Page 1

DOING OUR BEST TO PROVIDE YOU THE BEST

TO W -IT

TI110 & TI110SB TOW DOLLY

OPERATORS MANUAL

08/03

RD20006, Rev 3

ASSEMBLY

CALIBRATION

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

DEMCO Dethmers Mfg. Co. 4010 320th St. P.O. Box 189 Boyden, IA 51234

PH: (712) 725-2311 Toll Free: 1-800-543-3626 FAX: 1-800-845-6420

www.demco-products.com

Page 1

Page 2

IMPORTANT

We have discovered 1992 and newer model cars that are too wide in the body area to properly fit on a TI110 - 8' wide tow dolly

even though the front tire measurement is less than 70".

The 1992 and newer Oldsmobile 88 and 98 are in this category, there may be others. In addition to the standard measurement,

always follow weight limitations when using a Demco TOW-IT Tow Dolly.

TI100 - Standard Unit

3350 lbs. - Total Towed Vehicle Weight

WARNING: Exceeding weight limitations or not using a towing vehicle larger and at least 1,000 lbs. heavier

than the tow dolly and the towed vehicle combined can result in loss of towing vehicle control, separation of the tow

dolly from the towing vehicle, or separation of the towed vehicle from the tow dolly, causing severe personal injury,

death, or property damage.

CAUTION: All vehicles to be towed on Demco Tow Dollies must be towed with the front axle on the dolly.

TI110SB - Brake Unit

3500 lbs. - Total Towed Vehicle Weight

Table of Contents

General information............................................................................................................... 2

Safety Sign Locations ..........................................................................................................3

Bolt T orque ............................................................................................................................4

Safety and Maintenance .......................................................................................................4

T esting Lights........................................................................................................................5

Loading Instructions ........................................................................................................... 6-8

Limited Warranty ................................................................................................................... 9

Tow Dolly Parts List and Breakdown..................................................................................10-11

Assembly Instructions .......................................................................................................12-13

Surge Brake Assembly........................................................................................................ 14

Model DA66 Actuator Parts (replacemant only) ................................................................... 14

Model DA603 Actuator Parts ............................................................................................... 15

Model DA91 Actuator Parts (replacement only) ................................................................... 16

10î Brake Cluster Parts List and Breakdown .......................................................................17

Optional Winch..................................................................................................................... 18

Optional T ool Box ................................................................................................................. 18

Optional Spare Tire and Mount ............................................................................................ 18

Optional Wheel Jack ............................................................................................................ 19

Optional Deflector ................................................................................................................ 19

Optional Light Bar ................................................................................................................ 19

Tow Dolly Parts List and Breakdown..................................................................................16-17

Assembly Instructions .......................................................................................................18-19

"Reporting Safety Defects"

If you believe that your vehicle has a defect

which could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Dethmers Manufacturing Company (DEMCO).

If NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems between you, your dealer, or Dethmers Manufacturing

Page 2

Company (DEMCO).

To contact NHTSA, you may either call the

Auto Safety Hotline toll-free at

1-800-424-9393 (or 366-0129 in

Washington, D.C. area) or write to:

NHTSA,

U.S. Department of Transportation

Washington, D.C. 20590.

You can also obtain other information about

motor vehicle safety from the Hotline.

Page 3

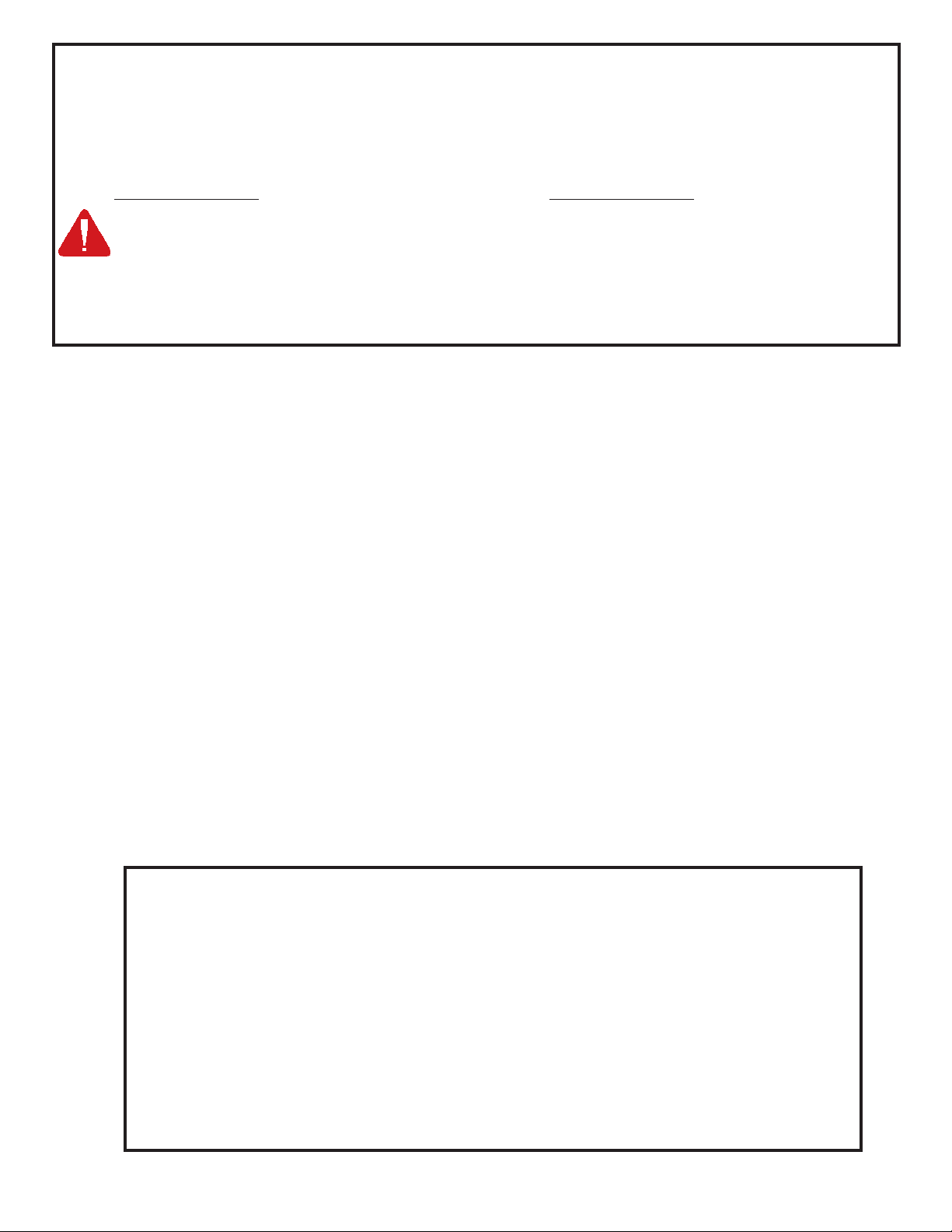

SAFETY SIGN LOCATIONS

Types of safety sign and locations on Tow It are shown in illustration below. Good safety

requires that you familiarize yourself with various safety signs, type of warning, and particular

function related to that area, that requires your SAFETY AWARENESS.

3

4

SAFETY DECAL PARTS LIST

REF.

