Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

^1 HARDWARE REFERENCE MANUAL

^2 PMAC2-PC & PMAC2-PC LITE

^3 Programmable Multi-Axis Controllers

^4 3xx-602598-xHxx

^5 January 28, 2003

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Copyright Information

© 2003 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained

in this manual may be updated from time-to-time due to product improvements, etc., and may not

conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain

static sensitive components that can be damaged by incorrect handling. When installing or

handling Delta Tau Data Systems, Inc. products, avoid contact with highly insulated materials.

Only qualified personnel should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial

environment, install them into an industrial electrical cabinet or industrial PC to protect them

from excessive or corrosive moisture, abnormal ambient temperatures, and conductive materials.

If Delta Tau Data Systems, Inc. products are exposed to hazardous or conductive materials and/or

environments, we cannot guarantee their operation.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

PMAC2-PC & Lite Hardware Reference

i

Contents

INTRODUCTION...................................................................................................................................................1

Overview...................................................................................................................................................................1

Features .....................................................................................................................................................................1

PMAC2 ASICs..........................................................................................................................................................1

DSPGATE1 Servo ASIC..............................................................................................................................1

DSPGATE2 I/O ASIC..................................................................................................................................2

PMAC2-PC Configuration..........................................................................................................................2

PMAC2-Lite Configuration.........................................................................................................................2

PMAC2-PC Board Configuration...............................................................................................................2

PMAC2-PC Setup........................................................................................................................................3

PMAC2 CPUs ...........................................................................................................................................................4

P/N 602398..................................................................................................................................................4

P/N 602405..................................................................................................................................................4

P/N 602705..................................................................................................................................................4

Related Technical Documentation.............................................................................................................................5

CONNECTORS AND JUMPERS..........................................................................................................................7

PMAC2-PC AND PMAC2-Lite Connector Summary..............................................................................................7

J1 (JANA) Analog Input Port Connector....................................................................................................8

J2 (JTHW) Multiplexer Port Connector......................................................................................................9

J3 (JI/O) General I/O Connector..............................................................................................................10

J4 (JMACRO) 26-Pin Connector..............................................................................................................11

J5 (JRS232) Serial Port Connector...........................................................................................................11

JRS422 (26-Pin Connector) ......................................................................................................................12

JRS422 (DB-15 Connector).......................................................................................................................12

J6 (JDISP) Display Connector..................................................................................................................13

J7 (JHW) Handwheel Encoder Connector................................................................................................13

J8 (JEQU) Position Compare Output Connector......................................................................................14

J9 (JMACH1) Connector Description.......................................................................................................14

J10 (JMACH2) Connector Description.....................................................................................................17

J11 (JMACH3) Connector Description.....................................................................................................20

J12 (JMACH4) Connector Description.....................................................................................................23

TB1 (2/4-Pin Terminal Block)...................................................................................................................26

TB2 (3-Pin Terminal Block)......................................................................................................................26

PMAC2-PC and PMAC2-Lite Jumper Summary....................................................................................................27

PMAC2-VME CPU Connector Summary...............................................................................................................29

J1...............................................................................................................................................................29

J2 (JEXP)..................................................................................................................................................29

J3...............................................................................................................................................................29

J4 (JEXP)..................................................................................................................................................29

J5 (JTAG/OnCE).......................................................................................................................................29

J6...............................................................................................................................................................29

J7...............................................................................................................................................................29

PMAC2-PC CPU Piggyback Board Jumpers ...........................................................................................31

Table of Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

PMAC2-PC & Lite Hardware Reference

ii Table of Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

PMAC2-PC & Lite Hardware Reference

INTRODUCTION

Overview

The PMAC2-PC and PMAC2-Lite provide state-of-the-art motion control for a wide variety of

applications, including machine tools, robotics, semiconductor manufacturing, packaging equipment, and

general-purpose automation. They utilize the latest developments in electronics, software, and modern

control theory to bring motion control capabilities to a whole new level.

The PMAC2-PC and PMAC2-Lite are designed as ISAbus expansion cards, but are capable of standalone

operation. The configurations are:

• PMAC2-PC: ISAbus-compatible, 1-1/2 slots, 4 or 8 machine interface channels.

• PMAC2-Lite: ISAbus-compatible, 1 slot, 4 machine interface channels.

Features

PMAC2-PC and PMAC2-Lite support a wide variety of servo and stepper interfaces:

• Analog +/-10V velocity command (requires ACC-8E or equivalent)

• Analog +/-10V torque command (requires ACC-8E or equivalent)

• Sinusoidal analog +/-10V phase current commands (requires ACC-8E or equivalent)

• Direct digital pulse-width modulated (PWM) phase voltage commands (requires ACC-8F, -8K or

equivalent)

• Pulse-and-direction commands (requires ACC-8S or equivalent)

• MACRO

TM

ring network commands (requires ACC-42)

PMAC2-PC and PMAC2-Lite also provide unparalleled speeds and resolutions:

• 40 MHz encoder count rate

• 18-bit analog outputs

• 18 microsecond per axis servo update time (60 MHz)

• 120 MHz PWM clock frequency (10-bit resolution at 120 kHz, 12-bit and 30 kHz, 14-bit at 7.5 kHz)

• 120 MHz MLDT (e.g. Temposonics

TM

) timer frequency (0.024mm, 0.9mil resolution)

• 10 MHz maximum pulse-and-direction output frequency

• 10 MHz maximum position-compare output update rate

• 125 Mbit/sec optical ring network data rate

PMAC2 ASICs

Delta Tau has designed its own custom application-specific integrated circuits (ASICs) for the PMAC2PC and PMAC2-Lite using the latest sub-micron gate-array technology. Each ASIC contains 45,000

active logic gates. These ASICs contain all of the digital interface circuitry to tie the DSP to the machine;

the rest of the circuitry on the board is buffer circuitry.

DSPGATE1 Servo ASIC

The “DSPGATE1” ASIC contains the digital servo interface circuitry for 4 channels, usually sufficient

for four axes of control. Each channel contains:

Three command output sets:

1. Top-and-bottom PWM or serial DAC data with clock

2. Top-and-bottom PWM or serial DAC data with strobe

3. Top-and-bottom PWM or PFM pulse-and-direction

• Encoder quadrature or pulse-and-direction decode and count

Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 7

PMAC2-PC & Lite Hardware Reference

• Index channel input internally gated to 1 quadrature state wide

• 4 flags with capability to perform hardware latching of encoder position

• HOME, PLIM, MLIM, USER

• Double-sided position-compare output with auto-increment capability

• Amplifier enable output

• Amplifier fault input

• 4 supplementary flag inputs (T, U, V, W)

• 2 inputs from serial analog-to-digital converters (ADCs)

• ADC clock and strobe signal outputs

The DSPGATE1 ASIC also generates several clock frequencies necessary for hardware and software

operation, under the user’s software control:

• PWM output frequency

• DAC clock frequency

Phase interrupt clock frequency and Servo interrupt clock frequency are generated from the first

DSPGATE1 only.

• ADC clock frequency

• Encoder sample clock frequency

• Pulse-frequency modulation (PFM) clock frequency

• Phase interrupt clock frequency

• Servo interrupt clock frequency

DSPGATE2 I/O ASIC

There is also a “DSPGATE2” ASIC on PMAC2-PC and PMAC2-Lite, which is used for interface to other

I/O. The DSPGATE2 ASIC has 3 parts:

• General-purpose digital I/O: 56 I/O points for JIO, JTHW, and JDISP ports

• Servo interface circuitry for 2 supplemental channels with clock generation

• MACRO ring interface circuitry

The general-purpose I/O and the servo interface circuitry on the DSPGATE2 generally share pins, except

for two 2-channel encoder inputs and 2 PWM/PFM output sub-channels. The shared pins are almost

always used for general-purpose I/O instead of extra servo interface circuitry, but this is up to the

individual user.

PMAC2-PC Configuration

A PMAC2-PC can have 1 or 2 DSPGATE1 ASICs; the first one is standard, and the second one comes if

Option 1 is ordered. Each also has a DSPGATE2 ASIC supporting the non-servo I/O.

PMAC2-Lite Configuration

A PMAC2-Lite board (PC bus only) has a single DSPGATE1 ASIC on-board, supporting up to 4 axes of

servo interfaces. It also has a DSPGATE2 ASIC supporting the non-servo I/O. It cannot be expanded

on-board to add a second DSPGATE1 ASIC to support a full 8 axes.

PMAC2-PC Board Configuration

Jumpers on the PMAC2-PC determine the frequency at which the DSP on the PV CPU board will

operate. The 56002 DSP has a “phased-locked loop” (PLL) that allows it to multiply the crystal

frequency by a programmable integer value, permitting very high CPU frequencies with a moderate

crystal frequency. The crystal frequency on the PV CPU board is always 19.6608 MHz, commonly called

“20 MHz”.

2 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

PMAC2-PC & Lite Hardware Reference

The component rating of the DSP IC specifies the highest frequency at which it safely can run, but it is

the multiplication factor typically set by jumpers that specifies the frequency at which it actually runs.

Usually this is a frequency at or near the maximum for the component.

It is safe to run a DSP at a frequency below the maximum. It may be possible to run a DSP at a frequency

higher than its maximum frequency, particularly at low ambient temperatures, but safe operation cannot

be guaranteed. Unpredictable and possibly dangerous operation may result.

On power-up/reset, the DSP, operating at the crystal frequency of 20 MHz, reads the frequency jumpers

(E2 and E4) and writes into its own PLL multiplier register at X:$FFFD. Bits 0-3 of this word contain a

value one less than the multiplier value (if the frequency is being multiplied by 3, these bits contain a

value of 2).

If you wish to check the value of your multiplier, you can use the on-line command RHX:$FFFD and

look at the last hexadecimal digit. The actual multiplier is one greater than the value in this last digit.

Alternately, you can define an M-variable such as M99->X:$FFFD,0,4 and then read from or write to

these bits with the M-variable.

