DEMI Part Number L70-28CK and K

Power Out Maximum:

Nominal 25 W linear

Noise Figure and Gain:

>1.0 dB maximum @ 17 dB conversion gain minimum

DC Power Requirement:

11.5 - 15.5 VDC @ 6 Amp Max.

IF Drive Level Maximum:

Range Selectable between -20dBm and 25 watts

Keying Option with/ without Sequencer:

PTT-L ( to ground) or PTT – H ( Positive Voltage)

User Installed Options:

IF Drive Sense , Negative Voltage Gen., Cooling Fan

Sequencer, External Local Oscillator

Transverter Specifications

Configuration Overview:

operate with most High Frequency transceivers that are available on the market today. Since you

choose to purchase a kit version, you may configure it to your specifications and interface it with

your desired transceiver. This configuration may be changed or altered at any time if you desire to

utilize a different transceiver or change you system’s configuration.

DEMI Part Number Verification: All DEMI VHF/UHF transverters contain the operating

frequency within the part number, i.e., 70-28CK or K is equated to 70 MHz being converted to 28

MHz. Understand that the conversion is simple math. If you desire to operate on 71.500 MHz. with

your 70-28, it will require you to adjust you transceiver to 29.500 MHz.

The DEMI VHF/UHF transverter line is designed to interface and

Power Out Maximum: The maximum linear

should not be exceeded if linear operation is expected. The transverter may be capable of

producing higher output power but is not recommended because of excessive heating that will

interfere with its frequency stability while producing excessive “on the air” distortion products

Noise Figure and Gain: The noise figure and gain listed are nominal minimum requirements

and all transverters will exceed these specifications if assembled and adjusted correctly. In utilizing

the latest PHEMPT technology, we have designed the complete receive section of the transverter

with extra filtering, diplexing, and gain management in mind complete with a RXIF gain control.

DC Power Requirement: The DC power requirement is listed and should be used as a guideline.

Please include some “Buffer” in your power supply to eliminate voltage drop delivered to the

transverter. Basically, do not utilize a 6-amp power supply for a 6-amp requirement transverter.

RF Option: The 50 Mhz. RF section may be configured with either a single port (Common RF) for

both TX and RX or two separate ports, (Split RF) one RX and one TX. There is a PC board relay

/Kits/L70-28CK.doc 1 Rev. A 4/21/2011

output power indicated on this kit is 25W. This level

doing the Common RF switching. Once configured, the unit may be changed from Comm o n to Spli t

RF if the user desires. It will be covered in the manual.

IF Option: The IF (28 Mhz.) configuration options may be set up as Split IF (separate TXIF and

RXIF in/out lines) or can be configured as a Common IF. There is a relay that will switch the RX

and TX in the correct direction and is controlled by the PTT circuit.

IF Drive Level Maximum: After configuration, the transverter will operate at its maximum output

power with any drive level between -20dBm and 25 watts. The overall drive level range is

determined by different attenuators and/or gain stages if required. The TXIF gain control with 15-20

dB of dynamic range will allow the user to tailor a specific output power less than maximum.

Keying Option: The keying options are either PTT-L or PTT-H. PTT-L requires a connection

to Ground to transmit. This is the most common keying option. PTT-H requires a voltage between

1.7 and 17VDC to transmit. This option can also be placed on the IF coax if desired. If you desire

the sequencer to be utilized, the PTT connection will go directly to the sequencer to key it. In turn,

it will key the transverter on the last step of the sequence. Now doing so creates other caveats if

you choose to use a High IF drive level (above 1/2W). This is covered in the next section.

User installed Options:

The IF Drive Sense option should be i nstalled for any Common IF drive

level above 100 mW. This circuit is a protection circuit that will prevent excessive IF drive levels

from damaging the RXIF circuitry and the Mixer. When utilizing a high- level IF drive transceiver,

the IF drive from your transceiver may be applied to the transverter at the same time as the PTT is

energized. If the transverters sequencer is utilized, the transverter will be keyed last in the

sequence. This would resu l t in the high level IF drive being applied to the transverter’s RXIF

section which would cause the damage. With the IF drive sense circuit installed, it detects the highlevel drive and enables the TXIF attenuator. This protects the transverter’s RXIF section and Mixer.

It then holds and waits for the Transverter to “Catch up” in the sequence. This circuit will allow a

user to key the sequencer circuit with the standard PTT circuit of a transceiver without having an

issue or requiring external wiring and modifications to the transceivers PTT circuit. This circuit will

also protect the transverter in case the PTT circuit fails between the transverter and the

transceiver. If the transverter is keyed directly with the PTT (sequencer is disabled) it will function

normally. CAUTION: The IF drive sense circuit should not be used to key the sequencer because it

will produce long delays between transmit and receive or chop off the beginning of a transmission.

The transverter’s IF drive sense was desig ne d for pr otect ion only.

The Negative Voltage option may be utilized by

transceivers withou t transverter ports

but with ALC inputs to adjust the output power of the transceiver. If the transceiver has an ALC

input, this connection can be made through the AUX connecter and will be indicated.

The Cooling Fan should be installed and used with the tem per ature sense circuit because it

is crucial for frequency stability in digital modes. As the temperature increases the fan speed will

increase to provide the additional cooling and frequency stability.

/Kits/L70-28CK.doc 2 Rev. A 4/21/2011

R1 1K

R20 330

R37 220

R53 470

R69 10K

R2 470

R21 150 ½ LEAD

R38 1K POT

R54 10K

R70 10K

R3 470

R22 51

R39 220

R55 10K

R71 10K

R4 1.5K

R23 470

R40 220

R56 10K

R72 1M

R5 100

R24 1K

R41 10K

R57 10K

R73 10K

R6 51

R26 51

R42 10K

R58 1M

R75 100

R7 100

R27 5.6

R43 470

R59 10K

R76 51

R8 470

R28 51

R44 10K

R60 220

R77 1K

R9 5.6K

R29 51

R45 220K

R61 10K

R78 220

R10 10K

R30 51

R46 1M

R62 10K

R81 5.6K

R11 220

R31 12

R47 10K

R63 1M

R82 5.6K

R12 330

R32 51

R48 10K

R64 10K

R84 5.6K

R14 330

R33 1K

R49 1K

R65 220

R85 470

R15 12

R34 330

R50 5.6K

R66 10K

560,390,0 ohm

R17 470

R35 220

R51 5.6K

R67 10K

R19 470

R36 1K POT

R52 22K

R68 1M

The Sequencer is a 4 step circuit that may be used to key any external devices and the

transverter itself. It may be configured in any fashion and set up to switch external voltages such

as a 24 VDC relay. The voltage may be run into the transverter through the AUX connector and

switched through the sequencer.

The transverter has a provision for an External Local Oscillator connection. This will be

discussed in the text and explained how to either configure a future Synthesized LO or use an

external one of your own design.

The KIT Details: This assembly manual calls out a reference to one or two picture numbers for

most assembly procedures. The pictures can be found on our website in the “Product Manuals”

section. It is a full copy of this manual with all numbered pictures at the end of the document in

.PDF format. You may down load a complete copy of this document or just reference the pictures.

You will find that the details offered in the pictures will aid any assemble instruction.

The following component list contains both pre-assembled components and components to

be assembled by the kit builder which are in Bold Print. Verify that all components in Bold print

are supplied in the kit. Some Vials have extras components. There may also be component values

included in the kit not found on the list. These will be used in the testing section of the document.

ALSO, because this is a board used for all transverters from 50 thru 432 MHz, there are some

components installed on the circuit board that will need to be removed, changed, or not used in the

circuit (labeled NA) because they will have no function in your frequency specifi c version. It is

suggested to Highlight the components on the component placement document that are to be

installed as you inventory the values.

DEM 70-28 COMPONENT LIS T

Resistors (R) values are in Ohms and chips unless otherwise specified. “LEAD” = Leaded Resistor.

