Page 1

^2 Advantage 900

Remote Operator Pendant

^1 USER MANUAL

^3 Handheld Machine Control Device

^4 3AO-ROPEND-363

^5 April 10, 2008

Single Source Machine Control Power // Flexibility // Ease of Use

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

Page 2

Copyright Information

© 2008 Delta Tau Data Systems, Inc. All rights reserved.

This document is furnished for the customers of Delta Tau Data Systems, Inc. Other uses

are unauthorized without written permission of Delta Tau Data Systems, Inc.

Information contained in this manual may be updated from time-to-time due to product

improvements, etc., and may not conform in every respect to former issues.

To report errors or inconsistencies, call or email:

Delta Tau Data Systems, Inc. Technical Support

Phone: (818) 717-5656

Fax: (818) 998-7807

Email: support@deltatau.com

Website: http://www.deltatau.com

Operating Conditions

All Delta Tau Data Systems, Inc. motion controller products, accessories, and amplifiers

contain static sensitive components that can be damaged by incorrect handling. When

installing or handling Delta Tau Data Systems, Inc. products, avoid contact with highly

insulated materials. Only qualified personnel should be allowed to handle this

equipment.

In the case of industrial applications, we expect our products to be protected from hazardous or

conductive materials and/or environments that could cause harm to the controller by damaging

components or causing electrical shorts. When our products are used in an industrial

environment, install them into an industrial electrical cabinet or industrial PC to protect them

from excessive or corrosive moisture, abnormal ambient temperatures, and conductive materials.

If Delta Tau Data Systems, Inc. products are exposed to hazardous or conductive materials and/or

environments, we cannot guarantee their operation.

Page 3

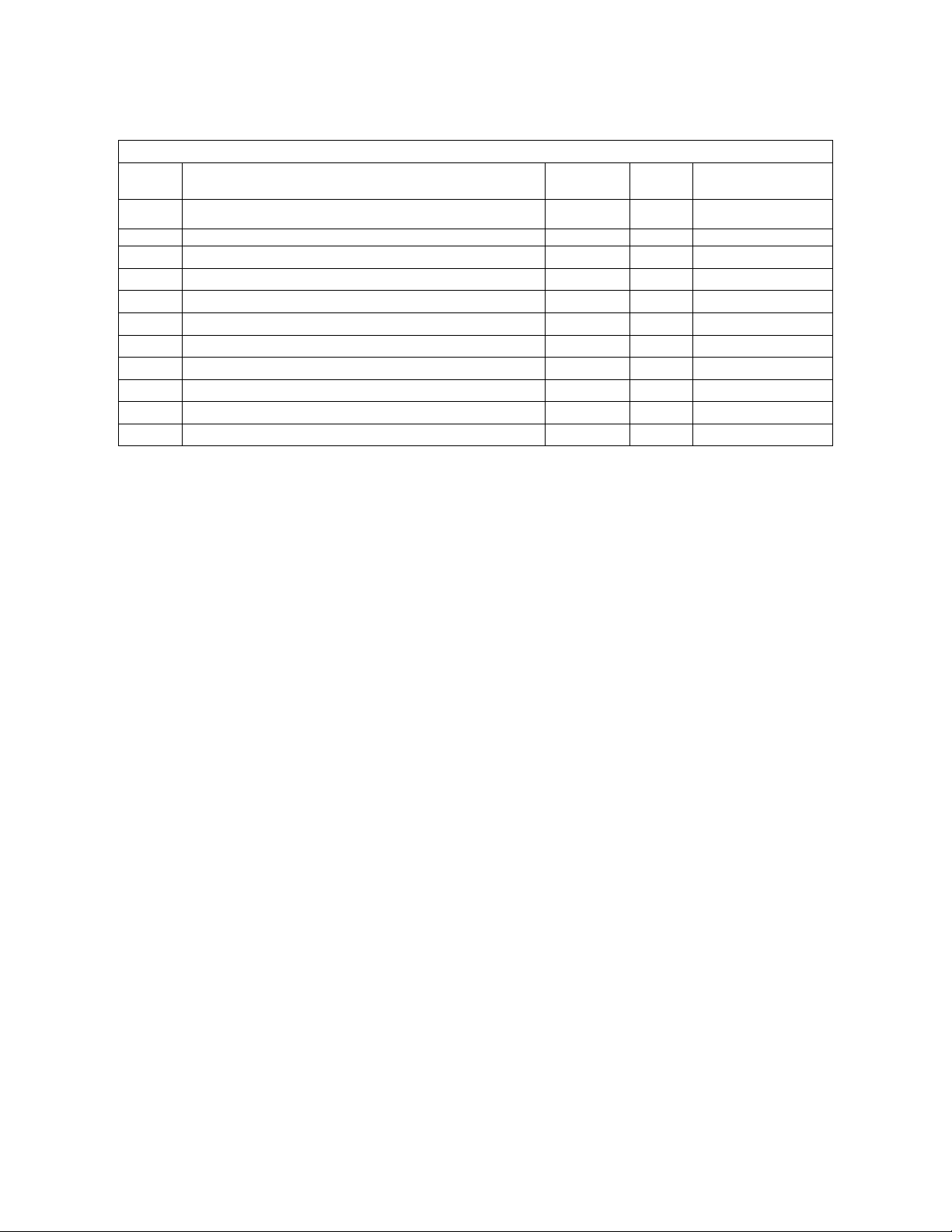

REV. DESCRIPTION DATE CHG APPVD

1 PRELIMINARY MANUAL CREATION 01/28/08 Cp V. BUROKAS

REVISION HISTORY

1 UPGRADE TO FULL RELEASE STATUS 04/09/08 CP V. BUROKAS

Page 4

Advantage 900 Remote Operator Pendant

Table of Contents

INTRODUCTION .......................................................................................................................................................3

