Demco KK260, KK360 User Manual

8-03

RD20005,Rev 3

DOING OUR BEST TO PROVIDE YOU THE BEST

KAR-KADDY

KK260 (8’WIDE) & KK360 (8-1/2’ WIDE) |

|

|

OPERATORS MANUAL |

ASSEMBLY |

READ complete manual CAREFULLY |

CALIBRATION |

BEFORE attempting operation. |

OPERATION |

|

REPLACEMENT PARTS |

|

DEMCO • Dethmers Mfg. Co. • 4010 320th St. • P.O. Box 189 • Boyden, IA 51234 |

|

PH: (712) 725-2311 • Toll Free: 1-800-543-3626 • FAX: 1-800-845-6420 |

|

|

www.demco-products.com |

Page 1

Introduction

Thank you for purchasing a Demco Kar-Kaddy. We feel you have made a wise choice and hope you are completely satisfied with your new piece of equipment.

GENERAL INFORMATION

1.Unless otherwise specified, high-strength (grade 5) (3 radial-line head markings) hex head bolts are used throughout assembly of this piece of equipment.

2.Whenever the terms "LEFT" and "RIGHT" are used in this manual it means from a position behind the Kar-Kaddy and facing forward.

3.When placing a parts order, refer to this manual for proper part numbers and place order by PART NO. and DESCRIPTION.

TABLE OF CONTENTS

General Information ................................................................................................................ |

Page 2 |

Bolt Torque ............................................................................................................................. |

Page 3 |

Safety, Maintenance, & Important Loading Instructions ......................................................... |

Page 4 |

Testing Lights Before Use .................................................................................................... |

Pages 5 |

Loading Instructions ............................................................................................................ |

Page 5-7 |

Kar-Kaddy 260 and 360 Parts Breakdown and List ............................................................ |

Page 8-9 |

Kar-Kaddy 260 and 360 Parts List cont. .............................................................................. |

Page 10 |

Limited Warranty Information ............................................................................................... |

Page 11 |

DA66 Brake Actuator Parts Breakdown and List ................................................................. |

Page 12 |

DA603 Brake Actuator Parts Breakdown and List ............................................................... |

Page 13 |

DA91 Brake Actuator Parts Breakdown and List ................................................................. |

Page 14 |

10" Self-Adjusting Brake Cluster Parts Breakdown and List ............................................... |

Page 15 |

Optional Surge Brakes Parts Breakdown and List .............................................................. |

Page 16 |

KK260 and KK360 Parts Assembly Instructions .......................................................... |

Pages 17-18 |

Wiring and Fender Assembly Instructions ........................................................................... |

Page 19 |

Kar-Kaddy Toe-In Adjustment .............................................................................................. |

Page 20 |

Wheel Jack, Deflector, & Light Bar (optional) Parts Breakdown and List ............................ |

Page 21 |

Winch, Tool Box, & Spare Tire w/Mounting Bracket (optional) Parts Breakdown and List .. |

Page 22 |

Notes.................................................................................................................................... |

Page 23 |

"Reporting Safety Defects"

If you believe that your vehicle has a defect which could cause a crash or could cause injury or death, you should immediately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Dethmers Manufacturing Company (DEMCO).

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. However, NHTSA cannot become involved in individual problems be-

tweenyou,yourdealer,orDethmersManufacturing Company (DEMCO).

To contact NHTSA, you may either call the Auto Safety Hotline toll-free at

1-800-424-9393 (or 366-0129 in Washington, D.C. area) or write to:

NHTSA,

U.S. Department of Transportation

Washington, D.C. 20590.

You can also obtain other information about motor vehicle safety from the Hotline.

