Page 1

^1 HARDWARE REFERENCE MANUAL

^2 Turbo PMAC2 PCI

^3 Programmable Multi-Axis Controller

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^4 4xx-603367-xHxx

^5 May 26, 2004

Page 2

Copyright Information

© 2003 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained

in this manual may be updated from time-to-time due to product improvements, etc., and may not

conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain

static sensitive components that can be damaged by incorrect handling. When installing or

handling Delta Tau Data Systems, Inc. products, avoid contact with highly insulated materials.

Only qualified personnel should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial

environment, install them into an industrial electrical cabinet or industrial PC to protect them

from excessive or corrosive moisture, abnormal ambient temperatures, and conductive materials.

If Delta Tau Data Systems, Inc. products are exposed to hazardous or conductive materials and/or

environments, we cannot guarantee their operation.

Page 3

Turbo PMAC2 PCI Hardware Reference Manual

Table of Contents

INTRODUCTION.......................................................................................................................................................1

Board Configuration.................................................................................................................................................1

Base Version ........................................................................................................................................................1

Option 1: Additional Four Channels Axis Interface Circuitry............................................................................1

Option 2: Dual-Ported RAM...............................................................................................................................1

Option 5: CPU and Memory Configurations......................................................................................................2

Option 7: Plate Mounting ...................................................................................................................................2

Option 8: High-Accuracy Clock Crystal.............................................................................................................3

Option 9: Serial Port Configuration...................................................................................................................3

Option 10: Firmware Version Specification.......................................................................................................3

Option 12: Analog-to-Digital Converters...........................................................................................................3

Option 16: Battery-Backed Parameter Memory.................................................................................................3

Option 18: Identification Number and Real Time Clock/Calendar Module .......................................................3

HARDWARE SETUP.................................................................................................................................................5

Piggyback Turbo CPU Board Jumper Configuration...............................................................................................5

Watchdog Timer Jumper......................................................................................................................................5

Dual-Ported RAM Source Jumper.......................................................................................................................5

Power-Up State Jumpers......................................................................................................................................5

Firmware Load Jumper........................................................................................................................................5

Base Board Jumper Configuration............................................................................................................................5

Servo and Phase Clock Direction Control...........................................................................................................5

Re-Initialization Jumper.......................................................................................................................................6

Encoder Sample Clock Source Jumpers...............................................................................................................6

Serial Port Selection Jumper................................................................................................................................6

Output Disable State Jumpers..............................................................................................................................6

Resistor Pack Configuration.....................................................................................................................................6

Termination Resistors ..........................................................................................................................................6

Pull-Up/Pull-Down Resistors...............................................................................................................................7

Connections..............................................................................................................................................................7

Mounting..............................................................................................................................................................7

Power Supply Connection....................................................................................................................................8

Machine Port Connections...................................................................................................................................8

Display Port.........................................................................................................................................................8

Multiplexer Port...................................................................................................................................................8

I/O Port................................................................................................................................................................8

Serial Ports ..........................................................................................................................................................9

A/D-Converter Port..............................................................................................................................................9

Handwheel Port ...................................................................................................................................................9

COMMUNICATIONS SETUP................................................................................................................................11

CPU BOARD E-POINT DESCRIPTIONS.............................................................................................................13

E1: Watchdog Disable Jumper ...............................................................................................................................13

E2: DPRAM Location Configure ...........................................................................................................................13

E4 – E6: Power-Up/Reset Load Source..................................................................................................................13

E7: Firmware Reload Enable..................................................................................................... .............................13

BASE BOARD JUMPER DESCRIPTIONS...........................................................................................................15

E1: Servo and Phase Clock Direction Control.......................................................................................................15

E2: CPU Frequency Select ....................................................................................................................................15

E3: Normal/Re-Initializing Power-Up/Reset.........................................................................................................15

E4: CPU Frequency Select .....................................................................................................................................15

E5 – E6: (Reserved for Future Use).......................................................................................................................15

E13 - E14: Encoder Sample Clock Direction Control...........................................................................................16

Table of Contents i

Page 4

Turbo PMAC2 PCI Hardware Reference Manual

E17 - E18: Serial Port Type Selection...................................................................................................................16

E111-118: Command Output Disable State...........................................................................................................17

MATING CONNECTORS.......................................................................................................................................19

CPU Board Connectors...........................................................................................................................................19

J2 (JEXP)/Expansion.........................................................................................................................................19

J8 (JAUX232)/Auxiliary RS232 .........................................................................................................................19

Base Board Connectors...........................................................................................................................................19

J1 (JANA)/Analog (Option 12)...........................................................................................................................19

J2 (JTHW)/Multiplexer Port ..............................................................................................................................19

J3 (JIO)/Digital I/O............................................................................................................................................19

J5 (JRS232)/RS-232 Serial Communications.....................................................................................................19

J5A (JRS422)/RS-422 Serial Communications ..................................................................................................19

J6 (JDISP)/Display............................................................................................................................................19

J7 (JHW)/Auxiliary Channel..............................................................................................................................19

J8 (JEQU)/Position Compare............................................................................................................................20

J9 (JMACH1)/Machine Port 1...........................................................................................................................20

J10 (JMACH2)/Machine Port 2.........................................................................................................................20

J11 (JMACH3)/Machine Port 3.........................................................................................................................20

J12 (JMACH4)/Machine Port 4.........................................................................................................................20

CPU BOARD CONNECTOR PINOUTS................................................................................................................21

J8 (JAUX232)/Auxiliary Serial Port.......................................................................................................................21

BASEBOARD CONNECTOR PINOUTS...............................................................................................................23

J1 (JANA) Analog Input Port Connector................................................................................................................23

J2 (JTHW) Multiplexer Port Connector..................................................................................................................24

J3 (JI/O) General Input/Output Connector..............................................................................................................24

J5 (JRS232) Serial Port Connector.........................................................................................................................25

J5A: RS422 Serial Port Connector .........................................................................................................................26

J6 (JDISP) Display Connector................................................................................................................................26

J7 (JHW) Handwheel Encoder Connector..............................................................................................................27

J8 (JEQU) Position Compare Output Connector....................................................................................................27

J9 (JMACH1) Connector Description ....................................................................................................................28

J10 (JMACH2) Connector Description ..................................................................................................................31

J11 (JMACH3)........................................................................................................................................................34

J12 (JMACH4)........................................................................................................................................................37

TB1 (2/4-Pin Terminal Block)................................................................................................................................40

TB2 (3-Pin Terminal Block)................................................................................................................................... 40

BASE BOARD JUMPERS LAYOUT......................................................................................................................41

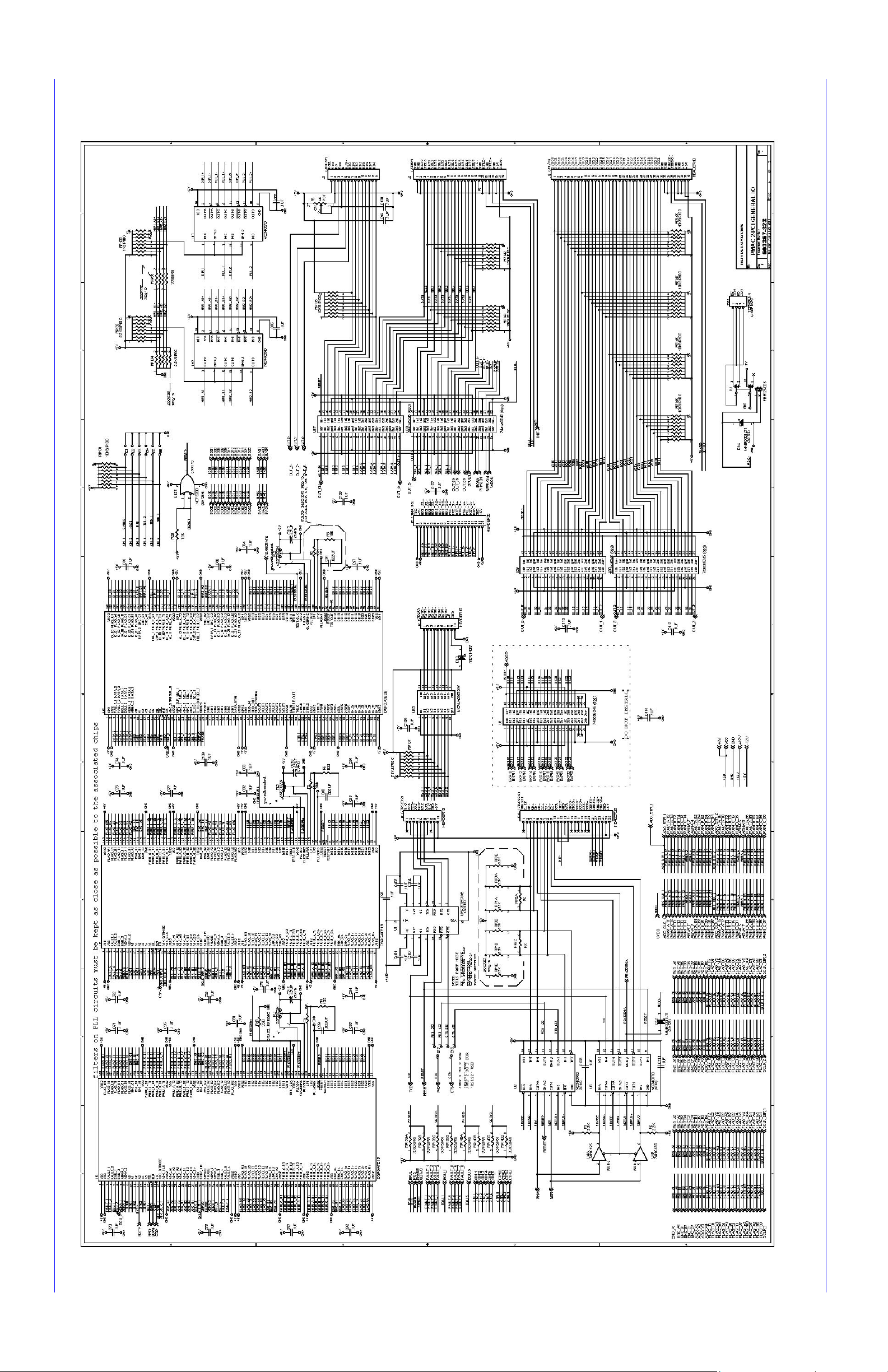

SCHEMATICS..........................................................................................................................................................43

ii Table of Contents

Page 5

Turbo PMAC2 PCI Hardware Reference Manual

INTRODUCTION

The Turbo PMAC2 PCI (part number 400-603367-TRx) is a member of the Turbo PMAC family of

boards optimized for interface to sinewave or direct-PWM servo drives and to pulse-and-direction stepper

drives. Its software is capable of 32 axes of control. It can have up to eight channels of on-board axis

interface circuitry. It can also support up to 32 channels of off-board axis interface circuitry through its

expansion port, connected to Acc-24P or Acc-24P2 ISA-format boards (Acc-24 boards in PCI format are

not yet available).

