Page 1

Single Source Machine Control

……………………………………………..…...……………….

Power // Flexibility // Ease of Use

21314 Lassen St. Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^3 Programmable Servo Amplifier

^4 5xx-603800-xUxx

^5 February 14, 2015

^1 USER MANUAL

^2 Geo Brick Drive

DELTA TAU

Data Systems, Inc.

NEW IDEAS IN MOTION …

Page 2

Geo Brick Drive User Manual

Copyright Information

© 2015 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses are

unauthorized without written permission of Delta Tau Data Systems, Inc. Information contained in this

manual may be updated from time-to-time due to product improvements, etc., and may not conform in

every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Web: www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller, accessory, and amplifier products contain static

sensitive components that can be damaged by incorrect handling. When installing or handling Delta Tau

Data Systems, Inc. products, avoid contact with highly insulated materials. Only qualified personnel

should be allowed to handle this equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial environment, install

them into an industrial electrical cabinet to protect them from excessive or corrosive moisture, abnormal

ambient temperatures, and conductive materials. If Delta Tau Data Systems, Inc. products are directly

exposed to hazardous or conductive materials and/or environments, we cannot guarantee their operation.

Page 3

Geo Brick Drive User Manual

WARNING

A Warning identifies hazards that could result in personal injury

or death. It precedes the discussion of interest.

Caution

A Caution identifies hazards that could result in equipment damage. It

precedes the discussion of interest.

Note

A Note identifies information critical to the user’s understanding or

use of the equipment. It follows the discussion of interest.

Safety Instructions

Qualified personnel must transport, assemble, install, and maintain this equipment. Properly qualified

personnel are persons who are familiar with the transport, assembly, installation, and operation of

equipment. The qualified personnel must know and observe the following standards and regulations:

IEC364resp.CENELEC HD 384 or DIN VDE 0100

IEC report 664 or DIN VDE 0110

National regulations for safety and accident prevention or VBG 4

Incorrect handling of products can result in injury and damage to persons and machinery. Strictly adhere

to the installation instructions. Electrical safety is provided through a low-resistance earth connection. It

is vital to ensure that all system components are connected to earth ground.

This product contains components that are sensitive to static electricity and can be damaged by incorrect

handling. Avoid contact with high insulating materials (artificial fabrics, plastic film, etc.). Place the

product on a conductive surface. Discharge any possible static electricity build-up by touching an

unpainted, metal, grounded surface before touching the equipment.

Keep all covers and cabinet doors shut during operation. Be aware that during operation, the product has

electrically charged components and hot surfaces. Control and power cables can carry a high voltage,

even when the motor is not rotating. Never disconnect or connect the product while the power source is

energized to avoid electric arcing.

2

Page 4

Geo Brick Drive User Manual

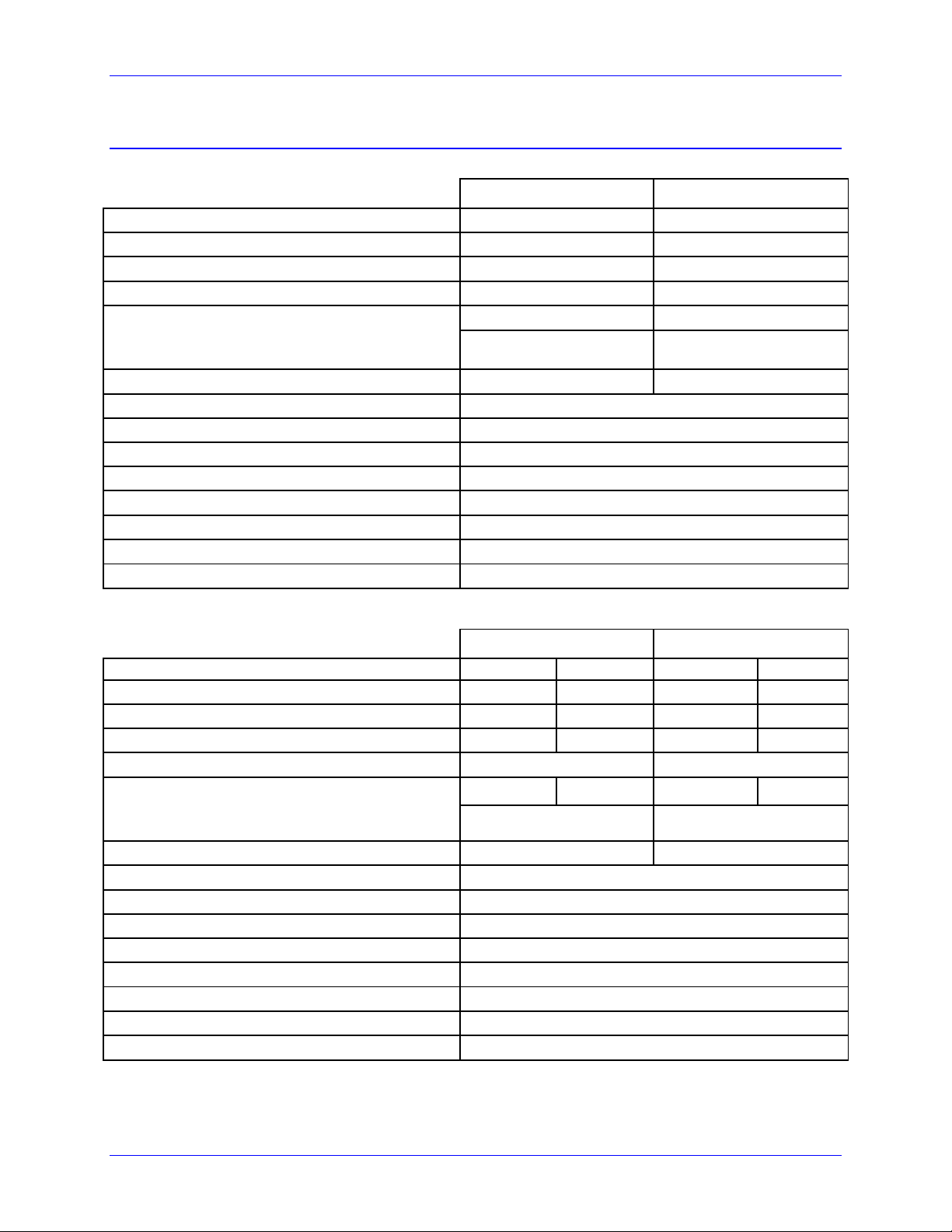

MANUAL REVISION HISTORY

REV

DESCRIPTION

DATE

CHANGE

APPROVED

10

MANUAL REFORMATTING. CORRECTIONS AVAILABLE UPON

REQUEST.

8/10/11

R.N

R.N

11

CORRECTED Ixx71 FOR QUADRATURE LINEAR

10/10/11

R.N

R.N

12

UPDATED +5V ENC PWR SECTION

10/13/11

R.N

R.N

13

UPDATED ABSOLUTE SERIAL ENCODER SECTION. GENERAL

UPDATES.

4/15/12

R.N

R.N

14

- UPDATED PART NUMBER TREE

- UPDATED UPDATES AND MODIFICATIONS SECTION

- UPDATED MAIN POWER INPUT SECTION

- ADDED POWER ON/OFF SEQUENCE

- UPDATED LOGIC POWER INPUT SECTION

- ADDED STO INFORMATION

- UPDATED X9-X12 SECTION

- UPDATED MACRO CONNECTIVITY SECTION

- ADDED SERIAL N0 AND BOARD IDENTIFICATION

- CORRECTED IXX81 TABLE IN HALLS

- GENERAL FORMATTING, CORRECTIONS, AND UPDATES

12/14/12

R.N

R.N

15

MISCELLANEOUS CORRECTIONS.

02/24/14

R.N

R.N

16

- CORRECTED ENCODER LOSS FOR SINUSOIDAL ENCODERS

- UPDATED GP IO, LIMITS EQU SECTIONS

- CORRECTED HALLS SCALE FACTOR

- GENERAL FORMATTING AND UPDATES

02/04/2015

R.N

R.N

Note

Older revision correction notes have been removed for obsolescence

and clarity.

3

Page 5

4

Page 6

Geo Brick Drive User Manual

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................... 12

Documentation ............................................................................................................................12

Downloadable Turbo PMAC Script ...............................................................................................13

SPECIFICATIONS ................................................................................................................. 14

Part Number ...............................................................................................................................14

Geo Brick Drive Options ..............................................................................................................16

Environmental Specifications ........................................................................................................17

Protection Specifications ..............................................................................................................17

Agency Approvals .......................................................................................................................17

Electrical Specifications ...............................................................................................................18

4-Axis Geo Brick Drive ..................................................................................................................... 18

6-Axis Geo Brick Drive ..................................................................................................................... 18

8-Axis Geo Brick Drive ..................................................................................................................... 19

RECEIVING AND UNPACKING ......................................................................................... 20

Use of Equipment ........................................................................................................................20

MOUNTING ........................................................................................................................... 21

Connector Locations ....................................................................................................................22

4-Axis Geo Brick Drive ...............................................................................................................23

6-Axis Geo Brick Drive ...............................................................................................................24

8-Axis Geo Brick Drive ...............................................................................................................25

PINOUTS AND SOFTWARE SETUP ................................................................................... 26

J1: Main Bus Power Input ............................................................................................................26

Power On/Off Sequence .................................................................................................................... 27

Cycling Main Bus Power .................................................................................................................. 27

Recommended Main Bus Power Wiring/Protection ........................................................................... 29

J2: 24VDC Logic Power and Safe Torque Off (STO) .......................................................................33

Older Models ................................................................................................................................... 34

Newer Models .................................................................................................................................. 34

Disabling the STO (Backward compatibility) .................................................................................... 35

Wiring and Using the STO ................................................................................................................ 35

J3: External Shunt Resistor ...........................................................................................................36

J4: Limits, Flags, EQU [Axis 1- 4].................................................................................................38

J5: Limits, Flags, EQU [Axis 5- 8].................................................................................................39

Wiring the Limits and Flags ............................................................................................................. 40

Limits and Flags [Axis 1- 4] Suggested M-Variables ........................................................................ 41

Limits and Flags [Axis 5- 8] Suggested M-Variables ........................................................................ 41

J6: General Purpose Inputs/Outputs ...............................................................................................42

J7: General Purpose Inputs/Outputs (Additional) ................................................................ .............43

About the Digital Inputs and Outputs ................................................................................................ 44

Table of Contents vi

Page 7

Geo Brick Drive User Manual

Wiring the Digital Inputs and Outputs .............................................................................................. 45

General Purpose I/Os (J6) Suggested M-Variables ........................................................................... 46

General Purpose I/Os Additional (J7) Suggested M-Variables ................................ .......................... 46

J8: PWM Amplifier Interface ................................ ................................ ................................ ........47

J9: Handwheel and Analog I/O ......................................................................................................48

Setting up the Analog Inputs (J9) ...................................................................................................... 49

Setting up the Analog Output (J9) ..................................................................................................... 51

Setting up Pulse And Direction Output PFM (J9).............................................................................. 53

Setting up the Handwheel Port (J9) .................................................................................................. 55

X1-X8: Encoder Feedback, Digital A Quad B .................................................................................56

Setting up Quadrature Encoders ....................................................................................................... 58

Encoder Count Error (Mxx18) .......................................................................................................... 58

Encoder Loss Detection, Quadrature ................................................................................................ 59

Step and Direction PFM Output (To External Stepper Amplifier) ...................................................... 61

X1-X8: Encoder Feedback, Sinusoidal ...........................................................................................64

Setting up Sinusoidal Encoders ......................................................................................................... 65