Page 2

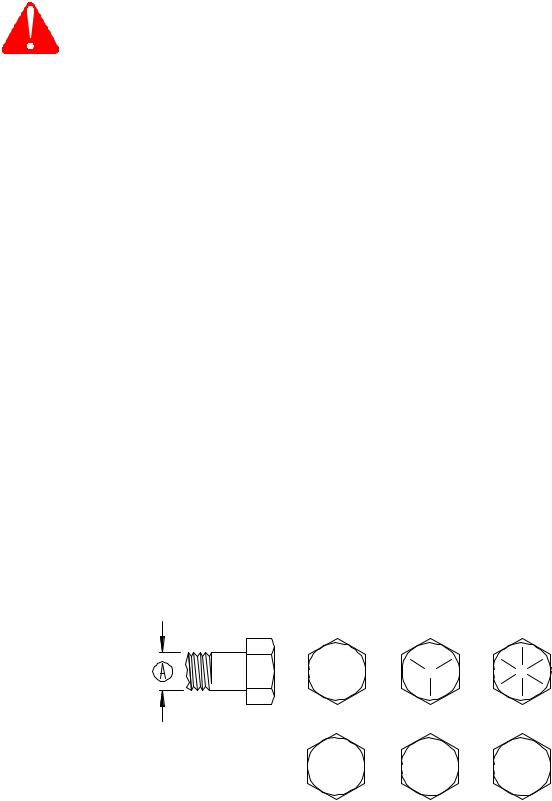

BOLT TORQUE

TORQUE DATA FOR STANDARD NUTS, BOLTS, AND CAPSCREWS.

Tighten all bolts to torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt chart as guide. Replace hardware with same grade bolt.

NOTE: Unless otherwise specified, high-strength Grade 5 hex bolts are used throughout assembly of equipment.

|

|

|

Bolt Torque for Standard bolts * |

|

|||

Torque Specifica- |

|

|

|

|

|||

|

GRADE 2 |

GRADE 5 |

GRADE 8 |

||||

tions |

“A” |

lb-ft |

(N.m) |

lb-ft |

(N.m) |

lb-ft |

(N.m) |

|

1/4” |

6 |

(8) |

9 |

(12) |

12 |

(16) |

|

5/16” |

10 |

(13) |

18 |

(25) |

25 |

(35) |

|

3/8” |

20 |

(27) |

30 |

(40) |

45 |

(60) |

|

7/16” |

30 |

(40) |

50 |

(70) |

80 |

(110) |

|

1/2” |

45 |

(60) |

75 |

(100) |

115 |

(155) |

|

9/16” |

70 |

(95) |

115 |

(155) |

165 |

(220) |

|

5/8” |

95 |

(130) |

150 |

(200) |

225 |

(300) |

|

3/4” |

165 |

(225) |

290 |

(390) |

400 |

(540) |

|

7/8” |

170 |

(230) |

420 |

(570) |

650 |

(880) |

|

1” |

225 |

(300) |

630 |

(850) |

970 |

(1310) |

|

|

|

|

|

|

|

|

Bolt Torque for Metric bolts *

Torque figures indicated are valid for non-greased or non-oiled threads and heads unless otherwise specfied.

Therefore, do not grease or oil bolts or capscrews unless otherwise specified in this manual. When using locking elements, increase torque values

by 5%.

* GRADE or CLASS value for bolts and capscrews are identified by their head markings.

|

CLASS 8.8 |

CLASS 9.8 |

CLASS 10.9 |

||||

“A” lb-ft |

(N.m) |

lb-ft |

(N.m) |

lb-ft |

(N.m) |

||

6 |

9 |

(13) |

|

10 |

(14) |

13 |

(17) |

7 |

15 |

(21) |

|

18 |

(24) |

21 |

(29) |

8 |

23 |

(31) |

|

25 |

(34) |

31 |

(42) |

10 |

45 |

(61) |

|

50 |

(68) |

61 |

(83) |

12 |

78 |

(106) |

|

88 |

(118) |

106 |

(144) |

14 |

125 |

(169) |

|

140 |

(189) |

170 |

(230) |

16 |

194 |

(263) |

|

216 |

(293) |

263 |

(357) |

18 |

268 |

(363) |

|

-- |

-- |

364 |

(493) |

20 |

378 |

(513) |

|

-- |

-- |

515 |

(689) |

22 |

516 |

(699) |

|

-- |

-- |

702 |

(952) |

24 |

654 |

(886) |

|

-- |

-- |

890 |

(1206) |

|

|

|

|

|

|

|

|

GRADE-2 |

GRADE-5 |

GRADE-8 |

|

|

|||

CLASS 8.8 CLASS 9.8 CLASS 10.9

8.8 |

9.8 |

10.9 |

Page 3

! |

WARNING: FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN LOSS OF TOWING VEHICLE CONTROL, |