The Turbo PMAC2 PCI is a full-sized PCI-bus expansion card, with a small piggyback board containing

the CPU board. This piggyback board occupies part of the next slot, but ½-sized boards are permitted in

this next slot. While the Turbo PMAC2 PCI is capable of PCI bus communications, with or without the

optional on-board dual-ported RAM, it does not need to be inserted into a PCI expansion slot.

Communications can be done through the standard RS-232/RS-422 serial port; standalone operation is

possible.

Board Configuration

Base Version

The base version of the Turbo PMAC2 PCI provides a 1-1/2-slot board with:

• 80 MHz DSP56303 CPU (120 MHz PMAC equivalent)

• 128k x 24 SRAM compiled/assembled program memory (5C0)

• 128k x 24 SRAM user data memory (5C0)

• 1M x 8 flash memory for user backup and firmware (5C0)

• Latest released firmware version

• RS-232 serial interface, PCI (PC) bus interface

• One 16-node MACRO interface IC

• Four channels axis interface circuitry, each including:

• Three output command signal sets, configurable as either:

Two serial data streams to external DACs, one pulse-and-direction

Three PWM top-and-bottom pairs

• 3-channel differential/single-ended encoder input

• Nine input flags, two output flags

• Interface to two external serial ADCs, 8 to 18 bits

Two channels supplemental interface circuitry, each including:

•

• 2-channel differential/single-ended encoder input

• One output command signal set, configurable as pulse-&-direction or PWM top-and-bottom pair

• Display, MACRO, muxed I/O, direct I/O interface ports

• PID/notch/feedforward servo algorithms

• Extended pole-placement servo algorithms

• 1-year warranty from date of shipment

• One manual per set of one to four PMACs in shipment (Cables, mounting plates, mating connectors

not included)

Option 1: Additional Four Channels Axis Interface Circuitry

Option 1 provides an additional four channels of on-board axis interface circuitry, identical to the standard

first four channels. The key components are the DSPGATE1 IC at U7 and connectors J11 and J12.

Option 2: Dual-Ported RAM

Dual-ported RAM provides a high-speed communications path for bus communications with the host

computer through a bank of shared memory. DPRAM is advised if more than about 100 data items per

second are to be passed between the controller and the host computer in either direction.

Option 2 provides a 32k x 16 bank of dual-ported RAM. The key component on the board is U92.

Introduction 1

Page 6

Turbo PMAC2 PCI Hardware Reference Manual

Option 5: CPU and Memory Configurations

The various versions of Option 5 provide different CPU speeds and main memory sizes on the piggyback

CPU board. Only one Option 5xx may be selected for the board.

The CPU is a DSP5630x IC as component U1. It is currently available only as an 80 MHz device (with

computational power equivalent to a 120 MHz non-Turbo PMAC), but higher speed versions will be

available shortly.

The compiled/assembled-program memory SRAM ICs are located in U14, U15, and U16. These ICs

form the active memory for the firmware, compiled PLCs, and user-written phase/servo algorithms.

These can be 128k x 8 ICs (for a 128k x 24 bank), fitting in the smaller footprint, or they can be the larger

512k x 8 ICs (for a 512k x 24 bank), fitting in the full footprint.

The user-data memory SRAM ICs are located in U11, U12, and U13. These ICs form the active memory

for user motion programs, uncompiled PLC programs, and user tables and buffers. These can be 128k x 8

ICs (for a 128k x 24 bank), fitting in the smaller footprint, or they can be the larger 512k x 8 ICs (for a

512k x 24 bank), fitting in the full footprint.

The flash memory IC is located in U10. This IC forms the non-volatile memory for the board’s firmware,

the user setup variables, and for user programs, tables, and buffers. It can be 1M x 8, 2M x 8, or 4M x 8

in capacity.

Option 4C provides an 80 MHz DSP56309 CPU with expanded internal memory to improve

•

performance for large number of commutated axes.

• Option 5C0 is the standard CPU and memory configuration. It is provided automatically if no Option

5xx is specified. It provides an 80 MHz CPU (120 MHz PMAC equivalent), 128k x24 of

compiled/assembled program memory, 128k x 24 of user data memory; and a 1M x 8 flash memory.

• Option 5C1 provides an 80 MHz CPU (120 MHz PMAC equivalent), 128k x 24 of

compiled/assembled program memory, an expanded 512k x 24 of user data memory, and a 2M x 8

flash memor y.

• Option 5C2 provides an 80 MHz CPU (120 MHz PMAC equivalent), an expanded 512k x 24 of

compiled/assembled program memory, 128k x 24 of user data memory, and a 2M x 8 flash memory.

• Option 5C3 provides an 80 MHz CPU (120 MHz PMAC equivalent), an expanded 512k x 24 of

compiled/assembled program memory, an expanded 512k x 24 of user data memory, and a 4M x 8

flash memor y.

• Option 5D0 provides a 100 MHz CPU (120 MHz PMAC equivalent), 128k x24 of

compiled/assembled program memory, 128k x 24 of user data memory; and a 1M x 8 flash memory.

It is not compatible with Option-4C.

• Option 5D1 provides a 100 MHz CPU (120 MHz PMAC equivalent), 128k x 24 of

compiled/assembled program memory, an expanded 512k x 24 of user data memory, and a 2M x 8

flash memory. Check with the factory for availability.

• Option 5D2 provides a 100 MHz CPU (120 MHz PMAC equivalent), an expanded 512k x 24 of

compiled/assembled program memory, 128k x 24 of user data memory, and a 2M x 8 flash memory.

Check with the factory for availability.

• Option 5D3 provides a 100 MHz CPU (120 MHz PMAC equivalent), an expanded 512k x 24 of

compiled/assembled program memory, an expanded 512k x 24 of user data memory, and a 4M x 8

flash memory. Check with the factory for availability.

Option 7: Plate Mounting

Option 7 provides a mounting plate connected to the Turbo PMAC2 PCI with standoffs. It is used to

install the Turbo PMAC2 PCI in standalone applications.

2 Introduction

Page 7

Turbo PMAC2 PCI Hardware Reference Manual

Option 8: High-Accuracy Clock Crystal

The Turbo PMAC2 PCI has a clock crystal (component Y1) of nominal frequency 19.6608 MHz (~20

MHz). The standard crystal’s accuracy specification is +/-100 ppm.

• Option 8A provides a nominal 19.6608 MHz crystal with a +/-15 ppm accuracy specification.

Option 9: Serial Port Configuration

The Turbo PMAC2 PCI comes standard with a single serial port that can use either RS-232 or RS-422

transceivers. Optionally, a second independent serial port can be added.

Option 9T adds an auxiliary RS-232 port on the CPU piggyback board. The key components added

•

are IC U22 and connector J8 on the CPU board.

Option 10: Firmware Version Specification

Normally the Turbo PMAC2 PCI is provided with the newest released firmware version. A label on the

U10 flash memory IC on the CPU board shows the firmware version loaded at the factory.

• Option 10 provides for a user-specified firmware version.

Option 12: Analog-to-Digital Converters

Option 12 permits the installation of 8 or 16 channels of on-board multiplexed analog-to-digital

converters. One or two of these converters are read every phase interrupt. The analog inputs are not

optically isolated, and each can have a 0 – 5V input range, or a +/-2.5V input range, individually

selectable.

• Option 12 provides an 8-channel 12-bit A/D converter. The key components on the board are U28

and connector J1.

• Option 12A provides an additional 8-channel 12-bit A/D converter. The key component on the board

is U29.

Option 16: Battery-Backed Parameter Memory

The contents of the standard memory are not retained through a power-down or reset unless they have

been saved to flash memory first. Option 16 provides supplemental battery-backed RAM for real-time

parameter storage that is ideal for holding machine state parameters in case of an unexpected powerdown.

The battery is located at component BT1.

• Option 16A provides a 32k x 24 bank of battery-backed parameter RAM in components U17, U18,

and U19 on the CPU board, fitting in the smaller footprint for those locations.

• Option 16B provides a 128k x 24 bank of battery-backed parameter RAM in components U17, U18,

and U19 on the CPU board, filling the full footprint for those locations.

Option 18: Identification Number and Real Time Clock/Calendar Module

Option 18 provides a module at location U5 on the CPU board that contains an electronic identification

number, and possibly a real-time clock/calendar.

• Option 18A provides an electronic identification number module.

• Option 18B provides an electronic identification number module with a real-time clock and calendar.

The year representation in the calendar is a 4-digit value, so there are no Year 2000 problems.

Introduction 3

Page 8

Turbo PMAC2 PCI Hardware Reference Manual

4 Introduction

Page 9

Turbo PMAC2 PCI Hardware Reference Manual

HARDWARE SETUP

Piggyback Turbo CPU Board Jumper Configuration

Watchdog Timer Jumper

Jumper E1 on the Turbo CPU board must be OFF for the watchdog timer to operate. This is a very

important safety feature, so it is vital that this jumper be OFF in normal operation. E1 should only be put

ON to debug problems with the watchdog timer circuit.

Dual-Ported RAM Source Jumper

On Turbo CPU boards with revision suffixes – 10A and newer, jumper E2 must connect pins 1 and 2 to

access dual-ported RAM (addresses $06xxxx) from the baseboard. If using the Option 2 DPRAM on the

baseboard, jumper E2 must be in this setting.

Jumper E2 must connect pins 2 and 3 to access dual-ported RAM (addresses $06xxxx) through the JEXP

expansion port. If using the DPRAM on an external accessory board, jumper E2 must be in this setting.

On Turbo CPU boards with revision suffixes – 109 and older, there is no jumper for this purpose, and the

boards can access DPRAM from either source, but with less robust buffering.

Power-Up State Jumpers

Jumper E4 on the Turbo CPU board must be OFF, jumper E5 must be ON, and jumper E6 must be ON in

order for the CPU to copy the firmware from flash memory into active RAM on power-up/reset. This is

necessary for normal operation of the card. (Other settings are for factory use only.)

Firmware Load Jumper

If jumper E7 on the CPU board is ON during power-up/reset, the board comes up in bootstrap mode,

which permits the loading of new firmware into the flash-memory IC on the board. When the PMAC

Executive program tries to establish communications with a board in this mode, it will detect that the

board is in bootstrap mode automatically and ask what file to download as the new firmware.