Counts Per User Units ...................................................................................................................... 66

Encoder Count Error (Mxx18) .......................................................................................................... 67

Encoder Loss Detection, Sinusoidal .................................................................................................. 68

X1-X8: Encoder Feedback, Resolver .............................................................................................69

Setting up Resolvers ......................................................................................................................... 69

Resolver Excitation Magnitude ................................ ......................................................................... 70

Resolver Excitation Frequency ......................................................................................................... 70

X1-X8: Encoder Feedback, HiperFace ...........................................................................................75

Setting up HiperFace On-Going Position.......................................................................................... 76

Setting up HiperFace Absolute Power-On Position ........................................................................... 78

Setting up HiperFace Encoders Example .......................................................................................... 82

Encoder Count Error (Mxx18) .......................................................................................................... 87

Encoder Loss Detection, HiperFace ................................................................................................. 88

X1-X8: Encoder Feedback, SSI ................................ ................................ .....................................89

Configuring SSI ................................................................................................................................ 89

SSI Control Registers Setup Example ................................................................................................ 93

X1-X8: Encoder Feedback, EnDat 2.1/2.2 ......................................................................................95

Configuring EnDat ................................................................................................ ........................... 95

EnDat Control Registers Setup Example ................................................................ ........................... 99

X1-X8: Encoder Feedback, BiSS C/B .......................................................................................... 101

Configuring BiSS ............................................................................................................................ 101

BiSS Control Registers Setup Example............................................................................................ 105

Setting up SSI | EnDat | BiSS ...................................................................................................... 107

Setup Summary ............................................................................................................................... 108

Technique 1 Example ..................................................................................................................... 110

Technique 2 Example ..................................................................................................................... 113

Technique 3 Example ..................................................................................................................... 118

X1-X8: Encoder Feedback, Yaskawa Sigma II & III ...................................................................... 123

Yaskawa Sigma II 16-Bit Absolute Encoder .................................................................................... 128

Table of Contents vii

Page 8

Geo Brick Drive User Manual

Yaskawa Sigma II 17-Bit Absolute Encoder .................................................................................... 131

Yaskawa Sigma III 20-Bit Absolute Encoder ................................................................................... 134

Yaskawa Sigma II 13-Bit Incremental Encoder ............................................................................... 137

Yaskawa Sigma II 17-Bit Incremental Encoder ............................................................................... 139

Yaskawa Incremental Encoder Alarm Codes ................................................................................... 141

Homing with Yaskawa Incremental Encoders ................................................................................. 142

X9-X10: Analog Inputs/Outputs .................................................................................................. 143

X11-X12: Analog Inputs/Outputs ................................................................................................ 143

Setting up the Analog (ADC) Inputs ................................................................................................ 144

Setting up the Analog (DAC) Outputs ............................................................................................. 146

Setting up the General Purpose Relay, Brake .................................................................................. 148

Setting up the External Amplifier Fault Input .................................................................................. 150

X13: USB 2.0 Connection .......................................................................................................... 151

X14: RJ45, Ethernet Connection ................................................................................................. 151

X15: Watchdog and ABORT (TB2) ............................................................................................. 152

Wiring the Abort Input .................................................................................................................... 152

Wiring the Watchdog Output .......................................................................................................... 153

RS232: Serial Communication Port ............................................................................................. 154

A1 - A8: Motor Wiring ................................................................................................ .............. 155

Motor Cable, Noise Elimination ..................................................................................................... 156

Motor Selection .............................................................................................................................. 158

+5V ENC PWR (Alternate Encoder Power) .................................................................................. 160

Wiring the Alternate (+5V) Encoder Power .................................................................................... 161

Functionality, Safety Measures ....................................................................................................... 162

MOTOR SETUP ................................................................................................................... 163

Motor Setup Flow Chart ............................................................................................................. 163

Dominant Clock Settings ................................................................................................ ............ 164

ADC Strobe Word (I7m06) ......................................................................................................... 166

AC/DC Brushless (Rotary/Linear) Motor Setup ............................................................................ 167

Before you start ................................................................ .............................................................. 167

Commutation Angle, Current Mask: Ixx72, Ixx84............................................................................ 167

PWM Scale Factor: Ixx66............................................................................................................... 167

Current Feedback Address: Ixx82 ................................................................................................... 167

Commutation Position Address, Commutation Enable: Ixx83, Ixx01 ............................................... 168

I2T Protection: Ixx57, Ixx58, Ixx69 ................................................................................................. 170

Commutation Cycle Size: Ixx70, Ixx71 ............................................................................................ 171

ADC Offsets: Ixx29, Ixx79 .............................................................................................................. 172

Current-Loop Tuning: Ixx61, Ixx62, Ixx76 ...................................................................................... 173

Motor Phasing, Power-On Mode: Ixx73, Ixx74, Ixx80, Ixx81, Ixx91 ................................................ 174

Open-Loop Test, Encoder Decode: I7mn0 ...................................................................................... 194

Position-Loop PID Tuning: Ixx30…Ixx39 ....................................................................................... 196

High Speed Motors ......................................................................................................................... 197

AC Induction (Asynchronous) Motor Setup – With Encoder ........................................................... 198

Before you start ................................................................ .............................................................. 198

Table of Contents viii

Page 9

Geo Brick Drive User Manual

Commutation Angle, Current Mask: Ixx72, Ixx84............................................................................ 198

PWM Scale Factor: Ixx66............................................................................................................... 198

Current Feedback Address: Ixx82 ................................................................................................... 198

Commutation Position Address, Commutation Enable: Ixx83, Ixx01 ............................................... 199

Magnetization Current, Slip Gain: Ixx77 ........................................................................................ 199

Motor Slip Gain: Ixx78 ................................................................................................................... 199

I2T Protection: Ixx57, Ixx58, Ixx69 ................................................................................................. 200

Commutation Cycle Size: Ixx70, Ixx71 ............................................................................................ 201

ADC Offsets: Ixx29, Ixx79 .............................................................................................................. 201

Current-Loop Tuning: Ixx61, Ixx62, Ixx76 ...................................................................................... 201

Open-Loop Test, Encoder Decode: I7mn0 ...................................................................................... 202

Position-Loop PID Tuning: Ixx30…Ixx39 ....................................................................................... 204

Optimizing Magnetization Current Ixx77, Slip Gain Ixx78 .............................................................. 205

Correcting I2T Settings .................................................................................................................. 207

Closed-Loop vs. Open-Loop Operation ........................................................................................... 207

Field Weakening............................................................................................................................. 208

High Speed Spindles ....................................................................................................................... 209

AC Induction (Asynchronous) Motor Setup – Without Encoder, Direct Micro-Stepping .................... 210

Before you start ................................................................ .............................................................. 210

Encoder Conversion Table Setup .................................................................................................... 210

Motor Activation, Position, Velocity Pointers: Ixx03, Ixx04 ............................................................ 211

Commutation Angle, Current Mask, Flag Mode Control: Ixx72, Ixx84, Ixx24.................................. 211

PWM Scale Factor: Ixx66............................................................................................................... 211

Current Feedback Address: Ixx82 ................................................................................................... 211

Commutation Position Address, Commutation Enable: Ixx83, Ixx01 ............................................... 211

Commutation Cycle size: Ixx70, Ixx71 ............................................................................................ 211

Maximum Achievable Motor Speed, Output Command Limit: Ixx69 ................................................ 212

I2T Protection, Magnetization Current: Ixx57, Ixx58, Ixx69, Ixx77 ................................................. 213

Magnetization Current: Ixx77 ................................................................ ......................................... 213

Motor Slip Gain: Ixx78 ................................................................................................................... 214

ADC Offsets: Ixx29, Ixx79 .............................................................................................................. 214

Current-Loop Tuning: Ixx61, Ixx62, Ixx76 ...................................................................................... 215

Position-Loop PID Tuning: Ixx30…Ixx39 ....................................................................................... 215

Moving the Motor ........................................................................................................................... 216

DC Brush Motor Setup ............................................................................................................... 217

Before you start ................................................................ .............................................................. 217

Phasing Search Error Bit, Current-Loop Integrator Output (Ixx96) ................................................ 217

Commutation Enable, Phase Angle, Current Mask: Ixx01, Ixx72, Ixx84 .......................................... 217

PWM Scale Factor: Ixx66............................................................................................................... 218

Current Feedback Address: Ixx82 ................................................................................................... 218

Commutation Cycle Size: Ixx70, Ixx71 ............................................................................................ 218

I2T Protection: Ixx57, Ixx58, Ixx69 ................................................................................................. 219

ADC Offsets: Ixx29, Ixx79 .............................................................................................................. 220

Current-Loop Gains, Open-Loop/Enc. Decode: Ixx61, Ixx62, Ixx76, I7mn0 .................................... 220

Position-Loop PID Gains: Ixx30…Ixx39 ......................................................................................... 221

MACRO CONNECTIVITY ................................................................................................ . 222

Table of Contents ix

Page 10

Geo Brick Drive User Manual

Introduction to MACRO ............................................................................................................. 222

MACRO Configuration Examples ............................................................................................... 223

Review: MACRO Nodes and Addressing ......................................................................................... 224

Review: MACRO Auxiliary Commands ........................................................................................... 225

Configuration Example 1: Brick - Brick ....................................................................................... 226

Setting up the Slave in Torque Mode ............................................................................................... 227

Setting up the Master in Torque Mode ............................................................................................ 230

Setting up the Slave in PWM Mode ................................................................................................. 233

Setting up the Master in PWM Mode............................................................................................... 234

Configuration Example 2: Brick – Geo MACRO Drive .................................................................. 240

Brick – Brick MACRO I/O Data Transfer..................................................................................... 248

Transferring the Digital (Discrete) Input and Outputs .................................................................... 249

Transferring the X9-X12 Analog Inputs/Outputs ............................................................................. 254

Transferring the J9 Analog Inputs .................................................................................................. 256

MACRO Limits, Flags and Homing ............................................................................................. 257

Limits and Flags ................................................................ ............................................................. 257

Homing from Master ...................................................................................................................... 257

Homing from Slave ......................................................................................................................... 257

MACRO Suggested M-Variables ..................................................................................................... 258

Absolute Position Reporting over MACRO .................................................................................. 260

MACRO Configuration Power-Up Sequence ................................................................................ 260

DRIVE STRUCTURE AND TROUBLESHOOTING ........................................................ 261

Geo Brick Drive Structure ................................ ................................ .......................................... 261

Serial Number and Board Revisions Identification ......................................................................... 262

Default Mode, Strobe Word (I7m06) Setting ................................................................................. 263

Enhanced Mode (Reading IGBT Temperature and Bus Voltage) ..................................................... 264

Error Codes ................................ ................................ .............................................................. 265

Axis Faults (n = 1 - 8) .................................................................................................................... 265

Global Faults ................................................................................................................................. 266

Reading IGBT Temperature and Bus Voltage ................................................................................. 267

Calculating Motor Current Output Example ................................................................................... 268

LED Status ............................................................................................................................... 269

Error 18 (Erro18) ....................................................................................................................... 270

Watchdog Timer Trip................................................................................................................. 271

Geo Brick Drive Specific Online Commands ................................................................................ 272

Type ............................................................................................................................................... 272

Ampversion .................................................................................................................................... 273

Ampmod ......................................................................................................................................... 273

Ampsid ........................................................................................................................................... 274

Ampclrf ................................................................................................ .......................................... 274

Boot Switch SW (Firmware Reload) – Write-Protect Disable .......................................................... 275

Reloading PMAC firmware............................................................................................................. 276

Changing IP Address, Gateway IP, Gateway Mask ......................................................................... 278

Enabling ModBus ........................................................................................................................... 279

Table of Contents x

Page 11

Geo Brick Drive User Manual

Reloading Boot and Communication Firmware .............................................................................. 280

Reset Switch SW (Factory Reset) ................................................................................................ 281

LIST OF CHANGES AND UPDATES ................................................................ ................ 282

AMPVER Command, December 2007 ......................................................................................... 282

External Encoder Power Supply Connector, April 2010 ................................................................. 283

EEPROM Write-Protect Enable. April 2010 ................................................................................. 283

AMPVER Fail-Safe Mechanism. Configuration Error, May 2010 .................................................... 284

Modifications and Improvements, October 2012 ........................................................................... 285

Control board................................................................................................................................. 285

Power board(s) .............................................................................................................................. 285

APPENDIX A ........................................................................................................................ 286

Schematic Samples .................................................................................................................... 286

APPENDIX B ........................................................................................................................ 289

DB Connector Spacing Specifications .......................................................................................... 289

APPENDIX C ........................................................................................................................ 290

Control Board Jumpers (For Internal Use) ................................................................ .................... 290

APPENDIX D ........................................................................................................................ 292

Absolute Serial Encoders Limitation With Turbo PMAC................................................................ 292

Table of Contents xi

Page 12

Geo Brick Drive User Manual

INTRODUCTION

The Geo Brick Drive combines the intelligence and capability of the Turbo PMAC2 motion controller

with IGBT-based drive technology, resulting in a compact, smart 4-, 6- or 8-axis servo drive package.