NO. PART NO. DESCRIPTION

1. 04508 Amber Reflector

2. 04804 Red Reflector

3. RD21007 Instructions

4. DD21016 Winch Operation

5. DA21001 Tire Pressure

2

5

1

Page 3

Page 4

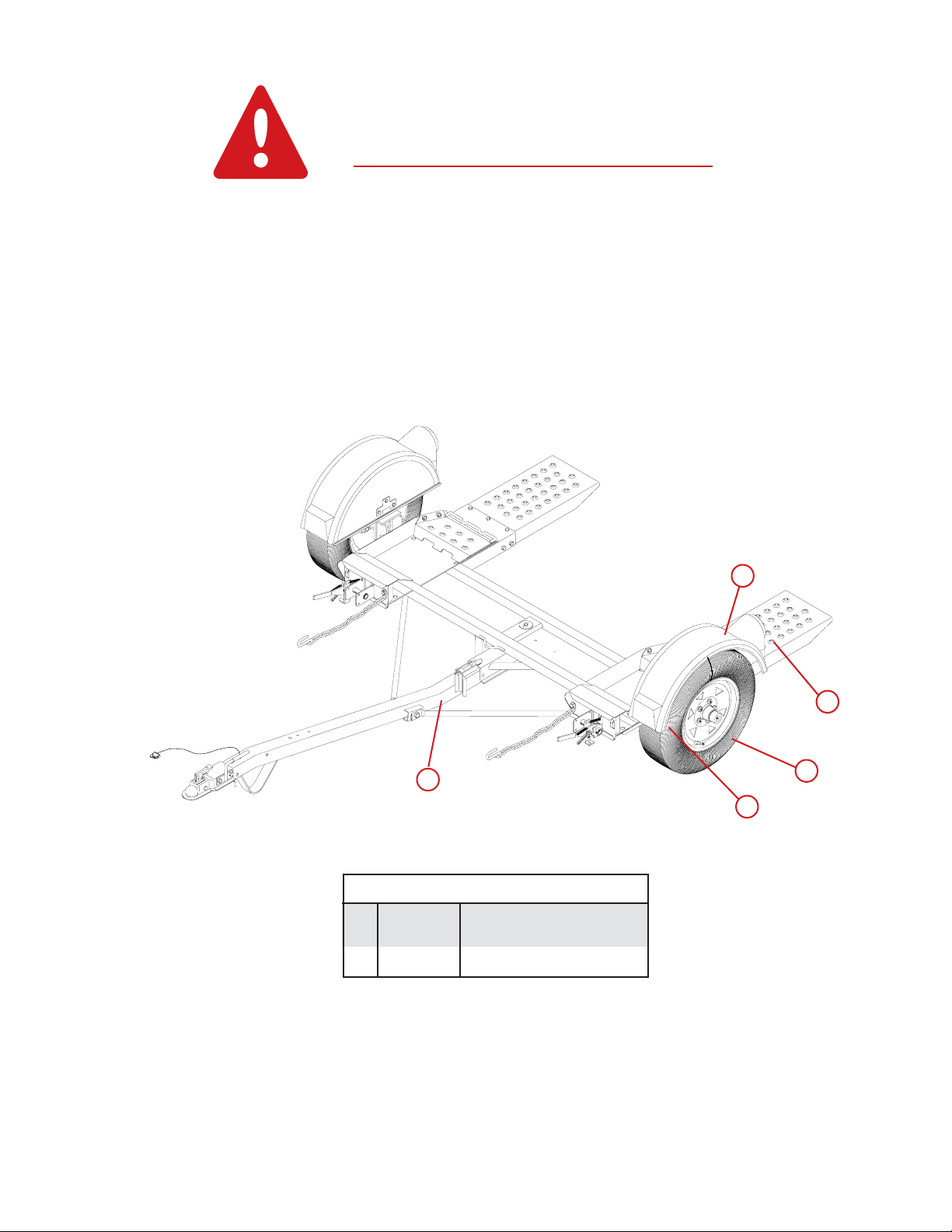

BOLT TORQUE

TORQUE DATA FOR STANDARD NUTS, BOLTS, AND CAP SCREWS.

Tighten all bolts to torques specified in chart unless otherwise noted. Check tightness of bolts

periodically, using bolt chart as guide. Replace hardware with same grade bolt.

NOTE: Unless otherwise specified, high-strength Grade 5 hex bolts are used throughout

assembly of equipment.

Bolt T orque for Standard bolts *

Torque Specifications

Torque figures indicated are valid for

non-greased or non-oiled threads and

heads unless otherwise specified.

Therefore, do not grease or oil bolts or

cap screws unless otherwise specified

in this manual. When using locking

elements, increase torque values

by 5%.

* GRADE or CLASS value for bolts

and capscrews are identified by their

head markings.

GRADE 2 GRADE 5 GRADE 8

A lb-ft (N.m) lb-ft (N.m) lb-ft (N.m)

1/4 6 (8) 9 (12) 12 (16)

5/16 10 (13) 18 (25) 25 (35)

3/8 20 (27) 30 (40) 45 (60)

7/16 30 (40) 50 (70) 80 (110)

1/2 45 (60) 75 (100) 115 (155)

9/16 70 (95) 115 (155) 165 (220)

5/8 95 (130) 150 (200) 225 (300)

3/4 165 (225) 290 (390) 400 (540)

7/8 170 (230) 420 (570) 650 (880)

1 225 (300) 630 (850) 970 (1310)

Bolt T orque for Metric bolts *

CLASS 8.8 CLASS 9.8 CLASS 10.9

A lb-ft (N.m) lb-ft (N.m) lb-ft (N.m)

6 9 (13) 10 (14) 13 (17)

7 15 (21) 18 (24) 21 (29)

8 23 (31) 25 (34) 31 (42)

10 45 (61) 50 (68) 61 (83)

12 78 (106) 88 (118) 1 06 (144)

14 125 (169) 140 (189) 170 (230)

16 194 (263) 216 (293) 263 (357)

18 268 (363) -- -- 364 (493)

20 378 (513) -- -- 515 (689)

22 516 (699) -- -- 702 (952)

24 654 (886) -- -- 890 (1206)

GRADE-2 GRADE-5 GRADE-8

CLASS 8.8 CLASS 9.8 CLASS 10.9

8.8

9.8

Page 4

10.9

Page 5

WARNING:

VEHICLE CONTROL, SEPARATION OF THE TOW DOLLY FROM THE TOWING VEHICLE, SEPERATION OF THE

TOWED VEHICLE FROM THE TOW DOLLY, CAUSING SEVERE PERSONAL INJURY, DEATH, OR PROPERTY

DAMAGE.

SAFETY

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN LOSS OF TOWING

MAINTENANCE

Safety is of utmost importance at all times. There are

several items that must be checked each time

using and

Make sure all bolts are properly tightened and those

requiring a set torque are up to specifications:

Lug Nuts - 75 to 80 ft./lbs.

Check Lug Nut tension after the first 5 miles and

periodically thereafter.

The ball hitch must latch securely around the ball and

the safety lock pin or lever must be in position to lock the

hitch on the ball.

RECOMMENDED BALL HEIGHT: 18 inches to the top

of the ball on the towing vehicle.

Hook the towed vehicle safety chains to the frame of the

vehicle directly above the area where the chain is

mounted on the Tow-It. Leave some slack in the chain

to allow suspension movement.

Check to make sure that all lights are in proper working

order.

Examine the winches and straps, making sure they are

in good conditon.

Be certain the safety lock pins are locking the strap

winches.

Retighten straps over the tires after the first 5 miles and

every 50 miles thereafter. Ensure that they are tight.

The TI110 tires must be inflated to the recommended 35

PSI.

The TI110SB tires must be inflated to the recommended

50 PSI.

The strap on the optional tongue winch must be in good

condition and should be stored neatly on winch when

not in use.

NOTE: The winch strap must not be left connected to

the towed vehicle after it is loaded and strapped down.

Make sure the optional light bar is fastened

the rear of the towed vehicle.

The wires to the optional light bar should be run along the

car and fastened so as not to damage the finish of the

towed vehicle.

NOTE: This unit cannot be backed up when loaded.

All vehicles mounted on the Tow-It must be mounted

with the front of the vehicle facing forward.

Rear Wheel Drive: Disconnect the towed vehicle

driveshaft for rear wheel drive vehicles with automatic

transmission.

For manual transmission: Consult your vehicle owners

manual for towing suitability with the drive shaft connected.

while using the Tow-It.

before

securely at

Periodically check all bolts and nuts to ensure proper

tension or torque.

An occasional drop of oil may be required on the moving

parts of the tie down winches.

Grease the center pivot pin grease zerk every 1500

miles.

Grease the main frame platform skids every 1500 miles.

These grease zerks are readily accessible from under

the front tire stop main platform.

Grease the Sure Lube

TM

Hubs every 3,000 miles.

Use High Quality Bearing

Grease with Hand Operated

Grease Gun.

IMPORTANT LOADING INSTRUCTION

Check your wheel tie-down straps.

Your Tow-It is equipped with custom made wheel

tie-down straps of a standard size that will fit most

tires, however if your tires are too large or too small

you will want to exchange these new straps for the

proper size straps.