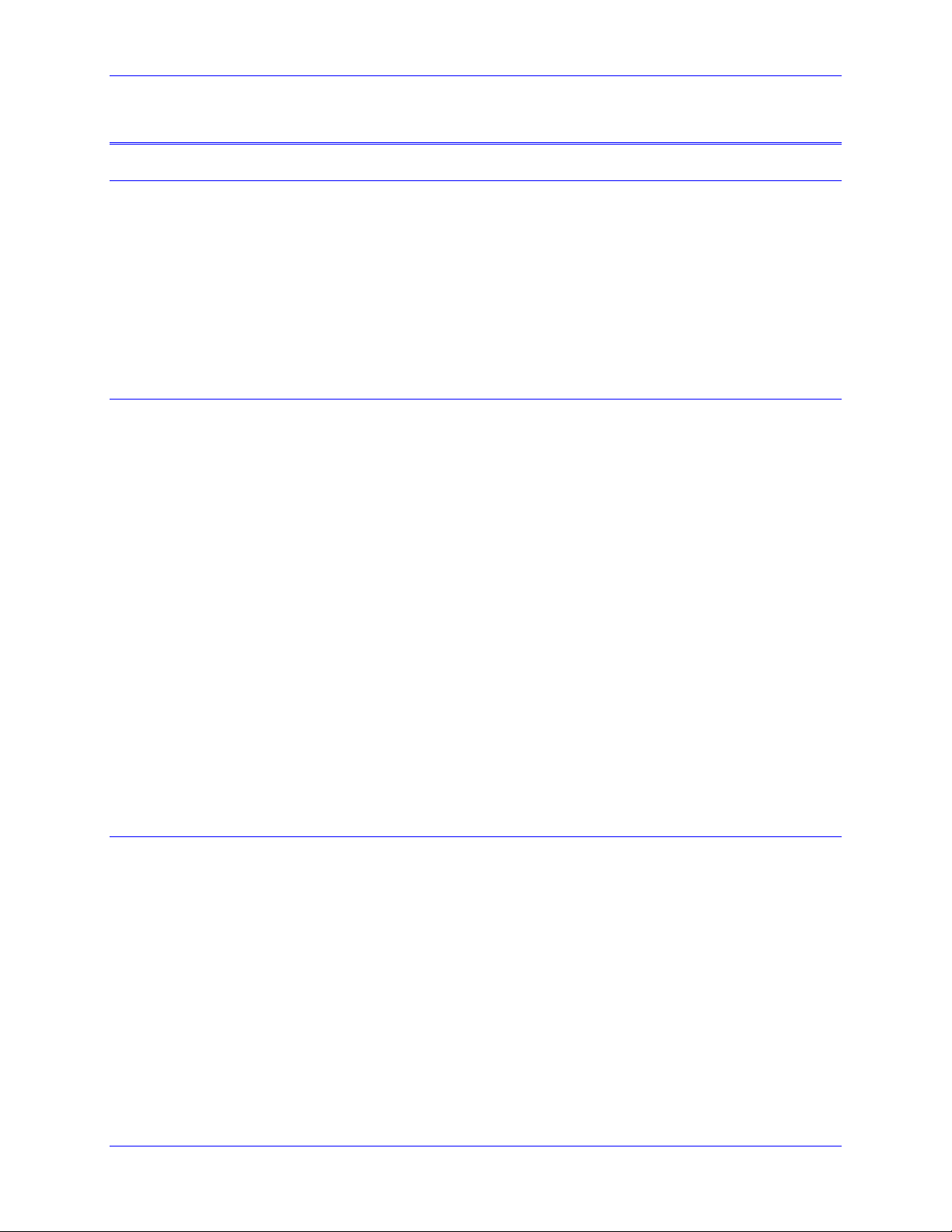

PMAC2-PC Setup

On PMAC2-PC, jumpers E2 and E4 control the frequency of operation of the DSP according to Table 1-

2.

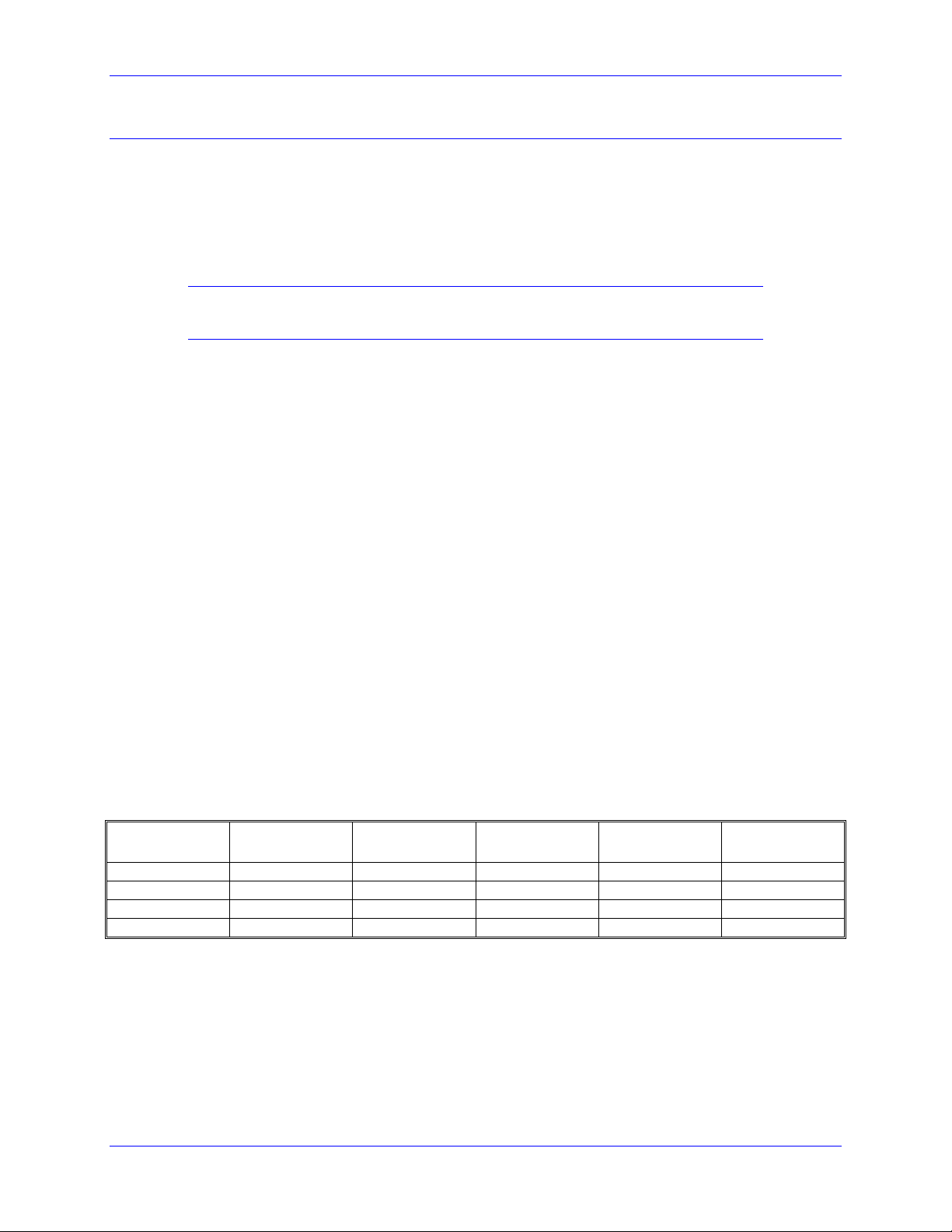

E2 E4 X:$FFFD; 0-3 True Multiplier DSP Frequency

OFF OFF 1 x2 40 MHz

ON OFF 2 x3 60 MHz

OFF ON 3 x4 80 MHz

On the PMAC2-PC, I54 is read at power-up to set the baud rate clock. Because this clock is derived from

the CPU clock frequency, the proper setting of I54 is dependent on the CPU clock frequency as set by E2

and E4. Table 1-3 shows the settings of I54 for 40, 60, and 80 MHz CPU operation.

I54 Baud Rate for

40 MHz CPU

0 600 DISABLED 1200

1 900* (-0.05%) 900 1800* (-0.1%)

2 1200 1200 2400

3 1800* (-0.1%) 1800 3600* (-0.19%)

4 2400 2400 4800

5 3600* (-0.19%) 3600 7200* (-0.38%)

6 4800 4800 9600

7 7200* (-0.38%) 7200 14,400*(-0.75%)

8 9600 9600 19,200

9 14,400*(-0.75%) 14,400 28,800*(-1.5%)

10 19,200 19,200 38,400

11 28,800*(-1.5%) 28,800 57,600*(-3.0%)

12 38,400 38,400 76,800

13 57,600*(-3.0%) 57,600 115,200*(-6.0%)

14 76,800 76,800 153,600

15 DISABLED 115,200 DISABLED

* Not an exact baud rate

Baud Rate for

60 MHz CPU

Baud Rate for

80 MHz CPU

Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 9

PMAC2-PC & Lite Hardware Reference

PMAC2 CPUs

The PMAC2-PC CPU communicates with the axes through specially designed custom gate array ICs,

referred to as "DSPGATES". Each of these ICs can handle four analog output channels, four encoders as

input, and four analog-derived inputs from accessory boards. One PMAC2-PC can utilize from one to

four of these gate array ICs, so specifying the hardware configuration amounts to counting the numbers

and types of inputs and outputs. Up to 16 PMAC2-PCs may be ganged together with complete

synchronization, for a total of 128 axes. A PMAC2-PC may have one of three available CPU

configurations. These configurations are described in the following paragraphs.

Note:

The CPUs are only installed on the PMAC2-PC.

P/N 602398

This is the original standard CPU board for the PMAC2-PC. It has a 20MHz clock and a battery backup

RAM.

P/N 602405

This is a flash memory CPU board with no battery backup. This board provides either a 40MHz or

60MHz clock.

P/N 602705

The PMAC2-PC PV CPU piggyback board provides 80 MHz CPU operation and supplemental batterybacked RAM for the PMAC2-

The PV CPU board gets its name from the PV package style of the Motorola 56002 DSP IC on the board.

The board is also called the Universal CPU because it can support all speeds and configurations of the

CPU section.

The PV CPU has operational differences from earlier CPU configurations to support the new features.

The following paragraphs explain these differences and are only relevant if you have the 602705 CPU

piggyback board on your controller.

