Page 1

^1 USER MANUAL & REFERENCE

^2 Geo MACRO Drive

^3 Direct PWM Amplifier over MACRO

^4 500-603701-xUxx

^5 April 27, 2010

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Page 3

Copyright Information

© 2010 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in this

manual may be updated from time-to-time due to product improvements, etc., and may not conform in

every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers contain static

sensitive components that can be damaged by incorrect handling. When installing or handling Delta Tau

Data Systems, Inc. products, avoid contact with highly insulated materials. Only qualified personnel

should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment, install

them into an industrial electrical cabinet or industrial PC to protect them from excessive or corrosive

moisture, abnormal ambient temperatures, and conductive materials. If Delta Tau Data Systems, Inc.

products are directly exposed to hazardous or conductive materials and/or environments, we cannot

guarantee their operation.

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC 364 resp. CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It is

vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

Page 4

After removing the power source from the equipment, wait at least 10 minutes before touching or

disconnecting sections of the equipment that normally carry electrical charges (e.g., capacitors, contacts,

screw connections). To be safe, measure the electrical contact points with a meter before touching the

equipment.

The following text formats are used in this manual to indicate a potential for personal injury or equipment

damage. Read the safety notices in this manual before attempting installation, operation, or maintenance

to avoid serious bodily injury, damage to the equipment, or operational difficulty.

WARNING

A Warning identifies hazards that could result in personal injury or death. It

precedes the discussion of interest.

Caution

A Caution identifies hazards that could result in equipment damage. It precedes

the discussion of interest

Note

A Note identifies information critical to the user’s understanding or use of the

equipment. It follows the discussion of interest.

Page 5

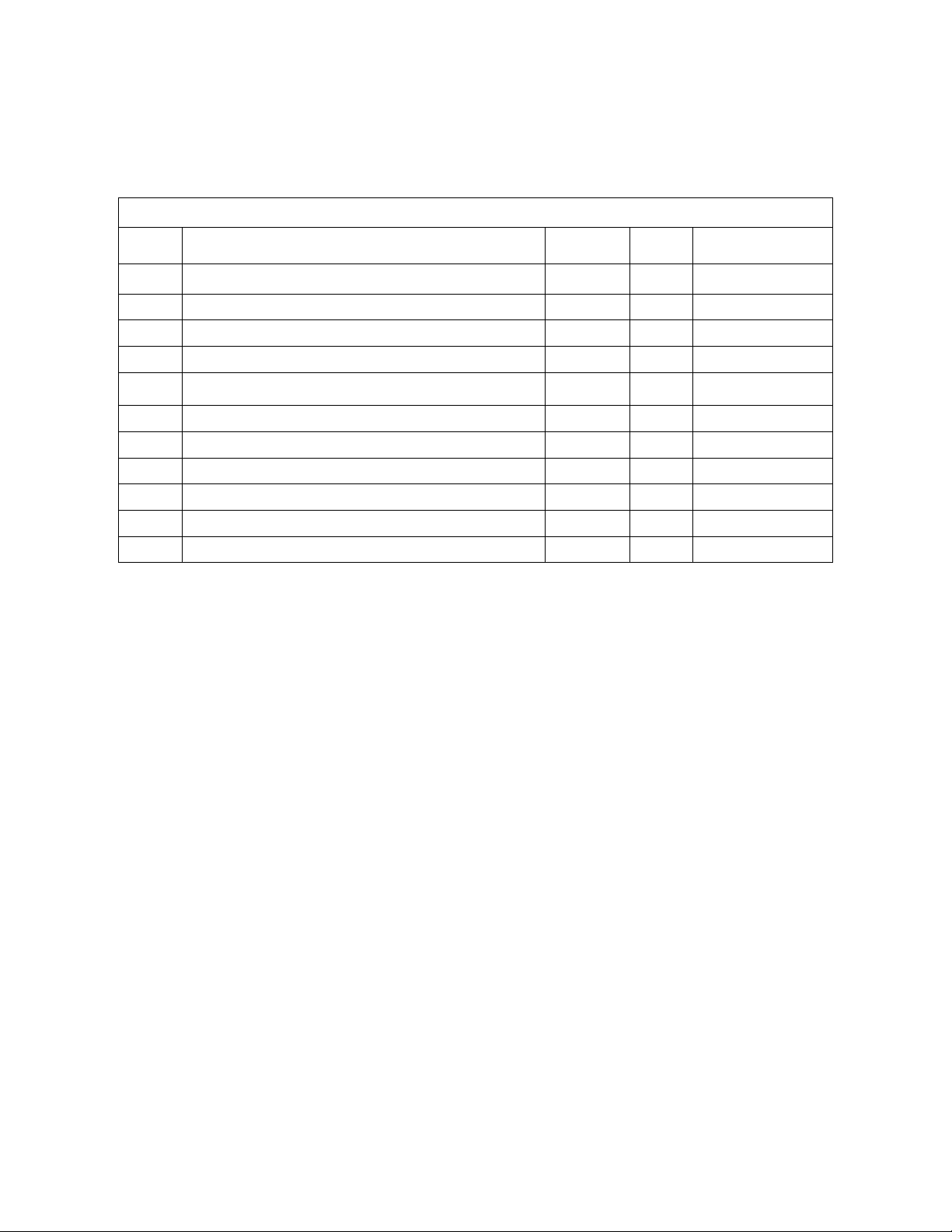

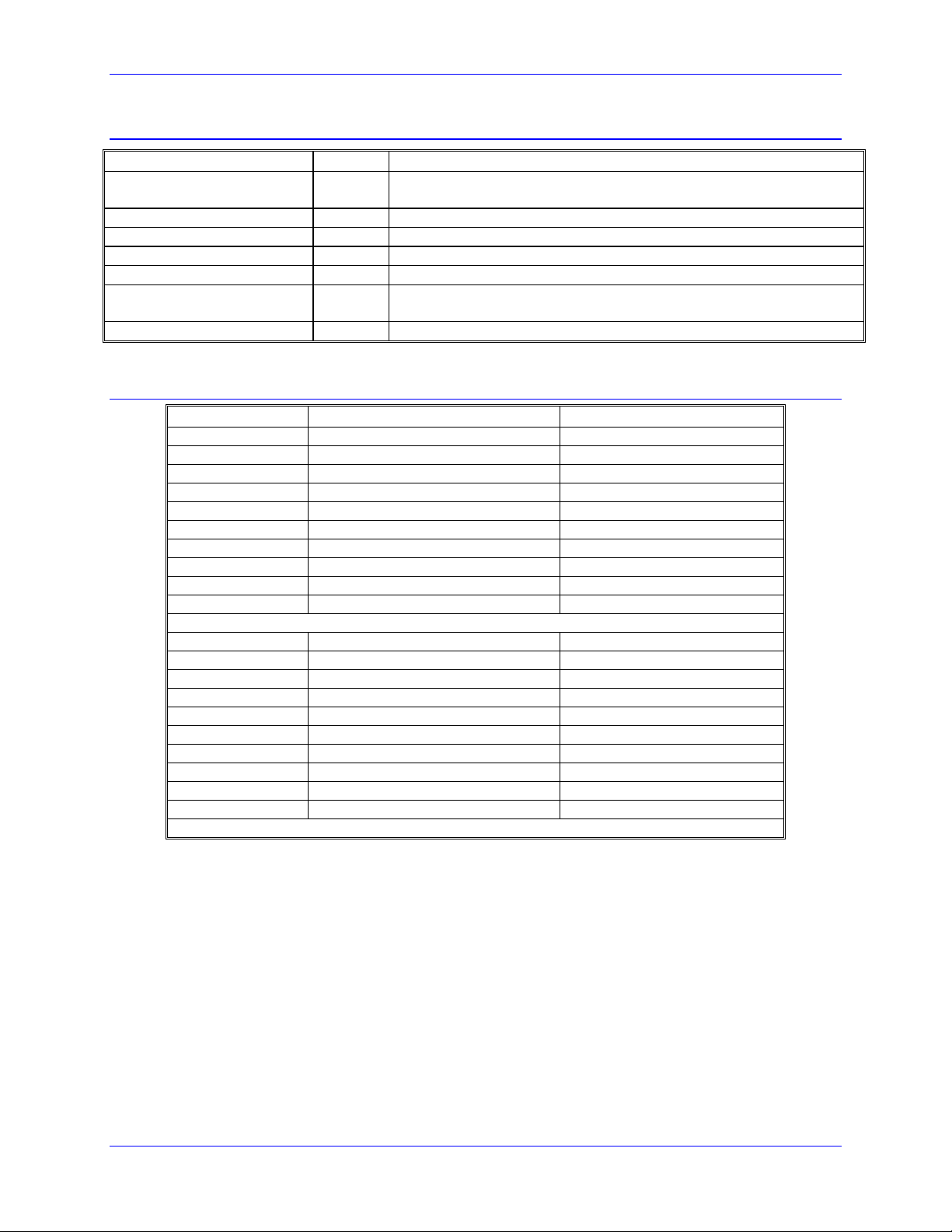

REVISION HISTORY

REV. DESCRIPTION DATE CHG APPVD

1 UPDATED ENDAT SETUP INFO, P. 82 07/18/06 CP P.SHANTZ

2 UPDATED ERROR CODE EF GATE DRIVE INFO 09/21/06 CP P.SHANTZ

3 CORRECTED GP OUT INPUT FUNCTIONS, P. 39 06/11/08 CP K.ZHAO

4 CORRECTED RESET COMMAND, P. 138 10/30/08 CP S. MILICI

5 CORRECTED M-VARIABLE DEFINITIONS, P. 87

6 CORRECTED ERRORS PPS. 85-87 02/25/10 CP S. MILICI

7 CORRECTED COVER PAGE FORMATTING 03/01/10 CP C. PERRY

8 ADDED SAFETY RELAY PN INFO, P. 108 04/27/10 CP S. MILICI

12/08/09 CP S. MILICI

Page 6

Page 7

Geo MACRO Drive User and Reference Manual

Table of Contents

Copyright Information................................................................................................................................................i

Operating Conditions .................................................................................................................................................i

Safety Instructions......................................................................................................................................................i

INTRODUCTION .......................................................................................................................................................1

User Interface ............................................................................................................................................................1

Geo MACRO Drives .............................................................................................................................................1

Geo PMAC Drives ................................................................................................................................................2

Geo Direct-PWM Drives.......................................................................................................................................2

MACRO Defined ......................................................................................................................................................2

Feedback Devices......................................................................................................................................................3

Compatible Motors....................................................................................................................................................3

Maximum Speed....................................................................................................................................................3

