Page 1

Single Source Machine Control

……………………………………………..…...……………….

Power // Flexibility // Ease of Use

21314 Lassen St. Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^1 USER’S MANUAL

^2 Power PMAC

^3 Power PMAC User’s Manual

^4 050-PRPMAC-0U0

^5 January 6, 2015

DELTA TAU

Data Systems, Inc.

NEW IDEAS IN MOTION …

Page 2

Power PMAC User’s Manual

Copyright Information

© 2015 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses

are unauthorized without written permission of Delta Tau Data Systems, Inc.

Information contained in this manual may be updated from time-to-time due to product

improvements, etc., and may not conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers

contain static sensitive components that can be damaged by incorrect handling. When

installing or handling Delta Tau Data Systems, Inc. products, avoid contact with highly

insulated materials. Only qualified personnel should be allowed to handle this

equipment.

In the case of industrial applications, we expect our products to be protected from

hazardous or conductive materials and/or environments that could cause harm to the

controller by damaging components or causing electrical shorts. When our products are

used in an industrial environment, install them into an industrial electrical cabinet or

industrial PC to protect them from excessive or corrosive moisture, abnormal ambient

temperatures, and conductive materials. If Delta Tau Data Systems, Inc. products are

directly exposed to hazardous or conductive materials and/or environments, we cannot

guarantee their operation.

Page 3

Power PMAC User’s Manual

A Warning identifies hazards that could result in personal injury or

death. It precedes the discussion of interest.

Warning

!

Caution

A Caution identifies hazards that could result in equipment damage. It

precedes the discussion of interest.

Note

A Note identifies information critical to the understanding or use of

the equipment. It follows the discussion of interest.

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC364resp.CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It

is vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

Page 4

Power PMAC User’s Manual

REVISION HISTORY

REV.

