Page 1

^1 USER MANUAL

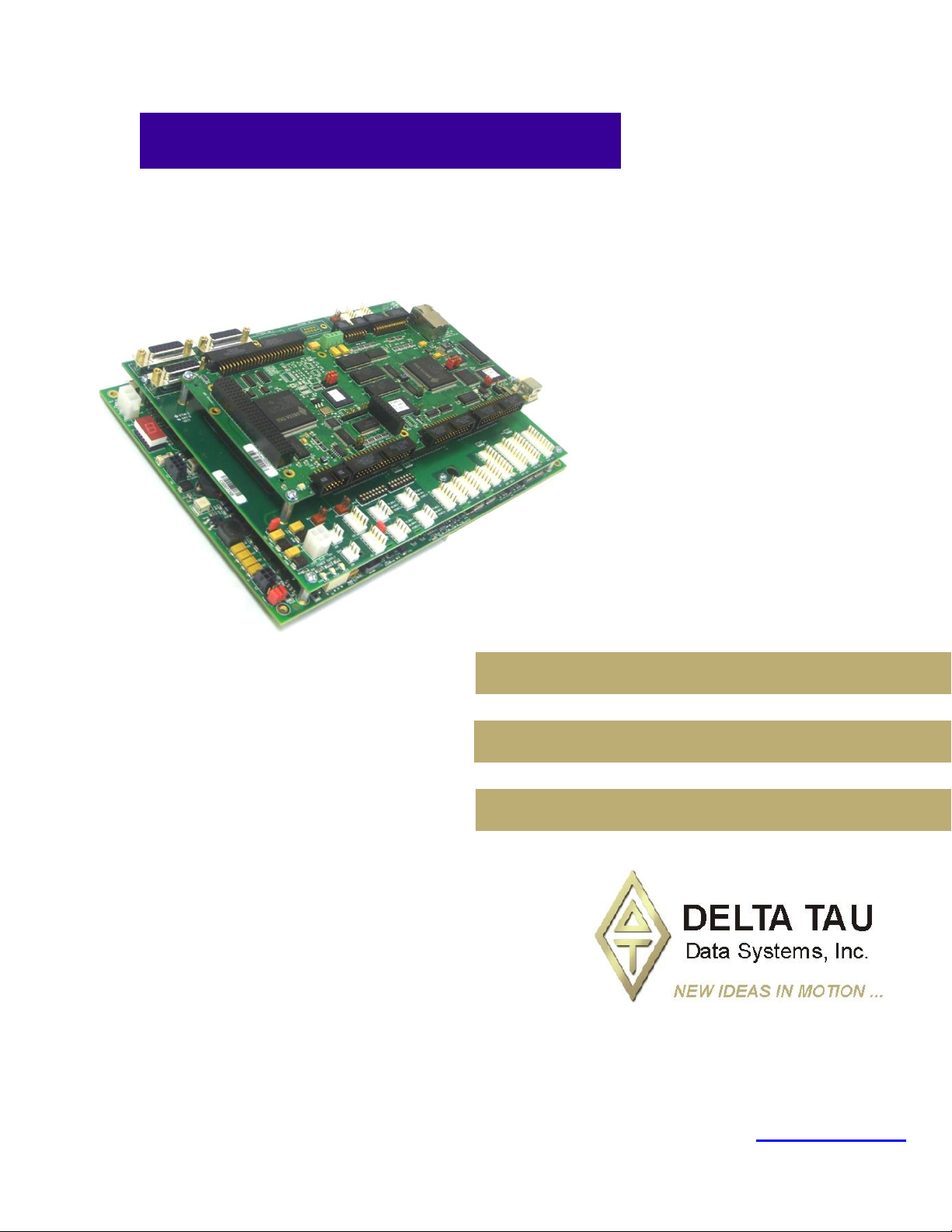

^2 Turbo Clipper Drive

^3 4-Axis Low Voltage Intelligent Amplifier

^4 TCD 4-XX-400-0X1-0XXX

^5 November 19, 2013

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Turbo Clipper Drive User Manual

Copyright Information

© 2010 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc.

Other uses are unauthorized without written permission of Delta Tau Data

Systems, Inc. Information contained in this manual may be updated from time-totime due to product improvements, etc., and may not conform in every respect to

former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and

amplifiers contain static sensitive components that can be damaged by incorrect

handling. When installing or handling Delta Tau Data Systems, Inc. products,

avoid contact with highly insulated materials. Only qualified personnel should be

allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from

hazardous or conductive materials and/or environments that could cause harm to the

controller by damaging components or causing electrical shorts. When our products are

used in an industrial environment, install them into an industrial electrical cabinet or

industrial PC to protect them from excessive or corrosive moisture, abnormal ambient

temperatures, and conductive materials. If Delta Tau Data Systems, Inc. products are

exposed to hazardous or conductive materials and/or environments, we cannot guarantee

their operation.

Page 3

Turbo Clipper Drive User Manual

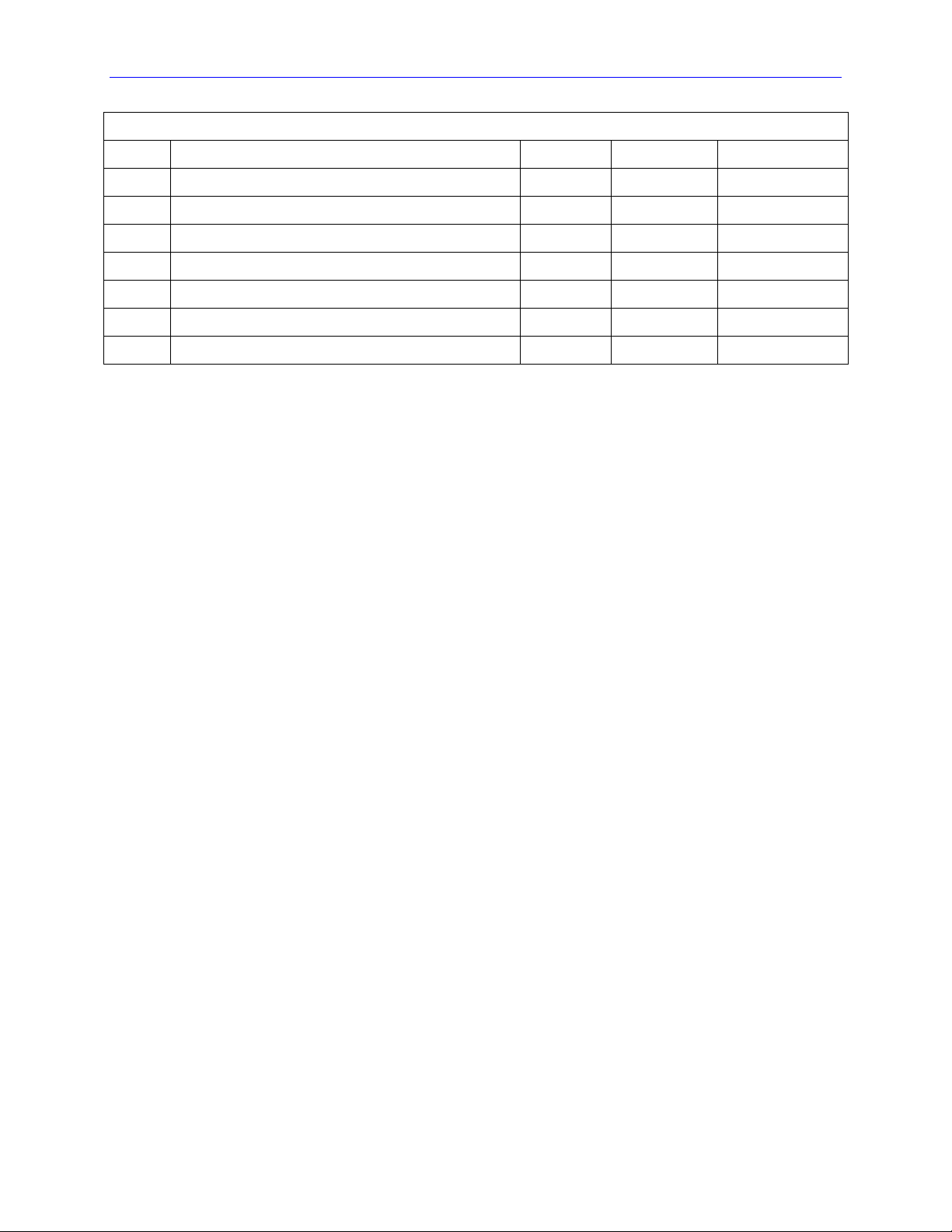

MANUAL REVISION HISTORY

REV.

DESCRIPTION

DATE

CHANGE

APPROVED

1

PRELIMINARY MANUAL CREATION

07/01/10

M.Y

R.N

2

FORMATTING & CORRECTIONS

09/25/10

M.Y

R.N

3

MANUAL RELEASE

01/13/10

R.N

R.N

4

ASSEMBLY DRAWING

03/29/11

M.Y

R.N

5

CORRECTED PIN-OUT, PAGE 43

04/18/11

M.Y

R.N

6

FORMAT. FIXED LABES J37

12/18/12

R.N

R.N

7

ADDED E4 JUMPER IN REV103

11/19/13

M.C

R.N

Page 4

Turbo Clipper Drive User Manual

Table of Contents

INTRODUCTION .....................................................................................................................7

Documentation ........................................................................................................................7

Turbo Clipper Drive Features ..................................................................................................7

SPECIFICATIONS ...................................................................................................................8

Part Number ............................................................................................................................8

Electrical Specifications ..........................................................................................................9

Environmental Specifications ..................................................................................................9

RECEIVING AND UNPACKING ......................................................................................... 10

Use of Equipment.................................................................................................................. 10

Mounting .............................................................................................................................. 11

CAD Drawing ....................................................................................................................... 12

POWER BOARD: WIRING, SOFTWARE SETUP ............................................................. 14

TB1-TB4: Motor Wiring ....................................................................................................... 14

TB5: 24-Volt Logic Power .................................................................................................... 15

TB6: Bus Voltage.................................................................................................................. 16

J13: E-Stop, Reset ................................................................................................................. 17

D1: AMP STATUS ............................................................................................................... 20

Error Codes.......................................................................................................................... 20

BREAKOUT BOARD: WIRING, SOFTWARE SETUP ...................................................... 21

TB1: External Power Supply ................................................................................................. 21

J11-J14: Encoder Feedback, Digital A Quad B ................................................................ ...... 21

ACC-51S: Sinusoidal Feedback (Optional) ........................................................................... 24

J15: Flag(s) Power Supply ................................................................................................ ..... 25

J16-J19: Axis 1 thru 4 Limits & Home Flags ......................................................................... 25

J20: Axis 1 thru 4 EQU Outputs ............................................................................................ 26

J21: Axis 1 thru 4 User Flags ................................................................................................ 26

Wiring The Flags .................................................................................................................. 28

J23: Watchdog Output ........................................................................................................... 29

J24: DAC Output, 12-bit Filtered PWM ................................................................................ 30

J25: ADC Inputs ................................................................................................................... 31

J26: Thumbwheel Multiplexer Port Inputs ............................................................................. 32

J27: Thumbwheel Multiplexer port Outputs (sinking) ............................................................ 33

J37: Thumbwheel Multiplexer port Outputs (Sourcing) ......................................................... 34

Thumbwheel Port As Discrete I/Os, Suggested M-Variables ................................................. 34

Wiring The Thumbwheel As Discrete I/Os ............................................................................ 35

J28: General Purpose Inputs .................................................................................................. 37

Table Of Contents 4

Page 5

Turbo Clipper Drive User Manual

J29: General Purpose Outputs (sinking) ................................................................................. 38

J30: General Purpose I/O Power ............................................................................................ 39

J38: General Purpose Outputs (sourcing) ............................................................................... 40

General Purpose I/Os, Suggested M-Variables ..................................................................... 43

J31-J32: Handwheel Port(s) ................................................................................................... 44

J33-J34: Pulse and Direction Output(s) (PFM) ...................................................................... 45

J35: Programmable Output ................................................................................................ .... 48

External Amp 1-4: ................................................................................................................. 49

CLIPPER BOARD: WIRING, SOFTWARE SETUP ........................................................... 51

USB 2.0 Connector ............................................................................................................... 51

RJ45, Ethernet Connector ...................................................................................................... 51

RS232: Serial Communication Port ....................................................................................... 52

MOTOR TYPE & PROTECTION POWER-ON PLCs ........................................................ 53

Stepper Motor Power-On PLC .............................................................................................. 53

Brushless/Brush Motor Power-On PLC ................................................................................. 54

Hybrid Motor Power-On PLC Example ................................................................................. 54

MOTOR SETUP GUIDELINES ............................................................................................ 55

Motor Setup Flow Chart ........................................................................................................ 55

Dominant Clock Settings ................................ ....................................................................... 56

Setting Up Stepper Motor, Direct Micro-Stepping ................................................................. 57

Before you start .................................................................................................................... 57

Encoder Conversion Table Setup ................................ .......................................................... 57

Position, Velocity Pointers: Ixx03, Ixx04 .............................................................................. 58

Motor Activation, Commutation Enable: Ixx00, Ixx01........................................................... 58

Command Output Address: Ixx02 ......................................................................................... 58

Current Feedback, ADC Mask, Commutation angle: Ixx82, Ixx84, Ixx72 .............................. 58

Flag Address, Mode Control: Ixx25, Ixx24 ........................................................................... 59

Commutation Address, Cycle size: Ixx83, Ixx70, Ixx71 ......................................................... 59

Maximum Achievable Motor Speed, Output Command Limit: Ixx69 ..................................... 60

PWM Scale Factor: Ixx66 ..................................................................................................... 61

I2T Protection, Magnetization Current: Ixx57, Ixx58, Ixx69, Ixx77 ....................................... 62

Phasing, Power-On Mode: Ixx80, Ixx73, Ixx74, Ixx81, Ixx91 ................................................ 63

Position-Loop PID Gains: Ixx30…Ixx39 ............................................................................... 63

Current-Loop Gains: Ixx61, Ixx62, Ixx76 .............................................................................. 64

Number Of Counts Per Revolution (Stepper Motors) ............................................................ 64

Setting Up DC Brushless Motor ............................................................................................ 65

Before you start .................................................................................................................... 65

Flag Control, Commutation Angle, Current Mask: Ixx24, Ixx72, Ixx84 ................................. 65

PWM Scale Factor: Ixx66 ..................................................................................................... 65

Table Of Contents 5

Page 6

Turbo Clipper Drive User Manual

Current Feedback Address: Ixx82 ......................................................................................... 65

Commutation Position Address, Commutation Enable: Ixx83, Ixx01 ..................................... 66

I2T Protection: Ixx57, Ixx58, Ixx69 ....................................................................................... 66

Commutation Cycle Size: Ixx70, Ixx71 .................................................................................. 67

ADC Offsets: Ixx29, Ixx79 .................................................................................................... 67

Current-Loop Gains: Ixx61, Ixx62, Ixx76 .............................................................................. 67

Open-Loop Test, Encoder Decode: I7mn0 ............................................................................ 68

Motor Phasing, Power-On Mode: Ixx73, Ixx74, Ixx80, Ixx91 ................................................ 70

Position-Loop PID Gains: Ixx30…Ixx39 ............................................................................... 75

Setting Up DC Brush Motor .................................................................................................. 77

Before you start .................................................................................................................... 77

Phasing Search Error Bit, Current-Loop Integrator Output .................................................. 77

Flag Control, Commutation Enable, Phase Angle, Current Mask: Ixx24, Ixx01, Ixx72, Ixx84

............................................................................................................................................. 77

PWM Scale Factor: Ixx66 ..................................................................................................... 78

Current Feedback Address: Ixx82 ......................................................................................... 78

Commutation Cycle Size: Ixx70, Ixx71 .................................................................................. 78

I2T Protection, Magnetization Current: Ixx57, Ixx58, Ixx69, Ixx77 ....................................... 79

ADC Offsets: Ixx29, Ixx79 .................................................................................................... 79

Current-Loop Gains, Open-Loop/Enc. Decode: Ixx61, Ixx62, Ixx76, I7mn0 .......................... 79

Position-Loop PID Gains: Ixx30…Ixx39 ............................................................................... 80

APPENDIX A .......................................................................................................................... 82

D-Sub Connector Spacing Specifications .............................................................................. 82

APPENDIX B: CLIPPER BOARD E-POINT JUMPERS .................................................... 83

E0: Forced Reset Control ..................................................................................................... 83

E3: Re-Initialization On Reset Control ................................................................................. 83

E4: Watchdog Disable Jumper ............................................................................................. 83

E5: Reserved for factory use only ......................................................................................... 83

E6: ADC Inputs Enable ........................................................................................................ 84

E7 – E8: USB/Ethernet Reset Jumpers ................................................................................. 84

E10 – E12: Flash IC Jumpers ............................................................................................... 84

E13: Power-Up/Reset Load Firmware .................................................................................. 85

E14- E17: Ports Direction Control ......................................................................................... 85

APPENDIX C: BREAKOUT BOARD E-POINT JUMPERS ............................................... 86

J36: GPO E-Stop Automatic Feature .................................................................................... 86

J39: User Flag 4 E-Stop Status ............................................................................................. 86

APPENDIX D: POWER BOARD E-POINT JUMPERS ................................ ...................... 87

E1- E2- E3- E4: E-Stop and Reset Control ............................................................................ 87

Table Of Contents 6

Page 7

Turbo Clipper Drive User Manual

INTRODUCTION

The Turbo Clipper Drive (Low Voltage), 12~60V(DC) bus power input, combines the

intelligence and capability of the Turbo PMAC2 motion controller with the latest MOSFET

technology, resulting in a compact 4-axis smart servo package. The flexibility of the Turbo

PMAC2 enables the Turbo Clipper Drive to drive Stepper, Brush, or Brushless motors with

unsurpassed pure digital DSP performance.

