Page 1

P

HOENIX

TM

P

Pouch / Roll Laminator

Operators

TM

HOENIX

44 Laminator

Manual

Model ML44

REV C

Page 2

TABLE OF CONTENTS

S

•

OVERVIEW 3

•

SAFETY INFORMATION 4

•

SET-UP AND ELECTRICAL REQUIREMENTS 5

•

STAND ASSEMBLY (OPTIONAL) 6

•

ROLLER KIT INSTALLATION (OPTIONAL) 7

•

ROLLER GAP CONTROL KNOB, REAR PANEL 8

•

OPERATIONAL CONTROL PANEL 9

•

MOUNTING USING A HEAT ACTIVATED MOUNTING BOARD 10

•

MOUNTING AND LAMINATING USING A POUCH BOARD 11

•

ENCAPSULATING USING A FLEXIBLE POUCH 12

•

USING ROLL FILMS IN A PHOENIX 13

•

CLEANING YOUR PHOENIX LAMINATOR 14

•

TROUBLESHOOTING GUIDE 15

•

TECHNICAL SERVICE / REPAIR CENTERS 16

•

MOUNTING AND LAMINATING TERMS 17

•

TECHNICAL SPECIFICATIONS 18

•

WIRING DIAGRAM 19

•

PARTS LIST 20

•

LIMITED WARRANTY 23

•

PHOENIX SUPPLIES 24tor

PHOENIX 44 LAMINATOR

Page 3

Owner’s Manual Overview

Thank you for purchasing a PHOENIX

laminator. We have designed the PHOENIX

Laminator to give you years of reliable

service. As you become familiar with the

PHOENIX laminator, you will appreciate the

high quality of its production and the

excellence in its engineering design.

By following the guidelines for proper care

and use of the PHOENIX laminator, you

can depend on many years of trouble-free

profitability from your investment.

The purpose of this manual is to outline

materials and processes. This manual will

show you how to use PHOENIX supplies

with your laminator to create signs,

displays, and flexible graphics with

professional results.

The manual includes instructions of

various laminating procedures, which are

meant to give you comprehensive

information needed for the efficient use of

your laminator.

Please read and fully understand the

entire manual before proceeding to

use your laminator.

MOUNTING AND LAMINATING USE

Your Phoenix Laminator has been designed to

be used with pouch boards, thermal laminating films and flexible pouches. When using

pouch boards and film pouches, you are able

to laminate and encapsulate prints in one

step. You may also use roll film products and

the PHOENIX has been tested and laminates

well with polyester based films with low temperature adhesives (I.e. adhesive which work

below 200 degrees). For other materials, you

will have to test those films to determine the

best settings and applicability of those products.

WARNING! This laminator is designed

for mounting and laminating. Any use

other than the intended may cause

damage to the laminator or physical

harm to the user.

WARNING! Any unauthorized changes or

modifications to this unit without our prior

written approval will void the user’s warranty

and will transfer health and safety obligations

to the user.

LIABILITY STATEMENT

The details given in this manual are based on

the most recent information available to us.

They may be subject to change in the future.

We retain the right to make changes to the

construction or the design of our products

without accepting any responsibility for

modifying earlier versions.

CAUTION! Please pay attention to all passages marked this way. This information is

vital to preventing user injury and/or damage

to the unit. Failure to follow this information

could void the user's warranties and transfer

all safety obligations to the user.

PHOENIX 44 LAMINATOR

3

Page 4

S

AFETY

I

NFORMATION

When using electrical appliances, basic

precautions should always be taken to reduce the risk of electrical shock and injury

to persons, including the following:

1. Read all instructions before connecting

or operating this unit.

2. Retain this Owners Manual for future

reference. For technical assistance

beyond what is covered in this manual

contact Technical Service.

3. Save your carton! PHOENIX laminators

are shipped in special cartons and should

be used in case your PHOENIX laminator

should ever require service or need to be

transported.

NOTICE! Failure to return machines

properly packed in original packaging

will impose a fifteen percent

restocking fee plus costs to repair

shipping damage. Contact Technical

Service for a return authorization

(see WARRANTY AND AUTHORIZED

REPAIR CENTERS).

4. Do not use the laminator for other

than its intended use.

5. The Laminator case may be cleaned

with a lint-free cloth, lightly

dampened with a mild soap and

water solution. Do not use spray-on

cleaners.

NOTE: Disconnect the laminator from

the main power supply before

cleaning!

6. Do not immerse any part of the

laminator in water or other liquids..

7. The laminator's location or position should

not interfere with its proper ventilation. Do

not install or place in a built-in enclosure

such as a bookcase.

8. Do not operate the laminator with a

damaged cord or plug, or after the laminator

has been dropped or damaged in any

manner. If purchased in U.S./Canada,

return the laminator to your ADEMCO reseller for

examination, repair or adjustment.

8. Do not let the cord hang over the edge of a

counter/bench or touch hot surfaces.

9. Always unplug the laminator when it is not

in use for a long period.

10. This unit should only be connected to a

power supply outlet of the voltage,

amperage, and frequency marked on the

rear panel. The laminator has a grounded

plug (three prongs). To reduce the risk of

electrical shock, this plug is intended to fit

only a grounded outlet of the proper

amperage, and in only one way.

If the plug does not fit in the outlet, contact

a qualified electrician.

WARNING! Do not modify the plug in

any way.

4

PHOENIX 44 LAMINATOR

Page 5

S

ET-UP AND

E

LECTRICAL

R

EQUIREMENTS

The PHOENIX 44 is a professional laminator

designed for ease of use. The process speed

and temperature have been preset to eliminate

operator guesswork. The factory setting will

facilitate good quality results using the

Flexible Pouches and Pouch Boards using low

temperature adhesives.

The PHOENIX 44 can handle Flexible Pouches

and Pouch Boards up to 44 inches (1120mm) wide.

Please familiarize yourself with machine

operation before installation, operating the

Control Panel and the Nip Control Knob.

Installation of your PHOENIX Laminator

Please read and fully understand the entire manual

before proceeding to use your laminator.

