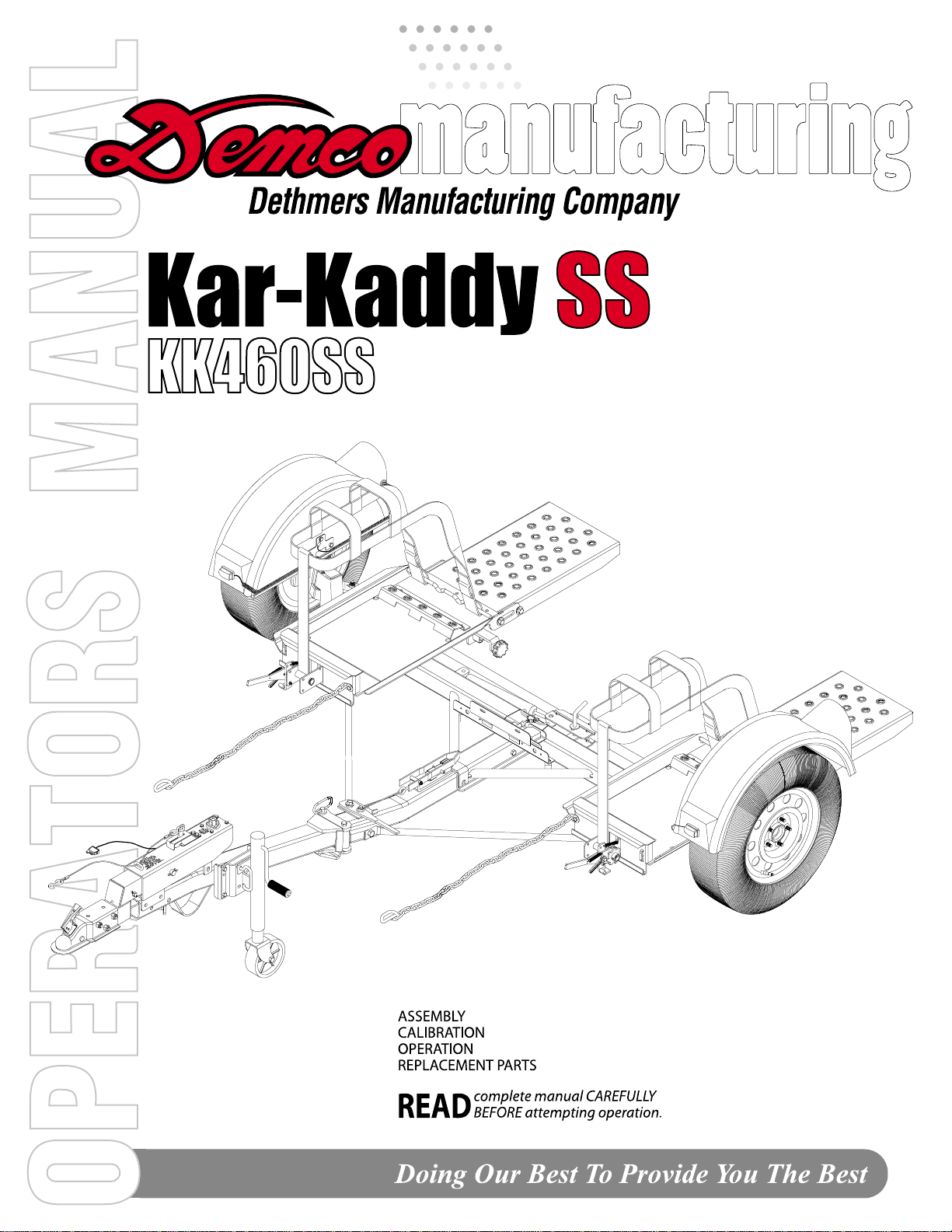

Page 1

7-06

RD20010,Rev 6

1

Page 2

Introduction

Thank you for purchasing a Demco Kar-Kaddy. We feel you have made a wise choice and hope you

are completely satisfied with your new piece of equipment.

GENERAL INFORMATION

1. Unless otherwise specified, high-strength (grade 5)

(3 radial-line head markings) hex head bolts are

used throughout assembly of this piece of equipment.

2. Whenever the terms "LEFT" and "RIGHT" are

used in this manual it means from a position behind

the

Kar-Kaddy and facing forward.

TABLE OF CONTENTS

General Information ................................................................................................................................ Page 2

Safety, You can Live With.................................................................................................................... Page 3-7

Decal Location ........................................................................................................................................ Page 8

Bolt Torque ............................................................................................................................................. Page 9

Tongue and Ramp Assembly ............................................................................................................... Page 10

Fender Assembly .................................................................................................................................. Page 11

Wiring Diagram ..................................................................................................................................... Page 12

Testing Lights........................................................................................................................................ Page 12

Tongue Folding ..................................................................................................................................... Page 13

Folding Ramps................................................................................................................................. Page 14-15

Loading Angle Clearance Guide........................................................................................................... Page 15

Safety, Maintenance, & Important Loading Instructions ....................................................................... Page 16

Loading Instructions...................................................................................................................... Pages 17-19

Toe-In Adjustment................................................................................................................................ Page 20

DA91 Brake Actuator Parts Breakdown and List.................................................................................. Page 21

10" Self-Adjusting Brake Cluster Parts Breakdown and List ................................................................ Page 22

Brakes Line Parts Breakdown and List................................................................................................. Page 23

Kar-Kaddy Breakdown Parts Assembly Instructions .................................................................... Pages 24-25

Winch and Tilt-Bed Parts Breakdown................................................................................................... Page 26

Ramp Latch and License Plate Bracket Parts Breakdown ................................................................... Page 27

Fender Parts Breakdown ...................................................................................................................... Page 28

Winch, Tool Box, & Spare Tire w/Mounting Bracket (optional) Parts Breakdown and List .................. Page 29

Deflector, & Light Bar (optional) Parts Breakdown and List .................................................................. Page30

Product Warranty .................................................................................................................................. Page 31

Warranty Registration ...................................................................................................................... Page 33-34

3. When placing a parts order, refer to this manual for

proper part numbers and place order by PART NO.

and DESCRIPTION.

"Reporting Safety Defects"

If you believe that your vehicle has a defect

which could cause a crash or could cause injury or

death, you should immediately inform the National

Highway Traffic Safety Administration (NHTSA) in

addition to notifying Dethmers Manufacturing Company (DEMCO).

If NHTSA receives similar complaints, it may

open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA

cannot become involved in individual problems between you, your dealer, or Dethmers Manufacturing

Company (DEMCO).

To contact NHTSA, you may either call the

Auto Safety Hotline toll-free at

1-800-424-9393 (or 366-0129 in

Washington, D.C. area) or write to:

NHTSA,

U.S. Department of Transportation

Washington, D.C. 20590.

You can also obtain other information about

motor vehicle safety from the Hotline.

2

Page 3

SAFETY

T AKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS MANUAL IS USED TO

CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY AND THE

SAFETY OF OTHERS. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN INJURY

OR DEATH.

THIS SYMBOL MEANS

ATTENTION

BECOME ALERT

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and

CAUTION with the safety messages . The appropriate signal

word for each has been selected using the following

guidelines:

DANGER:

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

If you have questions not answered in this manual, or require additional copies, please contact your dealer or Dethmers

Mfg. Co., P.O. Box 189, 4010 320th Street, Boyden, IA 51234

ph: (712) 725-2311 Toll Free: 1-800-543-3626 Fax: (712) 725-2380 or 1-800-845-6420

http://www.demco-products.com

WARNING:

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury. It may also be used to

alert against unsafe practices.

CA UTION:

Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury . It ma y also be used to

alert against unsafe practices.

REMEMBER

Your best assurance against accidents is a careful and responsible operator. If there is any portion of this manual

or method of operation you do not understand, contact your local authorized dealer or manufacturer.

3

Page 4

SAFETY...YOU CAN LIVE WITH IT

EQUIPMENT SAFETY GUIDELINES

Every year many accidents occur which could have been avoided by a few seconds of thought and a more

careful approach to handling equipment. You, the operator , can av oid many accidents by observing the following

precautions in this section. To avoid personal injury, study the following precautions and insist those working

with you, or you yourself, follow them.

Replace any caution, warning, danger or instruction safety decal that is not readable or is missing. Location of

such decals is indicated in this booklet.

Do not attempt to operate this KK460SS under the influence of alcohol or drugs.

Review the safety instructions with all users.

Operator should be a responsible adult. DO NOT ALLOW PERSONS TO OPERATE OR ASSEMBLE THIS

UNIT UNTIL THEY HA VE DEVELOPED A THOROUGH UNDERST ANDING OF THE SAFETY PRECA UTIONS

AND HOW IT WORKS.

Do not paint over , remov e, or def ace any safety signs or w arning decals on your KK460SS . Observe all safety

signs and practice the instructions on them.

Never exceed the limits of a Kar Kaddy SS If its ability to do a job safely is in question

DON'T TRY IT.

LIGHTING AND MARKING

It is the responsibility of owner to know lighting and marking requirements of local highway authorities and to

install and maintain equipment to provide compliance with regulations.

Light bar kits are available from your dealer or from manufacturer.

TIRE SAFETY

• Failure to follow proper procedures when mounting a tire on a rim can produce an explosion which may result

in serious injury or death.

• Do not attempt to mount a tire unless you have proper equipment and experience to do the job.

• Inflating or servicing tires can be dangerous. Whenever possible, trained personnel should be called to

service and/or mount tires.

• KK460SS tires must be inflated to recommended P.S.I. . See decal on KK460SS for correct pressure.

• Always order and install tires and wheels with appropriate type and load capacity to meet or exceed gross

weight of unit.

SAFETY SIGN CARE

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

4

Page 5

• Replacement parts that displayed a safety sign should also display current sign.

• Safety signs are available from your distributor, dealer parts department, or factory.

How to install safety signs:

• Be sure installation surface is clean and dry.

• Decide on exact position before you remove backing paper.

• Remove smallest portion of split backing paper.

• Align decal over specified area and carefully press small portion with exposed sticky backing in place.

• Slowly peel back remaining paper and carefully smooth remaining portion of decal into place.

• Small air pockets can be pierced with a pin and smoothed out using piece of decal backing paper.

BEFORE OPERATION:

• Carefully study and understand this manual.

• Keep wheel and lug nuts tightened to specified torque.

• Assure tires are inflated evenly.

• Give unit a visual inspection for any loose bolts, worn parts, or cracked welds, and make necessary repairs.

Follow maintenance safety instructions included in this manual.

• Be sure there are no tools lying on or in KK460SS

• Do not use unit until you are sure that area is clear, especially around children and animals.

• Don't hurry learning process or take unit for granted. Ease into it and become familiar with your new KK460SS

• Practice operation of your KK460SS and its attachments. Completely familiarize yourself and other

operators with its operation before using.

• Make sure that brakes are evenly adjusted (if equipped with brakes)

• Securely attach to towing vehicle. Use an appropriately sized and rated hitch ball and attach safety chains.

• Do not allow anyone to stand between tongue or hitch and towing vehicle when backing up to unit.

• Make sure tow rating on vehicle is high enough for what it is towing.

