Page 1

DFBDFB

DFB

DFBDFB

01-21-94

AB20001

4040

40',

4040

ASSEMBLY

CALIBRATION

OPERATION

REPLACEMENT PARTS

45 45

45'

45 45

& 50 & 50

& 50'

& 50 & 50

OWNERS MANUALOWNERS MANUAL

OWNERS MANUAL

OWNERS MANUALOWNERS MANUAL

FLOTATION BOOM FLOTATION BOOM

FLOTATION BOOM

FLOTATION BOOM FLOTATION BOOM

READ complete manual CAREFULLY

BEFORE attempting operation.

DEMCO Dethmers Mfg. Co. P.O. Box 189 4010 320th Street Boyden, IA 51234

PH: (712) 725-2311 or (712) 725-2302 Toll Free: 1-800-543-3626 FAX: (712) 725-2380

Page 2

Thank you for purchasing a Demco boom. We

feel you have made a wise choice and hope you are

completely satisfied with your new flotation boom.

Your new Demco boom features the newest and

most up-to-date design of a boom it's type currently

marketed. DEMCO believes this to be a durable,

efficient, and easy to operate boom. If taken care

of properly it should serve you for many years.

If you have any questions regarding the applications of certain solutions or chemicals, contact your

chemical supplier and follow chemical manufacturer recommendations as well as all licensing and

use restrictions or regulations.

GENERAL INFORMATION

1. Unless otherwise specified, high-strength

(grade 5) (3 radial-line head markings) hex

head bolts are used throughout assembly of

this piece of equipment.

2. Whenever the terms "LEFT" and "RIGHT" are

used in this manual it means from a position

behind the machine and facing forward.

REMEMBER... Agricultural chemicals are dangerous. Know exactly what you're going to do and

what is going to happen before attempting to work

with these products. Improper selection or use can

injure people, animals, plants and soil. Always

wear protective clothing such as coveralls, goggles

and gloves when working with chemicals or the

boom.

3. When placing a parts order, refer to this manual

for proper part numbers and place order by part

number and description.

INDEX

Mounting the Center Section................................................................ Page 1

Mounting the Center Section With Hydraulic Height Adjust ................. Page 2

Mounting the Center Section With Manual Height Adjust..................... Page 3

Center Section Parts Breakdown and Parts List .................................. Page 4

Left Inner Wing Parts Breakdown and Parts List ................................. Page 5

Right Inner Wing Parts Breakdown and Parts List ............................... Page 6

Right and Left Outer Wing Parts Breakdown and Parts List ................ Page 7

Tip Placement and Nozzle Parts Breakdown and Parts List................ Page 8

Adjustment Procedures........................................................................ Page 9

Adjustment and Folding Procedures.................................................... Page 10

Maintenance and Lubrication............................................................... Page 11

Optional Hydraulic Wing Leveling and Wheel Tip Protector................. Page 12

Sprayer Calibration .............................................................................. Page 13

Sprayer Checklist................................................................................. Page 14

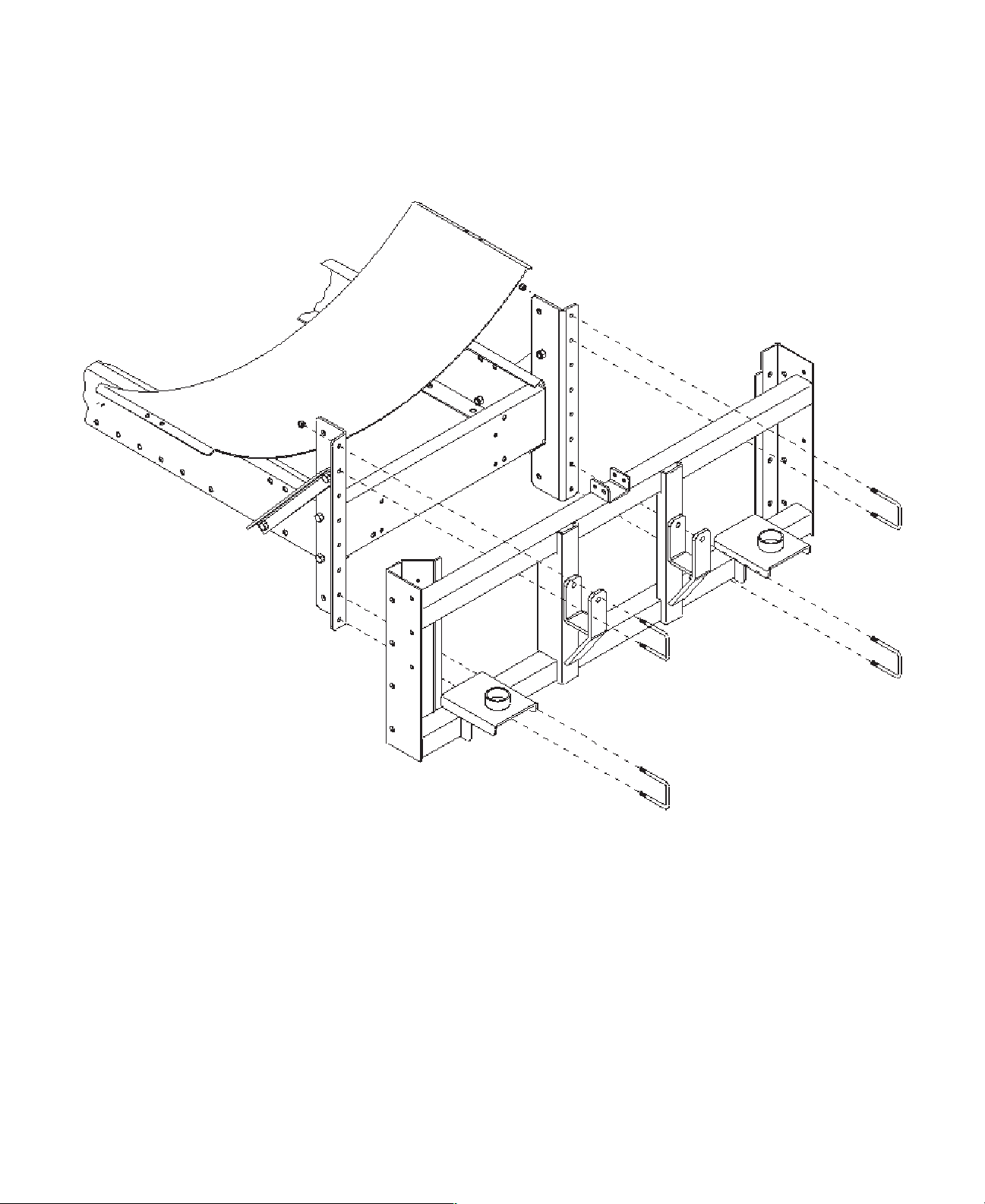

Page 3

Begin by attaching the center section of the boom to the sprayer. With the center section on the sprayer,

the boom can be assembled from the center section outward and final alignment made at that time.

4

2

4

2

3

3

1

3

3

MOUNTING THE BOOM CENTER SECTION

Normal sprayer frame, without Height Adjuster. (Shown Above)

1. Mount the Boom Carrier Center Section (#1) to the Mounting Angles (#2) on the back of the sprayer

frame using four 3/8" x 2-1/2" square U-bolts (#3) and eight 3/8" nylon locknuts (#4). NOTE: The mounting

brackets (#2) may need to be turned in or out depending on sprayer frame width.