1. Tire too large - This is very obvious. The strap

will not basket over the tire properly; call us,

we will provide at NO Charge on an exchange

basis, the proper size strap. You must return

your new unused straps and provide us with

the Make and Model of your car and the tire

size.

2. Tire too small - This is not as obvious. The

basket will fit down over the tire very well; the

problems cannot be readily seen. You must

tighten the straps down solid and then check

on the inside of the tire and be sure the strap,

when tightened, does not come in contact with

any metal that may cause wear or cutting such

as strut mounts. If there is contact, you need a

smaller strap, call us, we will provide on a NO

Charge, exchange basis, the proper size strap.

You must return your new unused straps and

provide us with the Make and Model of your

car and tire size.

Page 5

Thank you for Purchasing

Products.

Page 6

TESTING LIGHTS BEFORE USE

1. Check that the WHITE (ground) wire of the wiring harness

is connected to the Tow-It frame and the WHITE (ground)

wire is connected to the frame of the towing vehicle.

2. With headlights in "ON" position, the tail lights, the light

cluster bar, the license plate light, and the clearance lights

should be lighted.

3. Start engine and have someone depress brake pedal.

Brake lights of tow dolly and towing vehicle should come

"on" and "off" simultaneously with each application.

4. Turn left turn signal on. Left turn light of Tow-It and towing

vehicle should flash simultaneously. Should the turn

signal lights of the trailer function opposite to those of the

towing vehicle, it is probable that the YELLOW and GREEN

wires have been reversed. Check the plug connection

under the tongue of the Tow-It to make sure wire colors are

not crossed at that point. If plug connection is incorrect,

correct problem by reversing yellow and green wire connection on the towing vehicle.

LOADING INSTRUCTIONS

Refer to load limits on inside of front cover.

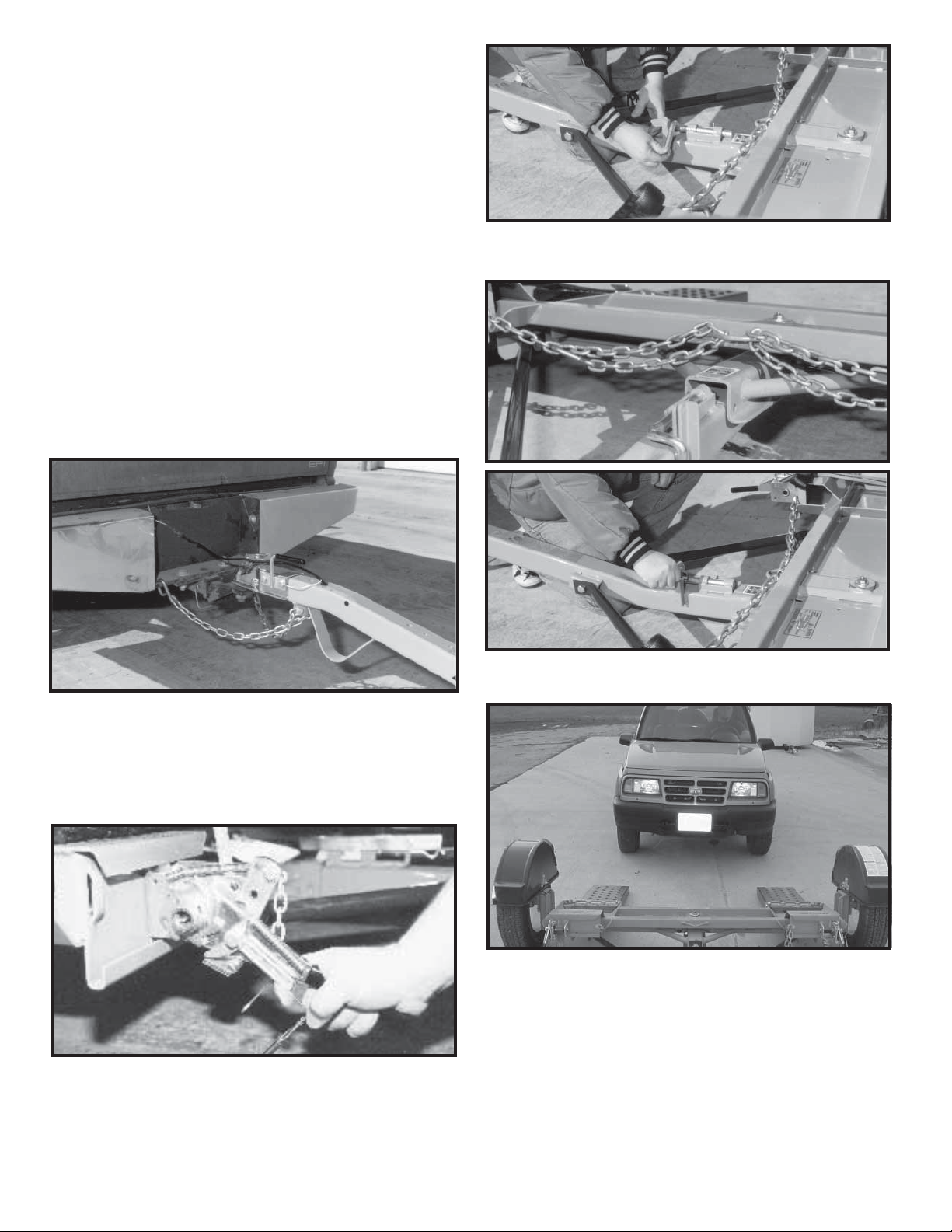

Step 3. To allow the wheel platform to tilt back for loading:

1) Swing the bottom of the locking latch (C) toward the hitch

far enough to allow locking pin handle to be lifted.

Step 1. Secure ball coupler to 2" (3,500 lb. capacity) towing

vehicle ball only. Make sure that the hitch and the hitch ball

are in good condition and not rusted, loose or stripped.

Recommended ball height is 18" to the top of the ball.

Make sure hitch is locked down and secured with safety clip.

Criss-cross safety chains under tongue and secure to towing

vehicle frame.

Step 2. Ensure that towed vehicle parking brake is fully

engaged, then release the tie-down straps. NOTE: Tie down

straps must be "quick -released" by grasping ratchet pawl and

ratchet handle simultaneously and pushing down sharply. This

process will permit easy removal of strap from winch.Remove

tie-down strap hook from its storage position at the rear of the

ramp. Lay the straps on the ground in front of the winches.

2) Pull locking pin toward the hitch as far as it will go. The wheel

platform will tilt back to allow loading.

Step 4. Before loading (and unloading) towed vehicle make

sure platform and towed vehicle are in straight alignment. Tow

dolly must be completely and properly hooked up to the towing

vehicle. Towing vehicle must be larger and at least 1000

lbs. heavier than the tow dolly and towed vehicle combined.

IMPORTANT: Tire tread width or body width of towed

vehicle must not exceed:

TI110 - 70" max. (outside to outside),

TI110SB 42" min. (inside to inside),

70" max. (body width)

Page 6

Page 7

Step 5. With someone safely guiding you, slowly drive vehicle onto platform FRONT FORWARD. (Any vehicle mounted

on tow dolly must be mounted with front of the vehicle facing

forward.) Drive the car forward until the tires touch the ramps.

Make sure the tire is aligned to ascend onto the ramps.

Step 7. Place one tie-down strap over each tire and secure

hooks to rods located at the rear of each wheel platform. The

short side of the hook must face the rear of the TOW-IT.

Step 8. Be sure tie-down winch is centered with the tire before

tightening straps.

Step 6. Drive vehicle onto platform - Front Forward - until

tires touch the wheel stops at the front of each side of the

platform and the platform tilts to a flat position. Make sure the

car is centered on the platform. Towed vehicle tires must fit in

wheel troughs without overhanging sides. Engage towed

vehicle parking brake. Shift loaded car into "park" and lock

steering wheel with front tires in a straight position. If the car

does not have a locking steering column the steering wheel

must be tied securely with front tires in a straight position.

Rear Wheel Drive: Disconnect towed vehicle driveshaft for

rear wheel drive vehicles with automatic transmission.

For manual transmission: Consult your vehicle owners

manual for towing suitability with the drive shaft connected.

IMPORTANT: Lock the platform in position by pushing

locking pin toward platform. Push the handle down as far

as possible so locking latch holds it in a locked down

position.