DURING OPERATION

• SAFETY CHAIN - Always follow state and local regulations regarding safety chains and auxiliary lighting

when towing. Be sure to check with local law enforcement agencies for your own particular regulations. Only

safety chains (not elastic or nylon/plastic tow straps) should be used to retain connection between towing

vehicle and towed unit in event of separation.

• Do not load towed vehicle with cargo. Towed vehicles exceeding weight limits will overload KK460SS and

may cause serious injury and damage.

• Criss cross safety chains under tongue, secure to mounting loops on towing vehicle.

5

Page 6

• Secure emergency brake actuator cable to mounting loop on towing vehicle.

• Beware of bystanders, PARTICULARLY CHILDREN! Always look around to make sure it is safe to start engine

of towing vehicle or move unit. This is particularly important with higher noise levels, as you may not hear people

shouting.

• NO PASSENGERS ALLOWED- Do not carry passengers anywhere on or in towed unit.

• When halting operation, even periodically, set towing vehicle parking brake, shut off engine, and remove ignition

key.

• Be extra careful on inclines.

• MANEUVER TOWING VEHICLE AT SAFE SPEEDS. Do not exceed 55 M.P.H.

• Avoid overhead wires or other obstacles. Contact with overhead lines could cause serious injury or death.

• Avoid loose gravel, rocks, and holes; they can be dangerous for unit operation or movement.

• Allow for unit length when making turns.

• Do not work under raised components or attachments unless securely positioned and blocked.

• Keep all bystanders and pets clear of work area.

• Operate towing vehicle from operators seat only.

• As a precaution, recheck hardware on KK460SS every 50 miles, and correct all problems. Follow

maintenance safety procedures.

FOLLOWING OPERATION

• Following operation, or when unhitching, stop towing vehicle, set parking brake, shut off

engine and remove ignition key.

• Store KK460SS in area away from human activity.

• Do not permit children to play on or around stored KK460SS.

• Make sure parked KK460SS is on hard, level surface.

• Wheel chocks may be needed to prevent unit from rolling.

HIGHW AY AND TRANSPORT OPERATIONS

• Adopt safe driving practices:

- Always drive at safe speed relative to local conditions and ensure that your speed is low enough for an emergency

stop. Do not exceed 55 M.P.H.

- Reduce speed prior to turns to avoid risk of overturning.

- Always keep towing vehicle in gear to provide engine braking when going downhill. Do not coast.

- Do not drink and drive!

• Comply with state and local laws governing highway safety.

6

Page 7

• Local laws should be checked for all highway lighting and marking requirements.

• Plan your route to avoid heavy traffic.

• Be a safe and courteous driver. Always yield to oncoming traffic in all situations, including narrow bridges,

intersections, etc.

• Watch for obstructions overhead and to both sides while transporting.

• Operate with maximum visibility at all times. Make allowances for increased length and weight of KK460SS when

making turns and stopping.

PERFORMING MAINTENANCE

• Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

• Make sure there is plenty of ventilation. Never operate engine of towing vehicle in a closed

building. Exhaust fumes may cause asphyxiation.

• Before working on KK460SS, stop towing vehicle, set parking brake, tur n off engine and remove ignition key.

• Always block wheels and never use a jack as sole support.

• Always use proper tools or equipment for job at hand.

• Use extreme caution when making adjustments.

• Follow torque chart in this manual when tightening bolts and nuts.

• Openings in skin and minor cuts are susceptible to infection from brake fluid.

Without immediate medical treatment, serious infection and reactions can occur.

• After servicing, be sure all tools, par ts and service equipment are removed.

• Do not allow grease or oil to build up on any step or platform.

• When replacing bolts, refer to owners manual for proper size and grade.

• Refer to bolt torque chart for head identification marking.

• Where replacement parts are necessar y for periodic maintenance and servicing, genuine factor y replacement

parts must be used to restore your KK460SS to original specifications. Manufacturer will not claim

responsibility for use of unapproved parts and/or accessories or other damages as a result of their use.

• If KK460SS has been altered in any way from original design, manufacturer does not accept any liability for

injury or warranty.

• A fire extinguisher and first aid kit should be kept readily accessible while perf orming maintenance on this KK460SS

7

Page 8

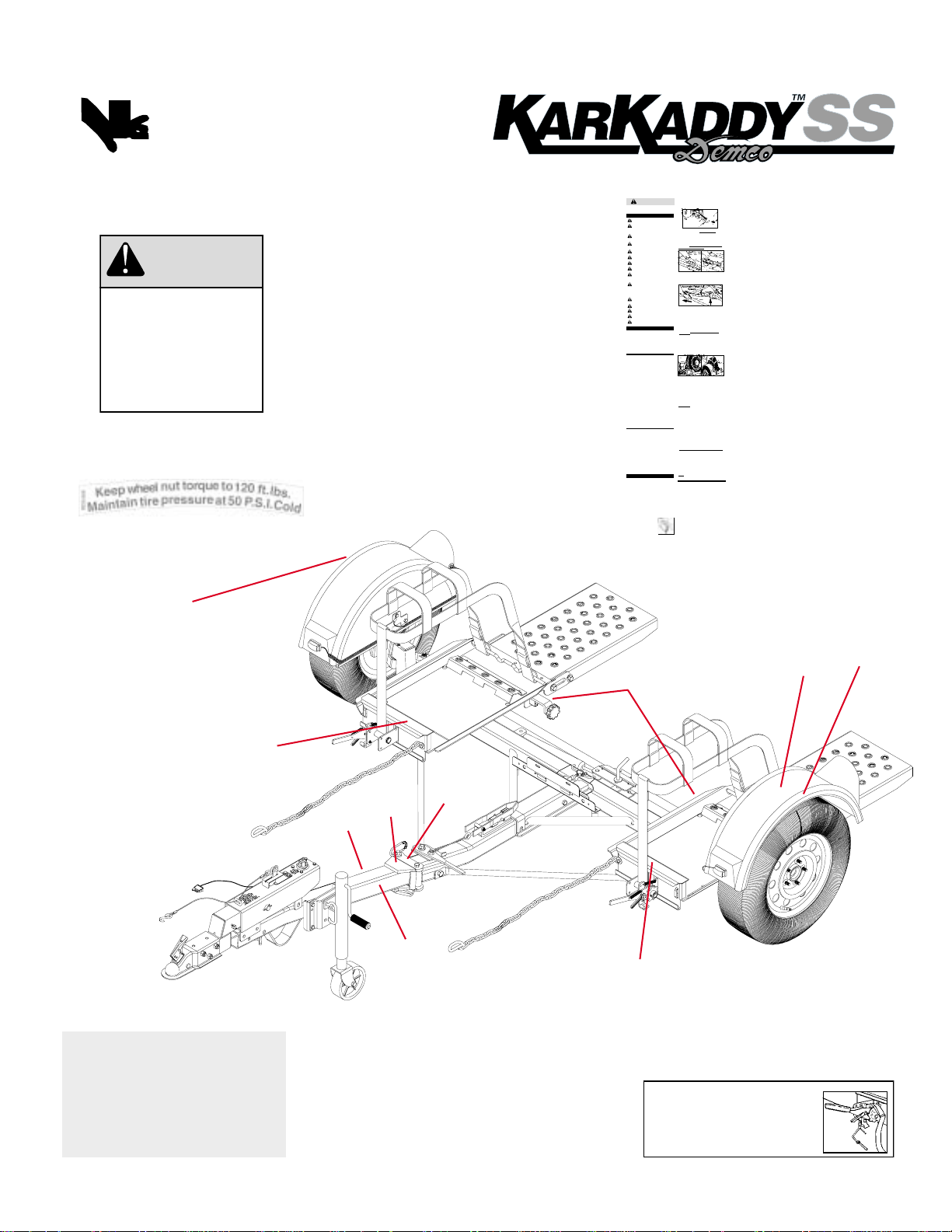

PINCH POINT

REV 0 DD21018

A. DD21018

WARNING

To prevent serious

injury or death.

Make sure tongue is in

forward locked position with

locking pin and retainer clip

properly installed before

hooking up or loading.

REV 0 DD21019

B. DD21019 QTY. 1

F. RD21008 QTY. 2

Decal Location

D. DD21017 QTY. 4

Loading Towed VehicleE

WARNING

Read towing instructions in towed vehicle

owners manual.

Use 2” 5000 lb. (or greater) capacity ball for Kar

Kaddy without surge brakes and 2” 6000 lb. (or

greater) capacity ball for Kar Kaddy with surge

brakes.

Assure towing vehicle parking brake is fully

engaged before starting hookup, loading,

unloading or unhooking Kar Kaddy.

Don’t load towed vehicle onto Kar Kaddy until Kar

Kaddy is completely and properly hooked up to

towing vehicle and setting on level surface.

Always drive front wheels of towed vehicle onto

Kar Kaddy. Don’t load backwards.

Tail lights and stop lights must be hooked up and

operating properly at all times.

Don’t load towed vehicle that exceeds weight or

size limits onto Kar Kaddy.

Always have someone safely guide you

when driving towed vehicle onto Kar Kaddy.

Assure tires of towed vehicle and Kar Kaddy are in

good condition and properly inflated. Tire pressure

may increase during travel, Do not bleed off this

increase in pressure.

Don’t back towing vehicle with Kar Kaddy

attached. Kar Kaddy swivels both at coupler and at

car platform. If you must back up, unload towed

vehicle first, disconnect Kar Kaddy and move

vehicle and Kar Kaddy separately. Play it safe...

park where you can pull ahead when leaving.

Braking distance increases when using Kar Kaddy.

Use caution and always allow sufficient braking

distance.

Avoid sharp turns or swerves.

Descend hills in lower gear. Avoid sudden braking

or lane changes when descending a hill.

Don’t transport passengers or cargo in vehicle

being towed.

Don’t unhook Kar Kaddy from towing vehicle

until towed vehicle is completely unloaded

from Kar Kaddy.

42” min.

42” min.

good condition and not rusted, loose or

stripped. Both hitch and hitch ball must

be securely attached to towing vehicle.

under tongue and attach

to mounting loops on

towing vehicle. If Kar Kaddy

is equipped with brakes

attach emergency brake

cable to one of these loops.

Allow some slack in chains

and cable for movement during turning.

Failure to follow these instructions could

result in serious injury or death.

1.Assure towing vehicle and Kar Kaddy are

straight, on level ground, and properly

hooked up before loading towed vehicle.

C

B

#2

A

2.Remove winch lock pins (A) from strap winches

on front of Kar Kaddy. RELEASE WINCH: Grasp

handle (B) squeeze trigger (C) push down and

pull all excess strap from winch. Lay tire strap

to outside of Kar Kaddy.

3. Remove STEERING LOCK PIN before loading

vehicle onto Kar Kaddy to allow AUTO STEER

WHEN KAR KADDY IS EMPTY, THIS

to operate.

PIN MUST BE REINSERTED

#3

4. Loosen wing nut on back of license plate holder,

turn clip on front to horizontal position and

put license in “down” position. Turn clip back

so it rests against back of light to hold license

“down” and tighten wing nut. (License must be

“up” with Kar Kaddy empty).

#5

5. Grasp bed release handle on tongue and

pull toward coupler. This releases tilt bed.

6. Before loading (and unloading) towed vehicle

make sure platform and towed vehicle are in

straight alignment. Don’t load towed vehicle

onto KAR KADDY until completely and properly

hooked up to towing vehicle and setting on

level surface.

