Page 1

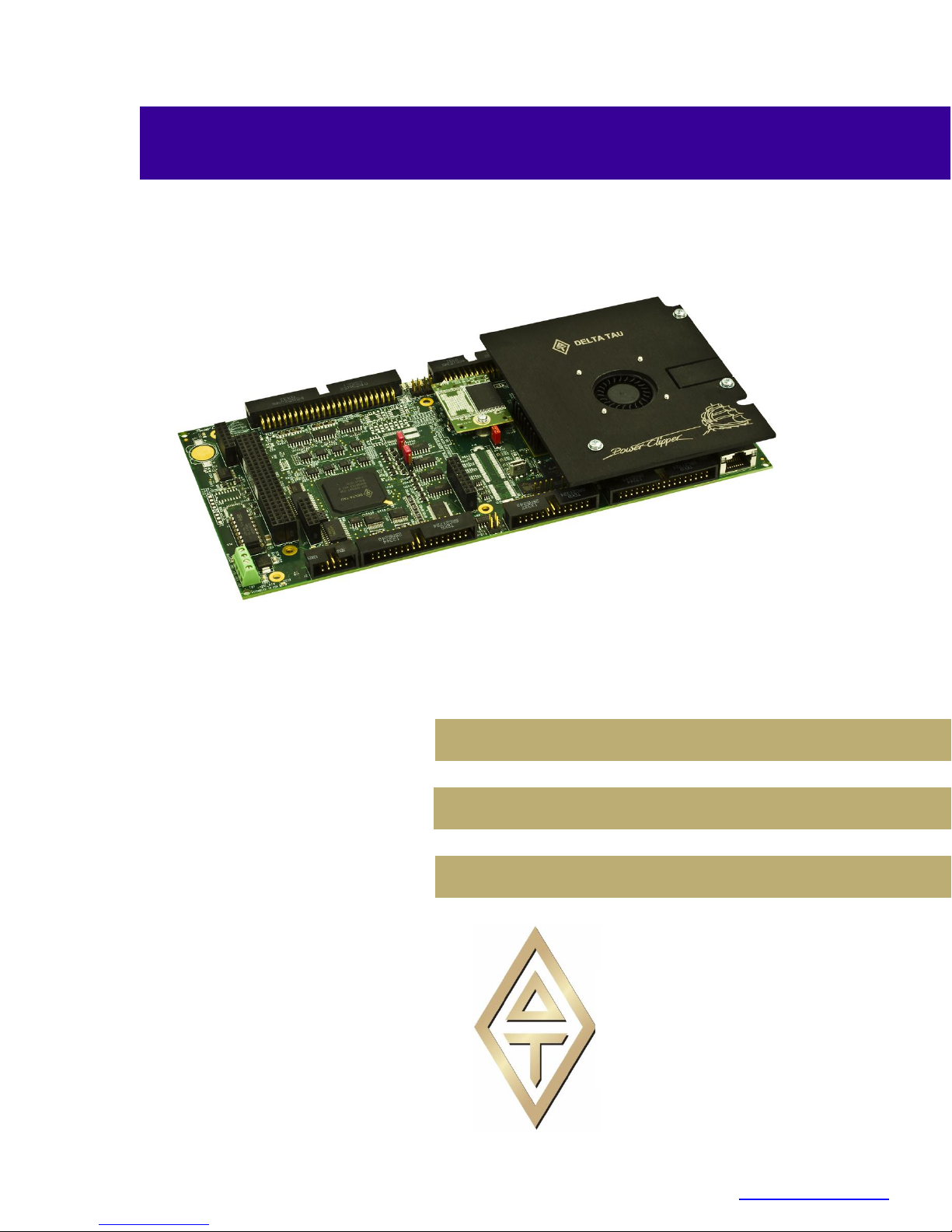

Single Source Machine Control

……………………………………………..…...……………….

Power // Flexibility // Ease of Use

21314 Lassen St. Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^1 User Manual

^3Power PMAC Clipper

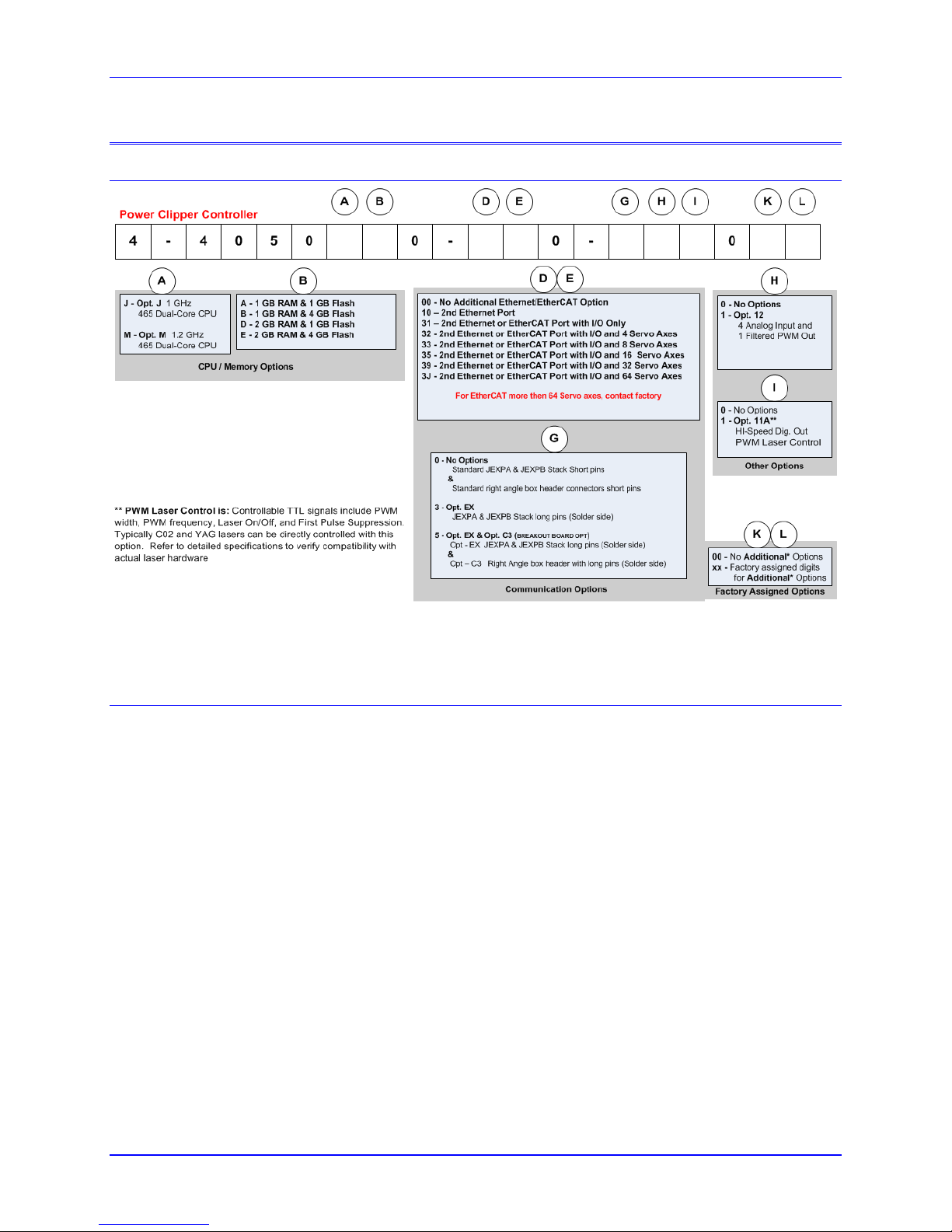

^4 4-4050xx0-xx0-xxx0xx

April 15, 2016

DELTA TAU

Data Systems, Inc.

NEW IDEAS IN MOTION …

^2 Power PMAC Clipper

Page 2

Power PMAC Clipper User Manual

Copyright Information

© 2016 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses

are unauthorized without written permission of Delta Tau Data Systems, Inc.

Information contained in this manual may be updated from time-to-time due to product

improvements, etc., and may not conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers

contain static sensitive components that can be damaged by incorrect handling. When

installing or handling Delta Tau Data Systems, Inc. products, avoid contact with highly

insulated materials. Only qualified personnel should be allowed to handle this

equipment.

In the case of industrial applications, we expect our products to be protected from

hazardous or conductive materials and/or environments that could cause harm to the

controller by damaging components or causing electrical shorts. When our products are

used in an industrial environment, install them into an industrial electrical cabinet or

industrial PC to protect them from excessive or corrosive moisture, abnormal ambient

temperatures, and conductive materials. If Delta Tau Data Systems, Inc. products are

directly exposed to hazardous or conductive materials and/or environments, we cannot

guarantee their operation.

Page 3

Power PMAC Clipper User Manual

A Warning identifies hazards that could result in personal injury or

death. It precedes the discussion of interest.

Warning

Caution

A Caution identifies hazards that could result in equipment damage. It

precedes the discussion of interest.

Note

A Note identifies information critical to the understanding or use of

the equipment. It follows the discussion of interest.

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC364resp.CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It

is vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

Page 4

Power PMAC Clipper User Manual

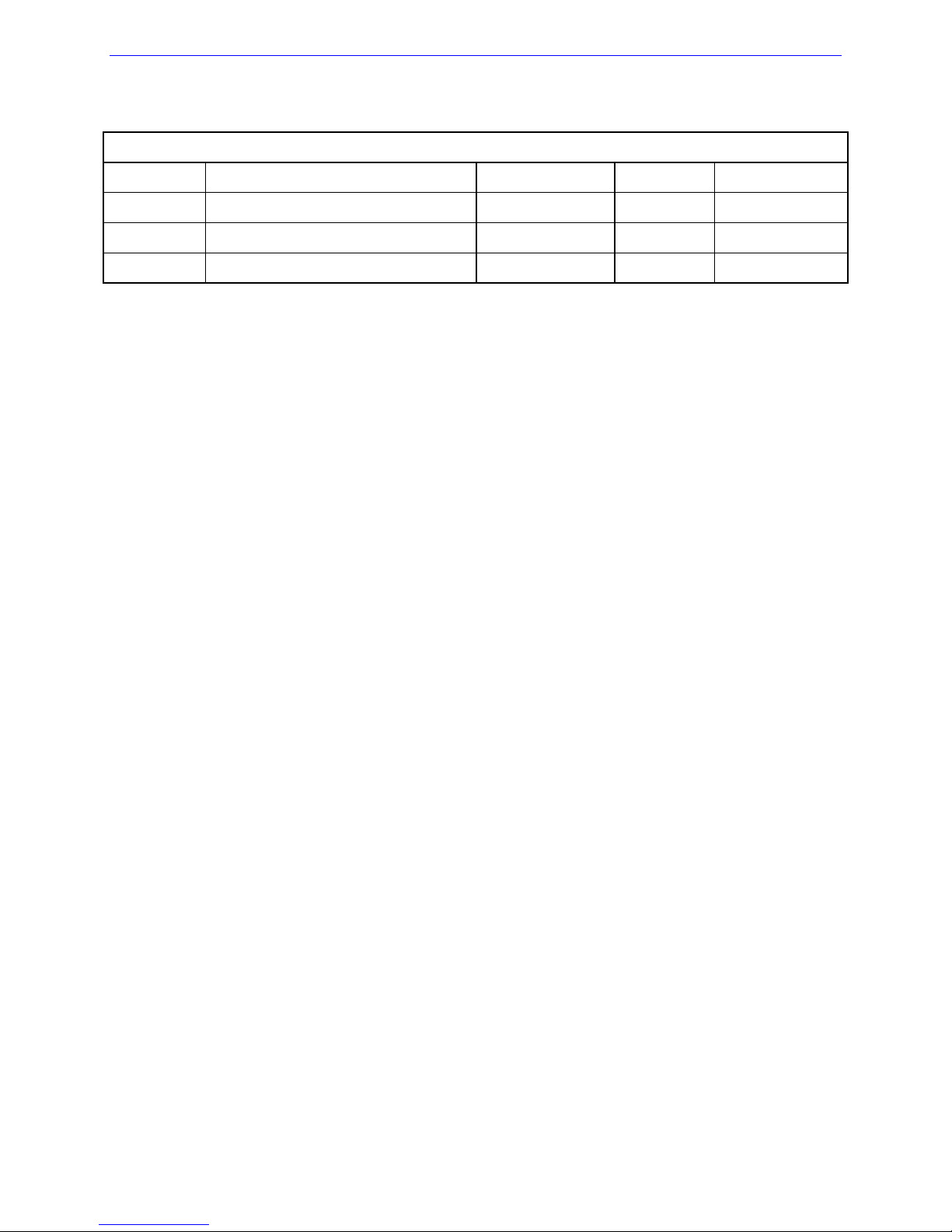

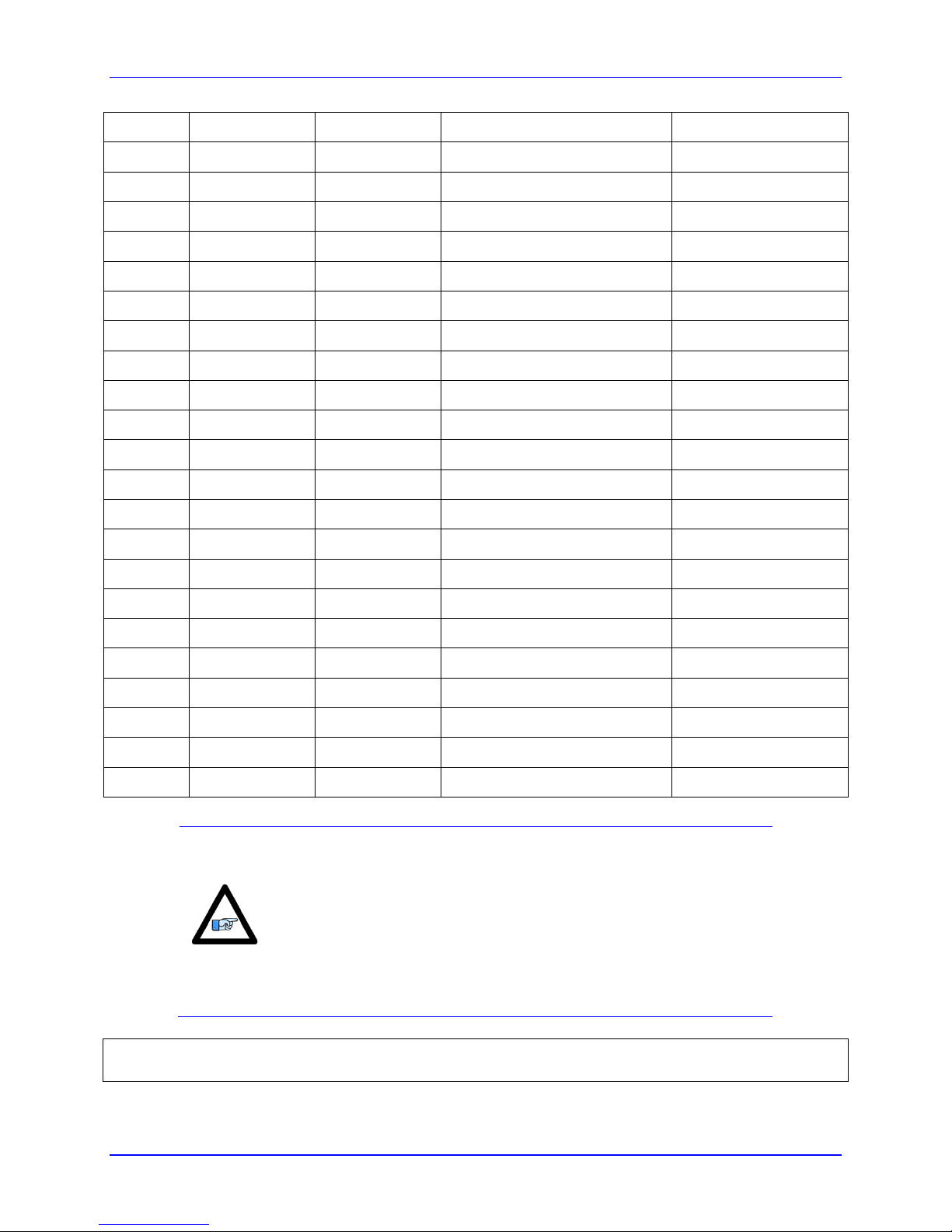

REVISION HISTORY

REV.

DESCRIPTION

DATE

CHG

APPVD

0

Preliminary

10/13/14

Sgm

1

Released

07/21/15

RN

RN

2

Update motor setup

04/15/16

Sgm

Sgm

Page 5

Page 6

Power PMAC Clipper User Manual

Table of Contents

INTRODUCTION ....................................................................................................................................... 9

Documentation .............................................................................................................................................. 9

Downloadable Power PMAC Script ........................................................................................................... 10

SPECIFICATIONS ................................................................................................................................... 11

Part Number ................................................................................................................................................ 11

Standard Configuration ............................................................................................................................... 11

Options ........................................................................................................................................................ 12

Accessories ................................................................................................................................................. 13

Environmental Specifications ..................................................................................................................... 16

Electrical Specifications .............................................................................................................................. 17

Digital Power Supply ............................................................................................................................. 17

DAC Outputs Power Supply .................................................................................................................. 17

Flags Power Supply ............................................................................................................................... 17

RECEIVING AND UNPACKING .......................................................................................................... 18

Use of Equipment ....................................................................................................................................... 18

MOUNTING .............................................................................................................................................. 19

Physical Specifications ............................................................................................................................... 20

Board Dimensions Rev101 .................................................................................................................... 20

Board Layout Rev101 ............................................................................................................................ 20

CONNECTIONS AND SOFTWARE SETUP ....................................................................................... 21

Default Jumper Configurations ................................................................................................................... 21

TB1 (JPWR): Power Supply Input.............................................................................................................. 21

J2: Serial Port .............................................................................................................................................. 23

J3: Machine Connector (JMACH1 Port) .................................................................................................... 24

Configuring Quadrature Encoders ........................................................................................................ 27

Wiring the DAC Output ......................................................................................................................... 29

Amplifier Enable Signal (AENAn/DIRn) ............................................................................................... 31

Amplifier Fault Signal (FAULT-) .......................................................................................................... 32

Analog Inputs ......................................................................................................................................... 33

Setting up the Analog (ADC) Inputs ...................................................................................................... 33

J4: Machine Connector (JMACH2 Port) .................................................................................................... 36

Overtravel Limits and Home Switches ................................................................................................... 37

Wiring the Limits and Flags .................................................................................................................. 37

Limits and Flags [Axis 1- 4] Structure Elements .................................................................................. 40

Step and Direction PFM Output (To External Stepper Amplifier) ........................................................ 41

Compare Equal Outputs ........................................................................................................................ 42

J7: Machine Connector (JMACH3 Port) .................................................................................................... 43

Brake Software Setup ............................................................................................................................. 44

Serial Encoder Software Setup .............................................................................................................. 44

J8: Thumbwheel Multiplexer Port (JTHW Port) ........................................................................................ 50

Table Of Contents vi

Page 7

Power PMAC Clipper User Manual

Thumbwheel Port Digital Inputs and Outputs ....................................................................................... 51

Configuring Multiplexed I/O on the JTHW port .................................................................................... 51

J9: General-Purpose Digital Inputs and Outputs (JOPT Port) .................................................................... 53

General Purpose I/O (J6) Structures ..................................................................................................... 54

J10: Handwheel and Pulse/Dir Connector (JHW/PD Port) ......................................................................... 56

Handwheel Encoder Software Setup...................................................................................................... 57

Handwheel PFM Software Setup ........................................................................................................... 57

Handwheel Option-12 DAC Software Setup .......................................................................................... 57

Handwheel 5th motor using the Option -12 DAC .................................................................................. 58

P2: USB Device Port .................................................................................................................................. 59

P20: EtherCat™/Ethernet Communications Port ........................................................................................ 59

P21: Ethernet Communications Port ........................................................................................................... 59

P17: USB Communications Port ................................................................................................................ 59

LED Indicators ............................................................................................................................................ 59

DRIVE - MOTOR SETUP ....................................................................................................................... 60

Filtered PWM Output (Analog ±10V) ........................................................................................................ 61

Clock Settings, Output Mode, Command Limit ..................................................................................... 61

Typical Motor Specific Settings ............................................................................................................. 61

Open Loop Test: Encoder/Decode ......................................................................................................... 62

Position-Loop PID Gains ...................................................................................................................... 63

Typical Settings for Four Channels of Filtered PWM Setup: ................................................................ 64

Pulse Frequency Modulation Output (Step and Direction) ......................................................................... 66

Multi-Channel Setup Elements .............................................................................................................. 66

Channel-Specific Setup Elements .......................................................................................................... 66

Motor-Specific Setup Elements .............................................................................................................. 67

Typical Settings for Four Channels of Open Loop PFM Setup: ............................................................ 68

ACC-24S3 4-CHANNEL AXIS EXPANSION STACK BOARD ......................................................... 70

Hardware Assembly .................................................................................................................................... 70

Default Jumper Configurations ................................................................................................................... 72

TB1 (JPWR): Power Supply Input.............................................................................................................. 73

J3: Machine Connector (JMACH1 Port) .................................................................................................... 74

Configuring Quadrature Encoders ........................................................................................................ 74

Wiring the DAC Output ......................................................................................................................... 74

Amplifier Enable Signal (AENAn/DIRn) ............................................................................................... 75

Amplifier Fault Signal (FAULT-) .......................................................................................................... 75

Analog Inputs ......................................................................................................................................... 75

Setting up the Analog (ADC) Inputs ...................................................................................................... 75

J4: Machine Connector (JMACH2 Port) .................................................................................................... 77

Limits and Flags [Axis 1- 4] Structure Elements .................................................................................. 77

Step and Direction PFM Output (To External Stepper Amplifier) ........................................................ 78

Compare Equal Outputs ........................................................................................................................ 78

J7: Machine Connector (JMACH3 Port) .................................................................................................... 79

Brake Software Setup ............................................................................................................................. 79

Serial Encoder Software Setup .............................................................................................................. 79

Table Of Contents vii

Page 8

Power PMAC Clipper User Manual

J8: Thumbwheel Multiplexer Port (JTHW Port) ........................................................................................ 80

Thumbwheel Port Digital Inputs and Outputs ....................................................................................... 80

Configuring Multiplexed I/O on the JTHW port .................................................................................... 80

J9: General-Purpose Digital Inputs and Outputs (JOPT Port) .................................................................... 81

General Purpose I/O (J6) Structures ..................................................................................................... 81

J10: Handwheel and Pulse/Dir Connector (JHW/PD Port) ......................................................................... 82

Handwheel Encoder Software Setup...................................................................................................... 82

Motor Setup Code ....................................................................................................................................... 83

Typical Settings for Four Channels of Filtered PWM Setup: ................................................................ 83

Typical Settings for Four Channels of Open Loop PFM Setup: ............................................................ 85

Table Of Contents viii

Page 9

Power PMAC Clipper User Manual

Note

The Power Clipper can also provide pulse and direction PFM output

signals to third-party stepper drives.

INTRODUCTION

The Power Clipper is a 4 axis motion controller combining the intelligence and capability of a Power

PMAC CPU with the convenience and savings of a low cost platform that is 100% hardware compatible

with its Turbo PMAC family member the Turbo PMAC Clipper.

It supports virtually any type of feedback device (with the optional ACC-84S and ACC-51S) and can

drive directly the following types of motors with the optional Clipper Drive Stack:

3-phase AC/DC brushless servo (synchronous) -- rotary/linear

2-phase stepper

DC brush

The number of axes in a Power Clipper application can be expanded to 8 with the optional ACC-24S3.