Overview.......................................................................................................................................................................3

Part Numbering ...........................................................................................................................................................4

Compatibility ...............................................................................................................................................................4

Communication Interface ...........................................................................................................................................5

Specifications................................................................................................................................................................5

HARDWARE SETUP .................................................................................................................................................7

Jumper Configuration.................................................................................................................................................7

Advantage 900 Remote Pendant – (P/N: 300-603812-10x)......................................................................................7

Advantage 900 Relay Board – (P/N: 300-603826-10x) ............................................................................................8

Connections..................................................................................................................................................................8

Advantage 900 Remote Operator Pendant ................................................................................................................8

Advantage 900 Relay Board......................................................................................................................................9

Field-Wiring Connections.......................................................................................................................................10

Wired diagram.........................................................................................................................................................11

SOFTWARE SETUP ................................................................................................................................................13

WIRELESS SOFTWARE SETUP...........................................................................................................................15

MOUNTING AND INSTALLATION .....................................................................................................................17

Mechanical Drawing..................................................................................................................................................18

Advantage 900 Relay Board Mechanical Layout....................................................................................................20

Advantage 900 Pendant Board Mechanical Layout ...............................................................................................21

CONNECTOR DESCRIPTIONS – 900 REMOTE PENDANT............................................................................23

J1: KEYPAD INPUT CONNECTION ....................................................................................................................23

J1 KEYPAD INPUT CONNECTION (10-PIN SOCKET) .................................................................................23

J2: USB CONNECTION............................................................................................................................................23

J3: HANDWHEEL CONNECTION..........................................................................................................................24

J4: KEYPAD LED CONNECTION ...........................................................................................................................24

J5: ON/OFF SWITCH CONNECTION ...................................................................................................................25

J6: ESTOP INDICATION CONNECTION .............................................................................................................25

J7: BATTERY CHARGE CONNECTION ................................................................................................................25

J8: RS-232 CONNECTION .......................................................................................................................................26

Table of Contents i

Page 5

Advantage 900 Remote Operator Pendant

J9: BATTERY CONNECTION..................................................................................................................................26

CONNECTOR DESCRIPTIONS – 900 RELAY BOARD ....................................................................................27

J4: PC POWER CONNECTION ...............................................................................................................................27

J7: RS-232 CONNECTION .......................................................................................................................................27

J8: POWER ON PUSHBUTTON CONNECTION...................................................................................................27

J9: E-STOP SWITCH CONNECTION .....................................................................................................................28

J13: (10-PIN TERMINAL BLOCK)........................................................................................................................28

J14: (6-PIN TERMINAL BLOCK)............................................................................................................................29

APPENDIX A - BLUETOOTH COMMANDER – PROGRAMMING WIRELESS UNITS ............................31

Bluetooth Re-Programming Procedure ...................................................................................................................31

APPENDIX B - SELECTED SCHEMATICS.........................................................................................................35

APPENDIX C – CONNECTOR PART NUMBERS ..............................................................................................36

Table of Contents ii

Page 6

Advantage 900 Remote Operator Pendant

INTRODUCTION

Overview

The Advantage 900 Remote Operator Pendant is a compact and highly functional handheld

machine control device. The unit is supplied with the Advantage 900 Basic Package or can be

purchased separately for custom machine control applications. The unit interfaces to PMAC

and/or UMAC controls via a special driver embedded in the Pcommserver Software device

driver. The Advantage 900 Remote Operator Pendant is optionally available in a wireless

Bluetooth version.

The Advantage 900 Remote Operator Pendant includes a secondary relay interface board. This

board provides a convenient way to interface a latching power-on circuit for machines, includes

provisions for interfacing Emergency Stop circuitry, and also serves to accommodate the

transceiver hardware when the optional Bluetooth hardware is present.

The Advantage 900 Relay Board requires a 24VDC always-on circuit if the latching power-on

features are to be utilized. This 24VDC power-supply is intended to be always on unless the

machine is disconnected from the main power disconnect. The current requirements of the

24VDC power supply depend on the user’s circuit design. Utilizing the always-on circuitry of the

relay board is optional and does not affect the functionality of the remote handheld pendant.