The flexibility of the Turbo PMAC2 enables the Geo Brick to drive Brush, Brushless or AC induction

motors with unsurpassed pure digital DSP performance. The absence of analog signals – required for

typical motion controller/drive interfacing – enables higher gains, better overall performance and tighter

integration, while significantly driving down costs and setup time.

The Geo Brick’s embedded 32-axis Turbo PMAC2 motion controller is programmable for virtually any

kind of motion control application. The built-in software PLCs allow for complete machine logic control.

The Geo Brick Drive supports the following types of motors:

Three-phase AC/DC brushless, synchronous rotary/linear

DC brush

AC Induction, asynchronous – with or without encoder

Stepper output to third party drives or through MACRO connectivity

Documentation

In conjunction with this user manual, the Turbo Software Reference Manual and Turbo PMAC User

Manual are essential for proper use, motor setup, and configuration of the Geo Brick Drive. It is highly

recommended to refer to the latest revision of the manuals found on Delta Tau’s website, under

Support>documentation>Manuals: Delta Tau Manuals

Introduction 12

Page 13

Geo Brick Drive User Manual

Caution

Some code examples require the user to input specific information

pertaining to their system hardware. When user information is

required, a commentary ending with –User Input is inserted.

Caution

All PLC examples are stated in PLC number 1. It is the user’s

responsibility to arrange their application PLCs’ properly and handle

power-on sequencing for various tasks.

Caution

Often times, downloadable example codes use suggested M-variables,

it is the user’s responsibility to make sure they are downloaded, or

perform necessary changes to use the intended registers.

Downloadable Turbo PMAC Script

This manual contains downloadable code samples in Turbo PMAC script. These examples can be copied

and pasted into the editor area in the Pewin32pro2. Care must be taken when using pre-configured Turbo

PMAC code, some information may need to be updated to match hardware and system specific

configurations. Downloadable Turbo PMAC Scripts are enclosed in the following format:

// TURBO PMAC SCRIPT EXAMPLE

P1=0 ; Set P1=0 at download

Open PLC 1 Clear ; Open PLC Buffer 1, clear contents

CMDP"Geo Brick User Manual Test PLC" ; Send unsolicited response to host port

P1=P1+1 ; Counter using variable P1

Disable PLC 1 ; Disable plc 1

Close ; Close open buffer

It is the user’s responsibility to use the PLC examples presented in this manual properly. That is,

incorporating the statement code in the application configuration, and handling tasks in a sequential

manner. For example, with serial absolute encoders, setting up the global control registers should be

executed before trying to read absolute position, and absolute phase referencing. Furthermore, other PLC

programs (which would be trying to move motors) should be disabled until these functions are executed.

Introduction 13

Page 14

Geo Brick Drive User Manual

B L 0 0 0 00C 5

- -

04 0 00 0 0

** ** ** **

G

Axes GBLA-BB-CDD-EFGHHHI0

4 : Four Axes Silver Enclosure

6 : Six Axes Silver Enclosure

8 : Eight Axes Silver Enclosure

CPU Options – GBLA-BB-CDD-EFGHHHI0

Turbo PMAC 2 Processor

C0: 80Mhz, 8Kx24 Internal, 256Kx24SRAM, 1MB Flash (Default)

C3: 80Mhz, 8Kx24 Internal, 1Mx24SRAM, 4MB Flash

F3: 240Mhz, 192Kx24 Internal, 1Mx24SRAM, 4MB Flash

Axes 1 to 4 Options GBLA-BB-CDD-EFGHHHI0

5: 5A/10A, with encoders and Flags for every axis (Default)

8: 8A/16A, with encoders and Flags for every axis

(Continuous / Peak)

4

axes

5-8 axis, 5A/10A, with encoder inputs for all axes

5-8 axis, 8A/16A, with encoder inputs for all axes

5 and 6 axis, 15A/30A, with encoders for channels 5 to 8 (2 secondary encoders)

5 and 6 axis, 15A/30A, plus PWM amplifier Interface for channel 7 with 2 secondary encoders on 7 & 8)

Axes 5 to 8 Options GBLA-BB-CDD-EFGHHHI0

If user wants to order 5V flag inputs then he needs to specify it at the Axes 5 to 8 options

For example:

“05" No secondary encoder inputs (total of 4 encoder inputs), 5V Flag inputs

“07" Four secondary encoder inputs (total of 8 encoder inputs), 5V Flag inputs

“W8” Hi-Power 5 & 6 axes, plus PWM amplifier Interface for channels 7 (total of 8 encoder inputs) , 5V Flag inputs

If the above Number of Amplifier Axes are selected then only the corresponding Axes 5 to 8 Options are available.

12-24V 5V Flags

00

05

02

P3

F2

W3

07

P8

F7

W8

52

57

82

87

6

axes

8

axes

Digital I/O Option GBLA-BB-CDD-EFGHHHI0

0: 16 IN / 8 OUT (Default)

1: Expanded digital I/O, additional 16 inputs and 8 outputs

(Total of 32 IN / 16 OUT)

Outputs are rated: 0.5A@12-24VDC

No options, 4-axis system

Four secondary encoders inputs (total of 8 encoder inputs)

PWM amplifier Interface for channel 7 with encoders for axes 5 to 8 ( 4 secondary encoders)

0: No options (Default)

2: Four GPIO Relays (On connectors X9-X12)

3: Two Analog In, two analog Out (On conn. X11-X12) & 4 GPIO Relays (On connectors X9-X12)

4: Four Analog In, four analog Out (On conn. X9-X12) & 4 GPIO Relays (On connectors X9-X12)

5: Two Analog In, two analog Out (On conn. X11-X12) & 2 AENA Relays for Chan. 3&4 (On conn. X11-X12) and 2 GPIO Relays

(On conn. X9-X10)

6: Four Analog In, four analog Out (Connectors X9-X12) with 2 AENA Relays for Chan. 3&4 (On conn. X11-X12) and 2 GPIO

Relays (On conn. X9-X10)

9: Two AENA Relays for Chan.3&4 (Conn.X11-X12) and 2 GPIO Relays (On conn.X9-X10)

4 axes

00 / 05

02 / 07

Note: Analog outputs are 12-bit filtered PWM and Analog Inputs are 16-bit.

0: No Analog Options available, for this configurations

To receive Analog Inputs for these configurations, you must order GBLA-BB-CDD-EFGHHHI0 MUXED ADC

Option in “MACRO and Special Feedback Options”

2: Four GPIO Relays (On connectors X9-X12)

9: Four AENA Relays for Chan.3&4 (On conn.X11-X12) and Chan.5&6 (On conn.X9-X10)

Analog I/O Options GBLA-BB-CDD-EFGHHHI0

4 axes

P3 / P8

0: No options (Default)

2: Four GPIO Relays (On connectors X9-X12)

7: Two Analog In, 2 analog Out (Conn.X9-X10) & 4 GPIO Relays (On connectors X9-X12)

8: Two Analog In, 2 analog Out (Conn.X9-X10) & 2 AENA Relays for Chan. 3&4 (On conn. X11-X12) and

2 GPIO Relays (On connectors X9-X10)

9: Two AENA Relays for Chan.3&4 (Conn.X11-X12) and 2 GPIO Relays (On conn.X9-X10)

6 axes

F2 / F7

0: No options (Default)

2: Four GPIO Relays (On connectors X9-X12)

3: Two Analog In, two analog Out (On conn. X11-X12) & 4 GPIO Relays (On connectors X9-X12)

5: Two Analog In, two analog Out (On conn. X11-X12) & 4 AENA Relays for Chan.3&4 (On conn.X11-X12) and

Chan.5&6 (On conn.X9-X10)

9: Four AENA Relays for Chan.3&4 (On conn.X11-X12) and Chan.5&6 (On conn.X9-X10)