DESCRIPTION

DATE

CHG

APPVD

1

New Manual Generated

11/28/2011

SS

Curt Wilson

2

Updating Table of Contents

01/19/2012

SS

Curt Wilson

3

Updating the manual for firmware version 1.5 release

08/10/2012

SS

Curt Wilson

4

Updating the manual for firmware version 1.6 release

03/17/2014

SS

Curt Wilson

5

Updating the manual for firmware version 2.0 release

01/06/2015

SS

Curt Wilson

Page 5

Page 6

Power PMAC User’s Manual

TABLE OF CONTENTS

Contents

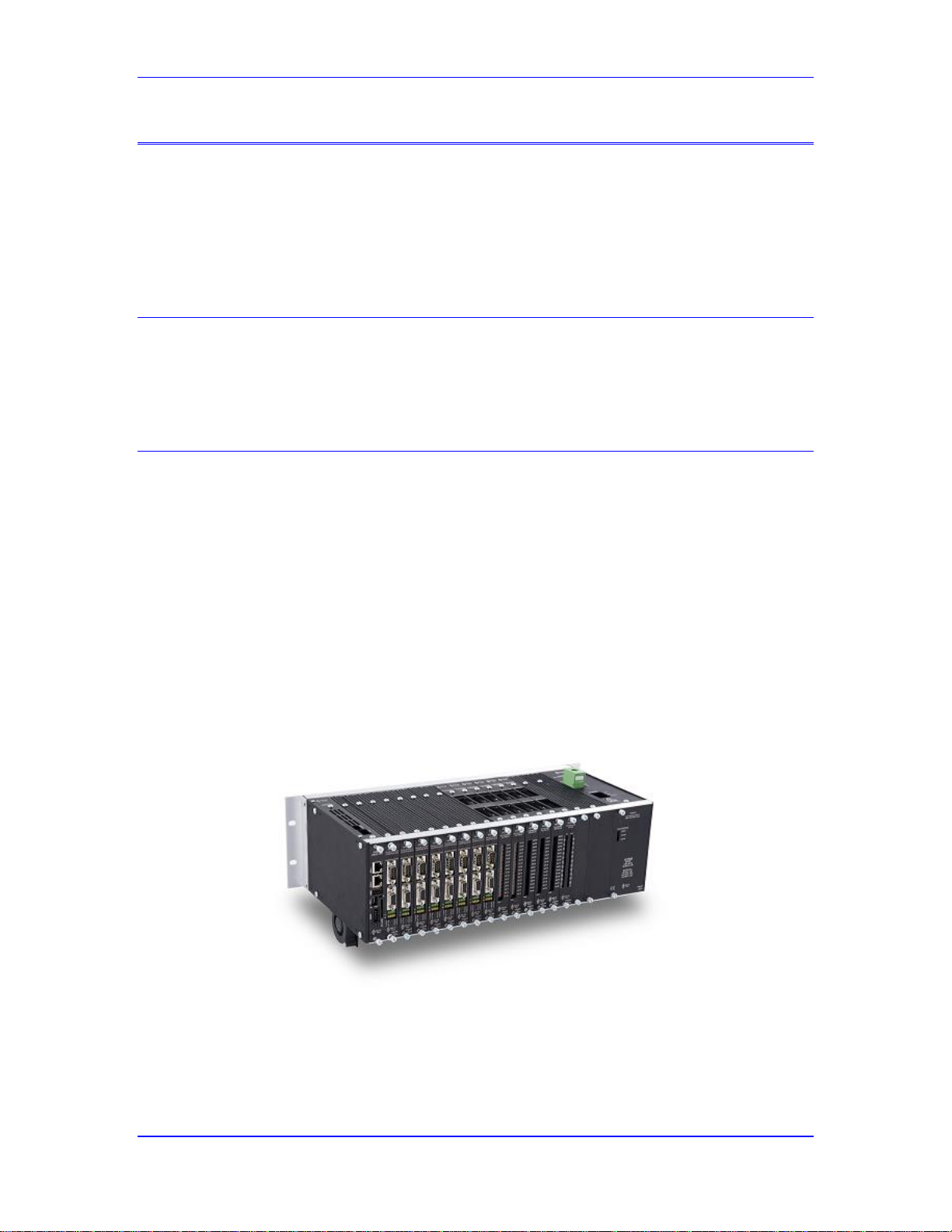

POWER PMAC FAMILY OVERVIEW ................................................................................................ 27

What Is Power PMAC? ............................................................................................................................... 27

Power PMAC Configurations ..................................................................................................................... 27

Power UMAC......................................................................................................................................... 27

Compact Power UMAC ......................................................................................................................... 28

Power PMAC Etherlite .......................................................................................................................... 28

Power Brick Configurations .................................................................................................................. 28

Power Clipper ........................................................................................................................................ 29

Soft Power PMAC .................................................................................................................................. 30

What Power PMAC Does ........................................................................................................................... 30

Execute Sequenced Motion Programs ................................................................................................... 30

Execute Asynchronous PLC Programs .................................................................................................. 30

Perform Kinematic Transformations ..................................................................................................... 30

Process Feedback and Master Position Data ........................................................................................ 31

Compute Commanded Motor Trajectories ............................................................................................ 31

Calculate Compensation Table Corrections .......................................................................................... 31

Close Motor Position/Velocity Servo Loops .......................................................................................... 31

Perform Electronic Phase Commutation ............................................................................................... 31

Close Motor Current Loops ................................................................................................................... 31

Provide Synchronous Data Gathering ................................................................................................... 32

Perform General Housekeeping and Safety Checks .............................................................................. 32

Respond to Host Computer Commands ................................................................................................. 32

Execute Independent C Applications ..................................................................................................... 32

Key Hardware Components ........................................................................................................................ 33

CPU Section........................................................................................................................................... 33

Machine Interface ICs ........................................................................................................................... 34

TALKING TO POWER PMAC .............................................................................................................. 39

Physical Interface ........................................................................................................................................ 39

Use of the Internet Protocol Suite ............................................................................................................... 39

Layers of the Internet Protocol Suite ..................................................................................................... 39

Low-Level Terminal Communications ....................................................................................................... 40

Terminal Emulator Programs ................................................................................................................ 41

Establishing First Communications....................................................................................................... 41

Table of Contents vi

Page 7

Power PMAC User’s Manual

Communicating with the Power PMAC Control Application ................................................................ 42

Establishing Communications with the IDE ............................................................................................... 44

Startup Communications Control Window ............................................................................................ 44

Embedded Communications Control Window ....................................................................................... 45

Changing the Power PMAC IP Address ................................................................................................ 46

Finding an Unknown IP Address ........................................................................................................... 47

Power PMAC Commands ........................................................................................................................... 48

On-Line (Immediate) Commands........................................................................................................... 48

Buffered Program Commands ............................................................................................................... 50

Power PMAC Processing of Commands ............................................................................................... 51

POWER PMAC SYSTEM CONFIGURATION ................................................................................... 55

Physical Configuration Status Reporting .................................................................................................... 55

General Configuration ........................................................................................................................... 55

Interface ICs Present ............................................................................................................................. 56

Interface IC Addresses ........................................................................................................................... 56

Interface IC Configuration Information ................................................................................................ 56

Change in Configuration ....................................................................................................................... 57

Power PMAC System Clock Source ........................................................................................................... 57

Default Clock Source ............................................................................................................................. 57

IC Clock Generation Facilities .............................................................................................................. 57

Distribution of Clock Signals ................................................................................................................. 58

Re-Initialization Clock Actions .............................................................................................................. 59

Normal Reset Clock Actions .................................................................................................................. 59

Changing the Clock Source from Default .............................................................................................. 60