The Turbo Clipper Drive also features a wide variety of options varying from processor speeds

as high as 240MHz, multiple digital and analog inputs/outputs, USB2.0, Ethernet 100 Base T,

and serial communication.

Documentation

In conjunction with this hardware reference manual, the Turbo Software Reference Manual and

Turbo PMAC User Manual are essential for proper use, motor setup, and configuration of the

Turbo Clipper Drive. It is highly recommended to always refer to the latest revision of the

manuals found on Delta Tau’s website, under Support>documentation>Manuals: Delta Tau

Manuals Link

Turbo Clipper Drive Features

The Turbo Clipper Drive supports the following types of motors:

Three-Phase DC Brushless

DC Brush

2-Phase Stepper

Some of the Turbo Clipper Drive’s outstanding features:

4 channel direct digital PWM control

Integral 4 servo amplifiers delivering 5Amps continous/15Amps peak per axis

Protection: over voltage, under voltage, over temperature, short circuit, over current

Motorola DSP 56k digital signal processor

Turbo PMAC2 CPU

Linear and circular interpolation

256 fixed motion program buffers

64 asynchronous PLC programs

Rotary buffer support

36-bit position range (± 64 billion counts)

Adjustable S-curve acceleration and deceleration

Cubic trajectory calculations, Splines, PVT

Set and change parameters in real time and on-the-fly, alter destination moves

Torque, Velocity and Position control

Small space-saving footprint

USB2.0, Ethernet 100 Base T

Operation from PC or standalone

Introduction 7

Page 8

Turbo Clipper Drive User Manual

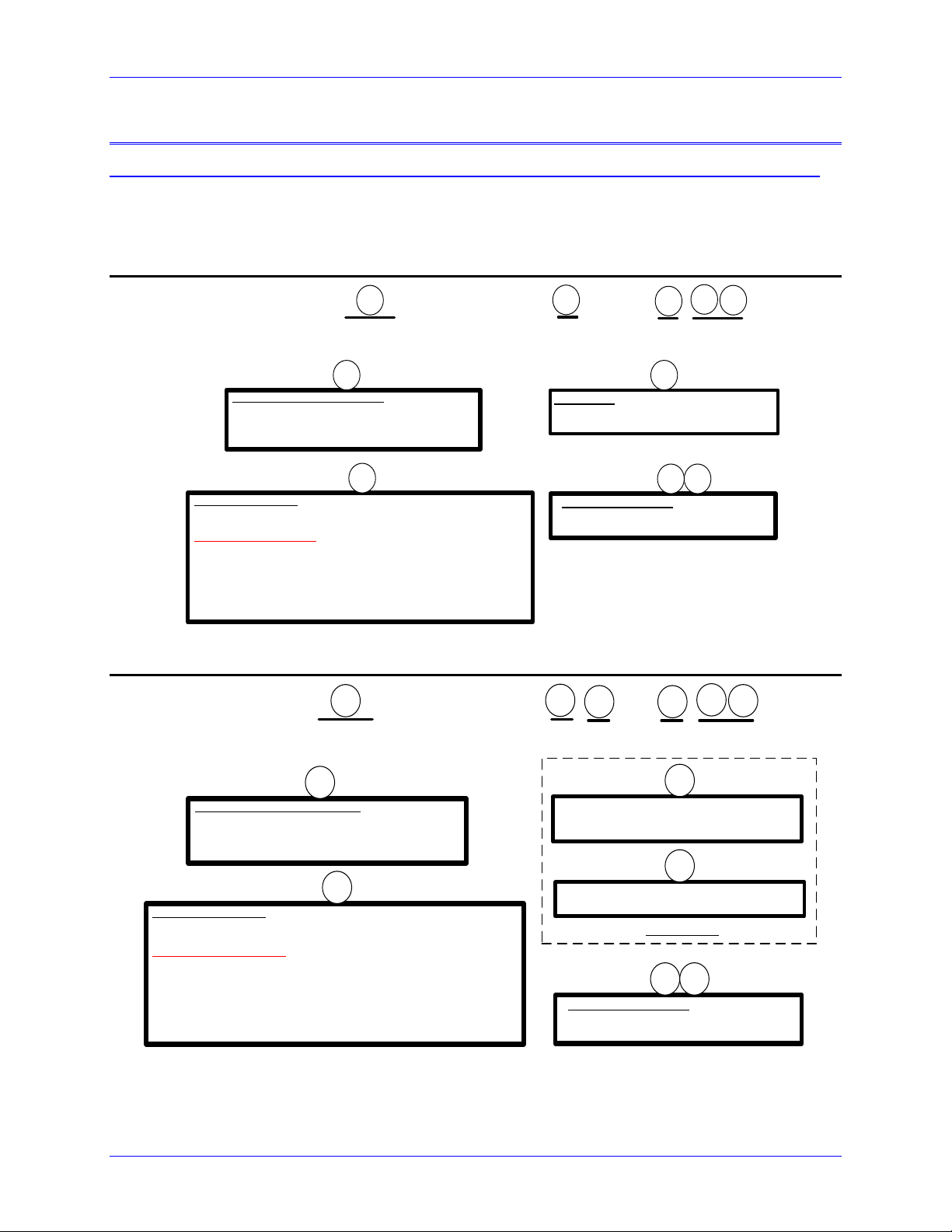

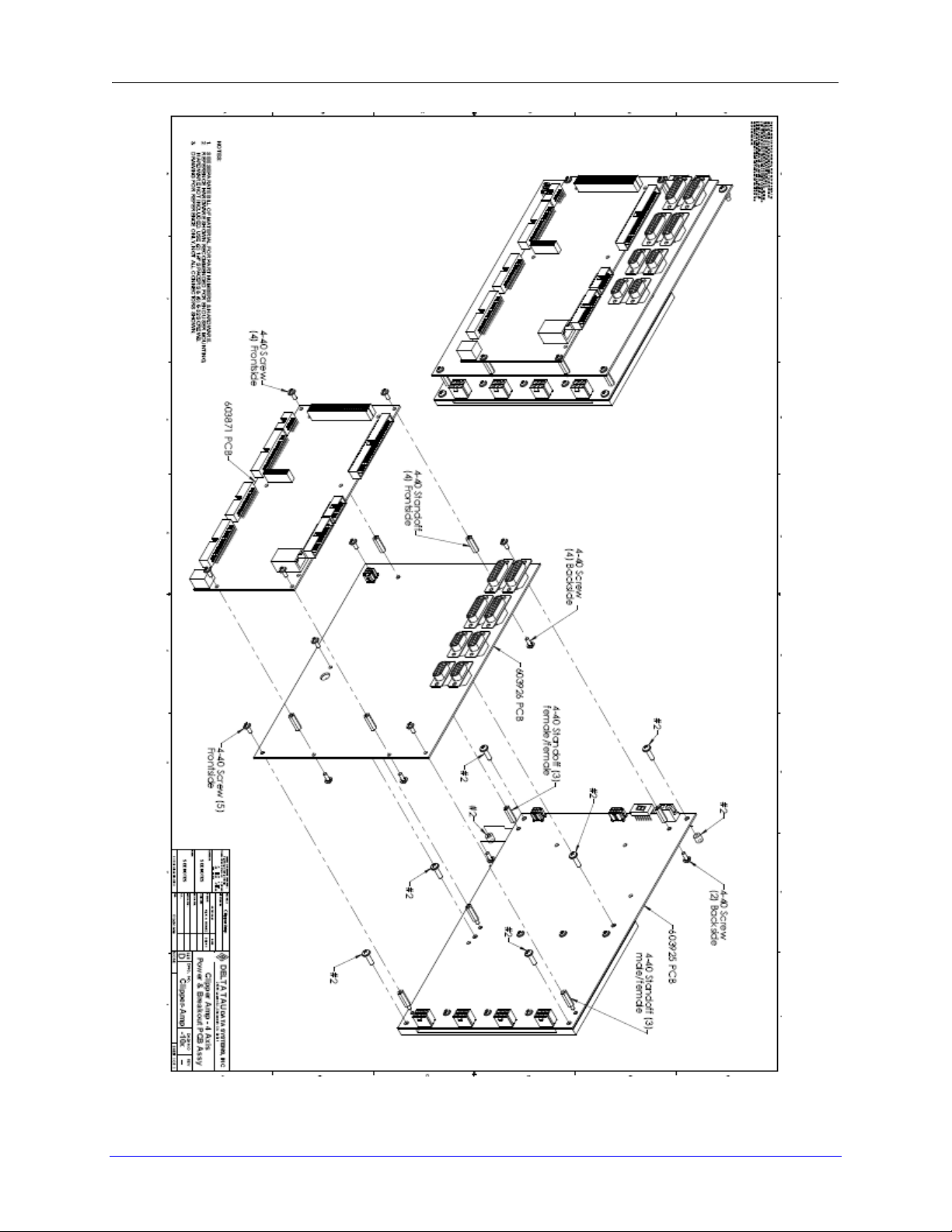

Delta Tau Assembly Numbers (top to bottom):

Control Board (Clipper)

603871

Breakout Board

603926

Power Board

603925

CD 0 0 0 10C 4

-- -

04 00 0 0T

CPU Options - Turbo PMAC 2 Processor

C0 - 80Mhz, 8Kx24 Internal, 256Kx24SRAM, 1MB Flash (Default)

C3 - 80Mhz, 8Kx24 Internal, 1Mx24SRAM, 4MB Flash

F3 - 240Mhz, 192Kx24 Internal, 1Mx24SRAM, 4MB Flash

B

G

L

B

Turbo Clipper Drive Number Definition

Communication Options

TCD X - XX - XXX – X?X - XXXX

USB2 and Eth100 are included

Note: To use PMAC-NC software, DPRAM is required

0 - No Options, Default

D - (Clipper OPT-2) DPRAM option, size 8K x 16-bit wide

M - (Clipper Opt-15M) ModBus Ethernet Communication Protocol(Software) option

S - (Clipper OPT-2 and Opt-15M) DPRAM and Modbus Options Combined

G

00 - No Additional* Options

xx - Factory assigned digits for Additional* Options

Factory Assigned Options

K L

* If Opt. 10xx (specific firmware version) or any other Additional Option

is required, contact factory for digits K and L (Factory Assigned digits).

If Opt. 10xx is not ordered the latest firmware is used.

Other Options

0 - No Options (Default)

1 - Opt. 11A HI-Speed Dig. Out PWM Laser Control

J

K

J

-

BB 0 0 5 00C 2

-- -

04 01 0 0C

CPU Options - Turbo PMAC 2 Processor

C0 - 80Mhz, 8Kx24 Internal, 256Kx24SRAM, 1MB Flash (Default)

C3 - 80Mhz, 8Kx24 Internal, 1Mx24SRAM, 4MB Flash

F3 - 240Mhz, 192Kx24 Internal, 1Mx24SRAM, 4MB Flash

B

G

L

B

Clipper with Breakout Board Part Number Definition

Communication Options

CBB X - XX - XXX – X?X - XXXX

USB2 and Eth100 are included

Note: To use PMAC-NC software, DPRAM is required

0 - No Options, Default

D - (Clipper OPT-2) DPRAM option, size 8K x 16-bit wide

M - (Clipper Opt-15M) ModBus Ethernet Communication Protocol(Software) option

S - (Clipper OPT-2 and Opt-15M) DPRAM and Modbus Options Combined

G

00 - No Additional* Options

xx - Factory assigned digits for Additional* Options

Factory Assigned Options

K L

* If Opt. 10xx (specific firmware version) or any other Additional Option is required, contact factory for digits K and L (Factory Assigned digits).

If Opt. 10xx is not ordered the latest firmware is used.

0 - No Options (Default)

1 - Opt. 11A HI-Speed Dig. Out PWM Laser Control

J

K

J

-

H

0 - No Options (Default)

1 - Opt. 12 2-channels 12-bit A/D converter & 1 12-bit

D/A converter

H

Other Options

SPECIFICATIONS

Part Number

Turbo Clipper Drive (Control+Breakout+Power)

Clipper & Breakout only (Control+Breakout, without Power)

Specification 8

Page 9

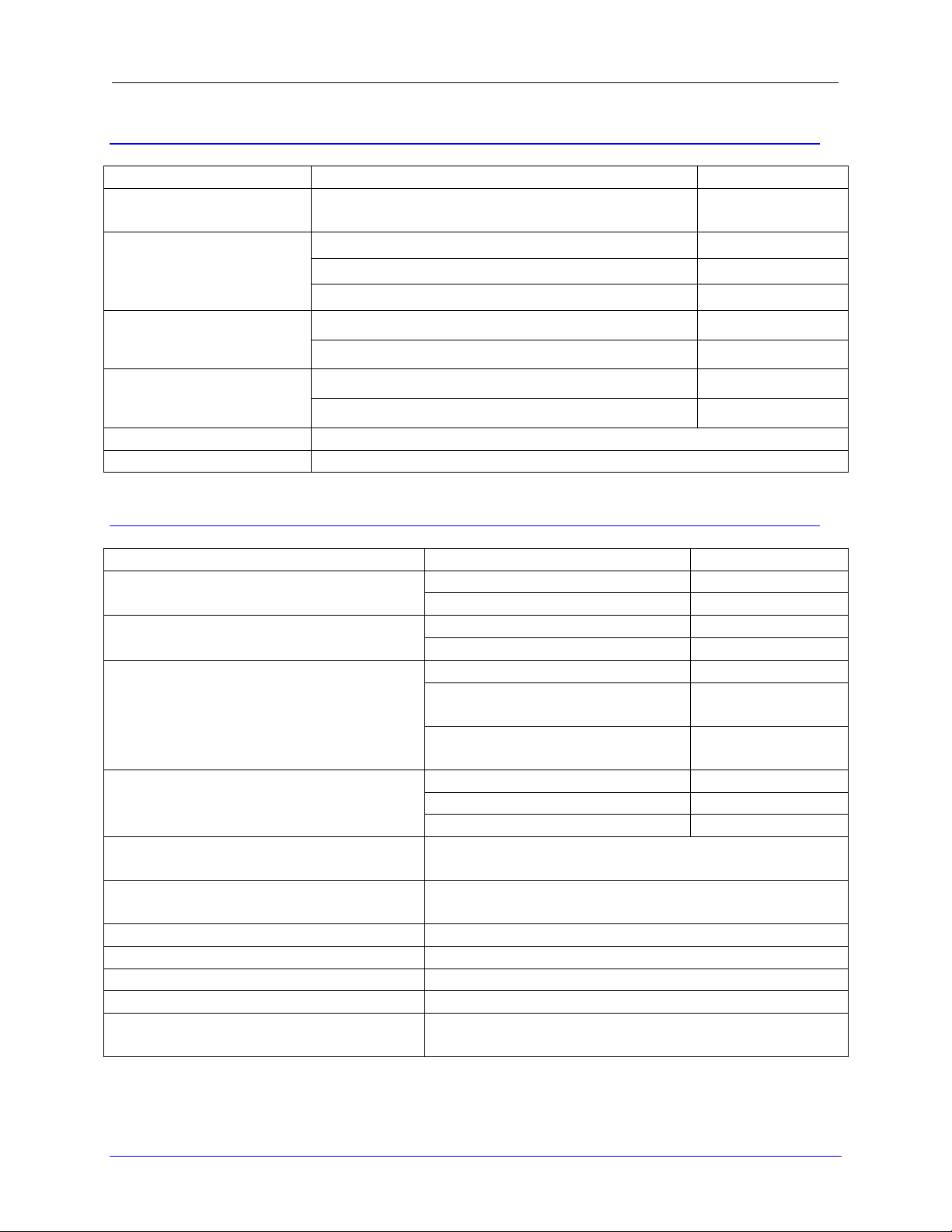

Specification

Description

Range

Max ADC

Full Range ADC reading (RMS/Axis)