The Power Clipper comes with 32 general-purpose digital I/O points which can be expanded through the

optional ACC-34AA, ACC-24S3 or EtherCat. These can be configured as input or outputs in groups of

eight. The default factory settings are 16 inputs and 16 outputs.

The outstanding trajectory planner, built-in software PLCs (programmable in Power PMAC script and / or

C language), and other features make the Power Clipper a very scalable machine automation controllerdrive which can be virtually integrated in any kind of motion control application.

Documentation

In conjunction with this manual, the following manuals are essential for the proper operation and use of

the Power Clipper:

Power PMAC Software Reference Manual

Power PMAC User Manual

These manuals are available for download, to registered members, at Delta Tau Forums.

Introduction 9

Page 10

Power PMAC Clipper User Manual

Caution

Some code examples require the user to input specific information

pertaining to their system hardware. When user information is

required, a commentary ending with –User Input is inserted.

Caution

It is the user’s responsibility to manage the application’s PLCs

properly. The code samples are typically enclosed in a PLC buffer

with the user defined name ExamplePLC.

Downloadable Power PMAC Script

This manual contains downloadable code snippets in Power PMAC script. These examples can be copied

and pasted into the editor area of the IDE software. Care must be taken when using pre-configured Power

PMAC code, some information may need to be updated to match hardware or system specific

configurations. Downloadable code found in this manual is enclosed in the following format:

// Power PMAC script format example

GLOBAL MyCounter = 0; // Arbitrary global variable, counter

GLOBAL MyCycles = 10; // Arbitrary global variable, number of cycles --User Input

OPEN PLC ExamplePLC // Open PLC buffer

WHILE (MyCounter < MyCycles) // While counter is less than number of cycles

{ // Start while loop

MyCounter ++ // Increment MyCounter by 1

} // End while loop

MyCounter = 0 // Reset Mycounter

DISABLE PLC ExamplePLC // Disable PLC

CLOSE // Close PLC buffer

It is the user’s responsibility to use the PLC examples presented in this manual properly, and incorporate

the statement code in the application project accordingly.

Introduction 10

Page 11

Power PMAC Clipper User Manual

SPECIFICATIONS

Part Number

The Power Clipper comes standard with a powerful set of hardware and software capabilities, plus a full

set of options and accessories.

Standard Configuration

The standard configuration of the Power Clipper provides the following features:

CPU

1.0 GHz Dual-Core Power PC 465EX CPU

Memory

1 GB DDRAM3 active memory, 1 GB NAND Flash non-volatile memory

Communications Ports

100 Mbps Ethernet port for host communications

RS-232 port

USB 2.0 Host port

USB 2.0 Device port

Servo Interface

4 channels servo interface, each including:

Quadrature encoder (with index) interface

UVW digital Hall sensor interface

Specifications 11

Page 12

Power PMAC Clipper User Manual

Serial encoder interface, with software selectable protocol, from the following:

o SSI

o EnDat 2.1/2.2 (2.1-compatible features only) with delay compensation

o Hiperface

o Yaskawa Sigma I

o Yaskawa II/III/V (no position reset or fault clear)

o Tamagawa FA-Coder

o Panasonic (no servo clock output)

o Mitutoyo

o Kawasaki

o Basic quadrature (no index, no capture)

Filtered PWM analog output (~13-bit resolution)

Pulse & direction output

Input flags (home, +limit, -limit, user) at 5V CMOS levels (24V tolerant)

Position compare (EQU) output

Amplifier-enable output and amplifier-fault input flags

Brake control output

General-Purpose I/O

JIO Port: 16 5V CMOS I/O points, direction selectable by byte (flat cable connection to Opto-22

or equivalent)

JTHW Port: 16 5V CMOS I/O points, direction selectable by byte (flat cable connection to Delta

Tau ACC-34x boards)

Stacking Connector Configuration

The standard configuration of the Power Clipper comes with:

The “short-pin” version of the expansion port connectors. These support accessories that stack on

top of the Power Clipper (e.g. ACC-24S3, 8AS, 8FS, 8TS, 51S, and 84S), but not those that stack

under it (e.g. LV Stack Amplifier).

The “short-pin” version of the right-angle box header connectors. These support flat cable

connections to field wiring, but not connections through breakout boards that stack under it (e.g.

Delta Tau’s stack breakout board or custom breakout boards).

Options

The following options can be ordered for the Power Clipper board:

CPU Options

1.2 GHz Dual-Core Power PC 465EX CPU

Memory Options

The following optional memory configurations can be ordered:

1 GB DDRAM3 active memory, 4 GB NAND Flash non-volatile memory

2 GB DDRAM3 active memory, 1 GB NAND Flash non-volatile memory

2 GB DDRAM3 active memory, 4 GB NAND Flash non-volatile memory

Specifications 12

Page 13

Power PMAC Clipper User Manual

Communications Port Options

Added Ethernet Port ,1 Gbps, EtherCAT compatible

EtherCAT Software License Options (require 2nd Ethernet port option)

When the second Ethernet port option is ordered, software license options can also be ordered to support

EtherCAT data transfers. The following software license options can be ordered:

EtherCAT I/O only (no servo axes)

EtherCAT I/O with 4 servo axes

EtherCAT I/O with 8 servo axes

EtherCAT I/O with 16 servo axes

EtherCAT I/O with 32 servo axes

EtherCAT I/O with 64 servo axes

Analog I/O Option

4-channels 12-bit ADC plus 1 additional channel filtered-PWM analog output (~13 bits)

Digital Laser Control Output Option

Programmable PWM laser-control IC with output drivers

Stacking Connector Options

“Long-pin” version of expansion-port connectors to support communications interface to boards

that stack under Power Clipper (e.g. LV Stack Amplifier). “Short-pin” version of right-angle box

header connectors that only support flat cable connections for field wiring.

“Long-pin” version of expansion-port connectors to support communications interface to boards

that stack under Power Clipper (e.g. LV Stack Amplifier). “Long-pin” version of right-angle box

header connectors to support connections through breakout boards that stack under it (e.g. Delta

Tau’s stack breakout board or custom breakout boards).

Accessories

The following accessory boards can be used with the Power Clipper board:

ACC-24S3 4-Channel Axis Expansion Stack Board

The ACC-24S3 can be stacked on top of the Power Clipper to provide an additional 4 channels of servo

interface circuitry and 32 additional digital I/O points equivalent to what is on the Power Clipper itself.

Optionally, it can provide 4 additional 12-bit ADCs and 1 additional filtered-PWM analog output (~13

bits).

Only one ACC-24S3 board can be used with the Power Clipper. If it is installed on top of the Power

Clipper, only one small stack board (ACC-8AS, 8FS, 8TS, 51S, 84S) can be installed directly on the

Power Clipper between it and the ACC-24S3. Two of these small stack boards can be installed on top of

the ACC-24S3.

ACC-8AS 4-Channel 2-Phase 16-Bit True-DAC Stack Board

The ACC-8AS can be stacked on top of either the Power Clipper or the ACC-24S3 to provide 4 channels

of 16-bit “true DAC” output with two DACs per channel. This board is mainly used for very high-

precision servo applications that require more resolution than the filtered-PWM analog outputs on the

Specifications 13

Page 14

Power PMAC Clipper User Manual

Power Clipper and the ACC-24S3. The dual-phase DAC outputs support the “sine-wave output” control

mode where brushless motor commutation is performed by the Power PMAC.

The true-DAC outputs of the ACC-8AS can be used simultaneously with the filtered-PWM analog output

on the same channel of the Power Clipper or ACC-24S3 without interference.

ACC-8FS 4-Channel Direct-PWM Interface Stack Board

The ACC-8FS can be stacked on top of either the Power Clipper or the ACC-24S3 to provide 4 channels

of 3-phase direct-PWM output through Mini-D 36-pin connectors to “power block” amplifiers. This board

is mainly used for applications where the Power Clipper is performing both the commutation and digital

current loop closure for brushless motors.

The 3-phase PWM outputs of the ACC-8FS cannot be used simultaneously with the filtered-PWM analog

output on the same channel of the Power Clipper or ACC-24S3. However, they can be used

simultaneously with the PFM (pulse-and-direction) outputs of the same channel of the Power Clipper or

ACC-24S3 without interference.

The ADC inputs passed through the ACC-8FS can be used simultaneously with the Option 12 ADCs on

the Power Clipper or ACC-24S3 without interference.

ACC-8TS Bridge Stack Board to ACC-28B ADCs

The ACC-8TS can be stacked on top of either the Power Clipper or the ACC-24S3 to provide a flat-cable

interface to one or two ACC-28B 4-channel 16-bit ADC boards.

The ADC inputs passed through the ACC-8TS can be used simultaneously with the Option 12 ADCs on

the Power Clipper or ACC-24S3 without interference.

ACC-51S 4-Channel Sinusoidal Encoder Interpolator Stack Board

The ACC-51S can be stacked on top of either the Power Clipper or the ACC-24S3 to provide 4 channels

of sinusoidal encoder interpolation with 16,384 states per line.

The sinusoidal encoder inputs passed through the ACC-51S cannot be used simultaneously with the main

quadrature encoder inputs of the same channel of the Power Clipper or ACC-24S3 without interference.

However, it is possible to pass digital quadrature signals through the ACC-51S.

ACC-84S 4-Channel Serial Encoder Interface Stack Board

The ACC-84S can be stacked on top of either the Power Clipper or the ACC-24S3 to provide 4 channels

of serial-encoder interface. The ACC-84S can be ordered from the factory with a single encoder protocol

installed from the following list:

EnDat2.2 with additional information, no delay compensation

BiSS-B/C

Yaskawa II/III/V with position reset and fault clear

Tamagawa FA-Coder with servo clock output

Matsushita (Nikon D)

Mitsubishi

SSI (no capabilities over Power Clipper’s built-in interface)

Panasonic (no capabilities over Power Clipper’s built-in interface)

Mitutoyo (no capabilities over Power Clipper’s built-in interface)

Specifications 14

Page 15

Power PMAC Clipper User Manual

The serial-encoder inputs on the ACC-84S can be used simultaneously with the serial-encoder input on

the same channel of the Power Clipper or ACC-24S3 without interference.

Clipper 4-Channel Breakout Board

The Clipper 4-Channel Breakout Board can be stacked under the Power Clipper board to provide discrete

connectors for each channel and each I/O functionality. It also provides optical isolation and driver

circuitry for axis flags and general-purpose I/O.

The Clipper 4-Channel Breakout Board cannot be used to provide connections for the ACC-24S3 Axis

Expansion Board.

Clipper 4-Channel LV Stack Amplifier

The Clipper 4-Channel LV (Low-Voltage) Stack Amplifier can be stacked under the Power Clipper board

or its 4-Channel Breakout board to provide the power amplifier circuitry for 4 motors with up to 60VDC

supply and a rating of up to 5A(rms) continuous, 15A(rms) peak. Each motor can be 1-phase (e.g. DC

brush motor), 2-phase (e.g. stepper motor), or 3-phase (e.g. brushless servo motor).

The Clipper 4-Channel LV Stack Amplifier cannot be used to provide the power stage for the ACC-24S3

Axis Expansion Board.

ACC-28B 4-Channel 16-Bit ADC Board

The ACC-28B provides 2 or 4 channels of 16-bit A/D converters on a DIN-rail mountable board. It can

be connected to the Power Clipper or ACC-24S3 by flat cable through an ACC-8TS bridge stack board.

ACC-34 Family Multiplexed I/O Boards

The ACC-34 family of multiplexed I/O boards each provide 32 general-purpose digital inputs and 32

general-purpose digital outputs. Up to 32 of these DIN-rail mountable boards can be connected to the

JTHW multiplexer port on the Power Clipper through standard flat cables. Due to the multiplexed access

and serial data transfers, these I/O points cannot react as quickly as the I/O points on the Power Clipper

itself.