Torque...................................................................................................................................................................3

Motor Poles ..........................................................................................................................................................4

Motor Inductance..................................................................................................................................................4

Motor Resistance ..................................................................................................................................................4

Motor Back EMF ..................................................................................................................................................4

Motor Torque Constant.........................................................................................................................................5

Motor Inertia ........................................................................................................................................................5

Motor Cabling.......................................................................................................................................................5

SPECIFICATIONS .....................................................................................................................................................7

Part Number ..............................................................................................................................................................7

Geo MACRO Feedback Options...............................................................................................................................8

Package Types...........................................................................................................................................................8

Electrical Specifications............................................................................................................................................9

230VAC Input Drives...........................................................................................................................................9

480VAC Input Drives..........................................................................................................................................11

Environmental Specifications..................................................................................................................................13

Recommended Fusing and Wire Gauge..................................................................................................................13

RECEIVING AND UNPACKING...........................................................................................................................15

Use of Equipment....................................................................................................................................................15

MOUNTING ..............................................................................................................................................................17

Low Profile..............................................................................................................................................................18

Single Width............................................................................................................................................................19

Double Width ..........................................................................................................................................................20

CONNECTIONS .......................................................................................................................................................21

System (Power) Wiring...........................................................................................................................................21

Wiring AC Input, J1 ............................................................................................................................................23

Wiring Earth-Ground .........................................................................................................................................23

Wiring 24 V Logic Control, J4............................................................................................................................24

Wiring the Motors ...................................................................................................................................................24

J2: Motor 1 Output Connector Pinout...............................................................................................................24

J3: Motor 2 Output Connector Pinout...............................................................................................................24

Wiring the Motor Thermostats................................................................................................................................25

Wiring the Regen (Shunt) Resistor, J5....................................................................................................................25

J5: External Shunt Connector Pinout ................................................................................................................26

Shunt Regulation.................................................................................................................................................27

Minimum Resistance Value.................................................................................................................................27

Maximum Resistance Value................................................................................................................................27

Energy Transfer Equations.................................................................................................................................27

Bonding...................................................................................................................................................................29

Filtering...................................................................................................................................................................30

Table of Contents i

Page 8

Geo MACRO Drive User Manual

CE Filtering ........................................................................................................................................................30

Input Power Filtering .........................................................................................................................................31

Motor Line Filtering ...........................................................................................................................................31

I/O Filtering........................................................................................................................................................31

Connecting Main Feedback Sensors (X1 & X2).....................................................................................................32

Digital Quadrature Encoders .............................................................................................................................32

Digital Hall Commutation Sensors.....................................................................................................................33

SSI Encoders.......................................................................................................................................................33

Sinusoidal Encoders ...........................................................................................................................................34

Hiperface® Interface..........................................................................................................................................35

EnDat Interface...................................................................................................................................................36

Resolvers.............................................................................................................................................................37

Connecting Secondary Quad. Encoders (X8 & X9)................................................................................................38

Connecting General Purpose I/O & Flags (X3).......................................................................................................39

Sample wiring the I/O .........................................................................................................................................39

Sample Wiring the Flags.....................................................................................................................................40

Connecting MACRO Ring ......................................................................................................................................41

Fiber Optic MACRO connections (X5)...............................................................................................................41

RJ-45 Copper MACRO connections (X10 &X11)...............................................................................................41

Connecting optional Analog Inputs (X6 & X7) ......................................................................................................42

SOFTWARE SETUP FOR GEO MACRO DRIVES.............................................................................................43

Introduction .............................................................................................................................................................43

Establishing MACRO Communications with Turbo PMAC ..................................................................................43

MACRO Ring Frequency Control Variables ......................................................................................................43

I7: Phase Cycle Extension ..................................................................................................................................43

I6840: MACRO IC 0 Master Configuration .......................................................................................................44

I6890/I6940/I6990: MACRO IC 1/2/3 Master Configuration ............................................................................44

I6841/I6891/I6941/I6991: MACRO IC 0/1/2/3 Node Activation Control...........................................................44

I70/I72/I74/I76: MACRO IC 0/1/2/3 Node Auxiliary Function Enable..............................................................45

I71/I73/I75/I77: MACRO IC 0/1/2/3 Node Protocol Type Control ....................................................................46

I78: MACRO Master/Slave Auxiliary Communications Timeout .......................................................................46

I79: MACRO Master/Master Auxiliary Communications Timeout.....................................................................46

I80, I81, I82: MACRO Ring Check Period and Limits .......................................................................................46

MACRO Node Addresses ....................................................................................................................................47

Using the Turbo PMAC Setup Program .............................................................................................................51

Using the PEWIN32PRO 2 MACRO Ring ASCII Feature..................................................................................58

PEWIN32PRO Suite 2 MACRO Status window..................................................................................................62

Ring Order Communications Method.................................................................................................................63

MACRO ASCII Communications........................................................................................................................64

How to Enable and Disable MACRO ASCII Communication Mode ..................................................................64

SETTING UP PRIMARY FEEDBACK..................................................................................................................67

Device Selection Control.........................................................................................................................................67

Setting up Digital Quadrature Encoders.................................................................................................................67

Setting up SSI Encoders..........................................................................................................................................67

Setting up Sinusoidal Encoders...............................................................................................................................69

Principle of PMAC Interpolation Operation ......................................................................................................69

Setting up Endat ......................................................................................................................................................72

Setting up Resolvers................................................................................................................................................72

Setting up the Phase Shift (MI941) Manually.....................................................................................................73

Setting up the Resolver for Power-On Absolute Position ...................................................................................73

Scaling the Feedback Units ................................................................................................................................74

SETTING UP SECONDARY ENCODERS............................................................................................................75

SETTING UP THE TURBO PMAC CONVERSION TABLE .............................................................................77

ii Table of Contents

Page 9

Geo MACRO Drive User and Reference Manual

SETTING UP TURBO MOTOR OPERATION ....................................................................................................79

Turbo PMAC Basic Setup for Brushless Servo or Induction Motor .......................................................................79

Turbo PMAC Basic Setup for DC Brush Motors................................................................................................80

Instructions for Direct-PWM Control of Brush Motors ..........................................................................................85

PWM/ADC Phase Match ....................................................................................................................................85

Synchronous Motor Stepper Action ....................................................................................................................85

Current Loop Polarity Check..............................................................................................................................85

Troubleshooting..................................................................................................................................................86

Testing PWM and Current Feedback Operation .....................................................................................................86

Purpose...............................................................................................................................................................86

Preparation.........................................................................................................................................................87

Position Feedback and Polarity Test..................................................................................................................87

Setting Up Hall Commutation Sensors....................................................................................................................88

Signal Format .....................................................................................................................................................88

Using Hall Effect Sensors for Phase Reference..................................................................................................89

Determining the Commutation Phase Angle.......................................................................................................89

Finding the Hall Effect Transition Points...........................................................................................................89

Calculating the Hall Effect Zero Point (HEZ)....................................................................................................90

Determining the Polarity of the Hall Effects – Standard or Reversed................................................................92

Software Settings for Hall Effect Phasing...........................................................................................................92

Setting I2T Protection ..............................................................................................................................................96

Calculating Minimum PWM Frequency .................................................................................................................97

SETTING UP DISCRETE INPUTS AND OUTPUTS...........................................................................................99

Inputs and Outputs ..................................................................................................................................................99

Ring Break Output indicator MS{node},MI13 .....................................................................................................100

Setting up the Analog Inputs (X6 and X7)............................................................................................................100

Limit and Flag Circuit Wiring...............................................................................................................................102

Connecting Limits/Flags to the Geo Drive .......................................................................................................102

Setting up Position Compare (EQU) Outputs........................................................................................................103

Setting up for a Single Pulse Output.................................................................................................................103

Setting up for Multiple Pulse Outputs...............................................................................................................104

CONNECTORS.......................................................................................................................................................105

Connector Pinouts .................................................................................................................................................105

X1: Encoder Input 1.........................................................................................................................................105

X2: Encoder Input 2.........................................................................................................................................106

X3: General Purpose I/O..................................................................................................................................107

X4: Safety Relay (Optional).............................................................................................................................108

X6: Analog IN 1 (Optional 3/4/5) ....................................................................................................................108

X7: Analog IN 2 (Optional 3/4/5) ....................................................................................................................108

X8: S. Encoder 1 ..............................................................................................................................................109

X9: S. Encoder 2 ..............................................................................................................................................109

X13: Discrete I/O.............................................................................................................................................109

J1: AC Input Connector Pinout .......................................................................................................................110

J2: Motor 1 Output Connector Pinout.............................................................................................................110

J3: Motor 2 Output Connector Pinout (Optional) ...........................................................................................110

J4: 24VDC Input Logic Supply Connector .......................................................................................................110

J5: External Shunt Connector Pinout ..............................................................................................................110

MACRO Link Connectors.....................................................................................................................................111

X5: MACRO I/O, MACRO Fiber Optic Transceiver (Optional).......................................................................111

X10 and X11 MACRO RJ-45 Copper Connectors ............................................................................................111

USB Connector .....................................................................................................................................................111

X12: USB Universal Serial Bus Port...............................................................................................................112

TROUBLESHOOTING..........................................................................................................................................113

Error Codes ...........................................................................................................................................................113

Table of Contents iii

Page 10

Geo MACRO Drive User Manual

D1: Geo MACRO Drive Status Display Codes.................................................................................................113

MACRO Network Errors...................................................................................................................................114

Status LEDs ......................................................................................................................................................115

Geo MACRO Drive Ring Status Error Codes.......................................................................................................116

MS{node},MI4 Geo MACRO Status Word (Read Only) ...............................................................................116

MS{node},MI6 Status Word Control.............................................................................................................117

Status Word.......................................................................................................................................................117

TURBO PMAC2 RELATED I-VARIABLE REFERENCE ...............................................................................119

Ixx10: Motor xx Power-On Servo Position Address............................................................................................119

Ixx25, Ixx24: Flag Address and Mode..................................................................................................................121

Ixx70, Ixx71: Commutation Cycle Size ...............................................................................................................123

Ixx72: Commutation Phase Angle.........................................................................................................................123

Ixx75: Absolute Phase Position Offset.................................................................................................................123

Ixx81: Motor xx Power-On Phase Position Address and Mode...........................................................................124

Ixx82: Current Loop Feedback Address................................................................................................................125

Ixx83: Commutation Feedback Address ..............................................................................................................126

Ixx91: Motor xx Power-On Phase Position Format .............................................................................................126

Ixx95: Motor xx Power-On Servo Position Format .............................................................................................129