Used in I2T Calculation

33.85 Amps

Bus Power Supply

Input Voltage

12~60VDC

Continuous Input Current (RMS)

12.5A

Peak Input Current (RMS)

25A @ 1s

Logic Power Supply

Input Voltage

24VDC ±20%

Continuous Input Current

2~3A (RMS)

Output Current

Nominal Current per axis (RMS)

5A

Maximum Peak Current per axis (RMS)

15A @ 1s

Power Dissipation

240W per axis (modulation depth of 60%)

PWM Frequency

2K~40KHz / recommended 20KHz

Specification

Description

Range

Ambient operating Temperature

EN50178 Class 3K3 – IEC721-3-3

Minimum operating temperature

0°C (32°F)

Maximum operating temperature

45°C (113°F)

Storage Temperature Range

EN 50178 Class 1K4 – IEC721-3-1/2

Minimum Storage temperature

-25°C (-13°F)

Maximum Storage temperature

70°C (158°F)

Humidity Characteristics w/

no condensation and no formation of ice

IEC721-3-3

Minimum Relative Humidity

5% HU

Maximum Relative Humidity

up to 35°C (95°F)

95% HU

Maximum Relative Humidity

from 35°C up to 50°C (122°F)

85% HU

De-rating for Altitude

0~1000m (0~3300ft)

No de-rating

1000 ~3000m (3300~9840ft)

-1%/m (-0.33%/ft)

3000 ~4000m (9840~13000ft)

-2%/m (-0.67%/ft)

Environment

ISA 71-04

Degree 2 environments

Atmospheric Pressure

EN50178 class 2K3

70 KPa to 106 KPa

Shock

Unspecified

Vibration

Unspecified

Air Flow Clearances

3" (76.2mm) above and below unit for air flow

Cooling

Natural convection and external fan

Standard IP Protection

IP20

IP 55 can be evaluated for custom applications

Electrical Specifications

Environmental Specifications

Turbo Clipper Drive User Manual

Specification 9

Page 10

Turbo Clipper Drive User Manual

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment.

Upon receipt of hardware, please follow carefully the instructions below for proper maintenance

and handling:

Observe the condition of the shipping container and report any damage immediately to the

commercial carrier.

Remove the hardware from the shipping container and remove all packing materials. Check all

shipping material for connector kits and documentation. Some components may be quite small

and can be accidentally discarded if care is not used when unpacking the equipment. The

container and packing materials may be retained for future shipment.

Verify that the part number of the unit received matches the part number listed on the purchase

order.

Inspect the drive for external physical damage that may have been sustained during shipping and

report damages immediately to the commercial carrier. Document any damage with photographs.

Electronic components in this unit are design-hardened to reduce static sensitivity. However, use

proper procedures when handling the equipment to avoid electrostatic discharges (ESD).

If the Turbo Clipper Drive is to be stored for several weeks before integration (i.e., spare part),

be sure that it is stored in a location that conforms to environmental specifications. Also, testing

of the unit is highly recommended before storing it for future use.

Use of Equipment

The following restrictions will ensure the proper use of the Turbo Clipper Drive:

The components built into electrical equipment or machines can be used only as integral

components of such equipment.

The Turbo Clipper Drive must not be operated on power supply networks without a ground or

with an asymmetrical ground.

If the Turbo Clipper Drive is used in residential areas, or in business or commercial premises,

implement additional filter measures.

The Turbo Clipper Drive may be operated only in a closed switchgear cabinet, taking into

account the ambient conditions defined in the environmental specifications.

Delta Tau guarantees the conformance of the Turbo Clipper Drive with the standards for

industrial areas stated in this manual only if Delta Tau components (cables, accessories, etc.) are

used.

Receiving and Unpacking 10

Page 11

Turbo Clipper Drive User Manual

Mounting

The drive placement in the machine cabinet is important. Installation should be in an area that is

protected from direct sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and

other contaminants. Exposure to these conditions can reduce the operating life and degrade

performance of the drive.

Several other factors should be carefully evaluated when selecting a location for installation:

For effective cooling and maintenance, the control should be mounted on a smooth, nonflammable vertical surface.

At least 76 mm (~3 inches) top and bottom clearance must be provided for air flow. At least 10

mm (~0.4 inches) clearance is required between amplifier, breakout board and clipper.

Temperature, humidity and Vibration specifications should also be taken in account.

The Turbo Clipper Drive can be mounted with a traditional 4-hole panel mount. This keeps the

heat sink and fan inside the mounting enclosure.

If multiple Turbo Clipper Drive Drives are used, they can be mounted side by side, leaving at

least 122 mm (~5 inches) center to center clearance. It is extremely important that the airflow is

not obstructed by the placement of conduit tracks or other devices in the enclosure.

If the drive is mounted to a back panel, the panel should be unpainted and electrically conductive

to allow for reduced electrical noise interference. The back panel should be machined to accept

the mounting bolt pattern of the drive. Make sure that all metal chips are cleaned up before the

drive is mounted so there is no risk of getting metal chips inside the drive.

The drive is mounted to the back panel with four M4 screws and internal-tooth lock washers. It

is important that the teeth break through any anodization on the drive’s mounting gears to

provide a good electrically conductive path in as many places as possible. Mount the drive on

the back panel so there is airflow at both the top and bottom areas of the drive (at least three

inches).

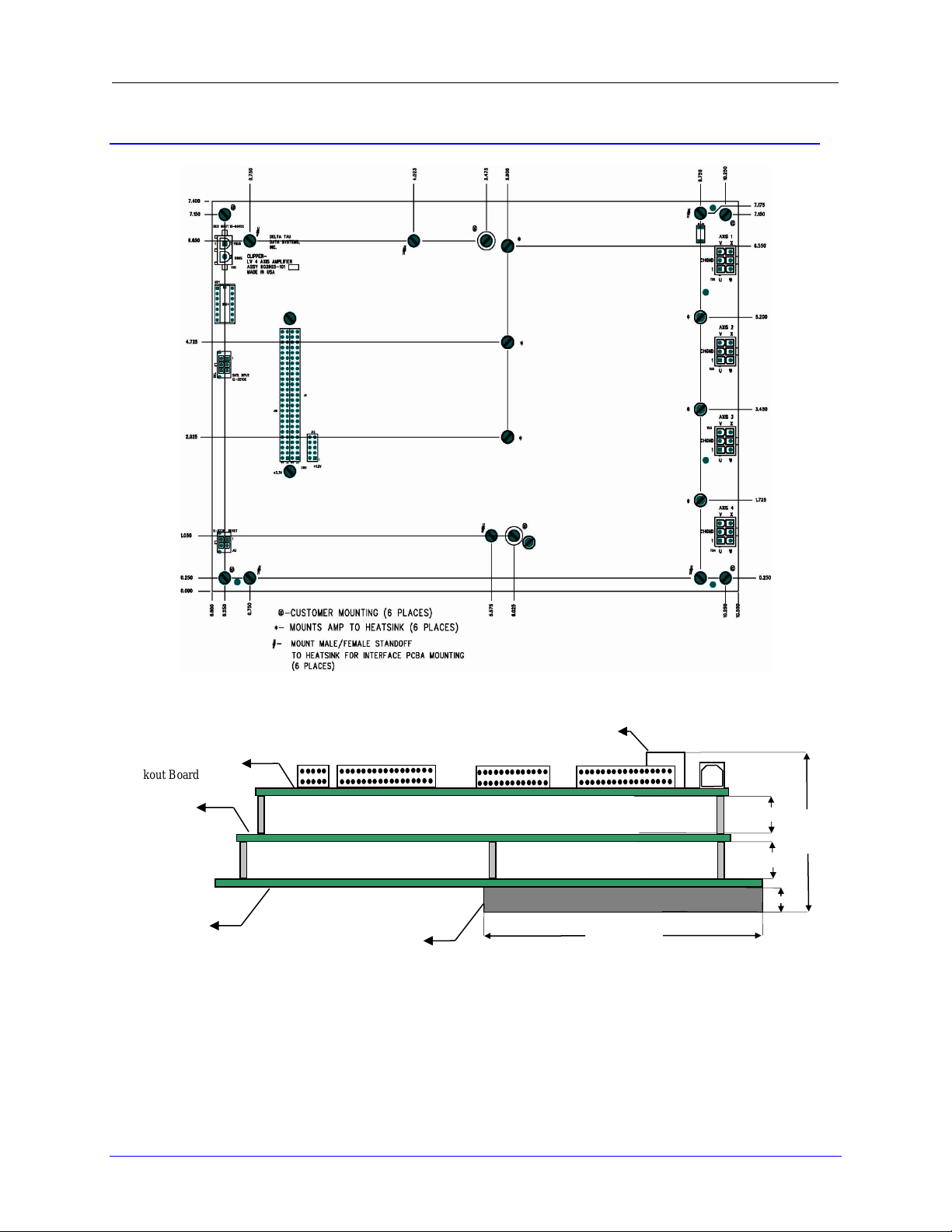

CAD drawing below shows the location of screws for mounting the drive to plate and mounting

the breakout board to the drive.

Receiving and Unpacking 11

Page 12

Breakout Board

(603926)

2.25

Power Board

Clipper Board

Ethernet

0.25

5.31

5.125

5.125

Heat Sink

CAD Drawing

Turbo Clipper Drive User Manual

(603871)

(603925)

Receiving and Unpacking 12

Page 13

Turbo Clipper Drive User Manual

Receiving and Unpacking 13

Page 14

Turbo Clipper Drive User Manual

WARNING

Installation of electrical control equipment is subject to

many regulations including national, state, local, and

industry guidelines and rules. General recommendations can

be stated but it is important that the installation be carried

out in accordance with all regulations pertaining to the

installation.

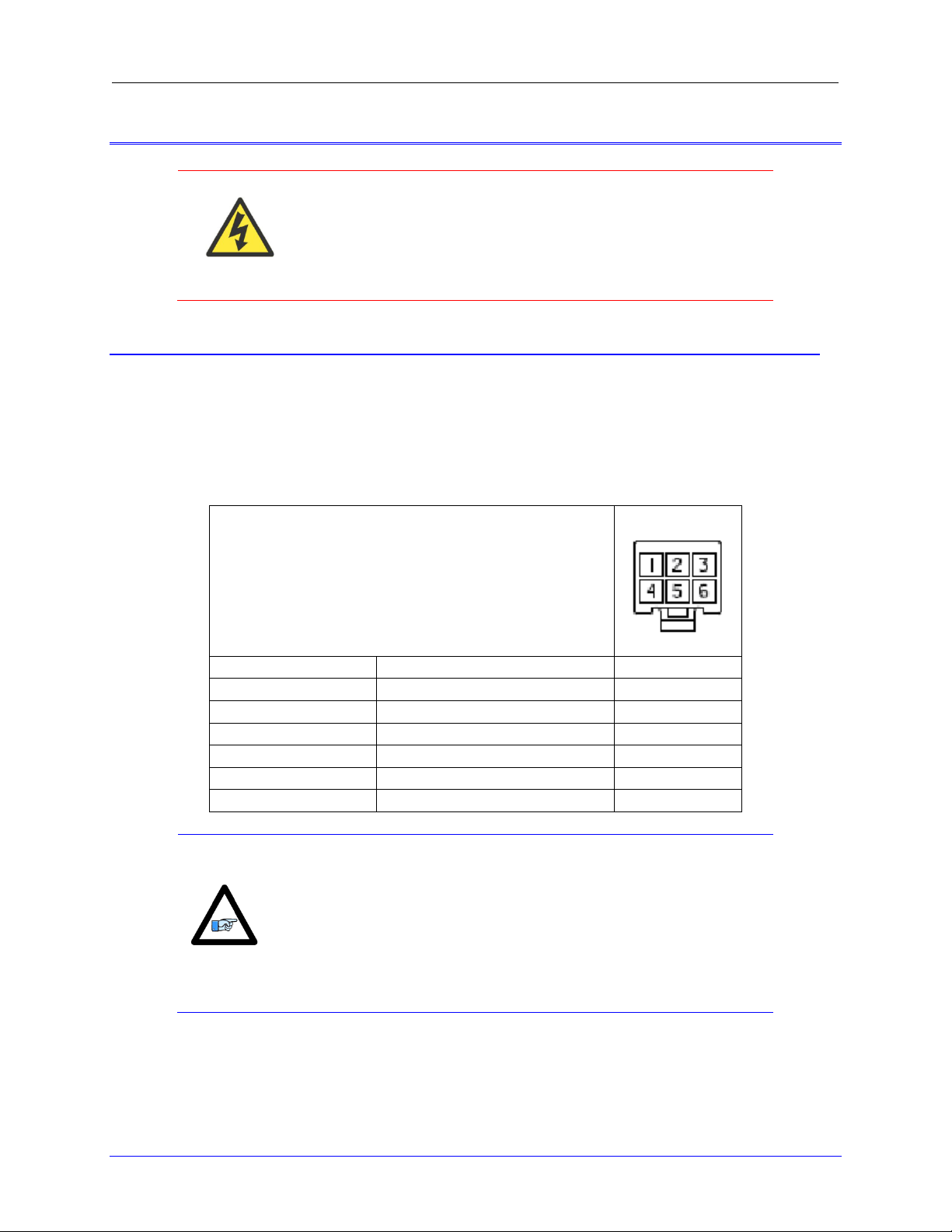

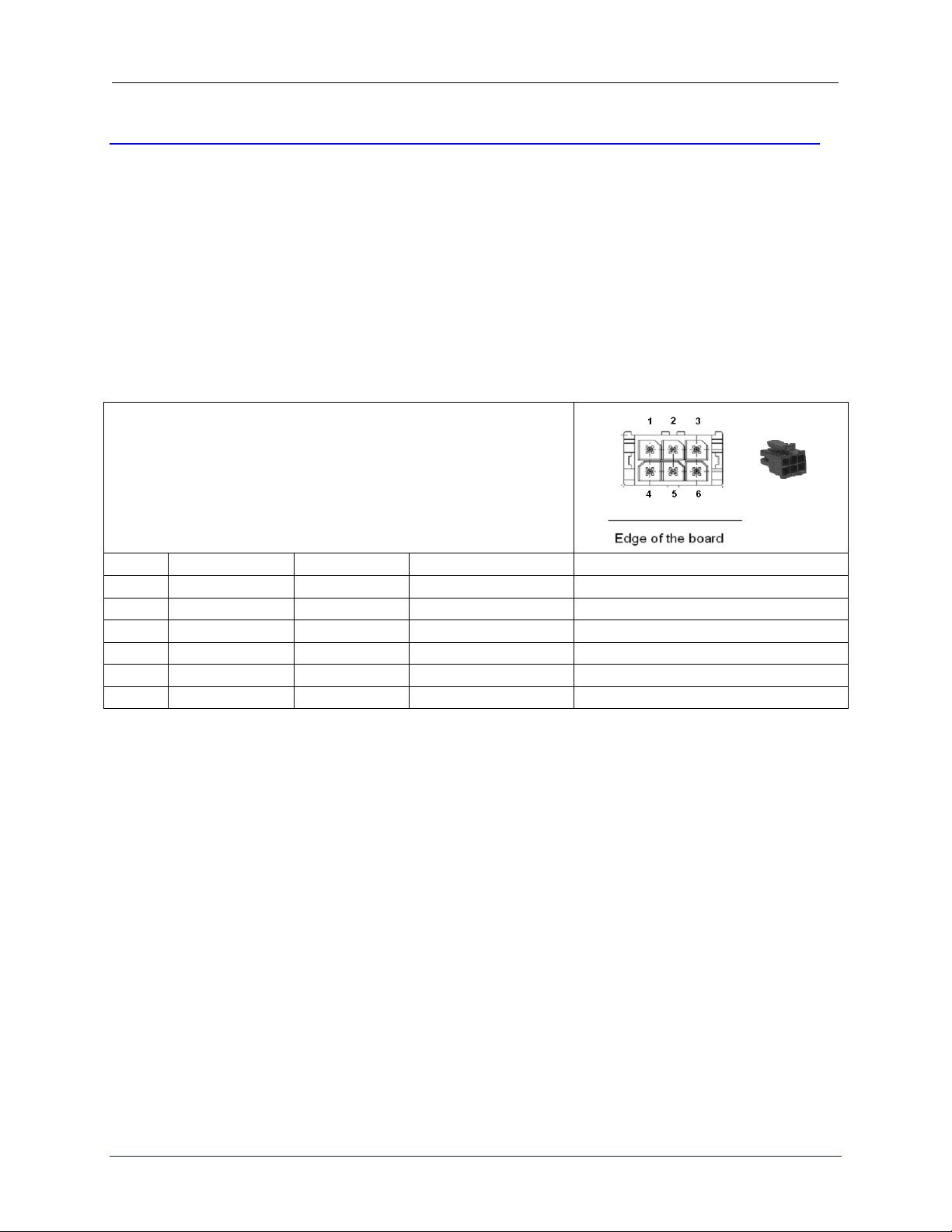

TB1-TB4: Molex (F)

Molex Mating Connector Part #: 39-01-2065 (M)

Molex Crimper Pin Part #: 39-00-0060

For Internal Use:

DT Part #: 014-390120-065

DT Part #: 014-555656-083

Pin #

Symbol

Description

1

U Phase

Axis 1-4

2

GND

Ground

3

V Phase

Axis 1-4

4

W Phase

Axis 1-4 5 GND

Ground

6

X Phase

Axis 1-4

Note

DC Brushless motors: Use U, V and W. Leave X floating

Stepper motors: Use U and W at one coil, V and X at the

other coil.