Without the PHOENIX Stand, your PHOENIX

laminator must be lifted and carried to the place

where it will be used. This should be done by at least

two people, one on each side. Grasp the machine

8-10 inches (20cm-25cm) from the side. It should

only be placed on a sturdy, clean, flat, level surface

able to support 150 lbs. (70kg). See Stand

instructions.

Keep the area around your laminator clear with

adequate space around it so you can feed, receive

and trim mounted and/or laminated images.

Unpacking your Laminator

1. Open the box, and lift the machine out (at least

two persons necessary!). Grasp the machine

8"-10" (200mm-250mm) from either side, at

the bottom metal parts. Be careful! The

polyethylene bag is slippery!

2. Place the machine on the work area described

above.

3. Remove the protective molded foam.

4. Remove the polyethylene bag.

5. Inspect the machine for any physical damage

(if damage does exist, report this to the Freight

Company on the BILL OF LADING. Contact

Your Dealer to determine if a replacement machine

should be shipped to you.

NOTICE! Retain original packaging.

Failure to return machines properly packed in

original packaging will impose a fifteen

percent restocking fee plus costs to repair

shipping damage. Contact Technical Service

for Return Authorization (see rear cover).

Setting up your Laminator

The PHOENIX laminator should be installed

next to a power/main outlet. We do not

recommend using an extension cord, but if

needed, make sure the cord rating meets or

exceeds the machine rating.

The plug and the outlet must be easily

accessible. Please ensure that you plug your

laminator into a grounded, three-prong

outlet. Please ensure that the total load of the

other items using the same circuit breaker do

not exceed its breaking value.

The US versions of the PHOENIX machines

are provided with a fixed power cable and

NEMA 5-20 plug.

Use 120Vac 20A grounded outlet

only.

110V 20 amp outlet

Using your PHOENIX 44

Plug the power cable into the grounded outlet

with appropriate service as described above.

Turn on power with main power switch. Roller

will turn continuously while power is on.

Depress the Heat switch and wait approximately 20 minutes for the unit to reach its

operating temperature. Also turn the Speed

on and set the Control Knob to zero so that

the roll heats uniformly. When Ready LED indicator is constantly lit, the PHOENIX laminator is ready for use.

CAUTION! Set the Control Knob to the

“Open” position when not in use.

NOTE: The laminator may emit vapors the

first few times it is used. This is normal and

will cease after several minutes of use.

PHOENIX 44 LAMINATOR

5

Page 6

S

TAND

Tools Required

Philips head screwdriver

4mm Allen wrench

14mm wrench or adjustable wrench

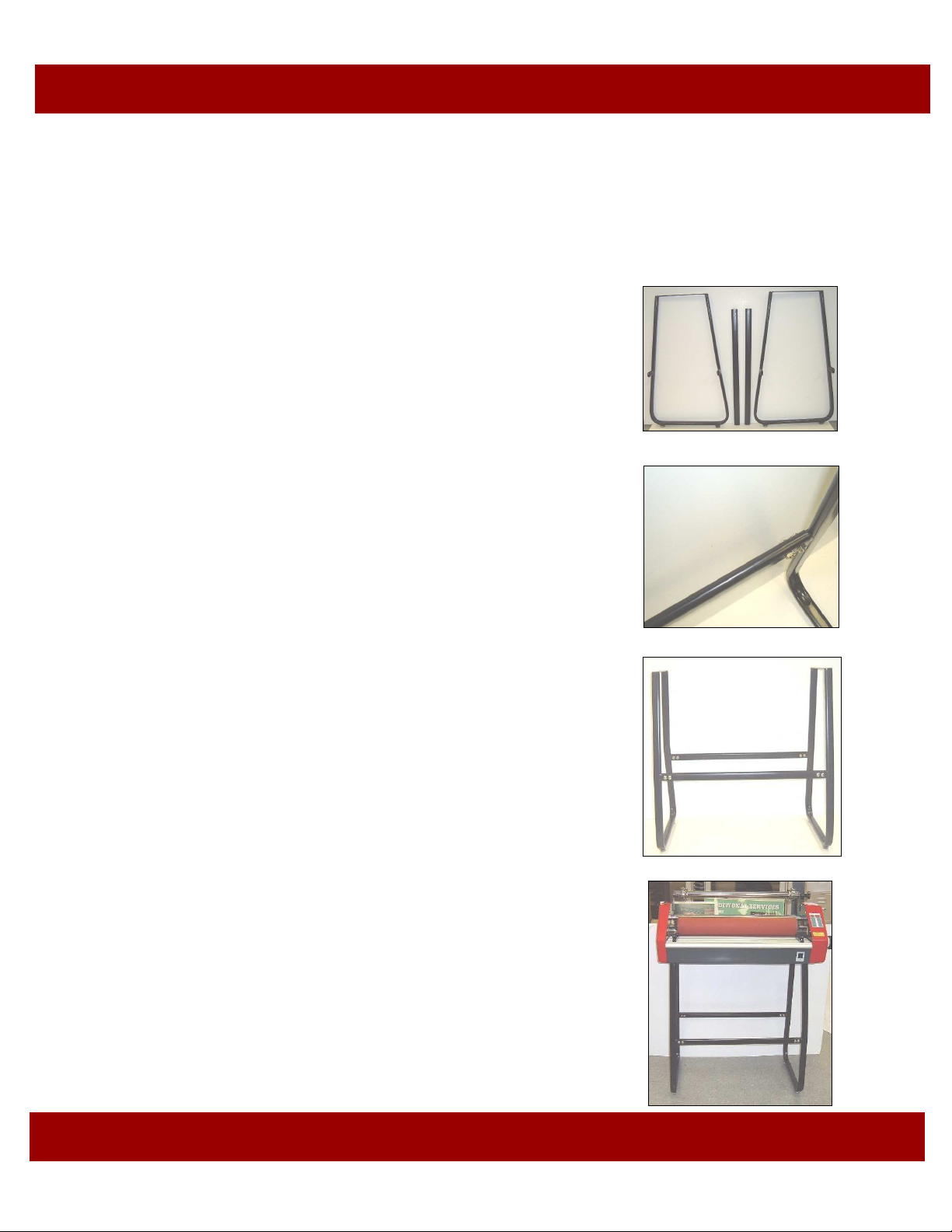

Stand Kit Contents (Figure 1)

(2) Side frames

(2) Cross straight supports

(8) 14mm Phillips screws & nuts

(4) 4mm Allen screws

A

SSEMBY AND

S

ET-UP

(O

PTIONAL

)

Assemble cross supports (Figure 2)

Attach the cross supports to the

side frames. Position the nuts on

the inside of the stand. Leave

the bolts finger tight until all

of the stand has been assembled

in Figure 3. Then tighten all of the

screws securely.