7.With someone safely guiding you, center

vehicle to Kar Kaddy. Slowly drive vehicle

forward, until tires touch wheel stops at front

of platform. DO NOT BACK VEHICLE ONTO

KAR KADDY. Assure that towed vehicle is

centered on Kar Kaddy platform and tires fit in

wheel pans without hanging over sides.

8.Place towed vehicle in park (low gear if it has

standard transmission), engage parking brake,

shut off engine, remove ignition key, lock

steering wheel of towed vehicle with tires in a

straight forward position. If towed vehicle does

not have a locking steering column, steering

wheel must be securely tied.

#9

9.Place tire straps over tires centering straps and

winches to tires, avoiding contact with

suspension components. Short side of hook

must face rear of Kar Kaddy. While tightening

straps, pull cross straps forward to ensure even

tightening. Tighten straps until each tire starts

to flatten against tire stop. After strap is tight

and with ratchet handle in down (horizontal)

position insert lock pin through hole in ratchet

pawl arm

and ratchet frame then attach retainer

clip.

Hook safety chains to frame of towed

vehicle directly above area where chains are

mounted on Kar Kaddy.

IMPORTANT: Chains must not attach to or go

over steering or brake parts. Leave enough

slack in chains for suspension movement.

Check tire straps after first 5 miles of travel and

every 50 miles thereafter to ensure they are

tight and not rubbing or fraying on suspension

components of towed vehicle.

10. If towed vehicle is rear wheel or four wheel

drive, disconnect drive shaft. (Simply placing

transmission in neutral is not sufficient to

prevent damage to transmission). You must

disconnect drive shaft at rear axle and remove

it. With the drive shaft removed it will be

necessary to cap the transmission tail shaft to

prevent transmission fluid loss.

Rear engine/transaxle vehicle cannot be towed

with Kar Kaddy. (All vehicles loaded on Kar

Kaddy must be loaded with front of vehicle

facing forward). Consult your vehicle owner’s

manual to help determine if and how your

vehicle is suitable to be towed.

RELEASE

PARKING BRAKE ON TOWED VEHICLE.

11.

Ensure that steering wheel is locked in straight

forward position, remove ignition keys and

lock doors of towed vehicle.

12. Release parking brake on towing vehicle and

drive forward 100 feet. Stop and perform safety

check. Check hitch, hitch ball, ball coupler,

safety chains, tire straps, bolts and other items

to ensure they are tight and in correct position.

Check all lights to make sure they are operating

properly. Repeat safety check after first 5 miles

and every 50 miles thereafter.

NOTE: Do not unhook Kar Kaddy from towing

vehicle until towed vehicle is completely

unloaded from Kar Kaddy.

Unloading Towed Vehicle

1.Assure towing vehicle and Kar Kaddy are

straight, on level ground, and properly hooked

up before unloading towed vehicle.

2.Fully engage parking brake of towing and

towed vehicles.

3.If removed, reinstall drive shaft of towed

vehicle.

4.Straps may be “quick released” by removing

locking pin, grasping ratchet pawl and ratchet

handle simultaneously and pushing down

sharply. This process will permit easy removal

of strap from winch.

5.Remove tire straps and safety chains from

towed vehicle. Also release tilt bed as shown in

illustration #5.

6.Release parking brake of towed vehicle and

slowly back towed vehicle off Kar Kaddy.

7.On level ground check the transmission fluid

level of towed vehicle. Fluid may have leaked

out during towing.

8.Store safety chains and straps in

their storage position on each side.

9.Return tilt bed to locked position and reinsert

steering lock pin. As shown in illustration #3

#4

Read following information before hooking up,

loading, using, unloading or unhooking Kar

Kaddy to prevent property damage, serious

injury, or death.

IMPORTANT DO’S & DON’TS

IMPORTANT INFORMATION

Customer Responsibilities

Customer assumes all risks inherent in

operation, use, or possession of Kar Kaddy.

Towing a vehicle is owners responsibility and it

is the owner who must ensure that weight and

size limits of Kar Kaddy will not be exceeded by

vehicle being towed. Any injury or damage that

results from improper use or exceeding weight

or size limits is sole responsibility of owner.

Towing Vehicle Requirements

Owner assumes all responsibility for towing

vehicle’s fitness and suitability to perform

towing task in safe, legal, and reliable manner.

These responsibilities may include, but are not

limited to:

Towing vehicle weight being substantially

greater (at least 1000 lbs.) than weight of

Kar Kaddy and towed vehicle combined.

Compliance with towing restrictions as stated

by towing vehicle owner’s manual or

manufacturer.

Towing vehicle having minimum of 5000 lb.

hitch and hitch ball for Kar Kaddy without surge

brakes, or 6000 lb. hitch and hitch ball for Kar

Kaddy with surge brakes. Hitch ball must be 2”.

Do not use any other size hitch ball.

Towing vehicle’s hitch being approximately 18

inches to top of hitch ball. Make sure that hitch

and hitch ball are in good condition and not

rusted, loose or stripped. Both hitch and hitch

ball must be securely attached to towing

vehicle.

Towing vehicle must be in good condition.

Towing vehicle having a current federal or state

inspection where applicable, and complying

with any applicable laws.

Assure all lights are properly hooked up and

operating at all times.

Load Weight and Size Limits

Load weight is total weight of towed vehicle.

Overloading Kar Kaddy may cause serious injury

or damage to both towed vehicle and Kar Kaddy.

Maximum Towed Vehicle Weight.

KK260 KK260SB KK360 KK360SB

4400 lbs. 4700 lbs. 4400lbs. 4700lbs.

Size limit is overall width. Towed vehicle

exceeding size limit will obstruct platform’s

turning action when towing and could damage

towed vehicle’s tires and fenders.

KK260: 70” max.

KK360 76” max.

INSTRUCTIONS

Kar Kaddy Hook-Up

1.Assure towing vehicle parking brake is

fully engaged.

2.Loosen coupler lock, place coupler of Kar

Kaddy over 2” hitch ball on towing vehicle.

Assure coupler is fully seated on ball then

completely tighten coupler lock. Pull up on Kar

Kaddy tongue to assure it is properly secured.

NOTE: Assure that hitch and hitch ball are in

3.Connect Kar Kaddy wire harness to connector

on towing vehicle and check lights for proper

operation.

4. Criss cross safety chains

REV 1 RD21002

E. RD21002 QTY. 1

F

F

C

E

D

A

B

D

D

D

PULL & LIFT

TO

FOLD RAMP

Rev 0 DD21020

C. DD21020 QTY. 2

Remove winch lock pins (A) from strap winches on front of tow dolly.

Release winch: Grasp handle (B) squeeze trigger (C) push down and pull all

excess strap from winch. Lay tire strap to outside of tow dolly.

Tighten straps: Place tire straps over tires centering straps and winches to

tires. While tightening straps, pull cross straps forward to ensure even tightening.

Tighten straps until each tire starts to flatten against tire stop. After strap is tight,

insert lock pin into winch.

REV 1 DD21016

WINCH OPERATING INSTRUCTIONS

B

C

A

F. DD21016 QTY. 2

8

Page 9

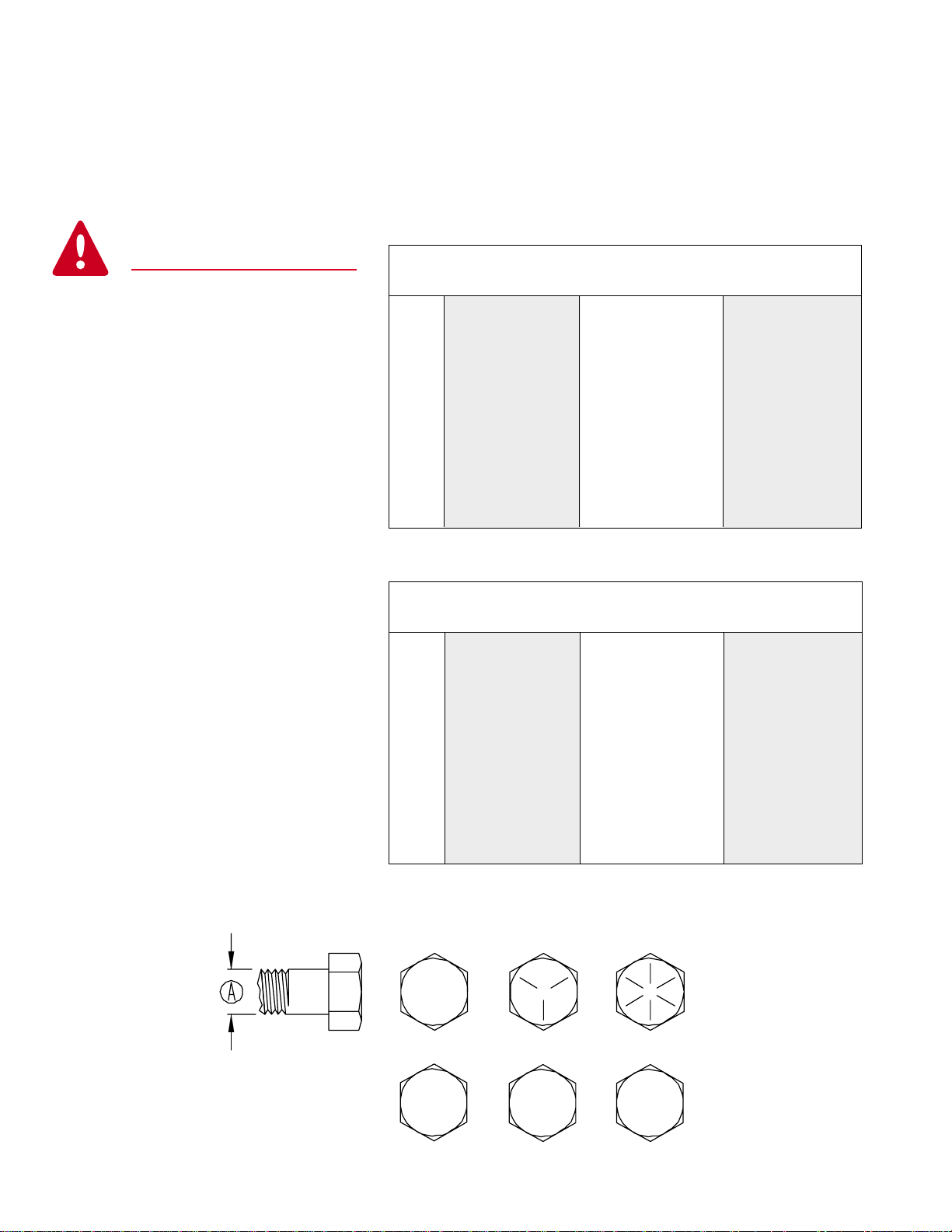

BOLT TORQUE

TORQUE DATA FOR STANDARD NUTS, BOLTS, AND CAPSCREWS.

Tighten all bolts to torques specified in chart unless otherwise noted. Check tightness of bolts

periodically, using bolt char t as guide. Replace hardware with same grade bolt.

NOTE: Unless otherwise specified, high-strength Grade 5 hex bolts are used throughout

assembly of equipment.