Specifications 15

Page 16

Power PMAC Clipper User Manual

Specification

Description

Range

Ambient operating Temperature

EN50178 Class 3K3 – IEC721-3-3

Minimum operating temperature

0°C (32°F)

Maximum operating temperature

45°C (113°F)

Storage Temperature Range

EN 50178 Class 1K4 – IEC721-3-1/2

Minimum Storage temperature

-25°C (-13°F)

Maximum Storage temperature

70°C (158°F)

Humidity Characteristics with

NO condensation and NO formation of ice

IEC721-3-3

Minimum Relative Humidity

5% HU

Maximum Relative Humidity

up to 35°C (95°F)

95% HU

Maximum Relative Humidity

from 35°C up to 50°C (122°F)

85% HU

De-rating for Altitude

0 ~ 1000m (0 ~ 3300ft)

No de-rating

1000 ~ 3000m (3300 ~ 9840ft)

-0.01%/m

3000 ~ 4000m (9840 ~ 13000ft)

-0.02%/m

Environment

ISA 71-04

Degree 2 environments

Atmospheric Pressure

EN50178 class 2K3

70 KPa to 106 KPa

Shock

Unspecified

Vibration

Unspecified

Air Flow Clearances

3" (76.2mm) above and below unit for air flow

Cooling

Natural convection and built-in CPU fan

Standard IP Protection

IP20

IP 55 can be evaluated for custom applications

Environmental Specifications

Specifications 16

Page 17

Power PMAC Clipper User Manual

Note

Clipper base board requires 2.75A with no other connections. Size

your application accordingly to your encoder load. The above assumes

typical encoder loads at ~100mA per encoder.

Electrical Specifications

Digital Power Supply

The +5V and ground reference lines from the power supply should be connected to TB1 terminal block of

the Power PMAC Clipper board using 18 AWG stranded wire. The power requirement (± 5%) is:

+5 V (20W) @ 3.5 A (Four-channel configuration with a typical load of encoders)

+5 V (20W) @ 5.5 A (Eight-channel ACC-24S3 configuration with a typical load of encoders)

DAC Outputs Power Supply

The ±12V lines from the supply, including the ground reference, can be brought in from the TB1 terminal

block.

+12 to +15 V (4.5W) @ 0.30 A (Four-channel configuration with a typical DAC load)

-12 to -15 V (3.8W) @ 0.25 A

+12 to +15 V (4.5W) @ 0.50 A (Eight-channel configuration with a typical DAC load)

-12 to -15 V (3.8W) @ 0.45 A

Flags Power Supply

Each channel of PMAC has five dedicated digital inputs on the machine connector: PLIMn, MLIMn

(overtravel limits), HOMEn (home flag), FAULTn (amplifier fault), and USERn. A power supply from 5

to 24V must be used to power the circuits related to these inputs. This power supply can be the same

used to Power PMAC Clipper and can be connected from the TB1 terminal block.

Specifications 17

Page 18

Power PMAC Clipper User Manual

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment. When the

Power PMAC Clipper is received, there are several things to be done immediately:

Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered the board.

Remove the Power PMAC Clipper from the shipping container and remove all packing materials.

Check all shipping material for connector kits, documentation, or other small pieces of

equipment. Be aware that some connector kits and other equipment pieces may be quite small

and can be accidentally discarded if care is not used when unpacking the equipment. The

container and packing materials may be retained for future shipment.

Verify that the part number of the board received is the same as the part number listed on the

purchase order.

Inspect for external physical damage that may have been sustained during shipment and report

any damage immediately to the commercial carrier that delivered the board.

Electronic components in this product are design-hardened to reduce static sensitivity. However,

use proper procedures when handling the equipment.

If the Power PMAC Clipper is to be stored for several weeks before use, be sure that it is stored

in a location that conforms to published storage humidity and temperature specifications.

Use of Equipment

The following restrictions will ensure the proper use of the Power PMAC Clipper:

The components built into electrical equipment or machines can be used only as integral

components of such equipment.

The Power PMAC Clipper must not be operated on power supply networks without a ground or

with an asymmetrical ground.

If the Power PMAC Clipper is used in residential areas, or in business or commercial premises,

implement additional filtering measures.

The Power PMAC Clipper may be operated only in a closed switchgear cabinet, taking into

account the ambient conditions defined in the environmental specifications.

Delta Tau guarantees the conformance of the Power PMAC Clippers with the standards for industrial

areas stated in this manual, only if Delta Tau components (cables, controllers, etc.) are used.

Receiving and Unpacking 18

Page 19

Power PMAC Clipper User Manual

Caution

Unit must be installed in an enclosure that meets the environmental IP

rating of the end product (ventilation or cooling may be necessary to

prevent enclosure ambient from exceeding 45° C [113° F]).

MOUNTING

The location of the Power PMAC Clipper is important. Installation should be in an area that is protected

from direct sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and other contaminants.

Exposure to these can reduce the operating life and degrade performance of the board.

Several other factors should be carefully evaluated when selecting a location for installation:

For effective cooling and maintenance, the Power PMAC Clipper should be mounted on a

smooth, non- flammable vertical or horizontal surface.

At least 10 mm (0.4 inches) top and bottom clearance must be provided for air flow.

Temperature, humidity and Vibration specifications should also be taken in account.

The Power PMAC Clipper can be mounted as a stand-alone controller using standoffs. At each of the

four corners of the board and at the center edges, there are mounting holes that can be used for this.

If the Power PMAC Clipper is mounted to a back panel, the back panel should be unpainted and

electrically conductive to allow for reduced electrical noise interference. The back panel should be

machined to accept the standoffs pattern of the board.

The board can be mounted to the back panel using four standoffs and internal-tooth lock washers. It is

important that the teeth break through any anodization on the board’s mounting gears to provide a good

electrically conductive path in as many places as possible. Mount the board on the back panel so there is

airflow at both the top and bottom areas of the board (at least 0.4 inches).

Mounting 19

Page 20

Power PMAC Clipper User Manual

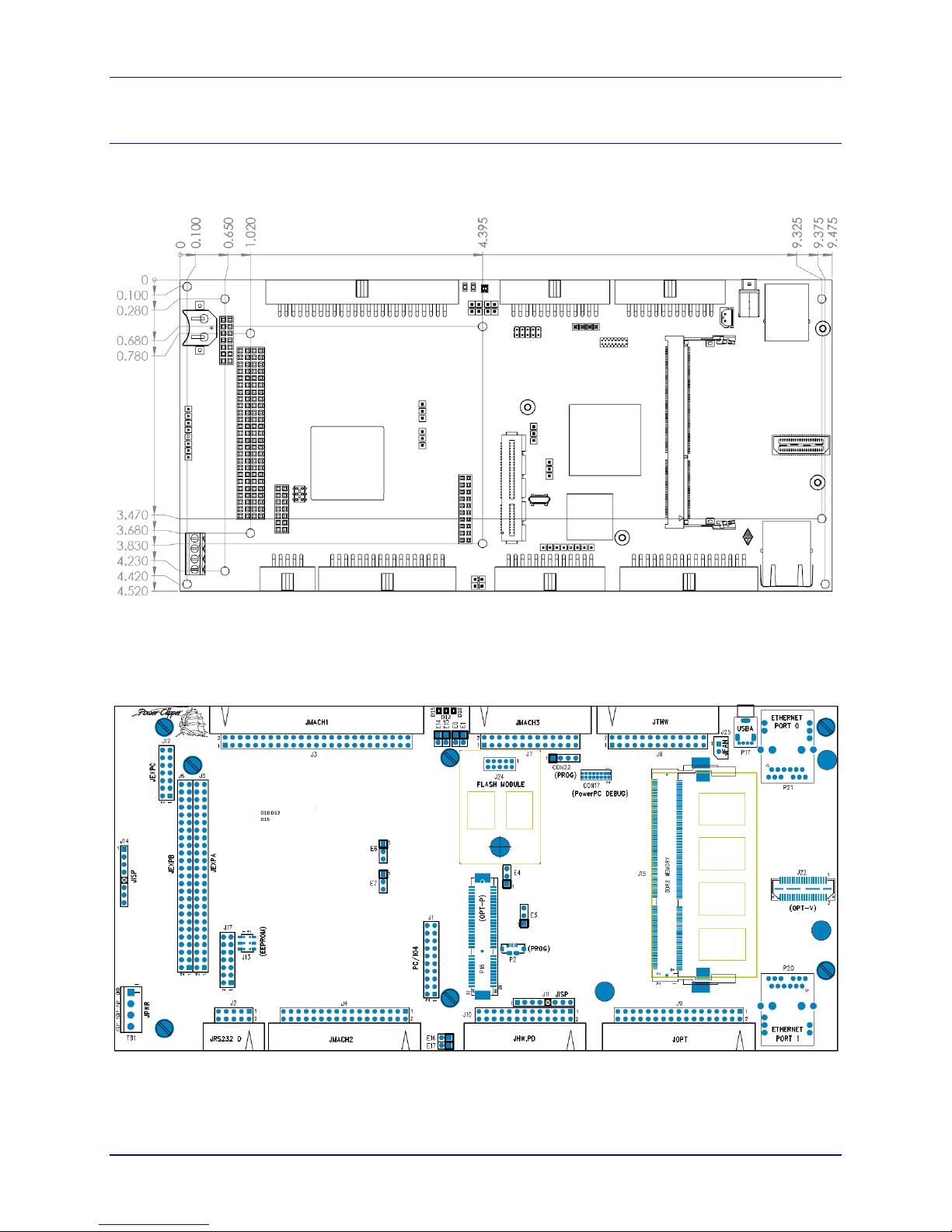

Physical Specifications

Board Dimensions Rev101

Top View

Board Layout Rev101

Top View

Mounting are holes shown with screw heads.

Mounting 20

Page 21

Power PMAC Clipper User Manual

WARNING

Installation of electrical equipment is subject to many regulations

including national, state, local, and industry guidelines and rules.

The following are general recommendations but it is important

that the integration be carried out in accordance with all

regulations pertaining to the installation.

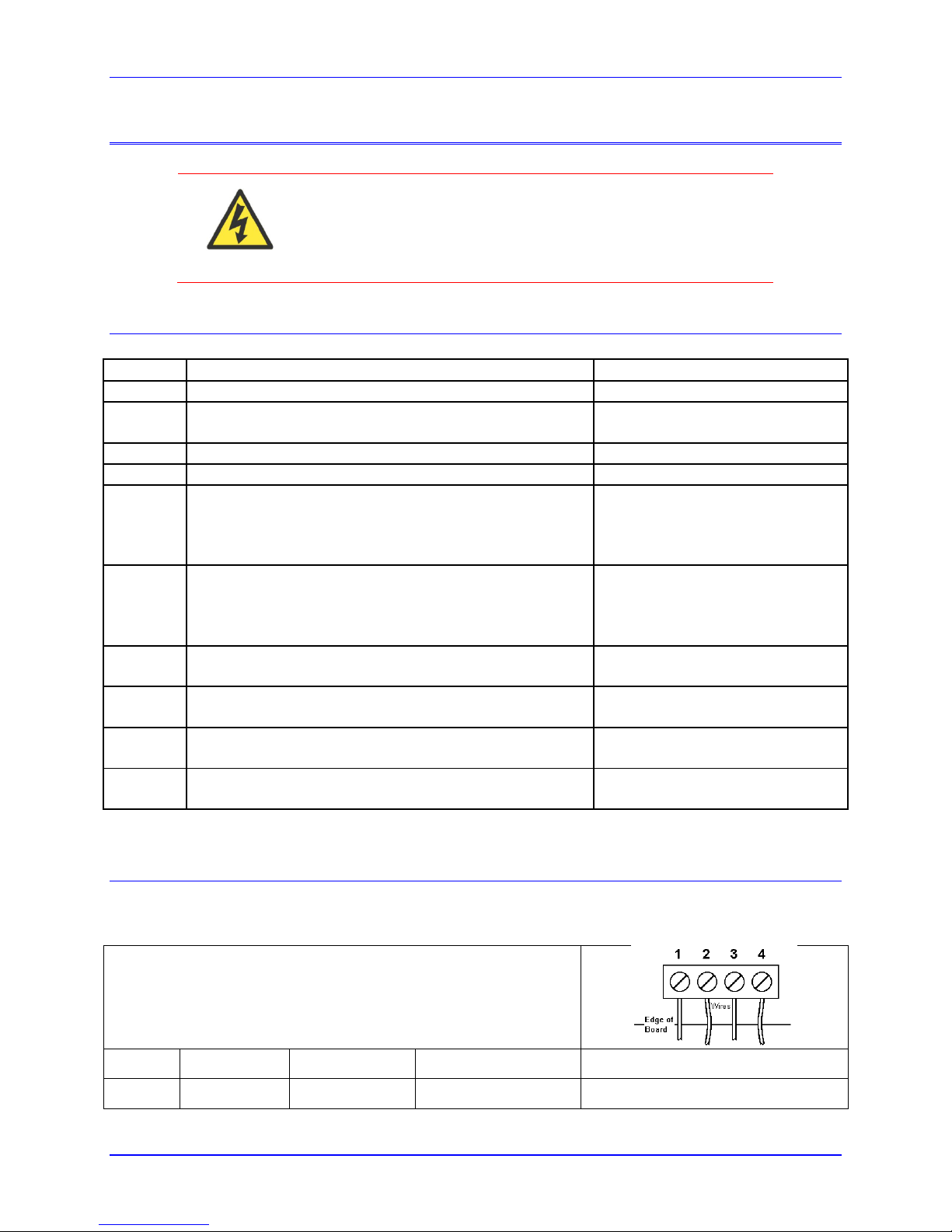

Jumper

Position Description

Note

E0

CPU RESET

Do Not Install

E1

Install E1 to bypass watchdog timer for bootstrap

software load.