Page 1

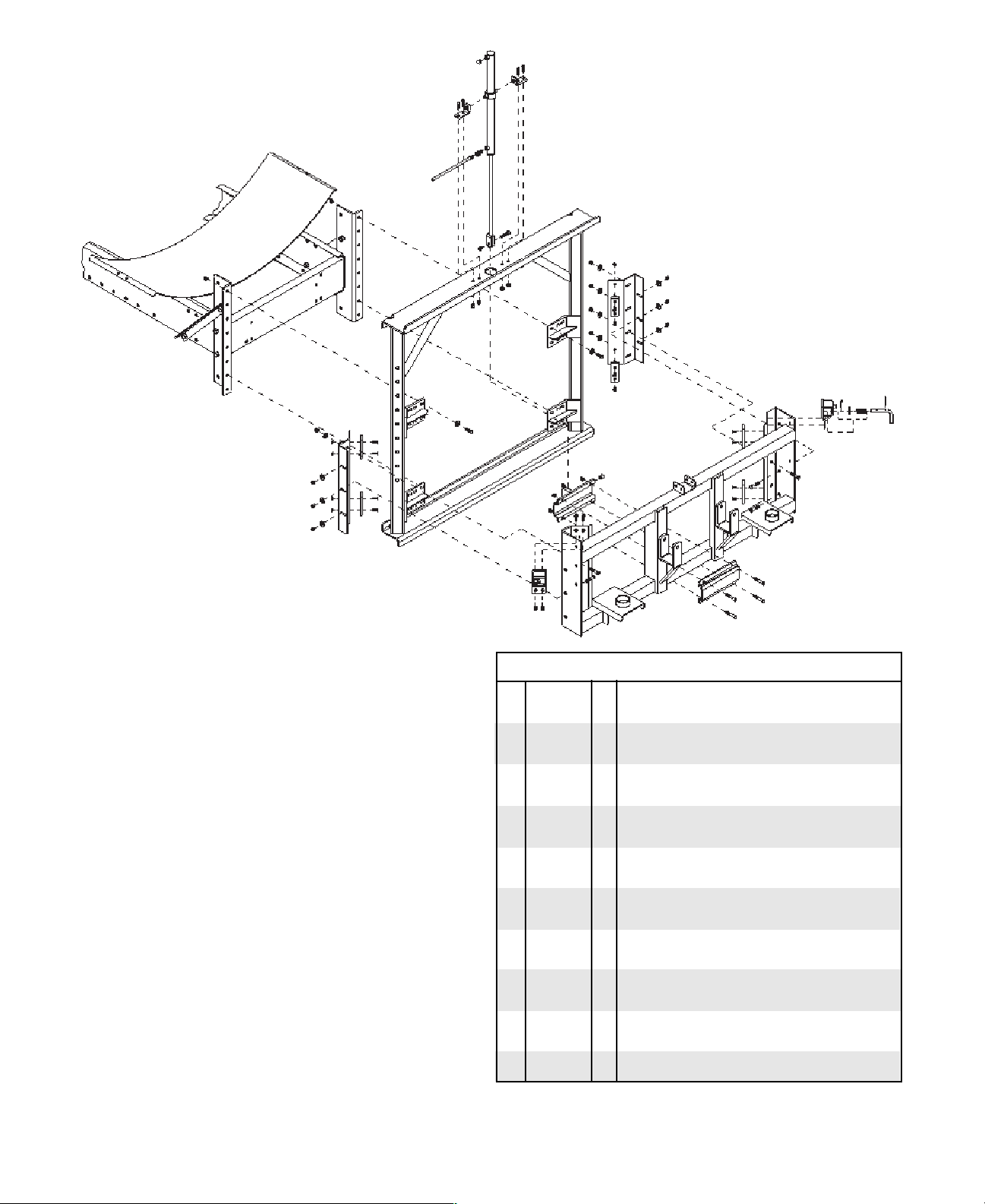

Page 4

MOUNTING THE BOOM CENTER SECTION TO HYDRAULIC HEIGHT ADJUST

8

2

2

6

9

10

5

11

4

5

4

1

3

2

CAUTION -Do not operate height

adjust until final adjustments

have been made. Never stand on

or near the boom during height adjust operation.

3

5

17

16

15

3

5

17

3

5

16

15

14

ASSEMBLY INSTRUCTIONS

1. Mount the height adjust main frame (#1) to the boom mounting

brackets (#4) on the sprayer frame with eight 3/8" x 1-14" bolts (#2),

eight 3/8" flatwashers (#3) and eight 3/8" locknuts (#5). NOTE:

The mounting brackets (#4) may need to be turned in or out

depending on sprayer frame width.

2. Mount the lock pin brackets (#20) to the boom carrier (#13), using

four 1/2" x 1-1/4" bolts (#19) and four 1/2" locknuts (#11), make

sure the bolts are inserted in the right direction as shown above.

Place the lock pin (#25) & roll pin (#24) through the bracket (#20).

Insert the spring (#23) and 7/16" flatwasher (#22) to the inside of

the lock pin bracket and push the pin (#25) through. Secure the

lock pin assembly with cotter pin (#21) between the washer and

bracket. Make sure pin moves in and out freely and rotates down

into the "latch out" position easily.

3. Before mounting the boom carrier to the main frame assembly,

mount the UHMW wear pads (#15) to the boom carrier (#13) and

boom carrier brackets (#14) using sixteen 1/4" x 1" flathead screws

(#16) and sixteen 1/4" locknuts (#17).

4. Now place the boom carrier (#13) on to the main frame assembly

(#1) so that the lock pins are in the holes of the main frame. Loosely

mount the boom carrier brackets (#14) to the boom carrier (#13)

using eight 3/8" x 1-1/4" bolts (#2), six 3/8" x 1-1/2" bolts (#18),

fourteen 3/8" flatwashers (#3) and fourteen 3/8" locknuts (#5).

5. Slide the hydraulic cylinder (#7) clevis end down through the large

hole in the top of the main frame assembly (#1). The hole is slotted

so the cylinder inlet can be maneuvered through. Slide one

mounting ear bracket (#6) onto each peg on the cylinder, align over

holes in the main frame top and secure the mounting ears with four

3/8" x 1-1/4" bolts (#2) and four 3/8" locknuts (#5).

6. Attach the bottom lift bracket and back-up plate (#27&28) to the

center of the boom carrier (#13) with four 3/8" x 2-1/4" bolts (#26)

and four 3/8" locknuts (#5). The hole in the lift bracket (#28) is

offset and the hole must go towards the bottom for total adjustment. Compress the cylinder and attach the cylinder clevis to the

lift bracket with one 1/2" x 2" bolt (#12) through the 1/2" I.D. x 5/8"

lg. bushing (#29) and one 1/2" locknut. See page 9 for adjustment.

2

2

6

7

12

5

3

5

5

5

3

5

3

3

2

5

5

28

19

2

20

18

11

REF. PART

NO. NO. QTY. DESCRIPTION

1. 05601 1 Height Adjuster Main Frame

2. 00523 20 3/8"-16UNC x 1-1/4" Hex Head Bolt Gr.5

3. 00059 20 3/8" Flatwasher

4. ---- 2 Boom Mounting Brackets (not included)

5. 02592 30 3/8"-16UNC Nylon Insert Locknut

6. 05605 2 Top Cylinder Mounting Ear

7. 05600 1 Hydraulic Cylinder

8. 00288 1 Air Vent - hydraulic cylinder

9. 05661 1 3/8" MPT x 3/8" FPT Orifice Restrictor

10. 05013 1 26' Hydraulic Hose

11. 02178 5 1/2"-13UNC Nylon Insert Locknut

12. 01253 1 1/2"-13UNC x 2" Hex Head Bolt Gr.5

13. 03306 1 Boom Carrier

14. 03305 2 Boom Carrier Brackets

15. 02946 8 UHMW Wear Pad

16. 05732 16 1/4"-20UNC x 1" Slotted Flat Head

17. 02772 16 1/4"-20UNC Hex Nylon Insert Locknut

18. 00914 6 3/8"-16UNC x 1-1/2" Hex Head Bolt Gr.5

19. 00967 4 1/2"-13UNC x 1-1/4" Hex Head Bolt Gr.5

20. 03340 2 Lock Pin Bracket

21. 02363 2 5/32" x 1/14" Cotter Pin

22. 00205 2 7/16" Flatwasher

23. 02208 2 Lock Spring

24. 03099 2 Roll Pin (3/16" x 1")

25. 03342 2 Lock Pin

26. 02494 4 3/8"-16UNC x 2-1/-4" Hex Head Bolt Gr.5

27. 05604 1 Bottom Lift Back Plate

28. 05603 1 Bottom Lift Bracket

29. 01839 1 1/2" I.D. x 5/8" lg. Spacer

Please order replacement parts by PART NO. and DESCRIPTION.

(DFBHAH OPTION)

17

14

5

3

15

16

5

3

15

16

16

29

15

16

27

13

26

PARTS LIST

15

18

18

20

2

13

26

21

22

23

24

25

NOTE: Use CAUTION when adjusting height. Make sure all air is

bled from the line before initial trial.