Bolt Torque for Standard bolts *

Torque Specifications

Torque Lug Nuts to 120 FT/LBS

Torque figures indicated are valid for

non-greased or non-oiled threads and

heads unless otherwise specified.

Therefore, do not grease or oil bolts or

capscrews unless otherwise specified

in this manual. When using locking

elements, increase torque values

by 5%.

* GRADE or CLASS value for bolts

and capscrews are identified by their

head markings.

GRADE 2 GRADE 5 GRADE 8

“A” lb-ft (N.m) lb-ft (N.m) lb-ft (N.m)

1/4” 6 (8) 9 (12) 12 (16)

5/16” 10 (13) 18 (25) 25 (35)

3/8” 20 (27) 30 (40) 45 (60)

7/16” 30 (40) 50 (70) 80 (110)

1/2” 45 (60) 75 (100) 115 (155)

9/16” 70 (95) 115 (155) 165 (220)

5/8” 95 (130) 150 (200) 225 (300)

3/4” 165 (225) 290 (390) 400 (540)

7/8” 170 (230) 420 (570) 650 (880)

1” 225 (300) 630 (850) 970 (1310)

Bolt Torque for Metric bolts *

CLASS 8.8 CLASS 9.8 CLASS 10.9

“A” lb-ft (N.m) lb-ft (N.m) lb-ft (N.m)

6 9 (13) 10 (14) 13 (17)

7 15 (21) 18 (24) 21 (29)

8 23 (31) 25 (34) 31 (42)

10 45 (61) 50 (68) 61 (83)

12 78 (106) 88 (118) 106 (144)

14 125 (169) 140 (189) 170 (230)

16 194 (263) 216 (293) 263 (357)

18 268 (363) -- -- 364 (493)

20 378 (513) -- -- 515 (689)

22 516 (699) -- -- 702 (952)

24 654 (886) -- -- 890 (1206)

GRADE-2 GRADE-5 GRADE-8

CLASS 8.8 CLASS 9.8 CLASS 10.9

8.8

9.8

9

10.9

Page 10

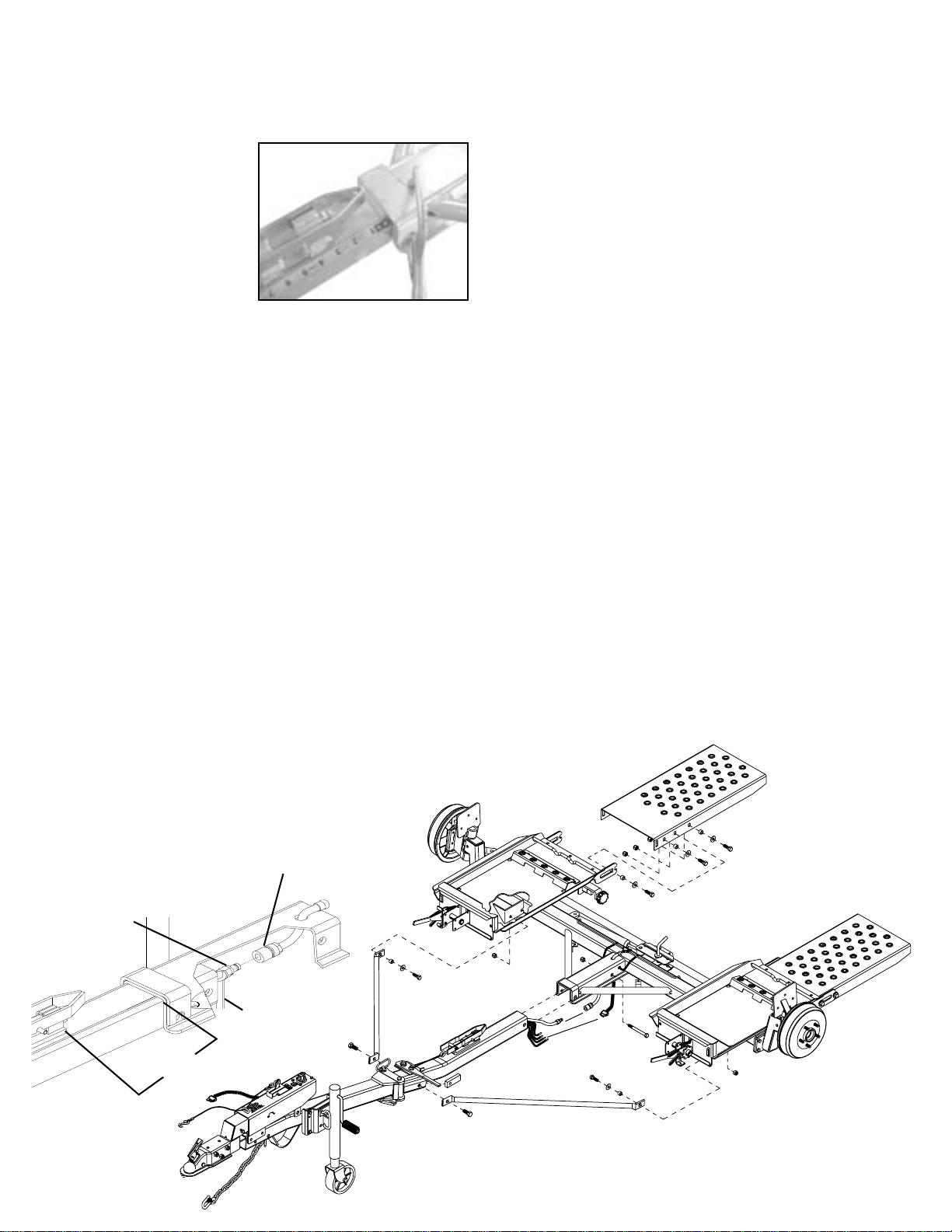

Tongue and Ramp Assembly Instructions

1. Place the main frame (#1) on blocks or some other sturdy

support so that the frame rests approximately 8" - 10" off

the ground.

2. With an assistant, place

tongue assembly (#2)

into main frame channel

and position latch on

tongue approximately 3”

from front of channel.

Clamp tongue to main

frame and support front

of tongue.

3. Locate the four bullet connectors extending out the back

of the tongue and plug into the connector protruding from

under the main frame channel. Plug into the flat four

connector by matching the colors. Do not cross colors

when making this connection. Make sure that the two

pigtails for the license plate bracket are out.

4. Using the open end of a 9/16” wrench to support the back

of the male coupler, (as shown below) push drip free quick

couplers together. (Factory setup units will not havequick

couplers)

5. With an assistant, mount the tongue assembly (#2) to the

front of the Kar Kaddy main frame and use a 5/8" x 4-1/2"

grade 5 bolt (#3) and lock nut (#4)(torque to 50 ft. lbs). Do

not torque over 50 ft. lbs. or bed will not tilt.

NOTE: Brake line and wiring must be above bolt also

coupler assembly must be ahead of bolt. Do this by

opening tongue about half way.

6. Lay the bracing struts (#5) out along the tow dolly tongue

with the back end (the end with the larger hole in it) of the

bracing strut toward the main frame. Loosely bolt the back

of each bracing strut to the trailer frame as shown using 1/

2" x 1-1/2" grade 5 bolt (#6), flatwasher (#7), pivot bushing

(#8) and locknut (#9). Hold up the front end (the end with

the smaller hole) of each bracing strut to the tongue and

secure with two 5/8" x 1-1/4" epoxied hex head bolts (#10)

and nut plate (#14). Torque the 1/2" x 1-1/2" bolt with the

pivot bushing to 75 ft. lbs. Torque the two 5/8" x 1-1/4"

epoxied hex head bolts to 100 ft. lbs.

7. On the main unit, pull ramp latch (#11) out and up in

unlatched position.

8. Use four 1/2” x 1-1/2” bolts (#6), 1/2” flat washers (#7) and

yellow plated bushings (#12) and place in the front slotted

hole and the rear slotted hole on both sides of ramp (#13).

Use four 1/2” nylon lock nuts (#9) and snug these bolts so

they can slide up and down in slot.

9. Place ramp (#13) in main frame (#1). Front bolts and

bushings go in front open slot of ramp mount. Lift ramp

up and push forward until rear bolts and bushings go into

rear half slot.

10. Engage Ramp latch (#11) and move ramp around so

latch can engage through ramp. With the use of two

clamps, secure ramp to main frame. Install the remaining

1/2” x 1-1/2” bolts (#6), flatwashers (#7), yellow bushings

(#12), and nylon lock nuts (#9) into the remaining slotted

holes.

11. Tighten all six bolts. Pull and lift ramp latch (#11) and pull

ramp back and fold up. If ramp is too tight when pulling

back, reclamp ramp as in previous step and loosen bolts

so ramp lowers away from main frame. Tighten bolts and

retry.

12. Repeat steps 7-11 for other side.

Connecting Drip Free Quick Coupler

brake couplers.

Not needed for factory setup units.

Female Coupler

Male Coupler

9/16 Wrench

5

10

3”

13

7

9

12

7

11

8

7

6

9

2

14

10

1

Connector

5

4

67

3

8

12

7

6

6

6

9

10

Page 11

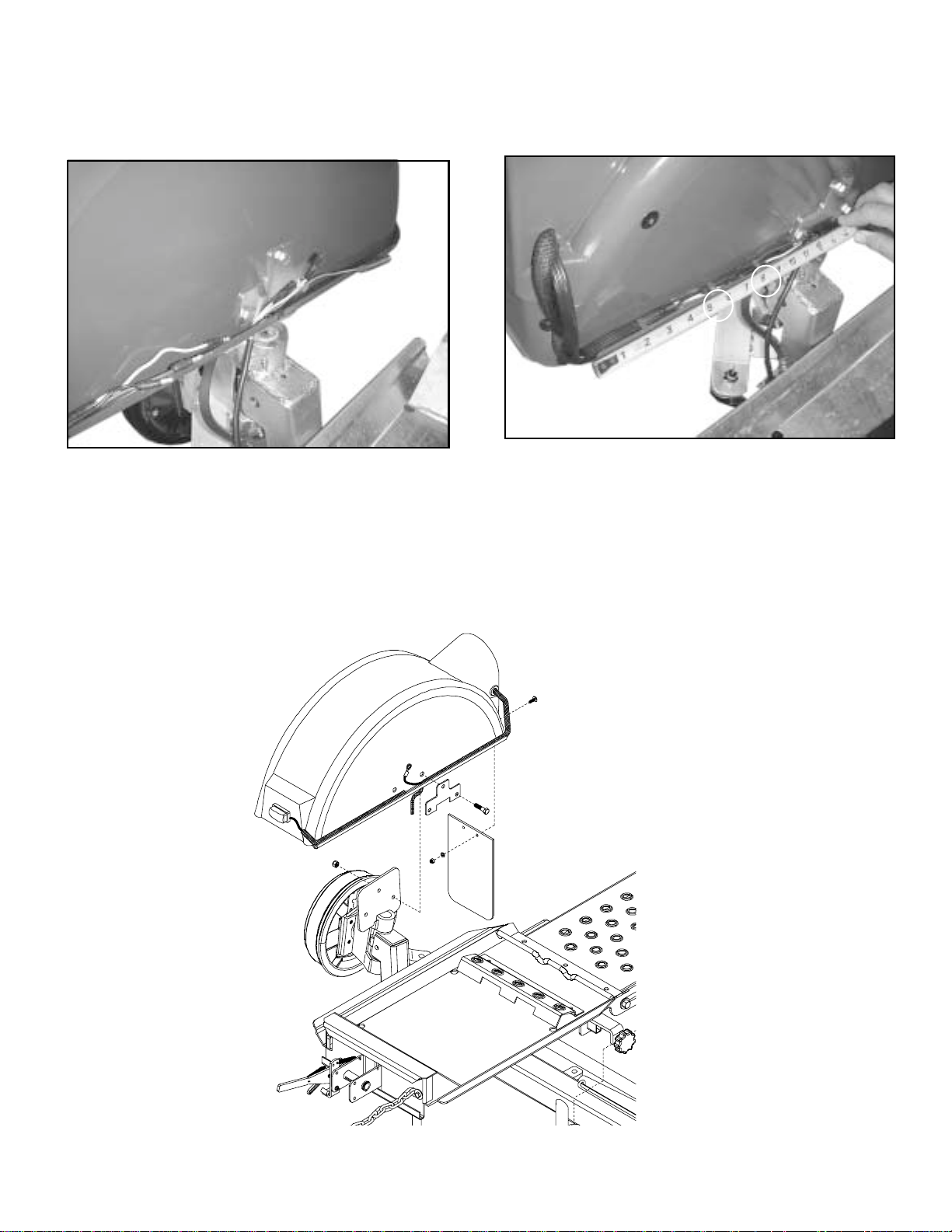

Fender Assembly Instructions

1. Install fender with fender backup plate (#1) and three 3/8”

x 1-1/2” bolts (#2). Put 3/8” nylon lock nuts (#3) inside of

fender and tighten.

