪜㪩

㪤㪦㪛㪜㪊 㪧㪚㪤㪆㪛㪪㪛 㪤㪧㪊

㪛㪭㪛㩷㪧㪩㪦㪚㪜㪪㪪㪦㪩

㪤㪥㪉㪛㪪㪇㪇㪇㪐

㪙㪛㪎㪐㪌㪍

㪘㪚㪫㪆㪪㪧

㪣㫆㪸㪻㫀㫅㪾

㪛㪩㪠㪭㪜㪩

㪚㪣㪢㩷㫀㫊㩷㫊㫎㫀㫋㪺㪿㪼㪻

㪩㪜㪪㪜㪫

㪠㪚

㫊㫐㫊㫋㪼㫄㩷㫌㪄㪺㫆㫄

㪤㪊㪇㪍㪉㪋㪣㪝㪞㪧

㪘㪬㪛㪠㪦

㩿㪧㪚㪤㪀

㪛㪭㪊㪅㪉

㪛㪯㪧㪍㪇㪇㪈㪤㪦㪛㪜㪉 㪋㪋㪅㪈㪆㪋㪏 㪊㪉

㪧㪚㪤 㪛㪪㪛㪆㪤㪧㪊㪤㪦㪛㪜㪈

㪤㪦㪛㪜 㪧㪚㪤 㪛㪪㪛 㪩㫆㫌㫋㪼㩷㫀㫊㩷㫊㫎㫀㫋㪺㪿㪼㪻

㪬㫊㪼㩷㫇㪸㫉㫋

㪬㪪㪙㩷㪬㪥㪠㪫

㪏㪬㪄㪉㪈㪇㪇㪏㪊㪄㪍

㪛㪪㪧㩷㪛㪠㪞㪠㪫㪘㪣㩷㪠㪦㩷㪬㪥㪠㪫

㪏㪬㪄㪉㪈㪇㪇㪏㪋

㪘㪛㪪㪧㪉㪈㪊㪍㪎

㪛㪪㪧

㩿㪽㫆㫉

㪩㪜㪪㪫㪦㪩㪜㪩㪀

㪪㪛㪩㪘㪤

㪝㪣㪘㪪㪟

㪩㪦㪤

㪣㪚㪏㪐㪇㪌㪏

㪛㪠㪩

㩿㪽㫆㫉㩷㪜㪯㪫㩷㪪㪼㫃㪀

㪪㪘㪚㪛㩷㪤㪦㪛㪬㪣㪜㩷㪬㪥㪠㪫

㪏㪬㪄㪊㪈㪇㪇㪋㪇

㪣㪟

STAND BY

TRANS

ANALOG

TRANS

DIGITAL

TRANS

43

Page 44

---MEMO---

44

Page 45

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

MN2DS0009VP (310040 : IC107)