Ixx97 Motor xx Position Capture and Trigger Mode ...........................................................................................131

GEO MACRO DRIVE MI-VARIABLE REFERENCE......................................................................................133

Global MI-Variables .............................................................................................................................................133

MS{node},MI0 Geo MACRO drive Firmware Version (Read Only)............................................................133

MS{node},MI1 Geo MACRO drive Firmware Date (Read Only)................................................................133

MS{node},MI2 and MI3 (Reserved for future use).......................................................................................133

MS{node},MI4 Geo MACRO drive Status Word (Read Only) ......................................................................134

MS{node},MI5 Ring Error Counter .............................................................................................................134

MS{node},MI6 Status Word Control............................................................................................................135

MS{node},MI7 Geo MACRO Error Counter ...............................................................................................135

MS{node},MI8 Geo MACRO Ring Check Period ........................................................................................135

MS{node},MI9 Geo MACRO Ring Error Shutdown Count..........................................................................135

MS{node},MI10 Geo MACRO Sync Packet Shutdown Count......................................................................136

MS{node},MI11 Station Order Number.......................................................................................................136

MS{node},MI12 Card Identification (Read Only)........................................................................................137

MS{node},MI13 Ring Break Output indicator .............................................................................................137

MS{node},MI100 Motor Activation Control word.......................................................................................138

MS{node},MI101-102 Primary Feedback Selection .....................................................................................138

MS{node},MI103 Sin Encoder/ Resolver #1 bias..........................................................................................139

MS{node},MI104 Sin Encoder/ Resolver #2 bias..........................................................................................139

MS{node},MI105 Cosine Encoder/ Resolver #1 bias....................................................................................139

MS{node},MI106 Cosine Encoder/ Resolver #2 bias....................................................................................139

MS{node},MI107 Motor 1 Encoder-Loss Mask ............................................................................................140

MS{node},MI108 Motor 2 Encoder-Loss Mask ............................................................................................140

Primary Channel Node-Specific Gate Array MI-variables....................................................................................142

MS{node},MI910 Primary Encoder/Timer n Decode Control......................................................................142

MS{node},MI911 Primary Enc. Position Compare n Channel Select ..........................................................143

MS{node},MI912 Primary Encoder n Capture Control................................................................................143

MS{node},MI913 Primary Encoder Capture n Flag Select Control.............................................................144

MS{node},MI914 Primary Encoder n Gated Index Select ............................................................................144

MS{node},MI915 Primary Encoder Index Gate State/Demux Control.........................................................145

MS{node},MI910 Secondary Encoder Decode Control................................................................................146

MS{node},MI911 Secondary Encoder counter Direction .............................................................................146

MS{node},MI912 Secondary Encoder Index Capture Control ....................................................................147

MS{node},MI913 Secondary Encoder Home Flag Capture Control...........................................................147

MS{node},MI914 Secondary Encoder Filter Control ...................................................................................147

MS{node},MI915 Secondary Encoder Capture Flag Select Control ............................................................148

iv Table of Contents

Page 11

Geo MACRO Drive User and Reference Manual

MS{node},MI916 Output n Mode Select .......................................................................................................148

MS{node},MI917 Output n Invert Control....................................................................................................148

MS{node},MI918 Output n PFM Direction Signal Invert Control ...............................................................149

MS{node},MI919 Hardware 1/T ...................................................................................................................149

MS{node},MI921 Flag Capture Position (Read Only)..................................................................................150

MS{node},MI922 ADC A Input Value (Read Only) ......................................................................................150

MS{node},MI923 Compare Auto-Increment Value.......................................................................................150

MS{node},MI924 ADC B Input Value (Read Only) ......................................................................................150

MS{node},MI925 Compare A Position Value...............................................................................................151

MS{node},MI926 Compare B Position Value...............................................................................................151

MS{node},MI927 (Reserved for future use)......................................................................................................151

MS{node},MI928 Compare-State Write Enable............................................................................................151

MS{node},MI929 Compare-Output Initial State...........................................................................................151

General Hardware Setup MI-variables..................................................................................................................152

MS{anynode}, MI930 SSI Channel 1 Control Word .....................................................................................152

MS{anynode}, MI931 SSI Channel 2 Control Word ....................................................................................152

MS{anynode}, MI932 Resolver Excitation Frequency Divider....................................................................153

MS{anynode}, MI933 SSI Clock Frequency Divider ...................................................................................153

MS{anynode},MI934-MI939 (Reserved for future use)................................................................................153

MS{anynode}, MI940 Resolver Excitation Gain .........................................................................................153

MS{anynode}, MI941 Resolver Excitation Phase Offset.............................................................................154

MS{anynode},MI942 ADC Strobe Word Channel 1* & 2* ..........................................................................154

MS{node},MI943 Encoder Power control bit ...............................................................................................154

MS{node},MI944-MI949 (Reserved for future use) .....................................................................................154

Global & 2-Axis Board I-Variables ......................................................................................................................155

MS{node},MI992 MaxPhase Frequency Control..........................................................................................155

MS{node},MI993 Hardware Clock Control Handwheel Channels...............................................................155

MS{node},MI994 PWM Deadtime ...............................................................................................................157

MS{node},MI995 MACRO Ring Configuration/Status .................................................................................157

MS{node},MI996 MACRO Node Activate Control .......................................................................................158

MS{node},MI997 Phase Clock Frequency Control ......................................................................................160

MS{node},MI998 Servo Clock Frequency Control.......................................................................................160

ABSOLUTE POWER ON ONLINE COMMANDS.............................................................................................161

$$*.........................................................................................................................................................................161

$*...........................................................................................................................................................................161

APPENDIX A...........................................................................................................................................................166

Fiber Optic Cable Ordering Information...............................................................................................................166

Mating Connector and Cable Kits.........................................................................................................................166

Mating Connector and Cable Kits ....................................................................................................................166

Connector and pins Part numbers ....................................................................................................................168

Cable Drawings ................................................................................................................................................170

Regenerative Resistor: GAR78/48 .......................................................................................................................176

Type of Cable for Encoder Wiring........................................................................................................................177

APPENDIX B...........................................................................................................................................................180

Schematics.............................................................................................................................................................180

X3: Discrete I/O...............................................................................................................................................180

X6 and X7: Analog Inputs................................................................................................................................182

X8 and X9 Secondary Encoders (3 and 4)........................................................................................................183

APPENDIX C...........................................................................................................................................................184

Communication to the Geo MACRO via the USB Port........................................................................................184

APPENDIX D...........................................................................................................................................................186

MACRO Flag Transfer Location...........................................................................................................................186

Turbo PMAC2 Node Addresses............................................................................................................................187

Table of Contents v

Page 12

Geo MACRO Drive User Manual

ADC Register Table ..............................................................................................................................................189

Stepping through an Electrical Cycle....................................................................................................................190

Manually Stepping through an Electrical Cycle at 30 degree increments........................................................190

Example 1 of Hall Effect Values .......................................................................................................................191

Example 2 of Hall Effect Values .......................................................................................................................192

USEFUL NOTES.....................................................................................................................................................193

vi Table of Contents

Page 13

Geo MACRO Drive User and Reference Manual

INTRODUCTION

The Geo Drive family of “bookcase”-style servo amplifiers provides many new capabilities for users.

This family of 1- and 2-axis 3-phase amplifiers, built around a common core of highly integrated IGBTbased power circuitry, supports a wide variety of motors, power ranges, and interfaces. The 2-axis

configurations share common power input, bus, and shunt for a very economical implementation.

Three command interfaces are provided: direct-PWM, MACRO-ring, and integrated PMAC controller,

each described in following sections. In all three cases, fully digital “direct PWM” control is used. Direct

PWM control eliminates D-to-A and A-to-D conversion delays and noise, allowing higher gains for more

robust and responsive tuning without sacrificing stability.

All configurations provide these power-stage features:

• Direct operation off AC power mains (100 – 240 or 300 – 480 VAC, 50/60 Hz) or optional DC

power input (24 – 350 or 24 – 700 VDC)

• Integrated bus power supply including soft start and shunt regulator (external resistor required)

• Separate 24VDC input to power logic circuitry

• Complete protection: over voltage, under voltage, over temperature, PWM frequency limit,

minimum dead time, motor over temperature, short circuit, over current, input line monitor

• Ability to drive brushed and brushless permanent-magnet servo motors, or AC induction motors

• Single-digit LED display and six discrete LEDs for status information

• Optional safety relay circuitry. Please contact factory for more details and pricing.

• Easy setup with Turbo PMAC and UMAC controllers.

User Interface

The Geo Drive family is available in different versions distinguished by their user interface styles.

Geo MACRO Drives

The Geo MACRO Drive interfaces to the controller through the 125 Mbit/sec MACRO ring, with

either a fiber-optic or Ethernet electrical medium, accepting numerical command values for direct

PWM voltages and returning numerical feedback values for phase current, motor position, and status.

It accepts many types of position feedback to the master controller, as well as axis flags (limits, home,

and user) and general-purpose analog and digital I/O. Typically, the Geo MACRO Drives are

commanded by either a PMAC2 Ultralite bus-expansion board, or a UMAC rack-mounted controller

with a MACRO-interface card. This provides a highly distributed hardware solution, greatly

simplifying system wiring, while maintaining a highly centralized software solution, keeping system

programming simple.

• Choices for main feedback for each axis: A/B quadrature encoder, sinusoidal encoder with

• Secondary A/B quadrature encoder for each axis

• General-purpose isolated digital I/O: 4 in, 4 out at 24VDC

EnDat

TM

or HiperfaceTM, SSI encoder, resolver

• 2 optional A/D converters, 12- or 16-bit resolution

Note:

Geo MACRO is not using the regular 8-axis or 16-axis MACRO station CPU.

A new MACRO CPU was developed for the Geo MACRO drive.

Introduction 1

Page 14

Geo MACRO Drive User Manual

Geo PMAC Drives

The Geo PMAC Drive is a standalone-capable integrated controller/amplifier with a built-in full

PMAC2 controller having stored-program capability. It can be operated standalone, or commanded

from a host computer through USB2.0 or 100 Mbps Ethernet ports. The controller has the full

software capabilities of a PMAC (see descriptions), with an internal fully-digital connection to the

advanced Geo power-stage , providing a convenient, compact, and cost-effective installation for one

and two-axis systems, with easy synchronization to other drives and controls.