Setting System Clock Frequencies .............................................................................................................. 60

Phase and Servo-Clock Hardware Tasks .............................................................................................. 60

Phase-Clock Software Tasks .................................................................................................................. 61

Servo-Clock Software Tasks .................................................................................................................. 61

Real-Time Interrupt Software Tasks ...................................................................................................... 62

Background Tasks .................................................................................................................................. 63

Multi-Tasking Example .......................................................................................................................... 64

Using the IDE to Set Phase and Servo Clock Frequencies ................................................................... 65

Setting Phase and Servo Clock Frequencies in PMAC2-Style ICs ........................................................ 65

Setting Phase and Servo Clock Frequencies in PMAC3-Style ICs ........................................................ 68

Clock-Related Software Settings ............................................................................................................ 69

Setting the Phase and Servo Clock Period in the CPU ......................................................................... 70

Diagnosing Issues with Clock Settings ....................................................................................................... 71

Missing Clock Signals ............................................................................................................................ 71

Task Priority Duty Cycles ...................................................................................................................... 71

Table of Contents vii

Page 8

Power PMAC User’s Manual

SETTING UP THE MACRO RING ....................................................................................................... 75

MACRO Ring Overview ............................................................................................................................ 75

Power PMAC MACRO Interfaces .............................................................................................................. 75

ACC-5E MACRO Interface for UMAC .................................................................................................. 75

ACC-5E3 MACRO Interface for UMAC ................................................................................................ 75

ACC-5EP3 MACRO Interface for Etherlite ........................................................................................... 76

MACRO Interface for Power Brick ....................................................................................................... 76

Configuring Master and Slave Devices ...................................................................................................... 76

PMAC2-Style MACRO IC ...................................................................................................................... 76

PMAC3-Style MACRO IC ...................................................................................................................... 77

Setting the Ring Frequency ......................................................................................................................... 79

PMAC2-Style MACRO IC ...................................................................................................................... 79

PMAC3-Style MACRO IC ...................................................................................................................... 80

Extending the Phase Software Update ................................................................................................... 80

Enabling MACRO Nodes ........................................................................................................................... 82

Node Allocation ..................................................................................................................................... 82

Typical Mapping of MACRO Nodes to Motors ..................................................................................... 82

Enabling Nodes in a PMAC2-Style MACRO IC .................................................................................... 83

Enabling Nodes in a PMAC3-Style MACRO IC .................................................................................... 84

Ring Check Function .................................................................................................................................. 85

Ring Check Parameters ......................................................................................................................... 85

MACRO Node Register Organization ........................................................................................................ 85

Standard Use of Registers in a Servo Node ........................................................................................... 85

Data Elements in a PMAC2-Style MACRO IC ...................................................................................... 85

Data Elements in a PMAC3-Style MACRO IC ...................................................................................... 86

Processing Position Feedback from the MACRO Ring .............................................................................. 86

Encoder Table Entry Method: EncTable[n].type .................................................................................. 86

Encoder Table Entry Source Address: EncTable[n].pEnc .................................................................... 87

Intermediate Processing: EncTable[n].index1, index2 ......................................................................... 88

Change Limiting: EncTable[n].index3, MaxDelta ................................................................................ 89

Setting Up Motor Addressing Elements ..................................................................................................... 90

Command Output Address ..................................................................................................................... 90

Position Feedback Address .................................................................................................................... 91

Interface Type ........................................................................................................................................ 91

Input Flag Addresses ............................................................................................................................. 91

Input Flag Bits ....................................................................................................................................... 91

Output Flag Addresses .......................................................................................................................... 92

Output Flag Bits .................................................................................................................................... 92

Table of Contents viii

Page 9

Power PMAC User’s Manual

Commutation Addresses ........................................................................................................................ 93

Setting Up a Motor as a Network Slave ...................................................................................................... 95

Command Modes ................................................................................................................................... 95

Coordinating Power PMAC Motor Setup .............................................................................................. 96

Network-Slave Power PMAC Motor Setup ............................................................................................ 99

SETTING UP FEEDBACK AND MASTER POSITION SENSORS ................................................ 102

Setting Up Digital Quadrature Encoders .................................................................................................. 102

Signal Format ...................................................................................................................................... 102

Hardware Setup ................................................................................................................................... 103

Hardware-Control Parameter Setup ................................................................................................... 105

Using the Resulting Position Information ........................................................................................... 107

Setting Up Digital Hall Sensors ................................................................................................................ 110

Signal Format ...................................................................................................................................... 110

Hardware Setup ................................................................................................................................... 111

Hardware-Control Parameter Setup ................................................................................................... 111

Using the Resulting Position Information ........................................................................................... 112

Setting Up Serial Encoders ....................................................................................................................... 113

Signal Format ...................................................................................................................................... 113