8 axes

52 / 57

82 / 87

6 axes

W3 / W8

B C D E F G H I

A B

C

D

E

F

-

A

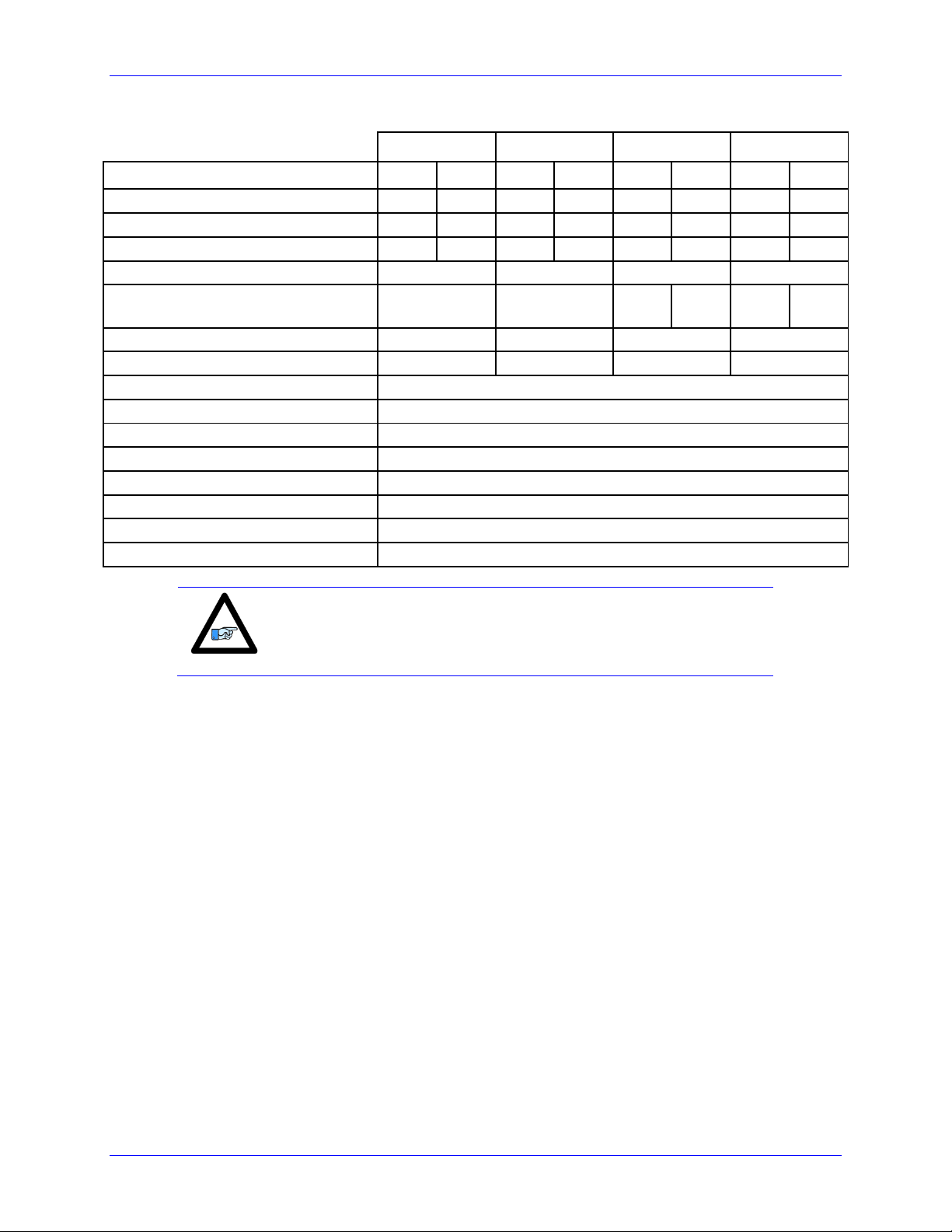

SPECIFICATIONS

Part Number

Specifications 14

Page 15

Geo Brick Drive User Manual

Communication Options GBLA-BB-CDD-EFGHHHI0

USB2 and Eth100 are included

Note: To use PMAC-NC software, DPRAM is required

0xxxxx: No Options, Default

Dxxxxx: DPRAM option, size 8K x 16-bit wide

Mxxxxx: ModBus Ethernet Communication Protocol (Software) option

Sxxxxx: DPRAM and Modbus Options Combined

R00000: RS232 port on 9-pin D-sub Connector*

E00000: DPRAM & RS232 Options Combined*

N00000: RS232 & ModBus Options Combined*

T00000: Modbus, DPRAM & RS232 Combined*

* If any of the “H” or “I” digits is non zero (GBLA-BB-CDD-EFGHHHI0) then RS232

is included as default. Options R, E, N and T are Incompatible

Special Feedback Number and Type of Channels

GBLA-BB-CDD-EFGHHHI0

000: No Special Feedback Channels

4A0: 4 Sinusoidal Encoder Feedback Channels

4B0: 4 Resolver Feedback Channels

4C1: 4 Serial Encoder Feedback Channels (SSI Protocol)

4C2: 4 Serial Encoder Feedback Channels (Yaskawa Sigma II & III & V Protocol)

4C3: 4 Serial Encoder Feedback Channels (EnDat 2.2 Protocol)

4C6: 4 Serial Encoder Feedback Channels (BISS-B & C Protocol)

4C7: 4 Serial Encoder Feedback Channels (Tamagawa Protocol)

4C8: 4 Serial Encoder Feedback Channels (Panasonic Protocol)

4D1: 4 Sinusoidal Encoder and Serial Enc. (SSI Protocol)

4D2: 4 Sinusoidal Encoder and Serial Enc. (Yaskawa Sigma II & III & V Protocol)

4D3: 4 Sinusoidal Encoder and Serial Enc. (EnDat 2.1 / 2.2 Protocol)

4D4: 4 Sinusoidal Encoder and Serial Enc. (HiperFace Protocol)

4D6: 4 Sinusoidal Encoder and Serial Enc. (BISS-B & C Protocol)

4D7: 4 Sinusoidal Encoder and Serial Enc. (Tamagawa Protocol)

4D8: 4 Sinusoidal Encoder and Serial Enc. (Panasonic Protocol)

4E1: 4 Resolver Feedback Channels and Serial Enc. (SSI Protocol)

4E2: 4 Resolver Feedback Ch. and Serial Enc. (Yaskawa Sigma II & III & V Prot.)

4E3: 4 Resolver Feedback Channels and Serial Enc. (EnDat 2.2 Protocol)

4E6: 4 Resolver Feedback Channels and Serial Enc. (BISS-B & C Protocol)

4E7: 4 Resolver Feedback Channels and Serial Enc. (Tamagawa Protocol)

4E8: 4 Resolver Feedback Channels and Serial Enc. (Panasonic Protocol)

8A0: 8 Sinusoidal Encoder Feedback Channels

8B0: 8 Resolver Feedback Channels

8C1: 8 Serial Encoder Feedback Channels (SSI Protocol)

8C2: 8 Serial Encoder Feedback Channels (Yaskawa Sigma II & III & V Protocol)

8C3: 8 Serial Encoder Feedback Channels (EnDat 2.2 Protocol)

8C6: 8 Serial Encoder Feedback Channels (BISS-B & C Protocol)

8C7: 8 Serial Encoder Feedback Channels (Tamagawa Protocol)

8C8: 8 Serial Encoder Feedback Channels (Panasonic Protocol)

8D1: 8 Sinusoidal Encoder and Serial Enc. (SSI Protocol)

8D2: 8 Sinusoidal Encoder and Serial Enc. (Yaskawa Sigma II & III & V Protocol)

8D3: 8 Sinusoidal Encoder and Serial Enc. (EnDat 2.1 / 2.2 Protocol)

8D4: 8 Sinusoidal Encoder and Serial Enc. (HiperFace Protocol)

8D6: 8 Sinusoidal Encoder and Serial Enc. (BISS-B & C Protocol)

8D7: 8 Sinusoidal Encoder and Serial Enc. (Tamagawa Protocol)

8D8: 8 Sinusoidal Encoder and Serial Enc. (Panasonic Protocol)

8E1: 8 Resolver Feedback Channels and Serial Enc. (SSI Protocol)

8E2: 8 Resolver Feedback Ch. and Serial Enc. (Yaskawa Sigma II & III & V Protocol)

8E3: 8 Resolver Feedback Channels and Serial Enc. (EnDat 2.2 Protocol)

8E6: 8 Resolver Feedback Channels and Serial Enc. (BISS-B & C Protocol)

8E7: 8 Resolver Feedback Channels and Serial Enc. (Tamagawa Protocol)

8E8: 8 Resolver Feedback Channels and Serial Enc. (Panasonic Protocol)

G

H

Note: If any of the “H” or “I” digits (GBLA-BB-CDD-EFGHHHI0) are ordered, you will also receive RS-232 comms port, 1

channel "handwheel" port.

MACRO and Special Feedback Options

MACRO Ring Interface and

8 Single or 4 Differential channel 12-bit 10v range

MUXED ADC

GBLA-BB-CDD-EFGHHHI0

0: No MACRO or ADC

1: RJ45 MACRO

2: Fiber Optic MACRO

3: MUXED ADC

4: RJ45 MACRO and MUXED ADC

5: Fiber Optic MACRO and MUXED ADC

I

Specifications 15

Page 16

Geo Brick Drive User Manual

Digital Quadrature

Sinusoidal

HiperFace

Resolver

SSI

EnDat 2.1 / 2.2

Yaskawa Sigma II / III

BiSS B / C

Panasonic

Tamagawa

Note

Regardless of the encoder feedback option(s) fitted, digital quadrature

encoders can always be utilized. However, Hall sensors cannot be

used with a channel which has been programmed for serial clocking.

Geo Brick Drive Options

CPU Options

C0: 80MHz Turbo PMAC2 CPU (Standard, default)

8Kx24 internal memory, 256Kx24 SRAM, 1MB flash memory

C3: 80MHz Turbo PMAC2 CPU

8Kx24 internal memory, 1Mx24 SRAM, 4MB flash memory

F3: 240MHz Turbo PMAC2 CPU

192Kx24 internal memory, 1Mx24 SRAM, 4MB flash memory

Encoder Feedback

Axes Power Configuration

5/10 Amps or 8/16 Amps, 15/30 Amps (limited to axes 5-6)

Encoder Inputs

Up to eight encoder inputs, one Handwheel quadrature input

Additional encoder inputs can be obtained through MACRO connectivity

Digital Inputs/Outputs

Up to 32 inputs and 16 outputs (Sinking or Sourcing)

Additional digital I/Os can be obtained through Fieldbus connectivity

Analog Inputs, DAC Outputs, Brakes, and Relays

Up to four 16-bit analog inputs, eight 12-bit analog inputs, four brake/ relay outputs , and five 12-

bit filtered PWM (±10V) outputs

Communication

USB 2.0, Ethernet 100 Base T, RS232, DPRAM (required for NC software/applications)

Fieldbus Connectivity

MACRO

ModBus

Specifications 16

Page 17

Geo Brick Drive User Manual

Description

Specifications

Operating Temperature

0 to 45°C

Above 40°C,de-rate current output by 2.5% per °C

Storage Temperature

-25°C to +70°C

Humidity

10% to 90% non-condensing

Operating Altitude

~3300 Feet (1000 m)

De-rate current output by 1.1% per additional 330 feet (100m)

Air Flow Clearances

~3 inches (76.2mm) above and below unit for air flow

Operating Environment

Pollution Degree 2 or equivalent

Caution

The internal I2T applies to and protects the amplifier power blocks.

The software I2T (described in later section) has to be configured

properly to protect against motor/equipment damage.

Description

Specifications

Over Voltage

~ 283 VAC / 400 VDC

Under Voltage

~ 87 VAC / 123 VDC

Over Temperature

~ 80C

Motor Short Circuit

500 % of rated peak Amps per axis

Over Current

110 % over rated peak Amps per axis

AC Input Phase Loss Detection

Loss of one or more phases (3 Phase operation only)

Shunt Fault Detection

Integrated, I2T model

Internal I2T protection

2 seconds at peak rated Amps (RMS) per axis

Note

The under voltage fault triggers when the AC Input dips below 87

VAC. However, if this threshold has not been reached (i.e. Low

Voltage/DC operation) the under voltage logic remains unarmed.