Do Not Install

E4

Factory use only, should always be 1-2.

Do Not change

E5

Not currently used

Not Installed

E6

Selection between handwheel input or serial encoder

input on Gate3[i].Chan[0].SerialEncDataA

1-2 FOR SENC1

2-3 ENC-HW-1

Default 1-2

E7

Selection between handwheel input or serial encoder

input on Gate3[i].Chan[1].SerialEncDataA

1-2 FOR SENC2

2-3 ENC-HW-2

Default 1-2

E14

Install to make GPIO 0-7 lines inputs

Remove jumper to make GPIO 0-7 lines outputs

Installed (Required for MuxIO)

E15

Install to make GPIO 8-15 lines inputs

Remove jumper to make GPIO 8-15lines outputs

Not Installed (Required for

MuxIO)

E16

Install to make GPIO 16-23 lines inputs

Remove jumper to make GPIO 16-23 lines outputs

Not Installed

E17

Install to make GPIO 24-31 lines inputs

Remove jumper to make GPIO 24-31 lines outputs

Installed

TB1 (JPWR): Power Supply

4-Pin Terminal Block

Pin#

Symbol

Function

Description

Notes

1

GND

Common

Digital Common

CONNECTIONS AND SOFTWARE SETUP

Default Jumper Configurations

The following table shows the default jumper configurations:

TB1 (JPWR): Power Supply Input

This 4-pin terminal block is used to bring the 5VDC logic power and +/-12VDC DAC supply into the

Power PMAC Clipper.

Connections and Software Setup 21

Page 22

Power PMAC Clipper User Manual

2

+5V

Input

Logic Voltage

Supplies all PMAC digital circuits

3

+12V

Input

DAC Supply Voltage

Ref to Digital GND

4

-12V

Input

DAC Supply Voltage

Ref to Digital GND

Note

For +5V and GND, 18 gauge (AWG) stranded wire is recommended.

For +12V and -12V, a minimum of 22 gauge (AWG) stranded wire is

recommended.

Connections and Software Setup 22

Page 23

Power PMAC Clipper User Manual

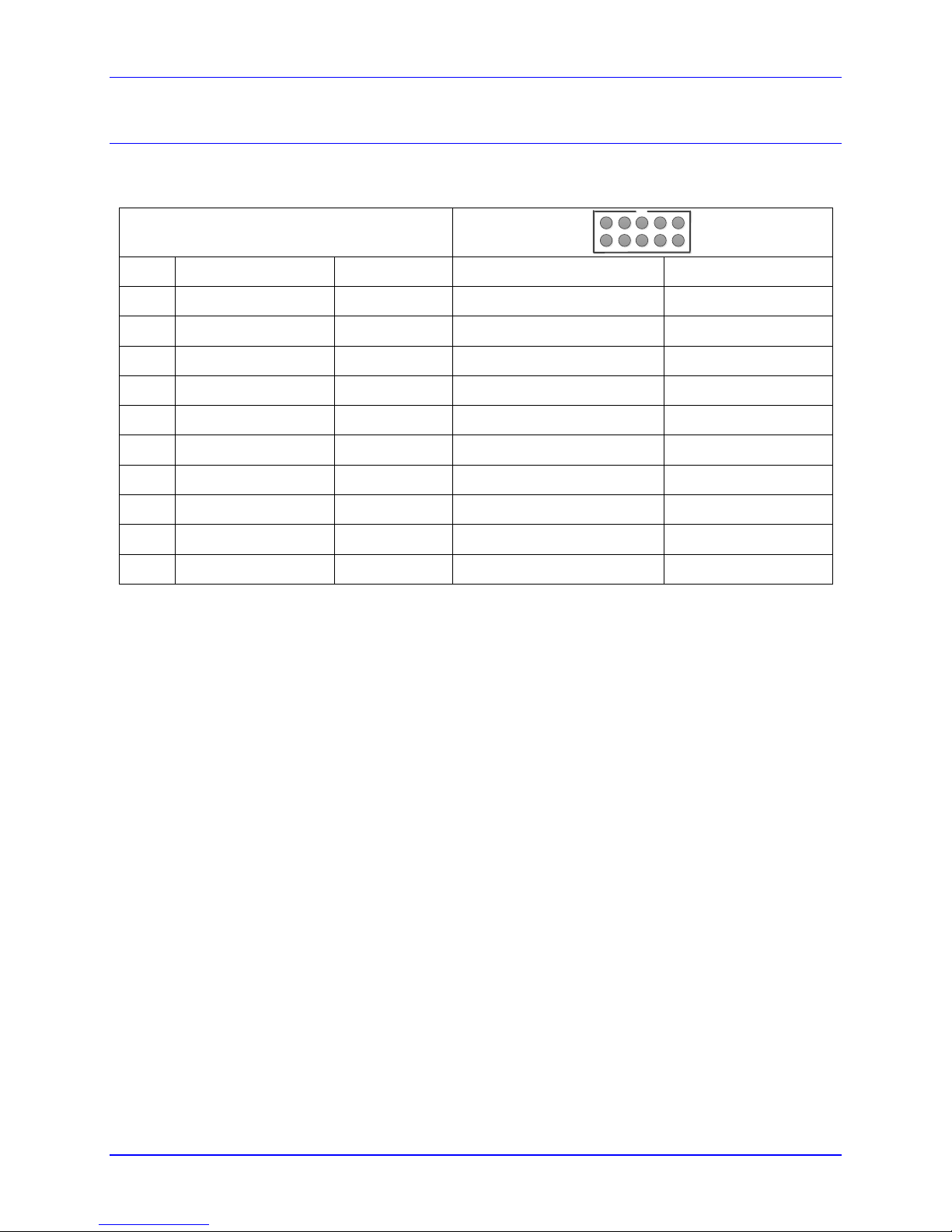

J2 (JRS232) Serial Port Connector

10-Pin Header

56341

2

9107

8

Pin#

Symbol

Function

Description

Notes

1

No Connection

2

DTR

Bidirect

Data Terminal Ready

Tied to "DSR"

3

TXD/

Output

Send Data

Host receive data

4

CTS

Input

Clear to Send

Host ready bit

5

RXD/

Input

Receive Data

Host transmit data

6

RTS

Output

Request to Send

PMAC ready bit

7

DSR

Bidirect

Data Set Ready

Tied to "DTR"

8

No Connection

9

GND

Common

Digital Common

10

RESET_SW#

Input

Hardware CPU Reset

Ground is Reset

J2: Serial Port

This connector allows communicating with Power PMAC Clipper from a host computer through a RS232 port. Delta Tau provides the Accessory 3L cable that connects the PMAC to a DB-9 connector.

10-pin female flat cable connector T&B Ansley P/N 609-1041

Standard flat cable stranded 10-wire T&B Ansley P/N 171-10

Connections and Software Setup 23

Page 24

Power PMAC Clipper User Manual

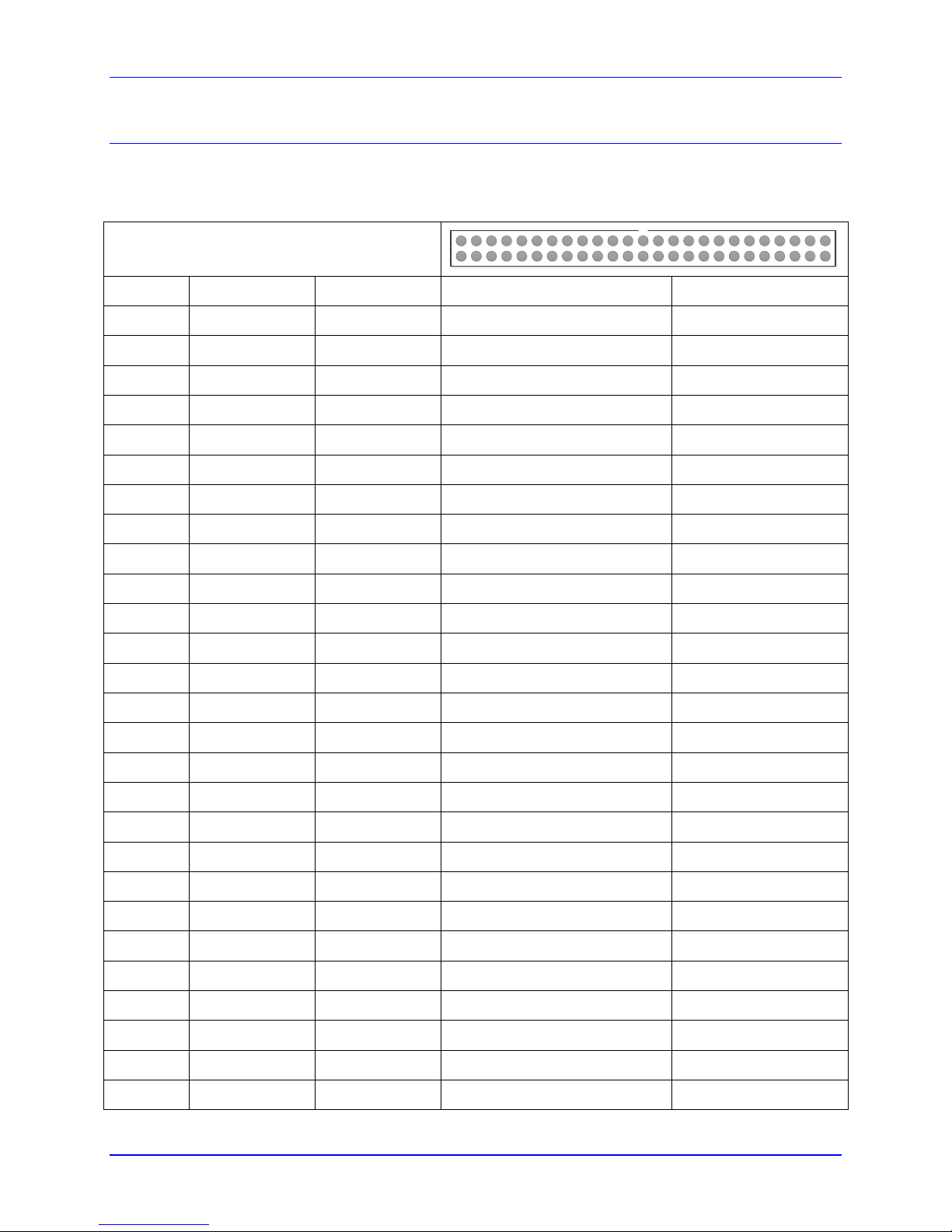

J3 (JMACH1): Machine Port Connector

50-Pin Header

495047484546434441423940373835363334313229302728252623242122192017181516131411129107856341