Hardware Setup ................................................................................................................................... 113

Hardware-Control Parameter Setup ................................................................................................... 113

Using the Resulting Position Information ........................................................................................... 123

Setting Up Analog Sinusoidal Encoders ................................................................................................... 127

Signal Format ...................................................................................................................................... 127

Sinusoidal Encoder Interfaces ............................................................................................................. 128

Hardware Setup ................................................................................................................................... 129

Hardware Control Parameter Setup .................................................................................................... 131

Using the Resulting Position Information ........................................................................................... 143

Setting Up Resolvers ................................................................................................................................. 149

Signal Format ...................................................................................................................................... 149

Hardware Setup ................................................................................................................................... 150

Hardware-Control Parameter Setup ................................................................................................... 150

Using the Resulting Position Information ........................................................................................... 153

Setting Up MLDTs ................................................................................................................................... 157

Signal Format ...................................................................................................................................... 157

Hardware Setup ................................................................................................................................... 158

Hardware-Control Parameter Setup ................................................................................................... 158

Using the Resulting Position Information ........................................................................................... 161

Setting Up Parallel Data Position Inputs ................................................................................................... 163

Table of Contents ix

Page 10

Power PMAC User’s Manual

Signal Format ...................................................................................................................................... 163

Hardware Setup ................................................................................................................................... 163

Hardware Control Parameter Setup .................................................................................................... 163

Using the Resulting Position Information ........................................................................................... 164

Setting Up Analog Data Position Inputs ................................................................................................... 166

Signal Format ...................................................................................................................................... 166

Hardware Setup ................................................................................................................................... 167

Hardware Control Parameter Setup .................................................................................................... 168

Using the Resulting Position Information ........................................................................................... 171

SETTING UP THE ENCODER CONVERSION TABLE.................................................................. 177

What the Encoder Conversion Table Does ............................................................................................... 177

Conversion Table Execution ..................................................................................................................... 178

Conversion Table Structure ...................................................................................................................... 178

Conversion Method Overview .................................................................................................................. 179

IDE Table Configuration Window ............................................................................................................ 179

Scaling of Entry Results ............................................................................................................................ 180

Using Conversion Table Results ............................................................................................................... 181

Default Conversion Table Setup ............................................................................................................... 182

Conversion Method Details ...................................................................................................................... 182

Type 0: End of (Active) Table .............................................................................................................. 182

Type 1: Single-Register Read .............................................................................................................. 183

Type 2: Double-Register Read ............................................................................................................. 189

Type 3: Software 1/T Encoder Extension ............................................................................................ 191

Type 4: Software Arctangent Sinusoidal Encoder Extension .............................................................. 192

Type 5: Four-Byte Read ....................................................................................................................... 196

Type 6: Resolver Arctangent Direct Conversion ................................................................................. 197

Type 7: Extended Hardware Arctangent Interpolation ....................................................................... 198

Types 8 and 9: Addition and Subtraction ............................................................................................ 199

Type 10: Triggered Time Base............................................................................................................. 200

Type 11: Floating-Point Register Read ............................................................................................... 201

Type 12: Single Register Read with Error Check ................................................................................ 203

BASIC MOTOR SETUP ........................................................................................................................ 206

IDE Interactive Setup ................................................................................................................................ 207

Parameters to Set Up Basic Motor Operation ........................................................................................... 207

Table of Contents x

Page 11

Power PMAC User’s Manual

Initial Setup Parameters ............................................................................................................................ 209

Activating the Motor: Motor[x].ServoCtrl .......................................................................................... 209

Activating PMAC Motor Commutation: Motor[x].PhaseCtrl ............................................................. 209

Motor Address Setup Parameters .............................................................................................................. 210

Command Output Address: Motor[x].pDac ........................................................................................ 210

Motor vs. Load Feedback .................................................................................................................... 211

Outer (Position) Loop Feedback: Motor[x].pEnc, PosSf .................................................................... 212

Inner (Velocity) Loop Feedback: Motor[x].pEnc2, Pos2Sf ................................................................. 212

Changing Feedback on the Fly ............................................................................................................ 213

Feedback Source and Type: Motor[x].EncType .................................................................................. 213

Encoder Status Address: Motor[x].pEncStatus ................................................................................... 214

Position-Capture Flag Address: Motor[x].pCaptFlag, CaptFlagBit .................................................. 214

Limit Flag Address: Motor[x].pLimits, LimitBits ................................................................................ 214

Amplifier Fault Flag Address: Motor[x].pAmpFault, AmpFaultBit ................................................... 215

Amplifier Enable Flag Address: Motor[x].pAmpEnable, AmpEnableBit............................................ 215

Absolute Power-On Position Address: Motor[x].pAbsPos ................................................................. 216