/Kits/L70-28CK.doc 3 Rev. A 4/21/2011

C1 1000

C39 1.0 µF T

C62 1000

C89 0.1 µF

C2 0.1µF

C40 0.1 µF

C63 1-12pF

C90 1000

C4 1000

C41 1000

C64 1-6pF

C91 1000 OR 10

C7 SHORT

C42 1000

C66 0.1 µF

C92 1000

C8 0.1 µF

C43 1000

C67 0.1 µF 1210

C93 1000

C9 0.1 µF

C44 1000

C68 1000

C94 10

C11 1000

C45 1000

C69 0.1 µF

C95 1000

C12 1000

C46 1000

C70 75

C96 1000

C14 24

C47 0.1 µF

C71 24

C97 1000

C15 56

C48 0.1 µF

C72 1000

C98 0.1 µF

C17 0.1 µF

C49 1000

C75 1.0 µF T

C99 10 µF T

C18 1-12 pF

C50 1000

C76 0.1 µF

C100 1000

C23 1000

C51 0.1 µF

C77 0.1 µF

C25 100

C52 100

C78 1000

C102 1000

C26 120

C53 100 µF E

C79 1000

C103 22 µF T

C27 100

C54 75

C80 1000

C104 10 µF T

C28 1000

C55 75

C81 56

C105 10 µF T OPT

C31 1000

C56 75

C82 150

C106 10 µF T OPT

C32 0.1 µF

C57 1000

C83 150

C107 10 µF T OPT

C34 1000

C58 100

C85 150

C108 1000

C35 1000

C59 0.1 µF

C86 56

C112 100 µF E

C37 1000

C60 1.0 µF T

C87 1000

C115 22 µF T

C38 0.1 µF

C61 0.1 µF

C88 1000

C158 100 ATC

C19 1000

C20 27

C21 0.1 µF

C22 1000

L5 1.0 µH

L14 7 Turns #24 T37-12

L21 1.0 µH

L6 1.0 µH

L15 7 Turns #24 T37-12

L22 330

L7 150

L16 6 Turns #24 T37-12

L23 150

L8 330

L17 9 Turns #28 T25-12

L24 220

L9 330

L18 330

L25 150

L10 150

L19 220

L26 330

L13 6 Turns #24 T37-12

L20 56

L27 330

All capacitors (C) are in pF and are chip unless otherwise specified. “E” = Leaded Electrolytic,

“T” = chip Tantalum, Band is positive. NR = Not required for full functioning transverter

All inductors (L) are in ηH and 1008 chip unless otherwise specified. “HW”=hand-wound on

toroid using enamel wire

/Kits/L70-28CK.doc 4 Rev. A 4/21/2011

CR1 1N4000

IC3 MAR3

Q8 MJD31

CR3 MPN3404

IC4 MAV11

Q9 PMBT3904

CR4 MPN3404

IC5 RA30H0608M

Q10 MJD32

CR5 1N914

IC6 PAH-1

Q11 PMBT3904

CR6 1N914

IC7 MAR6 (option)

Q12 PMBT3904

CR7 HP2800

IC8 LM393

Q14 MJD31

CR8 HP2800

IC9 LM324

Q15 PMBT3904

CR9 MMBD914

IC10 7660 (OPTION)

Q24 PMBT3904

CR10 1N4000

K1 G5V

Q25 Remove and replace with JUMPER

CR11 HP2800

K2 G6Y

Q26 remove and replace with MBT3904

CR12 MMBD914

K3 G6Y

VR3 78L05

CR13 MMBD914

M1 SYM18H

VR4 78M05

CR14 1N4000

Q3 PMBT3904

VR5 78S09

CR21 MMBD914

Q4 PMBT3904

Y2 42.000 MHz.

F2 70M-3 (67188B)

Q5 PMBT3904

PTC-50 Thermistor

F3 70M-2 (67186B)

Q6 FPD750

Xtal Shield

F4 70M-2 (67186B)

Q7 PMBT3904

(1) Heatsink

(1) #6 flat washer

(1) Back Panel of enclosure

(1) #6 ground lug

(1) U-channel enclosure

(2) #4 Ground lug

(1) Bottom panel

(1) 50 Ohm load

(6) Black 4-40 screws

(1) Switch

(18) 4-40 x ¼” screws

(1) Green LED

(12) Aluminum Shoulder Bushings

(1) Red LED

(10) 4-40 x 7/16” screws

(2) BNC connectors and Hardware

(2) 4-40x ½” screws

(2) Type “N” connectors and hardware

(2) #4 flat washers

(1) RCA connector

(3) 4-40 x ¼” threaded standoffs

(1) 8 pin connector set

(2) 4-40 nuts

(1) Male 2 pin AMP connector

(1) 4-40 x3/8” screw

(1) Female 2 pin AMP connector and hood

(1) Brass shield for Power module

(2) 1000pf disc cap

(2) 6-32 x 5/16” screws

(1) ¾” hole plug

(2) 3/8” hole plug

Coax, 20”

#16 wire, 2” black, 3” color

#24 gauge wire, 6 feet (Green)

Power meter kit

(1) NTC Thermistor

(1) Fan

(4) 6-32 x 1-3/4” screws

(1) Fan guard

(4) Tie Wraps

Sleeving, 5”

(4) Rubber feet

Tube of thermal compound

4’ of Zip cord

Bundle of precut #26 colored wire

Solid State, Relays and Filter Components

Verify all of the listed hardware is in the Hardware Kit.

HARDWARE

/Kits/L70-28CK.doc 5 Rev. A 4/21/2011

Circuit Board Assembly:

Refer to the component placement diagram and install all topside components that require

soldering on the bottom side of the board. Install F2, F3, F4, K1, K2, K3, R36, R38, CR1, CR5,

CR6, CR10 and CR14. Even though K2 (RF relay) and K3 (IF relay) are to make the common RF

and IF connections, (combined TX and RX) separate TX and RX connections to both RF and IF

ports can be made. BUT—you may leave both relays un-installed if you only desire separate RX

and TX ports for the IF and RF connections. Be sure to heat the ground connections well before

flowing solder on the filters and relays. Cut the excess from the diode leads flush with the board.

See Picture 1 and 2

Now examine the Bottom Side Board Assembly picture on the next page. It is suggested t o

complete all of the wiring on the bottom side. Some wires are for features that you may never

utilize in your configuration but will provide ease of a configuration change at a later date if you

decide to change transceivers. If you do not see the need for certain features, some of the wiring

may be omitted. The signals are marked on the picture. The negative voltage generator, (+9

connection) the IF drive sense (three wires), and the wiring for the RF TR relay may be left out if

those circuits will not be utilized. They could be added to the top side if required in the future. All

other wire connections are required for full transverter function. Each marked wire shows its

approximate length.

Find the 6 foot wind of #26 Green hook up wire, then cut, trim, tin, and install. It is best to

cut the wire a bit long (1/4”) and trail fit after soldering one end in place. If you are close with the

measurements, the wires will fall into place as shown. If the wire is too long they may get pinched

during the assembly of the board. Please note that some wire attachment via-holes will have solder

mask on them. You may remove the mask if you desire, but the holes are plated through so if the

wire is tinned, it will solder in the via-hole, mask or not. One wire, the 9” 13.8SW, is only attached

at one end for now. Save the extra wire out of the 6’ bundle for topside wiring.

See picture 3

After all wires that you wish to install are installed, (10 max) be sure none of the wires cross

any of the bottom side solder connections of the filters, pots, and RF relays. This is to prevent any

RF signals from coupling to the DC connections. The exception is the 2-1/2” TXON wire. It crosses

under K1 which is a non-RF circuit relay. Also be sure that the wires do not cross any mounting

holes. Then with a small piece of tape, (any type) attach the wires as shown being sure that the

wires are laying flat on the circuit board. If you desire to attach other wires or configure the

transverter differently, or desire to use any type of adhesive to hold wire in place, please do so.

Just be sure to clear all mounting holes and exposed RF circuits and do not allow and excessive

amount of adhesive to prevent the circuit board from attaching flat to the mounting hardware on the

heatsink. A 1/8” clearance is required between the board and heatsink.

/Kits/L70-28CK.doc 6 Rev. A 4/21/2011

Bottom Side Board Assembly

/Kits/L70-28CK.doc 7 Rev. A 4/21/2011

Surface mounting assembly of components:

The rest of this document assumes that you have the complete kit version. If you have the

basic PC board kit, follow along in the instruction manual but skip the instructions that do n ot

pertain to your final assembly.

First, examine the board. It is a basic rectangle with two small notches and one large notch

on one corner. If you hold the board so you can read the majority of the screened text left to right,

you will find the large notch on the lower left hand side of the board. This is the orientation that the

top side component placement document will refer to. In brief, the TX chain and power amplifier is

in the lower left, the RX LNA in the upper left, the Local oscillator on the lower and center right. The

IF Drive sense and Negative voltage generator are on the upper right. The upper center of the

board is the IF section and the lower center is the sequencer as shown in Picture 4.

What is convenient for assembly is that the circuit board may be mounted to the heatsink

before any surface mount work is done. But, if you have a PC board vice that you utilize for board

projects, you may want to use it. It is your choice. Since there is no further work to be done on the

bottom side of the board, we recommend attaching the board to the heatsink to save a step.

Find the 11 shoulder bushings in the hardware kit and install them in the holes in the

heatsink. These act as spacers for the board. Some may fit snug and it is alright to gently “tap”

them in. Be sure that they are completely seated. Next locate the position for the NTC as shown on

the component placement. It is the largest recessed hol e in the heatsink. It requires to be fill ed

about ¾ of the way with thermal compound before the NTC is installed and is easier to do before

the board is attached to the heatsink. Find the tube of thermal compound, use, than save the rest

for the Power module mounting later in the kit instructions. See picture 5.