Step 9. While tightening straps, pull cross strap forward to

ensure even tightening. Tighten straps until each tire starts to

flatten against tire stop. After each strap is tight, insert a safety

pin in each winch. Disengage towed vehicle parking brake.

Straps must be retightened after first 5 miles of travel.

Check straps every 50 miles thereafter to ensure they are

tight and not rubbing or fraying.

(continue with Step 10 on following page)

Page 7

Page 8

Step 10. Make sure the tie-down strap is the correct size for

the auto tire. The picture above shows a correct fitting strap.

See page 1 of this instruction for proper fit and exchange

instructions.

Step 11. Hook the towed vehicle safety chains to frame of

vehicle directly above the area where the chains are mounted

on the TOW-IT. Leave some slack in the chains to allow

suspension movement of the towed vehicle. Review the

safety points on page 1 before moving vehicles.

Step 13. To pull the TOW-IT empty, make sure tie-down

straps are tightened in the storage position, and towed

vehicle safety chains are wrapped up and hooked. Tie-

down winch handles should be left in a down position (horizontal) with safety pins in place when towing loaded or empty. DO

NOT ATTEMPT TO PULL TOW-IT WITH WHEEL PLATFORM IN LOADING (tilted) POSITION.

DAMAGE PREVENTION

Check your vehicle manual or registration for vehicle weight.

Towing vehicle must be larger and at least 1,000 lbs. heavier

than the towed vehicle and tow dolly combined.

Do not pack goods in car that is being towed. Overloading the

Tow-It or exceeding the width limit may result in damage to

both car and Tow-It.

REAR WHEEL DRIVE PRECAUTIONS

Disconnect towed vehicle driveshaft for rear wheel drive

vehicles with automatic transmission. Simply placing transmission in neutral is not sufficient to prevent damage to

transmisssion. For manual transmission, consult your

vehicle owners manual for towing suitability with the drive

shaft connected.

ALL VEHICLES MOUNTED ON THE TOW-IT MUST BE WITH THE

FRONT OF THE VEHICLE FACING FORWARD.

Step 12. TO UNLOAD towed vehicle. Make sure that plat-

form and vehicle are straight. Reinstall driveshaft. Ensure that

towed vehicle parking brake is fully engaged, then unhook the

towed vehicle safety chains, and release the tie-down straps.

NOTE: Tie down straps must be "quick -released" by grasping

ratchet pawl and ratchet handle simultaneously and pushing

down sharply. This process will permit easy removal of strap

from winch.Swing the wheel platform locking latch handle

forward, towards the coupler. This will allow the platform to tilt

as you slowly drive off. Make sure the winch ratchet handles

are horizontal.

SAFETY

- Examine winches and straps to make sure they are in

good condition.

- Check wheel nuts every trip.

- Tires must be inflated to recommended pressure by tire

manufacturer.

- Be certain the safety lock pins lock the strap winches.

- Retighten the straps over the tires after the first 5 miles

of travel. Check straps every 50 miles thereafter to

ensure they are tight and not rubbing or fraying.

Page 8

Page 9

DEMCO PRODUCTS - TOW-IT Tow Dolly

ORIGINAL PURCHASERS LIMITED WARRANTY

1. Extent and Duration of this Warranty:

Your Demco Tow-It is warranted to be free from defects in

materials and workmanship under normal use and service for a

period of one year after date of purchase by the original (first)

retail owner, or until it is resold or transferred by the original

owner. Tires and lights are not included in this warranty.

Tires are warranted by the manufacturer against defects in

materials and workmanship, but not against road hazards.

Any part of the Demco Tow-It, except tires and lights, found in the

judgement of the manufacturer to be defective in materials or

workmanship will be repaired or replaced at the manufacturerís

option without charge for parts or labor to the original owner.

2. Manufacturer and Warrantor of Tow Dolly:

Dethmers Manufacturing Co.

4010 320th Street

P.O. Box 189

Boyden, IA 51234

(712) 725-2311

The manufacturer and warrantor of the tires has his name

permanently molded into the tires. Tire warranty questions and

claims can be taken directly to an authorized dealer of the tire

manufacturer.

3. Repair or Replacement Procedure:

If your Demco Tow-It develops a defect (except for tires or lights)

during the warranty period, promptly notify Dethmers Manufacturing Co. customer service department. Until such notice is

received, Warrantor will not be responsible for any repair or

replacement.

Upon receipt of notice from you, Warrantor will have a choice of

options in replacing any part it determines to be defective:

a) Warrantor may require you at your own expense to deliver

or ship the part to its factory or authorized dealer. Any

defective part will be repaired or replaced and returned to

you free of charge. Any part returned to Warrantor and

found not to be defective will be returned to you freight

collect with an explanation.

b) Warrantor may elect to ship a new part to its dealer to be

exchanged free of charge for the defective part returned

by you to the dealer.

c) Warrantor may elect to ship or deliver a replacement part

to your address.

Warranty claims on tires should be presented to a local authorized dealer of the tire manufacturer. Provide proof of purchase

when making a tire warranty claim.

4. Limitations on Warranty Coverage:

Coverage under this warranty will be effective only when a copy

of the original invoice, showing the date and location of purchase,

accompanies any claim for warranty.

Warrantor has no liability whatsoever and this warranty is null and void

if any Demco

negligence, misuse, accident or operated in any way contrary to the

operating and maintenance instructions as specified in the Demco

Ownerís Manual for that model tow dolly.

This warranty does not cover any tow dolly that has been altered

or modified so as to affect the tow dollyís operation, performance

or durability, or that has been modified to change the intended

use of the tow dolly.

Tow-It

has been misassembled or subjected to neglect,

This warranty does not cover:

1) normal wear and tear

2) road film or gravel damage to paint

3) paint

4) rust damage

5) Any Demco Tow-It that has been loaded in excess of the load

capacity stated on the tow dolly identification label.

Warrantor has a policy of continuous product improvement. We

reserve the right to change or improve the design of any Demco

Tow-It model, including but not limited to state of the art changes,

without assuming any obligation to modify any tow dolly previously manufactured.

Warrantor assumes no responsibility to the owner for loss of use

of the tow dolly, loss of time, inconvenience or other damage

consequential or otherwise, including, but not limited to expense for gasoline, expense of transporting the tow dolly to the

dealer and expense of returning the tow dolly, mechanicís

travel time, telephone or telegram charges, road service/towing

charges, rental of another tow dolly during the time warranty

repairs are being performed, travel, lodging, loss or damage to

personal property or loss of revenue or earnings.

5. Limitations of Implied Warranties:

All implied warranties, if any, expire and terminate upon expiration of this warranty. Some states do not allow limitation on

how long an implied warranty lasts, so this limitation may not

apply to you.

6. Limitation of Consequential Damages:

Warrantorís responsibility under this warranty extends solely to

repair or replacement of your Demco Tow-It and its component

parts.

Warrantor does not assume responsibility for, nor shall it be

liable for, any special, incidental or consequential damages.

Some states do not allow the exclusion or limitation on incidental or consequential damages, so the above exclusion or

limitation may not apply to you.

7. Use of Vehicle Identification Number (VIN):

The VIN is a 17 digit number located in the lower left corner of

the tow dolly identification label. The label is located on the left

side of the tow dolly frame. Be sure to include the VIN number

in all communications with Warrantor or its dealers concerning

the warranty.

8. Purchaserís Rights:

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

9. Exclusive Warranty:

This is the only express warranty made by Dethmers Manufacturing Co. on your Demco Tow-It and no agent, employee, or

other person is allowed to change or add to this warranty.

In addition, the warranty does not extend to repairs made necessary by normal use of parts, accessories or other equipment

which in the judgment of Warrantor, are either incompatible with

the Demco Tow-It, or affect its operation, performance or durability.

Page 9

Page 10

REF. QTY.