Jumper E7 must be OFF during power-up/reset for the board to come up in normal operational mode.

Base Board Jumper Configuration

Servo and Phase Clock Direction Control

Jumper E1 should be OFF if the board is to use its own internally generated phase and servo clock

signals. In this case, these signals are output on spare pins on the J5A RS-422 serial-port connector,

where they can be used by other PMAC controllers set up to take external phase and servo clock signals.

Jumper E1 should be ON if the board is to use externally generated phase and servo clock signals brought

in on the J5A RS-422 serial port connector. In this case, the clock signals are generated by another

PMAC controller and output on its serial port connector. Commonly, serial communications are also

shared over a multi-drop RS-422 cable, with software addressing of the cards matching the I0 serial card

number for each controller. Alternately, the phase and servo clock signals can come from clock signals

involved in the process.

If E1 is ON for external phase and clock signals, and these clock signals are not brought in on the serial

port connector, the watchdog timer will trip almost immediately and shut down the board.

In order to change the state of the card between use of internal clock and use of external clock, the card

must be re-initialized – either powered up with jumper E3 ON, or given the $$$*** command – with

jumper E1 in the new state. Before the card is reset again, a SAVE command must be issued to store the

new internal settings.

Hardware Setup 5

Page 10

Turbo PMAC2 PCI Hardware Reference Manual

Re-Initialization Jumper

If E3 is OFF during power-up/reset, the controller will load its last saved set-up parameters from flash

memory into active memory. T his is the setting for normal operation. If E3 is ON during power-up/reset,

the controller will load its factory-default set-up parameters from firmware into active memory.

Generally this is only done if communications cannot be established with the card when in comes up in

normal operational mode.

Encoder Sample Clock Source Jumpers

Jumpers E13 and E14 control the source of the SCLK encoder-sampling clock for each servo IC. The

default setting of no jumper installed means that the SCLK signal comes from the servo IC and is output

on the JMACH connectors. This setting is suitable for all but a few very special applications.

Serial Port Selection Jumper

Jumpers E17 and E18 control which serial-port connector is used. If E17 and E18 connect their pins 1 and

2, the 10-pin RS-232 port connector J5 is used. If E17 and E18 connect their pins 2 and 3, the 26-pin RS422 port connector J5A is used. The RS-422 port must be used if several cards are to be daisy chained

together on a single multi-drop cable.

Output Disable State Jumpers

Jumpers E111 through E118 control the hardware state of the digital command output signals for each

channel when the amplifier enable signal for that channel is in the disable state (false). Jumper E11n (n =

1 to 8) controls the output signals for Channel n on the board.

If E11n is OFF (default), the command output signals for Channel n are still active when the amplifier

enable signal is in the disable state. The Turbo PMAC software should be commanding a net zero

command to be output on these signals and the amplifier-enable signal should be used by the amplifier so

that no command output will cause action if it is receiving a disable signal. This OFF setting should be

definitely be used when DAC output format is selected for the channel.

If E11n is ON, the command output signals for Channel n are tri-stated when the amplifier-enable signal

is in the disable state. Typically, this setting is only used with direct-PWM power-block amplifiers that

do not use amplifier enable to gate the PWM signals and in which the zero-command format of 50% top

on-time, and 50% bottom on-time cannot be tolerated in the disable state.

Resistor Pack Configuration

Termination Resistors

The PMAC2 PCI provides sockets for termination resistors on differential input pairs coming into the

board. As shipped, there are no resistor packs in these sockets. If these signals are brought long distances

into the PMAC2 PCI board and ringing at signal transitions is a problem, SIP resistor packs may be

mounted in these sockets to reduce or eliminate the ringing.

All termination resistor packs are the type that has independent resistors (no common connection) with

each resistor using two adjacent pins. The following table shows which packs are used to terminate each

input device:

Input Pack Pack Size Input Pack Pack Size

Encoder 1 RP46 6-pin ADC 1 and 2 RP60 8-pin

Encoder 2 RP50 6-pin ADC 3 and 4 RP61 8-pin

Encoder 3 RP47 6-pin ADC 5 and 6 RP121 8-pin

Encoder 4 RP51 6-pin ADC 7 and 8 RP122 8-pin

Encoder 5 RP107 6-pin Fault 1 and 2 RP63 6-pin

Encoder 6 RP111 6-pin Fault 3 and 4 RP64 6-pin

Encoder 7 RP108 6-pin Fault 5 and 6 RP124 6-pin

Encoder 8 RP112 6-pin Fault 7 and 8 RP125 6-pin

SCLK12 and 34 RP52 6-pin SCLK56 and 78 RP113 6-pin

6 Hardware Setup

Page 11

Turbo PMAC2 PCI Hardware Reference Manual

Pull-Up/Pull-Down Resistors

The differential input signal pairs to the PMAC2 PCI have user-configurable pull-up/pull-down resistor

networks to permit the acceptance of either single-ended or differential signals in one setting, or the

detection of lost differential signals in another setting.

The ‘+’ inputs of each differential pair each have a hard-wired 1 kohm pull-up resistor to +5V. This

cannot be changed.

The ‘-‘ inputs of each differential pair each have a hard-wired 2.2 kohm resistor to +5V; each also has

another 2.2 kohm resistor as part of a socketed resistor pack that can be configured as a pull-up resistor to

+5V, or a pull-down resistor to GND.

If this socketed resistor is configured as a pull-down resistor (the default configuration), the combination

of pull-up and pull-down resistors on this line acts as a voltage divider, holding the line at +2.5V in the

absence of an external signal. This configuration is required for single-ended inputs using the ‘+’ lines

alone; it is desirable for unconnected inputs to prevent the pick-up of spurious noise; it is permissible for

differential line-driver inputs.

If this socketed resistor is configured as a pull-up resistor (by reversing the SIP pack in the socket),

thetwo parallel 2.2 kohm resistors act as a single 1.1 kohm pull-up resistor, holding the line at +5V in the

absence of an external signal. This configuration is required if encoder-loss detection is desired; it is

required if complementary open-collector drivers are used; it is permissible for differential line-driver

inputs even without encoder loss detection.

If Pin 1 of the resistor pack, marked by a dot on the pack, matches Pin 1 of the socket, marked by a wide

white line on the front side of the board, and a square solder pin on the back side of the board, then the

pack is configured as a bank of pull-down resistors. If the pack is reversed in the socket, it is configured

as a bank of pull-up resistors.

The following table lists the pull-up/pull-down resistor pack for each input device:

Device Resistor Pack

Encoder 1 RP43 ADC/Fault1&2 RP58

Encoder 2 RP48 ADC/Fault3&4 RP59

Encoder 3 RP44 ADC/Fault5&6 RP119

Encoder 4 RP49 ADC/Fault7&8 RP120

Encoder 5 RP104 SCLK12&34 RP62

Encoder 6 RP109 SCLK56&78 RP123

Encoder 7 RP105

Encoder 8 RP110

Device Resistor Pack

Connections

Mounting

The Turbo PMAC2 PCI can be mounted in one of two ways: in the PCI bus, or using standoffs.

• PCI bus: To mount in the PCI bus, simply insert the P1 card-edge connector into PCI socket. If there

is a standard PC-style housing, a bracket at the end of the PMAC2 PCI board can be used to screw

into the housing to hold the board down firmly.

• Standoffs: At each of the four corners of the PMAC2 PCI board, there are mounting holes that can be

used to mount the board on standoffs.

Hardware Setup 7

Page 12

Turbo PMAC2 PCI Hardware Reference Manual

Power Supply Connection

The standard PMAC2 PCI requires only 5V power: 3A in a 4-channel configuration, 4A in an 8-channel

configuration (with Option 1). If the Option 12 A/D converters are installed, a –12V supply is also

required. In this case, a +12V supply can be passed through the card and out to the analog devices feeding

the A/D converters.

The power can be provided in several ways:

• Bus connector: If the PMAC2 PCI is mounted in an electrically active PCI bus slot, it automatically

draws its 5V and +/-12V power from the bus.

• Terminal block: The TB1 2/4-point terminal block can be used to bring in 5V power, especially in

standalone applications. Point 1 is GND; Point 2 is +5V. Points 3 (+12V) and 4 (-12V) are needed

only if the Option 12 A/D converters are ordered.

• JMACH connectors: Up to 2A at 5V may be brought in through each 100-pin JMACH connector

from an Acc-8 board or its equivalent, provided the cable is 500 mm (20 in) or less in length.

Machine Port Connections

The Turbo PMAC2 PCI has a 100-pin high-density header for each pair of servo interface channels.

Through this connector pass all of the digital signals to and from the amplifier, encoder, and flags for the

two channels. Typically, this header is connected with a matching Delta Tau Acc-8 family 2-channel

breakout board or equivalent through a provided 100-pin flat cable.

The machine port connectors are:

• J9 (JMACH1) Board Channels 1 and 2

• J10 (JMACH2) Board Channels 3 and 4

• J11 (JMACH3) Board Channels 5 and 6 (Option 1 required)

• J12 (JMACH4) Board Channels 7 and 8 (Option 1 required)

Display Port

The J6 (JDISP) display port provides a 14-pin IDC header for connection to Delta Tau’s Acc-12 family of

displays. Flat cables are provided with each of the Acc-12 displays for direct connection between the

display and this port.

Multiplexer Port

The J2 (JTHW) multiplexer port provides eight TTL-compatible 5V CMOS inputs and eight TTLcompatible 5V CMOS outputs on a 26-pin IDC header. These can be used directly as general-purpose

digital I/O, or with PMAC2’s special M-variable support (TWB, TWD, TWR, and TWS formats) they

can be used to support hundreds, or even thousands of multiplexed I/O points on accessory boards.

Delta Tau provides the following accessory boards that can be connected to the multiplexer port. Each

comes with a flat cable for direct connection to the port.

• Acc-8D Option 7 Resolver-to-Digital Converter Board

• Acc-18 Thumbwheel Board

• Acc-34 family of Digital I/O boards

• Acc-35A and B Extender Board

I/O Port

The J3 (JIO) I/O port provides 32 TTL-compatible 5V CMOS I/O points on a 40-pin IDC header.

Direction is selectable by byte. These are intended for use as general-purpose digital I/O points.

8 Hardware Setup

Page 13

Turbo PMAC2 PCI Hardware Reference Manual

Serial Ports

The PMAC2 PCI has two serial-port connectors. Only one of these can be used in an application J5 is a

10-pin IDC header for RS-232 communications. It can be connected to a standard DB9 RS-232

connector on a host computer or terminal via a flat cable such as the Acc-3L. A commercially available

DB9-to-DB25 adapter can be added to such a flat cable if the host computer or terminal has a DB25 serial

connector. Jumpers E17 and E18 on the PMAC2 PCI must connect pins 1 and 2 to use this port.