2

Pin#

Symbol

Function

Description

Notes

1

+5V

Output

+5V Power

For encoders, 1

2

+5V

Output

+5V Power

For encoders, 1

3

GND

Common

Digital Common

For encoders, 1

4

GND

Common

Digital Common

For encoders, 1

5

CHA1

Input

Encoder A Channel Positive

2

6

CHA2

Input

Encoder A Channel Positive

2

7

CHA1/

Input

Encoder A Channel Negative

2,3

8

CHA2/

Input

Encoder A Channel Negative

2,3

9

CHB1

Input

Encoder B Channel Positive

2

10

CHB2

Input

Encoder B Channel Positive

2

11

CHB1/

Input

Encoder B Channel Negative

2,3

12

CHB2/

Input

Encoder B Channel Negative

2,3

13

CHC1

Input

Encoder C Channel Positive

2

14

CHC2

Input

Encoder C Channel Positive

2

15

CHC1/

Input

Encoder C Channel Negative

2,3

16

CHC2/

Input

Encoder C Channel Negative

2,3

17

CHA3

Input

Encoder A Channel Positive

2

18

CHA4

Input

Encoder A Channel Positive

2

19

CHA3/

Input

Encoder A Channel Negative

2,3

20

CHA4/

Input

Encoder A Channel Negative

2,3

21

CHB3

Input

Encoder B Channel Positive

2

22

CHB4

Input

Encoder B Channel Positive

2

23

CHB3/

Input

Encoder B Channel Negative

2,3

24

CHB4/

Input

Encoder B Channel Negative

2,3

25

CHC3

Input

Encoder C Channel Positive

2

26

CHC4

Input

Encoder C Channel Positive

2

27

CHC3/

Input

Encoder C Channel Negative

2,3

J3: Machine Connector (JMACH1 Port)

The primary machine interface connector is JMACH1, labeled J3 on the Power PMAC Clipper. It

contains the pins for four channels of machine I/O: analog outputs, incremental encoder inputs, amplifier

fault and enable signals and power-supply connections.

Connections and Software Setup 24

Page 25

Power PMAC Clipper User Manual

28

CHC4/

Input

Encoder C Channel Negative

2,3

29

DAC1

Output

Analog Output Positive 1

4

30

DAC2

Output

Analog Output Positive 2

4

31

DAC1/

Output

Analog Output Negative 1

4,5

32

DAC2/

Output

Analog Output Negative 2

4,5

33

AENA1/

Output

Amplifier-Enable 1

34

AENA2/

Output

Amplifier -Enable 2

35

FAULT1/

Input

Amplifier -Fault 1

36

FAULT2/

Input

Amplifier -Fault 2

37

DAC3

Output

Analog Output Positive 3

4

38

DAC4

Output

Analog Output Positive 4

4

39

DAC3/

Output

Analog Output Negative 3

4,5

40

DAC4/

Output

Analog Output Negative 4

4,5

41

AENA3/

Output

Amplifier -Enable 3

42

AENA4/

Output

Amplifier -Enable 4

43

FAULT3/

Input

Amplifier -Fault 3

44

FAULT4/

Input

Amplifier -Fault 4

45

ADCIN_1

Input

Analog Input 1

46

ADCIN_2

Input

Analog Input 2

47

FLT_FLG_V

Input

Amplifier Fault pull-up V+

48

GND

Common

Digital Common

49

+12V

Input

DAC Supply Voltage

7

50

-12V

Input

DAC Supply Voltage

7

Note

Note 1: These lines can be used as +5V power supply inputs to power

PMAC’s digital circuitry.

Note 2: Referenced to digital common (GND). Maximum of ±12V

permitted between this signal and its complement.

Note 3: Leave this input floating if not used (i.e. digital single-ended

encoders).

Note 4: ±10V, 10 mA max, referenced to common ground (GND).

Note 5: Leave floating if not used. Do not tie to GND.

Note 7: Can be used to provide input power when the TB1 connector is

not being used.

50-pin female flat cable connector T&B Ansley P/N 609-5041. Standard flat cable stranded 50-wire T&B

Ansley P/N 171-50. Phoenix varioface module type FLKM 50 (male pins) P/N 22 81 08 9

Connections and Software Setup 25

Page 26

Power PMAC Clipper User Manual

Note

Use an encoder cable with high quality shield.

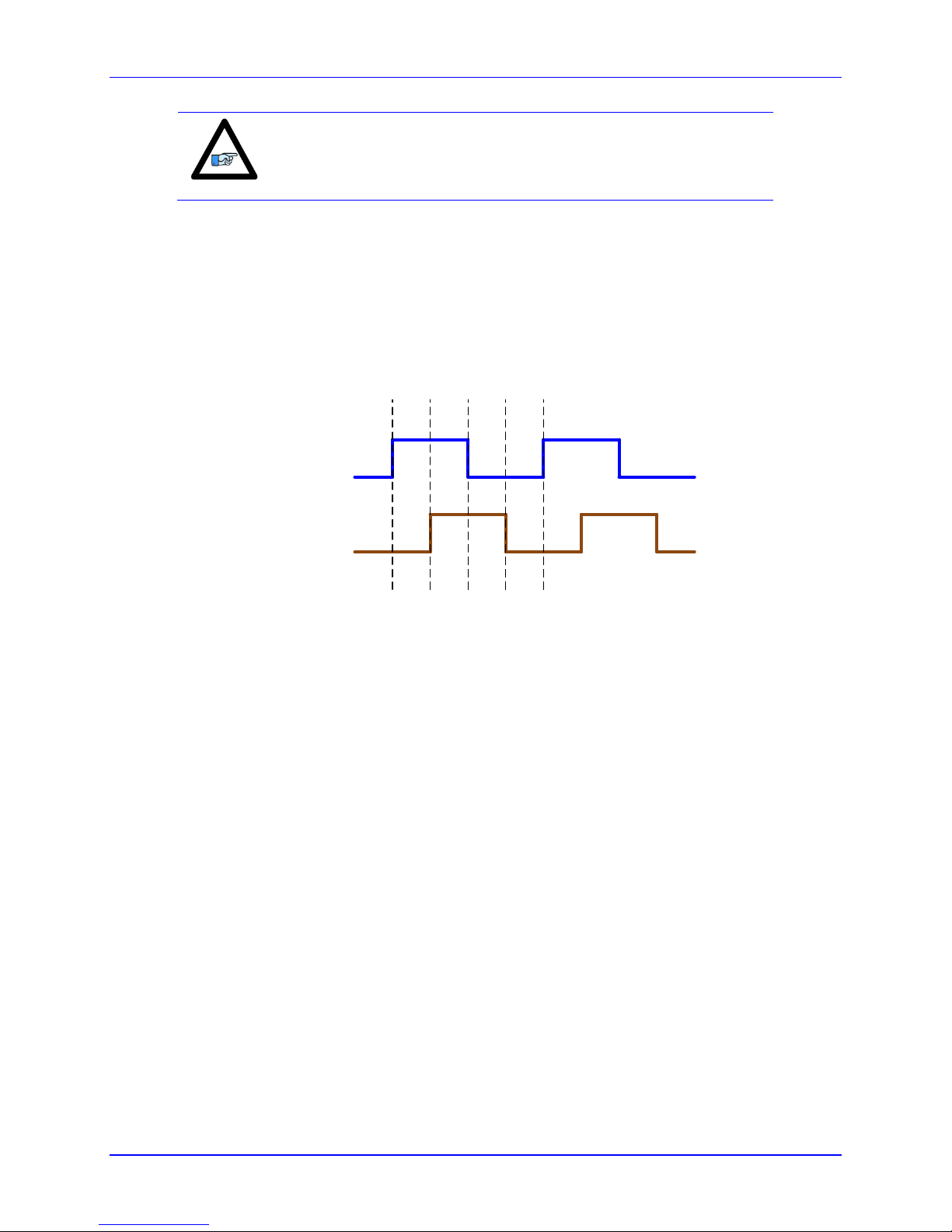

Channel A

Channel B

The standard encoder inputs on the Power PMAC Clipper are designed for differential quadrature type

signals.

Quadrature encoders provide two digital signals to determine the position of the motor. Each nominally

with 50% duty cycle, and nominally 1/4 cycle apart. This format provides four distinct states per cycle of

the signal, or per line of the encoder. The phase difference of the two signals permits the decoding

electronics to discern the direction of travel, which would not be possible with a single signal.

Typically, these signals are 5V TTL/CMOS level whether they are single-ended or differential.

Differential signals can enhance noise immunity by providing common mode noise rejection. Modern

design standards virtually mandate their use in industrial systems.

Connections and Software Setup 26

Page 27

Power PMAC Clipper User Manual

Encoder shield

25 23

24

21

22

19

20

17

18

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

B-

C-

C+

B+

A-

A+

GND

+5V

J3(JMACH1)

Note

For single-ended encoders, leave the complementary signal pins

floating – do not ground them. Alternately, some open collector

single ended encoders may require tying the negative pins to

ground in series with a 1-2 KOhm resistors.

Some motor manufacturers bundle the hall sensors with the

motor-lead cable. The hall sensors must be brought into J7

connector.

Differential Quadrature Encoder Wiring for Channel #1

Configuring Quadrature Encoders

The Power Clipper default settings are configured for quadrature encoders. Minimal setup is required to

configure them; quadrature encoder signals are processed as a single 32-bit read in the encoder

conversion table (ECT). 1/T extension is done in the Gate3 "hardware".

The default ECT settings for the first incremental quadrature encoder will be:

EncTable[1].type = 1; // Single 32-bit read

EncTable[1].pEnc = Clipper[0].Chan[0].ServoCapt.a; // Primary source, ch 1 Servo Capture

EncTable[1].pEnc1 = Sys.Pushm; // Secondary source, none

EncTable[1].index1 = 0; // left shift, none

EncTable[1].index2 = 0; // right shift, none

EncTable[1].index3 = 0; //

EncTable[1].index4 = 0; //

EncTable[1].ScaleFactor = 1/256; // Scale Factor, LSB location

Connections and Software Setup 27

Page 28

Power PMAC Clipper User Manual

Note

The hardware 1/T extension produces 8 bits of fractional data, thus the

(1 / 256) 0.00390625 scale factor.

Channel

Number

Quadrature Encoder

Source Address

1

Clipper[0].Chan[0].ServoCapt.a

2

Clipper[0].Chan[1].ServoCapt.a

3

Clipper[0].Chan[2].ServoCapt.a

4

Clipper[0].Chan[3].ServoCapt.a

Note

The top level structure name “Clipper” is an alias for “Gate3”. Either

may be used when referring to any “Gate3” structures with the Power

Clipper. This manual will use “Clipper”.

Warning

Loss of the feedback sensor signal is potentially a very dangerous

condition in closed-loop control, because the servo loop no longer has

any idea what the true physical position of the motor is – usually it

thinks it is “stuck” – and it can react wildly, often causing a runaway

condition.

Activating the corresponding channel is sufficient to display counts in the position window when the

motor / encoder shaft is moved by hand.

Motor[1].ServoCtrl = 1; // Channel activation

The position and velocity source(s) must be pointing to the proper ECT result. With quadrature encoders,

they are initialized by the firmware as:

Motor[1].pEnc = EncTable[1].a; // Position

Motor[1].pEnc2 = EncTable[1].a; // Velocity

Motor[2].pEnc = EncTable[2].a; // Position

Motor[2].pEnc2 = EncTable[2].a; // Velocity

Motor[3].pEnc = EncTable[3].a; // Position

Motor[3].pEnc2 = EncTable[3].a; // Velocity

Motor[4].pEnc = EncTable[4].a; // Position

Motor[4].pEnc2 = EncTable[4].a; // Velocity

Counts per User Units

With quadrature encoders, the number of counts per user units (usually revolution) is 4 times the specified

number of lines of the encoder. For example, a 1,000–line rotary encoder should result in 4,000 motor

units per revolution.