Brush motors: Use U and W. Leave V and X floating.

The cable wiring must be shielded and have a separate

conductor connecting the motor frame back to the

assembly ground.

POWER BOARD: WIRING, SOFTWARE SETUP

TB1-TB4: Motor Wiring

Motor phases are conversed in one of three conventions. Some motor manufacturers will call the

motor phases A, B, or C. Other motor manufacturers call them U, V, W. The Turbo Clipper

Drive outputs are called U, V, W, and X. For DC brushless motors (servo) use U,V and W, let X

float. For stepper motors, use U and W for one coil, V and X for the other coil. For DC Brush

motors, use U and W, float V and X. The motor’s frame drain wire and the motor cable shield

must be tied together and wired at the GND pin of the motor connector (Pin 5 or 2).

Power board: Wiring, Software Setup 14

Page 15

Turbo Clipper Drive User Manual

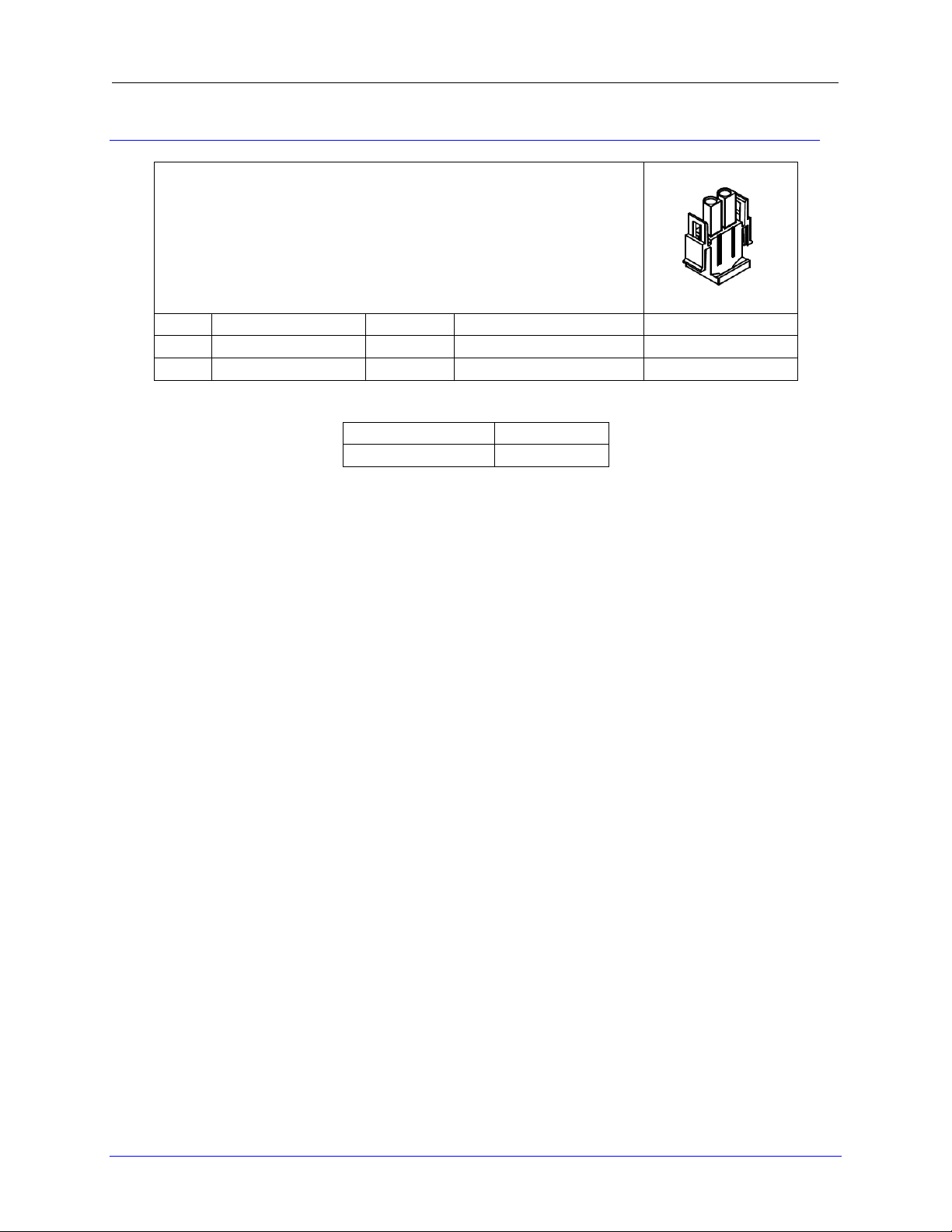

TB5: Molex (F)

Molex Mating Connector Part #: 43025 (M)

Molex Crimper Pin Part #: 43030-0008

For Internal Use:

DT Part #: 014-430250-600

DT Part #: 014-43030-008

Pin #

Symbol

Function

Description

Notes

1

24VDC

Input

Logic power input

+16~32VDC

2

NA

NA

NA

NA

3

24VDC RET

Common

Logic power return

Power Supply Return

4

24VDC

Input

Logic power input

+16~32VDC

5

NA

NA

NA

NA

6

24VDC RET

Common

Logic power return

Power Supply Return

TB5: 24-Volt Logic Power

An external 24Vdc power supply is required to power up the logic portion of the Turbo Clipper

Drive. This power can remain on, regardless of the main DC bus power, allowing the signal

electronics to be active while the main motor power control is inactive. The 24V is wired into

terminal block TB5. The polarity of this connection is extremely important. Carefully follow

the instructions in the wiring diagram. This connection can be made using 22 AWG wire

directly from a protected power supply. In situations where the power supply is shared with

other devices, it may be desirable to insert a filter in this connection.

The 24Volts power supply must be capable of providing 2~3Amps per Turbo Clipper Drive to

allow proper functionality. If multiple drives are sharing the same 24Volts power supply, it is

highly recommended to wire each drive back to the power supply terminals separately.

Power board: Wiring, Software Setup 15

Page 16

TB6: Molex (F)

Molex Mating Connector Part #:: 50-84-1020 (M)

Molex Crimper Pin Part #: 002081001

For Internal Use:

DT Part #: 014-030f02-HSM

DT Part #: 014-002081-001

Pin #

Symbol

Function

Description

Notes

1

+12~60VDC

Input

Bus power input VBus

+12~60VDC

2

+12~60VDC RET

Common

Bus power return 0Bus

+12~60VDC RET

Fuse (FRN/LPN)

Wire Gauge

15

12 AWG

TB6: Bus Voltage

Recommended Fuse, and wire gauge:

Turbo Clipper Drive User Manual

Power board: Wiring, Software Setup 16

Page 17

Turbo Clipper Drive User Manual

TB6: Molex (F)

Molex Mating Connector Part #: 430250-0400 (M)

Molex Crimper Pin Part #: 43030-0008

For Internal Use:

DT Part #: 014-430250-400

DT Part #: 014-43030-008

Pin #

Symbol

Description

1

Reset

Connect 1-2 to activate the reset.

2

Reset

3

E-STOP

Connect 3-4 to engage the E-Stop

4

E-STOP

Note

The built-in Emergency Stop circuitry disables the Mosfet

transistors but does NOT remove power from the DC bus. If this

additional level of protection is required, it is recommended to

add a separate external device to remove the DC Bus input from

the Turbo Clipper Drive.

J13: E-Stop, Reset

The Turbo Clipper Drive is equipped with a built-in Emergency Stop circuitry. It utilizes two

latching type relays to enable/disable the drive’s Mosfet transistors. Additionally, the following

safety and status features are implemented:

The E-Stop status, by default, is conveyed to the Turbo Clipper via User Flag Input #4

(X:$78018,19).See jumper J39.

The General Purpose Outputs (GPO), by default, is independent of the E-Stop status.

They can be disabled in an emergency stop condition. See jumper J36.

The Turbo Clipper Drive has an E-Stop software controllable enable bit (Y:$78402,15,1).

It is a low true logic meaning =0 to engage E-Stop, =1 to disengage E-Stop, allowing the

user to trigger an emergency stop condition through software logic.

Power board: Wiring, Software Setup 17

Page 18

Turbo Clipper Drive User Manual

The E-Stop button should be a normally-closed switch, so

that the circuit is closed when it is released and open when

it is pressed.

The Reset button should be a normally-open switch before

revision 103, so that the circuit is open when it is released

and closed when it is pressed. Revision 103 and after the

type of Reset button can be selectable via jumper E4.

Note

It is recommended to wire the EStop in series with the reset

circuit, so if the machine is in an

emergency stop condition, the

reset cannot be activated and has

no practical use.

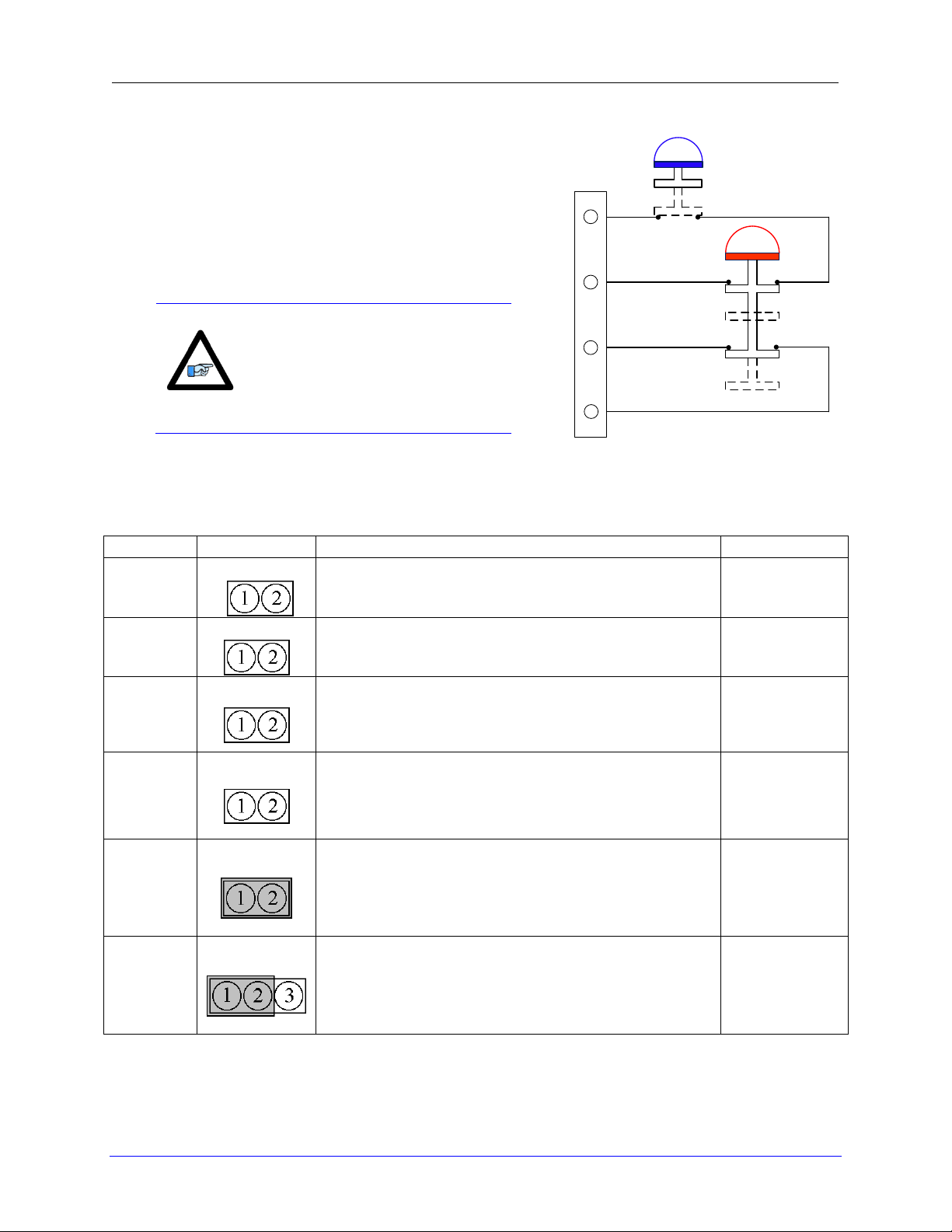

E-STOP

Normally

Open

Normally

Closed

RESET

1

2

3

4

J13

Board

Jumper

Function

Default

Power

E1

Remove to enable the hard E-Stop function.

Install to disable the hard E-Stop function.

Not Installed

Power

E2

Remove to enable hard & soft E-Stop functions.

Install to disable hard & soft E-Stop functions.

Not Installed

Power

E3

Remove to enable the soft E-Stop function.

Install to disable the soft E-Stop function

(Soft E-Stop bit has to be set, and saved to 1).

Not Installed

Power

E4

Remove jumper to use normally-open Reset switch

between pin 1 and 2 of J13.

Install jumper to use normally-closed Reset switch

between pin 1 and 2 of J13.

Not Installed

Breakout

J36

Install jumper to disable the GPO E-Stop automatic

feature (outputs unaffected by E-Stop status).

Remove Jumper to enable the GPO E-Stop

automatic feature (turn outputs off when in E-Stop)

Installed

Breakout

J39

Jump 1 to 2 to use User Flag 4 as an E-Stop status

in software.

Jump 2 to 3 to use User Flag 4 as a general purpose

user input.

Jumpered

1-2

Wiring The E-Stop, And Reset Switch

Emergency Stop, Reset Jumpers Summary

The following table summarizes the E-Stop and Reset features. The hard E-Stop designates the

actual hardware E-Stop button. The soft E-Stop designates the software controllable E-Stop bit:

Power board: Wiring, Software Setup 18

Page 19

Turbo Clipper Drive User Manual

Note

Upon releasing the E-Stop, the General Purpose Outputs (GPO)

state, otherwise handled by PLC/software, is re-established to

what it was prior to pressing the E-Stop.

Emergency Stop-Reset Example PLC

In addition to the automatic Emergency Stop functionality a PLC must be used to insure proper

and complete Emergency Stop function once the Mosfet transistors are disabled. During an

emergency stop condition, it is highly advised to implement the following:

Kill motors.

Turn off general purpose outputs (GPOs).

Other functions insuring machine safety.

With E1, E2, E3, and E4 removed allowing both hardware and software E-Stop functionality.