Insure all of the bolts are

tightened before attaching the

stand to your Phoenix laminator.

Attach stand to Phoenix laminator

Place your Phoenix Laminator

on a flat secure surface. Rotate

the laminator gently onto the back

panel (do not pinch the power cord).

Having one person holding

Figure 1

Figure 2

Figure 3

6

6

the laminator, remove the feet from

the bottom of the laminator and

attach the stand with

the 4mm screws supplied. The

angled side is the back. Tighten

securely. Then with 2 people lift

the Phoenix into position (Figure 4).

PHOENIX 44 LAMINATOR

Figure 4

Page 7

R

OLL

Tools Required

Philips head screwdriver

4mm Allen wrench

14mm wrench or adjustable wrench

Roll Kit Contents

K

IT

A

SSEMBLY

(O

PTIONAL

)

(1) Dispensing Bar with tensioner

(2) Dispensing bar Support brackets

(1) Idler bar with 4mm allen screws

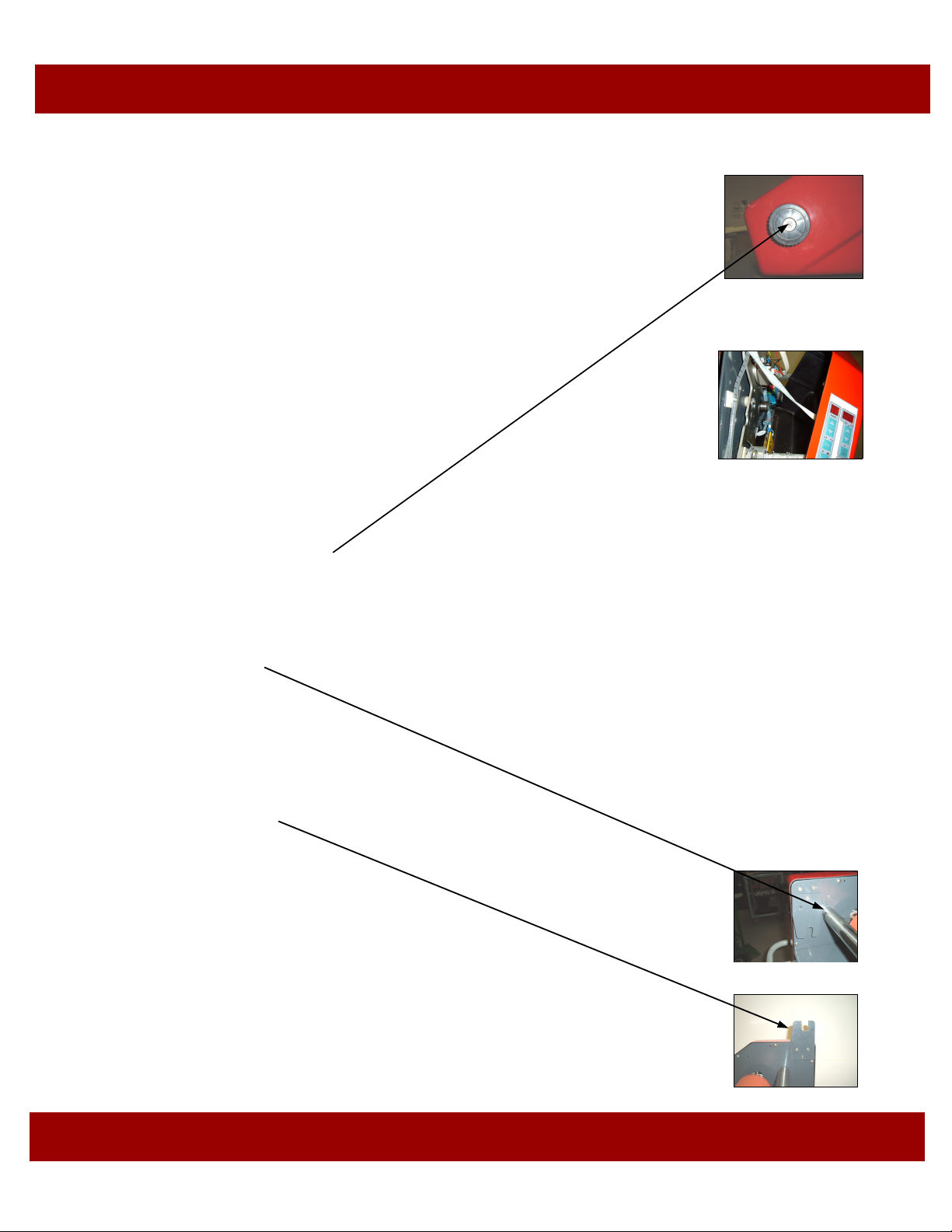

IMPORTANT! - Unplug you laminator

before installing the Phoenix Roll Kit

Remove the side panels

Lower the rollers to the closed or zero position.

Remove the roller gap control knob by taking off the

center cover of the Control Knob and unsrewing the

philips screw in the middle of the Control Knob (Figure 1)

and side panels gently and angle from the back

as the control panel will be attached to the circuit board

on the side frame (Figure 2).

Install Idler Bar (Figure 3)

Locate the pre-drilled holes in the sideframe in back of

Figure 1

Figure 2

the rollers. Attach the idler roll threading the 4mm

bolt through the hole in the side frame and tighten

with the corresponding nut. Repeat on the other side.

Install Roll holder (Figure 4)

Remove the upper back panel. Install roll

holder brackets with the 3 phillips screws.

Mount the roll holder in the bracket.

Replace the side panels and Control Knob.