|||

! |

SEPERATION OF THE TOW DOLLY FROM THE TOWING VEHICLE, SEPERATION OF THE TOWED VEHICLE FROM |

|||

THE TOW DOLLY, CAUSING SEVERE PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE. |

||||

SAFETY |

Rear Wheel Drive: Disconnect the towed vehicle |

|||

Safety is of utmost importance at all times. There are |

driveshaft for rear wheel drive vehicles with automatic |

|||

transmission. |

|

|||

several items that must be checked each time before |

|

|||

For manual transmission: Consult your vehicle owners |

||||

using and while using the Kar Kaddy. |

||||

manual for towing suitability with the drive shaft con- |

||||

|

|

|||

Make sure all bolts are properly tightened and those |

nected. |

MAINTENANCE |

||

|

||||

requiring a set torque are up to specifications: |

|

|

||

Tie Rod Castle Nut - 75 ft./lbs. |

Periodically check all bolts and nuts to insure proper |

|||

Lug Nuts - 75 to 80 ft./lbs. |

tension or torque. |

|||

Check Lug Nut tension after the first 5 miles and |

|

|

||

periodically thereafter. |

Grease the king pin and tie rod end grease zerks every |

|||

The ball hitch must latch securely around the ball and |

2500 miles. |

|

||

|

|

|||

the safety lock pin or lever must be in position to lock the |

An occasional drop of oil may be required on the moving |

|||

hitch on the ball. |

parts of the tie down winches. |

|||

RECOMMENDED BALL HEIGHT: 18 inches to the top |

|

|

||

of the ball on the towing vehicle. |

A light film of oil should periodically be applied to steering |

|||

Hook the towed vehicle safety chains to the frame of the |

stabilizer arm to prevent rust. |

|||

|

|

|||

vehicle directly above the area where the chain is |

NOTE: Proper toe-in is 1/32". This is preset at the |

|||

mounted on the Kar Kaddy. Leave some slack in the |

factory. |

|

||

chain to allow suspension movement. |

|

|

||

Check to make sure that all lights are in proper working order.

Examine the winches and straps, making sure they are in good conditon.

Be certain the safety lock pins are locking the strap winches.

Retighten straps over the tires after the first 5 miles and every 50 miles thereafter. Ensure that they are tight.

The KK260 tires must be inflated to the recommended 50 PSI.

The KK260SB, KK360 and KK360SB tires must be inflated to the recommended 50 PSI.

The strap on the optional tongue winch must be in good condition and should be stored neatly on winch when not in use.

NOTE: The winch strap must not be left connected to the towed vehicle after it is loaded and strapped down.

Make sure the optional light bar is fastened securely at the rear of the towed vehicle.

The wires to the optional light bar should be run along the car and fastened so as not to damage the finish of the towed vehicle.

NOTE: This unit cannot be backed up, when loaded or with the steering lock pin removed.

All vehicles mounted on the Kar Kaddy must be mounted with the front of the vehicle facing forward.

The operator should periodically have the toe-in checked and adjusted if needed at a qualified alignment shop. Improper toe-in can result in irregular tire wear.

IMPORTANT LOADING INSTRUCTION

Check your wheel tie-down straps.

Your Kar Kaddy is equipped with custom made wheel tie-down straps of a standard size that will fit most tires, however if your tires are too large or too small you will want to exchange these new straps for the proper size straps.

1.Tire too large - This is very obvious the strap will not basket over the tire properly, call us, we will provide at NO Charge on an exchange basis, the proper size strap. You must return your new unused straps and provide us with the Make and Model car and the tire size.