Terminal Function

Pin No. Pin Name Type Symbol Function

1 MDQ18 I/O SDRAM DATA18 SDRAM data 18

2 VSS - GND GND

3 VDD33 - 3.3V I/O supply

4 MDQ28 I/O SDRAM DATA28 SDRAM data 28

5 MDQ19 I/O SDRAM DATA19 SDRAM data 19

6 MDQ27 I/O SDRAM DATA27 SDRAM data 27

7 MDQ20 I/O SDRAM DATA20 SDRAM data 20

8 VDD33 - 3.3V I/O supply

9 VSS - GND GND

10 MDQ26 I/O SDRAM DATA26 SDRAM data 26

11 MDQ21 I/O SDRAM DATA21 SDRAM data 21

12 MDQ25 I/O SDRAM DATA25 SDRAM data 25

13 MDQ22 I/O SDRAM DATA22 SDRAM data 22

14 MDQ24 I/O SDRAM DATA24 SDRAM data 24

15 MDQ23 I/O SDRAM DATA23 SDRAM data 23

16 VSS - GND GND

17 VDD33 - 3.3V I/O supply

18 EXADTO I/O EXT ADRC External memory address 0 / data 0

19 NEXCE O EXT CE External memory chip select

20 NEXOE O EXT OE External memory output enable

21 VSS - GND GND

22 VDD12 - 1.2V Logic supply

23 EXDTO I/O EXT MEMORY DATA0 External memory data 0

24 EXDT8 I/O EXT MEMORY DATA8 External memory data 8

25 EXDT1 I/O EXT MEMORY DATA1 External memory data 1

26 EXDT9 I/O EXT MEMORY DATA9 External memory data 9

27 EXDT2 I/O EXT MEMORY DATA2 External memory data 2

28 EXDT10 I/O EXT MEMORY DATA10 External memory data 10

29 EXDT3 I/O EXT MEMORY DATA3 External memory data 3

30 EXDT11 I/O EXT MEMORY DATA11 External memory data 11

31 EXDT4 I/O EXT MEMORY DATA4 External memory data 4

32 EXDT12 I/O EXT MEMORY DATA12 External memory data 12

33 EXDT5 I/O EXT MEMORY DATA5 External memory data 5

34 VSS - GND GND

35 VDD33 - 3.3V I/O supply

36 EXDT13 I/O EXT MEMORY DATA13 External memory data 13

37 EXDT6 I/O EXT MEMORY DATA6 External memory data 6

38 EXDT14 I/O EXT MEMORY DATA14 External memory data 14

39 EXDT7 I/O EXT MEMORY DATA7 External memory data 7

40 EXDT15 I/O EXT MEMORY DATA15 External memory data 15

41 EXADR161 I/O EXT ADR16 External memory address 16

42 EXADT152 I/O EXT ADT15 External memory address 15 / data 8

43 EXADT142 I/O EXT ADT14 External memory address 14 / data 1

44 VSS - GND GND

45 VDD12 - 1.2V Logic supply

46 EXADT13 I/O EXT ADR13 External memory address 13 / data 9

47 EXADT12 I/O EXT ADR12 External memory address 12 / data 2

48 EXADT11 I/O EXT ADR11 External memory address 11 / data 10

49 EXADT10 I/O EXT ADR10 External memory address 10 / data 3

50 EXADT9 I/O EXT ADR9 External memory address 9 / data 11

51 EXADT8 I/O EXT ADR8 External memory address 8 / data 4

52 VSS - GND GND

53 VDD33 - 3.3V I/O supply

54 EXADR19 I/O EXT ADR19 External memory address 19

55 NEXWE O EXT WE External memory write enable

56 EXADR183 I/O EXT ADR18 External memory address 18

57 EXADR174 I/O EXT ADR17 External memory address 17

45

Page 46

Pin No. Pin Name Type Symbol Function