Page 2

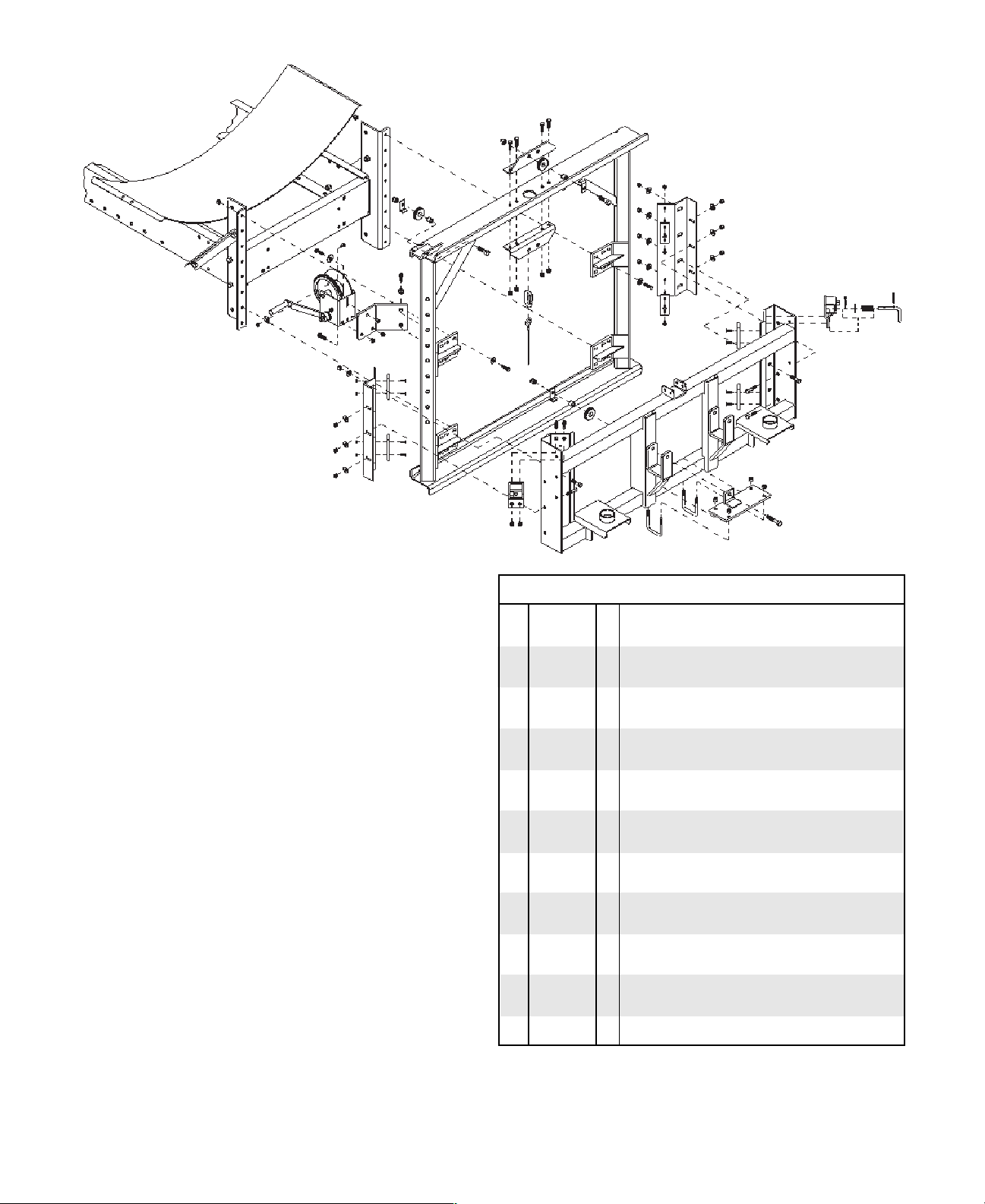

Page 5

MOUNTING THE BOOM CENTER SECTION TO MANUAL HEIGHT ADJUST

(DFBHA OPTION)

5

4

9

5

25

27

26

2

3

4

22

20

8

21

5

2

3

18

16

17

5

15

3

5

18

17

16

5

3

ASSEMBLY INSTRUCTIONS

1. Mount the height adjust main frame (#1) to the boom mounting

brackets (#4) on the sprayer frame with eight 3/8" x 1-1/4" bolts

(#2), eight 3/8" flatwashers (#3) and eight 3/8" locknuts (#5).

NOTE: The mounting brackets (#4) may need to be turned in or out

depending on sprayer frame width.

2. Mount the lock pin brackets (#6) to the boom carrier (#7) using four

1/2" x 1-1/4" bolts (#8) and four 1/2" locknuts (#9) make sure these

bolts are inserted in the right direction as shown above. Place the

lock pin (#14) & roll pin (#13) through the brackets (#6). Insert the

lock spring (#12) and 7/16" flatwasher (#11) to the inside of the lock

pin bracket and push the pin (#14) through. Secure the lock pin

assembly with cotter pin (#10) between the washer and bracket.

Make sure pin moves in and out freely and rotates down into the

"latch out" position easily.

3. Before mounting the boom carrier to the main frame assembly,

mount the UHMW wear pads (#16) to the boom carrier (#7) and

boom carrier brackets (#15) using sixteen 1/4" x 1" flathead screws

(#17) and sixteen 1/4" nuts (#18).

4. Now place the boom carrier (#7) on to the main frame assembly

(#1) so that the lock pins are in the holes of the main frame. Loosely

mount the boom carrier brackets (#15) to the boom carrier (#7)

using eight 3/8" x 1-1/4" bolts (#2), six 3/8" x 1-1/2" bolts (#19),

fourteen 3/8" flatwashers (#3) and fourteen 3/8" locknuts (#5).

5. Attach the two top pulley mounts (#23) to the main frame (#1) as

shown using four 3/8" x 1-1/2" bolts (#2) and four 3/8" locknuts (#5).

Attach the top pulley (#27), spacer (#26) and cable retainer bracket

(#25) with 1/2" x 1-3/4" bolt (#24) and 1/2" locknut (#9). Assemble

the pulley on the top left side of the height adjuster main frame.

Adjust cable retainer brackets (#25) to always keep the cable in the

pulley grove even when there is no tension on the cable.

6. Attach the bottom pulley mount (#28) to the center of the boom

carrier (#7) using two 3/8" x 2-1/2" sq. U-bolts (#29) and two 3/8"

locknuts (#5). Attach the pulley (#27) to the bottom pulley mount

(#28) ear, using one 1/2" x 1-3/4" bolt (#24), cable retainer bracket

(#25), and spacer (#26), then secure with a 1/2" locknut (#9). Align

this bracket so the cable runs straight down from the top, around

the bottom pulley and back up to the rapidlink (#30).

24

23

2

2

9

27

26

25

23

5

5

30

31

24

1

18

15

5

3

5

3

16

17

5

3

3

2

16

17

5

3

5

3

10

6

16

11

17

3

9

2

25

26

27

8

2

6

9

19

29

7

29

17

16

2

19

19

7

5

5

28

24

PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 05601 1 Height Adjuster Main Frame

2. 00523 23 3/8"-16UNC x 1-1/4" Hex Head Bolt Gr. 5

3. 00059 23 3/8" Flatwasher

4. ---- 2 Boom Mounting Brackets (not included)

5. 02592 33 3/8"-16UNC Nylon Insert Locknut

6. 03340 2 Lock Pin Bracket

7. 03306 1 Boom Carrier

8. 00967 6 1/2"-13UNC x 1-1/4" Hex Head Bolt Gr.5

9. 02178 7 1/2"-13UNC Nylon Insert Locknut

10. 02363 2 5/32" x 1/14" Cotter Pin

11. 00205 2 7/16" Flatwasher

12. 02208 2 Lock Spring

13. 03099 2 Roll Pin (3/16" x 1")

14. 03342 2 Lock Pin

15. 03305 2 Boom Carrier Brackets

16. 02946 8 UHMW Wear Pad

17. 05732 16 1/4"-20UNC x 1" Slotted Flat Head

18. 00062 16 1/4"-20UNC Hex Nut

19. 00914 6 3/8"-16UNC x 1-1/2" Hex Head Bolt Gr.5

20. 03345 1 Winch Mount Bracket

21. 00084 2 1/2" Lockwasher

22. 04967 1 Winch w/ disc brake - 1200 lb. cap. (w/ handle)

- 04971 1 Replacement Handle only

23. 05607 2 Top Pulley Mount

24. 00482 3 1/2"-13UNC x 1-3/4" Hex Head Bolt Gr.5

25. 01838 3 Cable Retainer Bracket

26. 01839 3 1/2" I.D. x 5/8" lg. Spacer

27. 01840 3 Pulley

28. 05609 1 Bottom Pulley Mount

29. 01887 2 3/8"-16UNC x 2-1/2" U-bolt

30. 04819 1 5/16" Rapid Link

31. 05611 1 3/16" Aircraft Cable x 20' lg. with thimble

Please order replacement parts by PART NO. and DESCRIPTION.

7. Attach the winch mounting bracket (#20) to the height adjust main

frame (#1) using two 1/2" x 1-1/4 bolts (#8) and two 1/2" lockwashers

(#21). Mount the winch (#22) to the winch mounting bracket (#20),

using three 3/8" x 1-1/4" bolts (#2), three 3/8" flatwashers (#3) and

three 3/8" locknuts (#5).

13

12

14

Page 3

Page 6

19

19

10

20

20

13

15

CENTER SECTION BOOM CARRIER BREAKDOWN

10

5

21

15

5

11

6

20

20

20

14

23

19

15

16

16

10

5

8

3

12

7

9

10

4

9

24

18

15

18

23

9

9

9

22

20

19

5

30

32

33

31

29

Note: This bracket must be 5" off center

in either direction.