Instructions for running cold films on Page 13

Figure 3

Figure 4

PHOENIX 44 LAMINATOR

7

Page 8

R

OLLER GAP CONTROL KNOB

The Control Knob (see figure 1A) is located on

the right hand side of the laminator and should

be operated from this side. The control knob is

used to adjust the height of the rollers.

The Nip Settings are 1/4"(6mm), 3/16" (5mm),

1/8" (3mm) and 1/16" (1.5mm) correspond to

Pouch Board thickness. There is also a closed

position - 0" (0mm) for film and paperboard

applications. Select the setting that indicates

the thickness of the material you are using.

To Operate the Nip Control Knob

1. Grasp it with your right hand and push

in approximately 1/4" (6mm).

2. Once the knob has disengaged from the

stop, it may be rotated forward or

backward (clockwise or counterclockwise, as

viewed from the right hand side of the unit).

3. Once the indicator has reached the desired

nip setting, release the knob or gently

pull the knob out to lock it in place. See

Figure 1A.

Figure 1A

Caution! Set the Nip Control Knob to

the “Open” position when not in use.

Note: When the machine is warming

up, set the control to the zero or

closed position.

REAR PAN

R

EAR

To turn the machine on and off, use the

main breaker switch below in figure 1B.

“O” is off and “1” is on.

Figure 1B

P

ANEL

Note: Always switch the power off when the

machine is not in use. The Control Panel is

always powered when the main power is

on.

In case of Emergency: Turn off the main

power breaker or unplug the machine

from the power outlet.

Caution! Turn off the main power

breaker and unplug the machine when

removing the side panels and performaing maintenance on your Phoenix.

8

PHOENIX 44 LAMINATOR

Page 9

O

PERATIONAL CONTROL

The Control Panel (see Figure 3) is located on the top right of the machine. A

diagram of the Control Panel is shown

in Figure 2.

Figure 2

Speed Control

The speed of the rollers is controlled in

the SPEED section of the Control Panel.

1. To turn the rollers on, press the

‘On/Off’ pad once. The Green LED

light will turn on indicating the bottom roller is turning. Note: the top

roller is free spinning as with all high

quality laminators. The PHOENIX will

automatically be set to the faster

‘Rabbit’ speed.

2. To adjust the speed of the rollers,

press the ‘Rabbit’ for the faster speed

(approximately 1 foot per minute) or

the ‘Turtle’ (approximately 6 inches

per minute) for the slower speed. All

standard pouches and pouch boards

with inkjet paper up to 11 mils thick

should work on the faster speed. For

thicker materials.use the slow ‘Turtle’

speed. The LED light which is on is

the current speed of the PHOENIX.

P

ANEL

Figure 3

Location of Control Panel

Heat Control

The Heat of the rollers is controlled in the

HEAT section of the Control Panel. When you

turn the PHOENIX on, the heat will be off and

the rollers cold. The LED Light above the

‘On/Off’ switch will be the color red.

1. To turn the heat on, press the ‘On/Off’

pad once. The LED above the ‘On/Off’

the PHOENIX will automatically be set to

the ‘Pouch’ heat setting and the ‘Pouch’

LED will be lit. The LED above the ‘On/

Off’ switch will be Green indicating the

roller is heating. When that light becomes yellow, the PHOENIX is ready to

process your pouch boards.

2. To adjust the heat of the rollers,

press the ‘Pouch’ button when using

pouch boards, mounting boards or flexible pouches. The ‘Pouch’ heat setting is

the higher setting and has a roll face

temperature of 150° Celsius. The Roll

temperature is a lower 90° Celsius (195°

Fahrenheit) for use with standard inkjet

laminating films.

In case of Emergency: Turn off the main

power switch or unplug the machine

from the power outlet. Open the Roller

Gap Control to its fully open position

and remove your work.

PHOENIX 44 LAMINATOR

9

Page 10

M

OUNTING WITH

H

EAT

A

CTIVATED

B

OARDS

Using a Heat Activated Mounting Board

Refer to the instruction sheet packed with

each box of Mounting Boards for specific

information on mounting with a heat activated Boards. All boards can not be thicker

than 1/4” inch and must use low temperature adhesive.

Also, refer to the instruction sheet for

information on Compatible Media, Process

Conditions and technical information.

Place the image to be mounted on the adhesive-coated side of the mounting board

(dull side of the board).

Cover your print with the "cover sheet" as

marked (included with each box of

Mounting Boards or use a sheet of non-stick

silicon paper). If the release paper is

longer, fold over the narrow end to make a

’pocket’ for the board to be inserted into.

Place your board with your print on it into

the fold of the cover sheet.

If you are overlaminating with roll film

while using Phoenix mount boards, do

not use any cover sheets but insure the

laminating film is equal to or wider

than your mount boards.

Set the Roller Gap Control knob to the correct setting that matches the Mounting

Board thickness.

Insert the board into the inlet opening. Ensure the board will enter centered and

straight. A gentle push may be required to

start the board into the laminator.

Hold the edges of the board until it is engaged in the unit and the laminator begins

pulling it on its own.

The board will feed through the laminator and automatically exit at the rear of

the unit.

CAUTION! The board will be hot! Allow it to lie flat while cooling.

CAUTION! USE ONLY WITH HEAT ACTIVATED MOUNTING BOARDS 1/4" (6mm)

THICK OR LESS.

DO NOT USE PLYWOOD, METAL,

CARDBOARD, SHARP OR HARD BOARD

WITH RAGGED EDGES OR ANY TYPE OF

PLASTIC.

MAKE SURE THAT ALL MEDIA FED INTO

THE LAMINATOR IS FREE OF STAPLES,

PAPER CLIPS, OR OTHER HARD

OBJECTS.

Foam board may be cut or trimmed using

a sharp hobby knife such as an X-ACTO

Knife. Lightly score the paper first. Several passes of the knife may be required.

We recommend a professional grade

trimmer with a standard utility knife

blade be used for professional and fast

results.

NOTE:

Ragged cuts or pulling of the foam

board indicates a dull blade.

10

PHOENIX 44 LAMINATOR

Page 11

L

AMINATING WITH

P

OUCH

B

OARDS

Refer to the instruction sheet packed with

each box of Pouch Boards for specific

information on mounting/laminating with a

Pouch Boards.