Description

Specifications

UL

UL508C File E307874

cUL

CSA C22.2 No. 14-05 File E307874

Environmental Specifications

Protection Specifications

Agency Approvals

Specifications 17

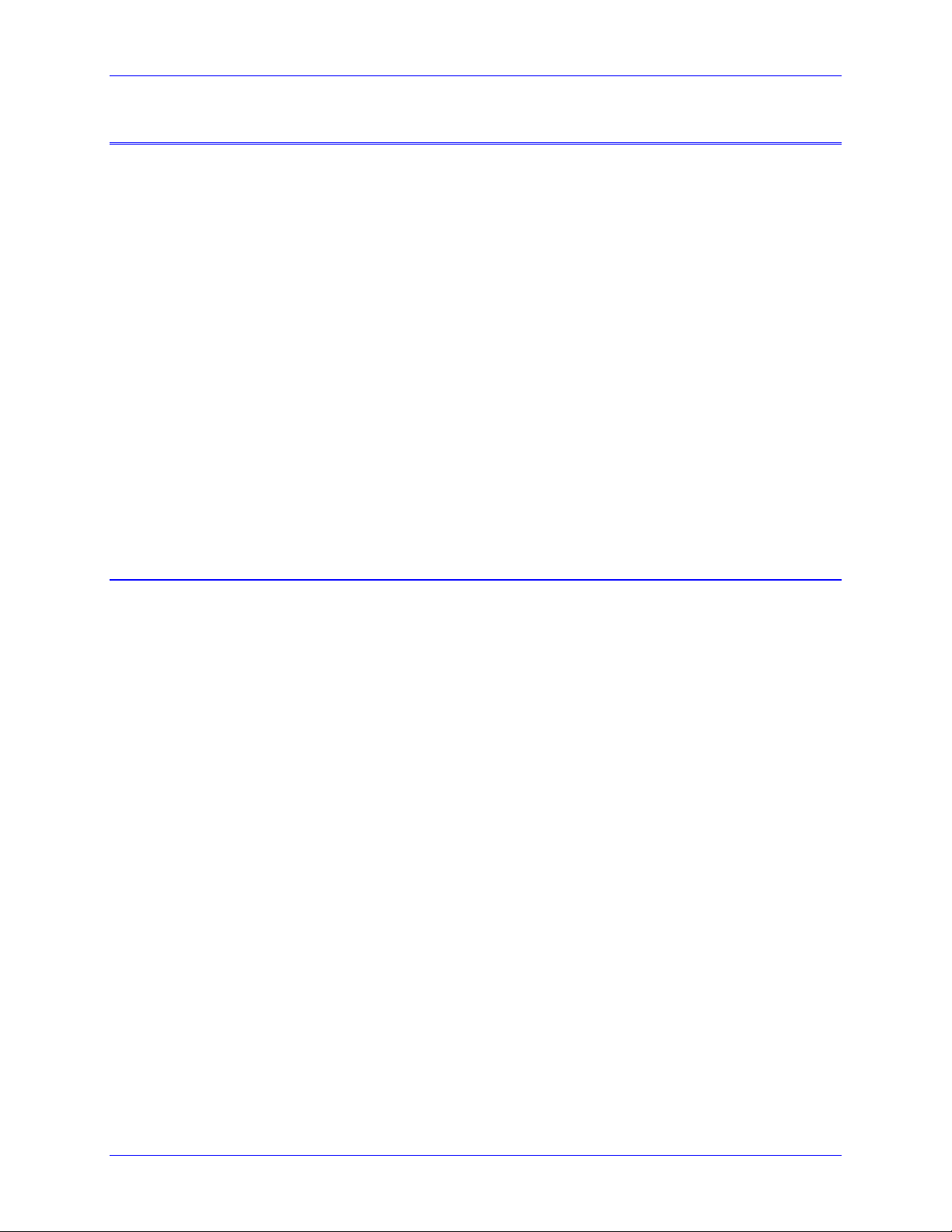

Page 18

Geo Brick Drive User Manual

4-Axis Geo Brick Drive

GBL4-xx-5xx-xxx xxxxx

GBL4-xx-8xx-xxx xxxxx

Output Continuous Current (rms/axis)

5A

8A

Output Peak Current for 2 seconds (rms/axis)

10A

16A

Rated Input Current @240VAC 3-phase(all axes)

13A

21A

Max ADC (I2T Settings)

16.26A

26.02A

Output Power Per Axis [Watts]

(Modulation depth of 60% RMS)

Output Power Total [Watts]

1247W

1995W

4988W

7980W

Power Dissipation [Watts]

498W

798W

PWM Frequency Operating Range [KHz]

1 – 18

AC Input Line Voltage [VAC rms]

110

-20%

– 240

+10%

(~87 -- 264)

DC Input Line Voltage [VDC]- DC operation

12VDC to 340VDC

Logic Power [VDC, A]

24VDC ±5%, 4A

Continuous Shunt Power rating [Watts]

5000W

Peak Shunt Power rating [Watts]

10000W

Recommended Shunt Resistor [Ohms]

GAR15 (15Ω)

Recommended Shunt Power Rating [Watts]

300W

6-Axis Geo Brick Drive

GBL6-xx-5xx-xxx xxxxx

GBL6-xx-8xx-xxx xxxxx

Axes

1-4

5-6

1-4

5-6

Output Continuous Current (rms/axis)

5A

15A

8A

15A

Output Peak Current for 2 seconds (rms/axis)

10A

30A

16A

30A

Max ADC (I2T Settings)

16.26A

48.8A

26.02A

48.8A

Rated Input Current @240VAC 3-phase(all axes)

33A

41A

Output Power Per Axis

(Modulation depth of 60% RMS)

Output Power Total

1247 W

3741 W

1995

3741

12470W

15462W

Power Dissipation [Watts]

1247W

1546W

PWM Frequency Operating Range [KHz]

1 – 18

AC Input Line Voltage [VAC rms]

110

-20%

– 240

+10%

(~87 -- 264)

DC Input Line Voltage [VDC]- DC operation

12VDC to 340VDC

Logic Power [VDC, A]

24VDC ±5%, 4A

Continuous Shunt Power rating [Watts]

7500W

Peak Shunt Power rating [Watts]

15000W

Recommended Shunt Resistor [Ohms]

GAR 10 (10 Ω)

Recommended Shunt Power Rating [Watts]

300W

Electrical Specifications

Specifications 18

Page 19

Geo Brick Drive User Manual

8-Axis Geo Brick Drive

GBL8-xx-552

GBL8-xx-882

GBL8-xx-582

GBL8-xx-852

Axes

1-4

5-8

1-4

5-8

1-4

5-8

1-4

5-8

Output Continuous Current (rms/axis)

5A

5A

8A

8A

5A

8A

8A

5A

Output Peak Current for 2 sec (rms/axis)

10A

10A

16A

16A

10A

16A

16A

10A

Max ADC (I2T Settings)

16.26A

16.26A

26.02A

26.02A

16.02A

26.02A

26.02A

16.02A

Rated Input Current @240 3-phase(all axes)

26A

42A

34A

34A

Output Power Per Axis

(Modulation depth 60% RMS)

1247W

1995W

1247W

1995W

1995W

1247W

Output Power Total

9976W

15960W

12968W

12968W

Power Dissipation

998W

1596W

1297W

1297W

PWM Frequency Operating Range [KHz]

1 – 18

AC Input Line Voltage [VAC]

110

-20%

– 240

+10%

(~87 -- 264)

DC Input Line Voltage [VDC]- DC operation

12VDC to 340VDC

Logic Power

24VDC ±5%, 4A

Continuous Shunt Power [Watts]

5000W

Peak Shunt Power rating [Watts]

10000W

Recommended Shunt Resistor [Ohms]

GAR 15 (15 Ω)

Recommended Shunt Power Rating [Watts]

300W

Note

Electrical specifications are specified for three-phase AC bus power.

De-rating applies in single-phase AC, or DC Operation.

Specifications 19

Page 20

Geo Brick Drive User Manual

RECEIVING AND UNPACKING

Delta Tau products are thoroughly tested at the factory and carefully packaged for shipment. When the

Geo Brick Drive is received, there are several things to be done immediately:

Observe the condition of the shipping container and report any damage immediately to the

commercial carrier that delivered the drive.

Remove the drive from the shipping container and remove all packing materials. Check all shipping

material for connector kits, documentation, or other small pieces of equipment. Be aware that some

connector kits and other equipment pieces may be quite small and can be accidentally discarded if

care is not used when unpacking the equipment. The container and packing materials may be retained

for future shipment.

Verify that the part number of the drive received is the same as the part number listed on the purchase

order.

Inspect the drive for external physical damage that may have been sustained during shipment and

report any damage immediately to the commercial carrier that delivered the drive.

Electronic components in this product are design-hardened to reduce static sensitivity. However, use

proper procedures when handling the equipment.

If the Geo Brick Drive is to be stored for several weeks before use, be sure that it is stored in a

location that conforms to published storage humidity and temperature specifications.

Use of Equipment

The following restrictions will ensure the proper use of the Geo Brick Drive:

The components built into electrical equipment or machines can be used only as integral components

of such equipment.

The Geo Brick Drive must not be operated on power supply networks without a ground or with an

asymmetrical ground.

If the Geo Brick Drive is used in residential areas, or in business or commercial premises, implement

additional filtering measures.

The Geo Brick Drive may be operated only in a closed switchgear cabinet, taking into account the

ambient conditions defined in the environmental specifications.

Delta Tau guarantees the conformance of the Geo Brick Drives with the standards for industrial areas

stated in this manual, only if Delta Tau components (cables, controllers, etc.) are used.

Receiving and Unpacking 20

Page 21

Geo Brick Drive User Manual

Caution

Unit must be installed in an enclosure that meets the environmental IP

rating of the end product (ventilation or cooling may be necessary to

prevent enclosure ambient from exceeding 45° C [113° F]).

MOUNTING

The location of the Geo Brick Drive is important. Installation should be in an area that is protected from

direct sunlight, corrosives, harmful gases or liquids, dust, metallic particles, and other contaminants.

Exposure to these can reduce the operating life and degrade performance of the drive.

Several other factors should be carefully evaluated when selecting a location for installation:

For effective cooling and maintenance, the Geo Brick Drive should be mounted on a smooth,

non- flammable vertical surface.

At least 76 mm (3 inches) top and bottom clearance must be provided for air flow. At least 10

mm (0.4 inches) clearance is required between units (each side).

Temperature, humidity and Vibration specifications should also be taken in account.

The Geo Brick Drive can be mounted with a traditional 4-hole panel mount, two U shape/notches on the

bottom and two pear shaped holes on top.

If multiple Geo Brick Drives are used, they can be mounted side-by-side, leaving at least a 122 mm

clearance between drives. This means a 122 mm center-to-center distance (0.4 inches) with the 4-axis

Drives. 8- and 6-axis Geo Brick Drives can be mounted side by side at 214 mm center-to-center distance

(8.4 inches). It is extremely important that the airflow is not obstructed by the placement of conduit tracks

or other devices in the enclosure.

If the drive is mounted to a back panel, the back panel should be unpainted and electrically conductive to

allow for reduced electrical noise interference. The back panel should be machined to accept the

mounting bolt pattern of the drive.

The Geo Brick Drive can be mounted to the back panel using four M4 screws and internal-tooth lock

washers. It is important that the teeth break through any anodization on the drive’s mounting gears to

provide a good electrically conductive path in as many places as possible. Mount the drive on the back

panel so there is airflow at both the top and bottom areas of the drive (at least three inches).