9

21

19

17

17

21

25

28

26

21

27

21

10

10

10

1

21

30

21

11

5

10

11

6

10

5

2

5

10

20

21

15

34

18

4

9

10

9

5

PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 03306 1 Boom Carrier

2. 03309 1 Boom Carrier Left Floater

3. 03310 1 Boom Carrier Right Floater

4. 03330 2 Spring

5. 03313 8 Pivot Bushing (2-7/8" long)

6. 03311 2 Linkage Plate

7. 03312 2 Auto-Level Linkage

8. 03331 1 Shock

9. 01338 8 1/2"-13UNC x 4-1/2" Hex Head Bolt Gr.5

10. 02178 14 1/2"-13UNC Nylon Insert Locknut

11. 01975 3 1/2"-13UNC x 5" Hex Head Bolt Gr.5

12. 04073 1 1/2"-13UNC x 3" Hex Head Bolt Gr.5

13. 03307 1 Left Auto-Level Sway Control Bracket

14. 03308 1 Right Auto-Level Sway Control Bracket

15. 03324 4 UHMW Wear Pad

16. 05732 4 1/4"-20UNC x 1" Slotted Flat Head

17. 02772 4 1/4"-20UNC Nylon Insert Locknut

18. 00516 4 1/4"-20UNC x 3/4" Slotted Flat Head

19. 00523 8 3/8"-16UNC x 1-1/4" Hex Head Bolt Gr.5

20. 00059 16 3/8" Flatwasher

21. 02592 23 3/8"-16UNC Nylon Insert Locknut

22. 03314 1 Center Section

23. 02945 2 Auto-Level Sway Guide

24. 01348 2 Spring (1" O.D. x 3" long)

25. 03317 1 Auto-Level Latch

26. 01903 1 3/8"-16UNC x 3-1/2" Hex Head Bolt Gr.5

27. 00199 1 Lock Pin (3/8" O.D. x 3-1/2" lg.)

28. 00182 1 1/8" Small Hair Pin

29. 03334 3 Center Nozzle Tube Mounting Plate

30. 01887 7 3/8"-16UNC x 2-1/2" Square U-bolt

31. 00909 3 5/16"-18UNC x 1-1/4" Sq. U-bolt

32. 03333 1 Center Nozzle Mounting Tube

33. 02802 6 5/16"-18UNC Nylon Insert Locknut

34. 03399 2 Bottom Center Support Bracket

Please order replacement parts by PART NO. and DESCRIPTION.

1. Begin by referring to the boom carrier (#1) mounting to the sprayer

ASSEMBLY INSTRUCTIONS

frame (page 1) or mounting to the height adjust (pages 2 & 3). After the

boom carrier is mounted begin assembling the center section.

2. Mount the left floater tube (#2) to the boom carrier (#1) using one 1/2"

x 5" bolt (#11), pivot bushing (#5), and one 1/2" locknut (#10). Next

mount the right floater tube (#3) to the boom carrier (#1) using one 1/

2" x 5" bolt (#11), one pivot bushing (#5), and one 1/2" locknut (#10).

3. Place the auto-level springs (#4) between the left and right floater (#2

& 3) and the boom carrier (#1). Attach the left floater (#2) and right

floater (#3) using two linkage plates (#6), two pivot bushings (#5), two

1/2" x 4-1/2" bolts (#9), and two 1/2" locknuts (#10).

4. Now mount the shock (#8) to the right floater (#3) using one 1/2" x 5"

bolt (#11) and one 1/2" locknut (#10). Mount the opposite end of the

shock to the boom carrier (#1) using one 1/2" x 3" bolt (#12) and one

1/2" locknut (#10).

5. Mount the auto-level linkage (#7) to the left floater (#2) using one 1/2"

x 4-1/2" bolt (#9), one pivot bushing (#5), and one 1/2" locknut (#10).

NOTE: Make sure the arrows on the linkage are up as shown above.

Mount the auto-level linkage (#7) to the right floater (#3) using one 1/

2" x 4-1/2" bolt (#9), one pivot bushing (#5), and one 1/2" locknut (#10).

6. Mount the center section onto the boom center section (#22). Secure

the linkages (#7) on the right and left to the bottom of the boom center

section (#22) using two 1/2" x 4-1/2" bolts (#9), two pivot bushings (#5)

and two 1/2" locknuts (#10).

7. Attach the left and right auto-level sway control brackets (#13 & 14) to

the boom carrier (#1) using six 3/8" x 1-1/4" bolts (#19), six 3/8"

flatwashers (#20) and six 3/8" locknuts (#21). Next mount the UHMW

wear pads (#15) to the sway control brackets (#13 & 14) using four 1/

4" x 1" slotted flat head screws (#16) and four 1/4" locknuts (#17).

Assemble the UHMW wear pads (#15) to the auto-level sway control

guides (#23) and the bottom center support bracket (#34) using eight

1/4" x 3/4" slotted flat head screws (#18). Mount the sway control

guides (#23) with UHMW wear pads to the right and left sway control

brackets (#13 & 14) using two 3/8" x 1-1/4" bolts (#19), two 3/8"

flatwashers (#20) and two 3/8" locknuts (#21). Bolt the top of the sway

control guides and sway control brackets together using two 1/2" x 41/2" bolts (#9), two springs (#24) and two 1/2" locknuts (#10). Mount

the bottom center support bracket (#34), with UHMW, to bottom tube

of boom carrier (#1) using four 3/8" x 2-1/2" square u-bolts (#30), eight

3/8" flatwashers (#20) and eight 3/8" nylon insert locknuts (#21).

8. Assemble the center boom nozzle mounting plates (#29) to the center

section (#22) as shown using three 3/8" x 2-1/2" sq. U-bolts (#30) and

six 3/8" locknuts (#21). Next mount the center nozzle tube (#32) to the

mounting plates (#29) using three 5/16" x 1-1/2" sq. U-bolts (#31) and

six 5/16" locknuts (#33).

Page 4

Page 7

LEFT INNER WING PARTS BREAKDOWN

15

28

24

25

19

27

26

21

22

20

12

9

10

8

9

6

7

9

7

1

26

23

14

31

33

30

27

27

32

33

NOTE: To attach the gusset

35

36

34

plate (#36) follow step

7 on page 7.

ASSEMBLY INSTRUCTIONS

1. Attach the upper offset linkage (#6) to center section (#1) using

one 1/2" x 2" bolt (#7), bushing (#8) and one 1/2" locknut (#9).

2. Next attach the lower linkage bracket (#10) to the upper offset

linkage (#6) using one 1/2" x 2" bolts (#7) and one 1/2" locknut

(#9).

3. Mount the left center hinge (#2) to the center section (#1). Secure

with pin (#3), 3/4" machine washer (#16), 3/8" x 3/4" setscrew (#5)

and 3/8" jam nut (#4).

4. Bolt the linkage mounting plate (#11) to the left center hinge (#2)

as shown using two 3/8" x 2-1/2" U-bolts (#12) and four 3/8"

locknuts (#13). Bolt the lower linkage bracket (#10) to the linkage

mounting plate (#11) using one 1/2" x 2" bolt (#7), bushing (#8),

and one 1/2" locknut (#9).

5. Attach the left inner wing (#14) to the left center hinge (#2) with the

3/4" machine washer (#16) between the wing and hinge, using the

center hinge pin (#15). Secure with two 5/16" x 1/2" setscrews

(#17).

6. Insert the 1/2" x 1-1/2" bolt (#18) and 1/2" nut (#19) into the center

hinge (#2) as shown above.

7. Assemble the wing latch handle (#20) to the center hinge (#2)

using the 7/16" clevis pin (#21), 3/8" flatwasher (#22) and secure

with 5/32" x 1" cotter pin (#23). Next attach the wing latch channel

(#24) to the wing latch handle (#20) using one 5/16" x 2-1/2" bolt

(#25), two 5/16" flatwashers (#26), and one 5/16" locknut (#27).

Next screw the tee bolt (#28) into the wing latch channel (#24) and

secure with 1/2" jam nut (#19) on back side.

8. Bolt the wing storage bracket (#30) to the left wing approximately

23" from latch plate on the left wing, using two 5/16" x 2" sq. U-bolt

(#35) and four 5/16" locknuts (#27).

Page 5

11

7

5

4

13

8

17

2

29

19

29

16

16

18

3

29

17

16

PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 03314 1 Center Section

2. 03315 1 Left Hinge

3. 03319 1 Center Hinge Pin

4. 04886 1 3/8"-16UNC Jam Nut

5. 00095 1 3/8"-16UNC x 3/4" Square Head Setscrew

6. 00171 1 Upper Offset Linkage Bracket

7. 01253 3 1/2"-13UNC x 2" Hex Head Bolt Gr.5

8. 02491 2 Bushing (3/4" O.D. x 1/2" I.D. x 1/2" lg.)