Now find VR5, the 9 VDC regulator. Its leads are mounted through the bottom side of the

board. Insert VR5’s leads through the board from the bottom side as far as it will go. Then bend it

over in the direct i on as shown in the placement diagram. Do not solder! Align and place the circuit

board on the bushings along with VR5 in place. Be sure the one end of the +13 8SW wire that is

not attached is out from under the board on the lower right hand side. This wire is connected to the

switch during final wiring. Then verify that the board sits flat on the bushings (no wires being

pinched) and attach the board with nine 4-40 x 7/16”, two 4-40 x1/2” with flat washers and one 440 x ¼” screw for VR5. The longer screws and washers go in the local oscillator section (lower

right hand side of the board) and will hold the shield in place after testing. Start all screws first then

tighten. Some screws will be removed to ease assembly later during the process and will be

specified, but for now, you have a solid mounted circuit board ready for assembly. Solder VR5’s

leads in place after all screws are seated. See Pictures 6 and 7

Next step in the board assembly is to remove the components that will inhibit the operation

of your transverter. They were either placed wrong during machine assembly, not required or are

the wrong values for the 50 transverter. Remove Q25, R 83, and Q26 (IF Drive sense circuit upper

right).Then find and remove C66, C67, and C69 (LNA section). Wick all connections clean if you

/Kits/L70-28CK.doc 8 Rev. A 4/21/2011

can. Replace Q26 with a MPN3904 and install a Zero ohm resistor or wire jumper as shown on the

component placement document in the Q25 position. See Picture 8 and 9

It is now recommended to follow the assembly steps listed below but if you are an

experienced builder, you may start on the board anywhere you want placing all of the components

listed on the component lists. The assembly steps will cover some options and place importance

on some order of assembly but again, nothing is critical and does not need to be assembled in any

particular order. If you decide to go about this on your own path, the only precaution is if you desire

to test the local oscillator for the correct output level, do not install the Mixer, M1. Leaving the mixer

un-installed allows testing of the RF, LO and IF stages independently.

1. Install Q1 and Q2 by first cutting the 4th lead off. It is the ground lead and its attached to the

can internally. Measure with a ohm meter if unsure of it’s pictorial on the component

placement diagram. Cut the other three leads to ¼” long. Place the cans in the holes on the

board as shown on the component placement and solder the cans into place. Then bend the

leads in a “Π” shape and attach to the circuit board. You can check the leads for a solder

short to ground with an Ohm meter or just do a visual inspection. See Picture 10

2. Install C5,C6,C10,C39,L2,L3,L4,L11,L12,CR2,IC2 and R18. Check the polarity on C10 and

C39. The band is positive.

3. Prep the leads of the Y1 Crystal as shown in the next group of pictorials. Solder it to the

circuit board with the leads pointed at Q1. Prep the PTC Thermistor and Xtal shield as

shown. With a solder iron, remove one lead from the Thermistor then solder the Thermistor

to the shield. When cooled, bend to shape and place the PTC and shield assembly over the

Xtal. Attach the previously removed wire to the side of the shield and connect to ground

near C2 and C6 with the shortest connection possible. Cut and fit a piece of the sleeving to

fit the “Hot” lead then connect the “Hot” PTC wire to the via-hole near the L3 designator on

the board. See picture 13.

/Kits/L70-28CK.doc 9 Rev. A 4/21/2011

L2

To via

near L3

PCB

To GND

4. Install L7, L8, L9, L10, C25, C26, and C27. This is the local oscillator low pass filter and

completes the oscillato r . If you wish to test the oscillator level and have an mW power

meter, skip Step7. Leaving the mixer un-installed also allows you to test the individual

sections of the transver ter if you desir e. BU T — if you do not have gain measuring capability

and accuracy to at least a dB, install the mixer. See Picture 14.

5. If you do not wish to test the Oscillator level, install the mixer M1.Line it up on the pads and

solder. It is best to tin one pad and hold the mixer in place while heating the tinned pad.

Solder the other two by flowing solder and then do the ground pads (3) .It will require some

heat to flow the ground connections! See Picture 15.

6. Next assemble the IF section of the transverter. Install L22- L27. Then install CR3 and CR4

by surface mounting the leads. Bend and cut to fit on the pads as shown on the component

placement. See Picture 16.

7. The rest of the components are dependent on the IF configuration that you require but all

maybe installed except for IC7 and then configured for use later. BUT--- an explanation of

what components do what is in order.

a. CR5 and CR6 are only required for drive levels higher than 1/2W but not if you use

separate TX and RX ports. Having them installed does not inhibit any configuration.

b. CR7, CR8, C94 and C99 are part of the RF sense protection circuit. The circuit is

only required for a common IF greater tha n 1/ 2W drive configurations but will not

inhibit any configuration. Check polarity of C99

c. The 50 Ohm load is required with any drive level above 200 mw regardless of any IF

configuration. It will provide attenuation at all drive levels so only install for higher

drive levels. Attach one lead to a #4 ground lug mounted to the load with a 4-40 x3/8”

d. C91 is a 1000pf if the drive level is below 1/2W and 10 pF for all drive levels above ½

watt.

e. IC7 is the TXIF gain stage and is only installed if the IF drive level is 1 mw (0dBm) or

less. Depending on test results, it may be installed later to compensate for lower TX

gains in the transverter.

/Kits/L70-28CK.doc 10 Rev. A 4/21/2011

f. For further explanation, Refer to the “ TXIF Drive Level Range” section found in the

P in Out

1 RF I n

2 Bi as ( T XON)

3 Vcc (+13.8VDC)

4 RF Ou t

5 RF & DC ground (Flange)

1 2

3 4

55

“Options Setup

” section on page 25 and See Picture 17.

8. If you require the negative voltage generator circuit, Install IC10, C105- C107. These

components need to be ordered separately. This circuit provides a negative voltage that is

supplied to transceivers that do not have a transverter port or a way of limiting the output

power, and of course, have an ALC input. When voltage is supplied to ALC input of a

transceiver, it will limit the power delivered to a transverter. It will be discussed further in the

set up and operation section of this manual. See Pict ur e 18.

9. Complete the assembly of the sequencer by installing Q8, Q10, C103 and C104. Do not mix

up Q8 and Q10 and check polarity of C103 and 104! See pict ur e 19.

10. Install TXRF gain stage components IC3, IC4, R21, C60 and VR3. Surface one lead of R21

(the connection to IC4) and all three leads of VR3. Form the lead of IC3 and IC4 before

soldering if required. Then install C53 and C112 by surface mounting the leads. Pictur e 20 .

11. Install the TX low pass filter. Place and solder C54-C56 first. Then using the pre-wound

3/16” dia. Coils, install L13-L16. The coils have different pitches so follow the pictorial for

installation. See picture 21.

12. Install CR11 (lower left hand corner) the power detector diode. Then install Q14 and C115,

the fan speed control circuit. See picture 21.

13. Begin to install the RX section by installing Q6. Then install C63, C64, L17, C67, R27,

C158, C66, C69 and L18. Be sure that C63 and 64 adjust after soldering. See picture 22.

14. Complete the diplexer circuit by installing L19, L20, C70 and C71. See Picture 23.

15. Finish the RX section by installing IC6, L21, VR4 and C75. See picture 23.

Power Module Installation:

Place the power module (IC5) on the heatsink in

its mounting location. Trim the leads so they do not

extend past the solder pads. They should be

approximately 3/8"-1/2” long once trimmed. Remove

the Module and wipe the mounting surfaces of the

heatsink and flange of IC5, verify the surfaces are free

of any foreign matter. Apply a thin even coating of the

supplied thermal compound to the mounting flange and the heatsink and the bottom of the power

module. Place IC5 on the heatsink and “Lap” the thermal compound by moving the module side to

side while exerting slight down ward pressure. You will

feel the resistance build up when lapped. Line up the

leads with the traces of the circuit board. Find the brass

shield and form to fit as shown. Using one 6-32 screw

and flat washer, install it through the shield and the

mounting flange, into the heatsink hole nearest the

Q11, 3 and PH3 marking on the PC board. Then install the other 6-32 screw with a #6 Lug in the

other hole. Tighten evenly into the heat sink. NOTE: Make sure IC5 is mechanically sound to the

heat sink because improper seating of the hybrid could result in poor grounding and heat transfer

/Kits/L70-28CK.doc 11 Rev. A 4/21/2011

DC POWER

TX

AUX

PTT 10 MH Z

TX IF

IFANT/RX

causing damage to the power module. Also be sure that the shield does not shift of contact any of

the module leads. The shiel d fro nt sh ould fit between the module and the part of PC board with the

bare metal and two board mounting screws. Form the module leads flat to the traces, and then

solder all leads of IC5 to the circuit board. Now observe where the shield contacts the bare metal

of the PCB. Tack solder along that edge. It will require a lot of heat so take your time. It helps if you

loosen the board mounting screws or remove completely. Just don’t fill the holes with solder. Retighten when complete. See picture 24.