58 EXADT7 I/O EXT ADR7 External memory address 7 / data 12

59 EXADT6 I/O EXT ADR6 External memory address 6 / data 5

60 EXADT5 I/O EXT ADR5 External memory address 5 / data 13

61 EXADT4 I/O EXT ADR4 External memory address 4 / data 6

62 EXADT3 I/O EXT ADR3 External memory address 3 / data 14

63 EXADT2 I/O EXT ADR2 External memory address 2 / data 7

64 EXADT1 I/O EXT ADR1 External memory address 1 / data 15

65 P0 I/O EXT ADR20 External memory address 20

66 P1 I/O SDA Serial 0 output data

67 P2 I/O SCL Serial 0 clock

68 VSS - GND GND

69 VDD33 - 3.3V I/O supply

70 P3 I/O SYSRXD Serial 1 input data

71 P4 I/O SYSTXD Serial 1 output data

72 P5 I/O REMO/INTST External interrupt 2

73 P6 I/O V-CS Serial 2 input data

74 P7 I/O V-DATA Serial 2 output data

75 P8 I/O V-CLK Serial 2 clock

76 P9 I/O MSDATAI Serial 3 input data

77 P10 I/O MSDATAO Serial 3 output data

78 P11 I/O MSCLK Serial 3 clock

79 P12 I/O CS1 Extension chip select

80 P13 I/O SACD-READY Serial 3 data receipt flag

81 P14 I/O MSLAT Serial 3 data transmit flag

82 VSS - GND GND

83 VDD12 - 1.2V Logic supply

84 NRST I RESET Master reset

85 FG I/O FG-IN System ucom port 21

86 DRV5 I/O CD/DVD System ucom port 15

87 DRV4 I/O IN_SW System ucom port 16

88 DRV3 I/O HFM_ON/OFF System ucom port 17

89 DRV2 I/O TRY_DRV System ucom port 18

90 DRV1 I/O SP_DRV System ucom port 19

91 DRVO I/O SL_DRV System ucom port 20

92 VSS - GND GND

93 VDD33 - 3.3V I/O supply

94 MONl7 I/O PSP-MCK/MONI7 System ucom port 22

95 MONl6 I/O PSP-WAD7/MONI6 System ucom port 23

96 MONl5 I/O PSP-WAD6/MONI5 System ucom port 24

97 MONl4 I/O PSP-WAD5/MONI4 System ucom port 25

98 MONl3 I/O PSP-WAD4/MONI3 System ucom port 26

99 MONl2 I/O PSP-WAD3/MONI2 System ucom port 27

100 MONl1 I/O PSP-WAD2/MONI1 System ucom port 28

101 MONlO I/O PSP-WAD1/MONI0 System ucom port 29

102 AVDDD - 3.3V Analog supply

103 PLF1L1 O PLFIL1 External filter for DRC-VCO

104 AVSSD - GND Analog GND

105 VREFH7 O V-REF-H7 ADC reference voltage for DRC (TOP)

106 VREFL7 O V-REF-L7 ADC reference voltage for DRC (BTM)

107 CCAPA O CCAPA Inline filter for CAPA block

108 AVSSC - GND Analog GND

109 CDATA O CDATA Inline filter for DATA block

110 AVDDG - 3.3V Analog supply

111 ANAMONl1 O TP_ANAMONI1 Internal analog monitor 1

112 ANAMONI2 O TP_ANAMONI2 Internal analog monitor 2

113 RFINN I RFINN External RF input (-)

114 RFINP I RFINP External RF input (+)

115 VINIRF I VIN1RF RF input 1

116 VIN2RF I VIN2RF RF input 2

117 VIN4RF I VIN4RF RF input 4

118 VIN3RF I VIN3RF RF input 3

119 AVDDB - 3.3V Analog supply

120 VREFH5 I V-REF-H5 5 bit AD reference Voltage "H"

121 VREFL5 I V-REF-L5 5 bit AD reference Voltage "L"