In addition, refer to the instruction sheet for

information on Compatible Media, Process

Conditions and technical information.

Carefully examine the board to determine

which edge is sealed. There is a 1/8" (3mm)

sealed edge where the laminate film is attached to the board.

Starting at one of the corners, opposite the

sealed edge, gently lift and peel back the film.

Care should be taken not to break the sealed

hinge.

Center the image to be laminated on the

board and lay the film back over it.

Set the Control Knob to the correct setting

that matches the Pouch Board thickness.

Ensure that the PHOENIX rollers are turned on

and set either at the ‘Rabbit’ or ‘Turtle’ speed.

With the Heat is on, set at the ‘Pouch’ setting

and the LED light is Yellow indicating the roll

temperature is ready to use.

Note: If your laminate appears cloudy or

your print is not fully adhered to the

board, adjust the speed to the ’Turtle’

setting and reprocess your pouch board.

Slowly insert the Pouch Board into the inlet

opening. Ensure that the Pouch Board will

enter centered and straight. A gentle push

may be required to start the board into the

laminator.

Hold the edges of the Pouch Board until it is

engaged and the laminator begins pulling it

on its own.

The Pouch Board will feed through the

laminator and automatically exit at the rear

of the unit.

CAUTION! The board will be hot! Allow

it to lie flat while cooling.

If there is any dirt or adhesive on the surface of the board, it can be removed by

dampening a lint free cloth with Isopropyl

Alcohol (IPA) and wiping the surface.

CAUTION! Always use care when using

Isopropyl Alcohol (IPA)! IPA is very

flammable. The flash point of IPA is 11ºC

(51.8ºF). The self-ignition temperature is

400ºF (752ºF).

PHOENIX 44 LAMINATOR

11

Page 12

E

NCAPSULATING WITH

F

LEXIBLE

F

ILM

P

OUCHES

Refer to the instruction sheet packed with

each box for specific information on encapsulating Flexible Film Pouches.

In addition, refer to the instruction sheet for

information on Compatible Media, Process

Conditions and technical information.

The Flexible Pouch consists of two

pieces of film that are hinged at one end,

along a short side. Separate the two pieces

starting at the end opposite the hinge. Take

care not to break the hinged seal.

1. Insert the article to be laminated in the

pouch so there is at least a 1/8" (3.5mm)

board around each of the sides. This

ensures that moisture never reaches the

image.

2. Place the pouch with the image on the

sled included with the Flexible Pouches or

Purchase Sleds separately.

Note: The Sled is a non-stick board used

to assist in the handling of large Flexible

Pouches. It is made of materials that

will not damage or cause excessive

wear to your PHOENIX Laminator.

3. Smooth out any wrinkles with the side of

your hand or a soft flexible squeegee.

4. Tape the leading edge of the pouch to the

sled using masking tape.

5. Adjust the Control Knob to the

3/16" (5mm) setting for the Sled included

with your Dealers Flexible Pouches. (Or set

the thickness to the thickness of the nonstick sled material you are using.)

6. Ensure that the PHOENIX rollers are

turned on and set either at the ‘Rabbit’ or

‘Turtle’ speed. Turn the Heat is on, set at

the ‘Pouch’ setting and wait for the LED light

is Yellow indicating the roll temperature is

ready to use.

Note: If your laminate appears cloudy

or your print is not fully adhered to the

board, adjust the speed to the ’Turtle’

setting and reprocess your pouch

board.

7. Slowly insert the sled with the Flexible

Pouch on top into the inlet opening.

8. Ensure that the sled is centered and

straight. A gentle push may be required to

start the sled into the laminator.

9. Hold the edge of the sled until it is engaged, and the laminator begins pulling it

on its own.

10. The sled should feed through the laminator and automatically exit at the rear of

the laminator.

CAUTION! The Sled will be hot! Allow it

to lie flat and cool before removing the

tape.

If there is any dirt or adhesive on the surface of the board, it can be removed by

dampening a lint free cloth with Isopropyl

Alcohol (IPA) and wiping the surface.

CAUTION! Always use care when using

Isopropyl Alcohol (IPA)! IPA is very flammable. The flash point of IPA is 11(51.8).The

self-ignition temperature is 400(752).

12

PHOENIX 44 LAMINATOR

Page 13

L

AMINATING WITH

R

OLL

F

ILM

Refer to the instruction sheet packed with

each box for specific information on the roll

film you are using. We recommend

using low temperature adhesives on

either a 3 or 5 mil construction.

The Phoenix is designed for roll films to

laminate one side of a print, over-laminate

a mounted print, or simultaneously mount

and laminate using heat activated board.

If you are laminating one-side of a print,

place your print on a sled or non-stick

board. Phoenix sleds are all 3/16” thick.

We recommend starting with the temperature to the ‘Roll’ setting and the Speed to

the ‘Rabbit’ setting.

If you are simultaneously mounting

and laminating using a heat activated

board, we recommend using boards

which use a low temperature

adhesive (i.e. below 160ºF). Set the

temperature to ‘Pouch’ and the speed

to the ‘Rabbit’ setting.

1. Set the Control Knob to the 3/16”

thickness setting.

2. Mount you laminate roll on the top roll

dispensing bar/supply mandrel. Note:

The Roll should be mounted on the

Phoenix such that the film is being

pulled from the bottom of the roll so

that you are looking at the adhesive or

dull sized of the film.

3. Pull the film from the roll, place it behind the idler bar and drape the film over

the top roller and roller nip opening (the

adhesive on the film should begin to ’wetout’ or activate.

4. Using a Threading board (3/16” thick is

supplied with the Phoenix Roll Kit), push

the threading board into the nip of the rollers. Turn the Motor control on and select

either the ‘Rabbit’ or ‘Turtle’ speeds. The

threading board will be automatically

pulled through the Phoenix with your roll

film.

5. Inspect the film on the top roll of the

Phoenix. It should be smooth and taught

against the roll. If it is not, pull the threading board on the back of the Phoenix until

the film smooths out. Once smooth, you

are ready to laminate.