Finally, install the NTC in the hole through the board and in the thermal compound in the

heatsink. Attach the leads as shown on the components placement after installing sleeving on the

leads. The PCB is complete. See picture 20.

Final Wiring and Assembly

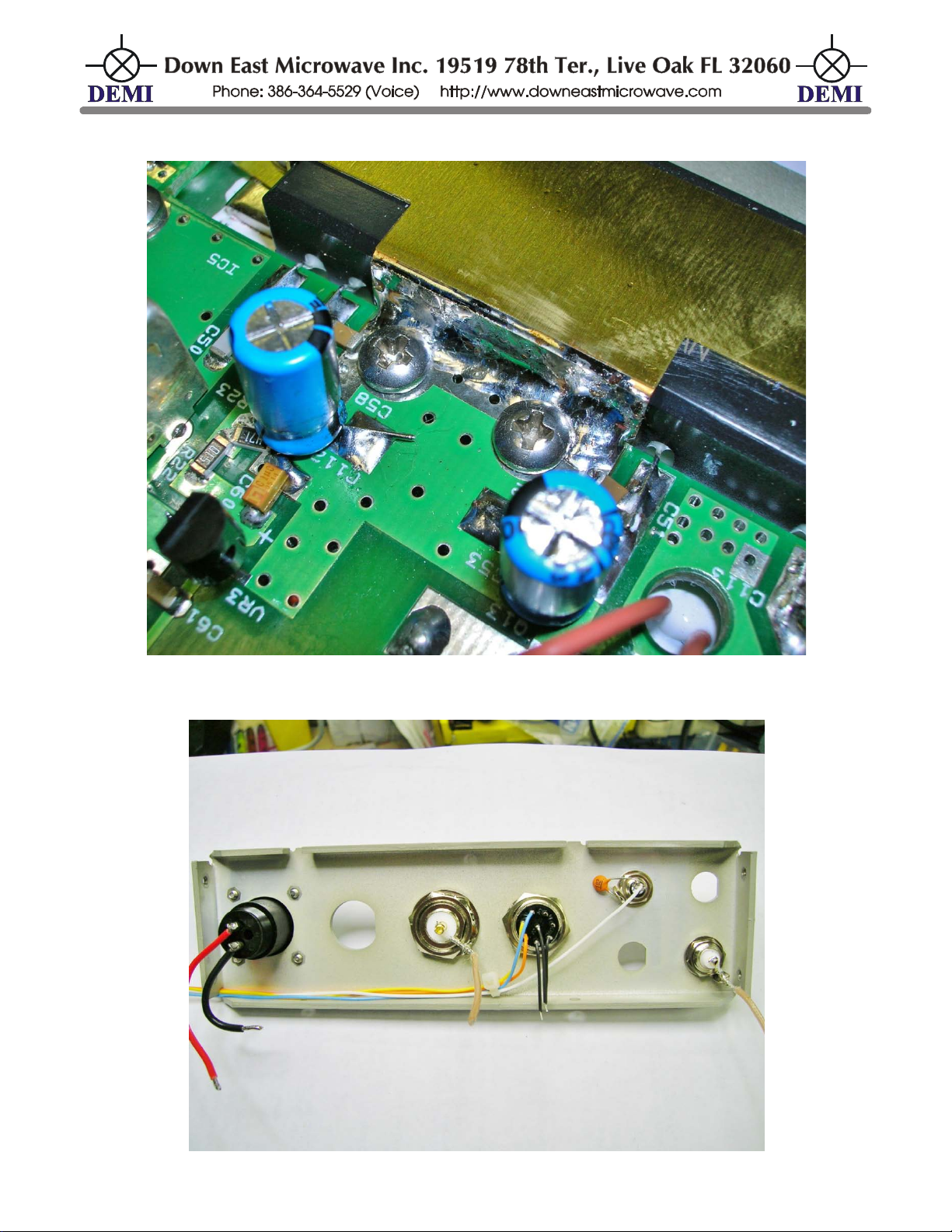

The final wiring and assembly starts with installing the connectors in the rear panel. You

may install all of them or only the connectors you will use. All connectors require all supplied

hardware. Install the BNC connectors through the labeled side of the panel and place the lock

washer, ground lug and nut on in that order. When tightened, the lug should be pointing up in

relation to the labeling but angled into the corner. Install the PTT connector (RCA) through the

panel, then washer, lug then nut. The lug should point at the AUX connector. The 8 pin AUX

connector is self aligning. Install it with the lock ring under the nut. Install the ANT/RX “N”

connector through the panel then install the lock washer, lug, and then nut. Tighten nut and have

the lug point between the AUX connector and the top of the panel in relation to the labeling. Install

the TX “N” connector the same way. Finally, install the DC power connector (flanged black plastic)

Position the connector so that Pin #4 is closest to the top of the panel in relationship to the

labeling. See pictu re 25.

Rear Panel view

Depending on your requirements, Cut, strip, and tin both ends of the coaxes as shown in the

next pictorial. Different configurations are explained in the Options Setup section at the en d of the

manual. The lengths of coax are shown below and depend on you specific configuration.

RFIF (the IF BNC Connector) 5-1/2”

TXIF (the TXIF BNC connector) 6 ½”

Common RF (the ANT/RX “N” connector) 3”

/Kits/L70-28CK.doc 12 Rev. A 4/21/2011

Common IF (the IF BNC Connector) 5-1/2”

Desired Length

1/4"

3/4"

Board end

Connector End

RXRF (the ANT/RX “N” connector) 2-1/2”

TXRF (the TX “N” connector) 3 ½”

See Picture 27.

Attach the longer stripped end of the coax to the connector as shown in the next pictorial.

Push the end through the hole in the ground lug, solder the center conductor to the center pin, then

solder the shield to the ground lug. See picture 26.

With the pre-cut bundle of colored wire, make wire connections to the AUX and PTT

connectors. Follow the wire chart. Strip and tin one end of the wires to 3/16”. Tin the connector

pins before soldering. All wires are required for sequencer operation and PTT control. Picture 26.

AUX Pin 1 11”Orange wire

AUX Pin 2 11” Yellow wire

AUX Pin 3 9” Blue wire

AUX Pin 6, 7, and 8 1-1/2” Black wires (cut from 6” wire)

PTT connector 12” White wire--- Also install 1000pF disc to ground

The DC power connector should now be wired. Attach a 1 ½” #18 Black wire to pin 4 and a

2 ½’ # 18 colored wire to Pin 1. Strip and tin each wire to ¼” on one end and 3/8” on the other.

Connect the ¼” end to the DC power connector. See picture 25.

Place one Ty-Wrap on the bundle of wires less the black ground wires and including the

PTT wire as close to the AUX connector as possible. Then attach the rear connector panel to the

heat sink using two 4-40 x ¼” screws. Run the bundled AUX and P TT wi r es between the panel and

the circuit board towards the DC power connector bending them around the corner and behind the

Power Module. Strip and tin one end of the 15” purple wire and connect it to the PWR via near

/Kits/L70-28CK.doc 13 Rev. A 4/21/2011

CR11 on the lower left corner of the board where the AUX wires wrap around the Power Module.

Install a second Ty-Wrap at that point. Now, connect the black wire from the Power connector to

the ground lug on IC5 flange. Attach the +DC wire form the power connector to the bare metal

marked 13.8V on pin 3 of the power Module. Then Ty-Wrap the bundle to the DC ground wire

connection on the side of the power module. See picture 28.

Finish the panel wiring by connecting the short Black wires from the AUX connector (Pins

6,7,8) to ground. Insert the three wires into any of the via-holes in the circuit board below the

connector. You may scrape some of the solder resist if you feel necessary but it is not required to

get a good solder connection. The via-holes are plated through so use a lot of heat to flow the

solder. Then begin to connect all of the coaxes to the circuit boards as you have planned for your

configuration. If you are unsure of their connections, you may refer to the “Common or Split IF

Option” and the “Common or Split RF connections” section found in the “Options Setup”

section on page 25 of this manual. There should be a Minimum of two and a maximum of four

coaxes. Be sure that the shields are soldered to the board well. It is Teflon coax so do not be afraid

to heat the connection! See picture 29. Then connect the other AUX connector wires to the

sequencer section. Pin 1 to Via 1 on the board, then Pin 2 to 2, Pin 3 to 3. This will provide Pin 1

with voltage on RX, Pin 2 with Voltage on TX and Pin 3 will be a connection to Ground on TX.

Trim, strip and tin the wires before connecting. If you desire anything other sequenced signal,

consult the Sequencer schematic and its matrix for alternative connections. See Picture 19.