J5A is 26-pin IDC header for RS-422 communications. It can be connected to a standard DB25 RS-422

connector on a host computer or terminal via a flat cable such as the Acc-3D. Jumpers E17 and E18 on

the PMAC2 PCI must connect pins 2 and 3 to use this port.

A/D-Converter Port

If the Option 12 A/D converters are ordered, the J1 (JANA) analog-input port is provided on the PMAC2

on a 20-pin IDC header. Option 12 provides eight analog inputs at 0 – 5V, or +/-2.5V levels. Option 12A

provides eight additional analog inputs at these levels. The +12V and –12V supplies can either be

brought in on this connector, or brought out on it for the external analog circuitry if they have been

brought in through TB1 or P1.

Handwheel Port

The J7 (JHW) handwheel port provides two limited supplemental channels, each with a 2-channel

encoder input, and a pulse-and-direction or PWM top-and-bottom pair output. All inputs and outputs are

digital 5V differential line-driver pairs.

Hardware Setup 9

Page 14

Turbo PMAC2 PCI Hardware Reference Manual

10 Hardware Setup

Page 15

Turbo PMAC2 PCI Hardware Reference Manual

p

COMMUNICATIONS SETUP

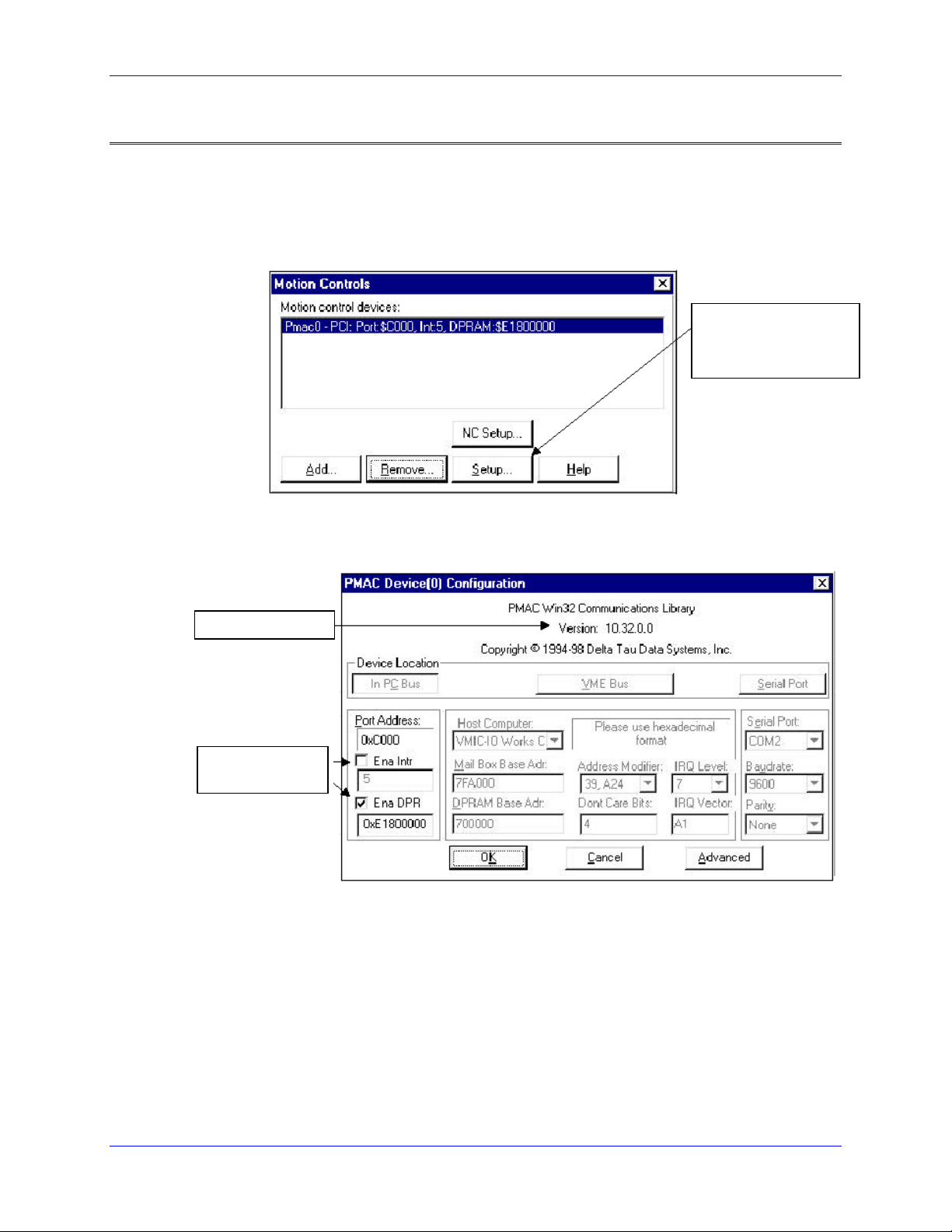

Delta Tau provides communication tools that take advantage of the PCI bus Plug and Play feature of 32bits Windows

Pewin 32 version 2.32 and newer, a PMAC2 PCI board plugged in a PCI bus slot will be recognized by

the operating system when the computer is boot up. The available PCI address, dual-ported RAM address

and Interrupt lines are set automatically by the operating system and can be checked (but not modified) in

the MOTIONEXE.EXE application.

The PMAC2 PCI board could have the optional on-board Dual Ported RAM circuitry, which is ordered

through Option 2. If the dual-ported RAM circuitry is not on-board, manually disable the automatically

assigned use through the setup page of MOTIONEXE:

©

based computers. Starting with MOTIONEXE.EXE version 10.32.00, which is included in

Open MOTIONEXE

and press Setup for

the PCI device

Disable

Interru

ts

The MOTIONEXE application will first look for PMAC PCI boards on the PCI bus and will sequentially

assign device numbers from Device0 to each PMAC PCI until all the PMAC PCI boards found have a

device number assigned. Then, manually add other devices for either ISA bus or Serial port

communications.

After each PMAC has a device number assigned to it, communications through the PCI bus are identical

to the ISA bus. Any application written for the ISA bus using the Delta Tau provided 32-bits

communication libraries will not require any further change and the process is transparent.

Communications Setup 11

Page 16

Turbo PMAC2 PCI Hardware Reference Manual

Note:

For example, if a Device0 for serial RS-232 communications was defined before a

PMAC PCI board was installed in the computer, its setup information will be

overwritten by the MOTIONEXE application when the PMAC2 PCI board is

found. Therefore, it is very important to take note of the all the devices and its

parameters defined in MOTIONEXE before installing a new PMAC board in the

computer.

12 Communications Setup

Page 17

Turbo PMAC2 PCI Hardware Reference Manual

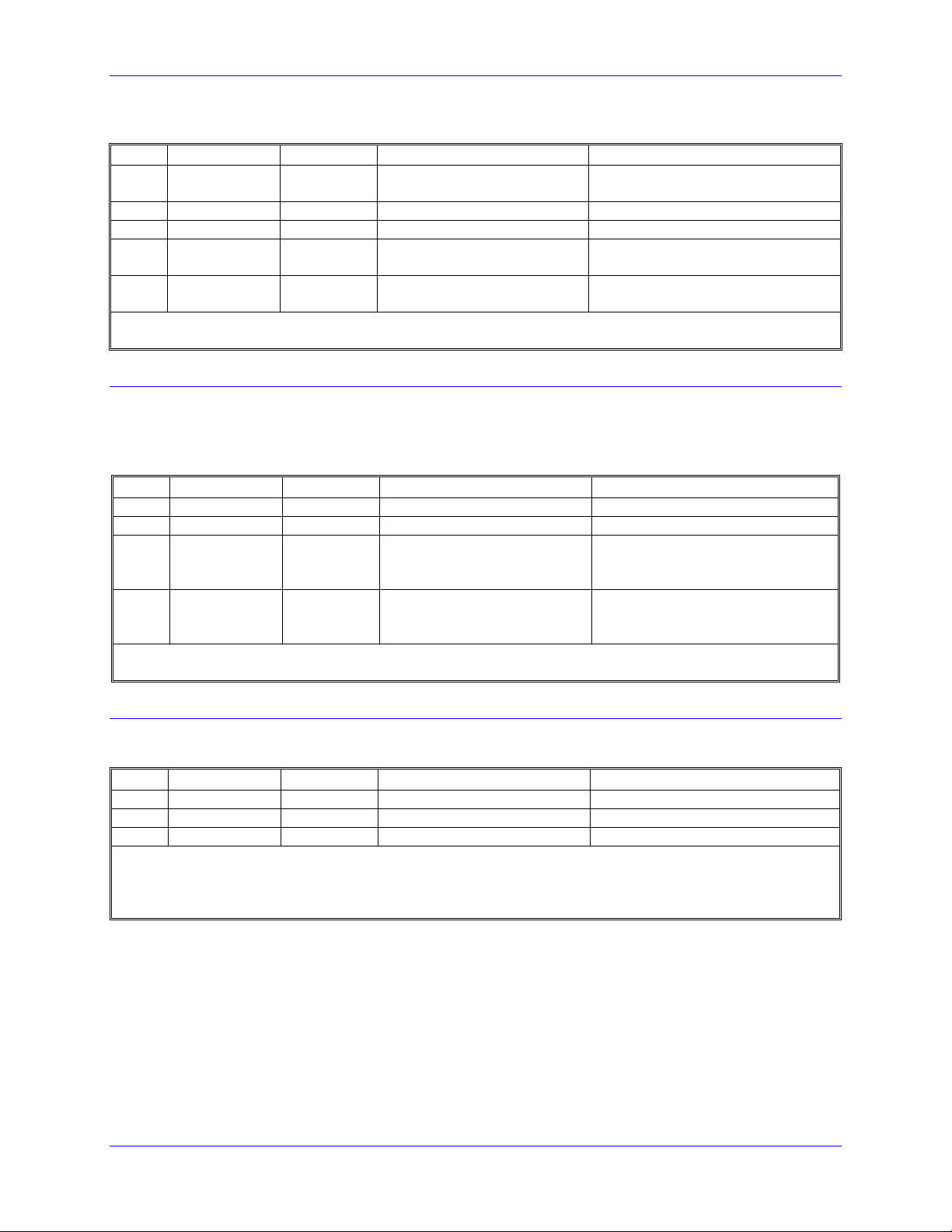

CPU BOARD E-POINT DESCRIPTIONS

E1: Watchdog Disable Jumper

E Point and

Description Default

Physical Layout

E1

Jump pin 1 to 2 to disable Watchdog timer (for test

purposes only).

