Page 1

Mode l E -96

2-Sp eed Lat he

Owner’s Manual

HIGH SPEED POLISHER GRINDER

Please Read All Instructions Before Operating

PULLEY REPLACEMENT (Figure 2)

Insert hex wrench into hexagonal hole at end of the shaft, to keep it from turning.

Unscrew nut and pull off old pulley. Replace with a new pulley and then replace nut.

BELT REPLACEMENT (Figure 2)

Loosen set screw. Rotate spindle by pushing handle forward to relieve belt tension.

Remove belt.

PROPER CARE OF MOTOR PULLEY & SPINDLE PULLEY

It is imperative that the belt tension be correct to assure a long life for pulley and bearings. To

set belt tension, loosen set screw(s) (see “BELT REPLACEMENT”). Align the motor pulley with

the spindle pulley by using a straight edge. Then move the spindle towards you by rotating

(Model E-96).

Adjust tension to allow approximately 3/8” play in the belt. This procedure

should be repeated as the new belt stretches. Motor pulleys and spindle pulleys should be

replaced when worn.

DRIVE MOTOR LUBRICATION

Newer Model E-96 motors have sealed, pre-lubricated bearings and DO NOT require oil.

Please visit our website for warranty policy, technique videos on proper care and usage.

Form DEMC ODFU Re v 3/ 2017

Div ision of CMP I ndust ries LLC

413 No rth Pear l Stree t

• Albany, Ne w York 12207

518.4 34.31 47 • 800.833.2 343 • www.n obili um.com

Demco

T

M

A Grinder you can rely on.

NEW

I

MPROVED!

E9

6

Caution

Protect Eyes

Manufacturer

Warning

Electric Shock Hazard

Regardless of control settings, on or off, a shock hazard exists at fuse located

below cover plate in components compartment. Unplug electric cord before

attempting any service.

Eye Safety

Wear safety glasses or eye shield while operating this machine.

Belt Guard

The belt guard must be in place while machine is in operation.

Do not wear loose clothing while opperating this machine.

Page 2

SAFETY FIRST!

Your DEMCO E96 Polisher/Grinder is designed with your

safety in mind. However, as with all power equipment, an

adherence to standard precautionary safety procedures will

protect the operator from possible injury.

RULES FOR SAFE OPERATION

POWER SUPPLY

The Polisher/Grinder is equipped with a three-pronged electrical plug intended

for a grounded three-hole receptacle. If an adapter is used to accommodate a

two-pronged receptacle, the adapter wire must be attached to a known ground.

EYE PROTECTION

Always wear safety glasses or an eye shield while operating the grinder. As

with any power tool, there is always a possibility of foreign objects being

thrown into the eye.

FUSE REPLACEMENT & BOTTOM COVER PLATE REMOVAL

(All Models)

Unplug the electric cord before attempting any service with the bottom cover

plate removed.

BELT GUARD

The belt guard must be in place while the polisher/grinder is in operation.

WEAR PROPER APPAREL

Do not wear loose clothing, jewelry, ties, ribbons, etc. See warning on back.