Is Power PMAC Commutating or Closing the Current Loop for This Motor? ......................................... 217

Setting Up Power PMAC for Velocity or Torque Control ....................................................................... 217

Hardware Setup ................................................................................................................................... 217

ASIC Programmable Signal Setup ....................................................................................................... 220

Setting Up Power PMAC for Pulse-and-Direction Control ...................................................................... 222

Hardware Setup ................................................................................................................................... 223

Signal Timing ....................................................................................................................................... 223

Power PMAC Parameter Setup ........................................................................................................... 224

Setting Up Power PMAC for Position-Output Control............................................................................. 230

Power PMAC Parameter Setup ........................................................................................................... 230

SETTING UP POWER PMAC-BASED COMMUTATION AND/OR CURRENT LOOP ............ 232

Selection of Phase Update Frequency ....................................................................................................... 232

Beginning Setup of Commutation............................................................................................................. 232

Commutation Enable: Motor[x].PhaseCtrl ......................................................................................... 233

Commutation Position Feedback Source: Motor[x].pPhaseEnc ......................................................... 234

Commutation Position Source Processing: Motor[x].PhaseEncRightShift, Motor[x].PhaseEncLeftShift

............................................................................................................................................................. 235

Commutation Position Scale Factor: Motor[x].PhasePosSf ............................................................... 235

Current Loop in Power PMAC or Not: Motor[x].pAdc ...................................................................... 236

Setting Up for Sine-Wave Output Control ................................................................................................ 238

Hardware Setup ................................................................................................................................... 238

Motor Software Setup .......................................................................................................................... 240

Table of Contents xi

Page 12

Power PMAC User’s Manual

Setting Up For Direct PWM Control ........................................................................................................ 244

Introduction ......................................................................................................................................... 244

Digital Current Loop Principle of Operation ...................................................................................... 244

Hardware Setup ................................................................................................................................... 247

Motor Software Setup .......................................................................................................................... 251

Direct PWM Control of Brush Motors ..................................................................................................... 261

Direct Microstepping with Direct PWM Control...................................................................................... 264

Principle of Operation ......................................................................................................................... 264

Speed Limitations................................................................................................................................. 265

Hardware Setup ................................................................................................................................... 265

Encoder Conversion Table Entry Setup ............................................................................................... 265

Simulated Servo Loop Setup ................................................................................................................ 266

Commutation and Current-Loop Setup ................................................................................................ 267

Limiting Parameters ............................................................................................................................ 269

Establishing a Phase Reference (Synchronous Motors)............................................................................ 270

Absolute Phasing Reads ...................................................................................................................... 272

Correcting an Approximate Phase Reference...................................................................................... 278

Finishing Setting Up Power PMAC Commutation (Direct PWM or Sine Wave), Asynchronous

(Induction) Motors .................................................................................................................................... 279

Calculating Motor[x].DtOverRotorTc Slip Constant .......................................................................... 279

Setting Motor[x].IdCmd Magnetization Current ................................................................................. 281

SETTING UP THE SERVO LOOP ...................................................................................................... 283

Servo Update Rate .................................................................................................................................... 283

Choosing an Update Rate .................................................................................................................... 283

Ramifications of Changing the Rate .................................................................................................... 283

Setting the Servo Clock Frequency/Period .......................................................................................... 284

Extending the Servo Update Period for a Motor ................................................................................. 284

Closing the Servo Loop Under the Phase Interrupt for a Motor ......................................................... 284

Types of Amplifiers .................................................................................................................................. 285

Amplifiers for Which Servo Produces Position Command .................................................................. 286

Amplifiers for Which Servo Produces Velocity Command .................................................................. 286

Amplifiers for Which Servo Produces Torque/Force Command ......................................................... 287

Selecting a Servo Algorithm ..................................................................................................................... 288

Position Command Output Algorithm ...................................................................................................... 289

Basic PID Algorithm ................................................................................................................................. 289

Feedback Terms ................................................................................................................................... 290

Feedforward Filter .............................................................................................................................. 292

Table of Contents xii

Page 13

Power PMAC User’s Manual

Standard Servo Algorithm ........................................................................................................................ 293

Polynomial Filters ............................................................................................................................... 293

Integration Mode ................................................................................................................................. 296

Friction Feedforward .......................................................................................................................... 296

Acceleration Feedback ........................................................................................................................ 296

Input Deadband Compensation ........................................................................................................... 296

Output Hysteretic Deadband ............................................................................................................... 298

Adaptive Servo Control ............................................................................................................................ 299

Selecting the Adaptive Control Algorithm ........................................................................................... 300

Establishing the Reference System ...................................................................................................... 300

Software Setup for Adaptive Control ................................................................................................... 300

Gain Scheduled Adaptive Control ....................................................................................................... 301

Executing the Adaptive Control Algorithm .......................................................................................... 302