• Choices for main feedback for each axis: A/B quadrature encoder, sinusoidal encoder with

• Secondary A/B quadrature encoder for each axis

• General-purpose isolated digital I/O: 8 in, 6 out at 24VDC

• 2 optional A/D converters 12- or 16-bit resolution

EnDat

TM

or HiperfaceTM, SSI encoder, resolver

Geo Direct-PWM Drives

The direct-PWM interface versions accept the actual power-transistor on/off signals from the PMAC2

controller, while providing digital phase-current feedback and drive status to the controller for closedloop operation. Interface to the direct-PWM amplifier is through a standard 36-pin Mini-D style

cable. The drive performs no control functions but has protection features. Drive installation,

maintenance, and replacement are simplified because there is less wiring (position feedback and I/O

are not connected to the drive) and there are no variables to set or programs to install in the drive.

• Fully centralized control means that all gains and settings are made in the PMAC; no software

setup of drive is required

• No position feedback or axis flags required at the drive

MACRO Defined

MACRO defined is a digital interface for connection of multi–axis motion controllers, amplifiers and

other I/O devices on a fiber optic or twisted pair copper (RJ45 connector) ring.

MACRO operates in a ring topology. Data is transmitted serially. Each station on the ring has an in port

for receiving data and an out port for transmitting data. Nodes, residing at a station can be amplifier axes,

I/O banks, or communication interfaces to other devices. A station can have one or several nodes

allowing for multi-axis amplifiers with a single in and single out port. Data packets, (groups of 96 bits of

serial data) from the motion controller or master node are addressed to a specific amplifier or slave node.

If the data packet is not for an amplifier, it is passed on unchanged. If it is for the node, it copies the

contents of the data packet (typically commands), places feedback data into a packet, and transmits the

data packet.

MACRO’s Advantages are:

• Single–plug connections between controls and amplifiers: A single fiber optic strand can provide a

controller with: position feedback, flag status (limits, home flag), amplifier status and machine input

status. This same strand can communicate to the amplifier and other devices on the MACRO network

(Amplifier enable and amplifier command signals, machine outputs, commands to D/A converters; all

can be implemented with a single plug connection).

• Noise Immunity: Fiber–optic cable transmits light, not electricity. Unlike electricity light is immune

to electromagnetic noise, capacitive coupling, ground loops, and other wiring problems.

• Speed: MACRO’s operation is 125 Mbits/second. This is at least 25 times faster than other digital

motion control interfaces.

2 Introduction

Page 15

Geo MACRO Drive User and Reference Manual

• One ring, multiple masters: In a ring network, several motion controllers (masters) can be on one

ring. Each controller controls several axes (up to 32 ea.).

• Simplicity: Transmission within the MACRO ring requires no software intervention. The

information sent to all nodes is written to a memory location and the MACRO hardware takes care of

the rest.

Feedback Devices

Many motors incorporate a position feedback device. Devices are incremental encoders, resolvers, and

sine encoder systems. The macro version of the Geo drive accepts feedback. In its standard form, it is set

up to accept incremental encoder feedback. With the appropriate feedback option, it is possible to use

either resolver or sinusoidal encoder feedback. Historically, the choice of a feedback device has been

guided largely by cost and robustness. Today, feedbacks are relatively constant for the cost and picked by

features such as size and feedback data. More feedback data or resolution provides the opportunity to

have higher gains in a servo system.

Geo MACRO drives have standard secondary quadrature encoder feedback. One secondary encoder (X8)

for one axis drive and two secondary encoders (X8 and X9) for dual axis drives (603542 rev-10A and

above). Earlier versions of the Geo MACRO drive cannot use the secondary encoders.

Compatible Motors

The Geo drive product line is capable of interfacing to a wide variety of motors. The Geo drive can

control almost any type of three-phase brushless motor, including DC brushless rotary, AC brushless

rotary, induction, and brushless linear motors. Permanent magnet DC brush motors can also be controlled

using two of the amplifiers three phases. Motor selection for an application is a science in itself and

cannot be covered in this manual. However, some basic considerations and guidelines are offered. Motor

manufacturers include a host of parameters to describe their motor.

Some basic equations can help guide an applications engineer to mate a proper drive with a motor. A

typical application accelerates a load to a speed, running the speed for a while and then decelerating the

load back into position.

Maximum Speed

The motor’s maximum rated speed is given. This speed may or may not be achievable in a given system.

The speed could be achieved if enough voltage and enough current loop gain are available. Also consider

the motor’s feedback adding limitations to achievable speeds. The load attached to the motor also limits

the maximum achievable speed. In addition, some manufacturers will provide motor data with their drive

controller, which is tweaked to extend the operation range that other controllers may be able to provide.

In general, the maximum speed can be determined by input voltage line-to-line divided by Kb (the

motor’s back EMF constant). It is wise to de-rate this a little for proper servo applications.

Torque

The torque required for the application can be viewed as both instantaneous and average. Typically, the

instantaneous or peak torque is calculated as a sum of machining forces or frictional forces plus the forces

required to accelerate the load inertia. The machining or frictional forces on a machine must be

determined by the actual application. The energy required to accelerate the inertia follows the equation:

T = JA, where T is the torque in Newton-meters or pound-feet required for the acceleration, J is the inertia

in kilogram-meters-squared or pound-feet-second squared, and A is in radians per second per second.

The required torque can be calculated if the desired acceleration rate and the load inertia reflected back to

the motor are known. The T=JA equation requires that the motor’s inertia be considered as part of the

inertia-requiring torque to accelerate.

Once the torque is determined, the motors specification sheet can be reviewed for its torque constant

parameter (Kt). The torque required at the application divided by the Kt of the motor provides the peak

current required by the amplifier. A little extra room should be given to this parameter to allow for good

Introduction 3

Page 16

Geo MACRO Drive User Manual

servo control.

Most applications have a duty cycle in which the acceleration profile occurs repetitively over time.

Calculating the average value of this profile gives the continuous rating required by the amplifier.

Applications also concern themselves with the ability to achieve a speed. The requirements can be

reviewed by either defining what the input voltage is to the drive, or defining what the voltage

requirements are at the motor. Typically, a system is designed at a 230 or 480V input line. The motor

must be able to achieve the desired speed with this voltage limitation. This can be determined by using

the voltage constant of the motor (Kb), usually specified in volts-per-thousand rpm. The application

speed is divided by 1000 and multiplied by the motor's Kb. This is the required voltage to drive the motor

to the desired velocity. Headroom of 20% is suggested to allow for good servo control.

Peak Torque

The peak torque rating of a motor is the maximum achievable output torque. It requires that the amplifier

driving it be able to output enough current to achieve this. Many drive systems offer a 3:1 peak-tocontinuous rating on the motor, while the amplifier has a 2:1 rating. To achieve the peak torque, the drive

must be sized to be able to deliver the current to the motor. The required current is often stated on the

datasheet as the peak current through the motor. In some sense, it can also be determined by dividing the

peak amplifier's output rating by the motor's torque constant (Kt).

Continuous Torque

The continuous torque rating of the motor is defined by a thermal limit. If more torque is consumed from

the motor than this on average, the motor overheats. Again, the continuous torque output of the motor is

subject to the drive amplifier’s ability to deliver that current. The current is determined by the

manufacturer’s datasheets stating the continuous RMS current rating of the motor and can also be

determined by using the motor’s Kt parameter, usually specified in torque output per amp of input current.

Motor Poles

Usually, the number of poles in the motor is not a concern to the actual application. However, it should

be noted that each pole-pair of the motor requires an electrical cycle. High-speed motors with high motor

pole counts can require high fundamental drive frequencies that a drive amplifier may or may not be able

to output. In general, drive manufacturers with PWM switching frequencies (16kHz or below) would like

to see commutation frequencies less than 400 Hz. The commutation frequency is directly related to the

number of poles in the motor.

Motor Inductance

PWM outputs require significant motor inductance to turn the on-off voltage signals into relatively

smooth current flow with small ripple. Typically, motor inductance of servomotors is 1 to 15 mH. The

Geo drive product series can drive this range easily. On lower-inductance motors (below 1mH), problems

occur due to PWM switching where large ripple currents flow through the motor, causing excessive

energy waste and heating. If an application requires a motor of less than 1mH, external inductors are

recommended to increase that inductance. Motors with inductance in excess of 15mH can still be driven,

but are slow to react and typically are out of the range of high performance servomotors.

Motor Resistance

Motor resistance is not really a factor in determining the drive performance, but rather, comes into play

more with the achievable torque or output horsepower from the motor. The basic resistance shows up in

the manufacturer's motor horsepower curve.

Motor Back EMF

The back EMF of the motor is the voltage that it generates as it rotates. This voltage subtracts from the

bus voltage of the drive and reduces the ability to push current through the motor. Typical back EMF

4 Introduction

Page 17

Geo MACRO Drive User and Reference Manual

ratings for servomotors are in the area of 8 to 200 volts-per-thousand rpm. The Geo drive product series

can drive any range of back EMF motor, but the back EMF is highly related to the other parameters of the

motor such as the motor inductance and the motor Kt. It is the back EMF of the motor that limits the

maximum achievable speed and the maximum horsepower capability of the motor.

Motor Torque Constant

Motor torque constant is referred to as Kt and usually it is specified in torque-per-amp. It is this number

that is most important for motor sizing. When the load that the motor will see and knowing the motor’s

torque constant is known, the drive amplifier requirements can be calculated to effectively size a drive

amplifier for a given motor. Some motor designs allow Kt to be non-linear, in which Kt will actually

produce less torque per unit of current at higher output speeds. It is wise to de-rate the systems torque

producing capability by 20% to allow headroom for servo control.

Motor Inertia

Motor inertia comes into play with motor sizing because torque to accelerate the inertia of the motor is

effectively wasted energy. Low inertia motors allow for quicker acceleration. However, consider the

reflected inertia from the load back to the motor shaft when choosing the motor’s inertia. A high ratio of

load-to-motor inertia can limit the achievable gains in an application if there is compliance in the

transmission system such as belt-drive systems or rubber-based couplings to the systems. The closer the

rotor inertia matches the load’s reflected inertia to the motor shaft, the higher the achievable gains will be

for a given system. In general, the higher the motor inertia, the more stable the system will be inherently.

Mechanical gearing is often placed between the load and the motor simply to reduce the reflected inertia

back to the motor shaft.

Motor Cabling

Motor cables are an integral part of a motor drive system. Several factors should be considered when

selecting motor cables. First, the PWM frequency of the drive emits electrical noise. Motor cables must

have a good-quality shield around them. The motor frame must also have a separate conductor to bring

back to the drive amplifier to help quench current flows from the motor due to the PWM switching noise.

Both motor drain wire and the cable shield should be tied at both ends to the motor and to the drive

amplifier.