2. Cut nylon wire tie from wiring to brake hose on main frame,

(used for shipping purposes only). Fish the three wires

from main unit through the hole in fender.

3. On the left side, plug in bullet plugs with white to white,

black to brown and yellow to red. On the right side, plug

white to white, black to brown and green to red.

4. With a pliers, install two wire clamps on fender. From rear

of fender lip, install one clamp at 5-1/2” and one at 8”.

5. Mount the mud flaps (#4) to the inside back of the fender

using two 1/4" x 3/4" truss head bolts (#5) with flat washers

(#6) and lock nuts (#7). Make sure the Kar Kaddy logo on

the flap faces the rear.

5

1

2

6

3

7

4

11

Page 12

Wiring Diagram

1

PARTS LIST

REF.

NO. PART NO. QTY. DESCRIPTION

1. 11590 1 Tongue Wiring Harness

2. 11591 1 Main Frame Wiring Harness

3. 01863 1 Rubber Grommet (not shown)

2

Please order replacement parts by PART NO. and DESCRIPTION.

TESTING LIGHTS BEFORE USE

1. Make sure that the WHITE ground wire is connected to the

frame of both the Kar Kaddy and the towing vehicle.

2. With headlights in "ON" position, the tail lights, the light

cluster bar, the license plate light, and the clearance lights

should be lighted.

3. Start engine and have someone depress brake pedal.

Brake lights of tow dolly and towing vehicle should come

"on" and "off" simultaneously with each application.

4. Turn left turn signal on. Left turn light of Kar Kaddy and

towing vehicle should flash simultaneously. If turn signal

light of the trailer function opposite to those of the towing

vehicle, it is probable that the YELLOW (Driver side) and

GREEN (Passenger side) wires have been reversed.

Check the plug connection under the tongue of the Kar

Kaddy to make sure wire colors are not crossed at that

point. If wires are crossed change them to match color for

color.

White

White

Brown

Yellow

Brown

Yellow

Green

Green

COLOR CODE FOR WIRING HARNESS

WHITE Ground

BROWN Tail Lights, License Plate Lights,

Light Cluster Bar & Clearance Lights

YELLOW Left Turn and Stop

GREEN Right Turn and Stop

WIRING OF THE TOWING VEHICLE

Connect wiring to towing vehicle, keeping in mind the color

code indicated below.

1. Make certain towing vehicle lights are "OFF".

2. Connect YELLOW wire to left turn signal and stop wire in

the left rear of towing vehicle with the wire splicer (01883)

supplied.

3. Connect GREEN wire to the right turn signal and stop

wire.

4. Connect BROWN wire to tail light wire.

5. VERY IMPORTANT - connect WHITE wire to frame body

of towing vehicle. This is the common ground, and a clean

metal - to - metal contact must be made.

CAUTION: Many flashers for vehicle turn signals will not

carry the additional load of Kar Kaddy turn signals. If

normal operation does not occur when connected to the

Kar Kaddy, a heavy duty replacement flasher may be

obtained through auto parts outlets.

12

Page 13

Tongue folding and storage

NOTE:

Tow Dolly must be empty and unhooked

to perform any and all of these steps. Do not

attempt while tow dolly is loaded or hooked up.

1. Pull retainer clip from bottom of tongue locking

pin. Lift locking pin out of tongue pivot.

2. With tongue wheel jack turned to its lowest

position, push/pull tongue to the left.

3. Push/pull tongue until it comes to a stop by

the left fender. It is recommended to place

lock pin and retainer clip back in tongue pivot

for storage.

13

Page 14

Folding Ramp Lock

NOTE:

Tow Dolly must be empty and unhooked

to perform any and all of these steps. Do not

attempt while tow dolly is loaded or hooked up.

1. Locate ramp locks at inside center of ramps.

2. Pull ramp lock straight out as far as it will go.

3. Lift ramp lock up as far as it will go and allow

lock to slide in until it stops.

4. If lock has been pulled and lifted properly the

ramp lock will extend out from it’s holder.

This will mean that the ramp is unlocked and

ramp may be folded up.

14

Page 15

Folding Ramp

NOTE:

Tow Dolly must be empty and unhooked

to perform any and all of these steps. Do

not attempt while tow dolly is loaded or

hooked up.

1. Pull ramp back as far as it will go. Bolt must be past

notch before attempting the next step.

2. Lift ramp until it is past center and resting on it stops.

IMPORTANT:

When taking this tow dolly out of storage it is very important to check all pins and retainers for damage. If damage is found

replace. Do not use damaged pins or retainers. Make sure that

tongue pin and retainer clip is replaced after tongue is folded back

to the forward and lock ed position. Fold ramps down as far as they

will go and push forward until you hear or see retainer handles

snap into their locked positions. Check to make sure they all fully

seated. Make sure that all pins and locking devices are double

checked before returning this unit to service.

Loading Angle Clearance Guide

NOTE: User’s responsibility for checking clearance

IMPORTANT:

Using this guideline will reduce the chance of the towed

vehicles air dam, or bottom of facia from interf ering with

tow dolly platform and or tire stop. “X” must be less

than 3-1/2 x “Y”.

Example: If Y measures 6”

3-1/2 x 6 = 21

X must measure less than 21”

15

Page 16

WARNING:

!

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN LOSS OF TOWING VEHICLE CONTROL, SEPARATION

OF THE TOW DOLLY FROM THE TOWING VEHICLE, SEPARATION OF THE TOWED VEHICLE FROM THE TOW DOLLY,

CAUSING SEVERE PERSONAL INJURY, DEATH, OR PROPERTY DAMAGE.

!

Safety is of utmost importance at all times. There are several

items that must be checked each time before using and while

using the Kar Kaddy.

Make sure all bolts are properly tightened and those requiring

a set torque are up to specifications:

Tie Rod Castle Nut - 75 ft./lbs.

SAFETY

Lug Nuts - 120 ft./lbs.

Check Lug Nut tension after the first 5 miles and

periodically thereafter.

The ball hitch must latch securely around the ball and the

safety lock pin or lever must be in position to lock the hitch on

the ball.

RECOMMENDED BALL HEIGHT: 18 inches to the top of the

ball on the towing vehicle.

Hook the towed vehicle safety chains to the frame of the

vehicle directly above the area where the chain is mounted on

the Kar Kaddy. Leave some slack in the chain to allow

suspension movement.

Check to make sure that all lights are in proper working order.

Examine the winches and straps, making sure they are in

good conditon.

Rear Wheel Drive: Disconnect the towed vehicle driveshaft for

rear wheel drive vehicles with automatic transmission.

For manual transmission: Consult your vehicle owners manual

for towing suitability with the drive shaft connected.

MAINTENANCE

Periodically check all bolts and nuts to insure proper tension or

torque.

Grease the king pin and tie rod end grease zerks every 2500

miles.

An occasional drop of oil may be required on the moving parts

of the tie down winches.

A light film of oil should periodically be applied to steering

stabilizer arm to prevent rust.

NOTE: Proper toe-in is 1/32". This is preset at the factory.

The operator should periodically have the toe-in checked and

adjusted if needed at a qualified alignment shop. Improper toein can result in irregular tire wear.

Wheel:

This tow dolly comes equipped with chrome wheels. To

maintain a high gloss to the chrome, clean and wax with a

soft cloth regularly. Do not use an abrasive to clean chrome,

this will cause scratches and this will lead to rust.

IMPORTANT LOADING INSTRUCTION

Be certain the safety lock pins are locking the strap winches.

Retighten straps over the tires after the first 5 miles and every

50 miles thereafter. Ensure that they are tight.

The Kar-Kaddy tires must be inflated to the recommended 50

PSI.

The strap on the optional tongue winch must be in good

condition and should be stored neatly on winch when not in

use.

NOTE: The winch strap must not be left connected to the

towed vehicle after it is loaded and strapped down.

Make sure the optional light bar is fastened securely at the

rear of the towed vehicle.

The wires to the optional light bar should be run along the car

and fastened so as not to damage the finish of the towed

vehicle.

NOTE: This unit cannot be backed up, when loaded or with

the steering lock pin removed.

All vehicles mounted on the Kar Kaddy must be mounted with

the front of the vehicle facing forward.

Check your wheel tie-down straps.

Your Kar Kaddy is equipped with custom made wheel tie-down

straps of a standard size that will fit most tires, however if your

tires are too large or too small you will want to exchange these

new straps for the proper size straps.

1. Tire too large - This is very obvious the strap will not basket

over the tire properly, call us, we will provide at NO Charge

on an exchange basis, the proper size strap. You must

return your new unused straps and provide us with the

Make and Model car and the tire size.

2. Tire too small - This is not as obvious, the basket will fit

down over the tire very well, the problems cannot be

readily seen. You must tighten the straps down solid and

then check on the inside of the tire and be sure the strap,

when tightened does not come in contact with any metal

that may cause wear or cutting such as strut mounts. If

there is contact, you need a smaller strap, call us, we will

provide on a NO Charge, exchange basis, the proper size

strap. You must return your new unused straps and

provide us with the Make and Model car and tire size.

Thank you for Purchasing

Products.

16

Page 17

LOADING INSTRUCTIONS

.

Step 1. Secure ball coupler to 2" (5,000 lb. capacity) towing

vehicle ball only. Make sure that the hitch and the hitch ball

are in good condition and not rusted, loose or stripped.

Recommended ball height is 18" to the top of the ball.

Make sure hitch is locked down and secured with safety clip.

Criss-cross safety chains under tongue and secure to towing

vehicle frame.

Step 2. Remove black locking pin BEFORE loading vehicle

onto the Kar Kaddy. The removal of the locking pin allows

"Auto Steer" to operate. When towing the dolly empty, this pin

must be in place.