The PTT wire may be connected to the PTT – H or L in the sequencer if you plan to use the

sequencer or connected directly to the transverter’s PTT –H or L near the K1 relay. This will

depend on your configurati on pl ans . If you are using the sequencer, install the 6” White/Org wire

from the “4” via in the sequencer to the PTT-L via near CR9. With the left over green wire, strip and

tin three 1”green wires and connect two from the +DC to the DC1 and DC2 vias in the sequencer.

Connect the third one from the +9 (near VR5) and the +LO via. Strip and tin a 3” wire and install

one end in the +13.8SW via near VR5. If you require the negative voltage option, connect an 8”

green wire from the ALC via and pin 4 on the AUX connector. See Picture 30 and 31.

Begin to Pre-wire the U-channel front panel by assembli ng the enclosed RFPM kit. This is

the bar graph power meter. The board and circuit has been modified and the kit only contains the

components (7) required for a positive voltage detection. When completed, install a 2” black wire

(GND Connection) and a 6” green wire (+V). Strip and Tin both ends of both wires. You may test

the RFPM separately before installing. It requires 12VDC (+ and -) on the two wires and a variable

voltage from 0 to 5 VDC on the DET connection. You should be able to vary the voltage and move

the Bar Graph display up and down. The Pot will adjust its sensitivity. When complete , find two ¼”

threaded hex stand-offs and two 4-40 nuts. Pass the threaded end of the stand-offs through the

two mounting holes on the RFPM board so that the threads are on the component side of the

board not the display side. Then hand-tighten the nuts. Install the RFPM in the front panel with two

4-40 Black screws. Center the display and tighten the nuts and the screws. See picture 31. Then

cut, strip and tin the wires on the two LEDs to 2”.Install the Green (ON) LED and the Red (XMIT).

Install the switch in the front panel then install the front panel to the heatsink with four 4-40 X ¼”

/Kits/L70-28CK.doc 14 Rev. A 4/21/2011

screws and four 4-40 black screws to the rear panel. Start all screws first, and then tighten. It may

be necessary to loosen the rear panel a bit to get all screws started. Be sure not to trap any wires

under the panel. See pict ur e 34.

The fron t panel wiring st arts by connecting the black wire of the power meter to any via hole

in the circuit board below. The +DC wire connects to the 13.8SW via near VR5. The 15” purple

wire from the PWR via on the board connects to the DET via on the RFPM. Strip, tin and connect.

The LED’s are connected next. The Red connects to the TX via and the Green to the ON LED via.

There is associated ground vias near each connection. Strip, tin, and solder. Now, attach the wire

coming out from under the board to the center pole of the switch. Strip, tin and solder. Then

connect the wire from the +13.8SW connection to the top lug on the switch. See picture 31.

Installation of the Fan Option is recommended for the best possible frequency stability for

digital operation. Turn the transverter over so the Heat sink is up. Notice that all of the holes are

not filled. There are four 6-32 tapped holes and a large thru- hole. The thru-hole is for the wire of

the fan. Feed the wire through the hole and place the fan on the heatsink, label down so that it

blow air into the fins. Be sure that the wire is not trapped between the fan and a rib of the heat sink,

There is a notch in the fan that the wire passes through. Place the fan grill on it and bolt down the

assembly with four 6-32 x 1-3/4” bolts. Make them snug but do not over tighten. See picture 33.

Turn the assembly back over and dress the wires by Ty-Wrapping them to the sequencer wires

near the step “3” connection. Then follow the PTT and DC power wire across the Module. Cut, trim

and tin the Red fan wire and attach it to the +13.8V pad with the DC power wire. Continue to route

the Black fan wire to the –F pad. Cut, trim and solder. Install a Fifth Ty-wrap to bundle the PTT,

+DC and fan wires if desired. See picture 20.

Last step before testing is to assemble the DC power cable. Find the left over mate to the

flange connector mounted on the transverter. Prep the Red/Black -#14 zip cable by striping and

tinning ¼’ on one end. Solder the red to Pin 1 and the Black to pin 4.Be sure to control the heat (it’s

not Teflon!) and be sure they are not touching when done. You could use tape or heat shrink if

desired. When complete, install the cable boot by screwing it on into place. You may prep the

other end as required for your power supply. ALSO—consider an inline fus e or limited power

supply for testing. The Basic assembly is complete and the transverter is now ready for test.

Test Section: Before applying DC power to the complete transverter, verify main DC wiring an d

have a proper fuse installed in the DC power cable or supply. Install some sort of 50 Ohm load on

the ANT, TXRF, or RXRF ports. Verify that the PTT port is not shorted. If all looks good, apply DC

power and switch on. The Green LED should light and the TX LED (RED) will remain off.

Start by verifying voltages on the board. All voltages should coincide with the DC input

voltage from the power supply unless it is on the output of a regulator. There is a voltage matrix at

the end of the test section that may be used f or checking and troubleshooting. You could verify

every point or in general, check VR4 (5 VDC) and VR5 (9 VDC). Verify the +13.8SW voltages and

the +DC in the sequencer. Check Pin one in the sequencer for +12VDC or greater. The bias

resistor side of IC2 and IC6 should be around +5 VDC +/-. The drain of Q6 (junction of L18 and

/Kits/L70-28CK.doc 15 Rev. A 4/21/2011

C69) should be around 3.8 VDC. CR2 is a dual diode and the biased end should be around

.8VDC.Verify –F to be somewhere between 6 and 13 VDC depending if the fan is running or not. If

voltages do not fall in line, check wiring or assembly. When complete, shut power switch off. All

other preliminary tests are complete and TX tests and will be covered in the TX test section.

Oscillator testing without

mixer installed: If you encounter a problem with the Oscillator, refer

to the voltage matrix and verify Q1 and Q2’s function. Start by connecting a test coax to the LO

input pad of the mixer M1 and ground. This will allow the measure m ent o f the level injected into the

mixer. You may also measure the frequency of the oscillator with this connection. Connect the

coax to a power meter set to measure 100 mW. Switch the DC power on. The osci l l ator m ay just

start up or require an adjustment of C3 (the gold piston) to start, then using a voltmeter, peak the

voltage for max at TP1 (junction ofQ2, C11 and R7 marked on the board) to ground. Verify the

output power level on the power meter to be between +15 and +19 dBm. If low, check IC2 for

function, missing components in the LO Low Pass Filter, or wire connections. Refer to the voltage

check sheet at the end of the test document if needed. If the level is OK and you have a spectrum

analyzer, you may verify the 2nd harmonic content. It should be a minimum of -40 dBC (40 dB

below the fundamental. If not verify the Low pass filter (the components between C24 and C28).

Now, if all tests are ok, you may install the mixer or not and proceed to the General Oscillator

testing section. Leaving the mixer un-installed when the Oscillator testing is complete will allow

other testing in the TX, RX and IF stages. Install i ng the mix er when testing is complete will

complete the transverter.

Oscillator testing

with

mixer installed: If you encounter a problem with the Oscillator, refer to

the voltage matrix and verify Q1 and Q2’s function. With the mixer installed, you only have the Test

point to verify the operation of the Oscillator. Switch the transverter on and verify voltage on TP1

(junction of Q2, C11, and R7). The oscillator may just star t up or require an adjustment o f C3 (the

gold piston) to start, then peak the voltage at TP1 (referenced to ground) to max.

General Oscillator testing: If the voltage peak is towards the top end of the range of the piston

(all the way up) spread the turns of L1 slightly and then move the piston cap down to re-peak. Do

the opposite if the peak is low in position. What is desired is the Piston to be in the center of its

range or slightly toward the top of its range for the peak. The frequency may be checked now but

allow the circuit to warm up about 15 minutes. The frequency may be probed at the LO input to the

mixer or on the coax if the mixer is not installed. You should be able to adjust to the frequency of

the oscillator with C3. For best oscillator performance, it is desired to have the “netted” frequency

coincide with the voltage peak on TP1. Because probing TP1 with a volt meter will pull the

oscillator frequency down a bit, if the final frequency is within 2 kHz of the voltage peak, it should

be fine and skip to the shield installation.

If the voltage peak coincides with a frequency of greater than 2 kHz but less than 6 kHz off

desired “Net”, it would be best to continue with the transverters final testing and allow a 48 hr burnin period before retesting. You may find that the frequency may move closer to the voltage peak

and the stability may be more than adequate after a 48 hr. burn in. It is suggested to skip to the

/Kits/L70-28CK.doc 16 Rev. A 4/21/2011

Oscillator Shield installation, net the frequency and continue with the testing. Th en, allow a burn in

for 48 hours before retesting.

If the frequency is more than 6 kHz of to start with, verify your assembly and the voltag e

matrix. If all correct, check C2 and R3 (machine assembled components) for soldering or damage.

If all look OK, proceed to the Frequency Net Modification. If the frequency is greater than 8 kHz,

please consult us before modification.