J36 removed, to automatically turn off the general purpose outputs, and J39 set to 1-2 to allow

reading the E-Stop status through User flag4:

// Definition and Substitutions

#define Estop_Latch P8000 ; General purpose Latching flag

#define Estop_Enable M47 ; Software Controllable E-Stop Bit

Estop_Enable->Y:$78402,15,1 ; =0 E-Stop, =1 Not in E-Stop

Estop_Enable=1

#define Estop_Status M415 ; S-Stop Status Bit, using User Flag 4

Estop_Status->X:$78018,19 ; =1 E-Stop, =0 Not in E-Stop

Open PLC 1 Clear

// Is E-Stop Pressed?

If (Estop_Status=1)

Estop_Latch=0

Else

Estop_Latch=1

EndIF

Estop_Enable=1 ; Set once on power-up

While (1=1)

// Emergency Stop Engaged

If(Estop_Status = 1 and Estop_Latch = 0)

// Put Emergency Stop Functions Here

&1 CMD^K ; Kill all axes in Coordinate System 1

// Set desired Outputs state (post E-Stop) here

// if automatic GPO kill is enabled

Estop_Latch = 1

Else

// Emergency Stop Released

IF(Estop_Status = 0 and Estop_Latch = 1)

// Put Emergency Stop Release Functions Here

&1 CMD^A ; Enable all axes in Coordinate System 1

Estop_Latch = 0

P8002=P8002+1

EndIf

EndIf

Endwhile

Close

Power board: Wiring, Software Setup 19

Page 20

Turbo Clipper Drive User Manual

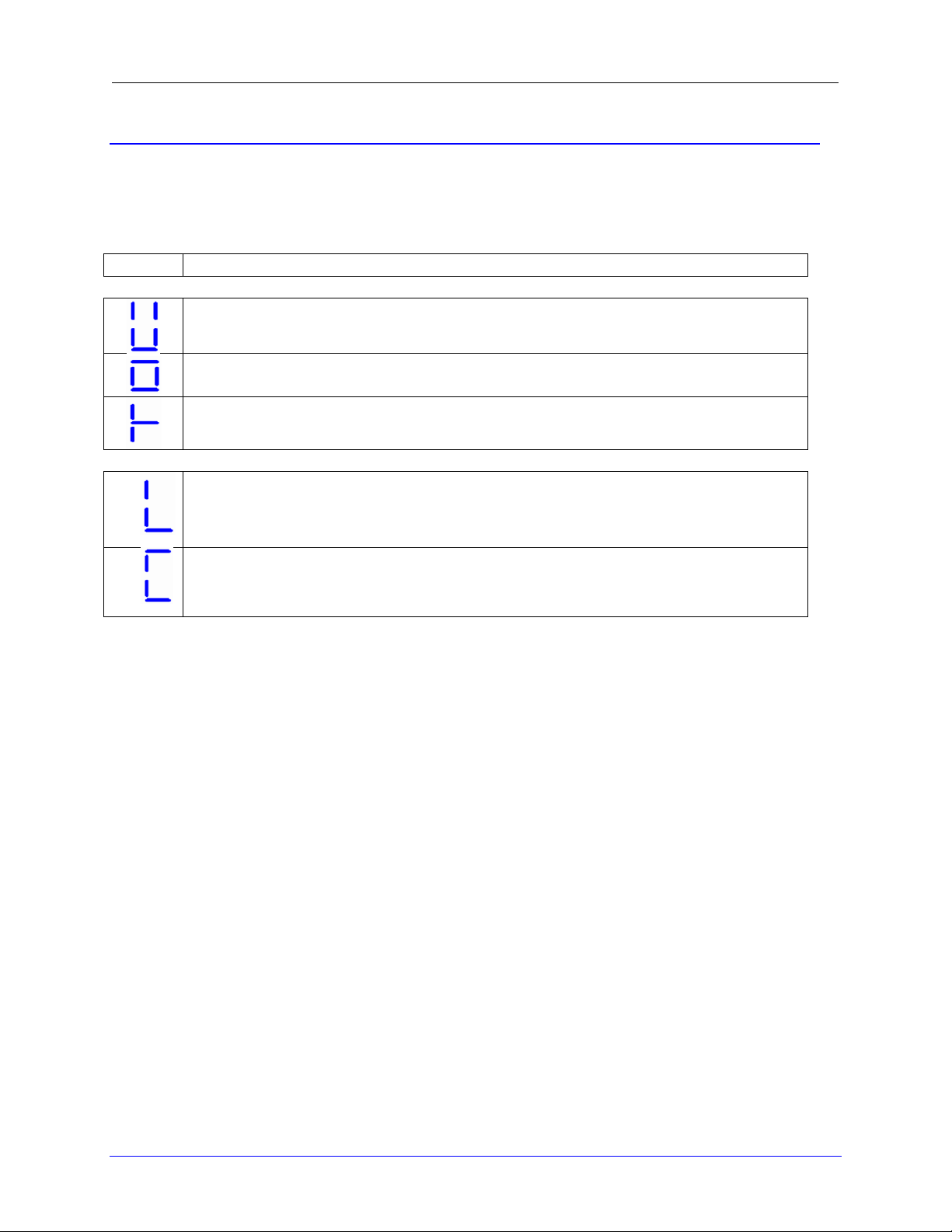

Display

Description

Global Faults

Under Voltage Fault:

Indicates that the bus voltage is not present or less than 12Volts

Over Voltage Fault:

Indicates that the bus voltage has exceeded 60Volts

Over Temperature Fault:

Indicates that the Board has exceeded 65°C

Axis n Faults (n=1 thru 4)

n

Axis n Over load Fault:

Indicates that the current rating (5/15A) of the drive has been exceeded

n

Axis n Over Current Fault:

Indicates that the peak current value has exceeded the permissible limit(20Amps)

D1: AMP STATUS

The Turbo Clipper Drive utilizes a scrolling single-digit 7-segment display to exhibit faults to the

outside world. When control and DC bus power are applied, the Drive will display a solid dot

indicating that the software and hardware are running normally.

Error Codes

Power board: Wiring, Software Setup 20

Page 21

Turbo Clipper Drive User Manual

Caution

This connector is only used if the power board is not present. It

is utilized to bring in logic power to the control (Clipper) and

breakout boards.

TB1: Molex (F)

Molex Mating Connector Part #:: 39-01-2045 (M)

Molex Crimper Pin Part #: 39-00-0060

For Internal Use:

DT Part #: 014-390120-045

DT Part #: 014-555656-083

Pin #

Symbol

Function

Notes

1

GRD

Input

Ground

2

+5 VDC

Input

5 volt Input

3

+12 VDC

Input

12 volt Input

4

-12 VDC

Input

-12 volt Input

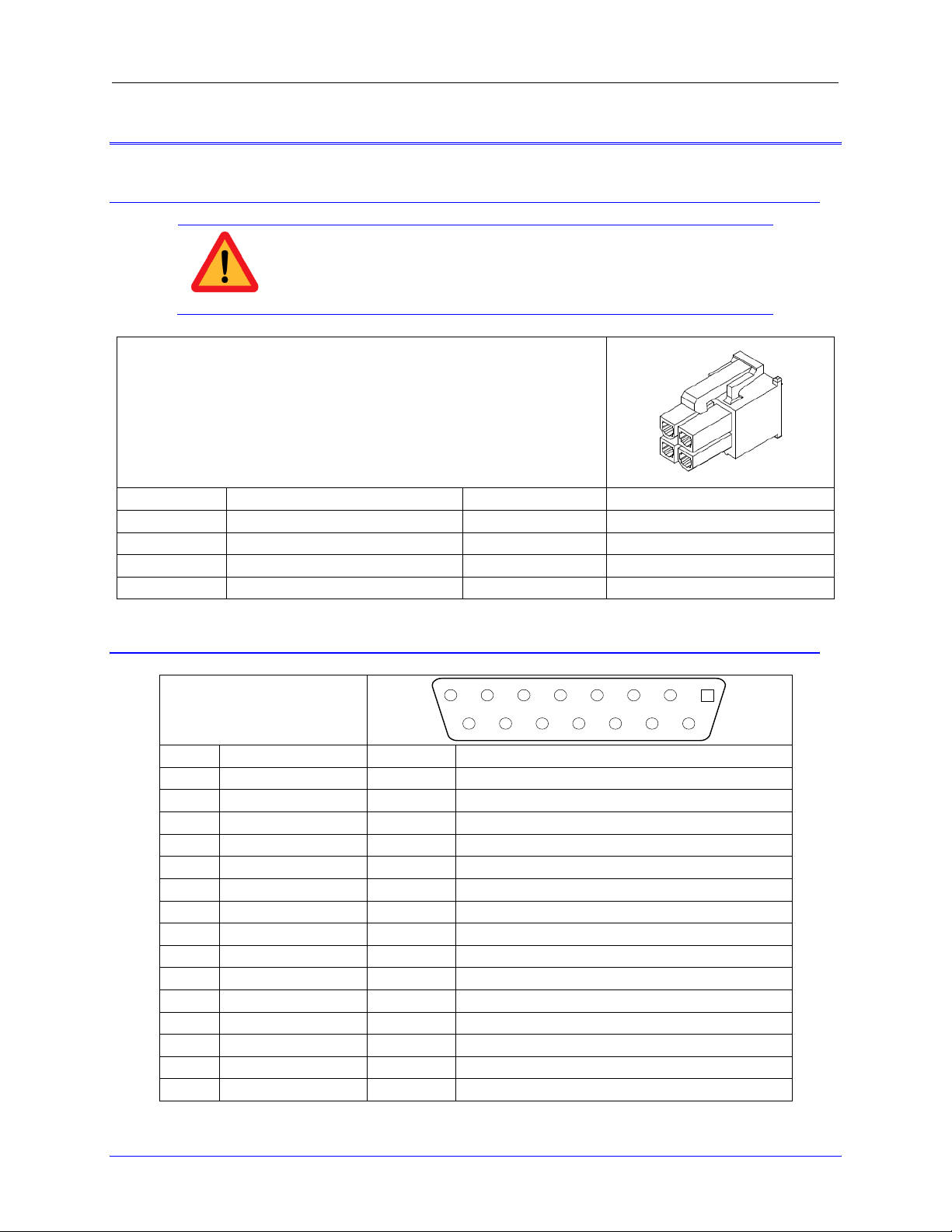

J11-J14: D-sub DA-15F

Mating: D-sub DA-15M

2345

9101112

67

1314

8

15

1

Pin#

Symbol

Function

Description

1

CHA+

Input

Axis Encoder A+

2

CHB+

Input

Axis Encoder B+

3

CHC+

Input

Axis Encoder Index+

4

ENCPWR

Output

Encoder Power 5V

5

CHU+ / DIR+

In/Out

Halls U+ / Direction Output + for Stepper

6

CHW+/ PUL+

In/Out

Halls W+ / Pulse Output + for Stepper

7

2.5V

Output

2.5V Reference power

8

Stepper Enable

Input

Tie to pin#4 (5V) to enable stepper output

9

CHA-

Input

Axis Encoder A-

10

CHB-

Input

Axis Encoder B-

11

CHC-

Input

Axis Encoder Index-

12

GND

Common

Common ground

13

CHV+ / DIR-

In/Out

Halls V+ / Direction Output- for Stepper

14

CHT+ / PUL-

In/Out

Halls T+ / Pulse Output- for Stepper

15

N/C

-

Reserved for future use

BREAKOUT BOARD: WIRING, SOFTWARE SETUP

TB1: External Power Supply

J11-J14: Encoder Feedback, Digital A Quad B

Breakout Board: Wiring, Software Setup 21

Page 22

Turbo Clipper Drive User Manual

Note

Spacing specs between DB-Connectors can be found in

Appendix section.

12345678

9101112131415

CHA+

CHACHB+

CHBCHC+

CHC+5VDC

GND

12345678

9101112131415

CHA+

CHB+

CHC+

+5VDC

GND

1.2KΩ

1.2KΩ

1.2KΩ

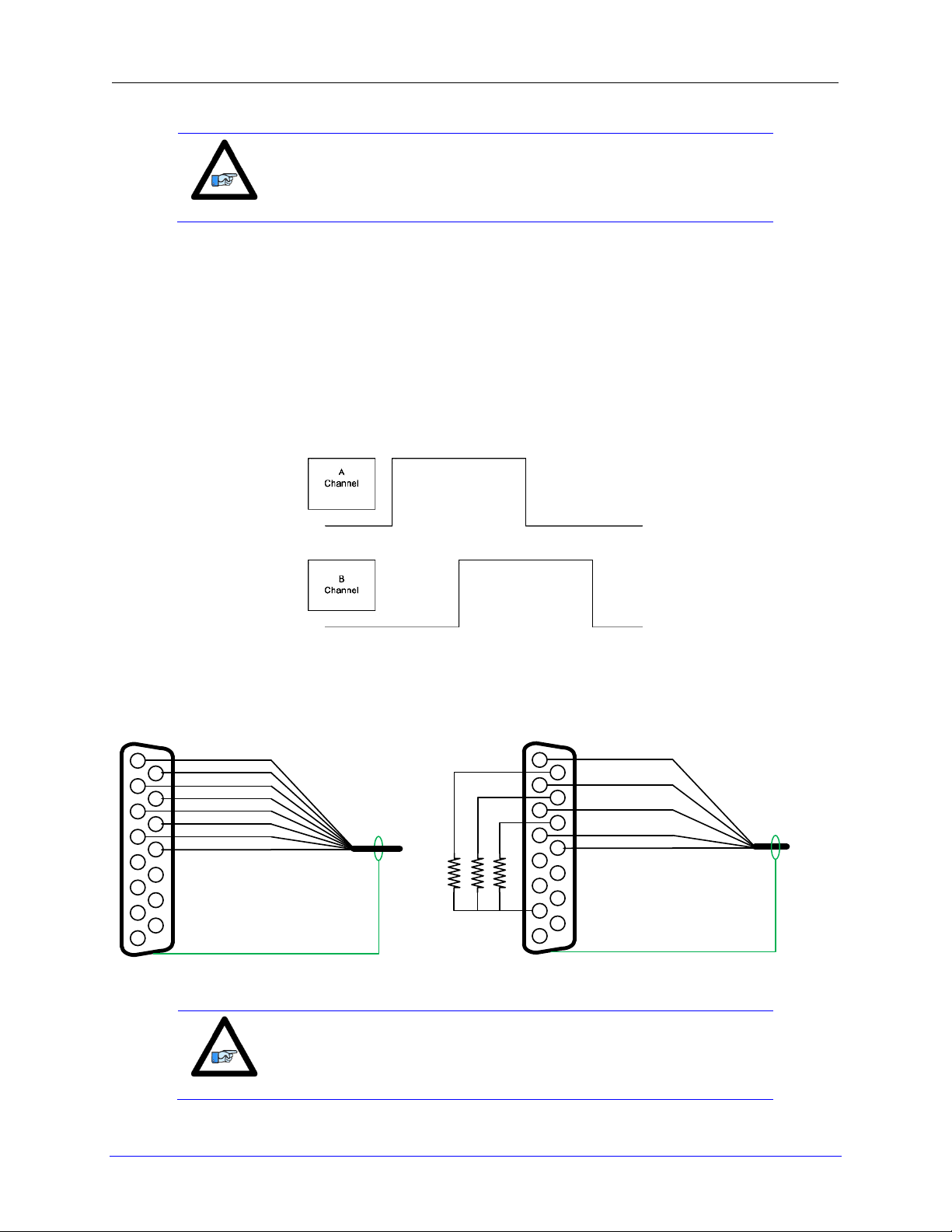

Differential Quadrature Encoder Wiring

Single-Ended Quadrature Encoder Wiring

Note

For single-ended encoders, tie the negative pins (i.e. CHAn-) to

reference (Pin#7) in series with a 1Kohm resistor.

The standard encoder input channels on the Turbo Clipper Drive Drive are designed for

differential quadrature feedback. To use single-ended encoders, the negative pins (i.e. CHAn-)

have to be tied to reference (Pin#7) in series with a 1Kohm resistor.

Quadrature encoders provide two digital signals to determine the position of the encoder/motor.

Each nominally with 50% duty cycle, and nominally 1/4 cycle apart. This format provides four

distinct states per cycle of the signal, or per line of the encoder. The phase difference of the two

signals permits the decoding electronics to discern the direction of travel, which would not be

possible with a single signal.

Typically, these signals are 5V TTL/CMOS level, whether they are single-ended or differential.

Differential encoder signals can enhance noise immunity by providing common mode noise

rejection. Modern design standards virtually mandate their use in industrial systems.