The Advantage 900 Remote Operator Pendant includes the following control features:

• Emergency Stop Twist and Release Button (stop only for wireless version)

• Dedicated Function buttons including:

o Auto Mode Select*

o MDI Mode Select*

o Reset*

o Single Block Mode*

o Block Delete Mode*

o Optional Stop Mode*

o Continuous Jog Mode Select*

o Handwheel/Incremental Jog Mode Select*

o Home Mode Select*

• Six User Definable and Legendable Buttons*

• ATC Forward or Reverse Function Buttons (can be used for alternate functions)

• Spindle Forward/Reverse Buttons (can be used for alternate functions)

• Analog Overrides for Feedrate, Rapid, and Spindle Speed

• Axis Select Rotary Switch (X/Y/Z/A/B/C)

• Jog Speed Select Rotary Switch (Lo/Med Lo/Med/Med Hi/Hi)

• Separate Feed Hold and Cycle Start Buttons

INTRODUCTION

3

Page 7

Advantage 900 Remote Operator Pendant

• Jog Plus and Minus Buttons

• Machine Tool Style Detented Manual Pulse Generator

* - Includes Illuminated Indicator LED

Part Numbering

The Advantage 900 Remote Operator Pendant is available with only one option, wireless

Bluetooth functionality. When the unit is purchased individually, the part numbers are as follows:

Standard Unit – A900-00000-S0

Wireless Unit – A900-00000-W0

When purchased as part of an Advantage 900 system, the zeros in the above part numbers will be

replaced by characters indicating system options.

Example: Advantage 900 Basic Package – A909-1VAP0-S1

The Wireless version (Option 1) provides wireless operation via Bluetooth Class 1(100m, 2.4 ~

2.4835GHz Freq.). Please note when the wireless option is ordered, the yellow Emergency Stop

label at the top of the unit is replaced with a red Stop label per safety regulations (IEC 204-1,

Section 9.2.7.3).

Compatibility

The Advantage 900 Remote Operator Pendant is compatible with any Delta Tau system using the

Pcommserver Pro2 device driver and a Turbo CPU based PMAC or UMAC which includes the

Dual Ported Ram option. In most cases the Advantage 900 Remote Operator Pendant will be

used with the PMAC-NC Pro2 Software. The PMAC-NC Pro2 software is compatible with

Windows XP based operating systems only. When used with the PMAC-NC Pro2 environment,

the Advantage 900 Remote Operator Pendant software setup is automatic.

Note:

Only Turbo CPUs with Dual Ported Ram are supported.

Alternatively the Advantage 900 Remote Operator Pendant can be used in custom software

applications which utilize the Pcommserver Pro2 as the communications device driver. When

using the Advantage 900 Remote Operator Pendant in custom applications with the Pcommserver

device driver, data transfer is automatically performed. The user must build all software logic

related to the Remote Pendants I/O per the I/O map discussed in the Custom Software Setup

section of this manual.

A host PC is required with a free USB2.0 port or RS232 serial port when using the optional

wireless version.

Note

Use only primary back panel USB2.0 ports when connecting any

Advantage 900 Remote Pendant or UMAC controller. Do not use auxiliary

USB2.0 ports.

INTRODUCTION

4

Page 8

Advantage 900 Remote Operator Pendant

Communication Interface

The Advantage 900 Remote Operator Pendant communicates to the PMAC/UMAC through the

Pcommserver device driver. The Pcommserver device driver is initialized when any Delta Tau

Pro2 based software is started. During the initialization sequence the device driver will

automatically detect when the Advantage 900 Remote Operator Pendant is present and begin

transferring data to the PMAC/UMAC via Dual Ported Ram memory addresses (see the Software

Setup section of this manual for more information).

The Advantage 900 Remote Operator Pendant connects directly to a PC via either a USB2.0 port

or RS232 Serial Port (when using the wireless option). The Pcommserver transfers the

information to the PMAC via the device driver. The Advantage 900 Remote Operator Pendant

does not connect directly to the PMAC.

When the optional wireless version is used, the connection to the PC is via the RS232 port located

on the Advantage 900 Relay Board, not directly from the handheld unit.

Specifications

Advantage 900 Remote Operator Pendant

USB2.0 Cabled Pendant

Model

Power

Requirements

Battery N/A Lithium Ion, +3.7VDC

Power

Requirements

(P/N: A90x-xxxxx-Sx)

+5VDC, 500mA

(Through USB2.0 Cable)

Advantage 900 Relay Board

+5VDC, +12VDC

(Through Small Disk Drive

Connector)

Wireless Bluetooth Pendant

(P/N: A90x-xxxxx-Wx)

+5VDC, 1.5A

(Through Charge Cable)

+5VDC, +12VDC

(Through Small Disk Drive

Connector)

INTRODUCTION

5

Page 9

Advantage 900 Remote Operator Pendant

INTRODUCTION

6

Page 10

Advantage 900 Remote Operator Pendant

HARDWARE SETUP

The Advantage 900 Remote Operator Pendant and Relay Board communication jumper settings

are configured at the factory depending on the communication format (USB2.0 or Bluetooth).

The Remote Operator Pendant jumpers should be left in their factory-supplied state and should

not require modification. They are described here for reference and troubleshooting purposes

only.