9. 02178 3 1/2"-13UNC Nylon Insert Locknut

10. 00170 1 Lower Linkage Bracket

11. 03318 1 Linkage Mounting Plate

12. 05294 2 3/8"-16UNC x 2-1/8" Square U-bolt

13. 02592 4 3/8"-16UNC Nylon Insert Locknut

14. 03322 1 Left Inner Wing

15. 03321 1 Inner Hinge Pin (3/4" x 20")

16. 02534 3 3/4" x 14 Ga. Machine Washer

17. 00091 2 5/16"-18UNC x 1/2" Square Head Set Screw

18. 01254 1 1/2"-13UNC x 1-1/2" Hex Head Bolt Gr.5

19. 00640 2 1/2"-13UNC Jam Nut

20. 05309 1 Wing Latch Handle

21. 00080 1 7/16" x 1-1/4" lg. Clevis Pin

22. 00059 1 3/8" Flatwasher

23. 00185 1 5/32" x 1" lg. Cotter Pin

24. 05310 1 Wing Latch Channel

25. 04221 1 5/16"-18UNC x 2-1/2" Hex Head Bolt Gr.5

26. 00004 2 5/16" Flatwasher

27. 02802 3 5/16"-18UNC Nylon Insert Locknut

28. 03320 1 Latch Bolt

29. 04642 4 Zerk

30. 03335 1 Storage Bracket

31. 04822 3 1/4"-20UNC x 1-1/16" Square U-bolt

32. 00199 1 3/8" Dia. x 3-1/2" lg. Lock Pin

33. 00182 1 1/8" Small Hair Pin

34. 02772 6 1/4"-20UNC Nylon Insert Locknut

35. 00909 1 5/16"-18UNC x 1-1/4" Square U-bolt

36. 03537 1 Gusset Plate

Please order replacement parts by PART NO. and DESCRIPTION.

Page 8

RIGHT INNER WING PARTS BREAKDOWN

12

28

31

27

32

35

26

27

36

37

26

34

27

25

19

20

27

24

21

22

26

9

23

10

9

9

6

7

29

8

7

1

5

4

16

16

8

7

2

29

33

ASSEMBLY INSTRUCTIONS

1. Attach the upper offset linkage (#6) to center section (#1) using

one 1/2" x 1-3/4" bolt (#7), bushing (#8) and one 1/2" locknut (#9).

2. Next attach the lower linkage bracket (#10) to the upper offset

linkage (#6) using one 1/2" x 1-3/4" bolts (#7) and one 1/2" locknut

(#9).

3. Mount the right center hinge (#2) to the center section (#1).

Secure with pin (#3), 3/4" machine washer (#16) and 3/8" x 3/4"

setscrew (#5) and 3/8" nut (#4).

4. Bolt the linkage mounting plate (#11) to the right center hinge (#2)

as shown using two 3/8" x 2-1/2" U-bolts (#12) and four 3/8"

locknuts (#13). Bolt the lower linkage bracket (#10) to the linkage

mounting plate (#11) using one 1/2" x 1-3/4" bolt (#7), bushing

(#8), and one 1/2" locknut (#9).

5. Attach the right inner wing (#14) to the right center hinge (#2) with

the 3/4" machine washer (#16) between the wing and hinge, using

the center hinge pin (#15). Secure with two 1/4" x 1/4" setscrews

(#17).

6. Insert the 1/2" x 1-1/2" bolt (#18) and 1/2" nut (#19) into the center

hinge (#2) as shown above.

7. Assemble the wing latch handle (#20) to the center hinge (#2)

using the 7/16" clevis pin (#21), 3/8" flatwasher (#22) and secure

with 5/32" x 1" cotter pin (#23). Next attach the wing latch channel

(#24) to the wing latch handle (#20) using one 5/16" x 2-1/2" bolt

(#25), two 5/16" flatwashers (#26) and one 5/16" locknut (#27).

Next screw the tee bolt (#28) into the wing latch channel (#24) and

secure with 1/2" jam nut (#19) on back side.

8. Bolt the wing storage bracket (#30) to the right wing approximately

23" from latch plate on the left wing, using two 5/16" x 1-1/4" sq.

U-bolt (#31) and four 5/16" locknuts (#27).

9. Mount all brackets in this step loosely in locations shown. When

boom is complete, fold and adjust brackets to support the boom in

the folded positon. Mount the wing storage upright (#32) to the top

of the center section (#1) using two 5/16" x 2-1/2" L-bolts (#33) and

four 5/16" locknuts (#27). Attach the storage cross tube (#34) to

the storage upright (#32) using two 5/16" x 1-1/4" square u-bolts

(#31), four 5/16" flatwashers (#26) and 5/16" nylon insert locknuts

(#27). Place the 1-1/4" Cap Plug (#35) in the end of the upright

(#32).

Page 6

15

36

14

30

27

17

29

27

37

NOTE: To attach the gusset

plates (#38) follow step

31

31

7 on page 7.

11

13

18

19

16

29

17

3

PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 03314 1 Center Section

2. 03316 1 Right Hinge

3. 03319 1 Center Hinge Pin

4. 04886 1 3/8"-16UNC Jam Nut

5. 00095 1 3/8"-16UNC x 3/4" Square Head Setscrew

6. 00171 1 Upper Offset Linkage Bracket

7. 01252 3 1/2"-13UNC x 2" Hex Head Bolt Gr.5

8. 02491 2 Bushing (3/4" O.D. x 1/2" I.D. x 5/8" lg.)

9. 02178 3 1/2"-13UNC Nylon Insert Locknut

10. 00170 1 Lower Linkage Bracket

11. 03318 1 Linkage Mounting Plate

12. 05294 2 3/8"-16UNC x 2-1/8" Square U-bolt

13. 02592 4 3/8"-16UNC Nylon Insert Locknut

14. 03323 1 Right Inner Wing

15. 03321 1 Inner Hinge Pin

16. 02534 3 3/4" x 14 Ga. Machine Washer

17. 00091 2 5/16"-18UNC x 1/2" Square Head Set Screw

18. 01254 1 1/2"-13UNC x 1-1/2" Hex Head Bolt Gr.5

19. 00640 2 1/2"-13UNC Jam Nut

20. 05309 1 Wing Latch Handle

21. 00080 1 7/16" x 1-1/4" lg. Clevis Pin

22. 00059 1 3/8" Flatwasher

23. 00185 1 5/32" x 1" lg. Cotter Pin

24. 05310 1 Wing Latch Channel

25. 04221 1 5/16"-18UNC x 2-1/2" Hex Head Bolt Gr.5

26. 00004 6 5/16" Flatwasher

27. 02802 15 5/16"-18UNC Nylon Insert Locknut

28. 03320 1 Latch Bolt

29. 04642 4 Zerk

30. 03338 1 Storage Bracket

31. 00909 5 5/16"-18UNC x 1-1/4" Sq. U-bolt

32. 03437 1 Storage Upright Bracket

33. 05818 2 5/16"-18UNC x 2-1/2" L-bolt

34. 03438 1 Storage Cross Tube Bracket

35. 05188 5 1-1/4" Square Cap Plug

- 04739 2 1" Square Cap Plug

36. 00199 2 Lock Pin (3/8" O.D. x 3-1/2" lg.)

37. 00182 2 1/8" Small Hairpin

38. 03537 1 Gusset Plate

39. 04822 1 1/4"-20UNC x 1-1/16" Square U-bolt

40. 02722 2 1/4"-20UNC Nylon Insert Locknut

Please order replacement parts by PART NO. and DESCRIPTION.