122 AVSSB - GND Analog GND

123 LPC1 I LPC1 DVD LPC input

124 LPCO1 O LPCO1 DVD LPC output

46

Page 47

Pin No. Pin Name Type Symbol Function

125 LPC2 I LPC2 CD LPC input

126 LPCO2 O LPCO2 CD LPC output

127 VREFH O V-REFH Reference Voltage 2.20V output

128 VHALF O V-HALF Reference Voltage 1.65V output

129 VIN10 I VIN10 CD head input

130 VIN9 I VIN9 CD head input

131 VIN5 I VIN5 CD head input

132 VIN6 I VIN6 CD head input

133 VIN7 I VIN7 DVD head input

134 VIN8 I VIN8 DVD head input

135 VIN3 I VIN3 DVD head input

136 VIN4 I VIN4 DVD head input

137 VIN2 I VIN2 DVD head input

138 VIN1 I VIN1 DVD head input

139 ADO I KEY0 Servo AD input 0

140 AD1 I KEY1 Servo AD input 1

141 AD2 I IOP_CHECK(CD/DVD) Servo AD input 2

142 AD4 I REG Servo AD input 4

143 AVSSH - GND Analog GND

144 PWM1 O TR_DRV Tracking drive output

145 PWMO O FO_DRV Focus drive output

146 AVDDH - 3.3V Analog supply

147 DAC3OUT O OPEN Cr/R analog video output

148 DAC2OUT O OPEN Cb/B analog video output

149 DAC1OUT O OPEN Y/G analog video output

150 AVDDF - 3.3V Analog supply for VDAC

151 COMP1 I COMP1 Compensation pin for DAC1

152 VREF I VREF Reference Voltage for DAC

153 IREF1 I IREF1 Bias current adjust pin for DAC

154 COMP2 I COMP2 Compensation pin for DAC2

155 AVSSF - GND Analog GND for VDAC

156 DAC4OUT O OPEN Y/Comp analog video output

157 DAC5OUT O OPEN C analog video output

158 AVDDE - 3.3V Analog supply for PLL

159 AVSSE - GND Analog GND for PLL

160 AVDDG - 3.3V Analog supply for PLL

161 AVSSG - GND Analog GND for PLL

162 OSCl I OSC-IN Oscillator input (27MHz)

163 OSCO O OSC-OUT Oscillator output (27MHz)

164 VSS - GND GND

165 VDD12 - 1.2V Logic supply

166 DACCK I/O MCK/SD7 Stream data output 7

167 LRCK O LRCK/SD6 Stream data output 6

168 SRCK O BCK/SD5 Stream data output 5

169 ADOUT3 O MIXLR/SD4 Stream data output 4

170 ADOUT2 I/O DATA2/SD3 Stream data output 3

171 ADOUT1 I/O DATA1/SD2 Stream data output 2

172 ADOUTO I/O DATA0/SD1 Stream data output 1

173 IECOUT O SPDIF/SD0 Stream data output 0

174 VSS - GND GND

175 VDD33 - 3.3V I/O supply

176 VDIO7 I/O DXP_CS CS for DXP6001

177 VDIO6 I/O DXP_RST RST for DXP6001

178 VDIO5 I/O DXP/DSD_DI DATA for DXP6001 and DSD1796

179 VDIO4 I/O DXP/DSD_CL CLOCK for DXP6001 and DSD1796

180 VDI03 I/O DSD_CS CS for DSD1796

181 VDIO2 I/O DSD_RST RST for DSD1796

182 VDI01 I/O SMUTE SMUTE for CXD2753

183 VDIOO I/O IO_RST RST for CXD2753

184 VDD33 - 3.3V I/O supply

185 VSS - GND GND

186 EXTRG1 I/O OPEN Video clock output

187 SCLOCK I SCLOCK Input clock for debug

188 SDATA I/O SDATA Input/output data for debug

189 EXTRGO I/O PDETECT/EXTRGO System ucom port 41