6. Ensure that the PHOENIX rollers are

turned on and set either at the ‘Rabbit’

speed. With the Heat is on, set at the ‘Roll’

setting and the LED light is Yellow indicating

the roll temperature is ready to use.

7. Set the Control Knob to match the thickness of the board you will be using.

8. Insert your board (either the sled with

your print/mounted print/or heat activated

board. with your print into the nip of the

rollers. It will automatically be pulled

through the laminator and over-laminated.

9. If laminating more than one print, insert

it after the first print is done. Check the

film on the roll face first. If it has some

wrinkles, pull you first print unit they disappear and adjust the tension on the dispensing bar to maintain the film being smooth

on the roll face.

10. Trim your print after it exits the Phoenix.

Note: If your laminate appears cloudy

or your print is not fully adhered to the

board, adjust the speed to the ’Turtle’

setting and reprocess your pouch

board.

Caution: Do not trim near the rollers.

Cuts and nicks in the roller can effect

the quality of your laminating and require maintenance. Cuts and nicks in

the roll face are not covered by the

Warranty.

PHOENIX 44 LAMINATOR

13

Page 14

C

LEANING YOUR

PHOENIX L

AMINATOR

Cleaning the Outside of the Laminator:

CAUTION! Disconnect the laminator

from the power supply before cleaning.

The laminator may be cleaned with a lintfree cloth, lightly dampened with a mild

soap and water solution. Do not use a

spray-on cleaner.

Do not immerse any part of the laminator in

water or other liquid.

Do not use an abrasive cleaner, which can

damage the painted surfaces.

Do not allow water or liquids to enter the

electrical circuits, which may cause personal

injury and/or damage the equipment when

power is applied.

Cleaning the Rollers

The laminating rollers of your PHOENIX should

be periodically cleaned of adhesive build up that

might occur during normal operation.

IMPORTANT! Clean the laminating rollers to

prevent adhesive build-up and to ensure quality

output. Adhesive build-up may eventually damage the rollers.

When laminating, a small amount of adhesive

will squeeze out between the laminate films and

onto the top and bottom rollers. This residue

accumulates through normal use and can be

easily cleaned off the rollers.

Use a Cleaning Board for regular cleaning:

A new sheet of 3/16” foam board may be

used to clean the rollers. Simply run the new

board through the machine to remove any

built up adhesive.

1. Turn on the unit. Once the machine has

reached process temperature set the

Control Knob to 3/16" (5mm).

2. Slowly insert the Cleaning Board into the

inlet opening. Ensure that the board enters

centered and straight. A gentle push may

be required to start the board into the

machine. Hold the edges of the board until

it is engaged in the unit and the laminator

begins pulling it on its own.

3. The board will feed through the laminator

and automatically exit at the rear of the

unit.

CAUTION! THE BOARD WILL BE HOT!

Allow the board to lie flat while cooling.

For heavier deposits of adhesive on the

rollers, turn your unit off and let it cool. Rub

the rollers with Isopropyl alcohol and a

Scotchbrite pad to remove the adhesive buildup.

14

PHOENIX 44 LAMINATOR

Page 15

T

ROUBLE-SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

The Red LED Light above the

rollers does not come on indicating the Main power

switch is turned on.

The Power cord is not

plugged in fully.

The main breaker is tripped.

The circuit breaker is tripped.

/ T

ECHNICAL

Check the Power cord.

Turn the breaker to the on.

Reset the circuit breaker.

S

ERVICE

Pouch Board is not being

pulled into the PHOENIX or

the motor is making a louder

humming noise or is stalling.

Only after pushing very hard

is the board pulled into the

PHOENIX.

The Quality of the lamination

is poor. There are silvery areas on dark surfaces which

are visable or the edges of

the image are not sealed

well.

The quality of the lamination

shows bubbles or ripples.

The Pouch Board is too thick

for the setting on the Roller

gap control Knob.

The set screw on the roller

gear may be loose

The roller temperature is too

low.

The Speed is too fast.

The Roller pressure is too

low.

The Roller temperature is too

high.

The Speed is too slow.

There is too much pressure.

Change the setting on the

Roller gap control to the next

thicker setting.

Contact Technical Service for

instructions how to tighten

set screw.

Contact Technical Service for

instructions on how to adjust

temperature.

If using the ‘Rabbit’ speed,

try the ‘Turtle’ speed. Otherwise contact Technical Service for instructions on how

to adjust speed.

Adjust the setting on the

Roller Gap Control to the

next narrower setting.

Contact Technical Service for

instructions on how to adjust

temperature.

If using the ‘Turtle’ speed,

try the ‘rabbit’ speed. Otherwise contact Technical Service for instructions on how

to adjust speed.

Adjust the setting on the

Roller Gap Control to the

next thicker setting.

There are wrinkles in either

the flexible pouch or pouch

board.

PHOENIX 44 LAMINATOR

There is too much pressure.

The seal of the leading edge

is not smooth.

Adjust the setting on the

Roller Gap Control to the

next thicker setting.

Re-tape the entire leading

edge smoothly

15

Page 16

S

PARE

P

ARTS

/ T

ECHNICAL

S

ERVICE

Technical Service

If the machine does not reach temperature

or you do not get the results you desire,

please contact your Technical Service

Representative. When calling for Technical

Service, please have the Laminator Serial

Number available.

Please contact your distributor or sales

person for replacement parts.

Your laminator is covered by a one-year

Warranty as described in this manual.

P

HOENIX

North East

Stover Graphics

7A Railroad Avenue Ext.

Beacon Falls, CT 06403

203-729-2846

A

UTHORIZED

Servicing and replacement parts

Service and maintenance must be performed

fully in accordance with the instructions.

Servicing by any unauthorized technician

voids the warranty. A service technician

must use replacement parts specified by

Technical Service.

NOTE! Service Technicians must perform

safety checks after completing any service or

repairs to the laminator.

R

EPAIR

Mid West

Film Source International

13878 Parks Steed drive

Earth City, MO 63045

314-739-4400

C

ENTERS

16

Mid Atlantic

Film Source International

6601 S Laburum Avenue

Richmond, VA 23231

804.226.0400

South

Smooth Finish

2385 Black Rock Drive

Duluth, GA

770.235.9374

PHOENIX 44 LAMINATOR

West Coast

Film Source International

1487 North Main Street

Orange, CA 92867

800.831.8947

Page 17

M

OUNTING

& L

AMINATING

T

ERMS

Cleaning Board:

Board used to capture any adhesive that may be

clinging to the rollers.