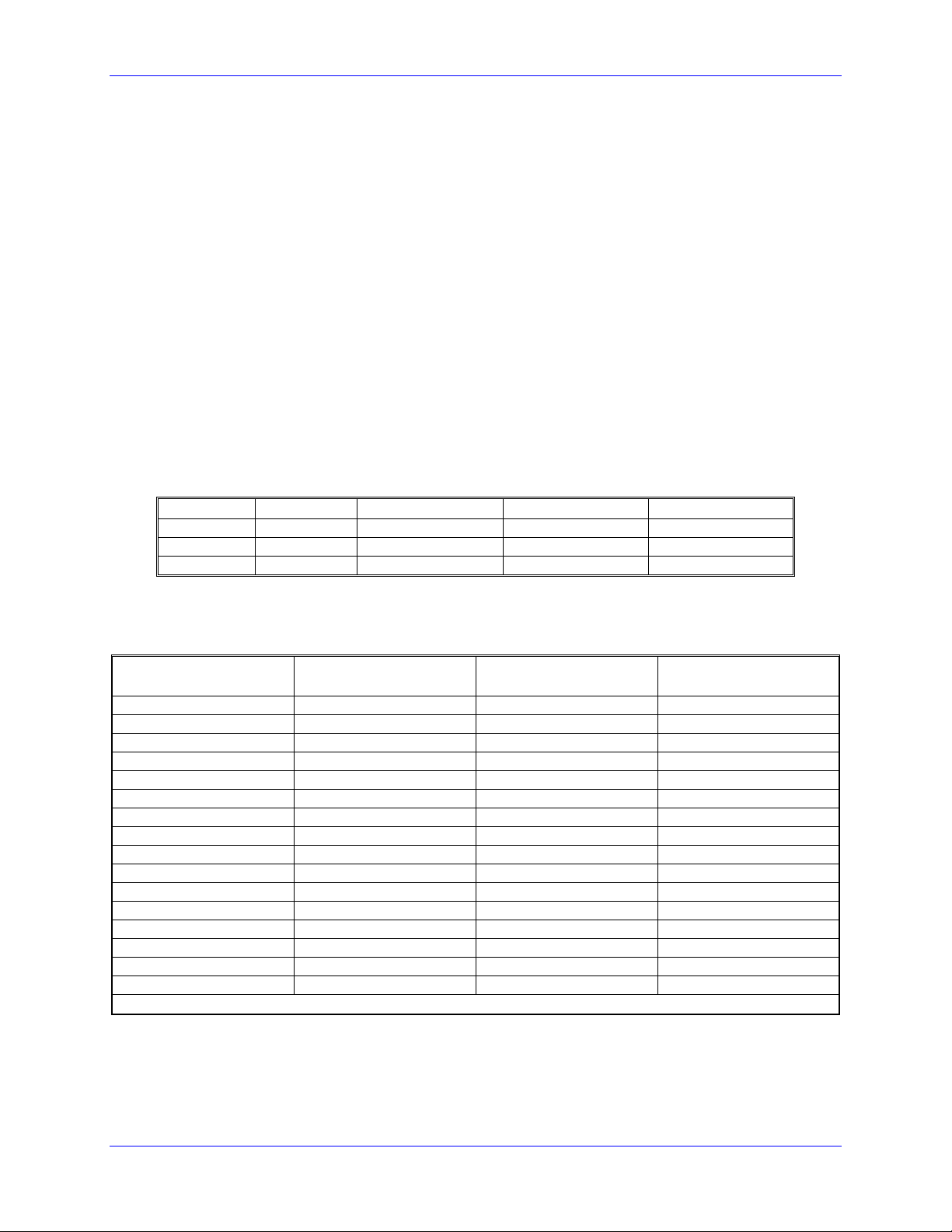

Configurations

The PV CPU board is configured at the factory to the customer’s specifications. The JEXP expansion port

is buffered, providing the capability to connect many boards on the expansion port.

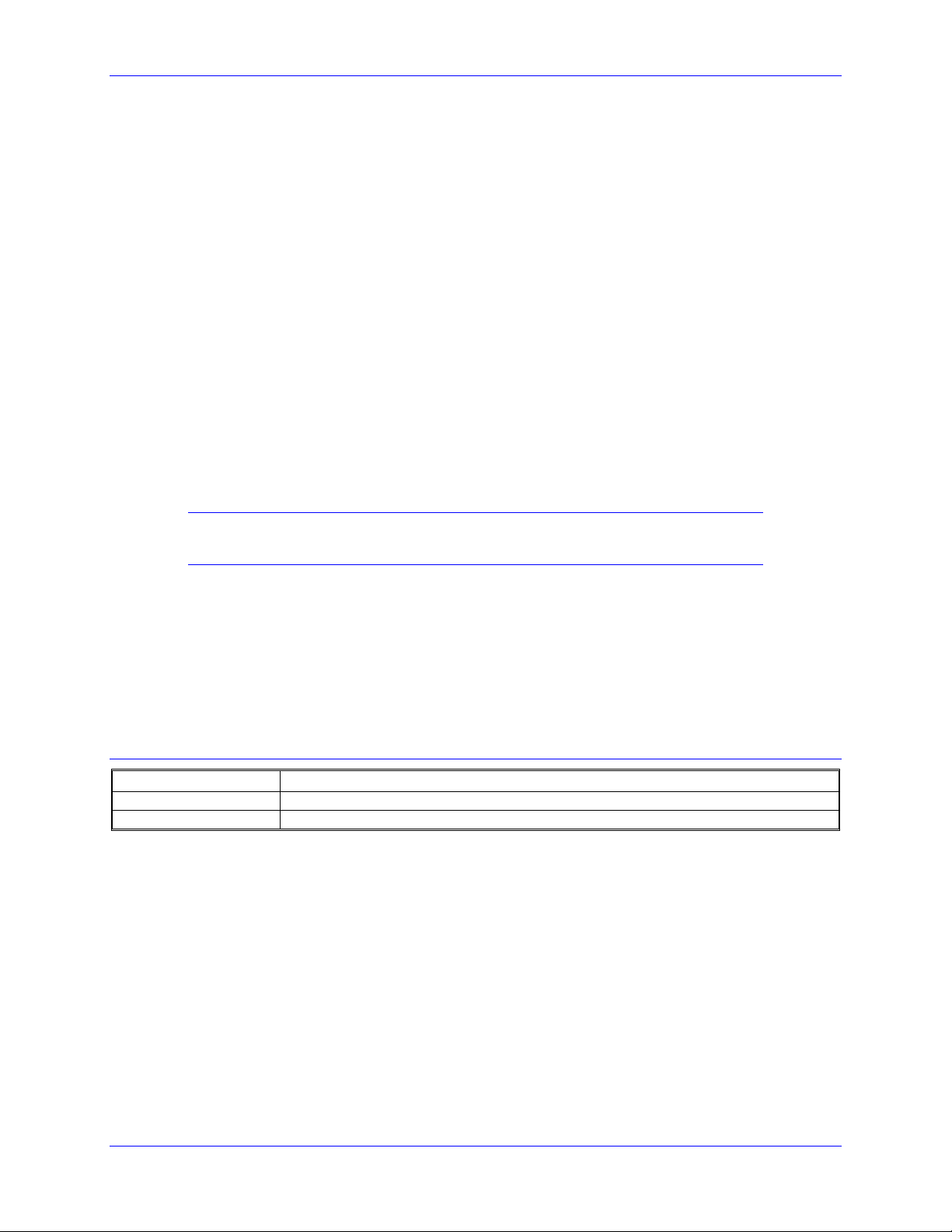

The following table shows the configuration of the key components on the PV CPU board for the

PMAC2-PC.

Version Main Memory

Backup

Standard Flash Empty 32-pin RAM Flash ROM Empty

Opt 5B Flash Empty 32-pin RAM Flash ROM Empty

Opt 5C Flash Empty 32-pin RAM Flash ROM Empty

+Opt 16 Flash 28-pin RAM 32-pin RAM Flash ROM Battery

U6, U9, U15

Components

U7, U10, U16

Components

U5

Components

BT1

Component

Firmware

The PV CPU board does not support firmware versions before V1.16 of August 1996 without changes in

programming of the on-board logic (GALs). If the firmware must be changed between a version previous

to V1.16 and a version V1.16 or newer, the on-board logic must be re-programmed.

When loading new firmware into the flash configurations of the PV CPU, E4 on the CPU board must be

ON in addition to having the PMAC2-PC reinitialization jumper E3 ON.

4 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

PMAC2-PC & Lite Hardware Reference

5

Option 16 Supplemental Memory

If the Option 16 supplemental battery-backed parameter memory is ordered, an extra bank of memory

with battery backup circuitry is provided. This option can only be ordered if the main memory is flash

backed (Option 4A, 5A, 5B, or 5C). This memory is for user parameter storage only. From PMAC

programs it can be accessed with M-variables only (L-variables also in compiled PLCs). The on-line

direct-memory read and write commands can be used from the host computer as well.

With M-variable access, arrays can be created with indirect addressing techniques by pointing a second

M-variable to the definition of a first M-variable that points into this memory area. For example, with the

M-variable definitions:

M0->L:$A000; 1st long word of Opt. 16 RAM; floating point

M10->Y:$BC000,0,16 ; Low 16 bits of M0 def., with pointer address

The following code segment could load a sine table into the first 360 words of the Option 16 RAM:

P1=0

WHILE (P1<360)

M10=$A000+P1 ; Sets address that M0 points to

M0=SIN(P1) ; Puts value in register that M0 points to

P1=P1+1

ENDWHILE

Note:

This technique is not possible with L-variables in compiled PLCs.

Physically, the Option 16 memory is a 16k x 24 bank of battery-backed static RAM. It maps into the

PMAC2-PC at addresses $A000 to $BFFF, on both the X and Y data buses, an 8k x 48 block of address

space. Addresses Y:$BC00 to Y:$BFFF are “double-mapped” with the main flash-backed RAM for the

M-variable definitions, and should not be used for user parameter storage.

Any value written into the Option 16 memory will automatically be retained through a power-down or

reset; no SAVE operation is required. The power draw on the battery is low enough that battery life will

typically be limited only by the quoted 10-year life of the battery.