190 TRCCLK I/O CLK33M Master clock for External AVDEC

191 TRCDATAO I/O SDEF System ucom port 44

47

Page 48

Pin No. Pin Name Type Symbol Function

192 TRCDATA1 I/O XSAK System ucom port 45

193 TRCDATA2 I/O SDCK System ucom port 46

194 TRCDATA3 I/O XSHD System ucom port 47

195 TRCST I/O XSRQ System ucom port 48

196 VSS - GND GND

197 VDD33 - 3.3V I/O supply

198 MDQ15 I/O SDRAM DATA15 SDRAM data 15

199 MDQO I/O SDRAM DATA0 SDRAM data 0

200 MDQ14 I/O SDRAM DATA14 SDRAM data 14

201 MDQ1 I/O SDRAM DATA1 SDRAM data 1

202 MDQ13 I/O SDRAM DATA13 SDRAM data 13

203 MDQ2 I/O SDRAM DATA2 SDRAM data 2

204 VDD33 - 3.3V I/O supply

205 VSS - GND GND

206 MDQ12 I/O SDRAM DATA12 SDRAM data 12

207 MDQ3 I/O SDRAM DATA3 SDRAM data 3

208 MDQ11 I/O SDRAM DATA11 SDRAM data 11

209 MDQ4 I/O SDRAM DATA4 SDRAM data 4

210 MDQ10 I/O SDRAM DATA10 SDRAM data 10

211 MDQ5 I/O SDRAM DATA5 SDRAM data 5

212 MDQ9 I/O SDRAM DATA9 SDRAM data 9

213 MDQ6 I/O SDRAM DATA6 SDRAM data 6

214 VDD33 - 3.3V I/O supply

215 VSS - GND GND

216 MDQ8 I/O SDRAM DATA8 SDRAM data 8

217 MDQ7 I/O SDRAM DATA7 SDRAM data 7

218 VDD12 - 1.2V Logic supply

219 DQMO O SDRAM DATA MASK0 SDRAM data mask 0

220 DQM1 O SDRAM DATA MASK1 SDRAM data mask 1

221 NWE O SDRAM WE Write enable for SDRAM

222 VSS - GND GND

223 MCK O SDRAM MCK Output clock for SDRAM

224 VDD33 - 3.3V I/O supply

225 MCKl I SDRAM MCK_RTN Input clock from SDRAM

226 VSS - GND GND

227 NCAS O SDRAM CAS Column address strobe for SDRAM

228 NRAS O SDRAM RAS Row address strobe for SDRAM

229 NCSM O SDRAM CS Chip select for SDRAM

230 MA11 I/O SDRAM ADDRESS11 SDRAM address 11

231 BAO O SDRAM BA0 SDRAM bank address 0

232 MA9 O SDRAM ADDRESS9 SDRAM address 9

233 VSS - GND GND

234 VDD12 - 1.2V Logic supply

235 BA1 O SDRAM BA1 SDRAM bank address 1

236 MA8 O SDRAM ADDRESS8 SDRAM address 8

237 MA10 O SDRAM ADDRESS10 SDRAM address 10

238 VSS - GND GND

239 VDD33 - 3.3V I/O supply

240 MA7 O SDRAM ADDRESS7 SDRAM address 7

241 MAO O SDRAM ADDRESS0 SDRAM address 0

242 MA6 O SDRAM ADDRESS6 SDRAM address 6

243 MA1 O SDRAM ADDRESS1 SDRAM address 1

244 MA5 O SDRAM ADDRESS5 SDRAM address 5

245 MA2 O SDRAM ADDRESS2 SDRAM address 2

246 MA4 O SDRAM ADDRESS4 SDRAM address 4

247 MA3 O SDRAM ADDRESS3 SDRAM address 3

248 VSS - GND GND

249 VDD33 - 3.3V I/O supply

250 DQM2 I/O SDRAM DATA MASK2 SDRAM data mask 2

251 DQM3 I/O SDRAM DATA MASK3 SDRAM data mask 3

252 MDQ31 I/O SDRAM DATA31 SDRAM data 31

253 MDQ16 I/O SDRAM DATA16 SDRAM data 16

254 MDQ30 I/O SDRAM DATA30 SDRAM data 30

255 MDQ17 I/O SDRAM DATA17 SDRAM data 17

256 MDQ29 I/O SDRAM DATA29 SDRAM data 29

48

Page 49

EP3C16F256C8N (310040 : IC510)