Cold Mode:

Heat is off.

Cover Sheet:

Release paper to be placed on the surface of

mounting boards.

Roller Gap Control Knob:

Adjusts the space between the rollers on the

PHOENIX 44.

Flashing Temperature Light:

The machine has not reached temperature.

Film:

A synonym used for laminate. The material used

in the laminating and encapsulating process.

Flexible Pouch:

Plastic Film Pouch for laminating paper.

Heat-Activated Films:

Films with an adhesive activated when heat is

applied. Once applied to an image, the adhesive

forms a strong bond between the laminate and

the image.

Hot Mode:

Heat is on.

Laminator:

A machine used to mount and laminate images.

LED:

Light Emitting Diode (light).

Mounting Board:

An adhesive coated board used for mounting

images.

Nip:

The spot where the top and bottom rollers

meet.

Out-Feed:

The back of the laminator where completed

images emerge.

Pouch Board:

An adhesive coated board with an overlaminate attached.

Pre-Coating:

The process of coating a substrate with an

adhesive mounting film onto which an image

can be mounted.

Pressure-Sensitive Films:

Films with an adhesive that is activated when

pressure is applied, forming a bond between

the protective laminate and the surface of the

image. Used primarily for fast mounting

applications and recommended for heatsensitive thermal and photographic prints.

Release Liner:

The backing on a pressure-sensitive film or

mounting adhesive used to keep the film from

sticking to itself. After peeling the release liner

off, the adhesive layer becomes exposed.

Roller Height:

The space between the rollers.

Sled:

A 3/16” (5mm) non-stick board used to place

flexible pouches to aide the laminating

process.

PHOENIX 44 LAMINATOR

17

Page 18

P

HOENIX

S

PECIFICATIONS

Dimensions

Width 17”

Length 56”

Roll Dimension 4”

Net Weight 145 pounds

Shipping weight 200 pounds

Height 15.25”

Operating Standards

Minimum Speed 6”/minute

Maximum Speed 12”/minute

Minimum temperature 195° Fahrenheit

Maximum temperature 300° Fahrenheit

Roll Core size 3” Inside Dimension (ID)

Maximum Roll size 6” Diameter

Roller Gap/Nip Settings

0 Closed (Rolls touch)

1/16”

1/8”

3/16”

1/4”

Stand Height 30”

Electrics

U.S. Version 110V/60Hz 17A

U.S. Plug Configuration AC Plug 3-Wire NEMA 5-20 Male

International 220V/50Hz 11A

Item Number

ML44

18

PHOENIX 44 LAMINATOR

Page 19

2 3 4

4

3 2 1

Phoenix

wiring diagram

Ademco

N

AC110V

L

N

9

Temp.switch 150 degree, closed normally

8

speed setting plate

control panel

7

heating tube

6

M

motor

5

4

RT heat-sensitized resistance PT1000

3

SR

solid state relay

2

XB junction

1

Q A switch

115V/2000W

YN80-25/110V speed rate 1:500

280V/50A

2P

20A

DZ47-32 25A

1

QA

1

L

2

N

XB

Text

Text

solid state relay

7

heating tube

Kr

5

N

SR

11

control panel

13

t

RT

3

4

8 2

speed setting plate

1 7 5 6

20 18 16 14

C

Title

Number Revision Size

A4

Date: 21-Mar-2008 Sheet of

C:\Documents and Settings\yg\ \

File:

20071212

.DDB Drawn By:

Page 20

P

Laminator

Parts Identification

18

26

22

21

5

HOENIX

19

20

24

23

6

15

10

16

15

14

13

12

Page 21

4

11

8

9

3

17

1

2

7

Page 22

P

HOENIX LAMINATOR PARTS IDENTIFICATION

Part No. Description

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Roller

Silicon Roller

Drive Motor

Mother Board

Front Table

Roller up-down Clamp

Speed Controller

Chain

SSR

Left Arm

Right Arm

Heating Tube

Stand for Heating Tube

Cover

Press Spring

Terminal Block

Overheating Protection

Supporting Roll for Film

End-Caps(Big)

Knob

Localizer

Left Frame

Right Frame

Heat-Shield

Contactor(Breaker)

Plank

Page 23

L

IMITED

W

ARRANTY

The Manufacturer warrants to the original

consumer purchaser that each new PHOENIX

Laminator which proves defective in materials

or workmanship within the applicable warranty

period will be repaired at our option or

replaced without charge.

The Applicable Warranty period for the New

PHOENIX Laminators shall be one year on

parts and three months on labor and rollers

from date of purchase.

After three months and for up to one year

after the date of purchase, the manufacturer

will complete Warranty repair labor at no

charge provided the labor is completed at one

of our Authorized Locations. It is the

responsibility of the original consumer

purchaser to return the PHOENIX laminator to

our Authorized Locations. For a list of

Authorized Repair Locations, please contact

your Dealer.

All Warranty Repairs must be approved in

advance by Technical Service. If returning the

PHOENIX for approved Warranty repairs, it is

the consumer’s responsibility to insure the

machine is packaged in its original packing to

minimize the chances of any shipping damage.

Shipping damage is not covered under this

Warranty and is a matter between the

consumer and the freight company used to

transport this back to the authorized repair

center. If you need proper packaging, your

Dealer can supply such packaging at a

nominal cost.

This Warranty extends to and is enforceable

by only the original consumer purchaser, and

only for the period (during the applicable

term), which the product remains in the

possession of the original consumer purchaser.

"Original consumer purchaser" means the

person who first purchased the product

covered by this warranty. It does not apply if

it is found that at any time the equipment has

not been used for its intended purpose.

Any unauthorized changes or modifications to

this unit without our prior written approval will

void the user's Warranty.

The applicable warranty period for Demo

Equipment shall vary, not exceeding the

maximum warranty period stated herein. All

Demo Equipment comes with a specific

warranty, which will be stated at the time of

purchase. If warranty period is not detailed in

writing, there is no remaining warranty.