Breakout Board: Wiring, Software Setup 22

Page 23

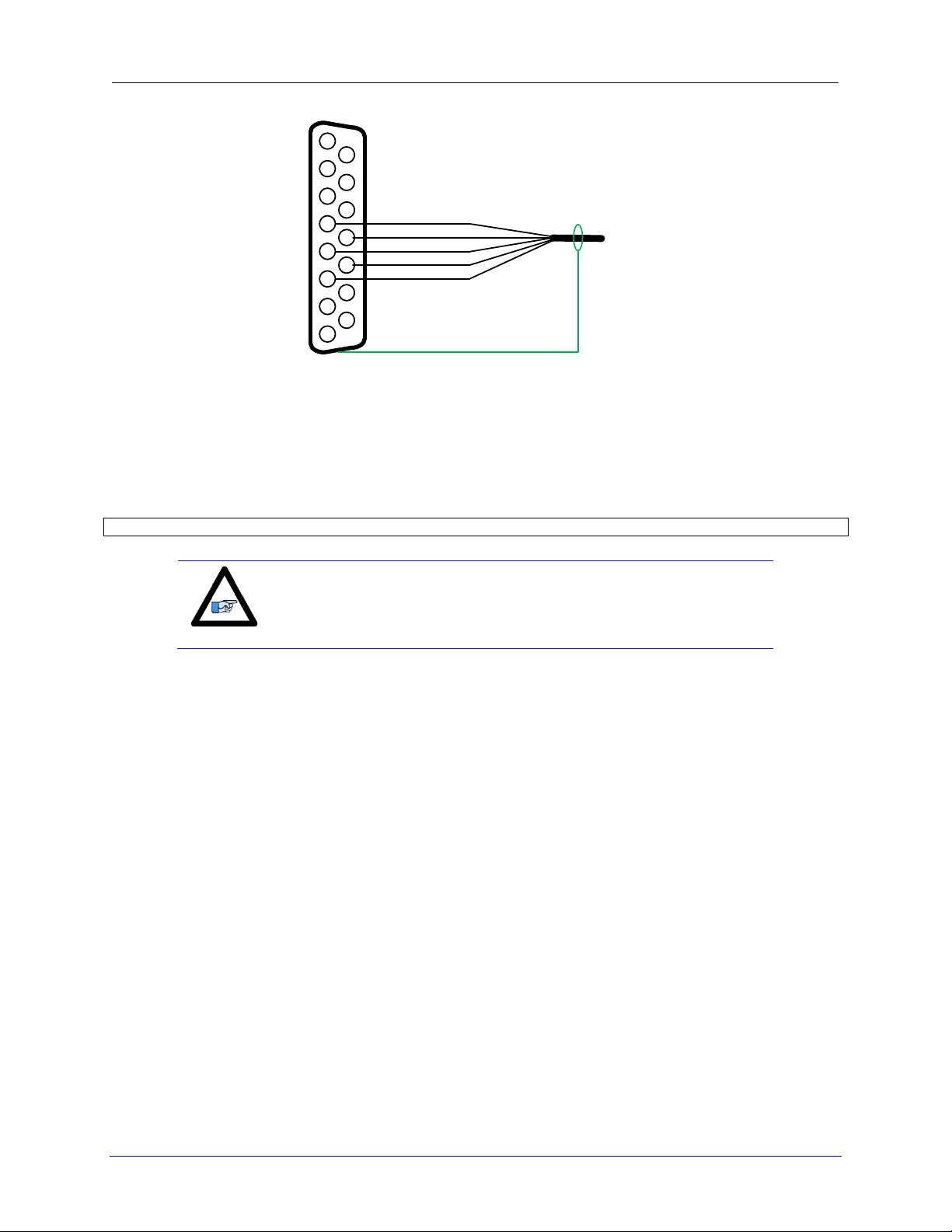

Turbo Clipper Drive User Manual

12345678

9101112131415

+5VDC

GND

CHU+

CHV+

CHW+

Note

At this point of the setup, you should be able to move the

motor/encoder shaft by hand and see ‘motor’ counts in the

position window

Hall-Effect Sensor Wiring

Motor Activation: Ixx00

Digital Quadrature Encoders use the 1/T incremental entry in the encoder conversion table.

Position and Velocity pointers are by default valid and in most cases no special software setup is

required, activating the motor(s) is sufficient to see encoder counts in the position window when

the motor/encoder shaft is moved by hand.

I100,4,100=1 ; Motors 1-4 activated

Breakout Board: Wiring, Software Setup 23

Page 24

Turbo Clipper Drive User Manual

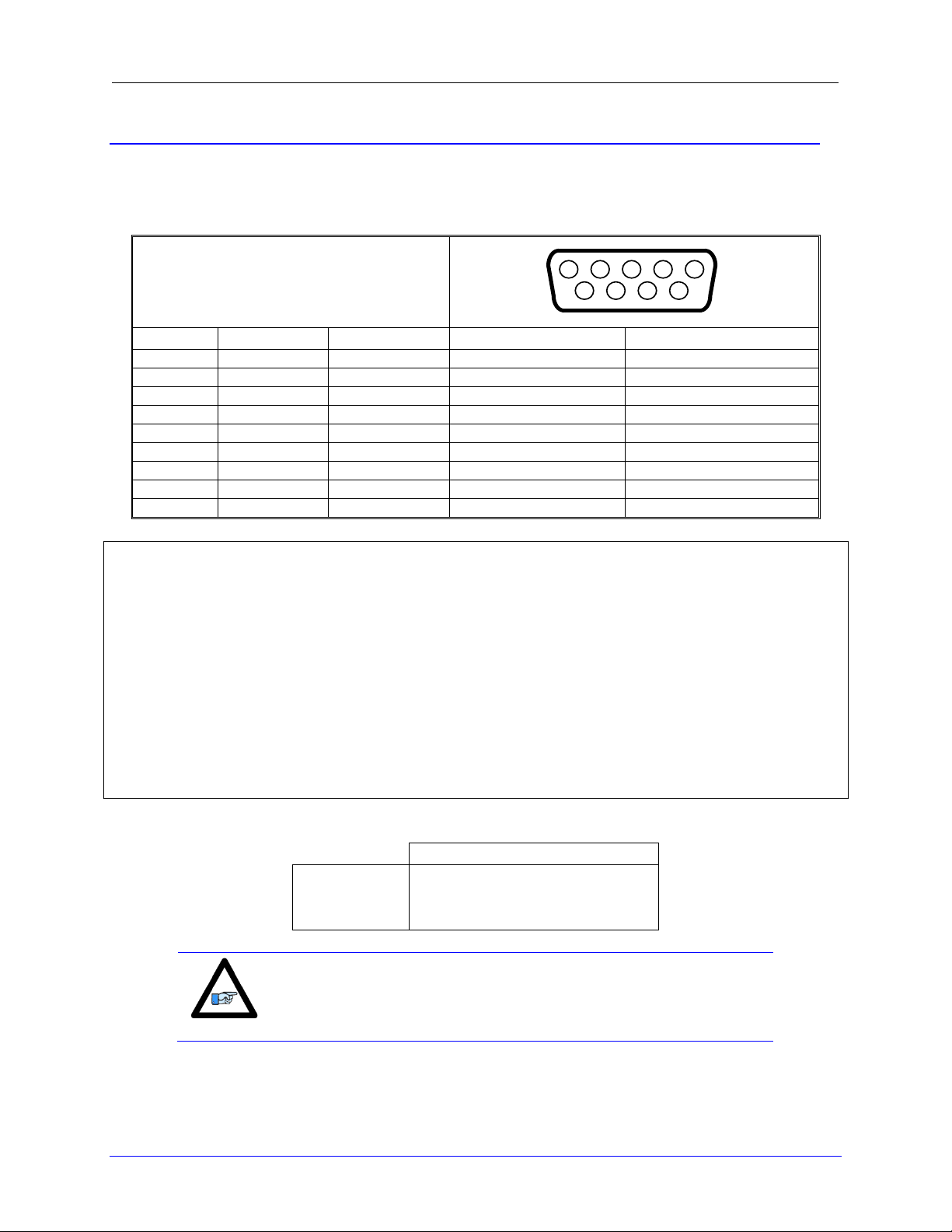

J9-J12: D-Sub DE-9F

Mating: D-Sub DE-9M

12345

6789

Pin #

Symbol

Function

Description

Notes

1

SIN +

Analog Input

Sinusoidal input+

2 COS +

Analog Input

Cosine input+

3 INDEX +

Input

Index input

Analog or TTL levels

4

ENCPWR

Output

Encoder power

+5VDC

5

GND

Digital ground

6

SIN -

Analog Input

Sinusoidal input-

7 COS -

Analog Input

Cosine input-

8 INDEX -

Input

Index input

Analog or TTL levels

9

VREF

2.5V Output

A-D reference output

Position And Velocity Pointers

Channels 1-4

I103=$3503 I104=$3503

I203=$3506 I204=$3506

I303=$3509 I304=$3509

I403=$350C I404=$350C

Note

At this point of the setup, you should be able to move the

motor/encoder shaft by hand and see ‘motor’ counts in the

position window

ACC-51S: Sinusoidal Feedback (Optional)

The accessory ACC-51S allows the Turbo Clipper Drive to interface to up to 4 sinusoidal

feedback devices. This high resolution interpolator circuitry accepts inputs from sinusoidal or

quasi-sinusoidal encoders (1-Volt peak to peak) and provides encoder position data. It creates

4,096 steps per sine-wave.

// Channel 1

I8000=$FF8000 ; High resolution interpolator

I8001=$078B00 ; A/D converter address

I8002=$000000 ; Bias Term and Entry result

// Channel 2

I8003=$FF8008 ; High resolution interpolator

I8004=$078B02 ; A/D converter address

I8005=$000000 ; Bias Term and Entry result

// Channel 3

I8006=$FF8010 ; High resolution interpolator

I8007=$078B04 ; A/D converter address

I8008=$000000 ; Bias Term and Entry result

// Channel 4

I8009=$FF8018 ; High resolution interpolator

I8010=$078B06 ; A/D converter address

I8011=$000000 ; Bias Term and Entry result

I100,4,100=1 ; Axis 1-4 active

Position and Velocity feedback pointers should now be set to the corresponding ECT result:

Breakout Board: Wiring, Software Setup 24

Page 25

Turbo Clipper Drive User Manual

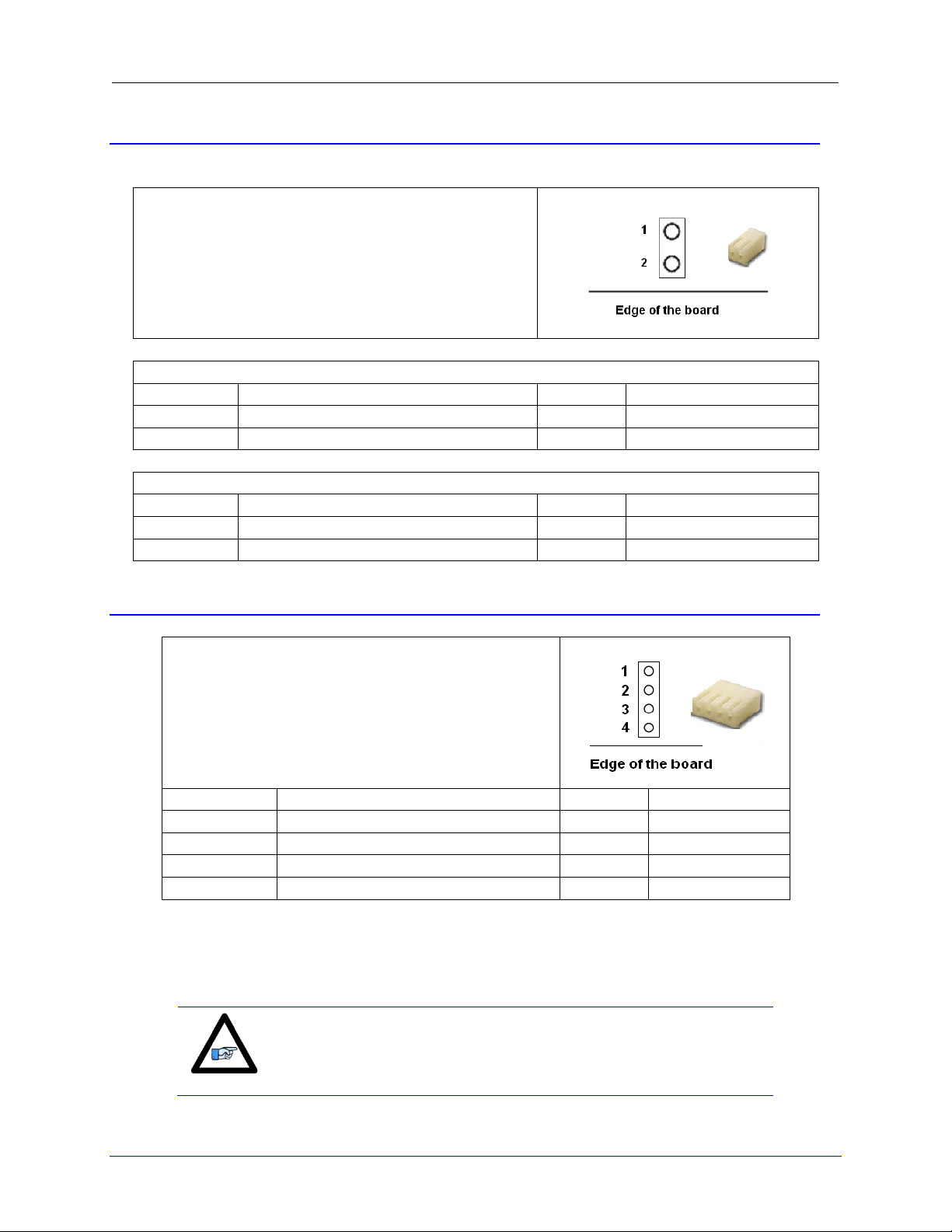

J15: Molex (M)

Molex Mating Connector Part #:: 22-01-3027 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R02-LHM

DT Part #: 025-500114-PNM

Sinking Configuration

Pin #

Symbol

Function

Description

1

24VDC FLA_PWR

Input

Flag Power (+24VDC)

2

24VDC FLA_RET

Input

Flag Return (Common)

Sourcing Configuration

Pin #

Symbol

Function

Description

1

24VDC FLA_RET

Input

Flag Return (Common)

2

24VDC FLA_PWR

Input

Flag Power (+24VDC)

J16/J17/J18/J19: Molex (M)

Molex Mating Connector Part #: 22-01-3047 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R04-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

PLIM +

Input

Positive Limit+

2

MLIM +

Input

Negative Limit+ 3 HOME +

Input

Home+

4

FLA_PWR/RET

Common

Flag PWR/RET

Note

For 5V flags: Install RP3, RP7, RP11, RP15 (1 kΩ sip).

SIPs are 8-pin, four independent Resistors.

For 12-24V flags: Empty bank (default).

J15: Flag(s) Power Supply

The flag(s) wiring is user configurable; it can be either sinking or sourcing.

J16-J19: Axis 1 thru 4 Limits & Home Flags

The Turbo Clipper Drive limits and flags circuitry offers a flexible 12-24Volts or 5Volts

connectivity. In its default configuration, the flags and limits are 12-24Volts inputs. If you are

using 5Volt flags and limits, make sure you have ordered the appropriate option before wiring

any flags.