NO. PART NO. REQíD DESCRIPTION

1. 5432 1 Left Ratchet Winch Assembly (Plated)

2. 5433 1 Right Ratchet Winch Assembly (Plated)

3. 03569-95 1 Ratchet Frame

4. 03570-95 1 Left Spool Tube

- 03571-95 1 Right Spool Tube

5. 03577 1 Heavy Duty External Snap Ring

6. 03574-95 1 Ratchet Handle

7. 03668 1 18 Ga. Shim Washer

8. 03575-95 1 Left Ratchet Gear

- 03576-95 1 Right Ratchet Gear

9. 03666 1 5/16" x 1-1/4" Roll Pin

10. 02243 1 Black Vinyl Hand Grip

11. 05450 1 Winch Pawl

12. 01864 2 Winch Pawl Spring SS

13. 05449 1 Winch Pawl Bushing SS

14. 00004 1 5/16" Flatwasher

15. 05444 1 3/8"-16 UNC x 3/4" Hex Bolt w/epoxy Gr.5

16. 03572-95 1 Left Ratchet Pawl Arm

- 03573-95 1 Right Ratchet Pawl Arm

17. 03578 1 5/16"-18 UNC x 1/2" Shoulder Screw

18. 01998 1 5/16" Flatwasher SS

19. 02002 1 1/4" Flatwasher SS

20. 02772 2 1/4"-20 UNC Nylon Locknut

21. 01076 1 1/4"-20 UNC x 3/4" Hex Hd. Bolt Gr.5

22. 00214 1 1/4" Flatwasher

23. 05337 1 Lock Pin w/Cable

24. 01883 9 Electrical Wire Splicer

25. 01881 1 Trunk Connector

26. 04785 1 Front Half Trailer Wiring Harness

27. 04786 1 Rear Half Trailer Wiring Harness

28. 01863 2 5/8" Grommet

29. 04496 1 Lever Lock Coupler (5,000 lb.)

- 01855 1 Safety Lock Pin for coupler

30. 01338 2 1/2"-13UNC x 4-1/2" Hex Head Bolt (gr.5)

31. 02288-95 1 Handle

32. 02189 1 1/2" I.D. Handle Grip

33. 02178 1 2 1/2"-13UNC Nylon Insert Locknut

34. 02771 2 7/16"-14UNC Nylon Insert Locknut

35. 01853 2 24" Safety Chain with Hook

- 04194 - 7/16" "S" Hook for safety chains

36. 00059 12 3/8" Flatwasher

37. 01898 4 7/16"-14UNC x 1-1/4" Hex Head Bolt (gr.5)

38. 04792-26 1 Tongue

39. 02587 1 5/8"-11UNC Nylon Insert Locknut

40. 02434 1 5/8"-11UNC x 4-1/2" Hex Head Bolt (gr.5)

41. 03503 2 5/8"-11 UNC x 1-1/4" Hex Hd. Epoxied Bolt

42. 02747-25 2 Bracing Strut

43. 01254 2 1/2-13UNC x 1-1/2" Hex Head Bolt (gr.5)

44. 00085 11 1/2" Flatwasher

45. 02579-95 2 Pivot Bushing

46. 04825 1 3/8" I.D. x 1/2" O.D. Grommet

47. 02574-95 1 Lock Pin (Tongue)

48. 02583 1 3/16" x 1-1/4" Roll Pin

49. 04780-26 1 Undercarriage (09533-26 for TI110SB)

50. 02209 8 7/16"-20UNF Hex Nut (gr.8)

51. 02377 8 7/16"-20UNF x 1-1/2" Epoxied Bolt (gr.8)

52. 04782 2 14 x 6 rim (5 on 4-1/2" BC)

53. 01725 1 0 1/2"-20UNF Chrome Lug Nut

54. 04826 2 ST205/75R14 "C" Range BW Radial Tire

55. 04323-25 2 Tilt Bed Ramp

56. 00967 8 1/2"-13UNC x 1-1/4" Hex Head Bolt (gr.5)

57. 04168 6 7/16"-20UNF Nylon Insert Locknut

58. 04167 6 7/16"-20UNF x 1" Hex Head Bolt (gr.8)

59. 02592 1 4 3/8"-16UNC Nylon Insert Locknut

60. 05358 1 Left Fender (w/ wire protector & gr. wire)

61. 05357 1 Right Fender (w/ wire protector & gr. wire)

62. 04425 4 Tinnerman Fender Clamp

REF. QTY.

NO. PART NO. REQíD DESCRIPTION

63. 02298 2 22-1/2" Wire Protector

64. 05443 2 Cable Hanger - wire harness

65. 04944 2 Wire Strain Relief

66. 04508 2 Amber Fender Reflector

67. 02316 2 White Ground Wire

68. 04424-95 2 Back-Up Plate for fender

69. 00914 6 3/8"-16UNC x 1-1/2" Hex Head Bolt (gr.5)

70. 04804 2 Red Fender Reflector

71. 02313 2 3-way Plug Pigtail (tail light)

72. 05447 2 Rubber Mounting Grommet for light

73. 05446 2 Sealed Round Tail Light

74. 04781-26 1 Upper Half Mainframe

75. 03528 2 3-point Tie-Down Strap w/J-Hook & buckle

76. 01674 4 1/4" Drive Type Grease Zerk

77. 02383 2 36" Safety Chain with hook

- 04194 - 7/16" "S" Hook for safety chains

78. 04270-25 2 Rear Tire Stop

79. 00907 8 3/8"-16UNC x 1" Hex Head Bolt (gr.5)

80. 05570 1 1/2"-13UNC x 1" Epoxied Bolt (gr.5) w/zerk

81. 02578-95 1 1/2" Special Flatwasher

82. 02584 1 3/16" x 3/4" Roll Pin

83. 04083 1 1-3/4" O.D. Bronze Bushing

84. 5341-26 2 SureLube

TM

Hub and Spindle Assembly

85. 04499 6 3/8 External Tooth Washer

86. 00078 2 7/16 Lock Washer

TM

- 5341 2 Sure Lube

Hub Assembly

89. 01747 1 Hub

90. 01743 1 Grease Seal (NOK AD 2548 E)

91. 01744 1 Inner Cup (L68111)

92. 01745 1 Inner Cone Bearing (L68149)

93. 01748 1 Outer Cup (L44610)

94. 02264 1 Outer Cone Bearing (L44643)

95. 02265 1 Hardened Tongue Washer

96. 02266 1 13/16-20 UNF Jam Nut

97. 02267 1 Retainer Adjustment Washer for Jam Nut

98. 00116 1 5/32" x 1-1/2" Cotter Pin

99. 04789 1 Sure Lube Dust Cap

100. 01746 5 1/2"-20UNF x 1-5/8" lg. Stud Bolt

101. 04790-26 1 Spindle

Please order replacement parts by PART NO. and DESCRIPTION.

not included

for

Fulton

5000 lb.

33

coupler

5217

29

Coupler Repair Kit

26

28

24

25

Part# 07426

35

34

36

Hook Retainer

Replacement Only

35

38

37

Page 10

Page 11

LEFT WINCH SHOWN

23

20

16

13

12

6

21

11

8

22

17

18

7

10

75

14

80

44

81

2

83

36

15

9

79

19

4

20

12

5

3

31

30

41

66

42

77

32

37

84

45

86

44

47

36

59

43

33

48

41

101

72

61

65

64

40

76

67

62

62

63

68

69

5341

Sure LubeTM Hub Assembly

90

92

100

91

89

93

94

49

26

42

71

95

96

73

98

97

27

82

28

99

43

44

1

74

46

45

69

68

Page 11

33

59

60

50

85

58

59

78

51

57

70

84

33

71

44

72

56

73

55

54

52

53

Page 12

TOW-IT ASSEMBLY INSTRUCTIONS

1

16

17

8

18

13

10

14

7

15

11

12

1. Place the mainframe on blocks or some other sturdy support

so that the frame rests approximately 8"-10" off the ground.

Attach the tilt bed ramps (#1) as shown using three 7/16" x 1"

grade 8 bolts (#2) and lock nuts (#3) on the top of each ramp

and four 1/2" x 1-1/4" grade 5 bolts (#4), flatwasher (#5) and

locknuts (#6) (two on each side of the ramp). Torque the 7/16"

bolts to 80 ft. lbs. and torque the 1/2" bolts to 75 ft. lbs.

2. Hold the tongue (#7) up to

the front of the tow dolly and

locate the three bullet

connectors extending out

the back of the tongue and

plug into the connector pro-

Brown

Yellow

Green

Pigtail

Brown/Yellow

Brown/Green

truding from under the mainframe channel. Do not cross colors when making this

connection.