The behavior of the Emergency Stop circuitry on the Relay Board may be modified depending on

the settings of Relay Board jumpers E3, E4, E5, and E6. Refer to the example wiring diagrams in

Appendix B for more information.

Jumper Configuration

Advantage 900 Remote Pendant – (P/N: 300-603812-10x)

E POINT & PHYSICAL

LAYOUT

E1

E2

E3

E4

E5

E6

Factory Programming.

Supplies +5VDC power

through USB cable when

present.

Supplies +5VDC power

through factory programming

cable.

Voltage monitor disable

jumper. When removed a

battery voltage drop below

+3VDC will cause the pendant

to shut down. Must be present

for cabled version.

Factory troubleshooting

jumper. Bluetooth signal

detection.

Factory troubleshooting

jumper. +5VDC bypass.

DESCRIPTION Cabled

USB2.0

Wireless

BlueTooth

ON ON

ON

OFF

ON

OFF

OFF

OFF

ON ON

OFF

OFF

HARDWARE SETUP

7

Page 11

Advantage 900 Remote Operator Pendant

Advantage 900 Relay Board – (P/N: 300-603826-10x)

E POINT &

PHYSICAL

LAYOUT

E1A1

Enables RS-232 Receiver Outputs. OFF 2-3 2-3

DESCRIPTION Cabled

USB2.0

Wireless 1

Bluetooth

Wireless 2

Bluetooth

E1B1

Runs RS-232 Transceiver in normal

OFF 2-3 2-3

mode.

E1C1

Not Installed. N/A N/A N/A

E3

Emergency Stop Status loop enable.

ON ON OFF

Must be present for cabled version.

Can be used to disable Bluetooth

watchdog relay K5B.

E4

Emergency Stop Loop configuration

ON OFF ON

jumper.

Can be configured for various

functions when Bluetooth option is

present (see schematics).

E5

Emergency Stop Loop configuration

ON OFF ON

jumper.

Can be configured for various

functions when Bluetooth option is

present (see schematics).

E6

Emergency Stop Loop configuration

OFF ON OFF

jumper.

Can be configured for various

functions when Bluetooth option is

present (see schematics).

Connections

Advantage 900 Remote Operator Pendant

The Advantage 900 Remote Operator Pendant requires very few connections. The USB2.0 cabled

version simply needs to be plugged into a PC’s back panel USB2.0 port and earth grounded for

safety (a grounding wire is included with the cable assembly). An Emergency Stop Loop is

included to interface with the machines safety circuitry. This loop passes through a normally

closed set of contacts in the Emergency Stop switch housed in the handheld unit. The Advantage

900 Relay board provides a convenient method to interface this circuitry.

The wireless version includes a charging cable which connects directly to a standard PC disk

drive connector. The Emergency Stop circuitry is not present on the wireless unit and is replaced

by a Stop circuit which is electronically sensed and distributed at the Advantage 900 Relay

Board.

HARDWARE SETUP

8

Page 12

Advantage 900 Remote Operator Pendant

No other connections are required for the handheld portion of the device.

Advantage 900 Relay Board

The Advantage 900 Relay Board provides a convenient way to interface a latching power-on

circuit for machines, includes various hooks for interfacing Emergency Stop circuitry, and also

serves to accommodate the transceiver hardware when the optional Bluetooth hardware is

present.

The Advantage 900 Relay Board requires a 24VDC always-on circuit if the latching power-on

features are to be utilized. This 24VDC power-supply is intended to be always on unless the

machine is disconnected from the main power disconnect. The current requirements of the

24VDC power supply depend on the user’s circuit design.

The following is a description of the connections when using the Advantage 900 Relay Board.

See the Connector Description section for complete details of these connectors.

J4 – PC Power Connector

J4 connects to a standard PC floppy drive power connector. The +12VDC controls the state of the

PC-Power relay for both versions. The +5VDC is used by the Bluetooth circuitry in the wireless

version.

J5 – Wireless Antennae Connector (Wireless Version Only)

J5 connects to the antennae for the wireless Bluetooth version only.

J7 – RS-232 Port (Wireless Version Only)

J7 connects to an RS-232 port on the PC. This is only required for wireless Bluetooth versions

only.

J8 – Machine Power On Button

J8 connects to a momentary switch which controls the latching power-on circuitry built into the

Advantage 900 Relay board. This is connected to the green power button on the front of the

Advantage 900 console units when complete systems are purchased.

J9 – Estop Switch

J9 usually connects to the Emergency Stop switch located on the front of Advantage 900 console

units. Pins 1-2 are part of the Estop Loop and must be connected to complete the circuit between

pins 5-6 on terminal block J13. Pins 3-4 are part of the Estop Status Loop and must be connected

to complete the circuit between pins 7-8 on terminal block J13.

See the wiring diagrams in Appendix B for example of how these circuits can be used.

J13 – Machine Interface Terminal Block 1

Pins 1-2: Latching Power-On circuit actuated via a momentary contact switch attached to

connector J8 (the Green button on Advantage 900 Console units). Once this circuit is energized it

latches the relay contacts through pins 3-4 of the same connector.