Mounting 21

Page 22

Geo Brick Drive User Manual

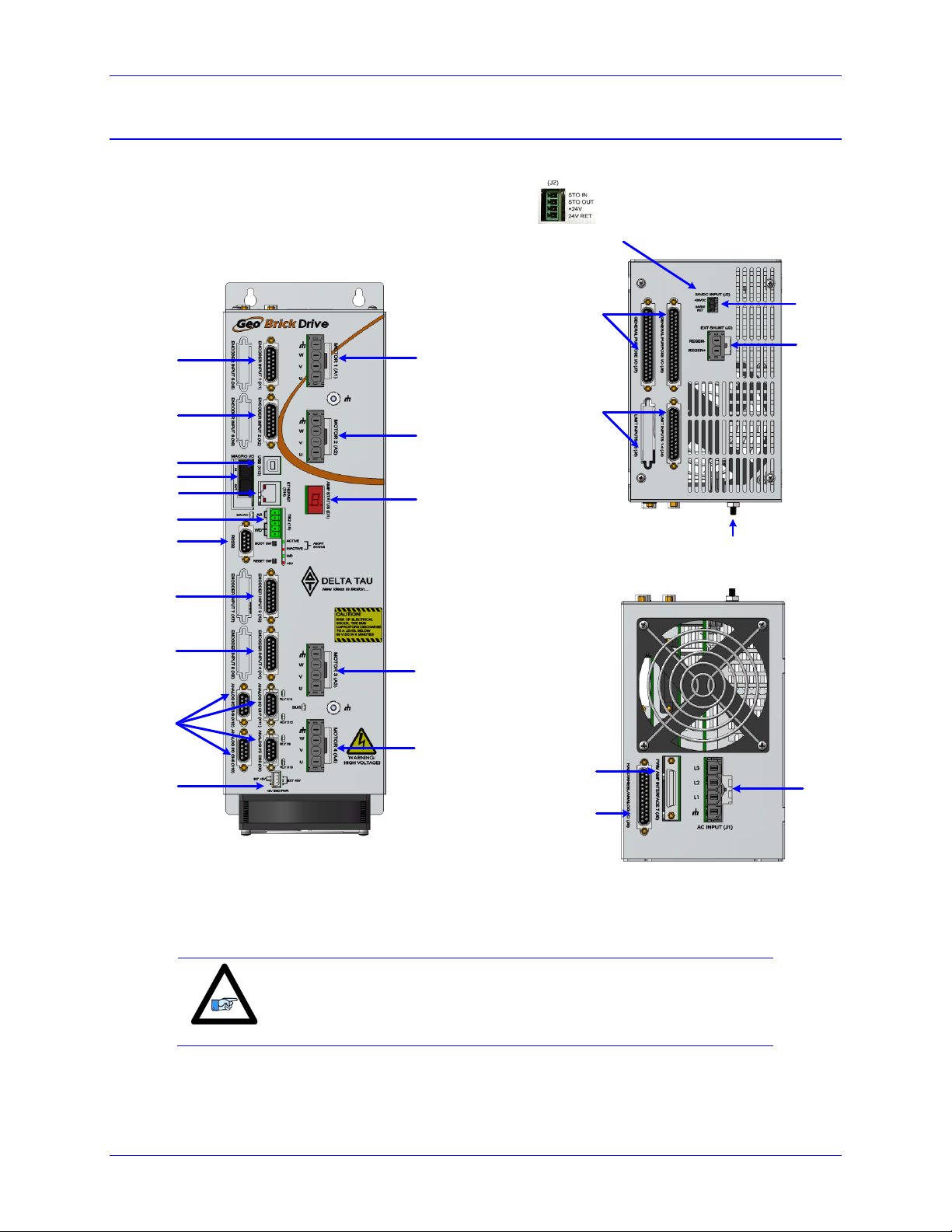

Motor #1

Motor #2

Motor #3

Motor #4

Status

Display

Alt. Enc. Pwr

Encoder #4

Encoder #3

Encoder #2

Encoder #1

USB

Ethernet

MACRO

Abort & WD

RS232

Analog I/O

Front View

Top View

24VDC

Logic Power

Shunt

Resitor

Motor Shield

Connection

General

Purpose I/O

Limits

& Flags

New Connector

(October 2012)

AC/DC

Bus Power

Input

PWM Interface

Analog I/O

Handwheel

Bottom View

Note

Newer models of the Geo Brick Drive were introduced in October of

2012. They can be recognized by the 4-pin terminal block logic and

STO connector.

Connector Locations

Mounting 22

Page 23

Geo Brick Drive User Manual

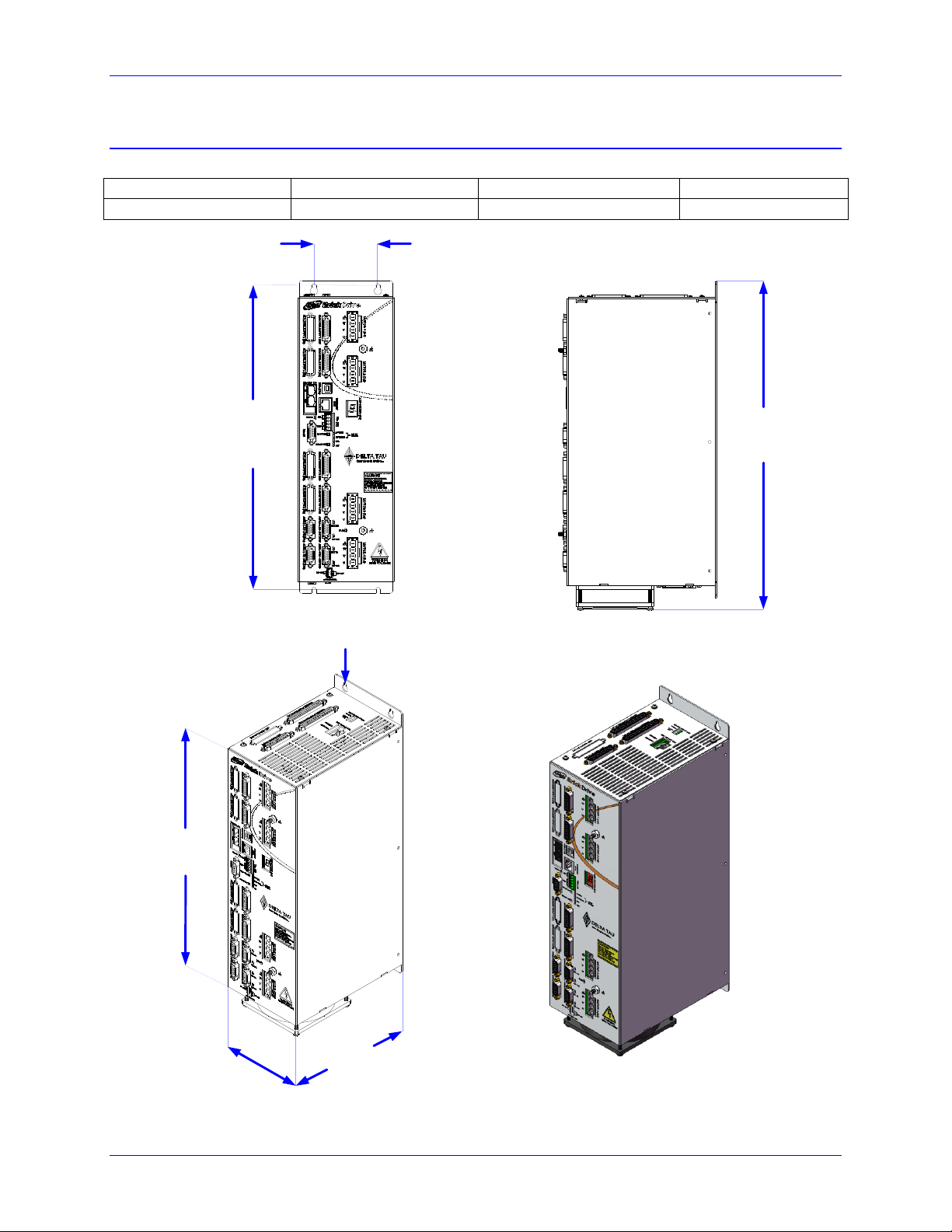

Width

Depth

Height

Weight

114mm/4.50in

178mm/7.00in

391mm/15.40in

4.4Kg/9.6lbs

3.00"

(76.20 mm)

14.31"

(363.52 mm)

15.40"

(391.16 mm)

13.38"

(339.73 mm)

4.50"

(114.29 mm)

7.00"

(177.83 mm)

4 x M4

4-Axis Geo Brick Drive

GBL4-xx-5xx-xxx-xxxx And GBL4-xx-8xx-xxx-xxxx

Mounting 23

Page 24

Geo Brick Drive User Manual

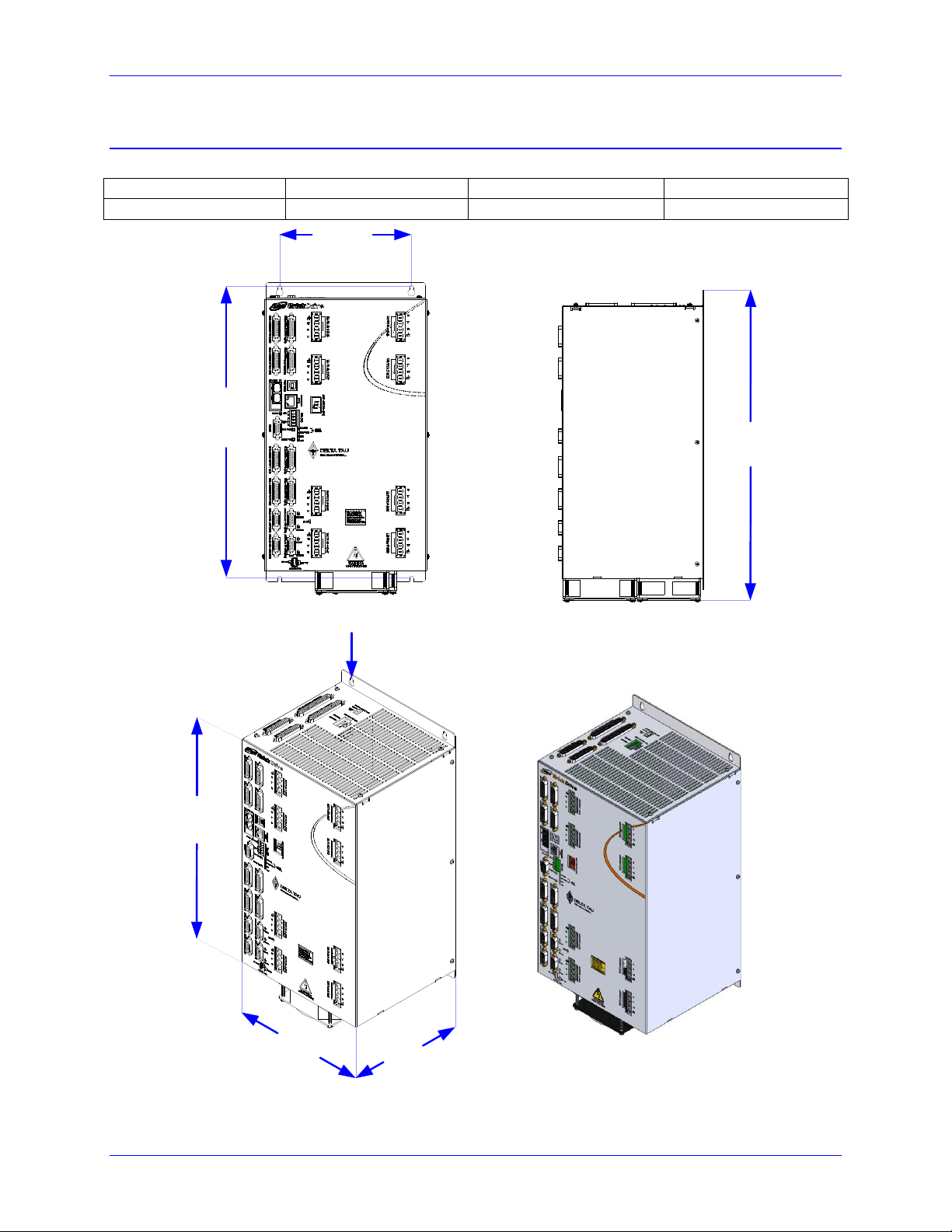

Width

Depth

Height

Weight

203mm/8.00in

178mm/7.00in

391mm/15.40in

13.38"

(339.73 mm)

8.00"

(203.20 mm)

7.00"

(177.83 mm)

4 x M4

6.50"

(165.10 mm)

14.31"

(363.52 mm)

15.40"

(391.16 mm)

6-Axis Geo Brick Drive

GBL6-xx-5xx-xxx-xxxx And GBL6-xx-8xx-xxx-xxxx

Mounting 24

Page 25

Geo Brick Drive User Manual

Width

Depth

Height

Weight

203mm/8.00in

178mm/7.00in

392mm/15.40in

9.0 Kg/19.9lbs

13.38"

(339.73 mm)