Remove jumper to enable Watchdog timer.

No jumper installed

E2: DPRAM Location Configure

E Point and

Physical Layout

E2

Note: Jumper E2 is present on –108 and newer boards only. Older versions could access DPRAM from either

source without a jumper configuration, but with less robust buffering.

Description Default

Jump pin 1 to 2 to access the dual-ported RAM on

baseboard.

Jump pin 2 to 3 to access the dual-ported RAM through

JEXP expansion port.

Jumper connects pins 1 and

2

E4 – E6: Power-Up/Reset Load Source

E Point and

Physical Layout

E4

Description Default

Remove jumper E4;

Jump E5 pin 1 to 2;

Jump E6 pin 1 to 2;

To read flash IC on power-up/reset.

Other combinations are for factory use only; the board will

not operate in any other configuration

No E4 jumper installed;

E5 and E6 jump pin 1 to 2.

E6

E7: Firmware Reload Enable

E Point and

Physical Layout

E7

CPU Board E-Point Descriptions 13

Description Default

Jump pin 1 to 2 to reload firmware through serial or bus

port.

Remove jumper for normal operation.

No jumper installed

Page 18

Turbo PMAC2 PCI Hardware Reference Manual

14 CPU Board E-Point Descriptions

Page 19

Turbo PMAC2 PCI Hardware Reference Manual

BASE BOARD JUMPER DESCRIPTIONS

E1: Servo and Phase Clock Direction Control

E Point and

Location Description Default

Physical Layout

E1

Note: If the E1 jumper is ON and the servo and phase clocks are not brought in on the J5A serial port, the watchdog

timer will trip immediately.

C2 Remove jumper for PMAC2 PCI to use its internally

generated servo and phase clock signals and to output

these signals on the J5A serial port connector.

Jump pins 1 and 2 for PMAC2 PCI to expect to receive

its servo and phase clock signals on the J5A serial port

connector.

No jumper installed

E2: CPU Frequency Select

E Point and

Physical Layout

E2

Location Description Default

C2 Remove jumper for 40 MHz operation (E4 OFF also) or

for 80 MHz operation (E4 ON).

Jump pin 1 to 2 for 60 MHz operation (E4 OFF).

No jumper installed

(standard or Option

5C)

Jumper installed

(Option 5B)

E3: Normal/Re-Initializing Power-Up/Reset

E Point and

Physical Layout

E3

Location Description Default

C2 Jump pin 1 to 2 to re-initialize on power-up/reset,

loading factory default settings.

Remove jumper for normal power up/reset, loading

user-saved settings.

No jumper installed

E4: CPU Frequency Select

E Point and

Physical Layout

E4

Location Description Default

C2 Remove jumper for 40MHz operation (E2 OFF also) or

for 60MHz operation (E4 ON).

Jump pin 1 to 2 for 80MHz operation (E2 OFF).

No jumper installed

(standard or Option

5B)

Jumper installed

(Option 5C)

E5 – E6: (Reserved for Future Use)

Baseboard Jumper Descriptions 15

Page 20

Turbo PMAC2 PCI Hardware Reference Manual

E13 - E14: Encoder Sample Clock Direction Control

E Point and

Location Description Default

Physical Layout

E13

E14

Note: E14 is installed only if Option 1 has been ordered.

D1 Remove jumper to output SCLK generated in first ASIC

on SCLK_12 and SCLK_34, or to control direction by

software.

Jump pins 1 to 2 to input SCLK signal for first ASIC on

SCLK_34 and output this signal on SCLK_12.

Jump pins 2 to 3 to input SCLK signal for first ASIC on

SCLK_12 and output this signal on SCLK_34.

D2 Remove jumper to output SCLK generated in second

ASIC on SCLK_56 and SCLK_78, or to control

direction by software.

Jump pins 1 to 2 to input SCLK signal for second ASIC

on SCLK_78 and output this signal on SCLK_56.

Jump pins 2 to 3 to input SCLK signal for second ASIC

on SCLK_56 and output this signal on SCLK_78

E17 - E18: Serial Port Type Selection

E Point and

Physical Layout

E17

Location Description Default

C1 Connect pins 1 and 2 to use the RS-232 port on the J5

connector.

Connect pins 2 and 3 to use the RS-422 port on the J5A

connector.

No jumper installed

No jumper installed

Jumper installed in 1-2

position.

E18

Serial Port Choice: Because both RS-232 and RS-422 ports are always provided, jumpers must be set correctly to

use the port of your choice. Jumpers E17 and E18 must connect pins 1 and 2 to use the RS- 232 port on the J5

connector; they must connect pins 2 and 3 to use the RS-422 port on the J5A connector.

C1

Connect pins 1 and 2 to use the RS-232 port on the J5

connector.

Connect pins 2 and 3 to use the RS-422 port on the J5A

connector.

Jumper installed in 1-2

position.

16 Baseboard Jumper Descriptions

Page 21

Turbo PMAC2 PCI Hardware Reference Manual

E111-118: Command Output Disable State

E Point and

Physical Layout

Location Description Default

C1 Jump pin 1 to 2 of E11n for digital servo command

output signals of Channel n to tri-state when amplifier

enable signal for Channel n is in disable state.

Remove jumper for digital servo command output

signals of Channel n to remain active (but typically with

zero command value) when amplifier enable signal for

Channel n is in disable state.

No jumper installed

Baseboard Jumper Descriptions 17

Page 22

Turbo PMAC2 PCI Hardware Reference Manual

18 Baseboard Jumper Descriptions

Page 23

Turbo PMAC2 PCI Hardware Reference Manual

MATING CONNECTORS

CPU Board Connectors

J2 (JEXP)/Expansion

1. Two 50-pin female flat cable connector Delta Tau P/N 014-R00F50-0K0 T&B Ansley P/N 609-5041

2. 171-50 T&B Ansley standard flat cable stranded 50-wire

3. Phoenix varioface module type FLKM 50 (male pins) P/N 22 81 08 9

J8 (JAUX232)/Auxiliary RS232

1. Two 10-pin female flat cable connector Delta Tau P/N 014-ROOF10-0K0 T&B Ansley P/N 609-1041

2. 171-10 T&B Ansley standard flat cable stranded 10-wire

3. Phoenix varioface module type FLKM 10 (male pins) P/N 22 81 01 8

Base Board Connectors

J1 (JANA)/Analog (Option 12)