39

27

38

40

Page 9

RIGHT AND LEFT OUTER WING PARTS BREAKDOWN

21

24

14

4

10

7

8

9

29

3

32

33

27

23

2

26

31

31

23

27

PARTS LIST

REF. PART

NO. NO. QTY. DESCRIPTION

1. 03322 1 Left Inner Wing

2. 03323 1 Right Inner Wing

3. 03328 2 Right and Left Outer Wing

4. 03326 2 Breakaway Pin

5. 03325 2 Outer Breakaway Hinge

6. 03329 2 Outer Hinge Pin

7. 04051 4 5/8"-11UNC x 1-1/2" Hex Head Bolt Gr.5

8. 00085 4 1/2" Flatwasher

9. 00490 4 Breakaway Bearing

10. 03327 2 Lock Collar

11. 05318 2 Spring

12. 00694 6 1/4"-20UNC x 1/2" Square Head Set Screw

13. 02772 8 1/4"-20UNC Nylon Insert Locknut

14. 00640 6 1/2"-13UNC Jam Nut

15. 00967 4 1/2"-13UNC x 1-1/4" Hex Head Bolt Gr.5

16. 02178 2 1/2"-13UNC Nylon Insert Locknut

17. 05309 2 Wing Latch Handle

18. 00080 2 7/16" x 1-1/4" lg. Clevis Pin

19. 00059 2 3/8" Flatwasher

20. 00185 2 5/32" x 1" lg. Cotter Pin

21. 05310 2 Wing Latch Channel

22. 04221 2 5/16"-18UNC x 2-1/2" Hex Head Bolt Gr.5

23. 02802 18 5/16"-18UNC Nylon Insert Locknut

24. 03320 2 Latch Bolt

25. 00004 4 5/16" Flatwasher

26. 05297 2 Tip Protector

27. 00909 8 5/16"-18UNC x 1-1/4" Square U-bolt

28. 03439 1 Storage Bracket

29. 04642 4 Zerk

30. 05319 2 Tip Offset Bracket

31. 04822 4 1/4"-20UNC x 1-1/16" Square U-bolt

32. 05171 2 Wing Tip Extension for 50' boom (optional)

33. 00209 2 3/8"-16UNC x 1" Square Head Set Screw

34. 00199 1 Lock Pin (3/8"O.D. x 3-1/2" lg.)

35. 00182 1 1/8" Small Hairpin

36. 03537 2 Gusset Plate

36

13

Please order replacement parts by PART NO. and DESCRIPTION.

5

20

12

16

23

27

22

31

21

23

36

13

4

7

10

8

12

29

11

8

29

9

9

24

14

22

23

9

13

12

11

18

19

17

1

25

27

29

20

6

15

14

5

12

8

30

16

25

23

6

7

12

29

29

27

25

14

15

18

19

30

34

25

23

17

28

35

ASSEMBLY INSTRUCTIONS

1. Attach the outer wing (#3) to the breakaway hinge (#5). Place

bearings (#9), 1/2" flatwashers (#8) and 1/2" x 1-3/4" bolts (#7) to

the outer wing (#3). Slide outer wing (#3) on to the breakaway

hinge (#5). Insert breakaway hinge pin (#4) through the outer

wing top bushing through the breakaway hinge top bushing,

through the lock collar (#10), through the 1/2" flatwasher, spring

(#11) and 1/2" flatwasher (#8), through the bottom bushing on the

outer wing and through the breakaway hinge, place 1/2" locknut

(#16) on the hinge pin (#4) do not tighten. Tighten the 1/4" x

1/2" sq. head setscrew (#12) on the lock collar (#10), now tighten

the 1/2" locknut (#16) to compress breakaway spring, the spring

should be compressed to about 3-1/4". Do not over compress.

2. Assemble the outer wing and breakaway hinge to the inner left

and right wing (#1 & 2). Insert hinge pin (#6) through the bushings

and secure using 1/4" x 1/2" square head set screw (#12).

3. Insert four 1/2" x 1-1/4" bolts (#15) and four 1/2" jam nut (#14) into

the inner left and right wing (#1 & 2).

4. Assemble the wing latch handle (#17) to the inner right and left

wing (#1 & 2) using the 7/16" clevis pin (#18), 3/8" flatwasher (#19)

and secure with 5/32" x 1" cotter pin (#20). Next attach the wing

latch channel (#21) to the wing latch handle (#17) using one 5/16"

x 2-1/2" bolt (#22), two 5/16" flatwashers (#25) and one 5/16"

locknut (#23). Next screw the tee bolt (#24) into the wing latch

channel (#21) and secure with 1/2" nut (#14) on back side.

5. Bolt the wing storage bracket (#28) to the right inner wing

approximately 30" from latch plate, using two 1/4" x 1-1/16" sq. Ubolt (#31) and four 1/4" locknuts (#13).

6. Bolt the wing tip protector (#26) to the outer right and left wing (#3)

approximately 17" from wing tip. Secure using four 5/16" x

1-3/8" sq. U-bolts (#27) and eight 5/16" locknuts (#23).

7. Attach the gusset plate to the bottom wing tube and the nozzle

tube, center them as close as possible, between the hinge points

and the welded in gusset. Attach them using one 5/16" x 1-1/4"

Square U-bolt (#27), two 5/16" Locknuts (#23), one 1/4" x 1-1/16"

Square U-bolt (#31) and two 1/4" Locknuts (#13).

3

7

Page 7

Page 10

TIP PLACEMENT

1. Marking location of boom clamps: Mark the clamp

locations by starting at the center of the center boom section.

From this mark, locate 20 inch spaces to both ends of the

boom.

2. Fasten preassembled boom lines: Fasten the boom

clamps (#3) on the boom so the sprayer tip will be on the back

side of the boom. The wing extensions for the 60 foot boom are

1 inch tubing. Therefore, this boom will have two size clamps.

NOTE: 40' Boom ......25 Tips

45' Boom ......27 Tips

50' Boom ......31 Tips(w/ 1" Ext.Tube)

BASIC PLUMBING PARTS LIST

REF. PART

NO. NO. DESCRIPTION

- 340RB 3/4" Rubber Hose

- B12H 3/4" Gear Clamp

- NHT11 Nylon Hose Ties

Please order replacement parts by PART NO. and DESCRIPTION.

Feeder Line Routing and Tip Placement for Outer HingeFeeder Line Routing and Tip Placement for Inner Hinge

CONVENTIONAL NOZZLES AND BOOM CLAMPS

1-1/4" BOOM CLAMP PARTS LIST

REF. PART

4

1

3

3

2

6

*

7

5

NO. NO. DESCRIPTION

- B11 114 1-1/4" Boom Clamp Assembly

1. 00068 1/4"-20UNC x 3/4" Hex Head Bolt

2. 00062 1/4"-20UNC Hex Nut

3. 00337 1-1/4" Boom Clamp

- 00338 1" Boom Clamp

3/4" NOZZLE PARTS LIST

REF. PART

NO. NO. DESCRIPTION

4. NTL34 3/4" Nozzle Tee

5. NTT34 3/4" Nozzle Elbow

6. B12 Nut

* ------ Tip (specify tip size) (not included)

7. 8027 11/16" FPS Cap

Please order replacement parts by PART NO. and DESCRIPTION.

DRIP FREE NOZZLES AND BOOM CLAMPS

1

3

3

2

9

14

*

10

13

8

12

11

REF. PART

NO. NO. DESCRIPTION

- DF34NTL 3/4" Nozzle Elbow & Check Valve Assembly

- DF34NTT 3/4" Nozzle Tee & Check Valve Assembly

8. DF34T 3/4" Nozzle Tee

9. DF34E 3/4" Nozzle Elbow

10. DFB12 Nut

11. DFCP Spring Retainer Cap Assembly

12. DFDV Diaphragm (viton)

13. DFFD Floodjet Cap (red)

- DFFT Flat Cap (yellow)

14. DFGE Gasket (EPDM)

* ------ Tip (specify tip size) (not included)

Please order replacement parts by PART NO. and DESCRIPTION.

3/4" NOZZLE PARTS LIST

Page 8

Page 11

ADJUSTMENT PROCEDURES

After the boom is completely assembled and before

attempting to fold the boom for the first time, the

boom should be adjusted so it lays straight both

horizontally and vertically. There are several adjustment points built into the boom for this purpose.

1.All adjustments must be done with the boom

unfolded and latched. Begin by adjusting the

right and left boom carrier brackets (#13 & 14 on

page 4). Adjust the brackets (#13 or 14) forward

or backward against the top tube of the boom

center section so as to act as a guide for the

center section to keep it straight up and down, not

tilting forward or backwards. When the auto-level

sway control brackets are adjusted and tightened, the 1/2" x 4-1/2" bolt through the top of the

sway guide can be adjusted to snug the bracket

against the rear side of the top of the center

section tube. This adjustment should not restrict

the side to side sway of the boom but be enough

to dampen it and support the boom from excessive rear forces.

3.The wings on either side must be adjusted horizontally by moving the linkage mounting plate

(#10 on pages 5 & 6) up or down on the inner

hinge to get the wing level.

4.The outer breakaway hinge can be adjusted for

breakaway tension by tightening or loosening the

1/2" locknut (#16 on page 7). You may have to

adjust the lock collar down to get more spring

compression. The outer wings should be set to

breakaway after a 50 lb force or better is applied

to the wing tips. The springs should not be

compressed more than 3-1/4 inches.

6.After the boom is setup and the storage brackets

are placed in their approximate location final

adjustments can be made by folding the boom, in

the proper procedure (see page 10), slide the

storage brackets into the exact location when the

wings are folded and tighten in place.