Cross-Coupled Gantry Control ................................................................................................................. 304

Selecting the Cross-Coupled Control Algorithm ................................................................................. 305

Tuning the Non-Coupled Terms ........................................................................................................... 305

Tuning the Cross-Coupled Terms ........................................................................................................ 306

Custom User Servo Algorithms ................................................................................................................ 306

Tuning the Servo Loop in the IDE ............................................................................................................ 307

Automatic Tuning................................................................................................................................. 308

Sample Interactive Tuning Process ..................................................................................................... 310

Cascading Servo Loops ............................................................................................................................. 315

Strategies for Coupling the Loops ....................................................................................................... 315

To Integrate Outer Loop Command or Not ......................................................................................... 316

Inner Loop General Setup ................................................................................................................... 316

Outer Loop General Setup ................................................................................................................... 317

Joining the Loops through Position Following Function .................................................................... 317

Joining the Loops through Compensation Table ................................................................................. 319

Tuning the Outer Loop ......................................................................................................................... 321

Programming the Outer-Loop Motor .................................................................................................. 322

Setup Examples .................................................................................................................................... 322

Changing the Operational Mode of Control ........................................................................................ 324

Trajectory Pre-Filter .................................................................................................................................. 325

Typical Uses of the Pre-Filter ............................................................................................................. 325

Overview .............................................................................................................................................. 326

Saved Setup Elements .......................................................................................................................... 327

Filter DC Gain ..................................................................................................................................... 327

Spliner Reconstruction ......................................................................................................................... 328

Automated Filter Setup ........................................................................................................................ 328

Manual Filter Calculations ................................................................................................................. 329

Table of Contents xiii

Page 14

Power PMAC User’s Manual

SETTING UP COMPENSATION TABLES ........................................................................................ 332

Table Data Structure ................................................................................................................................. 332

Reserving Memory for the Tables ............................................................................................................ 333

Defining the Table Structure ..................................................................................................................... 334

Dimension Indices ............................................................................................................................... 334

Number of Active Dimensions: Nx[n] > 0 ........................................................................................... 334

Source Motors for Each Dimension: Source[n] .................................................................................. 336

Source Position Used for Each Dimension: SourceCtrl ...................................................................... 336

Number of Data Zones in Each Active Dimension: Nx[n] .................................................................. 336

Starting Source Location for Each Active Dimension: X0[n] ............................................................. 337

Source Span for Each Active Dimension: Dx[n] ................................................................................. 337

Interpolation-Order and Boundary-Mode Control: Ctrl ..................................................................... 338

Target Register Addresses: Target[q] ................................................................................................. 340

Target Output Scale Factors: Sf[q] ..................................................................................................... 343

Overwriting vs. Additive Outputs: OutCtrl .......................................................................................... 343

Entering the Table Data Points ................................................................................................................. 344

Enabling Compensation Tables ................................................................................................................ 345

Action of the Compensation Tables .......................................................................................................... 345

Use of “0D” Compensation Tables ........................................................................................................... 346

Sample Compensation Tables ................................................................................................................... 347

1D “Leadscrew Compensation” Table................................................................................................ 347

2D “Planar” Position Compensation Table ....................................................................................... 347

SETTING UP ELECTRONIC CAM TABLES ................................................................................... 349

Uses of Electronic Cam Tables ................................................................................................................. 349

Position Commands ............................................................................................................................. 349

Torque Offset Commands .................................................................................................................... 349

Direct Output Commands .................................................................................................................... 349

Comparison to External Time Base Techniques ....................................................................................... 350

Table Design Techniques .......................................................................................................................... 351

Table Data Structure ................................................................................................................................. 352

Reserving Memory for the Tables ............................................................................................................ 353

Defining the Table Structure ..................................................................................................................... 353

Source Motor Number: Source ............................................................................................................ 353

Table of Contents xiv

Page 15

Power PMAC User’s Manual

Number of Data Zones: Nx .................................................................................................................. 354

Starting Source Location: X0, SlewX0 ................................................................................................ 354

Source Span: Dx .................................................................................................................................. 355

Target Motor Number: Target ............................................................................................................. 355

Target Position Scale Factor: PosSf ................................................................................................... 355

Target Position Offset Slew: SlewPosOffset ........................................................................................ 355

Target Torque Offset Enable Control: DacEnable .............................................................................. 355

Target Torque Scale Factor: DacSf ..................................................................................................... 355

Output Address: pOut .......................................................................................................................... 355

Buffered Output Address: pOutBuf ...................................................................................................... 356

Output Shifting:OutLeftShift ................................................................................................................ 356

Output Masking: OutBits ..................................................................................................................... 356

Entering the Table Data Points ................................................................................................................. 356

Returning vs. Non-Returning Position Tables .......................................................................................... 357