Frequency Net Modification: If the difference in frequency is greater than 2 kHz after a 48 hour

burn-in or as much as 8 kHz before burn-in, you may do the following. First, rech eck t he fr eq uency

vs. test point voltage to verify difference plus determine if it is high or low in frequency. If there isn’t

more than 2 kHz difference, the modification will not help very much. BUT—anything more than

that, improvement can be mad e. Remove the shield, (if installed) and look for a “C7” designator on

the board between Y1 (the crystal) and Q1. See picture 13. Cut and remove the trace between the

two pads. Remove the crystal from the circuit if you need the room. Now, if the frequency is low,

solder a 24 pF chip cap (extra in kit) between the pads. If the frequency is high, solder the HW

copper wire inductor (extra in kit) between the same pads. Re-install the crystal and start up the

oscillator. Allow warm up time and retest frequency vs. test point voltage. If OK, move on! If it is

still off more than 3 kHz, if you decrease the size of the cap, the frequency will move up. If you

increase the size of the inductor, the frequency will move down.

Oscillator Shield installation: Power down the board and remove the two 4-40 x1/2 screws and

flat washers from the board. Find the shield and line it up with the mounting holes and the pist on

cap adjustment hole. Gently press the shield down onto the Crystal assembly so that an

impression is left in the insulating material in the shield. With a knife, cut and remove the insulation

so the shield will fit over the oscillator. Depending on the route of the heater wire, make a cut to

accommodate the wire so that it does not get pushed down into the circuit. A bit of trimming may

be required for L1 but trial fit first. A snug fit is best. See picture 35. When everything fits, bolt the

shield down with the screws and washers. Verify that the base lead of Q2 does not touch the

shield. If so, re-solder the lead or trim the shield. You will find that the shield will pull the

frequency down a bit so re-peak the TP1 or net the frequency after a 5 min warm up and continue

with the rest of the testing. See picture 31.

Receiver Testing: With the mixer installed, depending on your configuration, the RXRF input port

and RXIF output ports will vary. It is assumed that the voltage checks were made and determined

to be in spec before the Receive RF test is made. Use whatever means to generate a signal into

the RF port (on air signal, signal generator -30dBm or less, or a Noi se fig ur e meter ) and us e

whatever 28 MHz receiving device you desire to peak C63 and C64 for maximum gain. See

picture 22. If you use a noise figure meter, you may find that the best noise figure is not the

maximum gain but if you only have gain measurement capabilities, the noise figure may not be

optimized but will be close. Be sure to rotate R39 (RXIF Gain adjustment) to verify function. There

should not be a need for adjusting the filters and is recommended not too unless you have test

equipment that a filter response can be verified on. If 17dB of conversion gain (15 minimum)

cannot be achieved, start by verifying voltages on Q6 and IC6 then check kit installed components.

/Kits/L70-28CK.doc 17 Rev. A 4/21/2011

Use whatever means to signal trace from input to output to find the proble m. Be sure of the RXRF

and RXIF configuration and check for shorts on the coaxes and solder shorts on the boards.

If you are testing the RX gain section without the mixer

installed, there should be a

minimum of 23 dB of gain depending on the tolerance of the filters and the active components. If

you have the ability to check the pass ban d or then desir e to optimize it, do so only with extreme

care. The filters have been matched to 50 ohm in/out and a specified pass band response to match

the weak signal portion of the band. There should not be a reason to “Re-adjust” but—you can if

desired. Just remember that F2, the three pole filter is also a TX filter and is responsible for the

local oscillator signal that bleeds through the mixer and all products of the LO-IF combination. If

testing the RXIF section of the transverter, there should be no more than 3 dB of loss at 28 MH z

and will roll off fast above 32 MHz. The low pass filter/ diplexer in the circu i t are there to keep all

signals above 32 MHz out of your receiver that may be produced within the mixer.

Transmit Testing: If you plan on using the Negative voltage generator to reduce the output power

of your transceiver for transverter configuration, proceed to the “Negative Voltage Option” test

section first. Then come back to this section for the complete Transmit testing.

Depending on your configuration, be sure to have some sort of 50 Ohm load and or RF

power meter connected to the designated TX port of the transverter. Preliminary TX testing is done

without IF drive being applied. Start by manually enabling the PTT signal (High or Low depending

on your configuration). This in turn will enable the TX section and disable the RX section of the

transverter through the sequencer or directly depending on your configuration. All relays installed

will actuate and the Hybrid power module will draw quiescent current of around 4-5 amps. T he

other TX driver stages and the TXIF amp if utilized will also be biased.

IMPORTANT NOTE: Do not assume that if the output power of the transverter is low that it is

because you do not have enough IF drive

. Please consult DEMI if you have problems obtaining

full output power with your specified drive level during the test procedure after you have exhausted

all possibilities discussed in the procedure.

When the transverter is first ke yed, (without IF Drive) verify that there is no relay chatter

and the total transverter current drain is less than 6 amps. In this state, verify the TX voltages on

the matrix. You may notice the fan speed increasing as the transverters TX time is extended.

When finished checking all of the TX voltages, un-key the transverter. If there is a problem, find it

by checking the wiring first then the kit assembled components. If all OK, rotate R36 fully counterclockwise (maximum attenuation) and then connect the TXIF drive source. Manually enable the

PTT and apply the minimum amount of drive that your transceiver can produce. Verify any output

on the power meter. Slowly increase the drive level of the transceiver to the maximum drive you

have configured the transverter for while observing the power meter. Then adjust the TXIF gain

control (R36) to obtain 20-25 watts o f output power.

If you cannot achieve any output power, verify opens or shorts starting with the TX output

connector then back through the TX section. Look for opens in the Low pass filter L13-L16. If the

/Kits/L70-28CK.doc 18 Rev. A 4/21/2011

TR relay is in your configuration, verify its function. You may disable the bias to the RF power

module by removing R22. The relay and Low pas filter can then be checked with an Ohm meter.

Recheck the TX voltages in the TX chain. Then proceed through the IF section looking for opens or

shorts and the function of the TX IF relay if in use. Retest with low drive power first after finding

problem.

If the correct amount of power cann ot be ach ieved, (low power) the problem can only be a

few things. First check the output low pass filter, L13-L16, C54-56. Verify the windings and you

may try to spread or compress the turns for an additional output power. The filter is there to

eliminate the 2nd harmonic so—no matt er ho w you adjust the “L’s” it will not affect the 2nd harmonic

but may increase or decrease the insertion loss at the operating frequency. Also verify that the fil t er

components are not heating. (Touch them with RF off) if warm, something is installed incorrectly.

Next suspect the TXIF components. Verify that the Pin diodes CR3 and CR4 are

functioning. If the RX gain is OK, the filter diplexer should be OK but you can verify with an ohm

meter anyway. Next understand that even if you have configured the transverter correctly, the

operating range may be on the edge. Your drive level from your transceiver may not be what was

specified. If you have measured and verified it, then depending on your configuration, you may

vary the value of C91 if you are using the load. If you are using a low drive level (around 0 dBm)

you may need to install the TXIF gain stage. Do not install it if you use more than 5 mW of drive.

Testing the TX section without the mixer

is easy. Apply a low level of around -10dBm to

the input of F2. Enable the PTT and measure power. Increase the drive to achieve the correct

amount of output power. Adjust the Low pass filter for maximum power. F3 may be optimized but it

should not need it. If F2 is tweaked, it will affect the RX section. You may now also check the TXIF

section of the transverter. Verify the TXIF gain control and the pin diode switching network. The

insertion loss of the TXIF section including the filter/diplexer should be less than 3 dB @ 28 MHz.

If all tests OK, you may now install the mixer and either test with your transceiver or your signal

generator if desired to verify the complete assembly.

Bar Graph RF Power Meter: While the power meter is connected, the RF bar graph meter

calibration can be done. During key down, obtain a 25 watt output level and adjust VR1 on the bar

graph to show 9 bars lit. Then vary the power or use SSB to generate RF and follow you speech

pattern on the bar graph. Remember that the Bar Graph display is relative and its function may be

affected by high VSWR.

IF Drive Sense Circuit: The IF drive sense circuit is a protection circuit only. It should only be

utilized with IF drive powers above 100 mW and is only used with a common IF configuration. It will

operate at drive levels down to 10 mW. To preliminary test it, you can apply a low level voltage to e

any RFS via (1-2 volts) and the TIF signal near Q26 should go high. This voltage energizes the K3

relay. The purpose of C94, CR7 and CR8 is to sample and convert the 28 MHz RF energy to DC

voltage. To test, lower your IF drive down to the lowest level possible. Then key your transceiver

and apply drive. The TIF signal should go high. If not verify the CR7 and CR8 diodes and the RFS

signal with an ohm meter. After the transverter is enabled on transmit either through the sequencer

/Kits/L70-28CK.doc 19 Rev. A 4/21/2011

or directly by your transceivers PTT, the K3 relay and the rest of the TXIF circuit will be energized

by the transverters TXON voltage through the CR21 isolation diode.