8.00"

(203.20 mm)

7.00"

(177.83 mm)

4 x M4

6.50"

(165.10 mm)

14.31"

(363.52 mm)

15.40"

(391.16 mm)

8-Axis Geo Brick Drive

GBL8-xx-552-xxx-xxxx, GBL8-xx-582-xxx-xxxx, GBL8-xx-852-xxx-xxxx, GBL8-xx-882-xxx-xxxx

Mounting 25

Page 26

Geo Brick Drive User Manual

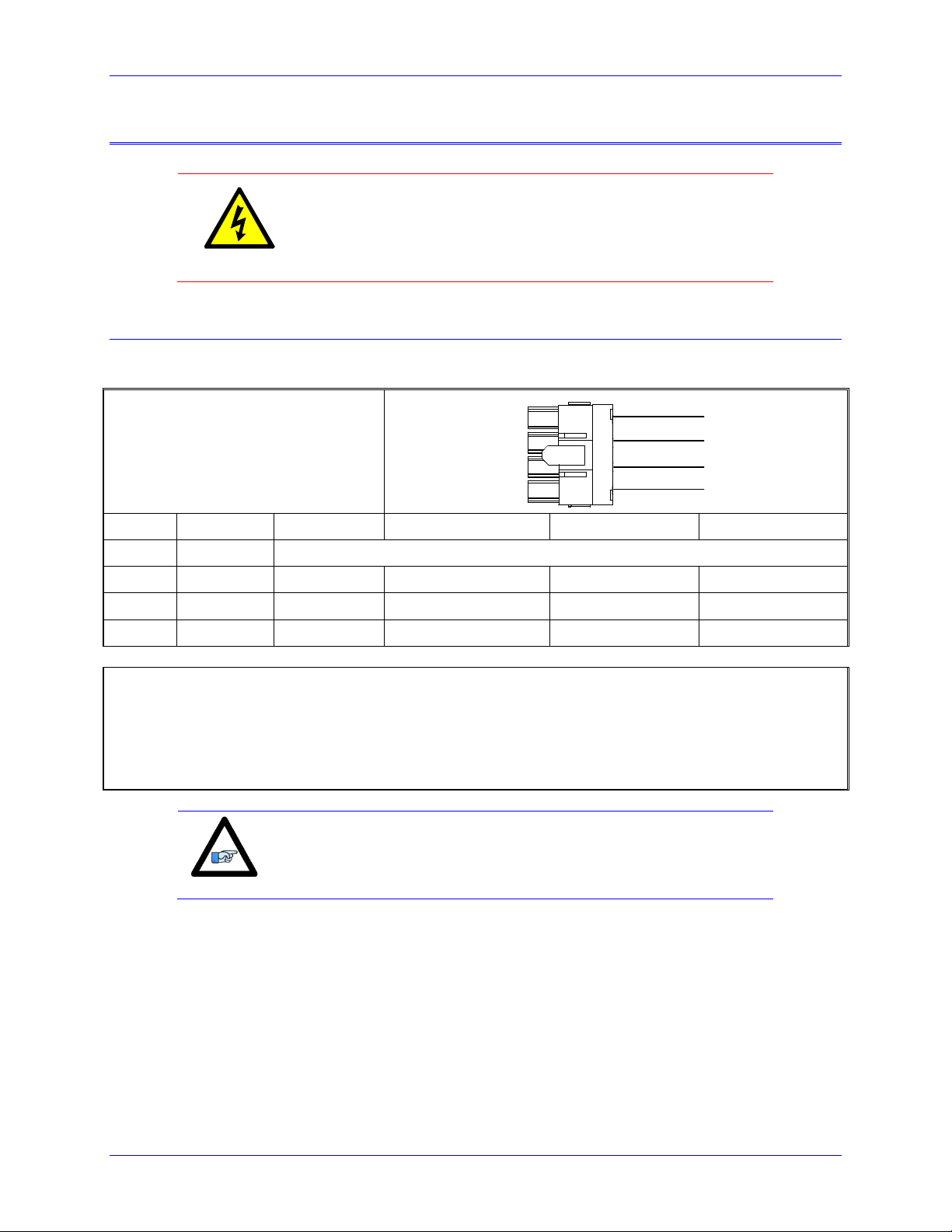

WARNING

Installation of electrical equipment is subject to many regulations

including national, state, local, and industry guidelines and rules.

The following are general recommendations but it is important

that the integration be carried out in accordance with all

regulations pertaining to the installation.

J1: Molex 4-pin Male

Mating: Molex 4-pin Female

L3

L2

L1

GND

Pin #

Symbol

Function

Three Phase

Single Phase

DC

1

GND

Ground

2

L1

Input

AC Line Phase 1

Not Connected

Not Connected

3

L2

Input

AC Line Phase 2

Neutral

DC- Return

4

L3

Input

AC Line Phase 3

Line

DC+

Molex Mating Connector p/n: 0428160412

Molex Pins p/n : 0428150031

Molex Crimper Tool p/n: 63811-1500

Delta Tau Mating Connector p/n: 014-H00F04-049 (for internal use)

Delta Tau Pins p/n: 014-042815-031 (for internal use)

Note

In single phase operation, use L2 and L3, and leave L1 floating.

In DC mode operation, use L3 for DC+ and L2 for DC return, and

leave L1 floating.

PINOUTS AND SOFTWARE SETUP

J1: Main Bus Power Input

J1 is used to bring the main AC/DC bus power into the Geo Brick Drive.

Pinouts and Software Setup 26

Page 27

Geo Brick Drive User Manual

Caution

The main bus power should NEVER be applied if the 24V logic

power is NOT applied.

Caution

Make sure that no motor commands (e.g. phasing, jogging, or open

loop) are being executed by or sent repeatedly to the controller

(PMAC) at the time of applying main bus power.

Caution

Main bus power should NEVER be applied or cycled if the 24V logic

power is NOT applied.

Power On/Off Sequence

Powering up a Geo Brick Drive must obey the following procedure:

1. Apply 24V logic power

2. Wait a minimum of ~3 seconds

3. Apply main bus power

Powering down a Geo Brick Drive must obey the following procedure:

1. Disconnect main bus power

2. Wait a minimum of ~5 seconds

3. Disconnect 24V logic power

Cycling Main Bus Power

Newer and older Geo Brick Drives differ in the delay restrictions between main power cycles.

The newer models were introduced in October of 2012. They can be recognized by the 4-pin

terminal block 24V logic with STO connector.

The older models carry the Molex type 2-pin 24V logic connector

Pinouts and Software Setup 27

Page 28

Geo Brick Drive User Manual

Caution

With older models, it is strongly advised NOT to cycle main bus

power frequently and rapidly within a few seconds.

Caution

Older models of the 4-axis Geo Brick Drives’ main bus power should not be recycled in

less than ~ 3 minutes.

Older models of the 6- and 8-axis Geo Brick Drives’ main bus power should not be

recycled in less than ~ 6 minutes.

Note

With the older models of the 6-axis Geo Brick Drives it is possible to

wire the external shunt resistor as a bleeding resistor to avoid the

extended downtime delay. Contact Delta Tau for details.

Caution

Newer models of the 4-axis Geo Brick Drives’ main bus power should not be recycled in

less than ~ 5 seconds.

Newer models of the 6- and 8-axis Geo Brick Drives’ main bus power should not be

recycled in less than ~ 10 seconds.

Note

The addition of an external shunt resistor (e.g. GAR15 or GAR10)

makes the residual power dissipation even faster.

Note

A red LED indicator, labeled “BUS”, on the front of the Geo Brick

Drive is illuminated when main bus power is applied.

Older Models of the Geo Brick Drive

With the older models of the Geo Brick Drives, cycling main bus power must obey the following warning

restrictions. A delay should be inserted in either software, hardware or both to ensure that these

restrictions are conformed.

With main bus power of 110 – 240VAC (single or three-phase):

Newer Models of the Geo Brick Drive

The newer models of the Geo Brick Drive are fitted with an internal shunt resistor (300W, 100-Ohm)

which is also used as a bleeding resistor when the main bus power is removed. This allows a rapid

discharge of the capacitors’ residual power, and shorter delay restrictions between main bus power cycles.

With main bus power of 110 – 240VAC (single or three-phase), and without an external shunt resistor,

the following delay restrictions are strongly advised:

Pinouts and Software Setup 28

Page 29

Geo Brick Drive User Manual

Caution

Main bus power lines should run in a separate duct (at least 12” or 30

cm away) from and should never be bundled with the I/O signal,

communication, or encoder cables.

Recommended Main Bus Power Wiring/Protection

Grounding, Bonding

System grounding is crucial for proper performance of the Geo Brick Drive. Panel wiring requires that a

central earth-ground (also known as ground bus bar) location be installed at one part of the panel. The

ground bus bar is usually a copper plate directly bonded to the back panel. This electrical ground

connection allows for each device within the enclosure to have a separate wire brought back to the central

earth-ground.

Implement a star point ground connection scheme; so that each device wired to earth ground

has its own conductor brought directly back to the central earth ground plate (bus bar).

Use an unpainted back panel. This allows a wide area of contact for all metallic surfaces,

reducing frequency impedances.

Use a heavy gauge ground earth conductors made up of many strands of fine conducts.

The Geo Brick Drive is brought to the earth-ground via one or two wire(s) connected to the

M4 mounting stud(s) through a heavy gauge multi-strand conductor to the central earthground.