Step 4. Before loading (and unloading) towed vehicle make

sure platform and towed vehicle are in straight alignment.

Tow dolly must be completely and properly hooked up to the

towing vehicle. Towing vehicle must be larger and at least

1000 lbs. heavier than the tow dolly and towed vehicle

combined.

IMPORTANT: Over all width of towed vehicle must not

exceed:

76" max. (outside to outside),

42" min. (inside to inside),

78" max. (body width).

Step 3. Loosen wing nut on back of license plate holder, turn

the clip on the front to a horizontal position and put license in the

"down" position. Turn the clip back so it rests against the back

of the light bar to hold the license down and tighten wing nut.

(License must be "UP" with the tow dolly empty).

17

Page 18

Step 5. Grasp bed release handle on tongue and pull

toward coupler. This releases the tilt bed to permit loading.

Step 7. Drive vehicle onto the platform - front forward - until

tires touch the wheel stops at the front of each side of the

platform and the platform tilts to a flat position. Make sure the

car is centered on the platform. Towed vehicle tires must fit in

wheel troughs without overhanging sides. Engage towed

vehicle parking brake. Shift loaded car into "park" and lock

steering wheel with front tires in a straight position. If the

car does not have a locking steering column the steering

wheel must be tied securely with front tires in a straight

position.

Rear Wheel Drive: Disconnect towed vehicle driveshaft for

rear wheel drive vehicles with automatic transmission.

For manual transmission: Consult your vehicle owners

manual for towing suitability with the drive shaft connected.

Step 6. With someone safely guiding you, slowly drive vehicle onto platform FRONT FORWARD. (Any vehicle mounted

on tow dolly must be mounted with front of the vehicle facing

forward.) Drive the car forward until the tires touch the ramps.

Make sure the tire is aligned to ascend onto the ramps.

Step 8. Place one tie-down strap over each tire and secure

hooks to rods located at the rear of each wheel platform. The

short side of the hook must face the rear of the Kar Kaddy.

Step 9. Be sure tie-down winch is centered with the tire

before tightening straps.

18

Page 19

A

B

Step 10. Thread tie-down strap through the slotted tube on

the tie-down winch. Pull approx. 6" of strap through this slot.

Begin tightening strap making sure the tail becomes enclosed

by the strap coming over the tire. Tighten the straps ensuring

that the strap fed through the slot binds between the shaft and

the strap being wound onto the winch shaft. While tightening

straps, pull cross strap forward to ensure even tightening.

NOTE: Be sure to tighten straps until each tire starts to

flatten against tire stop. After each strap is tight, insert a

safety pin in each winch. Disengage towed vehicle parking

brake.

Straps must be retightened after first 5 miles of travel.

Check straps every 50 miles thereafter to ensure they are

tight and not rubbing or fraying.

Step 11. Make sure the tie-down strap is the correct size for

the auto tire. See page 4 of this instruction for proper fit and

exchange instructions.

Step 13. TO UNLOAD towed vehicle. Never unhook tow

dolly coupler from towing vehicle, before unloading

todolly. Make sure that platform and vehicle are straight.

Reinstall driveshaft. Ensure that towed vehicle parking brake

is fully engaged, then unhook the towed vehicle safety chains,

and release the tie-down straps. NOTE: Tie down straps

must be "quick -released" by grasping ratchet pawl (A) and

ratchet handle (B) simultaneously and pushing down sharply.

This process will permit easy removal of strap from winch.

Grasp bed release handle on tongue and pull toward coupler.

This releases the tilt bed to permit unloading. This will allow

the platform to tilt as you slowly drive off. Make sure the winch

ratchet handles are horizontal. Replace the "Auto Steer"

locking pin (for towing empty).

Step 14. To pull the Kar Kaddy empty, make sure "AutoSteer" LOCKING PIN IS IN PLACE and towing vehicle

safety chains are up and hooked. Tie-down winch handles

should be left in a down postion (horizontal position) with

safety pins in place when towing loaded or empty. DO NOT

ATTEMPT TO PULL KAR KADDY WITH WHEEL PLATFORM IN LOADING (tilted) POSITION.

DAMAGE PREVENTION

Check your vehicle manual or registration for vehicle weight.

Towing vehicle must be larger and at least 1,000 lbs. heavier

than the towed vehicle and tow dolly combined.

Do not pack goods in car that is being towed. Overloading the

Kar Kaddy or exceeding the width limit may result in damage

to both car and Kar Kaddy.

Step 12. Hook the towed vehicle safety chains to frame of

vehicle directly above the area where the chains are mounted

on the Kar Kaddy. Leave some slack in the chains to allow

suspension movement of the towed vehicle.

REAR WHEEL DRIVE PRECAUTIONS

Disconnect towed vehicle driveshaft for rear wheel drive

vehicles with automatic transmission. Simply placing transmission in neutral is not sufficient to prevent damage to

transmisssion.

For manual transmission: Consult your vehicle owners

manual for towing suitability with the drive shaft connected.

ALL VEHICLES MOUNTED ON THE KAR KADDY MUST BE

WITH THE FRONT OF THE VEHICLE FACING FORWARD.

SAFETY

• Examine winches and straps to make sure they are in

good condition.

• Check wheel nuts every trip.

• Tires must be inflated to recommended pressure by

tire manufacturer.

• Be certain the safety lock pins lock the strap winches.

• Retighten the straps over the tires after the first 5 miles

of travel. Check straps every 50 miles there after to

ensure they are tight and not rubbing or fraying.

19

Page 20

KAR-KADDY TOE-IN ADJUSTMENT

FRONT MEASUREMENT

(1/32" to 1/16" less than back measurement)

BACK MEASUREMENT

LOCKING

CLAMP

12"

18"

Ground

MEASURING THE TOE-IN

Have the tongue in a "hooked-up” position with the ball

coupler 18" off the ground. Jack up the axle just enough to

allow you to take the wheels off and put blocks under the axle.

Take the wheels off.

Find two 24" long bars. These could be a level, a square

or a straight piece of iron bar. Clamp one bar tight to the face

of each hub/Brake Drum with 12" extending forward and

backward of the center of the spindle. The bars must be

parallel to the platform the car sits on. Measure across the

back end of the bars and then across the front end. The front

measurement should be 1/32" to 1/16" less than the back

measurement. If the unit needs to be adjusted, this must be

done by adjusting the tie rod.

12"

C

L

TOE-IN ADJUSTMENT

1.

Put a mark on each side of the locking clamp on the tie rod.

2. Loosen the locking nuts on each end of the tie rod and

then the six bolts on the tie rod locking clamp.

3. Turn the tie rod whichever direction is needed until you

have a front measurement of 1/32" to 1/16" less than the

back measurement.

4. Hold the tie rod and tighten the locknuts on each end.

5. Measure again to make sure the toe-in measurement has

not moved.

6. Tighten the locking clamp bolts while holding clamp

between the marks you previously put on the tie rod.

7. Reassemble the rest of the Kar Kaddy unit.

20

Page 21

MODEL DA91 ACTUATOR PARTS BREAKDOWN

8

23

**12

**10

13

8

14

17

14

18

5398 Master Cylinder Repair Kit

(gasket included)

not included

28

4

5696

Coupler Repair Kit

2

9

2

1

3

2” Lever Lock Coupler

RATED AT 6000#

BLEEDING THE SYSTEM

The first requirement for safe, sure hydraulic braking is the use

of quality brake fluid. Use only DOT-3 or DOT-4 brake fluid

from a sealed container.

If pressure bleeding equipment is available, follow the

manufacturer’s instruction in bleeding the system.

If system must be bled manually, proceed as follows: Fill

master cylinder with fluid. Install bleeder hose on first wheel

cylinder to be bled.

Have loose end of hose submerged in brake fluid in glass

container to observe bubbling.

By loosening the bleeder screw located in the wheel cylinder

one turn, the system is open to the atmosphere through the

passage drilled in the screw. Pump actuator with long steady

strokes. The bleeding operation is completed when bubbles no

longer rise to the surface of the fluid. Be sure to close bleeder

screw securely.

Repeat bleeding operation at each wheel cylinder. During the

bleeding process, replenish the brake fluid, so the level does

not fall below the 1/2 full level in the master cylinder reservoir.

After bleeding is complete, make sure master cylinder reservoir

is filled and filler cap is securely in place.

After the bleeding operation has been completed, apply pressure to the system and check the whole brake system for leaks.

28

27

**16

15

15

25

9

26

6

7

9

20

21

5

24

19

Model 91 ACTUATOR PARTS LIST

REF.

NO. PART NO. QTY. DESCRIPTION

1. 09417 1 6000# 2" Lever Lock Coupler (zinc plated)

2. 01896 3 1/2"-13UNC x 4" Hex Head Bolt (gr.5)

3. 02178 3 1/2"-13UNC Nylon Insert Lock Nut

4. 05426 1 Front Shock Pin (drop tube actuators)

5. 11079-95 1 Drop Tube Actuator Slider (plated)

6. SB12426 1 Damper/ Shock

7. 11164-95 1 3 Bolt Mount Outer Case (plated)

8. 05424 2 5/16" External Tooth Lock Washer

9. 02363 2 5/32" x 1 1/4 Cotter Pin(Qty 3 w/drop tube)

**10. 05408 1 3/32" Cable with hooks

**12. 05693-95 1 Emergency Lever Spring (plated)

13. 05961 2 5/16"-18UNC x 5/8" Hex Head Bolt (gr.5)

14. 00618 4 1/4-20UNC x 2" Hex Head Bolt (gr.5)

15. 00057 4 1/4" Lock Washer

**16. 05951 1 Emergency Lever Assembly

17. 03876 1 Master Cylinder Cap w/ Diaphragm & O-ring

- 05849 1 O-Ring Only (not shown)

18. 05977 1 Push Rod Assembly

19. 00062 4 1/4”-20 UNC Hex Nut

20. 09153 - Plastic Master Cyl. Gasket ONLY

21. 10616 1 Master Cylinder

22. SB12098 1 .018 Connector Orifice (Drum Brakes)

23. 03866-95 1 Lever Guide (plated)

24. 05687 1 Master Cylinder Protective Boot

25. 05986-95 1 Connecting Pin (plated)

26. 10965 1 Upper Slider

27. 10966 1 Lower Slider

28. 10967 2 Side Spacers

- 5401 - Lever Replacement Kit (incl. items w/**)

- 5650 - Master Cyl. Replacement Kit (drum)

- 5696 - Coupler Repair Kit

Please order replacement parts by PART NO. and DESCRIPTION

22

19

21

Page 22

10" SELF-ADJUSTING BRAKE CLUSTER and DRUM PARTS BREAKDOWN

4

5

5

7

16

1

6

4

16

2

3

2

8

11

13

10

3

12

19

9

10

17

18

15

17

BRAKE CLUSTER PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

- SB24429M - Left Hand Cluster (shown above)

- SB24428M - Right Hand Cluster

1. SB23871 1 Back Plate Assembly

2. SB9254 2 Cover Plate - Adjusting Hole

3. SB10954 1 Brake Shoe Kit (includes 2 Primary & 2 Secondary)

4. 04305 2 5/16"-18UNC-Gr5 x 1/2" Hex Hd Bolt

5. 05424 2 5/16" External Tooth Washer

6. SB9776 1 Wheel Cylinder Assembly - Right

- SB9777 1 Wheel Cylinder Assembly - Left

7. 05431 1 Bleeder - replacement

8. SB9783 1 Push Rod

9. SB24047 1 Adjusting Screw Assembly - "R" (for LEFT cluster)

- SB24048 1 Adjusting Screw Assembly - "L" (for RIGHT cluster)

10. SB10958 2 Spring - Shoe

11. SB10961-95 1 Shoe Guide

12. SB23937 1 Cable

13. SB23936 1 Cable Guide

14. SB23724 1 Spring - Adjusting Screw

15. 05415-95 1 Lever - Right

- 05414-95 1 Lever - Left

16. SB10959 2 Pin - Shoe Hold Down

17. SB9789 4 Cup Shoe Hold Down

18. 05983 2 Spring - Shoe Hold Down

19. 03380 1 Spring

14

17

18

17

- SB15845 1 Wheel Cylinder Repair Kit

- SB40929 2 10" Brake Drum

Please order replacement parts by PART NO. and DESCRIPTION.