Quadrature Encoder Count Error

With quadrature encoders, the Power Clipper has the capability of trapping encoder count (loss) errors.

This is described in detail in the Encoder Count Error section of this manual.

Quadrature Encoder Loss Detection

Connections and Software Setup 28

Page 29

Power PMAC Clipper User Manual

Note

Note the distinction between the encoder count error, which reports

loss of counts due to bad transitions of the quadrature signals, and

encoder loss, which indicates that one or more quadrature signals are

completely missing.

25 23

Analog

Device

COM

DAC1+

49

50

47

48

45

46

43

44

41

42

39

40

37

38

35

36

33

34

31

32

29

30

27

28 26

Single Ended DAC Output

J3 (JMACH1)

Analog

Device

COM

DAC1-

DAC1+

25 2349

50

47

48

45

46

43

44

41

42

39

40

37

38

35

36

33

34

31

32

29

30

27

28 26

Differential DAC Output

J3 (JMACH1)

Note

The analog outputs are intended to drive high-impedance inputs with

no significant current draw (10mA max). The 220 output resistors

will keep the current draw lower than 50 mA in all cases and prevent

damage to the output circuitry, but any current draw above 10 mA can

result in noticeable signal distortion. Software setup for analog outputs

can be found in the Drive-Motor setup section.

With quadrature encoders, the Power Clipper has the capability of detecting the loss of an encoder signal.

This is described in detail in the Encoder Loss Detection section of this manual.

Wiring the DAC Output

Example for Clipper Channel #1

Connections and Software Setup 29

Page 30

Power PMAC Clipper User Manual

Connections and Software Setup 30

Page 31

Power PMAC Clipper User Manual

25 2349

50

47

48

45

46

43

44

41

42

39

40

37

38

35

36

33

34

31

32

29

30

27

28 26

J3 (JMACH1)

AENA1

GND

}

Connect to the amplifier

enable input

Amplifier Enable Signal (AENAn/DIRn)

Most amplifiers have an enable/disable input that permits complete shutdown of the amplifier regardless

of the voltage of the command signal. PMAC’s AENA line is meant for this purpose. AENA1- is pin 33.

This signal is an open-collector output and an external 3.3 k pull-up resistor can be used if necessary.

Example for Clipper Channel #1

Connections and Software Setup 31

Page 32

Power PMAC Clipper User Manual

J3 (JMACH1)

5 – 24 VDC

Power Supply

25 2349

50

47

48

45

46

43

44

41

42

39

40

37

38

35

36

33

34

31

32

29

30

27

28 26

FAULT1-

}

Connect to the amplifier

fault output

+ -

Amplifier Fault Signal (FAULT-)

This input can take a signal from the amplifier so PMAC knows when the amplifier is having problems,

and can shut down action.

The polarity is programmable with Motor[x].AmpFaultLevel (Motor[1].AmpFaultLevel for motor 1) and the

return signal is ground (GND). FAULT1- is pin 35. With the default setup, this signal must actively be

pulled low for a fault condition. In this setup, if nothing is wired into this input, PMAC will consider the

motor not to be in a fault condition.

Example for Clipper Channel #1

Connections and Software Setup 32

Page 33

Power PMAC Clipper User Manual

}

+/- 10V Analog Signal

ADCIN_1

J3 (JMACH1)

495047484546434441423940373835363334313229302728252623242122192017181516131411129107856341

2

ADCIN_n/

Connector

Structure

Address

ADCIN_1, J3

Clipper[0].Chan[0].AdcEnc[0]

$900030

ADCIN_2, J3

Clipper[0].Chan[0].AdcEnc[1]

$900034

ADCIN_3, J7

Clipper[0].Chan[0].AdcEnc[2]

$900038

ADCIN_4, J7

Clipper[0].Chan[0].AdcEnc[3]

$90003C

Analog Inputs

The Power PMAC Clipper provides four 12-bit analog inputs with a ±10Vdc range. The first two inputs

are on JMACH1 pins 45 (ADCIN_1) and 46 (ADCIN_2) referenced to pin 3 (digital ground). Inputs 3

and 4 are on the JMACH3 connector pins 1 (ADCIN_3) and 2 (ADCIN_4). These are also referenced to

digital ground.

Example for Analog Input 1

Example for Analog Input 3

Setting up the Analog (ADC) Inputs

The analog inputs accept ±10V single-ended signals only.

The ADC data resides in the upper 12 bits of the 32-bit structure elements in the following table. The

structure elements do not allow bit definitions of the upper 12 bits, hence scaling (shifting) would be

required to obtain the raw ADC data. Using the explicit address registers with PTR definitions is one

alternative:

Connections and Software Setup 33

Page 34

Power PMAC Clipper User Manual

Note

The explicit address register(s) can be found by subtracting Sys.piom

from Clipper[0].Chan[0].AdcEnc[n].a (n=0-3).

Note

The ADC input data must be in the “unpacked” format to be read

properly; Clipper[0].Chan[0].PackInData = 0.

Single-Ended

[VDC]

Software

Counts

-10

-2048 0 0

10

+2048

Raw ADC Data (in bits)

Sys.WpKey = $AAAAAAAA; // Disable Write-Protection

Clipper[0].Chan[0].PackInData = 0; // Unpack Input Data all ADCs J3, J7

PTR ADCIN_1->S.IO:$900030.20.12; // ADCIN_1 J3 [bits]

PTR ADCIN_2->S.IO:$900034.20.12; // ADCIN_2 J3 [bits]

PTR ADCIN_3->S.IO:$900038.20.12; // ADCIN_3 J7 [bits]

PTR ADCIN_4->S.IO:$90003C.20.12; // ADCIN_4 J7 [bits]

Alternately use of bit shifting in PLC and Program with the structure, Clipper[0].Chan[0].AdcEnc[n], as in:

Bit shifting example

// This method is most efficient and uses the least PMAC resources

GLOBAL MyAnalog1 = 0; // Global variable for shifted analog value initialized to zero

OPEN PLC ExamplePLC

. . .

MyAnalog1 = Clipper[0].Chan[0].AdcEnc[0] >> 20; // shift right by 20 bits before assignment

. . .

CLOSE

Since the analog inputs have 12 bits of resolution (4,096 software counts) spanning over the full range of

the input voltage, wiring a ±10V voltage produces the following counts in software:

Scaled ADC Data (in volts)

For general purpose usage, the ADC data (reported in bits) can be easily scaled and converted into “user”

voltage. In the example PLC below:

The global parameter ADCnZeroOffset represents the voltage offset with a zero volt input. This

is user adjustable.

The pointer ADCIN_n reports the raw ADC data in software counts, units of 12-bit (±2048).

Connections and Software Setup 34

Page 35

Power PMAC Clipper User Manual

The global parameter ADCnVoltsIn reports the ADC data in “user” volts.

Where n is the ADC channel number (1 - 4).

GLOBAL ADC1VoltsIn = 0; // Voltage input, ADCIN_1

GLOBAL ADC2VoltsIn = 0; // Voltage input, ADCIN_2

GLOBAL ADC3VoltsIn = 0; // Voltage input, ADCIN_3

GLOBAL ADC4VoltsIn = 0; // Voltage input, ADCIN_4

GLOBAL ADC1ZeroOffset = 0.038; // Zero Volt Offset1, [volt] --USER ADJUSTABLE

GLOBAL ADC2ZeroOffset = 0.038; // Zero Volt Offset2, [volt] --USER ADJUSTABLE

GLOBAL ADC3ZeroOffset = 0.038; // Zero Volt Offset3, [volt] --USER ADJUSTABLE

GLOBAL ADC4ZeroOffset = 0.038; // Zero Volt Offset4, [volt] --USER ADJUSTABLE

OPEN PLC PtrExamplePLC

ADC1VoltsIn = (ADCIN_1 * 10 / 2048) - ADC1ZeroOffset ;

ADC2VoltsIn = (ADCIN_2 * 10 / 2048) – ADC2ZeroOffset ;

ADC3VoltsIn = (ADCIN_3 * 10 / 2048) – ADC3ZeroOffset ;

ADC4VoltsIn = (ADCIN_4 * 10 / 2048) – ADC4ZeroOffset ;

CLOSE

OPEN PLC ShiftExamplePLC // More efficient less resources

ADC1VoltsIn = ((Clipper[0].Chan[0].AdcEnc[0] >> 20) * 10 / 2048) - ADC1ZeroOffset ;

ADC2VoltsIn = ((Clipper[0].Chan[0].AdcEnc[1] >> 20) * 10 / 2048) – ADC2ZeroOffset ;

ADC3VoltsIn = ((Clipper[0].Chan[0].AdcEnc[2] >> 20) * 10 / 2048) – ADC3ZeroOffset ;

ADC4VoltsIn = ((Clipper[0].Chan[0].AdcEnc[3] >> 20) * 10 / 2048) – ADC4ZeroOffset ;

CLOSE

Using the ADC for Servo Feedback

Using the ADC data for servo feedback requires bringing it into the Encoder Conversion Table (ECT)

into which the motor’s position and velocity elements are assigned to. Example:

EncTable[5].pEnc = Clipper[0].Chan[0].AdcEnc[0].a;

EncTable[5].pEnc1 = Sys.pushm;

EncTable[5].index1 = 20;

EncTable[5].index2 = 20;

EncTable[5].index3 = 0;

EncTable[5].index4 = 0;

EncTable[5].index5 = 0;

EncTable[5].ScaleFactor = 1 / EXP2(20);

Motor[5].pEnc = EncTable[5].a;

Motor[5].pEnc2 = EncTable[5].a;

Connections and Software Setup 35

Page 36

Power PMAC Clipper User Manual

J4 (JMACH2): Machine Port CPU Connector

34-Pin Header

56341

2

9107

8

1516131411

12

192017

18

2526232421

22

293027

28

333431

32

Pin#

Symbol

Function

Description

Notes

1

FLG_1_2_V

Input

Flags 1-2 Pull-Up

2

FLG_3_4_V

Input

Flags 3-4 Pull-Up

3

GND

Common

Digital Common

4

GND

Common

Digital Common

5

HOME1

Input

Home-Flag 1

10

6

HOME2

Input

Home-Flag 2

10

7

PLIM1

Input

Positive End Limit 1

8,9

8

PLIM2

Input

Positive End Limit 2

8,9

9

MLIM1

Input

Negative End Limit 1

8,9

10

MLIM2

Input

Negative End Limit 2

8,9

11

USER1

Input

User Flag 1

12

USER2

Input

User Flag 2

13

PUL_1

Output

Pulse Output 1

14

PUL_2

Output

Pulse Output 2

15

DIR_1

Output

Direction Output 1

16

DIR_2

Output

Direction Output 2

17

EQU1

Output

Encoder Comp-Equal 1

18

EQU2

Output

Encoder Comp-Equal 2

19

HOME3

Input

Home-Flag 3

10

20

HOME4

Input

Home-Flag 4

10

21

PLIM3

Input

Positive End Limit 3

8,9

22

PLIM4

Input

Positive End Limit 4

8,9

23

MLIM3

Input

Negative End Limit 3

8,9

24

MLIM4

Input

Negative End Limit 4

8,9

25

USER3

Input

User Flag 3

26

USER4

Input

User Flag 3

J4: Machine Connector (JMACH2 Port)

This machine interface connector is labeled JMACH2 or J4 on the Power PMAC Clipper. It contains the

pins for four channels of machine I/O: end-of-travel input flags, home flag and pulse-and-direction

output signals. In addition, the B_WDO output allows monitoring the state of the Watchdog safety

feature.

Connections and Software Setup 36

Page 37

Power PMAC Clipper User Manual

27

PUL_3

Output

Pulse Output 3

28

PUL_4

Output

Pulse Output 4

29

DIR_3

Output

Direction Output 3

30

DIR_4

Output

Direction Output 4

31

EQU3

Output

Encoder Comp-Equal 3

32

EQU4

Output

Encoder Comp-Equal 4

33

B_WDO

Output

Watchdog Out

Indicator/driver

34

INIT-

Input

PMAC Reset

Low is Reset. See note 11

Note

Note 8: Pins marked PLIMn should be connected to switches at

the positive end of travel. Pins marked MLIMn should be

connected to switches at the negative end of travel.