Terminal Function

PINNo. Location Dir. Pin Name

1 A1 POWER 3.3V

2 A2 bidir EMPHASIS

3 A3 bidir S_TEST_4

4 A4 INPUT /INT_EXT

5 A5 INPUT DAC_DATA_IN

6 A6 INPUT DAC_CS_IN

7 A7 INPUT DAC_CK_IN

8 A8 INPUT TEST1

9 A9 INPUT OCXO_IN

10 A10 OUTPUT TEST6

11 A11 OUTPUT DFRST

12 A12 OUTPUT MDT

13 A13 INPUT DSD_MUTE_O

14 A14 OUTPUT DAC_CS_OUT

15 A15 INPUT SPDIF_IN

16 A16 POWER 3.3V

17 B1 INPUT FPGA_C4

18 B2 GND GND

19 B3 bidir S_TEST_5

20 B4 OPEN GND*

21 B5 OPEN GND*

22 B6 OPEN GND*

23 B7 OPEN GND*

24 B8 INPUT TEST2

25 B9 INPUT DIR_MCK_IN

26 B10 OUTPUT TEST7

27 B11 OUTPUT MCLK

28 B12 INPUT DAC_CONT_SEL

29 B13 INPUT DAC_RST_IN

30 B14 OPEN GND*

31 B15 GND GND

32 B16 OPEN GND*

33 C1 CONFIG ~ALTERA_ASDO_DATA1~

34 C2 INPUT FPGA_C3

35 C3 bidir S_TEST_3

36 C4 POWER 3.3V

37 C5 GND GND

49

Page 50

PINNo. Location Dir. Pin Name

38 C6 OPEN GND*

39 C7 POWER 3.3V

40 C8 OPEN GND*

41 C9 OPEN GND*

42 C10 POWER 3.3V

43 C11 OPEN GND*

44 C12 GND GND

45 C13 POWER 3.3V

46 C14 OPEN GND*

47 C15 INPUT PDATA0

48 C16 INPUT PLRCK

49 D1 INPUT FPGA_C1

50 D2 CONFIG ~ALTERA_FLASH_nCE_nCSO~

51 D3 OPEN GND*

52 D4 POWER 1.2V

53 D5 OPEN GND*

54 D6 OPEN GND*

55 D7 GND GND

56 D8 OPEN GND*

57 D9 OPEN GND*

58 D10 GND GND

59 D11 OPEN GND*

60 D12 OUTPUT SLAVE_MCK

61 D13 POWER 1.2V

62 D14 OPEN GND*

63 D15 INPUT /IO_RST

64 D16 OPEN GND*

65 E1 INPUT FS1

66 E2 INPUT FS0

67 E3 POWER 3.3V

68 E4 GND GND

69 E5 GND GND

70 E6 OPEN GND*

71 E7 OPEN GND*

72 E8 OPEN GND*

73 E9 OPEN GND*

74 E10 OPEN GND*

75 E11 OPEN GND*

76 E12 GND GND

77 E13 GND GND

78 E14 POWER 3.3V

79 E15 GND GND+

80 E16 GND GND+

81 F1 OPEN GND*

82 F2 OPEN GND*

83 F3 OPEN GND*

84 F4 CONFIG nSTATUS

85 F5 POWER 2.5V

86 F6 GND GND

87 F7 POWER 1.2V

88 F8 OPEN GND*

89 F9 OPEN GND*

90 F10 GND GND

91 F11 POWER 1.2V

92 F12 POWER 2.5V

93 F13 OPEN GND*

50

Page 51

PINNo. Location Dir. Pin Name

94 F14 OUTPUT DSD_CONT

95 F15 OUTPUT DSD_BCK_O

96 F16 OUTPUT ~ALTERA_nCEO~

97 G1 INPUT FPGA_C2

98 G2 OPEN GND*

99 G3 POWER 3.3V

100 G4 GND GND

101 G5 OPEN GND*

102 G6 POWER 1.2V

103 G7 POWER 1.2V

104 G8 POWER 1.2V

105 G9 POWER 1.2V

106 G10 POWER 1.2V

107 G11 OPEN GND*

108 G12 CONFIG MSEL2

109 G13 GND GND

110 G14 PO WER 3 .3V

111 G15 INPUT DSD_SW

112 G16 INPUT DSD_SL

113 H1 OUTPUT ~ALTERA_DCLK~

114 H2 CONFIG ~ALTERA_DATA0~

115 H3 JTAG TCK

116 H4 JTAG TDI

117 H5 CONFIG nCONFIG

118 H6 POWER 1.2V

119 H7 GND GN D

120 H8 GND GND

121 H9 GND GND

122 H10 GND GND

123 H11 POWER 1.2V

124 H12 CONFIG MSEL1

125 H13 CONFIG MSEL0

126 H14 CONFIG CONF_DONE

127 H15 INPUT DSD_FR

128 H16 INPUT DSD_C

129 J1 INPUT AUDIO

130 J2 INPUT ERROR

131 J3 CONFIG nCE

132 J4 JTAG TDO

133 J5 JTAG TMS

134 J6 POWER 1.2V

135 J7 GND GND

136 J8 GND GND

137 J9 GND GND

138 J10 GND GND

139 J11 GND GND

140 J12 OPEN GND*

141 J13 OPEN GND*

142 J14 OPEN GND*

143 J15 INPUT DMIX_R

144 J16 INPUT DSD_FL

145 K1 INPUT DIR_DATA_IN

146 K2 INPUT DIR_LRCK_IN

147 K3 POWER 3.3V

148 K4 GND GND

149 K5 OPEN GND*

51

Page 52

PINNo. Location Dir. Pin Name

150 K6 OPEN GND*

151 K7 POWER 1.2V

152 K8 GND GND

153 K9 OPEN GND*

154 K10 OPEN GND*

155 K11 POWER 1.2V

156 K12 OPEN GND*

157 K13 GND GND

158 K14 POWER 3.3V

159 K15 OPEN GND*

160 K16 INPUT DMIX_L

161 L1 INPUT DIR_BCK_IN

162 L2 OUTPUT SPDIF_OUT1

163 L3 OPEN GND*

164 L4 OPEN GND*

165 L5 POWER 2.5V

166 L6 OPEN GND*

167 L7 OPEN GND*

168 L8 OPEN GND*