Fan Speed Controller: The fan speed controller should operate on its own speeding the fan up

as the transverter heats. You can check the voltage at –F as the transverter is heating. This is the

negative lead to the fan and as the transverter i ncr eases in t e mp er at ur e, this voltage will move

closer to Zero or ground. If you find that the fan is running too early, you can lower the value of

R77 from 1K to 910 ohms or even 820 ohms. This also means it will start later in the temp cycle

which may affect the frequency stability but its adjustment may increase or decrease the delta in

frequency change over te mpera t ure.

Sequencer: Testing of the sequencer is simple. Just verify the steps are what it is connected to in

both TX and RX modes. If wired as recommended, 1 is positive voltage in RX, open in TX. 2 is

open in RX, positive voltage in TX. 3 is open in RX and Ground in TX. 4 is what enables the

transverter. It is open in RX and Ground in TX. This is reflected on the matrix on the sequencer

schematic. If you wire it differently, use that matrix to note your changes.

For mast mount LNA operation with the basic transverter or with an external high power

amplifier, all switching tests should be done without RF applied. Verify that the switching is

completed in your desired sequence and gradually add in external components as verified. The

last test should be with the transverter’s RF applied. All testing can be done without coaxial cables

connected. Connect the transverters IF or TXIF cable last.

Step 1 +12VDC on RX for a preamp @ 500 mA maximum

Step 2 +12VDC on TX for a TR relay (around the preamp) @ 500 mA maximum

Step 3 Ground on TX to key a power amplifier. Sinks 100 mA maximum

Step 4 Ground on TX to key Transverter. Sinks 100 mA maximum

Optional Sequencer Connections:

Step 1 and 2. They can be connected to switch higher DC voltages. The DC voltage is applied to

the DC1 and DC2 connections on the board (30VDC maximum).

Step 2 TL2 is a secondary connection to the second step. It is a “LOW” on transmit. It can be

used to drive a relay or key an amplifier but an external isolation device should be utilized. It will

sink 100 mA maximum

Step 3 and Step 4. They have secondary outputs that are both “High” on transmit. They are

labeled PH3 and PH4. These should be isolated from devices that require high currents and are

intended to drive low current devices or Pass transistors or FETs. They will source 5mA.

The transverter’s sequencer may be by-passed to eliminate switching time delays The

external PTT input of the transverter may be connected directly to the transverter’s PTT input (see

component placement document) near C100 bypassing the sequencer.

/Kits/L70-28CK.doc 20 Rev. A 4/21/2011

Device/mode

Input

Output

Emitter/Source

Base/Gate

Collector/Drain

Q1 RX

NA

NA

1.4-2.0VDC

1.7-2.2VDC

8.4-9.1VDC

Q2 RX

NA

NA

TP1-Peak

1.4-2.0VDC

8.4-9.1VDC

CR2 RX

0.65-0.95VDC

0 VDC

NA

NA

NA

IC2 RX

0.65-0.95VDC

4.5-5.5VDC

NA

NA

NA

IC6 RX

0.65-0.95VDC

4.5-5.5VDC

NA

NA

NA

SEQPin1 RX

NA

13-14VDC

NA

NA

NA

IC5 pin2 TX

4.2-4.8VDC

NA

NA

NA

NA

IC3 TX

2.2-2.8VDC

4.5-5.0VDC

NA

NA

NA

IC4 TX

IC7 TX

2.2-2.8VDC

4.5-5.0VDC

NA

NA

NA

SEQ Pin2TX

NA

13-14VDC

NA

NA

NA

TIF TX

NA

12-14VDC

NA

NA

NA

Negative Voltage Option: If you have installed the negative voltage generator option, an

approximate -9VDC will be available on the AUX connector pin 4. To set this up with your

transceiver, connect pin 4 and one of the ground pins to your transceiver’s ALC input. Connect

your transceivers output to a power meter and load. With both the transverter and Transceiver

powered on, measure the output power of the transceiver on somewhere in the 28 MHz band to

verify that the ALC circuit within your transceiver is operating correctly. With the negative voltage

applied, there should be minimum power output (less than 1 watt or as low as a few mW’s

depending on what type of transceiver it is) With the power meter still connected, if the transverter

is powered off, the transceivers output power should come back to normal. Be careful if you are

using an mW power meter!! If it all checks out, continue with the transverter testing and installation

Connect the RF drive to the transverter and with the transverter switch on, you may then adjust the

TXIF drive level in the transverter for your desired output power level.

IMPORTANT NOTE:

to use your transceiver for other than transverter use, operating it with the RF/IF cable connected

without the ALC voltage running will damage the transverter. What is suggested is to place a

coaxial relay (SPDT) between the transverter’s IF port and the Transceiver’s RF port. Wire the

relay so that it directs the RF path to the Transverter when energized. Connect the +13.8SW buss

and ground to the relay through the AUX connector.

When the Transverter is switch on, the relay will direct the RF path of the transceiver to the

transverter and the transverter will apply the negative voltage to the transceivers ALC port. Power

the transverter off will simply switch the transceiver back to normal.

With all circuitry now checked close up the transverter. The TXIF and RXIF adjustments are

accessible through the bottom cover. The frequency adjustment is not and it is best not to drill an

extra hole for it. This will be explained in the General Operation, Oscillator section.

If you are using the ALC (negative voltage generator) circuit and you desire

Test Point Matrix

Q6 RX NA NA 0.35-.65VDC 0VDC 3.4-3.9VDC

/Kits/L70-28CK.doc 21 Rev. A 4/21/2011

1.5-2.0VDC 5.0-6.0VDC NA NA NA

Installation and Oper a t ion

Theory of Operation:

band of operation to the 28 MHz. band of a HF transceiver. Following the recommendations of the

HF transceiver’s operation manual for transverter use is the most important aspect of correct

transverter operation. If configured correctly, the transverter will convert both transmit and receive

signals to a new band of operation and seam “invisible” to your HF transceivers operation. In

simple terms, the transverter will not improve the performance of your HF transceiver but will not

cause any degradation of performance in any way.

Interfacing and Operation:

MOST IMPORTANT: When interfacing your transverter, it is recommended that all usable

features of the transverter are tested and proven before integrating the transverter into your

system. This means verify the transverter functions correctly with the transceiver before interfacing

to High Power amplifiers, mast-mount LN A’ s, and ex t er nal TR rel ays. During the initial setup of the

transverter, test all switching functions before applying RF. Implement one accessory at a time

confirming the switching function, then RF function. Start with low RF drive levels and gradually

increase to the final desired level.

It is assumed that since you have assembled this transverter to your specifications,

interfacing will be easy. But—we will offer some tips that may have been over looked. Start the

interfacing with good quality 50 ohm cables for the IF (28 MHz.) connections. These connections

may be low level or at the 25 watt level depending on your configuration and good quality BNC

type connectors with adapters to your transceiver are fine! The shielding quality is important to

prevent other 28 MHz signals from “Creeping” into your transceiver.

All transverters will require a PTT (to ground or positive voltage on TX) to enable the

transmit mode of the transverter. The PTT input to the transverter is a RCA connector. This cable

does not need to be shielded, but extra protection in a QRO station is a good idea! Most

transceivers have RCA connectors for PTT outputs but others have various connections. Be sure

to have whatever cable that is required ready to go.

The DC power cable should be connected to the desired power supply. If you require a

longer DC power lead, consider moving up one gauge to eliminate a voltage drop problem. Plan on

6 amp current drain

The AUX connector will contain all sequencer connections and any other special

requirements such as the negative voltage or any other inputs or outputs you desire. The matching

connector to the AUX connecter is supplied and should be wired before final interfacing.

If using a mast mount LNA, the IP3 performance of the transverter will be limited by the LNA

and total system IP3 performance will be degraded. The amount of degradation will depend on the

performance characteristics of the LNA. Yes, the total system gain can be controlled by the RXIF

gain control but the dynamic range of the transverter will be reduced by the amount of gain of the

LNA at the minimum. Such a system should have the capability of switching the mast mount LNA

out of the system. Use of an “In the Shack” LNA in front of the transverter is total nonsense! If you

believe your system is lacking gain and the transverter is in spec, find the problem in your

The basic principle of a VHF/UHF transverter is to convert a chosen

/Kits/L70-28CK.doc 22 Rev. A 4/21/2011

transceiver or—if you must, install an IF amplifier on 28 MHz so not to degrade the transverters

“RF” performance.

Another suggestion is if you are to use a mast mount preamplifier, you may consider

bypassing the transverters LNA. It requires removing R31 and R26 from the circuit. Then move the

RXRF connector cable to the C68 pad. You will need to scrape some solder resist from the ground

plane. This will utilize the diplexer and first filter in the receive chain and disable all DC power to

the Q6 FET.

Unless you have ordered a special order Crystal, the national calling frequencies will be on

50.100 or 28.100 MHz on you IF transceiver. Use of the transverter out si d e of th e Weak Sig nal

portion of the band is possible but slightly degraded performance may be expected. The

transverter is designed specifically for the weak signal portion of the band.