7.If your flotation boom is equipped with a manual

or hydraulic height adjuster the following adjustments must be made. Adjust the boom carrier

brackets inwards by tightening the 3/8" x 1-1/2"

bolts that protrude sideways out through the

carrier bracket and the boom carrier, when these

brackets are snug on the height adjust tubes

tighten the 3/8" x 1-1/4" to lock these plates tight

against the boom carrier. Make sure the assembly slides up and down freely on the tubes. After

this is done adjust the height adjust lock pin

brackets. Carefully raise or lower the boom

carrier so the lock pins are lined up with holes in

the upright tube. Securely block the carrier at this

level and adjust the latch pin brackets so the pin

will latch securely and easily in the holes in the

upright tubes. Tighten the 1/2" bolts holding

these lock brackets securely and make sure the

pins are securely seated in the holes before

removing the blocks.

Note: Always make sure the lock pins are

securely locked after any type of height adjustment or before any work is done on the

boom.

8.Make sure all fasteners are tight or at the proper

tension, and hoses are not in the path of any

folding procedures.

5.At this time the latches should be adjusted at each

hinge so the wings will be locked securely after

unfolding. There are 1/2" bolts at each hinge

point that act as a stop. These stop bolts must be

adjusted in or out to straighten the lay of the

boom. After these bolts are adjusted, the tee bolt

in the clevis end of the latch should be adjusted to

securely latch each wing. It is important that the

latch locks over-center otherwise there will be

problems with it coming unlocked. If adjustment

is required with the latch not locking over-center

you must grind or file down the latch stop which

will then let the latch go over-center and lock

securely.

Page 9

Page 12

ADJUSTMENTS FOR FOLDING AND STORAGE

If the boom is adjusted correctly it should fold and store very easily . It is important to lock

the sway control in its storage position before beginning the folding procedures. If the boom

has hydraulic wing tip leveling, it is important not to operate these cylinders after the wings

are folded as damage may result to the boom.

1. Begin the folding operation at the left side (standing behind the boom looking forward) (1st Fold) of

the boom. Unlock the latch and fold the outer wing

into the storage bracket and lock in place with pin.

Make sure at this time and at every folding and

unfolding operation that the hoses and tips do not

interfere or bind around any corners. During all

folding operations you must support the wings until

they are in the storage brackets, otherwise extreme

twisting forces will be created and possibly damage

or twist the boom.

2. Next unlock the latch on the inner left wing (2nd

fold) and pull the outer left wing and the inner left

wing back and around to fold to the rear of the

center section and into the storage bracket and lock

in place with pin.

3. On the right side outer wing unlock the latch

between the inner and outer right wing. Fold the

outer right wing to the front of the inner right wing

(3rd fold) and into the storage bracket and lock in

place with pin.

4. Finally unlock the latch between the center

section and inner right wing. (4th fold) Fold the

inner right wing and outer right wing back and

around to fold to the rear of the center section and

into the storage bracket and lock in place with pin.

At this time the boom is completely folded and

ready for transport.

MAKE SURE ALL PINS ARE LOCKED IN PLACE

WITH HAIR PINS.

CHECK ALL HOSES AND TIPS TO MAKE SURE

THEY ARE NOT INTERFERING OR HUNG UP

ON ANY HINGES OR BOLTS.

DO NOT OPERATE THE HYDRAULIC WING TIP

LEVELING WHEN THE BOOM IS FOLDED (if

equipped).

3rd FOLD

1st FOLD

4th FOLD

2nd FOLD

Page 10

Page 13

MAINTENANCE AND LUBRICATION

FIVE GREASE

ZERKS

THREE

GREASE

ZERKS

FOUR

GREASE

ZERKS

FOUR GREASE

ZERKS

TWO

GREASE

ZERKS

TWO GREASE

ZERKS

LEFT WING

TWO

GREASE

ZERKS

Your Flotation Boom is designed to require

only occasional light maintenance. Attention to the following procedures will significantly prolong the useful life of your boom.

1.Prior to each use, carefully check all nuts,

bolts, fittings, plugs, hoses and hose clamps

to see that they are secure.

2.Check the latches to make sure that they

are not coming loose or worn. This must be

done daily to prolong their useful life.

3.All Grease Zerks must be greased daily

when this boom is in use. Also be certain to

replace any missing grease zerks or zerks

which will not accept grease.

RIGHT WING

TWO

GREASE

ZERKS

Page 11

Page 14

(OPTIONAL) HYDRAULIC BOOM LEVELING PARTS BREAKDOWN

13

9

6

8

12

7

11

6

5

11

1

5

3

6

10

2

5

4

11

REF. PART

NO. NO. QTY DESCRIPTION

1. 03348 1 Left DFHY Cylinder Mount

- 03349 1 Right DFHY Cylinder Mount

2. 02128 2 3/8"-16UNC x 2" Square U-bolt

3. 02592 4 3/8"-16UNC Nylon Insert Locknut

4. 03350 2 Linkage Mount

5. 01253 6 1/2"-13UNC x 2" Hex Head Bolt Gr.5

6. 02178 6 1/2"-13UNC Nylon Insert Locknut

7. 00286 2 Hydraulic Cylinder

8. 05661 2 3/8" MPT x 3/8" FPT Orifice Restrictor

9. 05013 2 26' Hydraulic Hose

10. 03405 2 Lower Linkage Mount

11. 01839 6 Bushing (3/4" OD x 1/2" ID x 5\8"lg.)

12. 05215 2 3/8" Steel Elbow Fitting

13. 00288 2 Air Vent

- 5222 - Cylinder Repair Kit

Please order replacement parts by PART NO. and DESCRIPTION.

DFHY PARTS LIST

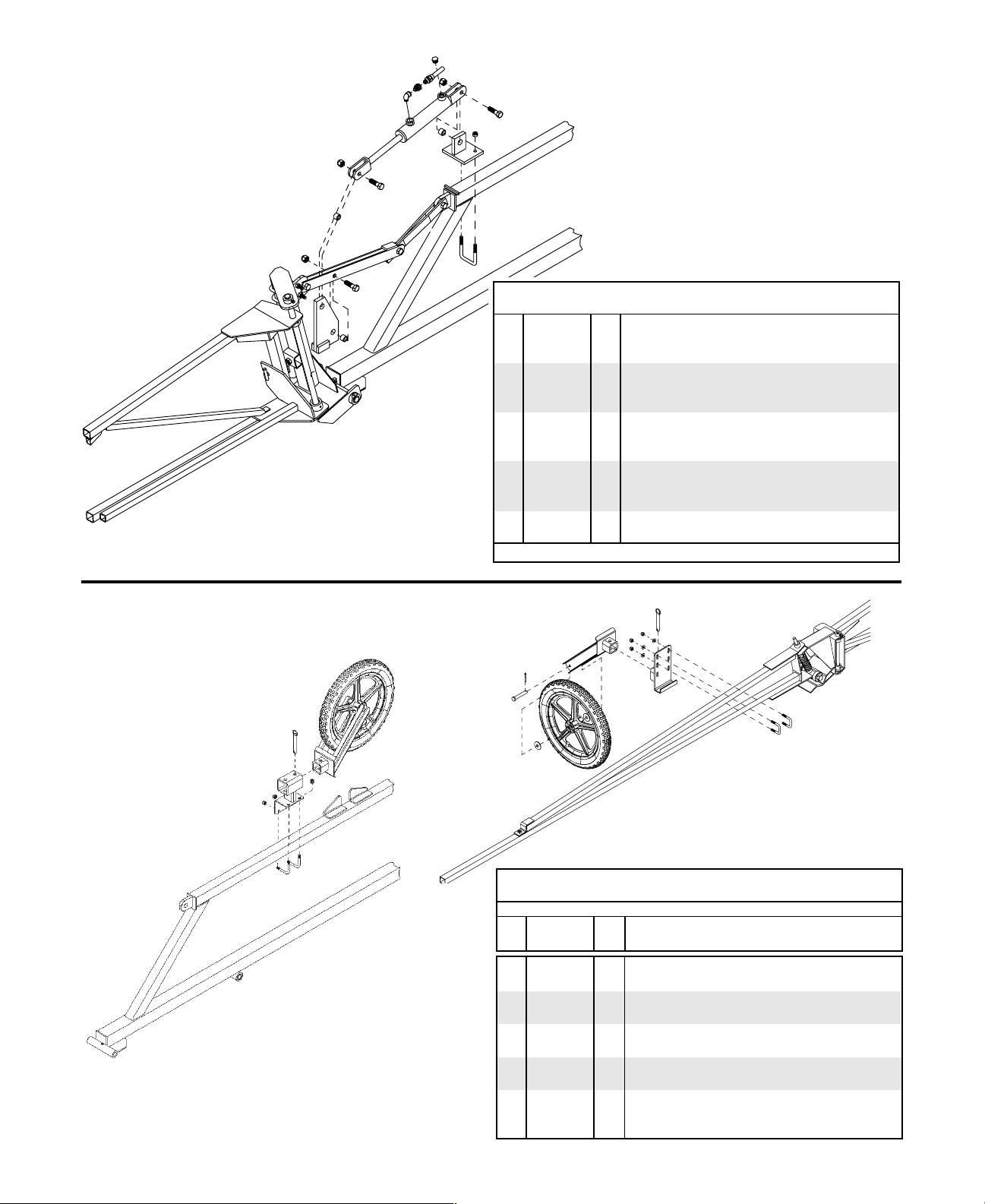

(OPTIONAL) WHEEL TIP PROTECTOR PARTS BREAKDOWN

7

6

1

2

7

11

9

9

5

3

2

4

9

13

8

1

10

12

DFBTP PARTS LIST

REF. PART

NO. NO. QTY DESCRIPTION

- 5328 2 16" Nylon Rim Assembly with Tire & Tube

1. 04744 1 16" x 2-1/8" Rubber Tire with Tube

2. 04743 1 16" Glass Filled Nylon Rim with Bearing

3. 05619 2 Pin (1/2" x 3" lg.)