Pins 3-4: Power-On relay contacts. Use this circuit to enable or turn on anything you wish after

the power-on latch is activated. Usually this is used to turn on a larger magnetic contactor inside

the main electrical cabinet. Through this circuit you can control the entire machine power on/off

HARDWARE SETUP

9

Page 13

Advantage 900 Remote Operator Pendant

circuitry.

Pins 5-6: Estop Circuit. Refer to the wiring diagrams in Appendix B for various ways to

configure this Emergency Stop circuit.

Pins 7-8: Estop Status Circuit. Refer to the wiring diagrams in Appendix B for various ways to

configure this Emergency Stop circuit.

Pins 9-10: Power-Off input. Applying 24VDC across this circuit will open the latched power-on

circuit. Use an external signal such as a PMAC or other output to power down the entire system.

J14 – Machine Interface Terminal Block 2

Pins 1-2: Remote Estop Enable. Applying 24VDC across this circuit from an external output or

safety PLC will actuate an Estop condition in both Estop circuits on J13 (Pins 5-6 and 7-8).

Pins 3-4: A convenient place to wire additional Estop devices. If your system includes a cabled

remote pendant it will be connected here. This circuit can also be used independently to monitor

the status of Bluetooth communication integrity in wireless versions. Refer to the wiring diagrams

in Appendix B for various ways to configure this circuit.

Pins 5-6: A dry relay contact for monitoring the PC power supply status. This can be used to

monitor the PC from the PMAC and initiate a complete system shutdown via pins 9-10 of J13

when a power-down is desired.

Field-Wiring Connections

There are two different relay boards, depending on which Pendant is being connected. For the

wired Pendant, configure the jumpers in the appropriate manner and follow the diagram

below.

HARDWARE SETUP

10

Page 14

Advantage 900 Remote Operator Pendant

Wired diagram

For the wireless Pendant, there are two configurations. In Wireless version 1, a loss of Bluetooth

communication does not cause ESTOP; in Wireless version 2, Bluetooth loss does cause ESTOP.

Both diagrams follow. In either case, the wireless relay board needs to be connected to the serial

port via the included cable.

Wireless version 1

HARDWARE SETUP

11

Page 15

Advantage 900 Remote Operator Pendant

Wireless Version 2

HARDWARE SETUP

12

Page 16

Advantage 900 Remote Operator Pendant

SOFTWARE SETUP

The Advantage 900 Remote Operator Pendant communicates to the PMAC/UMAC through the

Pcommserver device driver which is automatically installed with any Delta Tau Pro2-based

software (PMAC-NC Pro2 or PEWIN Pro2). The Pcommserver device driver is initialized when

any Delta Tau Pro2 based software is started. During the initialization sequence the device driver

will automatically detect when the Advantage 900 Remote Operator Pendant is present and begin

transferring data to the PMAC/UMAC via Dual Ported Ram memory addresses.

The DPR memory addresses are automatically defined by the NC Setup utility for a given

application and can be found in the file Adv900.h. If the Pendant is to be used in a custom

application, the same memory locations can be used. The appropriate M-variable definitions are

shown below for reference purposes and can be used for custom applications:

//Example Advantage 900 Remote Pendant Button M-Variable.

//Definitions and Example Macro Names.

#define KEY_DOWN_M M800

#define KEY_CODE_M M801

#define FEEDRATE_M M802

#define RAPID_M M803

#define AXISSEL_M M804

#define SPINDLE_M M805

#define JOGRATE_M M806

#define HANDLE900_COUNT_M M807

//Dual Port Ram Memory Map Locations.

//PcommServer Automatically writes to these locations.

M800->Y:$60FD2,0,8,U

M801->Y:$60FD2,8,8,U

M802->Y:$60FD3,0,16,U

M803->X:$60FD0,0,16,U

M804->Y:$60FD0,4,4,U

M805->Y:$60FD4,0,16,U

M806->Y:$60FD0,0,4,U

M807->X:$60FD1,0,16,U

//Example Advantage 900 Remote Pendant LED Output M-Variable.

//Definitions and Example Macro Names.

#define LT_AUTO_M M2000

#define LT_MDI_M M2001

#define LT_RESET_M M2002

#define LT_SINGBLOCK_M M2003

#define LT_BLOCKDELETE_M M2004

#define LT_OPTSTOP_M M2005

#define LT_CONT_M M2006

#define LT_HANDINC_M M2007

#define LT_HOME_M M2008

#define LT_USER1_M M2009

#define LT_USER2_M M2010

#define LT_USER3_M M2011

#define LT_USER4_M M2012

#define LT_USER5_M M2013

#define LT_USER6_M M2014

#define LT_CYCLE_START_M M2015

SOFTWARE SETUP

13

Page 17

Advantage 900 Remote Operator Pendant

#define LT_FEED_HOLD_M M2016

#define E_STOP_IN_M M2017

//Dual Port Ram Memory Map Locations.

//PcommServer Automatically writes to these locations.