2.Tire too small - This is not as obvious, the basket will fit down over the tire very well, the problems cannot be readily seen. You must tighten the straps down solid and then check on the inside of the tire and be sure the strap, when tightened does not come in contact with any metal that may cause wear or cutting such as strut mounts. If there is contact, you need a smaller strap, call us, we will provide on a NO

Charge, exchange basis, the proper size strap.

You must return your new unused straps and provide us with the Make and Model car and tire size.

Thank you for Purchasing  Products.

Products.

Page 4

TESTING LIGHTS BEFORE USE

1.Check that the WHITE (ground) wire of the wiring harness is connected to the Kar Kaddy frame and the WHITE (ground) wire is connected to the frame of the towing vehicle.

2.With headlights in "ON" position, the tail lights, the light cluster bar, the license plate light, and the clearance lights should be lighted.

3.Start engine and have someone depress brake pedal. Brake lights of tow dolly and towing vehicle should come "on" and "off" simultaneously with each application.

4.Turn left turn signal on. Left turn light of Kar Kaddy and towing vehicle should flash simultaneously. Should the turn signal lights of the trailer function opposite to those of the towing vehicle, it is probable that the YELLOW (Driver side) and GREEN (Passenger side) wires have been reversed. Check the plug connection under the tongue of the Kar Kaddy to make sure wire colors are not crossed at that point. If plug connection is incorrect, correct problem by reversing yellow and green wire connection on the towing vehicle.

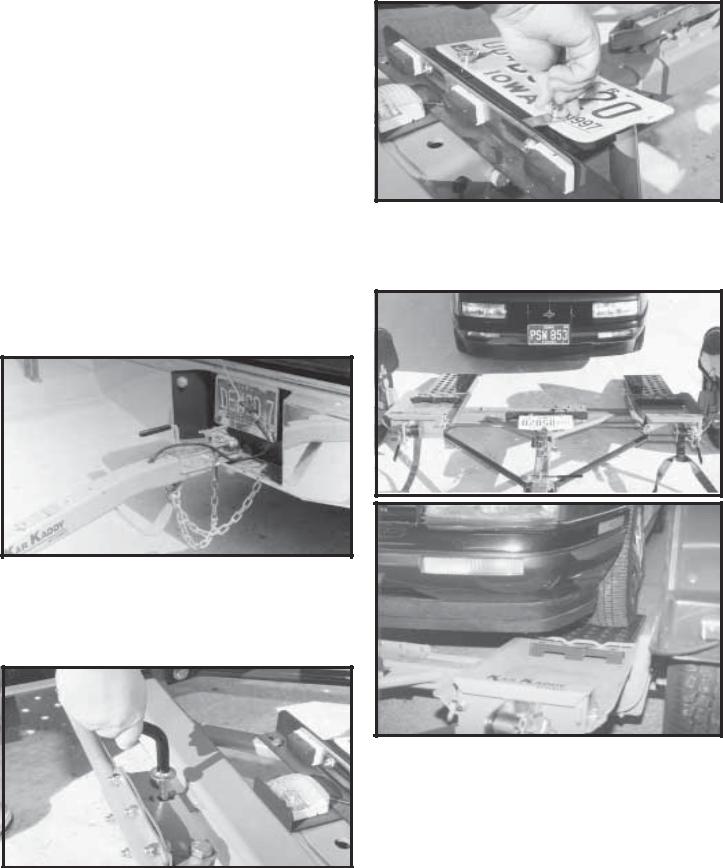

LOADING INSTRUCTIONS

Refer to load limits on inside of front cover.