Related Technical Documentation

Manual Number Manual Title

3A0-602413-363 PMAC2 User’s Manual

3A0-602XXX-363 PMAC User’s Software Reference

Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

PMAC2-PC & Lite Hardware Reference

6 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

PMAC2-PC & Lite Hardware Reference

7

CONNECTORS AND JUMPERS

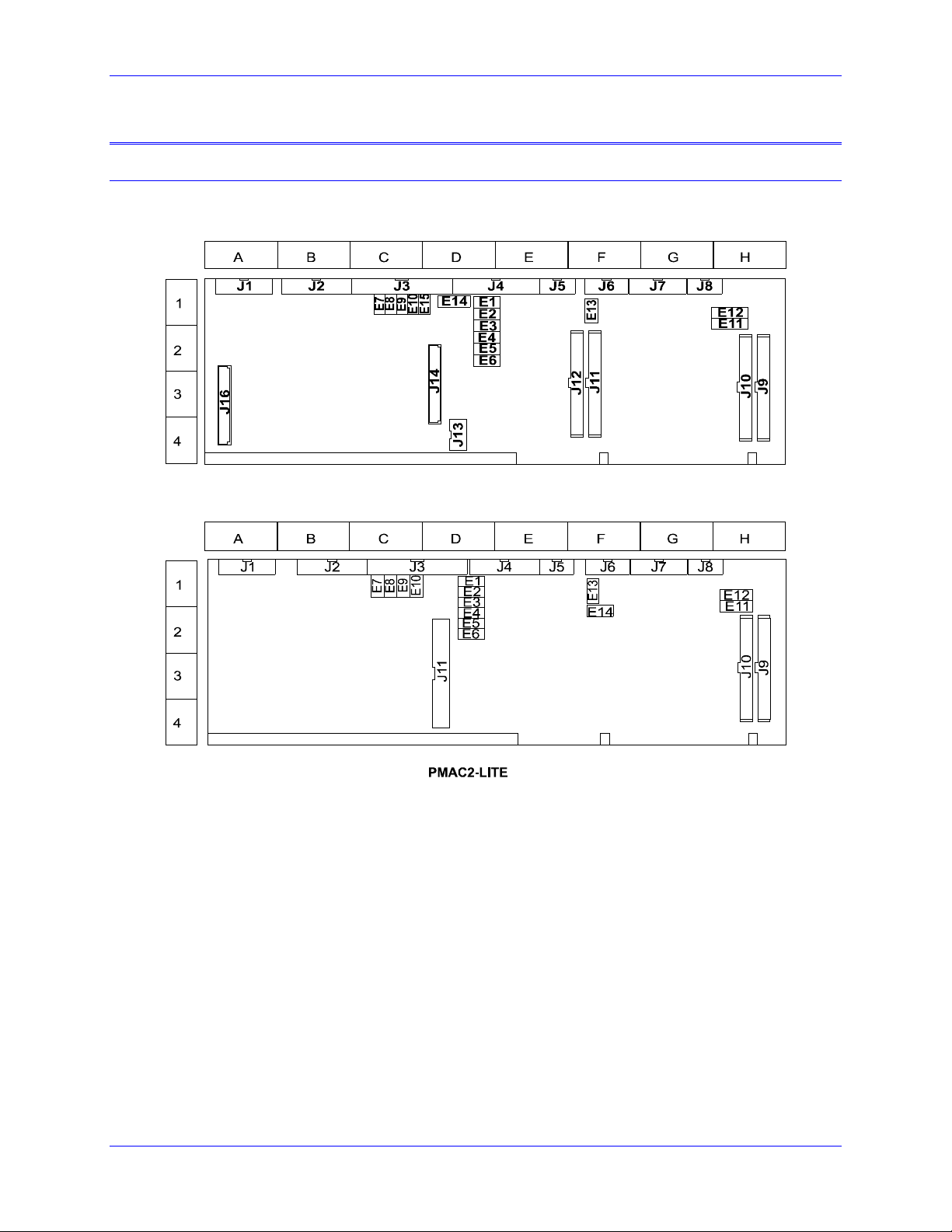

PMAC2-PC AND PMAC2-Lite Connector Summary

The following paragraphs provide a brief description of each connector on the PMAC2-PC and PMAC2Lite, its use, and individual pinout information (see Figure 2-1).

PMAC2-PC

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

PMAC2-PC & Lite Hardware Reference

J1 (JANA) Analog Input Port Connector

19

20

Front View

1

2

Pin # Symbol Function Description Notes

1 ANAI00 Input Analog Input 0 0-5V or +/-2.5V range

2 ANAI01 Input Analog Input 1 0-5V or +/-2.5V range

3 ANAI02 Input Analog Input 2 0-5V or +/-2.5V range

4 ANAI03 Input Analog Input 3 0-5V or +/-2.5V range

5 ANAI04 Input Analog Input 4 0-5V or +/-2.5V range

6 ANAI05 Input Analog Input 5 0-5V or +/-2.5V range

7 ANAI06 Input Analog Input 6 0-5V or +/-2.5V range

8 ANAI07 Input Analog Input 7 0-5V or +/-2.5V range

9 ANAI08 Input Analog Input 8 0-5V or +/-2.5V range

10 ANAI09 Input Analog Input 9 0-5V or +/-2.5V range

11 ANAI10 Input Analog Input 10 0-5V or +/-2.5V range

12 ANAI11 Input Analog Input 11 0-5V or +/-2.5V range

13 ANAI12 Input Analog Input 12 0-5V or +/-2.5V range

14 ANAI13 Input Analog Input 13 0-5V or +/-2.5V range

15 ANAI14 Input Analog Input 14 0-5V or +/-2.5V range

16 ANAI15 Input Analog Input 15 0-5V or +/-2.5V range

17 GND Common PMAC Common Not isolated from digital

18 +12V Output Positive Supply Voltag e To power external circuitry

19 GND Common PMAC Common Not isolated from digital

20 -12V Output Negative Supply Voltage To power external circuitry

The JANA connector provides the inputs for the 8 or 16 optional analog inputs on the PMAC2-PC and PMAC2Lite.

Note: This connector is only present if Option 12 is ordered.

8 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

PMAC2-PC & Lite Hardware Reference

J2 (JTHW) Multiplexer Port Connector

25

26

Front View

1

2

Pin # Symbol Function Description Notes

1 GND COMMON PMAC Common

2 GND COMMON PMAC Common

3 DAT0 INPUT Data-0 Input Data input from mux port

accessories

4 SEL0 OUTPUT Select-0 Output Address/data output for mux

port accessories

5 DAT1 INPUT Data -1 Input Data input from mux port

accessories

6 SEL1 OUTPUT Select-1 Output Address/data output for mux

port accessories

7 DAT2 INPUT Data -2 Input Data input from mux port

accessories

8 SEL2 OUTPUT Select-2 Output Address/data output for mux

port accessories

9 DAT3 INPUT Data-3 Input Data input from mux port

accessories

10 SEL3 OUTPUT Select-3 Output Address/data output for mux

port accessories

11 DAT4 INPUT Data-4 Input Data input from mux port

accessories

12 SEL4 OUTPUT Select-4 Output Address/data output for mux

port accessories

13 DAT5 INPUT Data-5 Input Data input from mux port

accessories

14 SEL5 OUTPUT Select-5 Output Address/data output for mux

port accessories

15 DAT6 INPUT Data-6 Input Data input from mux port

accessories

16 SEL6 OUTPUT Select-6 Output Address/data output for mux

port accessories

17 DAT7 INPUT Data-7 Input Data input from mux port

accessories

18 SEL7 OUTPUT Select-7 Output Address/data output for mux

port accessories

19 N.C. N.C. No Connection

20 GND COMMON PMAC Common

21 BRLD/ OUTPUT Buffer Request Low is "buffer req."

22 GND COMMON PMAC Common

23 IPLD/ OUTPUT In Position Low is "in position"

24 GND COMMON PMAC Common

25 +5V OUTPUT +5Vdc Supply Power supply out

26 INIT/ INPUT PMAC Reset Low is "reset"

The JTHW connector provides eight inputs and eight outputs at TTL levels that are dedicated to reading BCD

thumbwheel switches. Two thumbwheels may be read by direct connection to J3. More thumbwheels, up to 512

switches, may be read using Accessory 18 (ACC-18, Thumbwheel Multiplexer). J3 inputs and outputs may be

used as general purpose multiplexed TTL I/O if thumbwheels are not used.

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

Page 15

PMAC2-PC & Lite Hardware Reference

J3 (JI/O) General I/O Connector

39

40

Front View

Pin # Symbol Function Description Notes

1 I/O00 IN/OUT Digital I/O 0 Software direction ctrl.

2 I/O01 IN/OUT Digital I/O 1 Software direction ctrl.

3 I/O02 IN/OUT Digital I/O 2 Software direction ctrl.

4 I/O03 IN/OUT Digital I/O 3 Software direction ctrl.

5 I/O04 IN/OUT Digital I/O 4 Software direction ctrl.

6 I/O05 IN/OUT Digital I/O 5 Software direction ctrl.

7 I/O06 IN/OUT Digital I/O 6 Software direction ctrl.

8 I/O07 IN/OUT Digital I/O 7 Software direction ctrl.

9 I/O08 IN/OUT Digital I/O 8 Software direction ctrl.

10 I/O09 IN/OUT Digital I/O 9 Software direction ctrl.

11 I/O10 IN/OUT Digital I/O 10 Software direction ctrl.

12 I/O11 IN/OUT Digital I/O 11 Software direction ctrl.

13 I/O12 IN/OUT Digital I/O 12 Software direction ctrl.

14 I/O13 IN/OUT Digital I/O 13 Software direction ctrl.

15 I/O14 IN/OUT Digital I/O 14 Software direction ctrl.

16 I/O15 IN/OUT Digital I/O 15 Software direction ctrl.

17 I/O16 IN/OUT Digital I/O 16 Software direction ctrl.

18 I/O17 IN/OUT Digital I/O 17 Software direction ctrl.

19 I/O18 IN/OUT Digital I/O 18 Software direction ctrl.

20 I/O19 IN/OUT Digital I/O 19 Software direction ctrl.

21 I/O20 IN/OUT Digital I/O 20 Software direction ctrl.

22 I/O21 IN/OUT Digital I/O 21 Software direction ctrl.

23 I/O22 IN/OUT Digital I/O 22 Software direction ctrl.

24 I/O23 IN/OUT Digital I/O 23 Software direction ctrl.

25 I/O24 IN/OUT Digital I/O 24 Software direction ctrl.

26 I/O25 IN/OUT Digital I/O 25 Software direction ctrl.

27 I/O26 IN/OUT Digital I/O 26 Software direction ctrl.

28 I/O27 IN/OUT Digital I/O 27 Software direction ctrl.

29 I/O28 IN/OUT Digital I/O 28 Software direction ctrl.

30 I/O29 IN/OUT Digital I/O 29 Software direction ctrl.

31 I/O30 IN/OUT Digital I/O 30 Software direction ctrl.

32 I/O31 IN/OUT Digital I/O 31 Software direction ctrl.

33 GND COMMON Reference Voltage

34 GND COMMON Reference Voltage

35 PHASE/ OUTPUT Phase Clock For latching data

36 SERVO/ OUTPUT Servo Clock For latching data

37 GND COMMON Reference Voltage

38 GND COMMON Reference Voltage

39 +5V OUTPUT Supply Voltage To power external circuitry

40 +5V OUTPUT Supply Voltage To power external circuitry

The JI/O connector provides 32 input/output pins at TTL levels. Direction can be controlled in byte-wide groups.