4. 02384 4 Machine Washer (1/2" ID x 14 GA.)

5. 00185 2 5/32" x 1 Cotter Pin

6. 05564 2 Wheel Fork

7. 05328 2 1/2" x 3" lg. Ball Lock Hitch Pin

8. 05566 2 Wing Mounting Plate

9. 02802 12 5/16"-18UNC Nylon Insert Locknut

10. 00909 4 5/16"-18UNC x 1-1/4" Square U-bolt

11. 05567 1 Transport Storage Bracket

12. 05818 2 5/16"-18UNC x 2-1/2 L-bolt

13. 00004 8 5/16" Flatwasher

Please order replacement parts by PART NO. and DESCRIPTION.

Page 12

Page 15

SPRAYER CALIBRATION PROCEDURES

NOTE: To avoid wind drift, use lower pressure and higher spray volume.

Guidelines For Sprayer Calibration

Before calibrating your sprayer, first determine whether each nozzle is delivering at a uniform rate. Place

quart jars under all nozzles and watch as they fill up. The level should rise uniformly and take the same

time (within 10%) for all nozzles to fill the jars. Replace any nozzle showing a discharge rate different from

the others.

Sprayer Tips

Calibrating the Sprayer

1. Mark off 660 feet (1/8 mile).

2. Fill the tank with water.

3. Set the sprayer to your desired operating pressure.

4. Turn the sprayer on and drive at the constant speed you

will be spraying. Calibration on a road or unplowed field

will give different results than on soft cultivated ground.

Note tachometer reading so same speed can be maintained later.

5. Measure the amount of water it takes to refill the tank

completely.

6. Calculate the amount applied:

Number of gallons used x 66 (factor) Gallons applied

Spray Swath in Feet per acre

Example: If 10 gallons are used in 660 feet and the spray

swath is 40 feet, spraying rate is 16.5 gallons per acre.

10 x 66 660

40 40

=

or 16.5 gallons per acre

7. To calculate the amount of chemical to put in the tank:

Sprayer Tank Size Acres

Desired GPA Covered

Recommended amount

of chemical per acre

=

x

Covered

Acres

Example: If a 500 gallon tank is used and 16.5 gallons per

acre are applied, one tank will cover 30.3 acres. If three

pounds of chemical are required per acre, then 90 pounds

of chemical is required per tankful.

=

then;

Amount of

=

chemical per

tankful

Nozzle

XR8001VS X 20 .07 5.3 4.3 2.8 2.2

XR80015VS X 20 .11 7.8 6.3 4.3 3.2

XR8002VS X 20 .14 10.5 8.4 5.6 4.2

XR8003VS X 20 .21 15.7 12.6 8.4 6.3

XR8004VS X 20 .28 21.0 16.8 11.2 8.4

XR8005VS X 20 .35 26.0 21.0 14.0 10.5

XR8006VS X 20 .42 31.0 25.0 16.9 12.6

XR8008VS X 20 .56 42.0 34.0 22.0 17.0

8010SS X 20 .70 53.0 42.0 28.0 21.0

FLAT SPRAY NOZZLE for Broadcast Spraying

Gallons Per Acre

Based on 20" Nozzle Spacing

4 5 7.5 10

MPH MPH MPH MPH

No.

Liquid

Pressure

in PSI

Nozzle

Capacity

in GPM

25 .08 5.9 4.7 3.1 2.4

30 .09 6.4 5.1 3.4 2.6

40 .10 7.4 6.0 4.0 3.0

25 .12 8.8 7.1 4.7 3.6

30 .13 9.7 7.7 5.2 3.9

40 .15 11.1 8.9 6.0 4.5

25 .16 11.8 9.4 6.3 4.7

30 .17 12.9 10.3 6.9 5.2

40 .20 14.8 11.8 7.9 5.9

25 .24 17.6 14.1 9.4 7.1

30 .26 19.0 15.4 10.3 7.7

40 .30 22.0 17.8 11.8 8.9

25 .32 24.0 18.7 12.5 9.4

30 .35 26.0 21.0 13.7 10.3

40 .40 30.0 24.0 15.8 11.9

25 .40 29.0 23.0 15.7 11.7

30 .43 32.0 26.0 17.2 12.9

40 .50 37.0 30.0 19.8 14.9

25 .47 35.0 28.0 18.7 14.1

30 .52 39.0 31.0 21.0 15.5

40 .60 45.0 36.0 24.0 17.8

25 .63 47.0 37.0 25.0 19.0

30 .69 52.0 41.0 27.0 21.0

40 .80 59.0 48.0 32.0 24.0

25 .78 59.0 47.0 31.0 24.0

30 .86 64.0 51.0 34.0 26.0

40 1.00 74.0 59.0 40.0 30.0

500

=

30.3 acres covered then;

16.5

3 lbs. (gal.) x 30.3 = 90 lbs. (gal.) per tankful

To determine GPA at other nominal speed.

Tractor Multiply by

Speed Speed Factor

4 mph 1.25

5 mph 1.00

6 mph .83

7.5 mph .67

10 mph .50

To determine GPA for solutions other than water, determine the weight per gallon or specific gravity and use the

following conversion table.

Weight per

Gallon

7.0 lbs. .84 1.09

8.0 lbs. .96 1.02

8.34 lbs. (water) 1.00 1.00

9.0 lbs. 1.08 .96

10.0 lbs. 1.20 .91

11.0 lbs. 1.32 .87

12.0 lbs. 1.44 .83

Page 13

Specific

Gravity

Multiply

By

Page 16

SPRAYER CHECK LIST

Down time in the field caused by breakdowns is costly and time consuming. Many

breakdowns can be eliminated by periodic equipment maintenance. By spending time running over this checklist before seasonal spraying application time and following proper after season care, you can save time and money later on.

SAFETY FIRST

Keep hands, feet, and loose clothing away from rotating parts.

Wear the protective clothing recommended by your chemical

and fertilizer manufacturer when working with chemicals.

Be sure rear safety stand is lowered before unhooking sprayer

from tractor, if the sprayer is equipped with this stand.

CHECK Before Going To The Field:

1. NOZZLES

Check the tip for excessive wear by checking for

grooves in or near the tip opening.

2. HOSES

Check all hoses for worn or soft spots. Be sure all

hose clamps are tightened. Be sure no hoses are

kinked or pinched. Check for leakage in any of the

lines.

3. BOOM HINGES

Clean the hinges and grease to help the breaking

action of the boom.

4. REPLACEMENT PARTS

Replace all worn or damaged parts.

NOTE: Dethmers Manufacturing Company does not

and will not make any recommendations concerning

the application of various chemicals or solutions.

These recommendations relate to either amount or

procedure of materials applied. If you have any questions regarding the application of certain chemicals

or solutions, contact your chemical supplier and follow chemical manufacturer recommendations.

After Season Care

NOTE: It is important that when cleaning the sprayer

one wears proper safety equipment. See your chemical or fertilizer package for this information.

1. After spraying chemicals, run water mixed with

ammonia through the tank, pump, and all hose

hookups. If wettable powder dries out in the system, it is very difficult to put back into suspension

and can cause malfunction, damage or injury.

2. Disassemble the tips and rinse with water or cleaning solution. (Appropriate for chemical sprayed).

3. Clean the tip opening with a wooden toothpick.

Never use wire or a hard object that could distort

the opening.

4. Water rinse and dry the tips before storing.

5. Be sure to dispose of all unused chemicals or solutions in a proper and ecologically sound manner.

DETHMERS MFG. COMPANY

P.O. BOX 189

4010 320 th St., BOYDEN, IA. 51234

PH: (712) 725-2311 or (712) 725-2302

FAX: (712) 725-2380

TOLL FREE: 1-800-54DEMCO (1-800-543-3626)

Loading...

Loading...