Note 9: Must be conducting to 0V (usually GND) for PMAC to

consider itself not into this limit. Automatic limit function can be

disabled with Motor[x].pLimits.

Note 10: Functional polarity for homing or other trigger use of

HOMEn controlled by Encoder/Flag Variable

Clipper[0].Chan[j].CaptCtrl. HMFLn selected for trigger by

Encoder/Flag structure Clipper[0].Chan[j].CaptFlagSel. Must be

conducting to 0V (usually GND) to produce a 0 in PMAC

software.

Note 11: Even if it is not used but connected, long cabling may

pull this line low and cause PMAC to unintentionally reset.

34-pin female flat cable connector T&B Ansley P/N 609-3441. Standard flat cable stranded 34-wire T&B

Ansley P/N 171-34. Phoenix varioface module type FLKM 34 (male pins) P/N 22 81 06 3

Overtravel Limits and Home Switches

When assigned for the dedicated uses, these signals provide important safety and accuracy functions.

PLIMn and MLIMn are direction-sensitive over-travel limits that must conduct current to permit motion

in that direction. If no over-travel switches will be connected to a particular motor, this feature must be

disabled in the software by setting Motor[x].pLimits= 0.

Wiring the Limits and Flags

PMAC expects a closed-to-ground connection for the limits to not be considered on fault. This

arrangement provides a failsafe condition. Usually, a passive normally close switch is used. If a

proximity switch is needed instead, use a 5 to 24V normally closed to ground NPN sinking type sensor.

Connections and Software Setup 37

Page 38

Power PMAC Clipper User Manual

5

6

3

4

1

2

9

10

7

8

15

16

13

14

11

12

19

20

17

18

25

26

23

24

21

22

29

30

27

28

33

34

31

32

5 - 24 VDC

Power supply

USER 1

NC POS. LIMIT 1

NC NEG. LIMIT 1

HOME 1

COM

+

FLAG RETURN 3-4

FLAG RETURN 1-2

USER 2

NC POS. LIMIT 2

NC NEG. LIMIT 2

HOME 2

USER 3

NC POS. LIMIT 3

NC NEG. LIMIT 3

HOME 3

USER 4

NC POS. LIMIT 4

NC NEG. LIMIT 4

HOME 4

J4(JMACH2)

Example for Normally Closed Switch

Connections and Software Setup 38

Page 39

Power PMAC Clipper User Manual

5

6

3

4

1

2

9

10

7

8

15

16

13

14

11

12

19

20

17

18

25

26

23

24

21

22

29

30

27

28

33

34

31

32

5 - 24 VDC

Power supply

USER 1

NC POS. LIMIT 1

NC NEG. LIMIT 1

HOME 1

COM

+

FLAG RETURN 3-4

FLAG RETURN 1-2

USER 2

NC POS. LIMIT 2

NC NEG. LIMIT 2

HOME 2

USER 3

NC POS. LIMIT 3

NC NEG. LIMIT 3

HOME 3

USER 4

NC POS. LIMIT 4

NC NEG. LIMIT 4

HOME 4

J4(JMACH2)

Example for 15-24V Proximity Switch

Connections and Software Setup 39

Page 40

Power PMAC Clipper User Manual

Note

While normally closed-to-ground switches are required for the

overtravel limits inputs, the home switches could be either

normally close or normally open types. The polarity is

determined by the home sequence setup, through

Clipper[i].Chan[j].CaptCtrl.

Note

When using these lines as regular I/O points the appropriate setting to

disable the flag’s feature by setting Motor[x].pLimits = 0 and/or

Motor[x].pAmpEnable = 0.

Limits and Flags [Axis 1- 4] Structure Elements

Either the user flags or other unassigned axis flags on the base board can be used as general-purpose I/O

providing up to 20 inputs and 4 outputs at 5-24Vdc levels. The indicated Structure Elements allow

accessing each particular line as shown below:

Clipper[0].Chan[0].AmpEna ; AENA1 output status

Clipper[0].Chan[0].UserFlag ; User 1 flag input status

Clipper[0].Chan[0].HomeFlag ; Home flag 1 input status

Clipper[0].Chan[0].PlusLimit ; Positive Limit 1 flag input status

Clipper[0].Chan[0].MinusLimit ; Negative Limit 1 flag input status

Clipper[0].Chan[1].AmpEna ; AENA2 output status

Clipper[0].Chan[1].UserFlag ; User 2 flag input status

Clipper[0].Chan[1].HomeFlag ; Home flag 2 input status

Clipper[0].Chan[1].PlusLimit ; Positive Limit 2 flag input status

Clipper[0].Chan[1].MinusLimit ; Negative Limit 2 flag input status

Clipper[0].Chan[2].AmpEna ; AENA3 output status

Clipper[0].Chan[2].UserFlag ; User 3 flag input status

Clipper[0].Chan[2].HomeFlag ; Home flag 3 input status

Clipper[0].Chan[2].PlusLimit ; Positive Limit 3 flag input status

Clipper[0].Chan[2].MinusLimit ; Negative Limit 3 flag input status

Clipper[0].Chan[3].AmpEna ; AENA4 output status

Clipper[0].Chan[3].UserFlag ; User 4 flag input status

Clipper[0].Chan[3].HomeFlag ; Home flag 4 input status

Clipper[0].Chan[3].PlusLimit ; Positive Limit 4 flag input status

Clipper[0].Chan[3].MinusLimit ; Negative Limit 4 flag input status

Connections and Software Setup 40

Page 41

Power PMAC Clipper User Manual

5

6

3

4

1

2

9

10

7

8

15

16

13

14

11

12

17

External Stepper

Amplifier

DIR+

PUL+

GND

J4 (JMACH2)

Note

Software setup for PFM outputs are covered in detail in the Pulse

Frequency Modulation (PFM) section under DRIVE - MOTOR

SETUP.

Step and Direction PFM Output (To External Stepper Amplifier)

The Power PMAC Clipper has the capability of generating step and direction (Pulse Frequency

Modulation) output signals to external stepper amplifiers. The step and direction outputs can be

connected in single-ended configuration for 5V (input signal) amplifiers.

Example for Clipper Channel #1

Connections and Software Setup 41

Page 42

Power PMAC Clipper User Manual

5

6

3

4

1

2

9

10

7

8

15

16

13

14

11

12

17

J4 (JMACH2)

}

TTL level output

EQU_1+

GND

Compare Equal Outputs

The compare-equals (EQU) outputs have a dedicated use of providing a signal edge when an encoder

position reaches a pre-loaded value. This is very useful for scanning and measurement applications.

Instructions for use of these outputs are covered in detail in the Power PMAC User Manual.

Example for Channel #1

Clipper[0].Chan[0].EquOut ; EQU1, ENC1 compare output value

Clipper[0].Chan[1].EquOut ; EQU2, ENC2 compare output value

Clipper[0].Chan[2].EquOut ; EQU3, ENC3 compare output value

Clipper[0].Chan[3].EquOut ; EQU4, ENC4 compare output value

Connections and Software Setup 42

Page 43

Power PMAC Clipper User Manual

J7 (JMACH3): Machine Port

26-Pin Header

56341

2

9107

8

1516131411

12

192017

18

2526232421

22

Pin #

symbol

Function

Description

1

ADC3

Input

General Purpose ADC 3 (Requires Opt12)

2

ADC4

Input

General Purpose ADC 4 (Requires Opt12)

3

+5V

Output

4

+5V

Output

5

BRAKE1

Output

Brake output for Channel 1 (Open-collector Output)

6

BRAKE2

Output

Brake output for Channel 2 (Open-collector Output)

7

BRAKE3

Output

Brake output for Channel 3 (Open-collector Output)

8

BRAKE4

Output

Brake output for Channel 4 (Open-collector Output)

9

CHT1

Input

T-flag/Serial Encoder Data+ Input for channel 1

10

CHT2

Input

T-flag/Serial Encoder Data+ Input for channel 2

11

CHT3

Input

T-flag/Serial Encoder Data+ Input for channel 3

12

CHT4

Input

T-flag/Serial Encoder Data+ Input for channel 4

13

GND

Common

14

GND

Common

15

CHU1

Input

U-flag/Serial Encoder Data- input for channel 1

16

CHU2

Input

U-flag/Serial Encoder Data- input for channel 2

17

CHV1

Input

V-flag/Serial Encoder Clock+ input for channel 1

18

CHV2

Input

V-flag/Serial Encoder Clock+ input for channel 2

19

CHW1

Input

W-flag/Serial Encoder Clock- input for channel 1

20

CHW2

Input

W-flag/Serial Encoder Clock- input for channel 2

21

CHU3

Input

U-flag/Serial Encoder Data- input for channel 3

22

CHU4

Input

U-flag/Serial Encoder Data- input for channel 4

23

CHV3

Input

V-flag/Serial Encoder Clock+ input for channel 3

24

CHV4

Input

V-flag/Serial Encoder Clock+ input for channel 4

25

CHW3

Input

W-flag/Serial Encoder Clock- input for channel 3

26

CHW4

Input

W-flag/Serial Encoder Clock- input for channel 4

J7: Machine Connector (JMACH3 Port)

This machine interface connector is labeled JMACH3 or J7 on the Power PMAC Clipper. It contains the

pins for four channels of Gate3 serial encoders and is shared with the T, U, V, and W flags normally used

for hall device commutation with the Clipper Drive stack accessory. Also on this connector are the third

and fourth ADC inputs and four channels of brake outputs.

26-pin female flat cable connector T&B Ansley P/N 609-2641. Standard flat cable stranded 26-wire T&B

Ansley P/N 171.26. Phoenix varioface module type FLKM 26 (male pins) P/N 22 81 05 0

Connections and Software Setup 43

Page 44

Power PMAC Clipper User Manual

Caution

The brake’s output signal has a limited current capability (about

100mA) and should be wired using external relays to the motor.

Note

For diagnostics, set Motor[x].pBrakeOut = 0 and set the output using the

Clipper[0].Chan[j].OutFlagB bit element.

Global Control Register

Channels 1 – 4

Clipper[0].SerialEncCtrl

Brake Software Setup

The following settings are required to synchronize the enabling/disabling of the motor with the brake

output signal.

Motor[1].pBrakeOut = Clipper[0].Chan[0].OutFlagB.a; //

Motor[1].BrakeOutBit = 9; //

Motor[1].BrakeOffDelay = 1; // msec, Brake Off Delay --USER INPUT

Motor[1].BrakeOnDelay = 1; // msec, Brake On Delay --USER INPUT

Motor[2].pBrakeOut = Clipper[0].Chan[1].OutFlagB.a; //

Motor[2].BrakeOutBit = 9; //

Motor[2].BrakeOffDelay = 1; // msec, Brake Off Delay --USER INPUT

Motor[2].BrakeOnDelay = 1; // msec, Brake On Delay --USER INPUT

Motor[3].pBrakeOut = Clipper[0].Chan[2].OutFlagB.a; //

Motor[3].BrakeOutBit = 9; //

Motor[3].BrakeOffDelay = 1; // msec, Brake Off Delay --USER INPUT

Motor[3].BrakeOnDelay = 1; // msec, Brake On Delay --USER INPUT

Motor[4].pBrakeOut = Clipper[0].Chan[3].OutFlagB.a; //

Motor[4].BrakeOutBit = 9; //

Motor[4].BrakeOffDelay = 1; // msec, Brake Off Delay --USER INPUT

Motor[4].BrakeOnDelay = 1; // msec, Brake On Delay --USER INPUT

Serial Encoder Software Setup

Configuring Gate3 serial encoder protocols is achieved through the following structure elements:

Global Control Word, Clipper[0].SerialEncCtrl

Channel Control Word, Clipper[0].Chan[j].SerialEncCmd

Channel Enable Bit, Clipper[0].Chan[j].SerialEncEna

Global Control Register