2

9

3

6

5

4

19

20

6. When assembling the tie-down strap to the tow dolly winch,

make sure the tie-down strap does not contain any twists and

the overlaps are to the inside. Weave the front of the tie-down

strap through the openings in the buckle. The buckle should

be approximately 8" from the end of the strap. Thread the strap

end through the winch slot. Bring the strap up and thread it back

through the buckle again. The buckle should be approximately 1-1/2" - 2" from the winch.

(Refer to drawing on page 9 for following steps)

7. Attach Hub and Spindle Assembly (#19) using 7/16" x 1-1/4"

Fine Thread Bolts (#20) and hex nuts.

8. Bolt the fenders (#21) on using 3/8" x 1-1/2" gr. 5 bolts (#22),

back-up plates (#23) and locknuts (#24) in each fender. Mount

the fender with the light pocket to the rear. Attach the white

ground wire (#25) (the end with the eye loop on it) under the

center top bolt head.

3. Mount the tongue to the front of the tow dolly using one 5/8"

x 4-1/2" grade 5 bolt (#8) and locknut(#9) (torque to 50 ft. lbs.).

Do not torque over 50 ft. lbs. or the bed will not tilt. Make sure

the tongue latch is in the latched position to the tilt bed.

4. Secure the coupler (#10) and lift handle (#11) to the front end

of the tongue with two 1/2" x 4-1/2" gr.5 bolts (#12) and

locknuts (#13) . The white ground wire (#14) is attached under

the head of the second bolt attaching the coupler. (It is very

important that a good ground is made). Torque the locknuts

to 75 - 80 ft. lbs. Tap a rubber grip (#15) onto the handle with

a rubber hammer or a wooden mallet.

5. Remove the 7/16" x 1-1/4" bolt (#16), flatwasher, and locknut

from the outer front panel of each wheel platform tire stop.

Slide the tie-down winch (#17) into the channel at the front of

the wheel platforms as shown. Note that #17 is the left winch.

The ratchet handles are to the outside of each winch and

ratchet springs are to the top. Attach two 36" towed vehicle

safety chains (#18). Secure one chain to each wheel platform

tire stop with the 7/16" x 1-1/4" bolt (#16) , flatwasher and

locknut.

NOTE: It i s advantageous to wire the fender lights prior to

attaching the wheels.

9. Cut off stripped ends of the wiring harness, cut off stripped end

of the white ground wire. The yellow/brown wires must be run

to the left tail light pocket. The green/brown wires must be run

to the right tail light pocket. Start at either fender, pull the loom

at the center of the fender downward and push the green/

brown (or yellow/brown) wires upward through the loom until

it comes out the loom by the light pocket. Push the white ground

wire through the slit in the top of the loom in the fender trough

and push the wire toward the light pocket.

10. Make sure all three wires are coming out the fender wire loom.

Slide the rubber fender grommet over the wires and up close

to the wire loom.

Push the hollow looped end of the loom hanger into the small

hole under the fender pocket in the side of the fender. Leave

the holder open.

Pull the three wire pigtail wires through the hole in the fender

pocket outward. When wiring the pigtail into the tow dolly

Page 12

Page 13

Triple Wire Plug

from Light

White

Red

Black

Brown

Yellow or

Green

WIRING DIAGRAM FOR THE AUTO

TRANSPORT FENDER

Wire

Connector

White

White Ground Wire to

Yellow/Brown or

Green/Brown

Fender

24

33

34

21

29

25

32

23

31

22

30

34

COLOR CODE FOR WIRING HARNESS

WHITE Ground

BROWN Tail Lights and License Plate Light

YELLOW Left Turn and Stop

GREEN Right Turn and Stop

27

26

29

25

22

21

23

24

35

harness at the fender pocket, the wire ends SHOULD NOT be

stripped. Use the wire connectors to make all contacts. Lay

the wire in the connector, pinch securely with a pliers, closing

the wire connector. Splice the white wire of the pigtail to the

white ground wire from the fender. Splice the black wire to the

brown wire. Splice the green (or yellow) wire to the red wire

of the pigtail. The connections are made on the outside of the

fender pocket and pushed into the fender pocket through the

pocket hole. Pull the wires back into the fender pocket and

push the strain relief into the fender with the wire loom close

to the clip. Wrap the loom hanger tie around the wire loom and

insert the peg into the fender.

11. Push the round rubber light seal (#26) into the light pocket.

Be sure the lip is secured in the light housing. Plug the pigtail

into the fender light. Push the round light (#27) into the rubber

seal until it snaps in firmly. Wire the other fender in the same

manner.

12. Attach the tire/rim assembly to the mainframe. Use the

supplied lug nuts (#28) and torque to 75 - 80 ft. lbs.

38

35

37

36

28

14. Attach the two 24" transport safety chains (#35) to the two

holes in the angle located under the tongue using two 7/16"

x 1-1/4" grade 5 bolts (#36), flatwashers (#37), and locknuts

(#38). Torque bolts to 50 ft. lbs.

WIRING OF THE TOWING VEHICLE

Connect wiring to towing vehicle, keeping in mind the

color code indicated below.

1. Make certain towing vehicle lights are "OFF".

2. Connect YELLOW wire to left turn signal and stop

wire in the left rear of towing vehicle with the wire

splicer (01883 X) supplied.

3. Connect GREEN wire to the right turn signal and

stop wire.

4. Connect BROWN wire to tail light wire.

13. Lay the bracing struts (#29) out along the tow dolly tongue

with the back end (the end with the larger hole in it) of the

bracing strut toward the mainframe. Loosely bolt the back of

each bracing strut to the trailer frame as shown using 1/2" x

1-1/2" grade 5 bolt (#30), flatwasher (#31), pivot bushing

(#32) and locknut (#33). Hold up the front end (the end with

the smaller hole) of each bracing strut to the tongue, align

holes and secure with a two 5/8" x 1-1/4" epoxied bolt (#34).

Torque the 1/2" x 1-1/2" bolt with the pivot bushing to 75 ft. lbs.

5. VERY IMPORTANT - connect WHITE wire to frame

body of towing vehicle. This is the common ground,

and a clean metal - to - metal contact must be made.

CAUTION: Many flashers for vehicle turn signals

will not carry the additional load of TOW-IT turn

signals. If normal operation does not occur when

connected to the TOW-IT, a heavy duty replacement flasher may be obtained through auto parts

outlets.

Page 13

Page 14

NOTE: When installing DA603

onto T ow It be sure to pull

brake line out of tongue and

fasten it to the Actuator . Then

slide the Actuator , brake

line, and lift handle onto

tongue and attach with

supplied fasteners.

23

4

6

20

11

SURGE BRAKE ASSEMBLY

12

11

5

3

1

10

9

8

21

7

11

12

14

15

11

16

13

17

16

18

19

25

24

2

22

BRAKE LINES PARTS LIST

REF. QTY.

NO. PART NO. REQíD. DESCRIPTION

1. 02189 1 Handle Grip

2. 02383 2 36" Safety Chain

3. SB587 1 80" Brake Line

4. 01863 1 5/8" Rubber Grommet

5. 02746 1 54" Protective Hose

6. 04792-26 1 Tongue

7. SB7H66 1 7" Brake Hose

8. 00496 1 5/8 x 14 Ga. Machine Washer

9. SB7764 1 Retaining Clip

10. SB512 1 12" Brake Line

11. 02549 4 Rubber Brake Line Protector

12. SB544 2 44" Brake Line

DA66 ACTUATOR PARTS (REPLACEMENT ONLY)

5398 Master Cylinder Repair Kit

(gasket 05681 included)

5495 Coupler Repair Kit

not included

for

Fulton

6000 lb.

coupler

7

7

5

1

2

13

12

2

10

8

9

6

4

6

23

14

10

2

11

17

16

15

27

20

21

20

18

19

19

25

25

23

Page 14

13. 04791-26 2 Spindle w/Brake Flange

14. 02209 6 7/16"-20UNF Hex Nut (Gr.8)

15. 00078 6 7/16" Lockwasher

16. SB8798 6 7/16"-20UNF x 1-1/8" Knurled Shoulder Bolt

17. 00059 4 3/8" Flatwasher

18. 00060 2 3/8" Lockwasher

19. 00907 2 3/8"-16UNC x 1" Hex Head Bolt (Gr.5)

20. 02288-95 1 Handle

21. SB7785 1 Tee, Brass

22. 01338 3 1/2 -13 UNC x 4-1/2 Hex Head Bolt, Gr. 5

23. 02178 3 1/2 -13 UNC Nylon Insert Locknut

24. 8606301 1 Model DA603 plated drum brake Actutator

25. 10415 - Gr. 8 Stud (Replacement only)

- SB15545 4 10" Brake Drum

- SB23715 - Left Hand Cluster

- SB23714 - Right Hand Cluster

ACTUATOR PARTS LIST

REF. PART QTY.