M2000->Y:$60FD8,0,1

M2001->Y:$60FD8,1,1

M2002->Y:$60FD8,2,1

M2003->Y:$60FD8,3,1

M2004->Y:$60FD8,4,1

M2005->Y:$60FD8,5,1

M2006->Y:$60FD8,6,1

M2007->Y:$60FD8,7,1

M2008->Y:$60FD8,8,1

M2009->Y:$60FD8,9,1

M2010->Y:$60FD8,10,1

M2011->Y:$60FD8,11,1

M2012->Y:$60FD8,12,1

M2013->Y:$60FD8,13,1

M2014->Y:$60FD8,14,1

M2015->X:$60FD8,0,1

M2016->X:$60FD8,1,1

M2017->Y:$60FD0,8,1

SOFTWARE SETUP

14

Page 18

Advantage 900 Remote Operator Pendant

WIRELESS SOFTWARE SETUP

When the Bluetooth option is present, the user must set the switch to enable file transfer through

this method.

This is done through either the NC Setup application or directly through the Windows Registry.

When using the NC Setup application, enable the “Wireless Pendant On” checkbox and enter the

COM port to which the relay board is actually connected.

Wireless Bluetooth Enable

The actual Windows registry key can be found in the following location and only needs to be set

to the COM port connected to:

HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet\Services\PMAC\Device0\Nc0\SYSTEM\Wirel

esCOMPort

SOFTWARE SETUP

15

Page 19

Advantage 900 Remote Operator Pendant

SOFTWARE SETUP

16

Page 20

Advantage 900 Remote Operator Pendant

MOUNTING AND INSTALLATION

When the Advantage 900 Remote Operator Pendant is supplied with any Advantage 900 System

that includes an Advantage 900 Console, no separate mounting of the handheld unit is required.

If the unit is purchased as a stand-alone accessory, it will be necessary to mount both the Remote

Operator Pendant and the associated Relay Board. The handheld unit is supplied with a dualdovetail sliding mechanism and hardware to facilitate easy on/off removal and replacement.

See the following mechanical drawings included for dimensions and screw locations.

CONNECTOR DESCRIPTIONS

17

Page 21

Advantage 900 Remote Operator Pendant

Mechanical Drawing

Mounting Brackets

CONNECTOR DESCRIPTIONS

18

Page 22

Advantage 900 Remote Operator Pendant

Pendant

CONNECTOR DESCRIPTIONS

19

Page 23

Advantage 900 Remote Operator Pendant

Advantage 900 Relay Board Mechanical Layout

Relay Board

CONNECTOR DESCRIPTIONS

20

Page 24

Advantage 900 Remote Operator Pendant

Advantage 900 Pendant Board Mechanical Layout

CONNECTOR DESCRIPTIONS

21

Page 25

Advantage 900 Remote Operator Pendant

CONNECTOR DESCRIPTIONS

22

Page 26

Advantage 900 Remote Operator Pendant

CONNECTOR DESCRIPTIONS – 900 REMOTE PENDANT

J1: KEYPAD INPUT CONNECTION

J1 KEYPAD INPUT

Front View

CONNECTION

(10-PIN SOCKET)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 KBDY6 INPUT ROW 6 OF KEYPAD

MATRIX

2 KBDY5 INPUT ROW 5 OF KEYPAD

MATRIX

3 KBDY4 INPUT ROW 4 OF KEYPAD

MATRIX

4 KBDX4

5 KBDY3 INPUT ROW 3 OF KEYPAD

6 KBDX3 INPUT COLUMN 3 OF

7 KBDY2 INPUT ROW 2 OF KEYPAD

8 KBDX2 INPUT COLUMN 2 OF

9 KBDY1 INPUT ROW 1 OF KEYPAD

10 KBDX1 INPUT COLUMN 1 OF

INPUT

COLUMN 4 OF

KEYPAD MATRIX

MATRIX

KEYPAD MATRIX

MATRIX

KEYPAD MATRIX

MATRIX

KEYPAD MATRIX

J2: USB CONNECTION

J2 USB

CONNECTION

Front View

(5-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 +5V INPUT +5V POWER

2 USBDM INPUT DATA MINUS

3 USBDP INPUT DATA PLUS

4 GND COMMON DIGITAL COMMON

5 CHGND COMMON CHASIS COMMON

CONNECTOR DESCRIPTIONS

23

Page 27

Advantage 900 Remote Operator Pendant

J3: HANDWHEEL CONNECTION

J3 HANDWHEEL

CONNECTION

Front View

(6-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 HWCHA+ INPUT HANDWHEEL CHA+