TURN GRINDER “OFF” AFTER COMPLETION OF WORK

OPERATION & MAINTENANCE

SPINDLE OPERATION

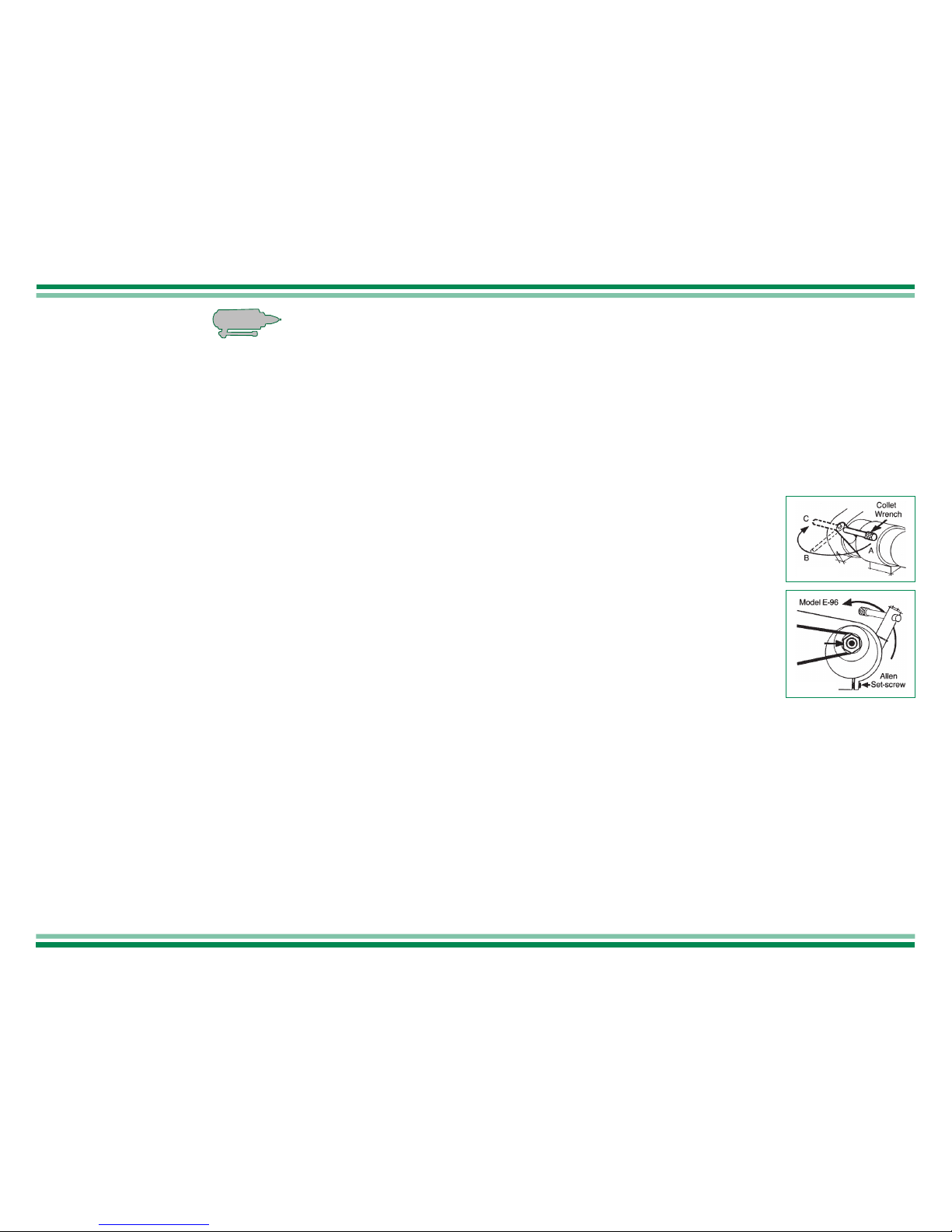

The collet is the part of the spindle nose with jaws that grasps a mandrel. To open the collet,

move the lever in (Figure 1) to the extreme left. Insert mandrel into the collet and move the lever

to the right.

Caution: Never close collet without having a mandrel or similar tool inserted. Spindle will bind

if lever is in position “A” without a mandrel in the collet.

To stop the mandrel, apply the brake by positioning the lever to the left. Once the mandrel stops,

stones and points can be removed and replaced in the collet. DO NOT apply the brake too

quickly, since mandrels may unscrew, causing needless wear. By loosening the set screw,

(Figure 2) the handle may be adjusted to the most comfortable operating position.

COLLET ADJUSTMENT

Please visit our website for technique videos on proper

care and usage.

If mandrel is loose when in the operating position, adjustment

of the collet may be necessary.

1) Open the collet to position.

2) Remove collet wrench from the end of the lever.

3) Place collet wrench in the collet and turn counter clockwise

to remove the collet.

4) Insert the hex wrench through the spindle nose and engage

the set screw deep inside the spindle.

5) Turn hex wrench clockwise to tighten (or counter-clockwise

to loosen).

6) Reinstall the collet using the collet wrench..

Note: If this procedure does not tighten the collet, replacement

of the collet may be necessary.

SPINDLE FAILURE

Caution: Spindle will not run without a tool or mandrel inserted in the collet.

Always check the collet first!

1) The collet must be clean.

2) Make sure the collet is not rusty and that it is lightly lubricated.

3) The collet must be screwed all the way in, with the clutch lever in position “C”.

4) Check to see if the collet is worn out. If it is, replace it.

5) If the spindle binds, it is usually the fault of the collet (it is advisable to have a new collet

on hand at all times).

Should the spindle become noisy or otherwise faulty, we can repair it for a fee.

SPINDLE CLEANING

Periodically, remove the collet (see COLLET ADJUSTMENT) and clean it. Also clean the

inside of the spindle nose to remove debris. Do not oil the spindle or collet.

Figu re 1

Figu re 2

Nut

Demco

TM

Loading...

Loading...