Another consideration in selecting motor cables is the conductor-to-conductor capacitance rating of the

cable. Small capacitance is desirable. Longer runs of motor cable can add motor capacitance loading to

the drive amplifier causing undesired spikes of current. It can also cause couplings of the PWM noise

into the earth grounds, causing excessive noise as well. Typical motor cable ratings would be 50 pf per

foot maximum cable capacitance.

Another factor in picking motor cables is the actual conductor cross-sectional area. This refers to the

conductors ability to carry the required current to and from the motor. When calculating the required

cable dimensions, consider agency requirements, safety requirements, maximum temperature that the

cable will be exposed to, the continuous current flow through the motor, and the peak current flow

through the motor. Typically, it is not suggested that any motor cable be less than 14 AWG.

The motor cable’s length must be considered as part of the application. Motor cable length affects the

system in two ways. First, additional length results in additional capacitive loading to the drive. The

drive’s capacitive loading should be kept to no more than 1000pf. Additionally, the length sets up

standing waves in the cable, which can cause excessive voltage at the motor terminals. Typical motor

cable length runs of up to 60 meters (200 feet) for 230V systems and 15 meters (50 feet) for 480V

systems are acceptable. Exceeding these lengths may put other system requirements in place for either a

snubber at the motor end or a series inductor at the drive end. The series inductor at the drive end

provides capacitance loading isolation from the drive and slows the rise time of the PWM signal into the

cable, resulting in less voltage overshoot at the motor.

Introduction 5

Page 18

Geo MACRO Drive User Manual

6 Introduction

Page 19

Geo MACRO Drive User and Reference Manual

SPECIFICATIONS

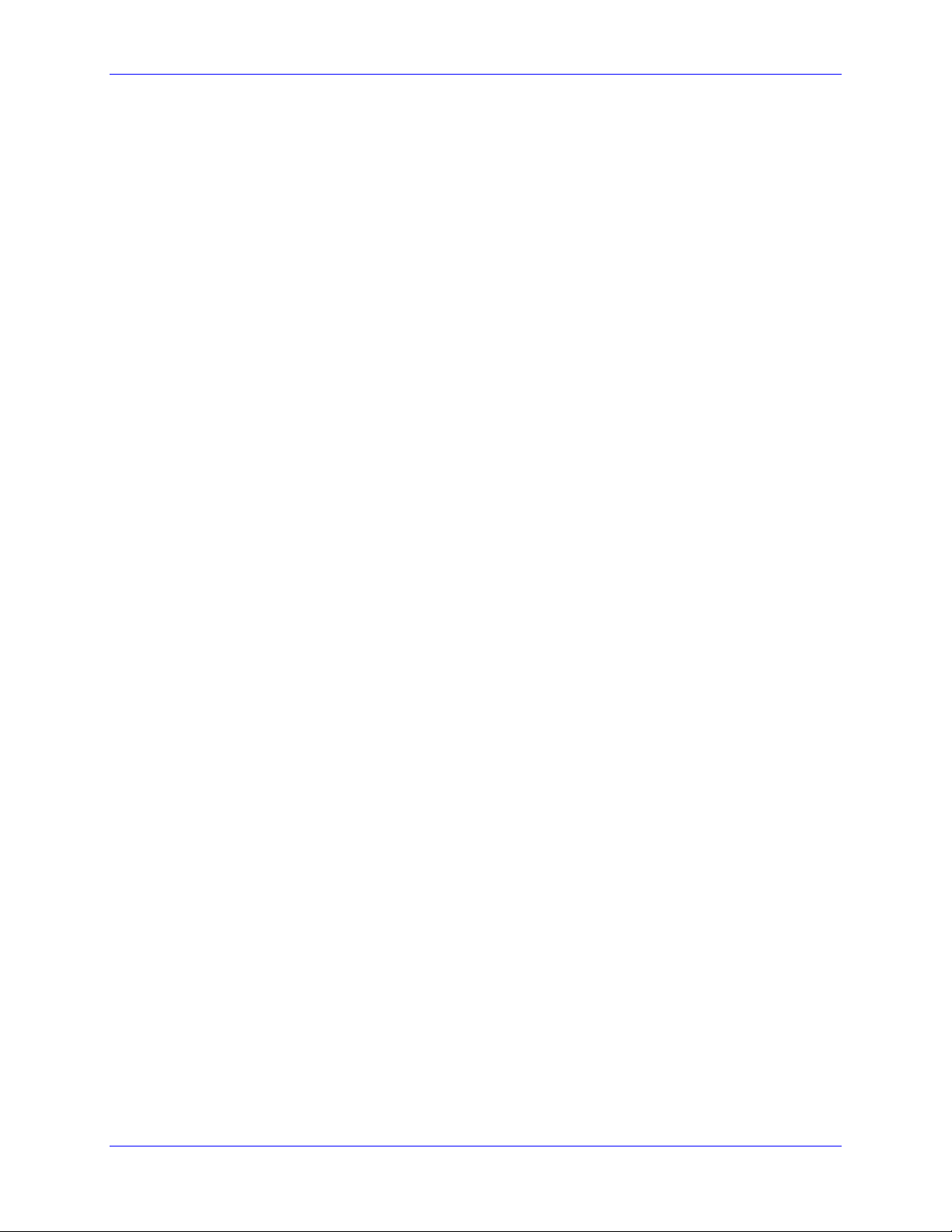

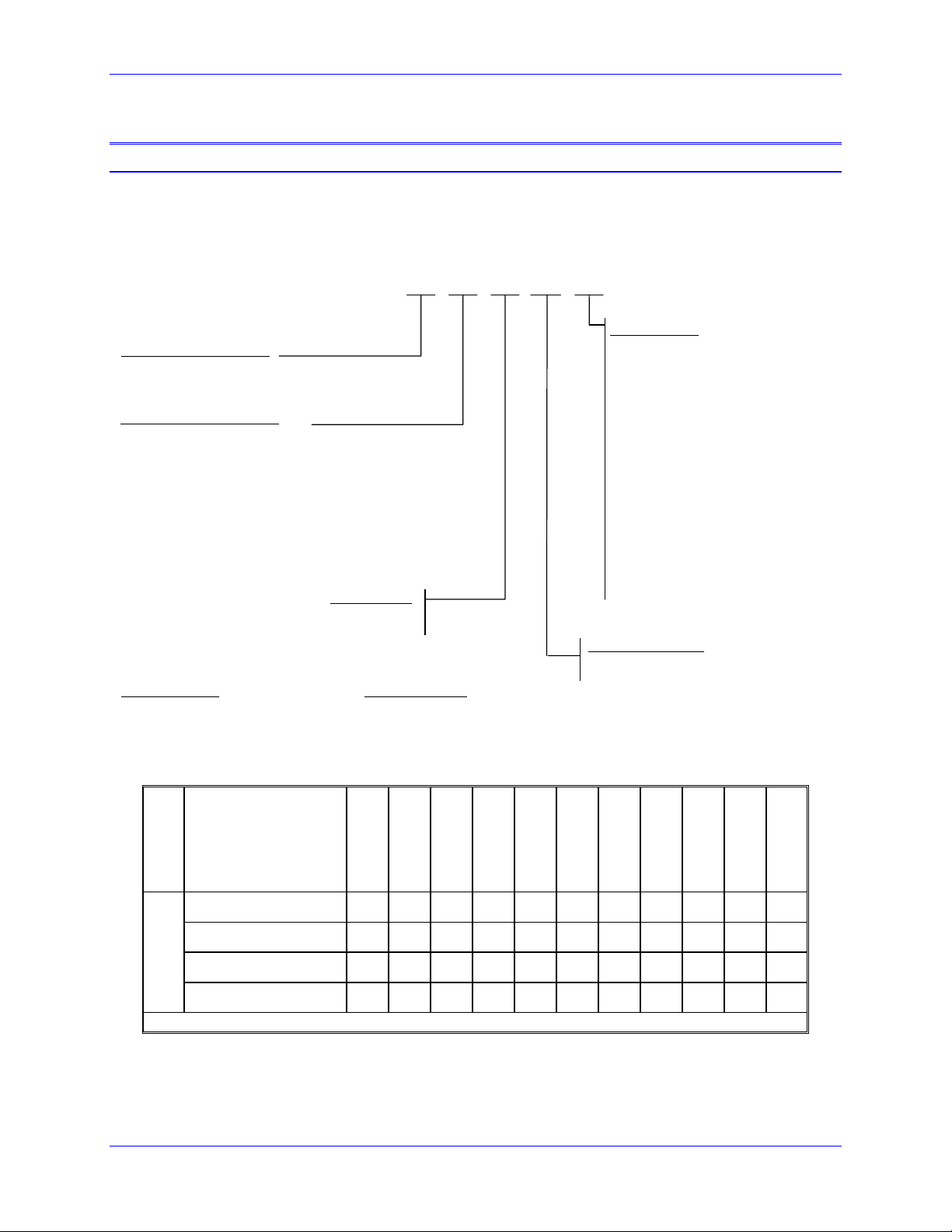

Part Number

Geo MACRO Drive

Model Number Definition

GL03 1 0

Voltage Rating (Direct M ains )

L = 110 - 240 VAC

H = 300 - 480 VAC

Continuous/Peak Current Rating

(Sinusoidal RMS)

φ

01 = 1.5/4.5 Amp (one or 3

03 = 3/9 Amp (one or 3

05 = 5/10 Amp (3

10 = 10/20 Amp (3

15 = 15/30 Amp (3

20 = 20/40 Amp (3

30 = 30/60 Amp (3

*For single phase input, need to derate 30%

Product Width According to Ratings

Single -Width U nits :

1.5/4.5 Dual Axis 10/20 Dual Axis (480VAC)

3/9 Dual Axis 15/30 Dual Axis

5/10 Single and Dual Axis 20/40 Single Axis

10/20 Single Axis and Dual Axis (240VAC) 30/60 Single Axis

15/30 Single Axis

φ

φ

φ

φ

φ

operation )

φ

operation )

input, for single φ need to derate 20%)

input*)

input*)

input*)

input*)

Number of Axes

1 = Single Axis

2 = Dual Axis

Double-Width Units:

RM

Feedback Options

0 = No options, Default; Standard feedback

per axis is quadrature differential

encoder with hall effect inputs or SSI

absolute encoder .

1 = Analog Feedback including:

• Option 0 Standard Feedback

• 4096x Sin/Cos interpolator

• Resolver Interface

2 = Absolute Feedback including :

• Option 1 Analog Feedback

• Endat™

• Hiperface™

3, 4, 5 = Same as Options 0, 1 and 2

described above but with two 16-bit

analog-to-digital converter inputs

Note: Any available method can be used for

feedback but only one method can be used at

any time . Feedback method is selected by

wiring.