Pinouts and Software Setup 29

Page 30

Geo Brick Drive User Manual

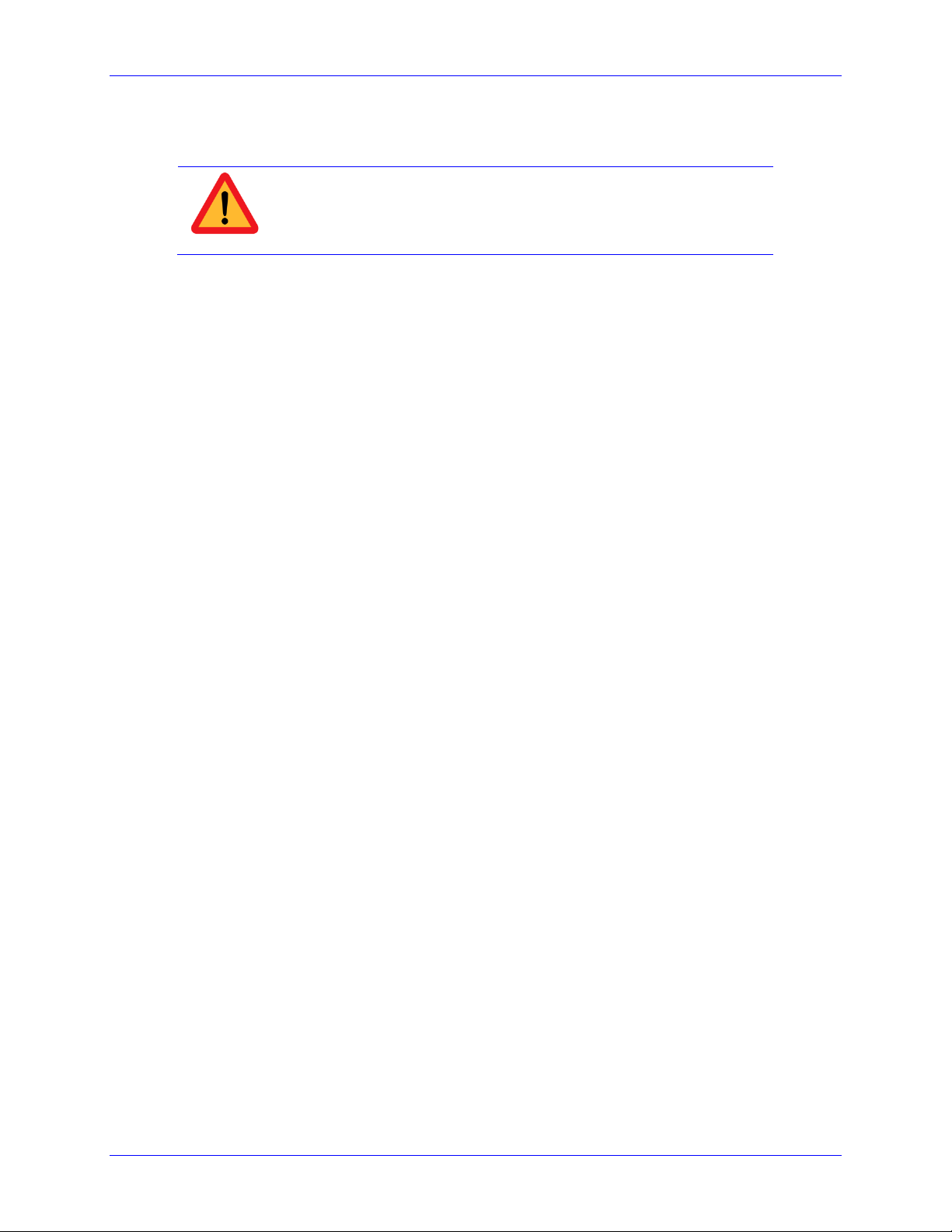

Three-Phase Main AC Power Wiring Diagram

3-PHASE

TRANSFORMER

110-240 VAC

GND L1 L2 L3

PROTECTION EARTH

FUSE

FUSE

FUSE

MAGNETIC

CONTACTOR

L1

L2

L3

GND

Shielded

And

Twisted

EMC/EMI

FILTER

Phase-Phase

Voltage

Suppressors

Single-Phase Main AC Power Wiring Diagram

GND

Neutral

Line

PROTECTION EARTH

FUSE

FUSE

MAGNETIC

CONTACTOR

L2

L3

GND

Shielded

And

Twisted

EMC/EMI

FILTER

Phase-Phase

Voltage

Suppressors

Single Phase Source

110-240 VAC

Pinouts and Software Setup 30

Page 31

Geo Brick Drive User Manual

Note

A line reactor should be installed if a transformer or reliable source of

power is not available. Line reactors suppress harmonics bidirectionally, eliminating low frequency spikes.

Model

Fuse (amps)

Model

Fuse (amps)

GBL4-xx-5xx

15

GBL8-xx-552

30

GBL4-xx-8xx

25

GBL8-xx-882

45

GBL6-xx-5xx

35

GBL8-xx-582

35

GBL6-xx-8xx

45

GBL8-xx-852

35

DC Bus Voltage:

[VDC]

Motor Phase voltage:

[VDC]

Power per axis:

[Watts]

Total power:

[Watts]

Dissipated power:

[Watts]

Current draw per phase

(for 3 bus input)

[Amps]

Current draw per phase

(for 1 bus input)

[Amps]

Transformers

Y-Y or Y- transformers should be used.

- Transformers are NOT advised. They try to balance phases dynamically, creating instances of

instability in the Geo Brick Drive’s rectifying circuitry.

Fuses

High peak currents and high inrush currents demand the use of slow blow time delayed type fuses.

RK1 or RK5 (i.e. current limiting) classes are recommended. FRN-R and LPN-RK from Cooper

Bussmann or similar fuses can be used.

The following table summarizes fuse gauges for three-phase bus input (240VAC) at full load:

Specific applications fuse sizing can be done using the following equations.

Take, as an example, a 4-axis Geo Brick (5/10A) on 240VAC bus, and driving 4 motors (5A continuous

current rating):

Thus, 15 and 25 –amp fuses are chosen for three and single phase bus power input lines respectively.

Pinouts and Software Setup 31

Page 32

Geo Brick Drive User Manual

Model

Wire Gauge

(AWG)

Model

Wire Gauge

(AWG)

GBL4-xx-5xx

12

GBL8-xx-552

10

GBL4-xx-8xx

10

GBL8-xx-882

8

GBL6-xx-5xx

8

GBL8-xx-582

8

GBL6-xx-8xx

8

GBL8-xx-852

8

Note

All ground conductors should be 8AWG minimum using wires

constructed of many strands of small gauge wire. This ensures the

lowest impedance to high-frequency noises.

Magnetic Contactors

SC-E series from Fuji Electric or similar contactor can be used.

Line Filters

Line filters eliminate electromagnetic noise in a bi-directional manner (from and into the system).

T type filters are NOT recommended. PI type line filters are highly advised:

Filter should be mounted on the same panel as the drive and power source.

Filter should be mounted as close as possible to the power source.

Filter should be mounted as close as possible to incoming cabinet power.

FN-258 series from Schaffner or similar filter can be used.

Voltage Suppressors

Voltage suppressors eliminate undesirable voltage spikes typically generated by the magnetic contactor or

external machinery in the plant.

This 3-phase voltage arrester from Phoenix Contact or similar suppressor can be used.

Bus Power Cables

The Geo Brick Drive electronics create a DC bus by rectifying the incoming AC lines. The current flow

into the drive is not sinusoidal but rather a series of narrow, high-peak pulses. Keeping the incoming

impedance small is essential for not hindering these current pulses.

Whether single- or three-phase, it is important that the AC input wires be twisted together to eliminate

noise radiation as much as possible. Recommended wire gauge:

Pinouts and Software Setup 32

Page 33

Geo Brick Drive User Manual

Note

The Safe Torque Off (STO) feature is not available with older models

of the Geo Brick Drive.

Note

The logic and STO connections can be made using a 22 gauge (AWG)

wire.

J2: 24VDC Logic Power and Safe Torque Off (STO)

J2 is used to bring the 24VDC logic power into the Geo Brick Drive. This power can remain on,

regardless of the main AC/DC bus power input, allowing the digital control electronics to be active while

the main motor power control is passive.

J2, in the newer models of the Geo Brick Drive, is also used to wire the Safe Torque Off (STO) input.

The STO allows the complete (hardware) disconnection of the power amplifiers from the motors. This

mechanism prevents unintentional “movement of” or torque output to the motors in accordance with

IEC/EN safety standards.

Newer and older models of the Geo Brick Drive have different 24V logic power connector. The new

connector is a 4-pin (as opposed to the older 2-pin) accommodating the STO function. It is a Phoenix

Contact terminal block (as opposed to the older Molex type) which allows for easier connection without

the need of special crimping tools:

The newer models were introduced in October of 2012. They can be recognized by the 4-pin

terminal block 24V logic with STO connector.

The older models carry the Molex type 2-pin 24V logic connector (no STO).

It is recommended to use a protected power supply. In situations where the power supply is shared with

other devices, it may be desirable to insert a filter before applying it to the Geo Brick Drive.

If multiple drives are driven out of the same 24VDC power supply, it is recommended that each Geo

Brick Drive be wired back to the power supply terminals independently. It is also recommended that the

power supply be sized to handle the instantaneous inrush current required to start up the DC-to-DC

converter action inside the Drive(s). See electrical specifications.

Pinouts and Software Setup 33

Page 34

Geo Brick Drive User Manual

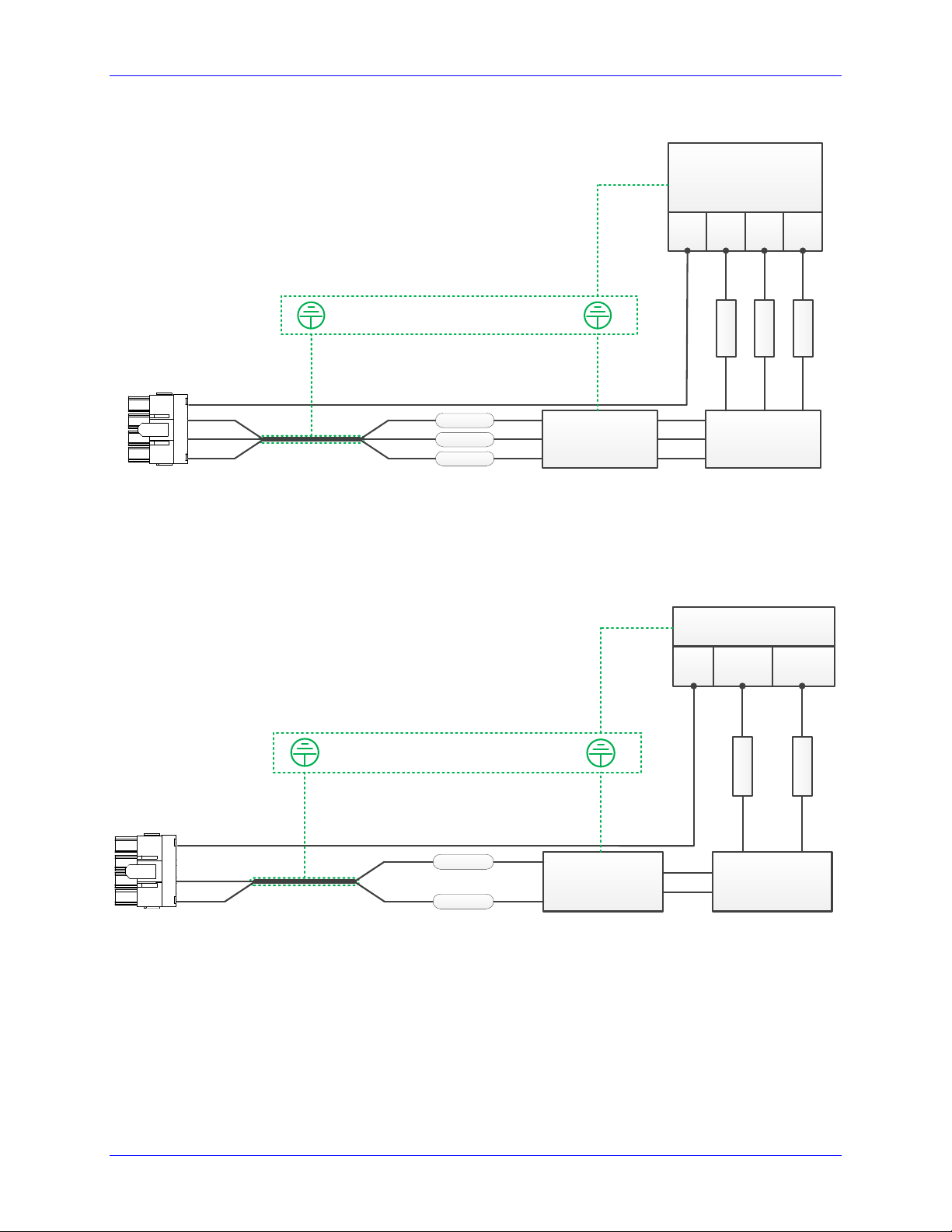

J2: Molex 2-pin Female

Mating: Molex 2-pin Male

GND

+24VDC

Molex Mating Connector p/n: 0436450200

Molex Pins p/n: 0430300008

Molex Crimper Tool p/n: 11-01-0185

Delta Tau Mating Connector p/n: 014-043645-200 (for internal use)

Delta Tau pins p/n: 014-043030-008 (for internal use)

Pin #

Symbol

Function

Description

Notes

1

24VDC RET

Common

Logic power return

Control power return

2

+24VDC

Input

Logic power input

±5 %

J2: Phoenix TB 4-pin Female