Brake shoe kit can be ordered for one complete axle only.

(includes spring, cup and boot)

22

Page 23

SURGE BRAKES PARTS BREAKDOWN

13

12

11

11

8

10

17

4

5

4

3

13

1

9

7

6

10

11

11

18

2

Model DA91

Brake Actuator

SURGE BRAKES FIELD SETUP PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 11968 1 6" Brake Line

2. 02034 1 45” Brake Hose

3. SB512 1 12” Brake Line

4. 05679 2 Brake Fitting

5. 11617 1 Male Coupler

6. 11618 1 Female Coupler

7.

11643

8. SB7785 1 Brake Line Tee

9. 05960 1 5/16” x 1/2” Self-threading Bolt

10. SB541 2 41” Brake Line

11. 02549 6 Rubber Protector

12. 02032 2 12” Brake Hose

13. SB7764 3 Brake Line Clip

14. SB24429 1 Left Brake Cluster

-- SB24428 1 Right Brake Cluster

15. SB40929 2 10” Brake Drum

16. 04174 4 Retainer Washer

17. 01863 1 Rubber Grommet

18. 12445-30 1 Spring Return System

Please order replacement parts by PART NO. and DESCRIPTION.

1 7" Brake Hose Swival Male/Solid Male

14

16

15

SURGE BRAKES FACTORY SETUP PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 11968 1 6" Brake Line

2. 02034 1 45” Brake Hose

3. 12449 1 15” Brake Line

4. N/A 2 Brake Fitting

5. N/A 1 Male Coupler

6. N/A 1 Female Coupler

7.

SB7H67

8. SB7785 1 Brake Line Tee

9. 05960 1 5/16” x 1/2” Self-threading Bolt

10. SB541 2 41” Brake Line

11. 02549 6 Rubber Protector

12. 02032 2 12” Brake Hose

13. SB7764 3 Brake Line Clip

14. SB24429 1 Left Brake Cluster

-- SB24428 1 Right Brake Cluster

15. SB40929 2 10” Brake Drum

16. 04174 4 Retainer Washer

17. 01863 1 Rubber Grommet

18. 12445-30 1 Spring Return System

Please order replacement parts by PART NO. and DESCRIPTION.

1 7" Brake Hose, Swival Male/Solid Female

BLEEDING THE SYSTEM

The first requirement for safe, sure hydraulic braking is the use

of quality brake fluid. Use only DOT-3 or DOT-4 brake fluid

from a sealed container.

Only use pressure bleeding equipment and follow the

manufacturer’s instruction in bleeding the system.

23

Page 24

KK460SS PARTS BREAKDOWN

2

1

4

5

60

6

50

55

56

57

54

58

24

7

11

6

10

41

13

9

20

23

12

19

21

22

75

46

47

48

45

46

26

23

26

52

28

22

27

53

41

25

21

43

52

39

29

38

40

53

36

37

20

19

19

21

60

71

76

59

21

49

61

58

56

64

63

62

65

26

32

24

37

24

51

32

Page 25

REF. PART

NO. NO. QTY. DESCRIPTION

1. 03528 2 Tie-down Strap assembly, Black

2. 5737 1 Right Fender Assembly with Lights

3. 5736 1 Left Fender Assembly with Lights

4. 04424-95 2 Fender Backing Plate

5. 00914 6 3/8”-16UNC x 1-1/2” Hex Head Bolt (gr.5)

6. 02592 18 3/8”-16UNC Nylon Lock Nut

7. 04165-80 1 Right Wheel Carrier

8. 04166-80 1 Left Wheel Carrier

9. 01732 4 1"I.D. x 1-1/4"O.D. x 1-1/2"lg. Bushing (brnz)

10. 11588 2 King Pin (1” x 6-1/2”)

35

27

33

32

31

26

6

30

6

34

21

15

18

16

19

14

17

3

8

72

67

22

19

66

35

73

44

34

21

74

22

34

21

42

68

22

REF. PART

NO. NO. QTY. DESCRIPTION

11. 01731 4 1-1/4" Dust Cap

12. 05587 2 1" I.D.x 14 GA Narrow Rim Machine Washer

13. 11566-80 1 Right Drop Axle Mount

14. 11550-80 1 Left Drop Axle Mount

15. 11551 2 King Pin Retainer Bolt

16. 03724 2 7/16”-20UNF Center Punched Nut

17. 02377 8 7/16”-20UNF x 1-1/2” Epoxy Bolt (gr.8)

18. 04168 8 7/16”-20UNF Nylon Lock Nut

19. 02178 18 1/2”-13UNC Nylon Lock Nut

20. 02579-95 2 Pivot Bushing

21. 00085 15 1/2" Flatwasher

22. 01254 15 1/2"-13UNC x 1-1/2" Hex Head Bolt (gr.5)

23. 02747-96 2 Bracing Strut

24. 03503 2 5/8”-11UNC x 1-1/4” Epoxy Bolt (gr.5)

25. 02434 1 5/8”-13UNC x 4-1/2” Hex Head Bolt (gr.5)

26. 02587 4 5/8”-13UNC Nylon Lock Nut

27. 02696 2 5/8"-11UNC x 2-3/4" lg. Hex Head Bolt (gr.5)

28. 00477 1 5/8" Flatwasher

29. 01729-30 1 Steering Stabilizer Shock

30. 11553-80 1 Tie Rod Clamp, Bottom

31. 11554-80 1 Tie Rod Clamp, Top

32. 00907 6 3/8”-16UNC x 1” Hex Head Bolt (gr.5)

33. 02494 2 3/8”-16UNC x 2-1/4” Hex Head Bolt (gr.5)

34. 11659-91 12 Ramp Bushing

35. 11529-96 2 Ramp

36. 01718-95 1 Tie Rod Locking Pin

- 02189 1 Replacement Black Handle Grip for Locking Pin

37. 00182 1 Hair pin

38. 11540-96 1 KK460SS Main Frame

39. 5740 1 License Plate Bracket Assembly

40. 04771-80 1 Tie Rod

41. 5179 1 Right Tie Rod End w\Right Hand Threads

42. 5178 1 Left Side Tie Rod End with Left Hand Threads

43. 01905 1 9/16"-18UNF Jam Nut w/Right Hand Threads

44. 01904 1 9/16"-18UNF Jam Nut w/Left Hand Threads

45. 04773-96 2 Rear tire Stop

46. 00523 4 3/8"-16UNC x 1-1/4" lg. Hex Head Bolt (gr.5)

47. 02243 1 Black Vinyl Hand Grip

48. 11978-96 1 Rear Tongue Half

49. 11969-96 1 Front Tongue Half

50. 5433 1 Right Winch assembly

51. 5432 1 Left Winch Assembly

52. 02772 2 1/4”-20UNC Nylon Lock Nut

53. 04176 2 1/4”-20UNC x 3/4" Carriage Bolt

54. 11967-95 1 5/8”-13UNC x 5 1/4” Hex Head Bolt (gr.5) Hinge Bolt

55. 11795 1 Pin, 5/8” x 4-7/8”

56. 01898 4 7/16”-14UNC x 1-1/4” Hex Head Bolt (gr.5)

57. 00078 2 7/16" Lockwasher

58. 00059 8 3/8” Flat Washer

59. 02771 2 7/16”-14UNC Nylon Lock Nut

60. 02383 4 36” Safety Chain

61. 02288-95 1 Bolt on Handle

62. 02189 1 Rubber Handle Grip

63. 01338 1 1/2"-12UNC x 4-1/2" lg. Hex Head Bolt (gr.5)

64. 01975 2 1/2"-12UNC x 5" lg. Hex Head Bolt (gr.5)

65. 11683 1 Wheel Jack

66. 04369 2 Hub and Spindle

- 02917 - Replacement 12mm x 1.50mm Stud Bolt

67. 02210 8 7/16”-20UNF x 1-1/4” Epoxy Bolt (gr.8)

68. 11913 2 ST205/75R14 "C"Range Radial Tire

69. 11574 2 Rim, 14 x 5.5, 5 on 115mm B.C.

70. 02933 10 Chrome Lug Nut

71. 5607 1 DA91 Actuator

72. SB24428 1 10” Brake Cluster, RH

- SB24429 1 10” Brake Cluster, LH

73. SB40929-30 2 10” Brake Drum

74. 04174 4 Retainer Washer

75. 11971-95 2 Nut Plate

76. 12445-30 1 Spring Return System

Please order replacement parts by PART NO. and DESCRIPTION.

25

70

69

Page 26

WINCH ASSEMBLY

5

1

2

Left Winch 5432 (Shown)

Right Winch 5433

14

18

3

4

- 5432 - Left Winch Assembly

- 5433 - Right Winch Assembly

1. 00214 11/4”Flat Washer

2. 01076 11/4”-20 UNC x 3/4” Hex Head Bolt

3. 01864 2 Spring

4. 02772 21/4”-20 UNC Nylon Insert Locknut

5. 05337 1 Lock Pin w/ Cable

6. 00004 2 5/16” Flat Washer

7. 02243 1 Black Vinyl Hand Grip

8. 05444 13/8”-16 UNC x 3/4” Hex Head Bolt w/ Epoxy

9. 05449 1 Winch Pawl Bushing (Stainless Steel)

10. 05450 1 Winch Pawl

11. 03572-95 1 Left Ratchet Pawl Arm

- 03573-95 1 Right Ratchet Pawl Arm

12. 03574-95 1 Ratchet Handle

13. 03575-95 1 Left Outer Ratchet Gear

- 03576-95 1 Right Outer Ratchet Gear

14. 03666 1 5/16” x 1-1/4” Roll Pin

15. 03668 11” x 18 Gauge Machine Washer

16. 03578 1 5/16”-18 UNC x 1/2” Socket Head Shoulder Bolt

17. 01998 1 5/16” Flat Washer (Stainless Steel)

18. 02002 11/4” Flat Washer (Stainless Steel)

11

7

12

17

16

3

9

6

8

10

15

13

TILT-BED LATCH ASSEMBLY

16

REF. PART

NO. NO. QTY. DESCRIPTION

5511 - Tilt-Bed Latch Kit

1*. 03434 1 5/16"-18 UNC x 4" Eye Bolt

2*. 04221 1 5/16"-18 UNC x 2-1/2 Hex Head Bolt (Gr 5)

3*. 00004 1 5/16" Flatwasher

4*. 00007 1 5/16"-18 UNC Hex Nut

5*. 03379-95 1 Latch Block

6*. 03435 1 Roll Pin (5/16" x 2-1/4")

7*. 03499 1 Latch Spring - Stainless Steel

8. 03382-95 1 Latch Handle Pivot Bushing

9. 03574-95 1 Latch Handle

10. 03381-95 1 Latch Catch

11. 03433 1 Latch Cable

12. 02802 1 5/16-18 UNC Nylon Insert Locknut

13. 00967 1 1/2"-13UNC x 1-1/4" lg. Hex Head Bolt (gr.5)

14. 00085 2 1/2" Flatwasher

15. 00059 1 3/8" Flat Washer

16. 02178 1 1/2"-13UNC Nylon Insert Locknut

17. 05449 1 Spacer Bushing - Stainless Steel

18. 05444 1 3/8"-16 UNC x 3/4" Epoxied Hex Bolt (Gr 5)

Please order replacement parts by PART NO. and DESCRIPTION.