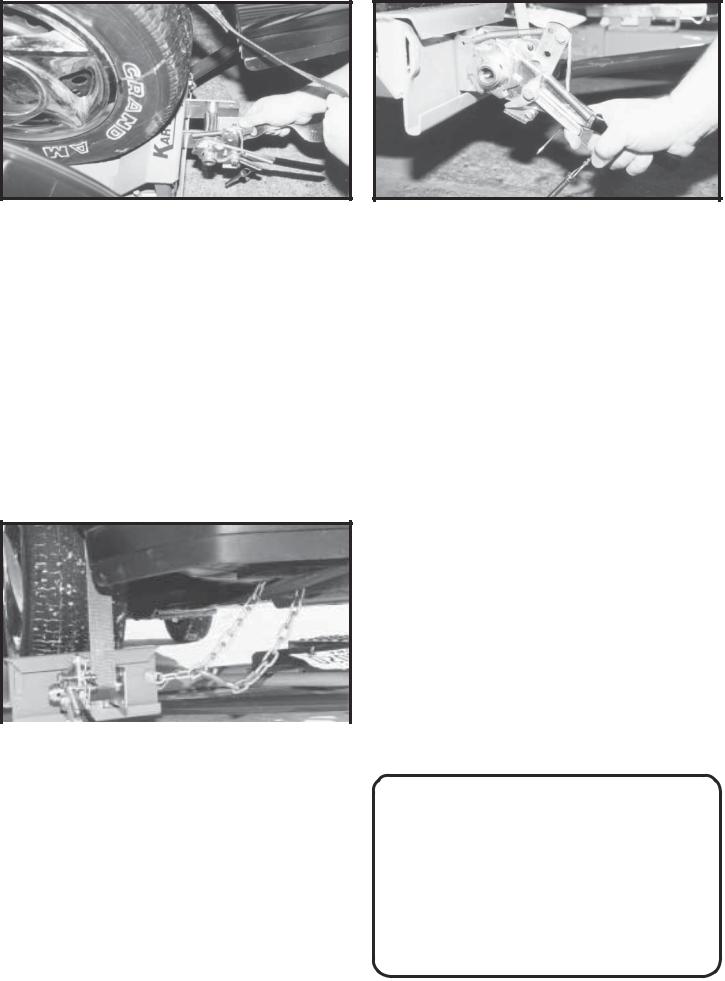

Step 1. Secure ball coupler to 2" (5,000 lb. capacity) towing vehicle ball only. Make sure that the hitch and the hitch ball are in good condition and not rusted, loose or stripped.

Recommended ball height is 18" to the top of the ball.

Make sure hitch is locked down and secured with safety clip. Criss-cross safety chains under tongue and secure to towing vehicle frame.

Step 2. Remove black locking pin BEFORE loading vehicle onto the Kar Kaddy. The removal of the locking pin allows "Auto Steer" to operate. When towing the dolly empty, this pin must be in place.

Step 3. Loosen wing nut on back of license plate holder, turn the clip on the front to a horizontal position and put license in the "down" position. Turn the clip back so it rests against the back of the light bar to hold the license down and tighten wing nut.

(License must be "UP" with the tow dolly empty).

Step 4. Before loading (and unloading) towed vehicle make sure platform and towed vehicle are in straight alignment. Tow dolly must be completely and properly hooked up to the towing vehicle. Towing vehicle must be larger and at least 1000 lbs. heavier than the tow dolly and towed vehicle combined.

IMPORTANT: Tire tread width or body width of towed vehicle must not exceed:

KK260 |

- |

70" max. (outside to outside), |

|

|

42" min. (inside to inside), |

|

|

72" max. (body width). |

KK360 |

- |

76" max. (outside to outside), |

|

|

42" min. (inside to inside), |

|

|

78" max. (body width). |

Page 5

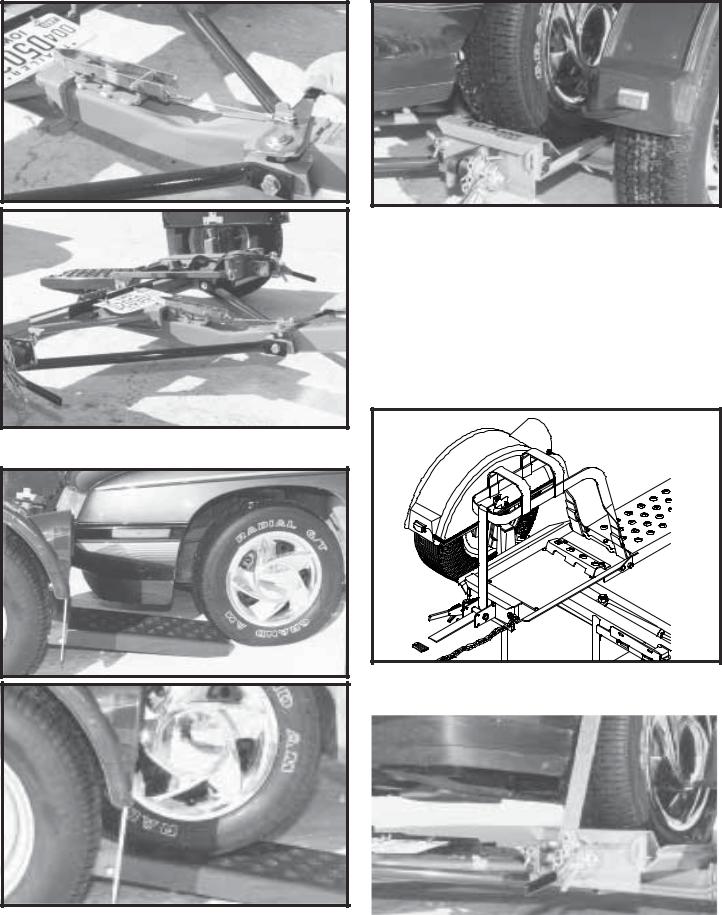

Step 5. Grasp bed release handle on tongue and pull toward coupler. This releases the tilt bed to permit loading.

Step 7. Drive vehicle onto the platform - front forward - until tires touch the wheel stops at the front of each side of the platform and the platform tilts to a flat position. Make sure the car is centered on the platform. Towed vehicle tires must fit in wheel troughs without overhanging sides. Engage towed vehicle parking brake. Shift loaded car into "park" and lock steering wheel with front tires in a straight position. If the car does not have a locking steering column the steering wheel must be tied securely with front tires in a straight position.

Rear Wheel Drive: Disconnect towed vehicle driveshaft for rear wheel drive vehicles with automatic transmission.

For manual transmission: Consult your vehicle owners manual for towing suitability with the drive shaft connected.

Step 8. Place one tie-down strap over each tire and secure |

hooks to rods located at the rear of each wheel platform. The short side of the hook must face the rear of the Kar Kaddy.

Step 6. With someone safely guiding you, slowly drive ve- |

|

|

Step 9. Be sure tie-down winch is centered with the tire before |

||

hicle onto platform FRONTFORWARD.(Anyvehiclemounted |

||

on tow dolly must be mounted with front of the vehicle facing |

tightening straps. |

|

forward.) Drive the car forward until the tires touch the ramps. |

|

Make sure the tire is aligned to ascend onto the ramps.

Page 6

Step 10. Threadtie-downstrapthroughtheslottedtubeonthe tie-down winch. Pull approx. 6" of strap through this slot. Begin tightening strap making sure the tail becomes enclosed by the strap coming over the tire. Tighten the straps ensuring that the strap fed through the slot binds between the shaft and the strap being wound onto the winch shaft. While tightening straps, pull cross strap forward to ensure even tightening.

NOTE: Be sure to tighten straps until each tire starts to flatten against tire stop. After each strap is tight, insert a safety pin in each winch. Disengage towed vehicle parking brake.

Strapsmustberetightenedafterfirst5milesoftravel. Check straps every 50 miles thereafter to ensure they are tight and not rubbing or fraying.

Step 11. Make sure the tie-down strap is the correct size for the auto tire. See page 11 of this instruction for proper fit and exchange instructions.

Step 13. TO UNLOAD towed vehicle. Make sure that platform and vehicle are straight. Reinstall driveshaft. Ensure that towed vehicle parking brake is fully engaged, then unhook the towed vehicle safety chains, and release the tie-down straps. NOTE: Tie down straps must be "quick -released" by grasping ratchet pawl (A) and ratchet handle (B) simultaneously and pushing down sharply. This process will permit easy removal of strap from winch.Swing the wheel platform locking latch handle forward, towards the coupler. This will allow the platform to tilt as you slowly drive off. Make sure the winch ratchet handles are horizontal. Replace the "Auto Steer" locking pin (for towing empty).