MACRO Link Options:

F = Fiber Optic

R = RJ/45 (Default)

GMx012xx

GMx051xx

GMx101xx

GMx151xx

GMx032xx

GMx052xx

GML102xx

GMx201xx

GMx301xx

GMH102xx

GMx152xx

Single axis

Dual Axis

Single Width

Size Axis

Double width

√ √ √ √ √

√ √ √ √ √ √

√* √ √ √ √ √ √

√ √ √ √

* Low Profile Unit, No heatsink, no Fan

Specifications 7

Page 20

Geo MACRO Drive User Manual

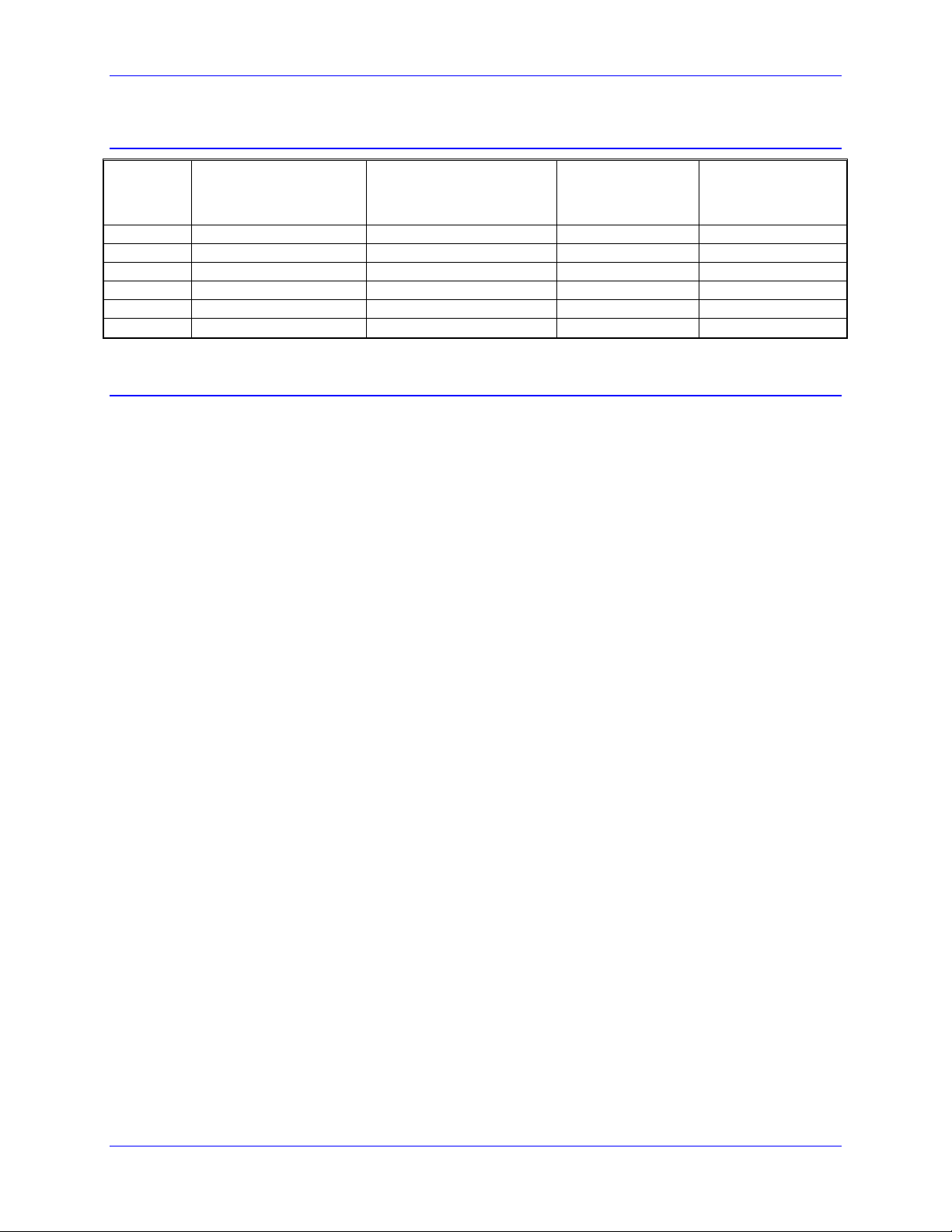

Geo MACRO Feedback Options

Model Default Configuration:

Quadrature Encoders

Or SSI Absolute Encoders

And Hall Effect inputs

GMxxxxx0

GMxxxxx1

GMxxxxx2

GMxxxxx3

GMxxxxx4

GMxxxxx5

√

√

√

√ √

√ √

√ √

Analog (Sin/Cos) Encoders:

x4096 Interpolator

Resolver to Digital

Converters

Absolute Encoder

Interfaces:

EnDat

Hiperface

Addition of two

channels of 16-bit

A/D converters with

each feedback option

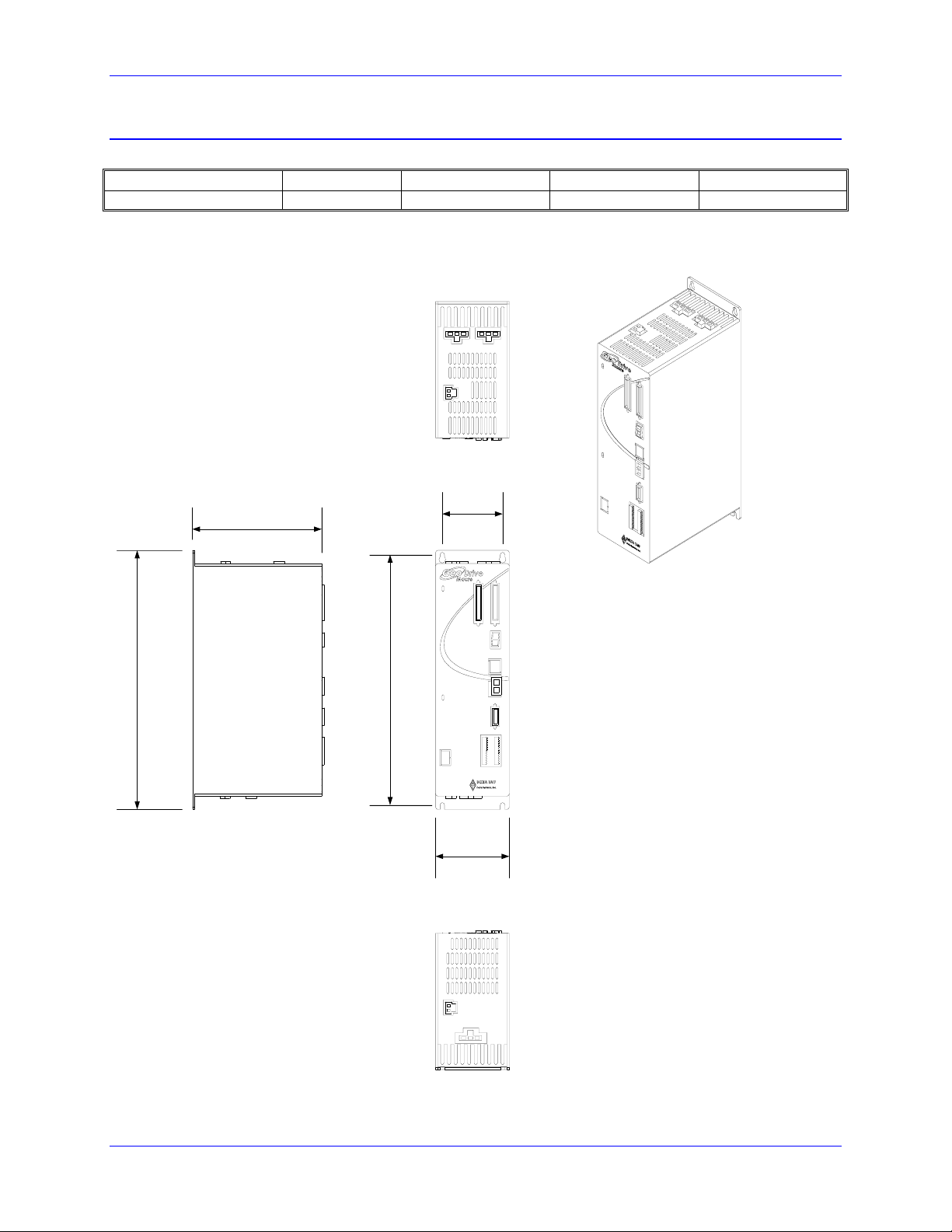

Package Types

Geo package types provide various power levels and one or two axis capability with three different

package types.

The Geo Drive has a basic package size of 3.3"W x 11"H x 8.0"D(84mm W x 280mm H x 203mm D).

This size includes the heat sink and fan. In this package size, Single Width, the Geo can handle one or

two low-to-medium power axes or only a single axis for medium to high power.

The mechanical design of the Geo drive is such that it allows two heat sinks to be easily attached together

to provide two high power axes in a double width configuration. This double package size is 6.5" W x

11" H x 8.0" D (165 mm W x 280 mm H x 203 mm D). It provides a highly efficient package size

containing two axes of up to about 10kW each thus driving nearly 24kW of power, but using a single

interface card. This results in a highly cost effective package.

There is also one more package type only for the low power (1.5A/4.5A) single width Geo drive, model

Gxx012xx. This package substitutes the heatsink and the fan with a smaller plate which has the same

mounting pattern as the regular single width drive, making the units depth 2.2inches (56mm) less than the

single width drive, 5.8" D (148mm D).

• Low Profile: GMx012xx (only)

3.3" wide (84 mm) (no heatsink, no fan), Maximum Power Handling ~1200 watts

Package Dimensions: 3.3" W x 11" H x 5.8" D (84 mm W x 280 mm H x 148 mm D)

Weight: 4.3 lbs. (1.95kgs)

• Single Width: GMx051xx, GMx101xx, GMx151xx, GMH032xx, GMx052xx and GML102xx.

3.3" wide (84 mm)(with heatsink and fan), Maximum Power Handling ~12000 watts

GML032xx Single Width, with heatsink, no Fan (Weight 5.4lbs/2.45kgs)

Package Dimensions: 3.3" W x 11" H x 8.0" D (84 mm W x 280 mm H x 203 mm D)

Weight: 5.5 lbs. (2.50kgs)

• Double Width: GMx201xx, GMx301xx, GMH102xx and GMx152xx.