Breakout Board: Wiring, Software Setup 25

Page 26

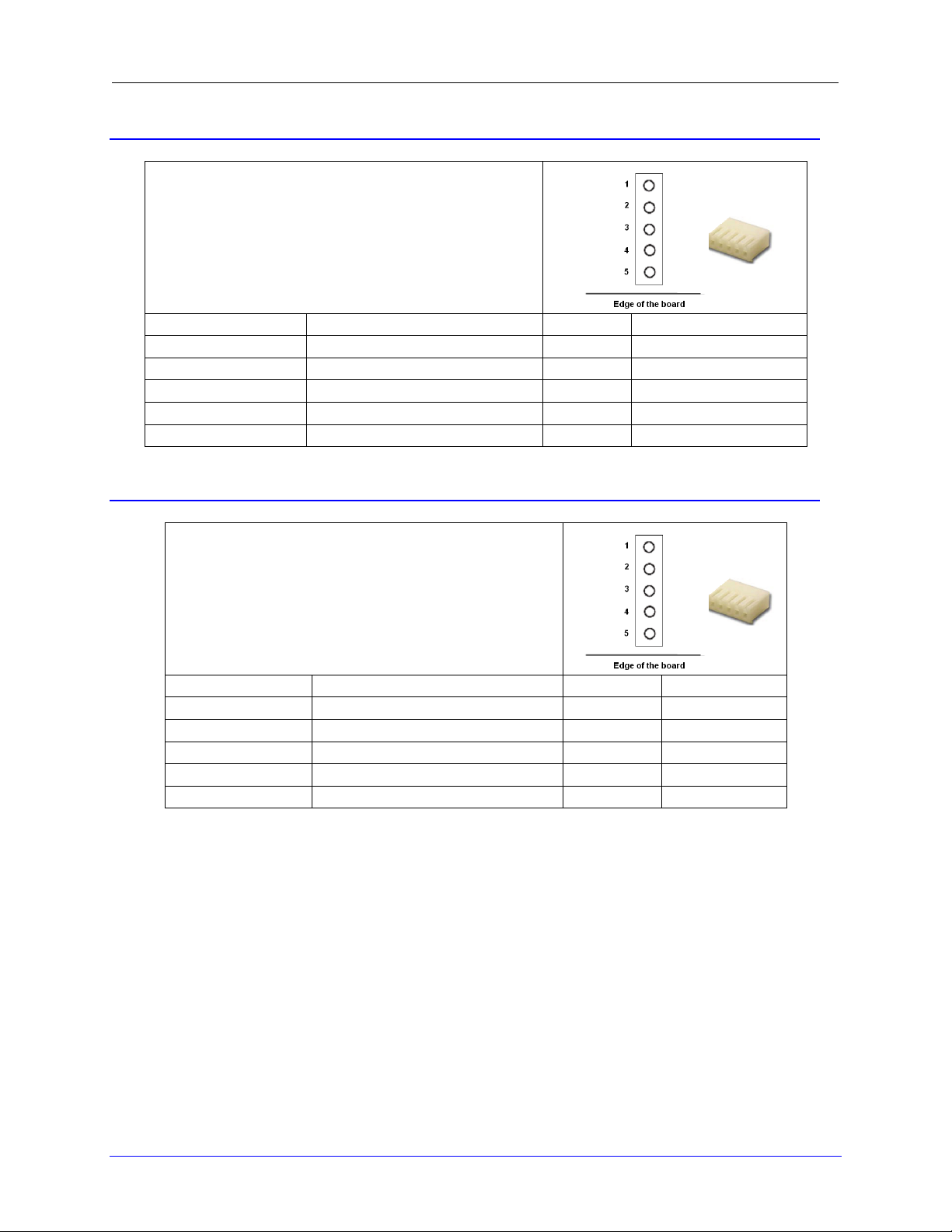

J20: Molex (M)

Molex Mating Connector Part #: 22-01-3057 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R05-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

EQU_1+

Input

Position Compare 1+

2

EQU_2+

Input

Position Compare 2+

3

EQU_3+

Input

Position Compare 3+

4

EQU_4+

Input

Position Compare 4+

5

GND

Common

Ground

J21: Molex (M)

Molex Mating Connector Part #: 22-01-3057 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R05-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

USER_1+

Input

User Flag 1+

2

USER_2+

Input

User Flag 2+

3

USER _3+

Input

User Flag 3+

4

USER _4+

Input

User Flag 4+ 5 GND

Common

Ground

J20: Axis 1 thru 4 EQU Outputs

J21: Axis 1 thru 4 User Flags

Turbo Clipper Drive User Manual

Breakout Board: Wiring, Software Setup 26

Page 27

Turbo Clipper Drive User Manual

J15:Power Supply Input

Sinking/Sourcing

Pin#1

Pin#2

Sinking

24VDC+

+24VDC RET

Sourcing

+24VDC RET

24VDC+

Flag Supply

12-24VDC

24V

Return

Flag

Sourcing

Separate

Supply

0V

Flag Supply

12-24VDC

24V

0V

Return

Flag

Sinking

Separate

Supply

Limits and Flags (Axis1- 4) Suggested M-Variables

M115->X:$078000,19 ; User 1 flag input status

M116->X:$078000,9 ; EQU1, ENC1 compare output value

M120->X:$078000,16 ; Home flag 1 input status

M121->X:$078000,17 ; Positive Limit 1 flag input status

M122->X:$078000,18 ; Negative Limit 1 flag input status

M215->X:$078008,19 ; User 2 flag input status

M216->X:$078008,9 ; EQU2, ENC2 compare output value

M220->X:$078008,16 ; Home flag 2 input status

M221->X:$078008,17 ; Positive Limit 2 flag input status

M222->X:$078008,18 ; Negative Limit 2 flag input status

M315->X:$078010,19 ; User 3 flag input status

M316->X:$078010,9 ; EQU3, ENC3 compare output value

M320->X:$078010,16 ; Home flag 3 input status

M321->X:$078010,17 ; Positive Limit 3 flag input status

M322->X:$078010,18 ; Negative Limit 3 flag input status

M415->X:$078018,19 ; User 4 flag input status

M416->X:$078018,9 ; EQU4, ENC4 compare output value

M420->X:$078018,16 ; Home flag 4 input status

M421->X:$078018,17 ; Positive Limit 4 flag input status

M422->X:$078018,18 ; Negative Limit 4 flag input status

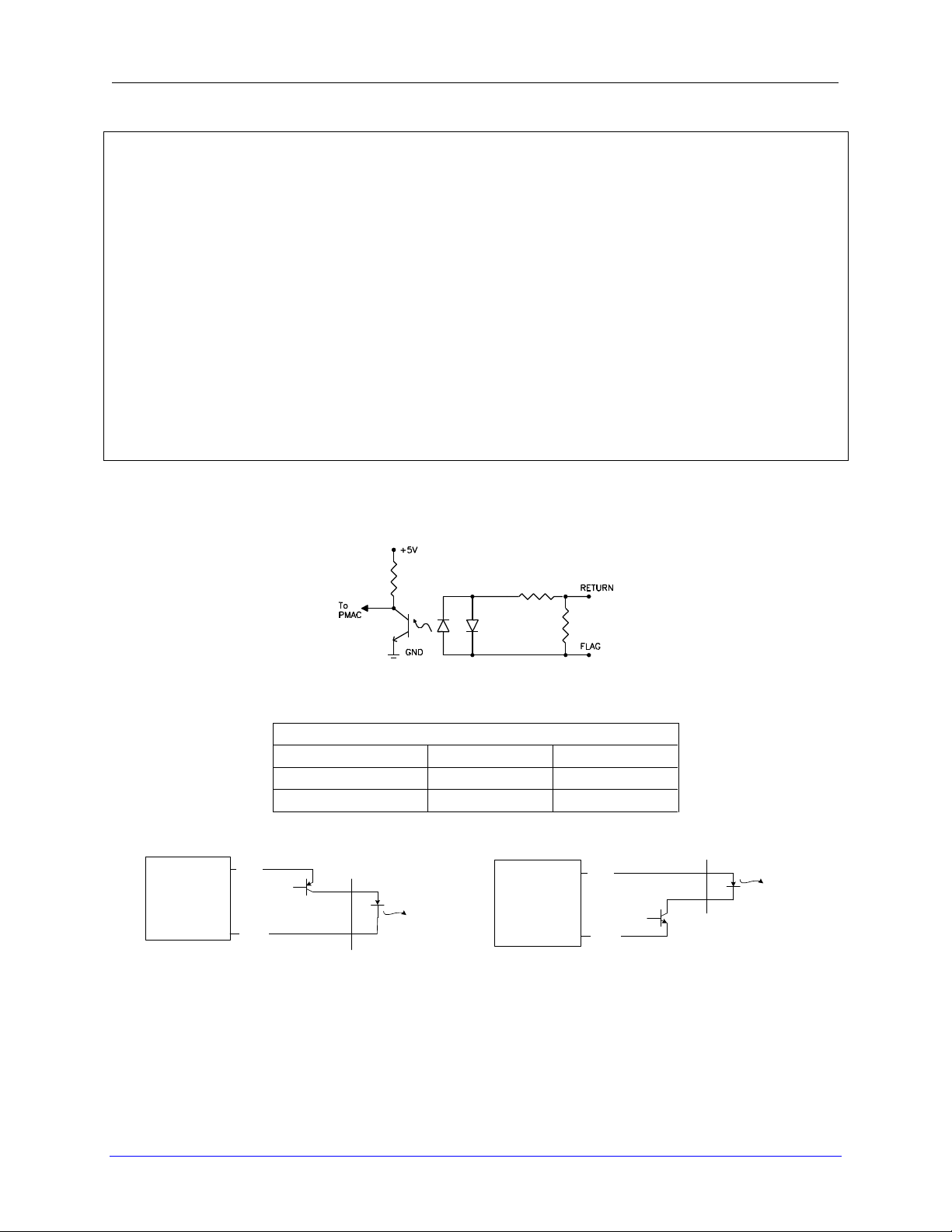

The Turbo Clipper Drive allows the use of sinking or sourcing limits and flags. The opto-isolator

IC used is a PS2705-1NEC quad phototransistor output type. This IC allows the current to flow

from return to flag (sinking) or from flag to return (sourcing).

The flags can be sinking and/or sourcing per channel depending on the Flag Input Power Supply

J15 wiring.

Breakout Board: Wiring, Software Setup 27

Page 28

1

2

3

4

Sinking

0V

24V

1

2

24 V Supply

J15

Breakout

Outside

FL_RT

FLA_PWR/RET

FLA_RET/PWR

Load

Load

Load

Pos.Limit

Neg.Limit

Home

1

2

3 4 5

User 1

User 2

User 3

User 4

1

2

3 4 5

EQU 1

EQU 2

EQU 3

EQU 4

1

2

3

4

J16-J19

0V

24V

1

2

24 V Supply

J15

Breakout

Outside

FL_RT

FLA_PWR/RET

FLA_RET/PWR

Load

Load

Load

Pos.Limit #n

Neg.Limit #n

Sourcing

0V

12~24V

24V

User Flags and EQU Outputs

J16-J19

J21

J20

Wiring The Flags

Turbo Clipper Drive User Manual

World

Flags

Board

World

Board

Flags

Supply

Breakout Board: Wiring, Software Setup 28

Page 29

Turbo Clipper Drive User Manual

J21: Molex (M)

Molex Mating Connector Part #: 22-01-3027 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R02-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

+5V_5A

Output

5 volts in normal operation

2

B_WDO

Output

Ground

J23: Watchdog Output

This connector allows the user to send Ohm output from the Turbo Clipper Drive to the machine

if a watchdog condition has occurred. This is an important safety feature because the Clipper

Amp is totally disabled when it is in watchdog condition and this output will allow the other

machine’s hardware/logic to bring the process to a safe condition. In normal operation there is 5

volts between pin 1 and 2 and in the time of watchdog this will drop to zero.

Breakout Board: Wiring, Software Setup 29

Page 30

Turbo Clipper Drive User Manual

Note

This feature is only available if the power board is not present.

J24: Molex (M)

Molex Mating Connector Part #: 22-01-3037 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R03-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

GRD

Output

Ground

2

DAC_PWM+

Output

DAC Output+

3

DAC_PWM-

Output

DAC Output-

M8000

DAC (V)

0

0

981

10

J24: DAC Output, 12-bit Filtered PWM

The Turbo Clipper board, ordered with Option-12, has an additional 12-bit filtered PWM output.

I6800= 981 ; PWM frequency ~30kHz

I6801= 5 ; Phase Clock ~10kHz

I6802= 3 ; Servo frequency ~2.5Hz

I6816= 0 ; Output Model PWM

I569= 981 ; DAC limit 10Vdc

I502 =$07841A ; Only Second output is used

M8000->Y:$7841A,8,16,S ; Supplementary Channel 2* Output A Command Value

; Min=0, Max= Ixx69

Testing The Filtered PWM DAC Output

Writing, directly to the suggested M-variable (i.e. M8000), produces corresponding voltages:

Breakout Board: Wiring, Software Setup 30

Page 31

Turbo Clipper Drive User Manual

Note

This feature is only available if the power board is not present.

J25: Molex (M)

Molex Mating Connector Part #: 22-01-3037 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R03-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

GRD

Input

Ground

2

ADC_IN 1

Input

ADC Input 1

3

ADC_IN 2

Input

ADC Input 2

Input Voltage

Software Counts

Bipolar

-10

-2048

-5

-1024

+10

+2048

+5

+1024

Input Voltage

Software Counts

Unipolar

+10

+2048

+5

+1024

Note

These ADCs do not provide full resolution in Unipolar (0-10V,

or 0-5V) mode. Only Bipolar inputs are supported for the full

12-bit (4096 count range) resolution.

J25: ADC Inputs

The Turbo Clipper board, ordered with Option-12, provides with two single ended 12-bit analog

inputs. The ±10V input range corresponds to ±2048 software counts.

Setting Up The Analog Inputs:

Bipolar Mode

I7003 = 1746 ; Set ADC clock frequency at 4.9152 MHz

I7006 = $1FFFFF ; ADC Strobe Word

M105->Y:$78005,12,12,S ; ADC Input 1 on J25 pin 2

M205->Y:$7800D,12,12,S ; ADC Input 2 on J25 pin 3

Unipolar Mode

I7003 = 1746 ; Set ADC clock frequency at 4.9152 MHz

I7006 = $1FFFFF ; ADC Strobe Word

M105->Y:$78005,12,12,u ; ADC Input 1 on J25 pin 2

M205->Y:$7800D,12,12,u ; ADC Input 2 on J25 pin 3

Testing the Analog Inputs:

Breakout Board: Wiring, Software Setup 31

Page 32

J26: Molex (M)

Molex Mating Connector p/n#:22-01-3107 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: : 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin#

Symbol

Function

Description

1

IN_PWR/RET

RTNFL

Return Flag (Tie to 0V or 24V)

2

IN_COM_1

RTNFL

Return Flag (Tie to 0V or 24V)

3

JTHW_IN00

Input

DAT0

4

JTHW_IN01

Input

DAT1

5

JTHW_IN02

Input

DAT2

6

JTHW_IN03

Input

DAT3

7

JTHW_IN04

Input

DAT4

8

JTHW_IN05

Input

DAT5

9

JTHW_IN06

Input

DAT6

10

JTHW_IN07

Input

DAT7

J26: Thumbwheel Multiplexer Port Inputs

Turbo Clipper Drive User Manual

Breakout Board: Wiring, Software Setup 32

Page 33

Turbo Clipper Drive User Manual

J27: Molex (M)

Molex Mating Connector Part #: 22-01-3107 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: : 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

COM_EMT _1

RTNFL

Tie to Common 0V (Sinking)

2

COM_EMT_1

RTNFL

Tie to Common 0V (Sinking)

3

JTHW_OUT1+

Input

SEL 0

4

JTHW_OUT2+

Input

SEL 1

5

JTHW_OUT3+

Input

SEL 2

6

JTHW_OUT4+

Input

SEL 3

7

JTHW_OUT5+

Input

SEL 4 8 JTHW_OUT6+

Input

SEL 5

9

JTHW_OUT7+

Input

SEL 6

10

N/A

N/A

N/A

J27: Thumbwheel Multiplexer port Outputs (sinking)

Breakout Board: Wiring, Software Setup 33

Page 34

Turbo Clipper Drive User Manual

J37: Molex (M)

Molex Mating Connector Part #: 22-01-3107 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

COM_COL_1

RTNFL

Tie to 24VDC (Sourcing)

2

COM_COL_1

RTNFL

Tie to 24VDC (Sourcing)

3

JTHW_OUT1-

Output

SEL0 4 JTHW_OUT2-

Output

SEL 1

5

JTHW_OUT3-

Output

SEL 2

6

JTHW_OUT4-

Output

SEL 3

7

JTHW_OUT5-

Output

SEL 4

8

JTHW_OUT6-

Output

SEL 5

9

JTHW_OUT7-

Output

SEL 6

10

N/A

N/A

N/A

J37: Thumbwheel Multiplexer port Outputs (Sourcing)

Thumbwheel Port As Discrete I/Os, Suggested M-Variables

The inputs and outputs on the thumbwheel multiplexer port (J26-J27-J37) can be used as

discrete, non-multiplexed general purpose I/Os, and accessed through M-Variable pointers:

M40->Y:$78402,8,1 ; SEL0 Output

M41->Y:$78402,9,1 ; SEL1 Output

M42->Y:$78402,10,1 ; SEL2 Output

M43->Y:$78402,11,1 ; SEL3 Output

M44->Y:$78402,12,1 ; SEL4 Output

M45->Y:$78402,13,1 ; SEL5 Output

M46->Y:$78402,14,1 ; SEL6 Output

M47->Y:$78402,15,1 ; SEL7 Output

M48->Y:$78402,8,8,U ; SEL0-7 Outputs treated as a byte

M50->Y:$78402,0,1 ; DAT0 Input

M51->Y:$78402,1,1 ; DAT1 Input

M52->Y:$78402,2,1 ; DAT2 Input

M53->Y:$78402,3,1 ; DAT3 Input

M54->Y:$78402,4,1 ; DAT4 Input

M55->Y:$78402,5,1 ; DAT5 Input

M56->Y:$78402,6,1 ; DAT6 Input

M57->Y:$78402,7,1 ; DAT7 Input

M58->Y:$78402,0,8,U ; DAT0-7 Inputs treated as a byte

Breakout Board: Wiring, Software Setup 34

Page 35

1

2

3

4

5

6 7 8

9

10

J26

Sinking

0V

24V

1

2

24 V Supply

Inputs

1-8

J30

Breakout

Outside

JTHW_IN01

PWR

COM

JTHW_IN02

JTHW_IN03

JTHW_IN04

JTHW_IN05

JTHW_IN06

JTHW_IN07

JTHW_IN08

1

2

3

4

5

6 7 8

9

10

J26

Sourcing

1

2

Inputs

1-8

J30

Breakout

Outside

JTHW_IN01

GRD

COM

JTHW_IN02

JTHW_IN03

JTHW_IN04

JTHW_IN05

JTHW_IN06

JTHW_IN07

JTHW_IN08

0V

24 V Supply

24V

PWR/RET

RET/PWR

RET/PWR

PWR/RET

Wiring The Thumbwheel As Discrete I/Os

Turbo Clipper Drive User Manual

World

Board

World

Board

Input

Input

Breakout Board: Wiring, Software Setup 35

Page 36

Turbo Clipper Drive User Manual

Sinking

1

2

3 4 5

6

7

8

9

10

J37

24V

0V

24 V Supply

Breakout

Outside

JTHW_OUT01-

COM_COL _1

COM_COL_1

JTHW_OUT02-

JTHW_OUT03-

JTHW_OUT04-

JTHW_OUT05-

JTHW_OUT06-

JTHW_OUT07-

JTHW_OUT08Output 01

Output 02

Output 03

Output 04

Output 05

Output 06

Output 07

Output 08

1

2

3

4

5

6

7

8

9

10

J27

Sourcing

24V

0V

24 V Supply

Breakout

Outside

JTHW_OUT01+

COM_EMT_1

COM_EMT_1

JTHW_OUT02+

JTHW_OUT03+

JTHW_OUT04+

JTHW_OUT05+

JTHW_OUT06+

JTHW_OUT07+

JTHW_OUT08+

Output 01

Output 02

Output 03

Output 04

Output 05

Output 06

Output 07

Output 08

World

Board

World

Board

Output

Output

Breakout Board: Wiring, Software Setup 36

Page 37

J28: Molex (M)

Molex Mating Connector pn#: 22-01-3107(F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

IN_PWR/RET

RTNFL

Return Flag (Tie to 0V or 24V)

2

IN_COM_2

RTNFL

Return Flag (Tie to 0V or 24V)

3

JOPT_IN01

Input

Input 1

4

JOPT_IN02

Input

Input 2

5

JOPT_IN03

Input

Input 3

6

JOPT_IN04

Input

Input 4

7

JOPT_IN05

Input

Input 5

8

JOPT_IN06

Input

Input 6

9

JOPT_IN07

Input

Input 7

10

JOPT_IN08

Input

Input 8

J28: General Purpose Inputs

Turbo Clipper Drive User Manual

Breakout Board: Wiring, Software Setup 37

Page 38

J29: Molex (M)

Molex Mating Connector pn#: 22-01-3107 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

COM_EMT_2

RTNFL

Tie to Common 0V (Sinking)

2

COM_EMT_2

RTNFL

Tie to Common 0V (Sinking)

3

JOPT_OUT1+

Output

Output 1 + 4 JOPT_OUT2+

Output

Output 2 +

5

JOPT_OUT3+

Output

Output 3 +

6

JOPT_OUT4+

Output

Output 4 +

7

JOPT_OUT5+

Output

Output 5 +

8

JOPT_OUT6+

Output

Output 6 +

9

JOPT_OUT7+

Output

Output 7 +

10

JOPT_OUT8+

Output

Output 8 +

J29: General Purpose Outputs (sinking)

Turbo Clipper Drive User Manual

Breakout Board: Wiring, Software Setup 38

Page 39

Turbo Clipper Drive User Manual

J30: Molex (M)

Molex Mating Connector Part #:: 22-01-3027 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R02-LHM

DT Part #: 025-500114-PNM

Sinking Configuration

Pin #

Symbol

Function

Description

1

12~24VDC IN_PWR

Input

Flag Power (+24VDC)

2

12~24VDC IN_RET

Input

Flag Return (Common)

Sourcing Configuration

Pin #

Symbol

Function

Description

1

12~24VDC IN_RET

Input

Flag Return (Common)

2

12~24VDC IN_PWR

Input

Flag Power (+24VDC)

J30: General Purpose I/O Power

The general purpose I/O(s) wiring is user configurable; it can be either sinking or sourcing.

Breakout Board: Wiring, Software Setup 39

Page 40

J38: Molex (M)

Molex Mating Connector pn#: 22-01-3107(F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000W10-LHM

DT Part #: 025-500114-PNM

Pin#

Symbol

Function

Description

1

COM_COL_2

RTNFL

Tie to 24VDC (Sourcing)

2

COM_COL _2

RTNFL

Tie to 24VDC (Sourcing)

3

JOPT_OUT1-

Output

Output 1 - 4 JOPT_OUT2-

Output

Output 2 -

5

JOPT_OUT3-

Output

Output 3 -

6

JOPT_OUT4-

Output

Output 4 -

7

JOPT_OUT5-

Output

Output 5 -

8

JOPT_OUT6-

Output

Output 6 -

9

JOPT_OUT7-

Output

Output 7 -

10

JOPT_OUT8-

Output

Output 8 -

J38: General Purpose Outputs (sourcing)

Turbo Clipper Drive User Manual

Breakout Board: Wiring, Software Setup 40

Page 41

1

2

3 4 5

6

7

8

9

10

J28

Sinking

0V

24V

1

2

12~24 V

Inputs

1-8

J30

Breakout

Outside

JOPT_IN01

PWR

COM

JOPT_IN02

JOPT_IN03

JOPT_IN04

JOPT_IN05

JOPT_IN06

JOPT_IN07

JOPT_IN08

1

2

3

4

5

6 7 8

9

10

J28

Sourcing

1

2

Inputs

1-8

J30

Breakout

Outside

JOPT_IN01

GRD

COM

JOPT_IN02

JOPT_IN03

JOPT_IN04

JOPT_IN05

JOPT_IN06

JOPT_IN07

JOPT_IN08

0V

12~24 V

24V

PWR/RET

RET/PWR

RET/PWR

PWR/RET

Wiring the General Purpose I/Os

Turbo Clipper Drive User Manual

World

Supply

Board

World

Supply

Board

Input

Input

Breakout Board: Wiring, Software Setup 41

Page 42

Turbo Clipper Drive User Manual

Sinking

1

2

3 4 5

6

7

8

9

10

J29

0V

24V

12~24 V

Breakout

Outside

JOPT_OUT01+

COM_EMT_2

COM_EMT_2

JOPT_OUT02+

JOPT_OUT03+

JOPT_OUT04+

JOPT_OUT05+

JOPT_OUT06+

JOPT_OUT07+

JOPT_OUT08+

Output 01

Output 02

Output 03

Output 04

Output 05

Output 06

Output 07

Output 08

1

2

3

4

5

6

7

8

9

10

J38

Sourcing

0V

24V

12~24 V

Breakout

Outside

JOPT_OUT01-

COM_COL_2

COM_COL_2

JOPT_OUT02-

JOPT_OUT03-

JOPT_OUT04-

JOPT_OUT05-

JOPT_OUT06-

JOPT_OUT07-

JOPT_OUT08Output 01

Output 02

Output 03

Output 04

Output 05

Output 06

Output 07

Output 08

World

Supply

Board

World

Supply

Board

Output

Output

Breakout Board: Wiring, Software Setup 42

Page 43

Turbo Clipper Drive User Manual

General Purpose I/Os, Suggested M-Variables

M1->Y:$78400,0 ; Digital Output 1

M2->Y:$78400,1 ; Digital Output 2

M3->Y:$78400,2 ; Digital Output 3

M4->Y:$78400,3 ; Digital Output 4

M5->Y:$78400,4 ; Digital Output 5

M6->Y:$78400,5 ; Digital Output 6

M7->Y:$78400,6 ; Digital Output 7

M8->Y:$78400,7 ; Digital Output 8

M9->Y:$78400,8 ; Digital Input 1

M10->Y:$78400,9 ; Digital Input 2

M11->Y:$78400,10 ; Digital Input 3

M12->Y:$78400,11 ; Digital Input 4

M13->Y:$78400,12 ; Digital Input 5

M14->Y:$78400,13 ; Digital Input 6

M15->Y:$78400,14 ; Digital Input 7

M16->Y:$78400,15 ; Digital Input 8

M32->X:$78400,0,8 ; Direction Control bits 0-7 (1=output, 0 = input)

M34->X:$78400,8,8 ; Direction Control bits 8-15 (1=output, 0 = input)

M40->X:$78404,0,24 ; Inversion control (0 = 0V, 1 = 5V)

M42->Y:$78404,0,24 ; J9 port data type control (1 = I/O)

//In order to properly setup the digital I/Os, an initialization PLC must be written scanning

//through once on power-up/reset, setting control statuses then disabling itself:

Open PLC 1 clear

M32=$FF ; BITS 0-7 are assigned as output

M34=$0 ; BITS 8-15 are assigned as input

M40=$FF00 ; Define inputs and outputs

M42=$FFFF ; All lines are I/O type

DIS PLC1 ; Disable PLC1 (scanning through once on power-up/reset)

Close

Breakout Board: Wiring, Software Setup 43

Page 44

J31-J32: Molex (M)

Molex Mating Connector Part #: 22-01-3067 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R06-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

DGND

Common

Ground

2

+5V

Output

5 Volts

3

HW_A+

Input

Handwheel Quadrature A

4

HW_A-

Input

Handwheel Quadrature A/

5

HW _B+

Input

Handwheel Quadrature B

6

HW_B-

Input

Handwheel Quadrature B/

Quadratur

1

3

4

5

6

2

GND

5 V+

HW_A+

HW_A-

HW_B+

HW_B-

J31-J32: Handwheel Port(s)

Turbo Clipper Drive User Manual

A quadrature encoder type device is normally brought in to the handwheel port; it can be wired

in either single-ended or differential mode. The ground has to be tied to the connectors’ ground,

especially in single-ended applications.

The encoder data can be exported to the Encoder Conversion Table allowing direct access with

an M-variable or used as a master position for a specific motor (Ixx05). Example:

I8000=$78410 ; Entry 1: 1/T extension of location $78410 MACRO IC 1

M8010->X:$3501,0,24,S ; ECT 1st entry result

I8001=$78418 ; Entry 2: 1/T extension of location $78418 MACRO IC 2

M8011->X:$3502,0,24,S ; ECT 2nd entry result

e Encoder

Breakout Board: Wiring, Software Setup 44

Page 45

J33-J34: Molex (M)

Molex Mating Connector Part #: 22-01-3067 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R06-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

DGND

Common

Ground

2

+5V

Output

5 Volts

3

PUL~+

Output

Pulse Plus

4

PUL~-

Output

Pulse Minus

5

DIR~+

Output

Direction Plus

6

DIR~-

Output

Direction Minus

Step1

Step2

Results

J33-J34: Pulse and Direction Output(s) (PFM)

Turbo Clipper Drive User Manual

The Turbo Clipper Drive offers two additional Step and Direction (Pulse Frequency Modulation)

outputs, using the supplementary channels. These signals can be connected in either differential

or single-ended configuration for 5V input drives. Using the Delta Tau Calculator or referring to

the Turbo Software Reference Manual, the desired maximum PFM Frequency and pulse width

can be chosen. DT Calculator Link

Breakout Board: Wiring, Software Setup 45

Page 46

Turbo Clipper Drive User Manual

M8000

PFM [KHz]

0

0

1213

11

2427

22

Step1 : Choose Max PFM clock by changing the PFM clock divider in the calculator

Step2 : Choose PFM Pulse Width by changing I7m04 in the calculator

For a PFM clock range 0-20 KHz, and a pulse width of ~20 μsec:

I6803=2290 ; PFM Clock divider equal to 6

I6804=13 ; PFM Pulse Width Control equal to 13

The output frequency control Ixx69 specifies the maximum command output value that

corresponds to the maximum PFM Frequency.

I6826=3 ; MACRO IC0 Channel2 Output Mode Select. C PFM

M8000->Y:$7841C,8,16,S ; Supplementary Channel 2* Output C Command Value

; Min=0, Max= Calculated Ixx69

Testing The PFM Output

Writing, directly to the suggested M-variable (i.e. M8000), values proportional to Ixx69

produces corresponding frequencies:

Breakout Board: Wiring, Software Setup 46

Page 47

Turbo Clipper Drive User Manual

Example:

Axis 5-6 to drive stepper amps, w/ PFM clock range 0-20 KHz and pulse width of ~20 μsec:

I6803=2290 ; PFM Clock divider equal to 6

I6804=13 ; PFM Pulse Width Control equal to 13

// Supplementary Channel 1, and 2 Settings:

I6816,2,10=3 ; Supp. channel 1-2 output mode, PFM

I6810,2,10=8 ; Supp. channel 1-2 Encoder Decode, Internal Pulse and Direction

I500,2,100=1 ; Motors 5,6 active

I511,2,100=0 ; Motors 5,6 disable fatal following error

I502=$78414 ; Motor #5 output to point to output c for PFM

I8004=$C78410 ; Encoder Conversion table to read, C for no extension

I503=$3505

I504=$3505

I524=$120001 ; Disable amp fault and overtravel limits

I525=$78410 ;

I602=$7841C ; #2 output to point to output c for PFM

I8005=$C78418 ; Encoder Conversion table to read, C for no extension

I603=$3506

I604=$3506

I624=$120001 ; Disable amp fault and over travel limit

I625=$78418

The position-Loop PID Gains are calculated using the following equations:

Ixx30=660000/Ixx08*PFM Clock[MHz]

Ixx31=0

Ixx32 = 6660* ServoFreq( kHz )

Ixx33...Ixx35=0

// Position-Loop PID Gains:

I530,2,100=11190 ; Motors 5-6 Proportional Gain

I531,2,100=0 ; Motors 5-6 Derivative Gain

I532,2,100=151515 ; Motors 5-6 Velocity FeedForward Gain

I533,2,100=0 ; Motors 5-6 Integral Gain

I534,2,100=0 ; Motors 5-6 Integral Mode

I535,2,100=0 ; Motors 5-6 Acceleration FeedForward Gain

Breakout Board: Wiring, Software Setup 47

Page 48

J35: Molex (M)

Molex Mating Connector Part #: 22-01-3067 (F)

Molex Crimper Pin Part #: 08-50-0114

For Internal Use:

DT Part #: 014-000R06-LHM

DT Part #: 025-500114-PNM

Pin #

Symbol

Function

Description

1

DGND

Common

Ground

2

+5V

Output

5 Volts

3

PGOUT0+

Output

Programmable output 0+

4

PGOUT0-

Output

Programmable output 0-

5

PGOUT1+

Output

Programmable output 1+

6

PGOUT1-

Output

Programmable output 1-

J35: Programmable Output

Turbo Clipper Drive User Manual

Clipper’s Option 11 consists of a programmable lattice chip which can be programmed based

upon customer’s requirements for laser control. Refer to Turbo Clipper Hardware Reference

Manual for more descriptions.

Breakout Board: Wiring, Software Setup 48

Page 49

Turbo Clipper Drive User Manual

External Amp 1-4: D-Sub DE-9F

Mating: D-Sub DE-9M

12345

6789

Pin#

Symbol

Function

Description

1

GND

Common

Ground

2

DAC-

Output

DAC Output -

3

GND

Common

Ground

4

DIR+

Output