1

2

10 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

PMAC2-PC & Lite Hardware Reference

J4 (JMACRO) 26-Pin Connector

25

26

Front View

1

2

Pin # Symbol Function Description Notes

1 DOUT7 OUTPUT Ring Out Bit 7 Macro ring command

2 DOUT6 OUTPUT Ring Out Bit 6 Macro ring transmit

3 DOUT5 OUTPUT Ring Out Bit 5 Macro ring transmit

4 DOUT4 OUTPUT Ring Out Bit 4 Macro ring transmit

5 DOUT3 OUTPUT Ring Out Bit 3 Macro ring transmit

6 DOUT2 OUTPUT Ring Out Bit 2 Macro ring transmit

7 DOUT1 OUTPUT Ring Out Bit 1 Macro ring transmit

8 DOUT0 OUTPUT Ring Out Bit 0 Macro ring transmit

9 CMD_IN INPUT

10 DIN7 INPUT Ring In Bit 7 Macro rin g rec e i ve

11 DIN6 INPUT Ring In Bit 6 Macro rin g rec e i ve

12 DIN5 INPUT Ring In Bit 5 Macro rin g rec e i ve

13 DIN4 INPUT Ring In Bit 4 Macro rin g rec e i ve

14 DIN3 INPUT Ring In Bit 3 Macro rin g rec e i ve

15 DIN2 INPUT Ring In Bit 2 Macro rin g rec e i ve

16 DIN1 INPUT Ring In Bit 1 Macro rin g rec e i ve

17 DIN0 INPUT Ring In Bit 0 Macro rin g rec e i ve

18 CMD_OUT OUTPUT

19 TCLK OUTPUT Ring Clock 10 MHz

20 GND COMMON Reference Voltage

21 STB_OUT OUTPUT Byte Strobe

22 GND COMMON Reference Voltage

23 DAT_STB INPUT Data Byte Strobe

24 GND COMMON Reference Voltage

25 CMD_STB INPUT CMD Byte Strobe

26 VLTN INPUT Violation Flag Taxi chip receive error

The JMACRO Network Ring Interface Connector provides the interface to the MACRO driver/receiver accessory

board.

J5 (JRS232) Serial Port Connector

9

10

Front View

1

2

Pin # Symbol Function Description Notes

1 PHASE OUTPUT Phasing Clock

2 DTR BIDIRECT Data Term Rdy Tied to DSR

3 TXD/ INPUT Receive Data Host transmit data

4 CTS INPUT Clear To Send Host ready bit

5 RXD/ OUTPUT Send Data Host receive data

6 RTS OUTPUT Req. To Send PMAC ready bit

7 DSR BIDIRECT Data Set Ready Tied to DTR

8 SERVO OUTPUT Servo Clock

9 GND COMMON PMAC Common

10 +5V OUTPUT +5Vdc Supply Power supply out

This connector is present and operational on the standard PMAC2-PC or PMAC2-Lite. If the Option-9L RS-422

interface has been ordered, this connector is non-functional. The serial interface is made through one of the RS422 connectors on the Option-9L piggyback board.

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Page 17

PMAC2-PC & Lite Hardware Reference

JRS422 (26-Pin Connector)

Front View

Pin # Symbol Function Description Notes

1 CHASSI COMMON PMAC Common

2 S+5V OUTPUT +5Vdc Supply Deactivated by "E8"

3 RD- INPUT Receive Data Diff I/O low true

4 RD+ INPUT Receive Data Diff I/O high true

5 SD- OUTPUT Send Data Diff I/O low true

6 SD+ OUTPUT Send Data Diff I/O high true

7 CS+ INPUT Clear To Send Diff I/O high true

8 CS- INPUT Clear To Send Diff I/O low true

9 RS+ OUTPUT Req. To Send Diff I/O high true

10 RS- OUTPUT Req. To Send Diff I/O low true

11 DTR BIDIRECT Data Term Read Tied to "DSR"

12 INIT/ INPUT PMAC Reset Low is "reset"

13 GND COMMON PMAC Common

14 DSR BIDIRECT Data Set Ready Tied to "DTR"

15 SDIO- BIDIRECT Special Data Diff I/O low true

16 SDIO+ BIDIRECT Special Data Diff I/O high true

17 SCIO- BIDIRECT Special Ctrl. Diff I/O low true

18 SCIO+ BIDIRECT Special Ctrl. Diff I/O high true

19 SCK- BIDIRECT Special Clock Diff I/O low true

20 SCK+ BIDIRECT Special Clock Diff I/O high true

21 SERVO- BIDIRECT Servo Clock Diff I/O low true

22 SERVO+ BIDIRECT Servo Clock Diff I/O high true

23 PHASE- BIDIRECT Phase Clock Diff I/O low true

24 PHASE+ BIDIRECT Phase Clock Diff I/O high true

25 GND COMMON PMAC Common

26 +5V OUTPUT +5Vdc Supply Power supply out

The JRS422 connector provides the PMAC with the ability to communicate both in RS422 and RS232. In

addition, this connector is used to daisy chain interconnect multiple PMACs for synchronized operation.

Note: This connector is only present if the Option 9L RS-422 interface has been ordered.

JRS422 (DB-15 Connector)

Pin # Symbol Function Description Notes

1 CHASSI COMMON PMAC Common

2 N.C. NONE No Connect

3 N.C. NONE No Connect

4 N.C. NONE No Connect

5 S+5V OUTPUT +5Vdc Supply Deactivated By "E8"

6 RS- OUTPUT Req. To Send Diff I/O low true

7 GND COMMON PMAC Common

8 CS+ INPUT Clear To Send Diff I/O high true

9 N.C. NONE No Connect

10 RD- INPUT Receive Data Diff I/O low true

11 RD+ INPUT Receive Data Diff I/O high true

12 SD- OUTPUT Send Data Diff I/O low true

13 SD+ OUTPUT Send Data Diff I/O high true

14 RS+ OUTPUT Req. To Send Diff I/O high true

15 CS- INPUT Clear To Send Diff I/O low true

This connector is only present if the Option-9L RS-422 interface has been ordered.

8

15

Front View

1

9

12 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

PMAC2-PC & Lite Hardware Reference

J6 (JDISP) Display Connector

13

14

1

2

Pin # Symbol Function Description Notes

1 Vdd OUTPUT +5V Power Power supply out

2 Vss COMMON PMAC Common

3 Rs OUTPUT Read Strobe TTL signal out

4 Vee OUTPUT Contrast Adjust. Vee 0 to +5 Vdc

5 E OUTPUT Display Enable High is enable

6 R/W OUTPUT Read Or Write TTL signal out

7 DB1 OUTPUT Display Data1

8 DB0 OUTPUT Display Data0

9 DB3 OUTPUT Display Data3

10 DB2 OUTPUT Display Data2

11 DB5 OUTPUT Display Data5

12 DB4 OUTPUT Display Data4

13 DB7 OUTPUT Display Data7

14 DB6 OUTPUT Display Data6

The JDISP connector is used to drive the 2 line x 24 character (ACC-12), 2 x 40 (ACC-12A) LCD, or the 2 x 40

vacuum fluorescent (ACC-12C) display unit. The DISPLAY command may be used to send messages and values

to the display.

J7 (JHW) Handwheel Encoder Connector

19

20

Front View

1

2

Pin # Symbol Function Description Notes

1 GND COMMON Reference Voltage

2 +5V OUT PU T Supply Voltage To power ext. Circuitry

3 HWA1+ INPUT HW Positive A Channel Also pulse input

4 HWA1- INPUT HW Negative A Channel Also pulse input

5 HWB1+ INPUT HW Positive B Channel Also direction input

6 HWB1- INPUT HW Negative B Channel Also direction input

7 HWA2+ INPUT HW Positive A Channel Also pulse input

8 HWA2- INPUT HW Negative A Channel Also pulse input

9 HWB2+ INPUT HW Positive B Channel Also direction input

10 HWB2- INPUT HW Negative B Channel Also direction input

11 PUL1+ OUTPUT PFM Positive Pulse Out Also PWM output

12 PUL1- OUTPUT PFM Negative Pulse Out Also PWM output

13 DIR1+ OUTPUT PFM Positive Direction Also PWM output

14 DIR1- OUTPUT PFM Negative Direction Also PWM output

15 PUL2+ OUTPUT PFM Positive Pulse Out Also PWM output

16 PUL2- OUTPUT PFM Negative Pulse Out Also PWM output

17 DIR2+ OUTPUT PFM Positive Direction Also PWM output

18 DIR2- OUTPUT PFM Negative Direction Also PWM output

19 GND COMMON Reference Voltage

20 +5V OUTPUT Supply Voltage To power external circuitry

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

Page 19

PMAC2-PC & Lite Hardware Reference

2

J8 (JEQU) Position Compare Output Connector

9

10

Front View

1

2

Pin # Symbol Function Description Notes

1 EQU1/ OUTPUT Encoder 1 COMP-EQ Low is true

2 EQU2/ OUTPUT Encoder 2 COMP-EQ Low is true

3 EQU3/ OUTPUT Encoder 3 COMP-EQ Low is true

4 EQU4/ OUTPUT Encoder 4 COMP-EQ Low is true

5 EQU5/ OUTPUT Encoder 5 COMP-EQ Low is true

6 EQU6/ OUTPUT Encoder 6 COMP-EQ Low is true

7 EQU7/ OUTPUT Encoder 7 COMP-EQ Low is true

8 EQU8/ OUTPUT Encoder 8 COMP-EQ Low is true

9 +V SUPPLY Positive Supply +5V to +24V

10 GND COMMON Digital Ground

This connector provides the position-compare outputs for the eight encoder channels.