2 HWCHA- INPUT HANDWHEEL CHA-

3 HWCHB+ INPUT HANDWHEEL CHB+

4 HWCHB- INPUT HANDWHEEL CHB-

5 +5V INPUT +5V POWER

6 GND COMMON DIGITAL COMMON

J4: KEYPAD LED CONNECTION

J4 KEYPAD LED

CONNECTION

Front View

(32-PIN SOCKET)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 NOT USED

2 NOT USED

3 LED27 INPUT

4 +3P3V_USB INPUT

5 LED26 INPUT

6 LED25 INPUT

7 LED24 INPUT

8 LED23 INPUT

9 LED22 INPUT

10 LED21 INPUT

11 LED20 INPUT

12 LED19 INPUT

13 LED18 INPUT

14 LED17 INPUT

15 LED16 INPUT

16 +3P3V_USB INPUT

17 LED15 INPUT

18 LED14 INPUT

19 LED13 INPUT

20 LED12 INPUT

21 LED11 INPUT

22 LED10 INPUT

23 LED9 INPUT

24 LED8 INPUT

25 LED7 INPUT

26 LED6 INPUT

27 LED5 INPUT

28 LED4 INPUT

29 LED3 INPUT

30 LED2 INPUT

31 LED1 INPUT

32 +3P3V_USB INPUT

CONNECTOR DESCRIPTIONS

24

Page 28

Advantage 900 Remote Operator Pendant

J5: ON/OFF SWITCH CONNECTION

J5 ON/OFF

SWITCH

Front View

CONNECTION

(2-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 ON INPUT ON/OFF SWITCH CONNECTS TO NC STOP

2 OFF INPUT ON/OFF SWITCH CONNECTS TO NC STOP

This connector is only used in the wireless version to prevent the battery from draining when the Pendant is

not in use.

BUTTON

BUTTON

J6: ESTOP INDICATION CONNECTION

J6 ESTOP

INDICATION

Front View

CONNECTION

(2-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 IND INPUT CONNECTS TO NC ESTOP

2 GND COMMON CONNECTS TO NC ESTOP

This connector is only used in the wired version to sense if the ESTOP button has been depressed.

BUTTON

BUTTON

J7: BATTERY CHARGE CONNECTION

J7 ON/OFF

SWITCH

CONNECTION

(2-PIN

Front View

TERMINAL

BLOCK)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 + +5V POWER FROM

2 - COMMON CONNECT TO COMMON

This connector is only used in the wireless version to charge the battery.

CONNECT THROUGH NC

CHARGING CABLE

ESTOP BUTTON

FROM CHARGING CABLE

CONNECTOR DESCRIPTIONS

25

Page 29

Advantage 900 Remote Operator Pendant

J8: RS-232 CONNECTION

J8 RS-232

CONNECTION

Front View

(4-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 +5V INPUT +5V POWER

2 R2IN INPUT RECEIVE DATA

3 T1OUT OUTPUT TRANSMIT DATA

4 GND COMMON DIGITAL COMMON

J9: BATTERY CONNECTION

J9 BATTERY

CONNECTION

Front View

(2-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 VBATT +3P3V

2 GND COMMON

This connector is only used in the wireless version to connect the battery.

CONNECTOR DESCRIPTIONS

26

Page 30

Advantage 900 Remote Operator Pendant

CONNECTOR DESCRIPTIONS – 900 RELAY BOARD

J4: PC POWER CONNECTION

J4 PC POWER

CONNECTION

Front View

(4-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 +5V INPUT +5V POWER

2 GND COMMON DIGITAL COMMON

3 GND COMMON DIGITAL COMMON

4 +12v INPUT +12V POWER

J7: RS-232 CONNECTION

J7 RS-232

CONNECTION

Front View

(4-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 NC NC NOT CONNECTED

2 NC NC NOT CONNECTED

3 PC_RXD OUTPUT RECEIVE DATA

4 PC_RTS INPUT TRANSMIT DATA

5 PC_TXD INPUT TRANSMIT DATA

6 PC_CTS OUTPUT RECEIVE DATA

7 NC NC NOT CONNECTED

8 NC NC NOT CONNECTED

9 GND COMMON DIGITAL GROUND

10 NC NC NOT CONNECTED

J8: POWER ON PUSHBUTTON CONNECTION

J8 POWER

SWITCH

CONNECTION

(2-PIN HEADER)

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 INPUT PC ON/OFF SWITCH CONNECTS TO PC

2 INPUT PC ON/OFF SWITCH CONNECTS TO PC

Use normally open pushbutton.

Front View

ON/OFF BUTTON

ON/OFF BUTTON

CONNECTOR DESCRIPTIONS

27

Page 31

Advantage 900 Remote Operator Pendant

J9: E-STOP SWITCH CONNECTION

J9 E-STOP SWITCH CONNECTION (4-PIN

HEADER)

Front View

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 INPUT ESTOP LOOP 1-2 See Connection Diagrams

2 INPUT ESTOP LOOP 1-2 See Connection Diagrams

3 INPUT ESTOP LOOP 3-4 See Connection Diagrams

4 INPUT ESTOP LOOP 3-4 See Connection Diagrams

J13: (10-PIN TERMINAL BLOCK)

J13 (10-PIN TERMINAL

BLOCK)

Front View

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 +24VDC INPUT USER SUPPLIED +24VDC

ALWAYS ON POWER.

2 GND COMMON +24V GROUND FOR LATCHING POWER-ON

3 PWR ON OUTPUT USED TO PWR ON

EXTERNAL DEVICES

4 PWR ON RET COMMON +24V GROUND

5 ESTOP LOOP INPUT WIRE TO ESTOP CNTRL

RLY

6 ESTOP LOOP

RET

7 ESTOP STATUS OUTPUT MONITOR ESTOP

8 ESTOP STATUS

RET

9 PWR OFF INPUT +24V CONNECT TO PMAC

10 PWR OFF RET COMMON +24V GROUND

COMMON +24V GROUND

STATUS

COMMON DIGITAL GND

FOR LATCHING POWER-ON

CIRCUIT.