NO. NO . REQíD. DESCRIPTION

- 8606701 1 Brake Actuator complete (incl. ref. 1-24)

1. 07599-95 1 6000# 2" Ball Coupler (Fulton)

2. SB23278 4 Roller

3. 05957-95 1 Front Roller Spacer

4. 02166 1 3/8"-16UNC x 2-3/4" Hex Head Bolt (gr.5)

5. 07176 1 3/8"-16UNC Stover Lock Nut

6. 05684 2 1/2"-13UNC x 4-7/16" Hex Head Bolt (gr.5)

26

7. 02178 2 1/2"-13UNC Nylon Insert Lock Nut

8. 05959 1 Push Rod Assembly

9. 05692 1 Damper/ Shock

10. 05958-95 2 Rear Roller Spacer

11*. 05951 1 Emergency Lever

12. 05955-95 1 Front Cover

13*. SB24700 1 2' Cable with S-Hooks

14. SB10555 2 Replacement S-Hook ONLY

15. 05960 2 5/16"-18UNC x 1/2" Self-Tapping Screw

16. 05424 2 5/16" External Tooth Lock Washer

22

17*. 05693-95 1 Emergency Lever Spring

18. 03876 1 Master Cylinder Cap

19. 01076 4 1/4-20UNC x 3/4" Hex Head Bolt Gr 5

24

20. 00057 2 1/4" Lock Washer

21. 03564-95 1 Outer Case

22. 05681 1 Replacement Master Cyl. Gasket ONLY

23. 5650 1 Composite Master Cylinder Kit w/ 09153

24. SB12098 1 1/8" pipe - 3/16" inverted Flare Fitting

25. 05695 2 1/4 Internal Tooth Lock Washer

26. 05966-95 1 Rear Cover

27. BH21004 1 Decal, Preset Fasteners

- 5400 - Lever Replacement Kit (incl. items w/*)

- 5398 - Master Cylinder Repair Kit w/ gasket

- 5495 - Coupler Repair Kit

Page 15

DA603 BRAKE ACTUA TOR P ARTS BREAKDOWN

Components not

sold separately

23

5695 Emergency Lock Cam

Replacement Kit

3

10a

21

13

20

22

11

11

17

12

Item #23

includes cable

23

6

12

18

22

9

7

4

1

20

15

16

14

21

8

5

2

2

10

Item #10 is not

included in 5696

18

5398 Master Cylinder Repair Kit (drum)

(gasket 09153 included)

ACTUATOR PARTS LIST

REF.

NO. PART NO. QTY. DESCRIPTION

- 8606301 - Plated Actuator f/ drum brakes

1. 00057 4 1/4î Lock Washer

2. 00062 4 1/4î-20 UNC Hex Nut

3. 00179 1 3/8î-16 UNC Lock Nut (Center Punch)

4. 00618 4 1/4"-20UNC x 2" Hex Head Bolt (Gr.5)

5. SB12098 1 .018 Connector Orifice (Drum Brakes)

6. 02207 1 3/8î-16UNC x 3î Hex Head Bolt (Gr. 5)

7. 03876 1 3 Tab Fill Cap w/ Diaphram & O-Ring

8. 09153 1 Master Cylinder Gasket

9. 10616 1 Composite Master Cylinder (drum)

10. 11367-95 1 Coupler/Inner Slider (plated)

10a. 5698 - Coupler/Inner Slider w/ Lever Lock Assy.

11. 11368 2 Top Plastic Slider

12. 11369 2 Bottom Plastic Slider

13. 11371-95 2 Shock Spacer (plated)

14. 11389-95 1 Rear Shock Pin (plated)

15. 11390-95 1 Outer Case (plated)

16. 11401 2 External Snap Ring

17. SB12426 1 Damper

18. 05687 1 Protective Boot (incl. in 10616 & 5398)

(incl. in 10616 & 11190)

5696 Coupler Repair Kit

(2î lever lock)

**Components not sold separately**

REPLACEMENT KITS

(components not sold separately)

5695 - Emergency Lock Cam Replacement Kit

20. ----- 1 7/16î-14UNC x 1 1/4î Hex Head Bolt (Gr. 5)

21. ----- 1 7/16î-14UNC Lock Nut (Center Punch)

22. ----- 1 Emergency Catch Cam (black oxide finish)

23. ----- 1 Pushrod Assembly (includes cable)

5696 - Coupler Repair Kit (2î lever lock)

5398 - Master Cylinder Repair Kit (drum)

Please order replacement parts by PART NO. and DESCRIPTION.

Page 15

Page 16

10î BRAKE CLUSTER PARTS LIST

4

5

16

7

16

1

Left Side Breakdown

6

2

2

8

13

19

3

11

10

12

9

10

17

15

18

17

14

17

18

17

10" BRAKE CLUSTER PARTS LIST

REF. PART QTY.

NO. NO . REQíD. DESCRIPTION

- SB23715 - Left Hand Cluster (shown above)

- SB23714 - Right Hand Cluster

1. SB24636-30 1 Back Plate Assembly

2. SB9254 2 Cover Plate - Adjusting Hole

3. SB10954 1 Brake Shoe Kit (includes 2 Primary & 2 Secondary)

4. 04305 2 5/16"-18UNC-Gr5 x 1/2" Hex Hd Bolt

5. 05424 2 5/16" External Tooth Washer

6. SB9776 1 Wheel Cylinder Assembly - Right

- SB9777 1 Wheel Cylinder Assembly - Left

7. 05431 1 Bleeder - replacement

8. SB9783 1 Push Rod

9. SB24047 1 Adjusting Screw Assembly - "R" (for LEFT cluster)

- SB24048 1 Adjusting Screw Assembly - "L" (for RIGHT cluster)

10. SB10958 2 Spring - Shoe

11. SB10961-95 1 Shoe Guide

12. SB23937 1 Cable

13. SB23936 1 Cable Guide

14. SB23724 1 Spring Adjusting Screw

15. 05414-95 1 Lever - Left

- 05415-91 1 Lever - Right

16. SB10959 2 Pin - Shoe Hold Down

17. SB9789 4 Cup Shoe Hold Down

18. 05983 2 Spring - Shoe Hold Down

19. 03880 1 Spring - Adjusting Screw Retainer

- SB15845 1 Wheel Cylinder Repair Kit (w/ spring, cup, & boot)

- SB15545A 10î Hub/Drum (w/ bearings, seals, nuts, & dust cap)

- SB15545 4 10" Brake Drum

Please order replacement parts by PART NO. and DESCRIPTION.

Brake shoe kit can be ordered for one complete axle only.

Page 16

Page 17

MODEL DA91 ACTUATOR PARTS BREAKDOWN

8

23

**12

**10

13

8

14

17

14

18

5398 Master Cylinder Repair Kit

(gasket 05681 included)

11

not included

28

4

5495

Coupler Repair Kit

2

9

2

1

3

2î Lever Lock Coupler

RATED AT 6000#

BLEEDING THE SYSTEM

The first requirement for safe, sure hydraulic braking is the use

of quality brake fluid. Use only DOT-3 or DOT-4 brake fluid from

a sealed container.

If pressure bleeding equipment is available, follow the

manufacturerís instruction in bleeding the system.

If system must be bled manually, proceed as follows: Fill

master cylinder with fluid. Install bleeder hose on first wheel

cylinder to be bled.

Have loose end of hose submerged in brake fluid in glass

container to observe bubbling.

By loosening the bleeder screw located in the wheel cylinder

one turn, the system is open to the atmosphere through the

passage drilled in the screw. Pump actuator with long steady

strokes. The bleeding operation is completed when bubbles

no longer rise to the surface of the fluid. Be sure to close

bleeder screw securely.