Returning Position Tables ................................................................................................................... 357

Non-Returning Position Tables ........................................................................................................... 358

Enabling the Cam Tables .......................................................................................................................... 359

Action of the Cam Tables ......................................................................................................................... 359

Adjusting of the Table Action ................................................................................................................... 361

Adjusting on Source Motor Position .................................................................................................... 361

Adjusting on Target Motor Position .................................................................................................... 361

Phasing the Cam Cycle on a Source Motor Trigger ........................................................................... 361

Rollover of the Table ................................................................................................................................ 363

Position Output at Rollover ................................................................................................................. 363

Torque Offset Output at Rollover ........................................................................................................ 363

General Purpose Outputs at Rollover ................................................................................................. 364

Iterative Learning Control ......................................................................................................................... 364

Combining Cam Motion with Other Motion ............................................................................................ 364

Reporting Motor Position with Cam Table Motion .................................................................................. 365

Disabling the Cam Tables ......................................................................................................................... 365

Switching Between Cam Tables ............................................................................................................... 365

MAKING YOUR POWER PMAC APPLICATION SAFE ............................................................... 366

Watchdog Timer ....................................................................................................................................... 366

Soft Watchdog Trips ............................................................................................................................ 366

Hard Watchdog Trips .......................................................................................................................... 368

Global Abort-All Input ............................................................................................................................. 369

Table of Contents xv

Page 16

Power PMAC User’s Manual

Software Setup ..................................................................................................................................... 369

Action on Trip ...................................................................................................................................... 369

Voltage Interlock Circuits ......................................................................................................................... 370

Following Error Limits ............................................................................................................................. 370

Fatal Following Error Limit ................................................................................................................ 370

Warning Following Error Limit .......................................................................................................... 372

Position (Overtravel) Limits ..................................................................................................................... 372

Software Overtravel Limit Parameters ................................................................................................ 372

Hardware Overtravel Limit Switches .................................................................................................. 374

Encoder Loss Detection ............................................................................................................................ 376

Signal Loss Detection Circuits ............................................................................................................ 377

Software Setup for Loss Detection ....................................................................................................... 379

Auxiliary Fault Detection ......................................................................................................................... 381

Software Setup for Auxiliary Fault Detection ...................................................................................... 381

Automatic Brake Control .......................................................................................................................... 383

Specifying the Brake Control Output ................................................................................................... 383

Specifying the Brake Timing ................................................................................................................ 383

Amplifier Enable and Fault Lines ............................................................................................................. 384

Current Limits ........................................................................................................................................... 385

Intermittent Current Limits .................................................................................................................. 385

Time-Integrated Current Limits ........................................................................................................... 386

RMS Current Calculations .................................................................................................................. 389

Reference Frame Conversions ............................................................................................................. 392

Torque Control Mode .......................................................................................................................... 393

Sinewave Output Mode ........................................................................................................................ 395

Direct PWM Output Mode ................................................................................................................... 397

Velocity Limits ......................................................................................................................................... 400

Programmed Vector Velocity Limit ..................................................................................................... 400

Programmed Motor Velocity Limit ...................................................................................................... 401

Position-Following Velocity Limit ....................................................................................................... 401

Acceleration Limits ................................................................................................................................... 401

Programmed Vector Acceleration Limits ............................................................................................ 401

Programmed Motor Acceleration Limits ............................................................................................. 402

Motor Move Acceleration Command ................................................................................................... 403

Position-Following Acceleration Limit ............................................................................................... 403

Jerk Limits ................................................................................................................................................ 403

Programmed Motor Jerk Limit ............................................................................................................ 403

Table of Contents xvi

Page 17

Power PMAC User’s Manual

Motor Move Jerk Command ................................................................................................................ 403

Commanded Safety Stops ......................................................................................................................... 404

Abort: Controlled Stop ........................................................................................................................ 404

Disable: Uncontrolled Stop ................................................................................................................. 404

Hybrid Abort/Disable .......................................................................................................................... 405

EXECUTING INDIVIDUAL MOTOR MOVES ................................................................................. 406

Jogging Move Control .............................................................................................................................. 406

Jog Speed Control ................................................................................................................................ 406

Jog Acceleration Control ..................................................................................................................... 406

Example Jog Move Profile ................................................................................................................... 410

Jog Commands..................................................................................................................................... 410

Triggered Motor Moves ............................................................................................................................ 412

Types of Triggered Moves ................................................................................................................... 412

Trigger Conditions............................................................................................................................... 413

Capturing the Position at Trigger ....................................................................................................... 417

Processing the Hardware-Captured Position ...................................................................................... 421

Processing the Software-Captured Position ........................................................................................ 430

Post-Trigger Move ............................................................................................................................... 430

Homing-Search Moves ......................................................................................................................... 430