CIRCUIT.

e.g. CABINET PWR RLY

WIRE TO PMAC INPUT

OUTPUT

CONNECTOR DESCRIPTIONS

28

Page 32

Advantage 900 Remote Operator Pendant

J14: (6-PIN TERMINAL BLOCK)

J13 (6-PIN TERMINAL

BLOCK)

Front View

PIN # SYMBOL FUNCTION DESCRIPTION NOTES

1 ESTOP ENA INPUT +24V

2 ESTOP ENA

RET

3 REM ESTOP INPUT CABLED PENDANT

4 REM ESTOP

RET

5 PCPWR INPUT DRY CONTACT TO

6 PCPWR RET COMMON GROUND

COMMON +24V GROUND

AND ADDITIONAL

ESTOP HERE

COMMON GROUND

MONITOR PC PWR

SUPLY STATUS

CONNECTOR DESCRIPTIONS

29

Page 33

Advantage 900 Remote Operator Pendant

CONNECTOR DESCRIPTIONS

30

Page 34

Advantage 900 Remote Operator Pendant

APPENDIX A - BLUETOOTH COMMANDER –

PROGRAMMING WIRELESS UNITS

Bluetooth-enabled Remote Operator Pendants and associated relay boards are programmed at the

factory to operate as a unique pair. A particular handheld unit will communicate to a particular

relay board only if it has been programmed to do so in advance.

In some rare instances, it is necessary to field program these devices. The following instructions

describe how to do so.

Please note that a special cable is necessary to program the unit. This cable is available through

Delta Tau or can be sourced from a third-party vendor. This cable connects to J2 (USB2.0) on the

Remote Handheld unit.

Bluetooth Re-Programming Procedure

Step 1

Be sure the Advantage 900 Relay Board is connected to the PC via an unused serial port. Make

note of the port number.

Step 2

Launch the Simply Blue Commander utility which is included with all Advantage 900 systems.

The application will be located in the following folder:

C:\Documents and Settings\Advantage 900 User\My Documents\Adv900 Comm Software\Util

If you do not have this application, contact Delta Tau technical support to have it emailed to you.

Step 3

Select the Local Bluetooth Settings Folder and expand it by double-clicking (see the screenshot

on the following page).

Step 4

Double-click the Read Local Device Address and record the value as shown in the screenshot on

the following page. Confirm that the Simply Blue Commander is in “Interpret Mode” by rightclicking in the Transport Layer Log screen and verifying that Interpret Traffic mode has been

checkmarked as shown below.

CONNECTOR DESCRIPTIONS

31

Page 35

Advantage 900 Remote Operator Pendant

Step 5

Convert the values from hexadecimal to decimal using a scientific calculator such as that included

with Microsoft Windows (see screenshots below). Record these values for future use.

Example: 0E 02 2D 17 00 08 Converts to: 14 2 45 23 0 8

Step 6

Connect the Advantage 900 Remote Handheld unit to the PC using the special USB2.0 cable (J2

on the Advantage 900 Pendant Board). You must open the remote handheld unit by removing the

six faceplate attaching screws to do this.

CONNECTOR DESCRIPTIONS

32

Page 36

Advantage 900 Remote Operator Pendant

At this time, a “Welcome to the Found New Hardware Wizard” dialog box should appear if the

unit has not been plugged in to a USB port previously. Follow the on-screen instructions and pay

attention to the following:

1) Do not

2) Allow Windows to Install the Software Automatically.

allow Windows to connect to Windows Update.

3) Choose Continue Anyway when prompted about Windows Logo Testing.

Step 7

At this time you may close the Simply Blue Commander application and open the Delta Tau

Configure Ethernet 100Base T application located in the Windows Start Menu as follows:

Start -> All Programs -> PMAC Executive Pro2 Suite -> Delta Tau Common

Step 8

Enter the Gateway IP by using the first 4 converted hexadecimal values as shown below. Enter

the Gateway Mask by using the last 2 converted hexadecimal values. Set the third address to 0

and the last to 1 as shown below.

Click on the Gateway IP and Gateway Mask buttons to complete the programming.

CONNECTOR DESCRIPTIONS

33

Page 37

Advantage 900 Remote Operator Pendant

CONNECTOR DESCRIPTIONS

34

Page 38

Advantage 900 Remote Operator Pendant

APPENDIX B - SELECTED SCHEMATICS

PENDANT SCHEMATIC

RELAY SCHEMATIC

INSERT 900_RelayBoard_Schematic_2.pdf HERE

SELECTED SCHEMATICS

35

Page 39

Advantage 900 Remote Operator Pendant

APPENDIX C – CONNECTOR PART NUMBERS

Molex - ????

SELECTED SCHEMATICS

36

Page 40

Advantage 900 Remote Operator Pendant

SELECTED SCHEMATICS

37

Loading...

Loading...