6.5” wide (164mm)(with heatsink and fan), Maximum Power Handling ~24,000 watts

Package Dimensions: 6.5" W x 11" H x 8.0" D (164 mm W x 280 mm H x 203 mm D)

Weight: 11.6lbs (5.3kgs)

8 Specifications

Page 21

Geo MACRO Drive User and Reference Manual

g

g

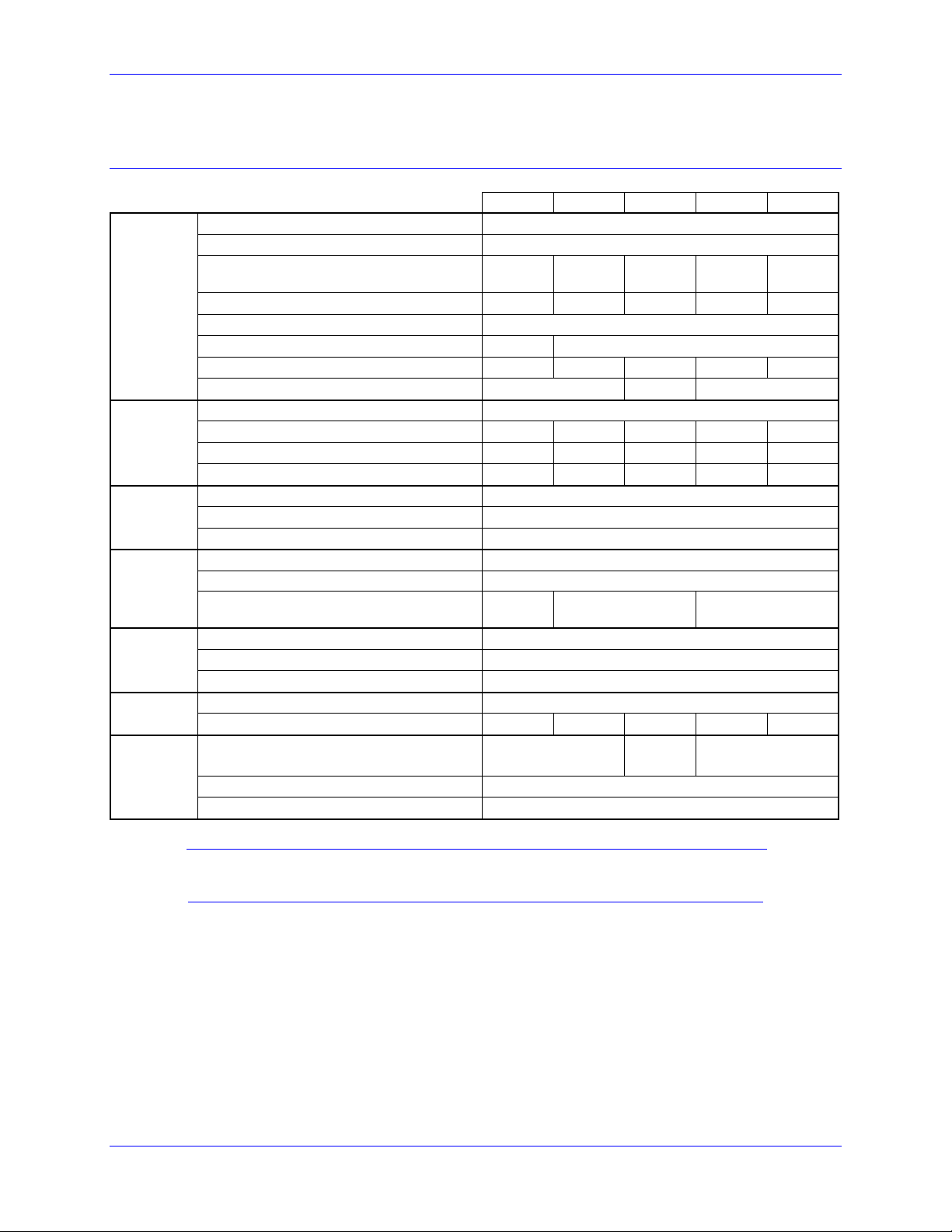

Electrical Specifications

230VAC Input Drives

Main

Input

Power

Output

Power

Bus

Protection

Shunt

Re

ulator

Ratings

Control

Lo

Power

Current

Feedback

Transistor

Control

GxL051 GxL101 GxL151 GxL201 GxL301

Nominal Input Voltage (VAC)

Rated Input Voltage (VAC)

Rated Continuous Input Current (A

AC

)

RMS

Rated Input Power (Watts)

Frequency (Hz)

Phase Requirements

Charge Peak Inrush Current (A)

Main Bus Capacitance (µf)

Rated Output Voltage (V)

Rated Cont. Output Current per Axis

Peak Output Current (A) for 2 seconds

Rated Output Power per Axis (Watts)

Nominal DC Bus

Over-voltage Trip Level (VDC)

Under-voltage Lockout Level (VDC)

Turn-On Voltage (VDC)

Turn-Off Voltage (VDC) 372

Delta Tau Recommended Load Resistor

(300 W Max.)

Input Voltage (VDC)

Input Current (A)

ic

Inrush Current (A)

Resolution (bits)

Full-scale Signed Reading (±A)

Delta Tau Recommended PWM

Frequency (kHz) @rated current

Minimum Dead Time (µs)

Charge Pump Time (% of PWM period.)

230

97-265

3.3 6.6 9.9 13.2 19.8

1315 2629 3944 5259 7888

50/60

1Φ or 3Φ 3Φ

3380 5020 6800

138

5 10 15 20 30

10 20 30 40 60

1195 2390 3585 4780 7171

325

410

10

392

GAR78 GAR48 GAR48-3

20-27

2A

4A

12

16.26 32.53

12 10 8

48.79 65.05 97.58

1

5

Note:

All values at ambient temperature of 0-45°C (113F) unless otherwise stated.

Specifications 9

Page 22

Geo MACRO Drive User Manual

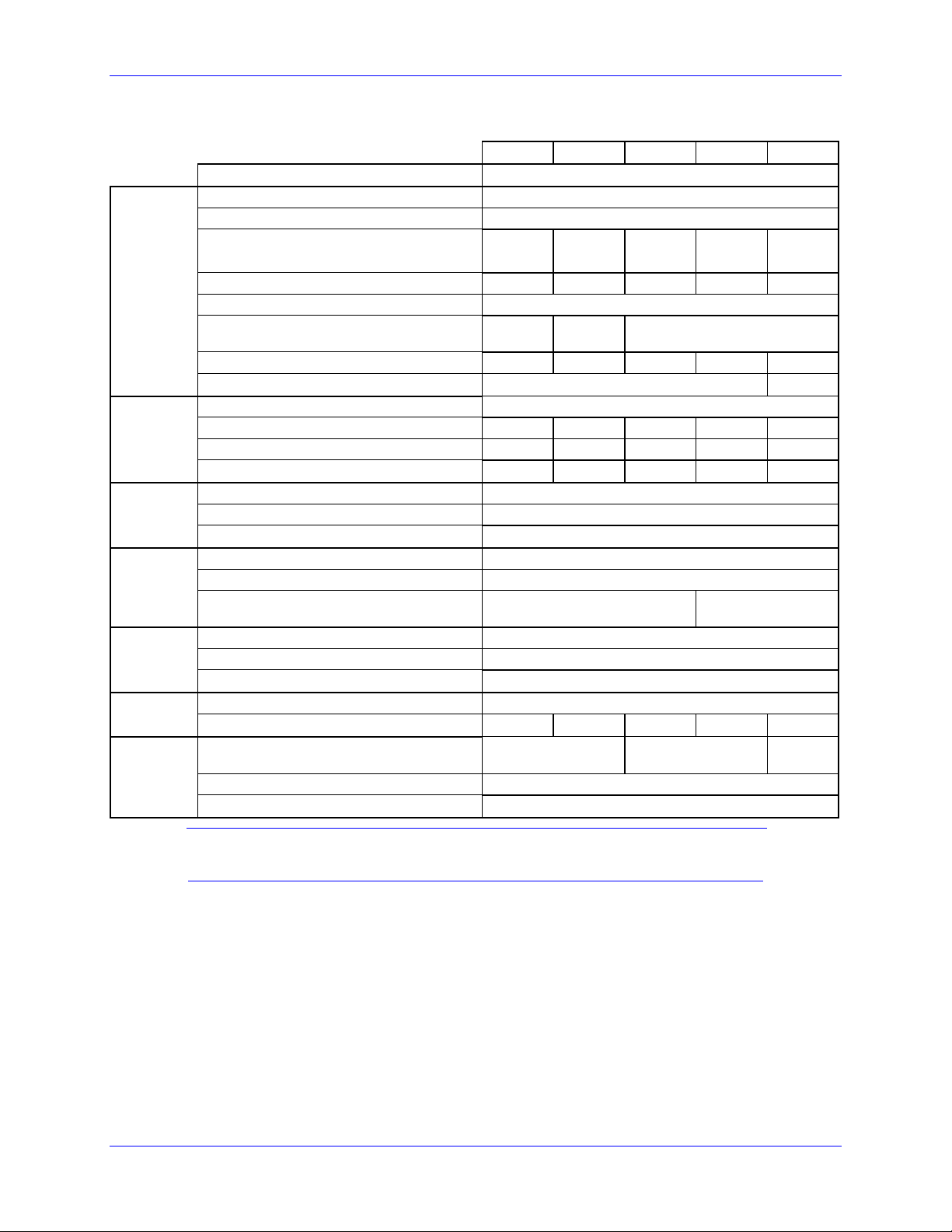

g

g

Main

Input

Power

Output

Power

Bus

Protection

Shunt

Re

ulator

Ratings

Control

Lo

ic

Power

Current

Feedback

Transistor

Control

GxL012 GxL032 GxL052 GxL102 GxL152

Output Circuits (axes)

Nominal Input Voltage (VAC)

Rated Input Voltage (VAC)

Rated Continuous Input Current (A

AC

)

RMS

Rated Input Power (Watts)

Frequency (Hz)

Phase Requirements

Charge Peak Inrush Current (A)

Main Bus Capacitance (µf)

Rated Output Voltage (V)

Rated Cont. Output Current per Axis

Peak Output Current (A) for 2 seconds

Rated Output Power per Axis (Watts)

Nominal DC Bus

Over-voltage Trip Level (VDC)

Under-voltage Lockout Level (VDC)

Turn-On Voltage (VDC)

Turn-Off Voltage (VDC)

Delta Tau Recommended Load Resistor

(300 W Max.)