Repeat bleeding operation at each wheel cylinder. During the

bleeding process, replenish the brake fluid, so the level does

not fall below the 1/2 full level in the master cylinder reservoir.

After bleeding is complete, make sure master cylinder reservoir is filled and filler cap is securely in place.

After the bleeding operation has been completed, apply pressure to the system and check the whole brake system for leaks.

28

27

**16

15

15

25

9

26

6

7

9

20

21

5

24

19

Model 91 ACTUATOR PARTS LIST

REF.

NO. PART NO. QTY. DESCRIPTION

1. 09417 1 6000# 2" Lever Lock Coupler (zinc plated)

2. 01896 3 1/2"-13UNC x 4" Hex Head Bolt (gr.5)

3. 02178 3 1/2"-13UNC Nylon Insert Lock Nut

4. 05426 1 Front Shock Pin (drop tube actuators)

5. 11079-95 1 Drop Tube Actuator Slider (plated)

6. SB12426 1 Damper/ Shock

7. 11164-95 1 3 Bolt Mount Outer Case (plated)

8. 05424 2 5/16" External Tooth Lock Washer

9. 02363 2 5/32" x 1 1/4 Cotter Pin(Qty 3 w/drop tube)

**10. 05408 1 3/32" Cable with hooks

11. SB10555 - Replacement S-Hooks ONLY

**12. 05693-95 1 Emergency Lever Spring (plated)

13. 05961 2 5/16"-18UNC x 5/8" Hex Head Bolt (gr.5)

14. 00618 4 1/4-20UNC x 2" Hex Head Bolt (gr.5)

15. 00057 4 1/4" Lock Washer

**16. 05951 1 Emergency Lever Assembly

17. 03876 1 Master Cylinder Cap w/ Diaphragm & O-ring

- 05849 1 O-Ring Only (not shown)

18. 05977 1 Push Rod Assembly

19. 00062 4 1/4-20 UNC Hex Nut

20. 09153 - Plastic Master Cyl. Gasket ONLY

21. 10616 1 Master Cylinder

- 11190 - Master Cylinder

22. SB12098 1 .018 Connector Orifice (Drum Brakes)

- 05679 1 Inverted Flare Adapter (Disc Brakes)

23. 03866-95 1 Lever Guide (plated)

24. 05687 1 Master Cylinder Protective Boot

25. 05986-95 1 Connecting Pin (plated)

26. 10965 1 Upper Slider

27. 10966 1 Lower Slider

28. 10967 2 Side Spacers

- 5401 - Lever Replacement Kit (incl. items w/**)

- 5650 - Master Cyl. Replacement Kit (drum)

- 5495 - Coupler Repair Kit

Please order replacement parts by PART NO. and DESCRIPTION

22

19

Page 17

Page 18

OPTIONAL WINCH

4

PARTS LIST

REF. QTY.

5

6

1

6

3

2

NO. PART NO. REQíD. DESCRIPTION

KK2W 1 Optional Winch

1. 04620 1 Winch Mechanism (1400 capacity)

- 04621 - Replacement Handle

2. 01738 1 Strap Assembly (includes strap & hook)

3. 02207 1 3/8"-18UNC x 3" Hex Hd. Bolt (gr.5)

4. 02769 2 3/8"-16UNC x 4" Hex Head Bolt (gr.5)

5. 00059 2 3/8" Flatwasher

6. 02592 3 3/8"-16UNC Nylon Insert Locknut

Please order replacement parts by PART NO. and DESCRIPTION.

* All options may not mount on tow dolly simultaneously.*

OPTIONAL TOOL BOX

PARTS LIST

KK2TB QTY. Optional Tool Box

1. 00059 4 3/8" Flatwasher

2. 02592 8 3/8"-16UNC Nylon Insert Locknut

3. 01888-25 1 Tool Box

4. 00182 1 Small Hair Pin

5. 02717-25 2 Mounting "Z" Bracket

6. 00907 4 3/8"-16UNC x 1" Hex Head Bolt (gr.5)

7. 02759 2 3/8"-16UNC x 3" Square U-Bolt

Please order replacement parts by PART NO. and DESCRIPTION.

* All options may not mount on tow dolly simultaneously.*

OPTIONAL SPARE TIRE and MOUNT PARTS BREAKDOWN

4

6

7

7

2

6

5

REF. QTY.

NO. PART NO. REQíD. DESCRIPTION

- KK10STB 1 Optional Spare Tire and Rim

1. 04826 1 ST205/75R 14"x"C" BSW Radial Tire

2. 04782 1 6" x 14" Rim 4-1/2" Bolt Circle

1

4

3

2

3

7

Drive in stud here for

tire with rim #04782 (4-

1/2" bolt circle)

8

2

1

5

* All options may not mount on tow dolly simultaneously.*

KK6STM 1 Spare Tire Mounting Bracket

3. 02193-25 1 Spare Tire Bracket

4. 02917 1 Stud Bolt (12mm x 1.5)

5. 02933 2 Wheel Nut (12mm)

6. 02759 2 3/8"-16UNC Square U-Bolt

7. 00059 2 3/8" Flatwasher

8. 02592 4 3/8"-16UNC Nylon Insert Locknut

- KK6TC Optional Spare Tire Cover

Please order replacement parts by PART NO. & DESCRIPTION.

Page 18

Page 19

OPTIONAL WHEEL JACK

3

2

3

2

- KK2WJ QTY. Optional Wheel Jack w/ hardware

1. 02769 4 3/8 UNC x 4 Bolt, Gr. 5

2. 00060 4 3/8 Lock Washer

WHEEL JACK PARTS LIST

3. 00061 4 3/8 Hex Head Nut

Please order replacement parts by PART NO. and DESCRIPTION.

1

* All options may not mount on tow dolly simultaneously.*

OPTIONAL DEFLECTOR PARTS BREAKDOWN

REF. PART QTY.

NO. NO. REQíD. DESCRIPTION

1. 02592 4 3/8"-16UNC Nylon Insert Lock Nut

2. 02759 2 3/8"-16UNC Square U-Bolt (fits around 3" tube)

3. 00161-95 2 Lock Handle

4. 02054-25 1 Deflector Slide Mount

5. 00095 4 3/8"-16UNC x 3/4" lg. Square Head Set Screw

6. 02743-25 1 Deflector Upright Post

7. 02165 1 Deflector Lacing Cord (1/8" x 25 ft.)

8. 02161 1 Deflector Fabric

9. 02055-25 2 Deflector Framework

Please order replacement parts by PART NO. and DESCRIPTION.

OPTIONAL DEFLECTOR PARTS LIST

KK2DF Optional Deflector

7

8

6

1

5

3

4

3

9

OPTIONAL LIGHT BAR (KKLB) PARTS BREAKDOWN

LIGHT BAR PARTS LIST

REF. PART QTY.

NO. NO. REQíD. DESCRIPTION

KKLB Kar Kaddy Light Bar (complete)

1. 01772 2 Nylon Security Strap with hooks & tightener

2. 01857 1 Left Tail/ Brake and Signal Light w/Lenses

3. 01773 1 Brown Jumper Wire

4. 01886 4 Wire Holder (metal)

5. 02385-25 1 Light Bar Framework

6. 02386-25 2 Adjustable Light Bracket

7. 01856 1 Right Tail/ Brake and Signal Light w/Lenses

8. 02772 10 1/4"-20UNC Nylon Insert Locknut

9. 00092 6 1/4"-20UNC x 1/2" Hex Head Bolt

10. 01777-25 2 Light Bar "Z" Bracket

11. 01778 4 3" Suction Cup w/Bolt (#13)

12. 02198 1 Light Bar Wiring Harness (new style)

13. 00068 4 1/4"-20UNC x 3/4" Hex Head Bolt

14. 01911 - Large Red Lens

15. 01912 - Small Red Lens

Please order replacement parts by PART NO. and DESCRIPTION.

2

6

1

8

9

8

9

1

4

8

12

7

14

9

8

5

9

1

13

10

11

2

3

15

13

1

11

COLOR CODE FOR WIRING HARNESS

WHITE Ground

BROWN Tail Lights, License Plate Lights,

Light Cluster Bar & Clearance Lights

YELLOW Left Turn and Stop

GREEN Right Turn and Stop

Page 19

Page 20

Page 20

Loading...

Loading...