J9 (JMACH1) Connector Description

99

00

Front View

1

Pin# Symbol Function Description Notes

1 +5V OUTPUT /

INPUT

2 +5V OUTPUT /

INPUT

3 GND COMMON Reference Voltage

4 GND COMMON Reference Voltage

5 CHA1+ INPUT Encoder 1 Positive A Channel Also pulse input

6 CHA1- INPUT Encoder 1 Negative A Channel Also pulse input

7 CHB1+ INPUT Encoder 1 Positive B Channel Also direction input

8 CHB1- INPUT Encoder 1 Negative B Channel Also direction input

9 CHC1+ INPUT Encoder 1 Positive C Channel Index channel

10 CHC1- INPUT Encoder 1 Negative C Channel Index channel

11 CHU1 INPUT Channel 1 U Flag Hall effect, fault code, or sub-

12 CHV1 INPUT Channel 1 V Flag Hall effect, fault code, or sub-

13 CHW1 INPUT Channel 1 W Flag Hall effect, fault code, or sub-

14 CHT1 INPUT Channel 1 T Flag Fault code, or sub-count

15 USER1 INPUT General Purpose

16 PLIM1 INPUT Positive Overtravel Limit Hardware capture flag

17 MLIM1 INPUT Negative Overtravel Limit Hardware capture flag

18 HOME1 INPUT Home Switch Input Hardware capture flag

19 ACCFLT1 INPUT Accessory Fault Flag For loss OF ACC supply voltage

20 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

21 SCLK12+ INPUT /

OUTPUT

22 SCLK12- INPUT /

OUTPUT

23 ADC_CLK1+ OUTPUT A/D Converter Clock Programmable frequency

24 ADC_CLK1- OUTPUT A/D Converter Clock Programmable frequency

25 ADC_STB1+ OUTPUT A/D Converter Strobe Programmable sequence

26 ADC_STB1- OUTPUT A/D Converter Strobe Programmable sequence

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

count

count

count

Hardware capture flag, or sub-

User Flag

count

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

14 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

PMAC2-PC & Lite Hardware Reference

5

27 ADC_DAA1+ INPUT Channel A ADC Serial Data MSB first

28 ADC_DAA1- INPUT Channel A ADC Serial Data MSB first

29 ADC_DAB1+ INPUT Channel B ADC Serial Data MSB first

30 ADC_DAB1- INPUT Channel B ADC Serial Data MSB first

31 AENA1+ OUTPUT Amplifier Enable High is enable

32 AENA1- OUTPUT Amplifier Enable Low is enable

33 FAULT1+ INPUT Amplifier Fault Programmable polarity

34 FAULT1- INPUT Amplifier Fault Programmable polarity

35 PWMATOP1+

DAC_CLK1+

36 PWMATOP1-

DAC_CLK1-

37 PWMABOT1+

DAC1A+

38 PWMABOT1-

DAC1A-

39 PWMBTOP1+

DAC_STB1+

40 PWMBTOP1-

DAC_STB1-

41 PWMBBOT1+

DAC1B+

42 PWMBBOT1-

DAC1B-

43 PWMCTOP1+

DIR1+

44 PWMCTOP1-

DIR1-

45 PWMCBOT1+

PULSE1+

46 PWMCBOT1-

PULSE1-

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B TOP CMD or DAC

Strobe

OUTPUT Phase B TOP CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B TOP CMD or PFM

Direction

OUTPUT Phase B TOP CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

47 GND COMMON Reference Voltage

48 GND COMMON Reference Voltage

49 +5V OUTPUT /

INPUT

50 +5V OUTPUT /

INPUT

51 +5V OUTPUT /

INPUT

52 +5V OUTPUT /

INPUT

53 GND COMMON Reference Voltage

54 GND COMMON Reference Voltage

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

55 CHA2+ INPUT Encoder 2 Positive A Channel Also pulse input

56 CHA2- INPUT Encoder 2 Negative A Channel Also pulse input

57 CHB2+ INPUT Encoder 2 Positive B Channel Also direction input

58 CHB2- INPUT Encoder 2 Negative B Channel Also direction input

59 CHC2+ INPUT Encoder 2 Positive C Channel Index channel

60 CHC2- INPUT Encoder 2 Negative C Channel Index channel

61 CHU2 INPUT Channel 2 U Flag Hall effect, fault code, or sub-

count

62 CHV2 INPUT Channel 2 V Flag Hall effect, fault code, or sub-

count

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 21

PMAC2-PC & Lite Hardware Reference

63 CHW2 INPUT Channel 2 W Flag Hall effect, fault code, or sub-

count

64 CHT2 INPUT Channel 2 T Flag Fault code, or sub-count

65 USER2 INPUT General Purpose

User Flag

Hardware capture flag, or sub-

count

66 PLIM2 INPUT Positive Overtravel Limit Hardware capture flag

67 MLIM2 INPUT Negative Overtravel Limit Hardware capture flag

68 HOME2 INPUT Home Switch Input Hardware capture flag

69 ACCFLT2 INPUT Accessory Fault Flag For loss of ACC supply voltage

70 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

71 SCLK12+ INPUT /

OUTPUT

72 SCLK12- INPUT /

OUTPUT

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

73 ADC_CLK2+ OUTPUT A/D Converter Clock Programmable frequency

74 ADC_CLK2- OUTPUT A/D Converter Clock Programmable frequency

75 ADC_STB2+ OUTPUT A/D Converter Strobe Programmable sequence

76 ADC_STB2- OUTPUT A/D Converter Strobe Programmable sequence

77 ADC_DAA2+ INPUT Channel A ADC Serial Data MSB First

78 ADC_DAA2- INPUT Channel A ADC Serial Data MSB First

79 ADC_DAB2+ INPUT Channel B ADC Serial Data MSB First

80 ADC_DAB2- INPUT Channel B ADC Serial Data MSB First

81 AENA2+ OUTPUT Amplifier Enable High is enable

82 AENA2- OUTPUT Amplifier Enable Low is enable

83 FAULT2+ INPUT Amplifier Fault Programmable polarity

84 FAULT2- INPUT Amplifier Fault Programmable polarity

85 PWMATOP2+

DAC_CLK2+

86 PWMATOP2-

DAC_CLK2-

87 PWMABOT2+

DAC2A+

88 PWMABOT2-

DAC2A-

89 PWMBTOP2+

DAC_STB2+

90 PWMBTOP2-

DAC_STB2-

91 PWMBBOT2+

DAC2B+

92 PWMBBOT2-

DAC2B-

93 PWMCTOP2+

DIR2+

94 PWMCTOP2-

DIR2-

95 PWMCBOT2+

PULSE2+

96 PWMCBOT2-

PULSE2-

97 GND COMMON Reference Voltage

98 GND COMMON Reference Voltage

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

16 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

PMAC2-PC & Lite Hardware Reference

7

1299

1

99 +5V OUTPUT /

INPUT

100 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

The JMACH1 connector provides the interface pins for channels 1 and 2. It is usually connected to a breakout

board, such as one of the ACC-8 (Series) family of boards, or an application-specific interface board.

Note: 100-pin male box header with cent er key , 00 5 0" pit c h. AMP pa rt # 1-04 06 8- 7. Del t a Tau part # 014 00010-FPB.