Step 14. To pull the Kar Kaddy empty, make sure "AutoSteer" LOCKING PIN IS IN PLACE and towing vehicle safety chains are up and hooked. Tie-down winch handles should be left in a down postion (horizontal) position with safety pins in place when towing loaded or empty. DO NOT

ATTEMPT TO PULL KAR KADDY WITH WHEEL PLATFORM IN LOADING (tilted) POSITION.

DAMAGE PREVENTION

Check your vehicle manual or registration for vehicle weight. Towing vehicle must be larger and at least 1,000 lbs. heavier than the towed vehicle and tow dolly combined.

Do not pack goods in car that is being towed. Overloading the Kar Kaddy or exceeding the width limit may result in damage to both car and Kar Kaddy.

|

|

REAR WHEEL DRIVE PRECAUTIONS |

||

|

Disconnect towed vehicle driveshaft for rear wheel drive |

|||

|

vehicles with automatic transmission. Simply placing trans- |

|||

|

mission in neutral is not sufficient to prevent damage to |

|||

|

transmisssion. |

|||

|

Formanualtransmission: Consultyourvehicleownersmanual |

|||

Step 12. Hook the towed vehicle safety chains to frame of |

for towing suitability with the drive shaft connected. |

|||

vehicle directly above the area where the chains are mounted |

ALL VEHICLES MOUNTED ON THE KAR KADDY MUST BE |

|||

on the Kar Kaddy. Leave some slack in the chains to allow |

WITH THE FRONT OF THE VEHICLE FACING FORWARD. |

|||

suspension movement of the towed vehicle. |

|

|

|

|

|

|

|

SAFETY |

|

|

|

|

|

|

|

• |

Examine winches and straps to make sure they are in |

||

|

|

good condition. |

||

|

• |

Check wheel nuts every trip. |

||

|

• Tires must be inflated to recommended pressure by tire |

|||

|

|

manufacturer. |

||

|

• Be certain the safety lock pins lock the strap winches. |

|||

• Retighten the straps over the tires after the first 5 miles of travel. Check straps every 50 miles therafter to ensure they are tight and not rubbing or fraying.