* Items included in 5511 kit

14

11

2

10

13

18

12

15

8

17

1

6

5

4

3

7

9

KIT #5511

TILT-BED LATCH

14

ASSEMBLY

26

Page 27

RAMP LATCH ASSEMBLY

REF. PART

NO. NO. QTY. DESCRIPTION

5763 - Ramp Latch Kit

1. 11622-95 1 5/16"-18 UNC Latch Rod

2. 00007 2 5/16"-18 UNC Hex Nut

3. 00004 1 5/16" Flatwasher

4. 00059 1 3/8” Flatwasher

5

1

6

4

2

3

7

2

8

9

5. 11570-95 1 Latch Block

6. 11623-95 1 Threaded Bushing

7. 03499 1 Latch Spring - Stainless Steel

8. 02384 1 1/2” Narrow Machine Washer

9. 11621 1 Handle/Knob

Please order replacement parts by PART NO. and DESCRIPTION.

LICENSE PLATE BRACKET ASSEMBLY

REF. PART

NO. NO. QTY. DESCRIPTION

(not available)

4

5

3

2

2

3

1

10

4

7

8

6

6

9

10

7

10

5740

License Plate Mount

and Light Cluster

Please order replacement parts by PART NO. and DESCRIPTION.

5740 - License Plate Bracket and Light Assembly

1. 04505-95 1 License Plate and Light Cluster Bracket

2. 04176 2 1/4”-20UNC X 3/4” Carriage Bolt

3. 02214 2 #10 NC X 1/2” Slotted Truss Head Screw

4. 02163 1 Square License Plate Light w/Washer and Nut

- 02164 - Clear License Plate Light Lens Only

5. 02580-95 1 License Plate Clip

6. 02770 2 1/4”-20UNC Nylon Insert Wing Nut

7. 02205 2 #10 NC Nylon Lock Nut

8. 00214 1 1/4”-20UNC Flat Washer

9. 11687* 1 3 Cluster Light Bar Only (No Lights)

10. 11688* 3 Red LED Light

- 11655* 1 3 Cluster LED Wiring Harness

- 11616 1 Gromment, 5/8” OD x 3/8” x 1/8” Thick

- 5765 - 3 Cluster LED Light Assembly (* Included)

27

Page 28

Fender Assembly

8

6

1

11

14

9

2

2

2

2

2

3

10

4

13

15

19

17

12

16

PARTS LIST

REF.

NO. PART NO. QTY. DESCRIPTION

5736 - Left Fender Assembly

5737 - Right Fender Assembly

1. 01883 2 Wire Splicer

2. 04425 5 Tinnerman U-clamp

3. 04515 1 17-1/2” Wire Loom

4. 04643 2 9/16” x 5/8” Pop Rivet

5. 05443 1 Nylon Cable Hanger

6. 05447 1 4” Light Grommet

7. 11206 1 Tail Light Wire Harness

8. 11209 1 4” LED Tail Light

9. 11595 1 Left Fender Assembly

- 11596 1 Right Fender Assembly

10. 11604 1 Chrome LED Marker Base Mount

11. 11605 1 Yellow LED Marker Light

12. 11619 1 12” Wire Loom

13. 11654 1 Front Marker Wiring Harness

14. 04508 1 Amber Reflector

- 04804 1 Red Reflector

15. 07490 2 3/16” Washer

16. 01769 1 Kar Kaddy Mud Flap

17. 02772 2 1/4” Nylon Lock Nut

18. 05338 2 1/4” Slotted Truss Head Bolt

19. 00214 2 1/4” Flat Washer

Please order replacement parts by PART NO. and DESCRIPTION.

7

18

5

28

Page 29

OPTIONAL SPARE TIRE and MOUNT PARTS BREAKDOWN

Drive in stud here for

tire with rim #11574

(115mm bolt circle).

6

4

1

- 5734 1 Optional Spare Tire and Rim

1. N/A 1 ST205/75R 14"x"C" ROWL RadialTire

2. 11574 1 6" x 14" Chrome Rim 115mm Bolt Circle

PARTS LIST

3

7

8

2

5

* All options may not mount on tow dolly simultaneously.*

OPTIONAL TOOL BOX

RKSTM 1 Spare Tire Mounting Bracket

3. 02193-30 1 Spare Tire Bracket

4. 02917 1 Stud Bolt (12mm x 1.5)

5. 02933 2 Wheel Nut (12mm) Chrome

6. 02759 2 3/8"-16UNC Square U-Bolt

7. 00059 2 3/8" Flatwasher

8. 02592 4 3/8"-16UNC Nylon Insert Locknut

- KK6TC Optional Spare Tire Cover

Please order replacement parts by PART NO. & DESCRIPTION.

PARTS LIST

RKTB 1 Optional Tool Box

1. 00059 4 3/8" Flatwasher

2. 02592 8 3/8"-16UNC Nylon Insert Locknut

3. 01888-30 1 Tool Box

4. 00182 1 Small Hair Pin

5. 02742-30 2 Mounting "Z" Bracket

6. 00907 4 3/8"-16UNC x 1" Hex Head Bolt (gr.5)

7. 02759 2 3/8"-16UNC x 3" Square U-Bolt

Please order replacement parts by PART NO. and DESCRIPTION.

* All options may not mount on tow dolly simultaneously.*

29

7

7

2

1

6

5

2

4

3

Page 30

OPTIONAL LIGHT BAR PARTS BREAKDOWN

LIGHT BAR PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

RKLB Kar Kaddy Light Bar (complete)

1. 01772 2 Nylon Security Strap with hooks & tightener

2. 01857 1 Left Tail/ Brake and Signal Light w/Lenses

3. 01773 1 Brown Jumper Wire

4. 01886 4 Wire Holder (metal)

5. 02385-50 1 Light Bar Framework

6. 02386.50 2 Adjustable Light Bracket

7. 01856 1 Right Tail/ Brake and Signal Light w/Lenses

8. 02772 10 1/4"-20UNC Nylon Insert Locknut

9. 00092 6 1/4"-20UNC x 1/2" Hex Head Bolt

10. 01777-50 2 Light Bar "Z" Bracket

11. 01778 4 3" Suction Cup w/Bolt (#13)

12. 02198 1 Light Bar Wiring Harness (new style)

13. 00068 4 1/4"-20UNC x 3/4" Hex Head Bolt

14. 01911 - Large Red Lens

15. 01912 - Small Red Lens

16. 01890 - Clear Lens

Please order replacement parts by PART NO. and DESCRIPTION.

6

1

8

9

8

9

1

4

8

12

7

14

9

8

5

4

9

1

13

10

11

2

3

15

16

13

1

11

COLOR CODE FOR WIRING HARNESS

WHITE Ground

BROWN Tail Lights, License Plate Lights,

Light Cluster Bar & Clearance Lights

YELLOW Left Turn and Stop

GREEN Right Turn and Stop

OPTIONAL DEFLECTOR

REF. PART

NO. NO. QTY. DESCRIPTION

1. 02055-30 2 Deflector Framework

2. 02592 4 3/8"-16UNC Nylon Insert Lock Nut

3. 02759 2 3/8"-16UNC Square U-Bolt (fits around 3" tube)

4. 00161-95 2 Lock Handle

5. 02054-30 1 Deflector Slide Mount

6. 00095 4 3/8"-16UNC x 3/4" lg. Square Head Set Screw

7. 02743-30 1 Deflector Upright Post

8

9

7

6

4

5

4

8. 02165 1 Deflector Lacing Cord (1/8" x 25 ft.)

9. 11710 1 Deflector Fabric

Please order replacement parts by PART NO. and DESCRIPTION.

1

OPTIONAL DEFLECTOR PARTS LIST

5762 Optional Deflector

2

3

30

Page 31

DEMCO PRODUCTS - KAR KADDY

ORIGINAL PURCHASER’S LIMITED WARRANTY

1. Extent and Duration of this Warranty:

Your Demco Kar Kaddy is warranted to be free from defects in

materials and workmanship under normal use and service for a

period of one year after date of purchase by the original (first)

retail owner, or until it is resold or transferred by the original

owner. Hubs used on the Kar Kaddy are warranted for a period

of three years after the date of purchase by the original (first) retail

owner or until it’s resold or transferred by the original owner. Tires

and lights are not included in this warranty.

Tires are warranted by the manufacturer against defects in

materials and workmanship, but not against road hazards.

Any part of the Demco Kar Kaddy, except tires and lights, found,

in the judgement of the manufacturer to be defective in materials

or workmanship will be repaired or replaced at the manufacturer’s

option without charge for parts or labor to the original owner.

2. Manufacturer and Warrantor of Tow Dolly:

Dethmers Manufacturing Co.

4010 320th Street

P.O. Box 189

Boyden, IA 51234

(712) 725-2311

The manufacturer and warrantor of the tires has his name

permanently molded into the tires. Tire warranty questions and

claims can be taken directly to an authorized dealer of the tire

manufacturer.

3. Repair or Replacement Procedure:

If your Demco Kar Kaddy develops a defect (except for tires or

lights) during the warranty period, promptly notify Dethmers

Manufacturing Co. customer service department. Until such

notice is received, Warrantor will not be responsible for any repair

or replacement.

Upon receipt of notice from you, Warrantor will have a choice of

options in replacing any part it determines to be defective:

a) Warrantor may require you at your own expense to deliver

or ship the part to its factory or authorized dealer. Any

defective part will be repaired or replaced and returned to

you free of charge. Any part returned to Warrantor and

found not to be defective will be returned to you freight

collect with an explanation.

b) Warrantor may elect to ship a new part to its dealer to be

exchanged free of charge for the defective part returned by

you to the dealer.

c) Warrantor may elect to ship or deliver a replacement part

to your address.

Warranty claims on tires should be presented to a local authorized dealer of the tire manufacturer. Provide proof of purchase

when making a tire warranty claim.

4. Limitations on Warranty Coverage:

Coverage under this warranty will be effective only when a copy

of the original invoice, showing the date and location of purchase,

accompanies any claim for warranty.

Warrantor has no liability whatsoever and this warranty is null and

void if any Demco Kar Kaddy has been misassembled or subjected

to neglect, negligence, misuse, accident or operated in any way