J10 (JMACH2) Connector Description

00

Front View

Pin# Symbol Function Description Notes

1 +5V OUTPUT /

INPUT

2 +5V OUTPUT /

INPUT

3 GND COMMON Reference Voltage

4 GND COMMON Reference Voltage

5 CHA3+ INPUT Encoder 3 Positive A Channel Also pulse input

6 CHA3- INPUT Encoder 3 Negative A Channel Also pulse input

7 CHB3+ INPUT Encoder 3 Positive B Channel Also direction input

8 CHB3- INPUT Encoder 3 Negative B Channel Also direction input

9 CHC3+ INPUT Encoder 3 Positive C Channel Index channel

10 CHC3- INPUT Encoder 3 Negative C Channel Index channel

11 CHU3 INPUT Channel 3 U Flag Hall effect, fault code, or sub-

12 CHV3 INPUT Channel 3 V Flag Hall effect, fault code, or sub-

13 CHW3 INPUT Channel 3 W Flag Hall effect, fault code, or sub-

14 CHT3 INPUT Channel 3 T Flag Fault code, or sub-count

15 USER3 INPUT General Purpose User Flag Hardware capture flag, or sub-

16 PLIM3 INPUT Positive Overtravel Limit Hardware capture flag

17 MLIM3 INPUT Negative Overtravel Limit Hardware capture flag

18 HOME3 INPUT Home Switch Input Hardware capture flag

19 ACCFLT3 INPUT Accessory Fault Flag For loss of acc supply voltage

20 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

21 SCLK34+ INPUT /

OUTPUT

22 SCLK34- INPUT /

OUTPUT

23 ADC_CLK3+ OUTPUT A/D Converter Clock Programmable frequency

24 ADC_CLK3- OUTPUT A/D Converter Clock Programmable frequency

25 ADC_STB3+ OUTPUT A/D Converter Strobe Programmable frequency

26 ADC_STB3- OUTPUT A/D Converter Strobe Programmable frequency

27 ADC_DAA3+ INPUT Channel A ADC Serial Data MSB first

28 ADC_DAA3- INPUT Channel A ADC Serial Data MSB first

29 ADC_DAB3+ INPUT Channel B ADC Serial Data MSB first

30 ADC_DAB3- INPUT Channel B ADC Serial Data MSB first

31 AENA3+ OUTPUT Amplifier Enable High is enable

32 AENA3- OUTPUT Amplifier Enable Low is enable

33 FAULT3+ INPUT Amplifier Fault Programmable polarity

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

count

count

count

count

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

Page 23

PMAC2-PC & Lite Hardware Reference

34 FAULT3- INPUT Amplifier Fault Programmable polarity

35 PWMATOP3+

DAC_CLK3+

36 PWMATOP3-

DAC_CLK3-

37 PWMABOT3+

DAC3A+

38 PWMABOT3-

DAC3A-

39 PWMBTOP3+

DAC_STB3+

40 PWMBTOP3-

DAC_STB3-

41 PWMBBOT3+

DAC3B+

42 PWMBBOT3-

DAC3B-

43 PWMCTOP3+

DIR3+

44 PWMCTOP3-

DIR3-

45 PWMCBOT3+

PULSE3+

46 PWMCBOT3-

PULSE3-

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

47 GND COMMON Reference Voltage

48 GND COMMON Reference Voltage

49 +5V OUTPUT /

INPUT

50 +5V OUTPUT /

INPUT

51 +5V OUTPUT /

INPUT

52 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

53 GND COMMON Reference Voltage

54 GND COMMON Reference Voltage

55 CHA4+ INPUT Encoder 4 Positive A Channel Also pulse input

56 CHA4- INPUT Encoder 4 Negative A Channel Also pulse input

57 CHB4+ INPUT Encoder 4 Positive B Channel Also direction input

58 CHB4- INPUT Encoder 4 Negative B Channel Also direction input

59 CHC4+ INPUT Encoder 4 Positive C Channel Index channel

60 CHC4- INPUT Encoder 4 Negative C Channel Index channel

61 CHU4 INPUT Channel 4 U Flag Hall effect, fault code, or sub-

count

62 CHV4 INPUT Channel 4 V Flag Hall effect, fault code, or sub-

count

63 CHW4 INPUT Channel 4 W Flag Hall effect, fault code, or sub-

count

64 CHT4 INPUT Channel 4 T Flag Fault code, or sub-count

65 USER4 INPUT General Purpose

User Flag

Hardware capture flag, or sub-

count

66 PLIM4 INPUT Positive Overtravel Limit Hardware capture flag

67 MLIM4 INPUT Negative Overtravel Limit Hardware capture flag

18 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

PMAC2-PC & Lite Hardware Reference

68 HOME4 INPUT Home Switch Input Hardware capture flag

69 ACCFLT4 INPUT Accessory Fault Flag For loss of ACC supply voltage

70 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

71 SCLK34+ INPUT /

OUTPUT

72 SCLK34- INPUT /

OUTPUT

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

73 ADC_CLK4+ OUTPUT A/D Converter Clock Programmable frequency

74 ADC_CLK4- OUTPUT A/D Converter Clock Programmable frequency

75 ADC_STB4+ OUTPUT A/D Converter Strobe Programmable sequence

76 ADC_STB4- OUTPUT A/D Converter Strobe Programmable sequence

77 ADC_DAA4+ INPUT Channel A ADC Serial Data MSB First

78 ADC_DAA4- INPUT Channel A ADC Serial Data MSB First

79 ADC_DAB4+ INPUT Channel B ADC Serial Data MSB First

80 ADC_DAB4- INPUT Channel B ADC Serial Data MSB First

81 AENA4+ OUTPUT Amplifier Enable High is enable

82 AENA4- OUTPUT Amplifier Enable Low is enable

83 FAULT4+ INPUT Amplifier Fault Programmable polarity

84 FAULT4- INPUT Amplifier Fault Programmable polarity

85 PWMATOP4+

DAC_CLK4+

86 PWMATOP4-

DAC_CLK4-

87 PWMABOT4+

DAC4A+

88 PWMABOT4-

DAC4A-

89 PWMBTOP4+

DAC_STB4+

90 PWMBTOP4-

DAC_STB4-

91 PWMBBOT4+

DAC4B+

92 PWMBBOT4-

DAC4B-

93 PWMCTOP4+

DIR4+

94 PWMCTOP4-

DIR4-

95 PWMCBOT4+

PULSE4+

96 PWMCBOT4-

PULSE4-

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

97 GND COMMON Reference Voltage

98 GND COMMON Reference Voltage

99 +5V OUTPUT /

INPUT

100 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

The JMACH2 connector provides the interface pins for channels 3 and 4. It is usually connected to a breakout

board, such as one of the ACC-8(Series) family of boards, or an application- specific interface board.

Note: 100-pin male box header with center key, 050" pitch. AMP part # 1-04068-7. Delta Tau part # 014 -00010FPB.

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

Page 25

PMAC2-PC & Lite Hardware Reference

2991

J11 (JMACH3) Connector Description

00

1

Pin# Symbol Function Description Notes

1 +5V OUTPUT /

INPUT

2 +5V OUTPUT /

INPUT

3 GND COMMON Reference Voltage

4 GND COMMON Reference Voltage

5 CHA5+ INPUT Encoder 5 Positive A Channel Also pulse input

6 CHA5- INPUT Encoder 5 Negative A Channel Also pulse input

7 CHB5+ INPUT Encoder 5 Positive B Channel Also direction input

8 CHB5- INPUT Encoder 5 Negative B Channel Also direction input

9 CHC5+ INPUT Encoder 5 Positive C Channel Index channel

10 CHC5- INPUT Encoder 5 Negative C Channel Index channel

11 CHU5 INPUT Channel 5 U Flag Hall effect, fault code, or sub-

12 CHV5 INPUT Channel 5 V Flag Hall effect, fault code, or sub-

13 CHW5 INPUT Channel 5 W Flag Hall effect, fault code, or sub-

14 CHT5 INPUT Channel 5 T Flag Fault code, or sub-count

15 USER5 INPUT General Purpose User Flag Hardware capture flag, or sub-

16 PLIM5 INPUT Positive Overtravel Limit Hard ware capture flag

17 MLIM5 INPUT Negative Overtravel Limit Hardware capture flag

18 HOME5 INPUT Home Switch Input Hardware capture flag

19 ACCFLT5 INPUT Accessory Fault Flag For loss of ACC supply voltage

20 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

21 SCLK56+ INPUT /

OUTPUT

22 SCLK56- INPUT /

OUTPUT

23 ADC_CLK5+ OUTPUT A/D Converter Clock Programmable frequency

24 ADC_CLK5- OUTPUT A/D Converter Clock Programmable frequency

25 ADC_STB5+ OUTPUT A/D Converter Strobe Programmable sequence

26 ADC_STB5- OUTPUT A/D Converter Strobe Programmable sequence

27 ADC_DAA5+ INPUT Channel A ADC Serial Data MSB First

28 ADC_DAA5- INPUT Channel A ADC Serial Data MSB First

29 ADC_DAB5+ INPUT Channel B ADC Serial Data MSB First

30 ADC_DAB5- INPUT Channel B ADC Serial Data MSB First

31 AENA5+ OUTPUT Amplifier Enable High is enable

32 AENA5- OUTPUT Amplifier Enable Low is enable

33 FAULT5+ INPUT Amplifier Fault Programmable polarity

34 FAULT5- INPUT Amplifier Fault Programmable polarity

35 PWMATOP5+

OUTPUT Phase A Top CMD or DAC

DAC_CLK5+

36 PWMATOP5-

OUTPUT Phase A Top CMD or DAC

DAC_CLK5-

37 PWMABOT5+

OUTPUT Phase A Bottom CMD or DAC A

DAC5A+

38 PWMABOT5-

OUTPUT Phase A Bottom CMD or DAC A

DAC5A-

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

count

count

count

count

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

Programmable function control

Clock

Programmable function control

Clock

Programmable function control

Serial Data

Programmable function control

Serial Data

20 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

PMAC2-PC & Lite Hardware Reference

39 PWMBTOP5+

DAC_STB5+

40 PWMBTOP5-

DAC_STB5-

41 PWMBBOT5+

DAC5B+

42 PWMBBOT5-

DAC5B-

43 PWMCTOP5+

DIR5+

44 PWMCTOP5-

DIR5-

45 PWMCBOT5+

PULSE5+

46 PWMCBOT5-

PULSE5-

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

47 GND COMMON Reference Voltage

48 GND COMMON Reference Voltage

49 +5V OUTPUT /

INPUT

50 +5V OUTPUT /

INPUT

51 +5V OUTPUT /

INPUT

52 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

53 GND COMMON Reference Voltage

54 GND COMMON Reference Voltage

55 CHA6+ INPUT Encoder 6 Positive A Channel Also pulse input

56 CHA6- INPUT Encoder 6 Negative A Channel Also pulse input

57 CHB6+ INPUT Encoder 6 Positive B Channel Also direction input

58 CHB6- INPUT Encoder 6 Negative B Channel Also direction input

59 CHC6+ INPUT Encoder 6 Positive C Channel Index channel

60 CHC6- INPUT Encoder 6 Negative C Channel Index channel

61 CHU6 INPUT Channel 6 U Flag Hall effect, fault code, or sub-

count

62 CHV6 INPUT Channel 6 V Flag Hall effect, fault code, or sub-

count

63 CHW6 INPUT Channel 6 W Flag Hall effect, fault code, or sub-

count

64 CHT6 INPUT Channel 6 T Flag Fault code, or sub-count

65 USER6 INPUT General Purpose User Flag Hardware capture flag, or sub-

count

66 PLIM6 INPUT Positive Overtravel Limit Hardware capture flag

67 MLIM6 INPUT Negative Overtravel Limit Hardware capture flag

68 HOME6 INPUT Home Switch Input Hardware capture flag

69 ACCFLT6 INPUT Accessory Fault Flag For loss of ACC supply voltage

70 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

71 SCLK56+ INPUT /

OUTPUT

72 SCLK56- INPUT /

OUTPUT

Encoder Sample Clock Direction controlled by PMAC 2

jumper

Encoder Sample Clock Direction controlled by PMAC 2

jumper

73 ADC_CLK6+ OUTPUT A/D Converter Clock Programmable frequency

74 ADC_CLK6- OUTPUT A/D Converter Clock Programmable frequency

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

21

Page 27

PMAC2-PC & Lite Hardware Reference

75 ADC_STB6+ OUTPUT A/D Converter Strobe Programmable sequence

76 ADC_STB6- OUTPUT A/D Converter Strobe Programmable sequence

77 ADC_DAA6+ INPUT Channel A ADC Serial Data MSB first

78 ADC_DAA6- INPUT Channel A ADC Serial Data MSB first

79 ADC_DAB6+ INPUT Channel B ADC Serial Data MSB first

80 ADC_DAB6- INPUT Channel B ADC Serial Data MSB first

81 AENA6+ OUTPUT Amplifier Enable High is enable

82 AENA6- OUTPUT Amplifier Enable Low is enable

83 FAULT6+ INPUT Amplifier Fault Programmable polarity

84 FAULT6- INPUT Amplifier Fault Programmable polarity

85 PWMATOP6+

DAC_CLK6+

86 PWMATOP6-

DAC_CLK6-

87 PWMABOT6+

DAC6A+

88 PWMABOT6-

DAC6A-

89 PWMBTOP6+

DAC_STB6+

90 PWMBTOP6-

DAC_STB6-

91 PWMBBOT6+

DAC6B+

92 PWMBBOT6-

DAC6B-

93 PWMCTOP6+

DIR6+

94 PWMCTOP6-

DIR6-

95 PWMCBOT6+

PULSE6+

96 PWMCBOT6-

PULSE6-

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

PULSE

OUTPUT Phase B Bottom CMD or PFM

PULSE

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

97 GND COMMON Reference Voltage

98 GND COMMON Reference Voltage

99 +5V OUTPUT /

INPUT

100 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

The JMACH3 connector (not present on PMAC2-Lite) provides the interface pins for channels 5 and 6. It is

usually connected to a breakout board, such as one of the ACC-8(Series) family of boards, or an applicationspecific interface board.