Jog-Until-Trigger Moves ..................................................................................................................... 435

Program Move-Until-Trigger .............................................................................................................. 436

Open-Loop Moves .................................................................................................................................... 436

SETTING UP COORDINATE SYSTEMS .......................................................................................... 437

What is a Coordinate System? .................................................................................................................. 437

Number of Coordinate Systems ........................................................................................................... 437

Strategy for Assigning Coordinate Systems ......................................................................................... 437

Fault Sharing ....................................................................................................................................... 438

What is an Axis? ....................................................................................................................................... 438

Single-Motor Axes ............................................................................................................................... 438

Multiple-Motor Axes ............................................................................................................................ 438

Phantom Axes ...................................................................................................................................... 439

Axis Definition Statements ....................................................................................................................... 439

Matching Motor to Axis ....................................................................................................................... 440

Scaling and Offset ................................................................................................................................ 440

The Null Definition .............................................................................................................................. 440

Defining a Motor to Multiple Axes ...................................................................................................... 440

Cartesian Axis Sets .............................................................................................................................. 442

The Spindle Axis Definition ................................................................................................................. 443

Table of Contents xvii

Page 18

Power PMAC User’s Manual

Conversion from Axis to Motor Position ............................................................................................. 444

Conversion from Motor to Axis Positions ............................................................................................ 444

Coordinate-System Kinematic Subroutines .............................................................................................. 446

Creating the Kinematic Program Buffers ............................................................................................ 447

Generalizing the Routines to Multiple Coordinate Systems ................................................................ 457

Axis Transformation Matrices .................................................................................................................. 460

Transformation Matrix Data Structures .............................................................................................. 461

Using the Matrices ............................................................................................................................... 462

Examples .............................................................................................................................................. 463

Rescaling Feedrate and Tool Radius ................................................................................................... 464

Segmentation Mode .................................................................................................................................. 464

Time-Base Control and Override Techniques........................................................................................... 466

Time-Base Control ............................................................................................................................... 466

Segmentation Override ........................................................................................................................ 469

Axis Target Position and Distance-to-Go Reporting ................................................................................ 472

Setting Up the Target Position Buffer .................................................................................................. 472

Querying the Target Position Data ..................................................................................................... 473

POWER PMAC COMPUTATIONAL FEATURES ........................................................................... 476

Computational Priorities ........................................................................................................................... 476

Phase (Commutation) Update ............................................................................................................. 476

Servo Update ....................................................................................................................................... 476

Real-Time Interrupt Tasks ................................................................................................................... 477

Background Tasks ................................................................................................................................ 477

Monitoring Processing Time ............................................................................................................... 477

Numerical Values ...................................................................................................................................... 478

Internal Formats .................................................................................................................................. 478

Pre-Defined Data Structures ..................................................................................................................... 481

Specifying Data Structure Indices ....................................................................................................... 482

User Variables ........................................................................................................................................... 483

Direct Access to User Variables .......................................................................................................... 483

User-Specified Variable Names Through IDE .................................................................................... 484

Automatically Assigned Declared Variables ....................................................................................... 484

System Global (“P”) Variables ........................................................................................................... 486

Coordinate System Global (“Q”) Variables ....................................................................................... 487

User Pointer (“M”) Variables ............................................................................................................. 488

Pre-Defined Setup Pointer (“I”) Variables ......................................................................................... 488

Local (“L”) Variables ......................................................................................................................... 489

Table of Contents xviii

Page 19

Power PMAC User’s Manual

Return/Stack (“R”) Variables .............................................................................................................. 490

Coordinate System Kinematic Axis (“C”) Variables........................................................................... 491

Non-Stack Local (“D”) Variables ....................................................................................................... 492

User Shared Memory Buffer Variables ............................................................................................... 493

Operators ................................................................................................................................................... 495

Arithmetic Operators ........................................................................................................................... 495

Bit-Wise Operators .............................................................................................................................. 495

Standard Assignment Operators .......................................................................................................... 496

Synchronous Assignment Operators .................................................................................................... 496

Functions ................................................................................................................................................... 497

Scalar Functions .................................................................................................................................. 497

Vector Functions .................................................................................................................................. 497

Matrix Functions ................................................................................................................................. 498

Expressions ............................................................................................................................................... 499

The {data} Syntax ..................................................................................................................................... 500

Standard Variable Value Assignment ....................................................................................................... 500

Synchronous Variable Value Assignment ................................................................................................ 501

Variables That Can Be Assigned Synchronously ................................................................................. 501

Why Needed in Motion Programs ........................................................................................................ 502

Why Needed in PLC Programs ............................................................................................................ 503

The Synchronous Assignment Buffer ................................................................................................... 503

Execution Details ................................................................................................................................. 504

Comparators .............................................................................................................................................. 504