Setting your final output power of the transverter is recommended to be done in the CW

mode. BUT—verify that if you change modes of your transceiver, the drive levels do not change or

overdrive may occur in the SSB mode causing undesirable effects on the band!

The bar graph display is a relative power meter and is driven by the directional coupler and

RF detector circuit found in the Low pass filter section of the board (CR11, R76,R75,C108) RF is

detected and converted to DC voltage and conducted to the Bar graph display on the front panel.

If you find that you operate the transverter at any other level than what it is calibrated to you may

change it by adjusting VR1 on the display board. Also remember being that is a reference meter, if

your VSWR should increase, it may or may not show an increase or decrease on the bar graph

display.

General Operation: General operation of the transverter, if everything is adjusted correctly,

should be transparent to the transceiver and the user. Except for the frequency read out, (if your

transceiver doesn’t allow its display to be adjusted for transverter operation) it will be like operating

on 10 Meters. All of the functions of the transceiver (filtering, DSP, split band operation, dual VFO)

will be transposed to the frequency band of the transverter.

Some cautions should be taken when operating CW or VOX. Operating the transverter in a

“Full Break-in” mode is not recommended. Because of the mechanical relays in the transverter,

there will be too much delay to operate “Full Break-in” effectively. AND—the relays would be

abused if “Full break-in “is enabled. It is best to operate in “semi break-in” and adjust the delay of

the PTT on your transceiver to match your comfortable CW operating speed in a way that the delay

will hold the PTT until your transmission is complete. If you have implemented the sequencer, its

delay will need to be longer to allow all components within the system (Power amplifier, LNA,

relays,) to complete their transition if utilized. If just the transverter is to be used alone, the

transceiver PTT signal may be connected directly to the transverter’s PTT input bypassing the

sequencer. This will shorten up the delay but will still not allow “full break-in” without relay chatter.

General Operation, Oscillator: The transverter will experience frequency drift through aging.

Even if you took time to “Net” the frequency of the transverter’s local oscillator at its normal

operating temperature after a long bur n-in, frequency shift from ageing may still cause a need to be

re-adjusted after prolonged operation. This is because of the physical nature of crystal ageing

/Kits/L70-28CK.doc 23 Rev. A 4/21/2011

through temperature cycling. As the hours of operation time increase, this “Zero Offset” frequency

will be less and less and eventually will not require adjustment.

As for frequency drift during operation, great care has been taken to minimize it in the

design. The oscillator section of the transverter board is “Ovenized” and the speed of the cooling

fan on the heat sink is controlled by the actual heat sink temperature. The problem still arises from

the internal air temperature of the transverter and the heat conduction of the heat sink to the

oscillator section of the transverter board. The frequency drift the transverter exhibits may not be

noticed on SSB and CW operati on. But, a carful understanding of how much “drift” the transverter

exhibits and in what direction is moves is important for dig i tal mod e operat ion.

Our testing of this design was done with 30 second transmit and receive times at the

transverter’s full rated outp ut power. After a 10-15 min warm up time, we have found that the most

extreme drift will occur during the first few transmissions while the transverter reaches its stable

internal operating temperature. If the room temperature is less than 75 degrees F (approximately

25 degrees C) the cooling fan may be running slow or not at all. The first or second transmission

will cause the Fan to cycle and if the heat sink temp rises enough, it will remain running. The first

cycle will cause the largest frequency shift. The next 3-4 transmissions will stabilize the frequency

drift. At the 5th or 6th transmissions, the frequency drift will settle down to be 1-2 Hz or less if all

conditions remain the same during 30-second cycles. Of course this may better or worse

depending on the transmit power and duty cycle. An operation recommendation would be to start

your digital Sked a few minutes early and you will achieve frequency stability at the actual start

time of the Sked. Realistically expect 50 Hz total drift. Some factory production units have achieved

less than 30 Hz

What is expected to keep the frequency drift to a minimum is to be sure all un-used

connector holes in the rear panel either have connectors or holeplugs in them. The IF adjustment

holes on the bottom cover plate may remain open but the addition of extra holes or enlarging the

existing ones will affect the cooling.

Removal of the fan from the transverter will allow the transverter to drift as much as 500 Hz

over a ½ hr. 30 second cycle schedule. This may be acceptable for SSB and CW operation but

we have found the ambient fan noise of the transverter to be un-noticeable so if you desire to

operate with a digital mode, install the fan. AND—the opposite goes for adding an extra fan. It will

not help the “Balance” of heat and air and most like cause excessive drift. But, feel free to

experiment if you desire.

Examine the fan control circuit schematic. Voltage from the NTC Thermistor drives the NPN

transistor which in turn drives the Pass transistor on the negative lead of the Fan. R77 controls at

what temperature the fan starts. The larger the resistance, the lower temp the fan starts at. BUT—if

you find that in the TX mode, the heat generated causes excessive drift, the –F connection may be

connected to the open contacts on K1 so that the fan operates at full spee d during TX. Simply,

make the relay’s common connection to ground and run a wire between the NO contact and the –F

connection. The fan will now run at full speed during TX and its thermal speed on RX. Understand

that there is a delay in heat transfer and that the heatsink still heats up after the transverter is in the

RX mode.

/Kits/L70-28CK.doc 24 Rev. A 4/21/2011

Options Setup:

Common or Split IF Option: The IF configuration may be change at any time according to the

type of transceiver you are utilizing. Refer to t he Comp one nt placement or schematic for

clarification. The component designators are also screened on the circuit board.

K3 is the common IF relay. To split the IF lines into separate RXIF and TXIF, remove the IF

coax from its position on the board (junction of C93 and C94) and re-attach the center conductor

between C95 and K3. You may need to scrape a little solder resist from the pad before soldering.

The shield may be now soldered where it was on the ground pad marked COM. The TXIF cable

can be prepped and soldered to the pad between K3 and C92. The shield can be soldered to the

ground pad labeled TXIF. Install a BNC connector in the rear panel (TXIF) and attach the TXIF

coax. Reverse the procedure if you want to change to or back to Common IF.

Please note that if you have a separate IF configuration, the IF drive sense option will no

longer function. It is not necessary with the split IF. It is to protect the RX circuit and Mixer from

being damaged with the TXIF drive power.

TXIF Drive Level Range: The TXIF drive level range can be changed at anytime to conform to

your transceiver type. Basically, there are three configurations. For high IF drive levels, (250 mW25 watts) the 50 Ohm load will be installed with a low value capacitor in the C91 position (10 pF or

less for 25 watts). Mid level drives between 1mW and 250 mW will not have the load installed and

will have a 1000 pF capacitor installed for C91. For the low drive levels (-20dBm to 0dBm or 1mW)

IC7 will be installed. If you desire to change the drive level for whatever reason, just duplicate the

info above. To install IC7, cut the ribs in the trace before installing. -10 to -6dBm inputs, use a

MAR-3 for IC7. For -20dBm, use a MAR-6. Other MMIC’s may be used but the bias resistor R34

may need to be changed. Adjust R36 to obtain desired level in all cases. The important thing to

understand is the IF drive range is wide and can accommodate different drive levels between the

specified ranges.

Common or Split RF connections: The transverter utilizes K2 as the common RF relay. It is

mounted on the circuit board. The common port is marked ANT on the board. The split RF

connections are labeled TX and RX on the board at each end of the relay. There is no need to

remove the relay for the split connections. Simply remove C57 and C62 and solder coax directly to

the marked pads. So--, depending on which way you are going, install/uninstall cables and

connectors as required. Remember, if you have separate ports, they may be combined with an

external coaxial relay to provide versatility.

External Local Oscillator or Synth es i zer I nst all at ion : This is a future option and will be covered

in a future document after it has been fully developed. For now, if you wish to experiment with your

own design or external referenced stabilized oscillator, the connections are available on the LO

section of the board. There is a jumper wire installed between the +9VDC buss (near VR5) and the

+LO. A SPDT DC switch may be installed between the +9VDC and the +LO inputs or the +SYNTH

buss near C42 and R17. A voltage applied to this point will energize the Pin diode switch (CR2)

and allow RF input to the LO circuit through C41. Connect and use as desired. A +3 to +7 dBm

input would work well. See picture 30.

/Kits/L70-28CK.doc 25 Rev. A 4/21/2011

C1 1000 DISC CAP

R1 2.7K 1/4W RESISTOR

C2 100µF ELECTROLYTIC CAP

VR1 10K POTENTIOMETER

C3 0.1µF DISC CAP

X

X

X

1

+DC

GND

Power Meter

BAR1 BAR GRAPH DISPLAY IC1 LM3914

/Kits/L70-28CK.doc 26 Rev. A 4/21/2011

144MHz and 222MHz

Transverter Schematic

09/30/2010