Input Voltage (VDC)

Input Current (A)

Inrush Current (A)

Resolution (bits)

Full-scale Signed Reading (±A)

Delta Tau Recommended Maximum

PWM Frequency (kHz)

Minimum Dead Time (µs)

Charge Pump Time (% of PWM period.)

1.98 3.96 6.6 13.2 19.8

789 1578 2629 5259 7888

1Φ or 3Φ 1Φ or 3Φ 3Φ

1.5 3 5 10 15

4.5 9 10 20 30

359 717 1195 2390 3585

GAR78 GAR48

7.32 14.64

16 12 10

2

230

97-265

50/60

3380 5020

138

325

410

10

392

372

20-27

2A

4A

12

16.26 32.53

1

5

48.79

Note:

All values at ambient temperature of 0-45°C (113F) unless otherwise stated.

10 Specifications

Page 23

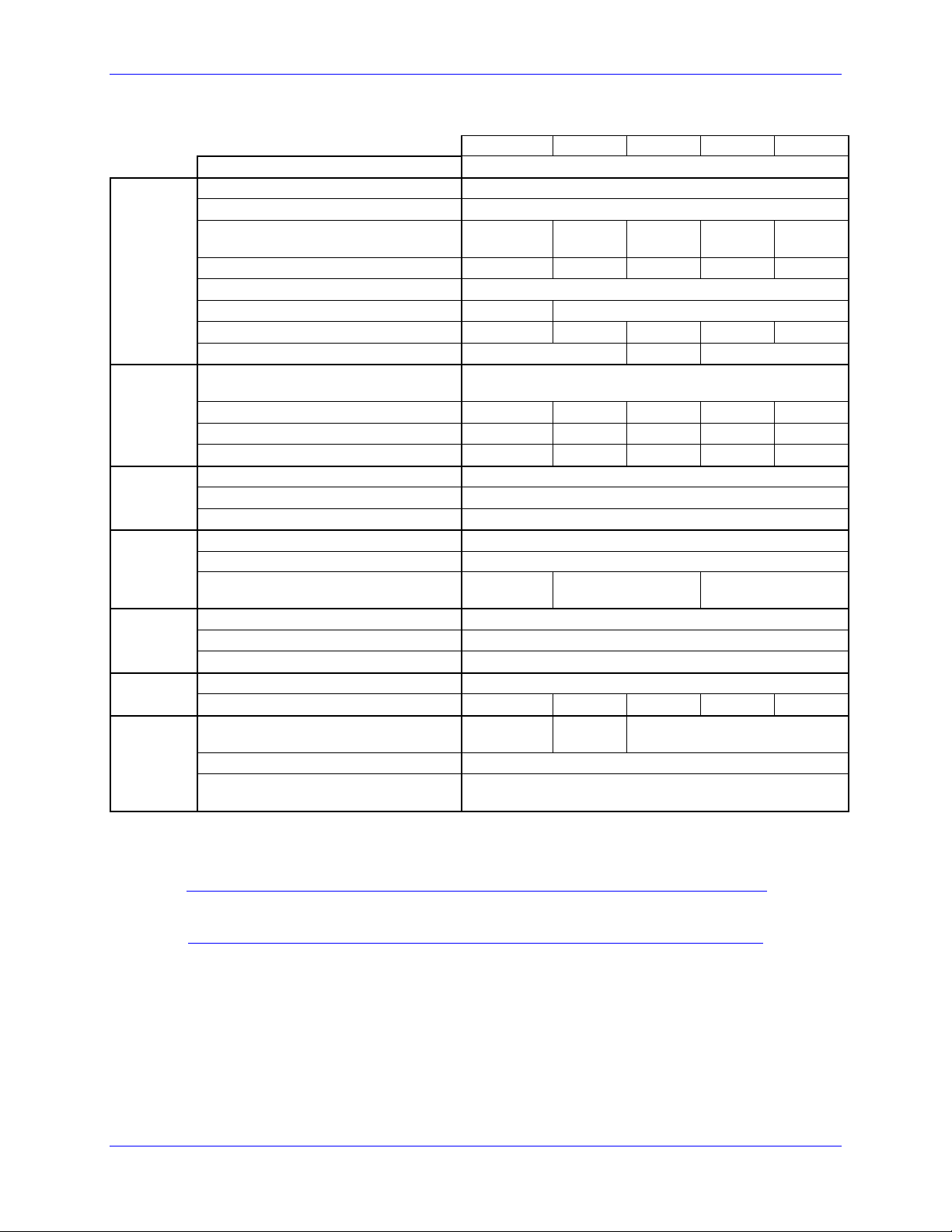

Geo MACRO Drive User and Reference Manual

g

g

480VAC Input Drives

Main

Input

Power

Bus

Protection

Shunt

Re

ulator

Ratings

Control

Lo

Power

Current

Feedback

Transistor

Control

GxH051 GxH101 GxH151 GxH201 GxH301

Output Circuits (axes)

Nominal Input Voltage (VAC)

Rated Input Voltage (VAC)

Rated Continuous Input Current (A

AC

)

RMS

Rated Input Power (Watts)

Frequency (Hz)

Phase Requirements

Charge Peak Inrush Current (A)

Main Bus Capacitance (µf)

Rated Output Voltage (V) @ Rated

Current

Rated Cont. Output Current per Axis

Peak Output Current (A) for 2 seconds

Rated Output Power per Axis (Watts)

Nominal DC Bus

Over-voltage Trip Level (VDC)

Under-voltage Lockout Level (VDC)

Turn-On Voltage (VDC)

Turn-Off Voltage (VDC) 744

Delta Tau Recommended Load

Resistor (300 W Max.)

Input Voltage (VDC)

Input Current (A)

ic

Inrush Current (A)

Resolution (bits)

Full-scale Signed Reading (±Amperes)

Delta Tau Recommended PWM

Frequency (KHz) @ rated current

Minimum Dead Time (µs)

Charge Pump Time (% of PWM

period.)

1

480

300-525

3.3 6.6 9.9 13.2 19.8

2744 5487 8231 10974 16461

50/60

1Φ or 3Φ 3Φ

845 1255 1700

288

5 10 15 20 30

10 20 30 40 60

2494 4988 7482 9977 14965

678

828

20

784

GAR78 GAR48 GAR48-3

20-27

2A

4A

12

16.26 32.53 48.79 65.05 97.58

12 10 8

1.6

5

Note:

All values at ambient temperature of 0-45°C (113F) unless otherwise stated.

Specifications 11

Page 24

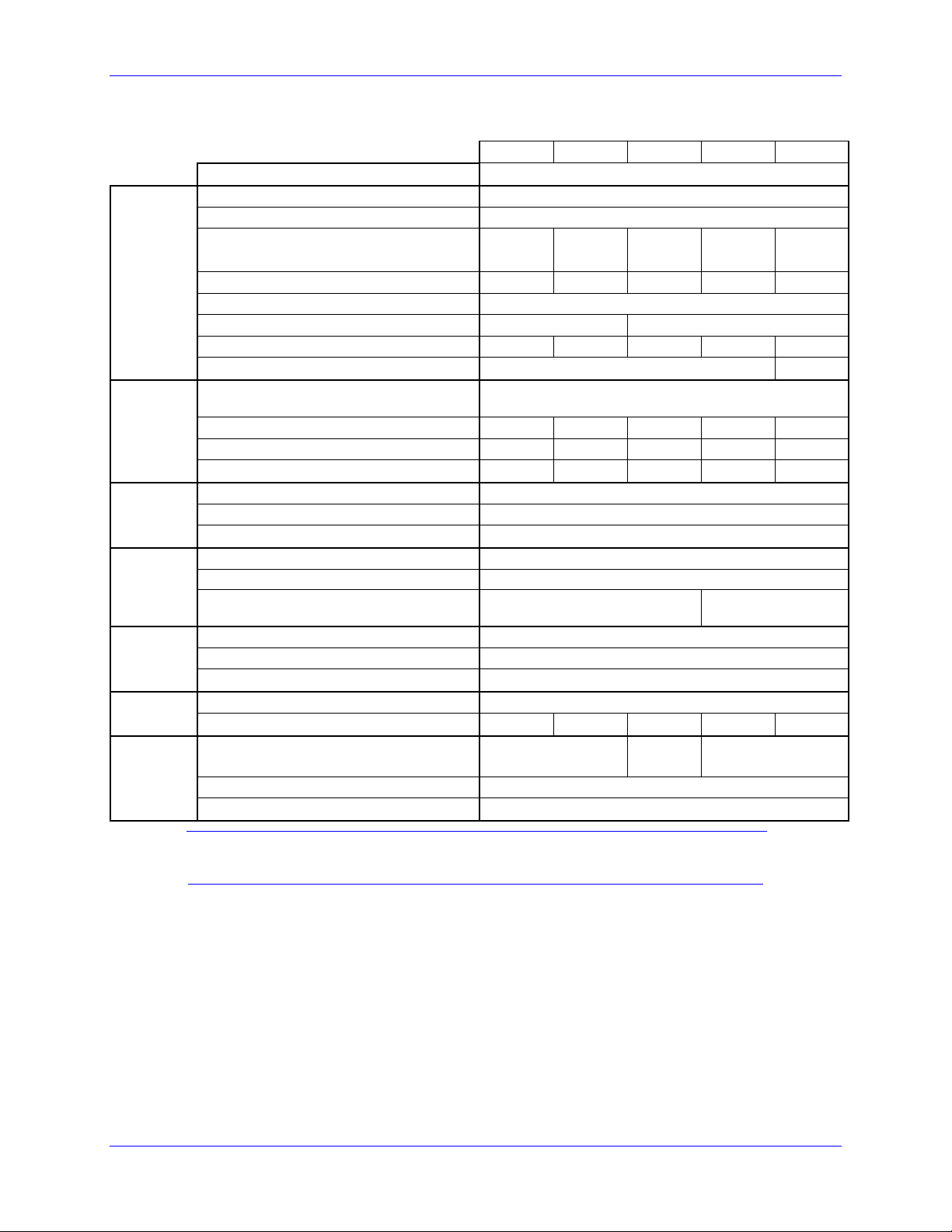

Geo MACRO Drive User Manual

g

g

Main

Input

Power

Bus

Protection

Shunt

Re

ulator

Ratings

Control

Lo

ic

Power

Current

Feedback

Transistor

Control

GxH012 GxH032 GxH052 GxH102 GxH152

Output Circuits (axes)

Nominal Input Voltage (VAC)

Rated Input Voltage (VAC)

Rated Continuous Input Current (A

AC

)

RMS

Rated Input Power (Watts)

Frequency (Hz)

Phase Requirements

Charge Peak Inrush Current (A)

Main Bus Capacitance (µf)