1. Two 14-pin female flat cable connector Delta Tau P/N 014-R00F14-0K0 T&B Ansley P/N 609-1441

2. 171-14 T&B Ansley standard flat cable stranded 14-wire

3. Phoenix varioface modules type FLKM14 (male pins) P/N 22 81 02 1

J2 (JTHW)/Multiplexer Port

1. Two 26-pin female flat cable connector Delta Tau P/N 014-R00F26-0K0 T&B Ansley P/N 609-2641

2. 171-26 T&B Ansley standard flat cable stranded 26-wire

3. Phoenix varioface module type FLKM 26 (male pins) P/N 22 81 05 0

J3 (JIO)/Digital I/O

1. Two 40-pin female flat cable connector Delta Tau P/N 014-R00F40-0K0 T&B Ansley P/N 609-4041

2. 171-40 T&B Ansley standard flat cable stranded 40-wire

3. Phoenix varioface module type FLKM 40 (male pins)

J5 (JRS232)/RS-232 Serial Communications

1. Two 10-pin female flat cable connector Delta Tau P/N 014-ROOF10-0K0 T&B Ansley P/N 609-1041

2. 171-10 T&B Ansley standard flat cable stranded 10-wire

3. Phoenix varioface module type FLKM 10 (male pins) P/N 22 81 01 8

J5A (JRS422)/RS-422 Serial Communications

1. Two 26-pin female flat cable connector Delta Tau P/N 014-R00F26-0K0 T&B Ansley P/N 609-2641

2. 171-26 T&B Ansley standard flat cable stranded 26-wire

3. Phoenix varioface module type FLKM 26 (male pins) P/N 22 81 05 0

J6 (JDISP)/Display

1. Two 14-pin female flat cable connector Delta Tau P/N 014-R00F14-0K0 T&B Ansley P/N 609-1441

2. 171-14 T&B Ansley standard flat cable stranded 14-wire

3. Phoenix varioface modules type FLKM14 (male pins) P/N 22 81 02 1

J7 (JHW)/Auxiliary Channel

1. Two 20-pin female flat cable connector Delta Tau P/N 014-R00F20-0K0 T&B Ansley P/N 609-2041

2. 171-20 T&B Ansley standard flat cable stranded 20-wire

3. Phoenix varioface modules type FLKM20 (male pins)

Mating Connectors 19

Page 24

Turbo PMAC2 PCI Hardware Reference Manual

J8 (JEQU)/Position Compare

1. Two 10-pin female flat cable connector Delta Tau P/N 014-ROOF10-0K0 T&B Ansley P/N 609-1041

2. 171-10 T&B Ansley standard flat cable stranded 10-wire

3. Phoenix varioface module type FLKM 10 (male pins) P/N 22 81 01 8

J9 (JMACH1)/Machine Port 1

1. Two 100-pin high-density box header with center key, 0.050” pitch, AMP P/N 1-04068-7, Delta Tau

P/N 014-00010-FPB

2. High-density flat cable stranded 100-wire

J10 (JMACH2)/Machine Port 2

1. Two 100-pin high-density box header with center key, 0.050” pitch, AMP P/N 1-04068-7, Delta Tau

P/N 014- 00010-FPB

2. High-density flat cable stranded 100-wire

J11 (JMACH3)/Machine Port 3

1. Two 100-pin high-density box header with center key, 0.050” pitch, AMP P/N 1-04068-7, Delta Tau

P/N 014-00010-FPB

2. High-density flat cable stranded 100-wire

J12 (JMACH4)/Machine Port 4

1. Two 100-pin high-density box header with center key, 0.050” pitch, AMP P/N 1-04068-7, Delta Tau

P/N 014-00010-FPB

2. High-density flat cable stranded 100-wire

20 Mating Connectors

Page 25

Turbo PMAC2 PCI Hardware Reference Manual

CPU BOARD CONNECTOR PINOUTS

J8 (JAUX232)/Auxiliary Serial Port

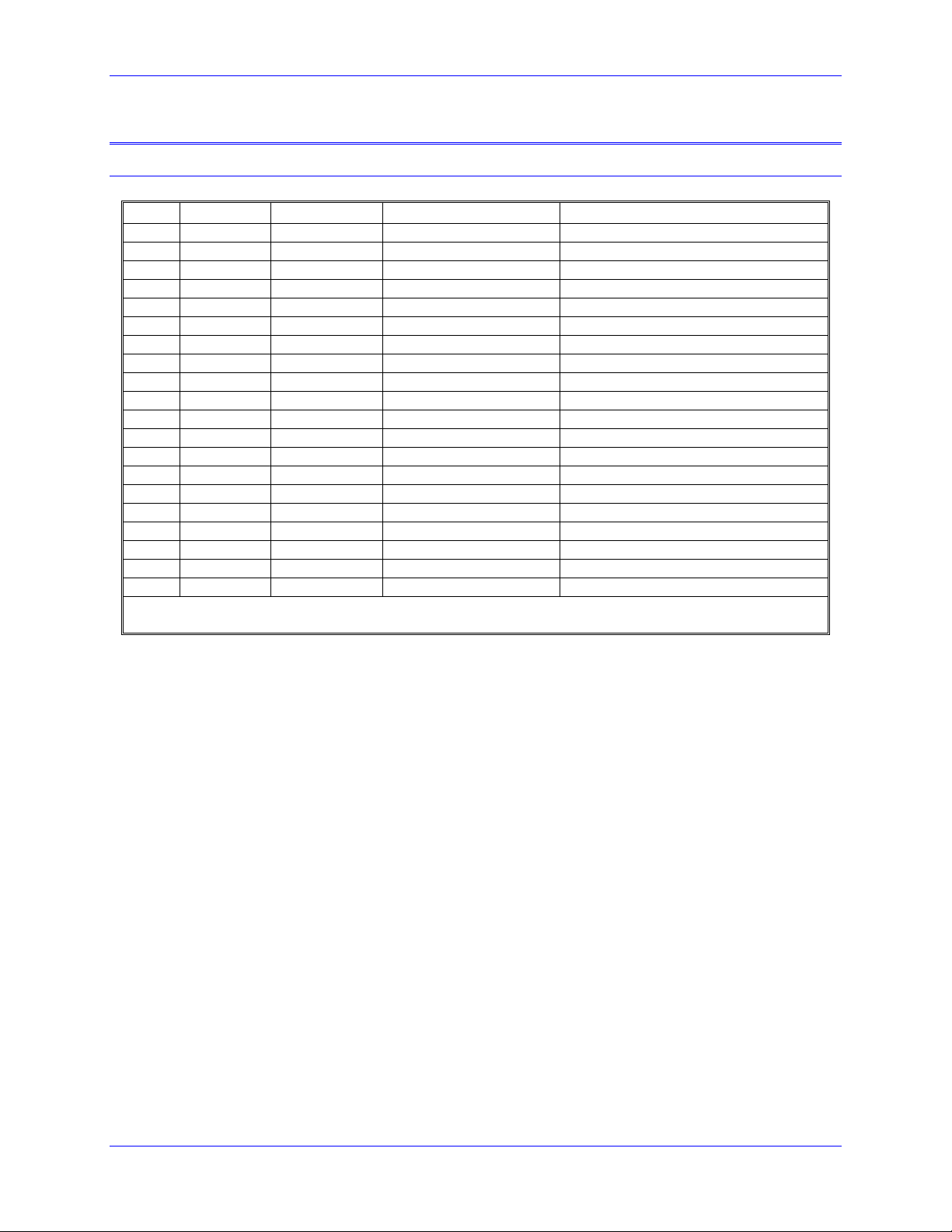

Pin # Symbol Function Description Notes

1

2 DTR Bidirectional Data terminal ready Tied to DRR

3 TXD/ Input Receive data Host transmit data

4 CTS Input Clear to Send Host ready bit

5 RXD/ Output Send data Host receive data

6 RTS Output Request to Send PMAC ready bit

7 DSR Bidirectional Data set ready Tied to DTR

8

9 GND Common PMAC common

10 +5V Output 10 +5Vdc supply Power supply out

The J8 connector on the Turbo CPU piggyback board, present if Option-9T has been ordered,

provides a second independent port for serial communications at RS-232 levels.

No connect

No connect

CPU Board Connector Pinouts 21

Page 26

Turbo PMAC2 PCI Hardware Reference Manual

22 CPU Board Connector Pinouts

Page 27

Turbo PMAC2 PCI Hardware Reference Manual

BASEBOARD CONNECTOR PINOUTS

J1 (JANA) Analog Input Port Connector

(Present only if Option 12 ordered)

Pin # Symbol Function Description Notes

1 ANAI00 Input Analog Input 0 0-5V or +/-2.5V range

2 ANAI01 Input Analog Input 1 0-5V or +/-2.5V range

3 ANAI02 Input Analog Input 2 0-5V or +/-2.5V range

4 ANAI03 Input Analog Input 3 0-5V or +/-2.5V range

5 ANAI04 Input Analog Input 4 0-5V or +/-2.5V range

6 ANAI05 Input Analog Input 5 0-5V or +/-2.5V range

7 ANAI06 Input Analog Input 6 0-5V or +/-2.5V range

8 ANAI07 Input Analog Input 7 0-5V or +/-2.5V range

9 ANAI08 Input Analog Input 8 0-5V or +/-2.5V range*

10 ANAI09 Input Analog Input 9 0-5V or +/-2.5V range*

11 ANAI10 Input Analog Input 10 0-5V or +/-2.5V range*

12 ANAI11 Input Analog Input 11 0-5V or +/-2.5V range*

13 ANAI12 Input Analog Input 12 0-5V or +/-2.5V range*

14 ANAI13 Input Analog Input 13 0-5V or +/-2.5V range*

15 ANAI14 Input Analog Input 14 0-5V or +/-2.5V range*

16 ANAI15 Input Analog Input 15 0-5V or +/-2.5V range*

17 GND Common PMAC common Not isolated from digital

18 +12V Output Positiv e supply voltage To power external circuitry

19 GND Common PMAC common Not isolated from digital

20 -12V Output Negative supply voltage To power external circuitry

The JANA connector provides the inputs for the 8 or 16 optional analog inputs on the PMAC2. * Only