Please ask your dealer or sales

representative for details.

Used Equipment or non-Demo equipment is

sold on an "AS IS" basis with No Warranty.

For more information regarding this warranty,

please contact your distributor.

The information contained in this document is

subject to change without notice.

The Manufacturer assumes no responsibility

for any errors that may appear in the Owner’s

Manual. Nor does it make expressed or

implied warranty of any kind with regard to

this material including, but not limited to, the

implied warranties of merchantability and

fitness for a particular purpose.

The Manufacturer shall not be liable for incidental or consequential damages in connection with, or arising out of the furnishing, performance, or use of this document and the

program material, which it describes.

PHOENIX 44 LAMINATOR

23

Page 24

Phoenix Pouch Mounting Supplies

We have the widest range of pouch boards to use on any pouch mounter-laminator.

The pouch boards listed on this page are our standard pouch boards. We can also make

pouch boards from a variety of boards. We can also customize the adhesive to be compatible with the most medias. Whatever your customer’s need, the chances are great

that you can meet their needs with your pouch mounter-laminator.

special request, give us a call and we’ll make those jobs fast and easy!

When you have that

P

HOENIX

black foam board. Choose from our low temperature adhesive boards or with one

of our over-laminate films attached including: Gloss; Matte non-reflective finish with a

slight texture which is scuff resistant; or Canvas. Mounting board cover sheets have

exclusive insert folded edge. No tape needed! 10/box.

White Foam Pouch Boards

Size Mounting Gloss Matte

9” x 11.5” (MB911WHT) (C911WHT) (M911WHT)

11.5”x17.5” (MB1117WHT) (C1117WHT) (M1117WHT)

18.5” x 25” (MB18WHT) (C18WHT) (M18WHT)

25” x 37” (MB25WHT) (C25WHT) (M25WHT)

37” x 49” (MB37WHT) (C37WHT) (M37WHT)

41” x 61” (MB41WHT)

Black Foam Pouch Boards

25” x 37” (MB25BLK) (C25BLK) (M25BLK)

37” x 49” (MB36BLK) (C36BLK) (M36BLK)

41” x 61” (MB41BLK) (C41BLK) (M41BLK)

™

Pouch Boards

Mount-a-Sign Thin Pouch Boards

low temperature heat activated adhesive available with or without gloss overlaminate film. Rigid enough to stand-up with an easel and can be used with all

pouch laminators. Great for presentations for easy transport. 25/box.

Size Mounting Gloss

9” x 11.5” (601182) (601181)

11.5”x 17.5” (601185) (601184)

18.5”x 25” (601187) (601186)

25” x 37” (601189) (601188)

Available in 3/16” thick white or all

(C41WHT) (M41WHT)

25 mil thick white paper board with

24

P

HOENIX

from 4mm thick white corrugated plastic coated with a heat activated adhesive and a gloss laminate for shortterm signage. Flutes run vertically and the first dimension is the width of the board. (10/box)

12”x18”(CWPB1218) 18”x24”(CWPB1824) 24”x36”(CWPB2436)

18”x12”(CWPB1812) 24”x18”(CWPB2418) 36”x24”(CWPB3624)

Corrugated Plastic Pouch Boards

Pouch Boards made

PHOENIX 44 LAMINATOR

Page 25

Mounting Supplies

Wide Format Pouch Film Supplies

P

HOENIX

Film pouches for roll-up and flexible graphics including items such as blueprints,

menus, maps, banners and other flexible graphics. Low temperature adhesive safe

for use with inkjet media. A Sled is included with each box of 18”x24”, 25”x37” and

36”x48” film pouches. Smooth Matte finish has a write-able surface and the matte

laminate has a textured surface. 25 pouches/box.

Film Pouches

Size Gloss Gloss/Matte Gloss/White

9”x11.5”(50) (601248)

12”x 18” (50) (601247)

18.5”x24.5” (606590)

25” x 37” (606660)

36” x 48” (606780)

P

HOENIX

Roll Films

——— ———–

——— ———–

(608513) (606860)

(608517) (606970)

(608519) (607080)

Cold Mounting Adhesives (double-sided adhesive)

Choose from indoor lo-tack adhesive - good for most inkjet prints—or outdoor adhesives designed for

heavier papers and hard to stick boards such as Gator or Sintra pvc. Both self-wound with a single silicon release liner. Rolls on 3” cores. Lo tack 25” and 51” rolls are 150’ long.

Type 25”x200’ 38”x200’ 41”x200’ 51”x200’

Lo Tack

$

119 (MES25150) $199 (MES38200) $229 (MES41200) $299 (MES51150)

Gloss Thermal Over-Laminate Roll Films

High quality over-laminate films with low temperature adhesive (i.e. 185 - 200 degrees F, operating

temperatures depend on running speed). Films are high grade optically clear polyester with UV absorbers

for maximum protection against fading.

Thickness 25”x200’ 38”x200’ 51”x200’ 61”x200’_

3 mil

5 mil

10 mil

$

45 (IG25203)

$

69 (IG25205)

$

189 (IG25254) $248 (IG38254) $349 (IG51254)

$

62 (IG38203)

$

98 (IG38205) $120 (IG51205)

$

87 (IG51203)

$

95 (IG61203)

$

157 (IG61205)

—————–

InkJet Thermal Over-Laminate Roll Films

Laminating film featuring Inkjet Adhesive Technology. Approved by Xerox and Canon for use on color prints

with Fuser oils and glossy papers.

Finish 25”x200’ 38”x200’ 41”x200’ __51”x 200’

Satin

Matte $165 (FGM25205) $228 (FGM38205) $248 (FGM41205)

Velvet

$

165 (FGL25205) $228 (FGL38205) $248 (FGL41205)

$

185 (FGV25207) $254 (FGV38207) $274 (FGV41207)

Gloss $179 (FGG25201) $218 (FGG38201) $230 (FGG41201)

$

299 (FGL51205)

$

299 (FGM51205)

$

340 (FGV51207)

$

290 (FGG51201)

PHOENIX 44 LAMINATOR

25

Loading...

Loading...