Page 7

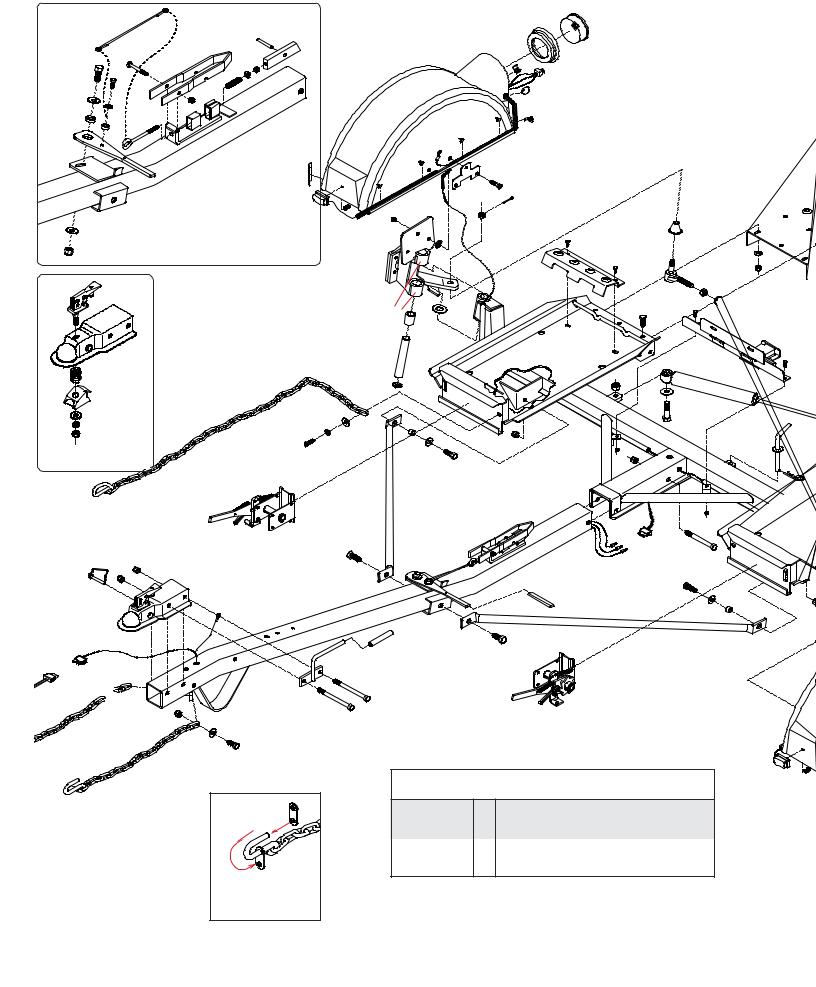

KK260 (8'wide) and KK360 (8-1/2' wide) PARTS BREAKDOWN

|

128 |

|

126 |

125 |

|

|

|

||

|

121 |

123 |

|

|

|

124 |

|

||

|

|

|

|

|

87 |

|

|

127 |

|

55 |

117 |

129 |

|

|

46 |

|

122 |

|

|

118 |

|

|

||

116 |

120 |

|

|

|

119 |

|

|

||

|

|

|

|

|

|

|

KIT #5511 |

55 |

|

TILT-BED LATCH |

|

42 |

ASSEMBLY |

|

|

not included

for |

|

Fulton |

|

5000 lb. |

|

coupler |

53 |

5217 Coupler Repair Kit

37 42

38

35 |

43 |

34

104

Right Fender

33

109

98  110

110

112

|

|

|

|

113 |

111 |

|

|

|

106 |

|

|

99 |

|

114 |

105 |

107 |

|

|

|

|

|

*69 |

|

|

|

|

|

|

|

100 |

|

75 |

|

|

*69 |

|

|

|

|

||

|

|

108 |

|

||

|

|

|

|

||

|

63 |

|

|

|

|

|

59 |

62 |

|

65 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

61 |

|

|

|

|

|

60 |

|

|

|

|

46 |

|

54 |

|

|

86 |

|

55 |

|

42 |

|

47 |

|

|

|

|

|

|

|

56 |

|

||

|

|

|

|

||

52

2

49

10

48

39 |

41 |

49 |

|

|

103

90 |

|

*69 |

|

|

|

46 |

|

89 |

|

|

|

|

*69 |

75 |

|

90 |

|

||

|

|

72 |

|

|

88 |

|

|

51 |

|

81 |

25 |

|

|

||

|

|

|

|

|

80 |

|

|

|

78 |

|

|

58 |

|

66 |

82 |

|

|

||

|

|

|

|

51 |

57 |

|

8 |

|

|

||

|

|

58 |

|

|

36 |

50 |

|

35 |

|

|

|

|

|

56 |

|

52 |

|

55 |

54 |

|

|

||

1

44 |

40 |

|

|

|

|

45 |

|

|

46 47 |

|

DECALS |

45 |

DECAL |

100 |

|

NO. |

QTY. |

DESCRIPTION |

71 |

RD21002 |

1 |

Instruction Decal |

|

RD21003 |

- |

5 ft. Gold Striping (for fenders) |

|

RD21001 |

4 |

Kar Kaddy Decal (brown) |

|

DA21005 |

- |

Check Wheel Nuts & 50 Psi. “C” Range BSW |

|

ZA21003 |

|

(KK360, KK260SB, KK360SB) |

Part# 07426 |

1 |

VIN |

|

|

|

|

|

Hook Retainer |

|

|

|

Replacement Only |

|

|

|

Page 8

Loading...

Loading...