present if Option-12A ordered

Baseboard Connector Pinouts 23

Page 28

Turbo PMAC2 PCI Hardware Reference Manual

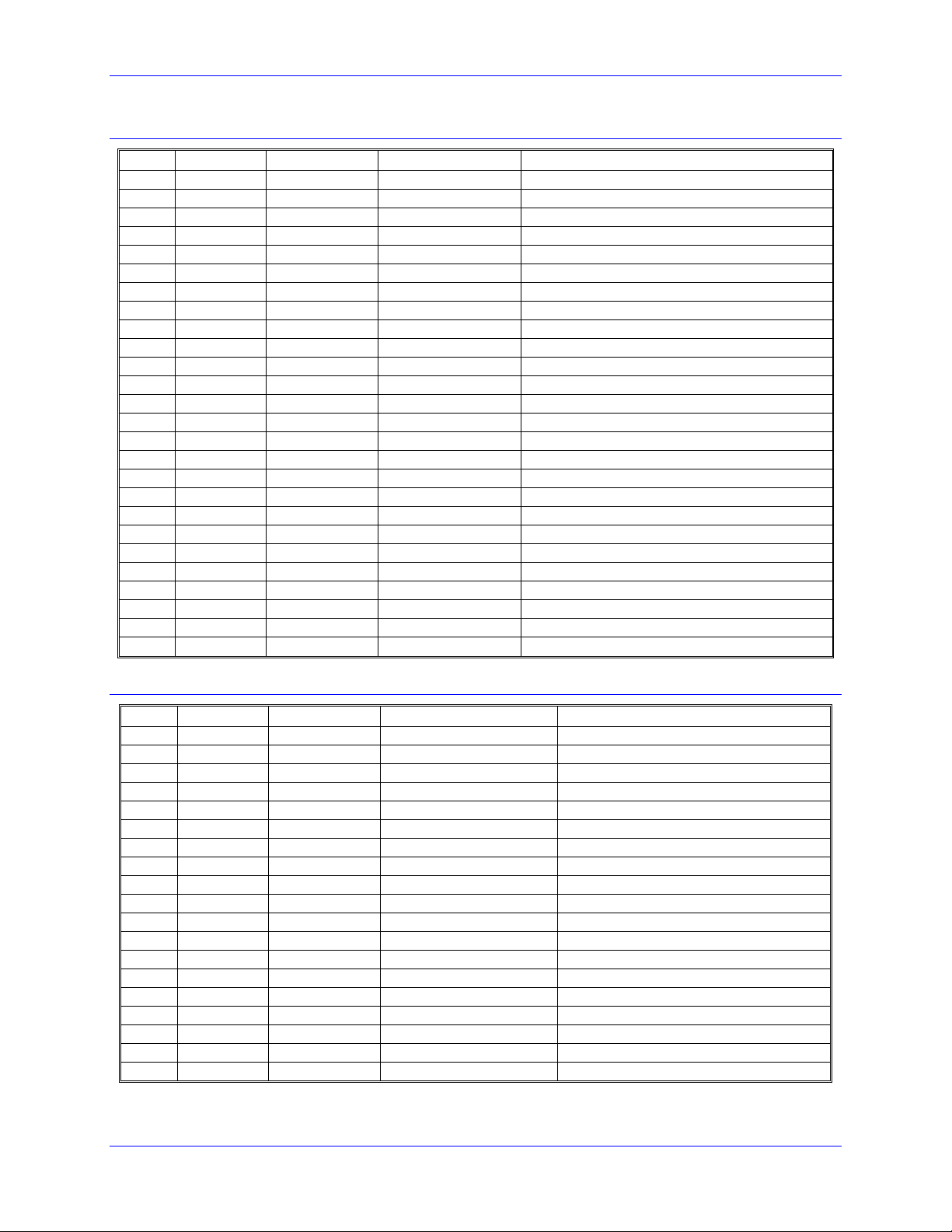

J2 (JTHW) Multiplexer Port Connector

Pin # Symbol Function Description Notes

1 GND Common PMAC common

2 GND Common PMAC common

3 DAT0 Input Data-0 input Data input from MUX port accessories

4 SEL0 Output Select-0 output Address/Data output for MUX port accessories

5 DAT1 Input Data-1 input Data input from MUX port accessories

6 SEL1 Output Select-1 output Address/Data output for MUX port accessories

7 DAT2 Input Data-2 input Data input from MUX port accessories

8 SEL2 Output Select-2 output Address/Data output for MUX port accessories

9 DAT3 Input Data-3 input Data input from MUX port accessories

10 SEL3 Output Select-3 output Address/Data output for MUX port accessories

11 DAT4 Input Data-4 input Data input from MUX port accessories

12 SEL4 Output Select-4 output Address/Data output for MUX port accessories

13 DAT5 Input Data-5 input Data input from MUX port accessories

14 SEL5 Output Select-5 output Address/Data output for MUX port accessories

15 DAT6 Input Data-6 input Data input from MUX port accessories

16 SEL6 Output Select-6 output Address/Data output for MUX port accessories

17 DAT7 Input Data-7 input Data input from MUX port accessories

18 SEL7 Output Select-7 output Address/Data output for MUX port accessories

19 NC NC NC

20 GND Common PMAC common

21 BRLD/ Output Buffer request Low is buffer required

22 GND Common PMAC common

23 IPLD/ Output In Position Low is in position

24 GND Common PMAC common

25 +5V Output +5Vdc supply Power supply out

26 INIT/ Input PMAC reset Low is reset

J3 (JI/O) General Input/Output Connector

Pin # Symbol Function Description Notes

1 I/O00 In/Out Digital I/O 0 Software direction control

2 I/O01 In/Out Digital I/O 1 Software direction control

3 I/O02 In/Out Digital I/O 2 Software direction control

4 I/O03 In/Out Digital I/O 3 Software direction control

5 I/O04 In/Out Digital I/O 4 Software direction control

6 I/O05 In/Out Digital I/O 5 Software direction control

7 I/O06 In/Out Digital I/O 6 Software direction control

8 I/O07 In/Out Digital I/O 7 Software direction control

9 I/O08 In/Out Digital I/O 8 Software direction control

10 I/O09 In/Out Digital I/O 9 Software direction control

11 I/O20 In/Out Digital I/O 10 Software direction control

12 I/O11 In/Out Digital I/O 11 Software direction control

13 I/O12 In/Out Digital I/O 12 Software direction control

14 I/O13 In/Out Digital I/O 13 Software direction control

15 I/O14 In/Out Digital I/O 14 Software direction control

16 I/O15 In/Out Digital I/O 15 Software direction control

17 I/O16 In/Out Digital I/O 16 Software direction control

18 I/O17 In/Out Digital I/O 17 Software direction control

19 I/O18 In/Out Digital I/O 18 Software direction control

24 Baseboard Connector Pinouts

Page 29

Turbo PMAC2 PCI Hardware Reference Manual

J3 (JI/O) General Input/Output Connector (Continued)

Pin # Symbol Function Description Notes

20 I/O19 In/Out Digital I/O 19 Software direction control

21 I/O20 In/Out Digital I/O 20 Software direction control

22 I/O21 In/Out Digital I/O 21 Software direction control

23 I/O22 In/Out Digital I/O 22 Software direction control

24 I/O23 In/Out Digital I/O 23 Software direction control

25 I/O24 In/Out Digital I/O 24 Software direction control

26 I/O25 In/Out Digital I/O 25 Software direction control

27 I/O26 In/Out Digital I/O 26 Software direction control

28 I/O27 In/Out Digital I/O 27 Software direction control

29 I/O28 In/Out Digital I/O 28 Software direction control

30 I/O29 In/Out Digital I/O 29 Software direction control

31 I/O30 In/Out Digital I/O 30 Software direction control

32 I/O31 In/Out Digital I/O 31 Software direction control

33 GND Common Reference voltage

34 GND Common Reference voltage

35 Phase/ Output Phase clock For latching data

36 Servo/ Output Servo clock For latching data

37 GND Common Reference voltage

38 GND Common Reference voltage To power external circuitry

39 +5V Output Supply voltage To power external circuitry

40 +5V Output Supply voltage

The JI/O connector provides 32 input/output pins at TTL levels. Direction can be controlled in byte-wide

groups.

J5 (JRS232) Serial Port Connector

Pin # Symbol Function Description Notes

1 PHASE Output Phasing clock

2 DTR Bidirectional Data terminal ready Tied to DSR

3 TXD/ Input Receive data Host transmit data

4 DTS Input Clear to send Host ready bit

5 RXD/ Output Send data Host receive data

6 RTS Output Request to send PMAC ready bit

7 DSR Bidirectional Data set ready Tied to DTR

8 SERVO Output Servo clock

9 GND Common PMAC common

10 +5V Output +5Vdc supply Power supply out

The JRS232 connector provides the PMAC2-PC with the ability to communicate serially with an RS232 port.

This connector cannot be used for daisy chain interconnection of multiple PMACs. The J5A RS-422 port must

be used for daisy chaining. E17 and E18 must connect pins 1 and 2 to use the RS-232 port for serial

communications.

Baseboard Connector Pinouts 25

Page 30

Turbo PMAC2 PCI Hardware Reference Manual

J5A: RS422 Serial Port Connector

JRS422 (26-Pin Connector)

Pin # Symbol Function Description Notes

1 CHASSI Common PMAC common

2 S+5V Output +5Vdc supply

3 RD- Input Receive data Diff. I/O low true

4 RD+ Input Receive data Diff. I/O high true

5 SD- Output Send data Diff. I/O low true

6 SD+ Output Send data Diff. I/O high true

7 CS+ Input Clear to send Diff. I/ O high true

8 CS- Input Clear to send Diff. I/O low true

9 RS+ Output Request to send Diff. I/O high true

10 RS- Output Request to send Diff. I/O low true

11 DTR Bidirectional Data terminal ready Tied to DSR

12 INIT/ Input PMAC reset Low is reset

13 GND Common PMAC common

14 DSR Bidirectional Data set ready Tied to DDTR

15 SDIO- Bidirectional Special data Diff. I/O low true

16 SDI0+ Bidirectional Special data Diff. I/O high true

17 SCIO- Bidirectional Special control Diff. I/O low true

18 SCIO+ Bidirectional Special control Diff. I/O high true

19 SCK- Bidirectional Special clock Diff. I/O low true

20 SCK+ Bidirectional Special clock Diff. I/O high true

21 SERVO- Bidirectional Servo clock Diff. I/O low true

22 SERVO+ Bidirectional Servo clock Diff. I/O high true

23 PHASE- Bidirectional Phase clock Diff. I/O low true

24 PHASE+ Bidirectional Phase clock Diff. I/O high true

25 GND Common PMAC common

26 +5V Output +5Vdc supply Power supply out

E17 and E18 must connect pins 2 and 3 to use the RS-422 port for serial communications. This connector

could also be used to daisy chain interconnect multiple PMACs for synchronized operation.

J6 (JDISP) Display Connector

Pin # Symbol Function Description Notes

1 VDD Output +5V power Power supply out

2 VSS Common PMAC common

3 RS Output Read strobe TTL signal out

4 VEE Output Contrast adjustment VEE 0 to +5Vdc*

5 E Output Display enable High is enable

6 R/W Output Read or write TTL signal out

7 DB1 Output Display Data1

8 DB0 Output Display Data0

9 DB3 Output Display Data3

10 DB2 Output Display Data2

11 DB5 Output Display Data5

12 DB4 Output Display Data4

13 DB7 Output Display Data7

14 DB6 Output Display Data6

The JDISP connector is used to drive the 2 lines x 24 character (Acc-12), 2 x 40 (Acc-12A) LCD, or the 2 x 40

vacuum fluorescent (Acc 12C) display unit. The Display command may be used to send messages and values

to the display.

26 Baseboard Connector Pinouts

Page 31

Turbo PMAC2 PCI Hardware Reference Manual

J7 (JHW) Handwheel Encoder Connector

Pin # Symbol Function Description Notes

1 GND Common Reference voltage

2 +5V Output Supply voltage To power external circuitry

3 HWAL+ Input HW positive A Channel Also pulse input

4 HWAL- Input HW negative A Channel Also pulse input

5 HWBL+ Input HW negative B Channel Also direction input

6 HWBL- Input HW negative B Channel Also direction input

7 HWA2+ Input HW positive A Channel Also pulse input

8 HWA2- Input HW negative A Channel Also pulse input

9 HWB2+ Input HW positive B Channel Also direction input

10 HWB2- Output HW negative B Channel Also direction input

11 PUL1+ Output PFM negative pulse Also PWM bottom output

12 PUL1- Output PFM negative pulse Also PWM bottom output

13 DIR1+ Output PFM positive direction out Also PWM top output

14 DIR1- Output PFM negative direction out Also PWM top output

15 PUL2+ Output PFM positive pulse Also PWM bottom output

16 PUL2- Output PFM negative pulse Also PWM bottom output

17 DIR2+ Output PFM positive direction out Also PWM top output

18 DIR2- Output PFM negative direction out Also PWM top output

19 GND Common Reference voltage

20 +5V Output Supply voltage To power external circuitry

J8 (JEQU) Position Compare Output Connector

Pin # Symbol Function Description Notes

1 EQU1/ Output Encoder 1 Comp - EQ Programmed polarity

2 EQU2/ Output Encoder 2 Comp – EQ Programmed polarity

3 EQU3/ Output Encoder 3 Comp – EQ Programmed polarity

4 EQU4/ Output Encoder 4 Comp – EQ Programmed polarity

5 EQU5/ Output Encoder 5 Comp – EQ Programmed polarity

6 EQU6/ Output Encoder 6 Comp – EQ Programmed polarity

7 EQU7/ Output Encoder 7 Comp – EQ Programmed polarity

8 EQU8/ Output Encoder 8 Comp – EQ Programmed polarity

9 +V Supply Positive supply +5V

10 GND Common Digital ground

This connector provides the position-compare outputs for the eight encoder ch annels.