Note: 100-pin male box header with center key, 00 5 0" pi t ch. AMP part # 1-04068-7. Delta Tau part # 01400010-FPB.

22 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

PMAC2-PC & Lite Hardware Reference

2991

J12 (JMACH4) Connector Description

00

1

Pin# Symbol Function Description Notes

1 +5V OUTPUT /

INPUT

2 +5V OUTPUT /

INPUT

3 GND COMMON Reference Voltage

4 GND COMMON Reference Voltage

5 CHA7+ INPUT Encoder 7 Positive A Channel Also pulse input

6 CHA7- INPUT Encoder 7 Negative A Channel Also pulse input

7 CHB7+ INPUT Encoder 7 Positive B Channel Also direction input

8 CHB7- INPUT Encoder 7 Negative B Channel Also direction input

9 CHC7+ INPUT Encoder 7 Positive C Channel Index channel

10 CHC7- INPUT Encoder 7 Negative C Channel Index channel

11 CHU7 INPUT Channel 7 U Flag Hall effect, fault code, or sub-

12 CHV7 INPUT Channel 7 V Flag Hall effect, fault code, or sub-

13 CHW7 INPUT Channel 7 W Flag Hall effect, fault code, or sub-

14 CHT7 INPUT Channel 7 T Flag Fault code, or sub-count

15 USER7 INPUT General Purpose User Flag Hardware capture flag, or sub-

16 PLIM7 INPUT Positive Overtravel Limit Hardware capture flag

17 MLIM7 INPUT Negative Overtravel Limit Hardware capture flag

18 HOME7 INPUT Home Switch Input Hardware capture flag

19 ACCFLT7 INPUT Accessory Fault Flag For loss of ACC supply voltage

20 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

21 SCLK78+ INPUT /

OUTPUT

22 SCLK78- INPUT /

OUTPUT

23 ADC_CLK7+ OUTPUT A/D Converter Clock Programmable frequency

24 ADC_CLK7- OUTPUT A/D Converter Clock Programmable frequency

25 ADC_STB7+ OUTPUT A/D Converter Strobe Programmable sequence

26 ADC_STB7- OUTPUT A/D Converter Strobe Programmable sequence

27 ADC_DAA7+ INPUT Channel A ADC Serial Data MSB first

28 ADC_DAA7- INPUT Channel A ADC Serial Data MSB first

29 ADC_DAB7+ INPUT Channel B ADC Serial Data MSB first

30 ADC_DAB7- INPUT Channel B ADC Serial Data MSB first

31 AENA7+ OUTPUT Amplifier Enable High is enable

32 AENA7- OUTPUT Amplifier Enable Low is enable

33 FAULT7+ INPUT Amplifier Fault Programmable polarity

34 FAULT7- INPUT Amplifier Fault Programmable polarity

35 PWMATOP7+

OUTPUT Phase A Top CMD or DAC

DAC_CLK7+

36 PWMATOP7-

OUTPUT Phase A Top CMD or DAC

DAC_CLK7-

37 PWMABOT7+

OUTPUT Phase A Bottom CMD or DAC A

DAC7A+

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

count

count

count

count

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

Programmable function control

Clock

Programmable function control

Clock

Programmable function control

Serial Data

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

23

Page 29

PMAC2-PC & Lite Hardware Reference

38 PWMABOT7-

DAC7A-

39 PWMBTOP7+

DAC_STB7+

40 PWMBTOP3-

DAC_STB7-

41 PWMBBOT7+

DAC7B+

42 PWMBBOT7-

DAC7B-

43 PWMCTOP7+

DIR7+

44 PWMCTOP7-

DIR7-

45 PWMCBOT7+

PULSE7+

46 PWMCBOT7-

PULSE7-

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

47 GND COMMON Reference Voltage

48 GND COMMON Reference Voltage

49 +5V OUTPUT /

INPUT

50 +5V OUTPUT /

INPUT

51 +5V OUTPUT /

INPUT

52 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

53 GND COMMON Reference Voltage

54 GND COMMON Reference Voltage

55 CHA8+ INPUT Encoder 8 Positive A Channel Also pulse input

56 CHA8- INPUT Encoder 8 Negative A Channel Also pulse input

57 CHB8+ INPUT Encoder 8 Positive B Channel Also direction input

58 CHB8- INPUT Encoder 8 Negative B Channel Also direction input

59 CHC8+ INPUT Encoder 8 Positive C Channel Index channel

60 CHC8- INPUT Encoder 8 Negative C Channel Index channel

61 CHU8 INPUT Channel 8 U Flag Hall effect, fault code, or sub-

count

62 CHV8 INPUT Channel 8 V Flag Hall effect, fault code, or sub-

count

63 CHW8 INPUT Channel 8 W Flag Hall effect, fault code, or sub-

count

64 CHT8 INPUT Channel 8 T Flag Fault code, or sub-count

65 USER8 INPUT General Purpose User Flag Hardware capture flag, or sub-

count

66 PLIM8 INPUT Positive Overtravel Limit Hardware capture flag

67 MLIM8 INPUT Negative Overtravel Limit Hardware capture flag

68 HOME8 INPUT Home Switch Input Hardware capture flag

69 ACCFLT8 INPUT Accessory Fault Flag For loss of ACC supply voltage

70 WD0/ OUTPUT Watchdog Output Low is PMAC watchdog fault

71 SCLK78+ INPUT /

OUTPUT

72 SCLK78- INPUT /

OUTPUT

Encoder Sample Clock Direction controlled by PMAC2

jumper

Encoder Sample Clock Direction controlled by PMAC2

jumper

24 Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

PMAC2-PC & Lite Hardware Reference

5

73 ADC_CLK8+ OUTPUT A/D Converter Clock Programmable frequency

74 ADC_CLK8- OUTPUT A/D Converter Clock Programmable frequency

75 ADC_STB8+ OUTPUT A/D Converter Strobe Programmable sequence

76 ADC_STB8- OUTPUT A/D Converter Strobe Programmable sequence

77 ADC_DAA8+ INPUT Channel A ADC Serial Data MSB first

78 ADC_DAA8- INPUT Channel A ADC Serial Data MSB first

79 ADC_DAB8+ INPUT Channel B ADC Serial Data MSB first

80 ADC_DAB8- INPUT Channel B ADC Serial Data MSB first

81 AENA8+ OUTPUT Amplifier Enable High is enable

82 AENA8- OUTPUT Amplifier Enable Low is enable

83 FAULT8+ INPUT Amplifier Fault Programmable polarity

84 FAULT8- INPUT Amplifier Fault Programmable polarity

85 PWMATOP8+

DAC_CLK8+

86 PWMATOP8-

DAC_CLK8-

87 PWMABOT8+

DAC8A+

88 PWMABOT8-

DAC8A-

89 PWMBTOP8+

DAC_STB8+

90 PWMBTOP8-

DAC_STB8-

91 PWMBBOT8+

DAC8B+

92 PWMBBOT8-

DAC8B-

93 PWMCTOP8+

DIR8+

94 PWMCTOP8-

DIR8-

95 PWMCBOT8+

PULSE8+

96 PWMCBOT8-

PULSE8-

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Top CMD or DAC

Clock

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase A Bottom CMD or DAC A

Serial Data

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Top CMD or DAC

Strobe

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Bottom CMD or DAC B

Serial Data

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Top CMD or PFM

Direction

OUTPUT Phase B Bottom CMD or PFM

Pulse

OUTPUT Phase B Bottom CMD or PFM

Pulse

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

Programmable function control

97 GND COMMON Reference Voltage

98 GND COMMON Reference Voltage

99 +5V OUTPUT /

INPUT

100 +5V OUTPUT /

INPUT

+5V Power For external circuit or from

external supply

+5V Power For external circuit or from

external supply

Note: 100-pin male box header with center key, 00 5 0" pi t ch. AMP part # 1-04068-7. Delta Tau part # 01400010-FPB.

The JMACH4 connector (Not present on PMAC2-Lite) provides the interface pins for channels 7 and 8. It is

usually connected to a breakout board, such as one of the ACC-8(Series) family of boards, or an applicationspecific interface board.

Connectors and Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

Page 31

PMAC2-PC & Lite Hardware Reference

TB1 (2/4-Pin Terminal Block)

Front View

Pin# Symbol Function Description Notes

1 GND COMMON Reference Voltage

2 +5V INPUT Positive Supply Voltage Supplies all PMAC digital

circuits

3 +12V INPUT Positive Supply Voltage +12V to +15V; not required on-

board; used on J1 to supply

analog inputs

4 -12V INPUT Negative Supply Voltage -12V to -15V; required for OPT-

12 ADCS; used on J1 to supply

analog inputs

Note: Unless Option 12 (Analog-to-Digital Converters) is included on the board, only pins 1 and 2 will be

provided on this terminal block.

This terminal block can be used to provide the input for the power supply for the circuits on the PMAC2 board

when it is not in a bus configuration. When the PMAC2 is in a bus configuration, these supplies automatically

come through the bus connector from the bus power supply. In this case, this terminal block should not be used.

TB2 (3-Pin Terminal Block)

Front View

Pin# Symbol Function Description Notes

1 WD_NC OUTPUT Watchdog Relay Out Normally closed