Baseboard Connector Pinouts 27

Page 32

Turbo PMAC2 PCI Hardware Reference Manual

J9 (JMACH1) Connector Description

J9 (JMACH1)

Connector Description

Pin # Symbol Function Description Notes

1 +5V Output/Input +5V power For external circuit or from

external supply

2 +5V Output/Input +5V power For external circuit or from

external supply

3 GND Common Reference voltage

4 GND Common Reference voltage

5 CHA1+ Input Encoder 1 positive A channel Also pulse input

6 CHA1- Input Encoder 1 negative A channel Also pulse input

7 CHB1+ Input Encoder 1 positive B channel Also direction input

8 CHB1- Input Encoder 1 negative B channel Also direction input

9 CHC1+ Input Encoder 1 positive C channel Index channe l

10 CHC1- Input Encoder 1 negative C channel Index channel

11 CHU1 Input Channel 1 U flag Hall effect, fault code, or sub-

count

12 CHV1 Input Channel 1 V flag Hall effect, fault code, or sub-

count

13 CHW1 Input Channel 1 W flag Hall effect, fault code, or sub-

count

14 CHT1 Input Channel 1 T flag Fault code or sub-count

15 USER1 Input General purpose user flag Hardware capture flag or sub-

count

16 PLIM1 Input Positive overtravel limit Hardware capture flag

17 MLIM1 Input Negative overtravel limit Hardware capture flag

18 HOME1 Input Home switch input Hardware capture flag

19 ACCFLT1 Input Accessory fault flag For loss of ACC supply voltage

20 WD0/ Output Watchdog output Low is PMAC watchdog fault

21 SCLK12+ Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

22 SCLK12- Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

23 ADC_CLK1+ Output A/D converter clock Programmable frequency

24 ADC_CLK1- Output A/D converter clock Programmable frequency

25 ADC_STB1+ Output A/D converter strobe Programmable sequence

26 ADC_STB1- Output A/D converter strobe Programmable sequence

27 ADC_DAA1+ Input Channel A ADC serial data MSB first

28 ADC_DAA1- Input Channel A ADC serial data MSB first

29 ADC_DAB1+ Input Channel B ADC serial data MSB first

30 ADC_DAB1- Input Channel B ADC serial data MSB first

31 AENA1+ Output Amplifier enable High is enable

32 AENA1- Output Amplifier enable Low is enable

33 FAULT1+ Input Amplifier fault Programmable parity

34 FAULT1- Input Amplifier fault Programmable parity

28 Baseboard Connector Pinouts

Page 33

Turbo PMAC2 PCI Hardware Reference Manual

J9 (JMACH1) Connector Description (Continued)

Pin # Symbol Function Description Notes

35 PWMATOP1+

DAC_CLK1+

36 PWMATOP1-

DAC_CLK1-

37 PWMABOT1+

DAC1A+

38 PWMABOT1-

DAC1A-

39 PWMBTOP1+

DAC_STB1+

40 PWMBTOP1-

DAC_STB1-

41 PWMBBOT1+

DAC1B+

42 PWMBBOT1-

DAC1B-

43 PWMCTOP1+

DIR1+

44 PWMCTOP1-

DIR1-

45 PWMCBOT1+

PULSE1+

46 PWMCBOT1-

PULSE147 GND Common Reference voltage

48 GND Common Reference voltage

49 +5V Output/Input +5V Power For external circuit or from external

50 +5V Output/Input +5V Power For external circuit or from external

51 +5V Output/Input +5V Power For external circuit or from external

52 +5V Output/Input +5V Power For external circuit or from external

53 GND Common Reference voltage

54 GND Common Reference voltage

55 CHA2+ Input Encoder 2 positive A Channel Also pulse input

56 CHA2- Input Encoder 2 negative A Channel Also pulse input

57 CHB2+ Input Encoder 2 positive B Channel Also direction input

58 CHB2- Input Encoder 2 negative B Channe l Also direction input

59 CHC2+ Input Encoder 2 positive C Channel Index channel

60 CHC2 Input Encoder 2 negative C Channel Index channel

61 CHU2 Input Channel 2 U flag Hall effect, fault code or sub-count

62 CHV2 Input Channel 2 V flag Hall effect, fault code or sub-count

63 CHW2 Input Channel 2 W flag Hall effect, fault code or sub-count

64 CHT2 Input Channel 2 T flag Hall effect, fault code or sub-count

65 USER2 Input General purpose user flag Hardware capture flag, or sub-count

Output Phase A top CMD or DAC

clock

Output Phase A top CMD or DAC

clock

Output Phase A bottom CMD or DAC

A serial Data

Output Phase A bottom CMD or DAC

A serial Data

Output Phase B top CMD or DAC

strobe

Output Phase B top CMD or DAC

strobe

Output Phase B bottom CMD or DAC

B serial data

Output Phase B bottom CMD or DAC

B serial data

Output Phase B top CMD or PFM

direction

Output Phase B top CMD or PFM

direction

Output Phase B bottom CMD or PFM

pulse

Output Phase B bottom CMD or PFM

pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

supply

supply

supply

supply

Baseboard Connector Pinouts 29

Page 34

Turbo PMAC2 PCI Hardware Reference Manual

J9 (JMACH1) Connector Description (Continued)

Pin # Symbol Function Description Notes

66 PLIM2 Inpu t Positive overtravel limit Hardware capture flag

67 MLIM2 Input Negative overtravel limit Hardware capture flag

68 HOME2 Input Home switch input Hardware capture flag

69 ACCFLT2 Input Accessory fault flag For loss of ACC supply voltage

70 WD0/ Output Watchdog output Low is PMAC watchdog fault

71 SCLK12+ Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

72 SCLK12- Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

73 ADC_CLK2+ Output A/D converter clock Programmable frequency

74 ADC_CLK2- Output A/D converter clock Programmable frequency

75 ADC_STB2+ Output A/D converter strobe Programmable sequence

76 ADC_STB2- Output A/D converter strobe Programmable sequence

77 ADC_DAA2+ Input Channel A ADC serial data MSB first

78 ADC_DAA2- Input Channel A ADC serial data MSB first

79 ADC_DAB2+ Input Channel B ADC serial data MSB first

80 ADC_DAB2- Input Channel B ADC serial data MSB first

81 AENA2+ Output Amplifier enable High is enable

82 AENA2- Output Amplifier enable Low is enable

83 FAULT2+ Input Amplifier fault Programmable polarity

84 FAULT2- Input Amplifier fault Programmable polarity

85 PWMATOP2+

DAC_CLK2+

86 PWMATOP2-

DAC_CLK2-

87 PWMABOT2+

DAC2A+

88 PWMABOT2-

DAC2A-

89 PWMBTOP2+

DAC_STB2+

90 PWMBTOP2-

DAC_STB2-

91 PWMBBOT2+

DAC2B+

92 PWMBBOT2-

DAC2B-

93 PWMCTOP2+

DIR2+

94 PWMCTOP2-

DIR2-

95 PWMCBOT2+

PULSE2+

96 PWMCBOT2-

PULSE2-

97 GND Common Reference voltage

Output Phase A top CMD. or DAC

clock

Output Phase A top CMD. or DAC

clock

Output Phase A bottom CMD or DAC

A serial data

Output Phase A bottom CMD or DAC

A serial data

Output Phase B top CMD or DAC

strobe

Output Phase B top CMD or DAC

strobe

Output Phase B bottom CMD or DAC

B serial data

Output Phase B bottom CMD or DAC

B serial data

Output Phase B top CMD or PFM

direction

Output Phase B top CMD or PFM

direction

Output Phase B bottom CMD or PFM

pulse

Output Phase B bottom CMD or PFM

pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

30 Baseboard Connector Pinouts

Page 35

Turbo PMAC2 PCI Hardware Reference Manual

J9 (JMACH1) Connector Description (Continued)

Pin # Symbol Function Description Notes

98 GND Common Reference voltage

99 +5V Output/Input +5V power For external circuit or from

external supply

100 +5V Output/Input +5V power For external circuit or from

external supply

The JMACH1 connector provides the interface pins for channels 1 and 2. Usually, it is connected to a breakout

board, such as one of the Acc-8x family of boards, or an application-specific interface board.

Connector: 100-pin male box header with center key, 0050" pitch. AMP part # 1-04068-7

Delta Tau part # 014-00010-FPB.

J10 (JMACH2) Connector Description

J10 (JMACH2)

Pin # Symbol Function Description Notes

1 +5V Output/Input +5V power For external circuit or from external

supply

2 +5V Output/Input +5V power For external circuit or from external

supply

3 GND Common Reference voltage

4 GND Common Reference voltage

5 CHA3+ Input Encoder 3 positive A channel Also pulse input

6 CHA3- Input Encoder 3 negative A channel Also pulse input

7 CHB3+ Input Encoder 3 positive B channel Also direction input

8 CHB3- Input Encoder 3 negative B channel Also direction input

9 CHC3+ Input Encoder 3 positive C channel Index channel

10 CHC3- Input Encoder 3 negative C channel Index channel

11 CHU3 Input Channel 3 U flag Hall effect, fault code, or sub-count

12 CHV3 Input Channel 3 V flag Hall effect, fault code, or sub-count

13 CHW3 Input Channel 3 W flag Hall effect, fault code, or sub-count

14 CHT3 Input Channel 3 T flag Fault code or sub-count

15 USER3 Input General purpose user flag Hardware capture flag or sub-count

16 PLIM3 Input Positive overtravel limit Hardware capture flag

17 MLIM3 Input Negative overtravel limit Hardware capture flag

18 HOME3 Input Home switch input Hardware capture flag

19 ACCFLT3 Input Accessory fault flag For loss of ACC supply voltage

20 WD0/ Output Watchdog output Low is PMAC watchdog fault

21 SCLK34+ Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

22 SCLK34- Input/Output Encoder sample clock Direction controlled by PMAC2

jumper

23 ADC_CLK3+ Output A/D converter clock Programmable frequency

24 ADC_CLK3- Output A/D converter clock Programmable frequency

25 ADC_STB3+ Output A/D converter strobe Programmable sequence

26 ADC_STB3- Output A/D converter strobe Programmable sequence

27 ADC_DAA3+ Input Channel A ADC serial data MSB first

Baseboard Connector Pinouts 31

Page 36

Turbo PMAC2 PCI Hardware Reference Manual

J10 (JMACH2) (Continued)

Pin # Symbol Function Description Notes

28 ADC_DAA3- Input Channel A ADC serial data MSB first

29 ADC_DAB3+ Input Channel B ADC serial data MSB first

30 ADC_DAB3- Input Channel B ADC serial data MSB first

31 AENA3+ Output Amplifier enable High is enable

32 AENA3- Output Amplifier enable Low is enable

33 FAULT3+ Input Amplifier fault Programmable parity

34 FAULT3- Input Amplifier fault Programmable parity

35 PWMATOP3+

DAC_CLK3+

36 PWMATOP3-

DAC_CLK3-

37 PWMABOT3+

DAC3A+

38 PWMABOT3-

DAC3A-

39 PWMBTOP3+

DAC_STB3+

40 PWMBTOP3-

DAC_STB3-

41 PWMBBOT3+

DAC3B+

42 PWMBBOT3-

DAC3B-

43 PWMCTOP3+

DIR3+

44 PWMCTOP3-

DIR3-

45 PWMCBOT3+

PULSE3+

46 PWMCBOT3-

PULSE347 GND Common Reference voltage

48 GND Common Reference voltage

49 +5V Output/Input +5V power For external circuit or from external

50 +5V Output/Input +5V power For external circuit or from external

51 +5V Output/Input +5V power For external circuit or from external